Patents

Literature

1364results about How to "Shorten adjustment time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

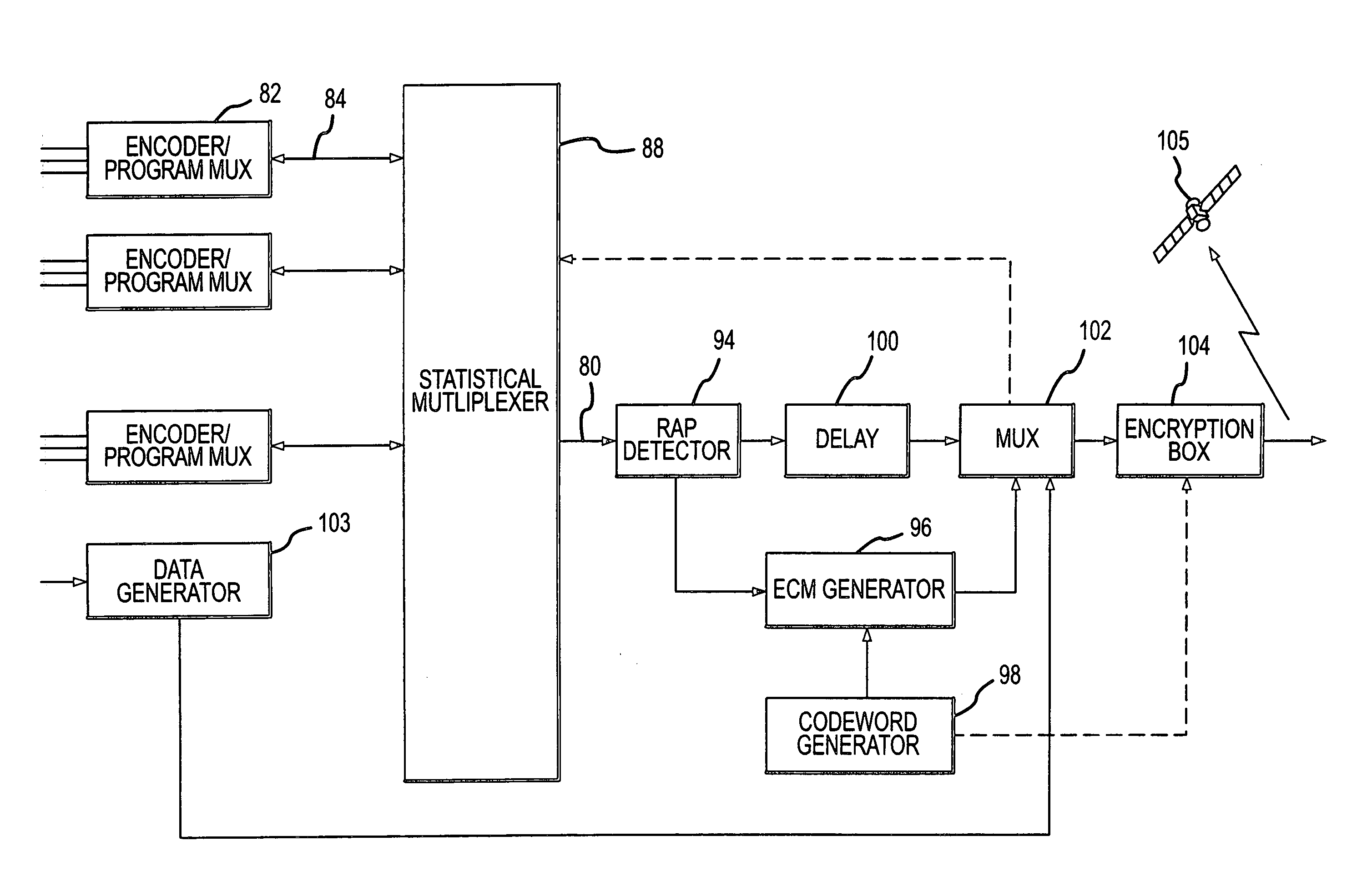

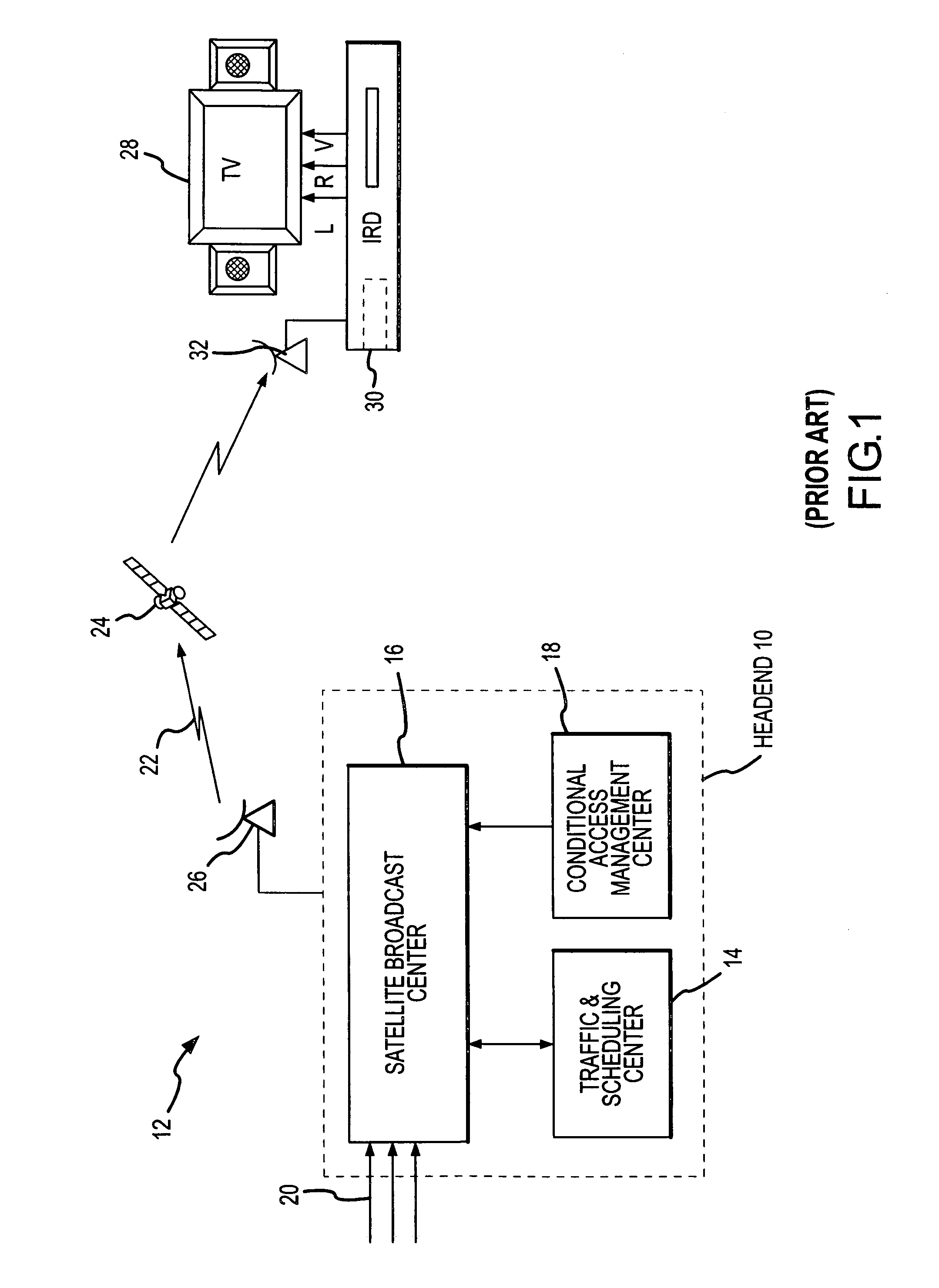

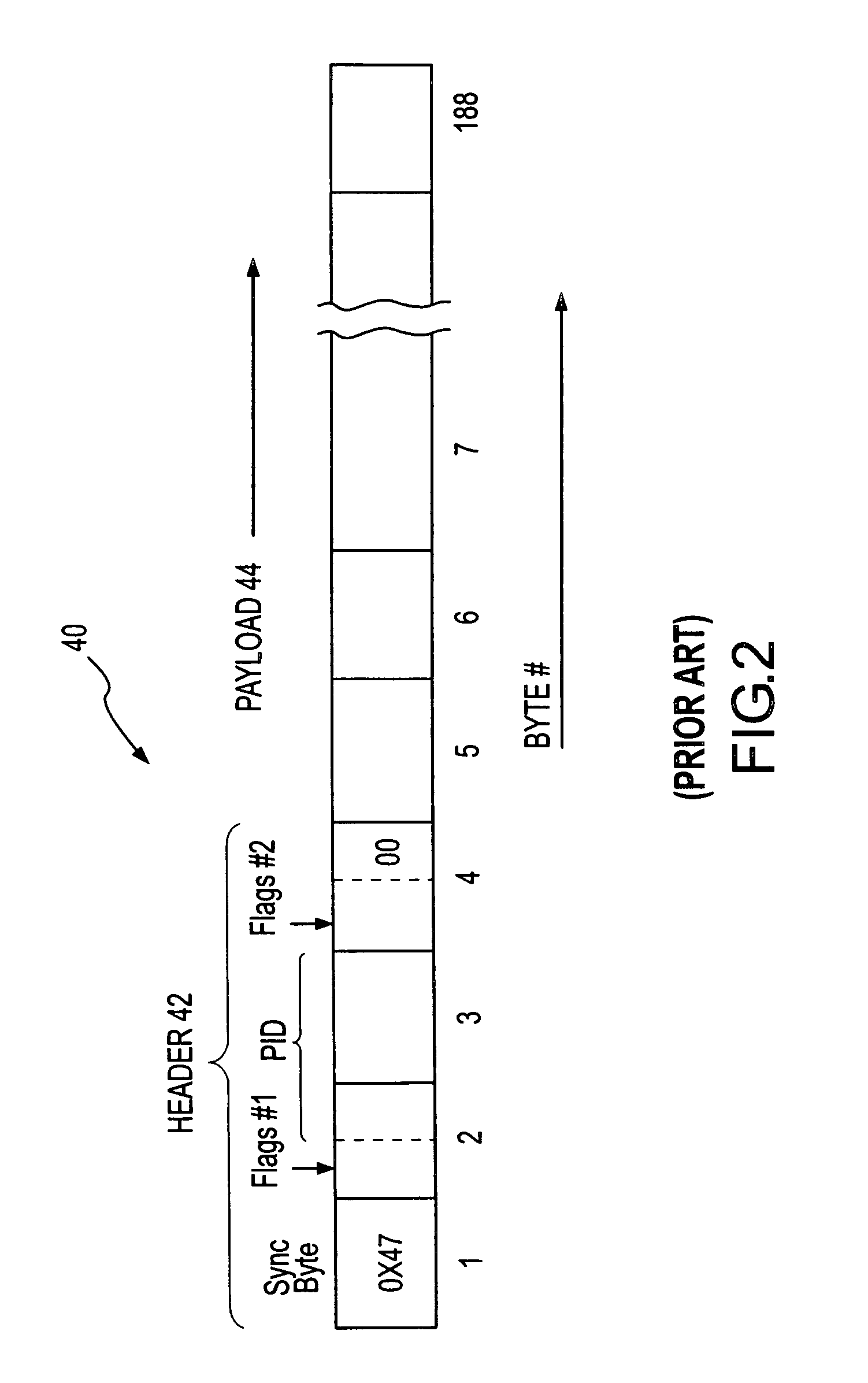

Just in time delivery of entitlement control message (ECMs) and other essential data elements for television programming

InactiveUS7912219B1Reduces overhead bit rateReduce rateDigital data processing detailsPicture reproducers using cathode ray tubesBit rateSatellite

Essential data elements, particularly entitlement control messages (ECMs), are inserted in a manner that reduces the overhead bit rate without effecting overall tuning time at the customer receiver or security in satellite, cable or other programming networks. ECMs are inserted into the transport stream by detecting random access points (RAPS) in the encoded programming and inserting the ECM packets in a window just ahead of the RAP.

Owner:THE DIRECTV GROUP

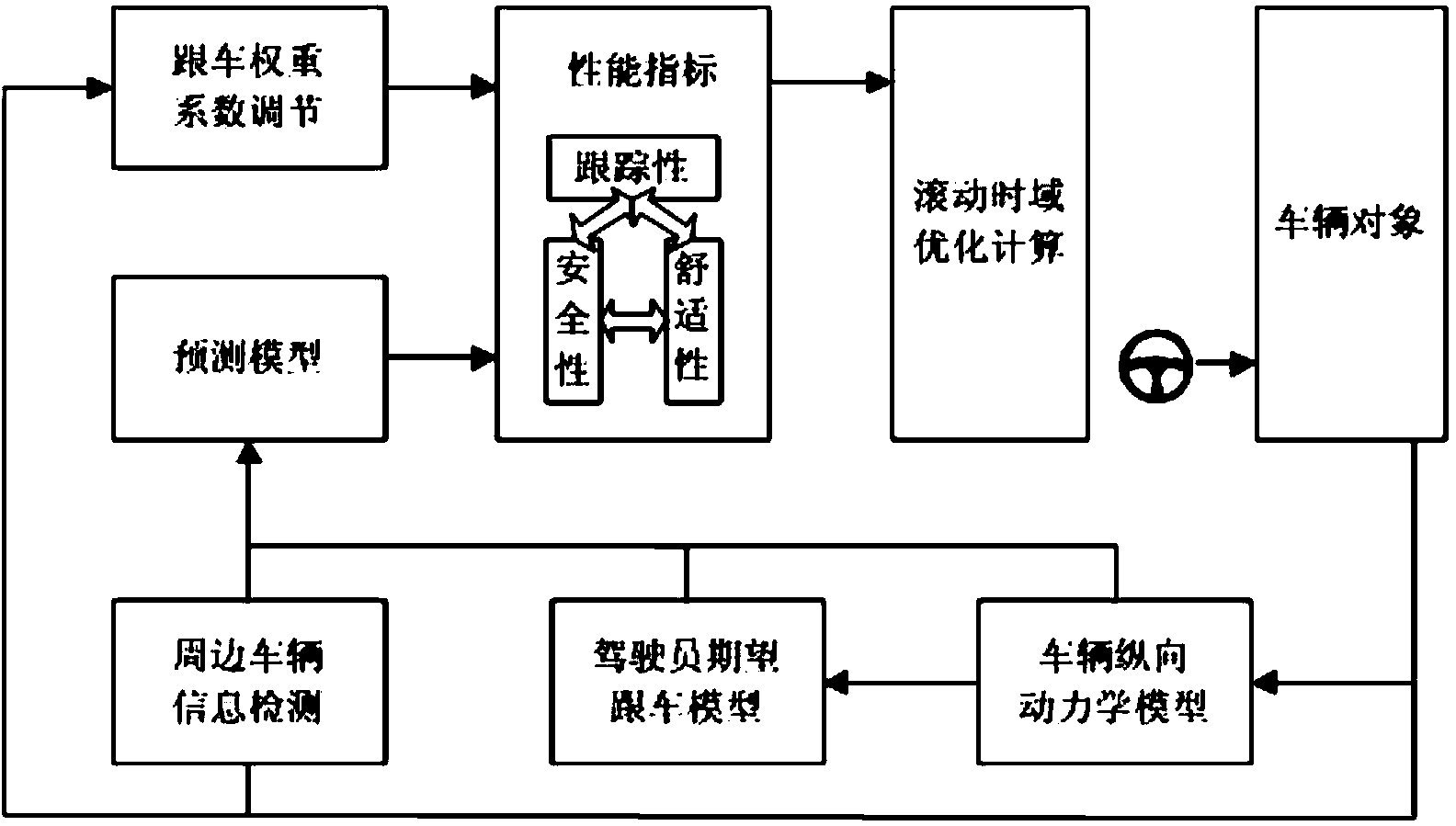

Vehicle multi-target coordinating lane changing assisting adaptive cruise control method

ActiveCN103754224AEnsuring the safety of changing lanesEnsure lane change safetyExternal condition input parametersExternal condition output parametersTime domainDriver/operator

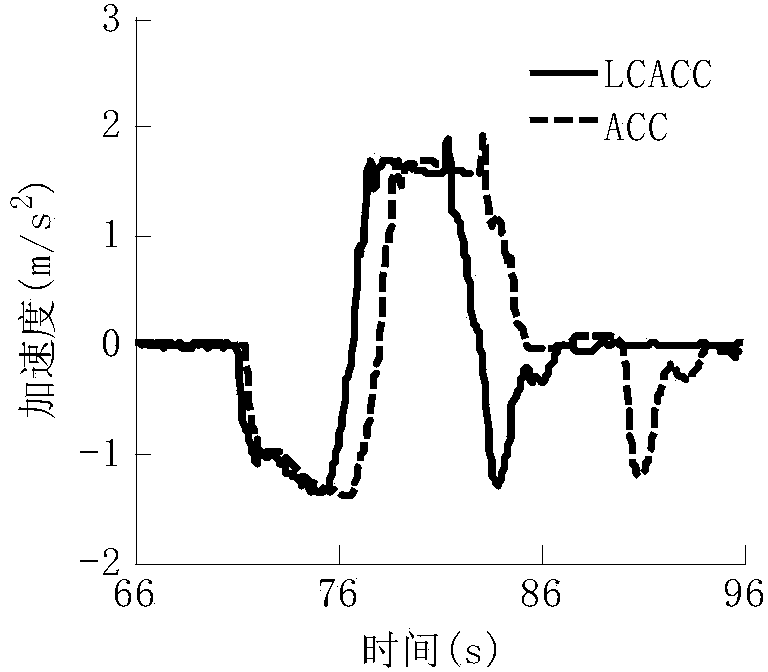

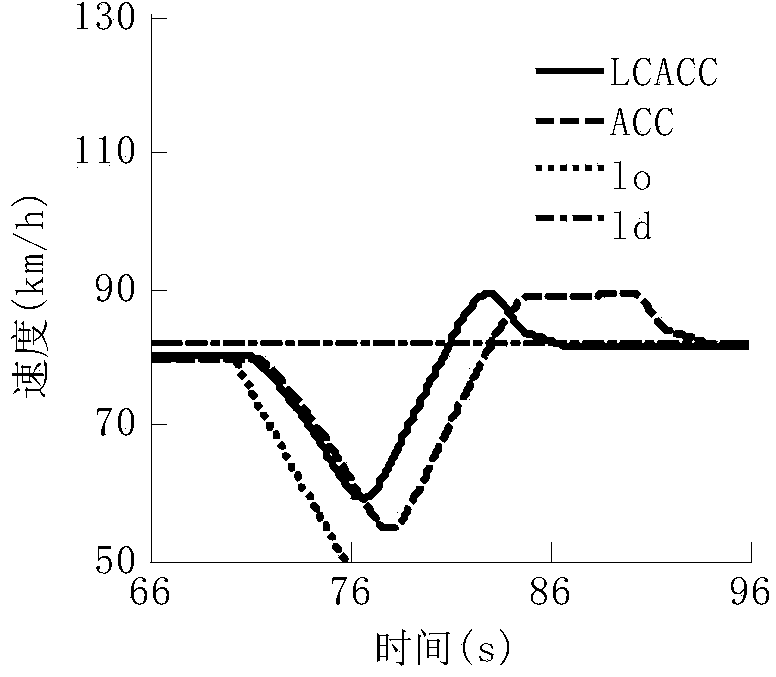

The invention relates to a vehicle multi-target coordinating lane changing assisting adaptive cruise control method. The method comprises the following steps that 1) LCACC combination property indexes are set according to two-front-vehicle traceability, multi-vehicle movement safety and longitudinal driving comfort requirements, and the LCACC combination property indexes comprise a cost function and I / O constraints; 2) a multi-target coordinating optimal control problem is built, solving is carried out through a rolling time domain optimization algorithm, the optimal control quantity is obtained, and optimal control is achieved. The LCACC cost function is set according to the following steps that a) a traceability cost function is built through a two-norm linear combination of the vehicle distance errors and vehicle speed errors of the own vehicle and two front vehicles; b) a comfort cost function is built by restraining longitudinal acceleration. The LCACC I / O constraints are set according to the steps that a) in the respect of tracking performance, vehicle following error constraints which are used for limiting the vehicle speed errors and the vehicle distance errors and allowed by a driver are obtained through driver experimental data in a statistic mode; b) in the respect of safety performance, the safety distance between the own vehicle and multiple surrounding vehicles is restrained in the view of vehicle following and collision avoidance; c) in the respect of comfort performance, the expected longitudinal acceleration data range is restrained.

Owner:TSINGHUA UNIV

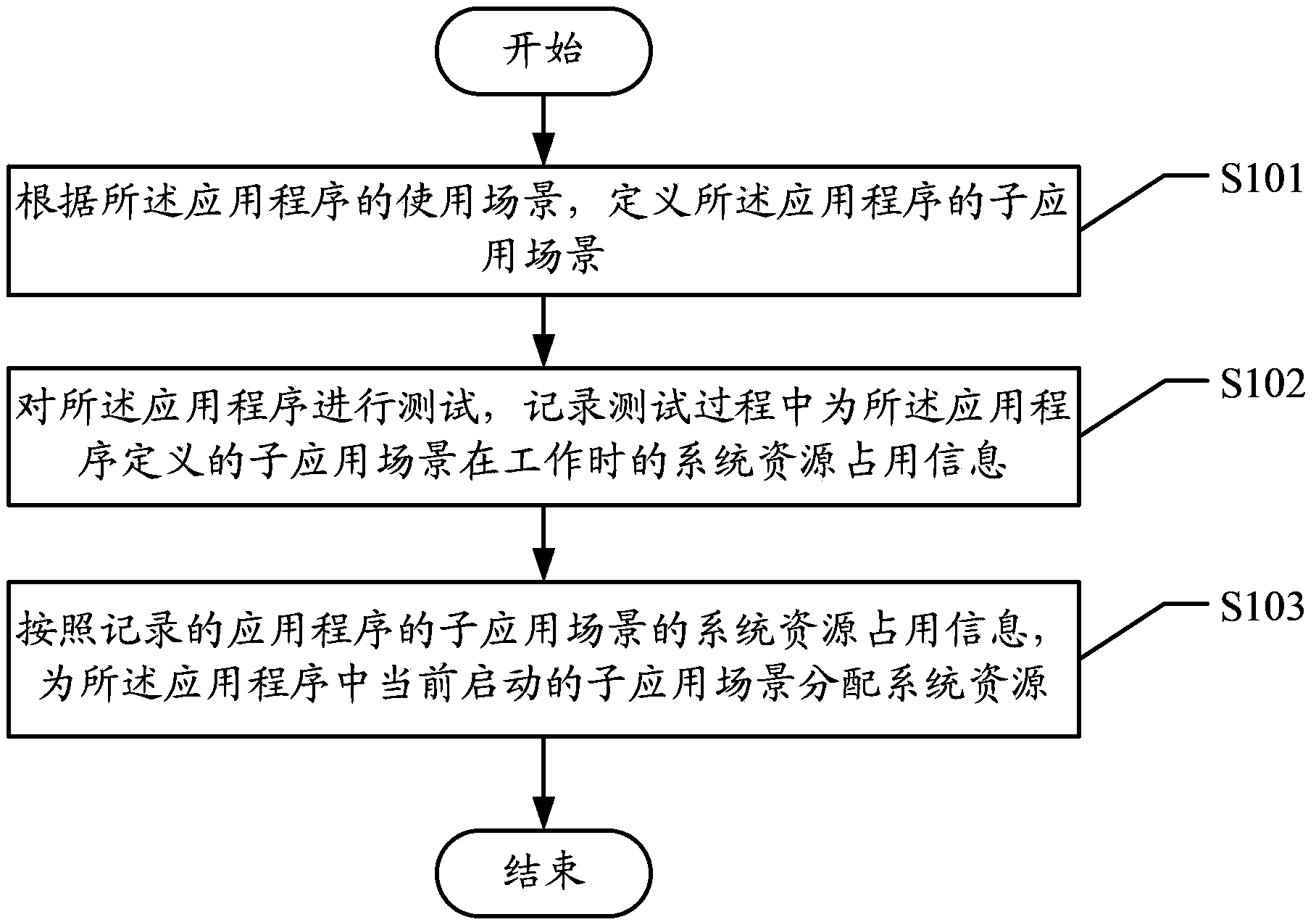

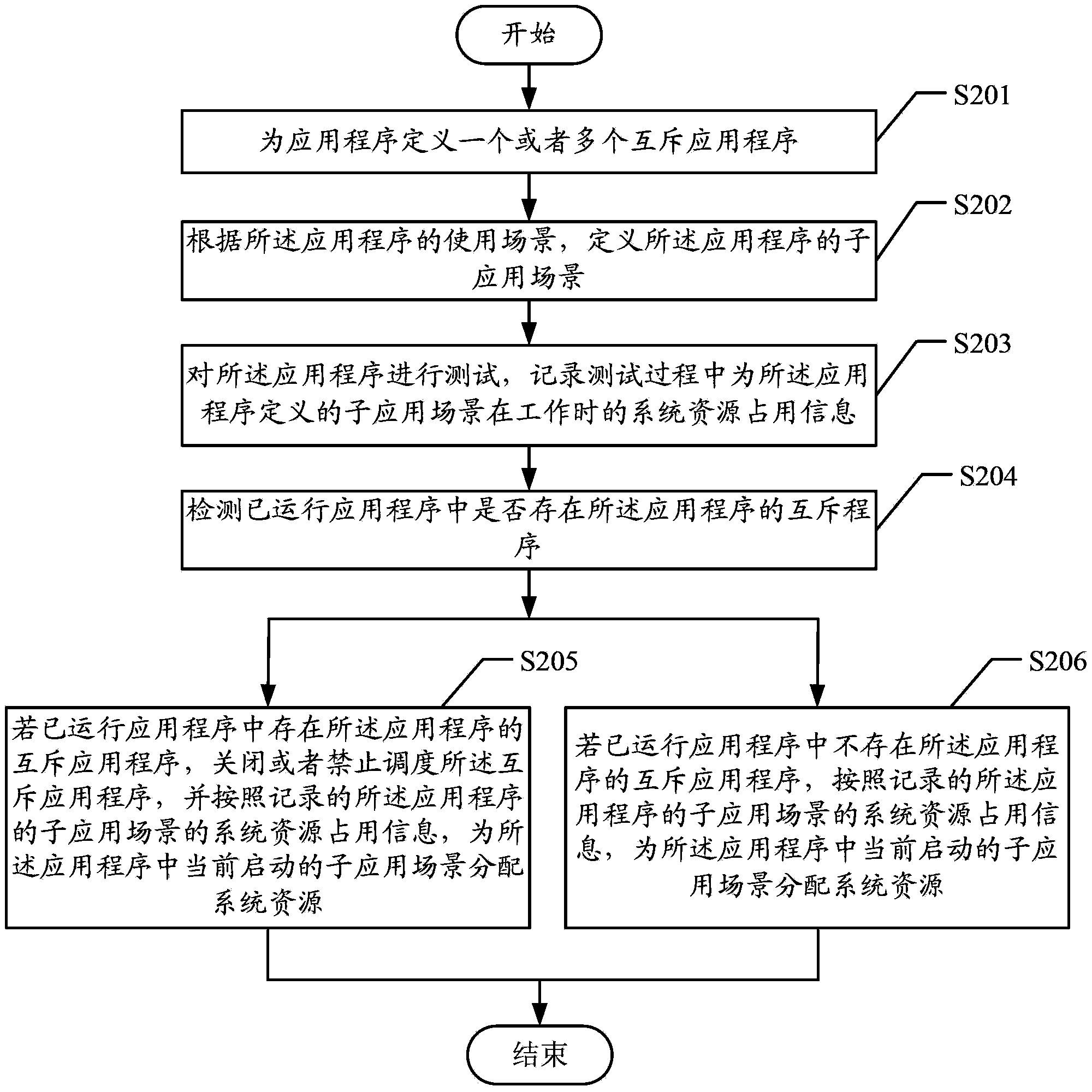

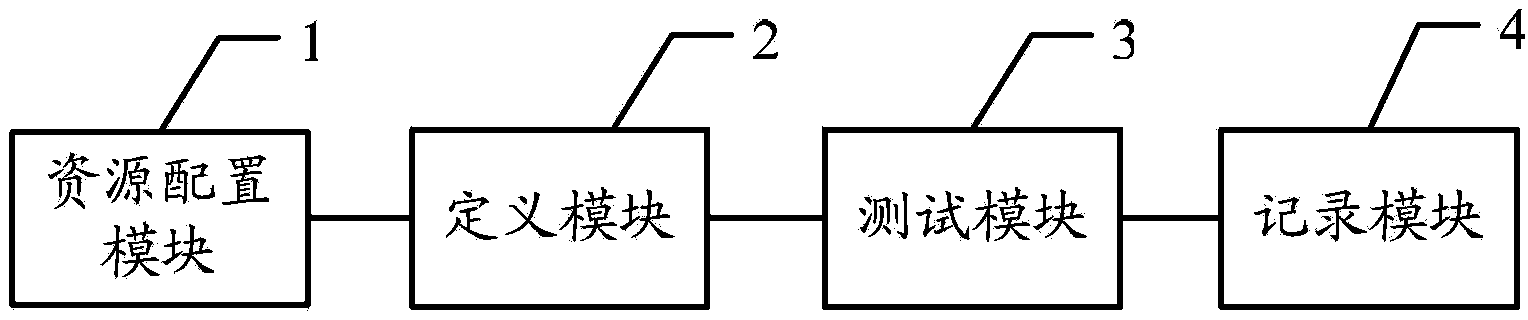

Method and apparatus for configuring resource

ActiveCN103430151AGuaranteed uptimeShorten adjustment timeEnergy efficient ICTResource allocationApplication softwareOperating system

Embodiments of the present invention disclose a method for configuring a resource and an apparatus. The method includes: allocating a system resource to a currently active application sub-scenario in an application according to recorded system resource occupation information of the application sub-scenario of the application, where the system resource occupation information of the application sub-scenario of the application includes the system resource occupation information recorded when the application sub-scenario works in a process of testing the application after the application sub-scenario of the application is defined. With the present invention, the system resource is configured for the application sub-scenario at a single attempt. Therefore, enough system resources are ensured to meet the requirements for running the currently active application sub-scenario of the application, the running performance is ensured, and the adjustment time and the power consumption are saved.

Owner:HUAWEI DEVICE CO LTD

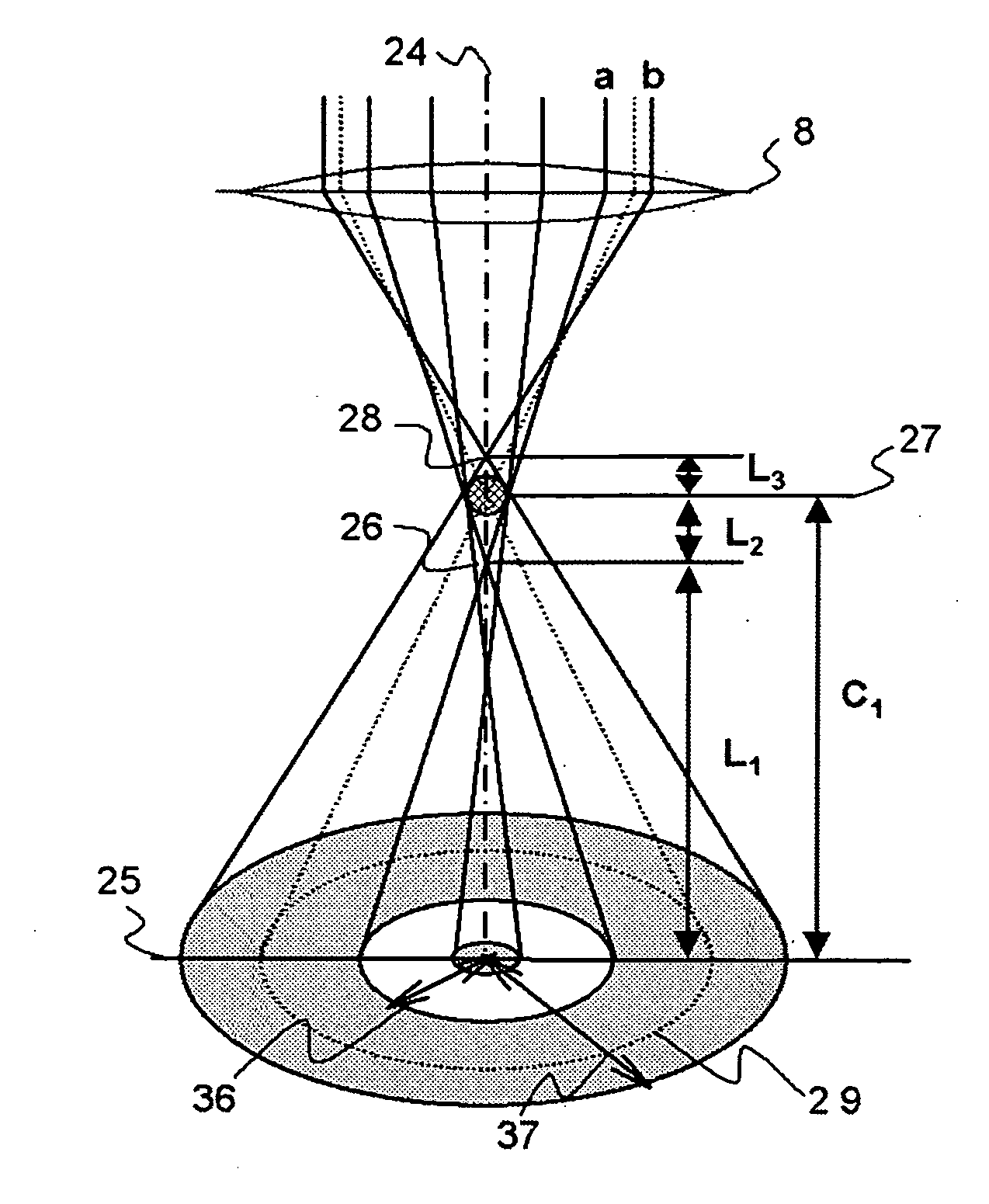

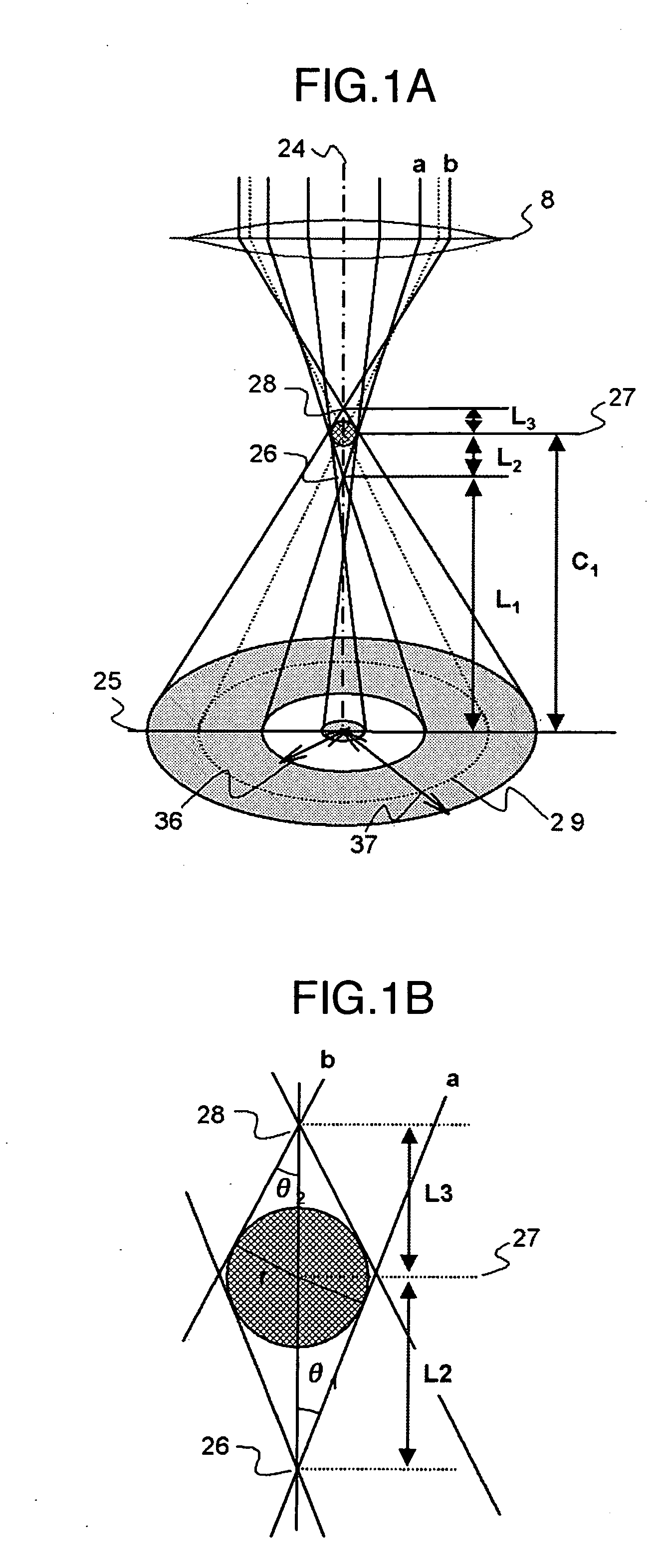

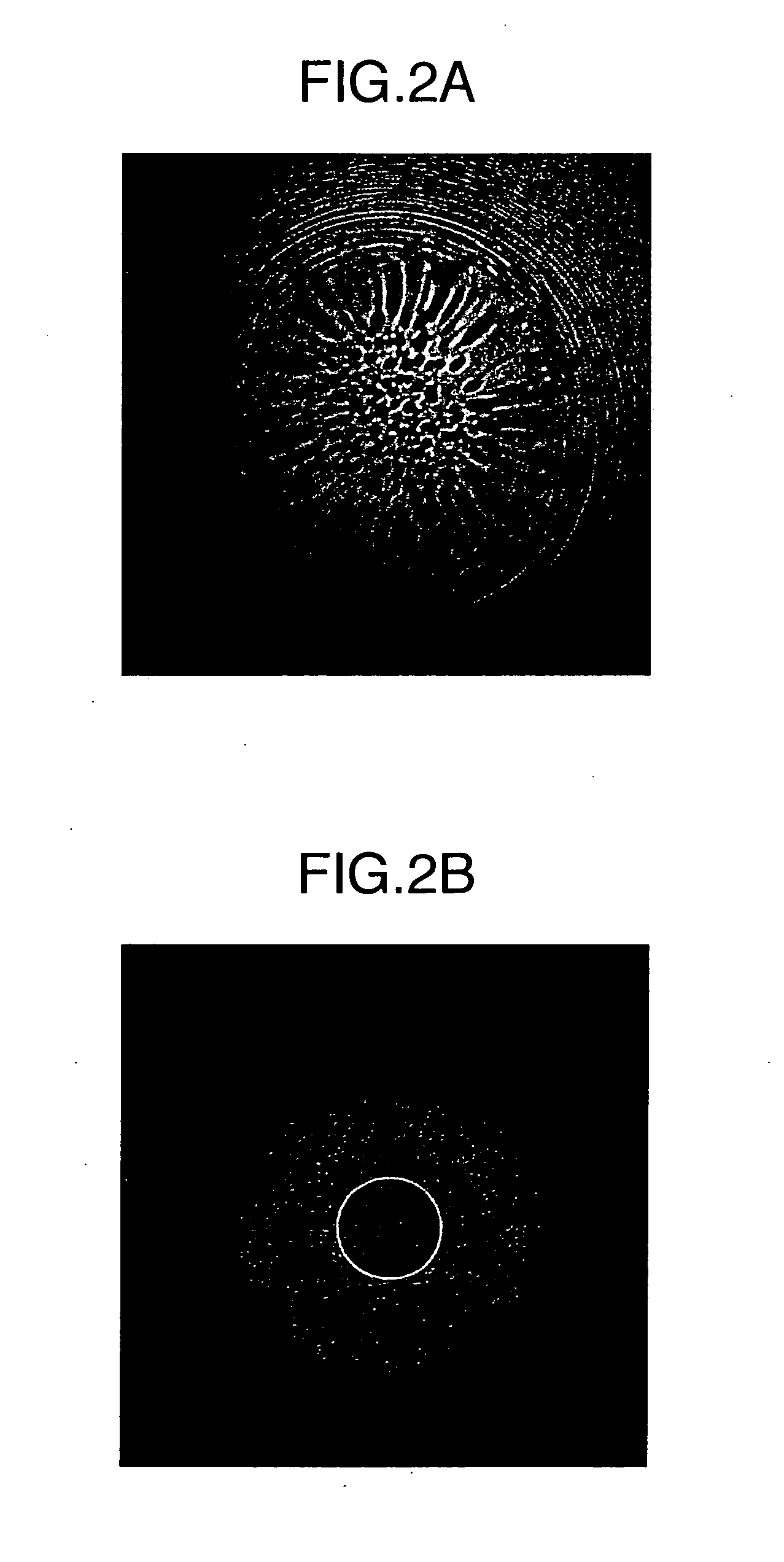

Apparatus and measuring method of aberration coefficient of scanning transmission electron microscope

InactiveUS20070158568A1Shorten adjustment timeMaterial analysis using wave/particle radiationElectric discharge tubesElectron microscopeMaterials science

In the type of scanning transmission electron microscopes carrying an aberration corrector, a method of assuring more simplified and manipulatable adjustment of the corrector and a scanning transmission electron microscope having that function are provided. A Ronchigram image is acquired using a spherical standard specimen and parameters necessary for the adjustment are acquired from the thus obtained Ronchigram.

Owner:HITACHI HIGH-TECH CORP

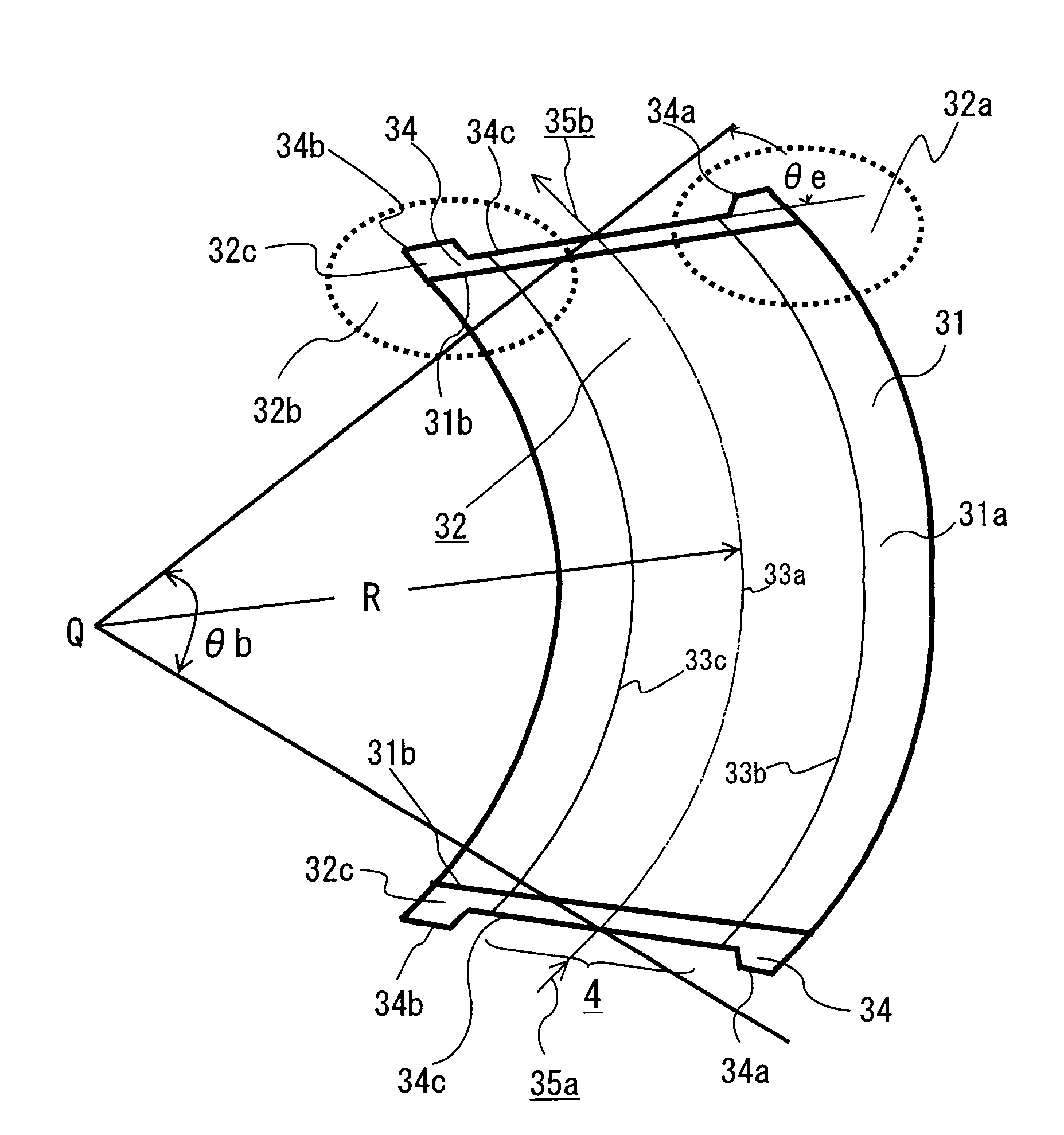

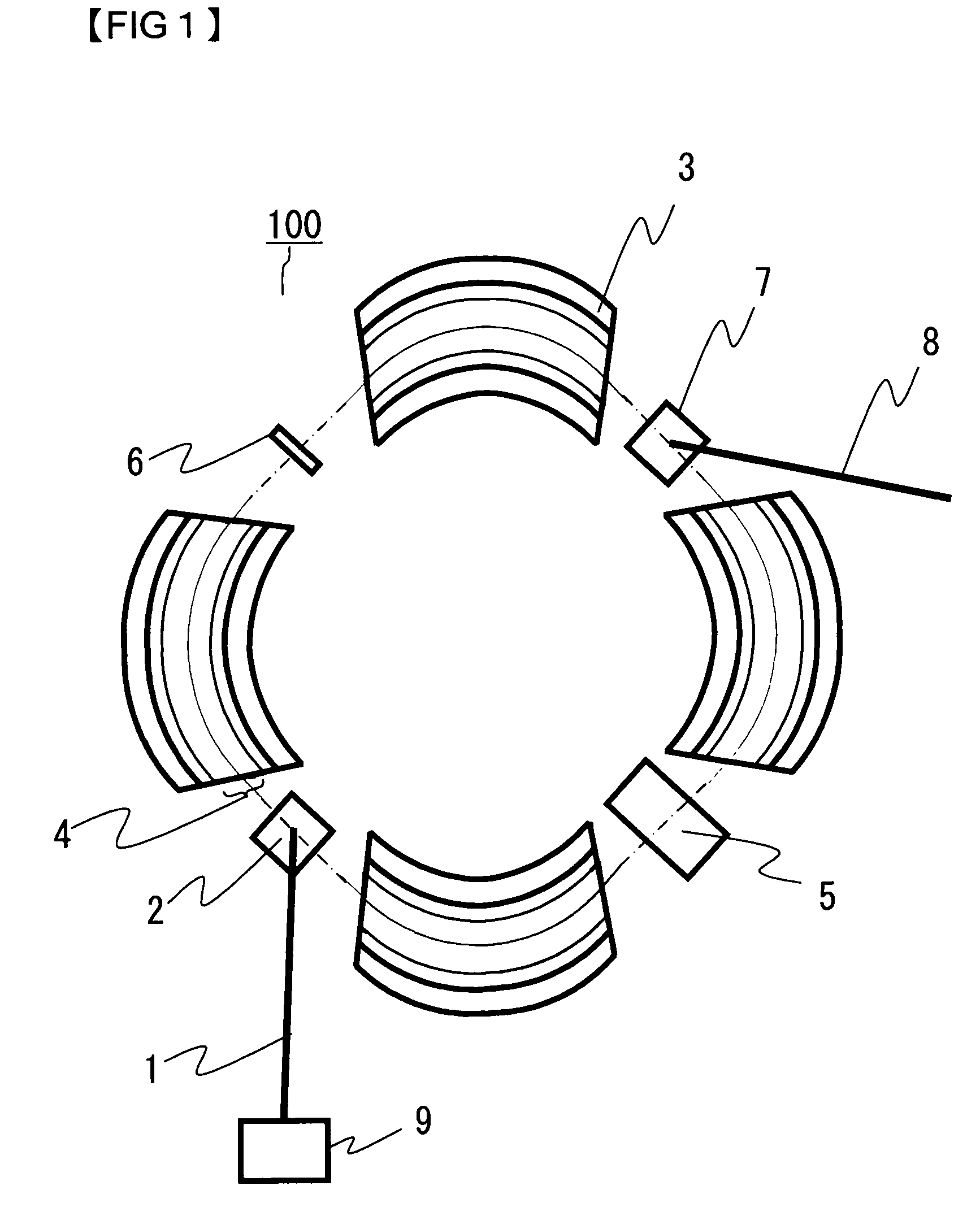

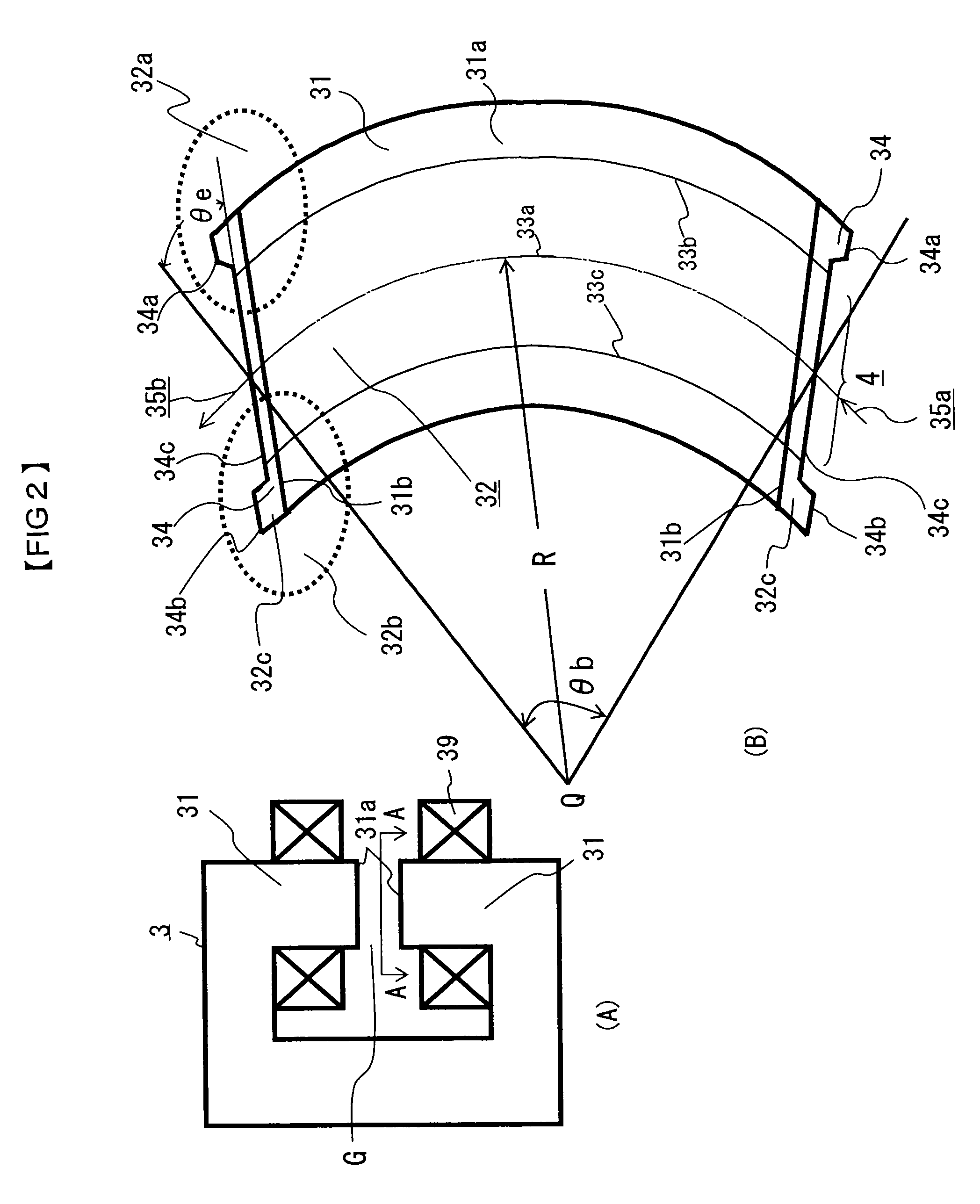

Circular accelerator

InactiveUS7982416B2Easy to controlShorten adjustment timeMagnetic induction acceleratorsTransit-time tubesMagnetic polesLight beam

In a circular accelerator, a magnetic pole edge portion of a bending electromagnet into and from which a charged particle beam enters and exits is provided with endpacks. A first protrusion is provided at that part of each end pack which is radially outside the equilibrium orbit of a center energy beam, while a second protrusion is provided at that part of each end pack which is radially inside the equilibrium orbit of the center energy beam. The shapes of the first and second protrusions are set so that the betatron oscillation numbers of beams of different acceleration energies may be held constant or become linear to the energies. In case of emitting the charged particle beam out of the circular accelerator, the change of a tune attributed to the change of the beam orbit can be statically corrected, the tune is linearly changed, and an adjustment of the emission of the beam becomes easy.

Owner:MITSUBISHI ELECTRIC CORP

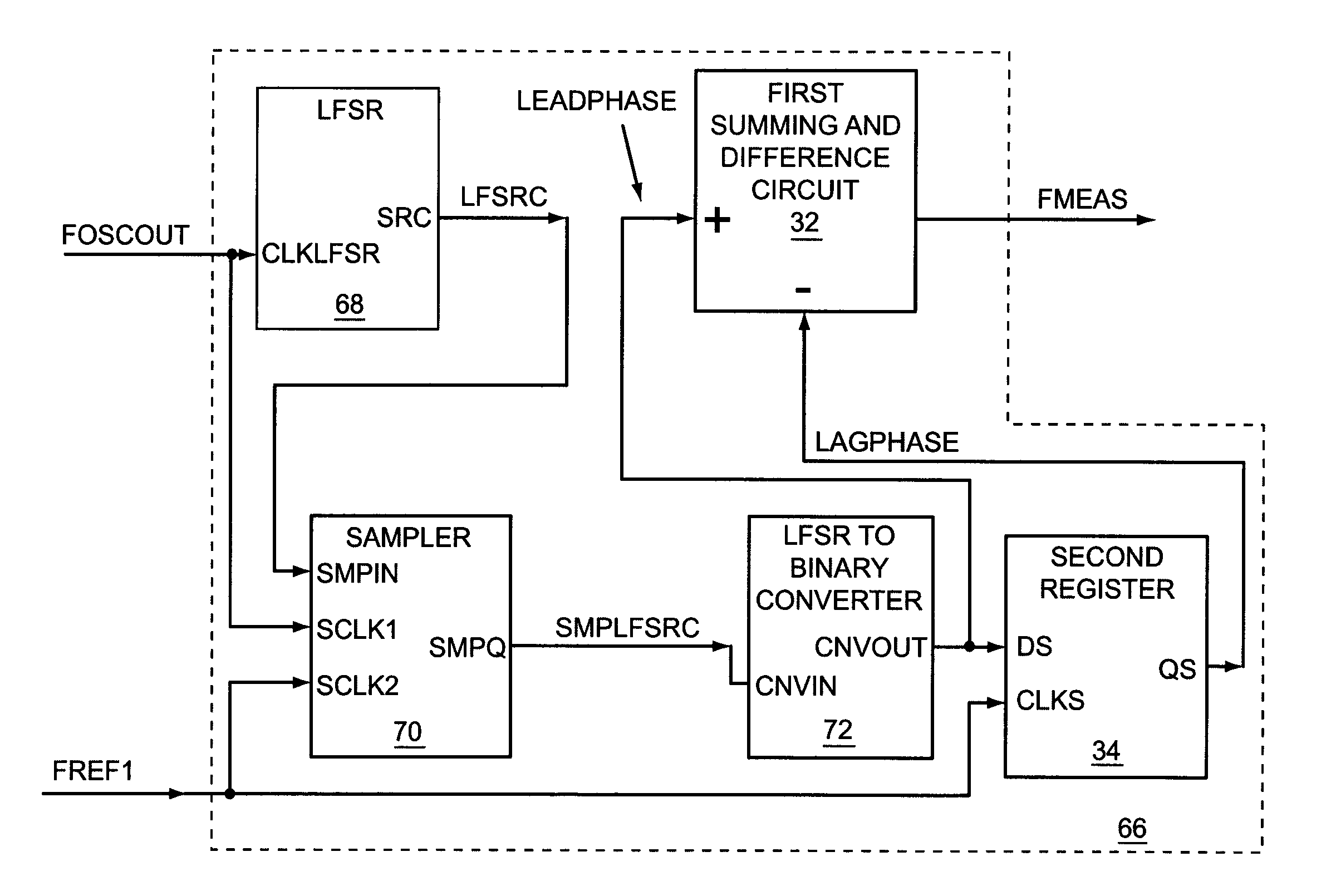

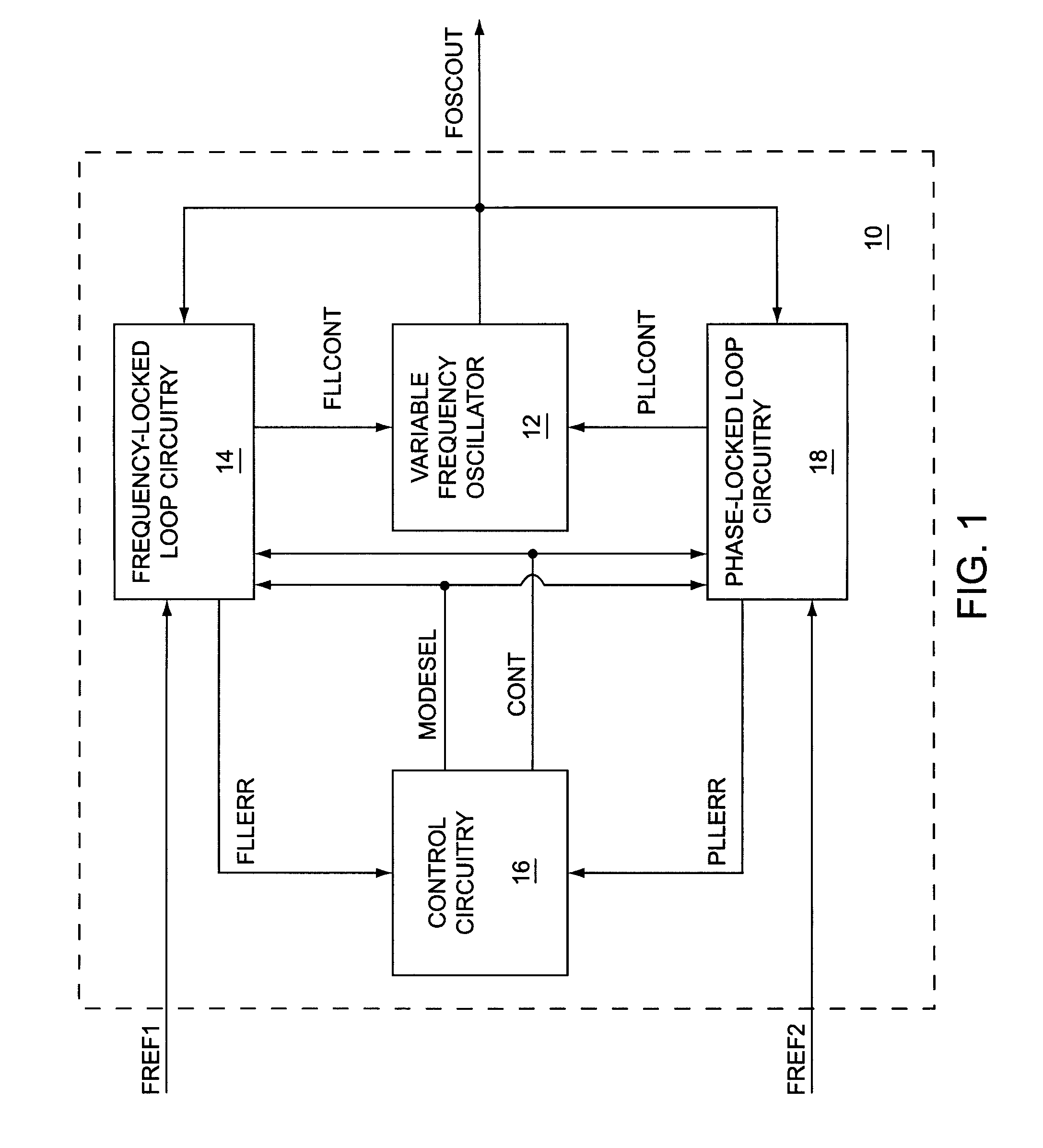

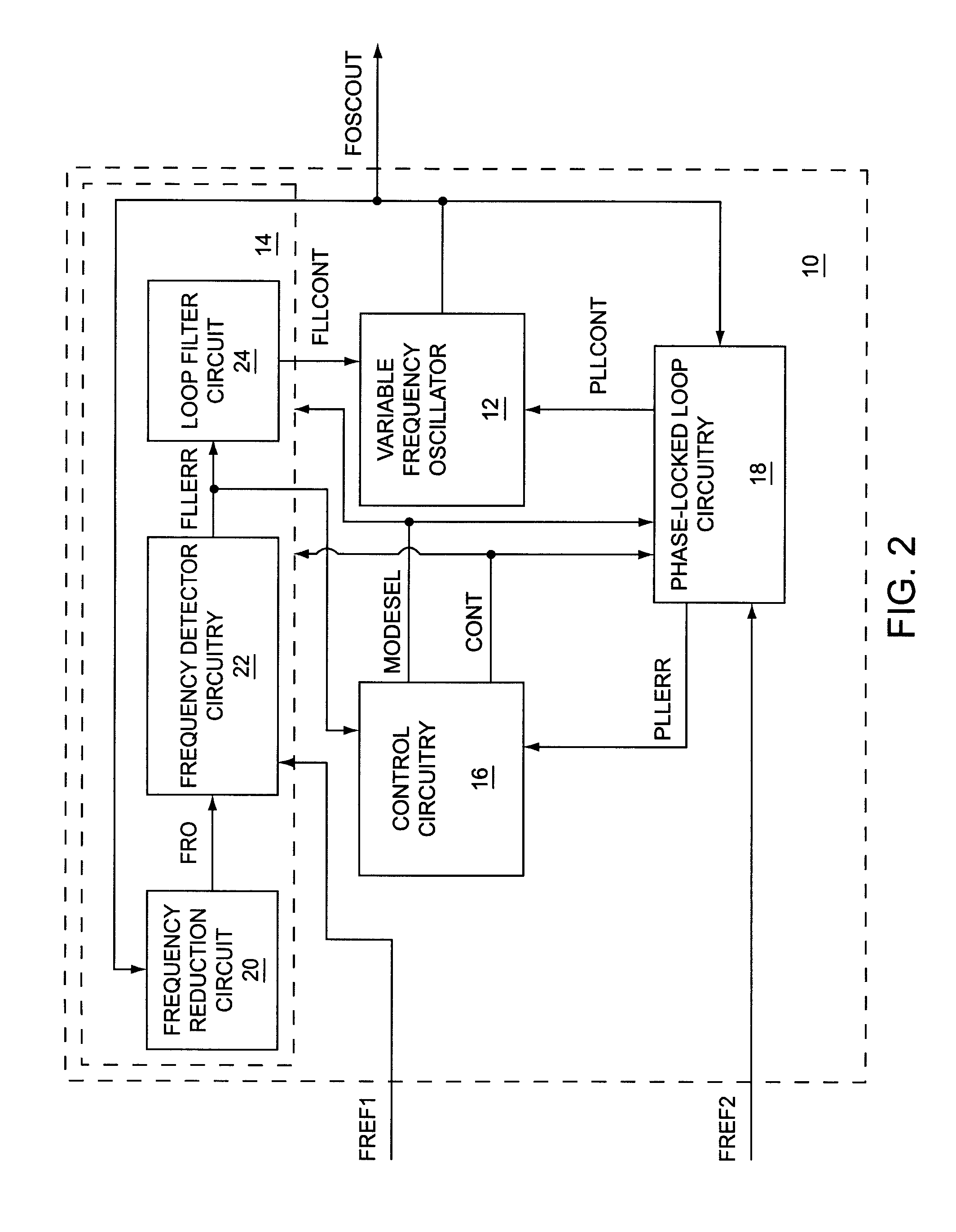

Frequency measurement based frequency locked loop synthesizer

ActiveUS7750685B1Fast settling timeReduce frequencyMultiple input and output pulse circuitsPulse automatic controlFrequency measurementsEngineering

A first embodiment of the present invention relates to a frequency and phase locked loop (FPLL) synthesizer having a frequency-locked loop (FLL) operating mode and a phase-locked loop (PLL) operating mode. The FLL operating mode is used for rapid coarse tuning of the FPLL synthesizer and is followed by the PLL operating mode for fine tuning and stabilization of the frequency of an output signal from the FPLL synthesizer. A second embodiment of the present invention relates to a high resolution frequency measurement circuit that is capable of directly measuring the frequency of a high frequency signal to provide a high resolution frequency measurement using a lower frequency reference signal, and may include linear feedback shift register (LFSR) circuitry and LFSR-to-binary conversion circuitry. A third embodiment of the present invention relates to an FPLL having an FLL that includes the high resolution frequency measurement circuit.

Owner:QORVO US INC

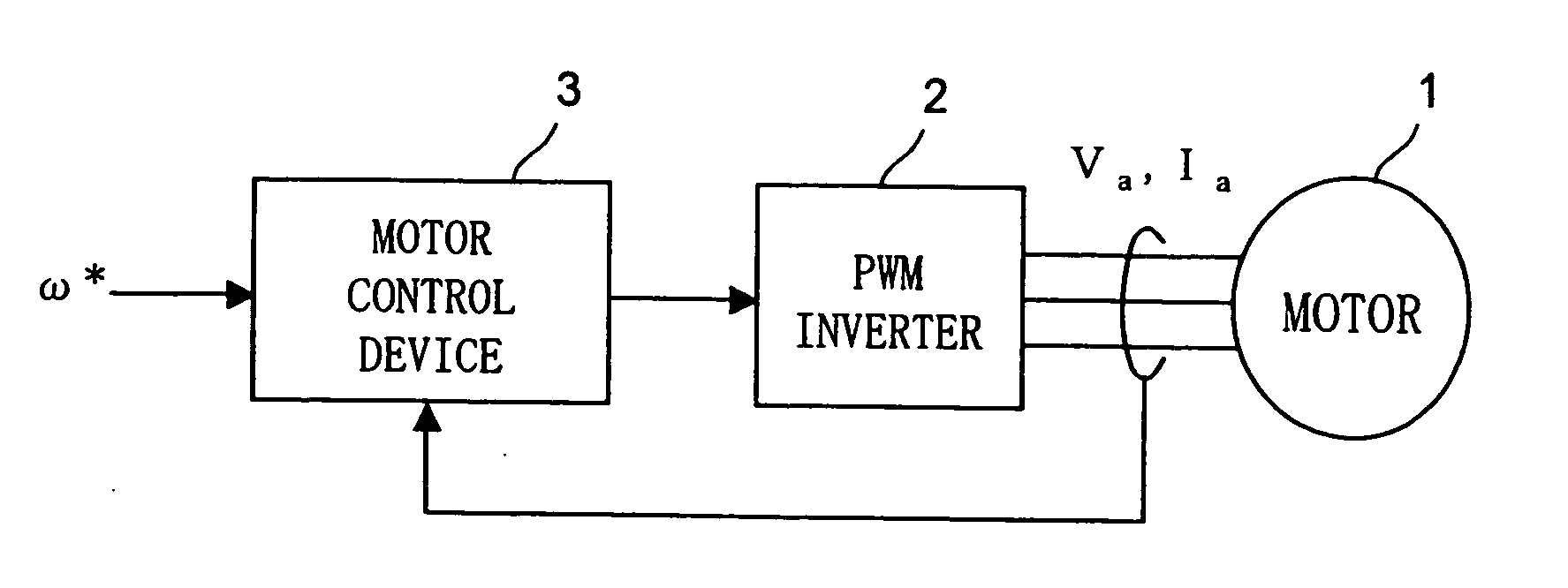

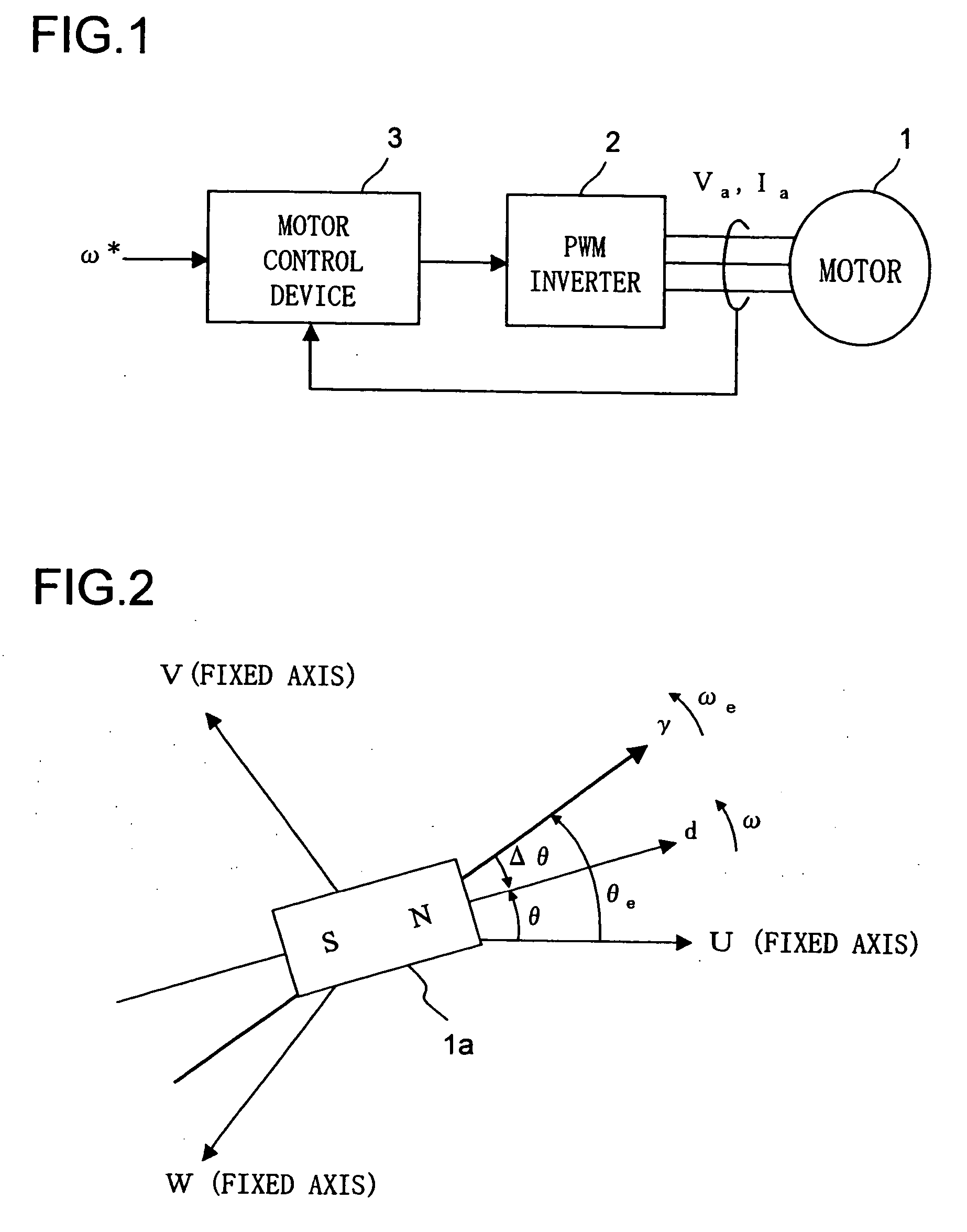

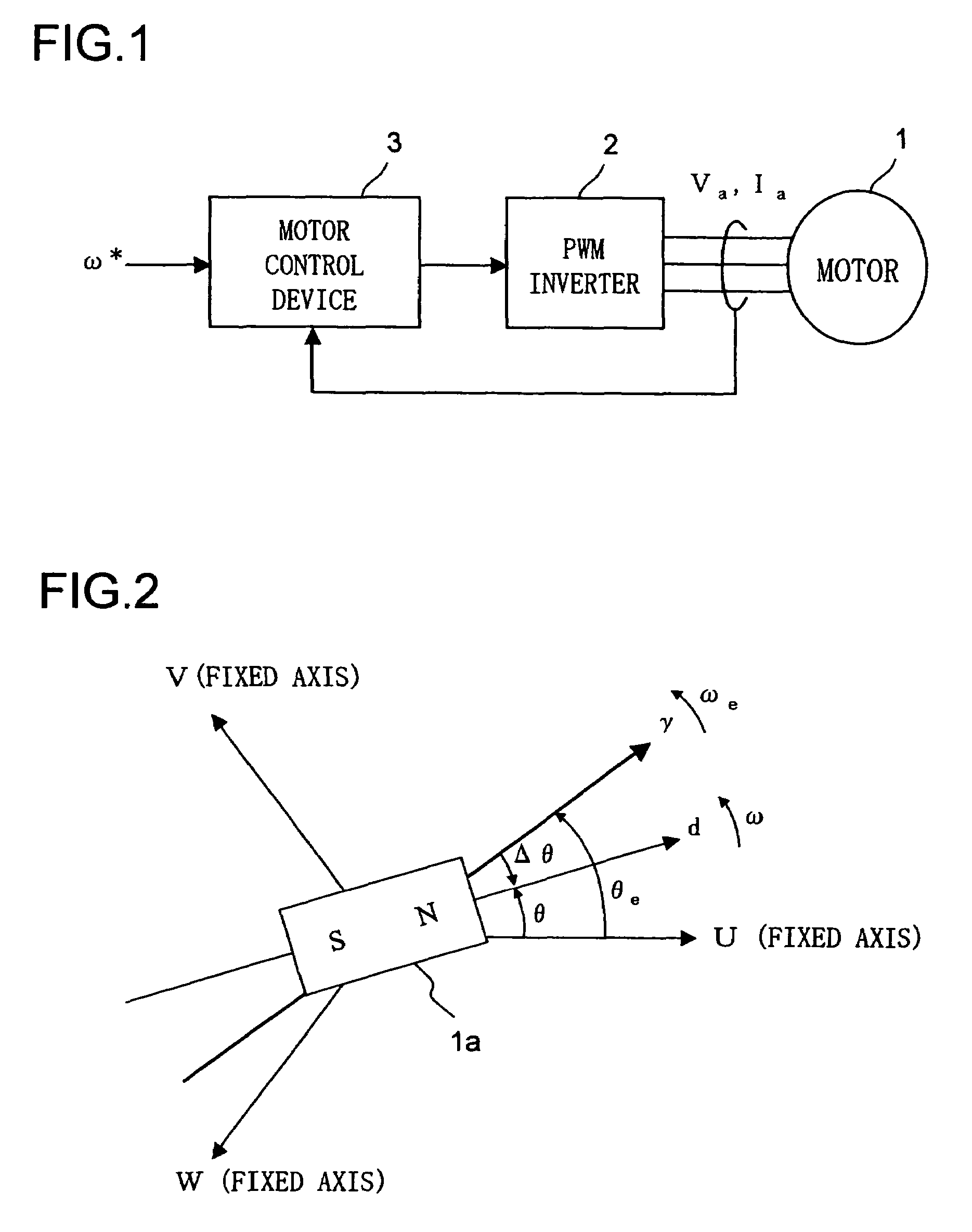

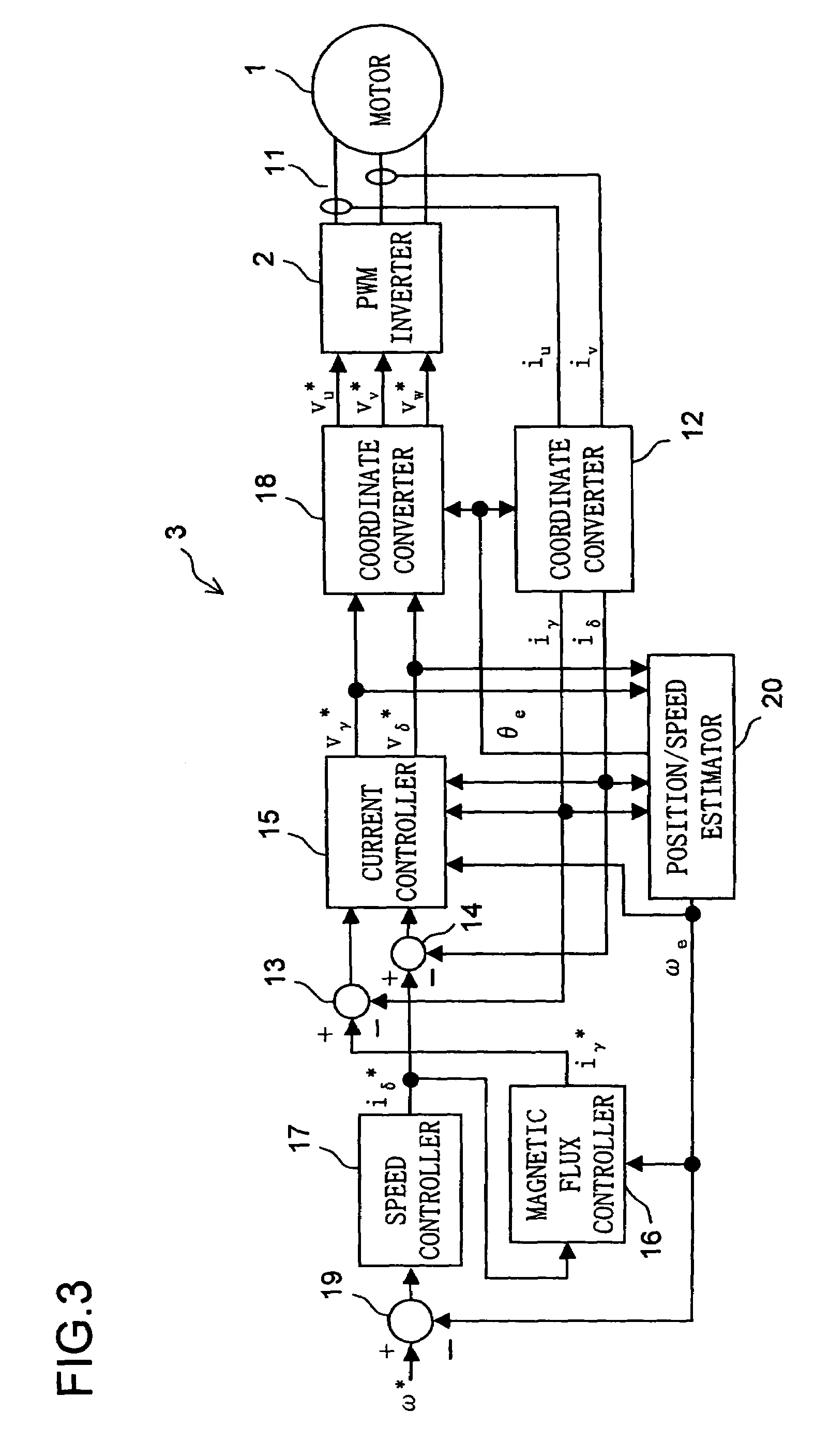

Motor control device

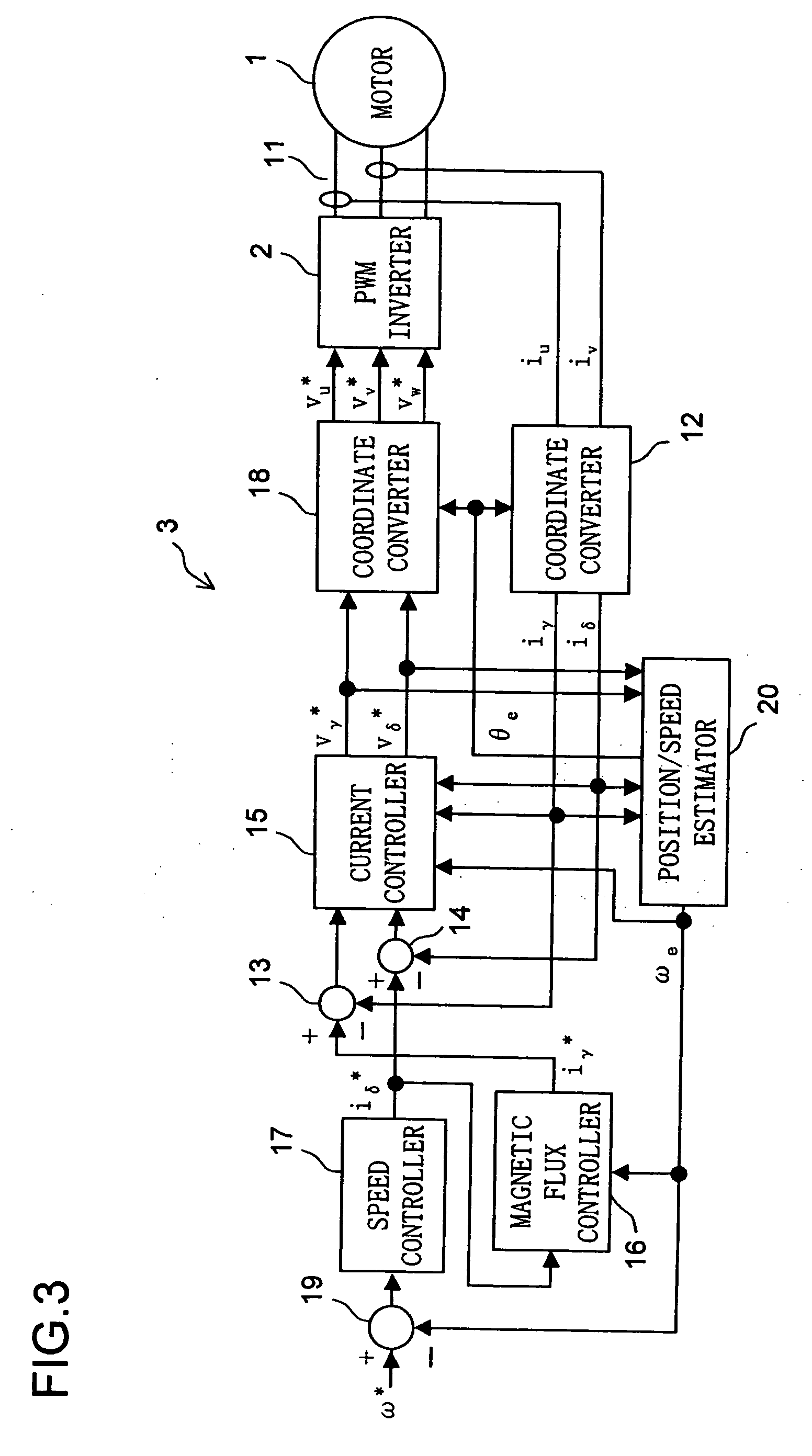

ActiveUS20070046249A1Reduce the amount of calculationEasy to adjustSingle-phase induction motor startersElectronic commutation motor controlMotor controlInductance

A motor control device includes an estimator for estimating a rotor position of a motor having a salient pole by using a value corresponding to a q-axis inductance of the motor as an operation parameter where an estimated axes for the control corresponding to d-q axes are γ-δ axes, and a controller for controlling the motor based on the estimated rotor position. The estimator generates a deviation between a d-axis and a γ-axis by performing the estimation of the rotor position based on a value between a real q-axis inductance and a real d-axis inductance of the motor adopted as the operation parameter. The controller controls the motor so that a γ-axis component of a motor current supplied to the motor is maintained to be a predetermined value of zero or close to zero regardless of a value of a δ-axis component of the motor current.

Owner:III HLDG 12 LLC

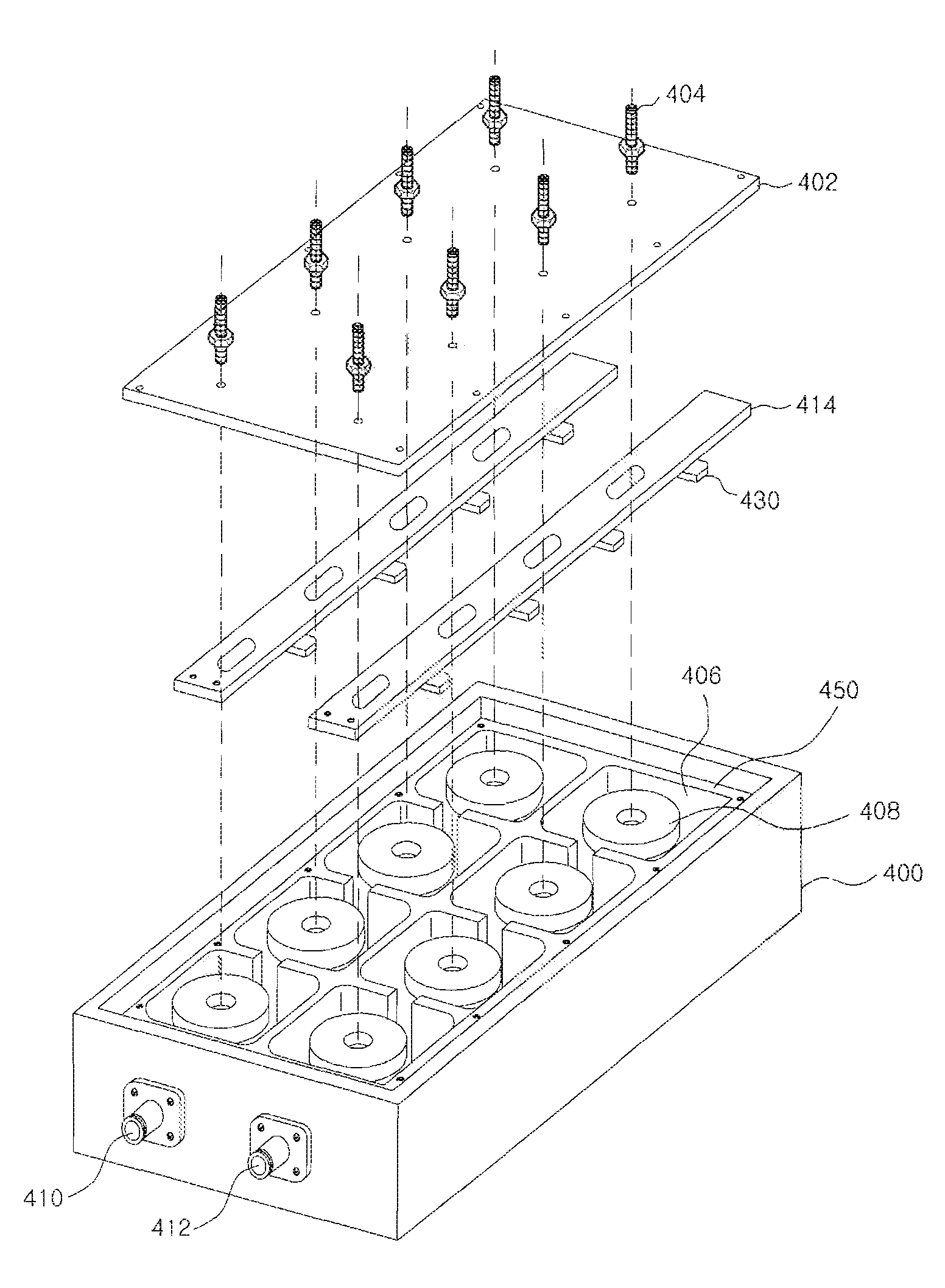

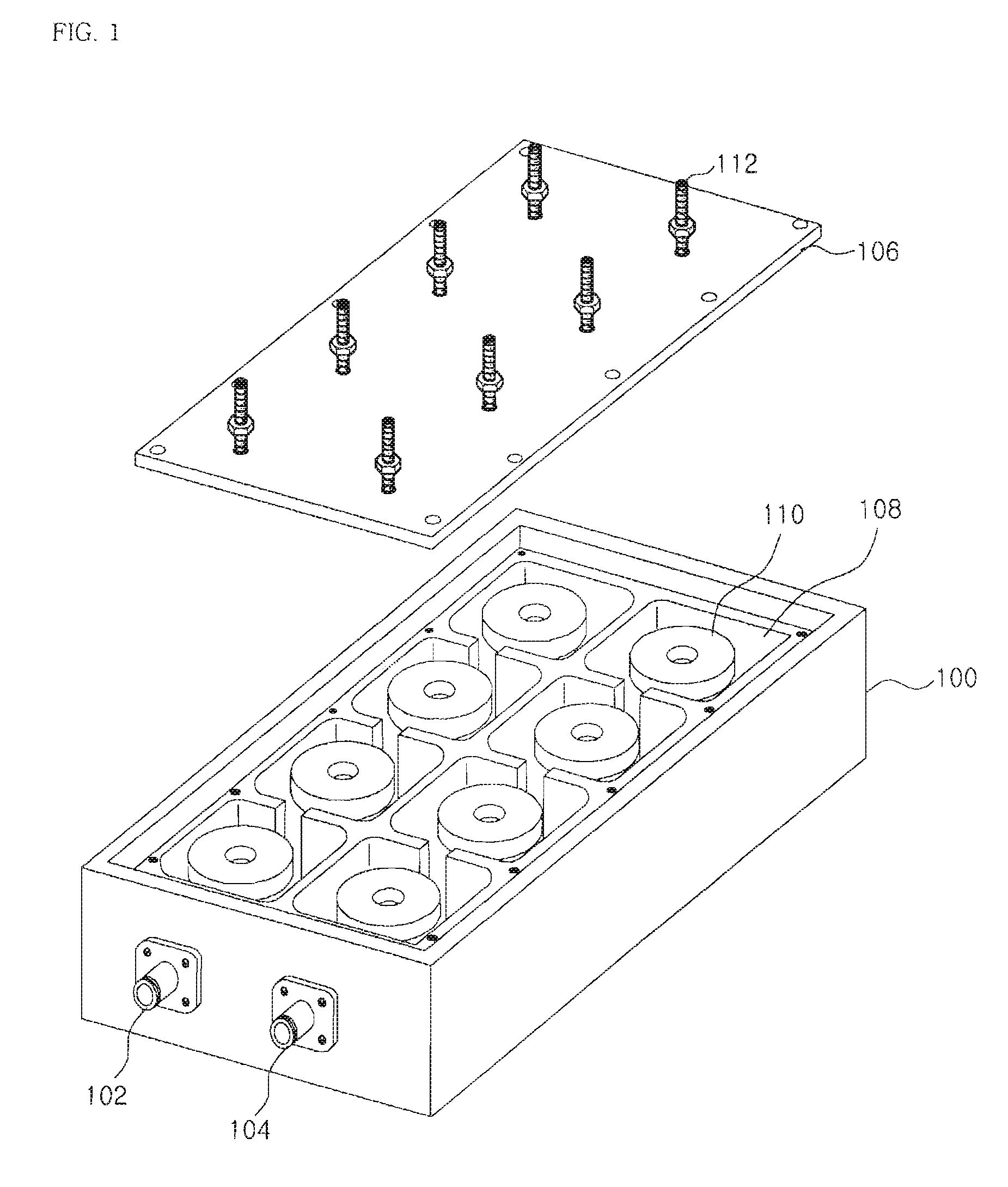

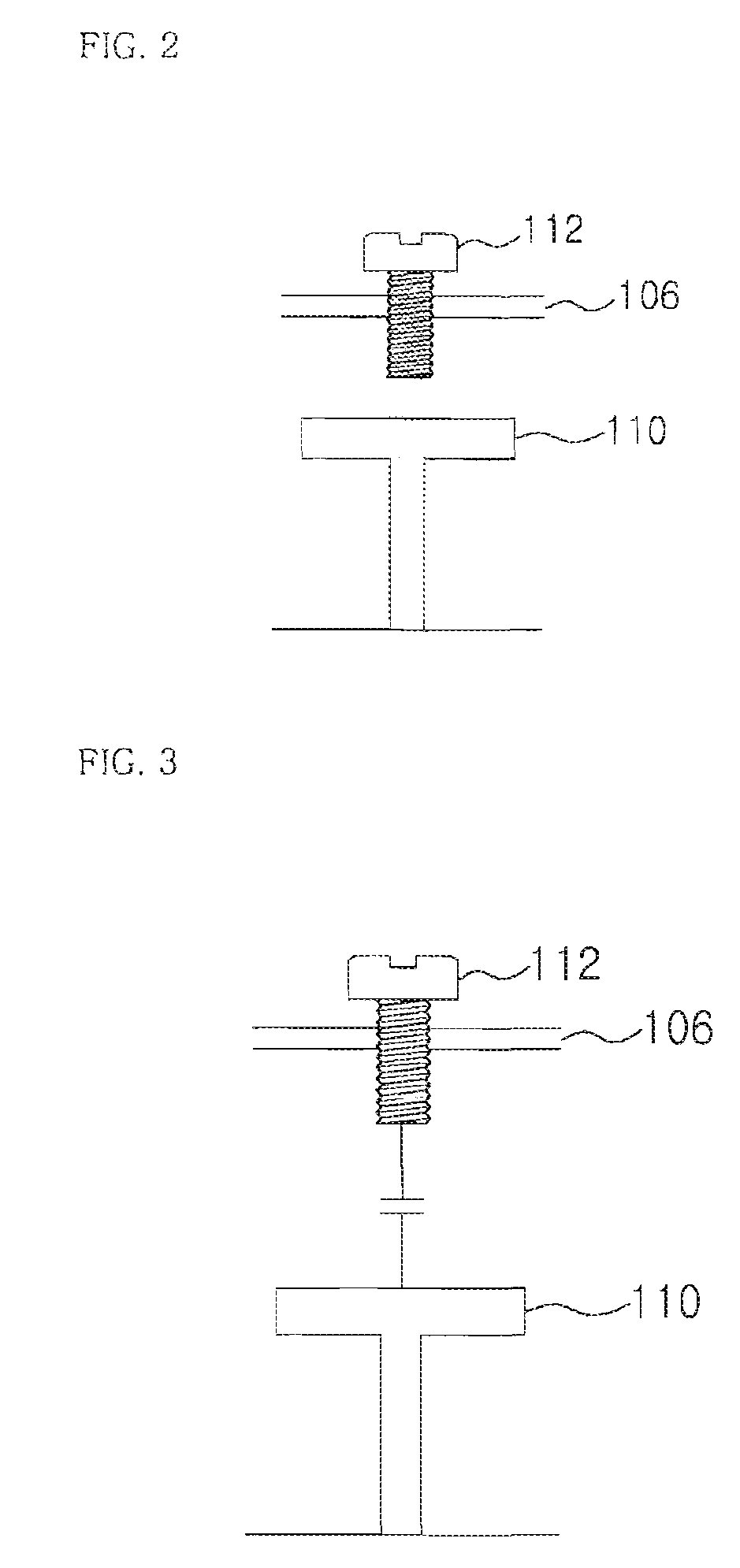

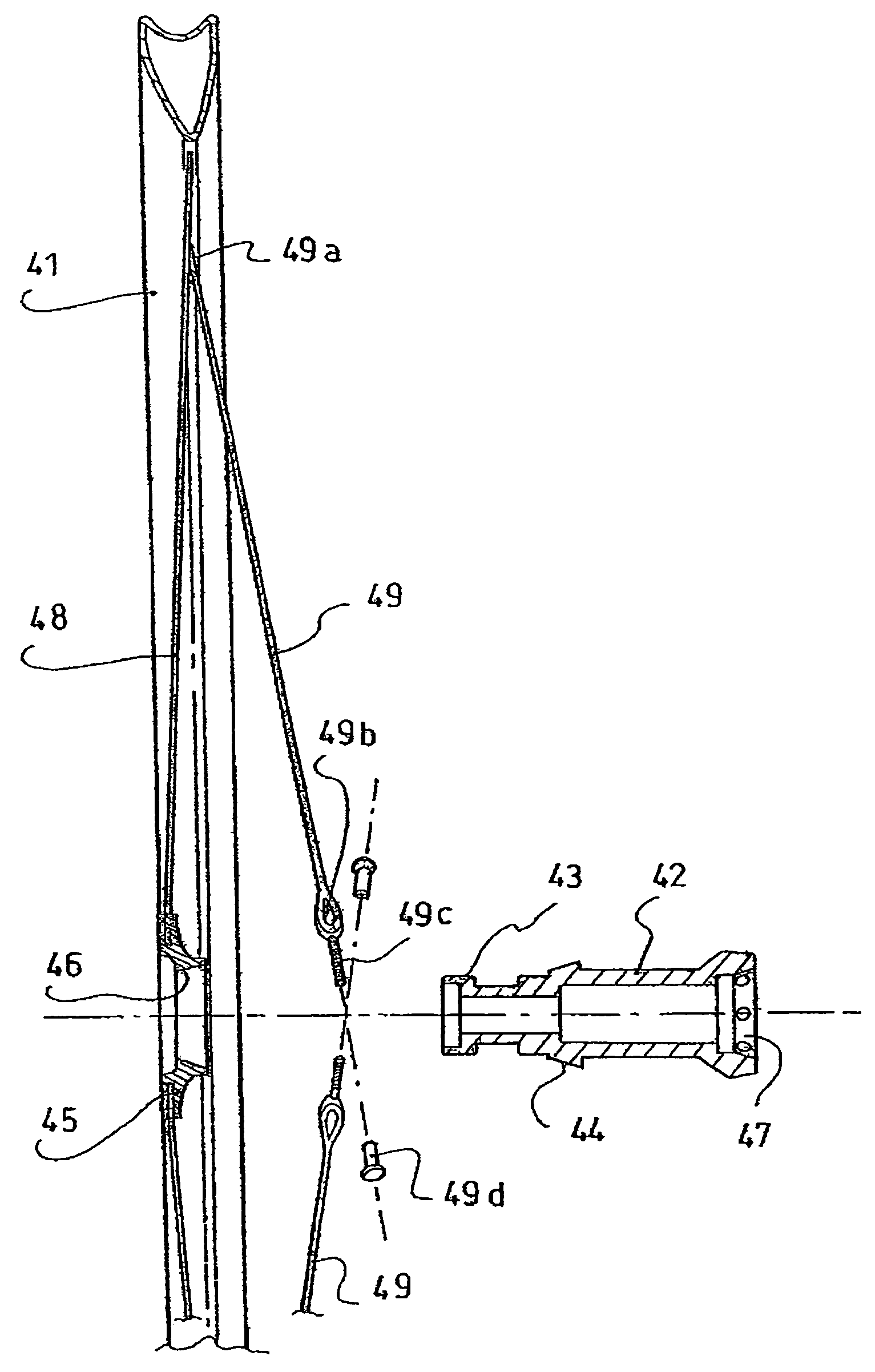

Frequency Tunable Filter

A frequency tunable filter comprises a housing having a plurality of walls therein defining a plurality of cavities; a cover mounted on the housing; a plurality of resonators contained in the cavities; at least one sliding member located between the cover and the resonators; and a plurality of metal tuning elements attached to a lower part of the sliding member, wherein frequency tuning is performed by sliding of the sliding member.

Owner:ACE TECH

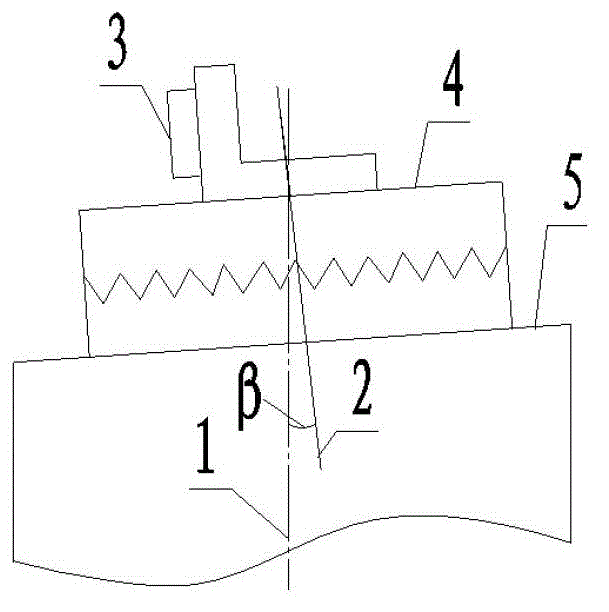

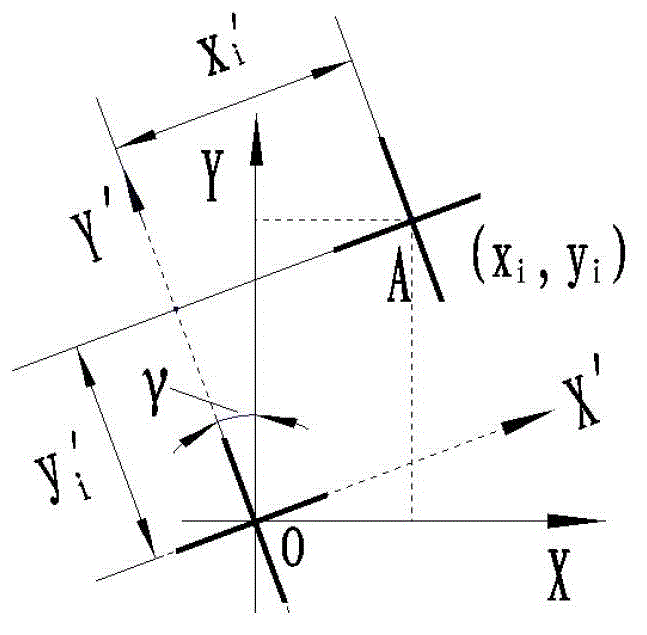

Two-axis photoelectric collimator based rotary table division error detection method

InactiveCN102914260AEliminate adjustment errorsEliminate interactionUsing optical meansDual axisComputer science

The invention discloses a two-axis photoelectric collimator based rotary table division error detection method. The two-axis photoelectric collimator based rotary table division error detection method includes the steps: (1) mounting a multi-tooth division table at the center of the working face of an inspected rotary table, fixing a planar mirror onto the multi-tooth division table and using an autocollimator for collimating the planar mirror; (2) enabling the inspected rotary table to rotate for a circle so that both two axes of the photoelectric autocollimator have numerical reading; (3) placing the inspected rotary table at the zero position, reading initial values of the two-axis photoelectric autocollimator, then rotating the multi-tooth division table by an angle phi, and enabling the planar mirror to rotate by the angle phi along with the inspected rotary table; (4) enabling the planar mirror to rotate by the angle phi towards the opposite direction along with the multi-tooth division table, enabling the photoelectric autocollimator to collimate the planar mirror again and read measurement values until a circle is completed; and (5) changing an inclination angle of the multi-tooth division table relative to the rotary table while keeping the two-axis photoelectric autocollimator immovable, repeating the step 2, the step 3 and the step 4 for secondary detection, and reading measurement values of the two-axis photoelectric autocollimator. By the aid of the method, the requirement on adjustment is lowered.

Owner:TIANJIN UNIV

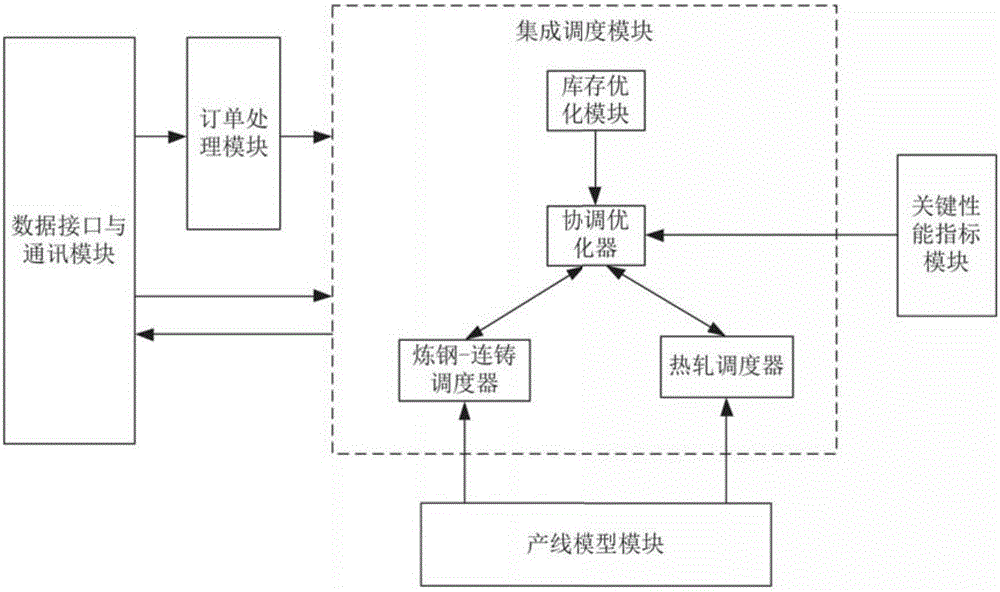

Steelmaking-continuous casting-hot rolling integrated scheduling method and system

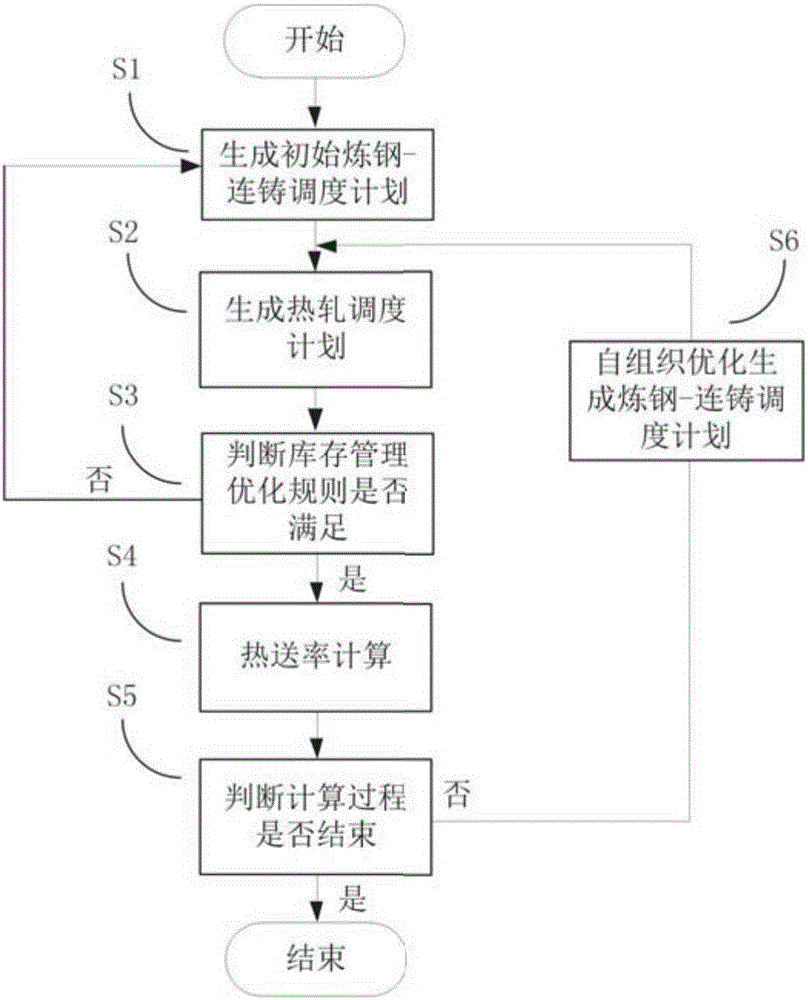

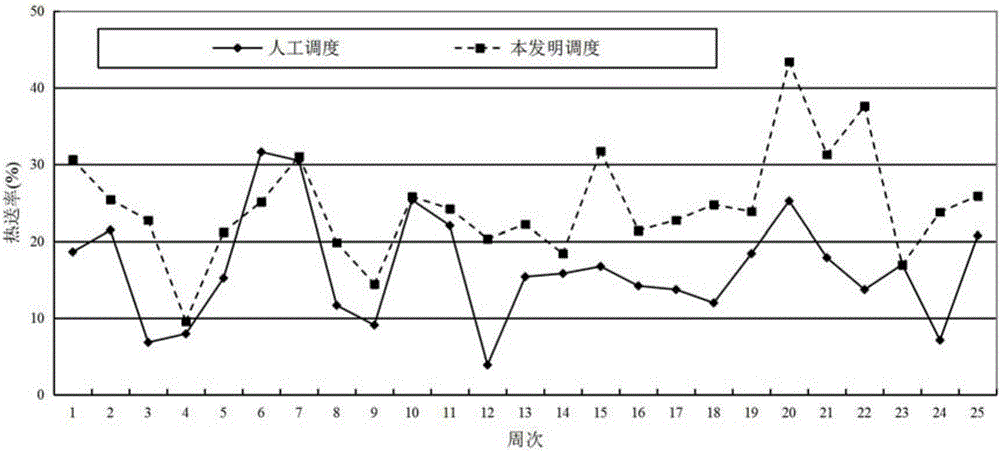

ActiveCN106779220AAvoid confictImprove heat transfer rateForecastingResourcesProduction lineHardness

The invention provides a steelmaking-continuous casting-hot rolling integrated scheduling method and system. The method comprises the steps of S1, performing initialization to obtain a steelmaking-continuous casting scheduling plan; S2, obtaining a hot rolling scheduling plan according to the current steelmaking-continuous casting scheduling plan as well as a working order demand, a production line model, a current production rhythm, a rolling unit length constraint, and a rolling unit internal adjacent plate blank width, thickness and hardness jump constraint; S3, determining whether an inventory change situation meets a preset inventory optimization plan or not according to the current steelmaking-continuous casting scheduling plan and the hot rolling scheduling plan, and if the preset rule is met, entering the next step, otherwise, adjusting current parameters related to inventory optimization and returning to the step S1; S4, obtaining overall heat supply rate data according to the current steelmaking-continuous casting scheduling plan and the hot rolling scheduling plan; S5, judging whether an integrated scheduling stop condition is met or not, and if the stop condition is met, performing the scheduling plan, otherwise, performing the next step; and S6, performing re-optimization to generate the steelmaking-continuous casting scheduling plan, and returning to the step S2.

Owner:ZHEJIANG SUPCON RES

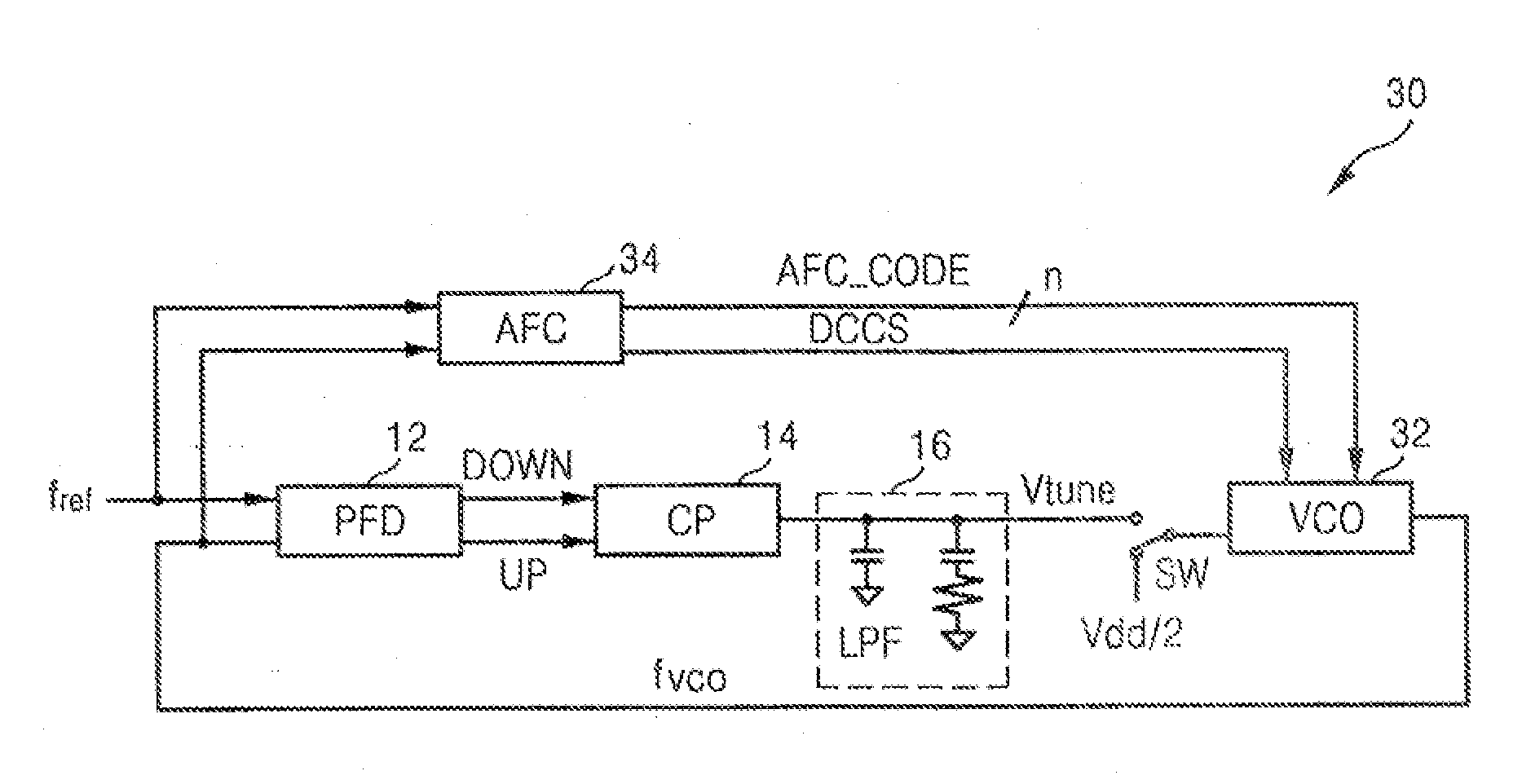

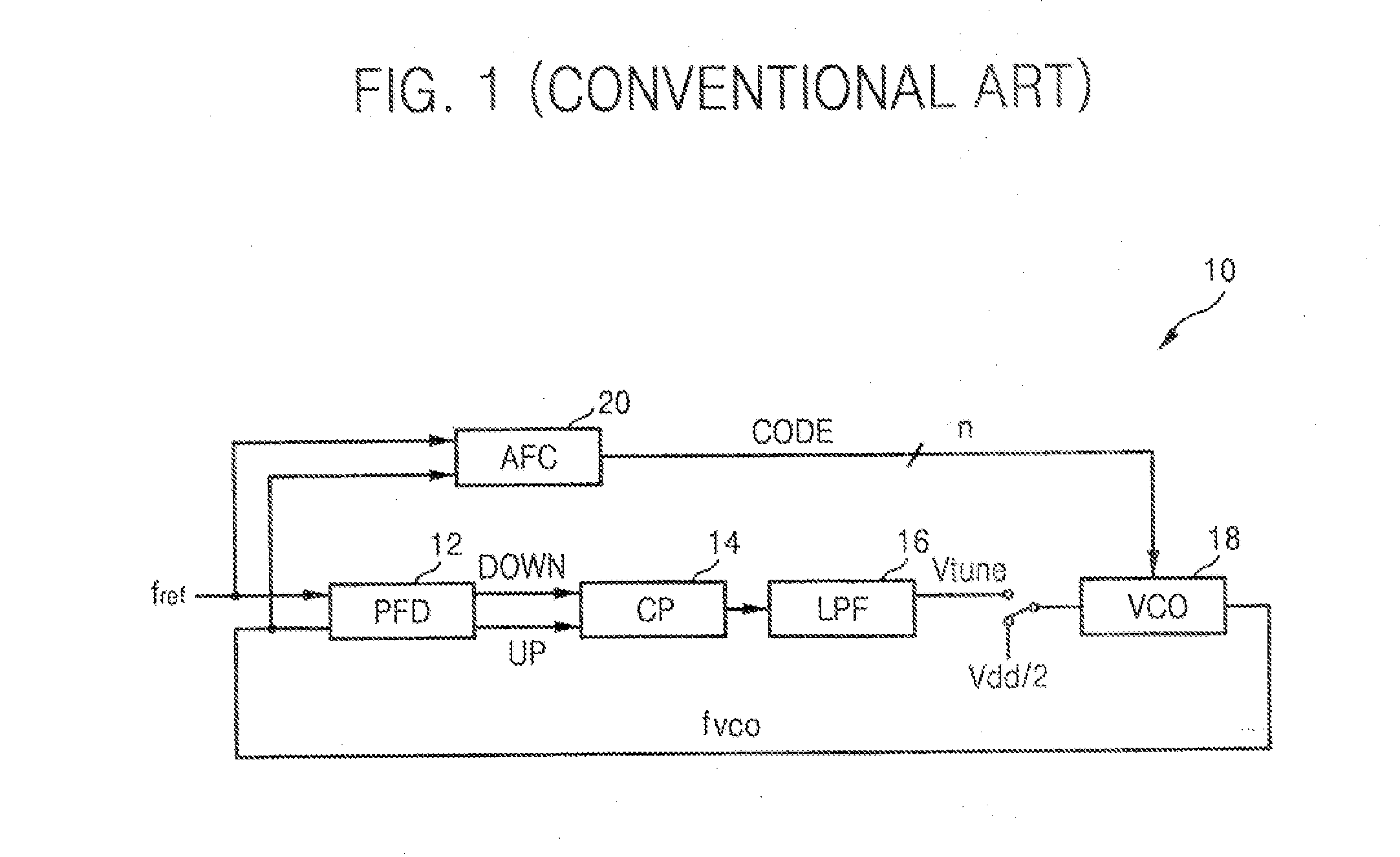

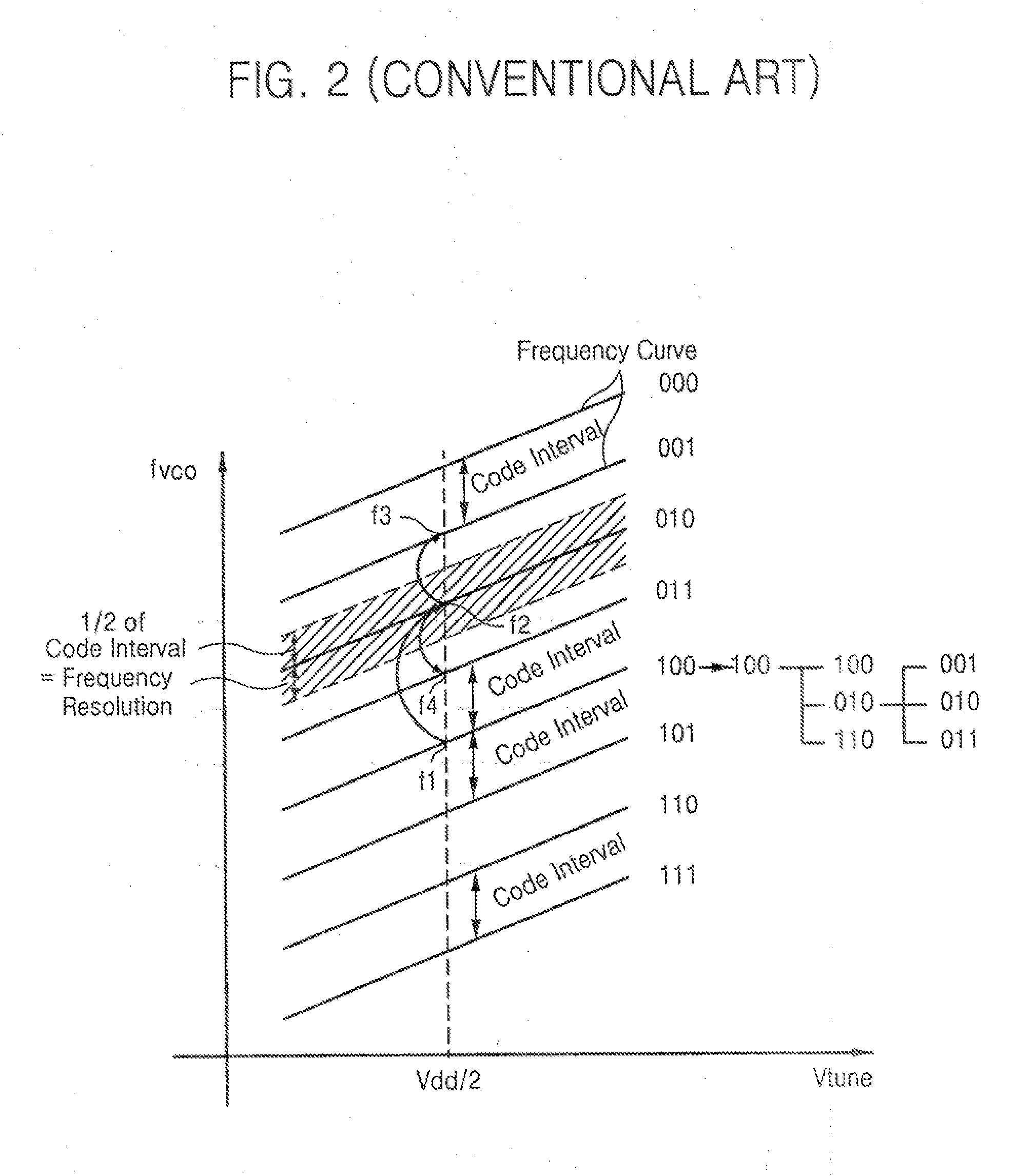

Frequency tuning method for voltage controlled oscillator and phase locked loop using the same

A frequency tuning method for a voltage controlled oscillator includes outputting a first frequency selected from 2n discrete frequencies included in a frequency tuning range of the voltage controlled oscillator based on a predetermined control voltage and an n-bit control code during coarse tuning; outputting a third frequency corresponding to an average of the first frequency and a second frequency, that is, ½ of a code interval in response to the predetermined control voltage, the n-bit control code, and a control bit; and locking an output frequency of the voltage controlled oscillator to a reference frequency based on an analog control voltage and the third frequency during fine tuning. The second frequency is adjacent to the first frequency amoung the 2n discrete frequencies and the third frequency is used as an initial frequency in the fine tuning.

Owner:SAMSUNG ELECTRONICS CO LTD

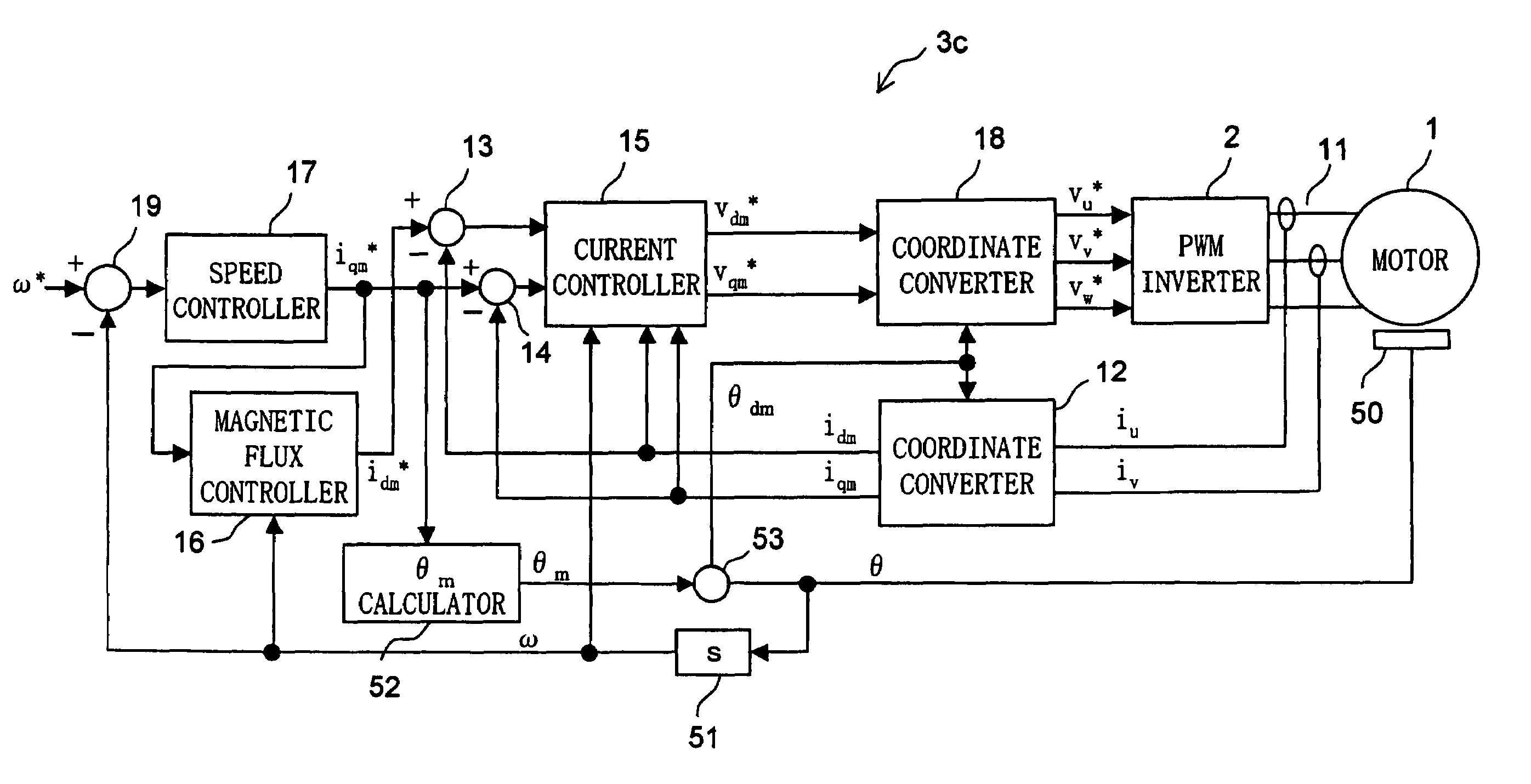

Motor control device

ActiveUS7504797B2Reduce the amount of calculationEasy to adjustSingle-phase induction motor startersElectronic commutation motor controlElectric machineMotor control

A motor control device includes an estimator for estimating a rotor position of a motor having a salient pole by using a value corresponding to a q-axis inductance of the motor as an operation parameter where an estimated axes for the control corresponding to d-q axes are γ-δ axes, and a controller for controlling the motor based on the estimated rotor position. The estimator generates a deviation between a d-axis and a γ-axis by performing the estimation of the rotor position based on a value between a real q-axis inductance and a real d-axis inductance of the motor adopted as the operation parameter. The controller controls the motor so that a γ-axis component of a motor current supplied to the motor is maintained to be a predetermined value of zero or close to zero regardless of a value of a δ-axis component of the motor current.

Owner:III HLDG 12 LLC

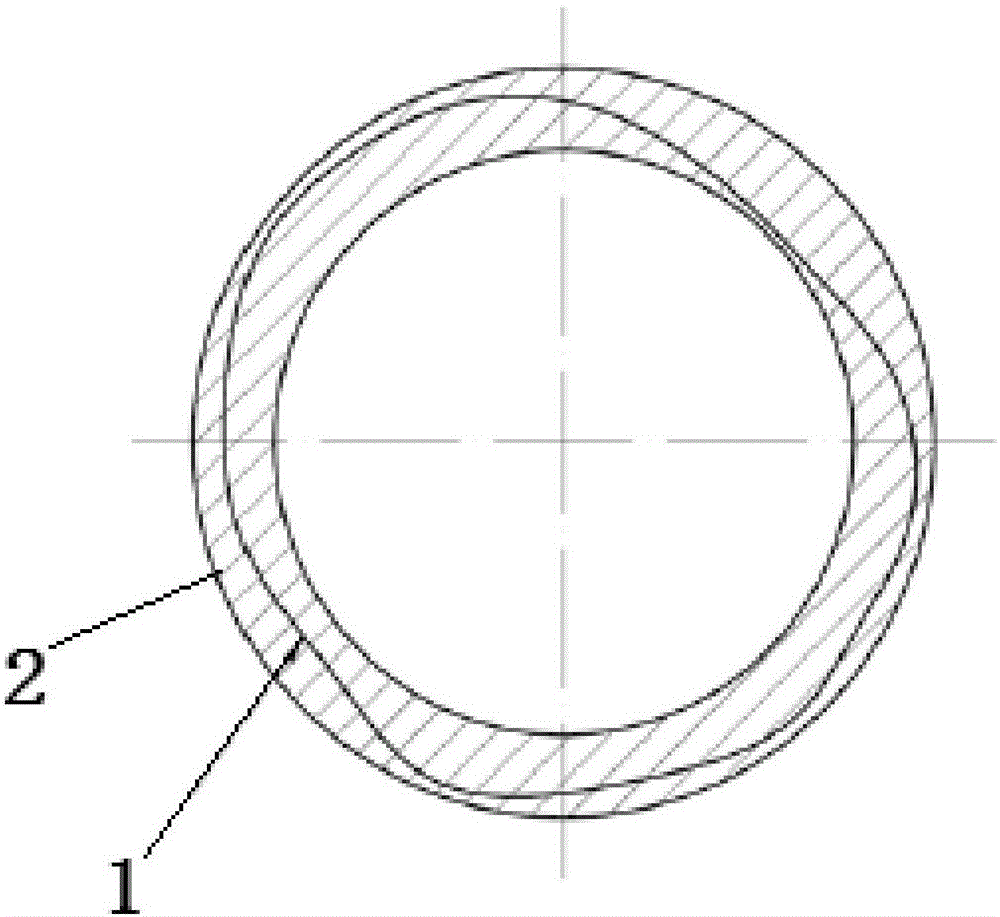

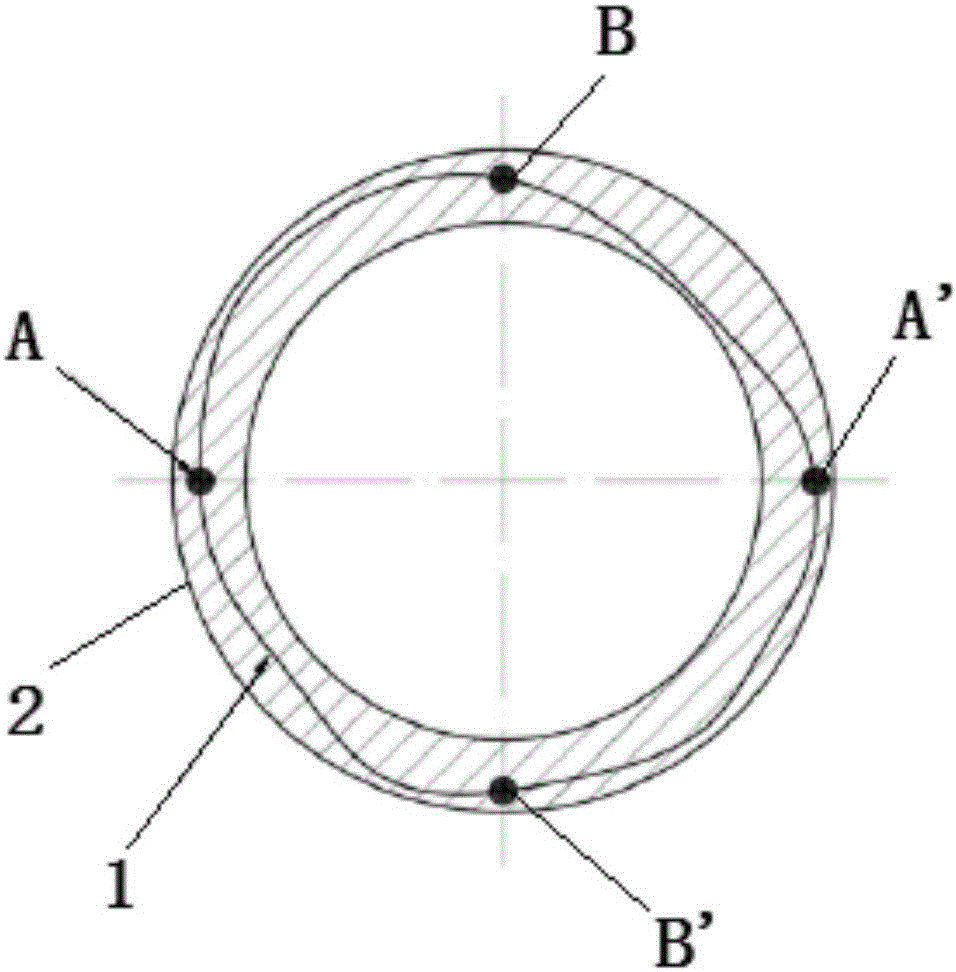

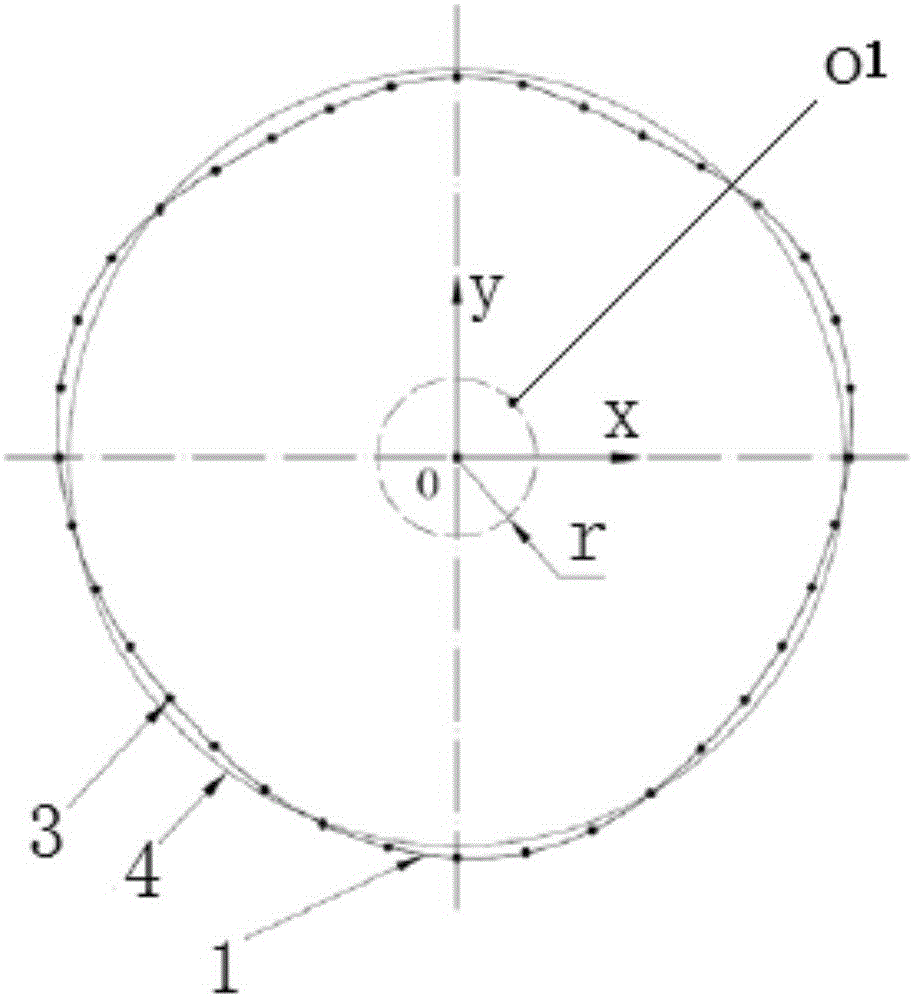

Circle center aligning method for aviation revolution part machining basic circle

ActiveCN106312690AThe result is accurateShorten adjustment timeMeasurement devicesMeasurement/indication equipmentsAviationMachine parts

The invention relates to a circle center aligning method for an aviation revolution part machining basic circle. According to the aligning method, multi-point measurement is conducted on the circumference of the basic circle, a least square method principle is adopted for calculating a measuring point, coordinates of the circle center of the basic circle are obtained, and therefore the accurate position of the basic center of a machined part in a machine tool rotation table is quantized. Compared with traditional circumference four-point alignment or circumference jerk value alignment, the method is more scientific in principle and more accurate in result.

Owner:杭州天扬机械有限公司

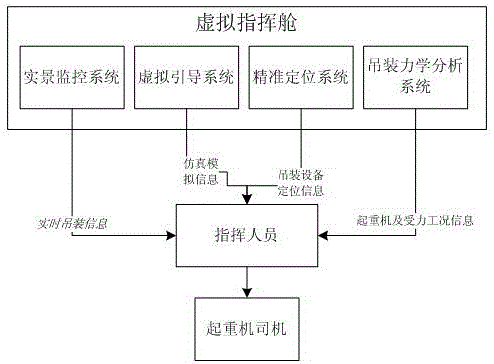

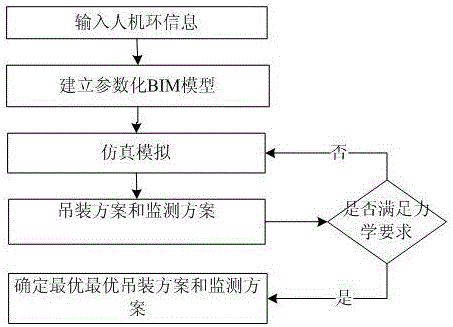

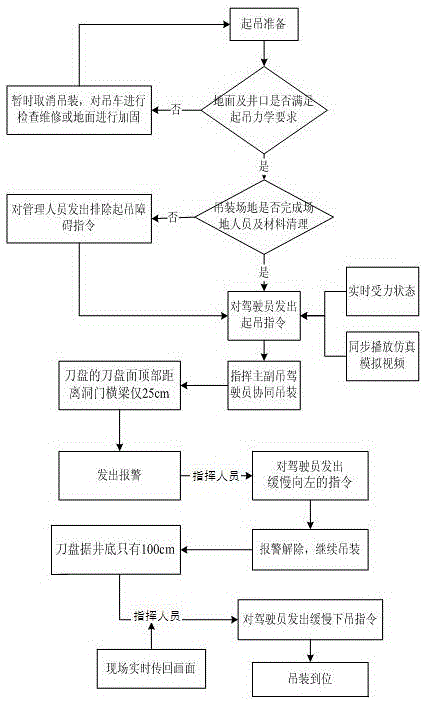

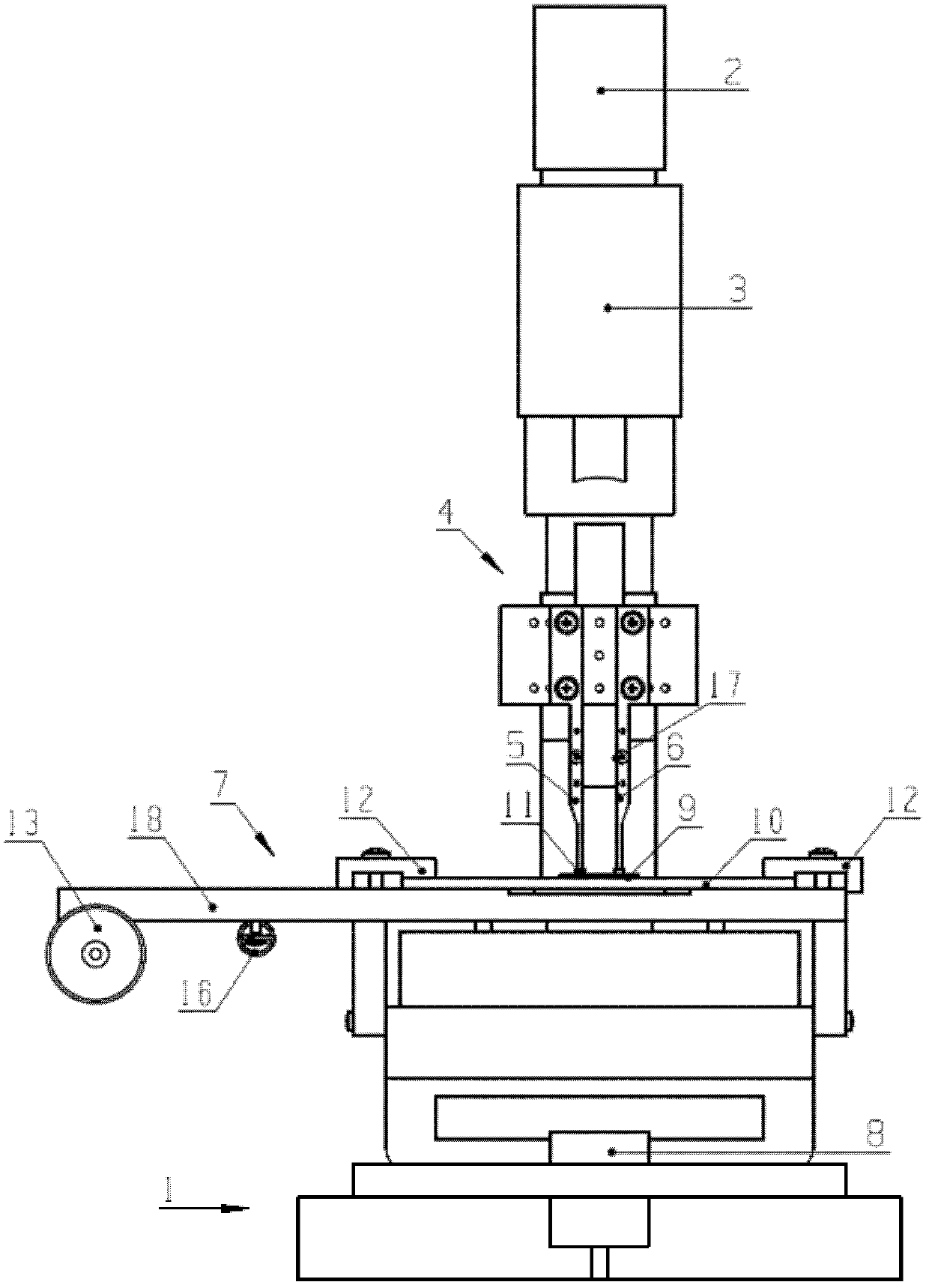

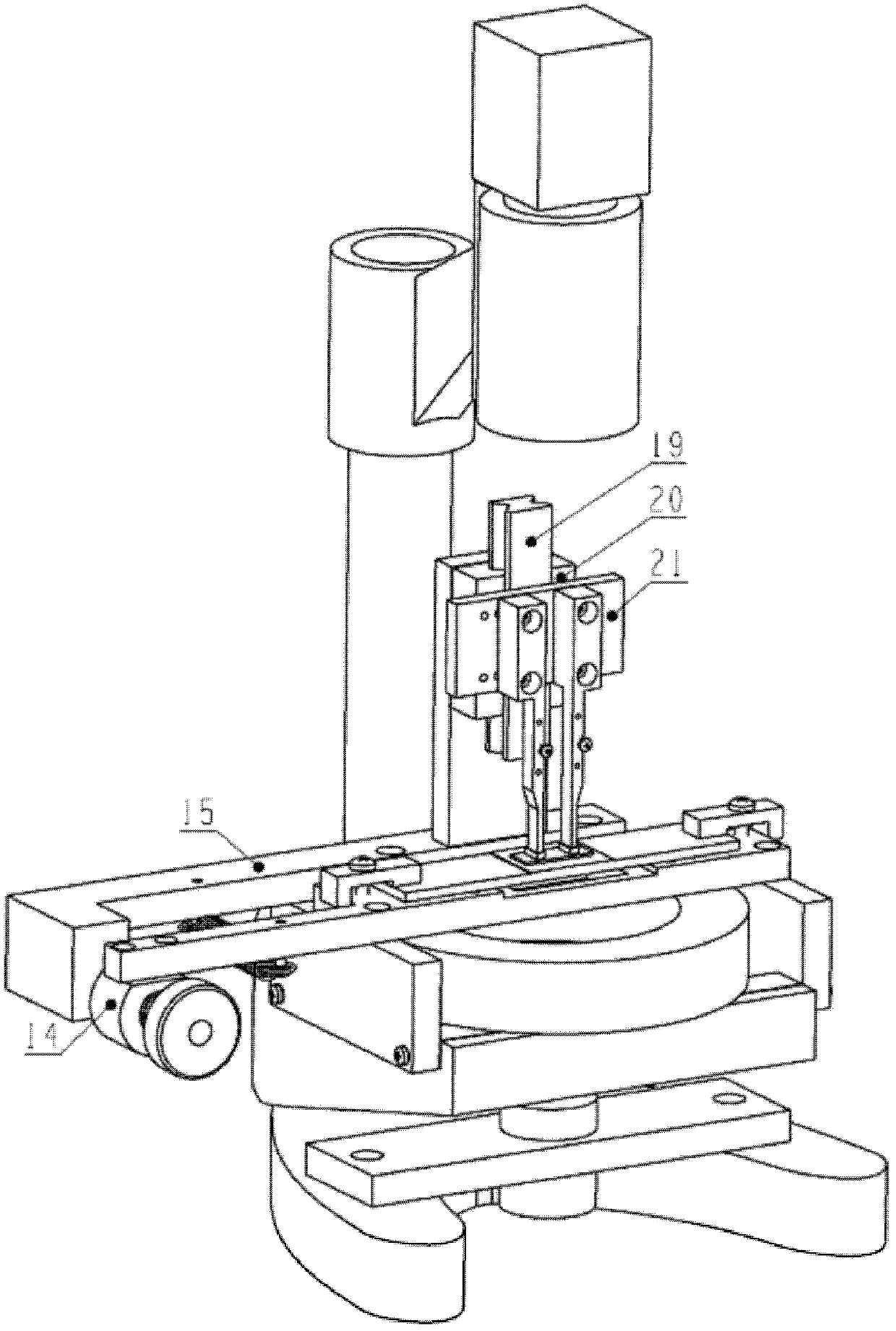

Virtual command module for large lifting operations and working method of virtual command module

ActiveCN105819339ASimple structureEasy to operateLoad-engaging elementsInformatizationDriver/operator

The invention belongs to the field of safety control on lifting operations and provides a virtual command module for large lifting operations and a working method of the virtual command module. The module comprises a live-action monitoring system, a virtual guiding system, a precise positioning system and a lifting mechanical analysis system. Visualization of global field monitoring of a lifting site can be realized, a virtual lifting rehearsal model is constructed on the basis of a BIM (building information model), and simulation and route optimization of a lifting process are realized through setting of working conditions and lifting parameters, so that lifting risks are mastered in advance, and a lifting scheme conforming to actual requirements is made; besides, through precise positioning and lifting mechanical analysis, automation and informatization of collision prevention and safety control on lifting are realized, accurate and direct early-warning information is provided for front-line commanders, unified and standard lifting commands are given to crane drivers, the crane drivers are assisted in completing lifting operations smoothly and safely, and the safe, real-time and effective technical support is provided for the large lifting operations.

Owner:HUAZHONG UNIV OF SCI & TECH

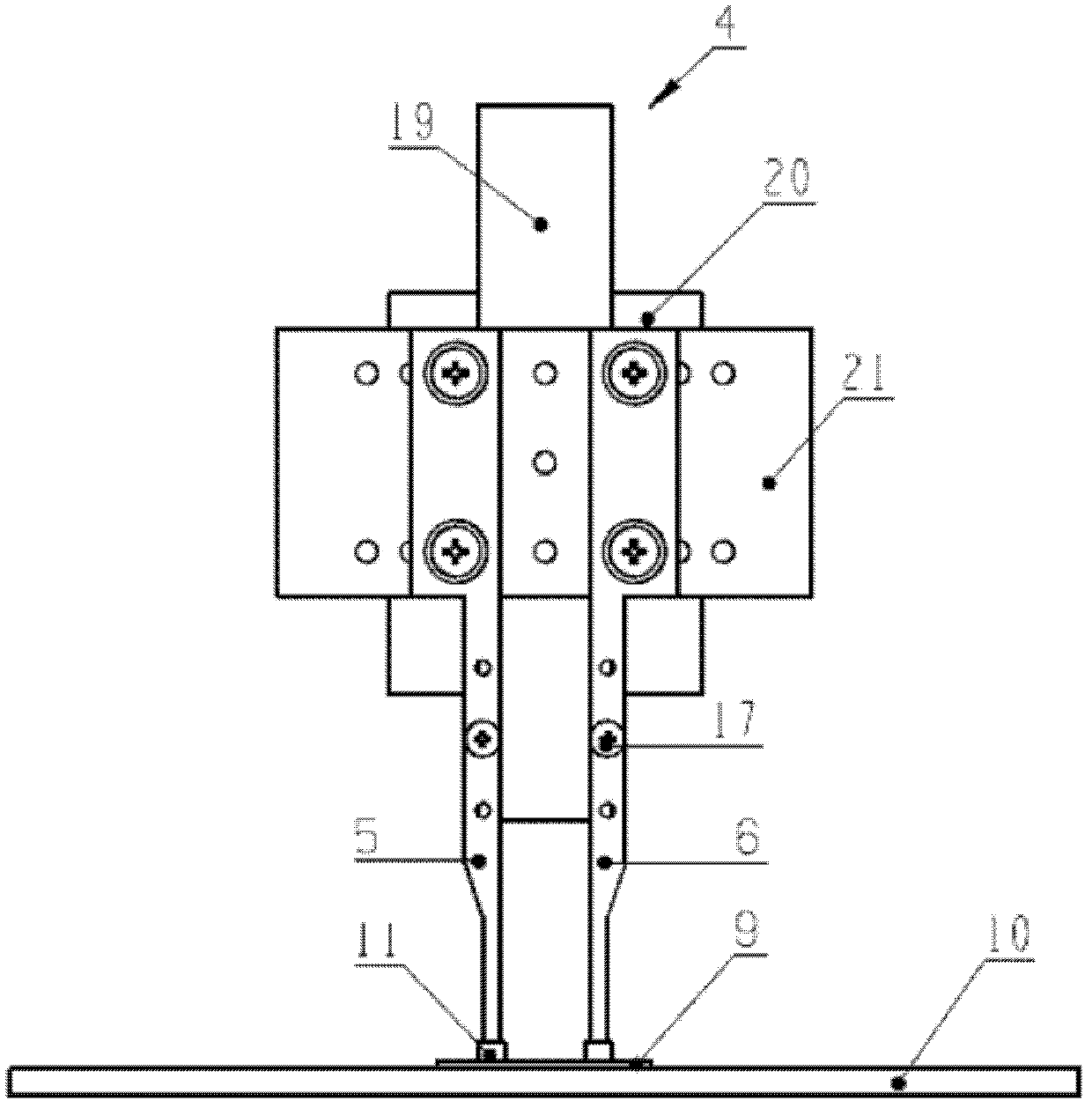

Positioning and splicing device of indicating grating

The invention provides a positioning and splicing device of an indicating grating, belongs to the technical field of photoelectric measurement, and aims to conveniently and accurately position the indicating grating before the indicating grating is spliced on an indicating grating carriage. The device comprises a supporting mechanism, a charge coupled device (CCD), an objective lens, a guide rail mechanism, a left pressing needle, a right pressing needle, a regulating mechanism, a light source, the indicating grating and a main grating, wherein the lower end of the CCD is connected to the objective lens; the guide rail mechanism is arranged below the objective lens and is fixedly arranged on the regulating mechanism; the left and right pressing needles are fixedly arranged on the guide rail mechanism; the indicating grating is pressed on the main grating by the left and right pressing needles; the main grating is fixedly arranged on the regulating mechanism; the regulating mechanism is fixedly arranged on a middle seat of the supporting mechanism; the light source is arranged at the bottom end of the supporting mechanism; and light emitted by the light source irradiates on the main grating and the indicating grating and is then imaged on the CCD via the objective lens. The positioning and splicing device is applied to the structure mounting process of a grating ruler, and the reliability of a grating ruler measuring mechanism is guaranteed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

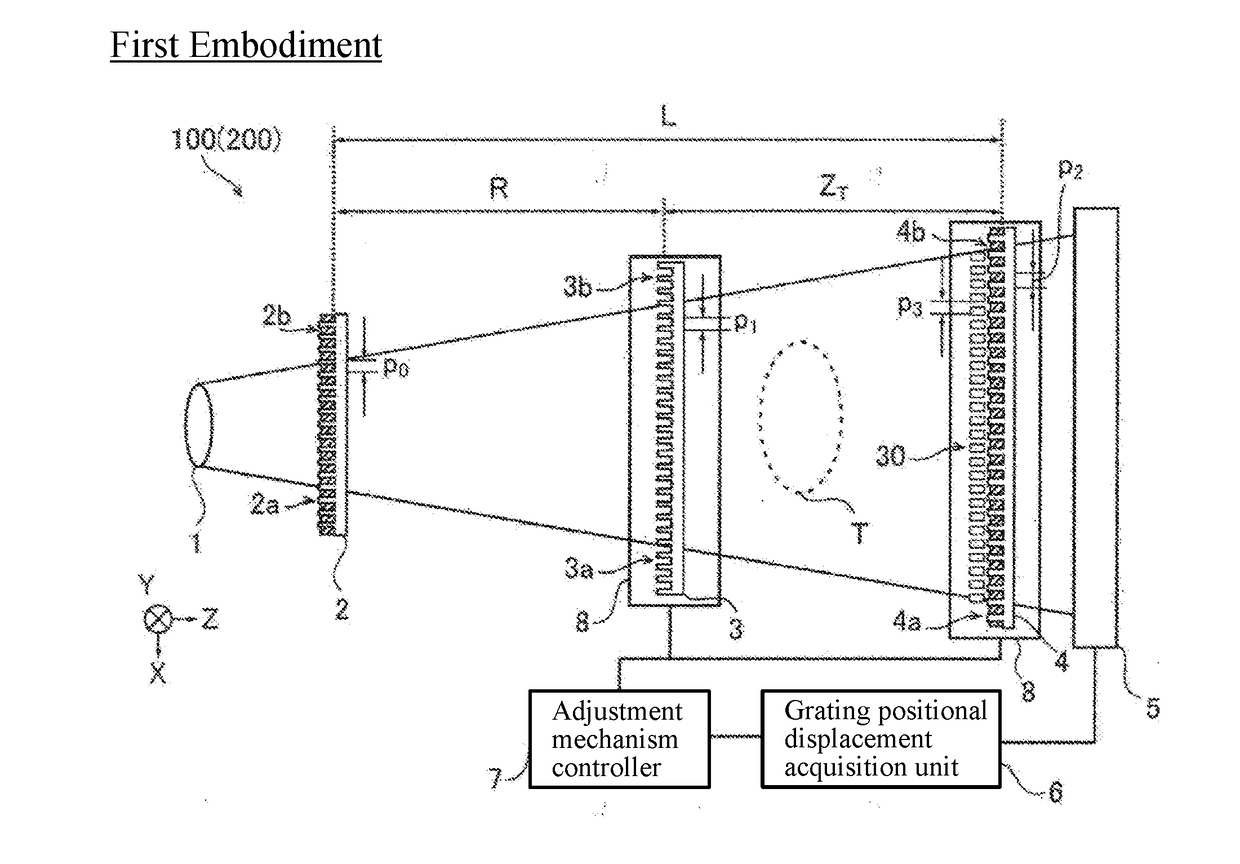

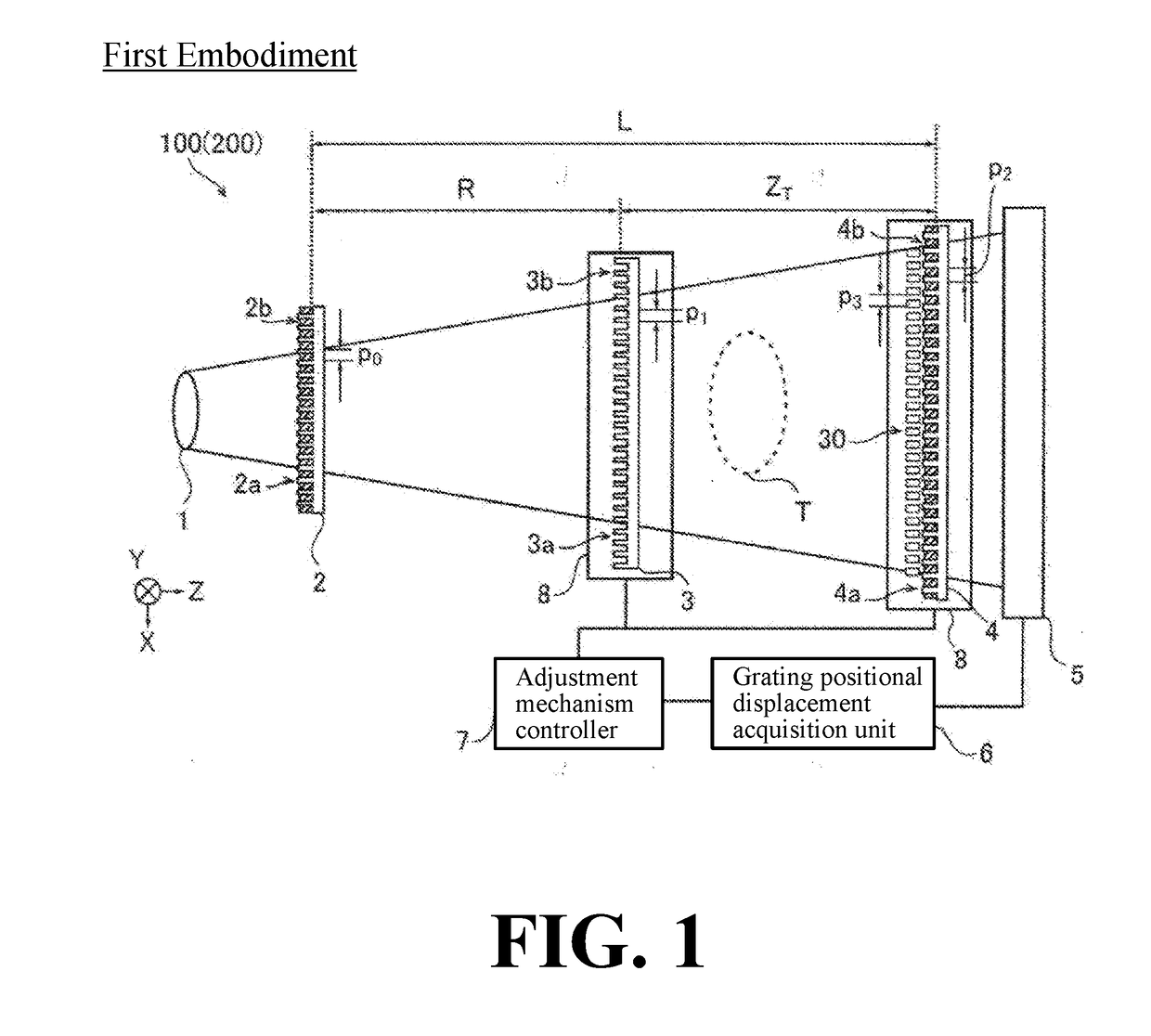

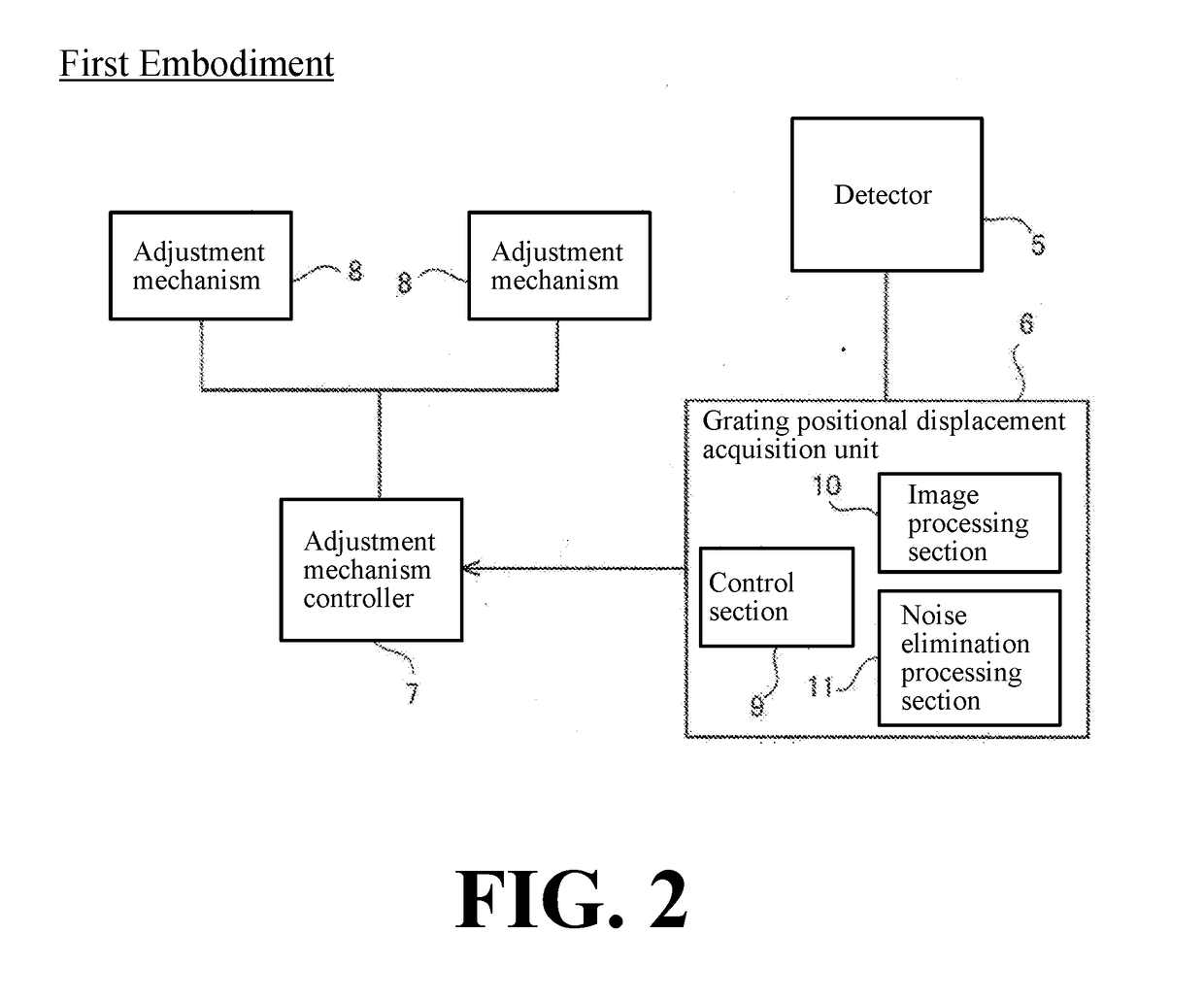

X-ray phase contrast imaging system

ActiveUS20180306734A1Shorten adjustment timeCancel noiseImage enhancementImaging devicesGratingX-Ray Phase-Contrast Imaging

An X-ray phase contrast imaging system includes an X-ray source, a detector, a plurality of gratings including a first grating and a second grating, and a grating positional displacement acquisition section configured to obtain a positional displacement of the grating based on a Fourier transform image obtained by Fourier transforming an interference fringe image detected by the detector.

Owner:SHIMADZU CORP

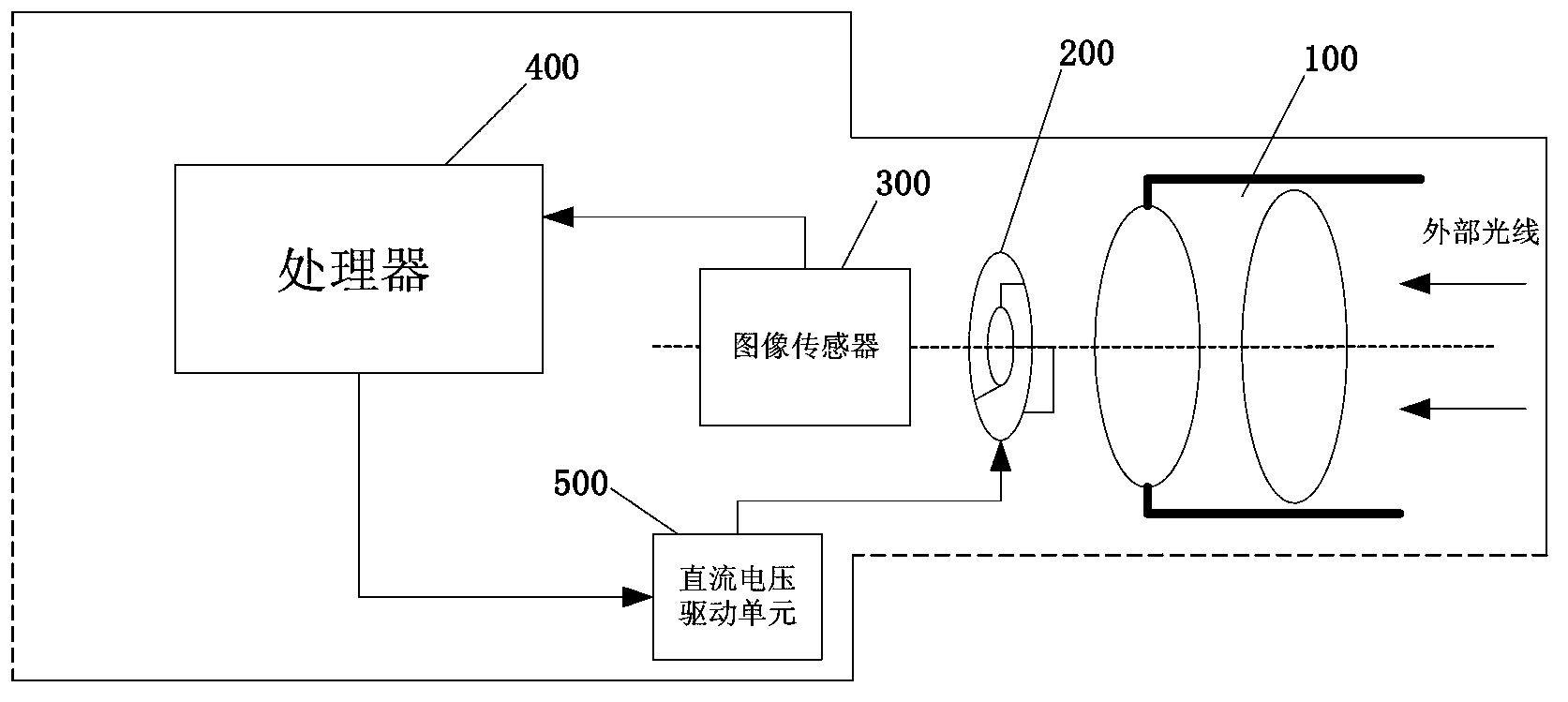

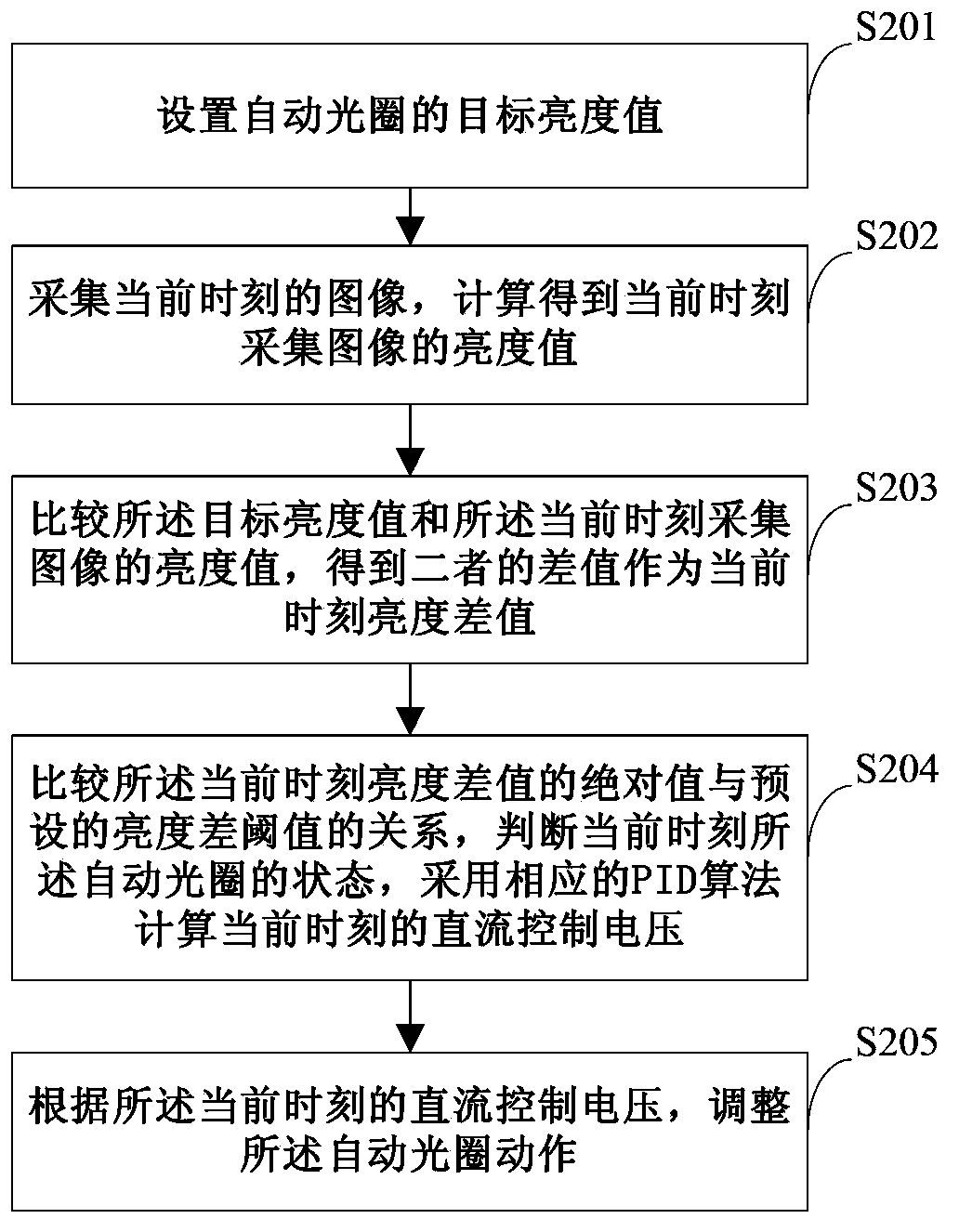

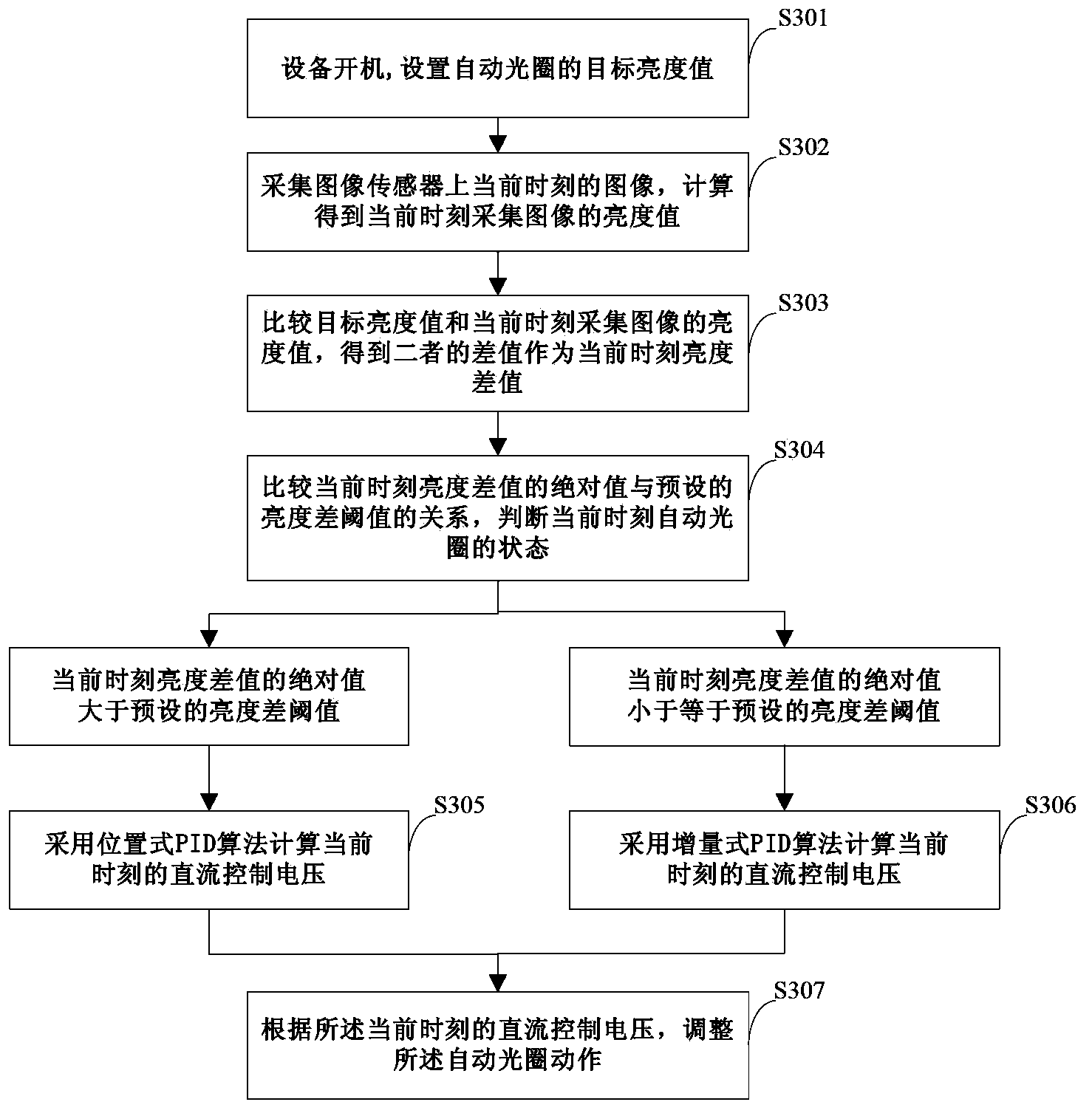

Automatic diaphragm control method and system

InactiveCN104243835ARealize full real-time dynamic feedback controlHigh control precisionTelevision system detailsColor television detailsControl systemControl circuit

The embodiment of the invention discloses an automatic diaphragm control method. The automatic diaphragm control method comprises the steps of setting a target brightness value of an automatic diaphragm; acquiring an image at the current moment, and calculating a brightness value of the image acquired at the current moment; comparing the target brightness value with the brightness value of the image acquired at the current moment to obtain a difference value of the target brightness value and the brightness value of the image acquired at the current moment to serve as a brightness difference value at the current moment; comparing the relationship between an absolute value of the brightness difference value at the current moment and a preset brightness difference threshold value, judging the state of the automatic diaphragm at the current moment, and calculating direct current control voltage at the current moment by means of a corresponding PID algorithm; regulating the action of the automatic diaphragm according to the direct current control voltage obtained by calculation. The embodiment of the invention further discloses an automatic diaphragm control system. By means of the automatic diaphragm control method and system, an automatic diaphragm lens can be calibrated automatically, time is shortened, and labor cost is reduced. Meanwhile, the problems of static shift and dynamic deviation of a diagram driving control circuit can be solved, and the control accuracy of the diaphragm is improved.

Owner:HUAWEI TECH CO LTD

Method for adjusting housings outside single stand reversible rolling mill

ActiveCN101664760AHigh adjustment accuracyMeet the acceptance criteriaMetal rolling stand detailsMeasuring devicesEngineeringRoll center

The invention relates to a method for adjusting a single stand reversible rolling mill, in particular to a method for adjusting housings outside the single stand reversible rolling mill, which comprises the following steps: a, determining that a housing base reaches assembly accuracy, and suspending the housings to correct positions; b, hanging a steel wire, checking vertical and transverse central lines of the rolling mill; c, connecting earphones to the vertical and transverse central lines of the rolling mill by lead wires; d, moving housings on a transmission side and an operation side towards the housing base direction on a discharge side respectively by a hydraulic jack to ensure that a bracket side of the housings is close to the lateral surface of the base on an outlet side, and moving a rail rest on an inlet side towards the outlet side; e, adjusting sizes of the housing rolling center and the transverse center of the rolling mill, and fastening a foundation bolt by 70 percentof a design torque; and f, hanging steel wires on housing windows and the rolling directions of the housings, and measuring the verticality and the horizontality of the windows and the rolling directions of the housings of the rolling mill. The method uses the steel wires and the earphones to ensure numerical reading, eliminates reading errors caused by visual errors of staff, and improves the assembly accuracy of equipment.

Owner:CHINA MCC20 GRP CORP

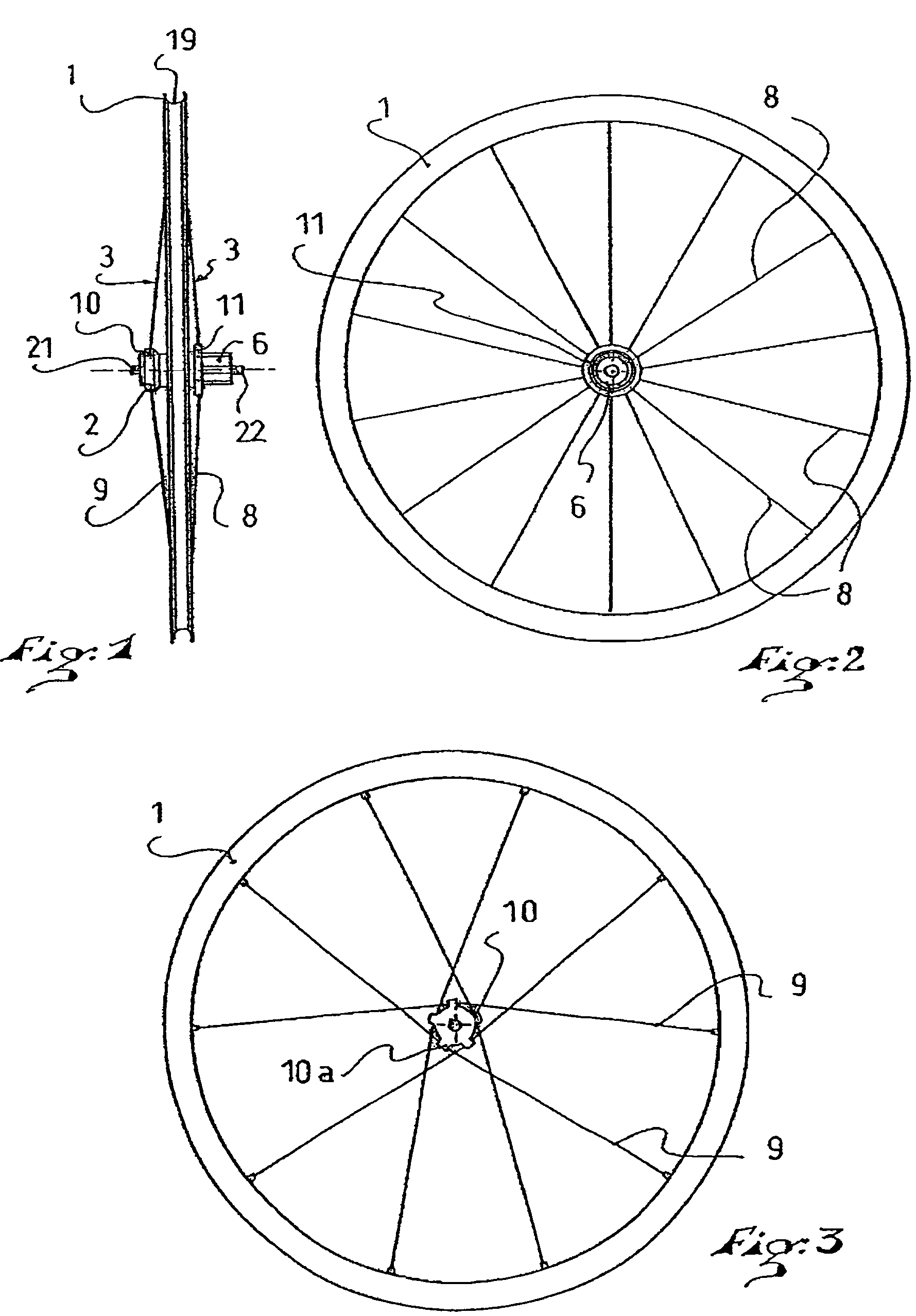

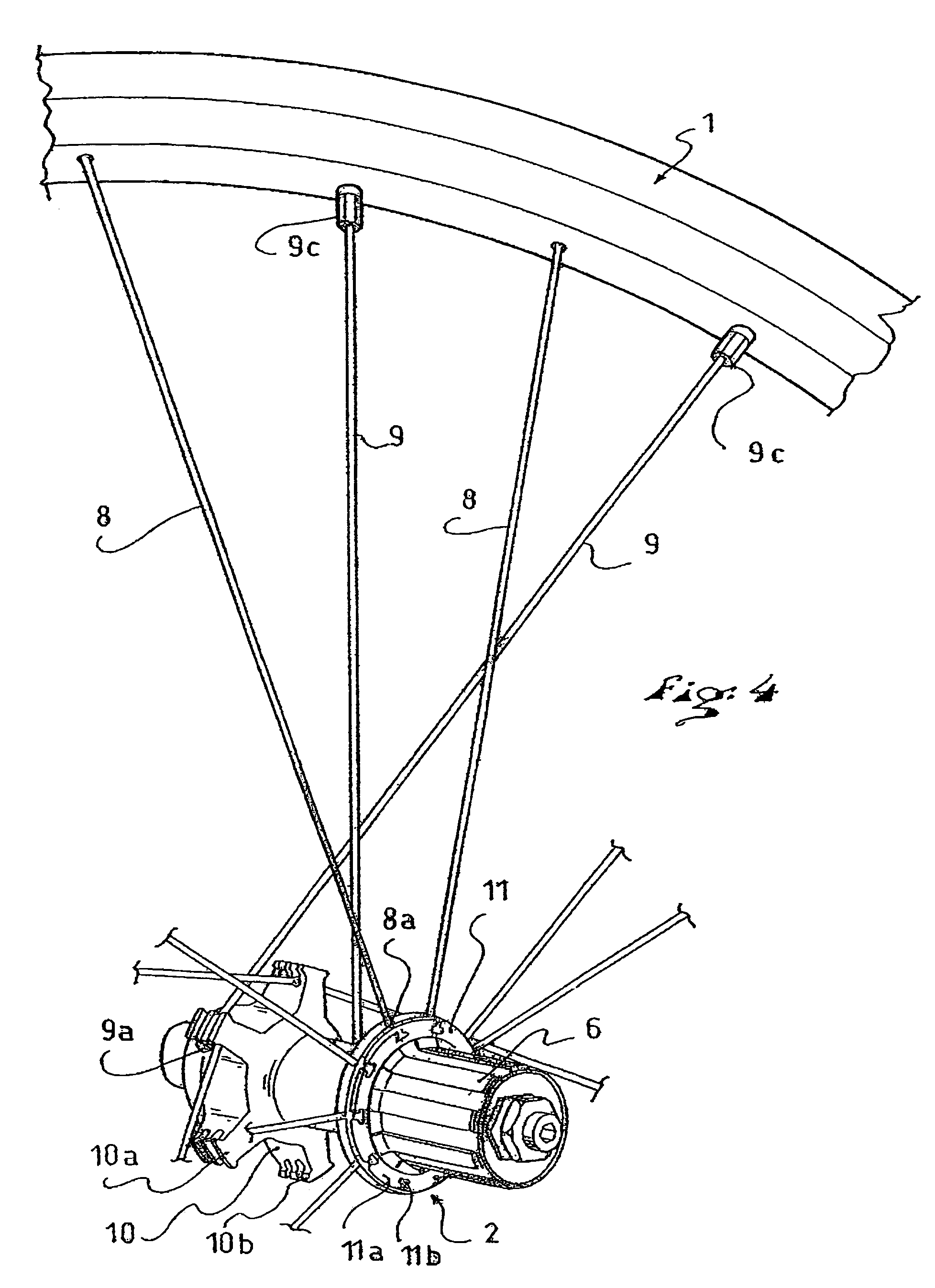

Wheel with tension spokes and a method of manufacturing such wheel

A wheel including a peripheral rim, a central hub, and spokes connecting extending and tensioned between the rim and the hub, as well as a method for manufacturing such a wheel. The method includes distributing the spokes in two groups, a first group of spokes lacking a tensioning device, and a second group of spokes having a tensioning device; assembling the spokes to the rim and to the hub, and then adjusting the tension of the spokes with tensioning devices of the second group of spokes.

Owner:MAVIC SA

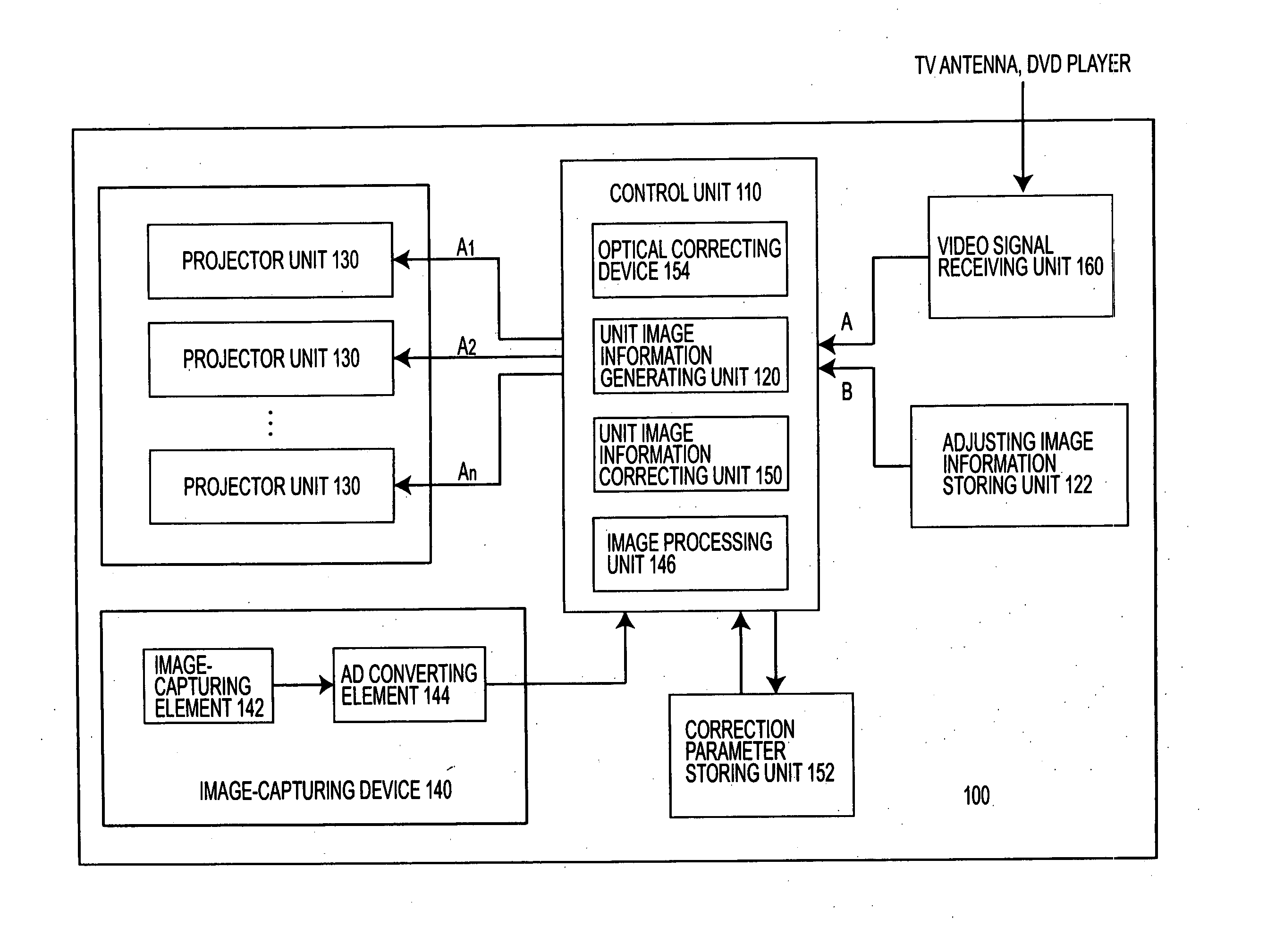

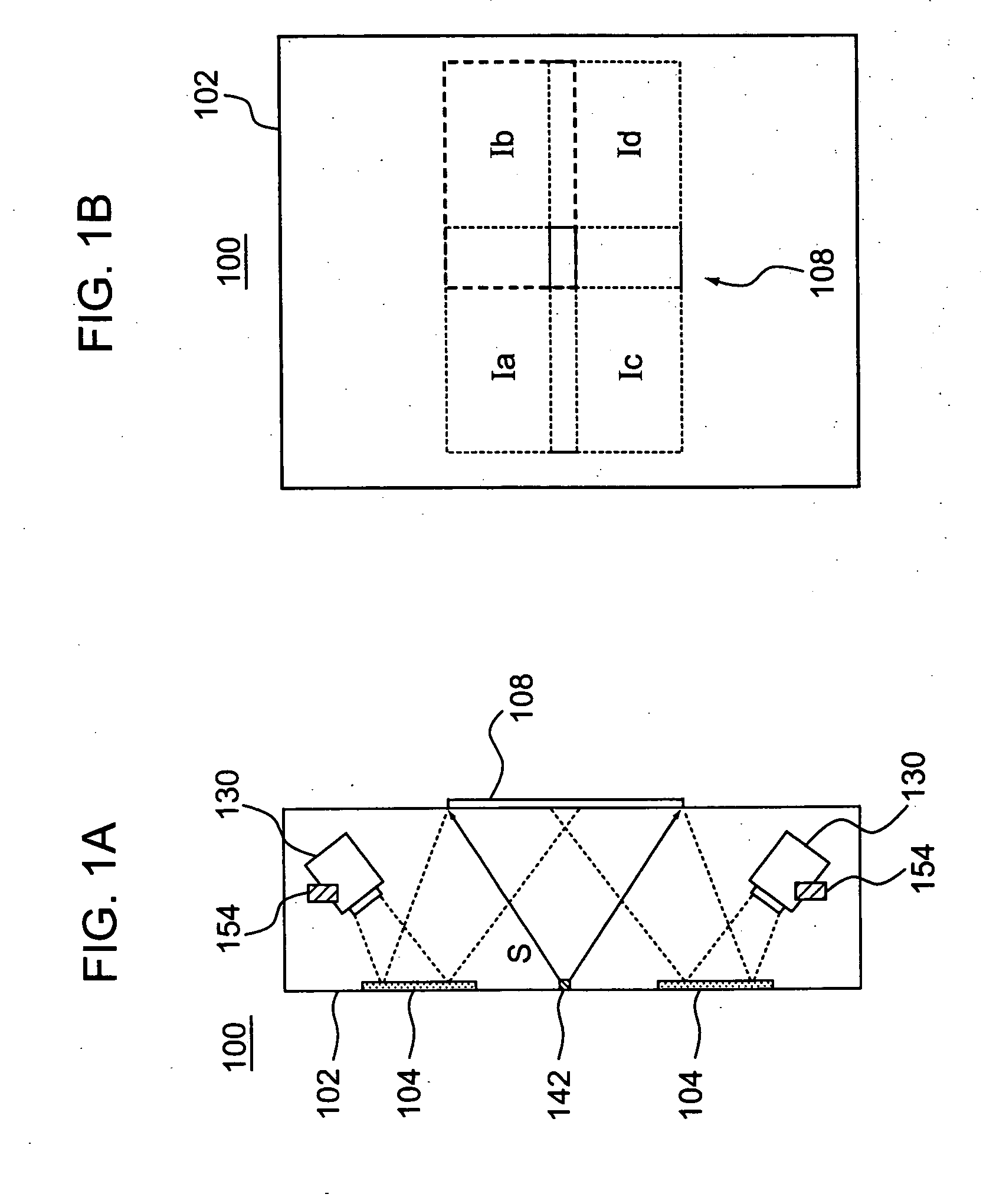

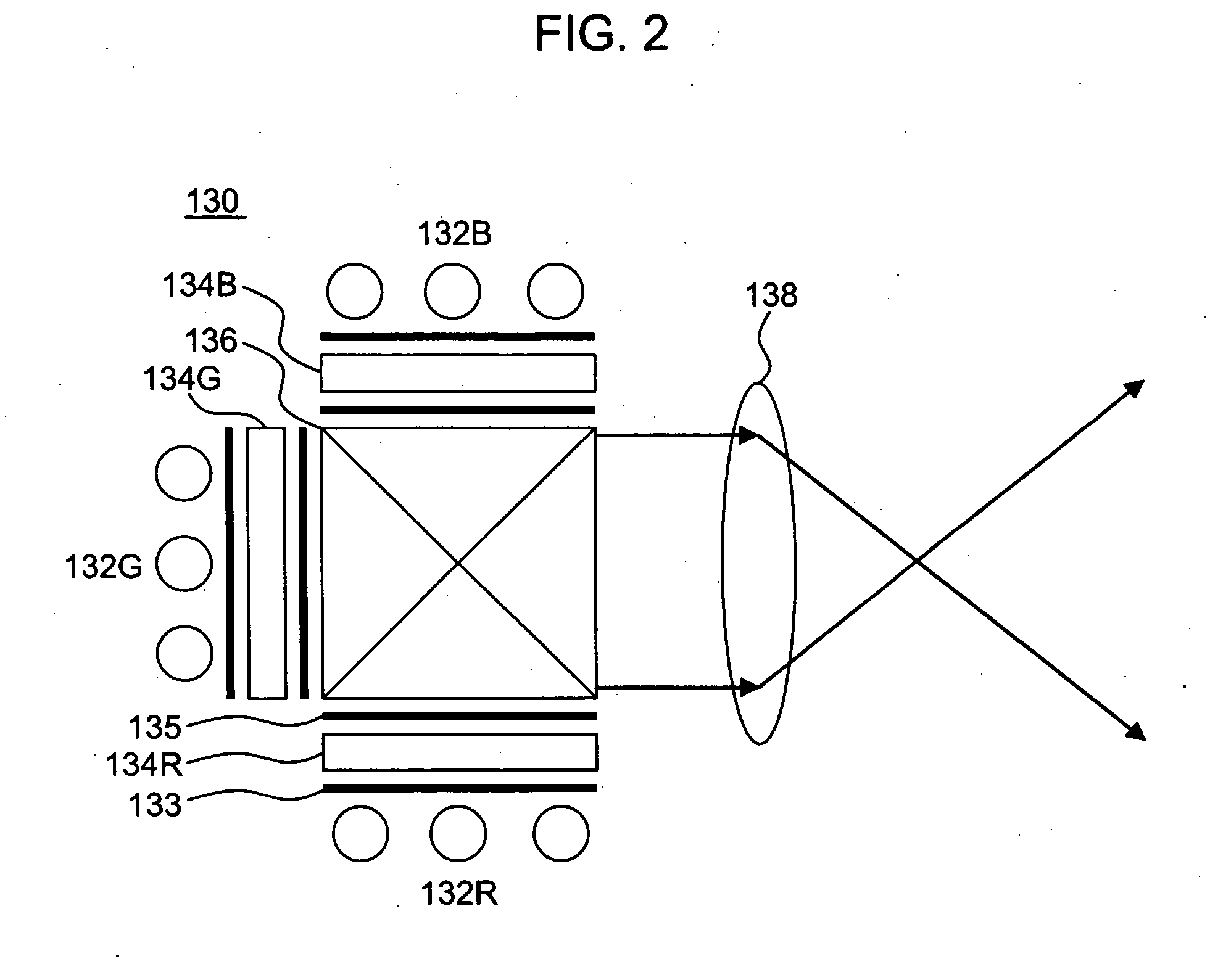

Rear projection type multi-projection display

InactiveUS20050146644A1Reduce smearingQuality improvementTelevision system detailsTelevision system scanning detailsProjection imageDisplay device

Exemplary embodiments of the invention provide a circuit that includes a plurality of projector units to modulate and project light from a light source based on image information, a transmissive screen to which projection images from the plurality of projector units are projected, an image-capturing device disposed in a housing to capture predetermined regions of the projection images projected onto the transmissive screen, a unit image information generating unit to generate image information to be inputted to each of the plurality of projector units, and a unit image information correcting unit to correct the unit image information based on a result captured by the image-capturing device. Therefore, it is possible to perform easily the adjustment process and to further reduce the adjustment time.

Owner:SEIKO EPSON CORP

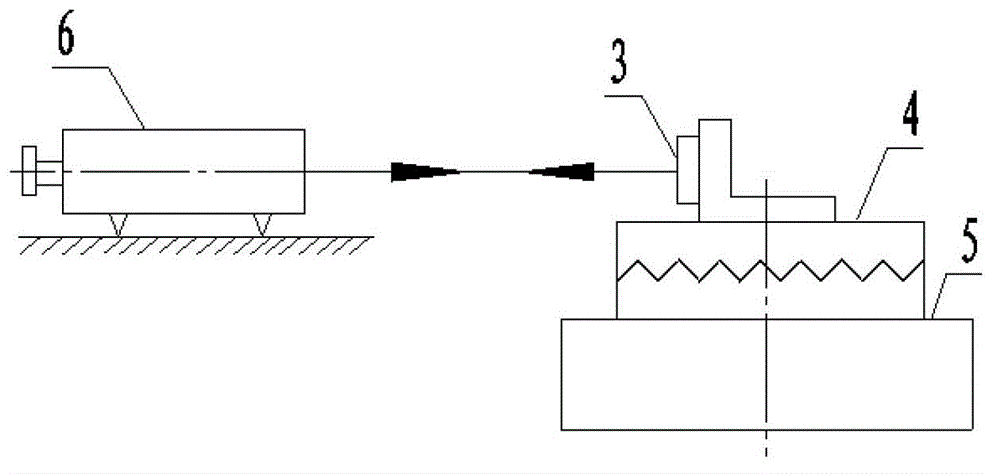

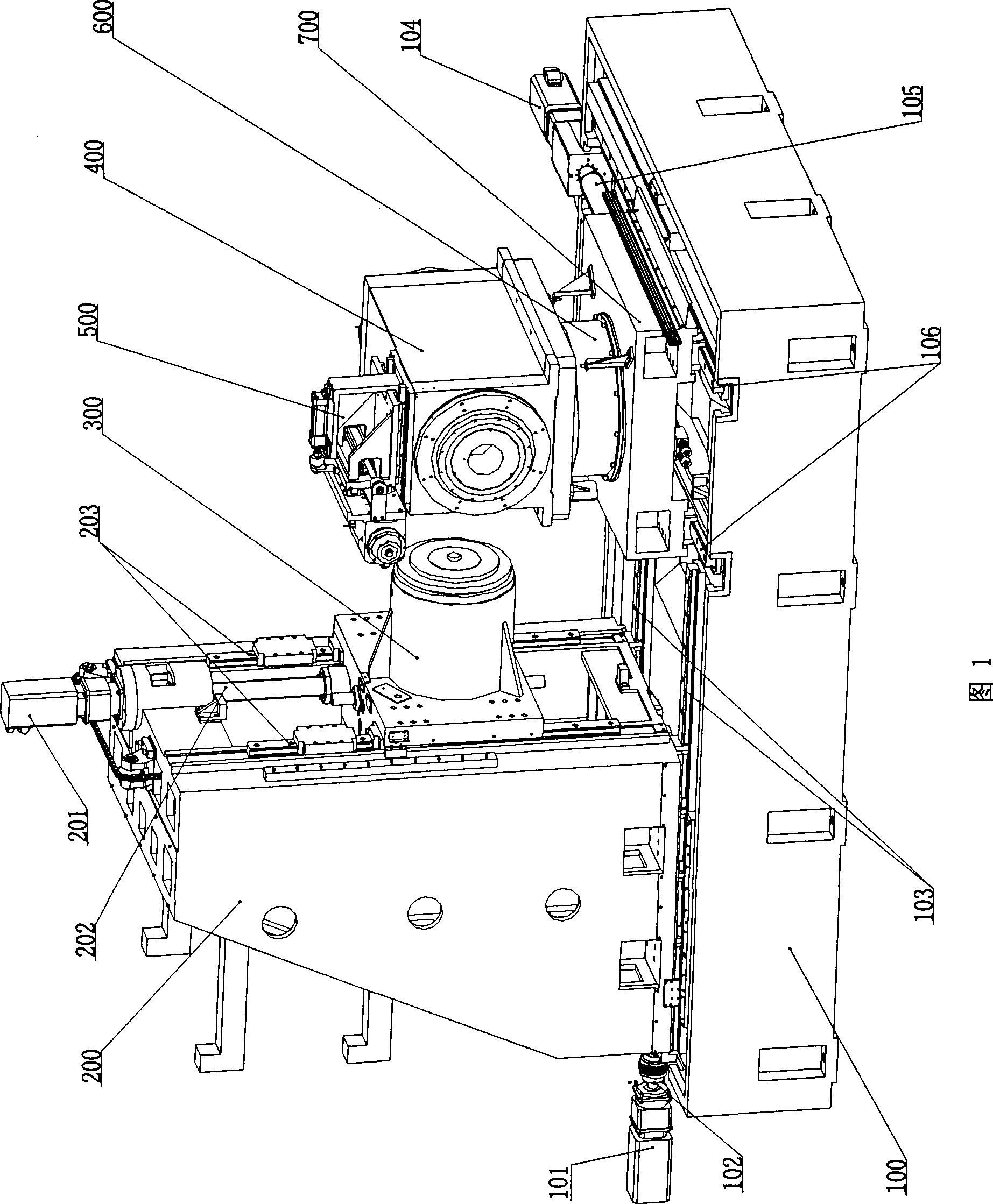

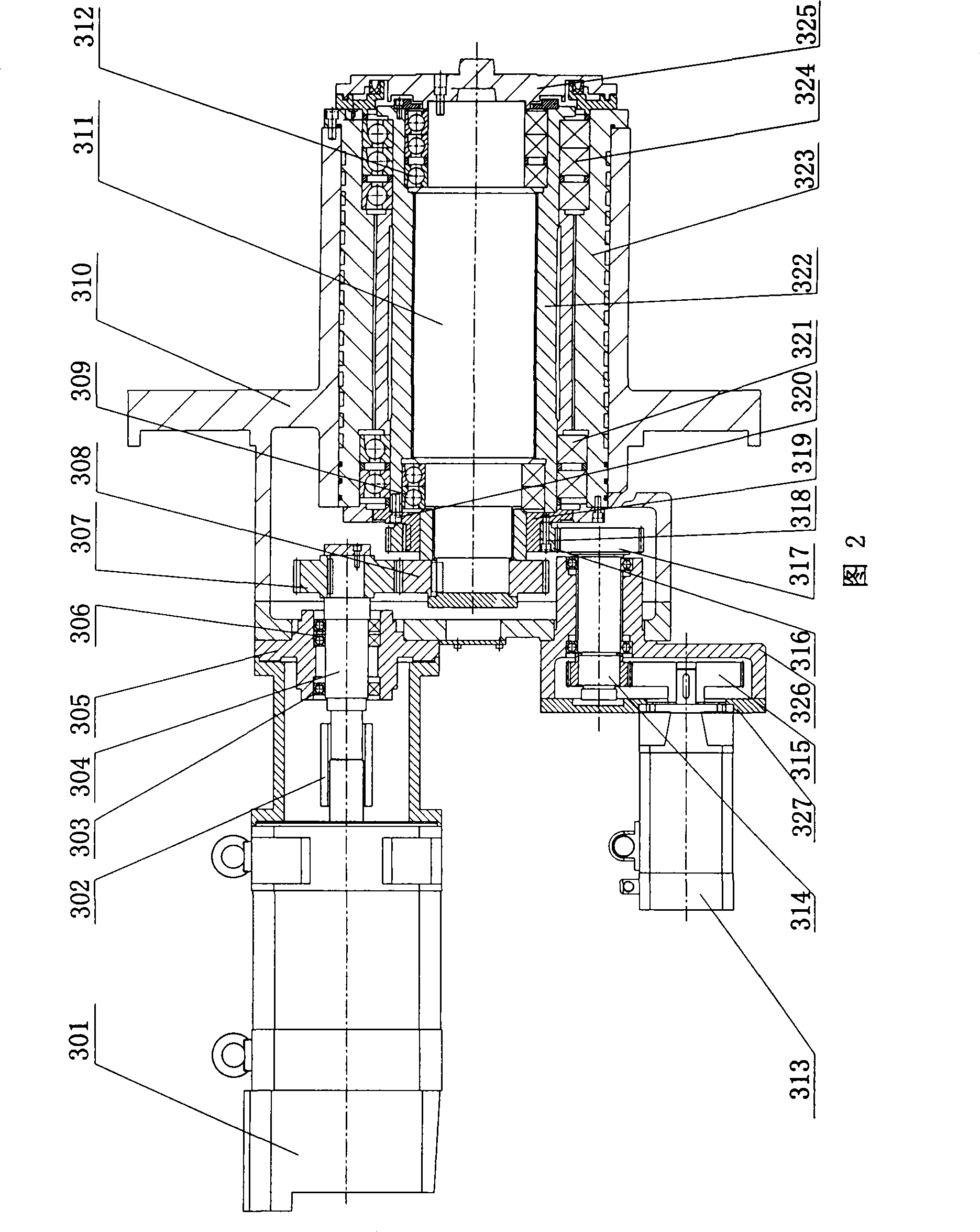

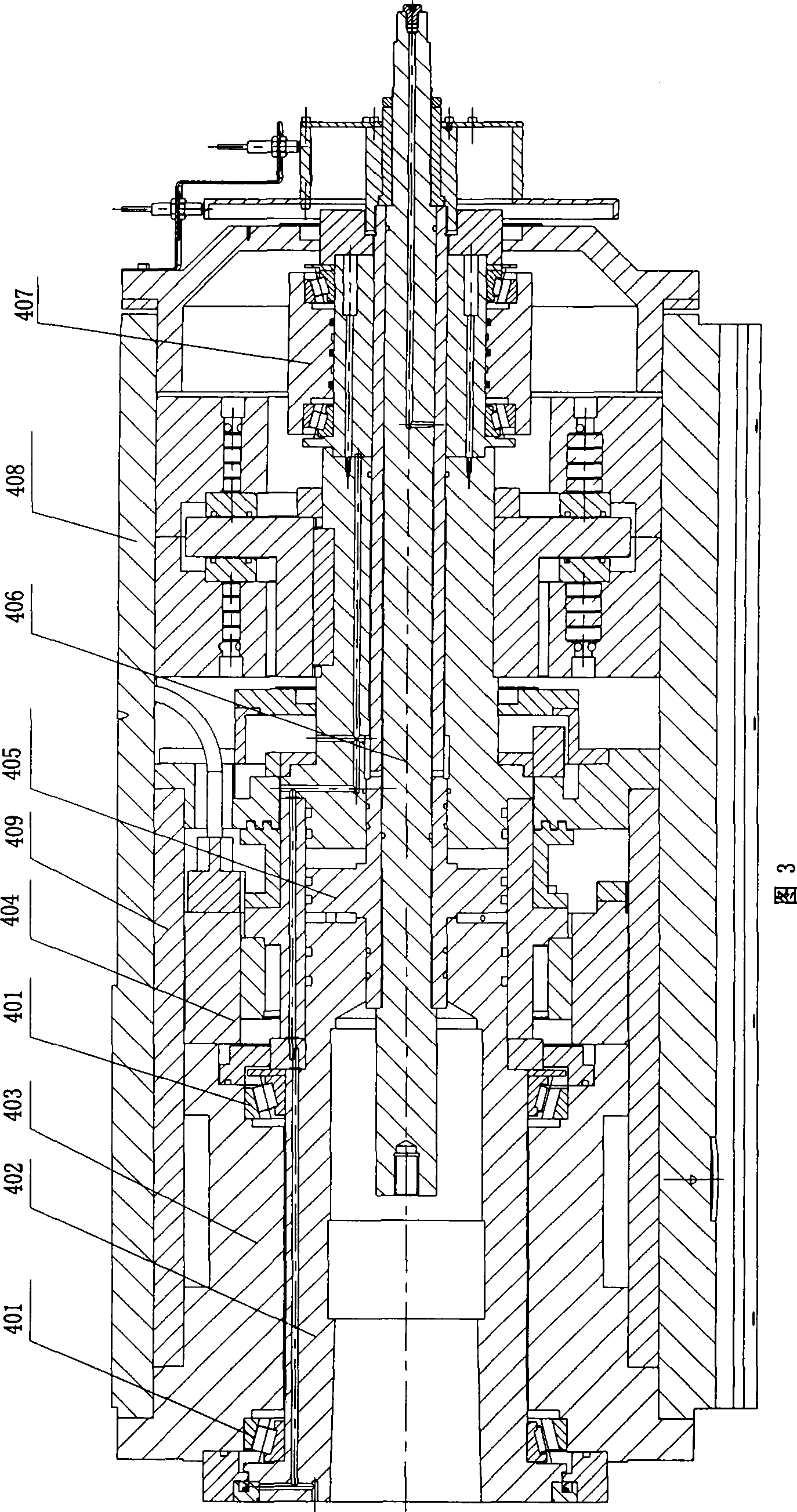

Numerical control tooth grinder for spiral bevel gear

InactiveCN101433983AGuaranteed stabilityCutting stabilityGear-cutting machinesGear teethGrinding wheelMachine tool

The invention relates to a numerical control curve-tooth bevel gear grinder, which comprises a lathe bed, and is characterized by also comprising an upright post, a grinding wheel main shaft box, a workpiece main shaft box, an electric turntable, a grinding wheel correcting mechanism and a numerical control system. The lathe bed in the horizontal direction is provided with linear guide rails vertical to each other, the upright post and a bed saddle are arranged on the linear guide rails respectively, and an upright post automatic moving mechanism is arranged between the bottom of the upright post and the lathe bed; one lateral surface of the upright post is provided with the linear guide rail and the grinding wheel main shaft box, and the same side of the upright posts close to the top is provided with a moving mechanism for driving the grinding wheel main shaft box to move; and the bed saddle is provided with the electric turntable which is provided with the workpiece main shaft box on which the grinding wheel correcting mechanism is arranged. The numerical control curve-tooth bevel gear grinder has the advantages that the grinder simplifies the prior mechanical transmission, shortens adjusting time of a machine tool, has compact and reasonable structure, accurate processing with high accuracy, high automation degree to remarkably improve processing efficiency, and has low manufacturing cost to relieve economic burden of enterprises.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

Projection system with touch control function

ActiveCN102914937AEasy to operateShorten adjustment timeProjectorsInput/output processes for data processingProjection systemTouch function

The invention relates to a projection system with a touch control function. The projection system comprises a projector, a light-emitting module and an adjusting mechanism. The projector and a display plane are oppositely arranged. The light-emitting module is arranged between the projector and the display plane and close to the display plane, and is used for sending light rays to form a light curtain. The adjusting mechanism is arranged on the light-emitting module for turning the light-emitting module to adjust an angle of the light curtain and the display plane. Since the projection system with the touch control function is provided with the adjusting mechanism capable of turning the light-emitting module, when the light curtain inclines relative to the display plane, any user can easily operate the adjusting mechanism to turn the light-emitting module for adjusting the angle of the light curtain and the display plane. The projection system with the touch control function is convenient to operate, special calibrating instruments are not needed, and adjusting time can be effectively saved.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD +1

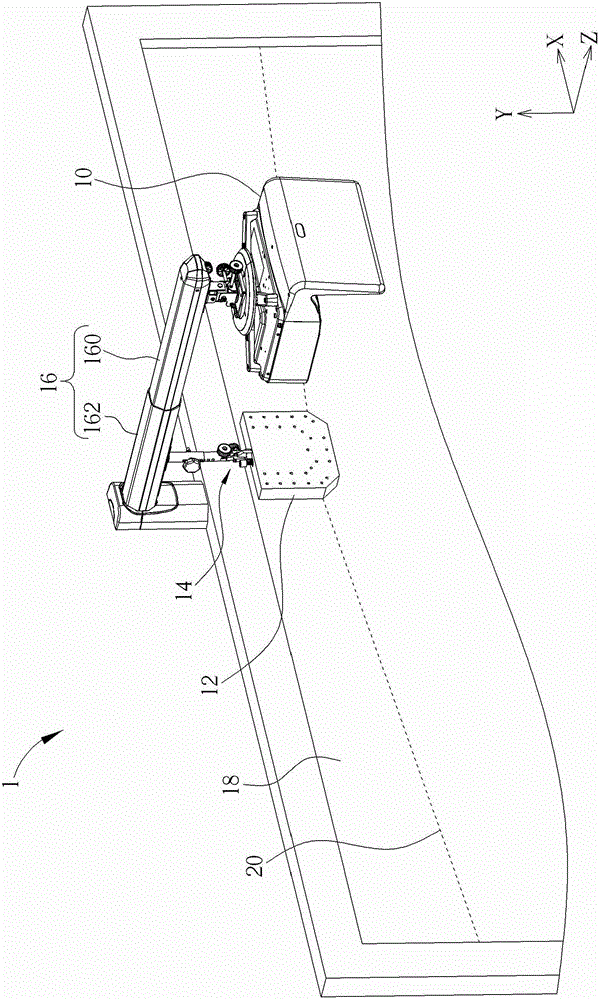

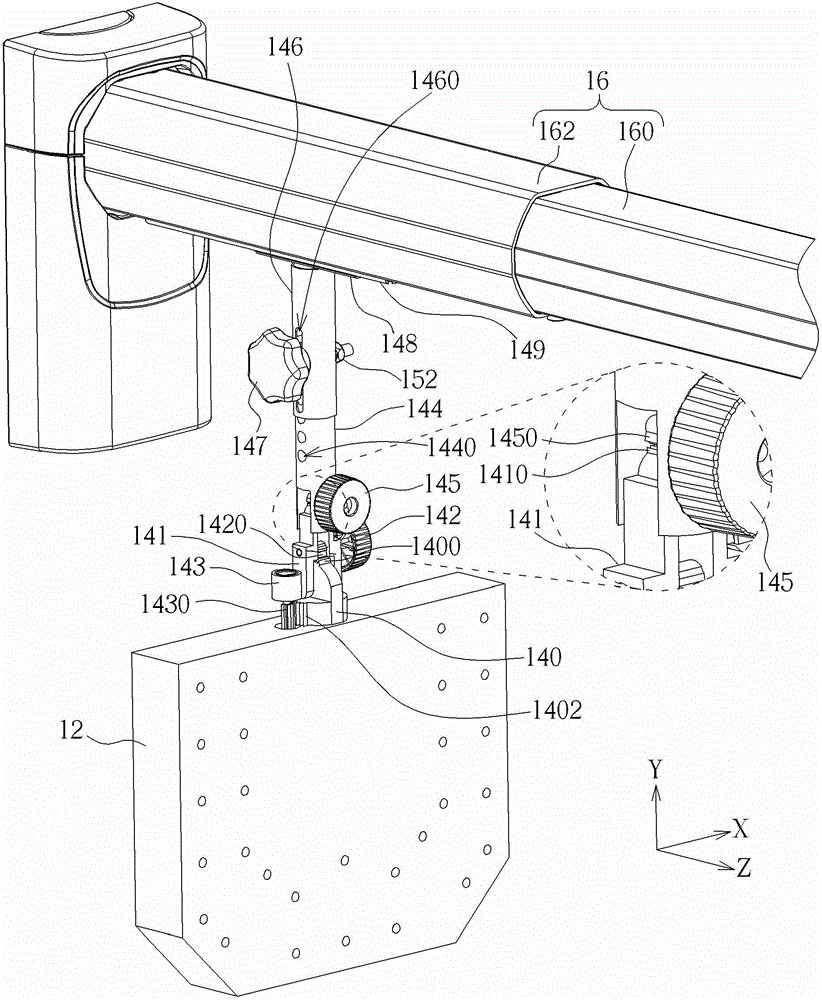

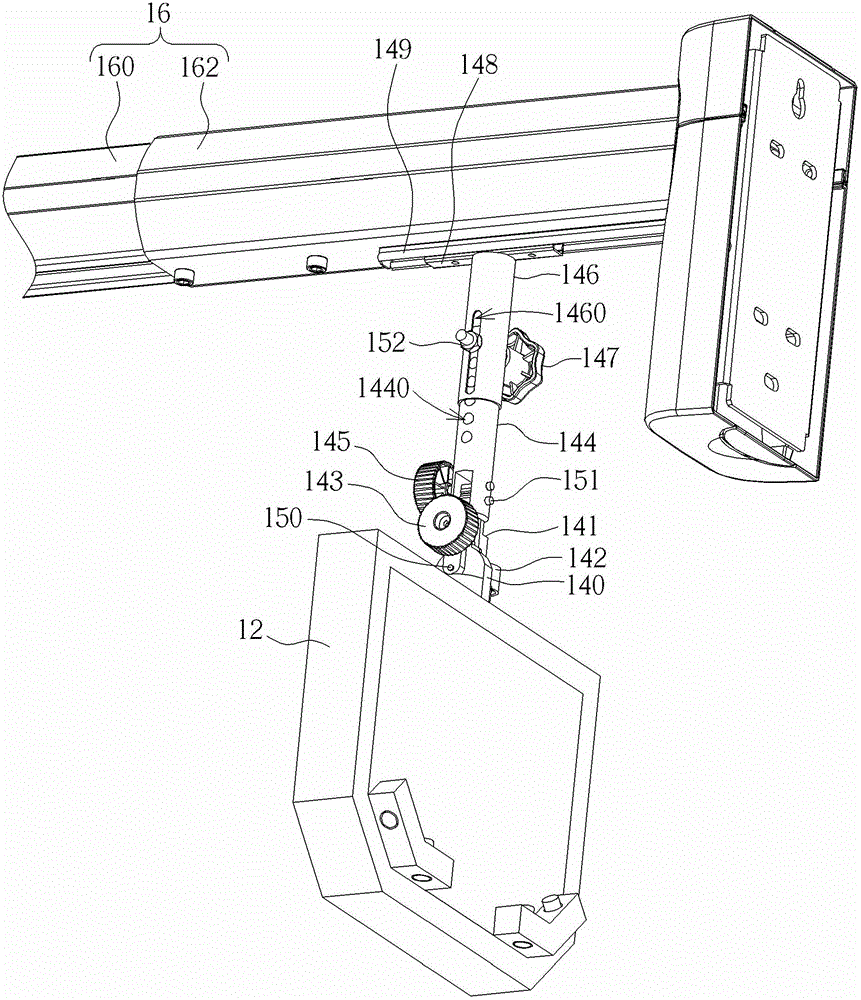

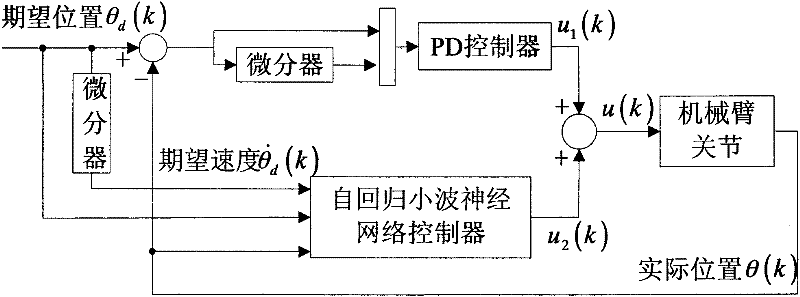

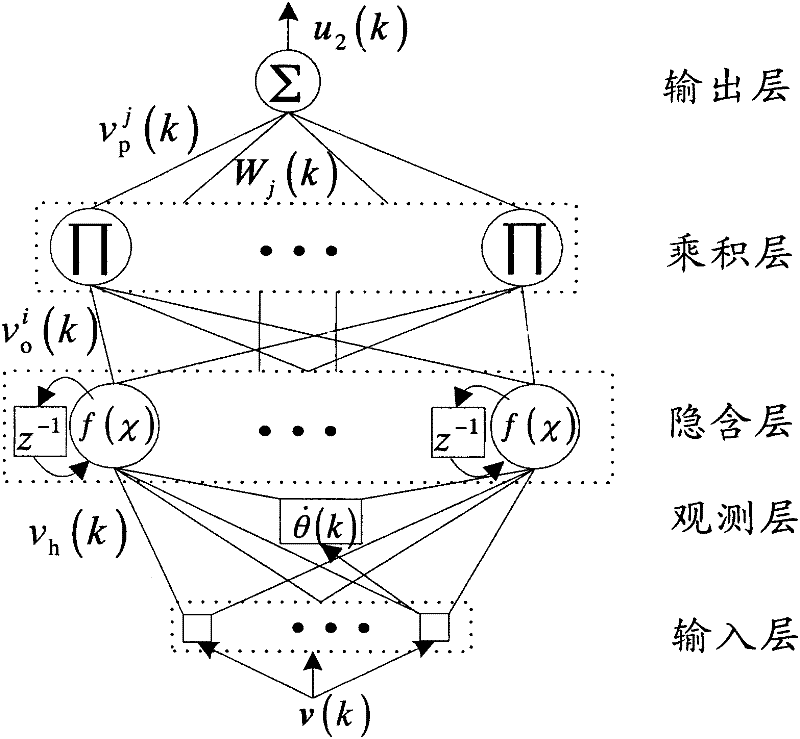

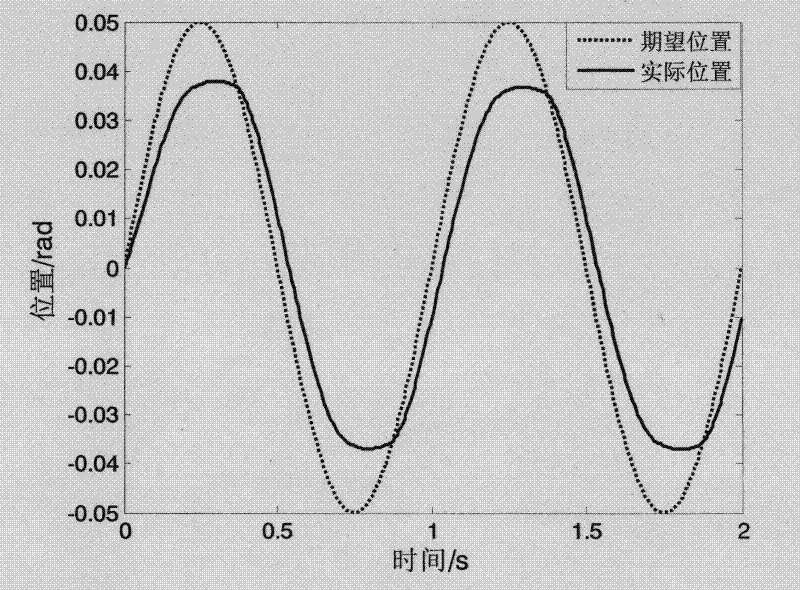

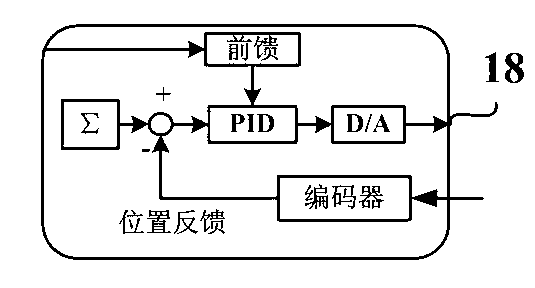

Mechanical shoulder joint position control method with dynamic friction compensation

InactiveCN102501251AShorten adjustment timeGuaranteed speedProgramme-controlled manipulatorNeural network controllerProportional differential

The invention relates to a mechanical shoulder joint position control method with dynamic friction compensation, which is realized through a global control unit and a local control unit. The global control unit is used for tracking the trajectory of a mechanical shoulder joint in a global large range, the trajectory tracking is realized through a PD (Proportional Differential) controller widely applied in the mechanical shoulder joint, and the input vector of the PD controller comprises the position error of the mechanical arm joint and the change rate of the position error; and the local control unit is used for completing dynamic friction compensation in a local small range, the dynamic friction compensation is realized through a five-layer autoregressive wavelet neutral network controller having an observation layer, and the input vector of the autoregressive wavelet neutral network controller comprises the expected position, the expected speed and the actual position of the mechanical shoulder joint. The actual speed of the mechanical shoulder joint required in the autoregressive wavelet neutral network controller can be calculated through the observation layer. The mechanical shoulder joint position control method provided by the invention can be realized by only installing one position sensor in the mechanical shoulder joint without installing a speed sensor.

Owner:BEIJING UNIV OF POSTS & TELECOMM

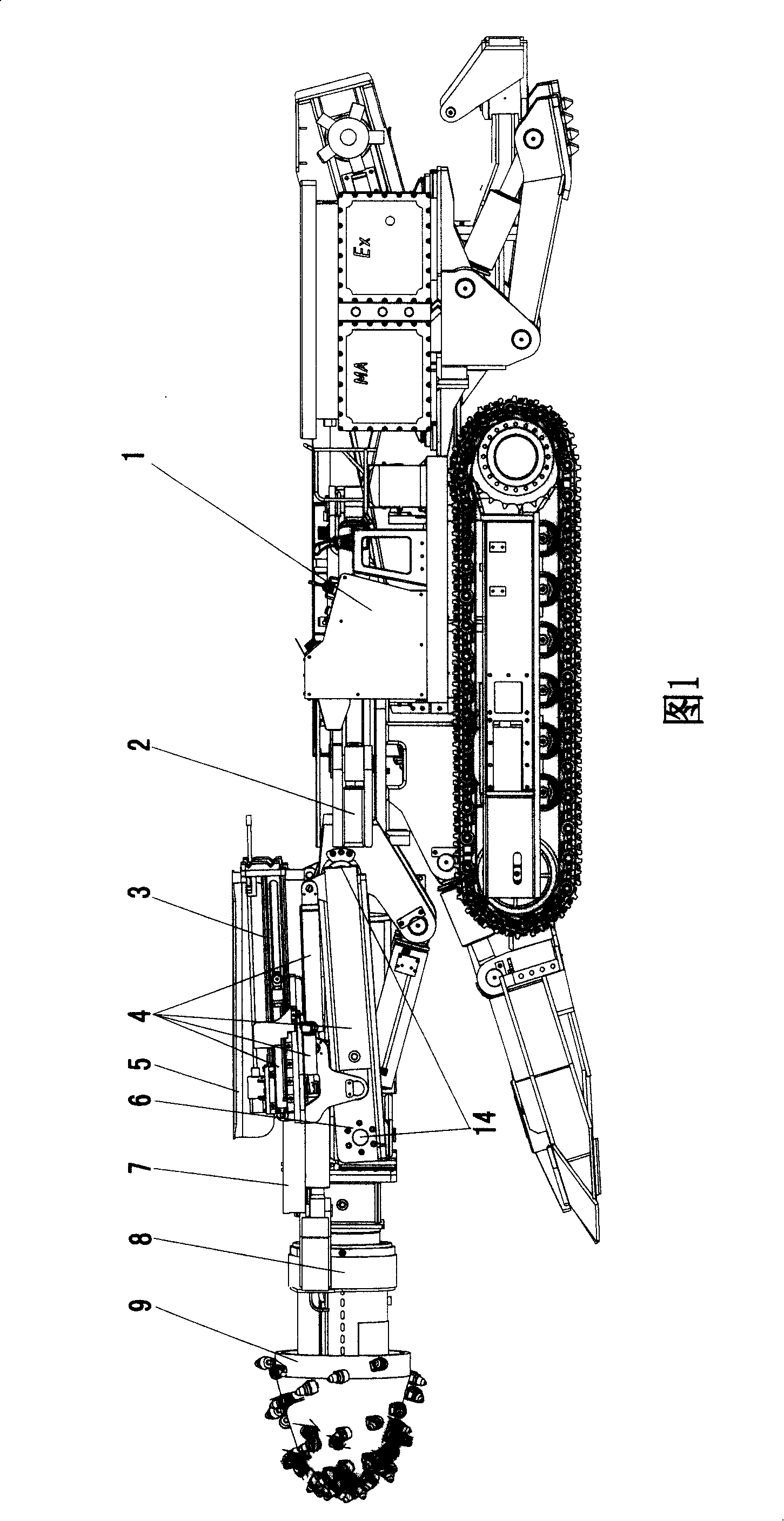

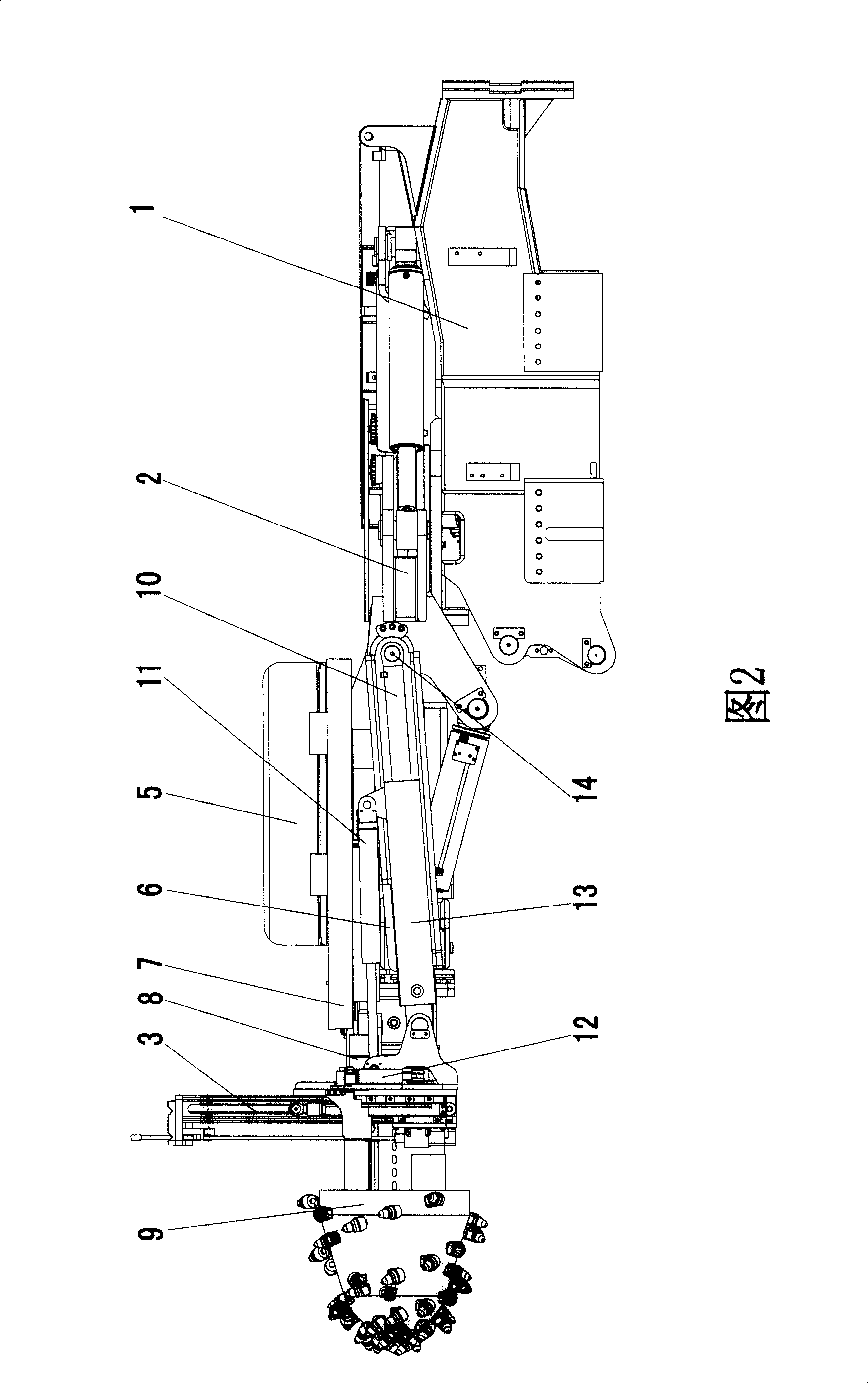

Grubbing anchoring integrative grub-anchor winch

The invention relates to a tunneling mining and supporting machine for a coal roadway, in particular to a tunneling and bolting machine which is a tunneling and bolting integrated new machine type, solves the problems of time wasting caused by separation work of a tunneling machine and a roof-bolter, big labor intensity and low efficiency caused by a roof bolt artificially operated, etc., and realizes integration efficiency of the tunneling machine and the roof-bolter. The tunneling and bolting machine is an integrated installation structure of the tunneling machine and the roof-bolter, and the roof-bolter is arranged at both end of a cutting part of the tunneling machine. With utilizing one side of the cutting part of the tunneling machine as an installation platform of the roof-bolter, the invention realizes the integration of the roof-bolter and the cutting part of the tunneling machine. With utilizing lift and sway of the cutting part and the own function of the roof-bolter, the invention completes bolt installation work of a roadway bolt. The tunneling and bolting machine of the invention has the functions of stretching back and forth, vertical and horizontal regulation, self rotation of the roof-bolter, etc. When the tunneling machine works, the roof-bolter is shrunken for folding, and special dimension of the roof-bolter is lowered in great extend.

Owner:SANY HEAVY EQUIP

Electroencephalogram cap

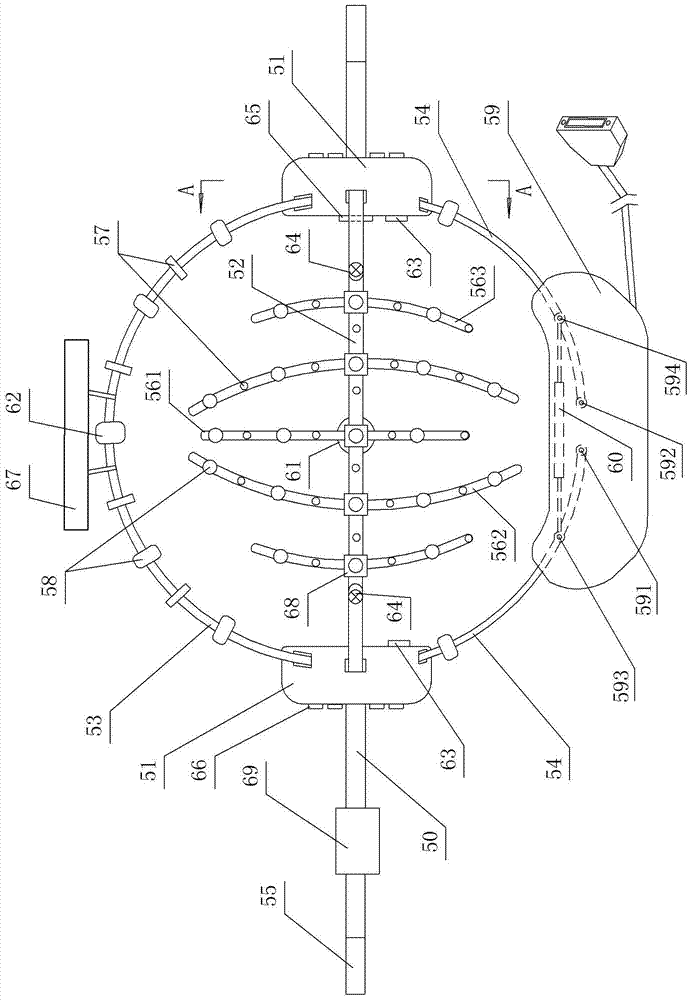

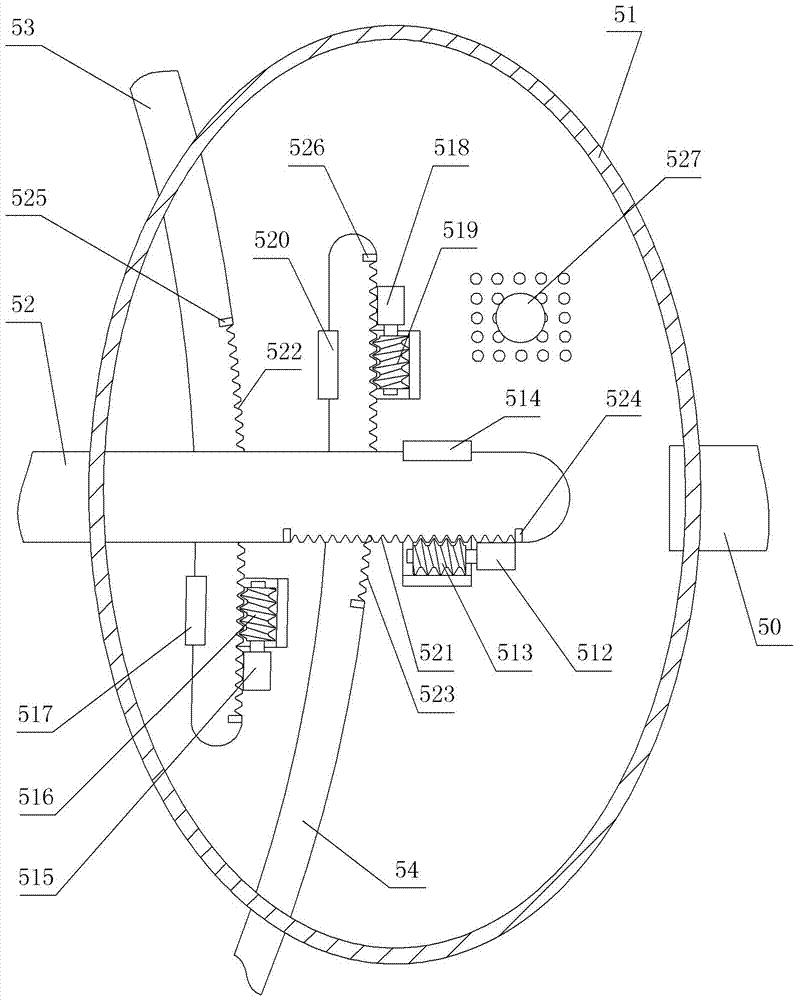

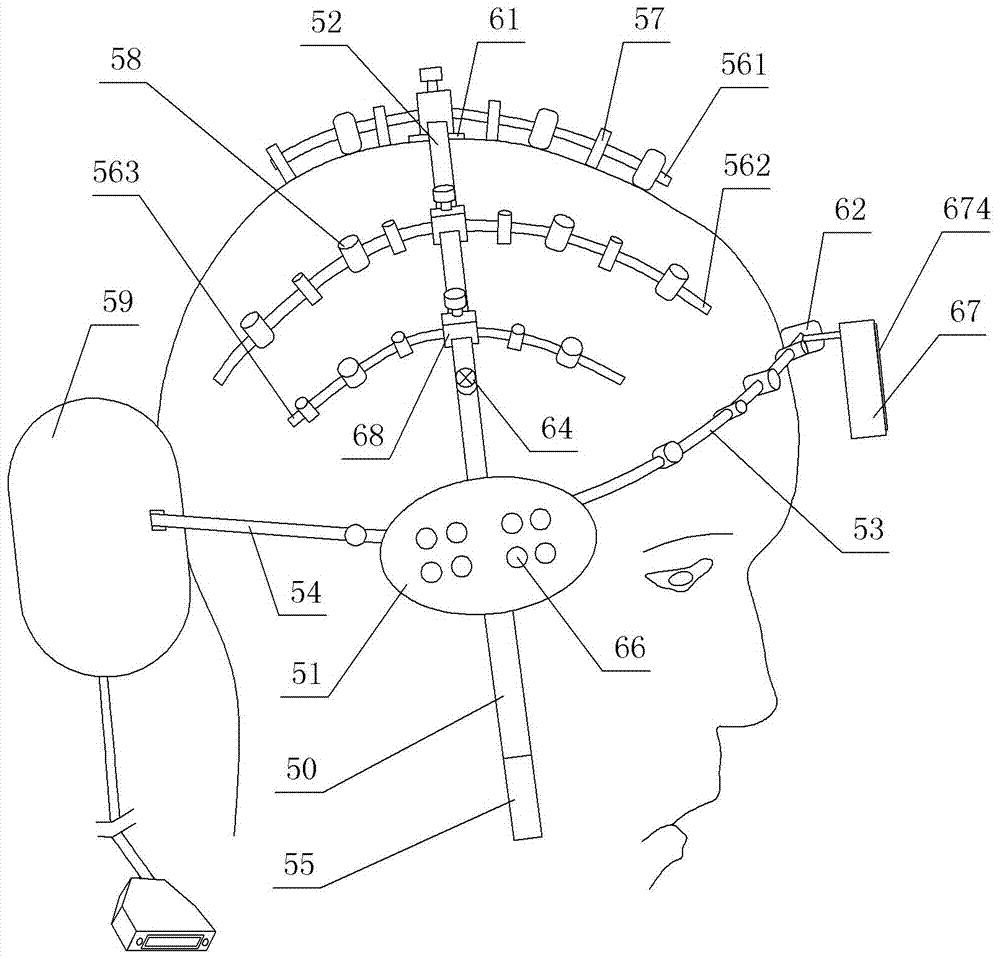

PendingCN107468241AAutomatically enlarge or reduce the spaceEasy to operateDiagnostic signal processingSensorsCross connectionElectroencephalography

The invention relates to an electroencephalogram cap and a method for establishing a three-dimensional head-shaped electroencephalogram and a brain oxygen distribution map. The electroencephalogram cap comprises a cap body and a control circuit, wherein the cap body is formed by two ear part supporting bodies, a top supporting rod, a front part supporting rod and a back part supporting rod; two ends of the top, front and back part supporting rods are respectively arranged on the two ear part supporting bodies; the top, front and back part supporting rods span places over the head, in front of the head and behind the head from left to right; the top supporting rod is in a cross-connection with N electrode fixing rods; the electrode fixing rods, the front part supporting rods and the back part supporting rods are all equipped with brain electrodes; and the brain electrodes are connected with the control circuit. The method for establishing electroencephalogram and the brain oxygen distribution map forms a scalp surface three-dimensional model according to the electroencephalogram cap and position parameters of the scalp surface, and then obtains an electroencephalogram and a brain oxygen distribution map matched with a practical head shape. The electroencephalogram cap is convenient to use and can accurately collect signals and has strong anti-interference capability; and the electroencephalogram and the brain oxygen distribution map achieved according to the method has great authenticity.

Owner:汪子锋

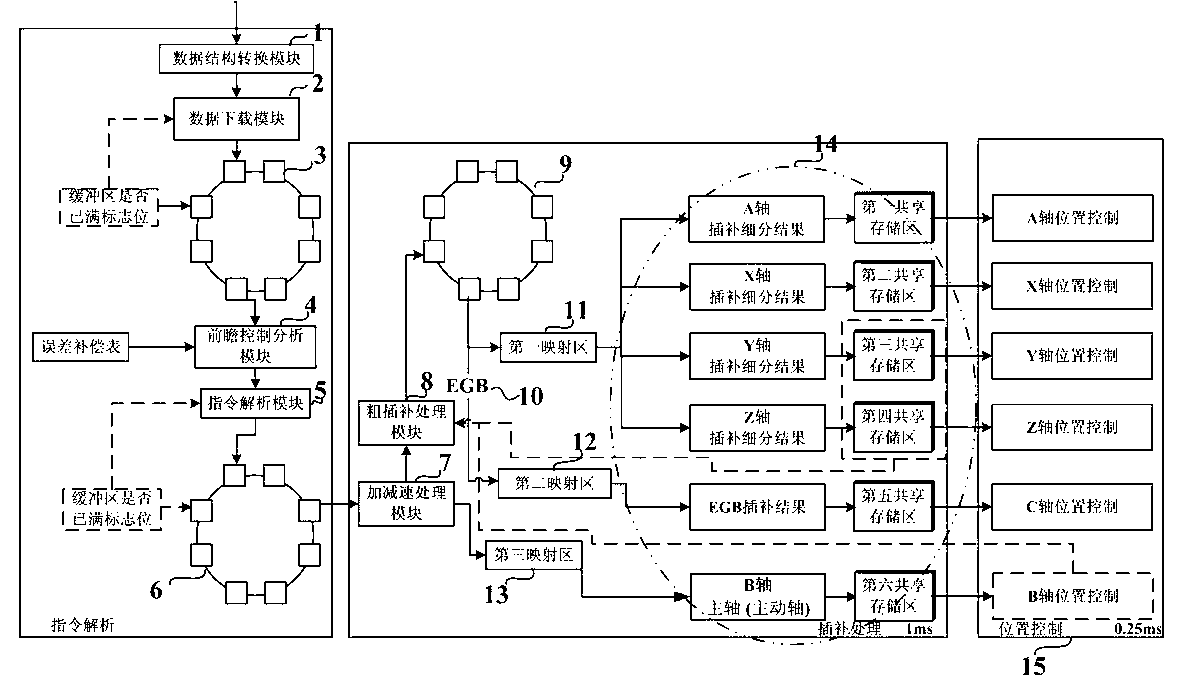

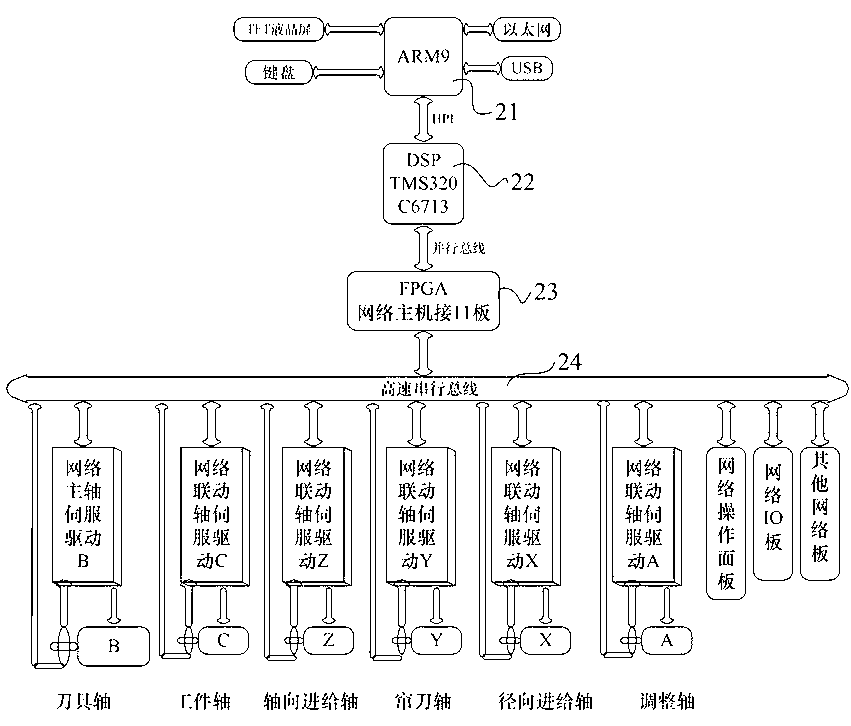

High-speed high-precision flexible electronic gear box control method

ActiveCN103294007AShorten programming timeImprove programming efficiencyProgramme controlComputer controlGear grindingGrating

The invention discloses a high-speed high-precision flexible electronic gear box control method based on an open numerical control system. An electronic gear box is a core part of a gear processing numerical control system, and by parameter setting, requirements, on multi-axis linkage strict speed ratio relationships, of different machine tools for gear hobbing, gear grinding and the like can be met. Each axis servo motor and a spindle motor are connected with the system through motor interfaces, main movement signals are fed back through a motor encoder or a grating ruler, processed by the numerical control system and distinguished and computed through the flexible electronic gear box, and follow-up numerical control shafts are controlled to complete master-slave electronic gear ratio movement.

Owner:HEFEI UNIV OF TECH

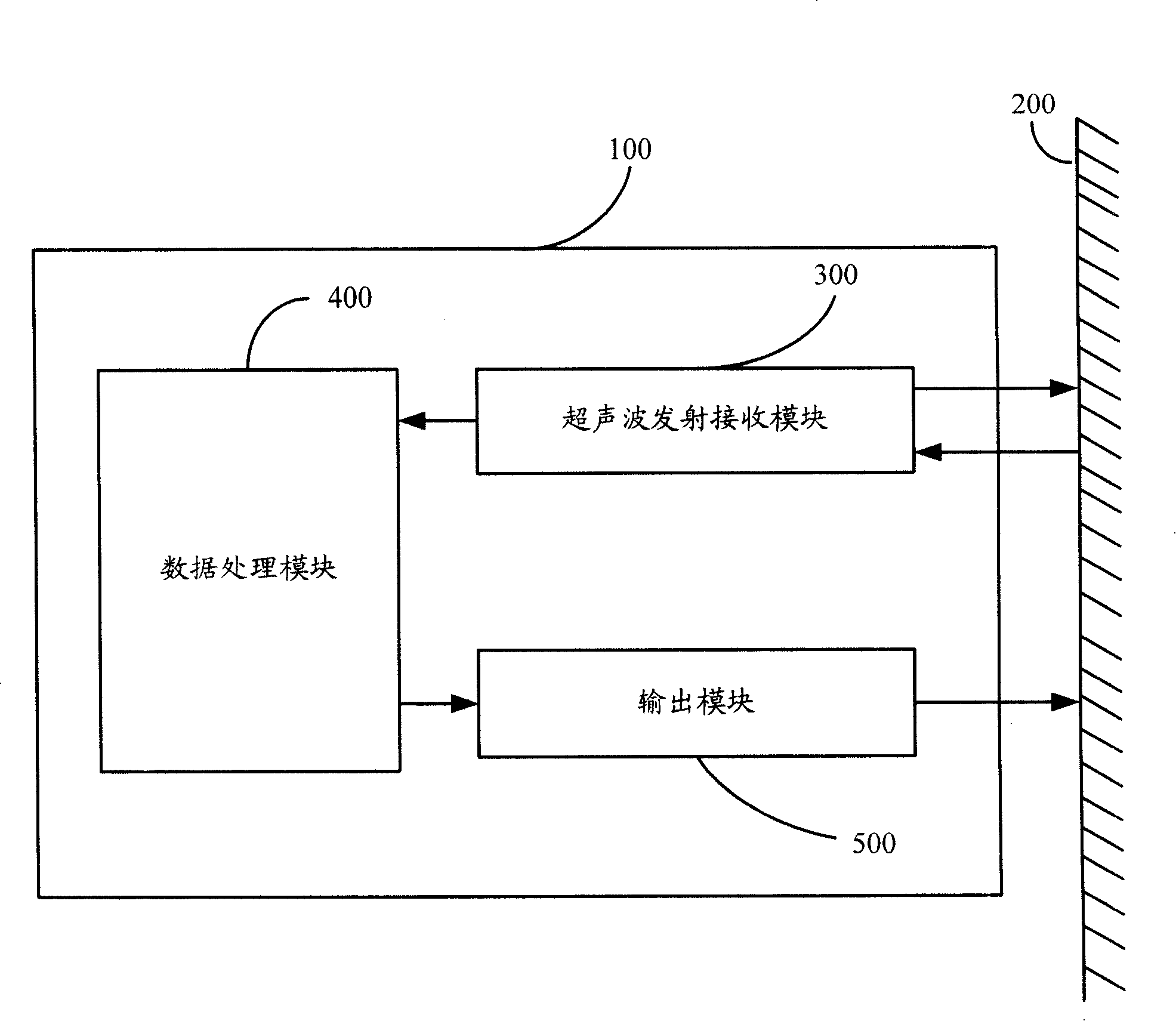

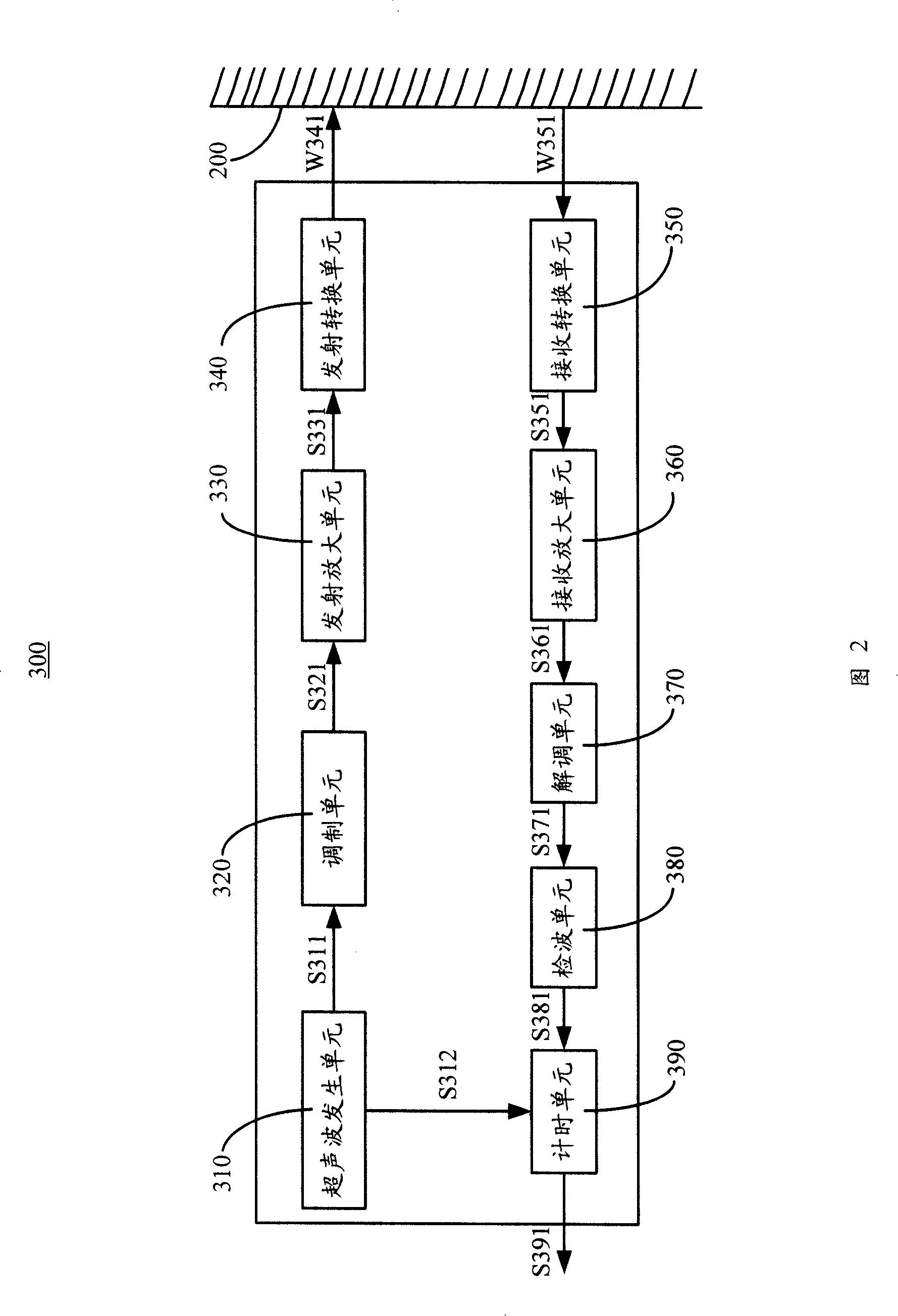

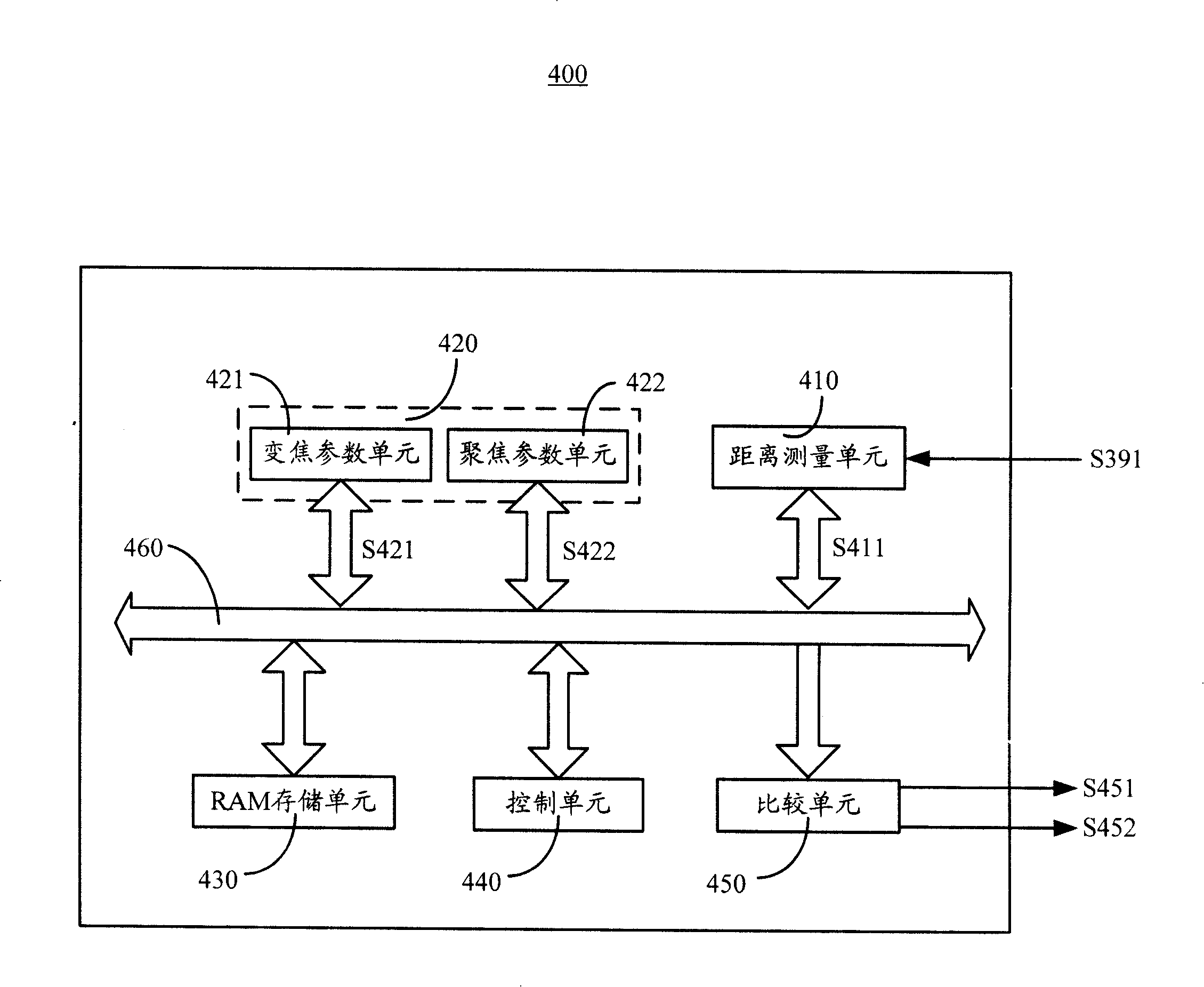

Automatic focus porjector and automatic focus method thereof

InactiveCN101178535AGood precisionShorten adjustment timeProjectorsColor television detailsElectric machineUltrasound

The invention provides an automatic focusing method for a projector. The method comprising the steps as follows: an ultrasonic wave signal is generated by an ultrasonic wave generating unit; the ultrasonic wave signal is modulated by a modulating unit; the ultrasonic wave is emitted and received by an ultrasonic wave receiving and emitting module; the received ultrasonic wave signal is demodulated by a demodulating unit; the transmission time of ultrasonic wave from emitting to receiving is detected by a timing unit; the distance between the projector and the displaying screen is detected by a data processing module and a zooming parameter signal and a focusing parameter signal are output by the data processing module; a zooming motor and a focusing motor are driven by an output module to act, so that the zooming parameter value and the focusing parameter value can be respectively adjusted by a zooming lens and a focusing lens; and then the image is projected on the display screen. Besides, the invention also provides an automatic focusing projector with the method mentioned above.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

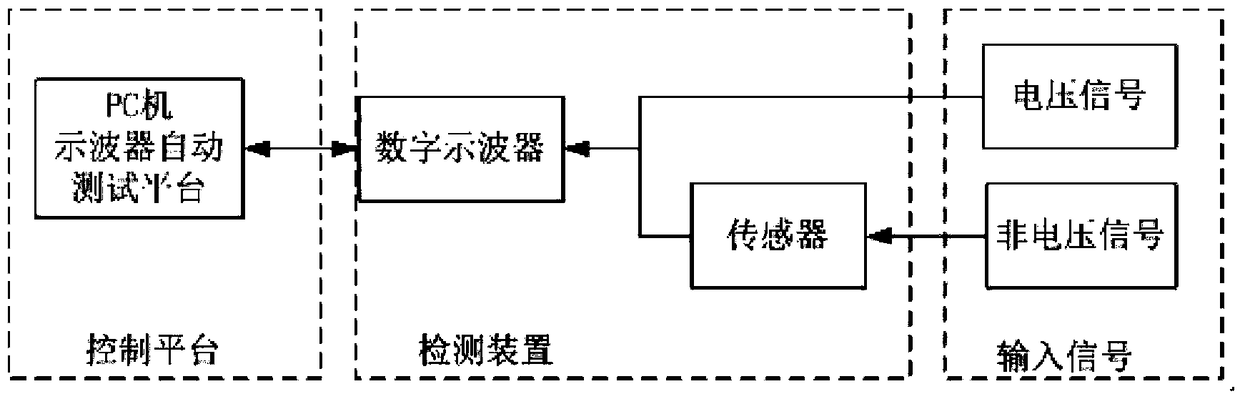

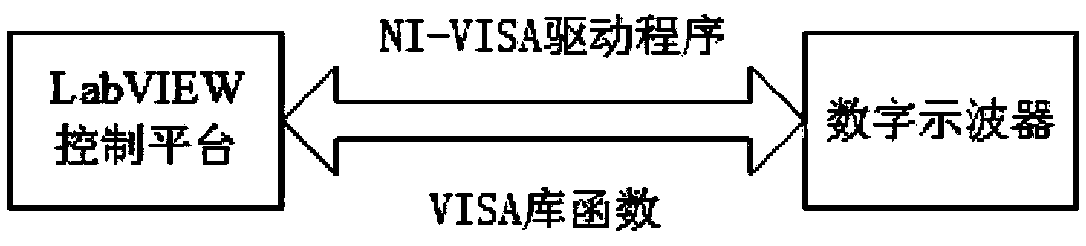

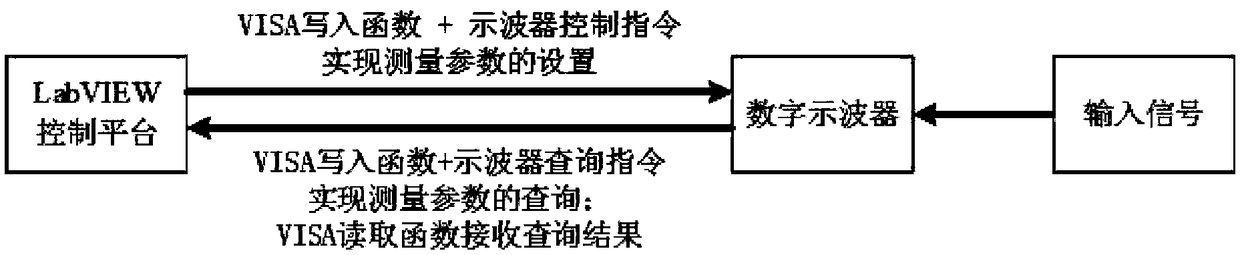

Automatic test system and method of oscilloscope

InactiveCN108802459ARealize automatic measurementImplement Adaptive MeasurementsDigital variable displayAutomatic test equipmentMeasuring instrument

The invention provides an automatic test system and method of an oscilloscope, and belongs to the technical field of measuring instruments. The automatic test method of an oscilloscope includes the steps: based on a LabVIEW platform, self-manufacturing a set of oscilloscope automatic test software being able to control a digital oscilloscope to automatically set measurement parameters; automatically releasing the acquisition stopping state after single time of triggering, and realizing continuous automatic acquisition of signals; and automatically storing acquired data in a PC, thus solving the problem that the digital oscilloscope is not enough in the storage depth, and realizing long time of measurement and recording of signals in an unattended operation condition; according to a test demand, realizing automatic measurement of the preset test sequence; and according to the change of the signal, automatically adjusting the measurement shift (horizontal time base and vertical shift), and realizing adaptive measurement of unknown signals.

Owner:BEIJING JIAOTONG UNIV

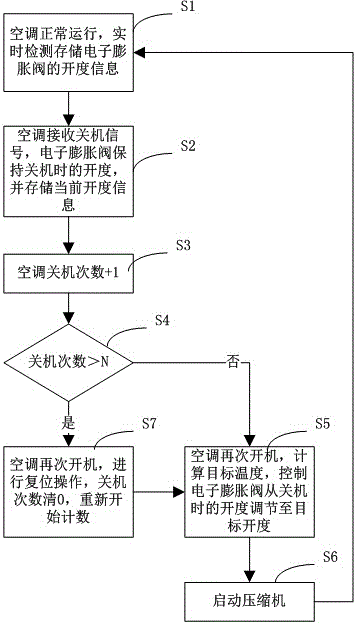

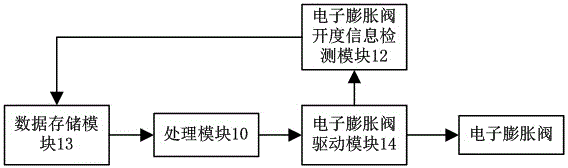

Control method and device for air conditioner electronic expansion valve

ActiveCN105783350AAvoid damageShorten adjustment timeMechanical apparatusSpace heating and ventilation safety systemsControl theoryElectronic expansion valve

The invention relates to a control method and device for an air conditioner electronic expansion valve. When an air conditioner runs, the aperture information of the electronic expansion valve is stored in real time, and therefore when the air conditioner is shut down, the current aperture of the electronic expansion valve is kept unchanged under the normal shutdown situation and the abnormal shutdown situation; in this way, when starting is conducted again, the current position of the electronic expansion valve when the electronic expansion valve is shut down last time can be read, the electronic expansion valve continues to be adjusted from the current position, and over-step reset is not needed; and the damage to the electronic expansion valve due to over-step reset is avoided, the adjusting time on the electronic expansion valve during starting can be shortened as well, and refrigerating and heating can be more rapidly conducted.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

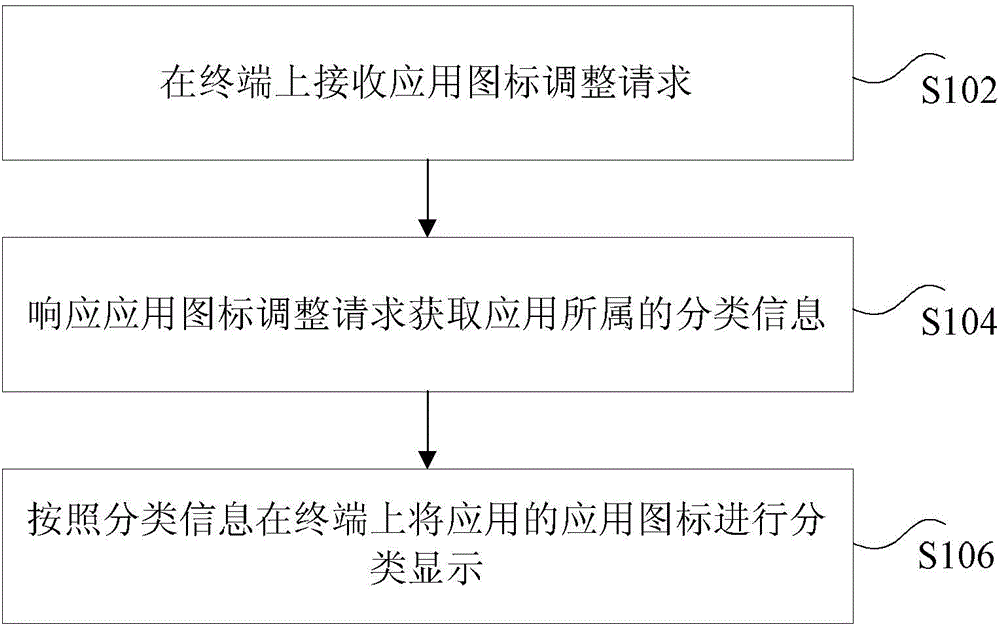

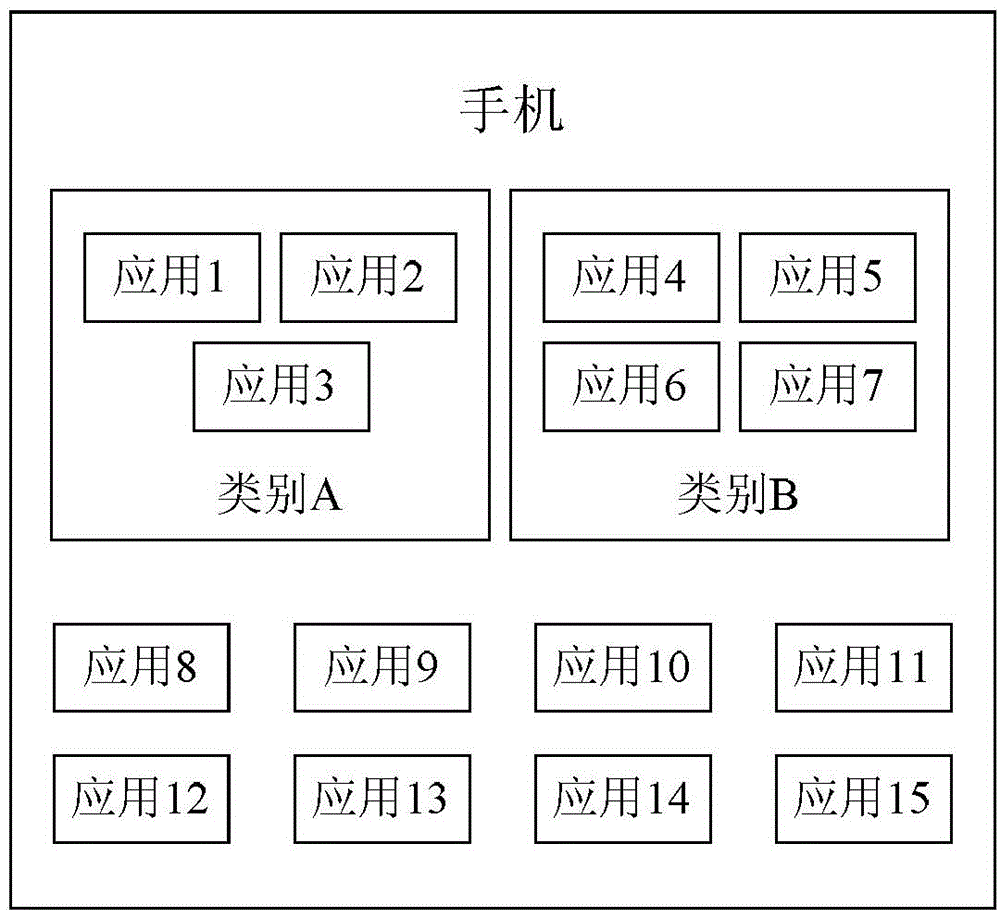

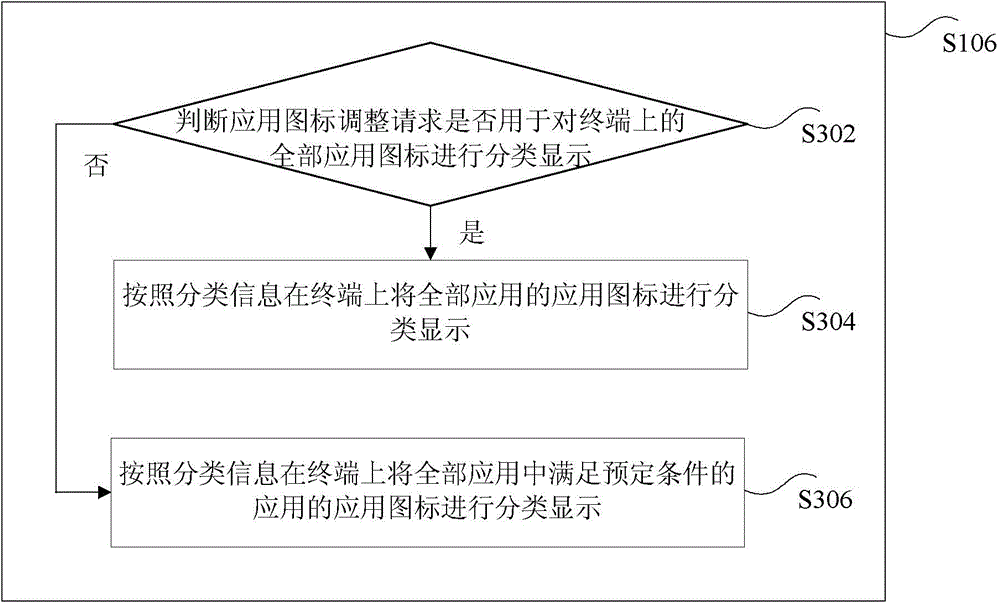

Method and apparatus for displaying application icon on terminal

ActiveCN104932781AShow fast and reasonableRealize automatic adjustmentSubstation equipmentInput/output processes for data processingComputer terminalComputer engineering

A method and an apparatus for displaying application icons on a terminal. The method comprises: receiving, on a terminal, an application icon adjustment request, the application icon adjustment request being used for requesting categorized display of application icons corresponding to applications installed on the terminal; acquiring categorization information of the applications in response to the application icon adjustment request; and displaying, according to the categorization information, the application icons of the applications by category on the terminal. It solves the technical problem of long adjustment time caused by that display positions of application icons on a terminal need to be adjusted manually in the existing technology, and achieves technical effects of system automatic adjustment, reduction in adjustment time, and increase in adjustment efficiency.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com