Circle center aligning method for aviation revolution part machining basic circle

A technology for machining parts and machining benchmarks, which is applied in the field of center alignment of the benchmark circle for machining of aviation rotary parts to achieve the effect of reducing adjustment time, accurate results and high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

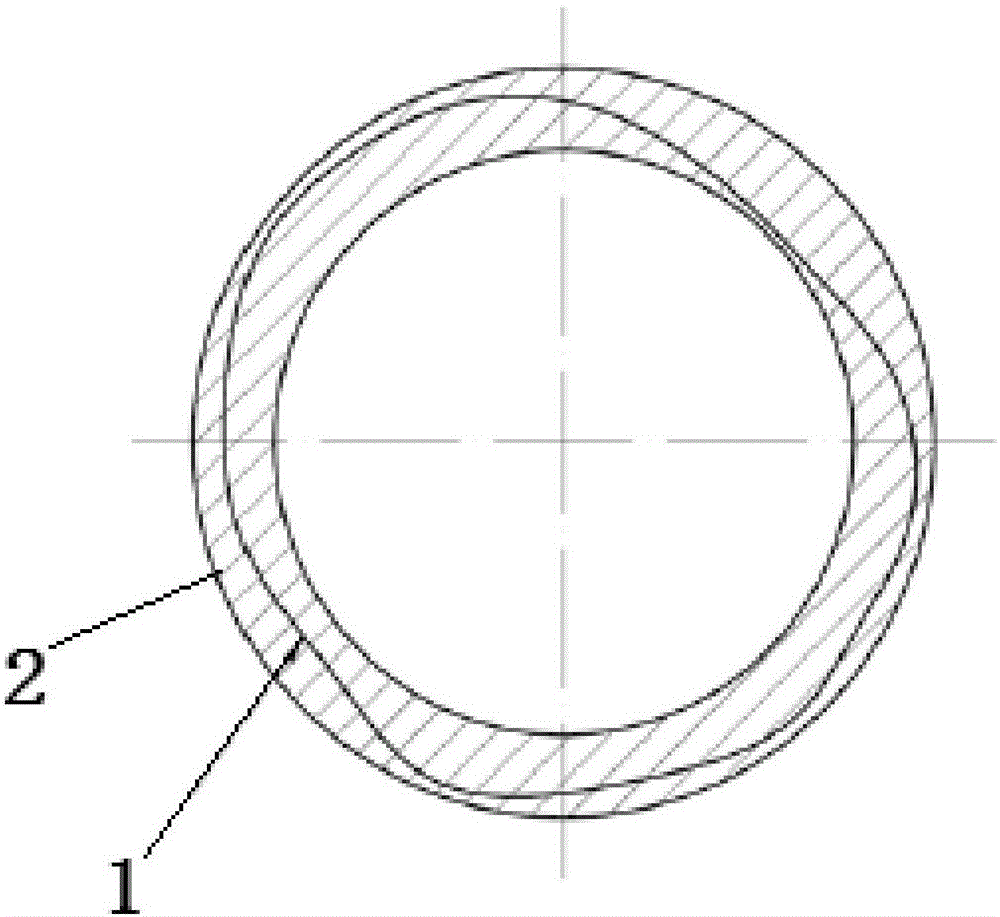

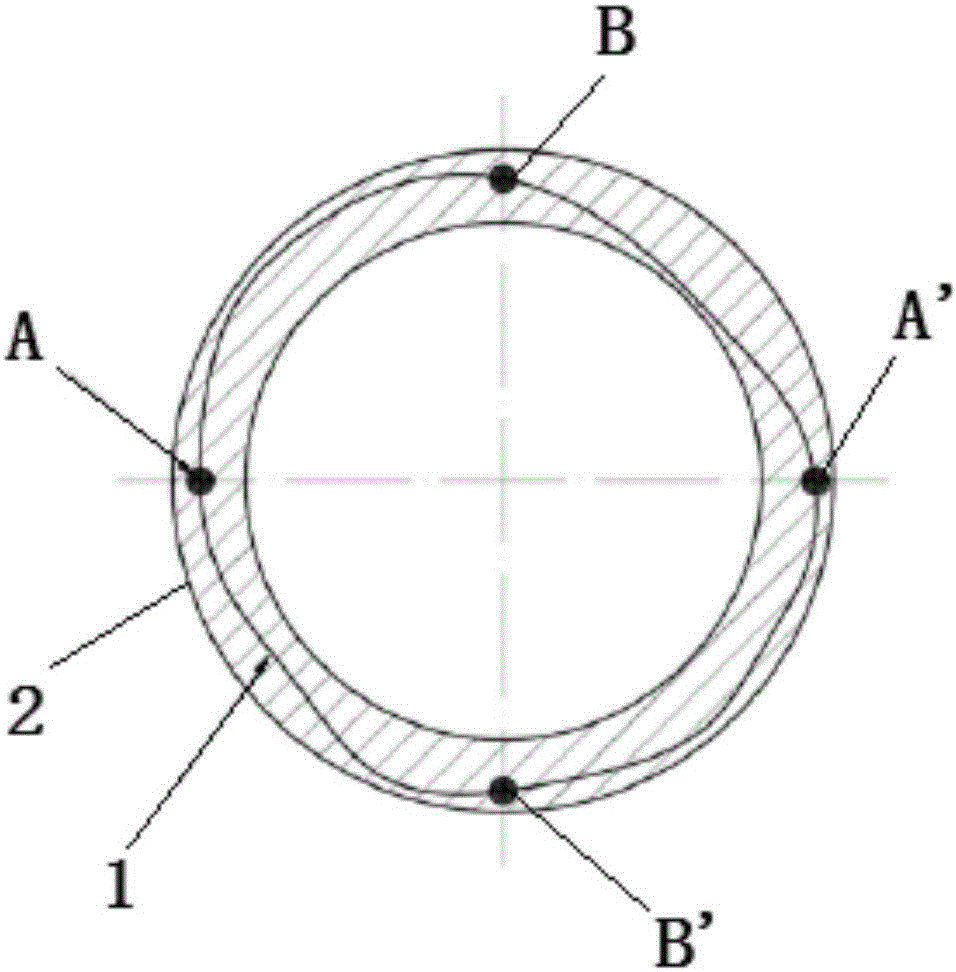

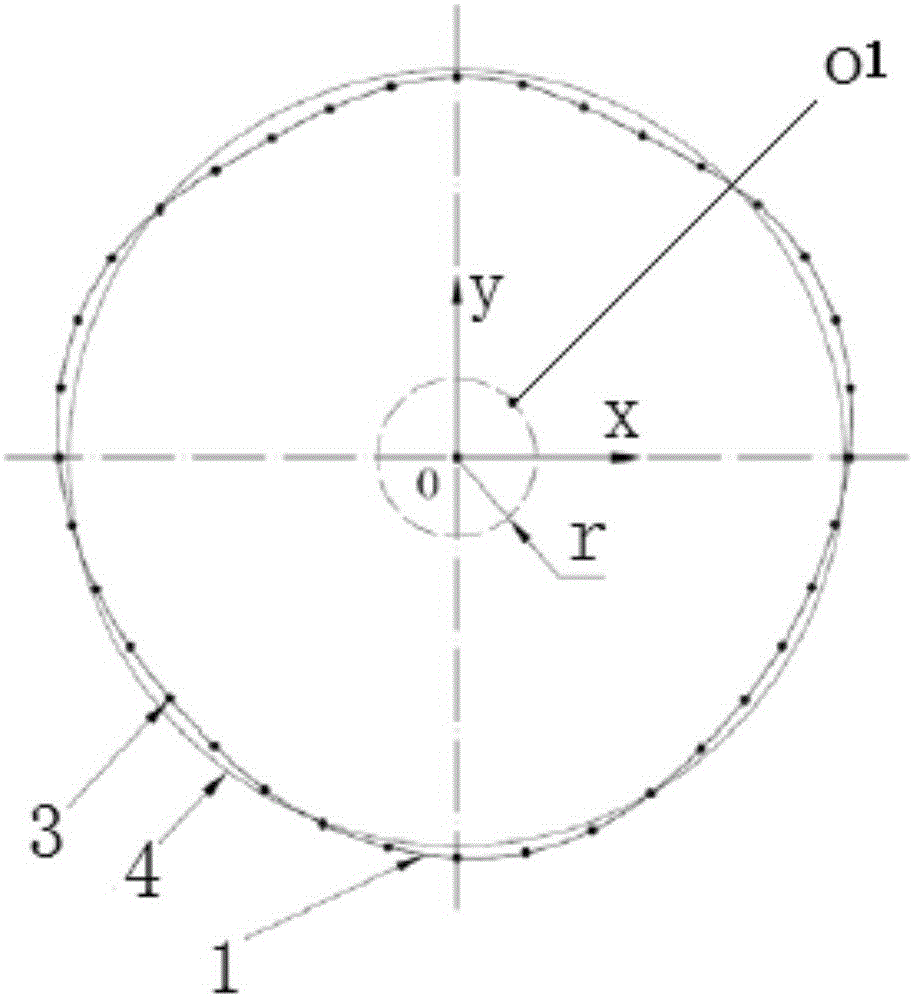

[0018] Example 1 as image 3 As shown, this embodiment is described with a method for center alignment of a circular part machining reference circle, and the specific steps include:

[0019] A. Initially assemble the ring parts, set the alignment coordinate system SCS, and the machine tool has returned to zero according to the alignment coordinate system SCS (the coordinate origin of the measurement program coincides with the center of the machine tool rotary table); place the parts on the machine tool to rotate The center of the workbench, so that the center of the reference circle roughly coincides with the center of the rotary table of the machine tool, that is, the center O1 of the part processing reference circle roughly coincides with the rotation center O of the machine tool table (four points are evenly distributed on the circumference of the part, and two symmetrical points are connected to the machine tool). The difference of the distance between the center of rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com