Virtual command module for large lifting operations and working method of virtual command module

A large-scale hoisting and working method technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of endangering the safety of hoisting operations, inconsistent instructions, and many cross-operations, so as to improve hoisting efficiency, reduce adjustment time, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical scheme of the patent of the present invention will be described in detail below in conjunction with the accompanying drawings and examples of implementation.

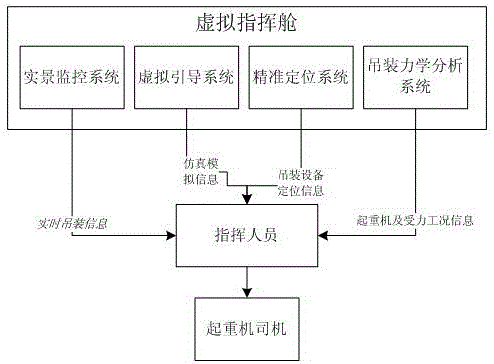

[0038] Such as figure 1 As shown, this implementation case provides a virtual command cabin for large hoisting operations, including a real scene monitoring system, a virtual guidance system, a precise positioning system and a hoisting mechanics analysis system.

[0039] The real-scene monitoring system is used to receive real-time monitoring images uploaded by high-definition network cameras deployed on the ground and underground, check site hoisting preparations, monitor and record hoisting trajectories, and assist commanders to check operation blind spots to ensure that they can grasp the images of all angles of the hoisting site to assist the crane driver in commanding the crane driver to adjust the posture of the hoisting object, so as to realize the visualization of the whole hoisting process;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com