High-speed high-precision flexible electronic gear box control method

A control method and gear box technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of restricting the development of gear processing equipment manufacturing industry, high price, etc., achieve high performance and price advantages, shorten adjustment time, and process The effect of speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

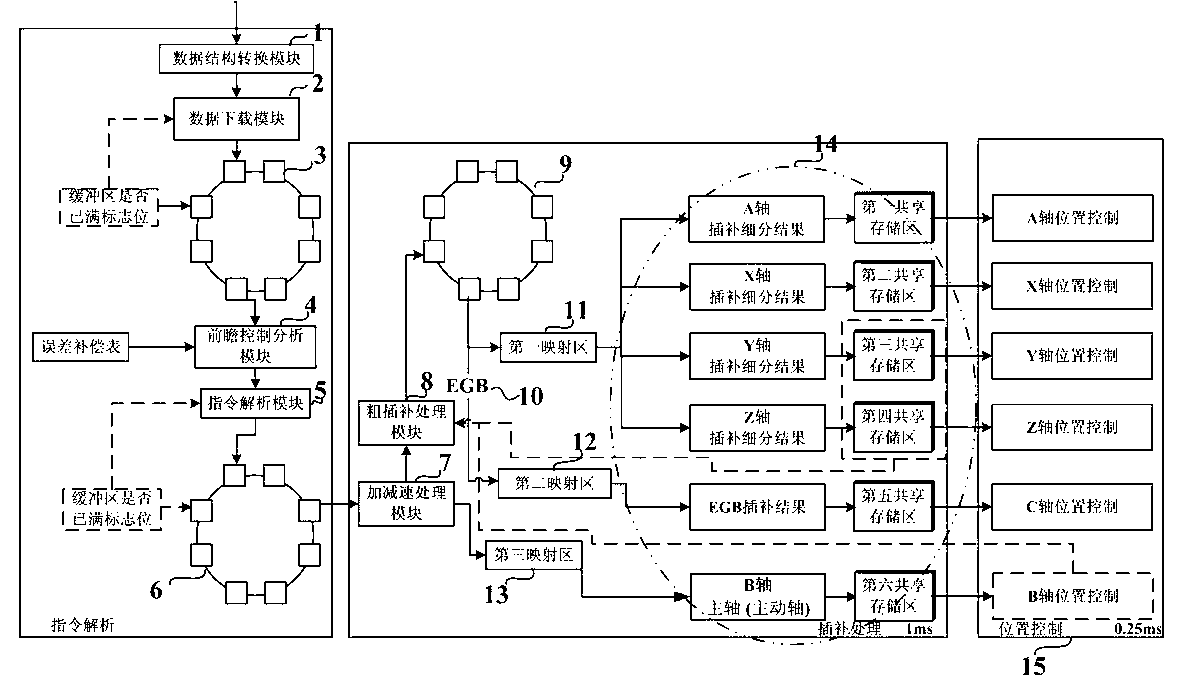

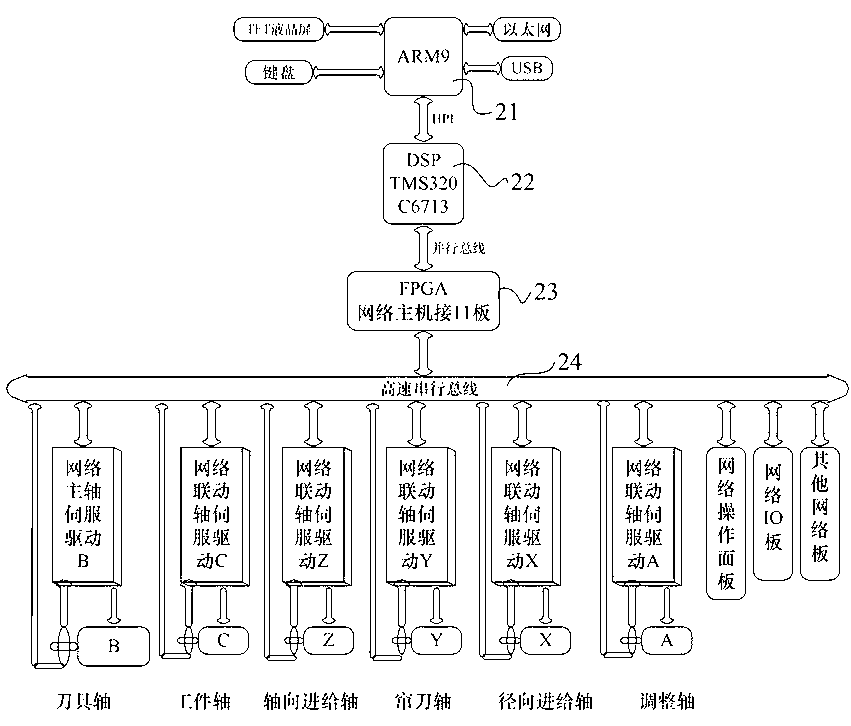

[0038] Below in conjunction with accompanying drawing, the patent of the present invention is described in further detail.

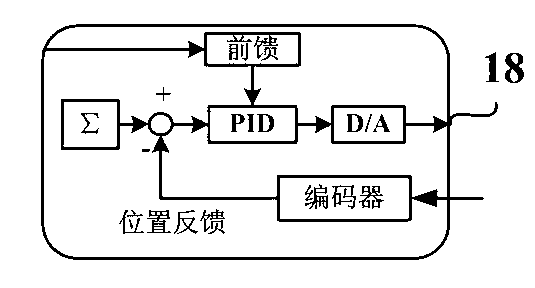

[0039] Gear processing usually has very strict requirements on two or more relative motion speeds, and there should be no relative error in the position of each other during the motion process. Traditional gear hobbing machines use complex gear transmission chains to achieve precise generative motion. The electronic gearbox uses computer control technology to realize high-precision and high-efficiency fixed-ratio and variable-ratio gear processing, replacing the cumbersome generation and differential mechanical transmission chains of traditional gear machine tools, and realizing a variety of complex motion mechanisms with simple functional relationships. The CNC gear hobbing machine tool has six CNC axes, namely the radial feed axis X axis, the tool movement axis Y axis, the axial feed axis Z axis, the hob installation angle adjustment axis A axis, the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com