Automatic test system and method of oscilloscope

An automatic test system and automatic test technology, applied in the field of measuring instruments, can solve the problems of expensive instruments, high test costs, application limitations, etc., and achieve the effects of saving storage resources, improving test efficiency, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

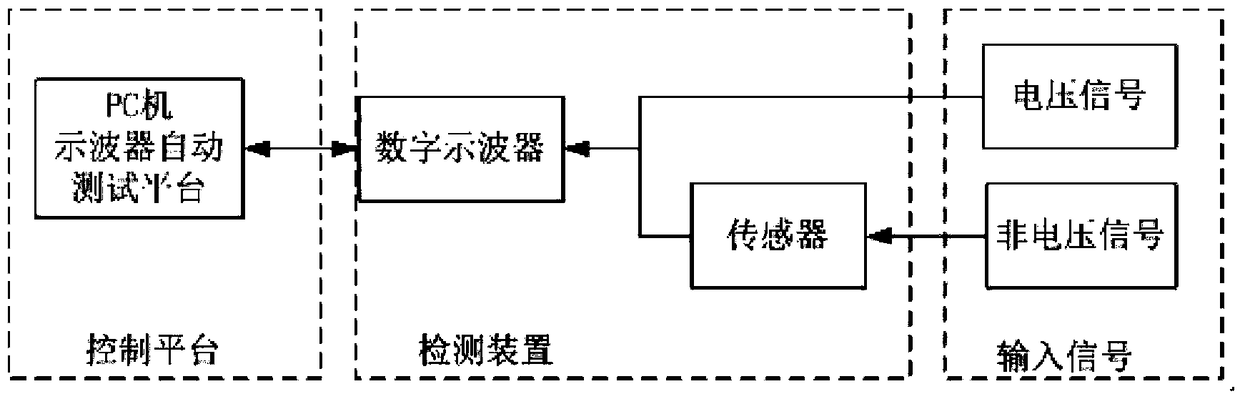

[0104] Embodiment 1: a kind of oscilloscope automatic testing method comprises the following steps;

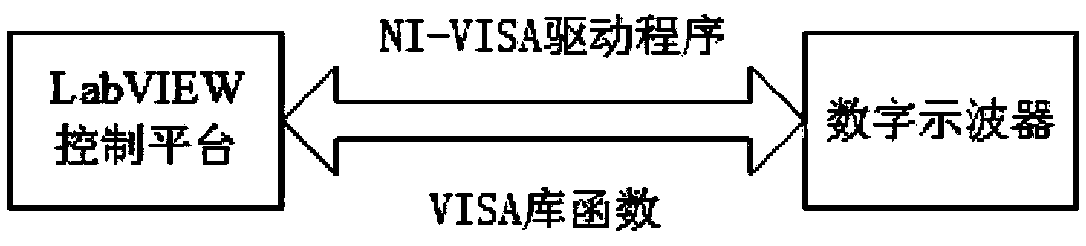

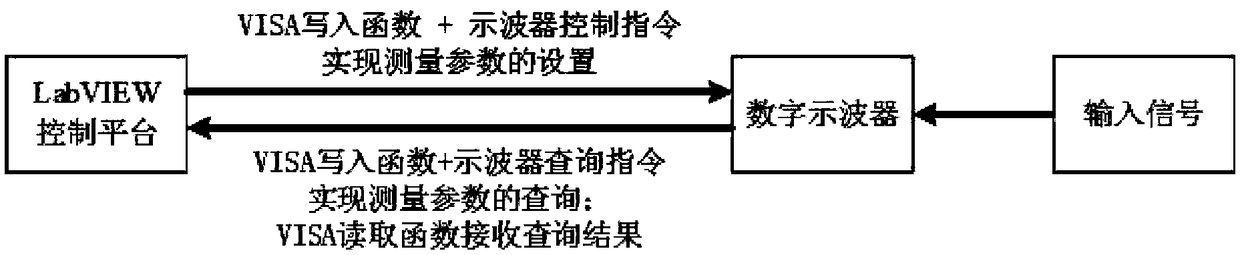

[0105] The digital oscilloscope measurement parameter setting and signal parameter query need to be completed manually. The oscilloscope automatic test system requires the system to automatically set the digital oscilloscope measurement parameters under the control of the host computer software.

[0106] The digital oscilloscope is in the state of stopping acquisition after a single trigger, and the automatic test system of the oscilloscope needs to automatically release the trigger to realize continuous automatic acquisition of signals.

[0107] The digital oscilloscope has a limited storage depth. In the normal mode, the DS1052E digital oscilloscope can store 16Kpts sampling points; in the long storage mode, it can store 1Mpts sampling points. Without deep storage, long-term signal recording cannot be realized. The oscilloscope automatic test system needs to have deep stora...

Embodiment 2

[0177] Embodiment 2: the automatic collection and storage of data contains the following steps;

[0178] The oscilloscope automatic test system automatically sets the measurement parameters of the digital oscilloscope under the control of the host computer software.

[0179] The digital oscilloscope is in the stop collecting state after a single trigger, and the oscilloscope automatic test system automatically releases the trigger to realize continuous and automatic signal collection.

[0180] The digital oscilloscope has a limited storage depth. In the normal mode, the DS1052E digital oscilloscope can store 16Kpts sampling points; in the long storage mode, it can store 1Mpts sampling points. Without deep storage, long-term signal recording cannot be realized. The oscilloscope automatic test system design program stores the collected data to the PC in real time, so that the system has deep storage capabilities and realizes long-term signal measurement and recording.

[0181]...

Embodiment 3

[0184] Automated testing of complex tests.

[0185] The oscilloscope automatic test system can complete the automatic measurement task according to the predetermined test sequence for the well-known signals, and set the measurement parameters of the oscilloscope before the possible arrival time of the signal, which is conducive to the measurement of signals with different characteristics and different test items, and improves the measurement efficiency and accuracy . The implementation method and program design have been introduced in the previous article, and now an experiment is designed to verify the function.

[0186] The present invention adopts two groups of representative test sequences for testing, and the test sequence information is as follows: Figure 14 shown.

[0187] For the convenience of measurement, each test time is set to 5 minutes, and the interval between adjacent test sequences is also set to 5 minutes. The first signal arrives at 13:47 and lasts 5 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com