Test device for measuring spray characteristic of local application nozzle of carbon dioxide fire-extinguishing system

A carbon dioxide and fire extinguishing system technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of low work efficiency, high test cost, heavy workload, etc., to avoid nozzle pipelines and Bracket, convenient and quick operation, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

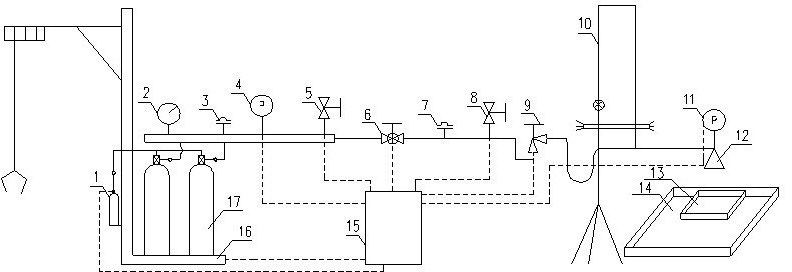

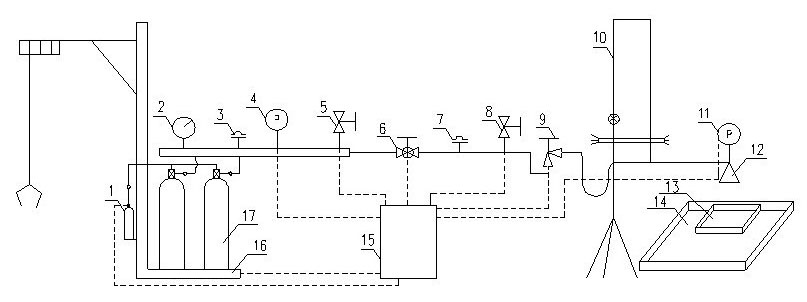

[0020] Such as figure 1 As shown, the hoisting and weighing device 16 is composed of a base frame, an electronic weighing platform scale and an electric hoist, an electric hoist support frame is arranged on the base frame, and an electric hoist is installed, and the electronic weighing platform scale is used to place the carbon dioxide storage container and weigh the weight. The driving gas bottle group 1 is installed on the side of the frame, and the driving gas bottle group 1 is composed of a driving container, a container valve, a solenoid valve, etc., and the driving gas bottle group 1 is driven by an electromagnetic driver;

[0021] The carbon dioxide storage container 17 is connected to the manifold through the container valve at the bottle mouth of the container. A pressure gauge 2, a safety valve a, a pressure sensor a, and a pneumatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com