Patents

Literature

109 results about "Spray characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

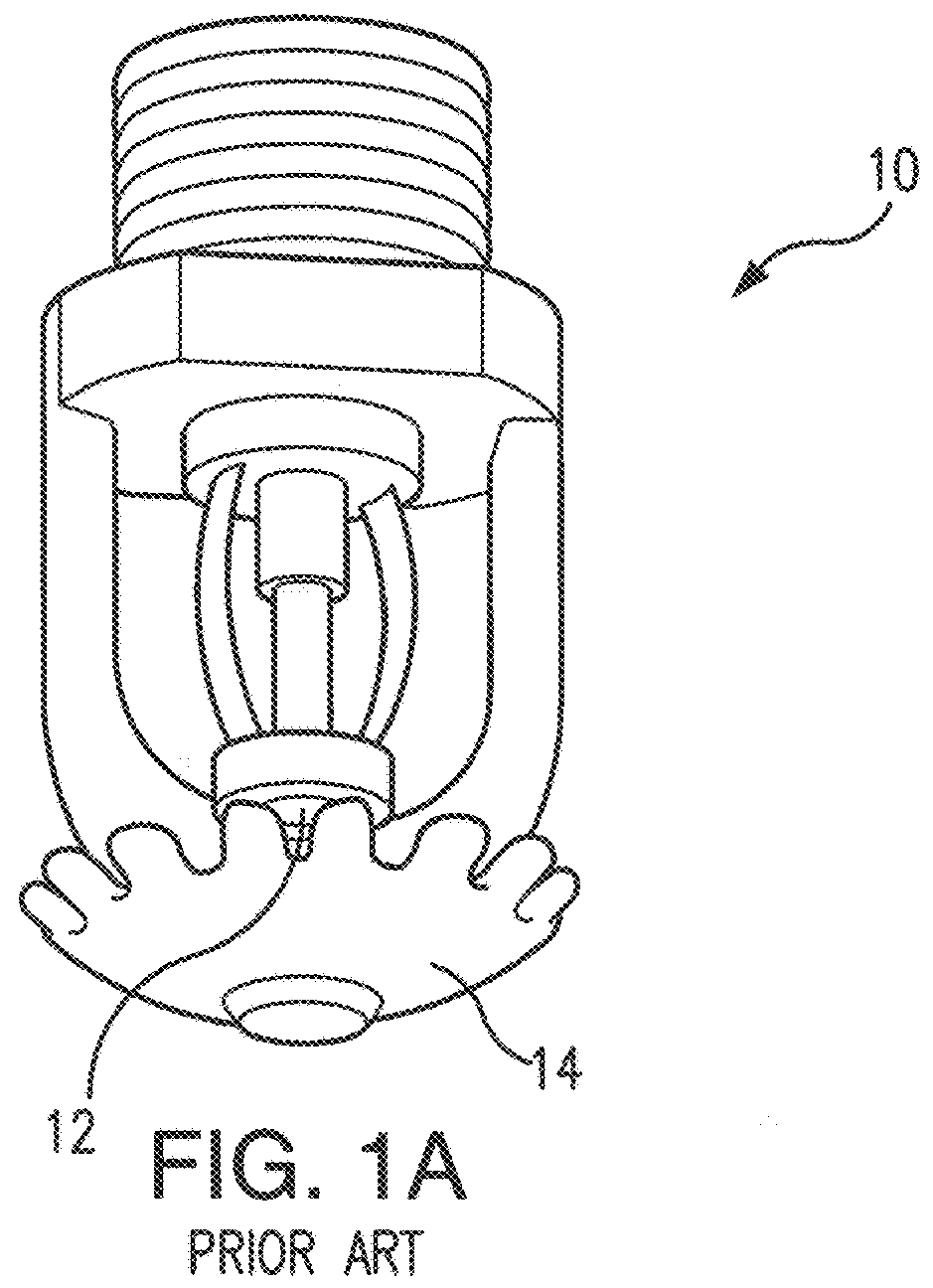

Spray nozzles are designed to perform under various operating conditions.

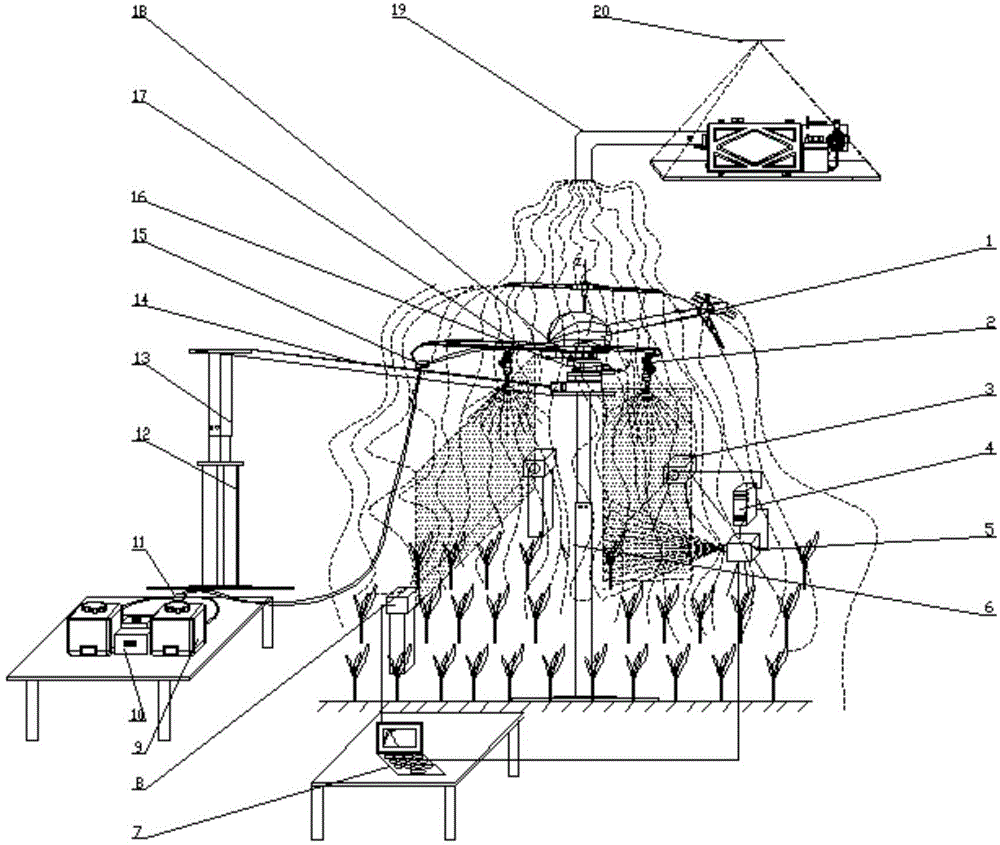

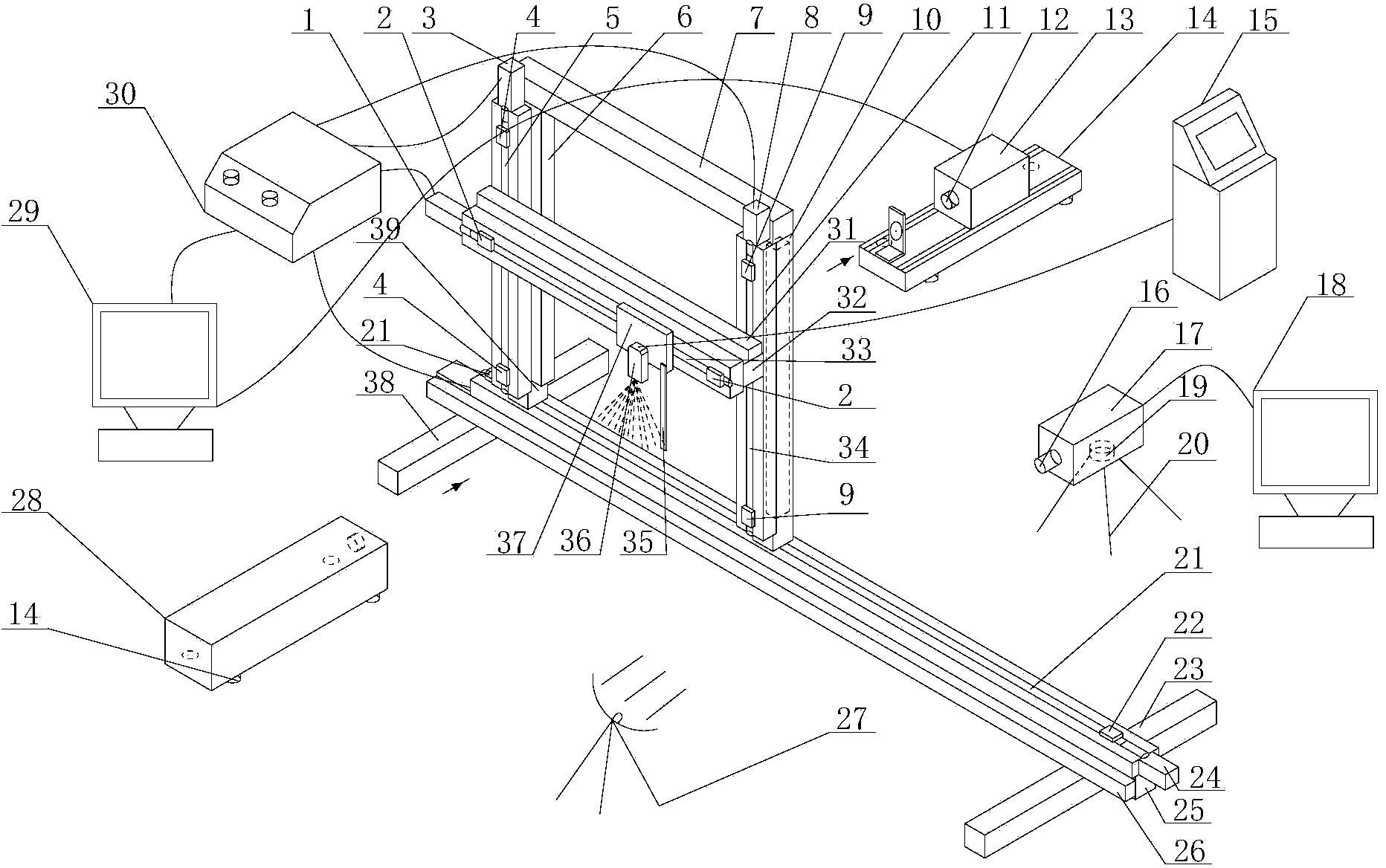

Agricultural unmanned gyroplane optimal working parameter testing device and method

ActiveCN104568006AOptimum Combination ParametersMeasurement devicesAttitude controlAgricultural engineering

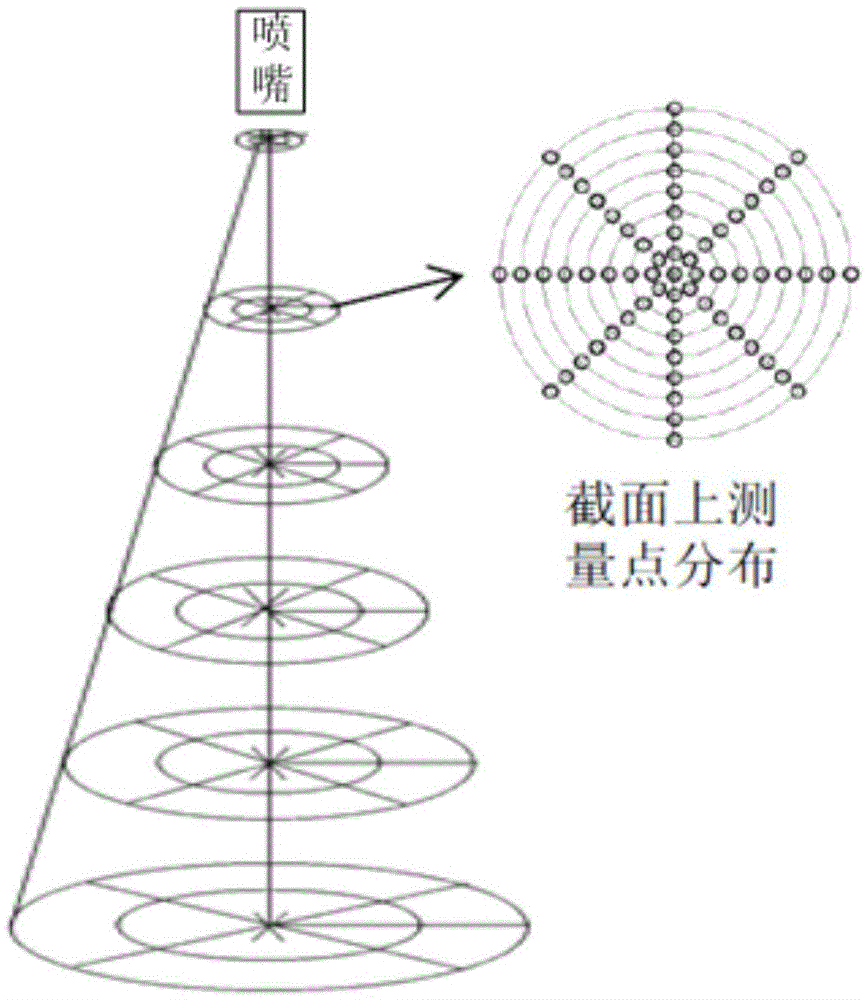

The invention discloses an agricultural unmanned gyroplane optimal working parameter testing device and method. The agricultural unmanned gyroplane optimal working parameter testing device comprises a gyroplane, a flight attitude console, a working altitude lifting platform, a pesticide spraying system, a wind speed flow field testing system and a spraying characteristic testing system, wherein the spraying characteristic testing system comprises a fogdrop flow field testing system, a fogdrop particle size measuring system and a spraying sedimentation testing system. According to the testing device and method, influences of single-rotor airplane structures, multi-rotor airplane structures, pesticide spraying parameters of pesticide application flow, pesticide application pressure, working altitudes and positions of spray nozzles relative to centers of airplane bodies, environmental influences of wind speed, wind direction, temperature and humidity and airplane attitude parameters of roll angles, pitching angles and yaw angles on fogdrop uniformity, wind speed flow field uniformity, fogdrop particle size distribution, other pesticide application effects and pesticide application efficiency can be provided comprehensively, systematically, synthetically and quantitatively, spraying characteristics of agricultural gyroplane spraying operation are tested, and optimal pesticide application combined parameters are researched.

Owner:南京林卫生态农业科技有限公司

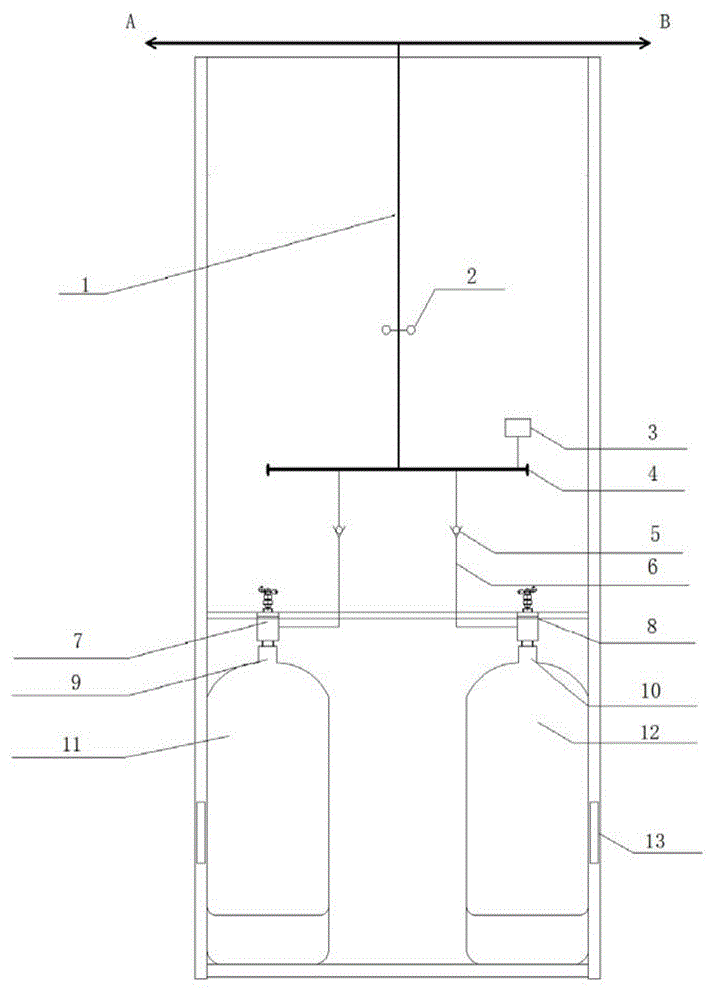

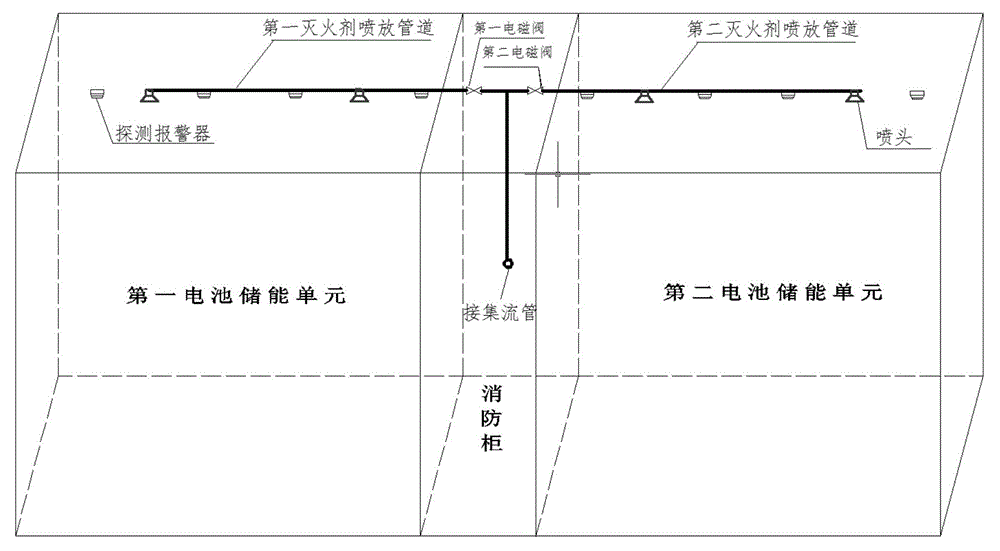

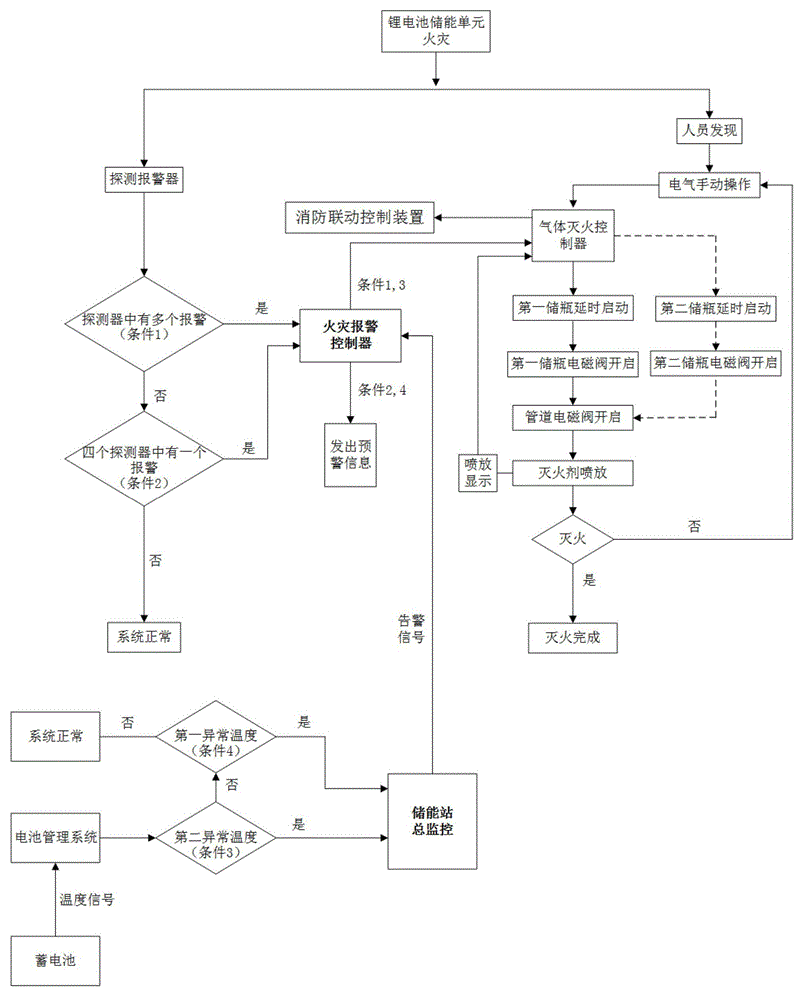

Fire extinguishing system for energy storage units of lithium batteries

ActiveCN103977516AAchieve fire protectionImplement manual operationFire rescueSystems designEngineering

The invention relates to a fire extinguishing system for energy storage units of lithium batteries. The fire extinguishing system mainly comprises an automatic fire alarm system, a gas fire extinguishing system, a fire extinguishing linkage control device, a fire emergent broadcasting and fire extinguishing special telephone device. Fire extinguishing devices of the fire extinguishing system can be automatically or manually started, the automatic starting is triggered mainly by a fire alarm control unit, the fire alarm control unit can receive triggering signals input by a battery management system and a detection alarm, when fire alarm conditions are met, starting signals are output to a gas fire extinguishing controller, and a fire extinguishing device is started to spray a fire extinguishing agent to the energy storage units; when an operator finds fire behavior in a protective zone, a start button outside the protective zone or on the gas fire extinguishing controller can be manually pressed down, and the manual operation of the fire extinguishment system is realized. Specific to multiple fire spraying characteristics of the lithium batteries, the two sets of fire extinguishing devices of the fire extinguishing system share one fire extinguishing cabinet, and the fire extinguishment protection of the two energy storage units of the lithium batteries is realized. The two sets of fire extinguishing devices are independent of each other and spare to each other, and the whole fire extinguishing system has a secondary fire extinguishment function.

Owner:UNIV OF SCI & TECH OF CHINA

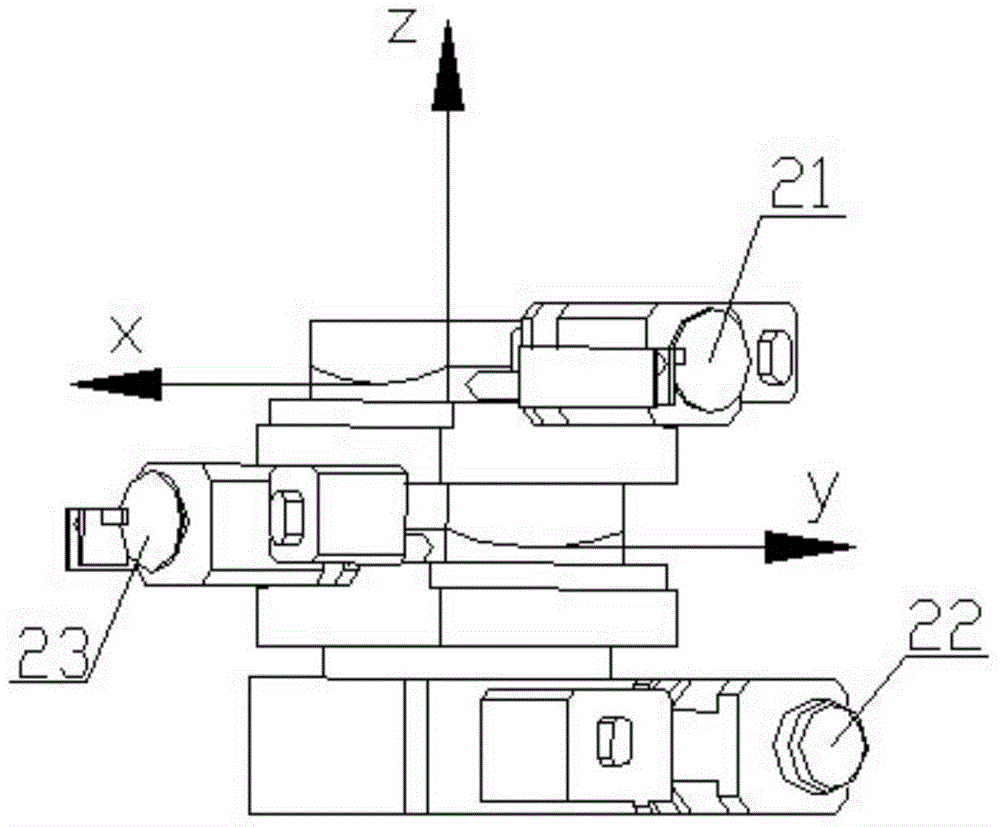

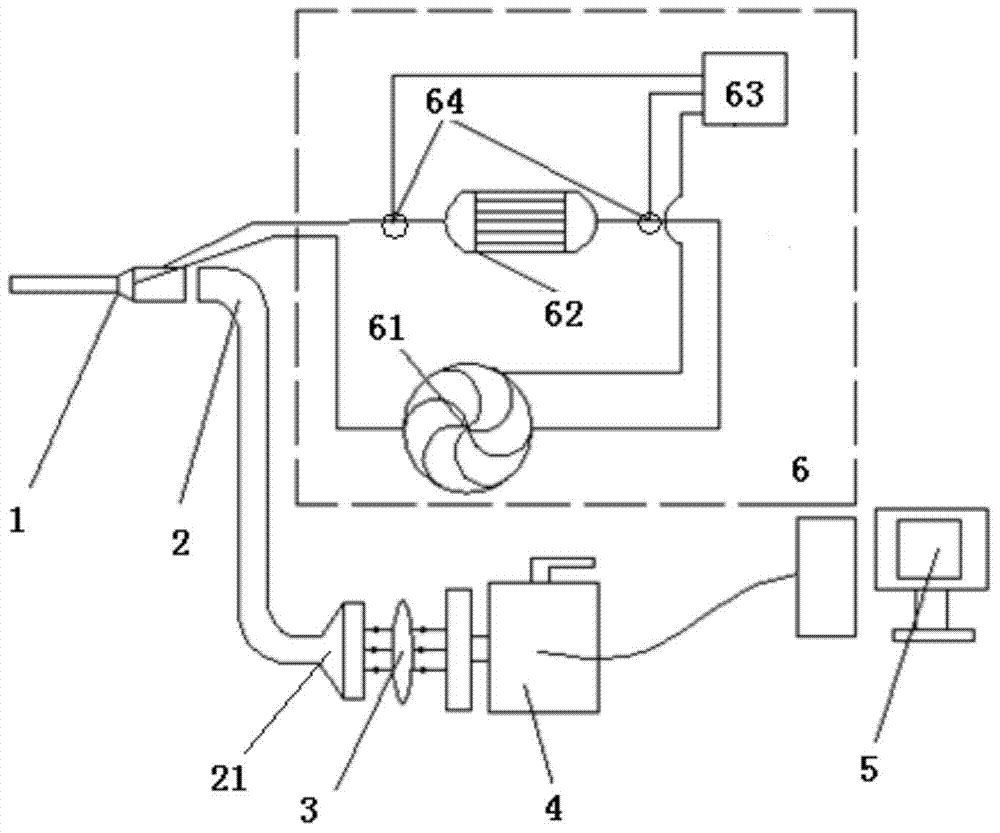

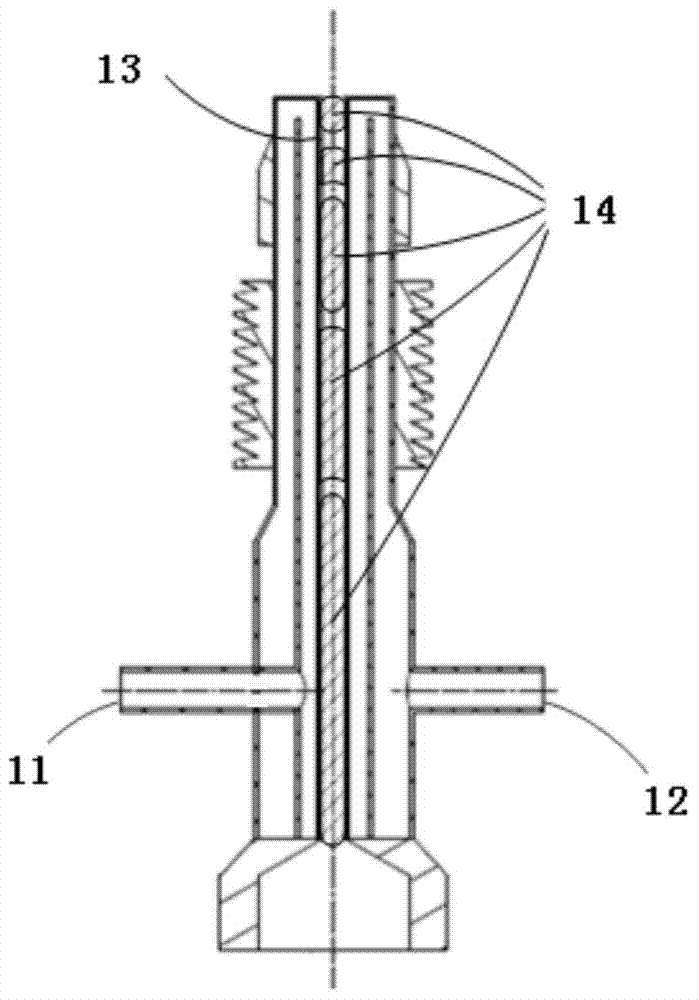

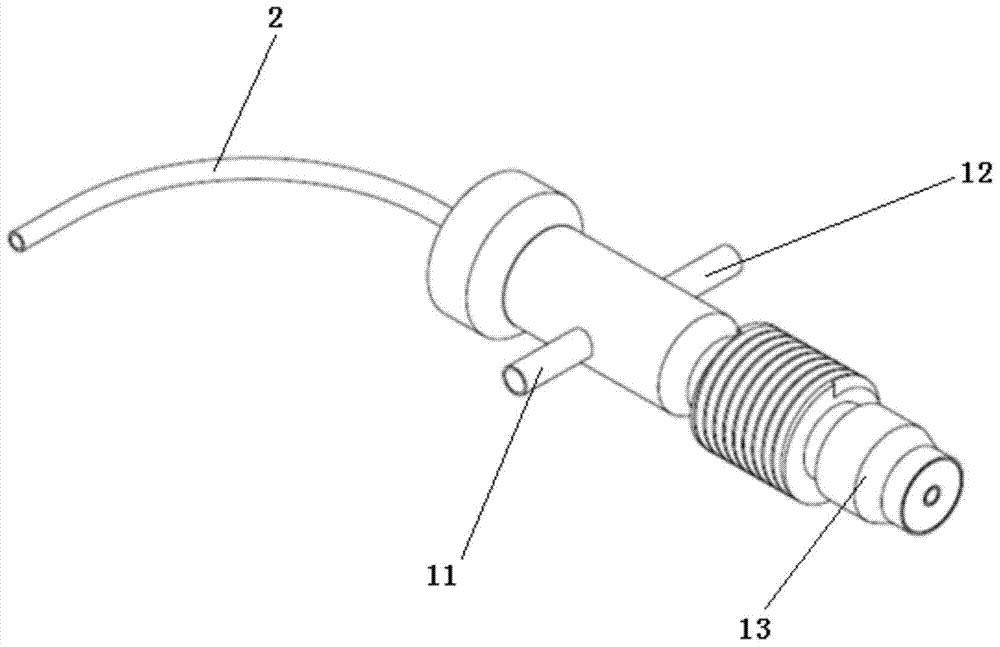

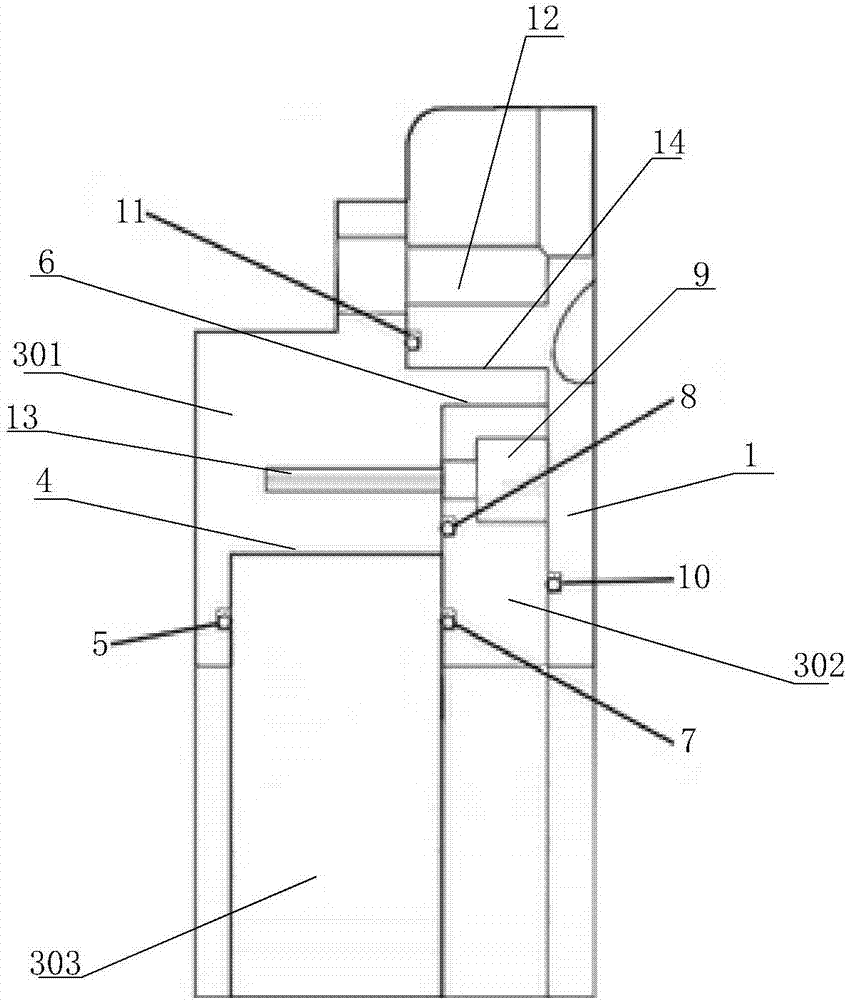

Spray characteristic parameter detection device and method

ActiveCN104181083AEasy to moveHigh degree of automationParticle size analysisControl systemEngineering

The invention discloses a spray characteristic parameter detection device and method. The spray characteristic parameter detection device comprises an integral support rack, a two-dimensional moving unit, a servo motor, a servo control unit, a spray control system, a pulse nozzle, a high-speed camera image acquisition system and a laser particle size analyzer system. On the basis of the device, the spray characteristic parameter detection method comprises the following steps: detecting an outline shape of spray, macroscopic two-dimensional distribution of spray and the flying speed of particles of spray by virtue of the high-speed camera image acquisition system; and detecting the particle size of spray with two-dimensional distribution in a spatial two-dimensional plane travel range by a two-dimensional precise servo driving system based on a laser particle size analyzer according to the outline and the macroscopic two-dimensional distribution of spray on the basis of a spray image acquisition result.

Owner:TIANJIN UNIV OF COMMERCE

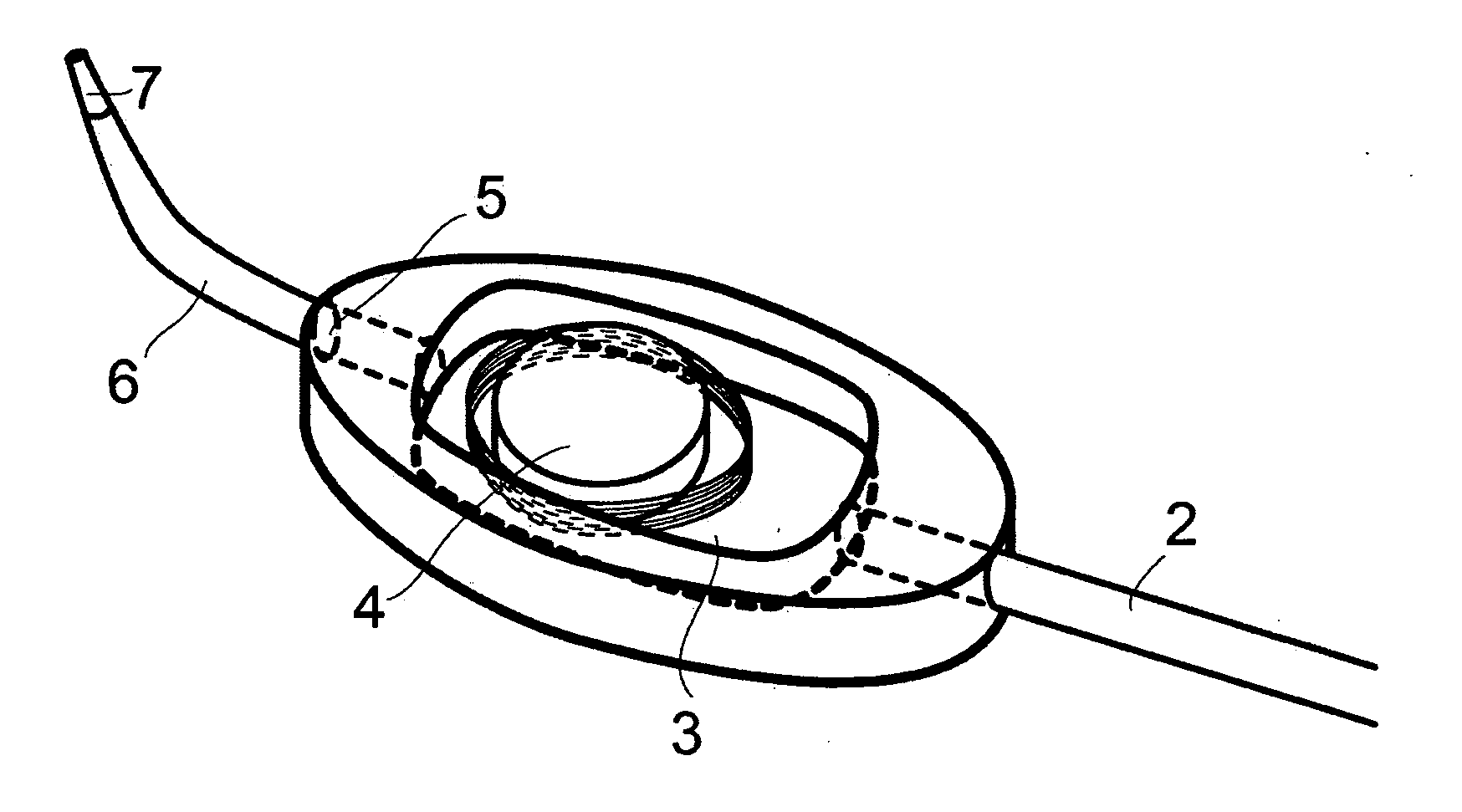

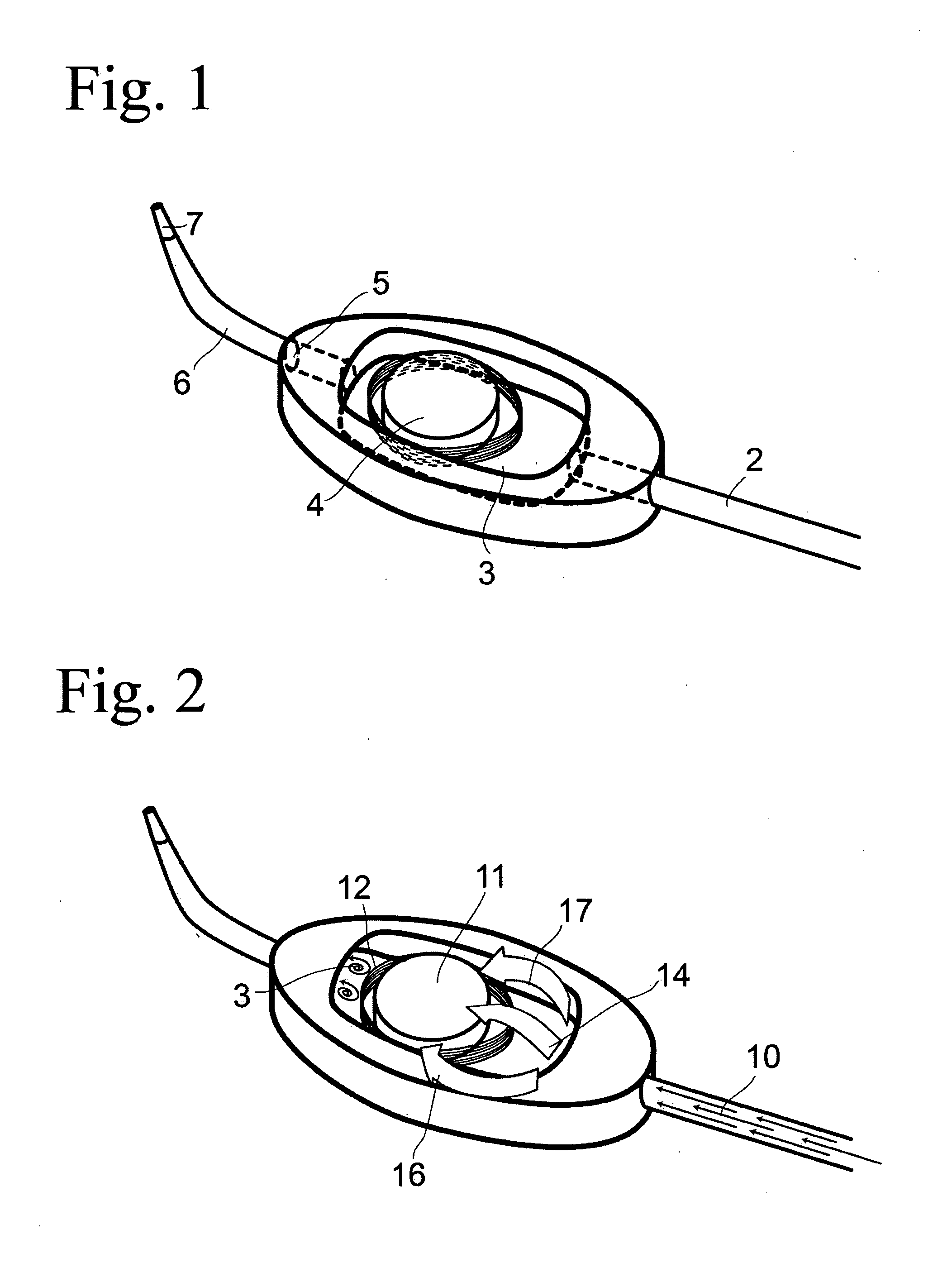

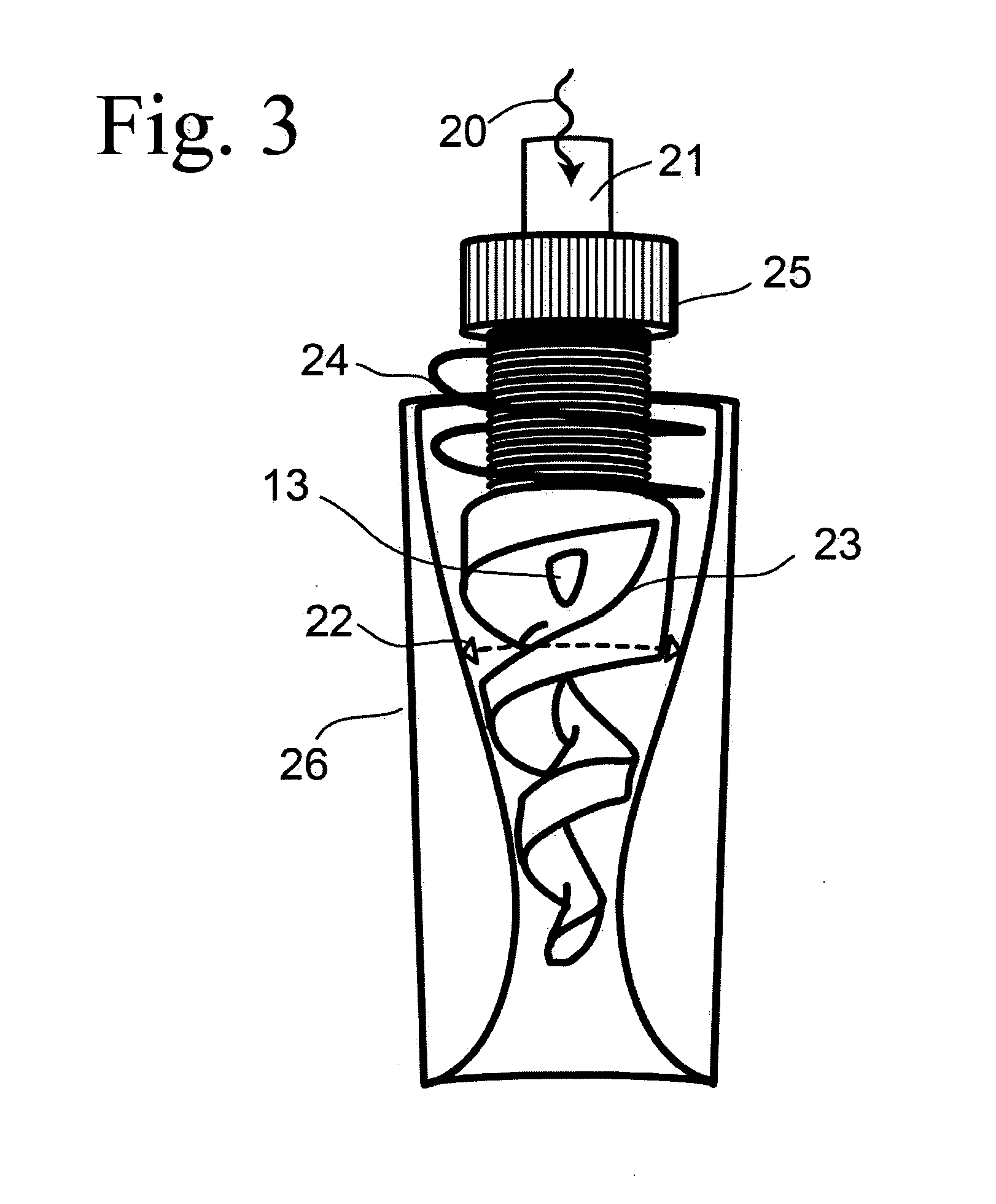

Toothcleaning Device

Equipment for daily dental care: teeth are cleaned by water jet with admixed softly abrasive media for the dissolution of plaques. A particular mixing chamber for the transfer of the ingredients from tabs may be branched either to by passes on faucets or showering mixing taps or to hereditary water jet pumping systems. Pressure and spray characteristics of the jet can be adjusted with a spiral nozzle.

Owner:DENTAL CARE INNOVATION

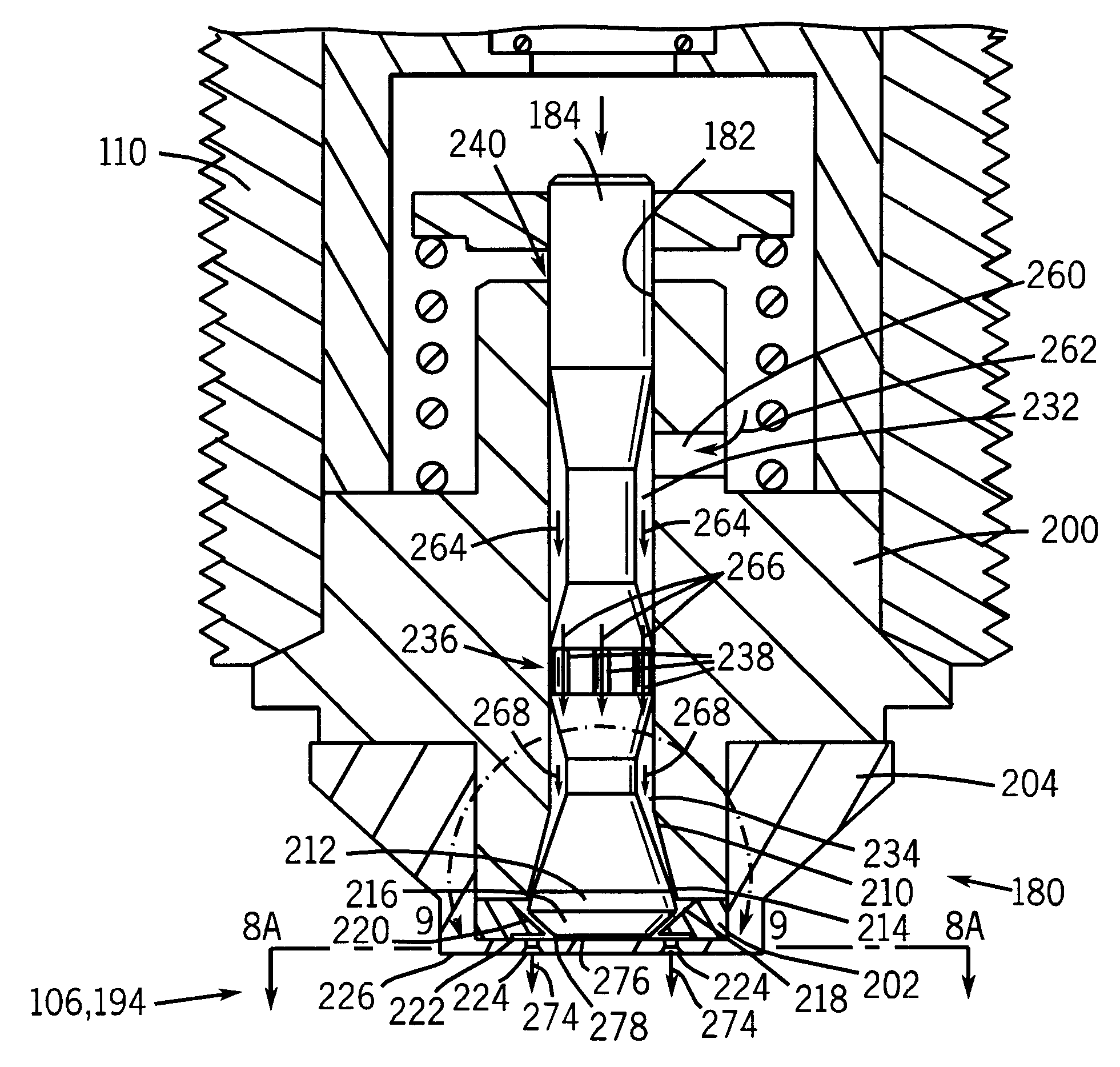

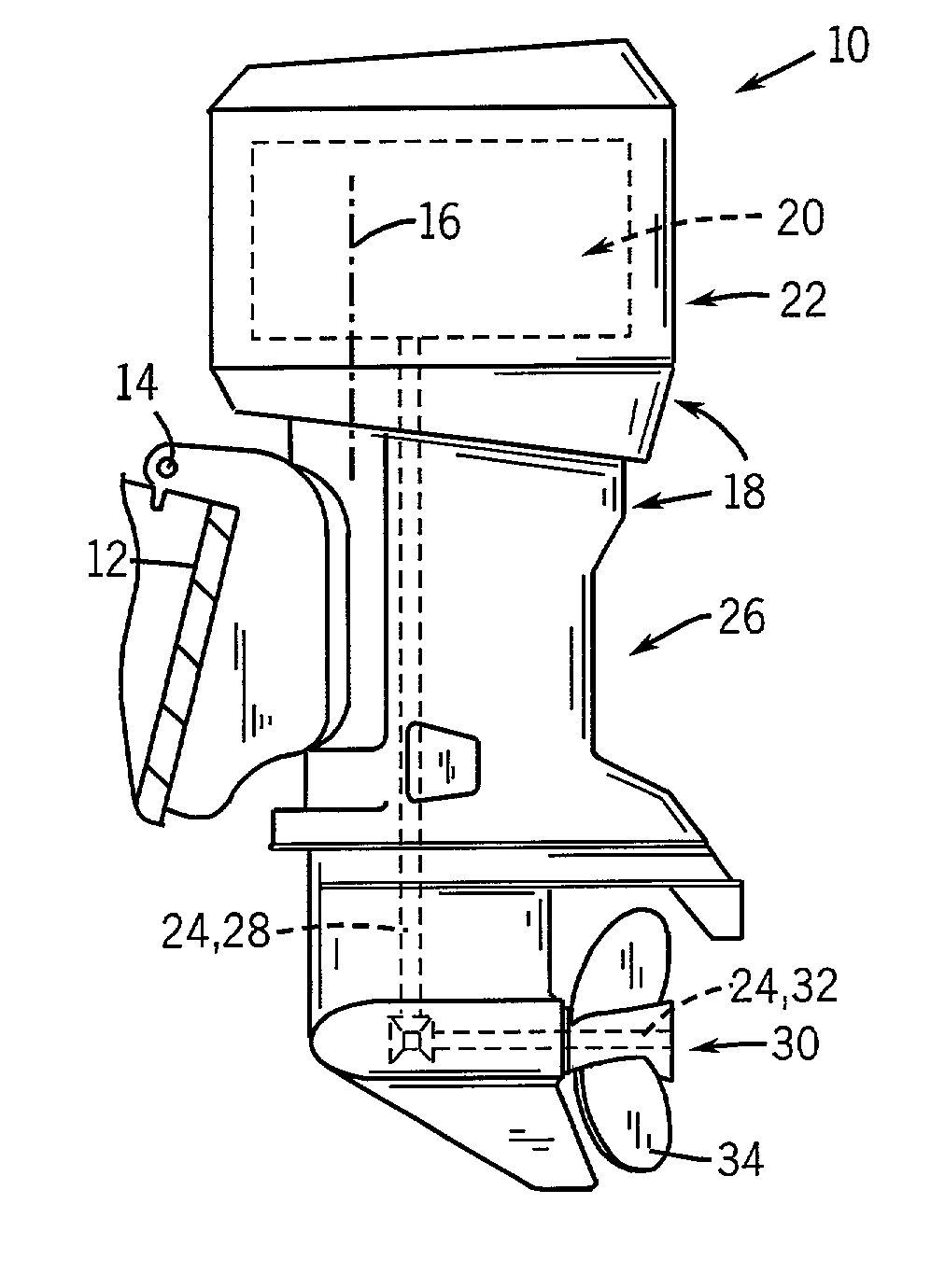

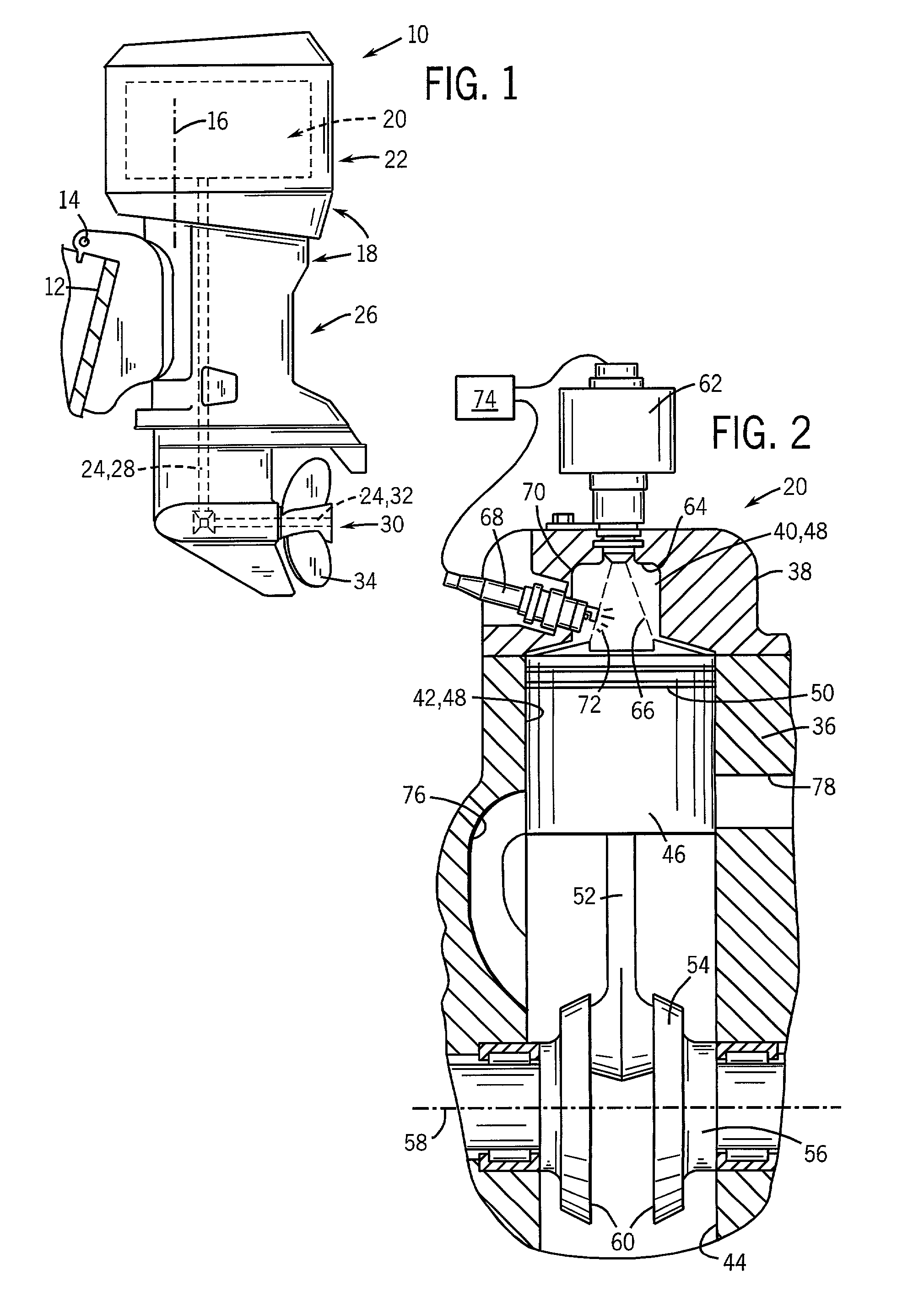

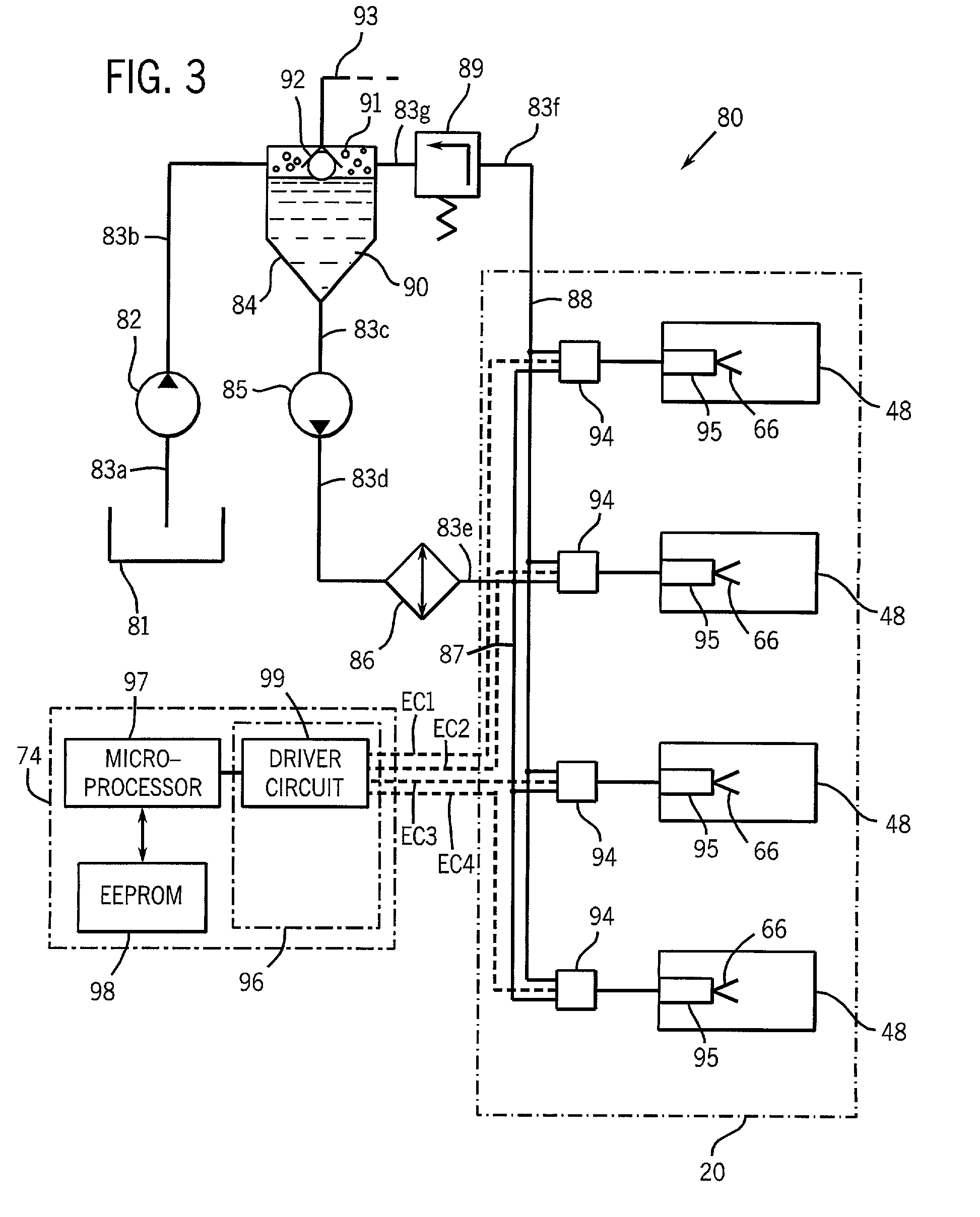

Multi-port fuel injection nozzle and system and method incorporating same

A technique is provided for enhancing fluid flow in an outwardly opening nozzle assembly. A flow enhancement assembly is provided adjacent an exit from an outwardly opening poppet to provide desired spray characteristics. The flow enhancement assembly includes converging and diverging passages and a plurality of ports to form a spray.

Owner:BRP US

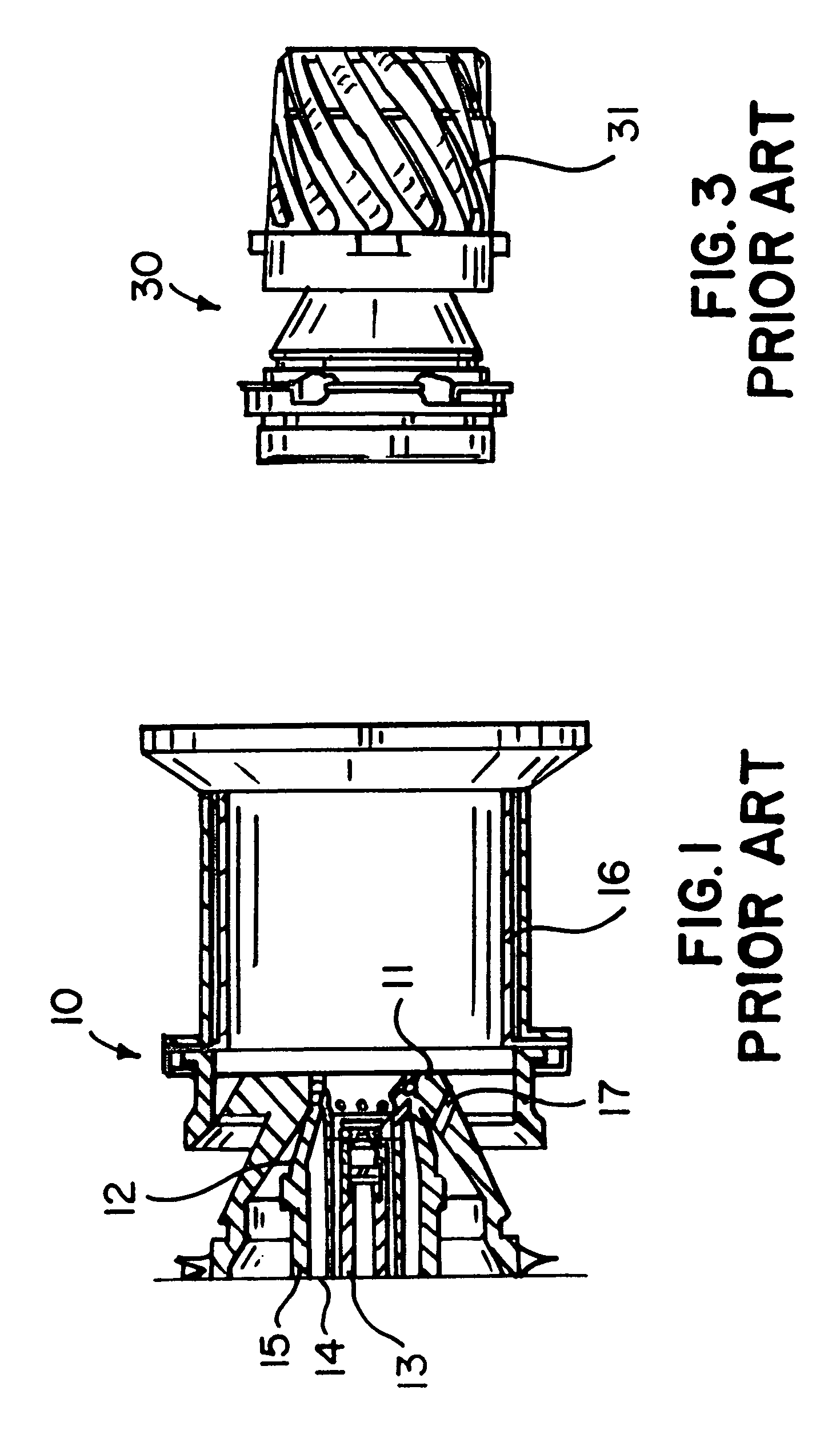

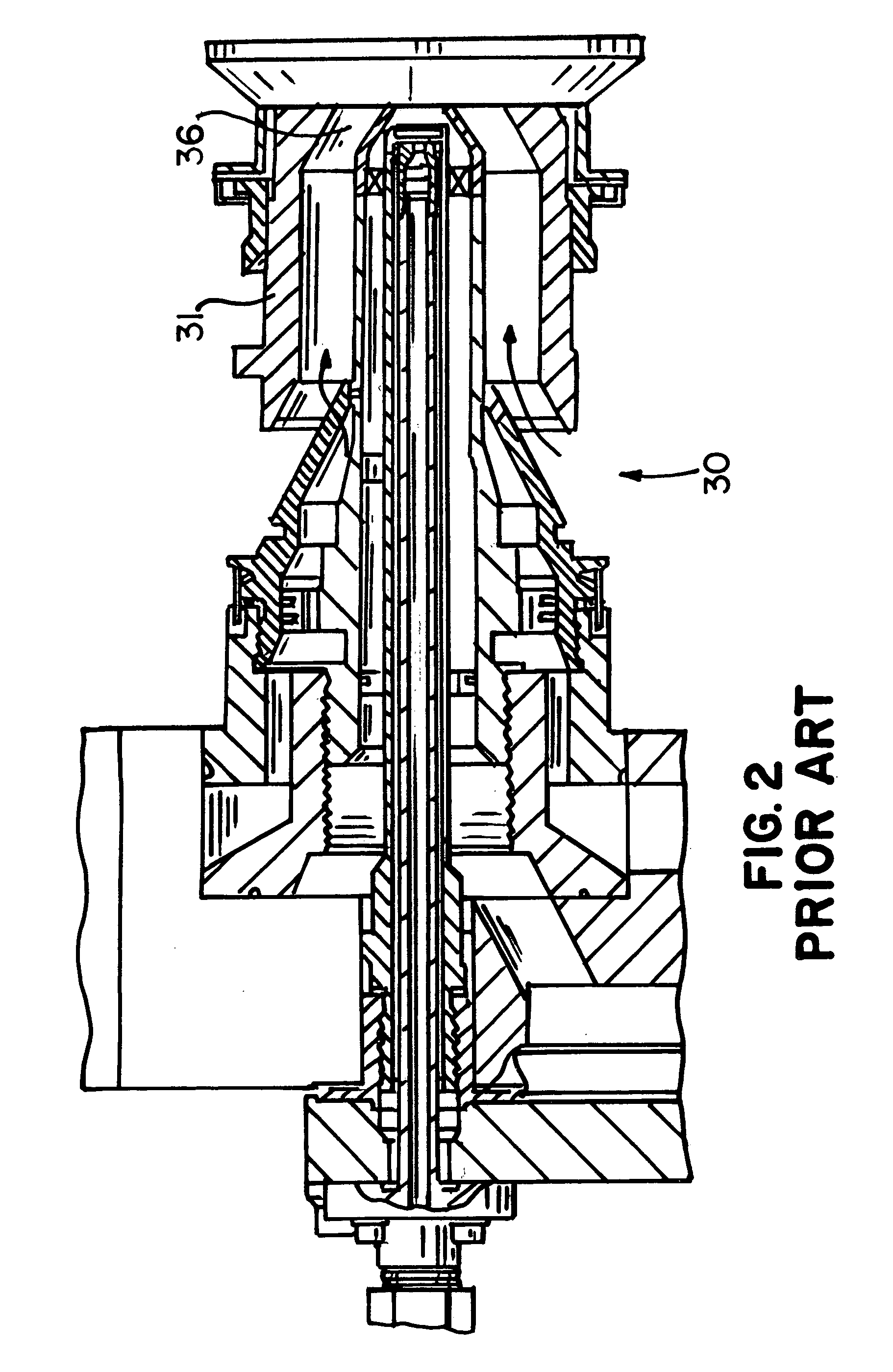

Primary fuel nozzle having dual fuel capability

InactiveUS7000403B2Reduce carbon depositionSimple configurationTurbine/propulsion fuel supply systemsContinuous combustion chamberMultifuelCombustor

A fuel nozzle and gas turbine combustor capable of operating on multiple fuels with reduced carbon build-up to the fuel nozzle and adjacent combustor components is disclosed. The fuel nozzle incorporates a reconfigured gas fuel assembly and mixing tube to eliminate known areas of recirculation. Furthermore, the liquid fuel assembly includes reconfigured spray characteristics to further reduce droplet interaction with the mixing tube.

Owner:ANSALDO ENERGIA SWITZERLAND AG

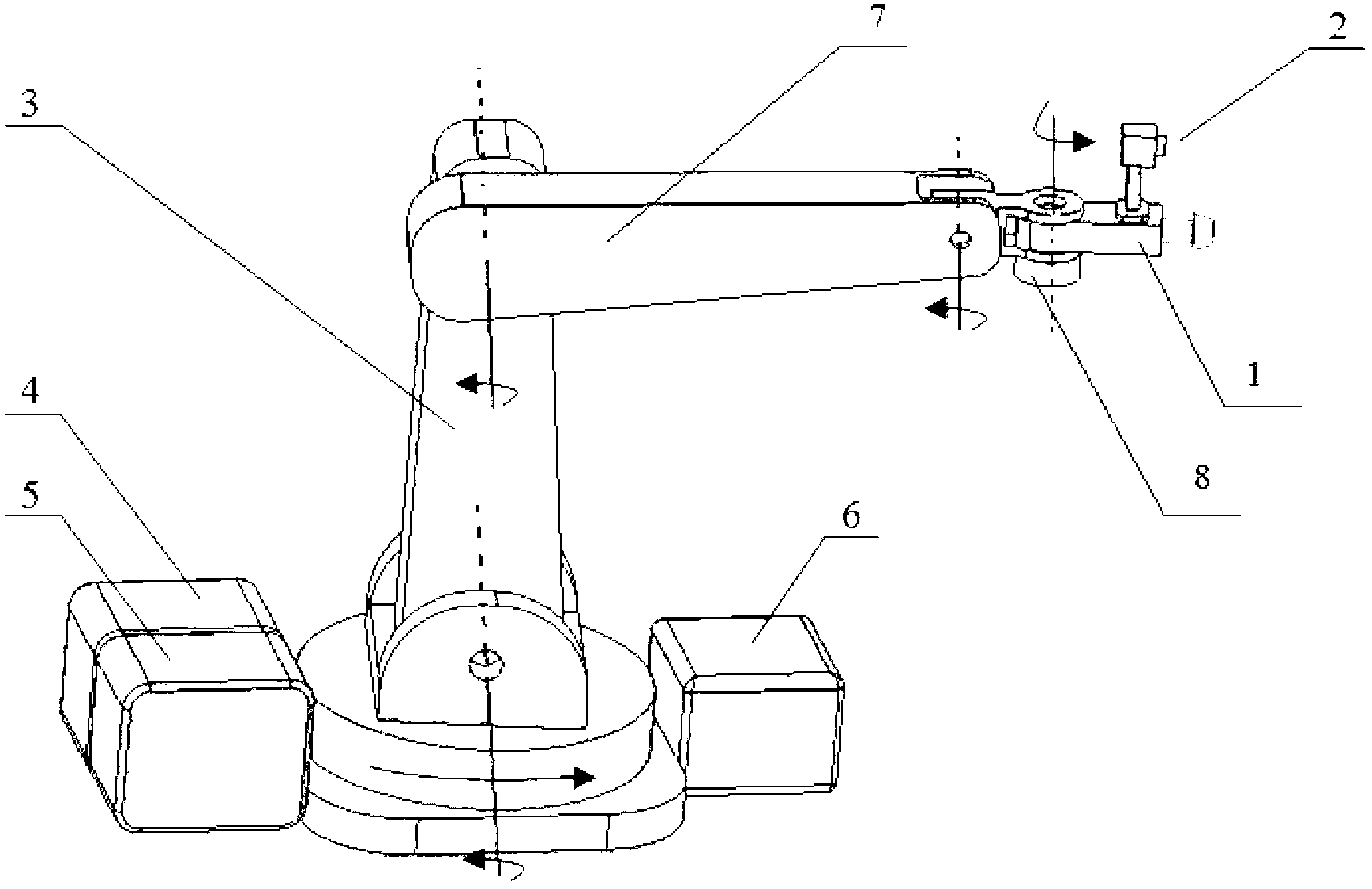

Flexibly operable hand-eye mode spraying robot device

InactiveCN102696570AReduce usageIncrease profitInsect catchers and killersAgricultural engineeringManipulator

The invention belongs to the technical field of automatic agricultural equipment, and particularly relates to a flexibly operable hand-eye mode spraying robot device which comprises a spray nozzle, a camera, a large mechanical arm, a small mechanical arm, a manipulator, a controller, a power source and a variable spray system. The flexibly operable hand-eye mode spraying robot device is arranged on a mobile platform; a hand-eye mode is formed by the camera arranged on the manipulator; contour recognition and detection of a spray operation object are realized by controlling movement of the camera; a spray strategy is formulated by the controller by combining the spray characteristic according to detected plant contour information; the spray nozzle is driven by a rotary pedestal, the large mechanical arm, the small mechanical arm and the manipulator; and accurate spray operation is realized under the control of the variable spray system. According to the flexibly operable hand-eye mode spraying robot device, the manual labor strength can be reduced, accurate spray operation is realized according to plant information, the using amount of a pesticide is reduced, the drift is reduced, the utilization rate of liquor is increased, the environment is protected, the health of laborers and consumers is protected, and sustainable development of agricultural production is realized.

Owner:CHINA AGRI UNIV

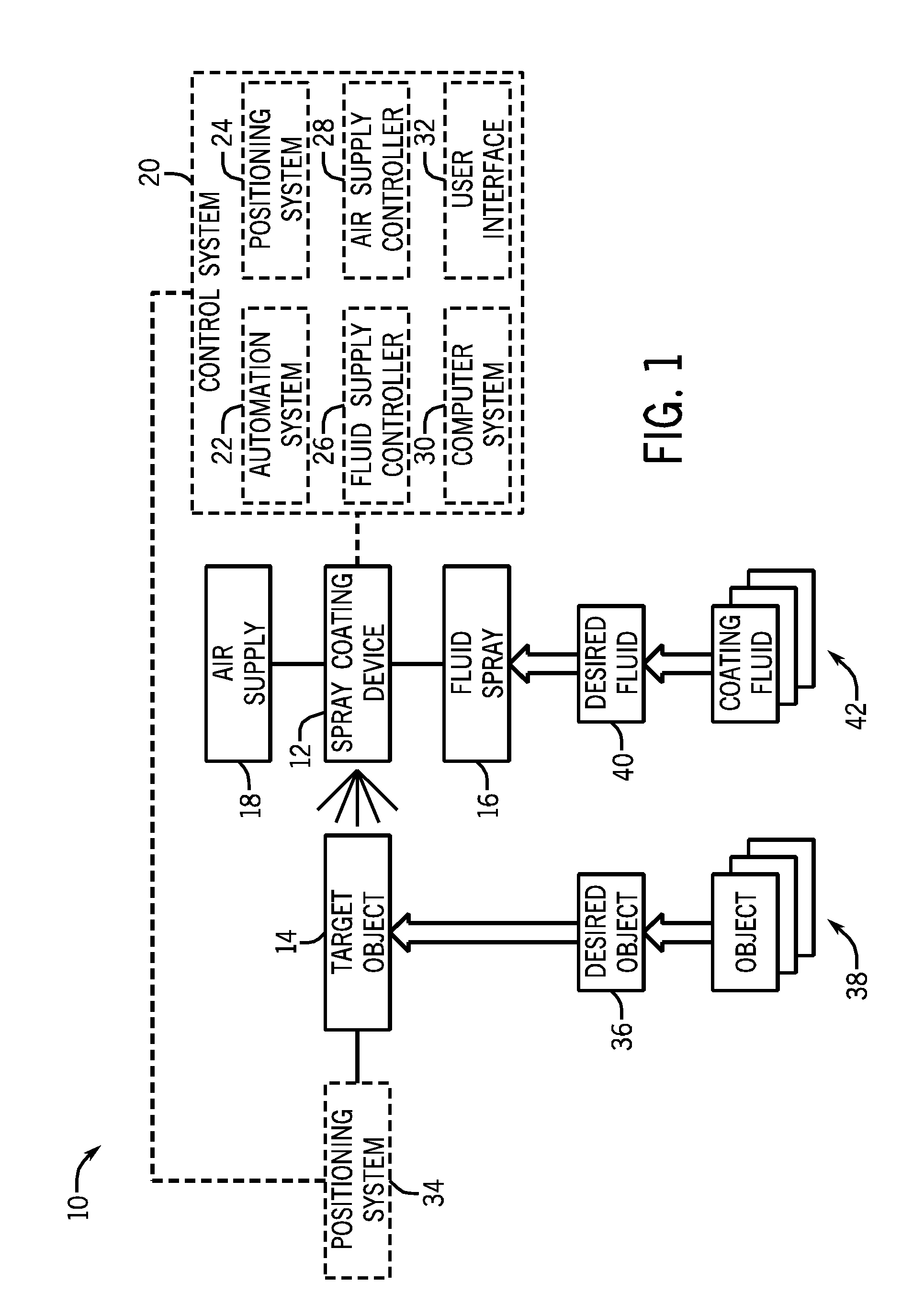

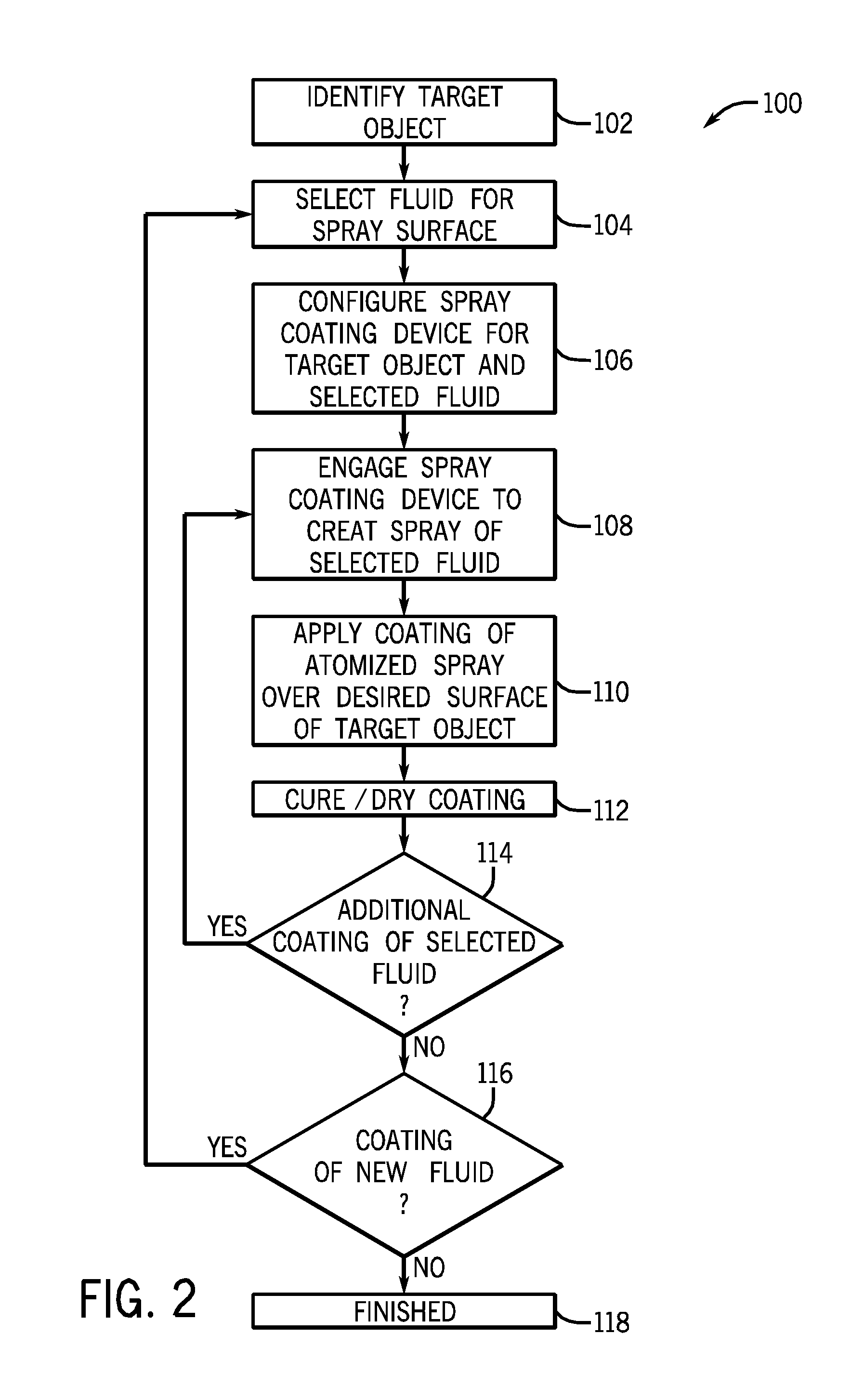

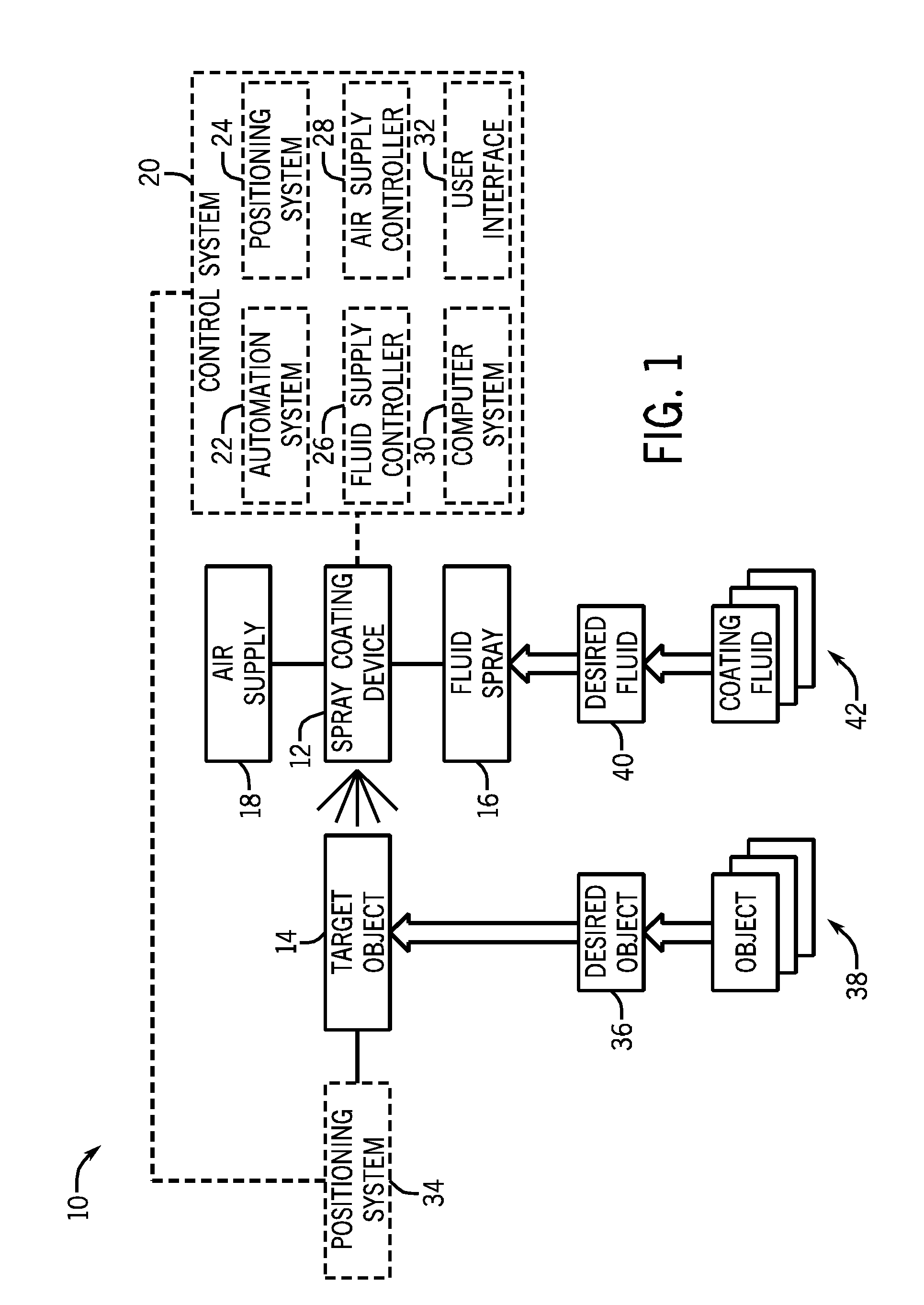

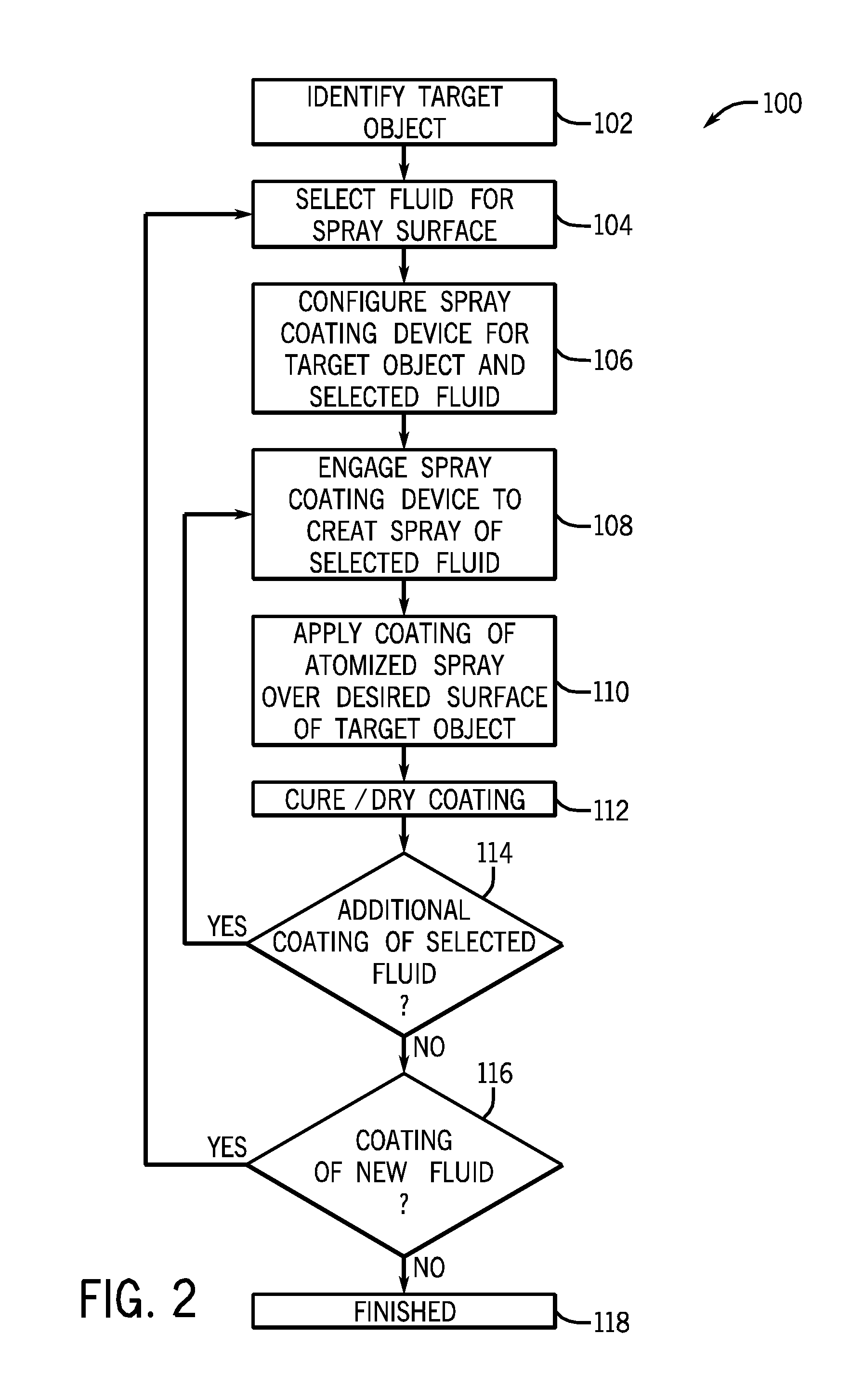

System and method of uniform spray coating

In certain embodiments, a method includes microblasting a spray tip of a spray device to refine spray characteristics of the spray tip. In other embodiments, a method includes outputting a substance from a microblasted output orifice of a spray device to create a spray having characteristics at least partially attributed to a microblast treatment of the microblasted output orifice; and applying the spray onto a surface of a product to create a coating having characteristics at least partially attributed to the microblast treatment.

Owner:ILLINOIS TOOL WORKS INC

Primary fuel nozzle having dual fuel capability

InactiveUS20050198965A1Reduce carbon depositionSimple fuel nozzle configurationContinuous combustion chamberTurbine/propulsion fuel supply systemsMultifuelCombustor

A fuel nozzle and gas turbine combustor capable of operating on multiple fuels with reduced carbon build-up to the fuel nozzle and adjacent combustor components is disclosed. The fuel nozzle incorporates a reconfigured gas fuel assembly and mixing tube to eliminate known areas of recirculation. Furthermore, the liquid fuel assembly includes reconfigured spray characteristics to further reduce droplet interaction with the mixing tube.

Owner:ANSALDO ENERGIA SWITZERLAND AG

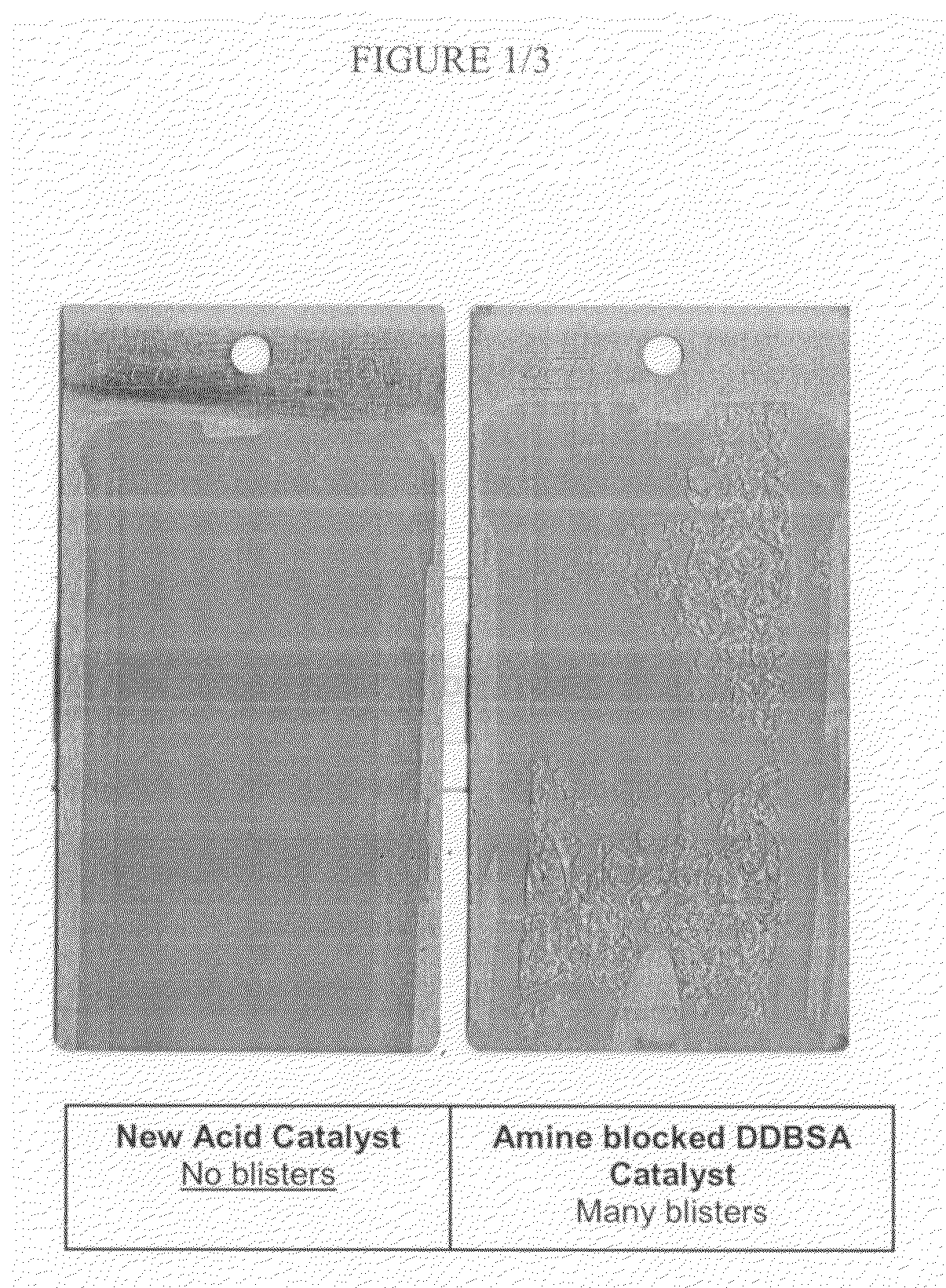

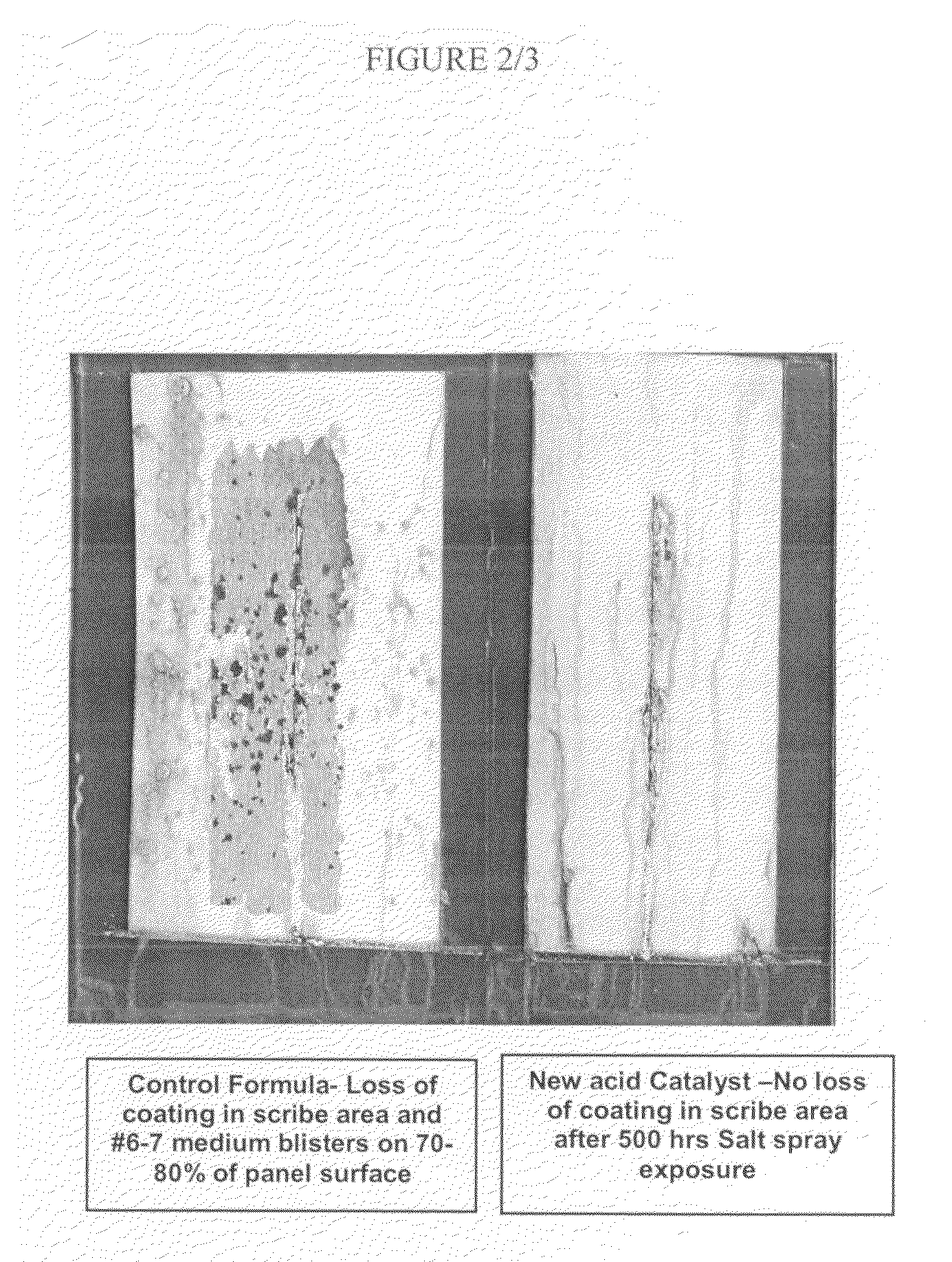

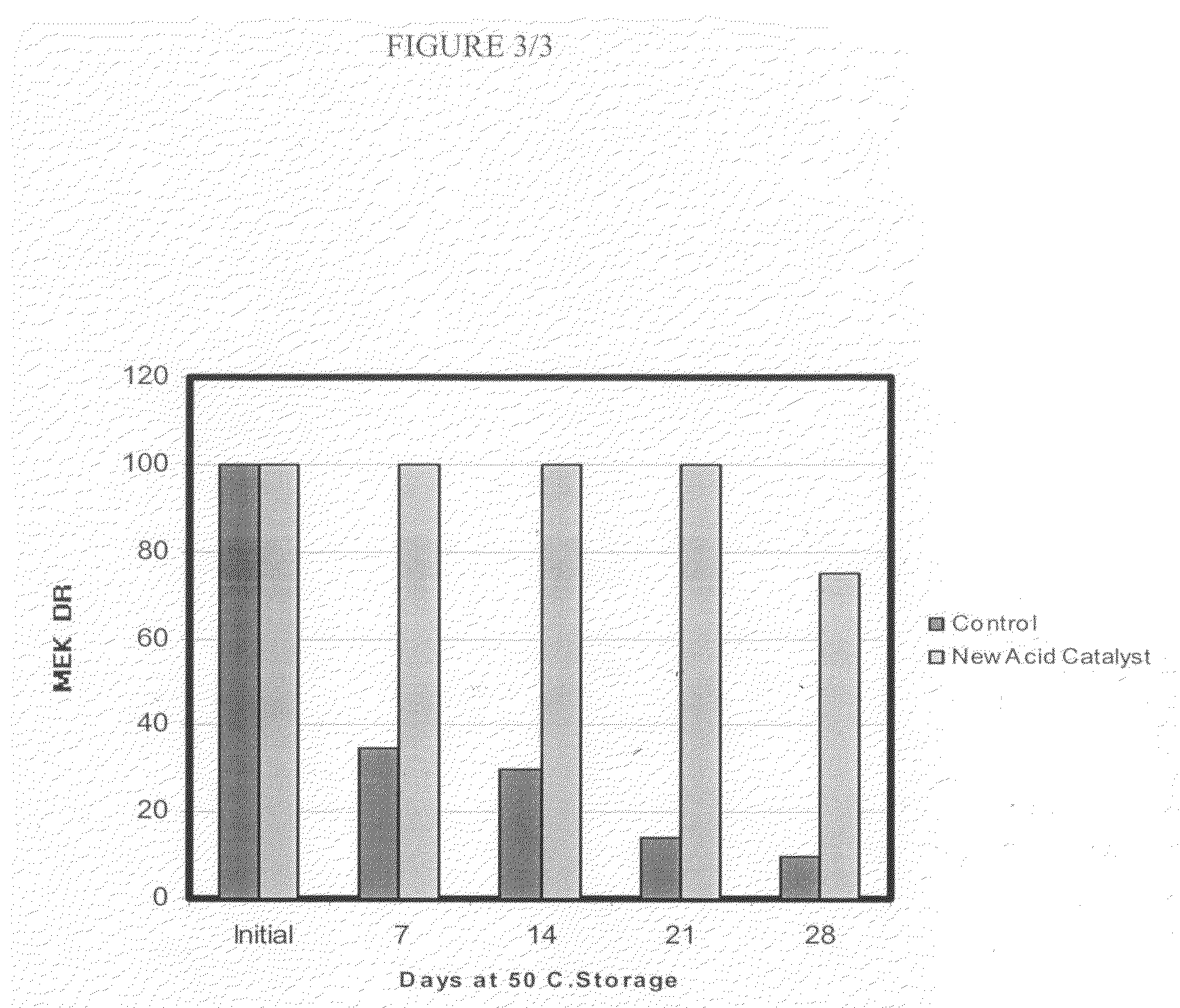

Sulfonate esters as latent acid catalysts

ActiveUS20090104363A1Remarkable activityReduce interactionOrganic compound preparationPretreated surfacesIon exchangeFilm coating

The present invention is directed towards novel sulfonic acid esters as catalysts for crosslinking of polymers having hydroxyl, carboxyl, and amide functional groups with a crosslinking agent and resin compositions containing the same. The present invention provides polymeric film coatings which have superior hardness, impact resistance, adhesion, improved blister resistance, salt spray characteristics and flexibility. These catalysts are especially effective in coil primer formulations containing calcium ion exchange anticorrosive pigments, where traditional blocked acid catalysts are ineffective.

Owner:KING INDUSTRIES INC

Fluidic oscillator and method

An oscillating spray device comprising an oscillation chamber. A power nozzle for projecting a jet of liquid under pressure into the oscillation chamber in a given direction. A reversing member in the chamber has a reversing wall for reversing the direction of flow of the fluid jet in a direction 180° opposite the given direction. A system of vortices is formed thereby for alternately passing fluid to one side or the other of the reversing member. A pair of passages, one on each side of the reversing member, convey alternate pulses of fluid through the passageways in the given direction past the reversing member to an outlet to ambient, and an island barrier positioned in the outlet to ambient and forming two separate passageways to the outlet and a third passageway between the reversing member and the island barrier. The spray characteristics can be adjusted by changing the spacing between the reversing member and island barrier.

Owner:DLHBOWLES INC

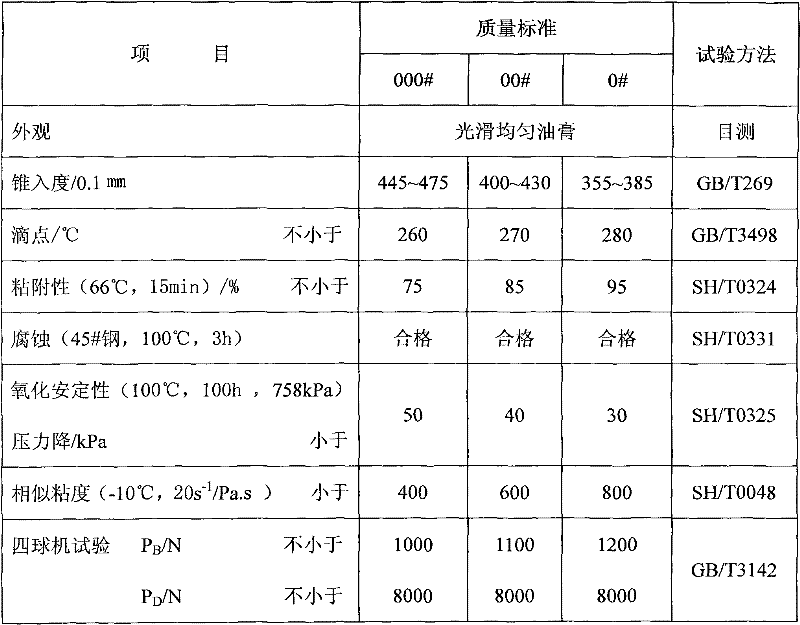

Grease specially used for heavy-load open-type gear and preparation method thereof

ActiveCN102311850AAvoid direct contactStrong extreme pressure and wear resistanceLubricant compositionDiphenylmethaneEngineering

The invention discloses grease specially used for a heavy-load open-type gear and a preparation method. The grease of the invention comprises the following raw materials by weight percentage: 1-2% of MDI (diphenylmethane-4,4'-diisocyanate), 0.2-1% of octadecylamine, 0.5-2% of cyclohexylamine, 35-50% of base oil A, 30-45% of base oil B, 0.5-1.0% of anti-oxidant A, 1.5-3.0% of anti-oxidant B, 0.5% of antirust agent, 0.5-1.5% of extreme pressure antiwear additive A, 4-8% of extreme pressure antiwear additive B, 2-5% of oiliness agent A, 0.1-0.3% of oiliness agent B, 10-15% of adhesive compound and 4-8% of solid lubricant. Various raw materials are stirred and mixed under certain sequence according to different temperature while preparing, the grease of the present invention has ultra-strong extreme pressure and antiwear property, and excellent adhesiveness, anticorrosion and antirust performance, good anti-oxidizability and water resistance performance and spray characteristic, and has good adaptability with routine seal elements. The grease has no heavy metal lead or a volatile solvent, and belongs to the energy saving and environment-friendly product.

Owner:安徽中天石化股份有限公司

Coating device for researching vacuum spraying characteristics

InactiveCN102692332AEvenly distributedReduce residual solventsLiquid supply arrangementsStructural/machines measurementInfraredConcentration ratio

The invention relates to a coating device for researching vacuum spraying characteristics. The front end of a vacuum spraying chamber composed of a quartz glass tube is connected with a vacuum door provided with a compound vacuum gauge and various lead flanges, and the rear end of the vacuum spraying chamber is connected with an air extraction device by virtue of an air release valve CF (conflat) flange; two atomizing nozzles adopt two-fluid-induction-charging pneumatic-type nozzles, and a nozzle flapper provided with a lifting device is arranged in front of each atomizing nozzle; a fluid delivery device and a high-pressure nitrogen delivery device which are composed of four beakers and two HPLC (high performance liquid chromatography) pumps are arranged in two paths to be respectively connected with each atomizing nozzles; an external electromagnet is used for controlling the operations of moving, taking out and putting in a substrate in the spraying chamber; an infrared heating tube and a silicon rubber heater are used for heating; and a testing device is composed of a transmitting light source, a CCD (charge coupled discharge) high-speed camera, a PC (personal computer) machine and a temperature detection device. The coating device disclosed by the invention has a simple structure, is easy to operate, good in intuitiveness and low in cost, and can be used for performing tests and comprehensive research on the various characteristics of vacuum spraying and also for preparing a multi-substrate polymer function gradient film and laminated film in different concentration ratios.

Owner:NORTHEASTERN UNIV

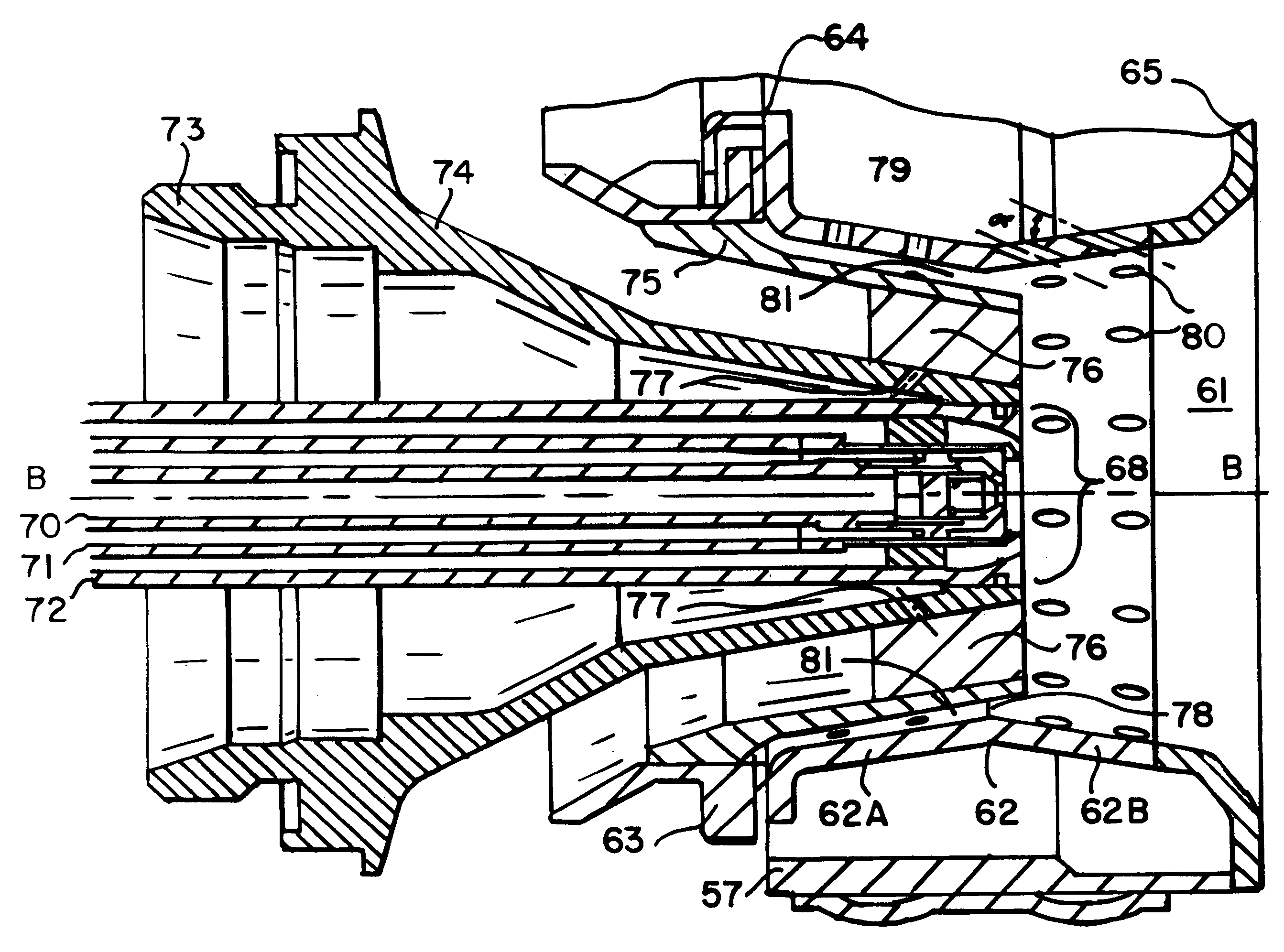

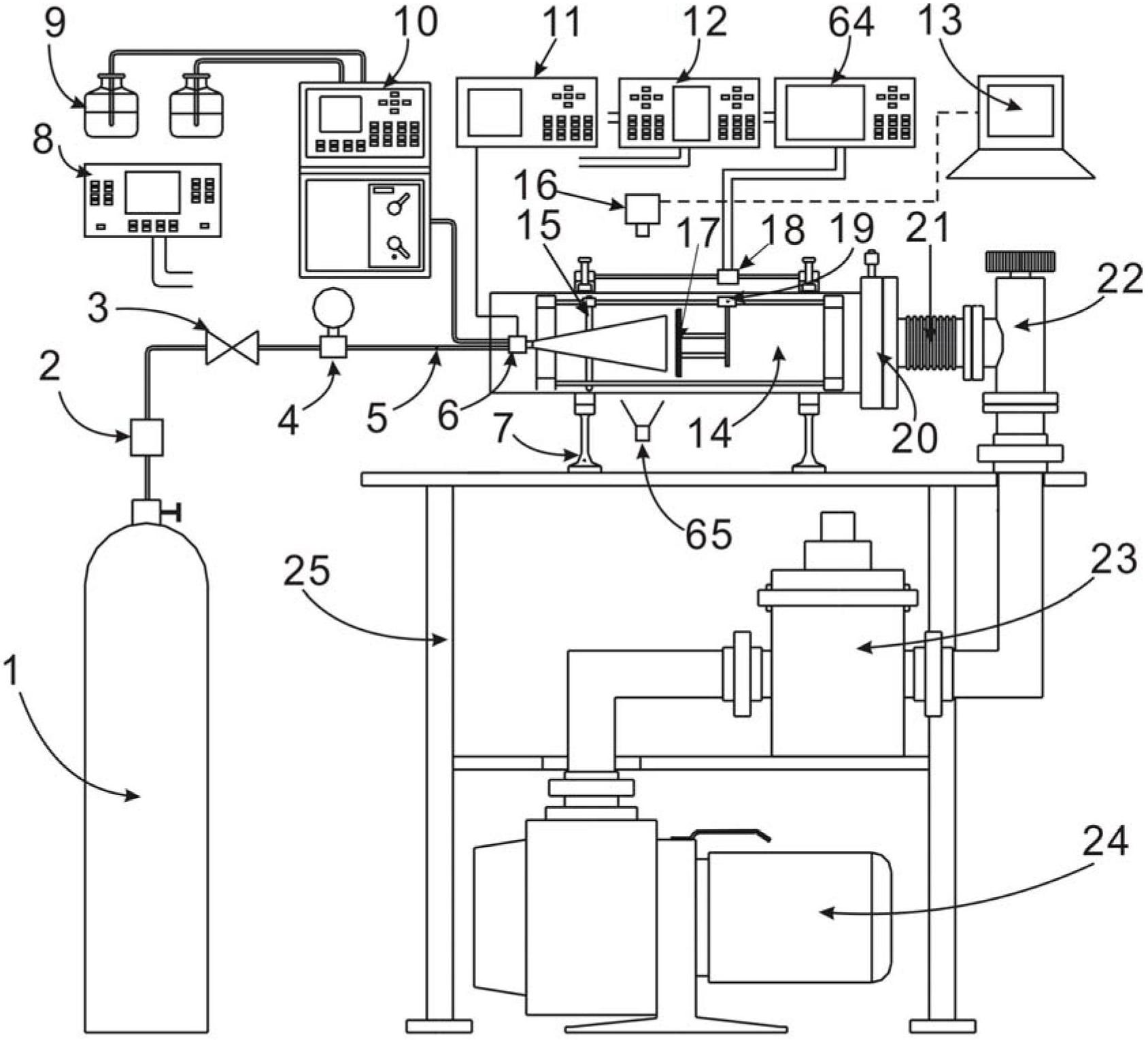

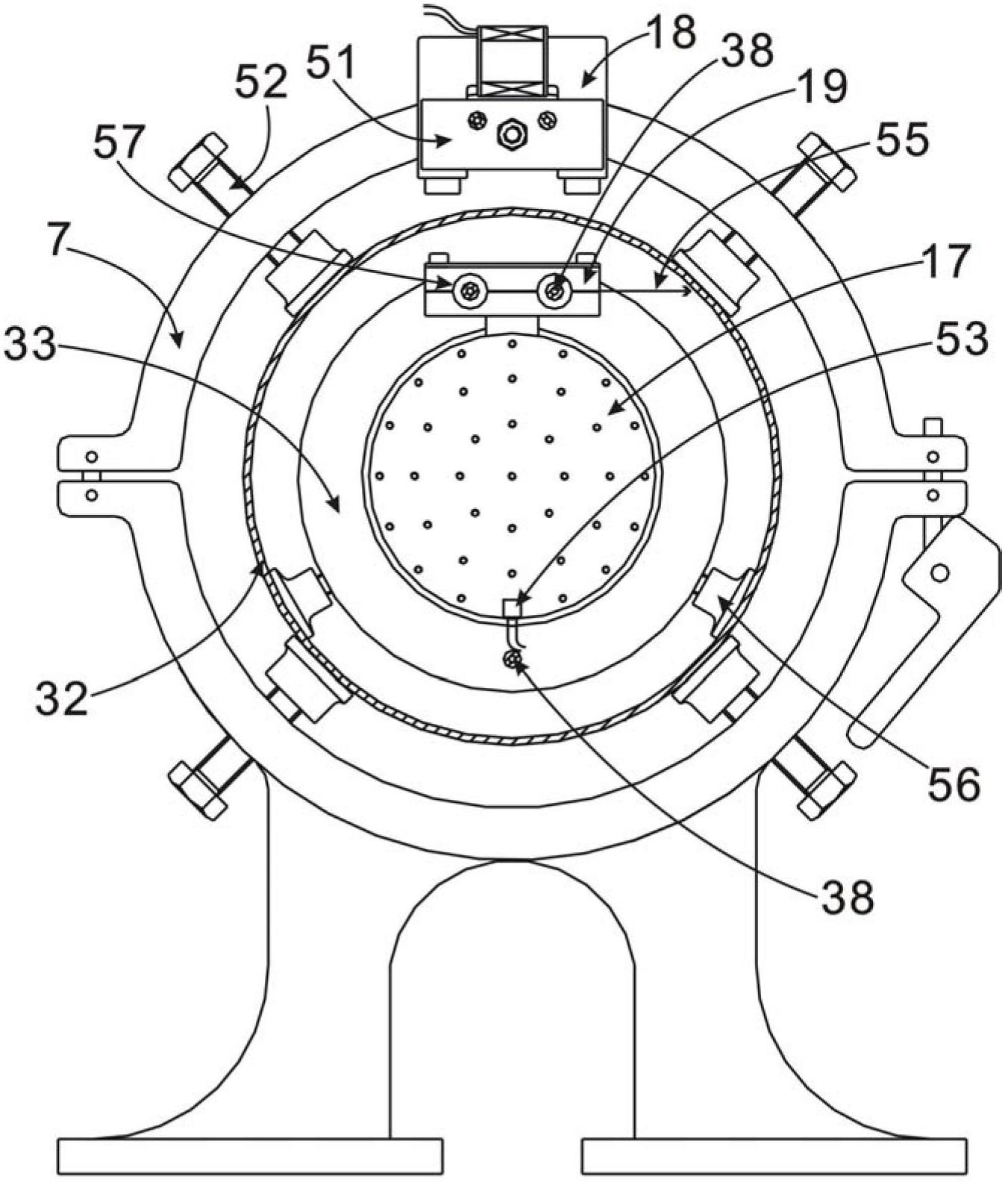

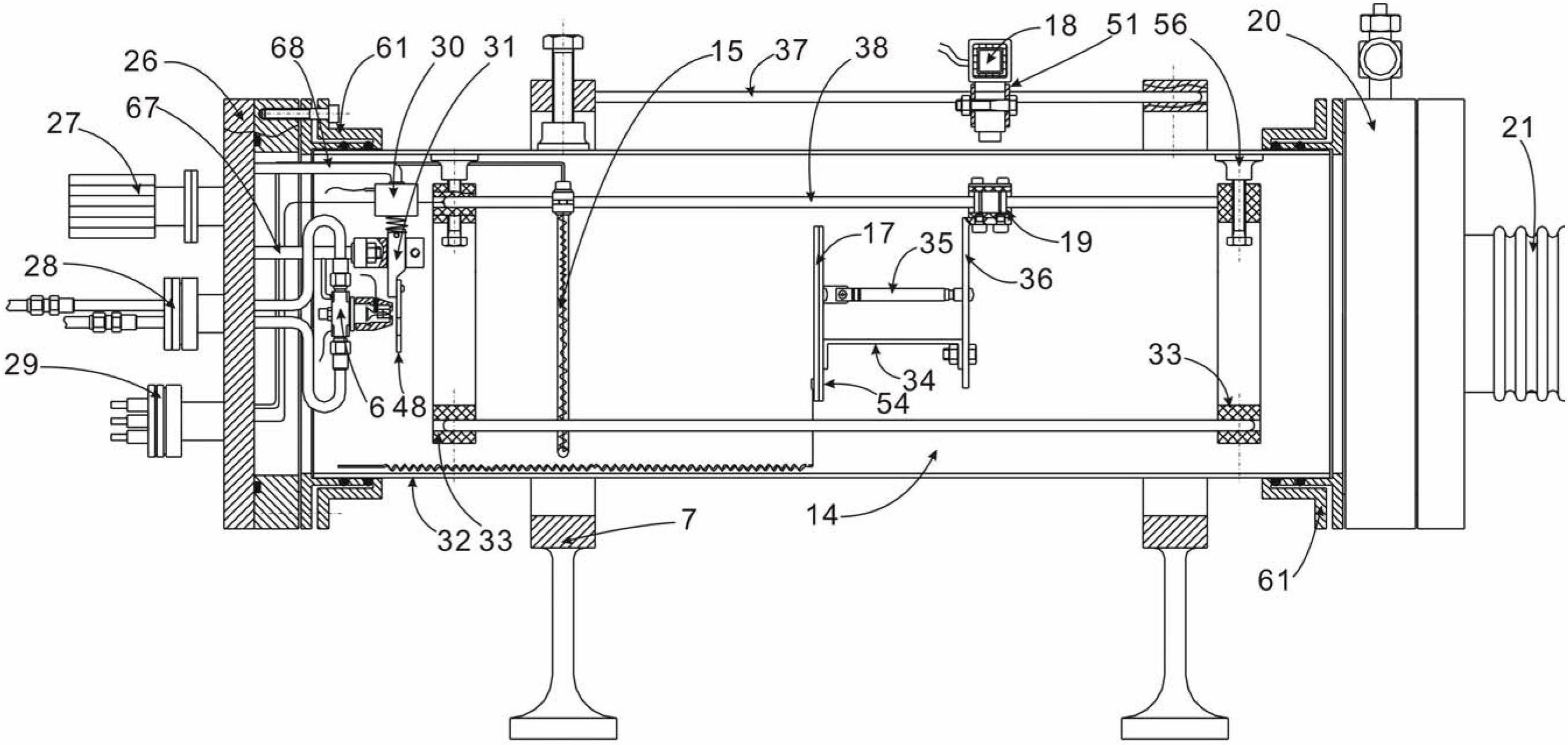

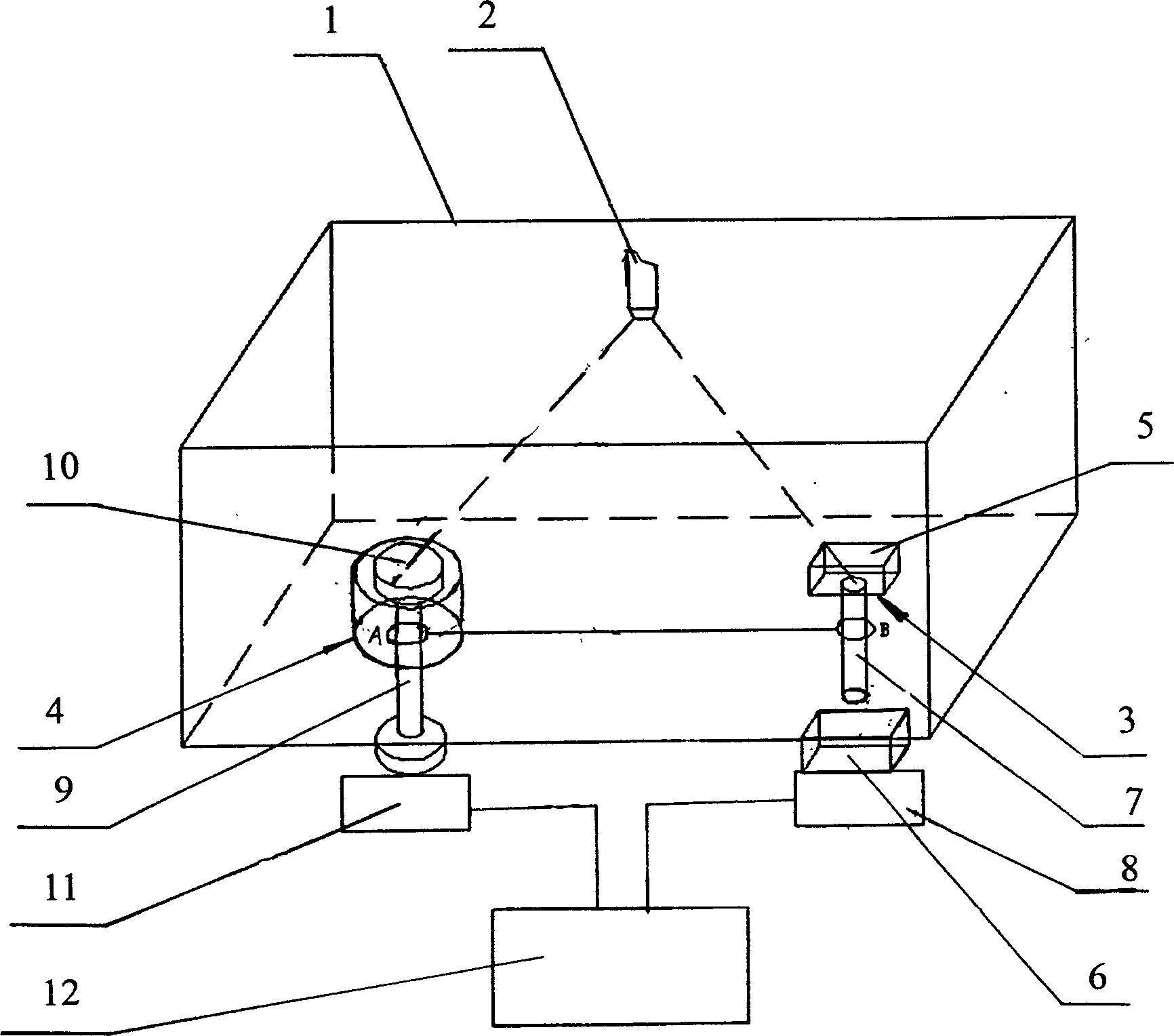

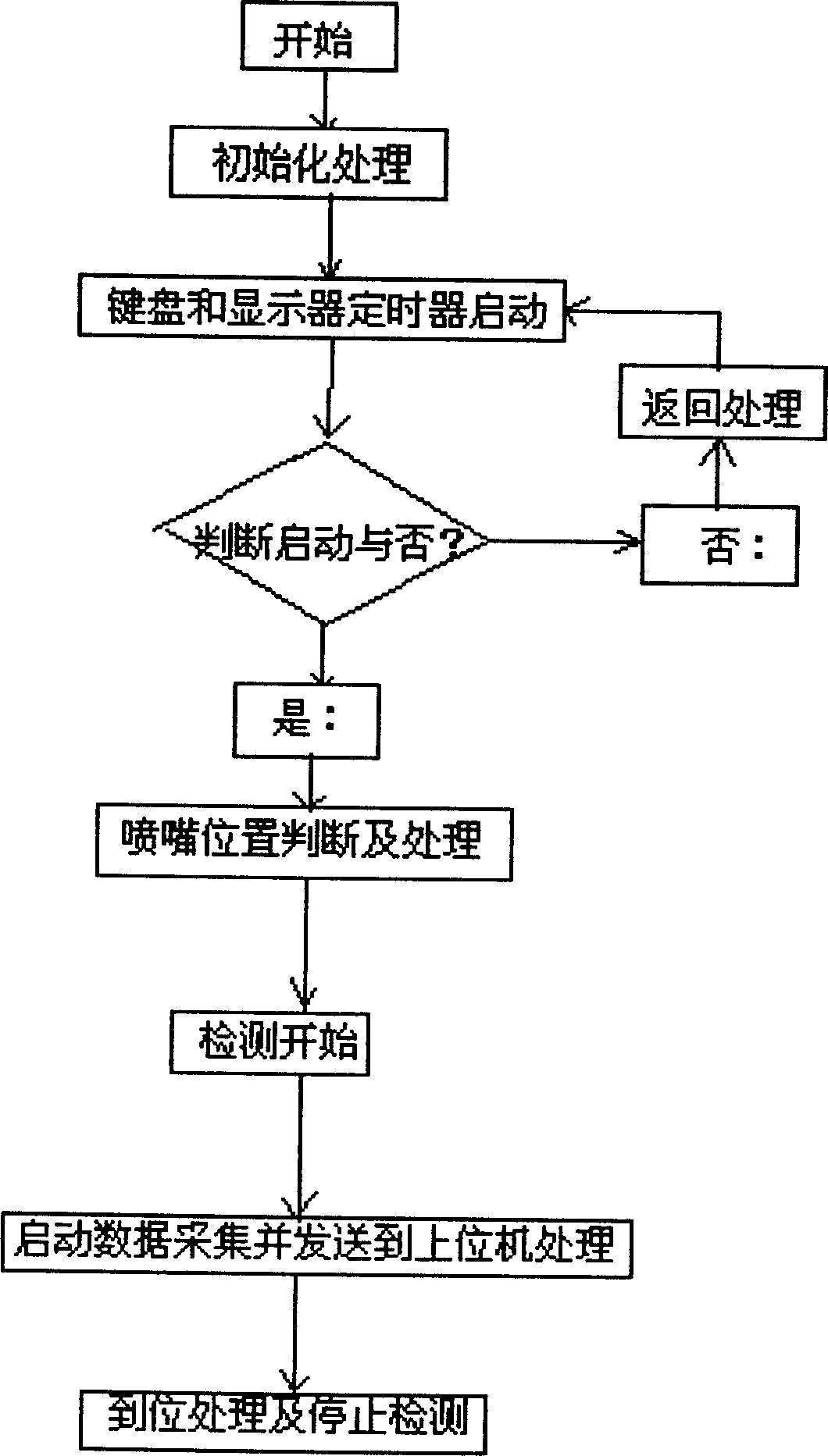

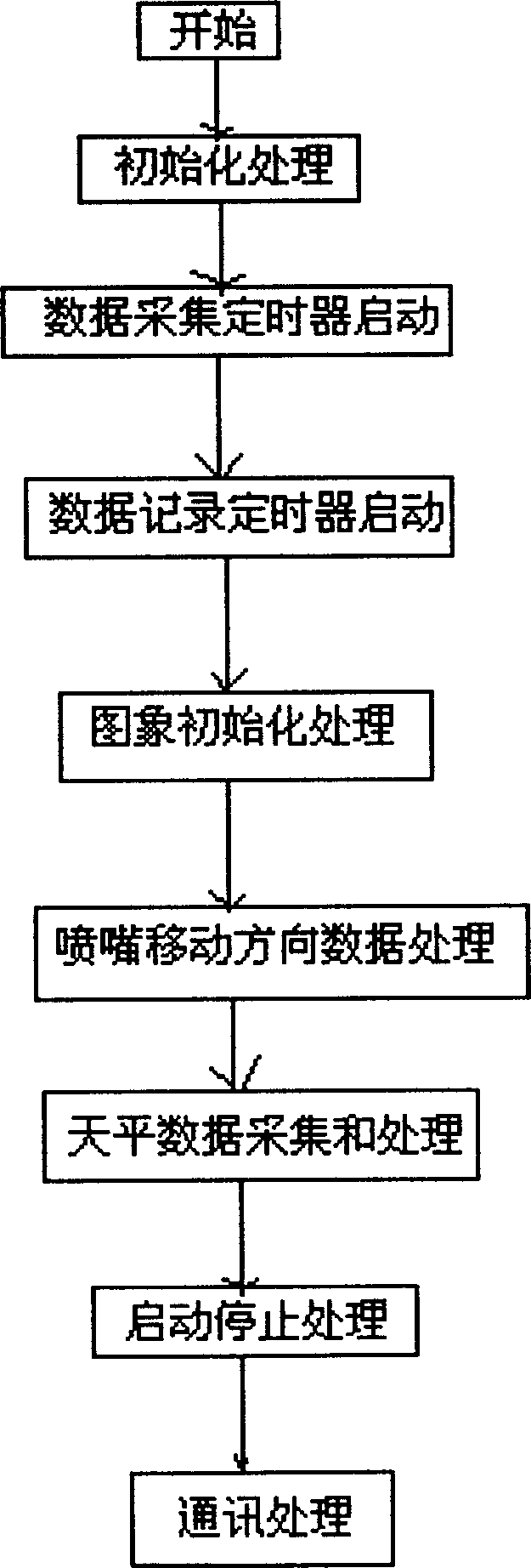

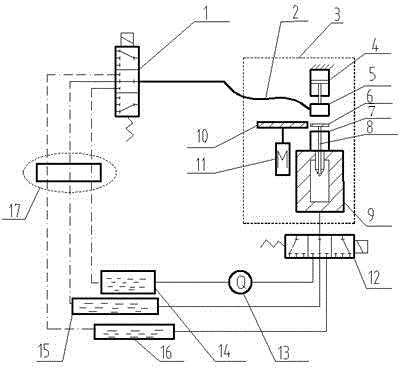

Method and apparatus for testing spraying characteristic of secondary cooling nozzle of continuous casting

InactiveCN1789951AHigh degree of automationSuitable nozzleFluid pressure measurement by electric/magnetic elementsStructural/machines measurementSprayerWater flow

The invention discloses a spray character test method and device of continuous casting two-cold-sprayer, which comprise the following steps: 1. the moving sprayer sprays water through the water-spray quality sensor and water-spray bunch pressure sensor on the downward moving gathering point; 2. the water-spray quality sensor and water-spray bunch pressure sensor transmits the real-time gathered spray quantity and increment and spray bunch pressure value to the computer; 3. the computer calculates the flow density value and bunch pressure value according to the setting parameter and program, which generates the distribution graph of spray flow density and bunch pressure. The entire course can be controlled by computer automatically, which improves the automatic degree greatly to finish the test by one person. The test result can be printed at the report pattern, which displays the distribution graph of spray flow density and bunch pressure.

Owner:CHONGQING UNIV +1

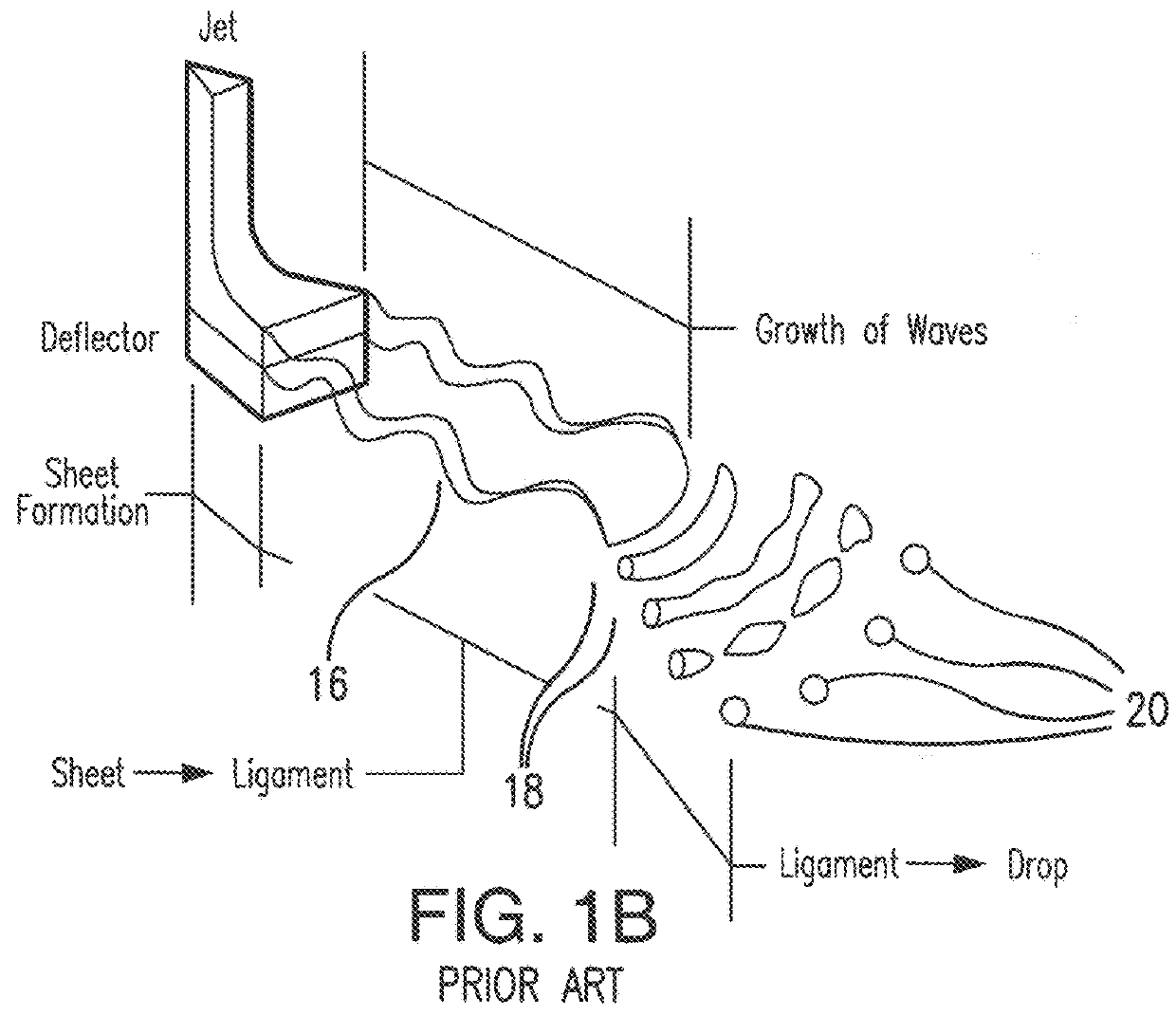

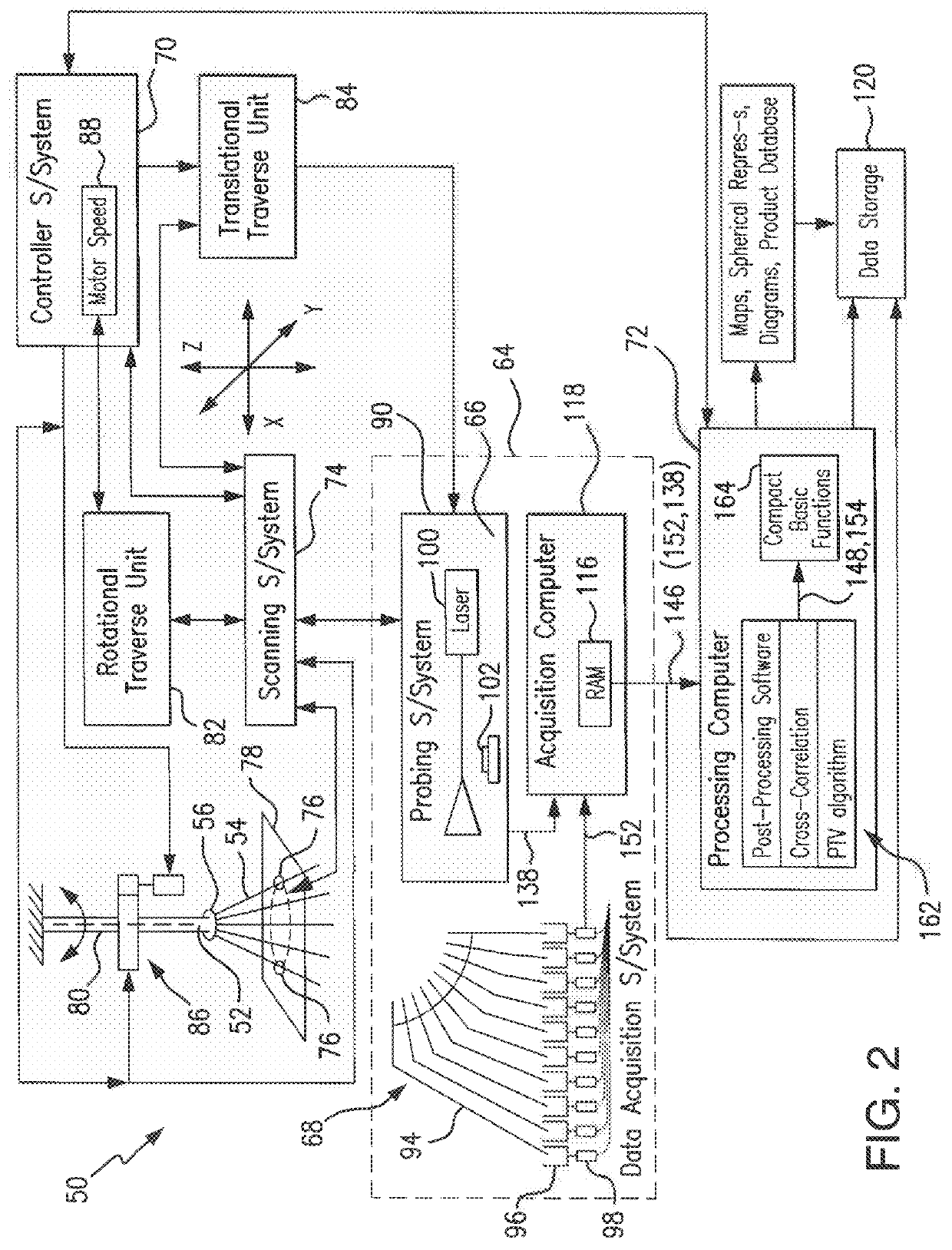

Method and system for spatially-resolved 3-dimensional characterization of near-field sprays

ActiveUS9964495B1Unprecedented accuracyAccurately dispersion performanceImage analysisInvestigating moving fluids/granular solidsData compressionMeasurement study

Near-field spray characteristics are established from local measurements which are acquired by data acquisition sub-system capable of complete scanning of the area (volume) of interest in the spray which uses different laser-based probes (shadowgraphy, PIV, diffraction) to obtain drops related measurements. A mechanical patternator measures volume flux distribution of the spray under study. The measurement data are post-processed to obtain spatially-resolved spray characteristics which are mapped in a spherical coordinate system consistent with the kinematics of the spray. A data compression scheme is used to generate compact analytical functions describing the nozzle spray based on the measurement data. These analytical functions may be useful for initiating the nozzle spray in computational fluid dynamics (CFD) based spray dispersion and fire suppression modeling.

Owner:UNIV OF MARYLAND

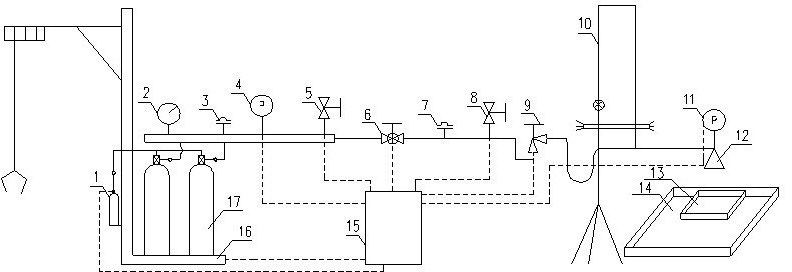

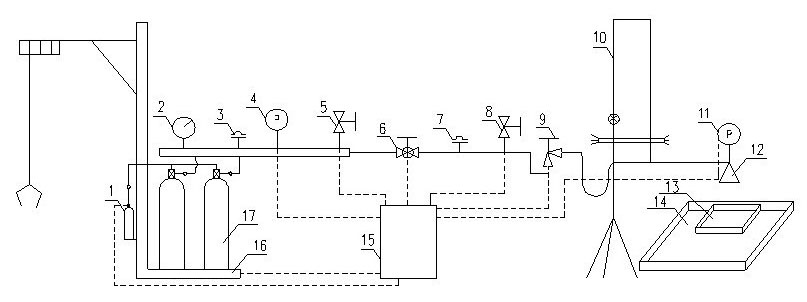

Test device for measuring spray characteristic of local application nozzle of carbon dioxide fire-extinguishing system

InactiveCN102305710ARealize automatic measurementAchieve recordMachine part testingSpecial purpose weighing apparatusVideo monitoringGas cylinder

The invention relates to a test device for measuring the spray characteristic of a local application nozzle of a carbon dioxide fire-extinguishing system. The test device comprises a hoisting weighing device, a driving gas cylinder group, a nozzle test interface, an adjustable oil tray, a video monitoring system, a data acquisition processing system and the like, wherein the hoisting weighing device is formed by combining an electric hoist and an electronic weighing platform scale effectively to measure and record the chemical weight of a carbon dioxide fire-extinguishing agent bottle group automatically; the installation height of the nozzle can be adjusted within the height range from 0.3 to 4 meters by an adjustable rack lifting frame, so the requirement of test height of an overhead type local application nozzle and a trough rim type local application nozzle which are specified by the standard is met; and the area of the oil tray can be adjusted within the range from 0.5 to 1 m<2>by the adjustable oil tray. The test device is convenient to operate, high in automaticity and high in measuring speed, improves work efficiency, reduces test cost and saves test space.

Owner:应急管理部天津消防研究所

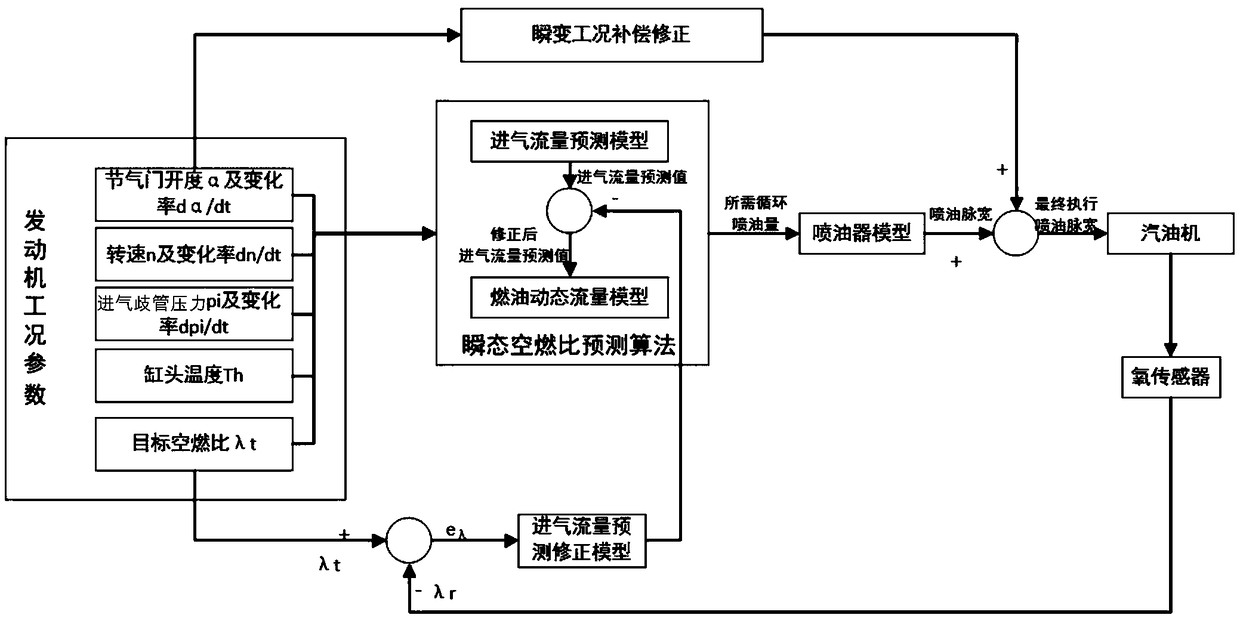

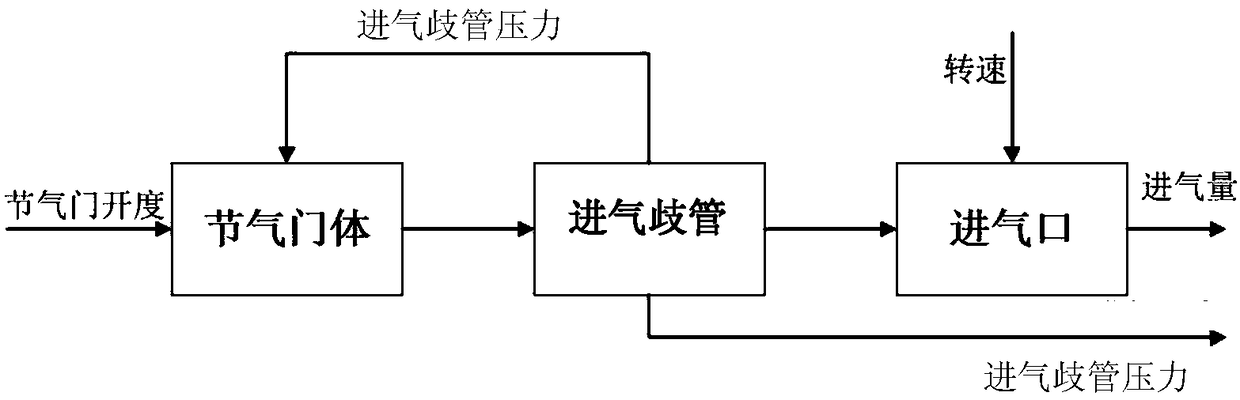

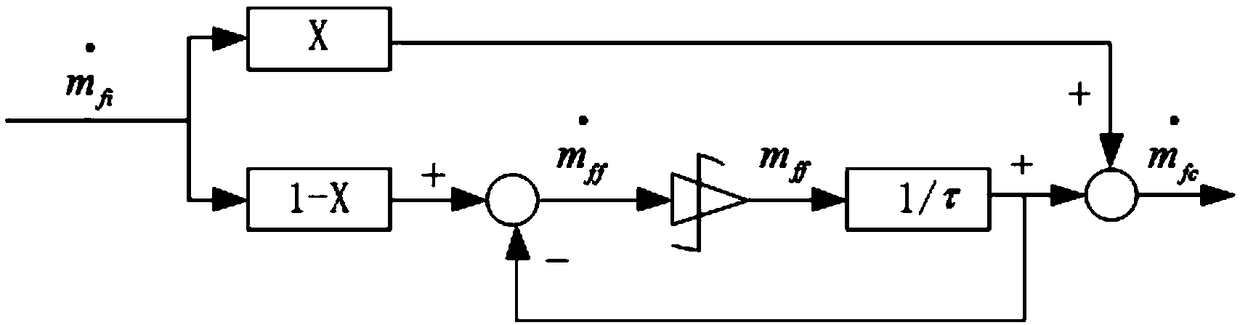

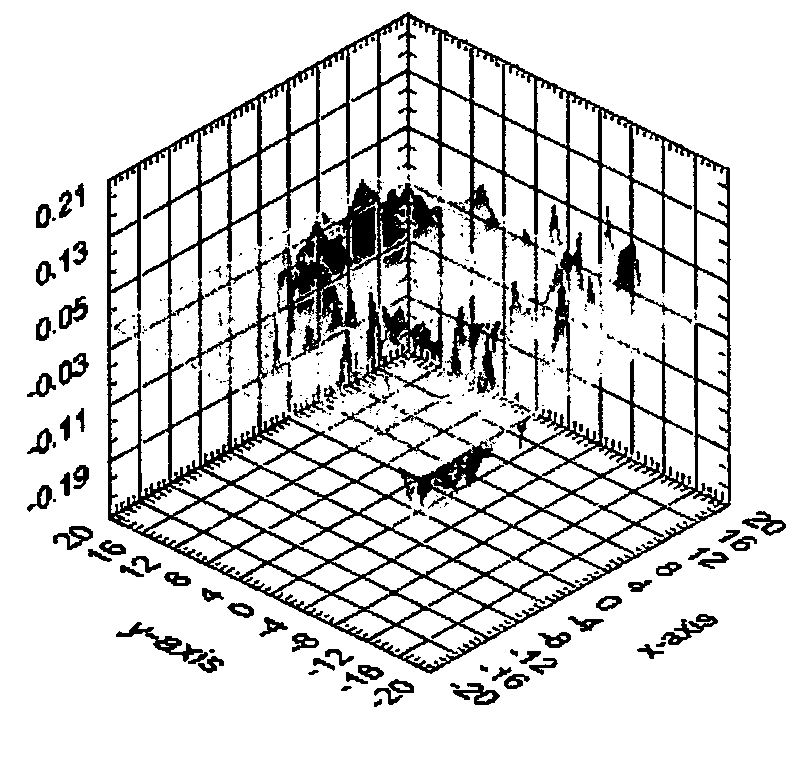

High-speed gasoline engine instantaneous condition air-fuel ratio control method

ActiveCN109184932ASmall steady state errorEmission reductionElectrical controlMachines/enginesFuel oilFeedback control

The invention discloses a high-speed gasoline engine instantaneous condition air-fuel ratio control method. The high-speed gasoline engine instantaneous condition air-fuel ratio control method comprises the following steps of acquiring gasoline engine instantaneous condition parameters, determining the key influence factors influencing instantaneous air-fuel control through multi-parameter sensitivity analysis, and building an intake air flow predication model; building a fuel oil dynamic flow model according to dynamic flow characteristics, spray characteristics and the evaporation rate of anoil atomizer; building an air-fuel ratio predication algorithm through the intake air flow predication model and the fuel oil dynamic flow model; correcting an intake air flow prediction model through an oxygen sensor feedback control algorithm; carrying out model training optimization to obtain instantaneous air-fuel ratio control strategy; calculating oil atomizer oil injection pulse width according to the set target air-fuel ratio, and using the oil injection pulse width as an oil injection instruction to carry out oil injection actions; and repeating the steps. With the high-speed gasoline engine instantaneous condition air-fuel ratio control method, variation trend of intake air flow can be predicated quickly and accurately on the high-speed gasoline engine instantaneous conditions,accurate control over the instantaneous air-fuel ratio is effectively achieved, emission is reduced, and the good dynamic property is guaranteed at the same time.

Owner:天津内燃机研究所(天津摩托车技术中心)

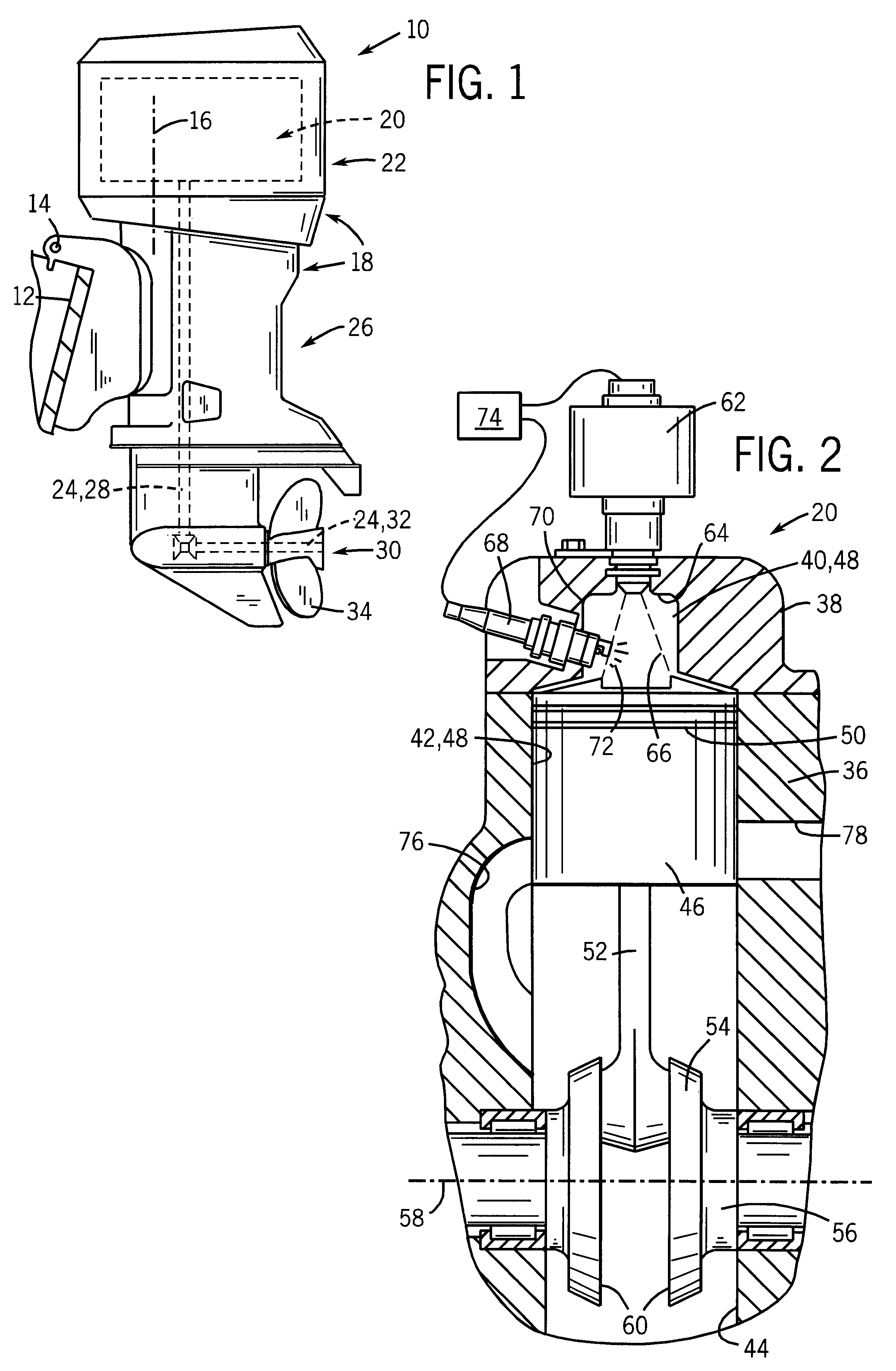

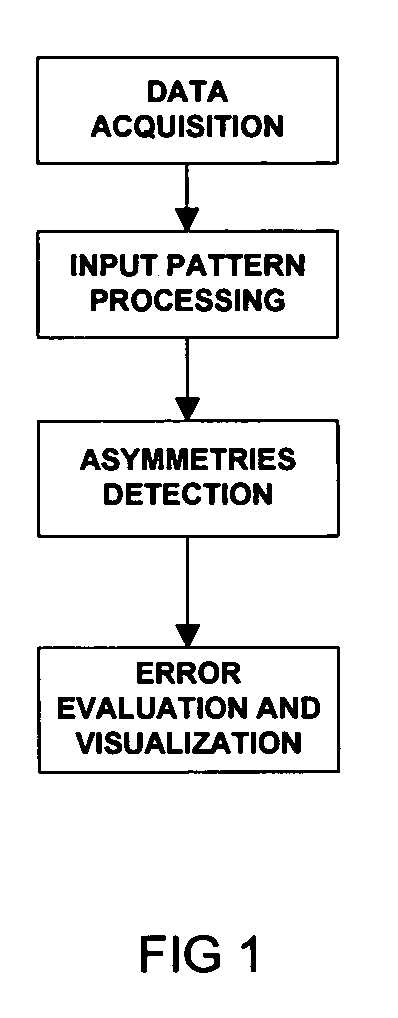

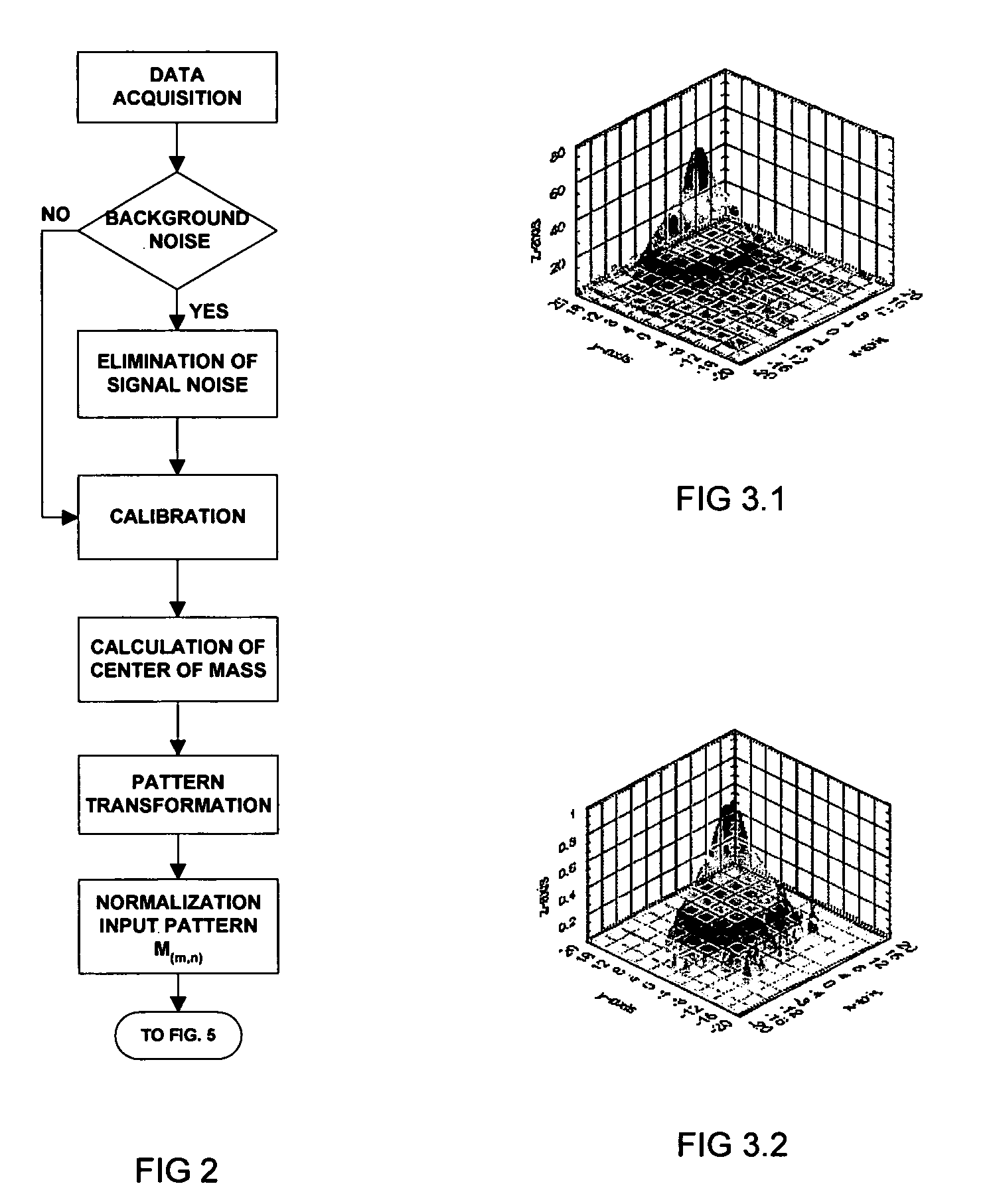

Spray pattern characterization and monitoring method and system

ActiveUS20060081039A1Easy to identifySimplified spray pattern comparisonMaterial analysis using sonic/ultrasonic/infrasonic wavesStatic/dynamic balance measurementEngineeringMonitoring methods

The purpose of the invention is to provide a method to characterize a spray pattern by detecting and quantifying asymmetries resulting in detailed information on location, size, and type of asymmetries within the spray pattern, which are important for spray characterization comparability and classification. A system is provided for in-situ monitoring of the spray characteristics.

Owner:IOOS LLC

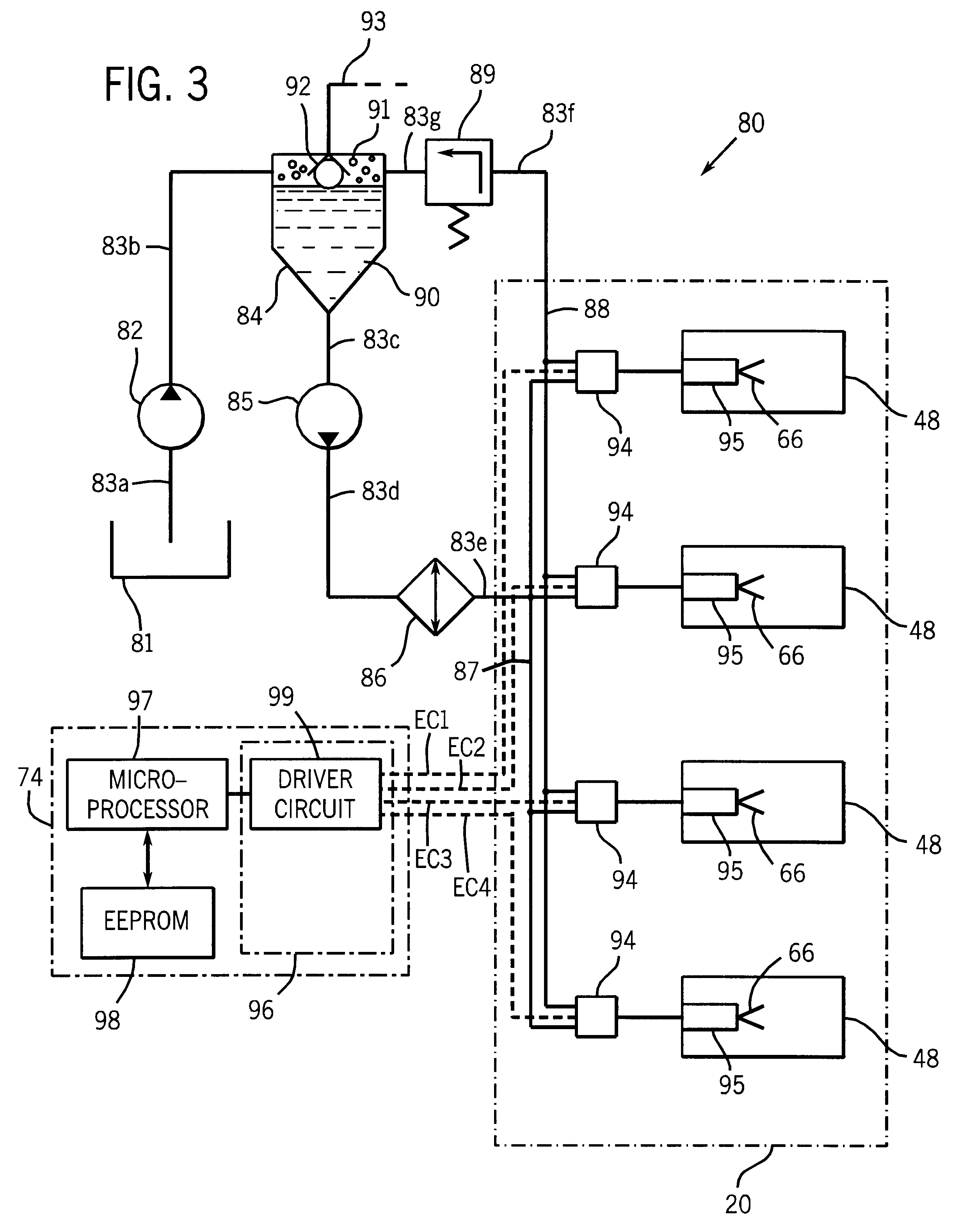

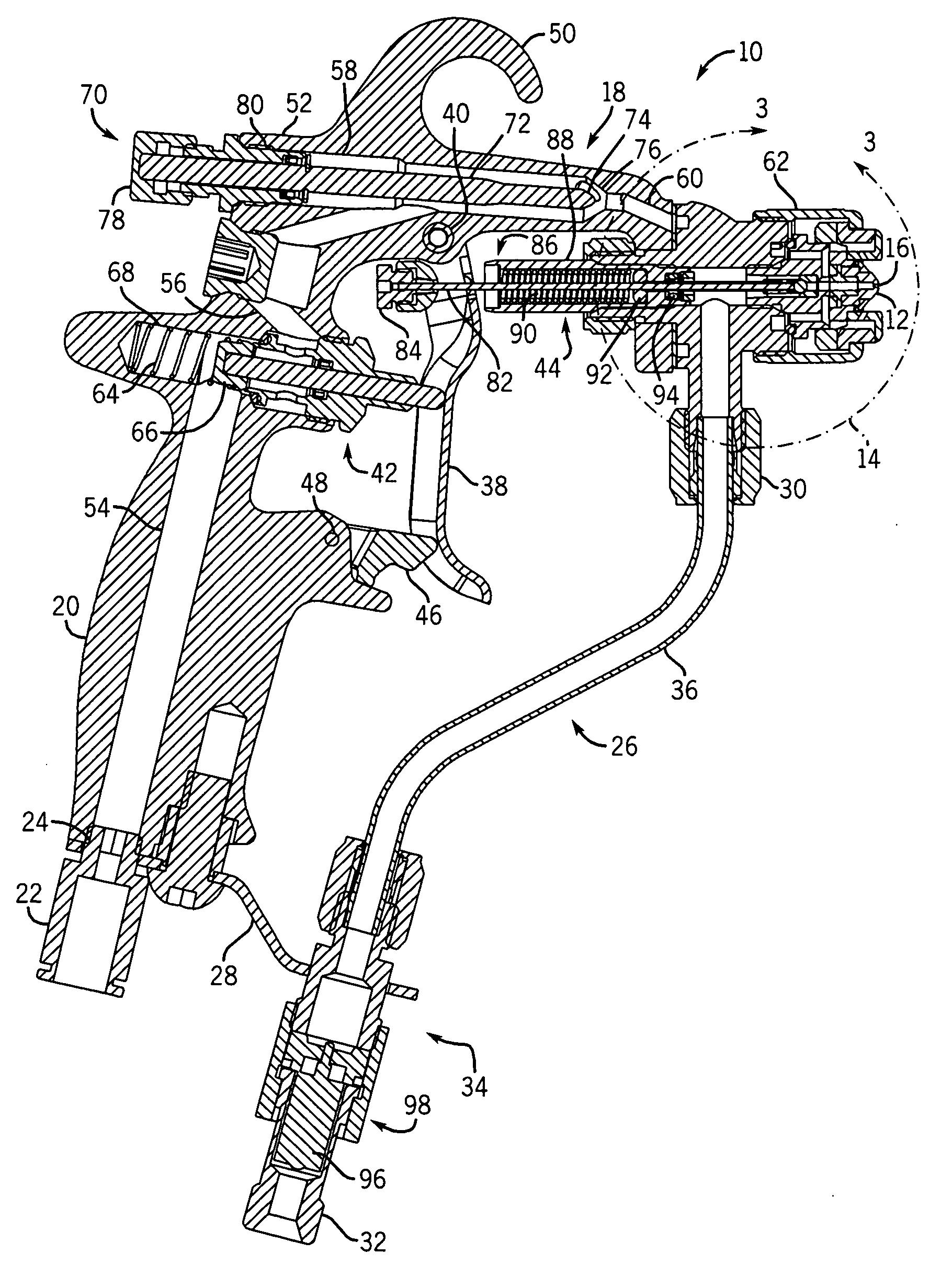

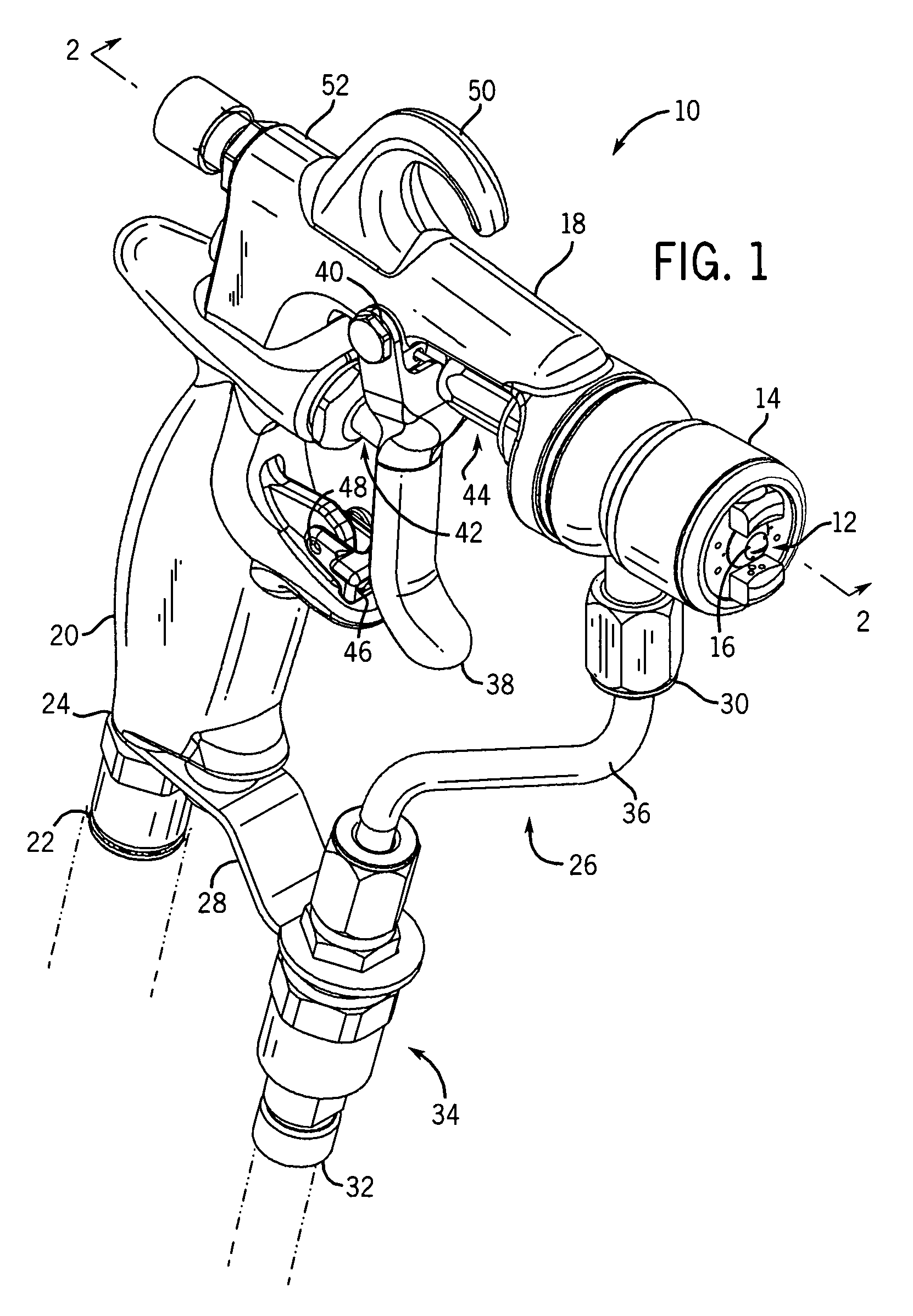

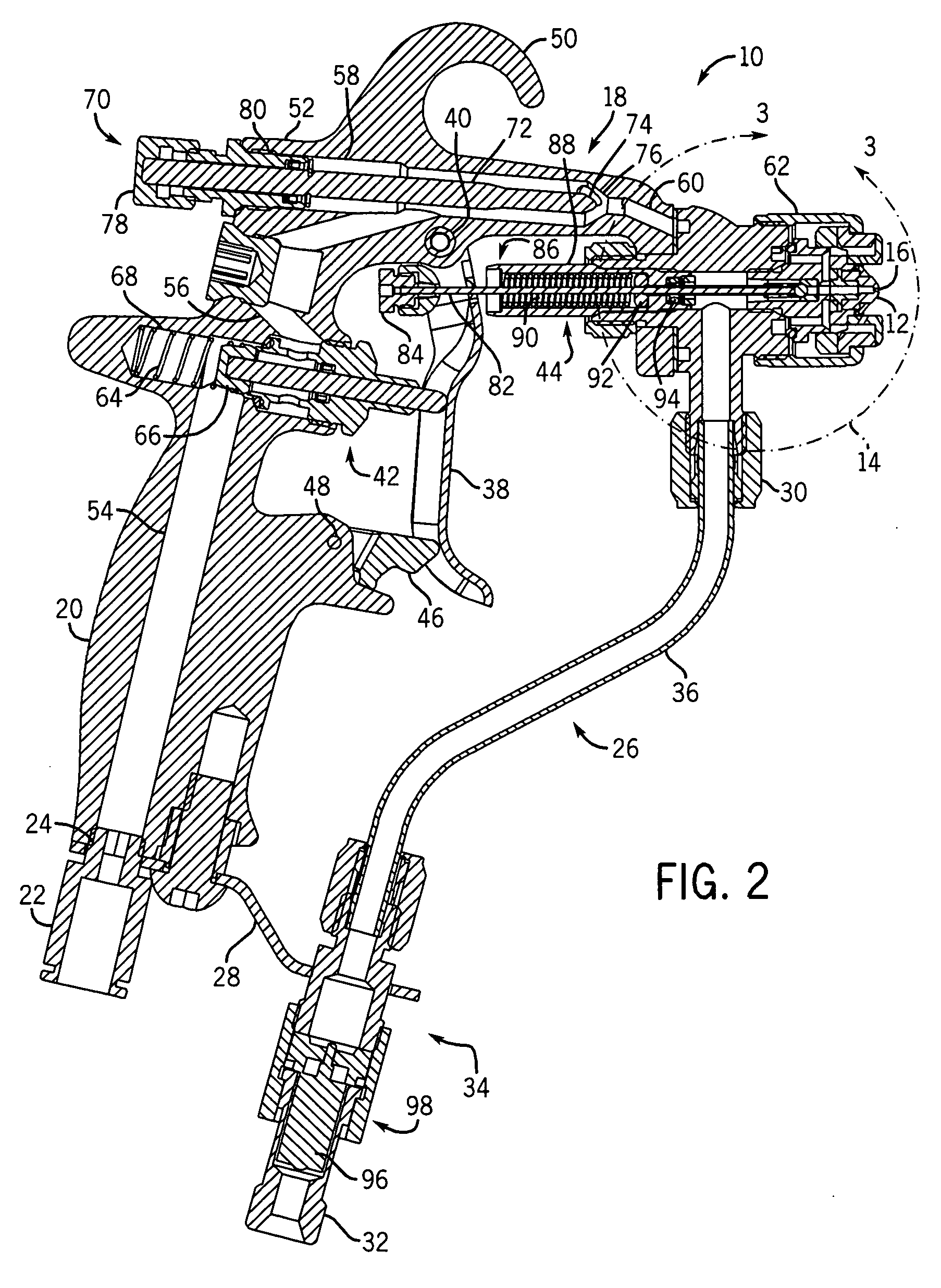

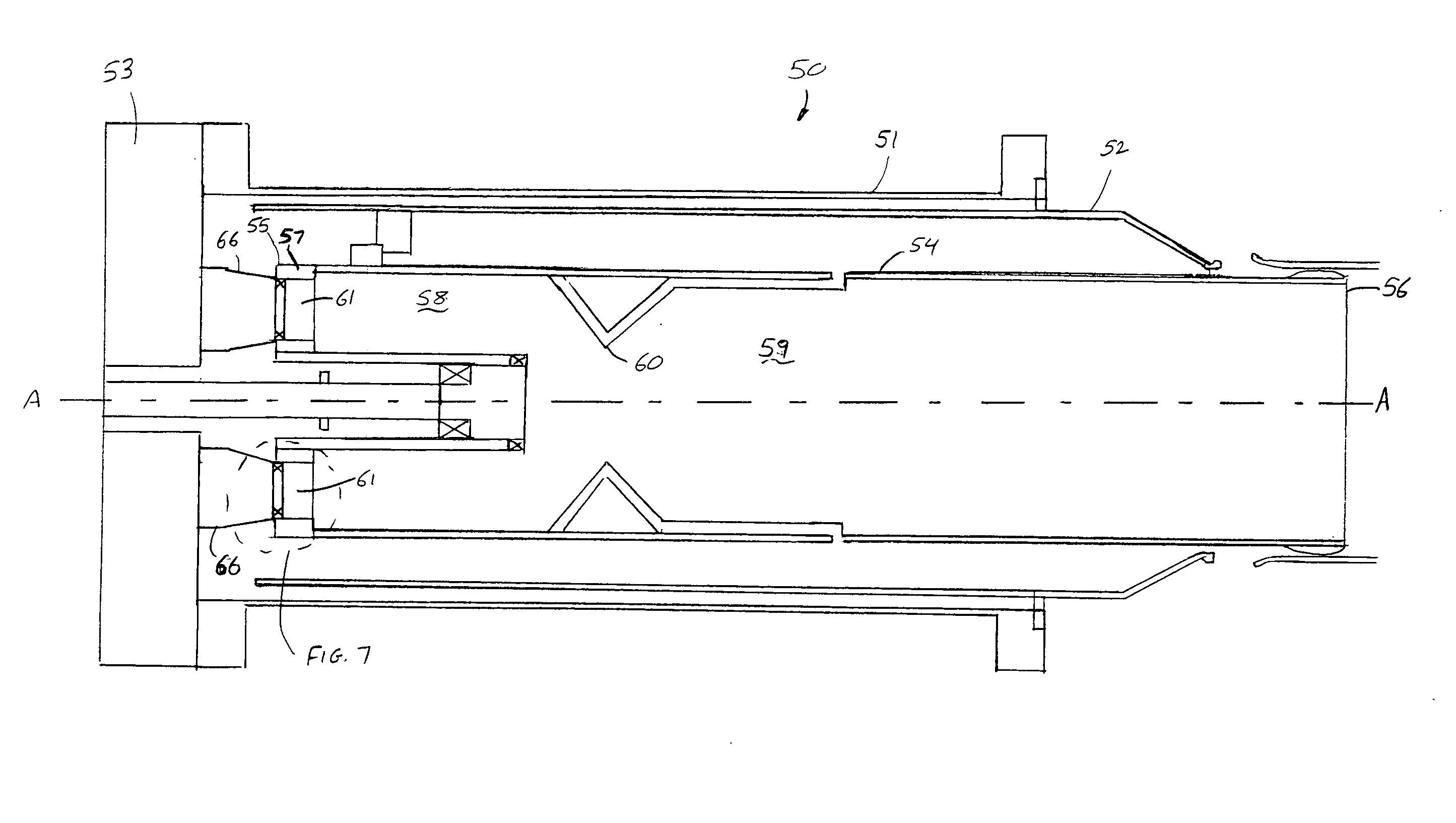

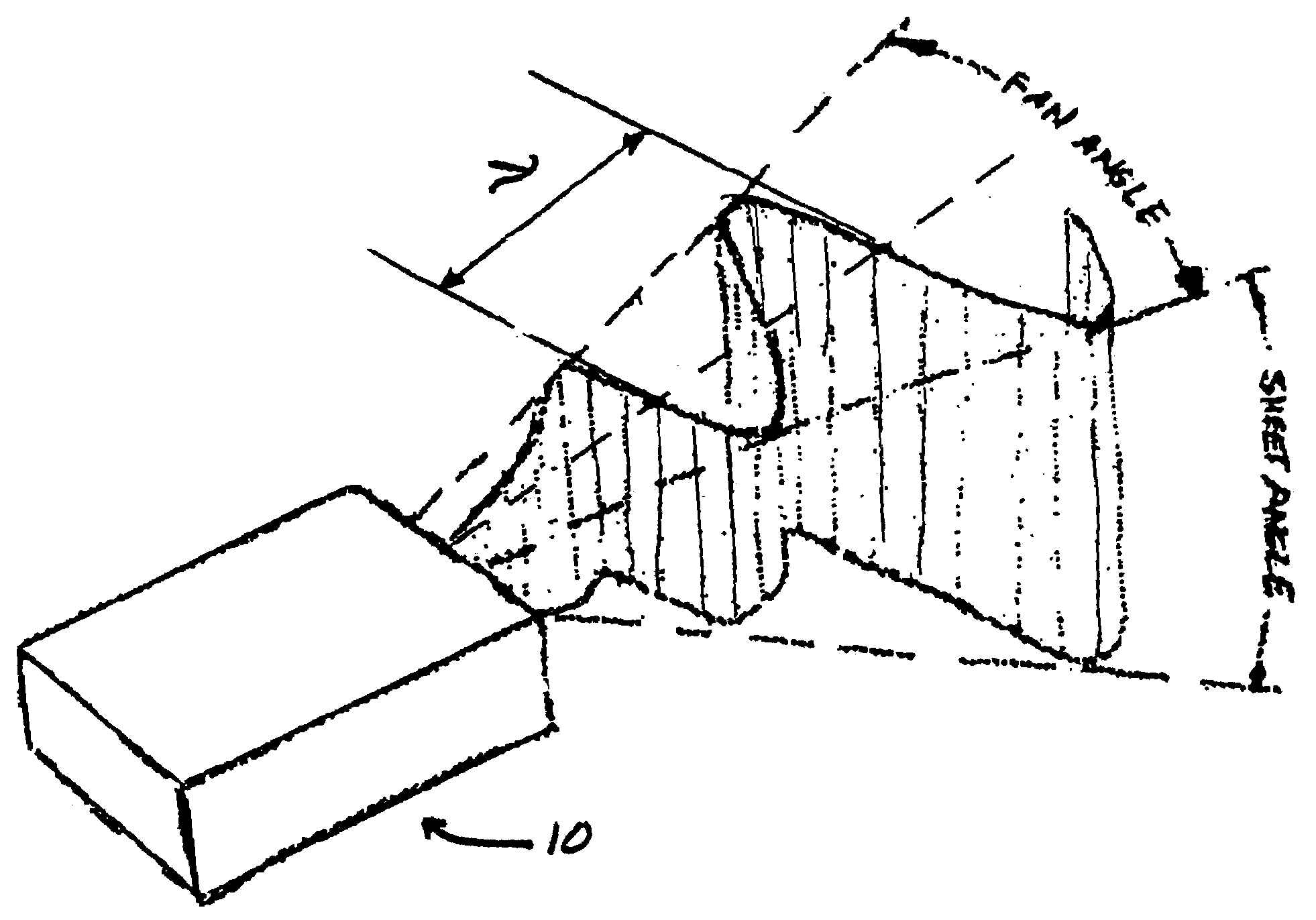

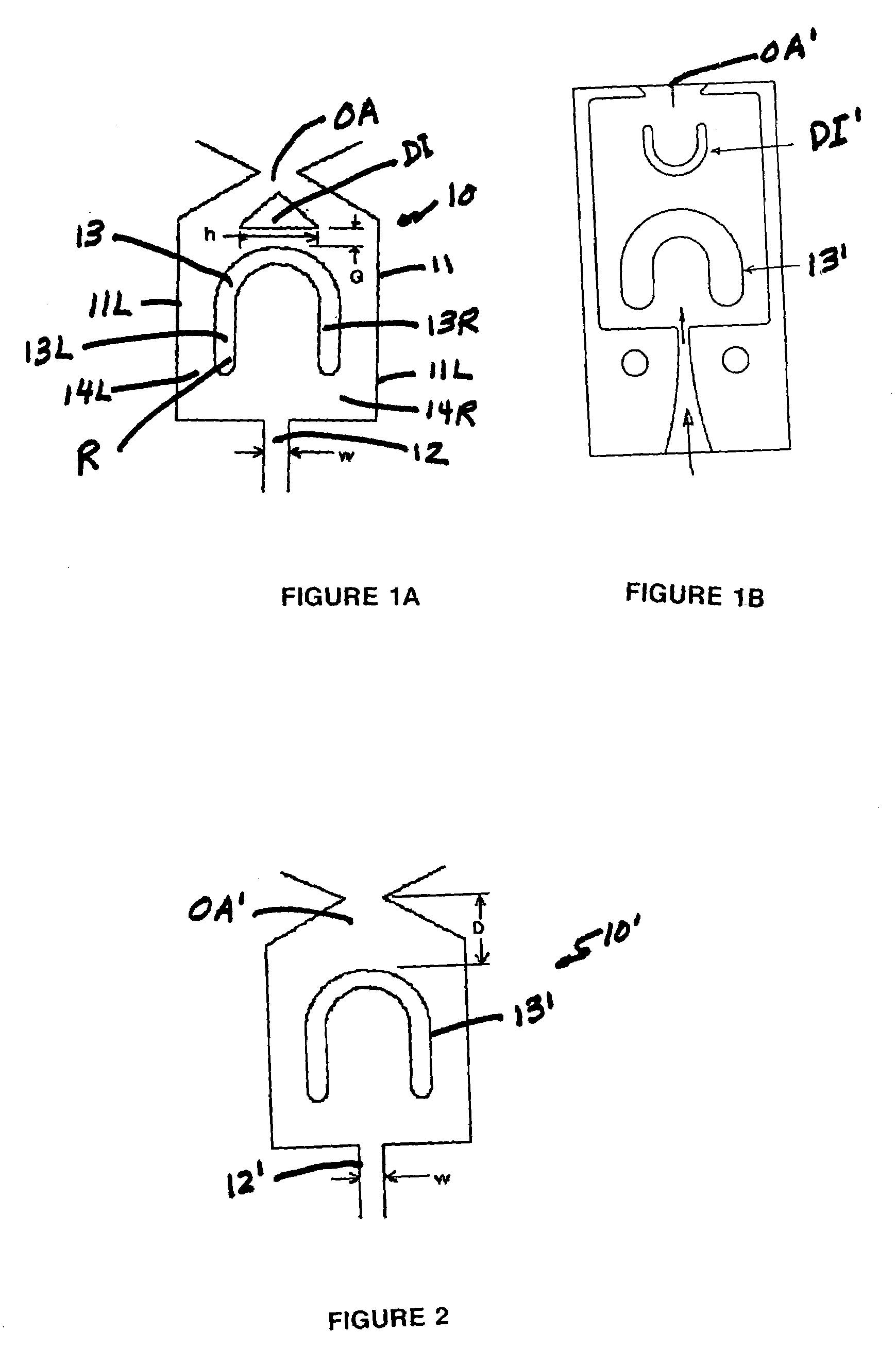

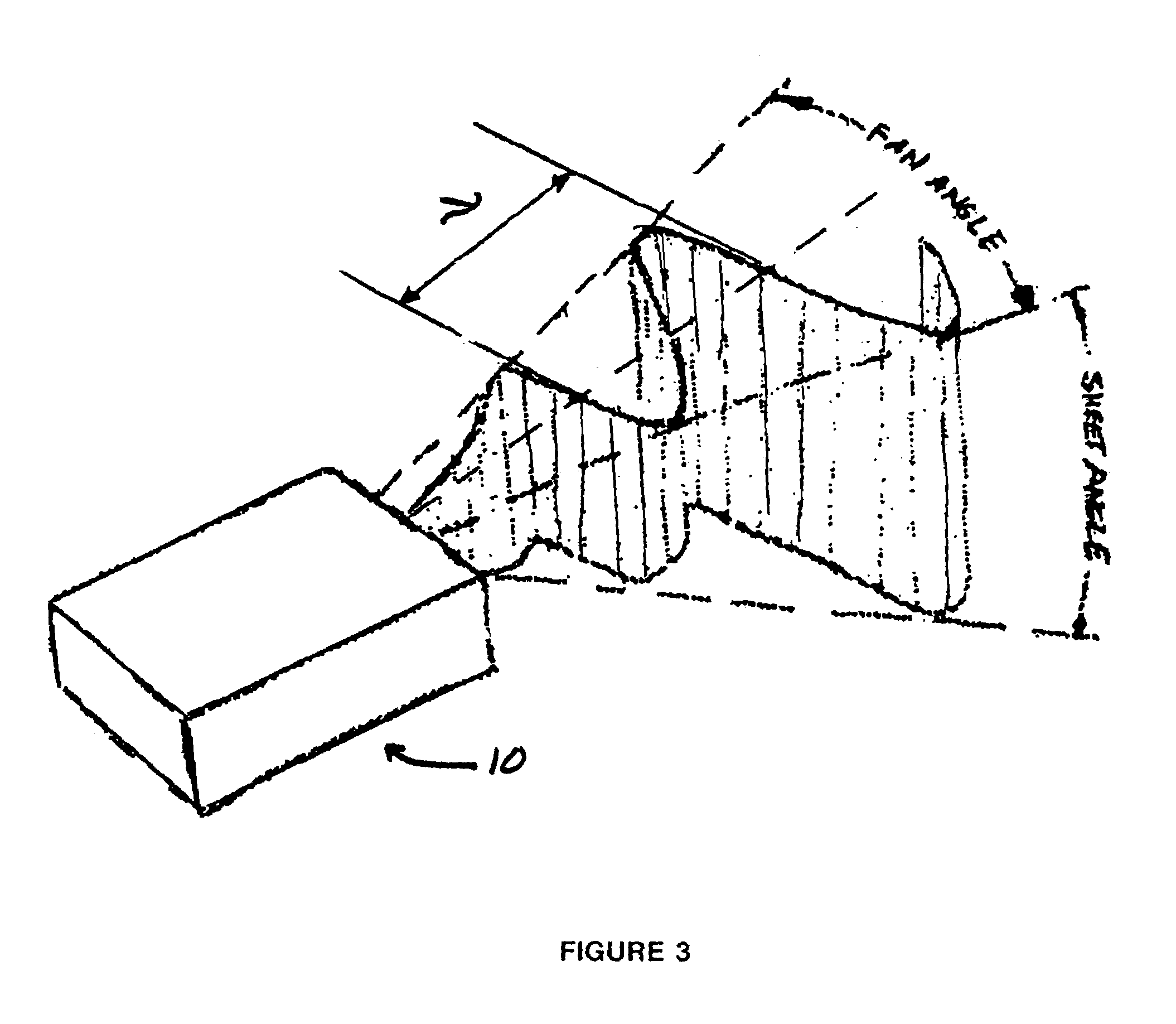

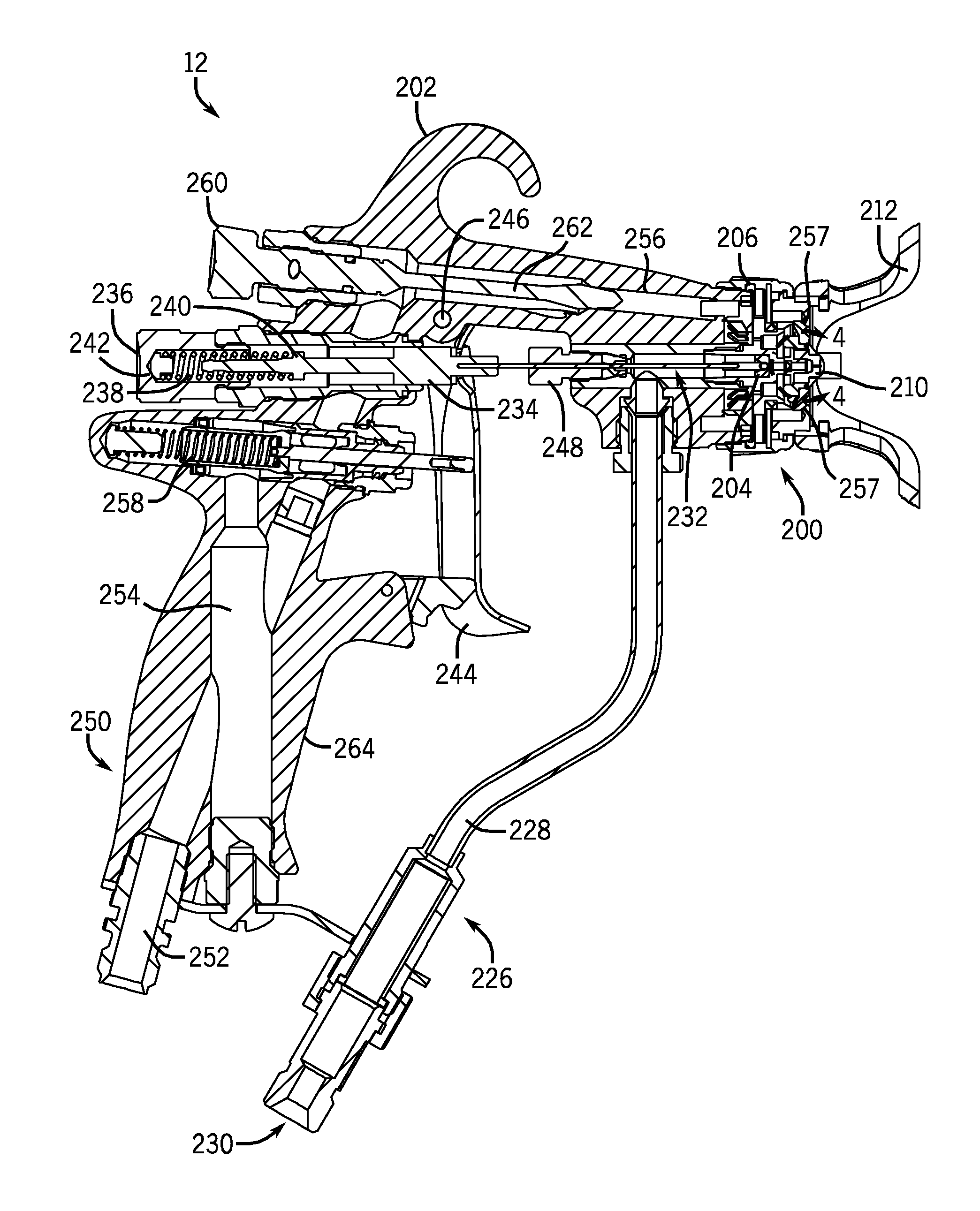

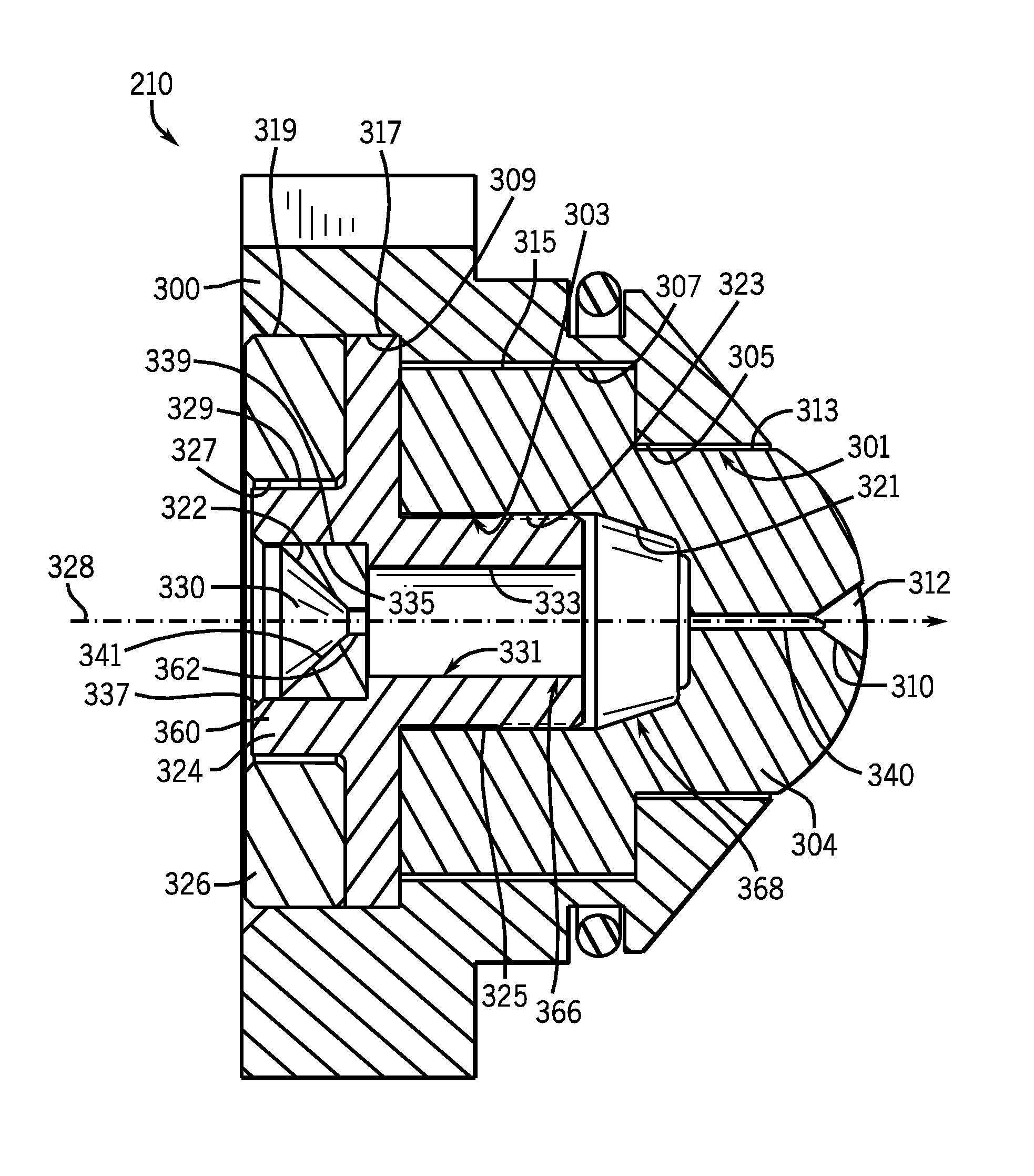

Fine Finish Airless Spray Tip Assembly for a Spray Gun

InactiveUS20120097765A1Easy to understandPromote atomizationSpray nozzlesFire rescueSpray coatingEngineering

The present technique provides a system and method for improving atomization in a spray coating device. An exemplary spray coating device of the present technique has a fine finish tip with an atomization section comprising a first fluid impingement orifice, i.e., a pre-orifice, angled toward an expansion chamber and a subsequent second fluid impingement orifice. The fine finish tip is provided as a unitary assembly that may be applied to a spray gun and that provides a fixed relationship between the pre-orifice, the expansion chamber, and the second orifice, which results in refined spray characteristics, such as uniform particle distribution and uniform fan pattern shapes.

Owner:CARLISLE FLUID TECH INC

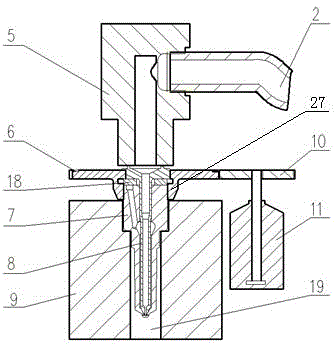

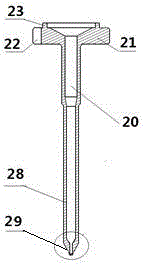

Engine hole type oil nozzle single-hole extruding and grinding device and use method

ActiveCN104588962AReduce consumptionImprove mix qualityMachine part testingOther manufacturing equipments/toolsElectromagnetic valvePetroleum engineering

The invention discloses an engine hole type oil nozzle single-hole extruding and grinding device and a use method. The engine hole type oil nozzle single-hole extruding and grinding device comprises an oil nozzle seat, an oil nozzle body and a shaft needle single-hole circulation rod sleeve which is arranged in the oil nozzle body and can rotate. A ball head at the bottom of the shaft needle single-hole circulation rod sleeve is provided with a rod sleeve spraying hole which can be communicated with any oil nozzle spraying hole after rotating, a sealing face is arranged between the ball head and the oil nozzle body, and the bottom of the oil nozzle seat is further connected with at least one working liquid box through a discharging electromagnetic valve. By means of the structure and the method, the shaft needle single-hole circulation rod sleeve can rotate and drive the rod sleeve spraying hole to rotate so that the rod sleeve spraying hole can be communicated with any oil nozzle spraying hole, and flow or spraying characteristic detection or uniformity evaluation or repairing operation can be conducted on any independent oil nozzle spraying hole. Due to the multiple working liquid boxes, the discharging electromagnetic valve and the like, fast switching of flow detection or grinding or cleaning operation can be achieved by directly controlling the actions of feeding and discharging electromagnetic valves.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

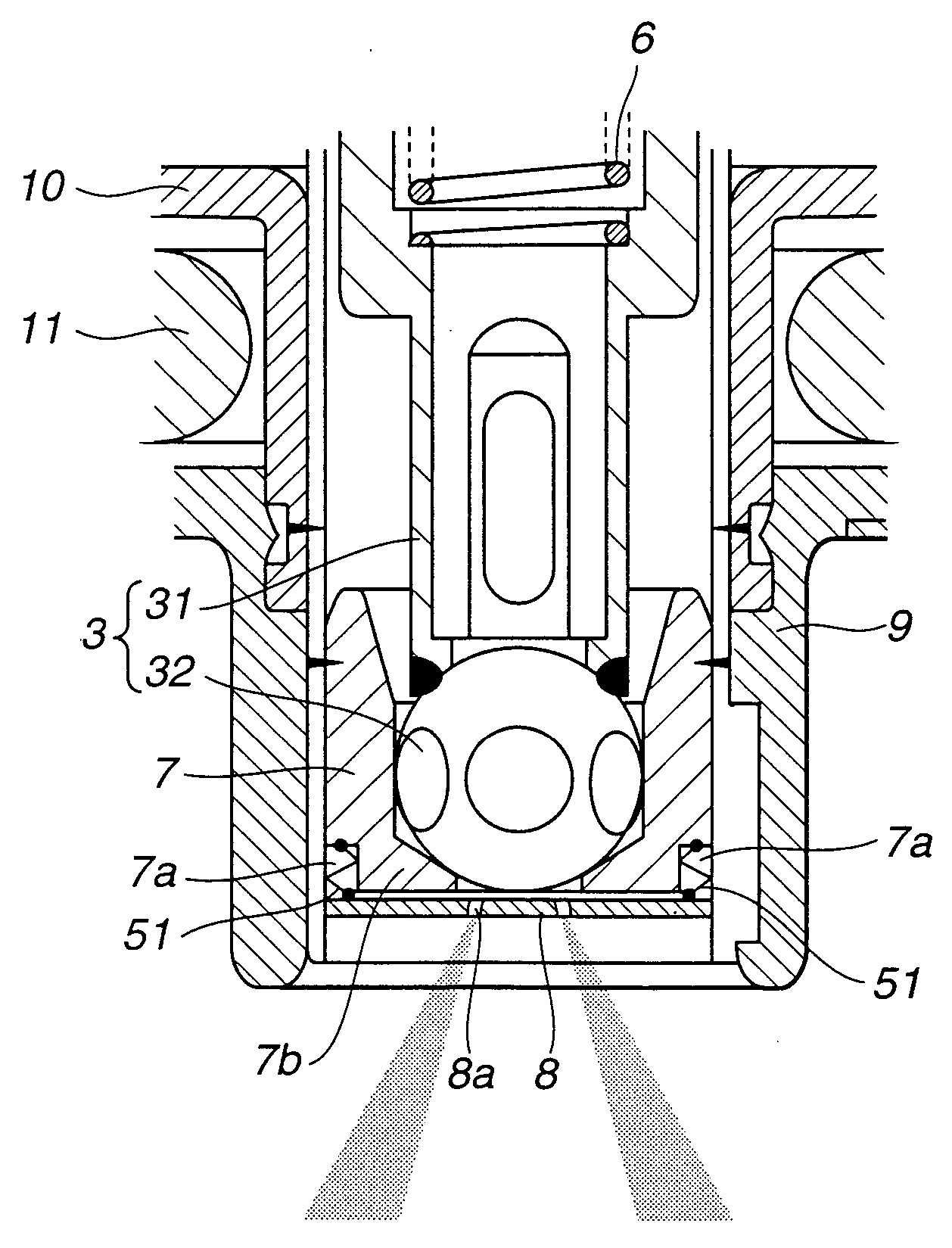

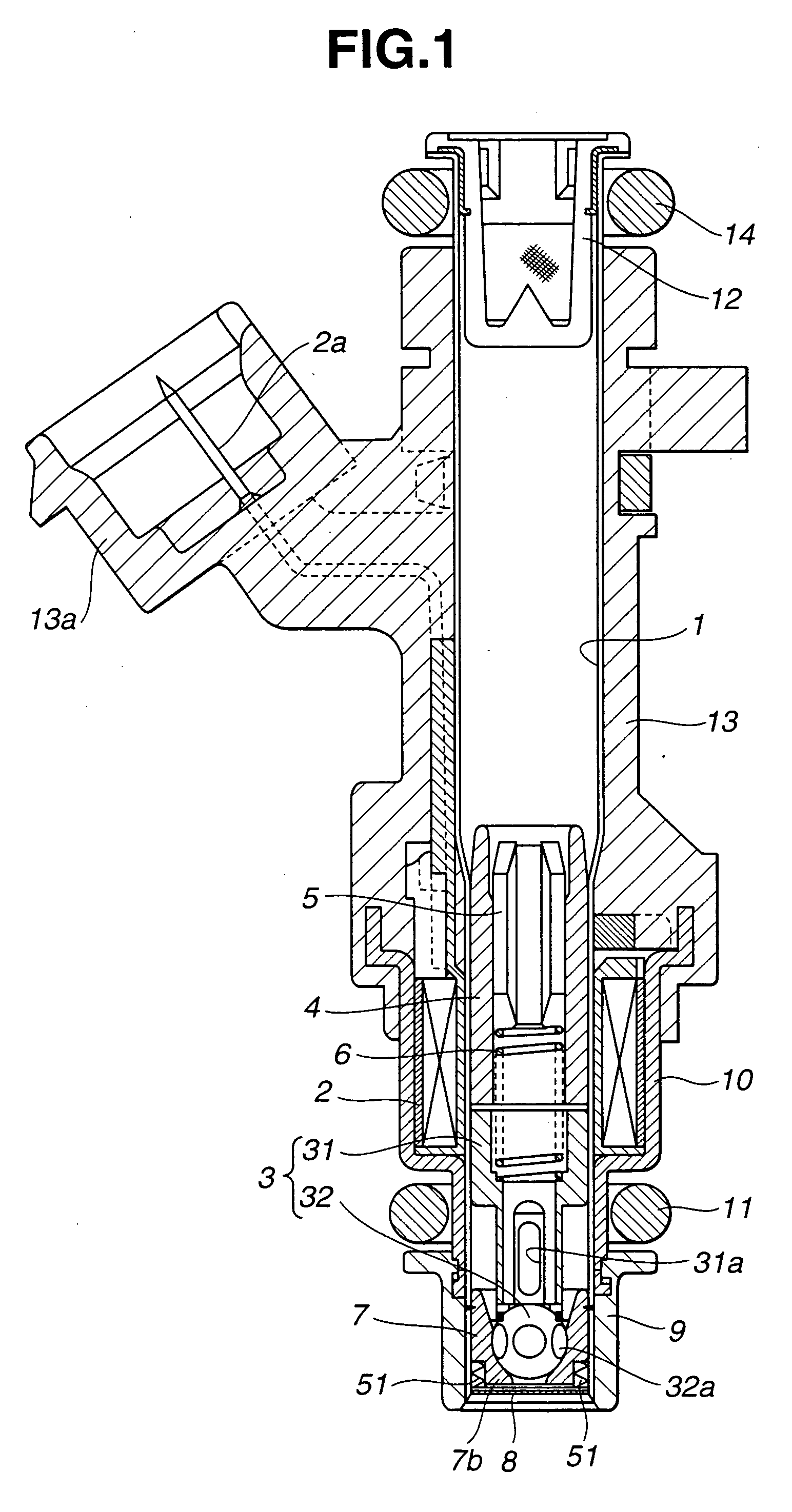

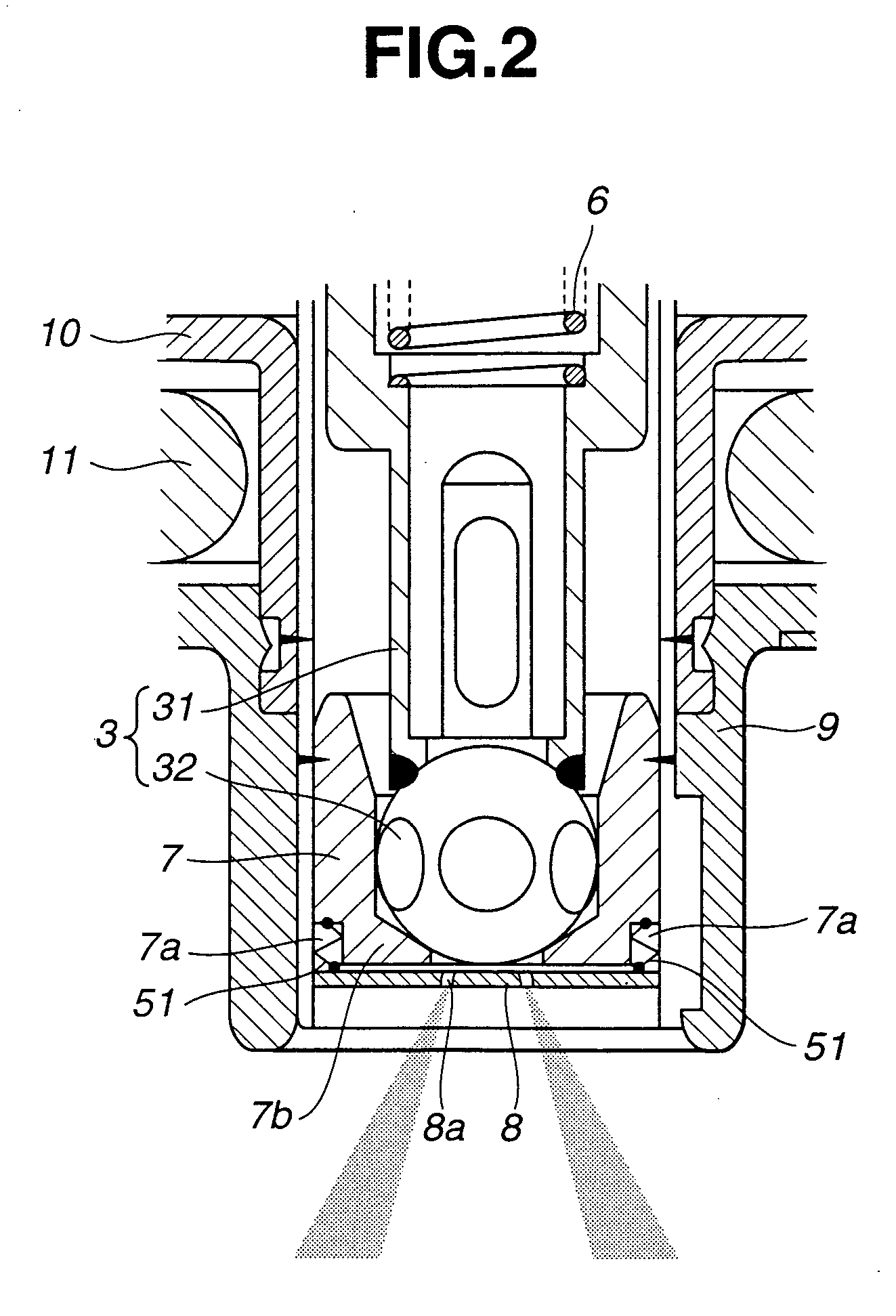

Fuel injection valve

InactiveUS20050056710A1Improve exhaust emissionsAccelerate emissionsMachines/enginesFuel injection with shape memory alloysEngineeringValve seat

A fuel injection valve includes a valve seat having a valve-seat portion on which a valve element is seated, and a nozzle plate disposed downstream from the valve seat and having a plurality of nozzle holes. A deformable member deforms with temperature to vary a space between the valve-seat portion of the valve seat and the nozzle plate, thus achieving change in spray characteristics.

Owner:HITACHI LTD

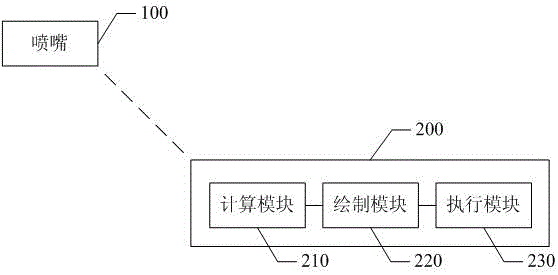

Wall spaying printing system and spraying method thereof

ActiveCN106269359AReduce mistakesReduce labor intensitySpraying apparatusGraphicsUltimate tensile strength

The invention discloses a wall spaying printing system and a spraying method thereof. The spraying method comprises the steps that A, calculation is conducted on a to-be-sprayed area, which is surveyed in advance, through graph parameters of an input sprayed pattern to obtain all orthographic projection coordinate sites of the sprayed pattern on the to-be-sprayed area; B, a corresponding relation between all the orthographic projection coordinate sites and corresponding spraying characteristic data is established, and a spraying track is drawn through all the orthographic projection coordinate sites and the corresponding spraying characteristic data; C, a nozzle is controlled to move to corresponding positions of the to-be-sprayed area in sequence according to the spraying track, the spraying characteristic data corresponding to all the coordinate sites is called, and the nozzle is controlled to spray paint according to the spraying characteristic data to complete pattern spraying. Through the system, a wall advertisement can be quickly sprayed and printed, and the sprayed pattern is vivid and small in error; compared with existing wall spraying schemes, the method is simple, easy to implement and low in construction cost, the labor intensity and construction difficulty of constructors are greatly lowered, and a huge wall advertisement can be realized.

Owner:GUANGDONG YINYANG ENVIRONMENT FRIENDLY NEW MATERIALS CO LTD

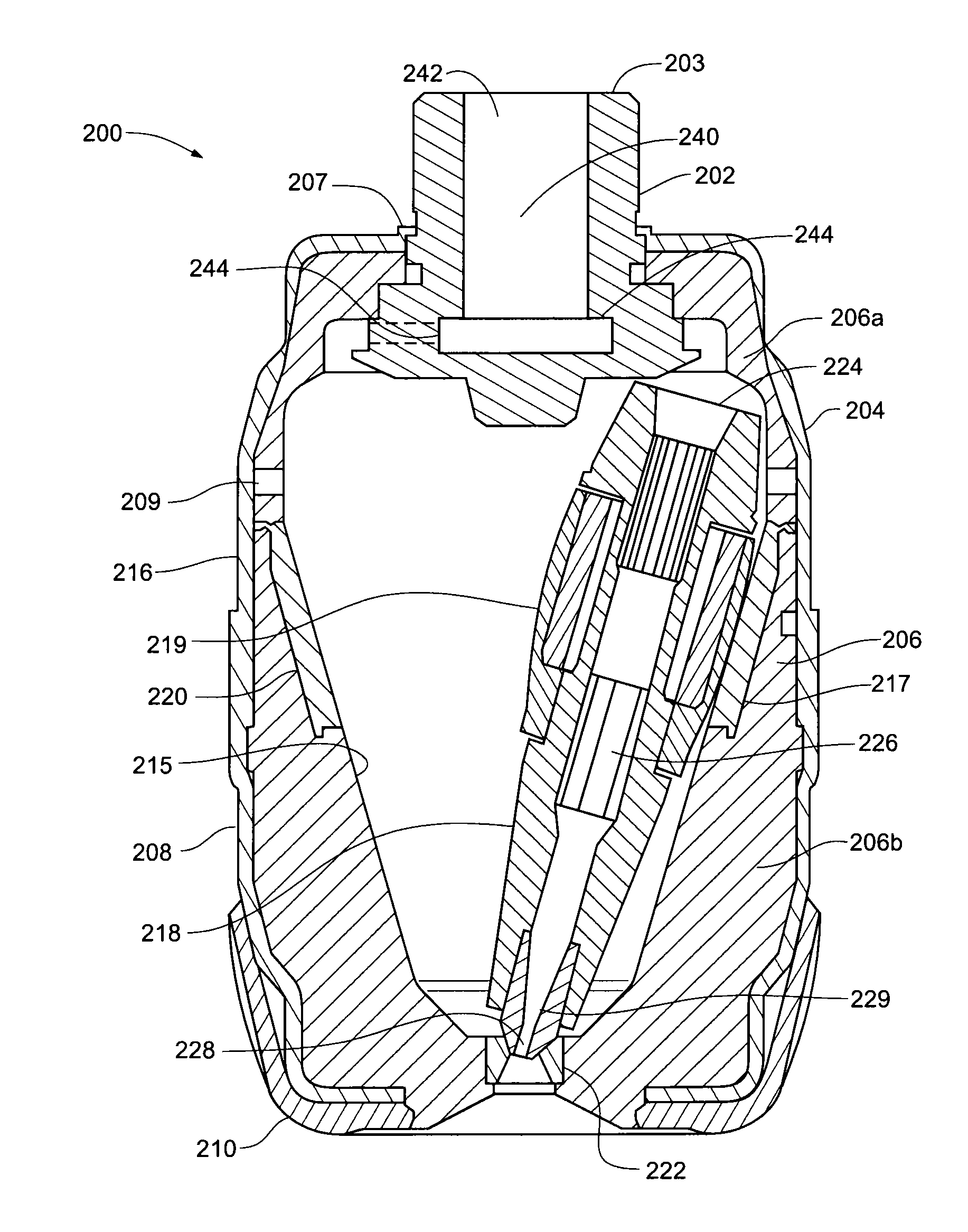

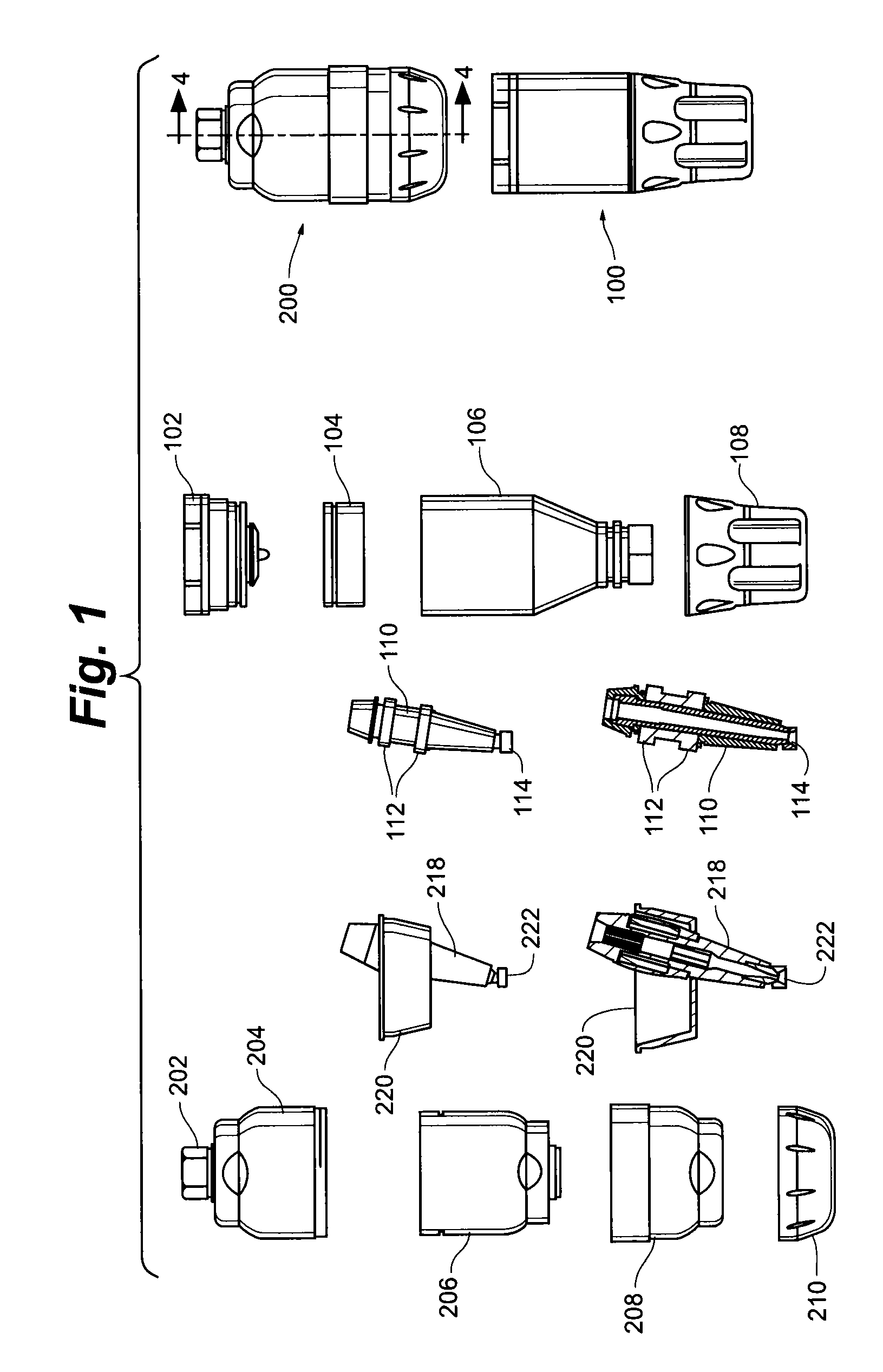

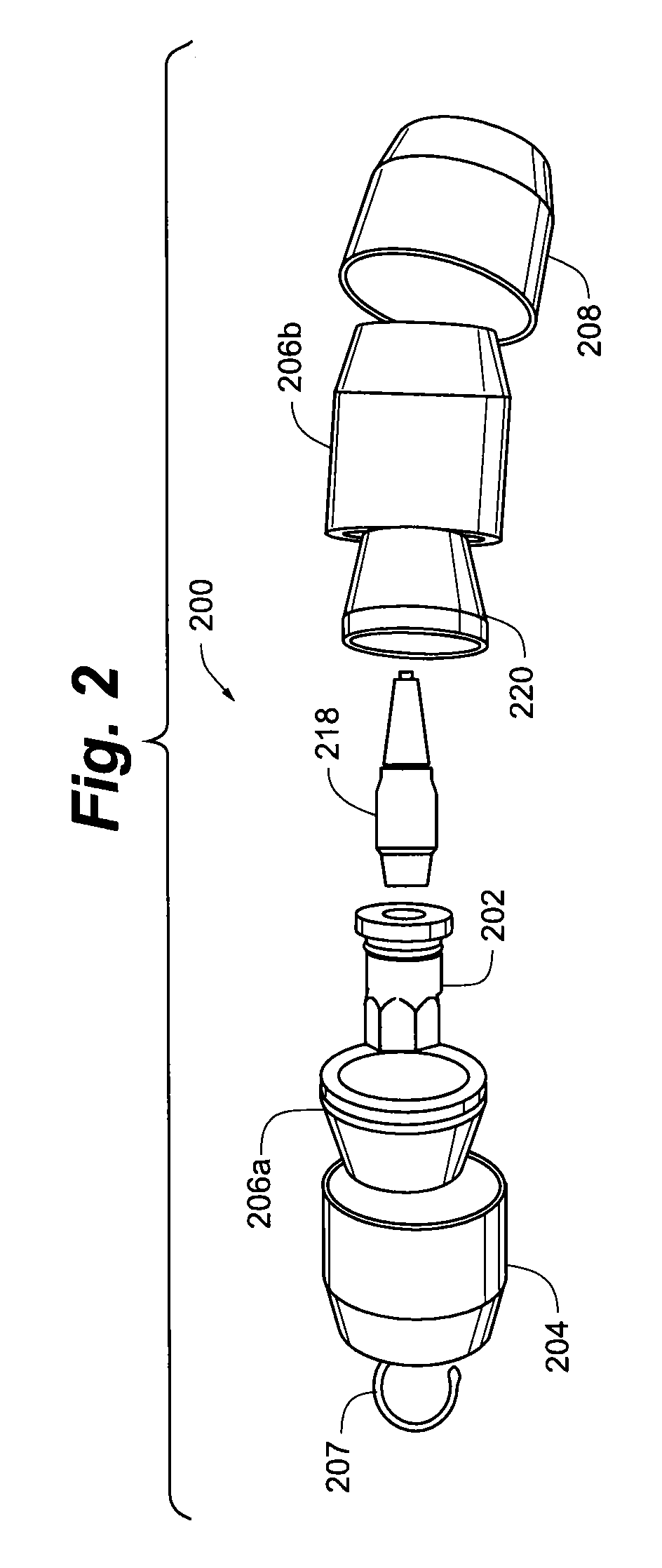

Multi-port fuel injection nozzle and system and method incorporating same

A technique is provided for enhancing fluid flow in an outwardly opening nozzle assembly. A flow enhancement assembly is provided adjacent an exit from an outwardly opening poppet to provide desired spray characteristics. The flow enhancement assembly includes converging and diverging passages and a plurality of ports to form a spray.

Owner:BRP US

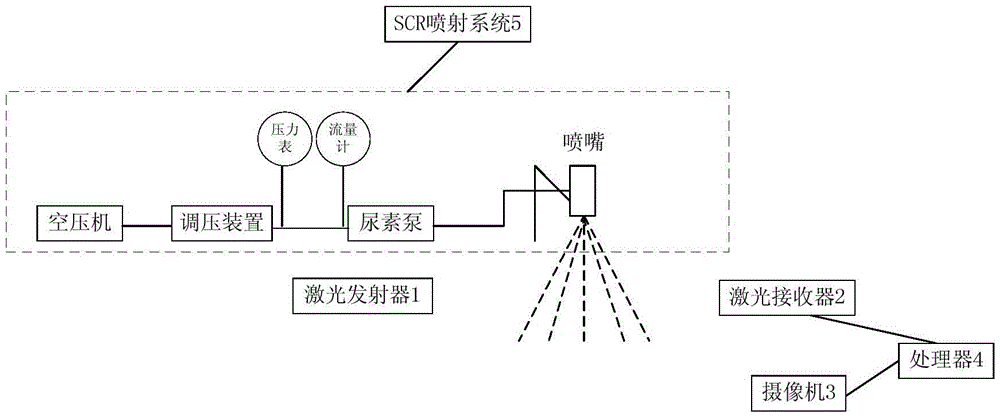

Spraying characteristic analysis device and method

InactiveCN105604665AImprove accuracyReduce verification effortInternal combustion piston enginesExhaust treatment electric controlLaser transmitterTime moment

The invention discloses a spraying characteristic analysis device and an analysis method based on the device. Key parameters for quantitatively evaluating the spraying condition of an SCR injection system can be accurately tested, and efficiency is high. The device comprises the SCR injection system, a laser emitter, a laser receiver, a camera and processors, wherein the processors include a signal processor and an image processor; laser emitted by the laser emitter is received by the laser receiver after being subjected to spraying of urea injected by a nozzle penetrating the SCR injection system; the signal processor is connected with the laser receiver and used for acquiring laser signals received by the laser receiver and processing the laser signals, and the urea spraying particle diameter and the distribution condition of the urea spraying particle diameter are acquired; the camera is connected with the image processor and used for acquiring urea spraying images at different time moments and transmitting the images to the image processor; the image processor is used for processing the images and acquiring the urea spraying penetration length and taper angle.

Owner:WEICHAI POWER CO LTD

System and method for measuring combustion characteristic of internal combustion engine based on infrared radiation

InactiveCN104502112AStrong infrared radiationEasy to detectInternal-combustion engine testingPyrometry using electric radation detectorsFiberCombustion chamber

The invention relates to a system and a method for measuring the combustion characteristic of an internal combustion engine based on infrared radiation. The system and the method are used for measuring the combustion and spraying characteristics of the internal combustion engine. The system comprises an infrared endoscope, an infrared optical fiber, an infrared filter, a thermal infrared imager, a data processor and an endoscope thermostat, wherein the infrared endoscope is arranged on a probe hole in a combustion chamber of the internal combustion engine; one end of the infrared optical fiber is connected with the infrared endoscope, and a fiber scope is arranged at the other end of the infrared optical fiber; the fiber scope and the thermal infrared imager are coaxially arranged; the infrared filter is arranged between the fiber scope and the thermal infrared imager; the infrared imager is connected with the data processor; the endoscope thermostat is connected with the infrared endoscope. Compared with the prior art, the system and the method have the advantages of adaptability under the condition of no light source, good detection effect, advanced method and the like.

Owner:TONGJI UNIV

Fine finish airless spray tip assembly for a spray gun

InactiveUS8814070B2Promote atomizationImprove featuresSpray nozzlesFire rescueSpray coatingEngineering

The present technique provides a system and method for improving atomization in a spray coating device. An exemplary spray coating device of the present technique has a fine finish tip with an atomization section comprising a first fluid impingement orifice, i.e., a pre-orifice, angled toward an expansion chamber and a subsequent second fluid impingement orifice. The fine finish tip is provided as a unitary assembly that may be applied to a spray gun and that provides a fixed relationship between the pre-orifice, the expansion chamber, and the second orifice, which results in refined spray characteristics, such as uniform particle distribution and uniform fan pattern shapes.

Owner:CARLISLE FLUID TECH INC

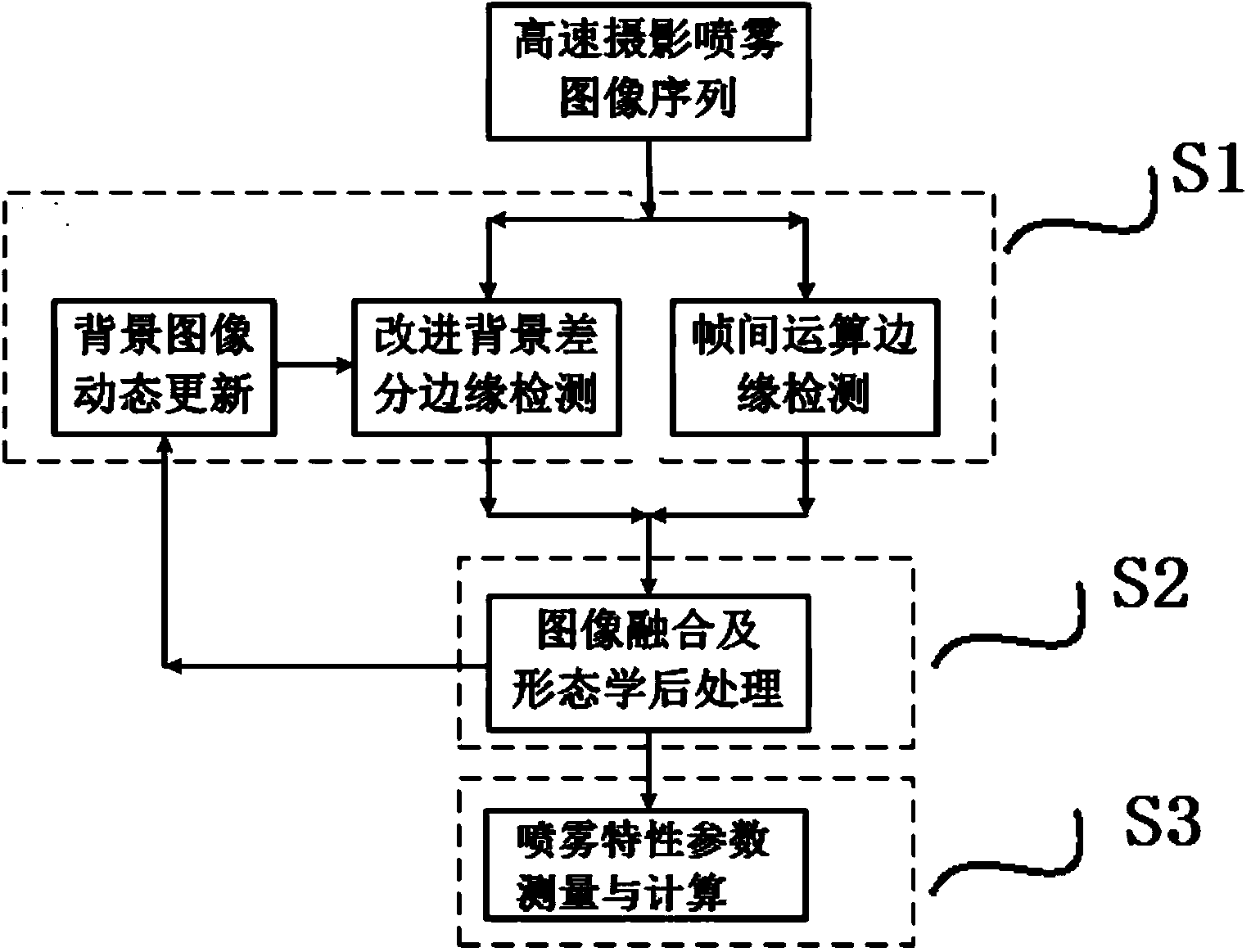

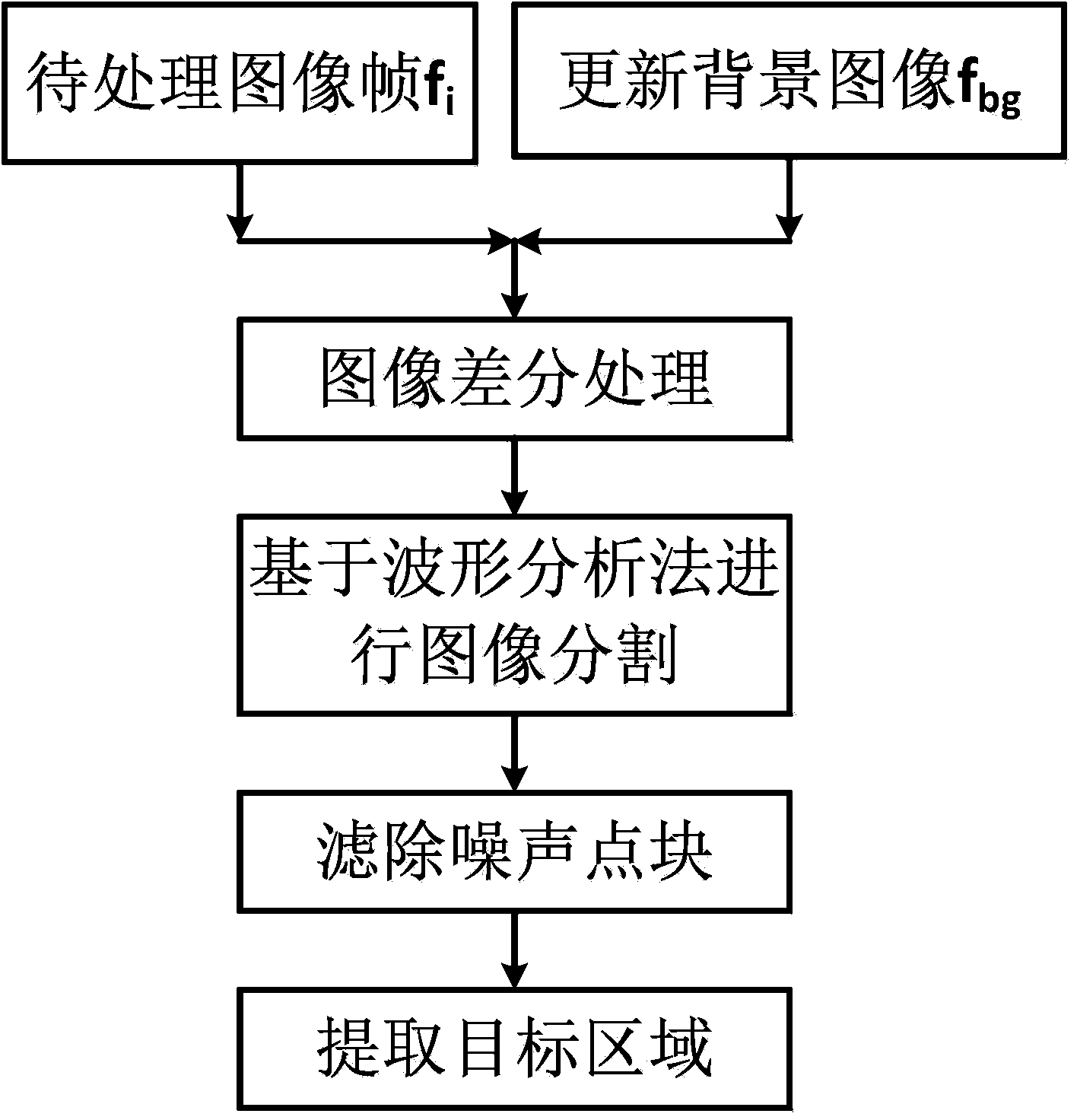

Identification and measurement method for high-temperature evaporation-type spray schlieren image

InactiveCN104252623AAccurate detectionImprove processing qualityImage analysisCharacter and pattern recognitionCombustionEvaporation

The invention discloses an identification and measurement method for a high-temperature evaporation-type spray schlieren image. Aiming at a morphological structure that the high-temperature evaporation image is comparatively complicated, a partition processing strategy is adopted; the identification and measurement method comprises the following steps: firstly, detecting a spray liquid phase region and a mixing region by adopting an improved background subtraction edge method; then, detecting a spray steam region and a mixing region by an inter-frame operation edge method; finally, performing post-processing steps of fusion, morphology and the like on the identified regions to obtain the complete outline of a spray evaporation region; subsequently, performing spray characteristic measurement calculation to obtain the quantitative indicator of a spray region. The identification and measurement method disclosed by the invention is capable of identifying and automatically measuring the high-temperature evaporation-type spray image of a premixed combustion-type constant volume bomb, and has the advantages that a threshold value is automatically determined, the processing speed is high, and the accuracy is high, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

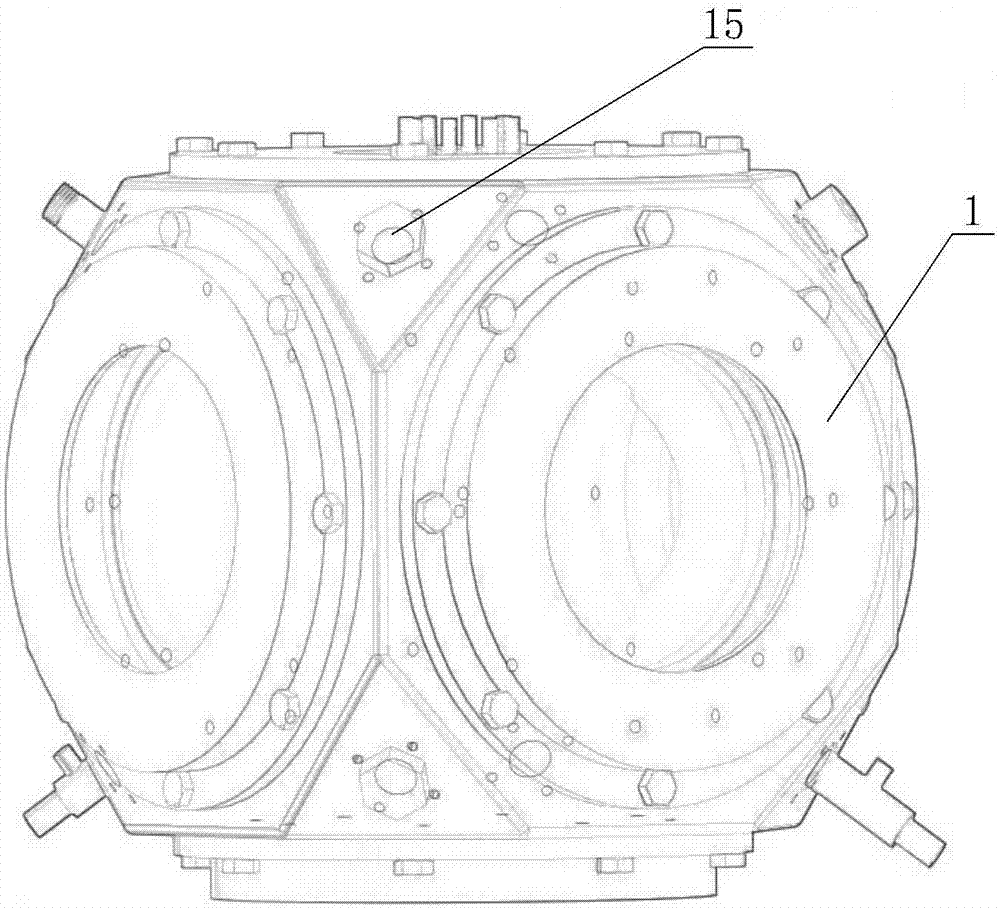

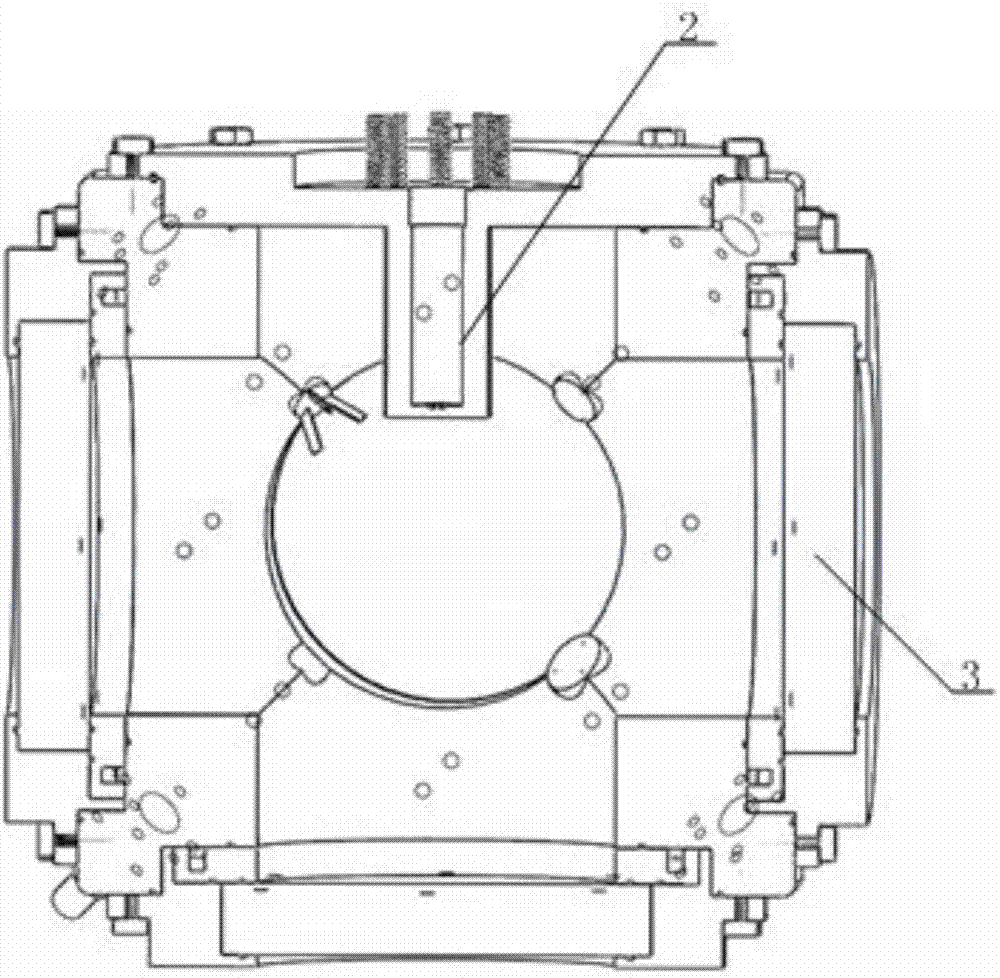

Constant volume chamber and oil atomizer spraying visual test system with same

InactiveCN107420241AImprove sealingEasy to buildEngine testingFuel injection apparatusVisual testIrradiation

The invention discloses a constant volume chamber and an oil atomizer spraying visual test system with the same and belongs to the field of oil atomizer spraying characteristic tests. The constant volume chamber comprises a constant volume chamber body which is of a cube shape; the constant volume chamber body is internally provided with through-holes in three axial directions, and the through-holes are perpendicular and crossed, so that an internal cavity is formed; one mouth portion of one of the through-holes is provided with an oil atomizer module, and the other mouth portion of the corresponding through-hole and the mouth portions of the other through-holes are each provided with a visual window module; each visual window module comprises an outer end cover, an inner side cover plate and quartz glass located between the outer end cover and the inner side cover plate; the visual test system comprises the constant volume chamber, and the two opposite sides of the constant volume chamber body are provided with an ultraviolet lamp and a camera correspondingly; and a fluorescent agent which can shine under the irradiation of the ultraviolet lamp is added to the diesel oil in the constant volume chamber. By means of the constant volume chamber and the oil atomizer spraying visual test system with the constant volume chamber, the leakproofness of the constant volume chamber can be improved, and the problem that the subsequent oil beam outline is disturbed by a background light in a visual test can also be solved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

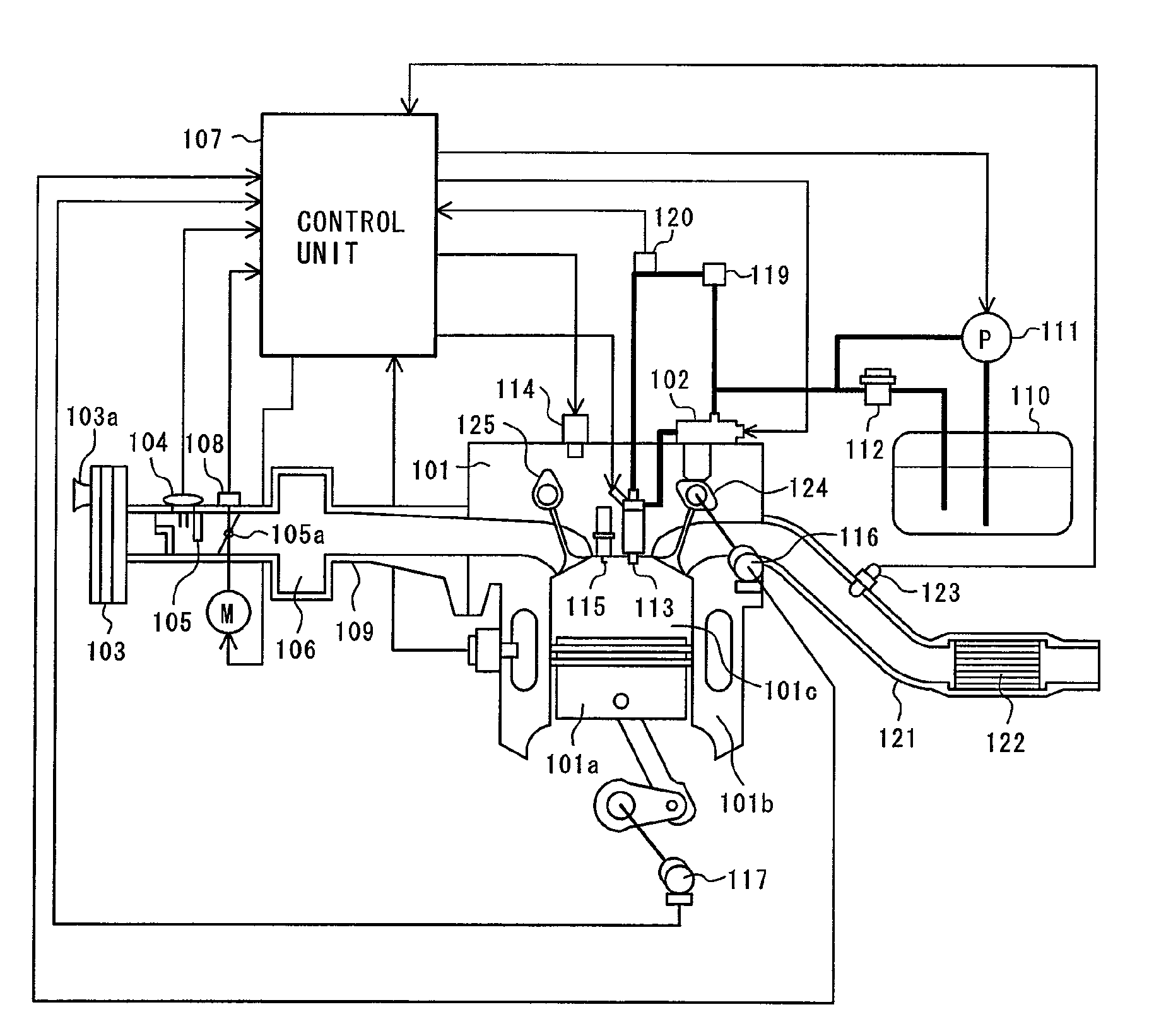

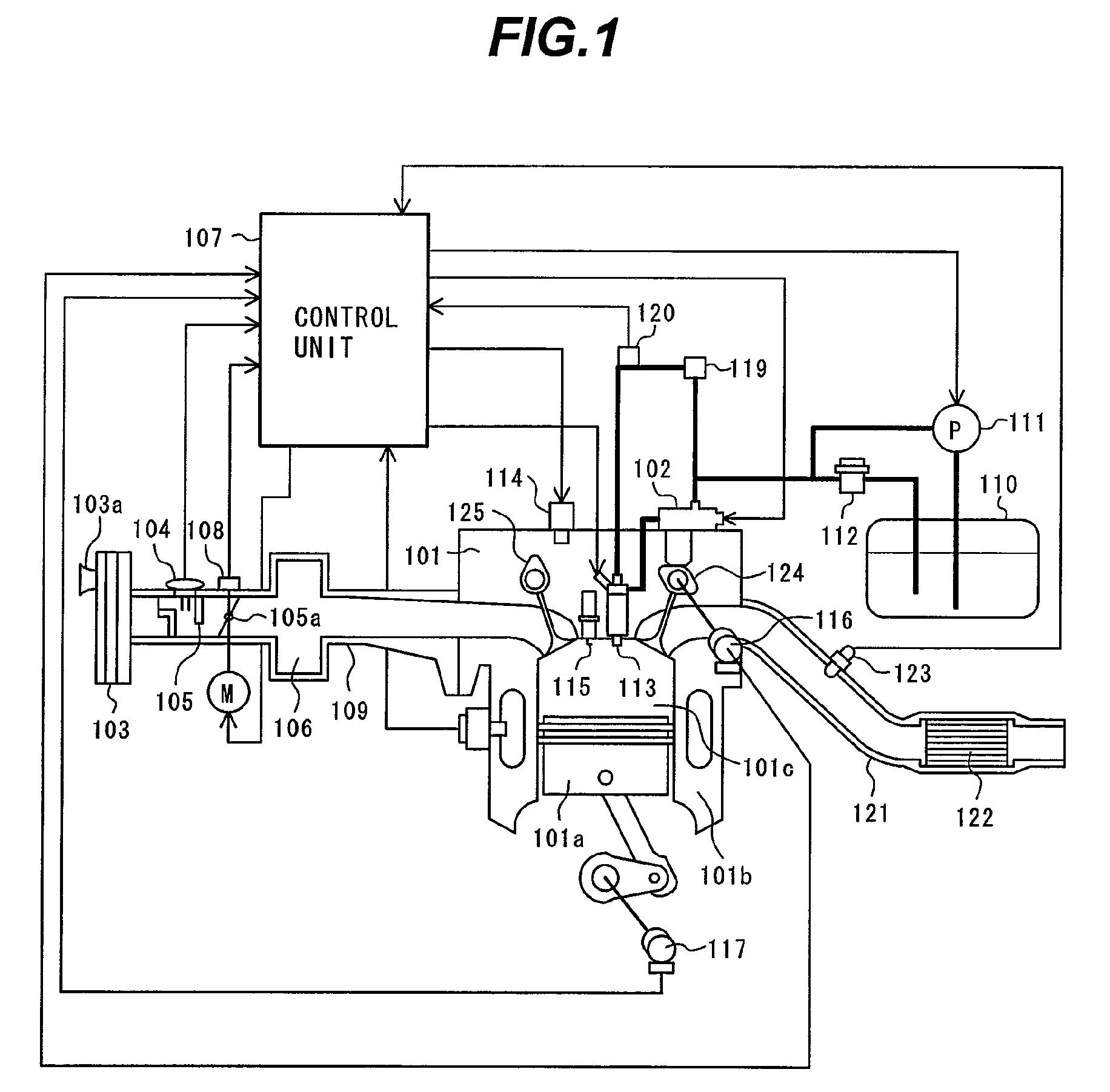

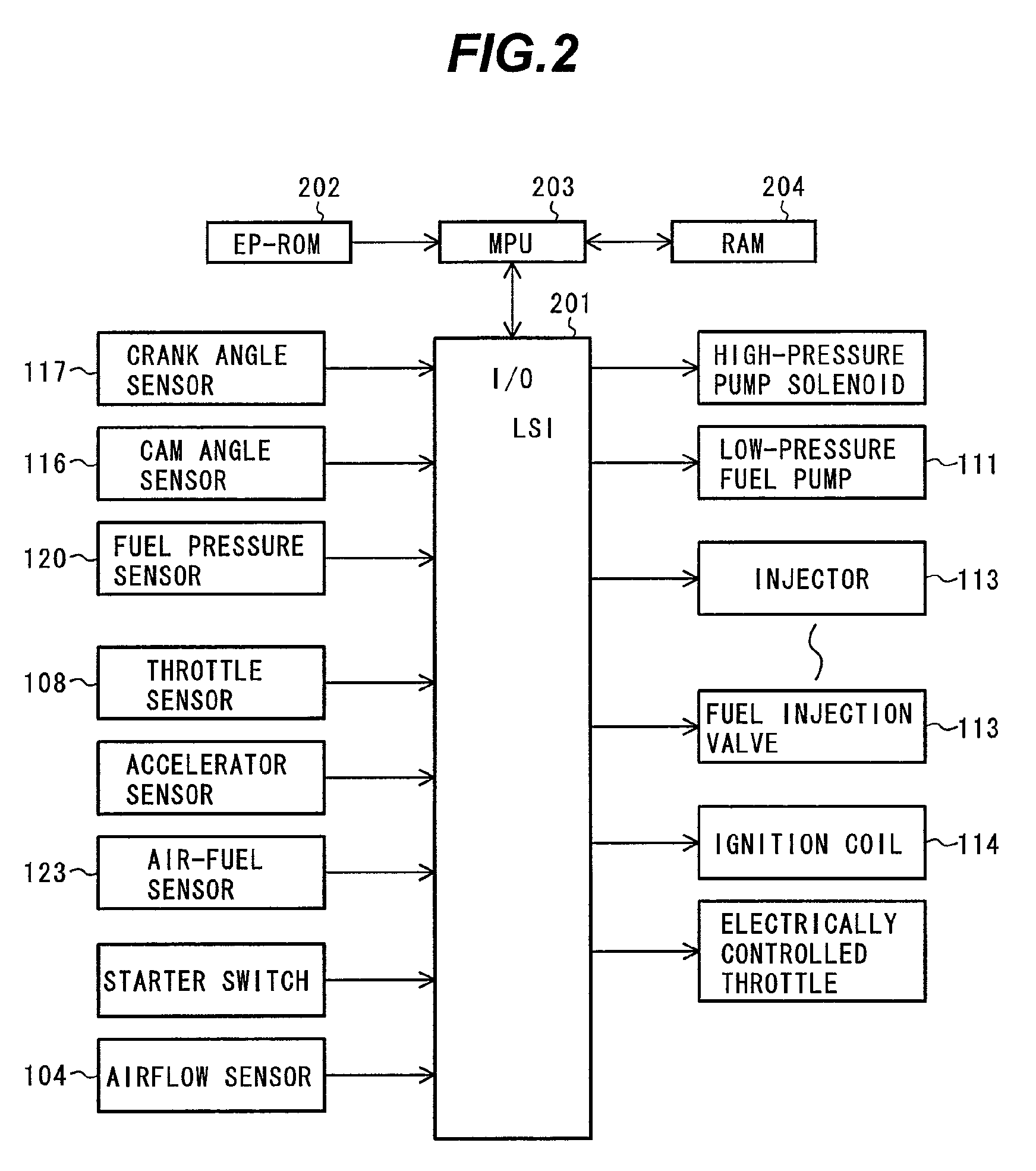

High-pressure fuel supply apparatus and control apparatus for internal combustion engine

InactiveUS7735472B2Control pressureInhibit overall enlargementElectrical controlDigital data processing detailsCommon railExternal combustion engine

In an internal combustion engine provided with a high-pressure fuel pump, if the discharging rate of the high-pressure fuel pump is greater than the injection quantity of fuel injected from a injector with the high-pressure fuel pump remaining uncontrollable due to failure or the like, it is probable that the fuel pressure in a common rail unintentionally rises to affect the injector. A high-pressure fuel supply apparatus is provided to solve such a problem.A high-pressure fuel supply apparatus according to the present invention is configured such that if the high-pressure fuel supply apparatus or a control apparatus thereof causes malfunction to increase the pressure in the common rail, the pressure in the common rail does not exceed pressure affecting the flow characteristic and spray characteristic of the injector after recovery from the malfunctioning state.

Owner:HITACHI LTD

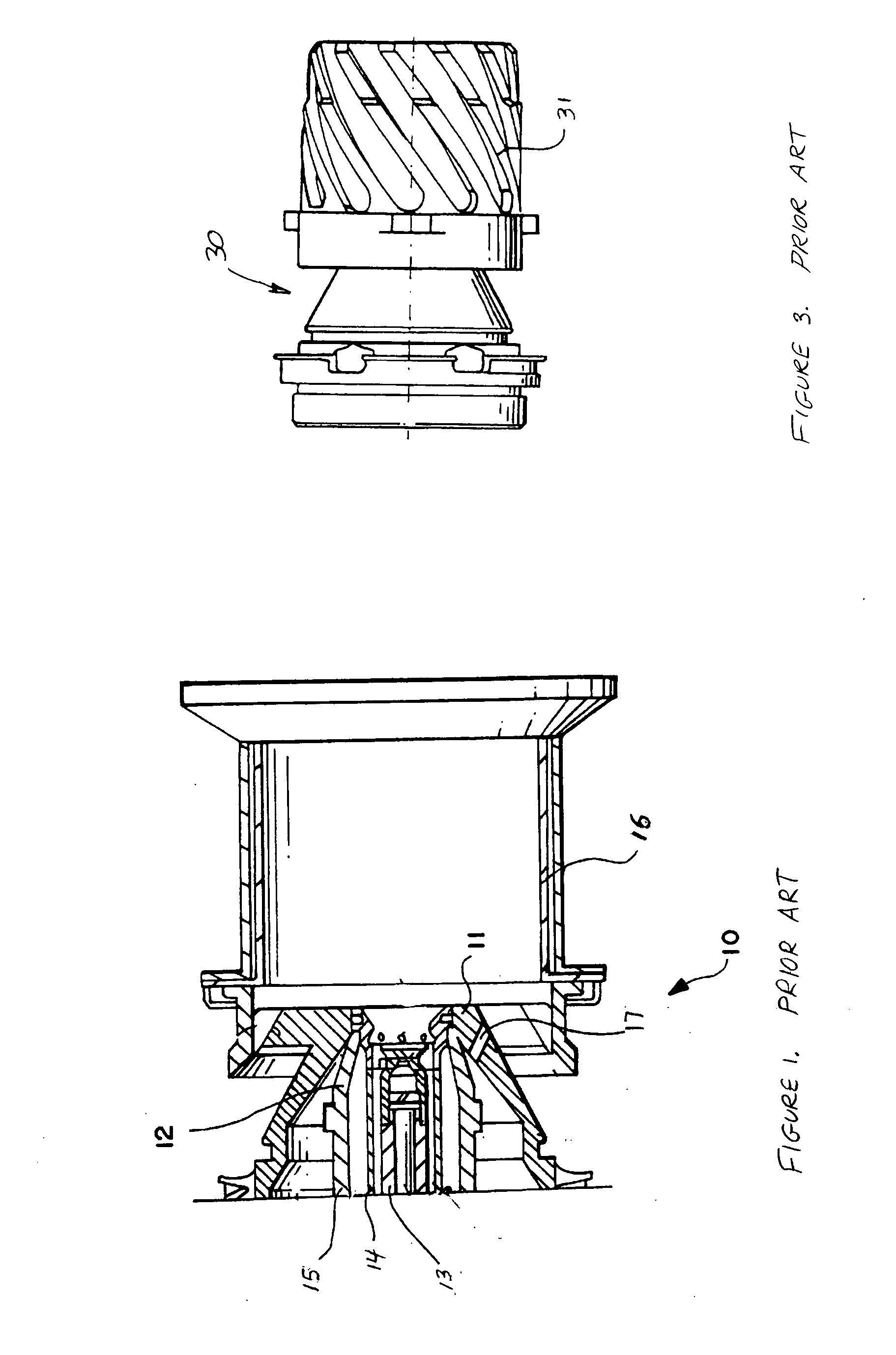

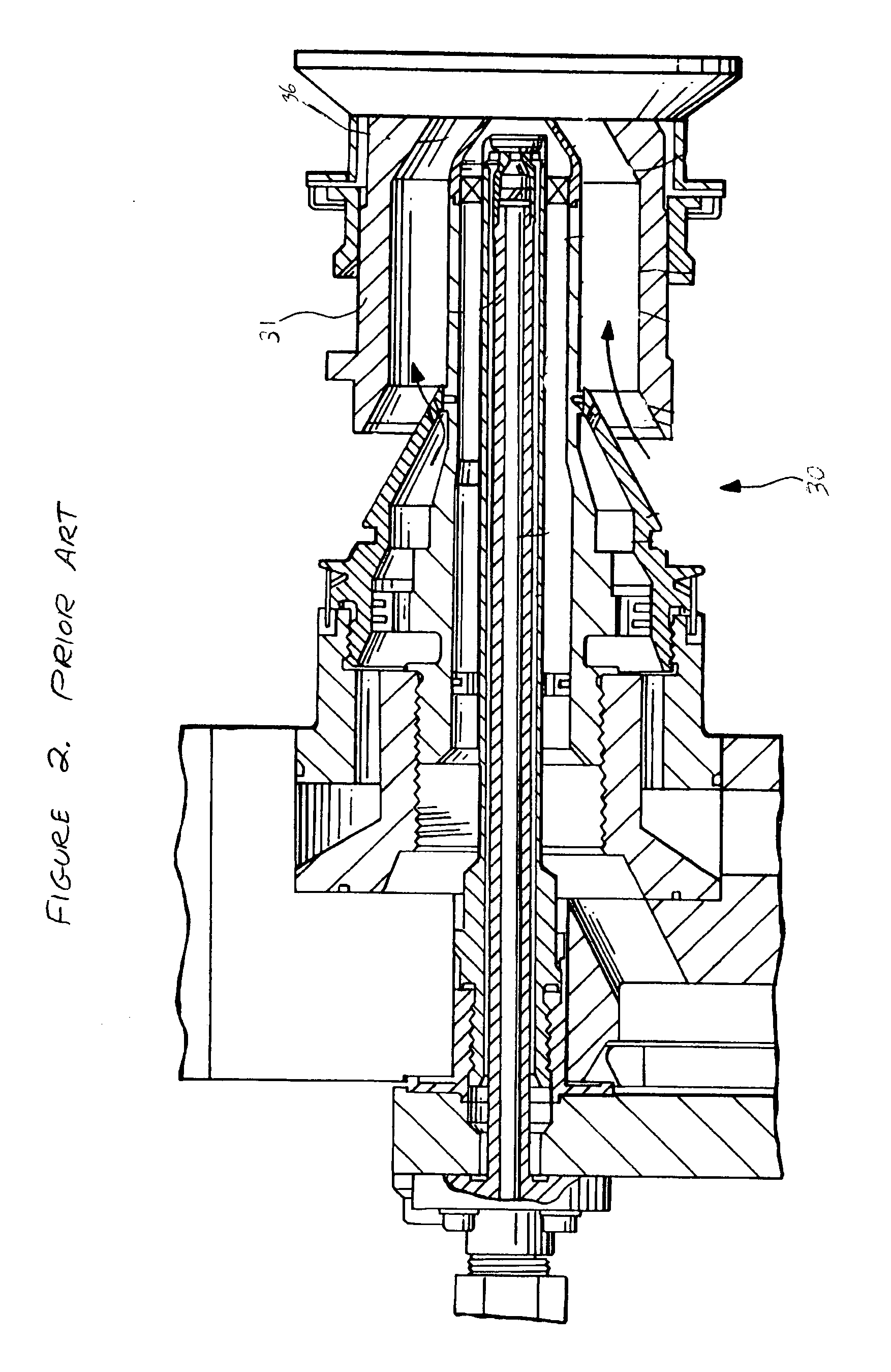

Configurable rotary spray nozzle

ActiveUS8500042B2Low manufacturing and maintenance costsLow costMovable spraying apparatusSpray nozzlesMachiningSpray characteristics

A configurable rotary spray nozzle having lower manufacturing and maintenance costs through the use of an external shell providing strength and resistance to damage such that molded internal components can be utilized to provide the desired spray characteristics. The molded internal wet components can comprise molded polymeric structures that allow for the formation of complex flow geometries and structures that are either impossible or economically impractical to achieve with conventional tooling and machining operations. The use of an external shell provides for use of replacement kits to maintain or otherwise replace worn and / or damaged internal wet components while reusing the external housing. The use of the external shell also allows a user to customize and change spray performance of the configurable rotary spray nozzle by swapping internal wet components having selected flow geometries and characteristics so as to provide a desired spray performance.

Owner:SONNYS HFI HOLDINGS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com