Patents

Literature

55 results about "Penetration length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

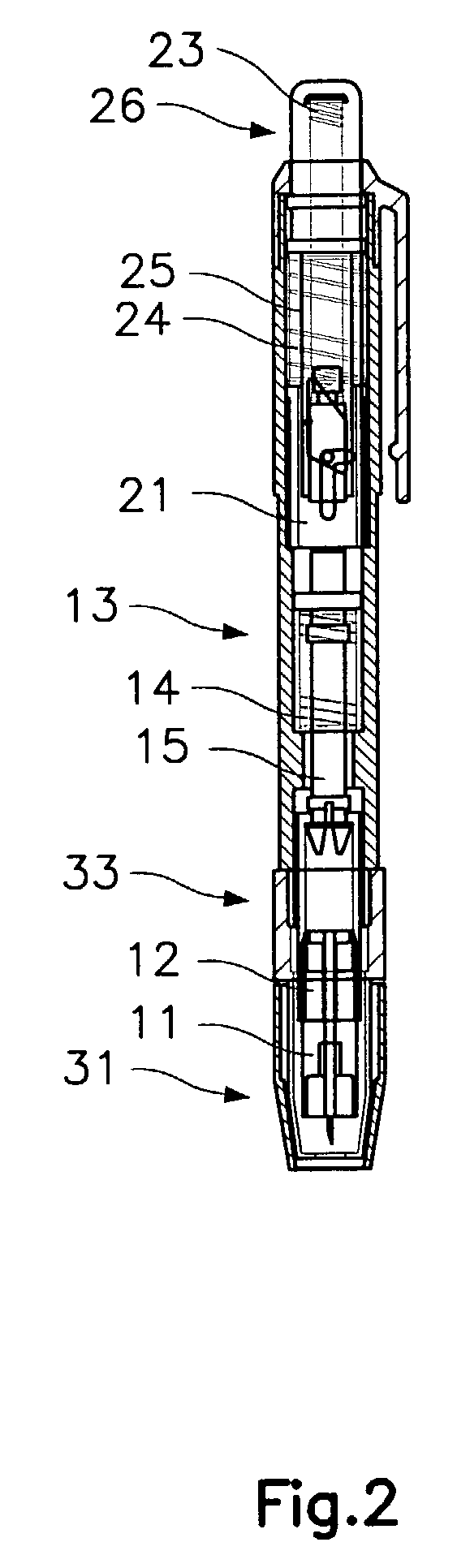

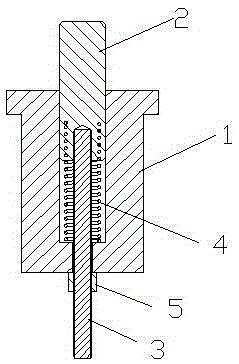

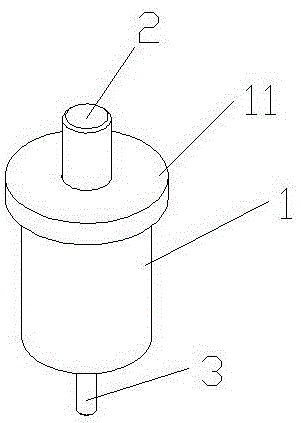

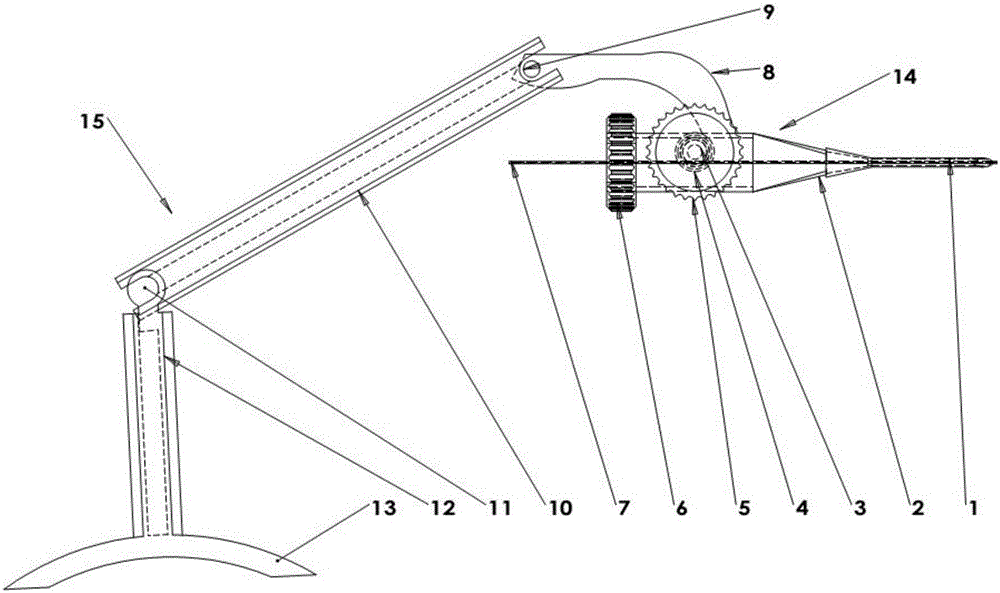

Automatic lancing device

The present invention generally relates to an automatic lancing device for withdrawing a blood sample, comprising a pushing member positioned at a back end of a body and a rotatable cap combined with a front end of the body for regulating the combination length of the body and the ejection length of a lancet, thereby obtaining a blood sample exactly at a desired position without misoperation and adjusting the penetration length of lancet according to depth of the skin.

Owner:KIM YONG PIL

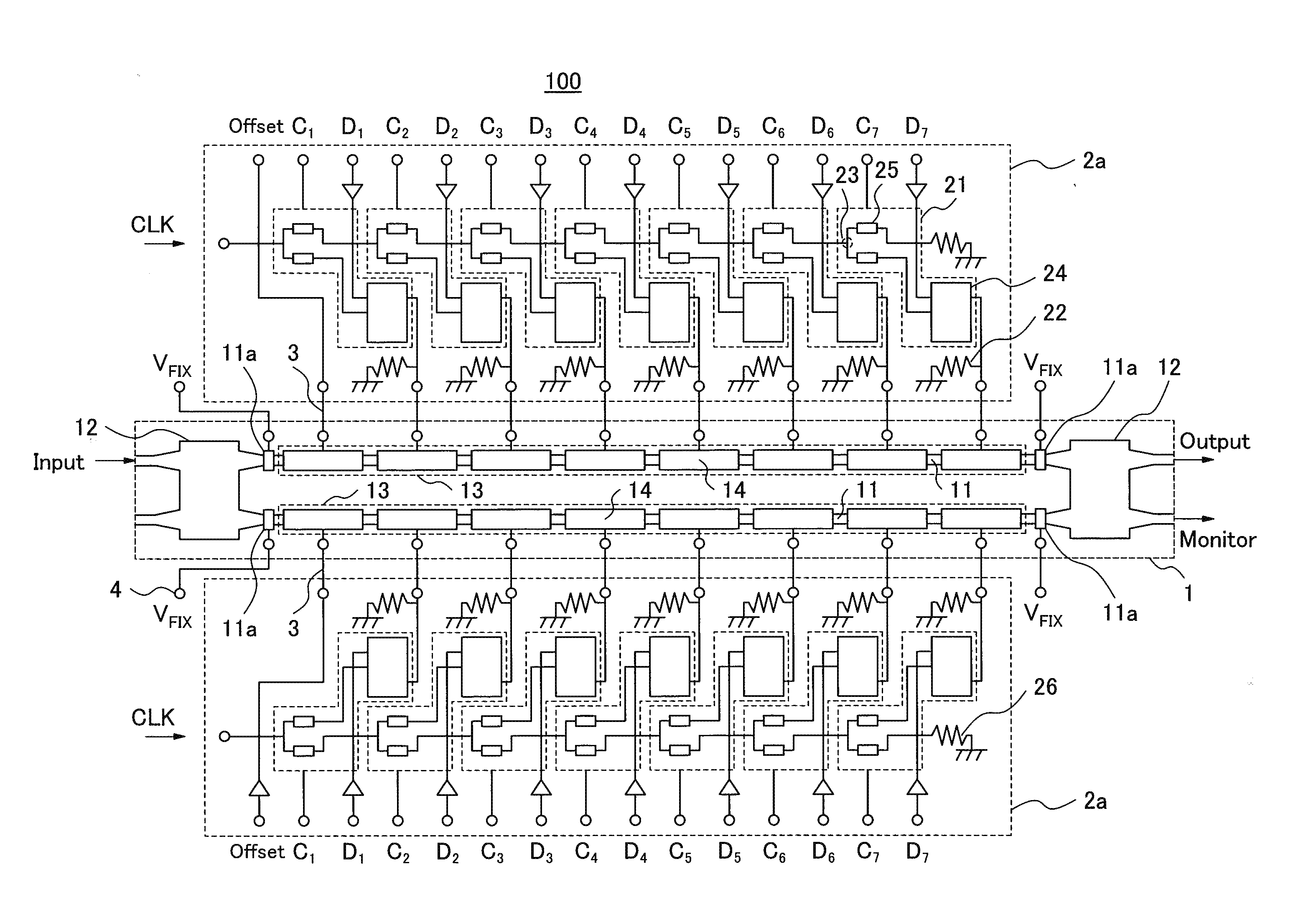

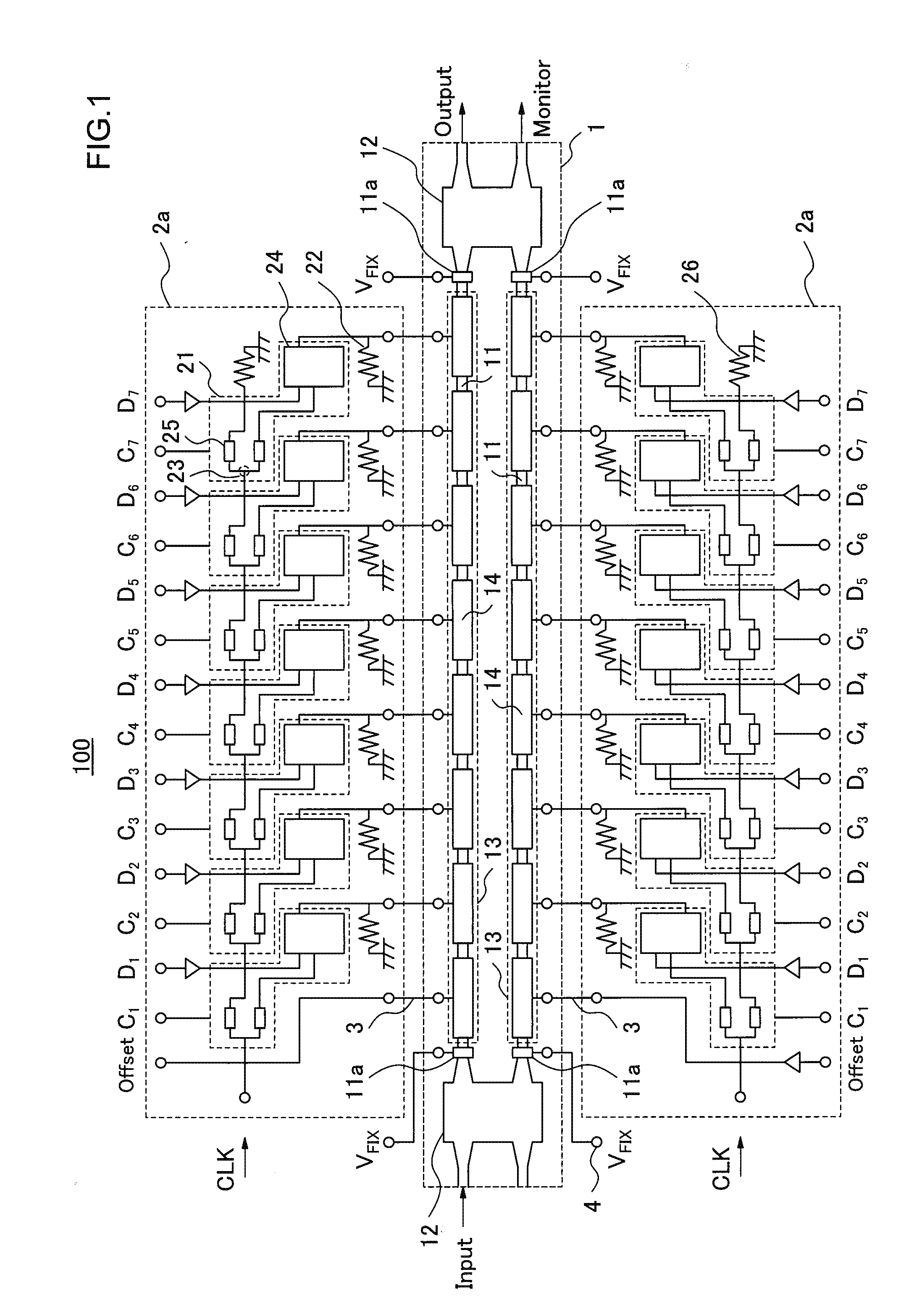

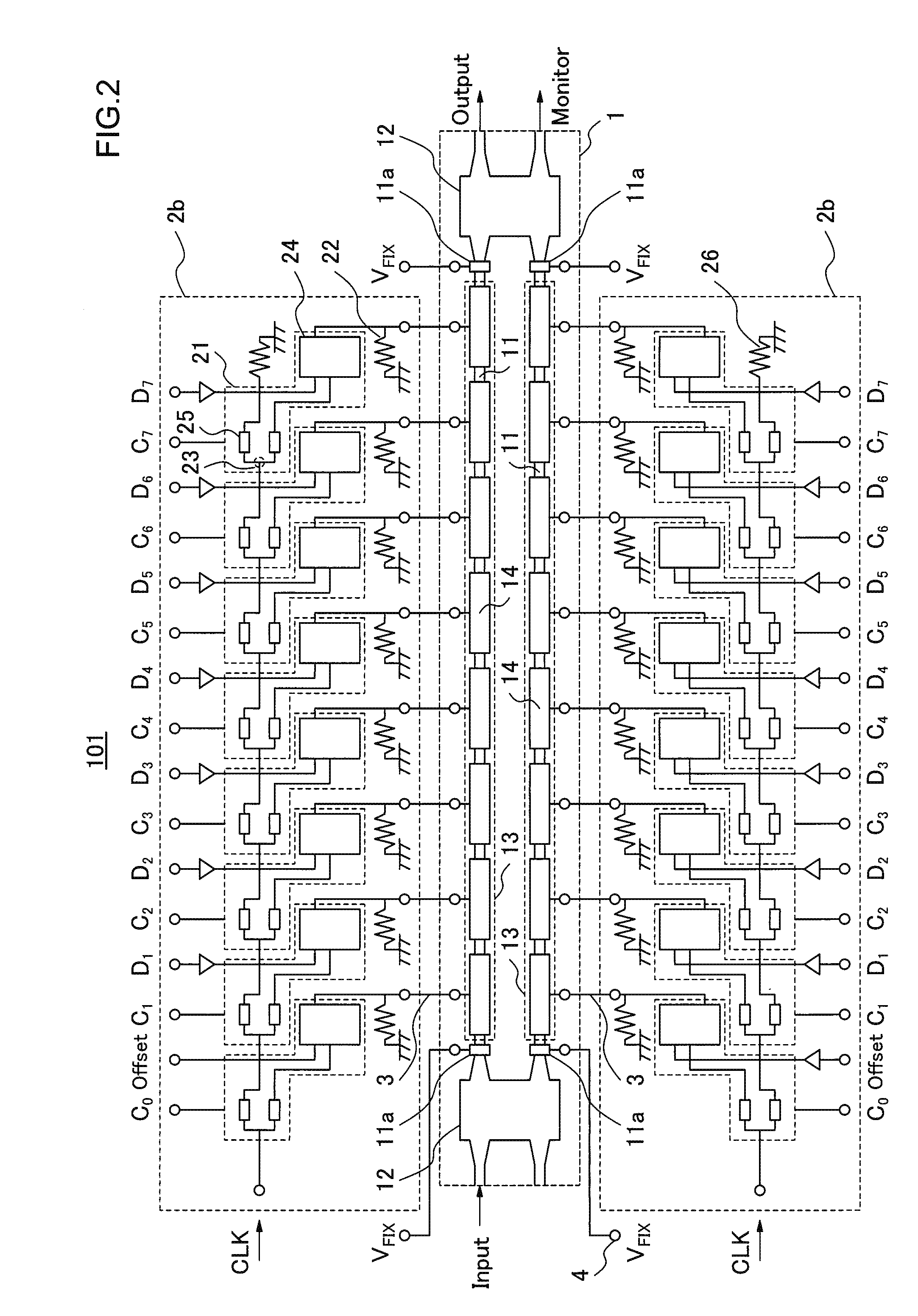

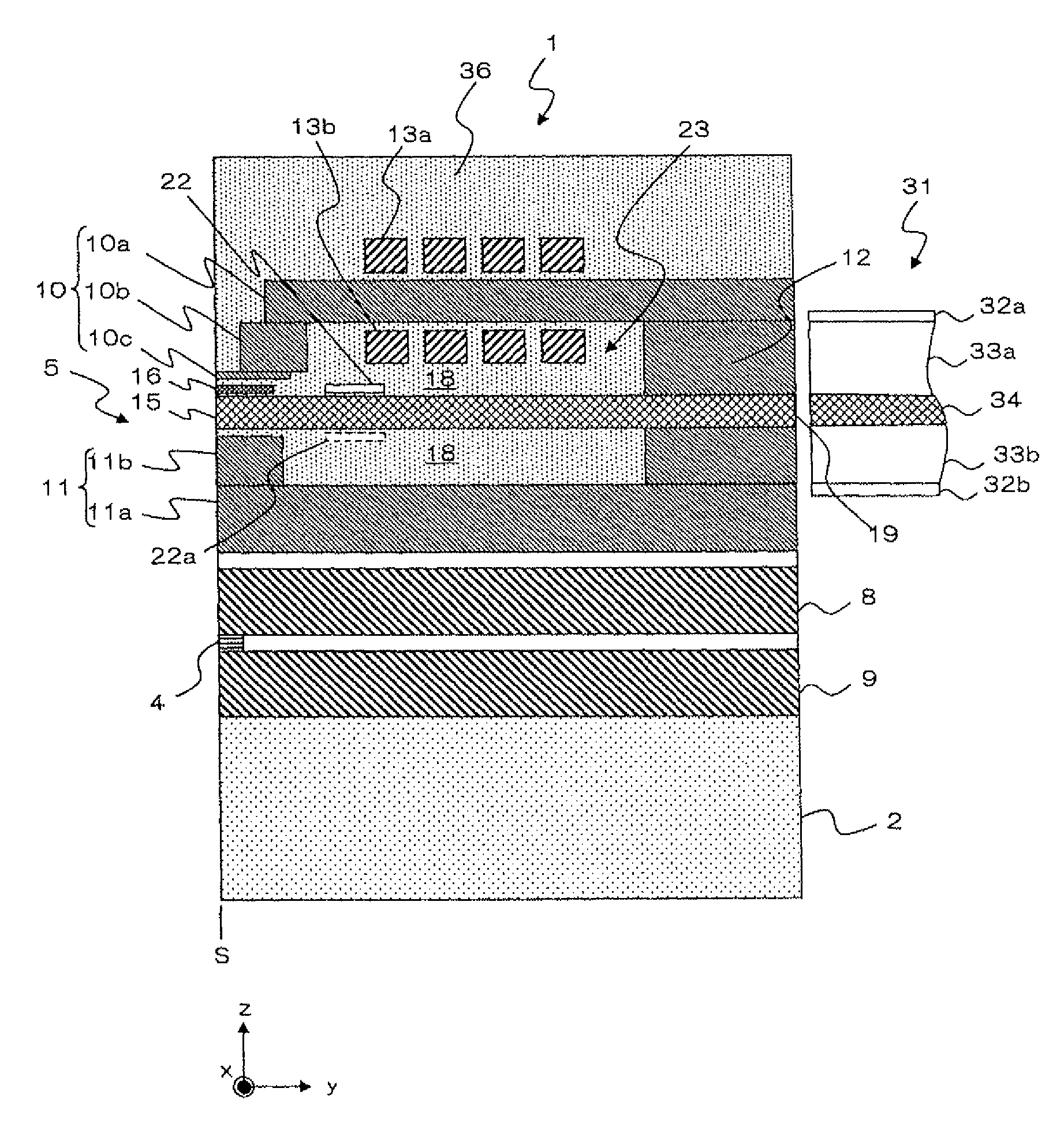

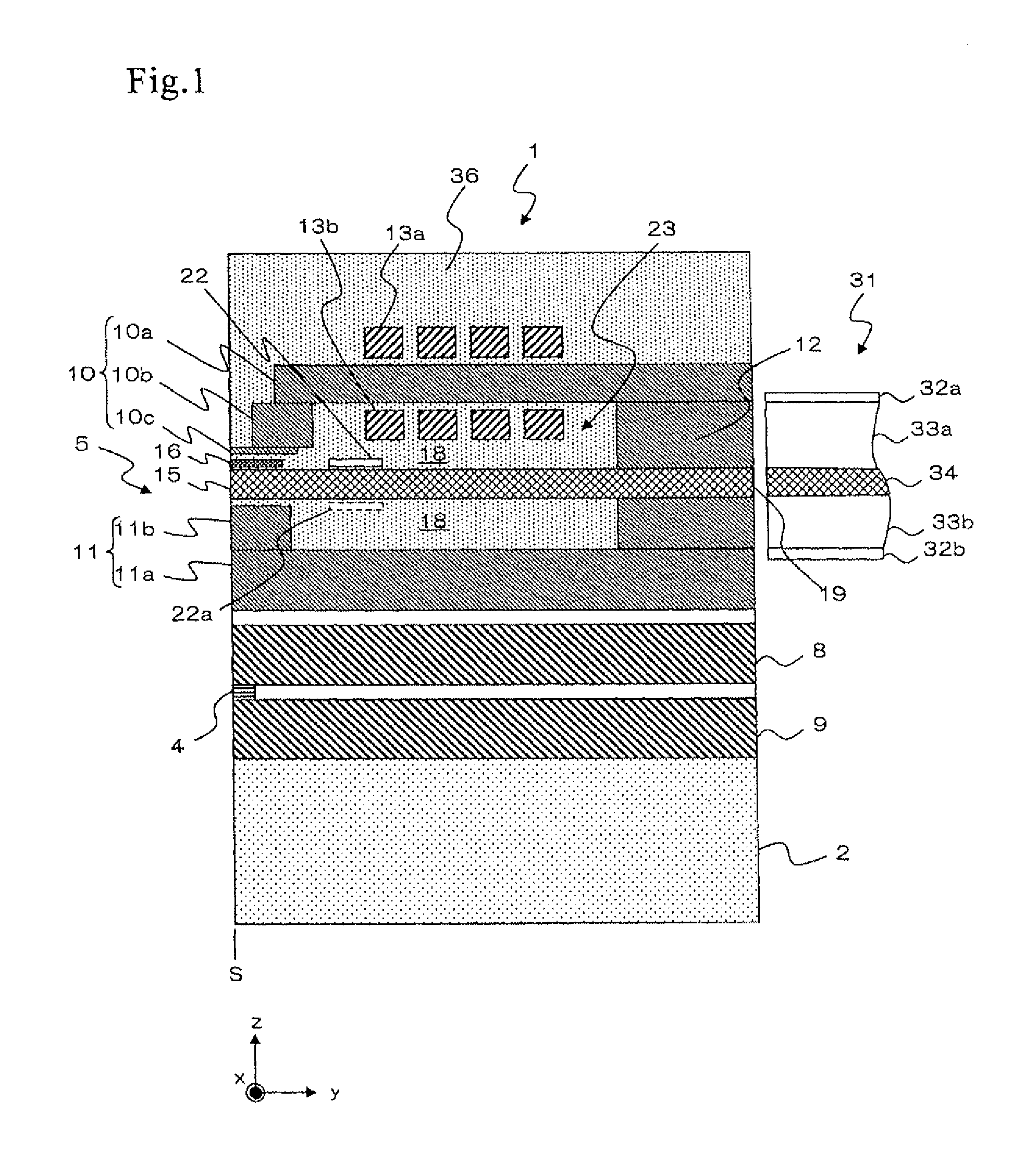

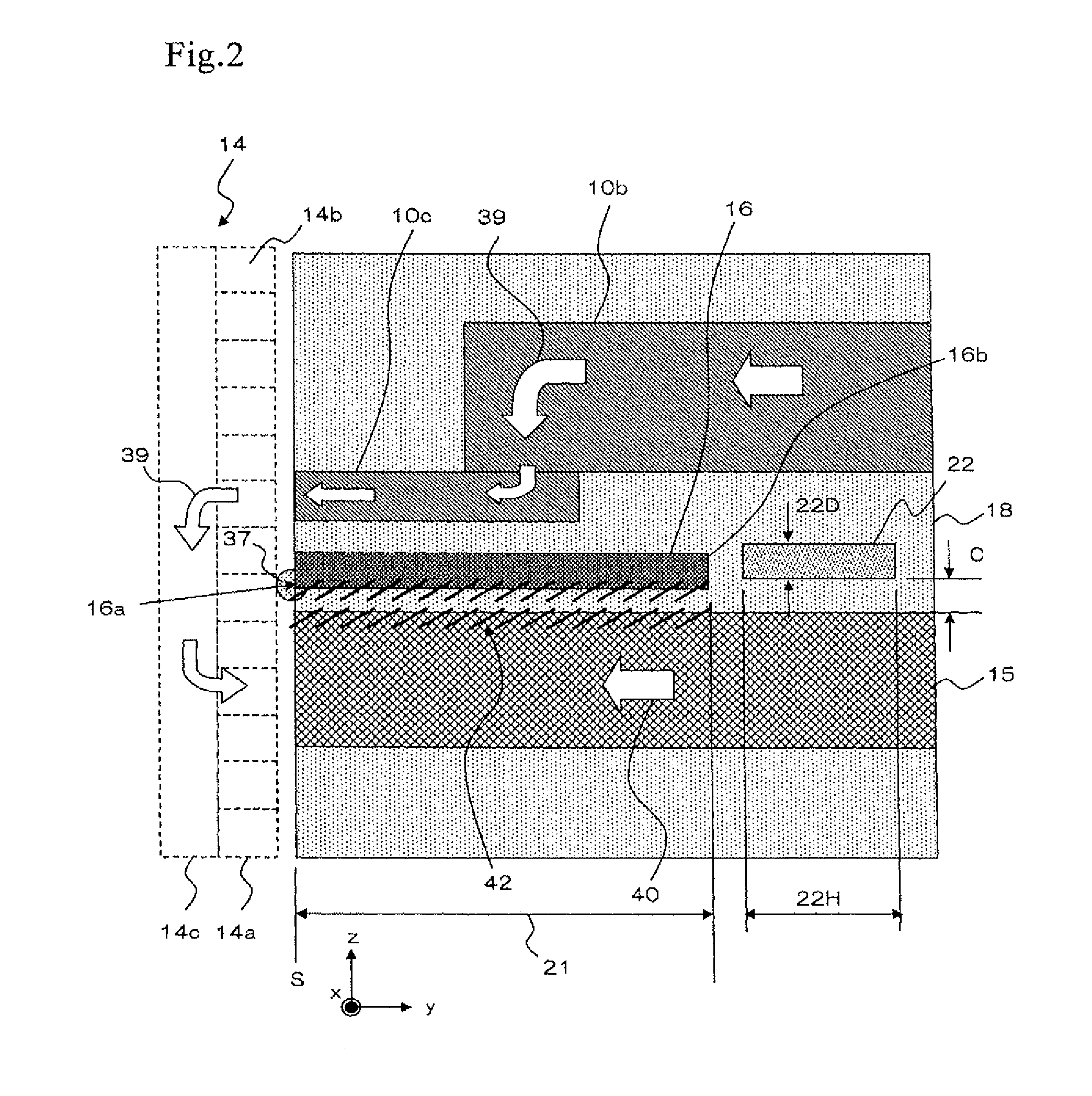

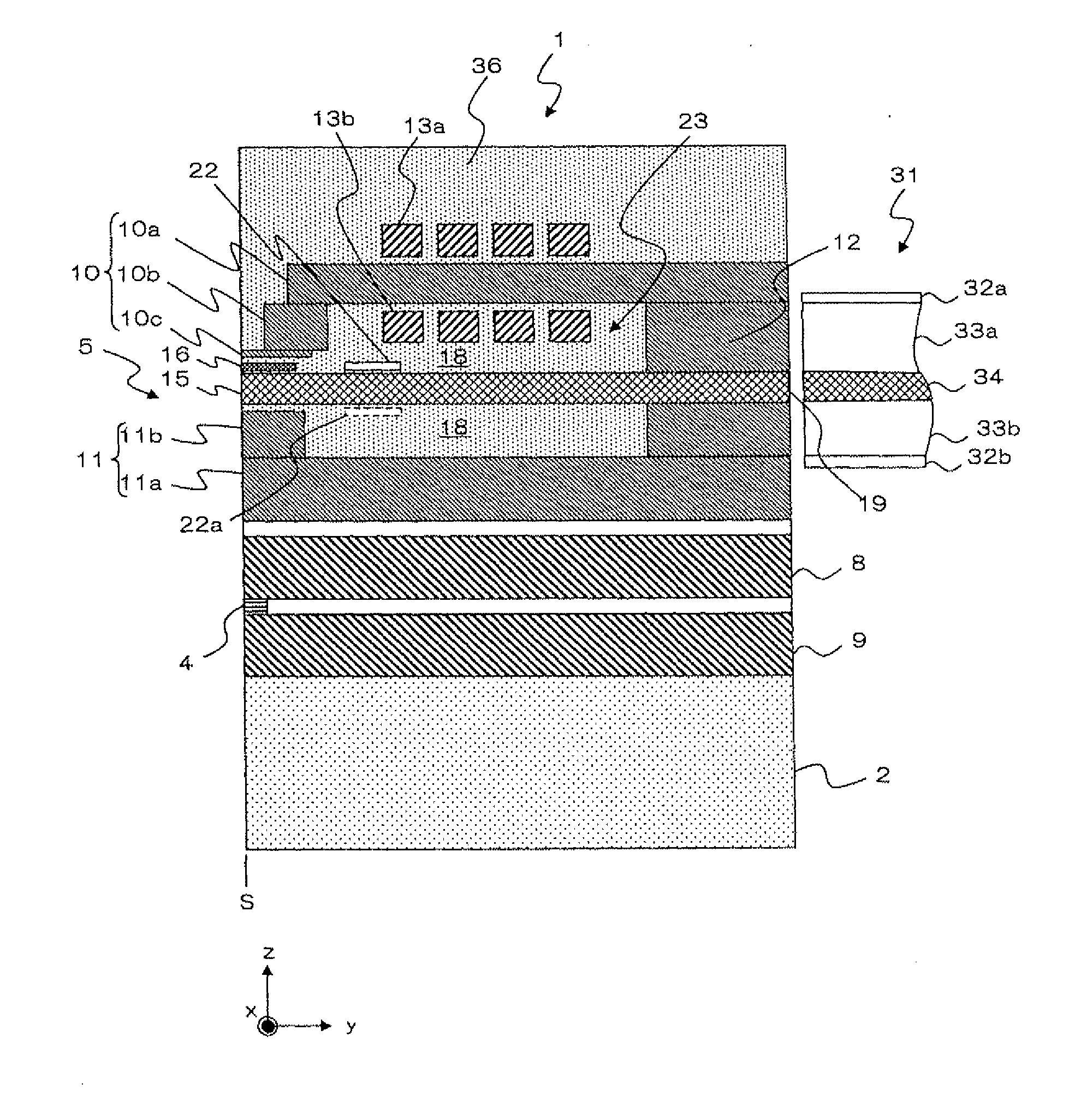

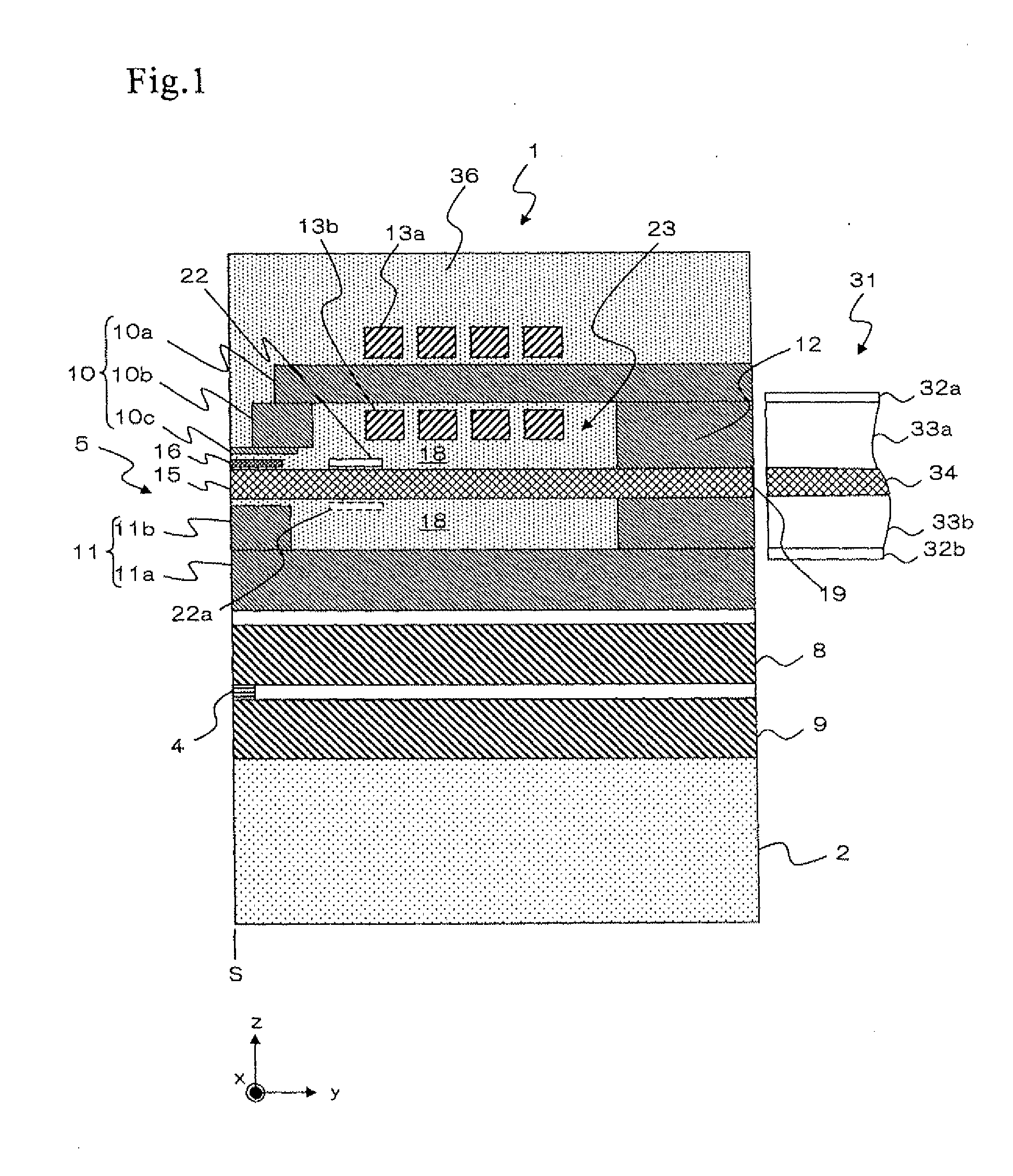

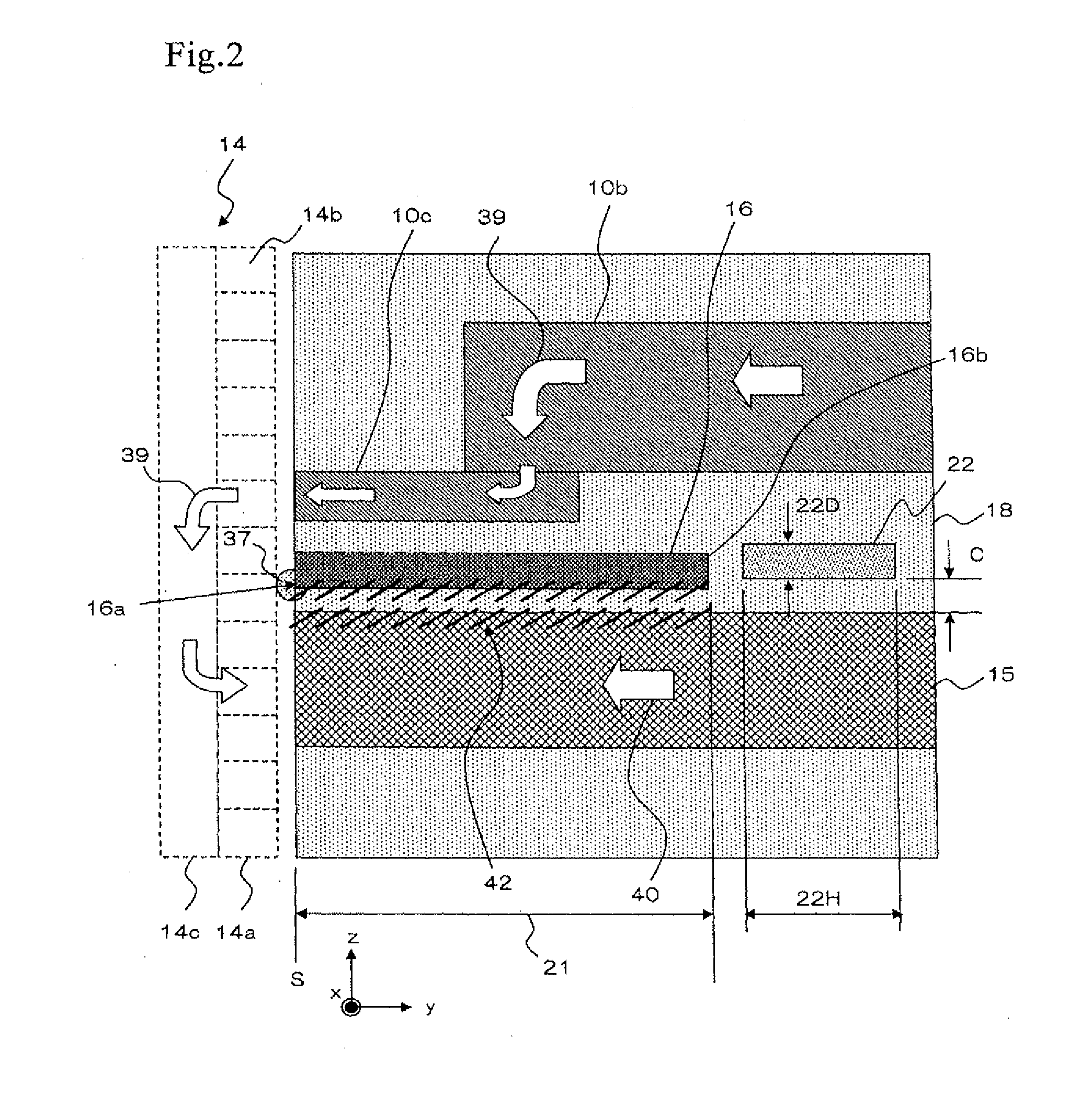

Optical modulator module and modulation method for optical signal

ActiveUS20140233962A1Less distortionElectromagnetic transmittersNon-linear opticsEngineeringWaveguide

An optical modulator module includes an optical modulator including an optical waveguide which conducts an inputted optical signal, and m modulator regions on the optical waveguide; and m discrete driving circuits serially connected to one another. The discrete driving circuits include a driving circuit which outputs a signal obtained from a digital input signal with a synchronization signal to one of the modulator regions, and a phase shifting circuit which outputs a signal resulting from giving a delay to a signal branched from the synchronization signal. A discrete driving circuit receives the signal outputted from the phase shifting circuit. Each of the modulator regions includes modulation electrodes, an electric field caused by a modulation electric signal applied to each of the modulation electrodes penetrates by a penetration length d, and every two adjacent modulation electrodes has a distance Lgap given by Lgap=2d.

Owner:NEC CORP

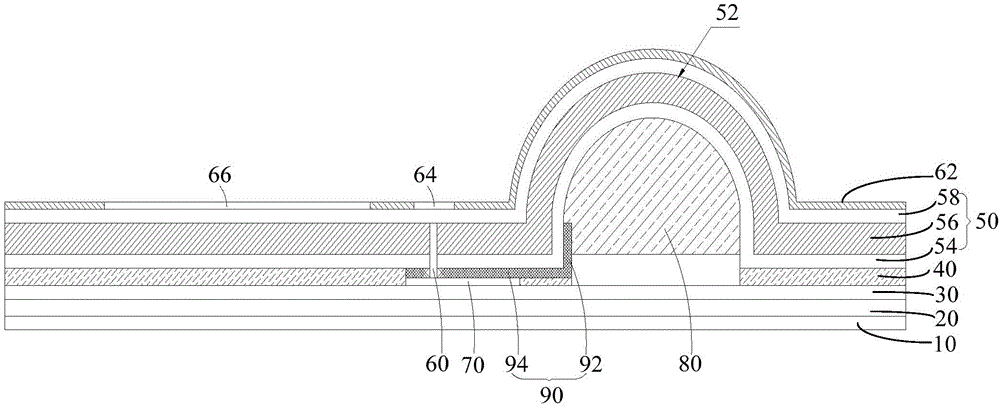

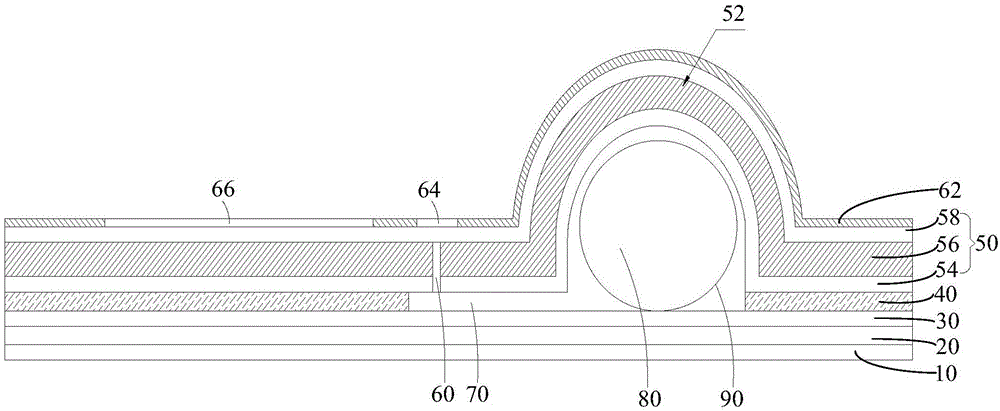

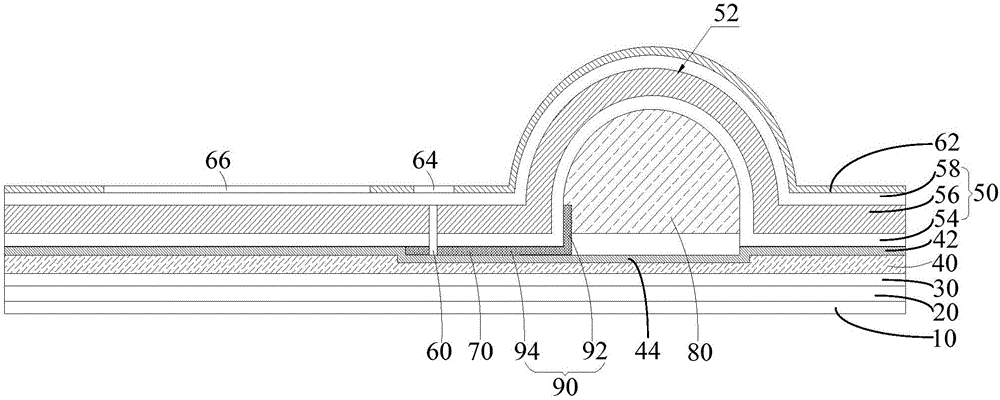

Time temperature indicator and manufacturing method thereof

ActiveCN105136330AMicroporous features are obviousHigh affinityThermometers using physical/chemical changesLiquid statePhase-change material

The invention discloses a time temperature indicator and a manufacturing method thereof. The time temperature indicator comprises a substrate layer, a bonding layer, an indication layer, a phase-change material and a blocking layer, wherein part of the indication layer forms a convex hull, and the convex hull is provided with a storage room; the indication layer comprises at least two interlayers and a sandwich layer arranged between the two interlayers, the interlayer between the sandwich layer and the bonding layer is a dense film layer, a notch passing through the sandwich layer is arranged on the dense film layer, and a liquid channel is communicated between the storage room and the notch; the phase-change material is located in the storage room, and the blocking layer is arranged between the phase-change material and the notch; and the liquid phase-change material can press the blocking layer broken under effects of an external force to enter the liquid channel and be penetrated in the sandwich layer through the notch, and the penetration length to the time length of the liquid phase-change material on the sandwich layer is in direct proportion. Due to the time temperature indicator of the invention, the liquid phase-change material can be prevented from passing through the interlayers to be penetrated in the sandwich layer.

Owner:SHENZHEN NINE STARS PRINTING & PACKAGING GRP

Wave guide that attenuates evanescent light of higher order TM mode

ActiveUS8149654B2High energy ratioCombination recordingRecord information storageLaser lightWaveguide

Owner:TDK CORPARATION

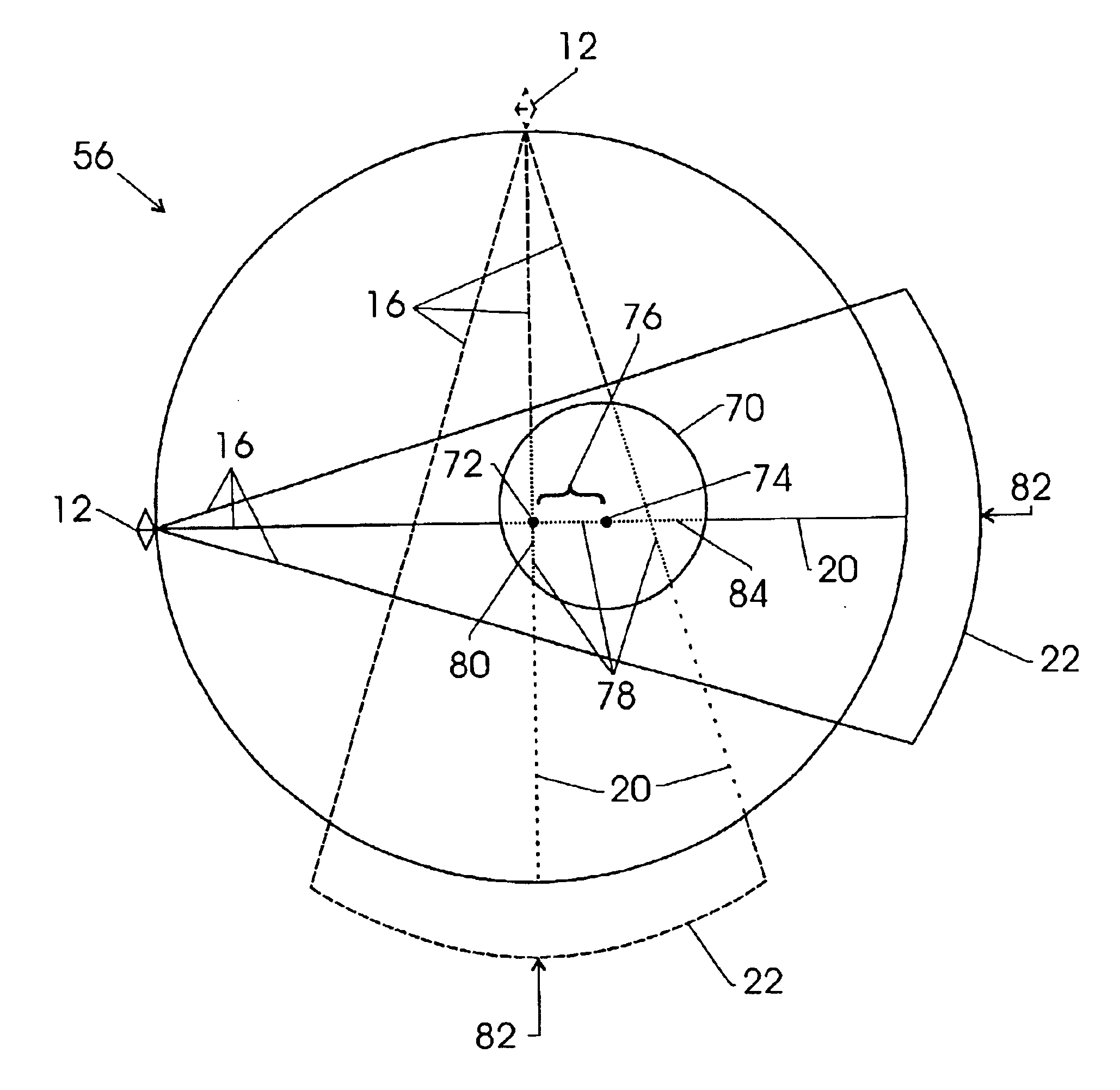

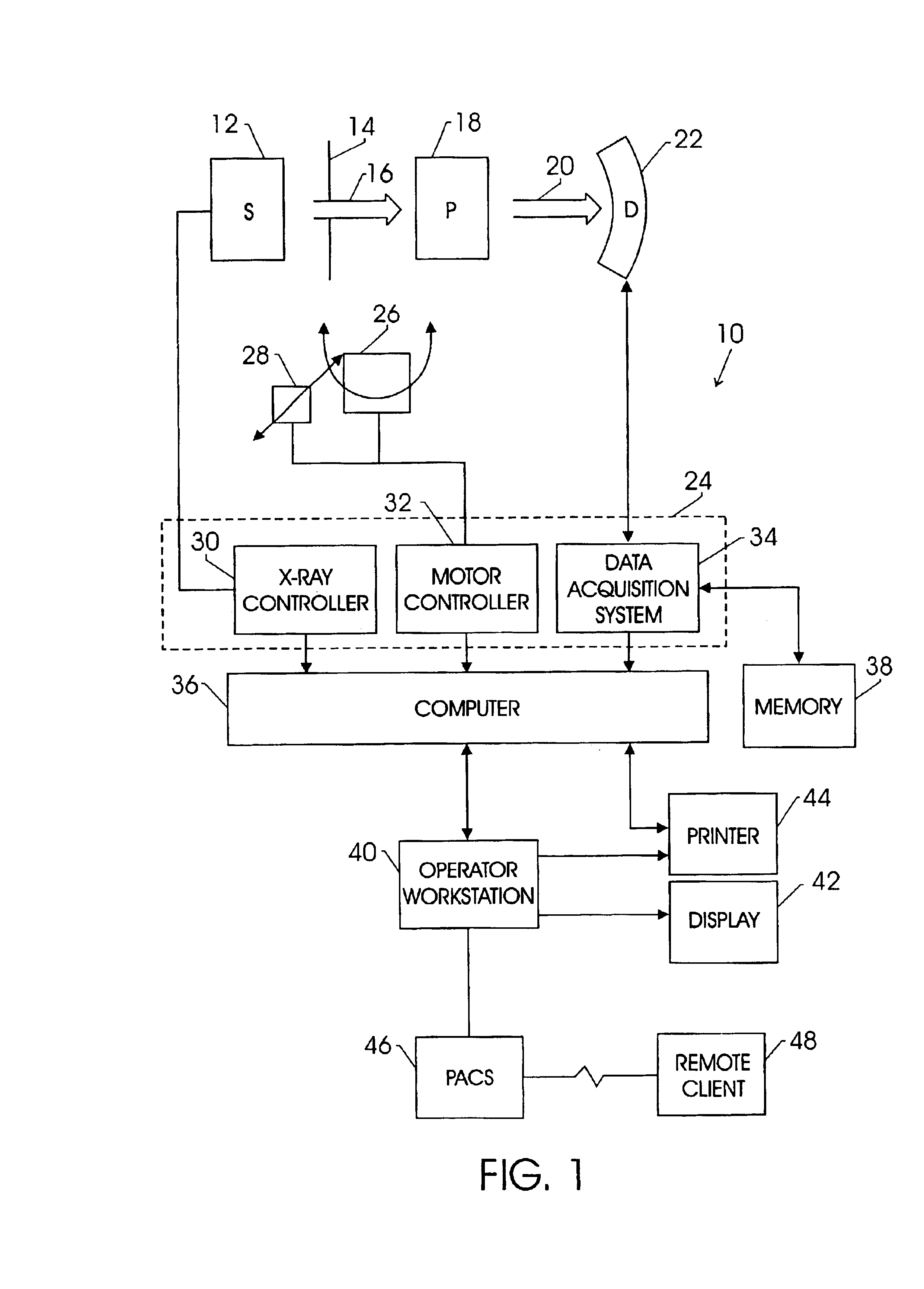

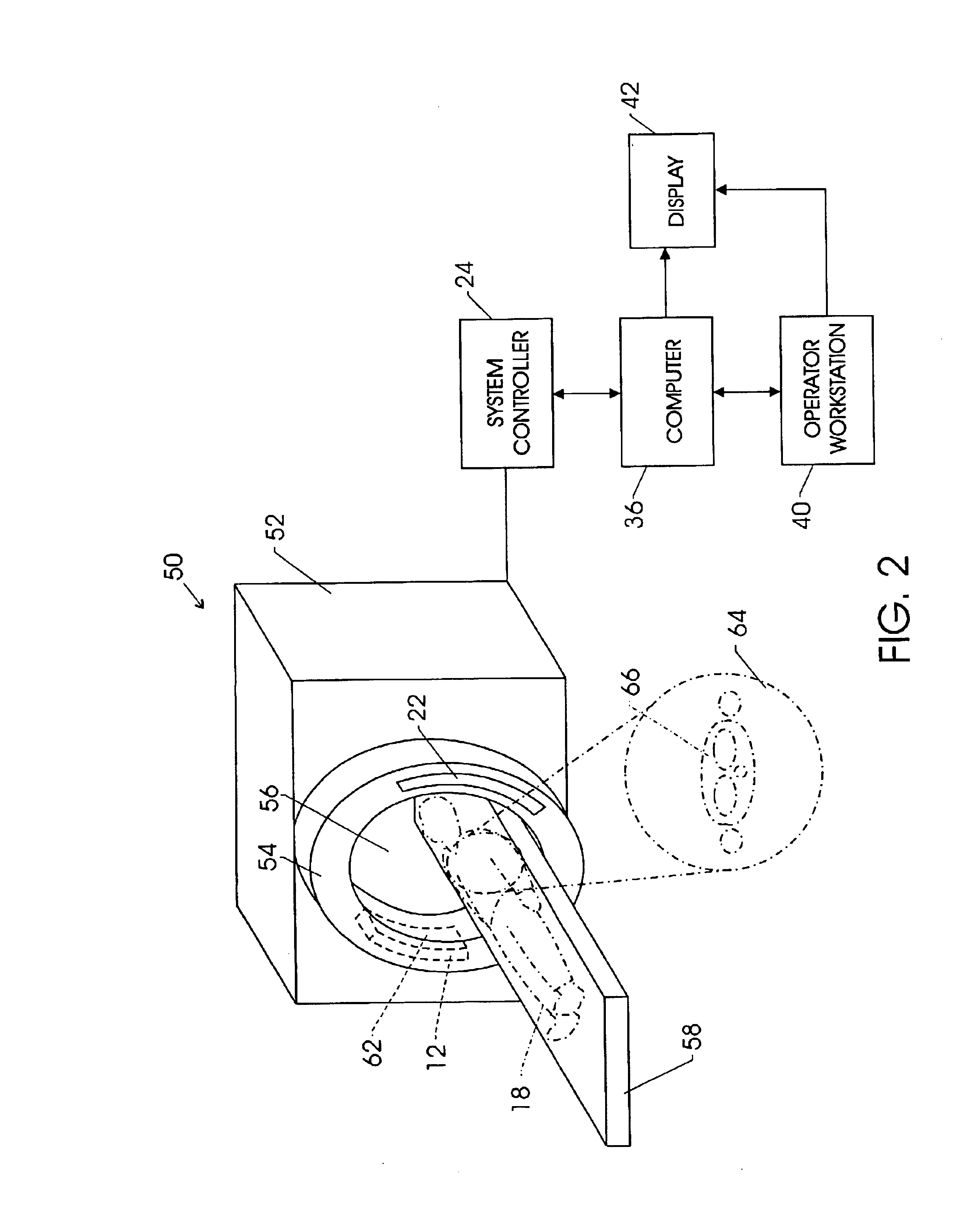

Method and apparatus for calibrating detector spectral response

InactiveUS6848827B2Increase coverageQuick calibrationMaterial analysis using wave/particle radiationRadiation/particle handlingSpectral responseOffset calibration

The present technique provides for the spectral calibration of the detector elements of a CT detector using one or more offset calibration phantoms. The offset phantoms provide greater coverage of the detector elements as well as spectral response data associated with penetration lengths ranging in length from a minimum chord of the phantom to the diameter of the phantom. The spectral response as a function of penetration length can be obtained for each detector element by comparing the fitting of each projection view to the corresponding measured projection view over all view angles. The fitting information may then be employed to derive the coefficients of the spectral response curve for each detector element, which may in turn be employed to provide rapid correction of the spectral response for each element.

Owner:GENERAL ELECTRIC CO

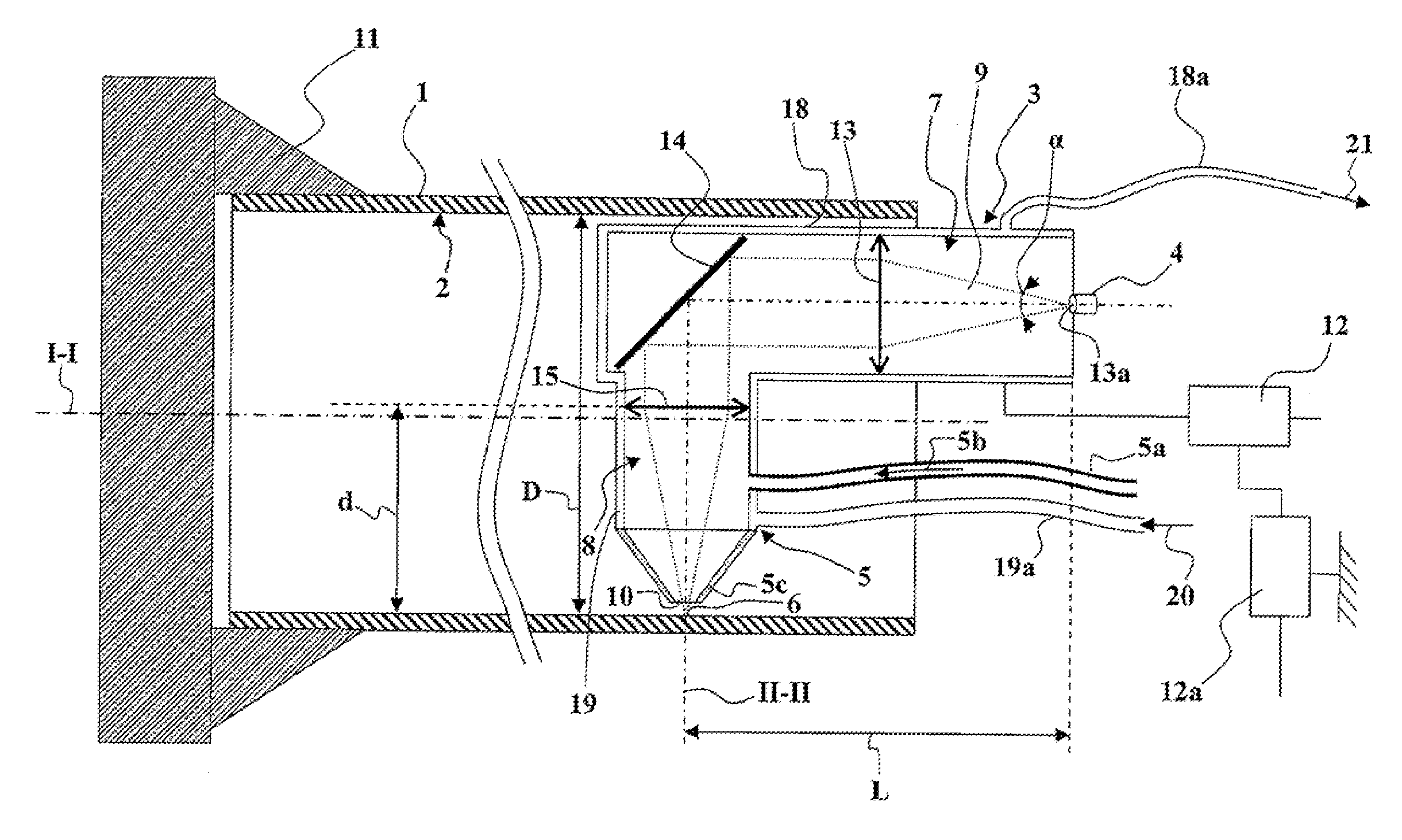

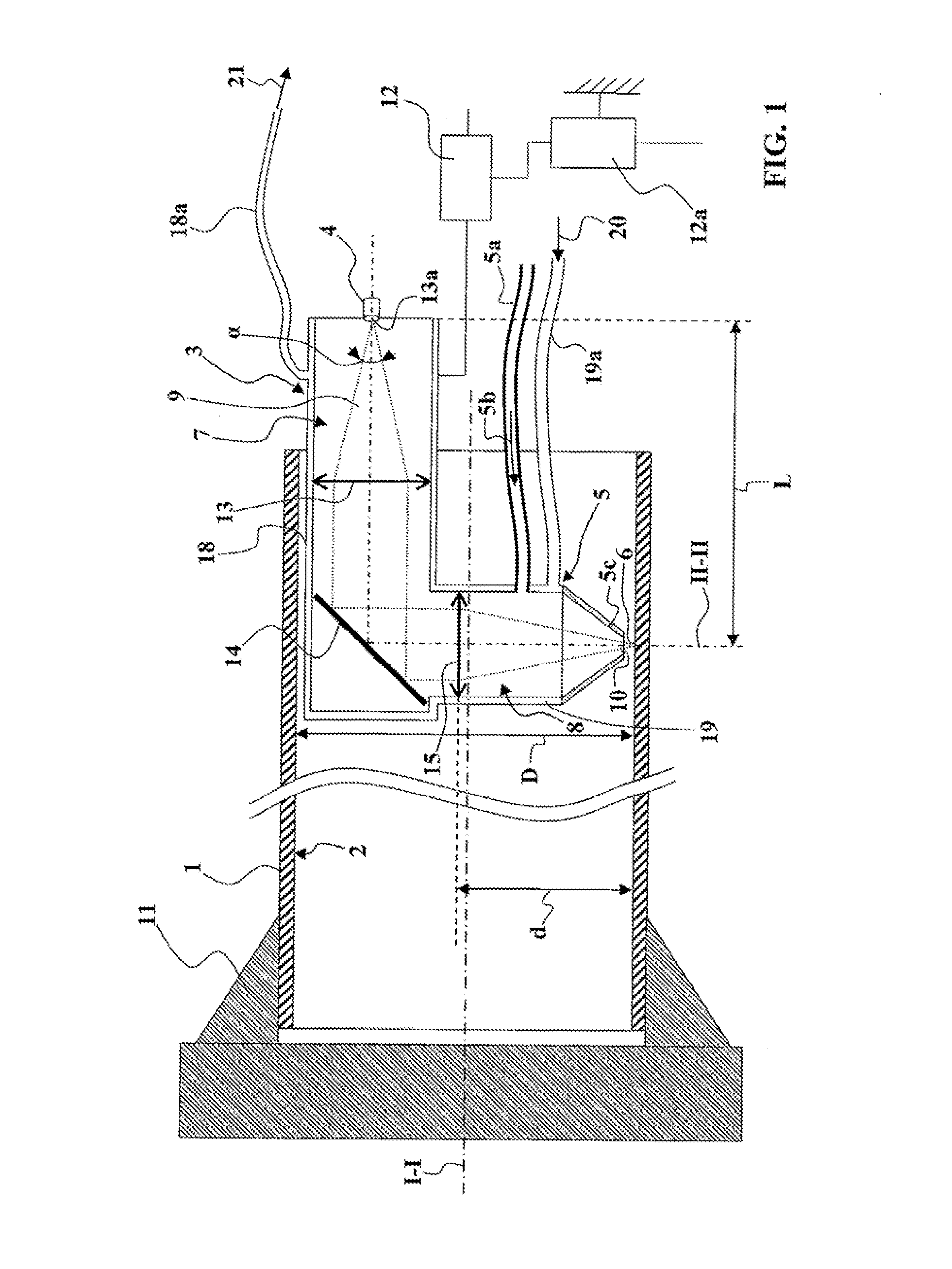

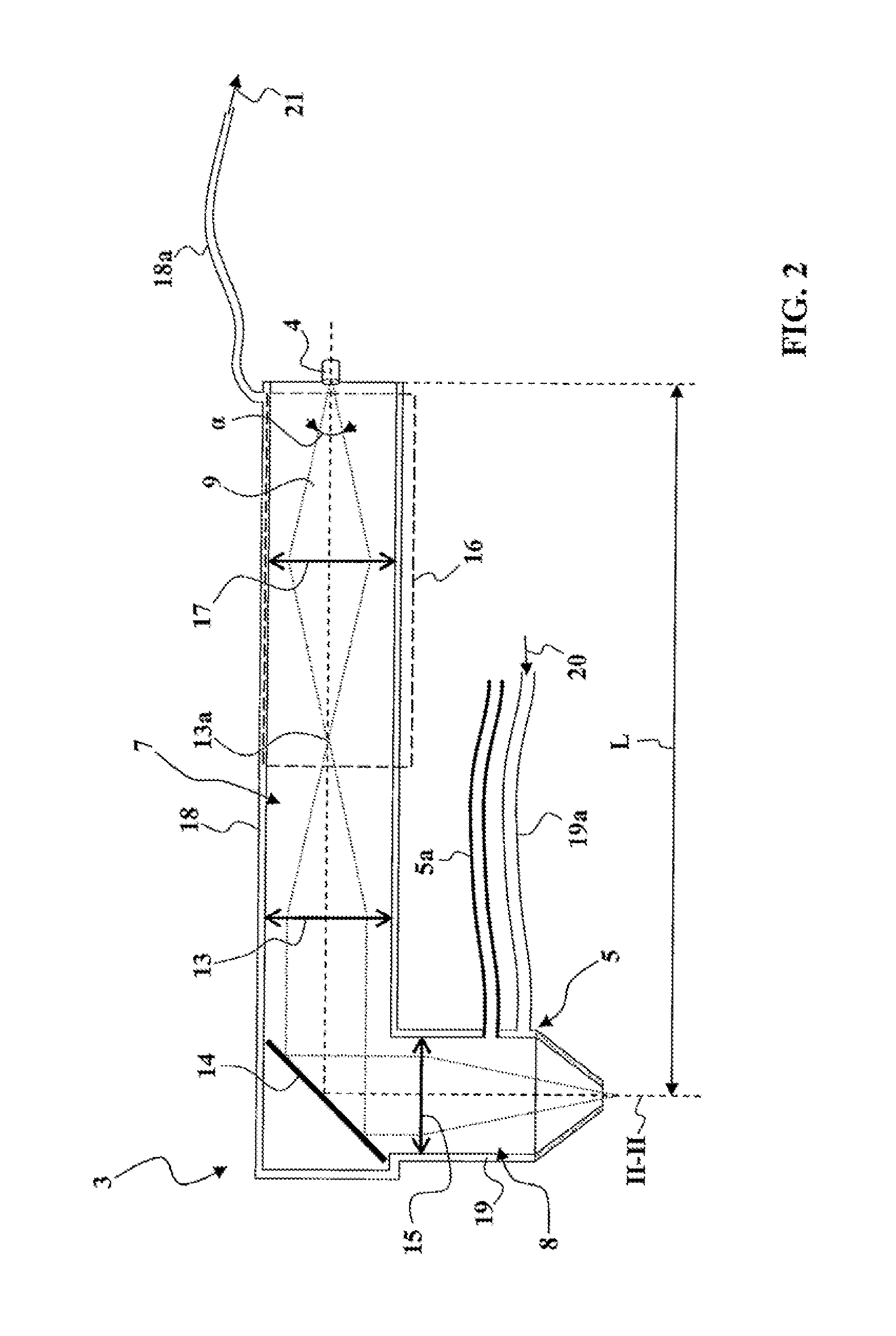

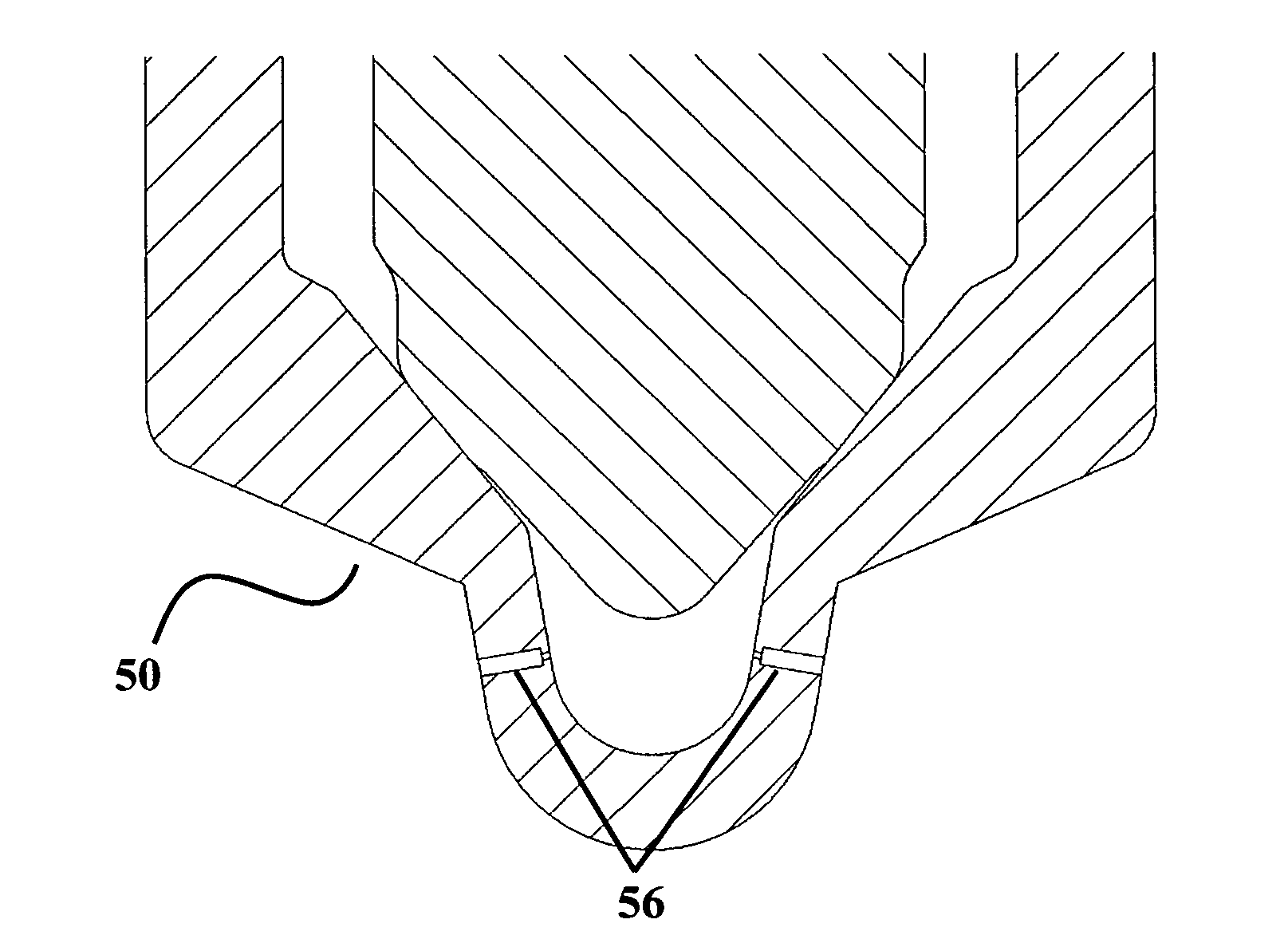

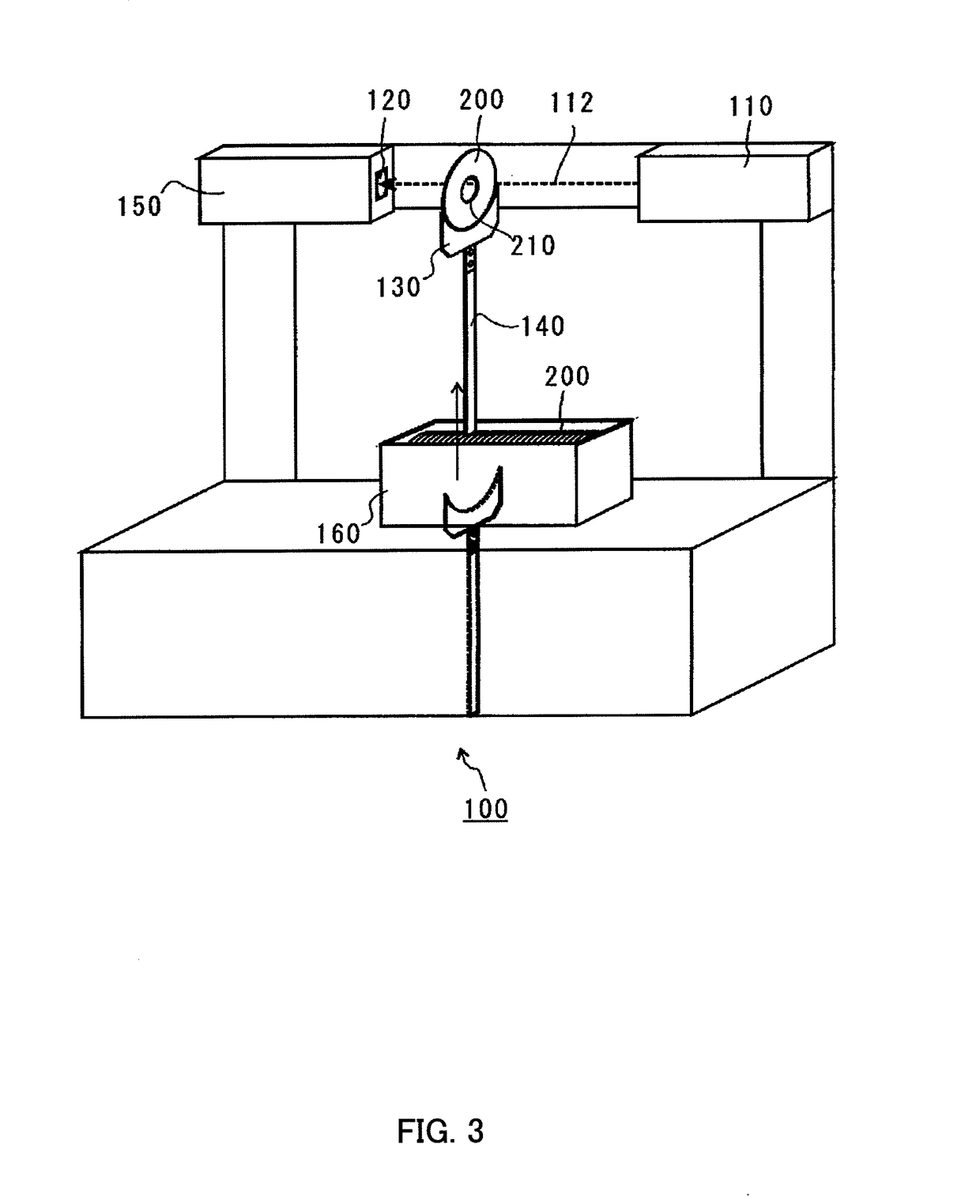

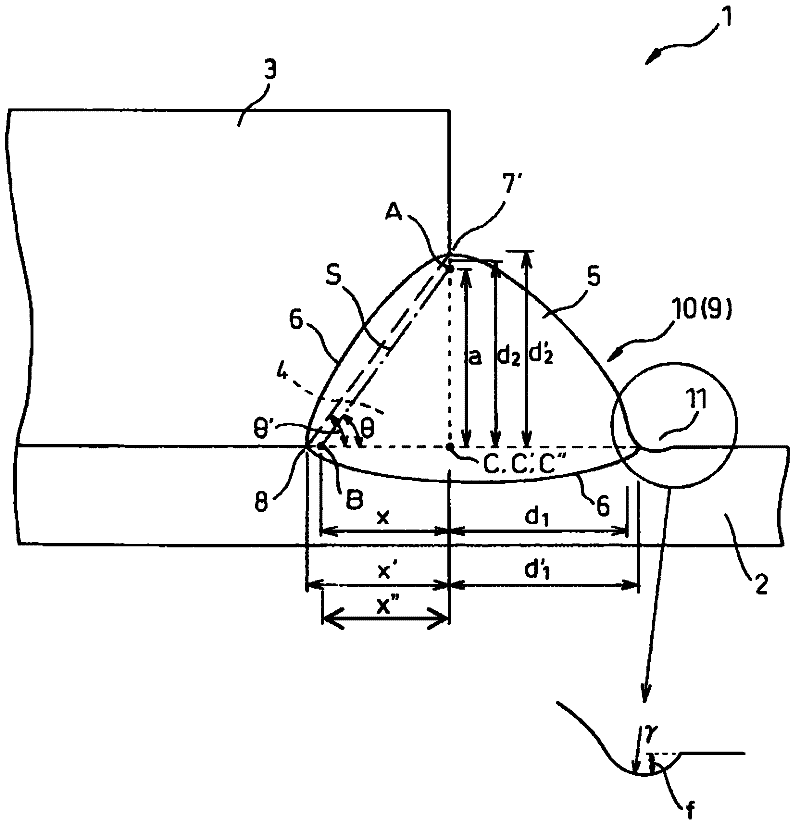

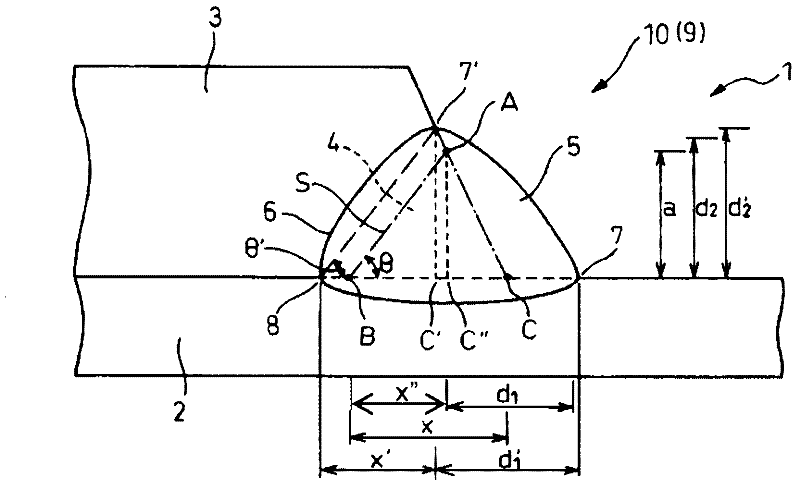

Concave laser-resurfaced part, method and device for producing it

InactiveUS20080127891A1Free from riskReduced effectivenessLiquid surface applicatorsOptical resonator shape and constructionMetal alloyRefractory

Device for resurfacing a concave face (2) of a tubular part (1) by supplying resurfacing material and energy by a laser, comprising a laser source for generating a laser beam (9), resurfacing material delivery means (5) based on hard refractory particles and metal alloy particles, in order to deliver the resurfacing material close to a resurfacing zone (6) on the concave face (2) of the tubular part (1) to be resurfaced, laser beam delivery means (7) and directing means (8) for directing the laser beam (9) into the resurfacing zone (6). The laser source is a diode laser (4) and the laser beam delivery means (7) conduct the latter over a penetration length (L) along a penetration direction and then the directing means (8) deflect the laser beam (9) into a radial direction (II-II) away from the penetration direction, so that the laser source may lie outside the tubular part (1) and the laser beam delivery means (7) may be axially engaged completely or partly in the tubular part (1).

Owner:TECHNOSYM SRL

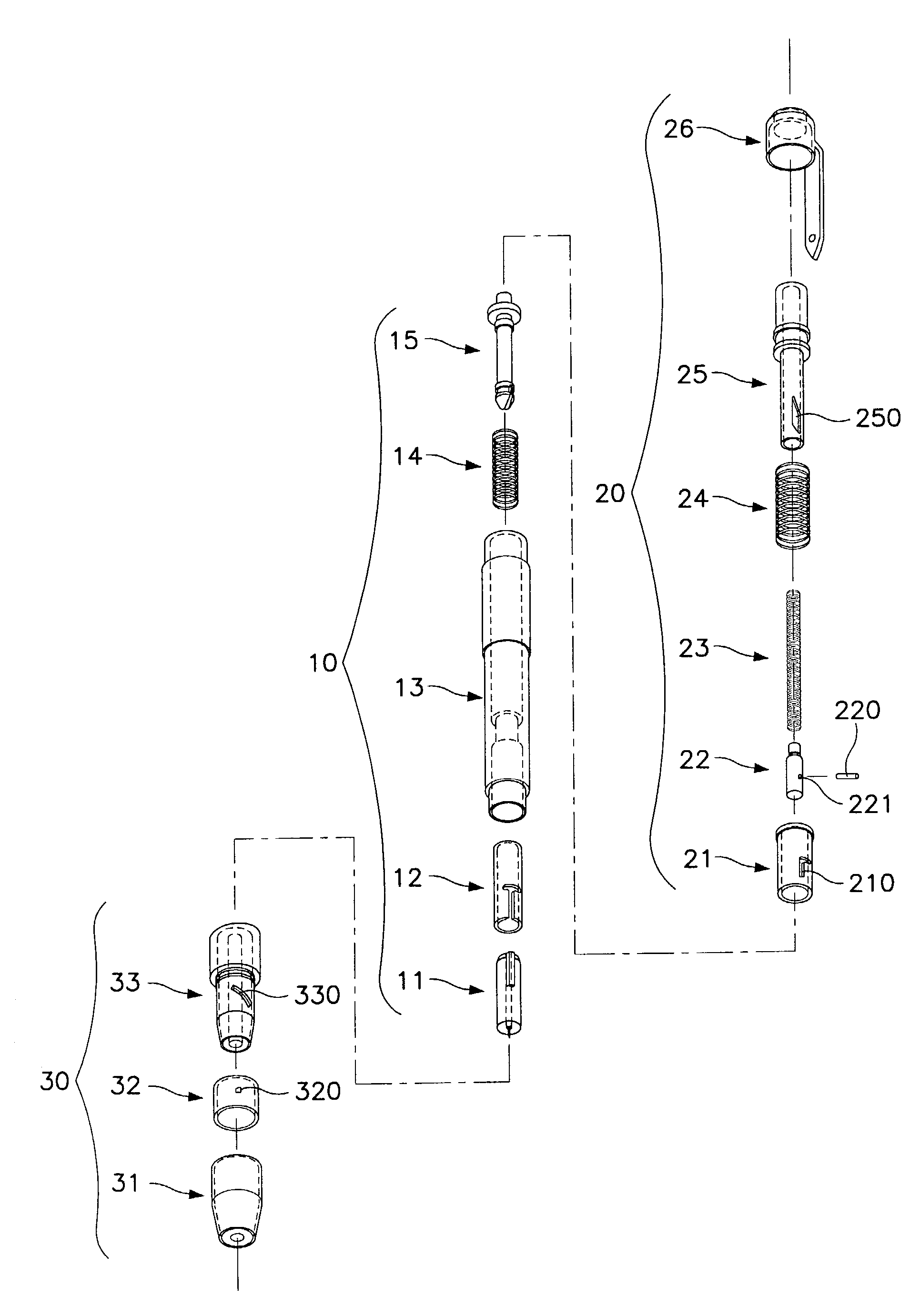

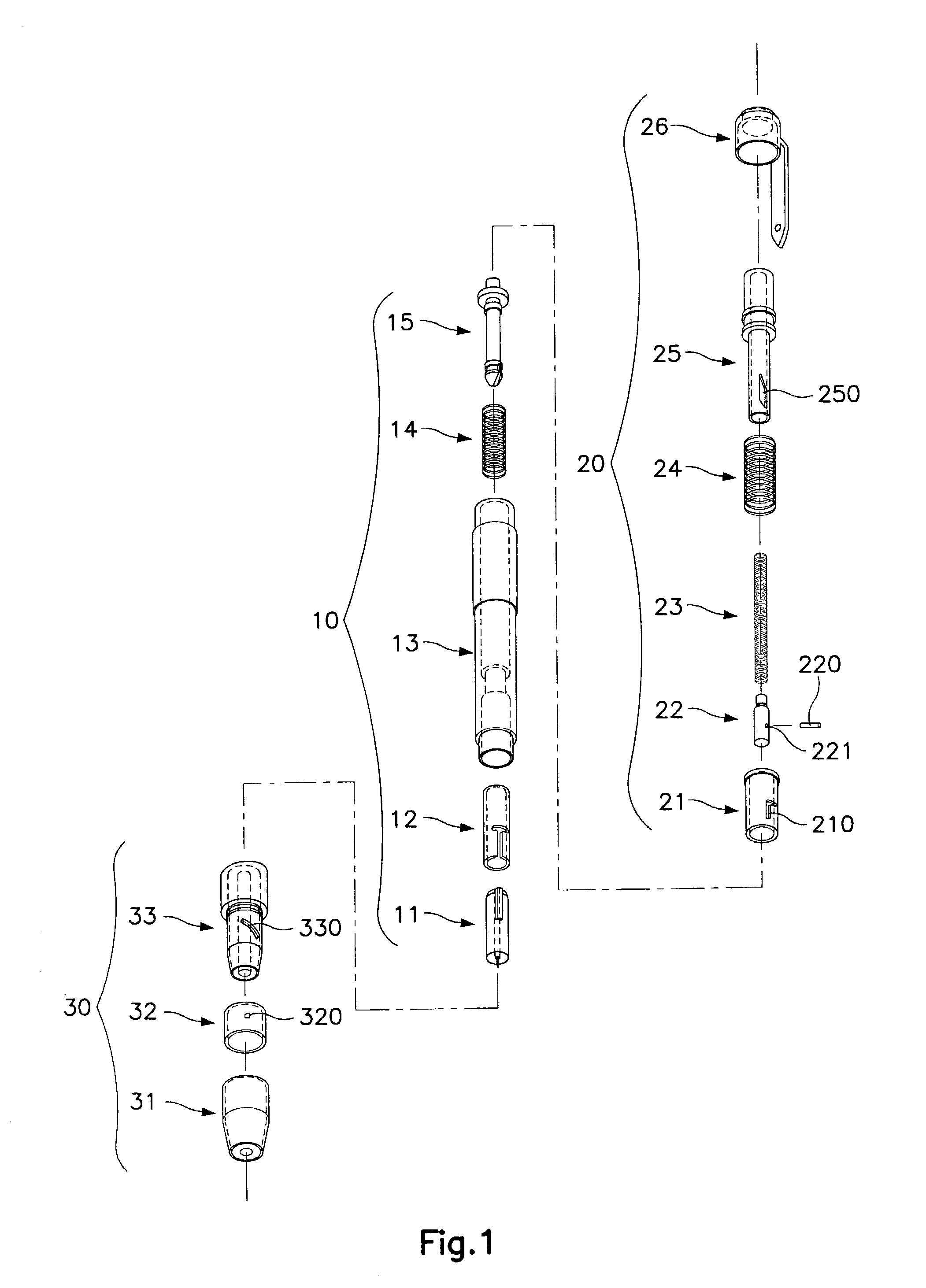

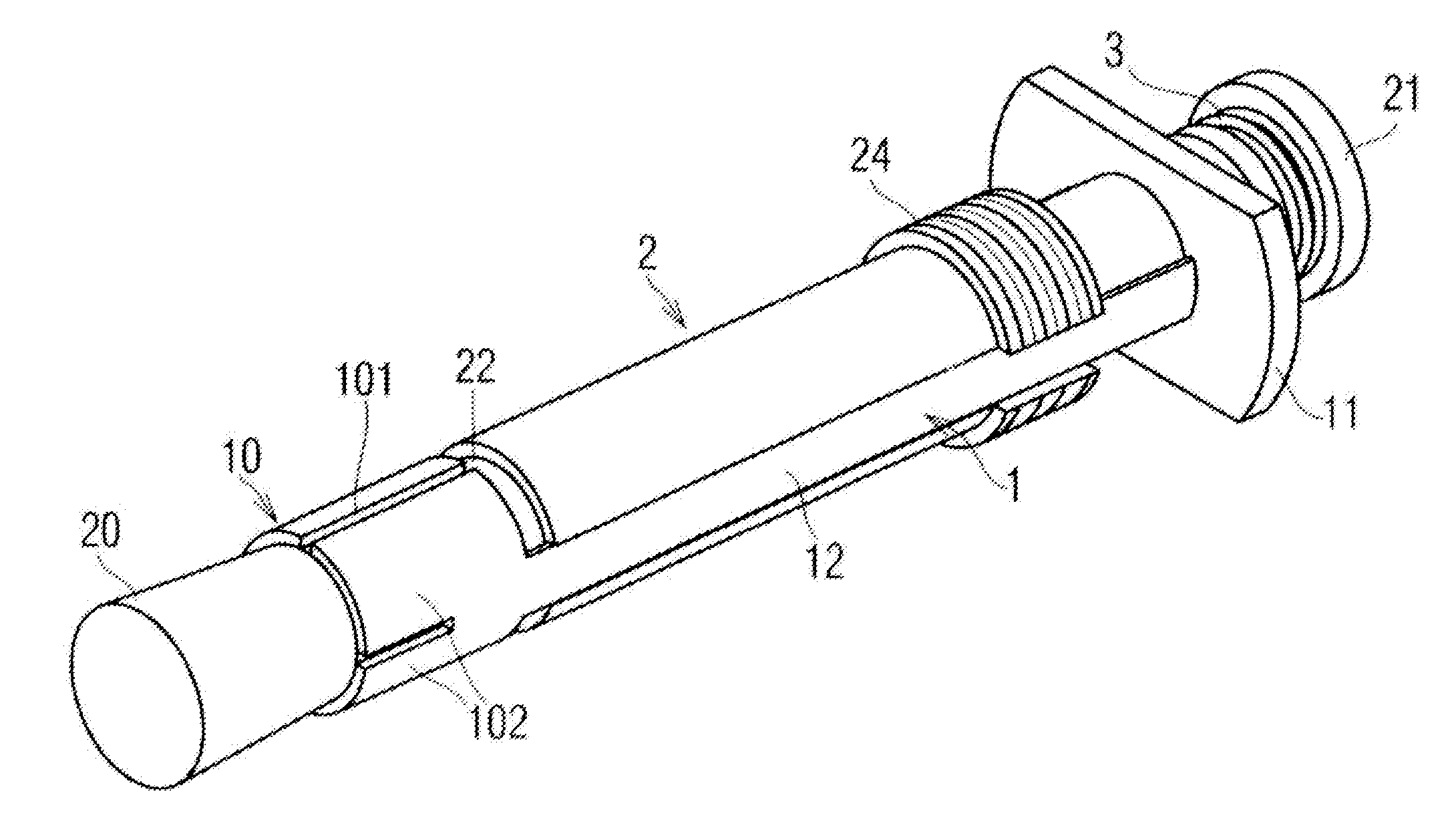

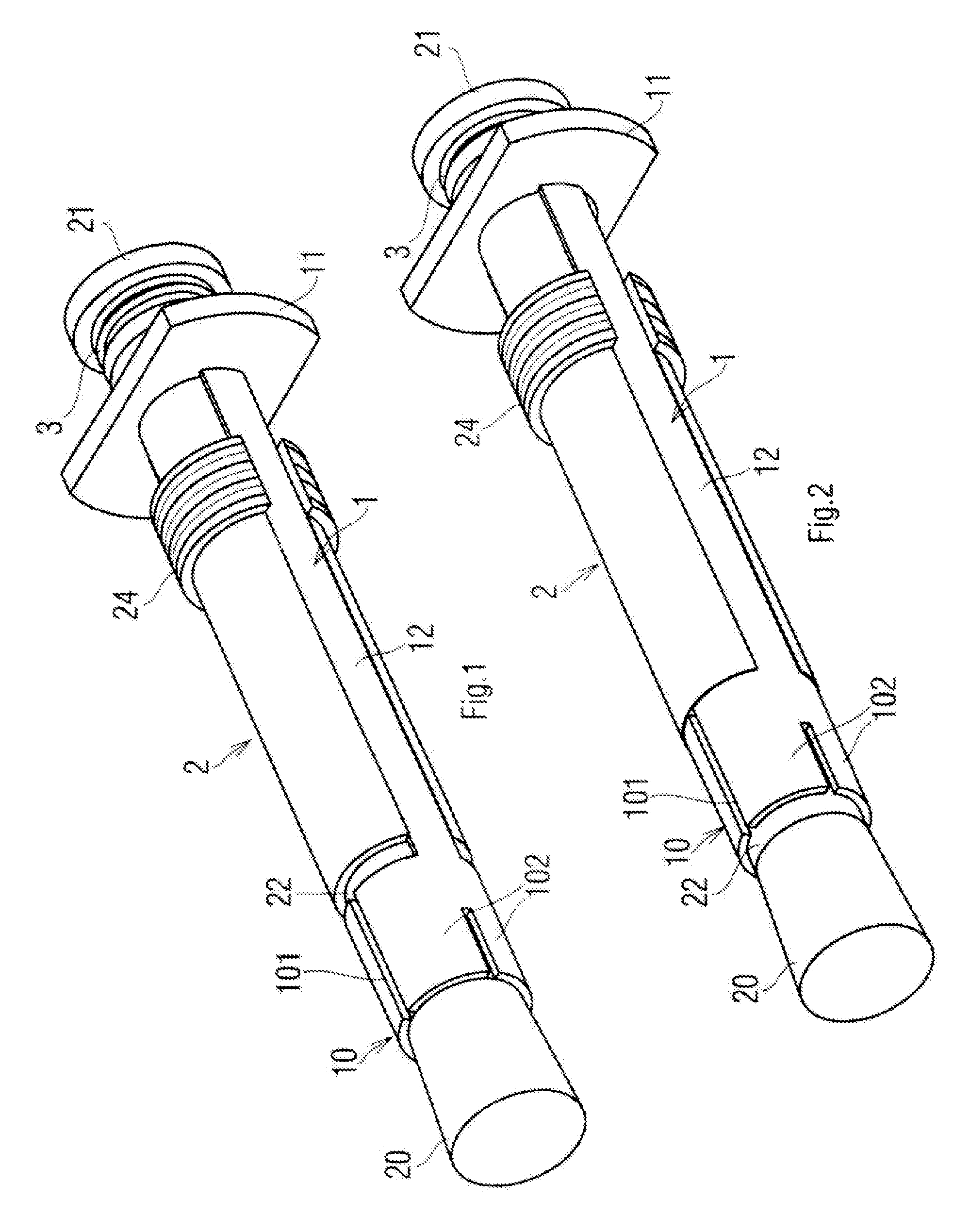

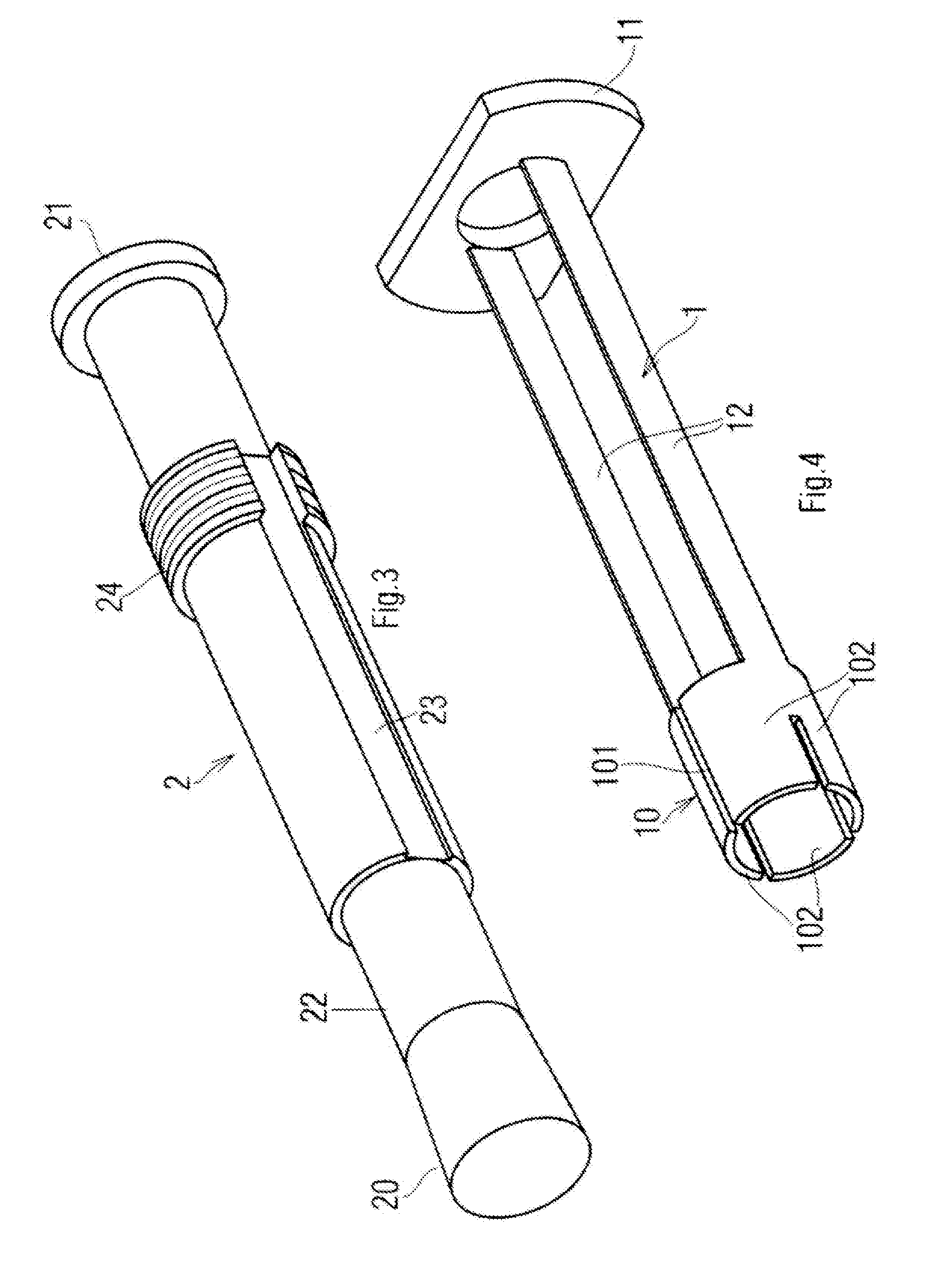

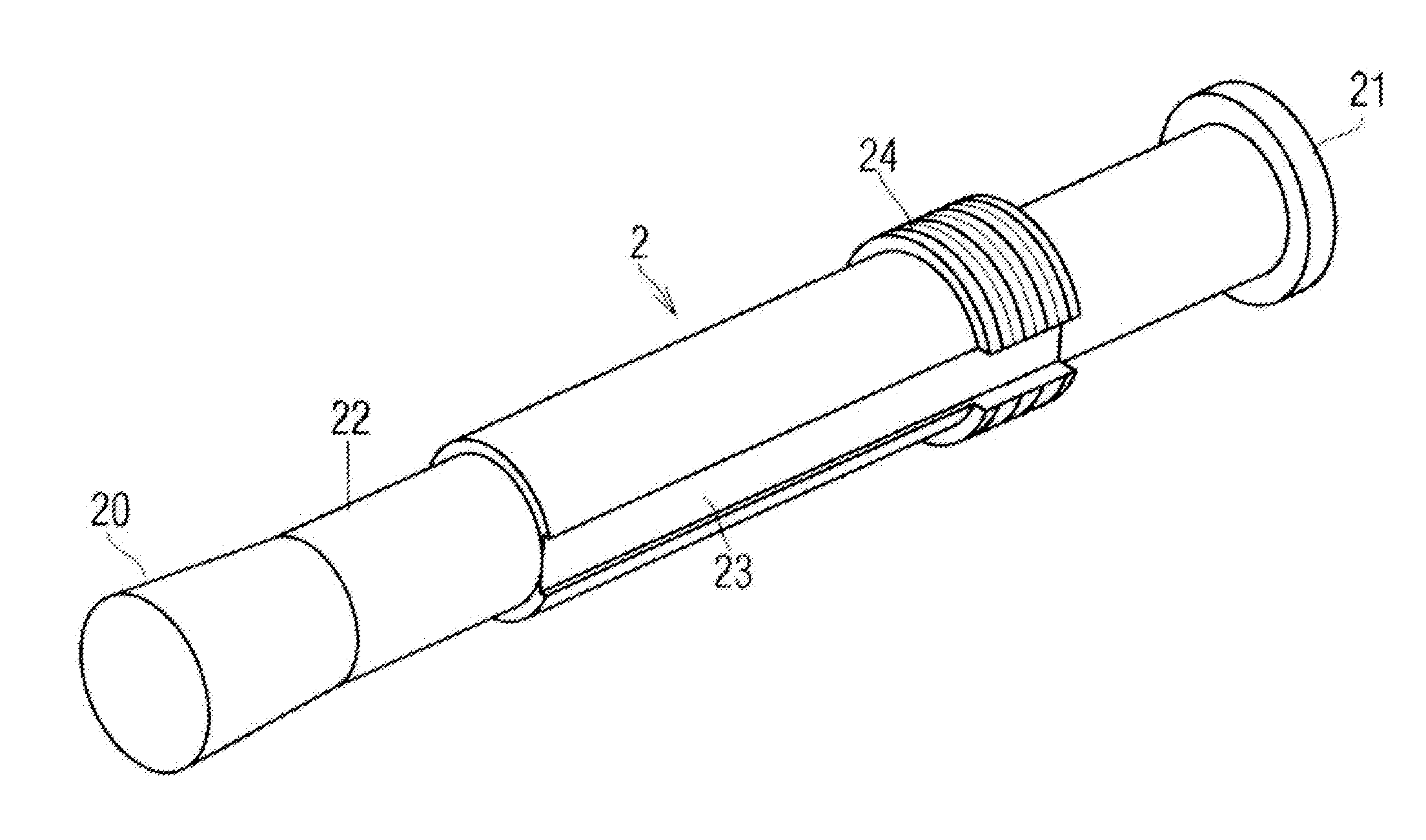

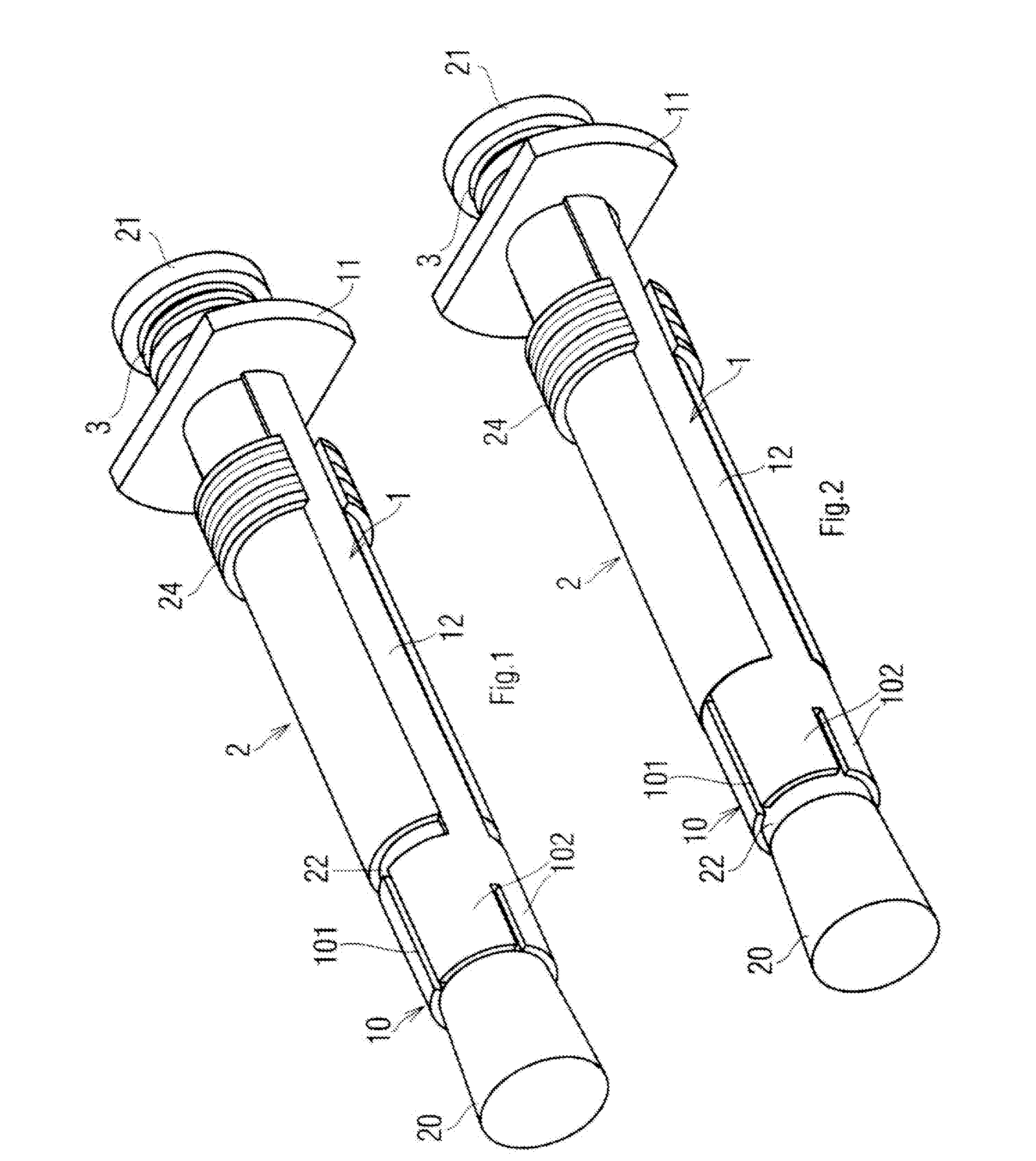

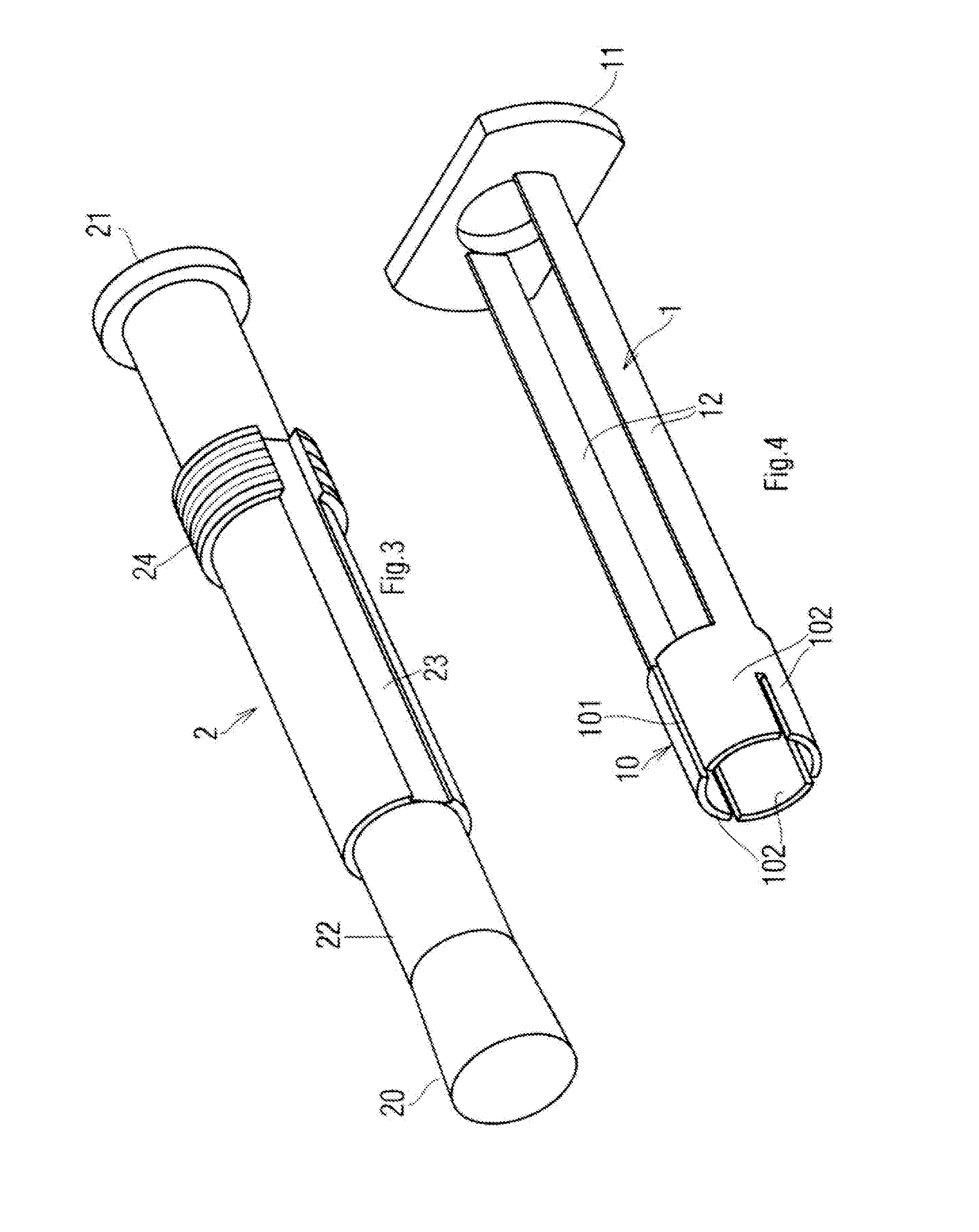

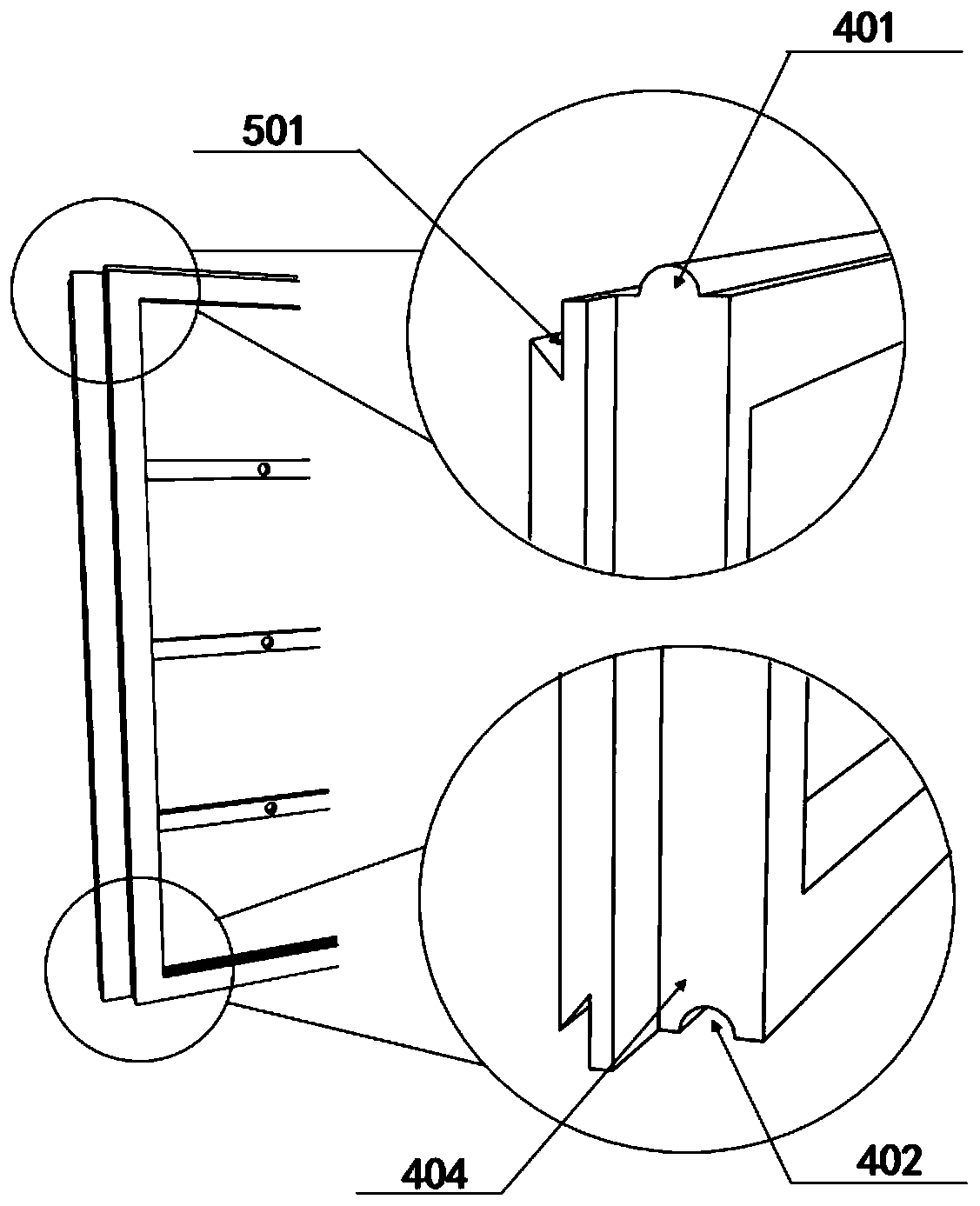

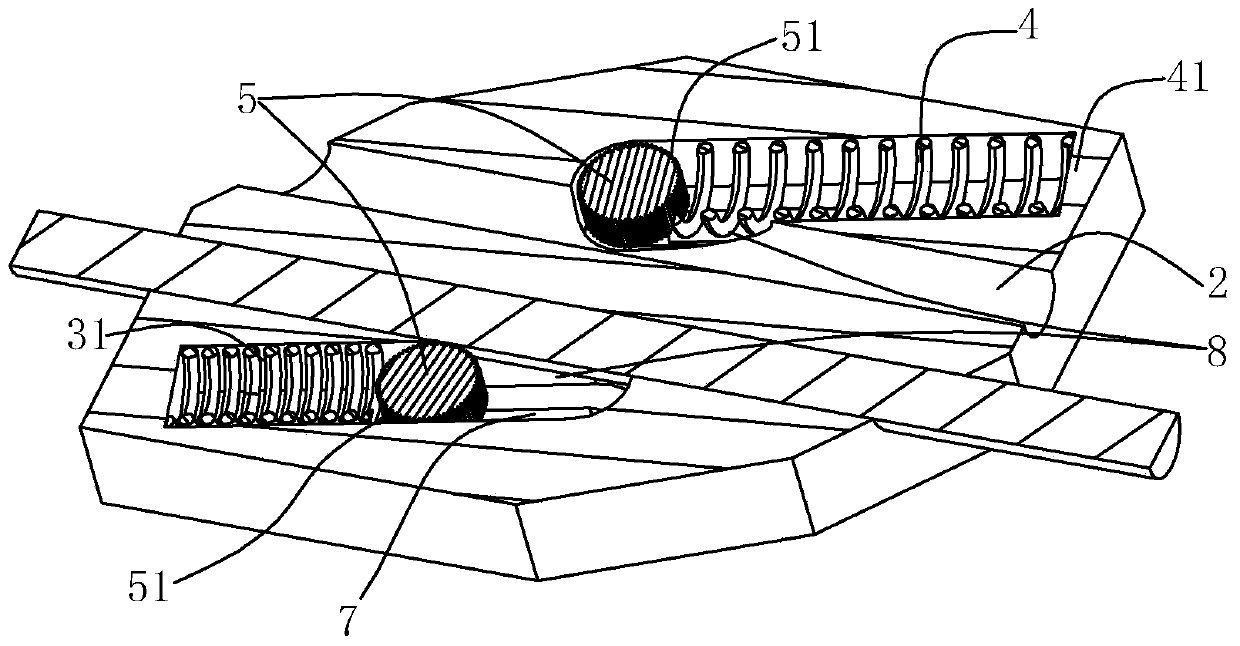

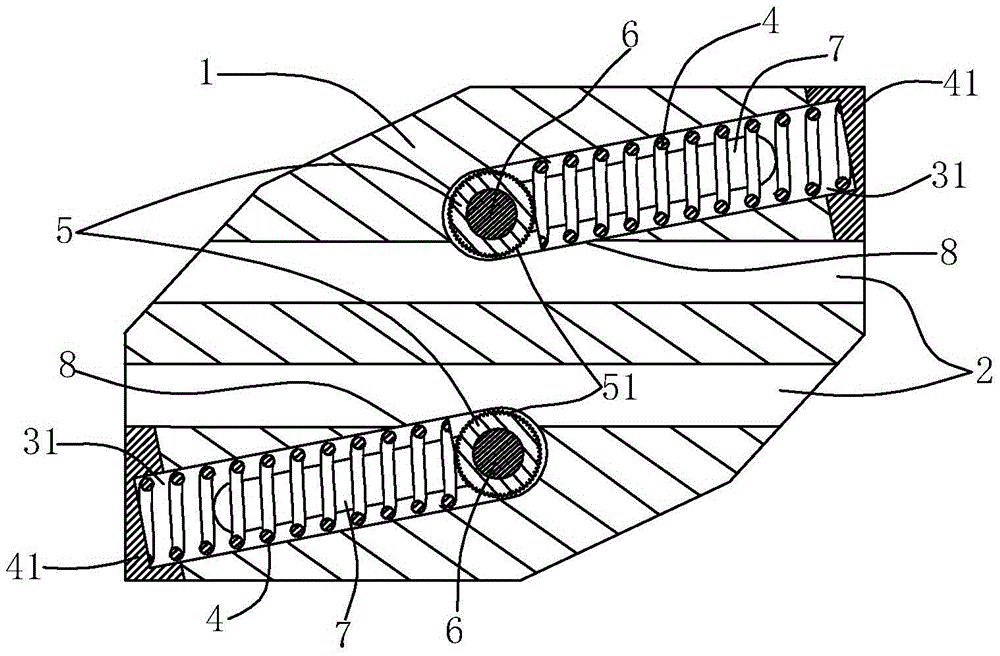

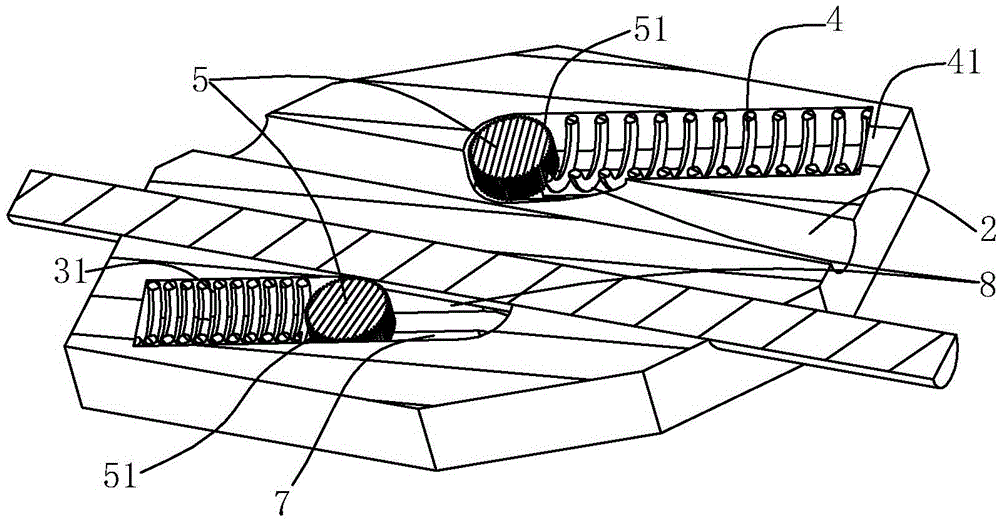

Removable anchoring device usable as a suspension bolt

ActiveUS9255594B2Easy to fixEasy to removeMachine supportsMountaineeringEngineeringPenetration length

A removable anchoring device designed to be inserted in a hole drilled in a wall, and designed to support a mechanical load, including a female body provided with a radially expandable front area designed to be inserted in the hole and with a rear stop designed to be outside the hole, a male body slidingly engaged in the female body including an expansion head at its front end, the male body including a rear stop designed to be outside the hole, a flexible compression part fitted in compression between the stop of the female body and the stop of the male body in order to bias the male body and the female body in the direction of engagement of the expansion head in the radially expandable area, the male body presenting a stop part determining a penetration length into the drilled hole.

Owner:ZEDEL CORP

Wave guide that attenuates evanescent light of higher order tm mode

ActiveUS20110235478A1High energy ratioCombination recordingRecord information storageLaser lightWaveguide

A waveguide has a core through which laser light can propagate in a TM mode, that has a rectangular cross section perpendicular to a propagative direction of the laser light, and through which the laser light can propagate in a fundamental mode in which only one portion exists on the cross section of the core where a light intensity of the laser light becomes maximal, and a higher order mode in which two or more portions exist where the light intensity becomes maximal, a clad surrounding the core, and a light absorbing element in the clad, and wherein a distance between the light absorbing element and the core is shorter than a penetration length of evanescent light in the higher order mode, but is longer than a penetration length of evanescent light in the fundamental mode.

Owner:TDK CORPARATION

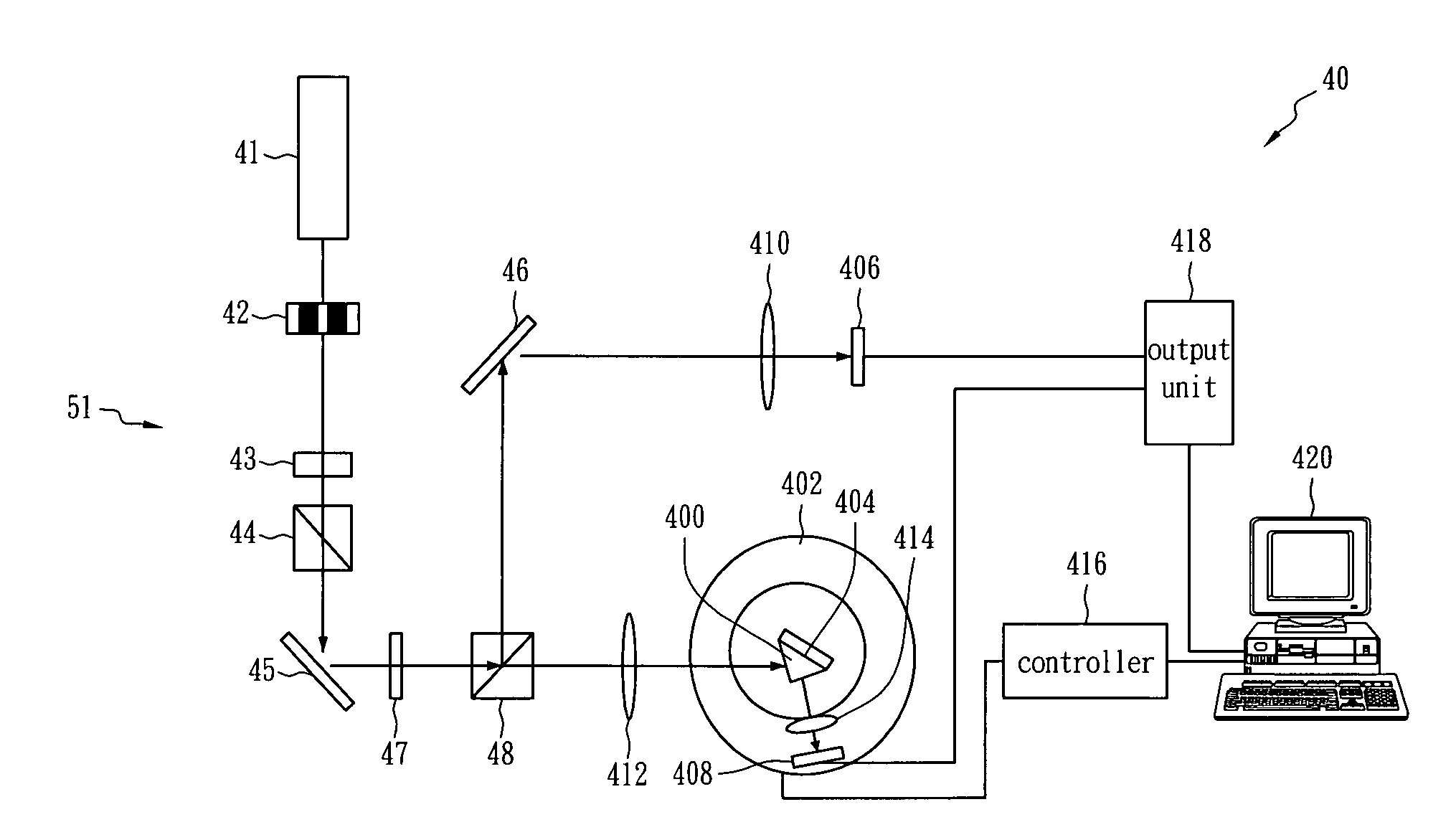

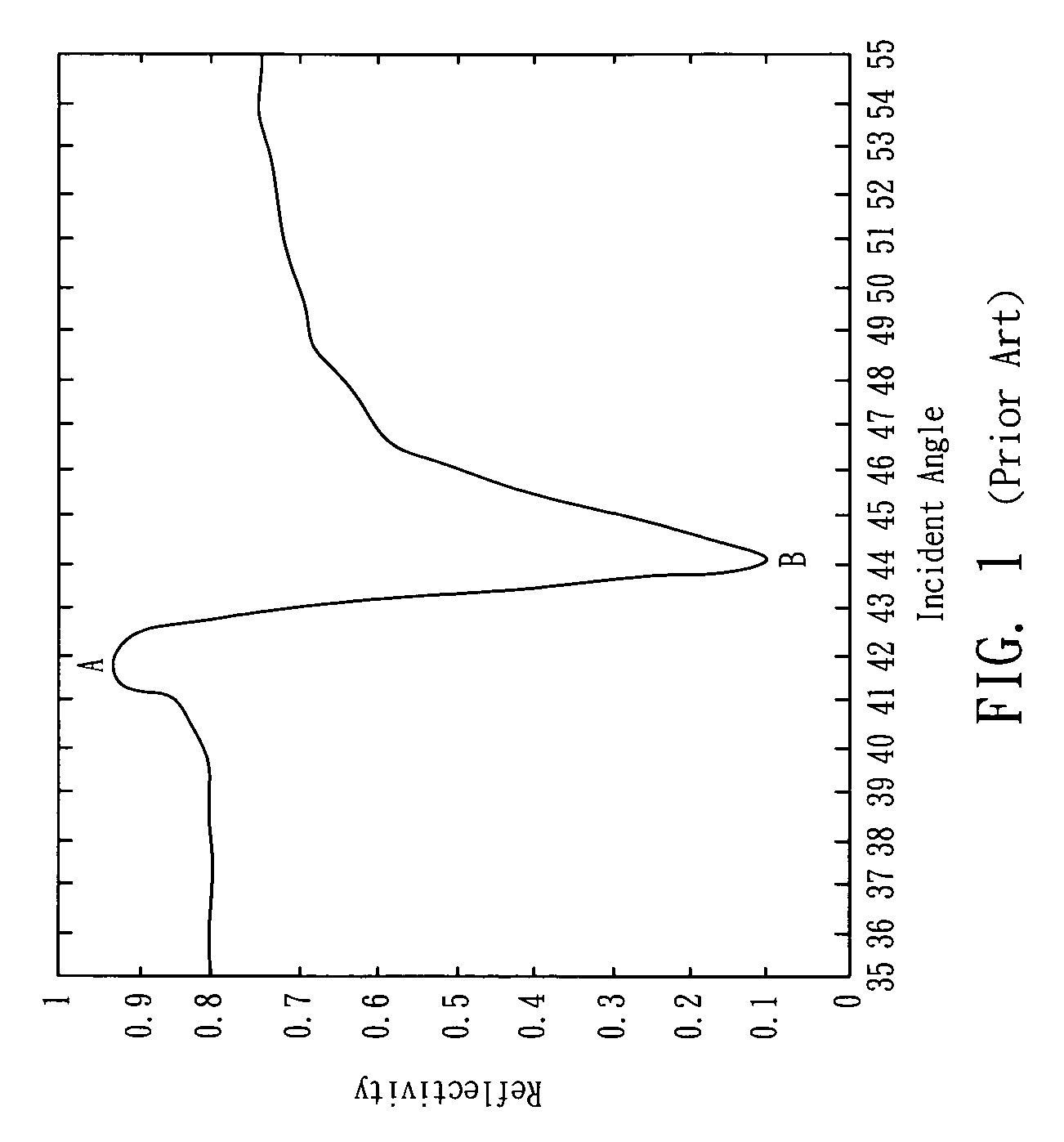

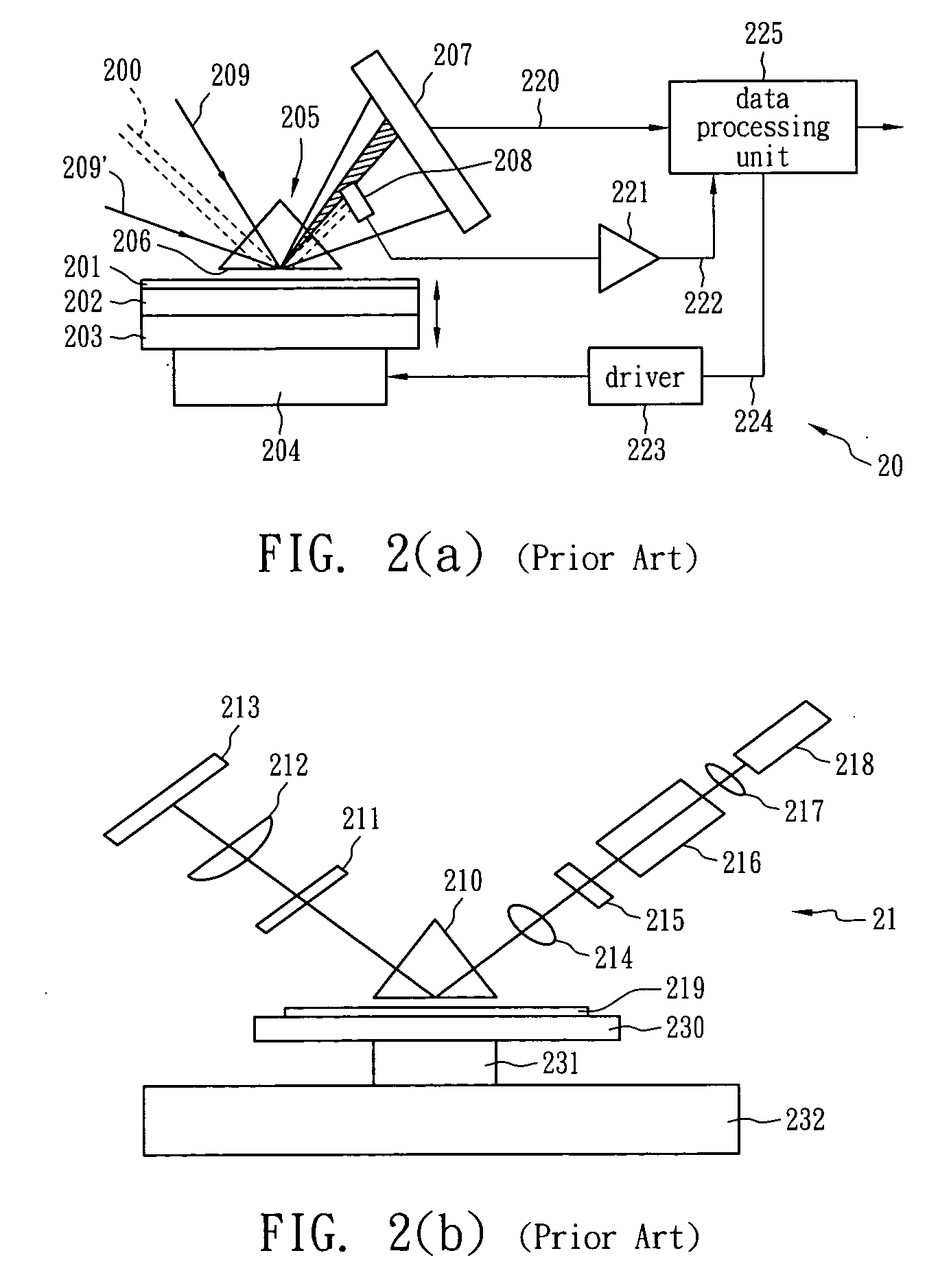

Measuring apparatus and method using surface plasmon resonance

InactiveUS20070279635A1Assure correctnessAssure reliabilityScattering properties measurementsUsing optical meansSurface roughnessLight beam

An apparatus and a method for measuring gap width, displacement shift or relative position between two subjects using surface plasmon resonance (SPR) are disclosed. First, a TM mode light beam is provided, so as to generate SPR on a surface of one of the two subjects. Then, the signal of the reflective light or penetrative light on the surface is measured. Because SPR is sensitive to the changes of the gap, displacement shift or relative position when the width of the gap is equal to or smaller than twice the penetration length of the surface plasmon wave, the gap, displacement shift and relative position can be acquired by sensing changes of the signal. Accordingly, the width of the gap, displacement shift, relative position and surface roughness smaller than twice the penetration length or even less than 10 nm can be measured.

Owner:NATIONAL TSING HUA UNIVERSITY

Diesel injector and method utilizing focused supercavitation to reduce spray penetration length

ActiveUS8905333B1Avoid excessive momentum fluxQuick fuel deliveryFuel-injection pumpsSpray nozzlesDiesel injectorHigh pressure

A method and apparatus are disclosed for inducing a supercavitating flow inside a fuel injection nozzle orifice to reduce the penetration length of the fuel spray, maintain high levels of fuel atomization, and improve uniformity of the fuel spray exiting the nozzle such that high-pressure injectors can be used on small engines. This reduction in penetration length is accomplished without any reduction in upstream fuel pressure.

Owner:MAINSTREAM ENG

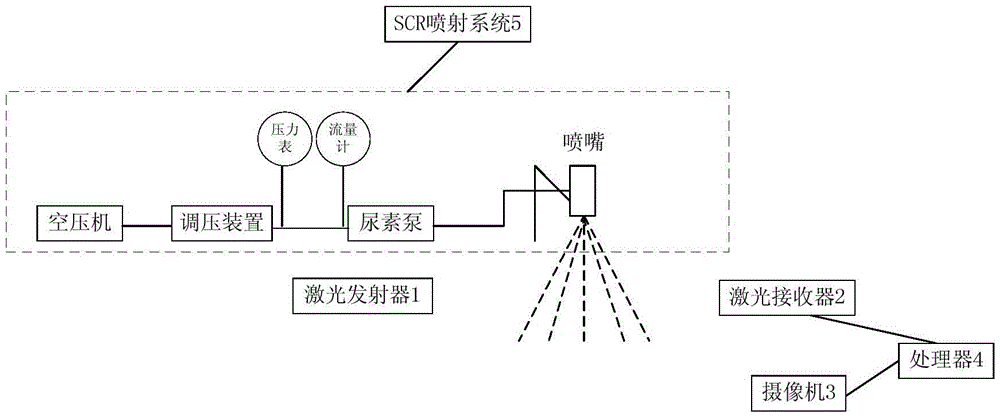

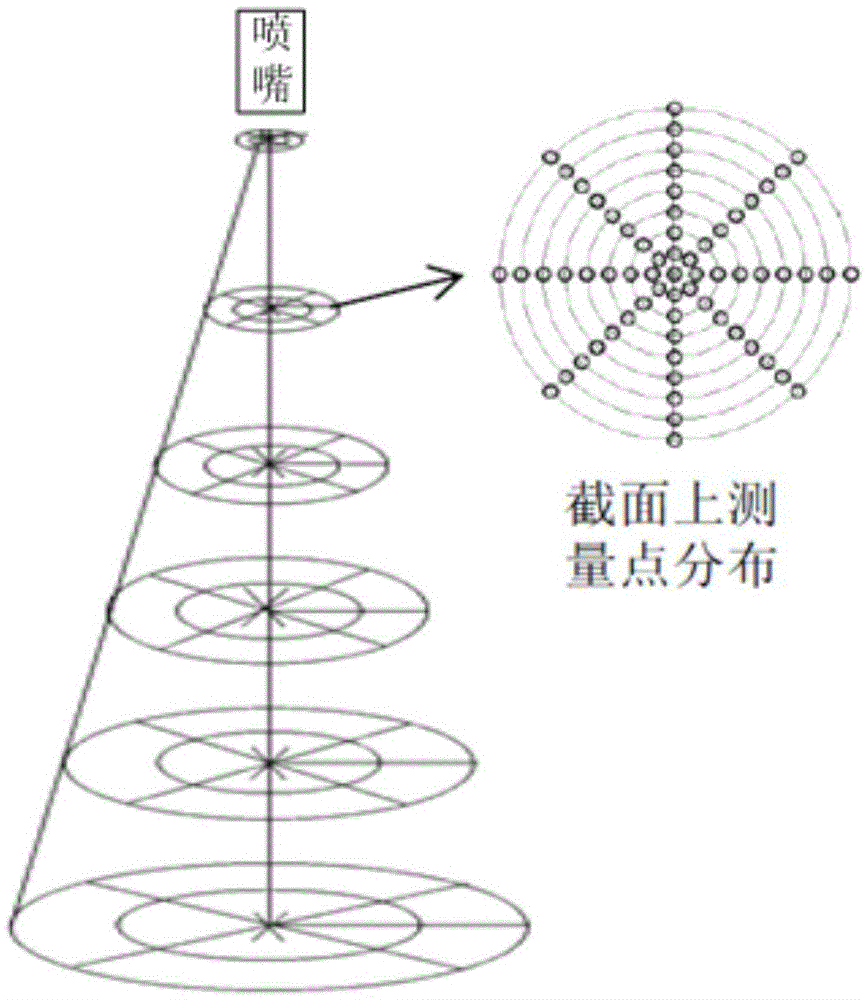

Spraying characteristic analysis device and method

InactiveCN105604665AImprove accuracyReduce verification effortInternal combustion piston enginesExhaust treatment electric controlLaser transmitterTime moment

The invention discloses a spraying characteristic analysis device and an analysis method based on the device. Key parameters for quantitatively evaluating the spraying condition of an SCR injection system can be accurately tested, and efficiency is high. The device comprises the SCR injection system, a laser emitter, a laser receiver, a camera and processors, wherein the processors include a signal processor and an image processor; laser emitted by the laser emitter is received by the laser receiver after being subjected to spraying of urea injected by a nozzle penetrating the SCR injection system; the signal processor is connected with the laser receiver and used for acquiring laser signals received by the laser receiver and processing the laser signals, and the urea spraying particle diameter and the distribution condition of the urea spraying particle diameter are acquired; the camera is connected with the image processor and used for acquiring urea spraying images at different time moments and transmitting the images to the image processor; the image processor is used for processing the images and acquiring the urea spraying penetration length and taper angle.

Owner:WEICHAI POWER CO LTD

Non-excavation type laying construction method of large-pipe-diameter pipeline of heat supply network

ActiveCN110778272AIncrease workloadEasy to weldDirectional drillingFlushingStructural engineeringPipe

The invention discloses a non-excavation type laying construction method of a large-pipe-diameter pipeline of a heat supply network. The method comprises the steps that drilling machine equipment is selected, the pull strength of a selected horizontal directional drilling machine needs to meet the requirement of the directional drilling penetration length, the pull strength is larger than or equalt 3*(the friction resistance generated by the pipeline in a hole and the viscous comprehensive friction resistance of the pipeline in the hole), 3 times of the safety coefficient is taken, and mud preparing, guide hole drilling, hole pre-expanding, pipe penetration treatment and pulling back are carried out. Compared with the pipe jacking construction manner, the method has the following advantages that long-distance uninterrupted penetration construction of the pipeline can be met, and the construction speed is high; destroy to the ground environment can be reduced, and the requirement of environment protection can be met; the method is not disturbed by uncertain factors such as the soil property, underground water and underground hidden pipelines, the procedures of work well construction and work pipe penetration are omitted, and time is saved; and long-distance welding and heat preservation can be carried out on the work pipe on the ground, the penetration depth is large, and the risk such as water penetration and pipe floating during river penetration is avoided.

Owner:POWER CHINA HENAN ENG CO LTD

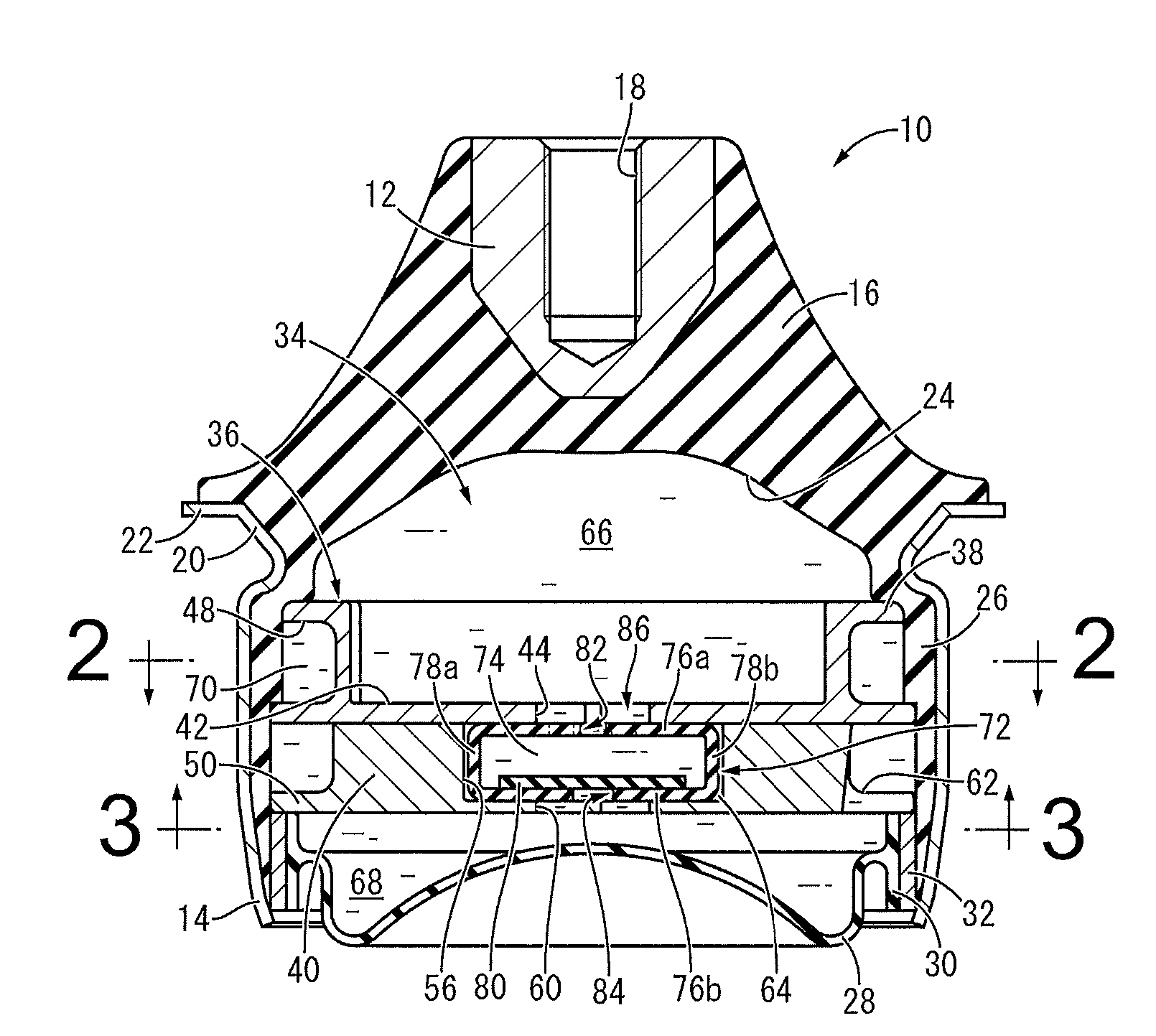

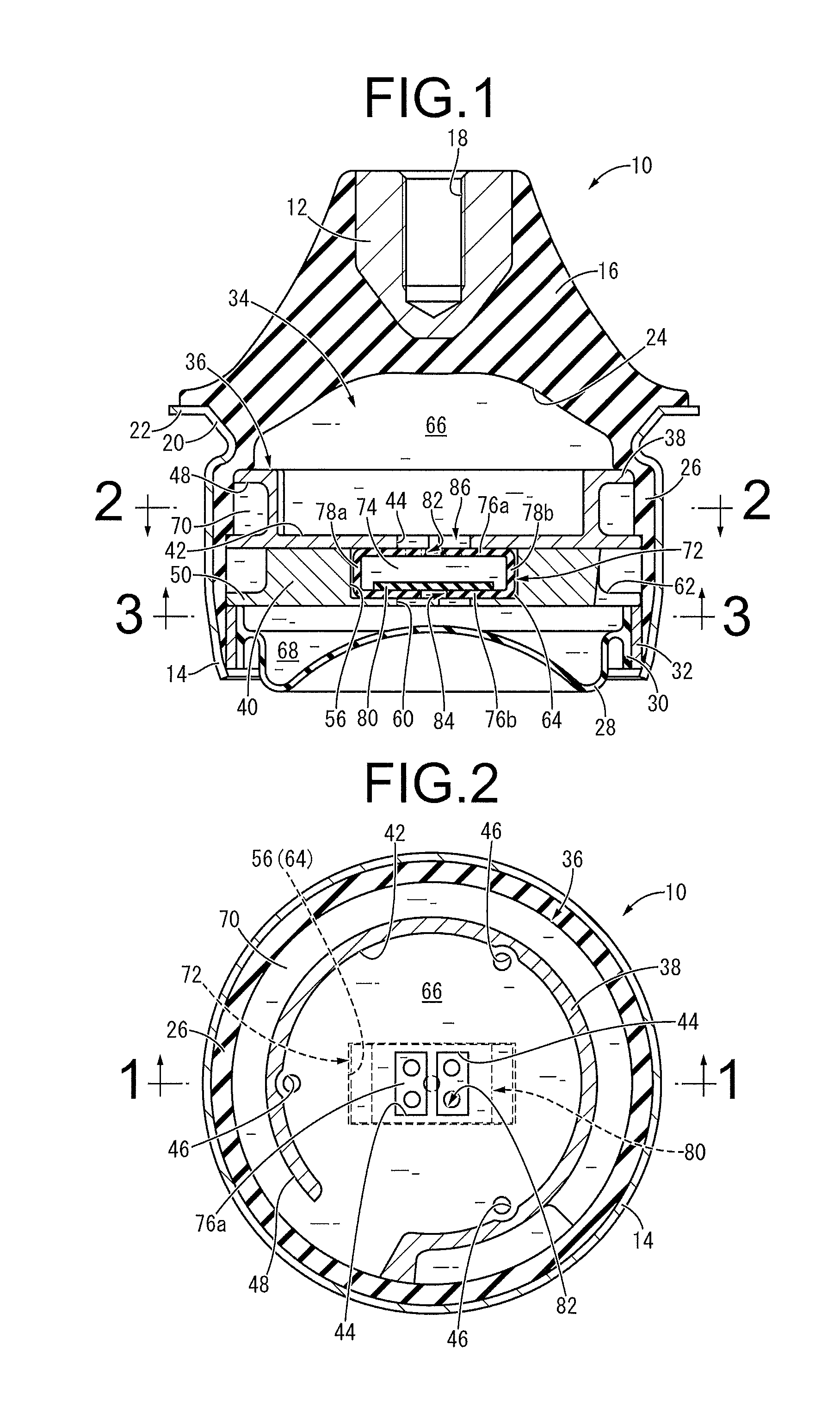

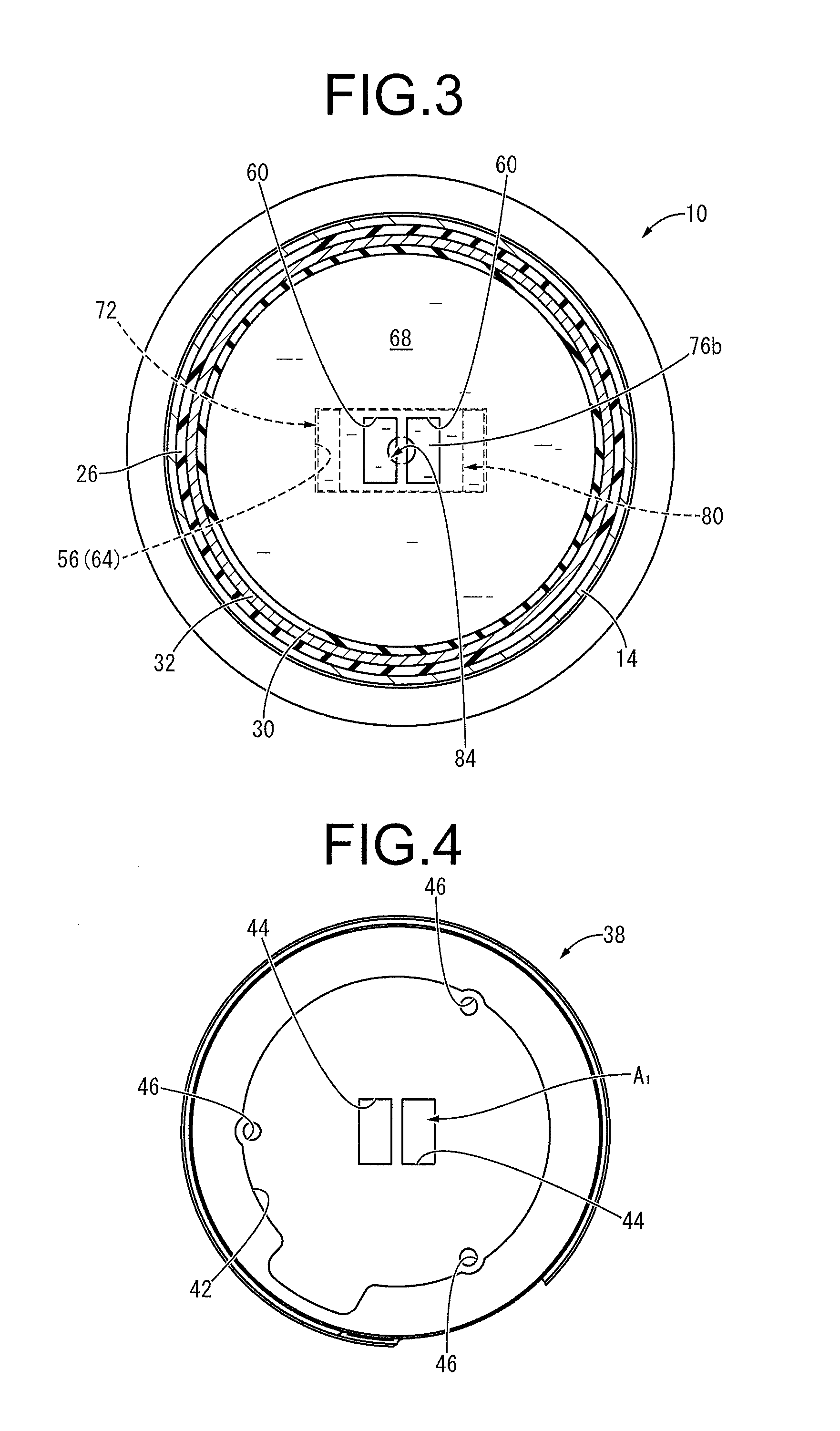

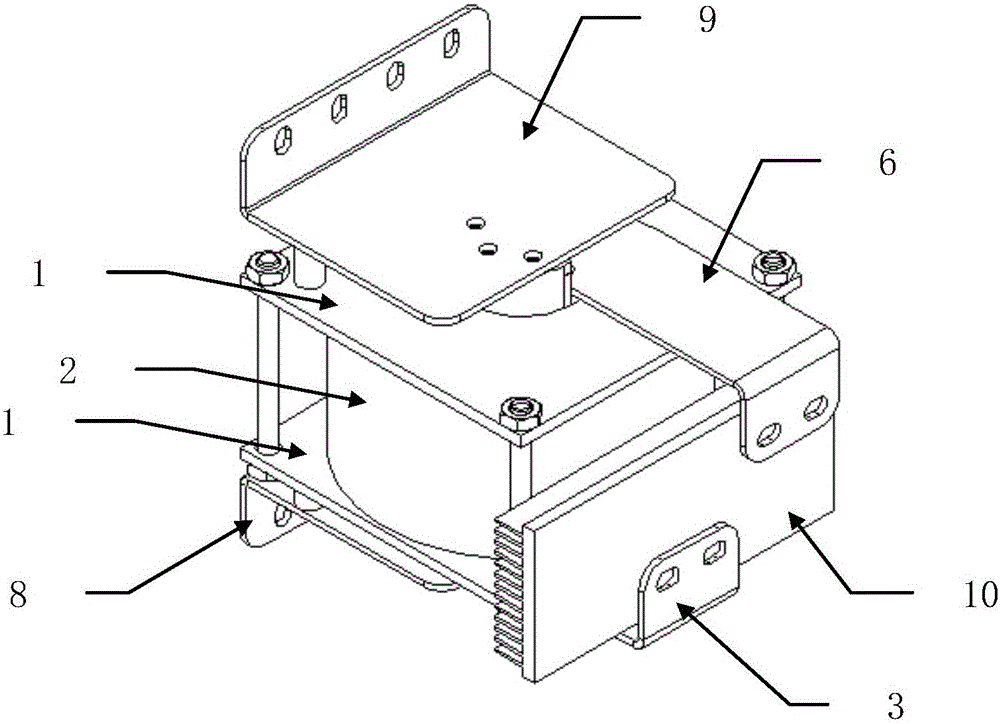

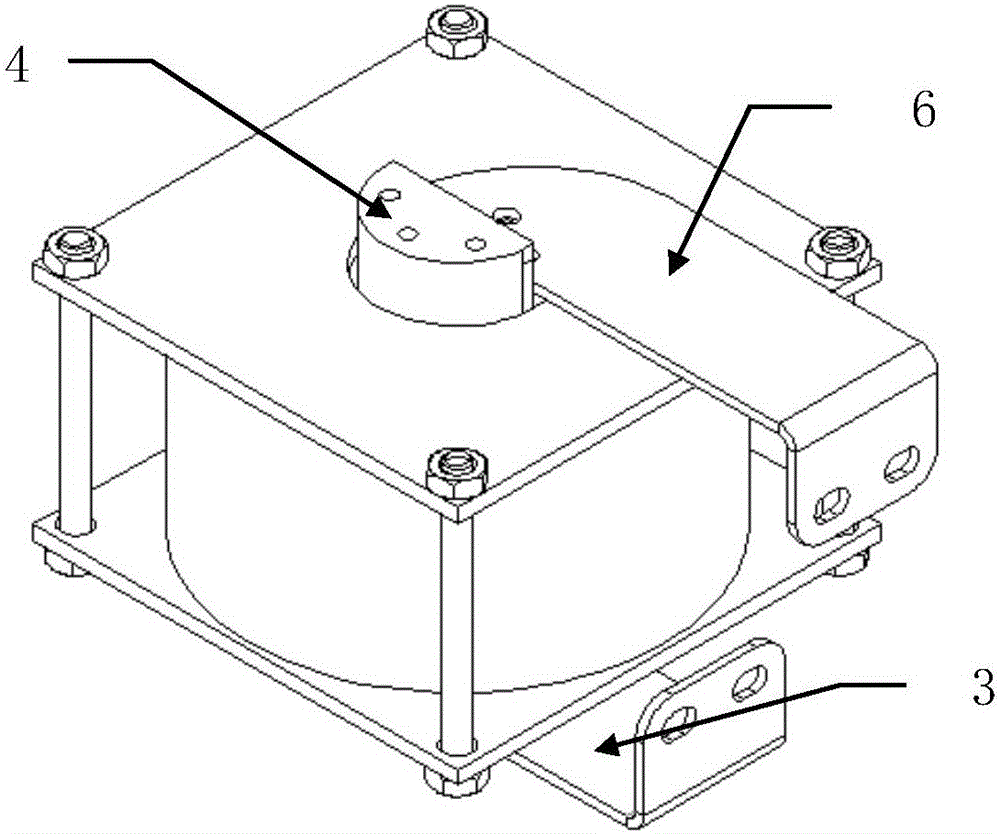

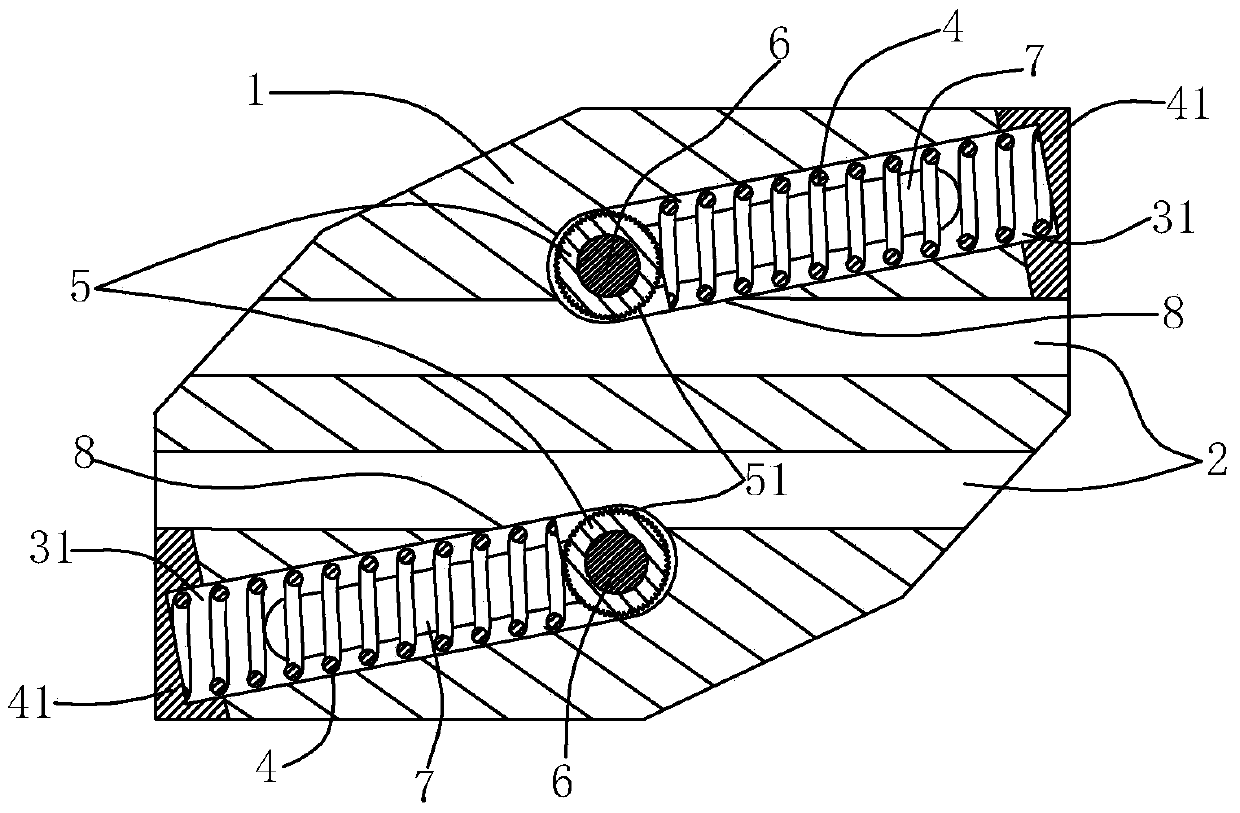

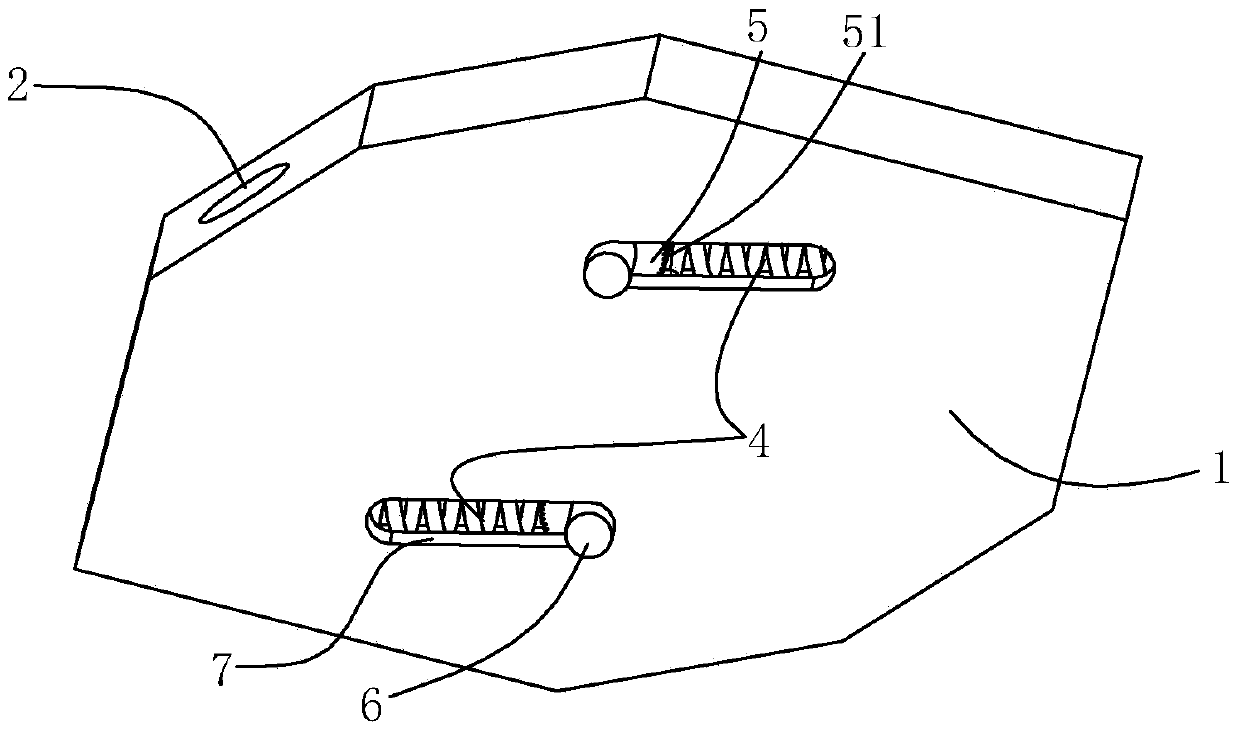

Fluid-filled vibration damping device

ActiveUS20140232049A1Reduce impact noiseSuppress pressure fluctuationsMachine framesLiquid springsEngineeringPenetration length

A fluid-filled vibration damping device including an elastic buffer body supported by a partition member and arranged in a housing space such that at least one of wall inner surfaces of the housing space on sides of a pressure-receiving chamber and an equilibrium chamber is covered by the elastic buffer body. Windows are formed to penetrate the elastic buffer body at portions corresponding to communication holes formed in walls of the housing space so that the communication holes are narrowed by the windows of the elastic buffer body, and a ratio (a / l) of an opening area (a) of the windows to a penetration length (l) thereof is made smaller than a ratio (A / L) of an opening area (A) of the communication holes to a penetration length (L) thereof.

Owner:SUMITOMO RIKO CO LTD

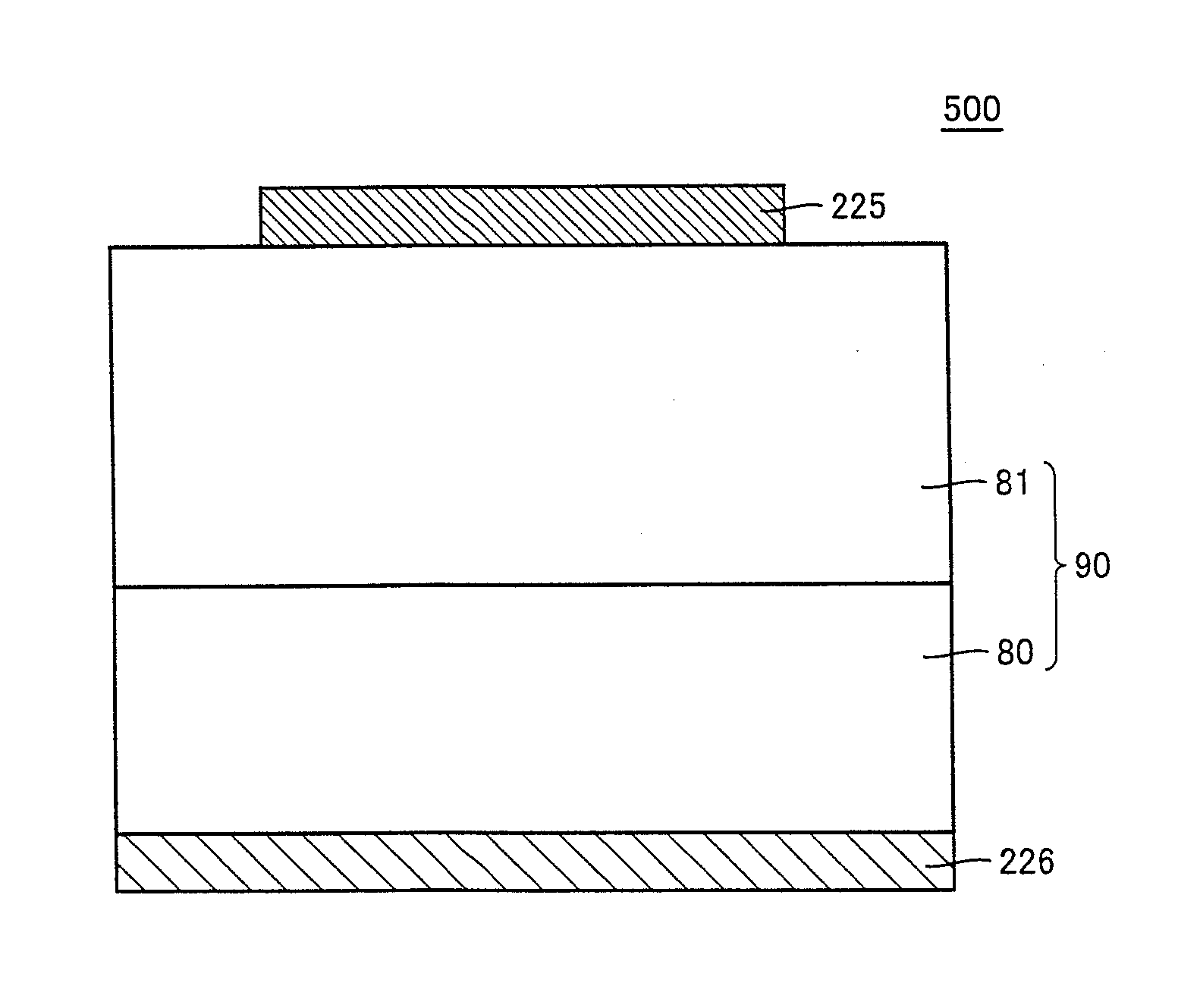

Glass substrate for magnetic disk and manufacturing method of the same

ActiveUS8119267B2Liquid surface applicatorsMagnetic materials for record carriersOptoelectronicsCompressive strength

Owner:HOYA CORP

Removable anchoring device usable as a suspension bolt

ActiveUS20150300392A1Simple designEasy to fixMountaineeringStands/trestlesEngineeringPenetration length

A removable anchoring device designed to be inserted in a hole drilled in a wall, and designed to support a mechanical load, including a female body provided with a radially expandable front area designed to be inserted in the hole and with a rear stop designed to be outside the hole, a male body slidingly engaged in the female body including an expansion head at its front end, the male body including a rear stop designed to be outside the hole, a flexible compression part fitted in compression between the stop of the female body and the stop of the male body in order to bias the male body and the female body in the direction of engagement of the expansion head in the radially expandable area, the male body presenting a stop part determining a penetration length into the drilled hole.

Owner:ZEDEL CORP

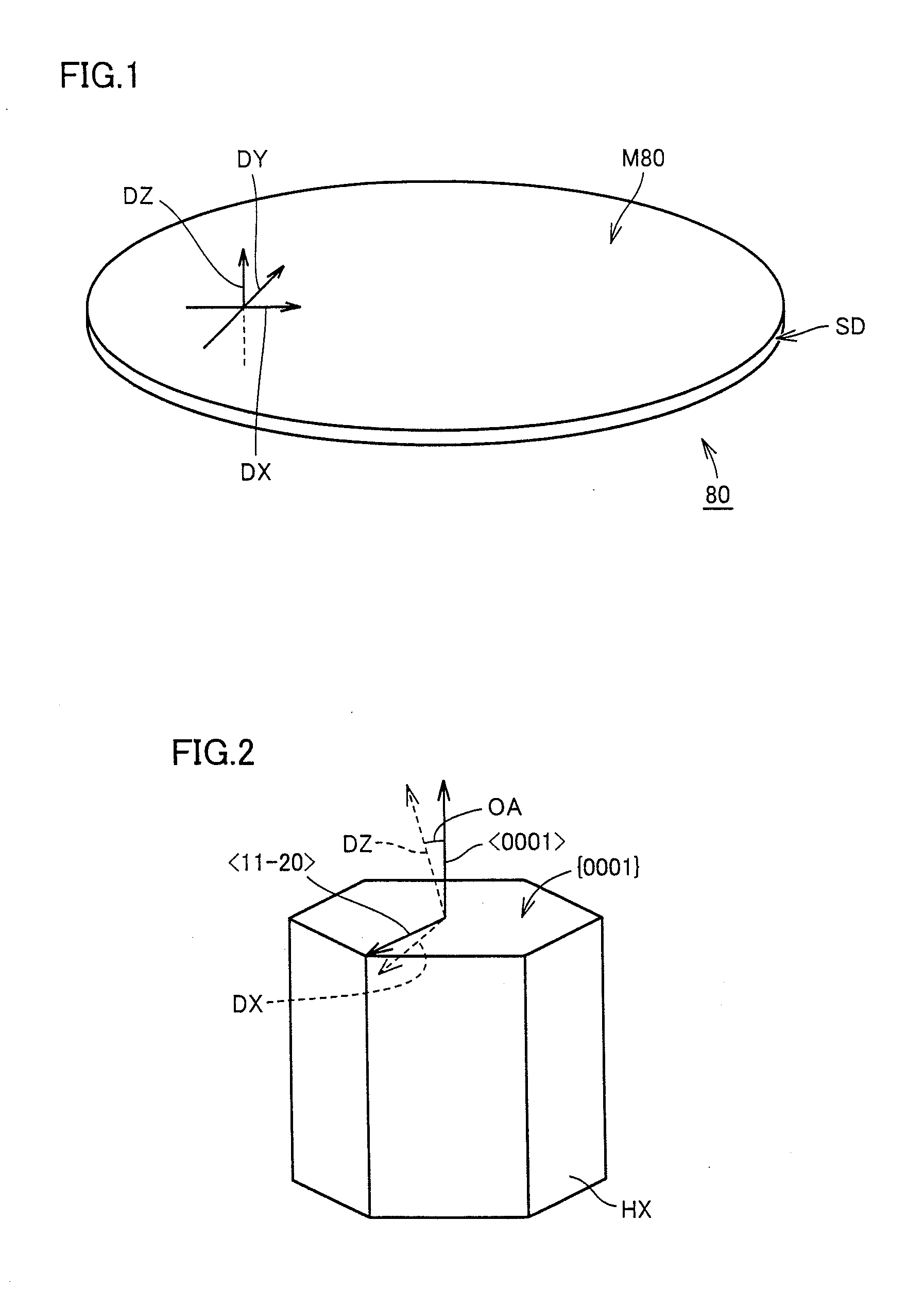

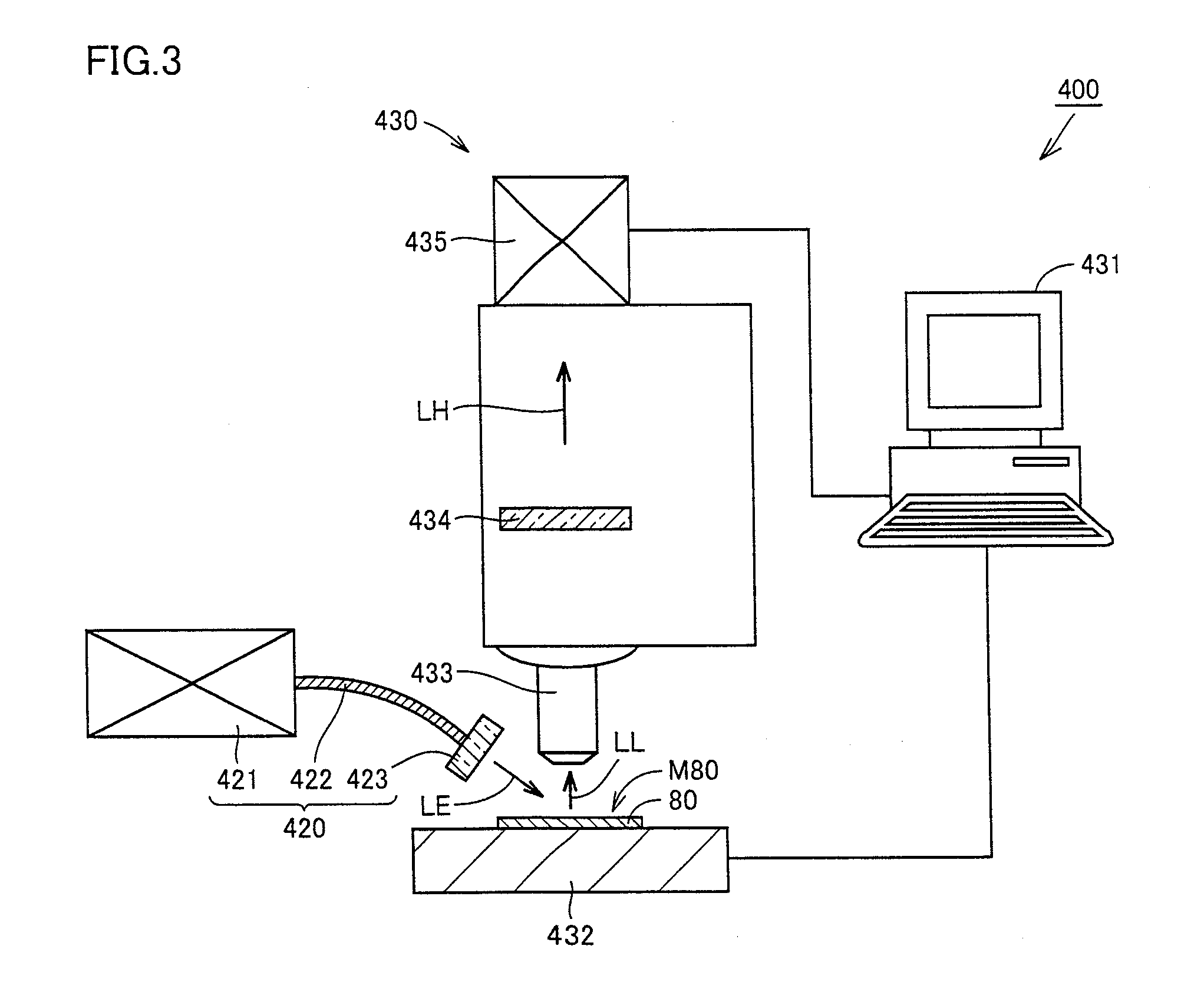

Silicon carbide substrate, semiconductor device, method of manufacturing silicon carbide substrate and method of manufacturing semiconductor device

ActiveUS20120161155A1Reduce reverse leakageReduce leakage currentPolycrystalline material growthSemiconductor/solid-state device testing/measurementHigh energyPhotoluminescence

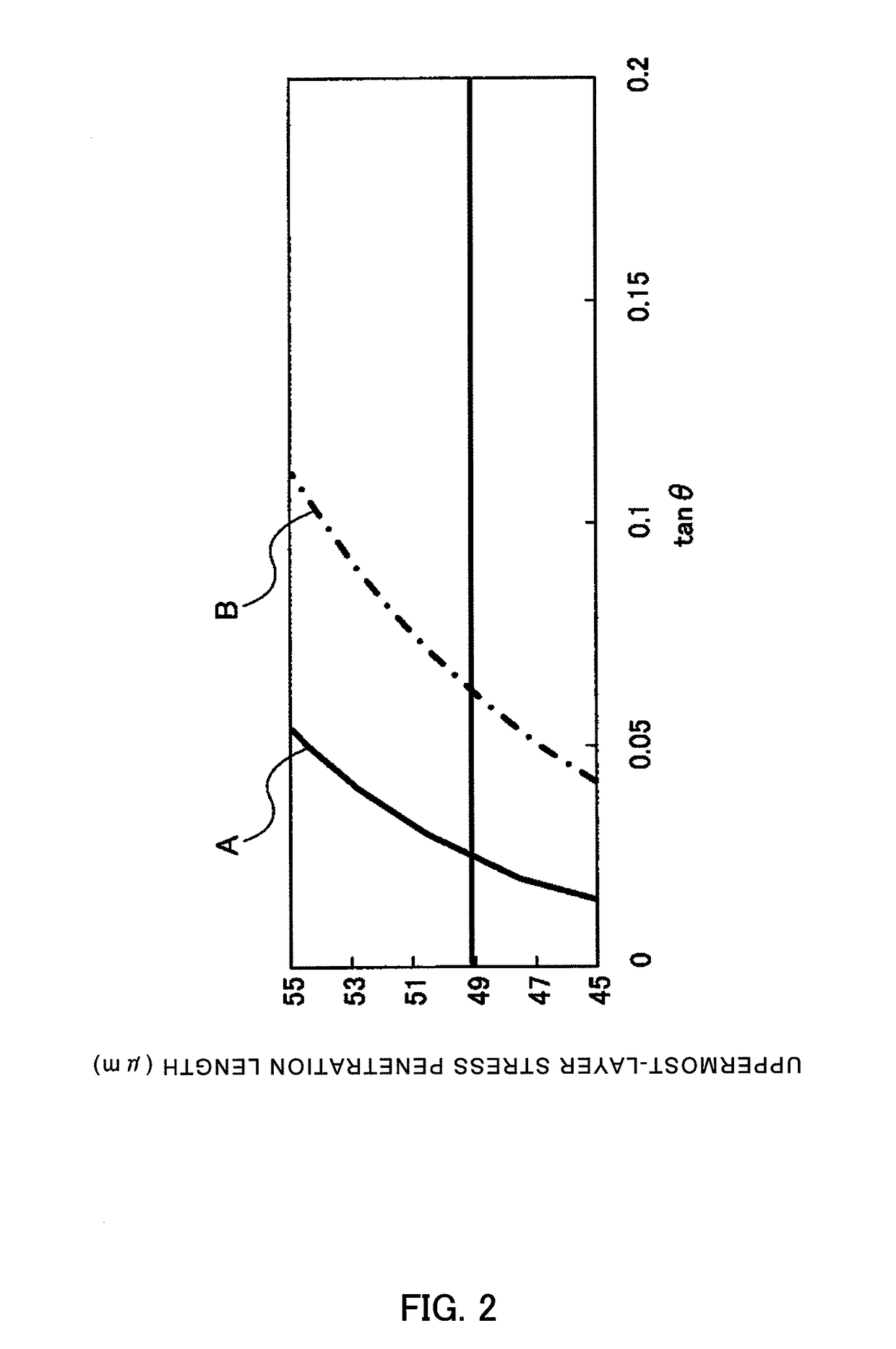

A main surface of a silicon carbide substrate is inclined by an off angle in an off direction from {0001} plane of a hexagonal crystal. The main surface has such a characteristic that, among emitting regions emitting photoluminescent light having a wavelength exceeding 650 nm of the main surface caused by excitation light having higher energy than band-gap of the hexagonal silicon carbide, the number of those having a dimension of at most 15 μm in a direction perpendicular to the off direction and a dimension in a direction parallel to the off direction not larger than a value obtained by dividing penetration length of the excitation light in the hexagonal silicon carbide by a tangent of the off angle is at most 1×104 per 1 cm2. Accordingly, reverse leakage current can be reduced.

Owner:SUMITOMO ELECTRIC IND LTD

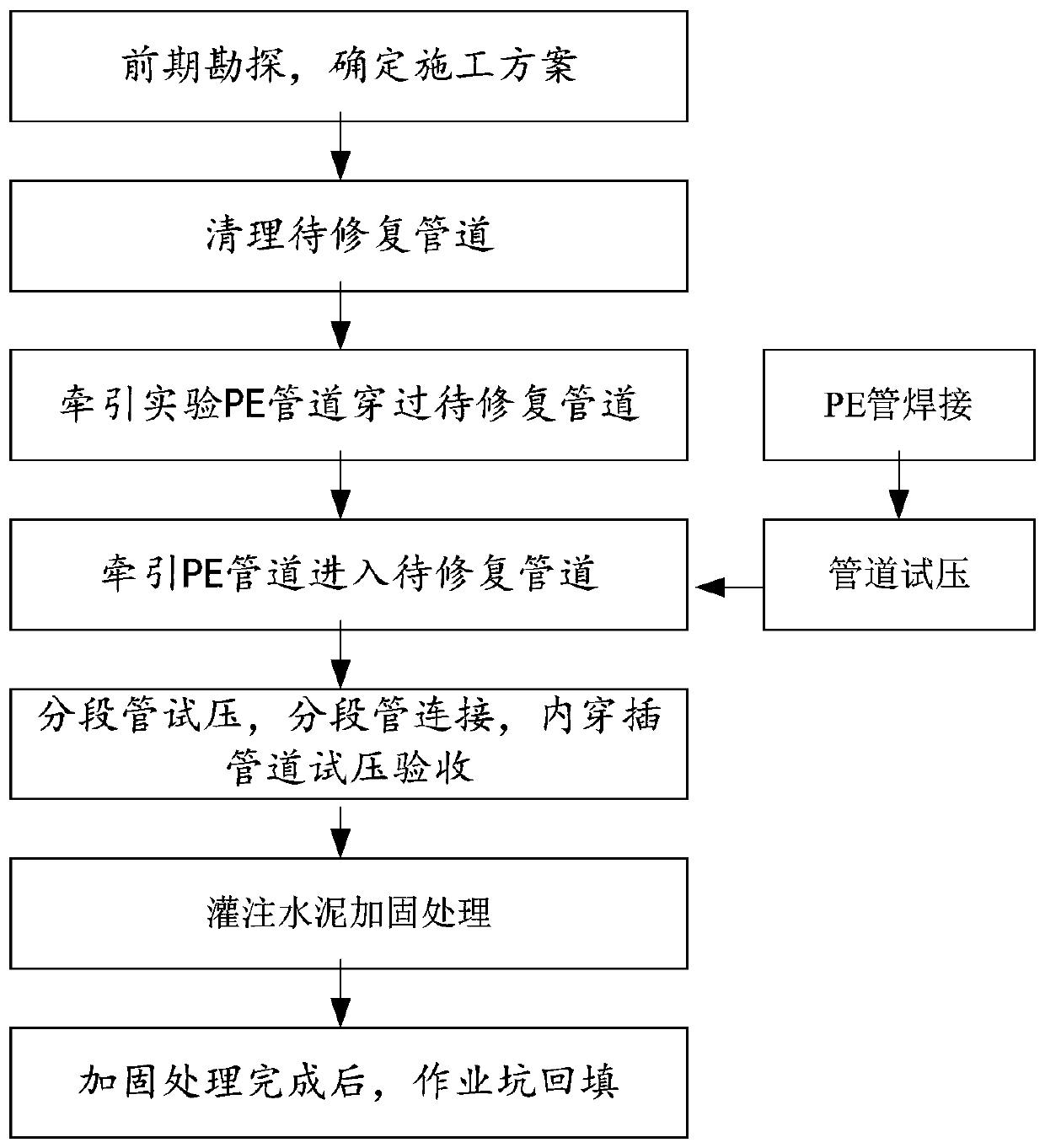

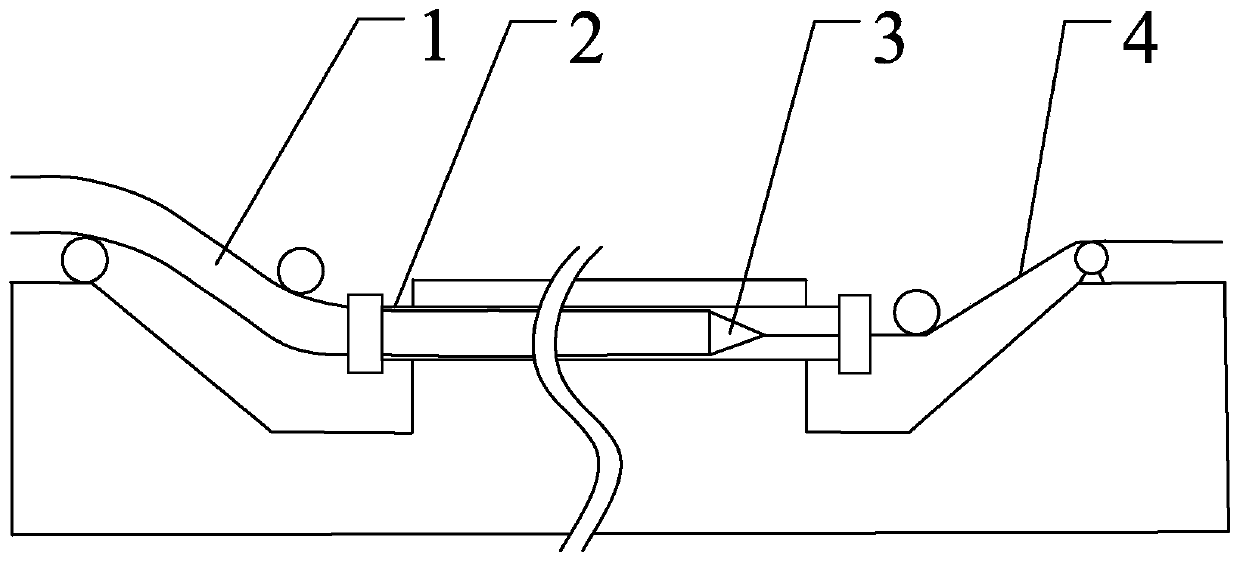

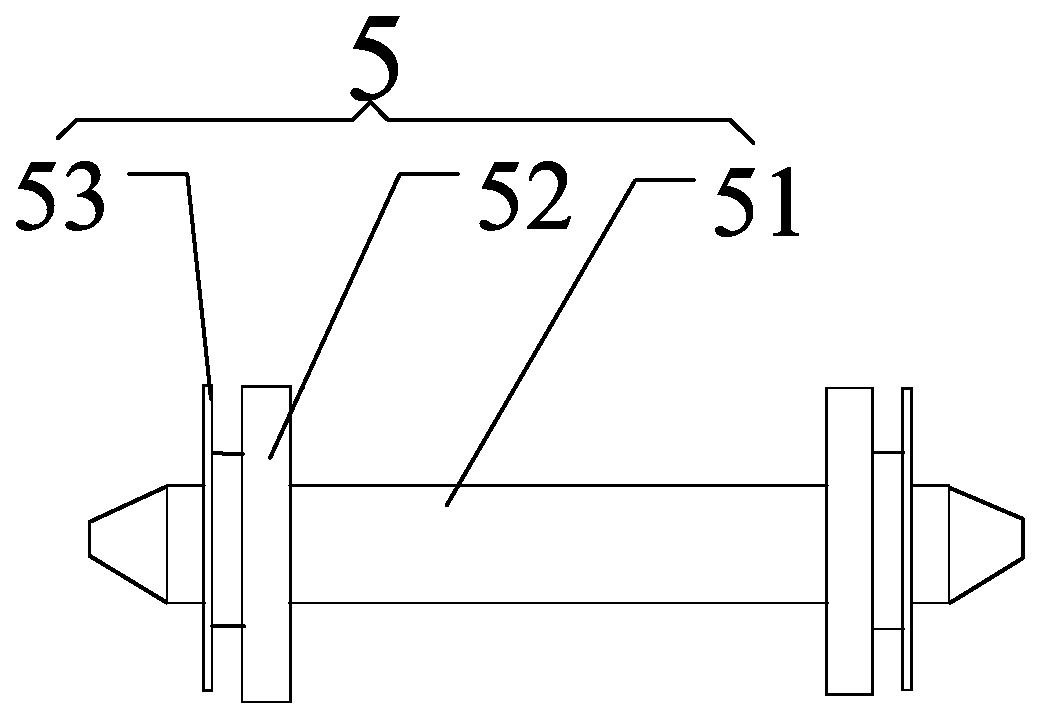

Non-excavation internal PE pipeline penetration restoration method

InactiveCN110159867AIncrease the lengthNo safety hazardPipe laying and repairPipeline systemsRestoration methodEngineering

The invention discloses a non-excavation internal PE pipeline penetration restoration method. The method comprises the following specific steps that early-stage exploration is performed; a working pitis excavated, and a to-be-restored pipeline is cleaned; an experiment PE pipeline is pulled to penetrate through the to-be-restored pipeline, and whether the damage degree of the experiment PE pipeline meets a standard or not is observed; the PE pipeline is pulled to enter the to-be-restored pipeline, wherein the PE pipeline is composed of a plurality of PE pipeline segments, the tail end of eachfront PE pipeline segment is welded to the front end of a corresponding rear PE pipeline segment, and pulling is performed again after cooling and pipeline pressure testing are completed; pressure testing is performed on the pipeline segments one by one, every two pipeline segments are connected, and a pipeline penetrates through the pipeline segments for pressure testing; and after reinforcing treatment is completed, working pit backfilling is performed. According to the non-excavation internal PE pipeline penetration restoration method adopting the above structure, the to-be-restored pipe does not need to bear pressure, no potential safety hazard exists, the single-time pipeline penetration length is increased and can reach 1500 meters, the excavation area is greatly decreased, and influences on transportation and production are less.

Owner:保定市金马漏水检测有限公司

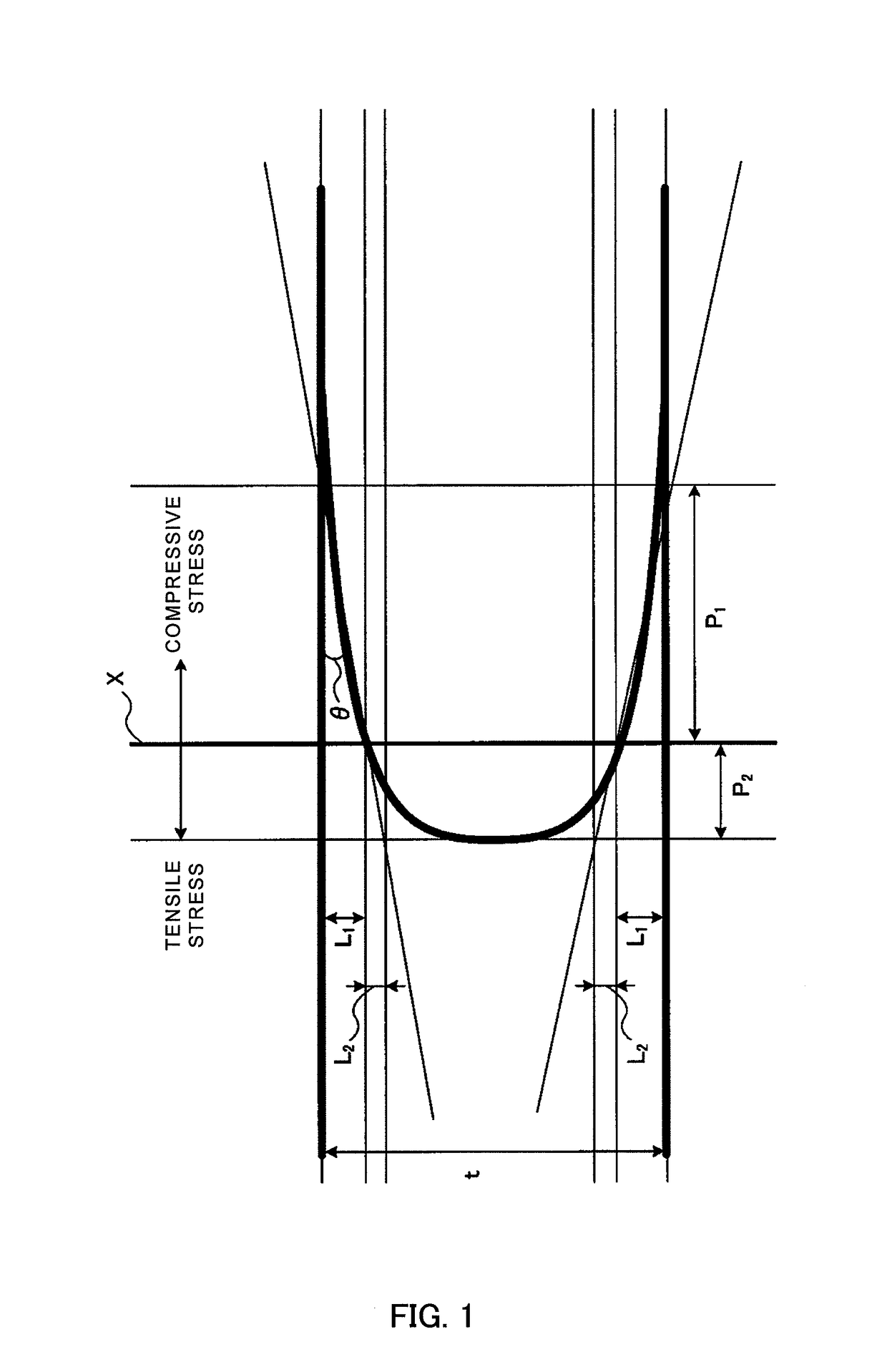

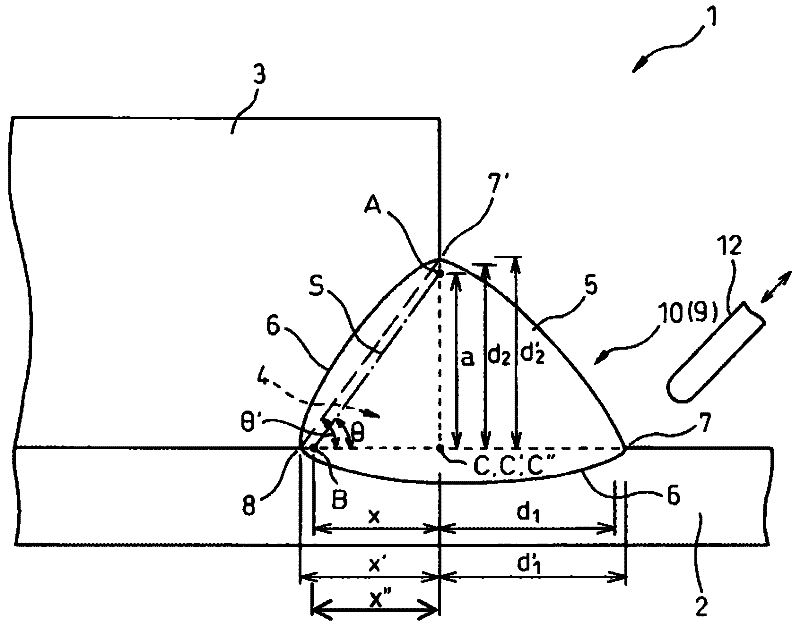

Out-of-plane gusset welded joint and fabrication method thereof

ActiveCN102481652AImprove fatigue strengthAvoid fatigue damageWelding/cutting auxillary devicesArc welding apparatusFillet weldGusset plate

Provided is a fabrication method of an out-of-plane gusset welded joint which is provided with a base plate, a gusset plate projecting from the surface of the base plate, and a fillet weld. In the fabrication method, an end of the gusset plate in the plate width direction at an end in the longitudinal direction is cut away in the plate width direction (w) to form a cut-away portion; the gusset plate is arranged on the surface of the base plate and fillet welding is performed so that an intended leg length d2 on the gusset plate side is not less than the height (a) of the cut-away portion to form a fillet weld in which the leg length d2' on the gusset plate side is not less than 1 / 3 of the thickness t2 of the gusset plate, and the leg length d2', the leg length d1' on the base plate side, the penetration length x', and the penetration angle theta' satisfy x' + d1' > d2' / sin theta'; and, at least the toe of the boxing weld portion of the fillet weld on the base plate side is subjected to an impact treatment to improve the fatigue properties.

Owner:NIPPON STEEL CORP

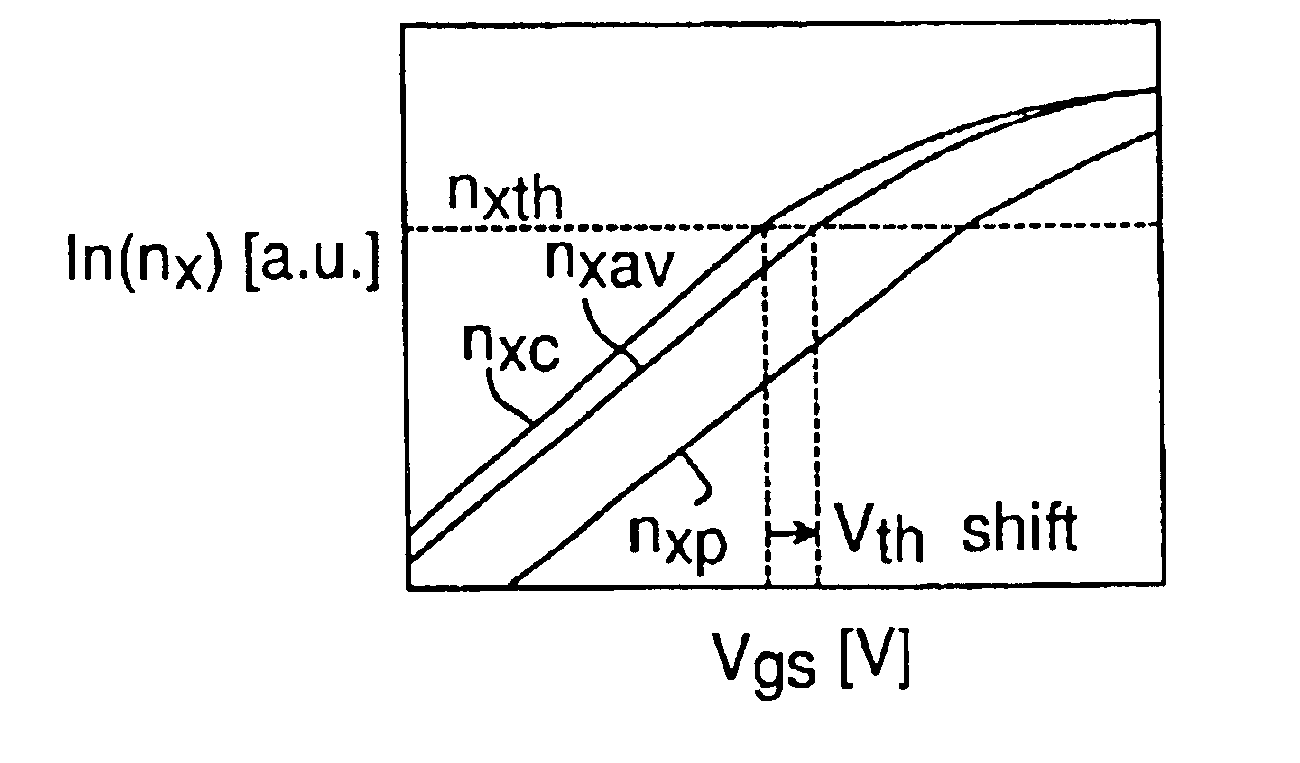

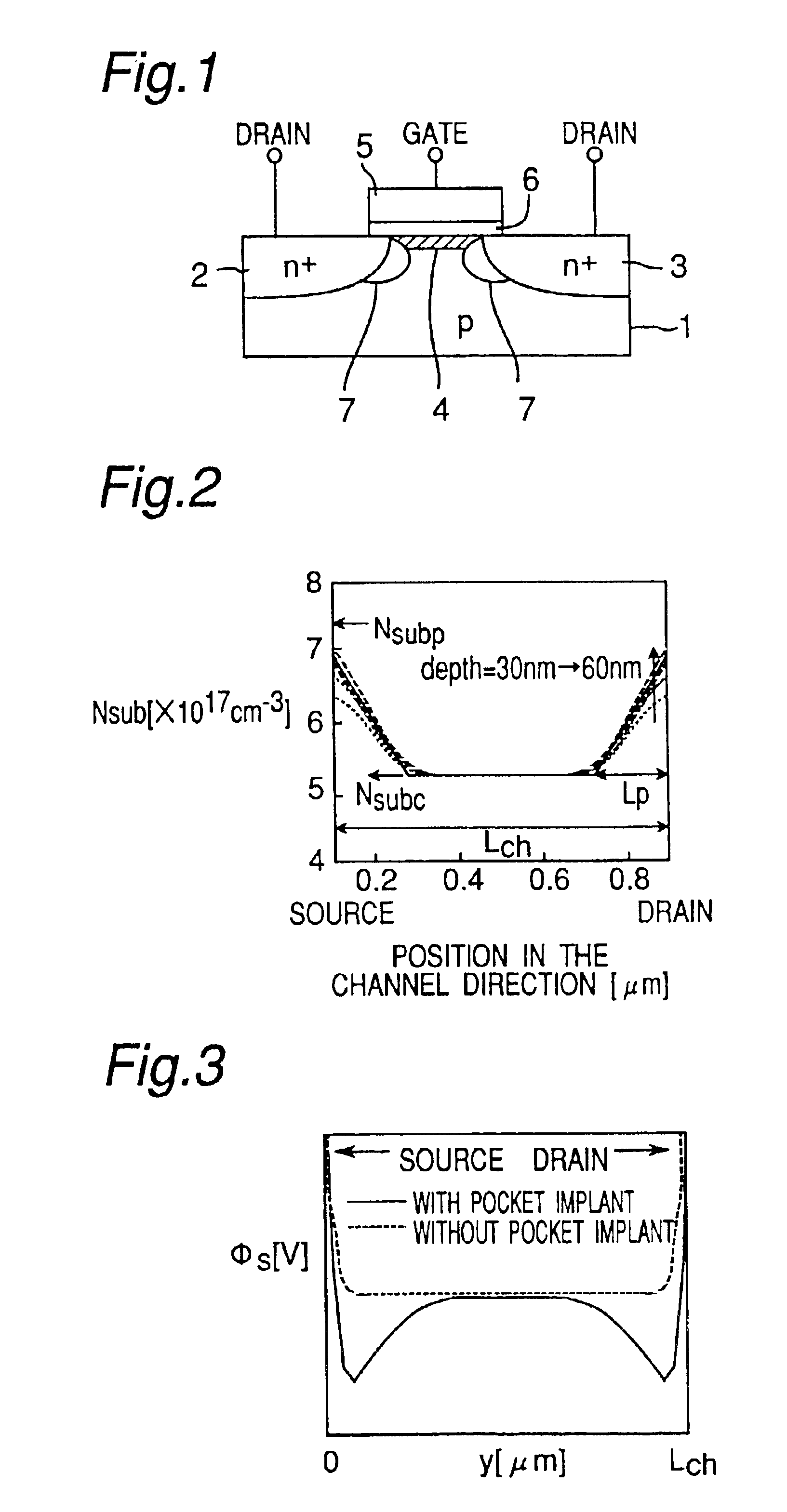

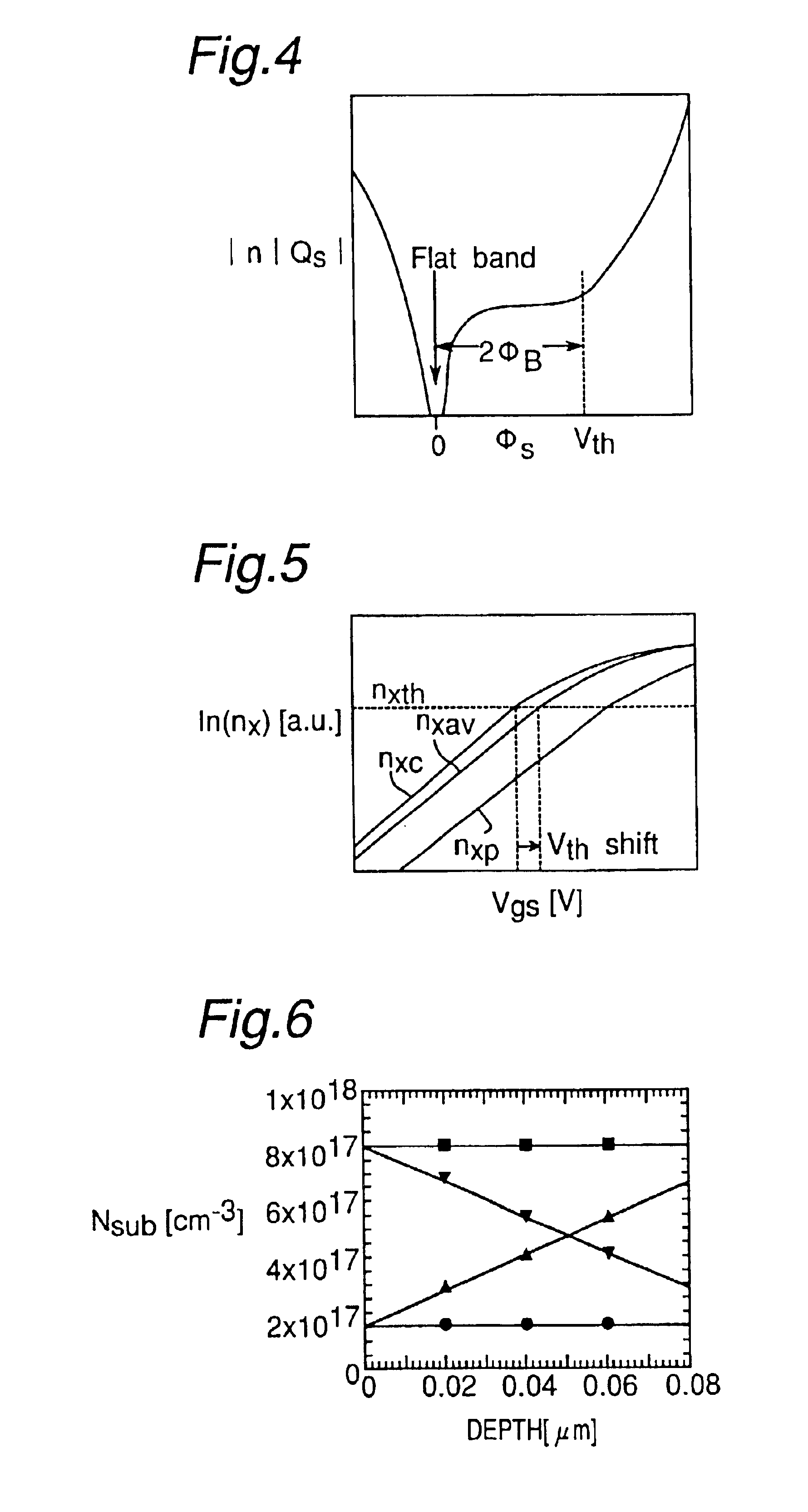

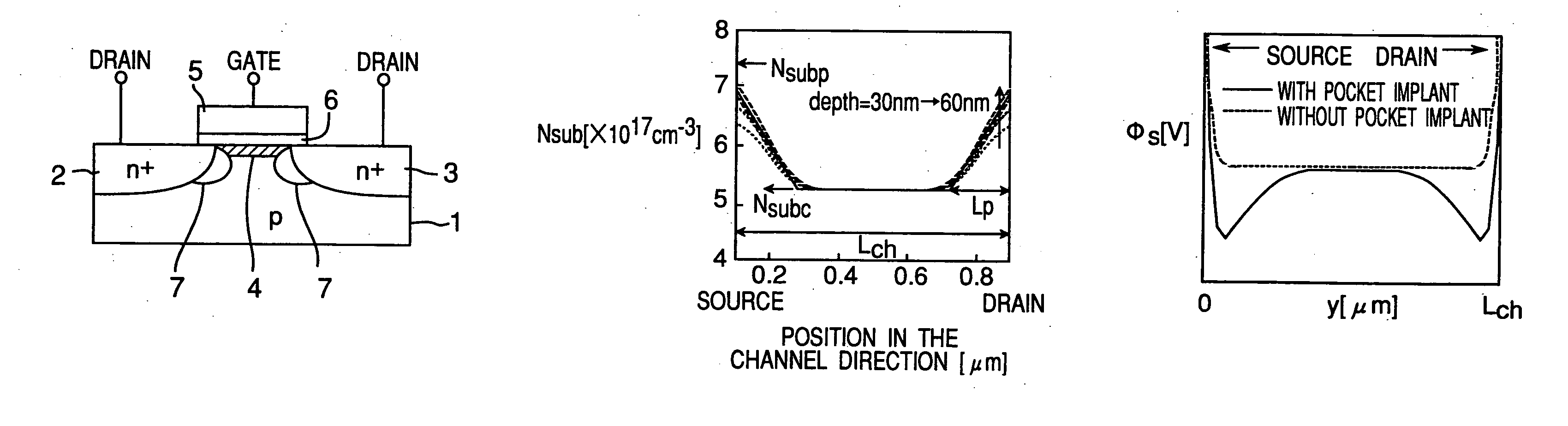

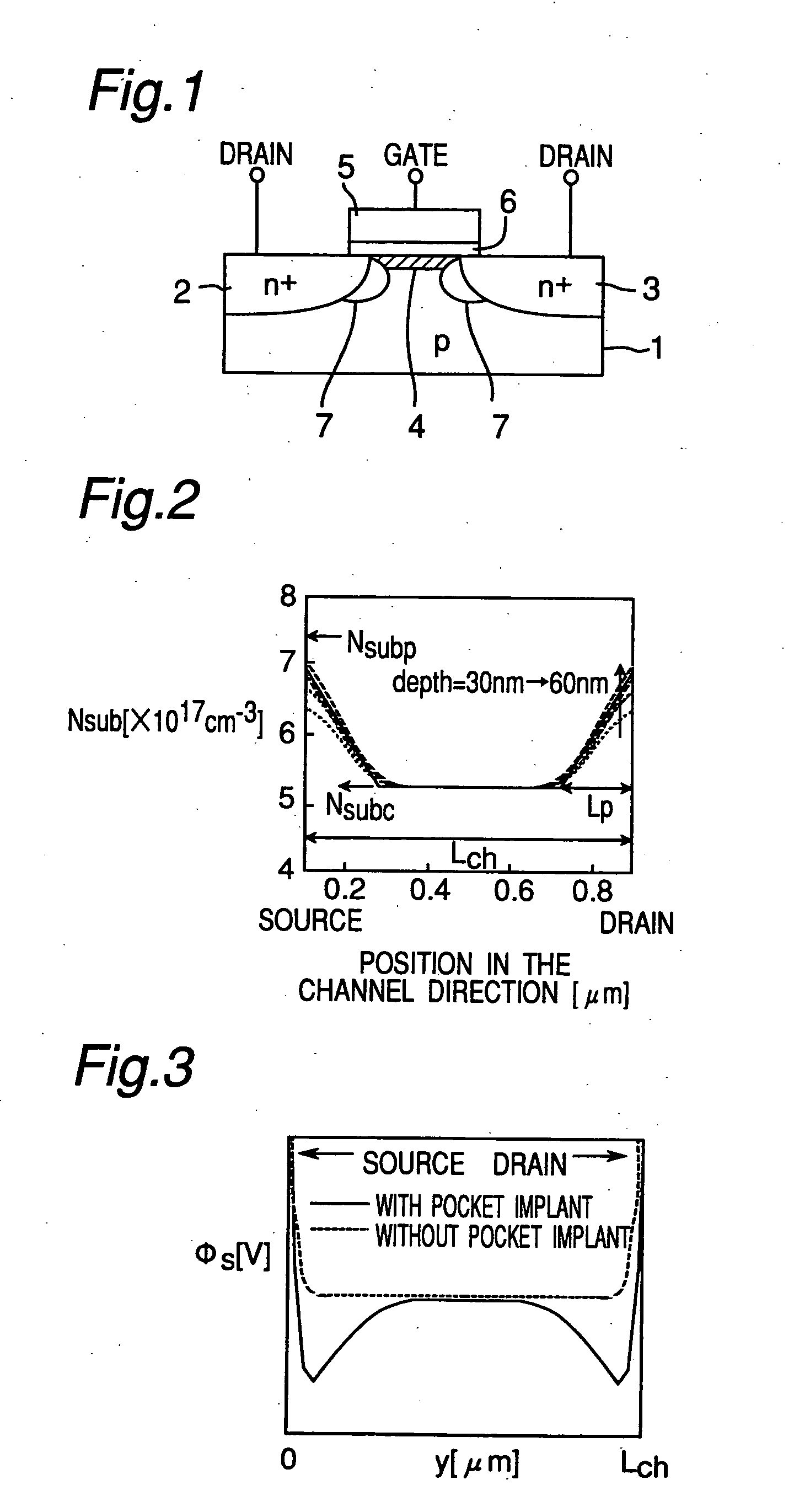

Method for calculating threshold voltage of pocket implant MOSFET

InactiveUS6909976B2Simplifying threshold voltageSemiconductor/solid-state device testing/measurementAmplifier modifications to reduce noise influenceMOSFETEngineering

A threshold voltage model with an impurity concentration profile in a channel direction taken into account is provided in the pocket implant MOSFET. With penetration length of the implanted pocket in the channel direction and the maximum impurity concentration of the implant pocket used as physical parameters, the threshold voltage model is obtained by linearly approximating the profile in the channel direction. By analytically solving the model by using a new threshold condition with inhomogeneous profile taken into account, the threshold voltage can be accurately obtained. Based on thus obtained model, the threshold voltage can be predicted and can be used for circuit design.

Owner:SEMICON TECH ACADEMIC RES CENT

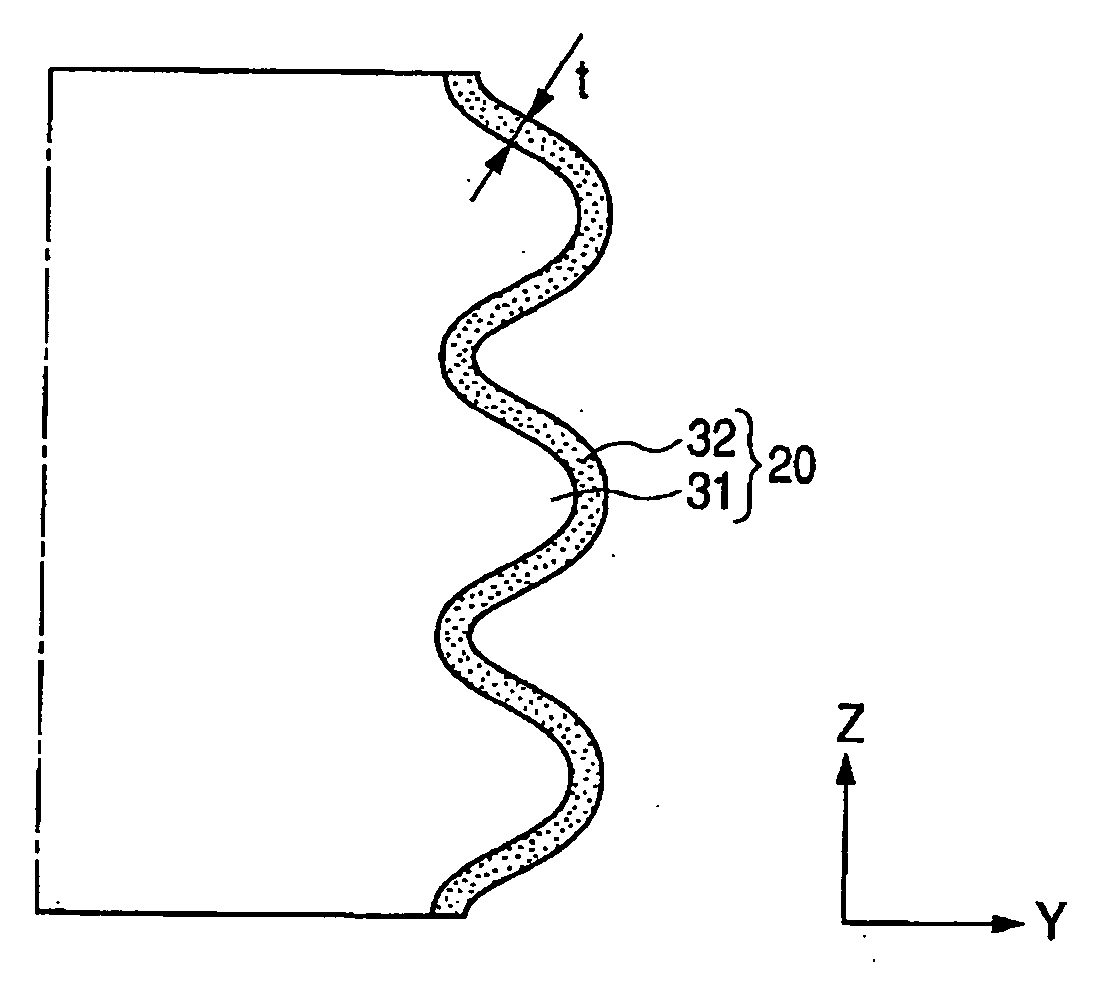

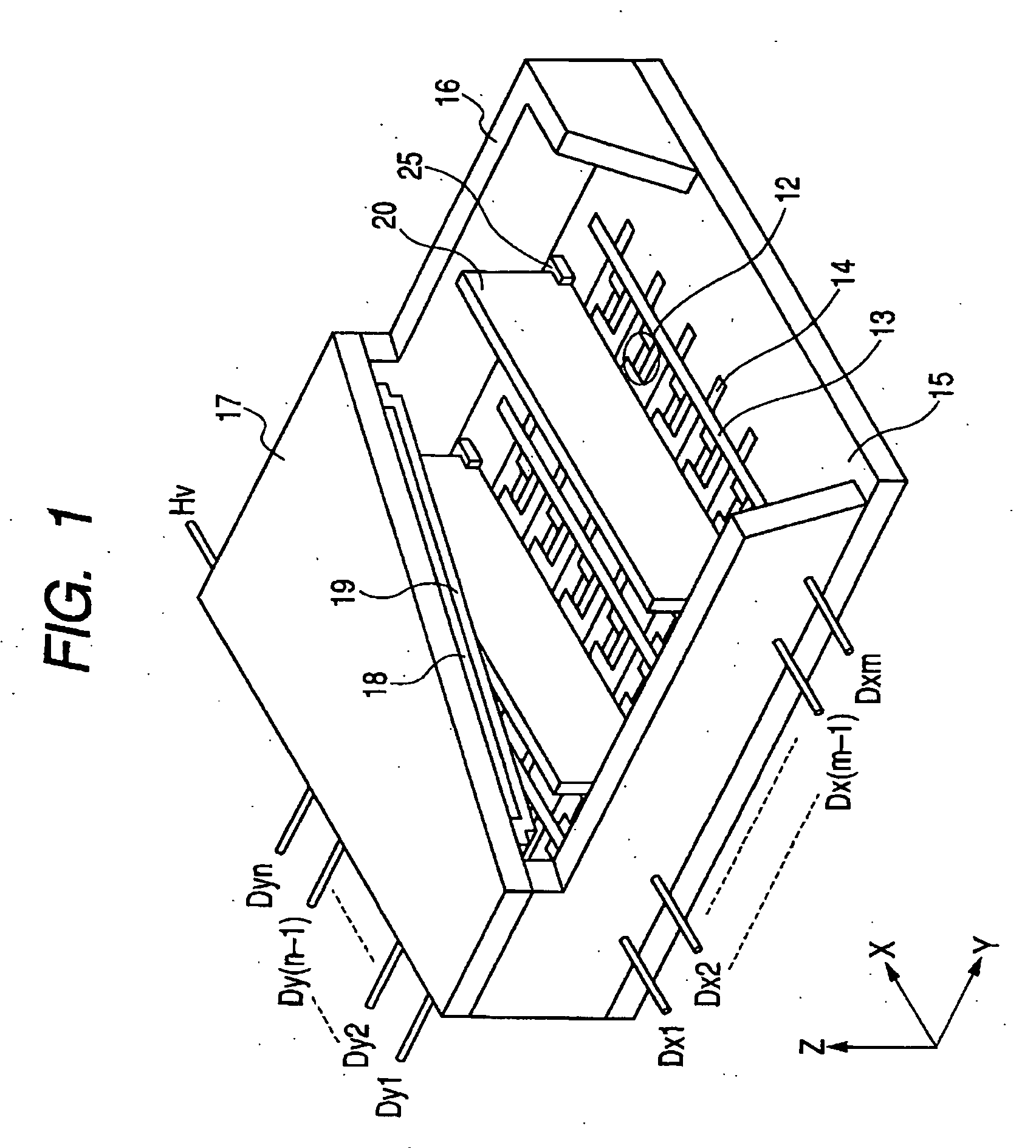

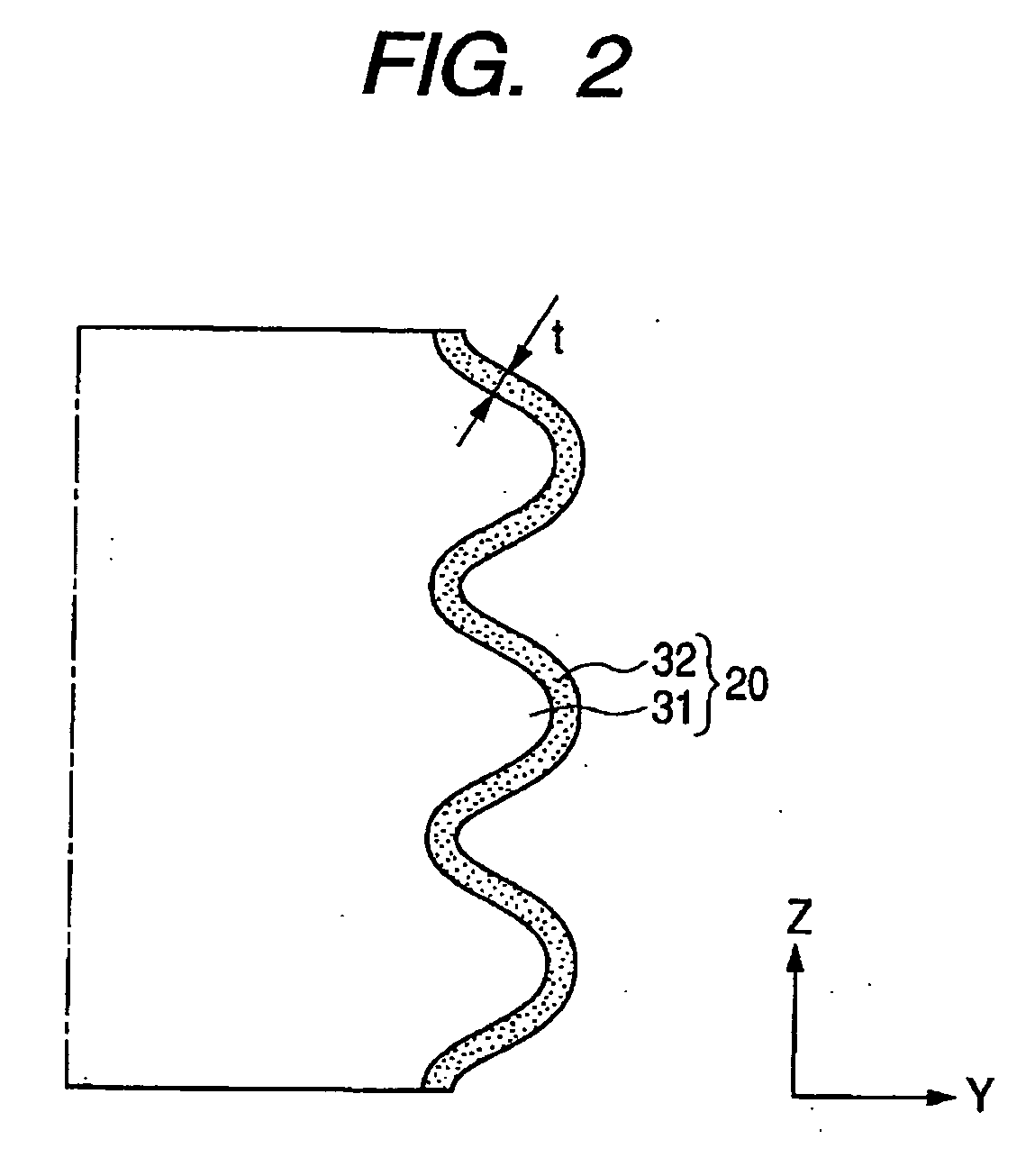

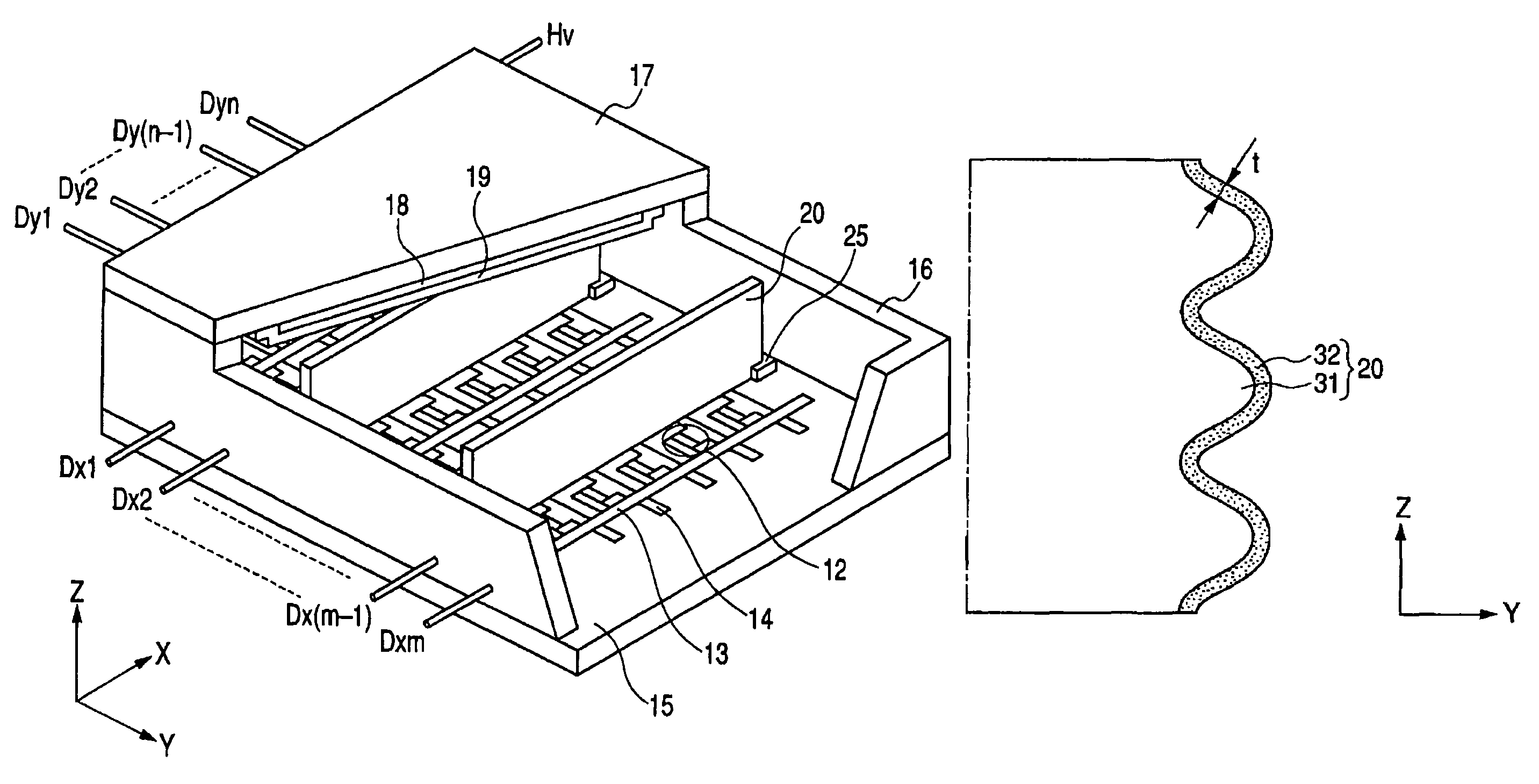

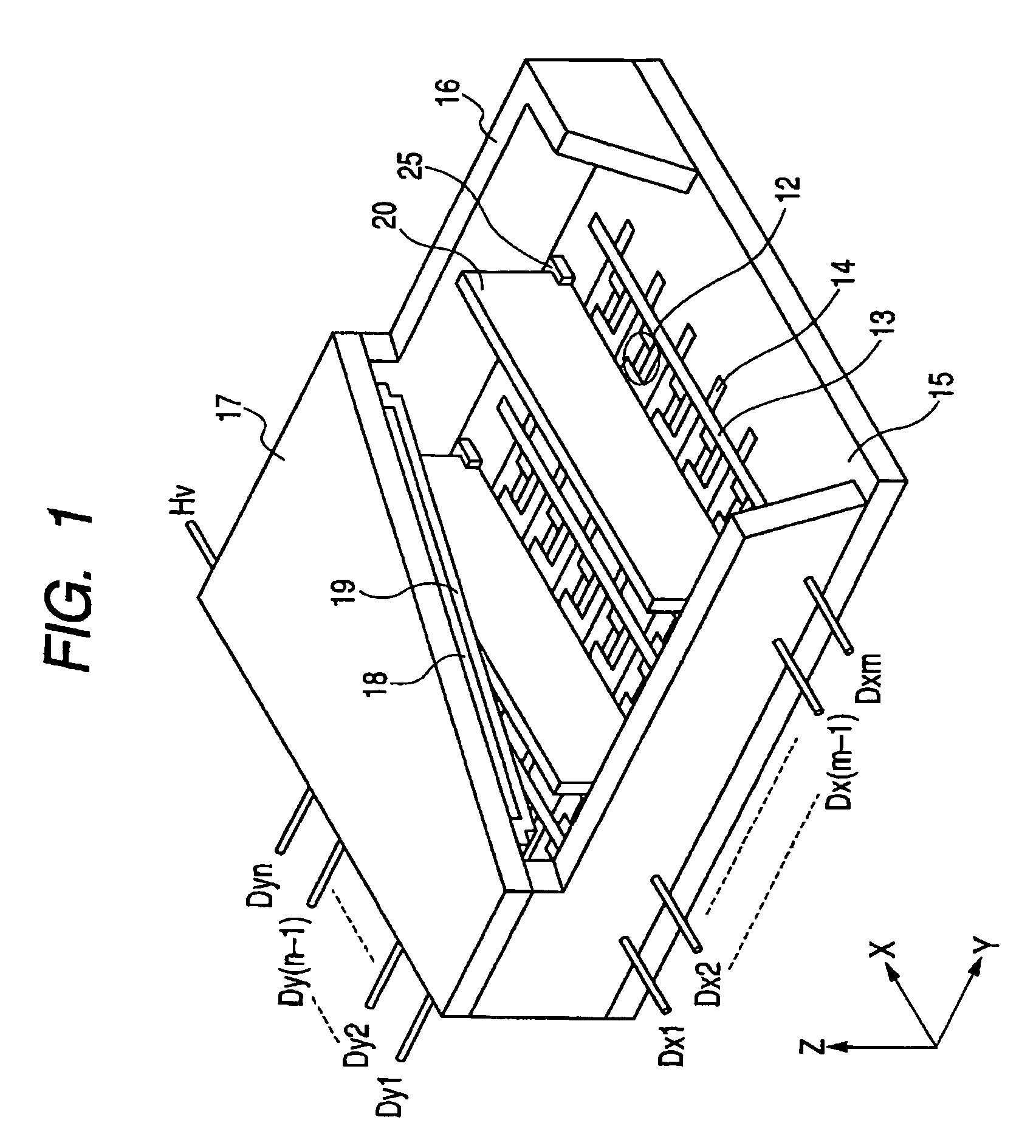

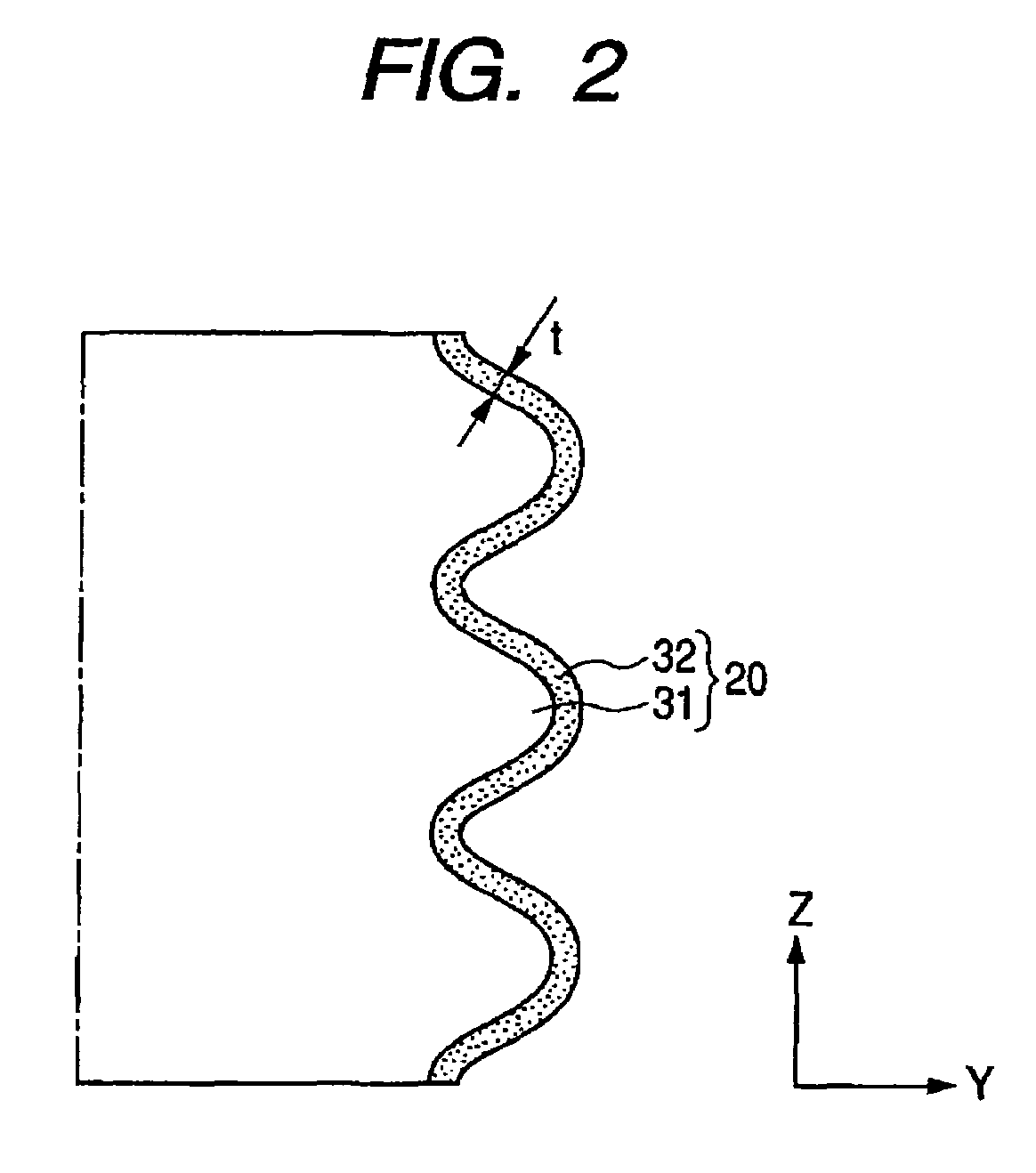

Image forming apparatus

InactiveUS20060125374A1Suppress cumulative chargingPrevents deterioration in display characteristicIncadescent body mountings/supportElectrode assembly support/mounting/spacing/insulationRough surfaceHigh resistance

In a spacer having concave / convex portions to prevent short-time charging in a flat type image forming apparatus in which an electron source substrate and an anode substrate are arranged so as to face each other through the spacer, the charging upon long-time driving due to the concave / convex portions is suppressed. In the spacer in which the surface of an insulating substrate having a rough surface is coated with a high resistance film, the high resistance film has double layers of a low resistance region locating on the substrate side and a high resistance region locating on the front surface side, and a thickness (t) of high resistance film on the slant surface of each of the concave / convex portions and a thickness (s) of high resistance region are set to (t≧dp+λ≧s) for the primary electron penetration length (dp) and the ionization electron diffusion length (λ).

Owner:CANON KK

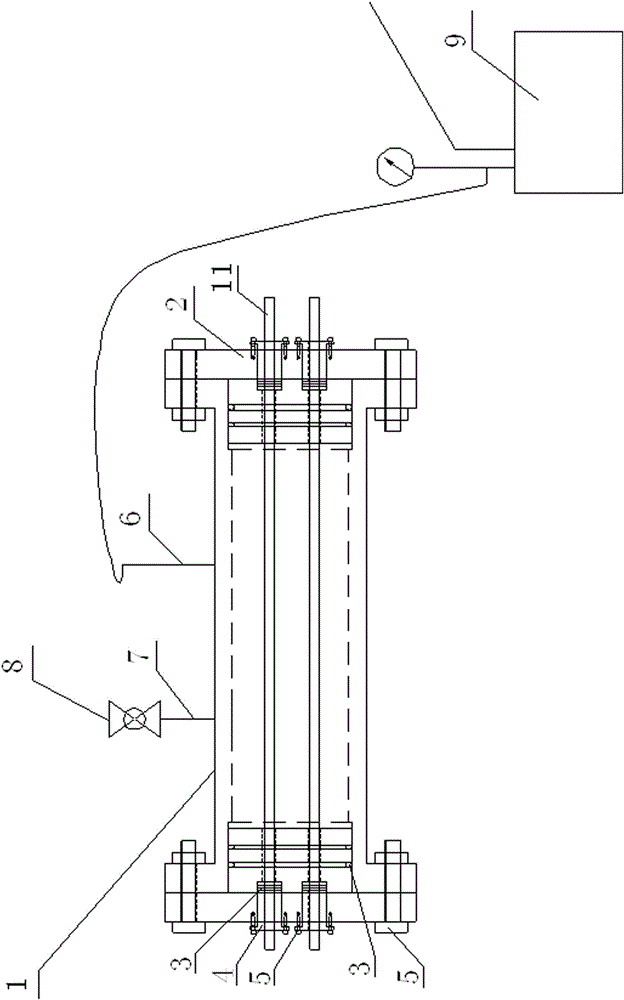

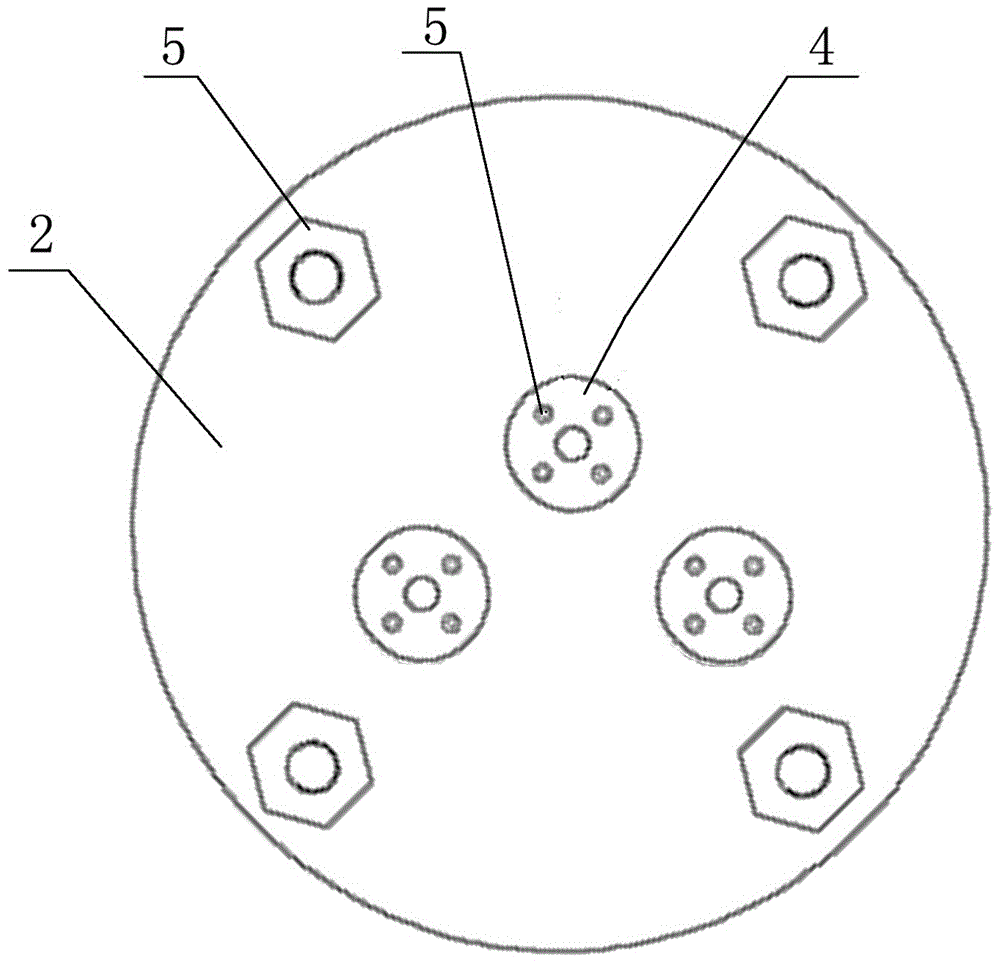

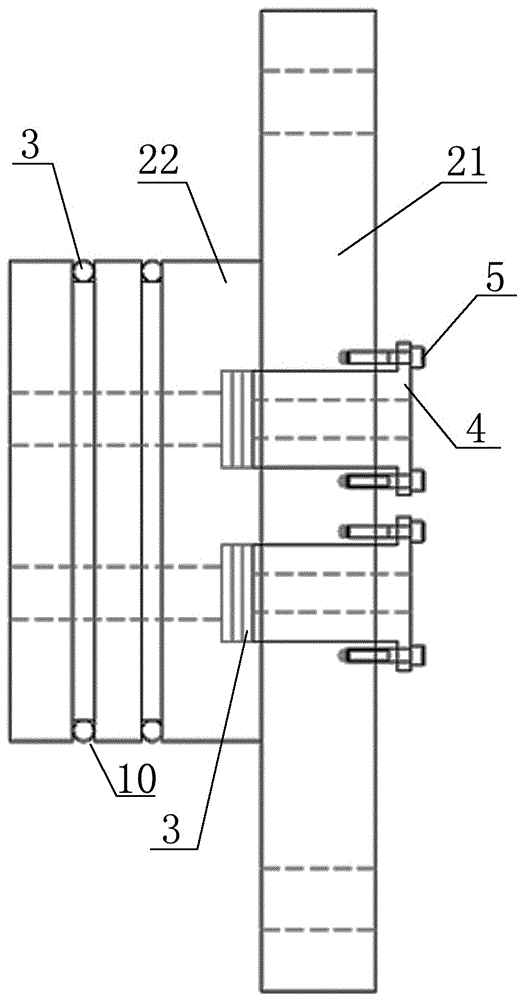

Hydrostatic test device for testing cable cores of submarine optical cables

InactiveCN106198234AReasonable structural designImprove sealingSurface/boundary effectMaterial strength using tensile/compressive forcesEngineeringHigh pressure water

The invention discloses a hydrostatic test device for testing cable cores of submarine optical cables. The hydrostatic test device comprises a cylinder, T-shaped cover plates and plugs. The two ends of the cylinder are open, the T-shaped cover plates cover the two ends of the cylinder and are fixed through fasteners, and the plugs are located in countersunk holes in the T-shaped cover plates and are fixed through fasteners. Each plug is of a through hole structure for cable cores of submarine optical cables to penetrate in. A high-pressure water inlet pipeline and a drain pipeline are welded to the outer surface of the cylinder, the high-pressure water inlet pipeline is connected with a booster pump, and the drain pipeline is connected with a ball valve. The hydrostatic test device is reasonable in structural design, good in sealing performance, easy and convenient to operate, capable of being repeatedly and safely used and capable of testing cable cores of multiple submarine optical cables at the same time; besides, a hydrostatic test and a water penetration length test can be carried out at the same time, so that working efficiency is greatly improved, and testing time is shortened.

Owner:江苏通光海洋光电科技有限公司

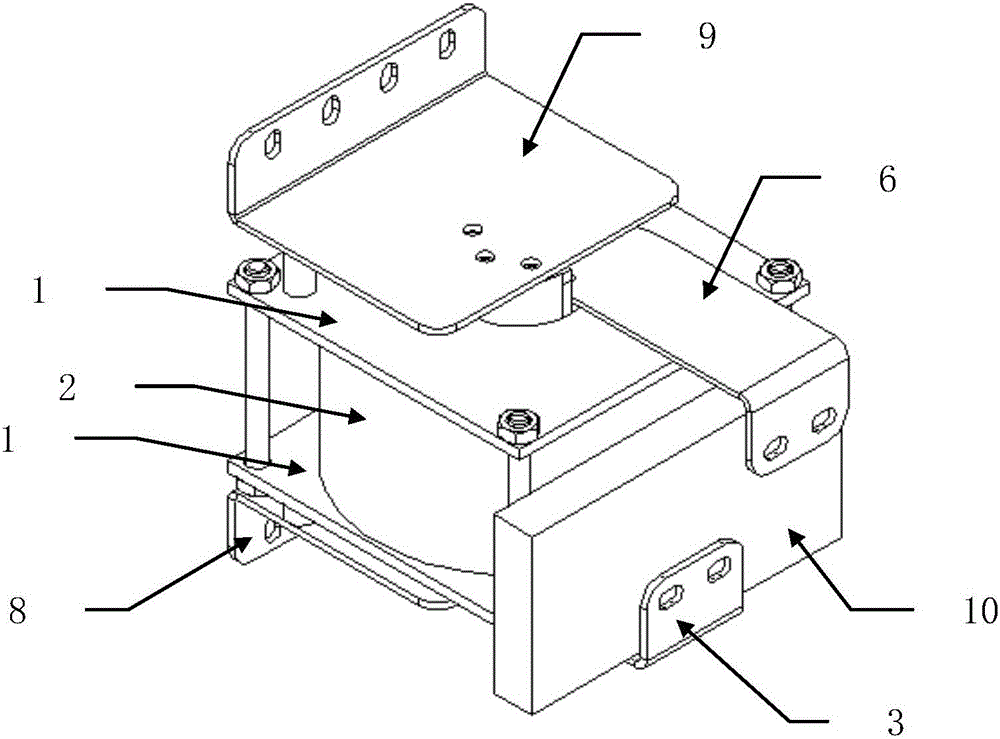

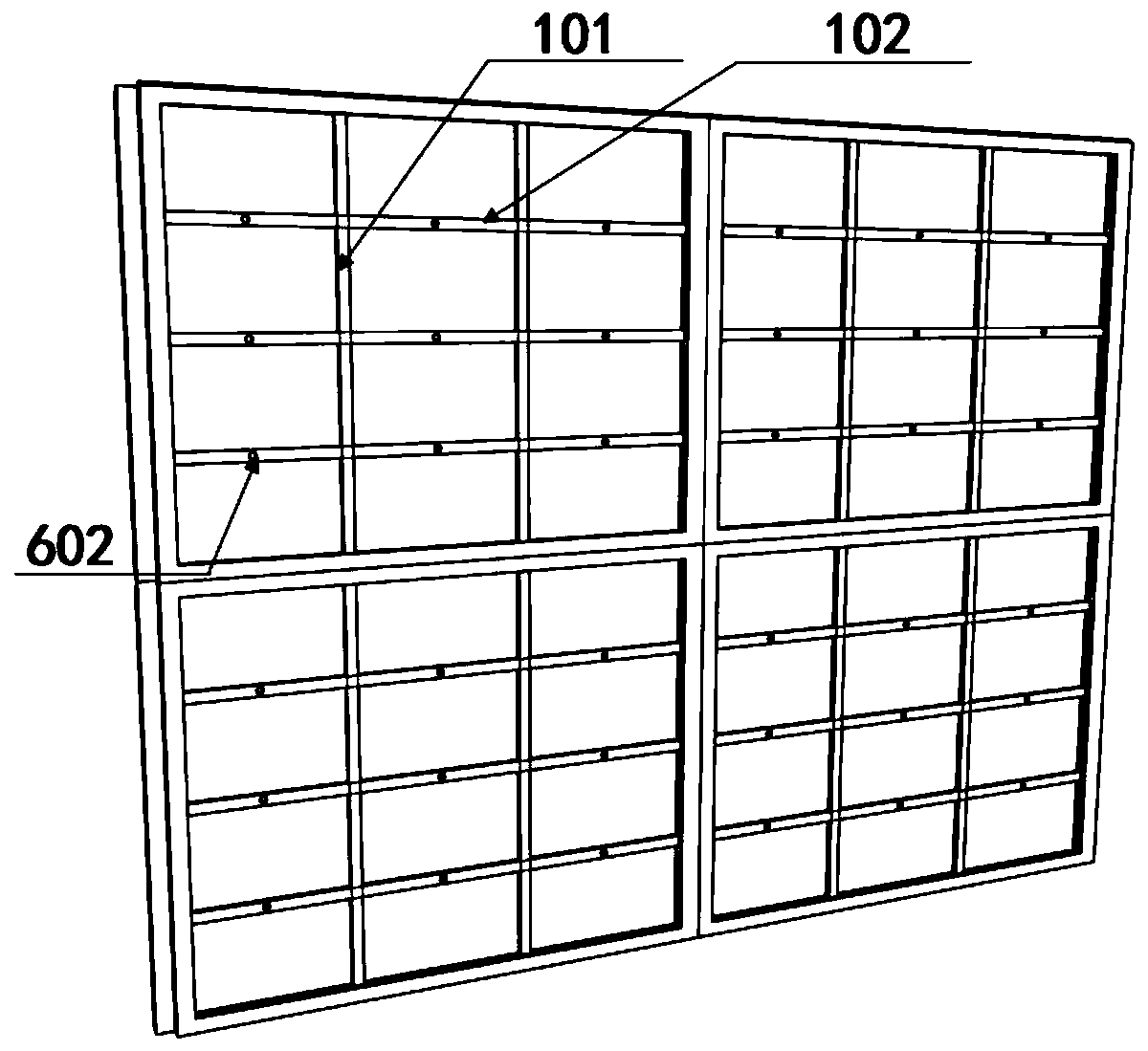

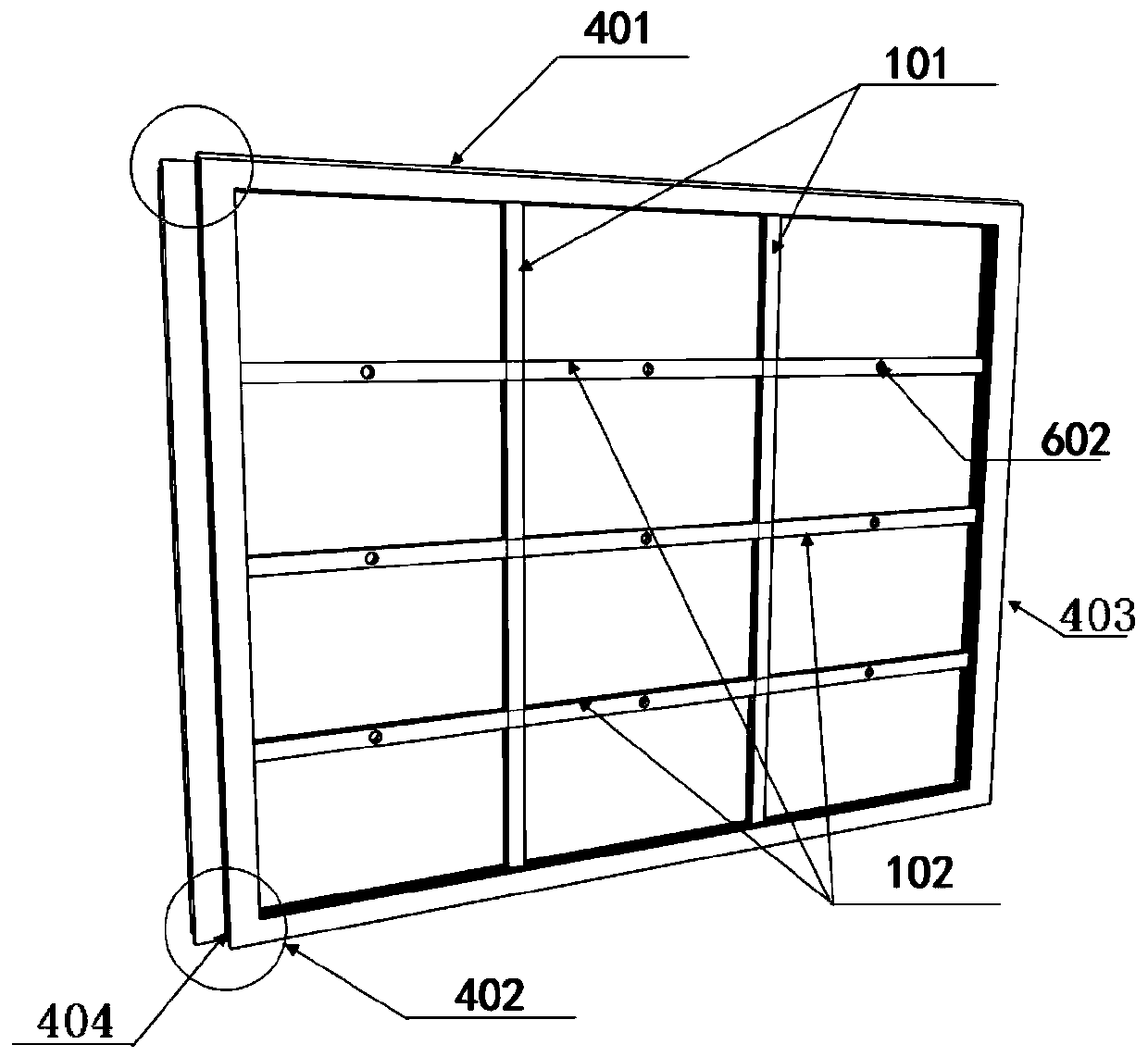

Low-voltage heavy-current ultracrystalline high-frequency transformer

ActiveCN106328346ALow failure rateLow costTransformers/inductances coils/windings/connectionsFixed transformers or mutual inductancesFailure rateLow voltage

The invention relates to a low-voltage heavy-current ultracrystalline high-frequency transformer which comprises an ultracrystalline magnetic core provided with a magnetic core inner ring, wherein the four corners of two glass silk plates are connected by bolts to clamp and fix the ultracrystalline magnetic core; a first aluminum profile column and a second aluminum profile column are arranged in the magnetic core inner ring, and isolated in an insulating manner; the upper end and the lower end of the first aluminum profile column penetrate out of the two glass silk plates respectively; the penetration length of the upper end is greater than that of the lower end; the upper end and the lower end of the second aluminum profile column penetrate out of the two glass silk plates respectively; the penetration length of the lower end is greater than that of the upper end; the lower end of the first aluminum profile column is connected with a first manifold plate; and the upper end of the second aluminum profile column is connected with a second manifold plate. According to the low-voltage heavy-current ultracrystalline high-frequency transformer, the magnetic core adopts an ultracrystalline soft magnetic material and can be simply fixed by the bolts by utilizing insulating materials; water-cooling heat dissipation or air-cooling heat dissipation can be performed; and the transformer is simple and compact in structure, high in integration degree, convenient to assemble, low in failure rate and low in cost, and is suitable for mass production.

Owner:北京京仪椿树整流器有限责任公司

Ultra-high-performance concrete combined permanent template and application thereof

PendingCN109853367AHigh strengthIncreased durabilityArtificial islandsBridge structural detailsLap jointTongue and groove

The invention belongs to the technical field of building materials, and discloses an ultra-high-performance concrete combined permanent template and application thereof. The outer side of a permanenttemplate is flat or curved surface, and the inner side is ribbed; the four side portions are thickened, and a tongue-and-groove is formed, and a lap joint of the tongue-and-groove is hydrophobic; andafter the tongue-and-groove is lap jointed, a caulking groove smaller on the outside and bigger on the inside is formed in the outer side of a template. According to the high-performance-concrete combined permanent template, a tongue-and-groove design is used on all four sides, on the one hand, the penetration length of an external substance is greatly increased; on the other hand, a lap joint surface of the tongue-and-groove is hydrophobic, infiltration of the external substance can be effectively prevented by coating a hydrophobic paste before installation, and durability can be effectivelyimproved; ultra-high-performance concrete is used as a caulking agent, the caulking groove and a bolt hole are both smaller on the outside and larger on the inside, release of an ultra-high performance concrete caulking agent can be effectively prevented, and structural durability is improved.

Owner:SOUTH CHINA UNIV OF TECH +2

Method for calculating threshold voltage of pocket implant MOSFET

InactiveUS20050086014A1Simple processEasy to giveAmplifier modifications to reduce noise influenceSemiconductor/solid-state device testing/measurementMOSFETLinearity

A threshold voltage model with an impurity concentration profile in a channel direction taken into account is provided in the pocket implant MOSFET. With penetration length of the implanted pocket in the channel direction and the maximum impurity concentration of the implant pocket used as physical parameters, the threshold voltage model is obtained by linearly approximating the profile in the channel direction. By analytically solving the model by using a new threshold condition with inhomogeneous profile taken into account, the threshold voltage can be accurately obtained. Based on thus obtained model, the threshold voltage can be predicted and can be used for circuit design.

Owner:SEMICON TECH ACADEMIC RES CENT

Conductive device

InactiveCN105470687AGuaranteed contactExtended service lifeSecuring/insulating coupling contact membersCoupling contact membersEngineeringCopper

The invention discloses a conductive device, which comprises an insulating base and a conductive connecting rod, wherein a first groove is formed in the upper end part of the insulating base; a conductive copper bar is arranged in the groove; an opening which is communicated with the groove is formed in the lower end part of the insulating base; a second groove is formed in the center position of the lower end part of the conductive copper bar along the axial direction; one end of the conductive connecting rod passes through the opening and enters the second groove to contact the conductive copper bar; and a compression spring is arranged on the conductive connecting rod between the lower end part of the conductive copper bar and the bottom part of the first groove. Acting force is applied to the conductive copper bar through the compression spring; the condition that the conductive copper bar is in contact with the lower surface of a tooling through elastic action even if the upper end surface of the conductive copper bar is abraded is ensured when the conductive copper bar is in contact with the tooling; and the service lifetime of the conductive device can be further prolonged by adjusting the penetration length of a conductive bolt under the condition of relatively large abrasion of the conductive copper bar.

Owner:SUZHOU AOGUAN ROBOTIZATION EQUIP

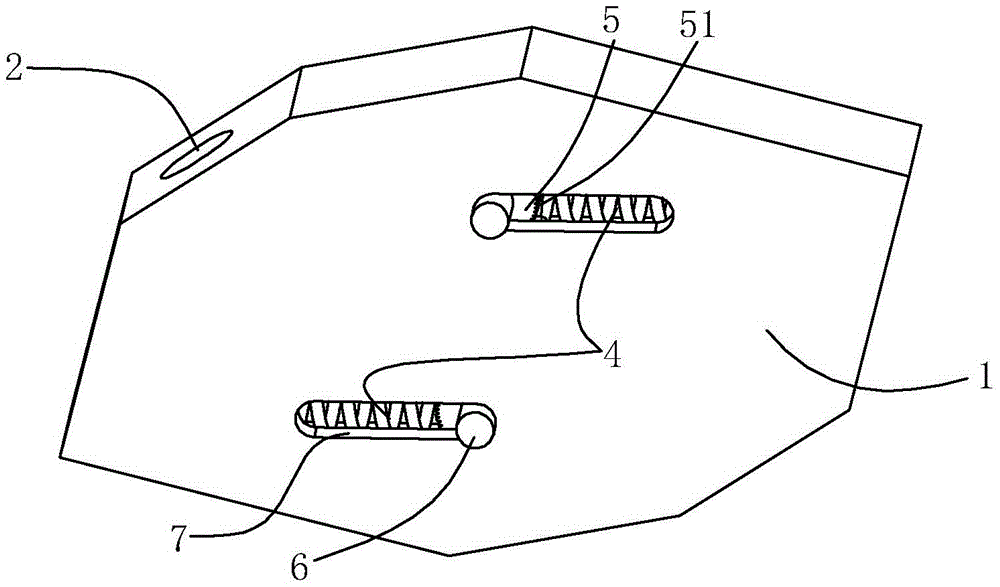

Tooth clamp type connector

ActiveCN103742595APromote sportsReal-time adjustment of penetration lengthRopes and cables for vehicles/pulleyTextile cablesMechanical engineeringPenetration length

The invention relates to a tooth clamp type connector. The tooth clamp type connector comprises a shell, wherein a threading hole and an accommodating cavity are formed in the shell and are locally communicated with each other; a clamping gear and an elastic piece are arranged in the accommodating cavity; the peripheral edge of the clamping gear is locally provided with clamping teeth at least; the elastic piece acts on the clamping gear, so that the clamping teeth of the clamping gear tend to a local communicated area of the threading hole and the accommodating cavity; outwards raised shifting rods are arranged on two side surfaces, which are perpendicular to the moving direction, of the clamping gear; long and narrow holes which are formed along the moving direction of the clamping gear are formed in the corresponding portions of the side wall of the accommodating cavity; and two ends of each shifting rod of the clamping gear are exposed out of the corresponding long and narrow hole. The tooth clamp type connector has a function of locking a connecting line, the clamping gear can be driven to press a spring by using the shifting rod, so that movable space is reserved for the penetrated connecting line, and the purpose of adjusting the penetration length of the connecting line or withdrawing the connecting line is achieved.

Owner:宁波迅联机械制造有限公司

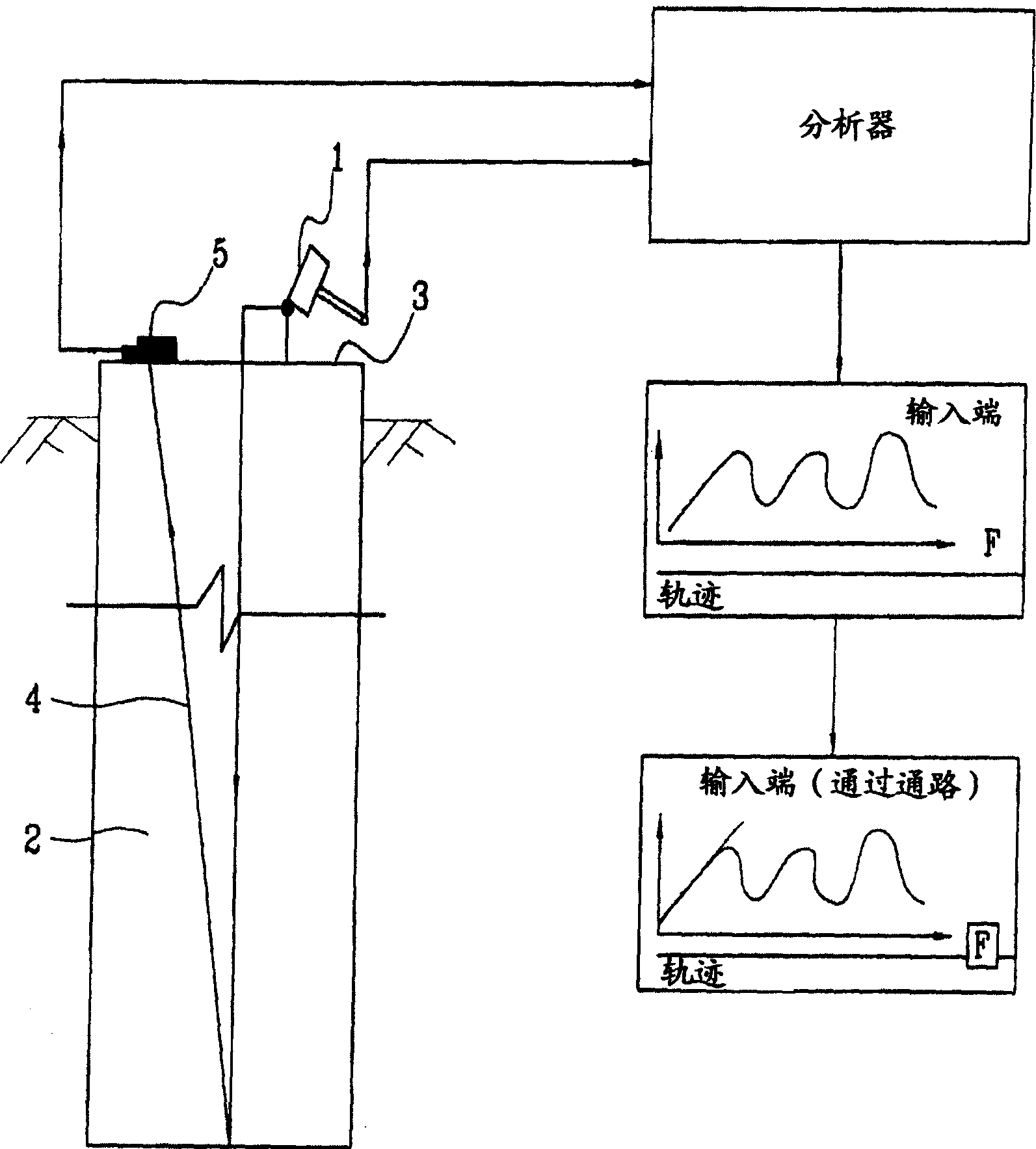

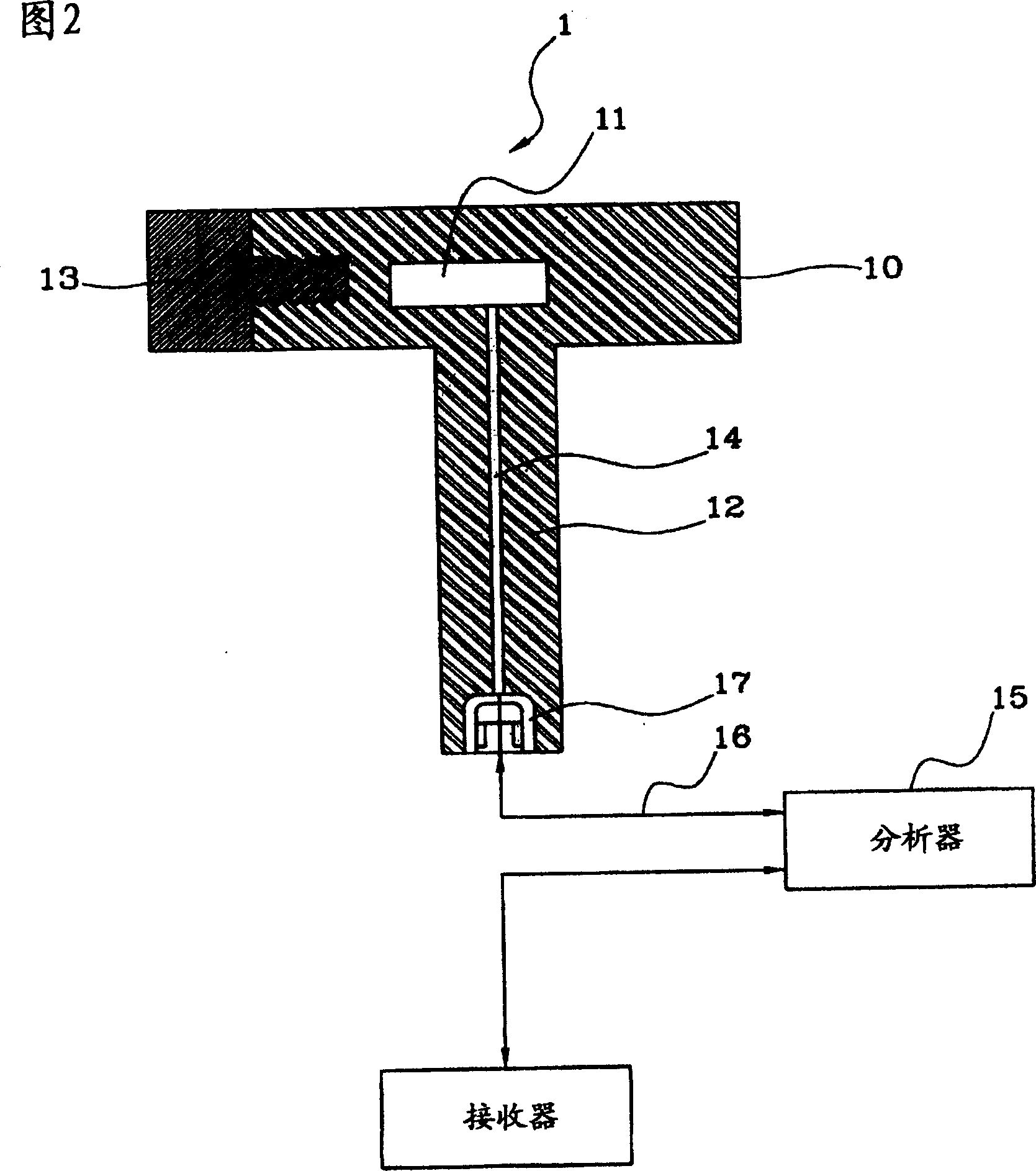

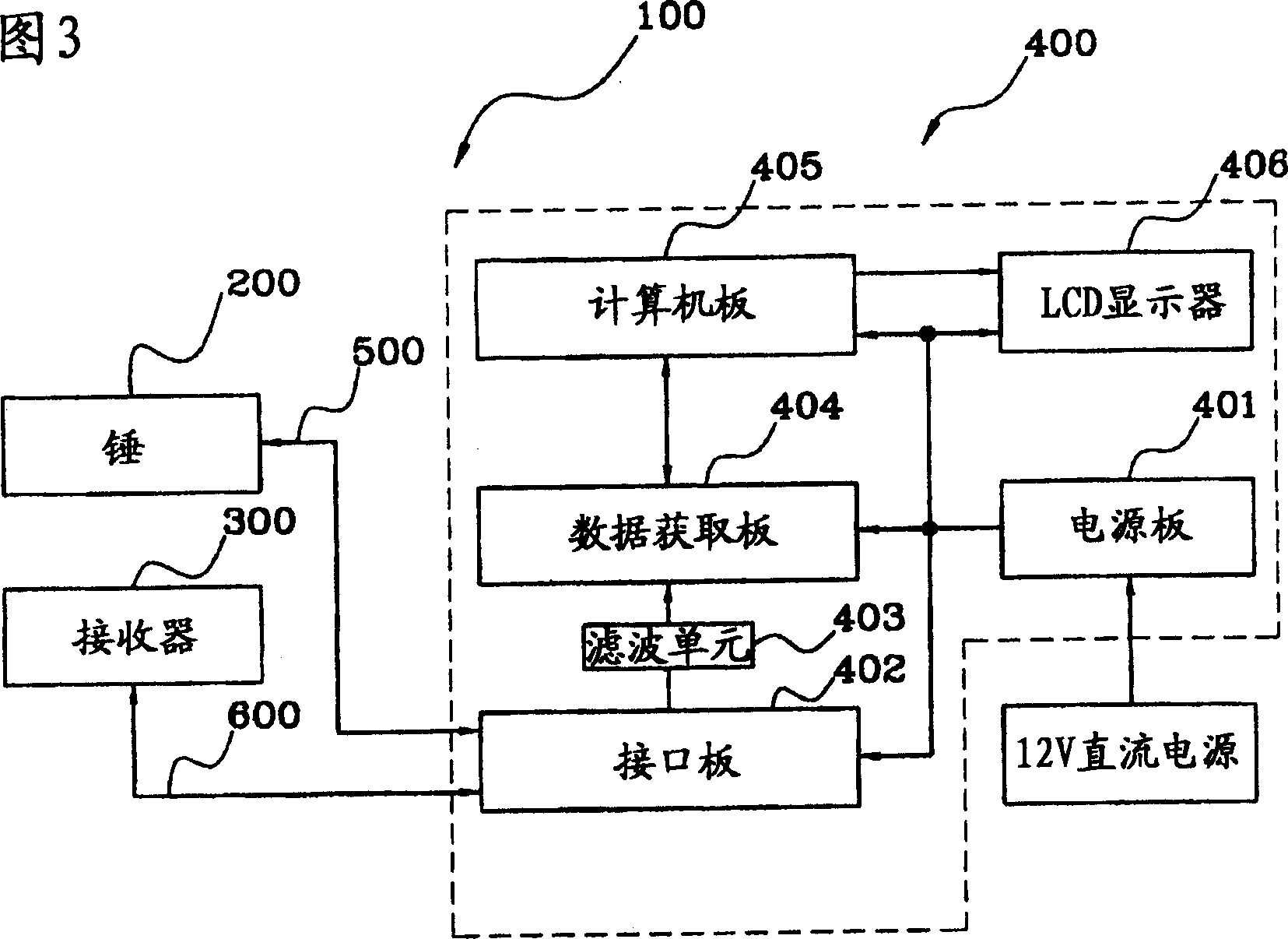

Harmless measuring method and device for analyzing and determining underground pile penetration length

InactiveCN1700042AEasy to replaceElastic waves are easy to generateMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial strength using repeated/pulsating forcesNon destructiveEngineering

The invention discloses a non-destructive inspection method and a hammer of a non-destructive inspection apparatus for analyzing and determining underground pile penetration length. The hammer of a non-destructive inspection apparatus comprises a steel main body for impacting, a handle connected with the steel main body and a strain sheet for applying impact force. The non-destructive inspection method comprises steps: a digging step for forming an inserting space portion, a cylindrical pipe inserting step for putting the cylindrical pipe into the inserting space portion, a receiver inserting step for inserting the receiver into the cylindrical pipe and an analyzing step for measuring and analyzing impact force signals generated by hammer knocking. When lifting the receiver in the cylindrical pipe at presetting intervals orderly, knocking the side of buildings in presetting intervals, the analyzer analyzes and measures impact force signals generated by knocking the side of buildings and horizontal elastic waves.

Owner:MI SUNG C&S INSPECTION

Spacer structure for image forming apparatus

InactiveUS7449827B2Suppress cumulative chargingPrevents deterioration in display characteristicIncadescent body mountings/supportElectrode assembly support/mounting/spacing/insulationHigh resistanceRough surface

Owner:CANON KK

Catheter pushing device

The invention provides a catheter pushing device. The device comprises a guide catheter needle, a pusher body, a pushing roller, a clutch, a pushing hand wheel, a self-rotating hand wheel, a catheter protection tube, a parallel rudder, a cardan joint, a cantilever, a self-locking joint, a vertical column, a base, a pusher assembly and a frame assembly. The pusher assembly comprises the guide catheter needle, the pusher body, the pushing roller, the clutch, the pushing hand wheel, the self-rotating hand wheel and a catheter protection tube. The pusher body is installed at the left end of the guide catheter needle. The self-rotating hand wheel is installed at the left end of the pusher body. The center of the pusher body is provided with the pushing hand wheel. According to the catheter pushing device, the pushing hand wheel and the self-rotating hand wheel are provided with microscales, therefore the penetration length and angle of the catheter can be precisely adjusted to facilitate the quantitative analysis by the medical personnel, the device is both stable and accurate. The arranged pusher assembly can be conveniently detached. Before use antiseptic treatment is necessary to the pusher assembly. The device can be used repeatedly, and the cost is reduced.

Owner:天津优视眼科技术有限公司 +1

A tooth card connector

ActiveCN103742595BPromote sportsReal-time adjustment of penetration lengthRopes and cables for vehicles/pulleyTextile cablesMechanical engineeringPenetration length

Owner:宁波迅联机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com