Tooth clamp type connector

A connector and card-type technology, applied in the direction of belts/chains/gears, transmission elements or pulleys, ropes or cables, textile cables, etc., can solve operational obstacles, inconvenient real-time adjustments, and difficult to accurately grasp the penetration length of steel wires And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

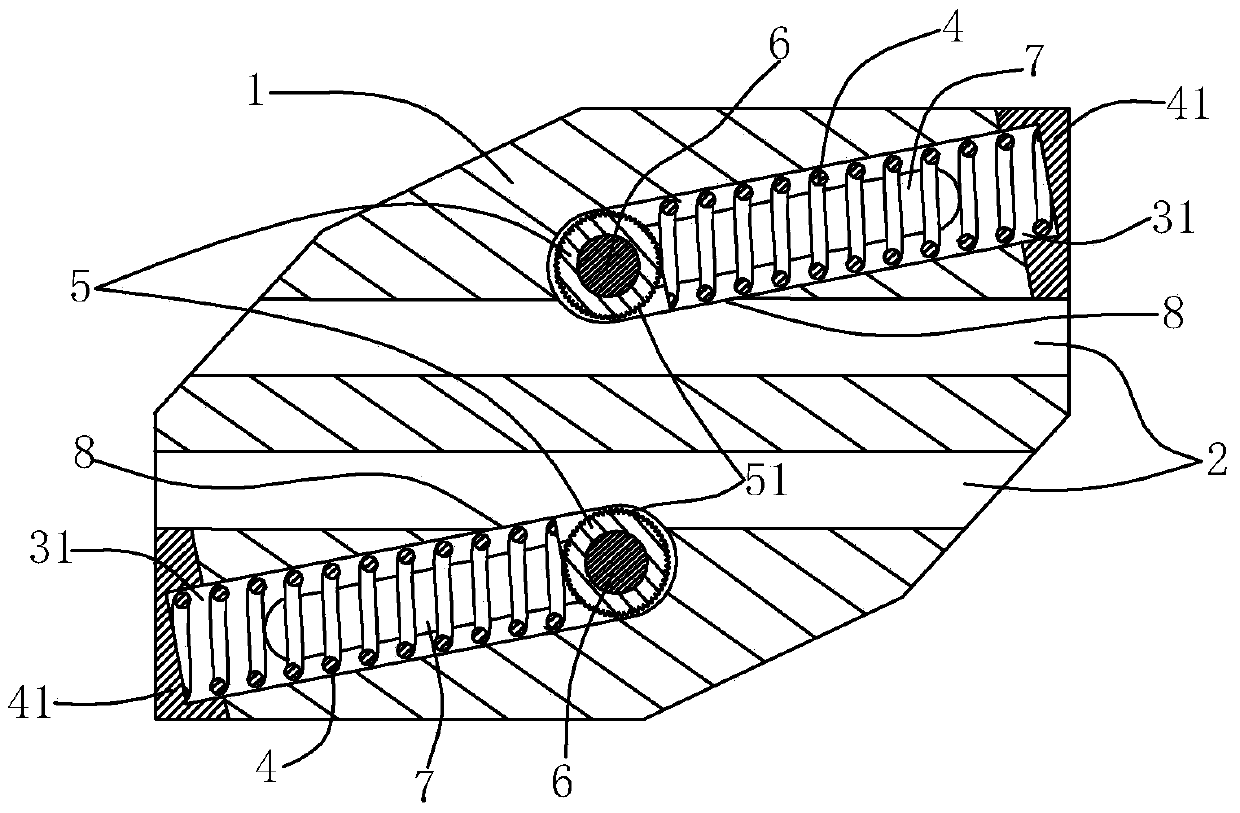

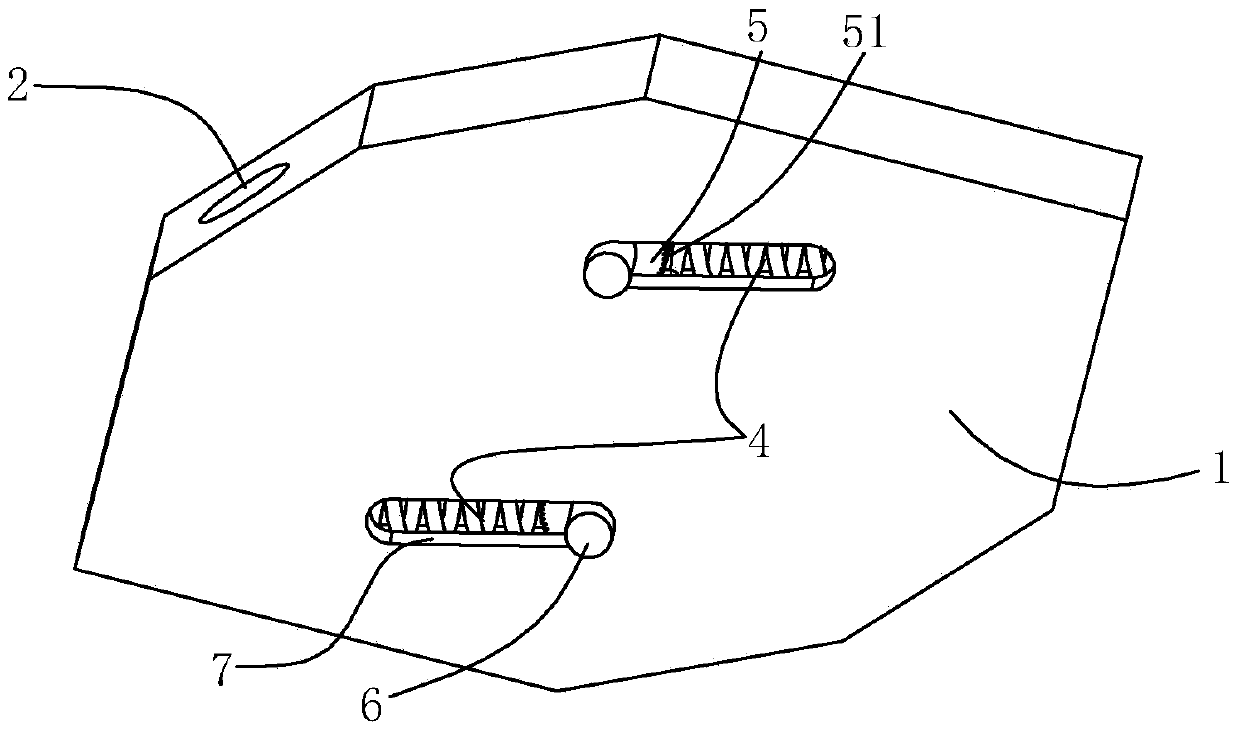

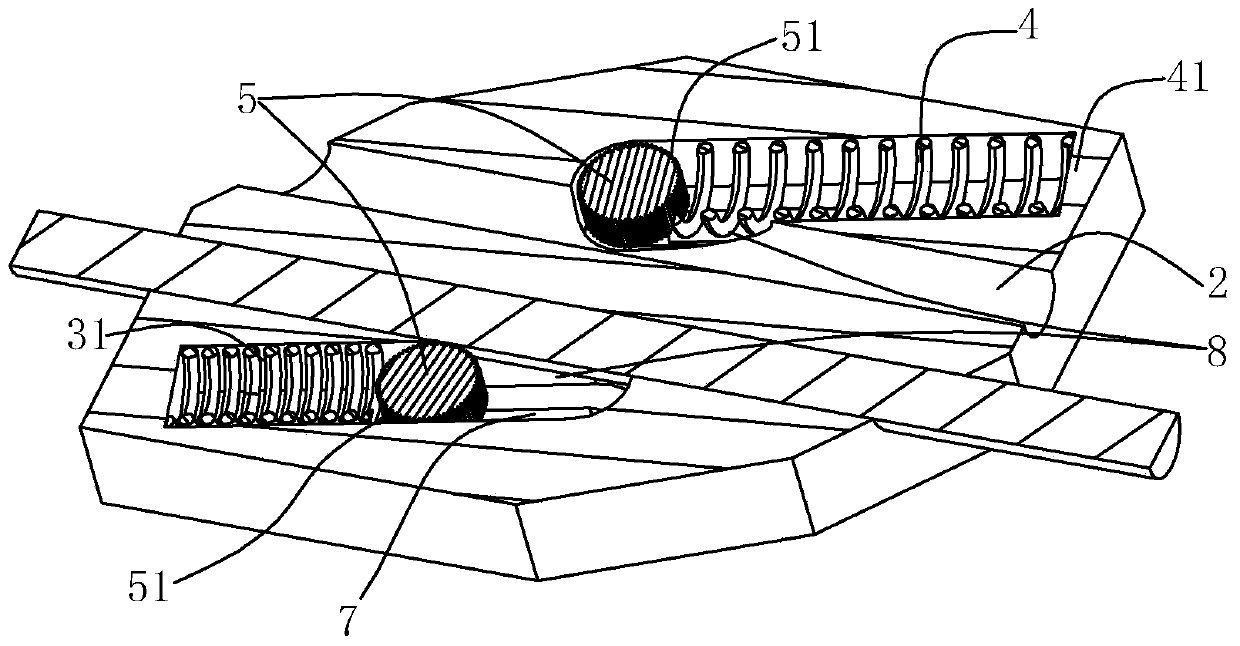

[0030] like figure 1 , figure 2 and image 3 As shown, the card connector in this embodiment includes

[0031] A card connector, comprising a housing 1, the housing 1 has a threading hole 2 and a bar hole 31;

[0032] The locking gear 5 is arranged in the bar hole 31, and the periphery of the locking gear 5 has locking teeth 51;

[0033] The elastic member 4 is arranged in the bar hole 31;

[0034] The strip hole 31 is arranged along the movement direction of the elastic member 4, the axis of the strip hole 31 intersects with the axis of the threading hole 2 to form a lock angle of α, and the angle of the lock angle α is 15°. The part where the hole 31 intersects with the threading hole 2 forms a local communication area 8, and the elastic member 4 acts on the locking gear 5 to drive the locking gear to move in the bar hole 31, so that part of the locking gear 5 is locked. 51 can enter and exit the local communication area 8, so as to realize the locking and release of t...

Embodiment 2

[0045] like Figure 4 As shown, the difference from the first embodiment is that there is an accommodating cavity 3 inside the casing, the threading hole 2 has a partly communicating area 8 with the accommodating cavity 3 , and the locking gear 5' is arranged in the accommodating cavity 3 , the peripheral portion of the locking gear 5' has locking teeth 51', and the rest is smooth, and the locking teeth 51' can enter and exit the local communication area 8;

[0046] In addition to being provided with an elastic member 4, the accommodating chamber 3 is also provided with a fixed rod 32, the first end of the elastic member 4 is fixedly arranged on the inner end surface of the accommodating chamber 3 near the exit end of the threading hole 2, and the elastic The second end of the piece 4 abuts against the locking gear 5' or is connected to the locking gear 5', and the first end of the fixing rod 32 is fixedly arranged on the inner end surface of the accommodating cavity 3 near th...

Embodiment 3

[0055] like Figure 5 and Image 6 As shown, the difference between the present embodiment and the first embodiment is that the tooth card connector also includes two push buttons 61, which are located outside the housing 1 and are respectively connected to the lever 6 of the card gear 5. end connected. Not only is it convenient to push the lever, but it also increases the comfort of fingers holding the lever,

[0056] In order to achieve a beautiful appearance and to facilitate production, the push button 61 is integrated outside the housing 1 in the shape of a sliding sleeve, straddling the housing 1, and is pushed when the user recognizes and releases the connecting line. Pushing direction of button (61), can also be provided with pushing direction mark protrusion on described sliding sleeve shape push button 61, or directly paste the pushing direction icon of sliding sleeve shape push button 61 on described sliding sleeve shape push button 61.

[0057] For the convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com