Low-voltage heavy-current ultracrystalline high-frequency transformer

A high-frequency transformer and ultra-microcrystalline technology, which is applied in the field of high-frequency transformers, can solve the problems that cannot meet the actual needs and the requirements are becoming more and more stringent, and achieve the effect of simple structure, simple and compact structure, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

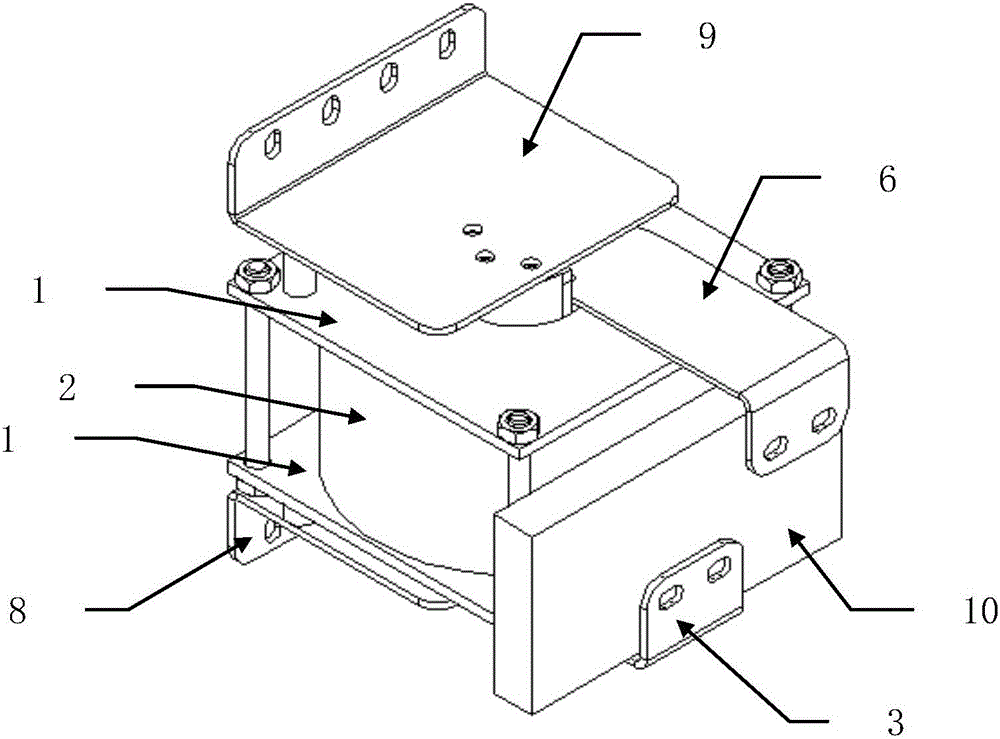

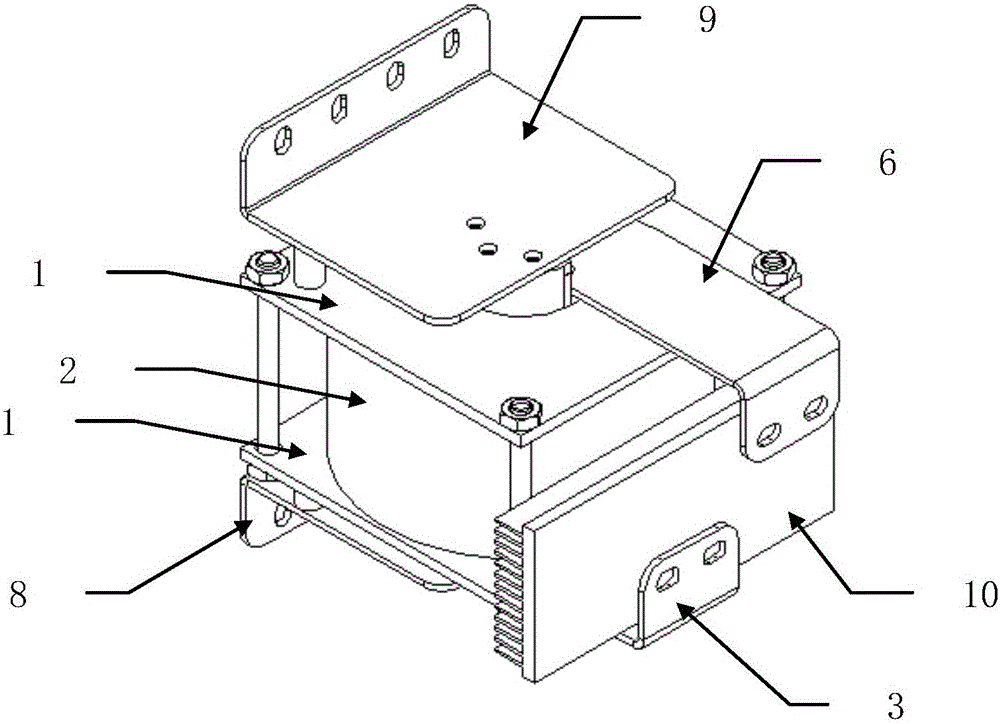

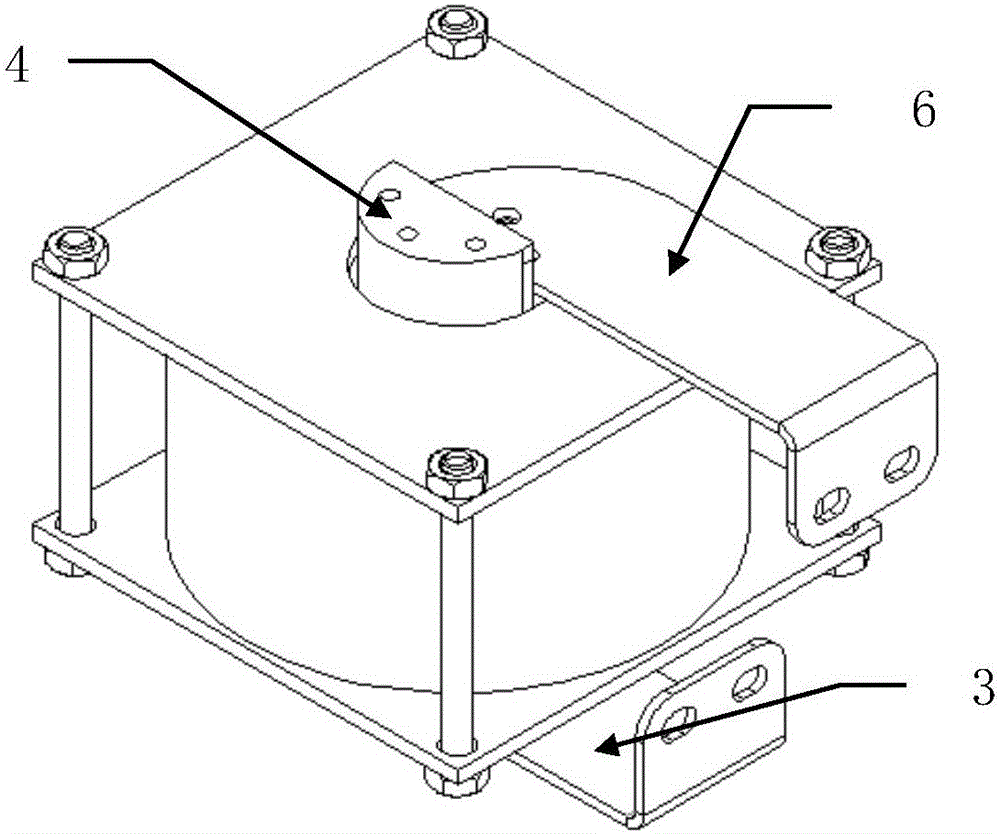

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0053] Such as Figure 4 , 5 , Shown in 6 and 7, the low-voltage high-current ultramicrocrystalline high-frequency transformer of the present invention includes:

[0054] The ultrafine crystal magnetic core 2 is cylindrical as a whole, and is provided with through holes along its axial direction to form the inner ring of the magnetic core.

[0055] A glass fiber plate 1 is respectively arranged on the top surface and the bottom surface of the nanocrystalline magnetic core 2,

[0056] The four corners of the two glass wool boards 1 are connected by bolts so that the glass wool boards 1 clamp and fix the ultramicrocrystalline magnetic core 2,

[0057] The first aluminum profile column 4 is in a semi-cylindrical shape as a whole,

[0058] The second aluminum profile column 7 is in a semi-cylindrical shape as a whole,

[0059] The first aluminum profile colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com