Patents

Literature

226results about How to "Suppress pressure fluctuations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

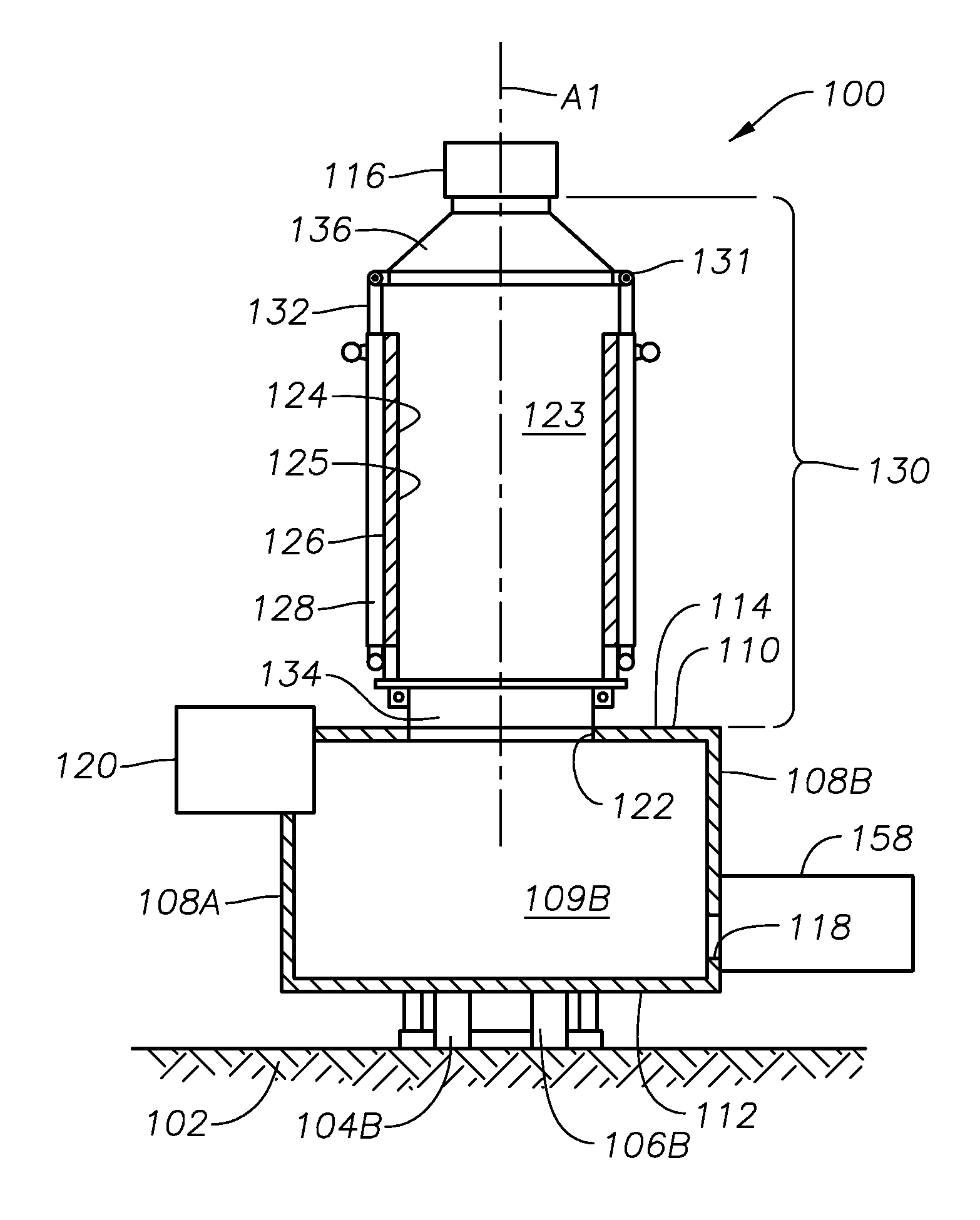

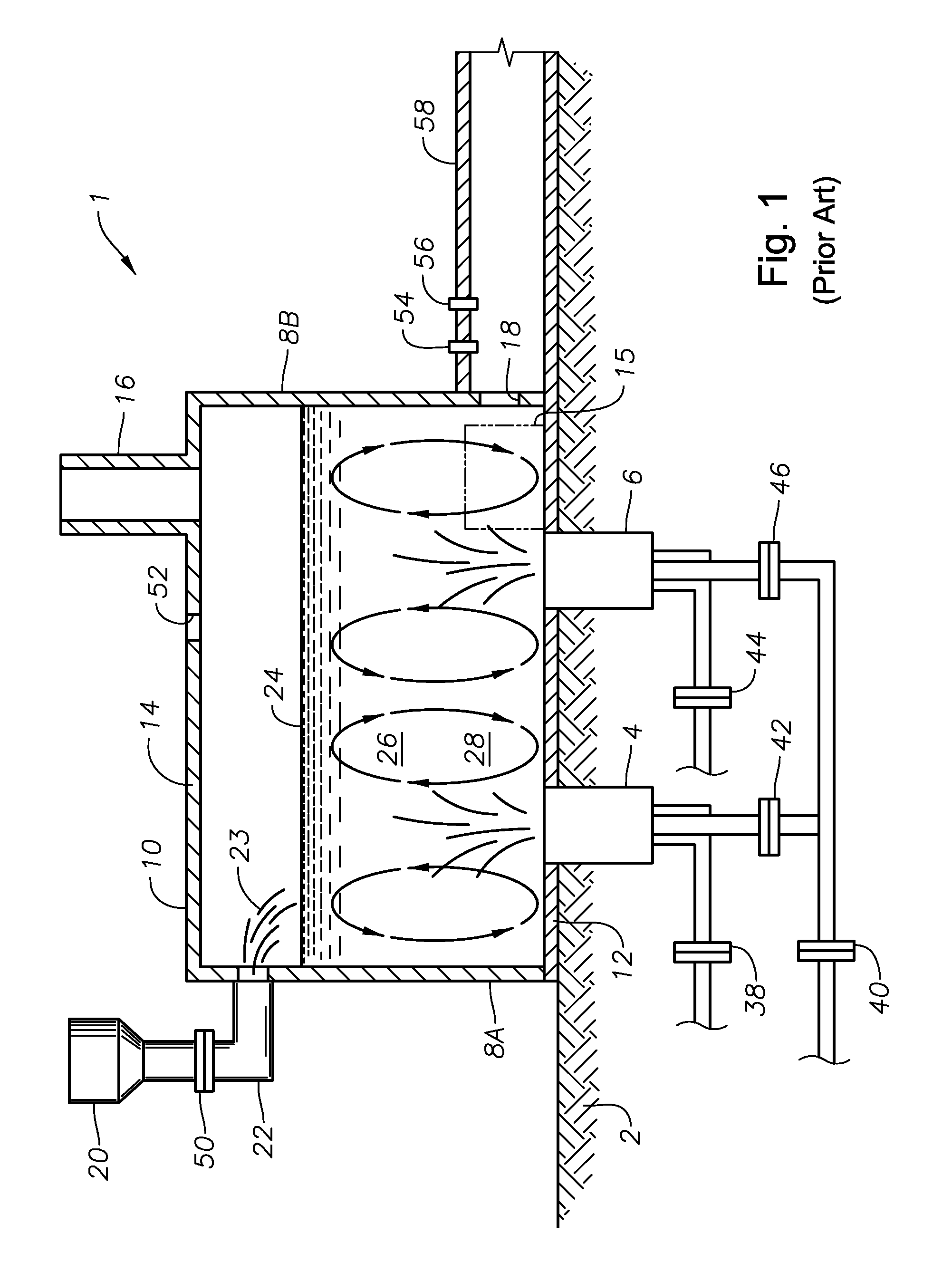

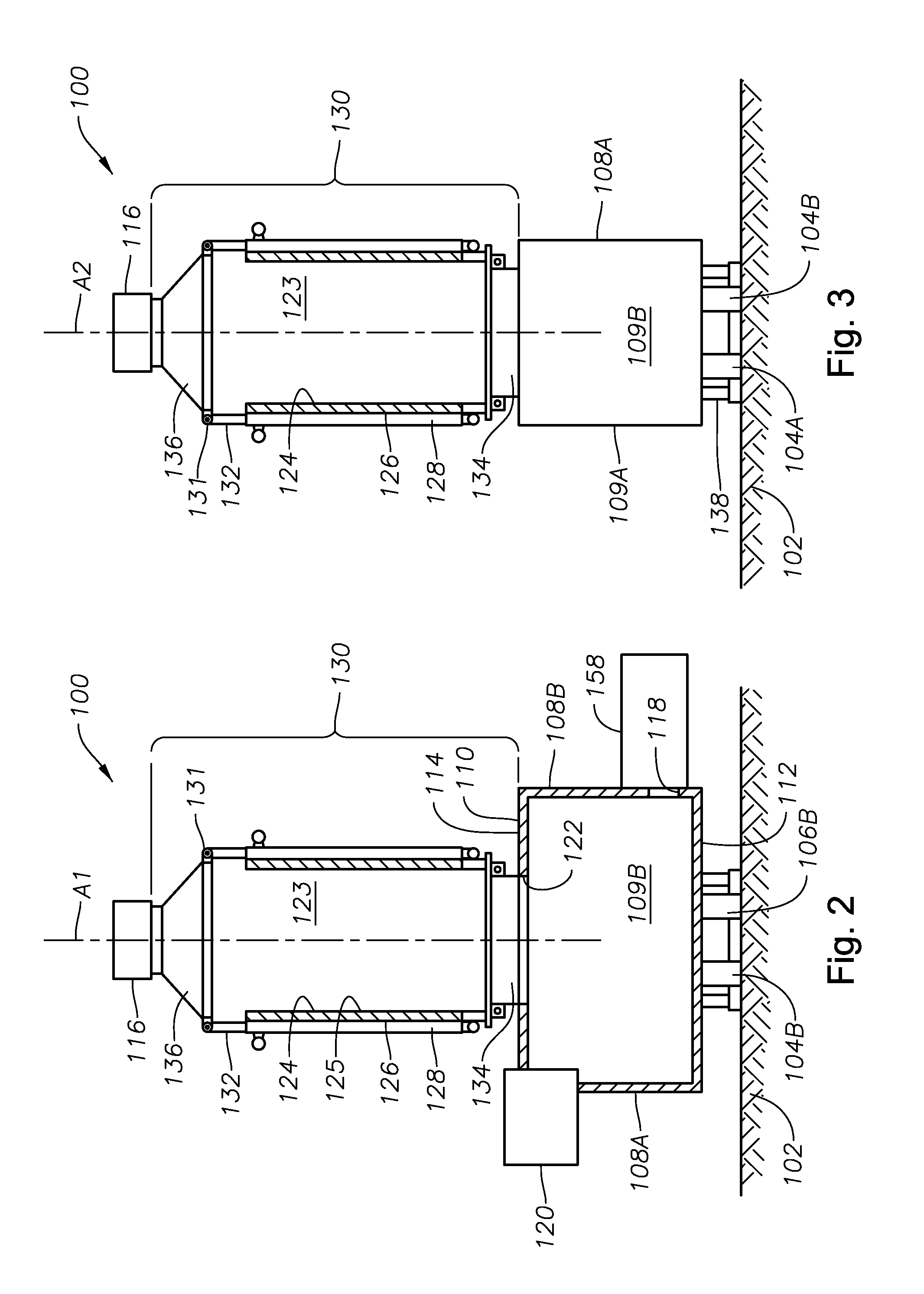

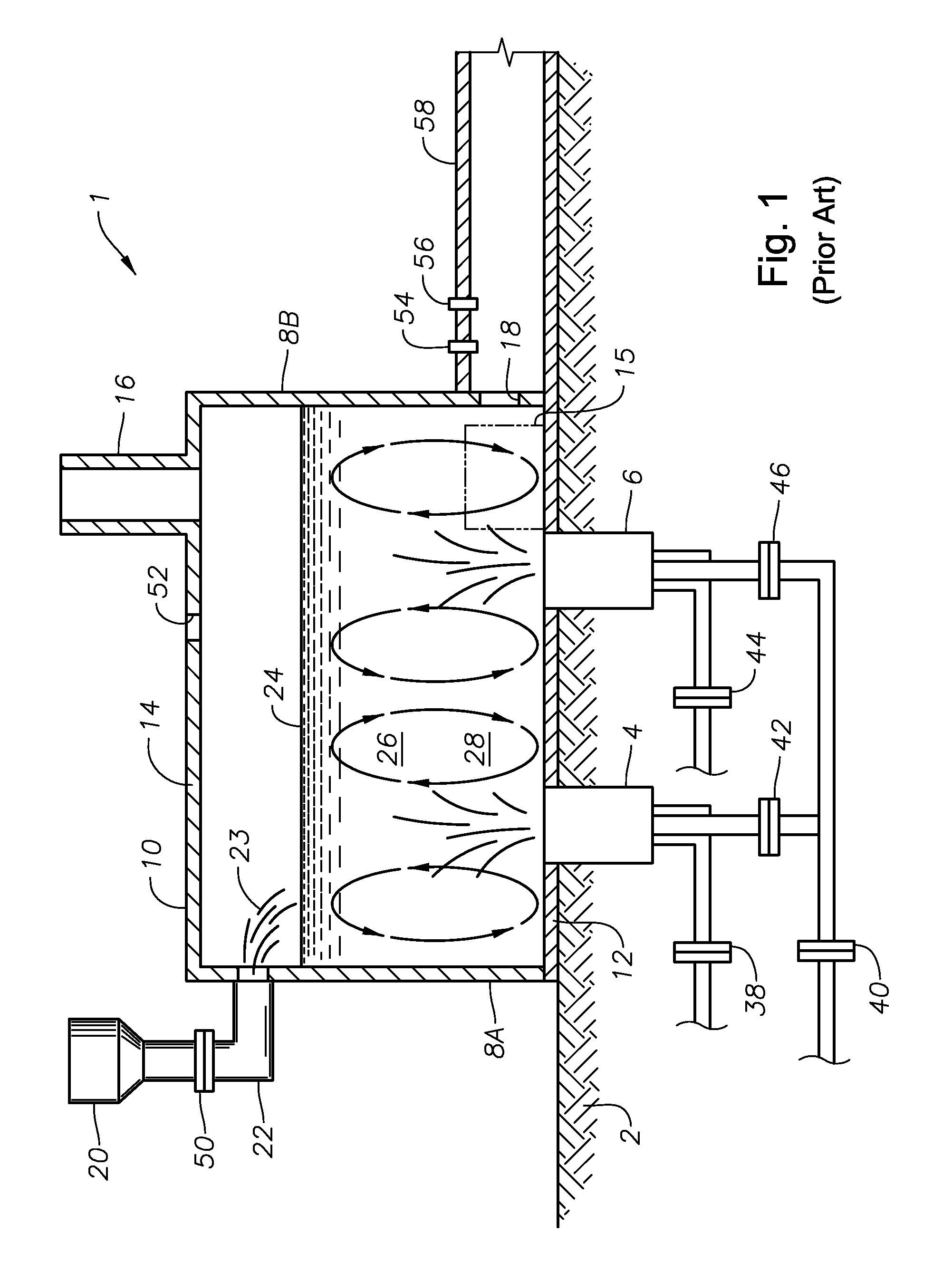

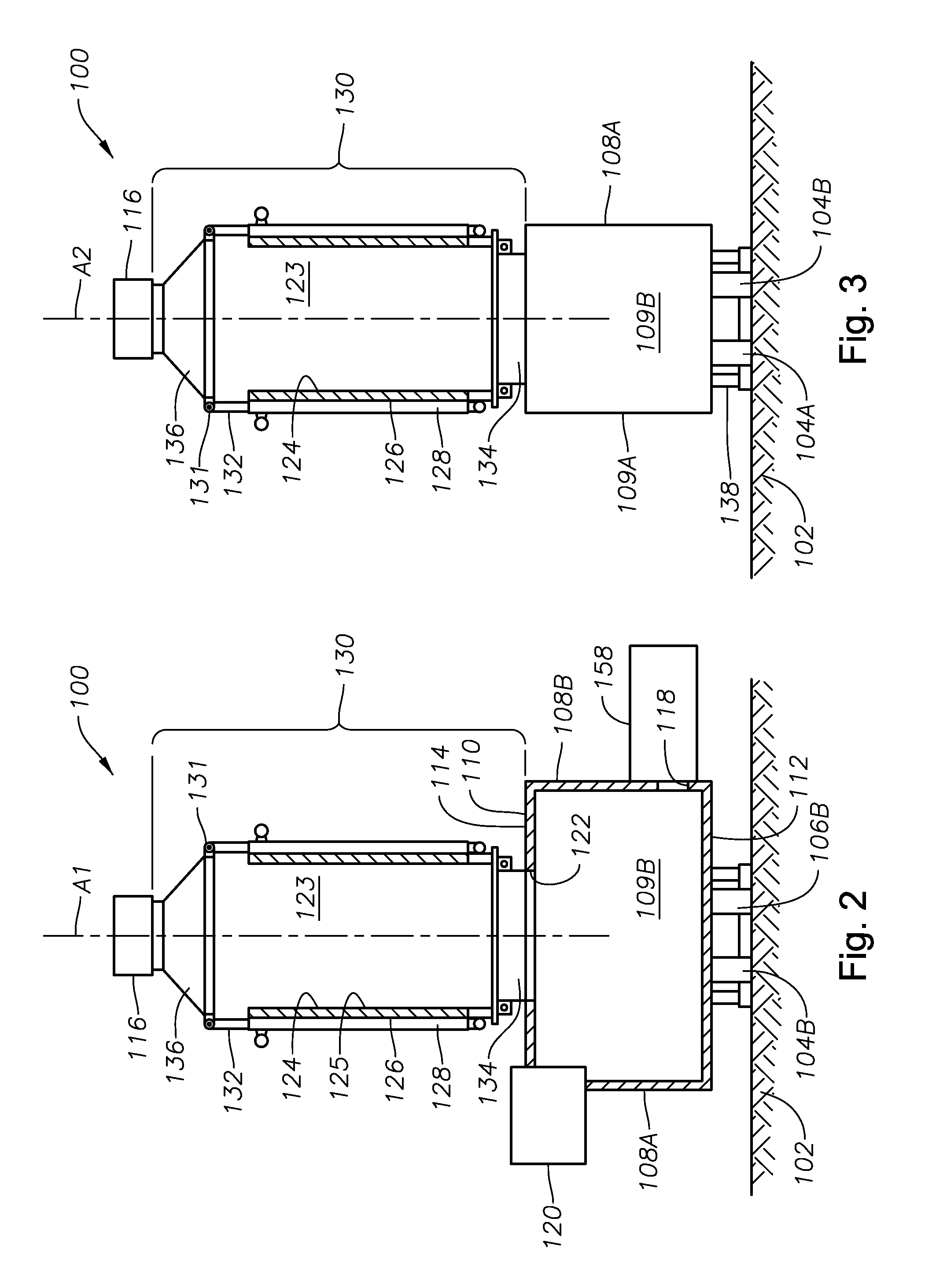

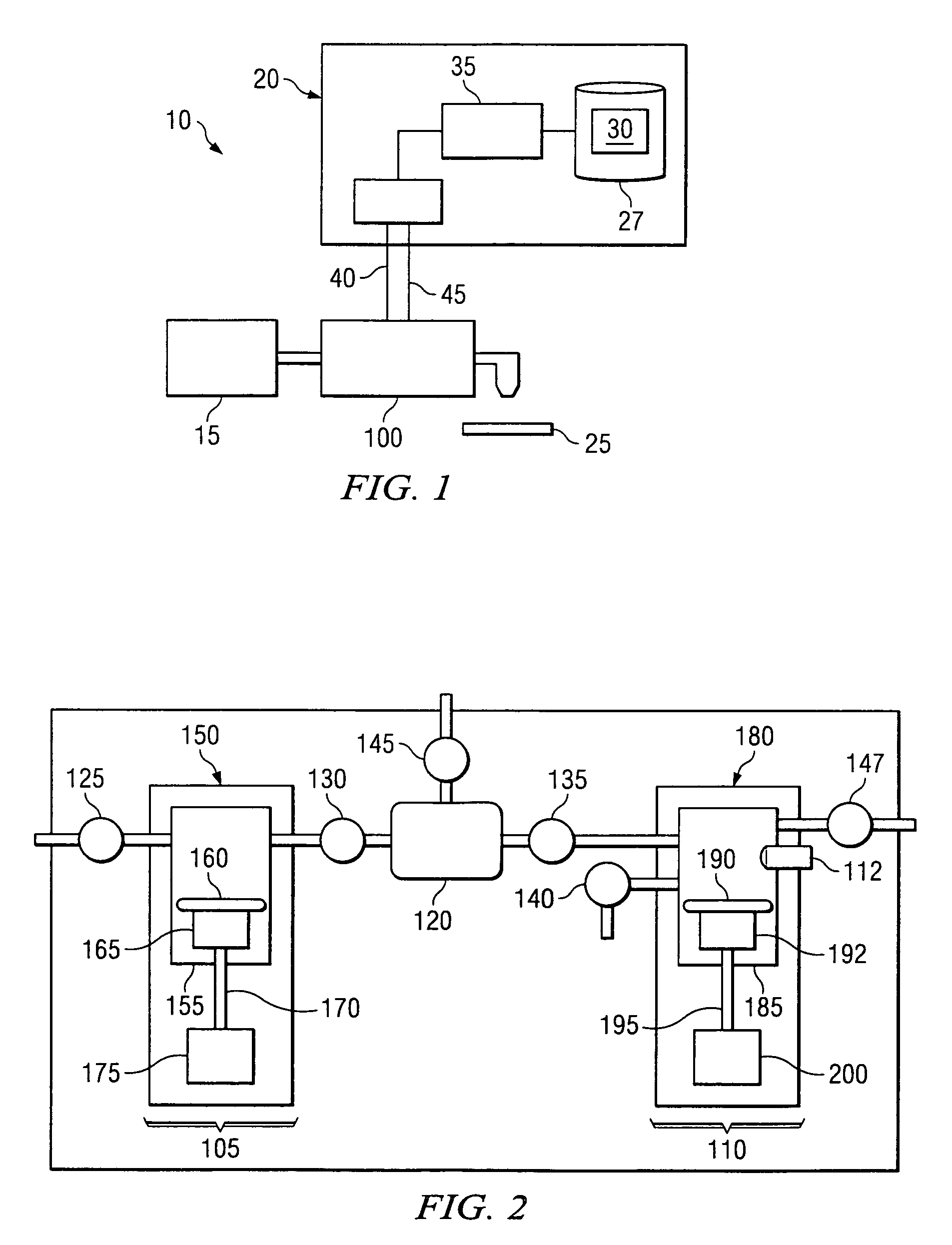

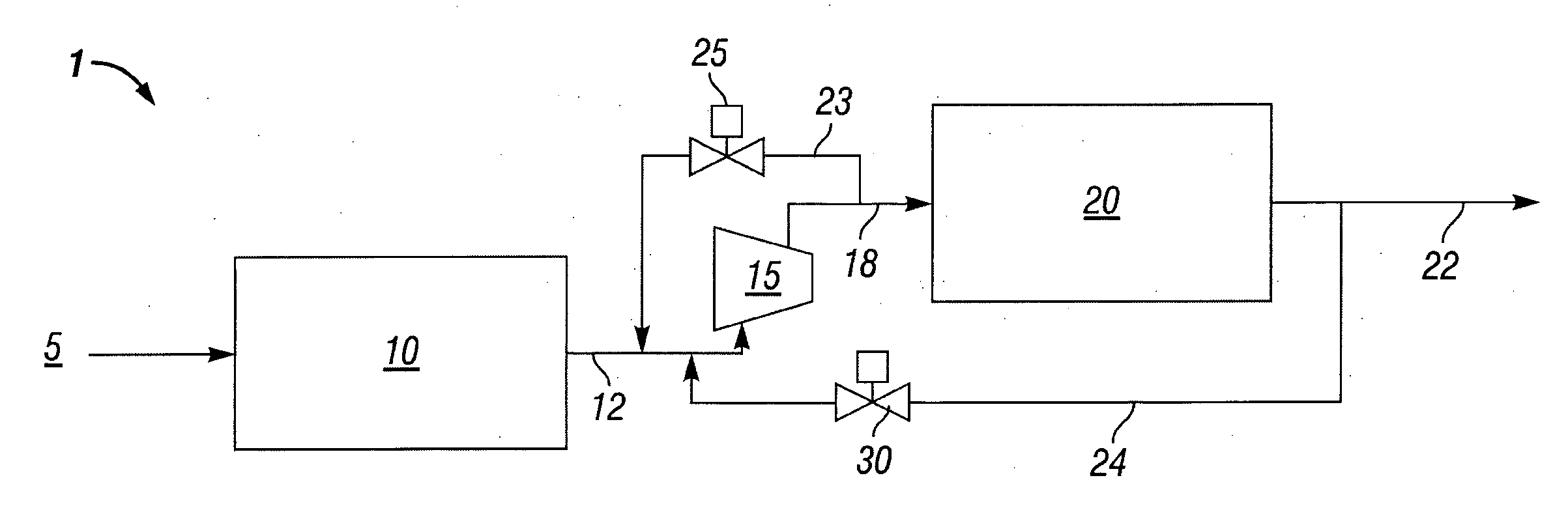

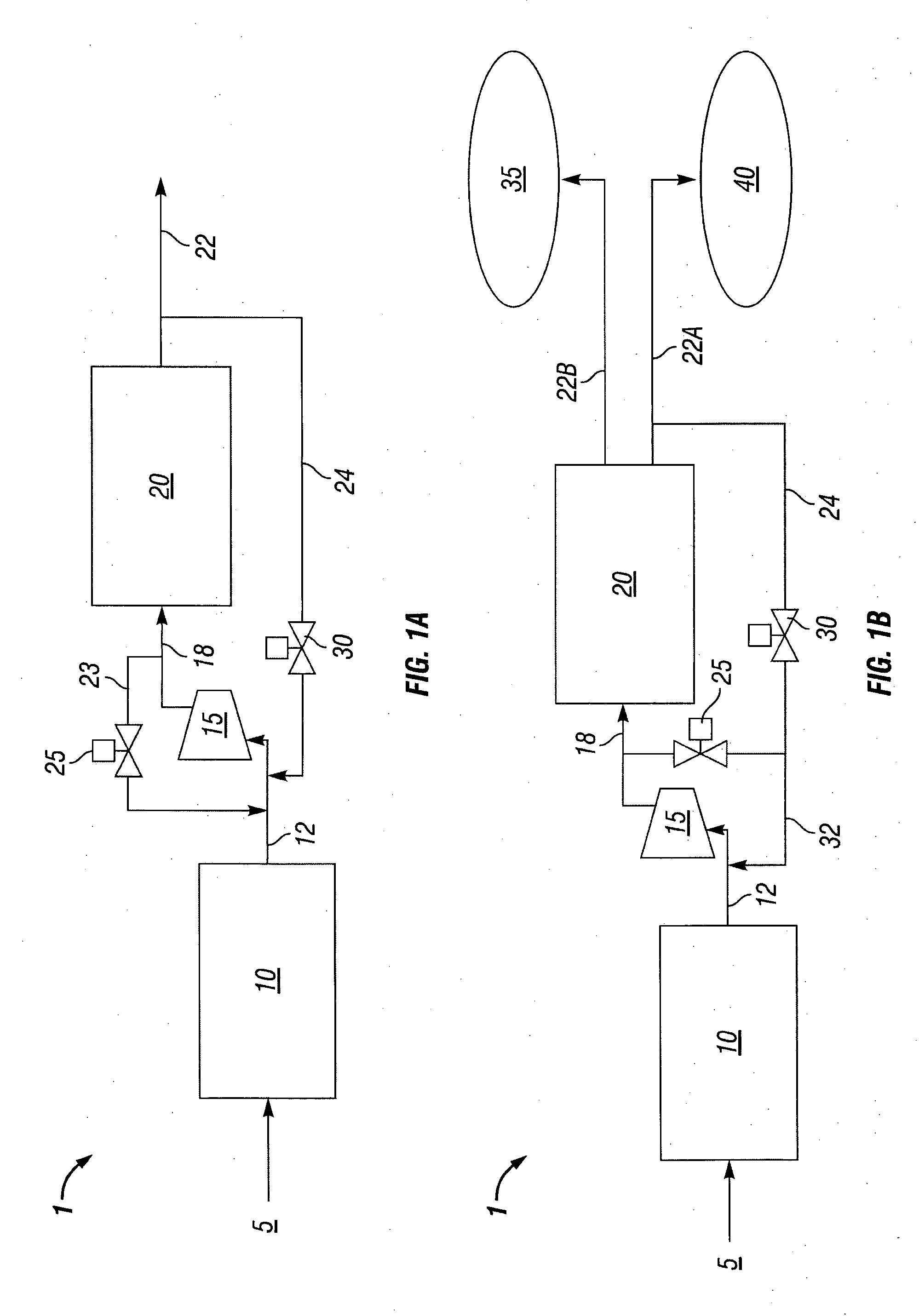

Submerged combustion glass manufacturing systems and methods

ActiveUS20130086950A1Reduction of melter pressure fluctuationReduce carryoverGlass furnace apparatusGlass melting apparatusGlass manufacturingTemperature and pressure

Submerged combustion glass manufacturing systems include a melter having a floor, a roof, a wall structure connecting the floor and roof, and an exhaust passage through the roof. One or more submerged combustion burners are mounted in the floor and / or wall structure discharging combustion products under a level of material being melted in the melter and create turbulent conditions in the material. The melter exhausts through an exhaust structure connecting the exhaust passage with an exhaust stack. The exhaust structure includes a barrier defining an exhaust chamber having an interior surface, the exhaust chamber having a cross-sectional area greater than that of the exhaust stack but less than the melter. The barrier maintains temperature and pressure in the exhaust structure at values sufficient to substantially prevent condensation of exhaust material on the interior surface.

Owner:JOHNS MANVILLE CORP

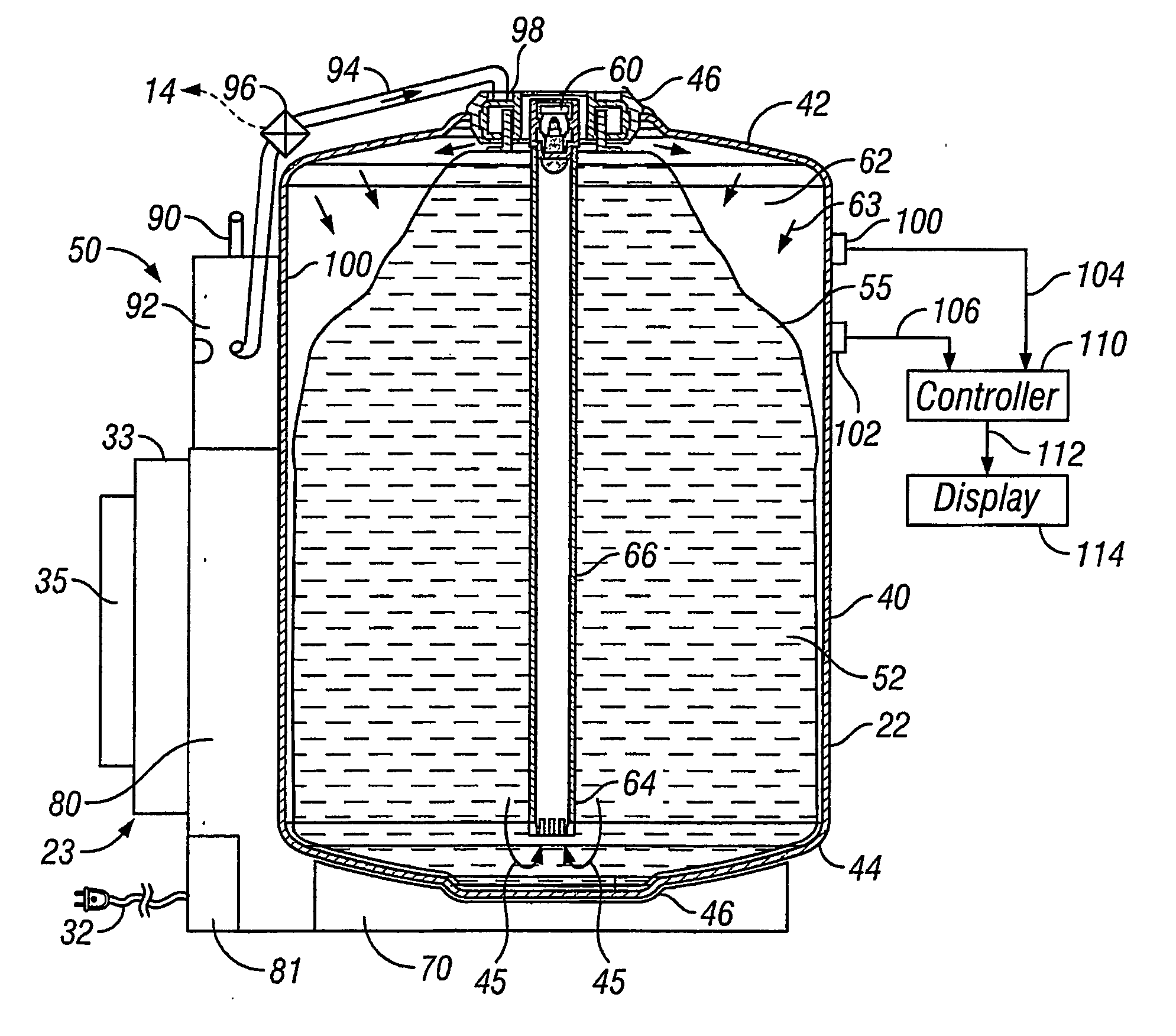

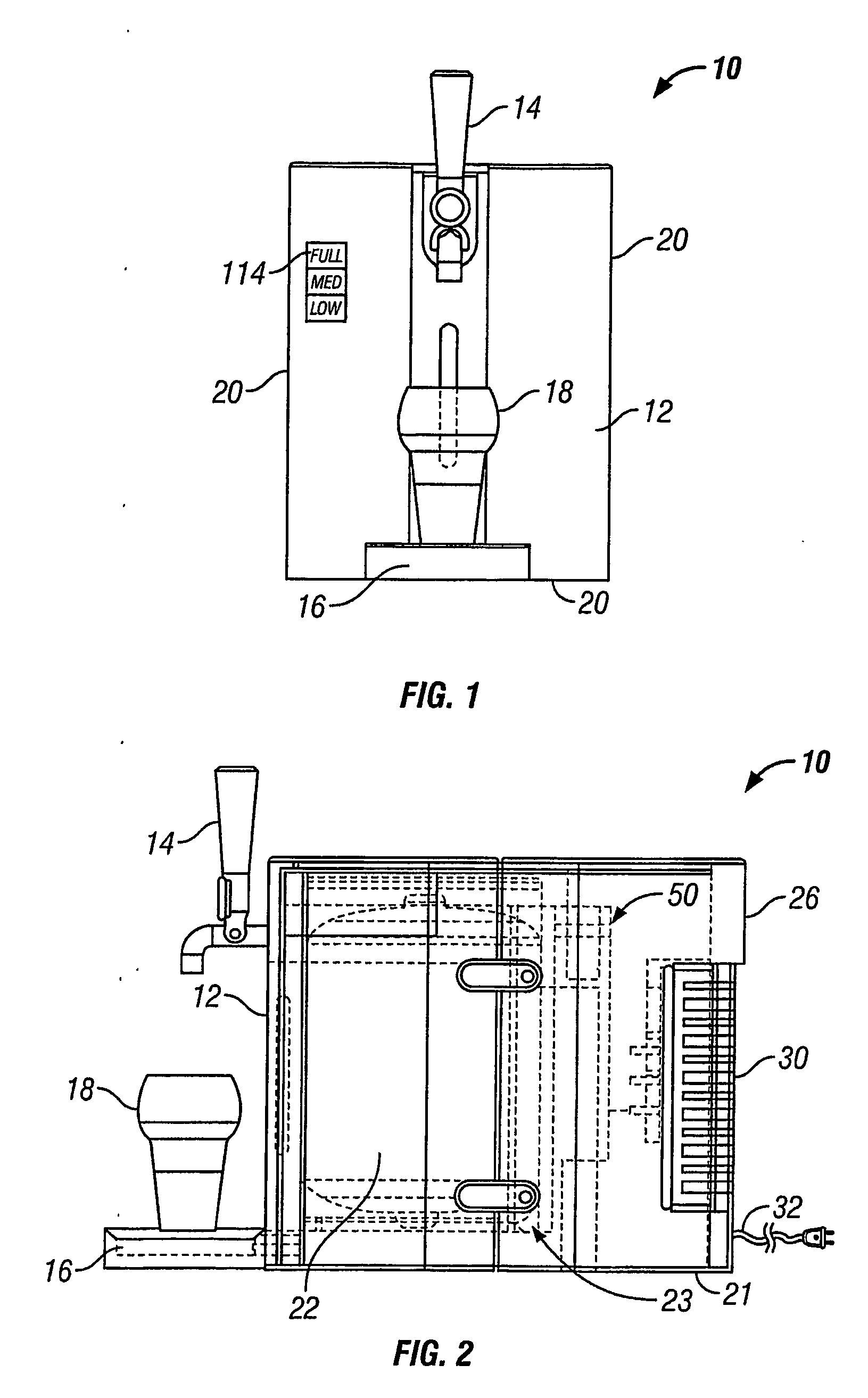

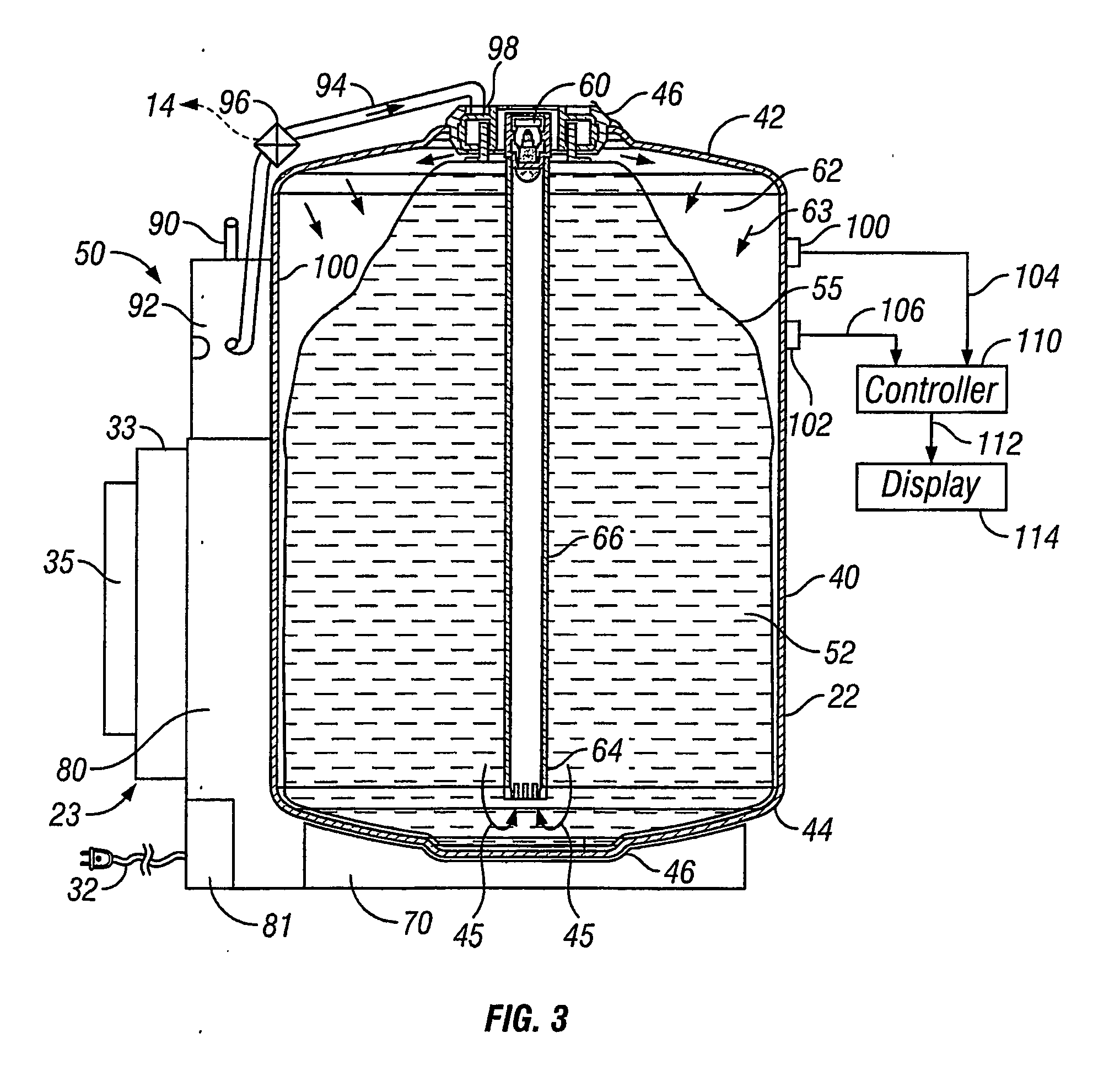

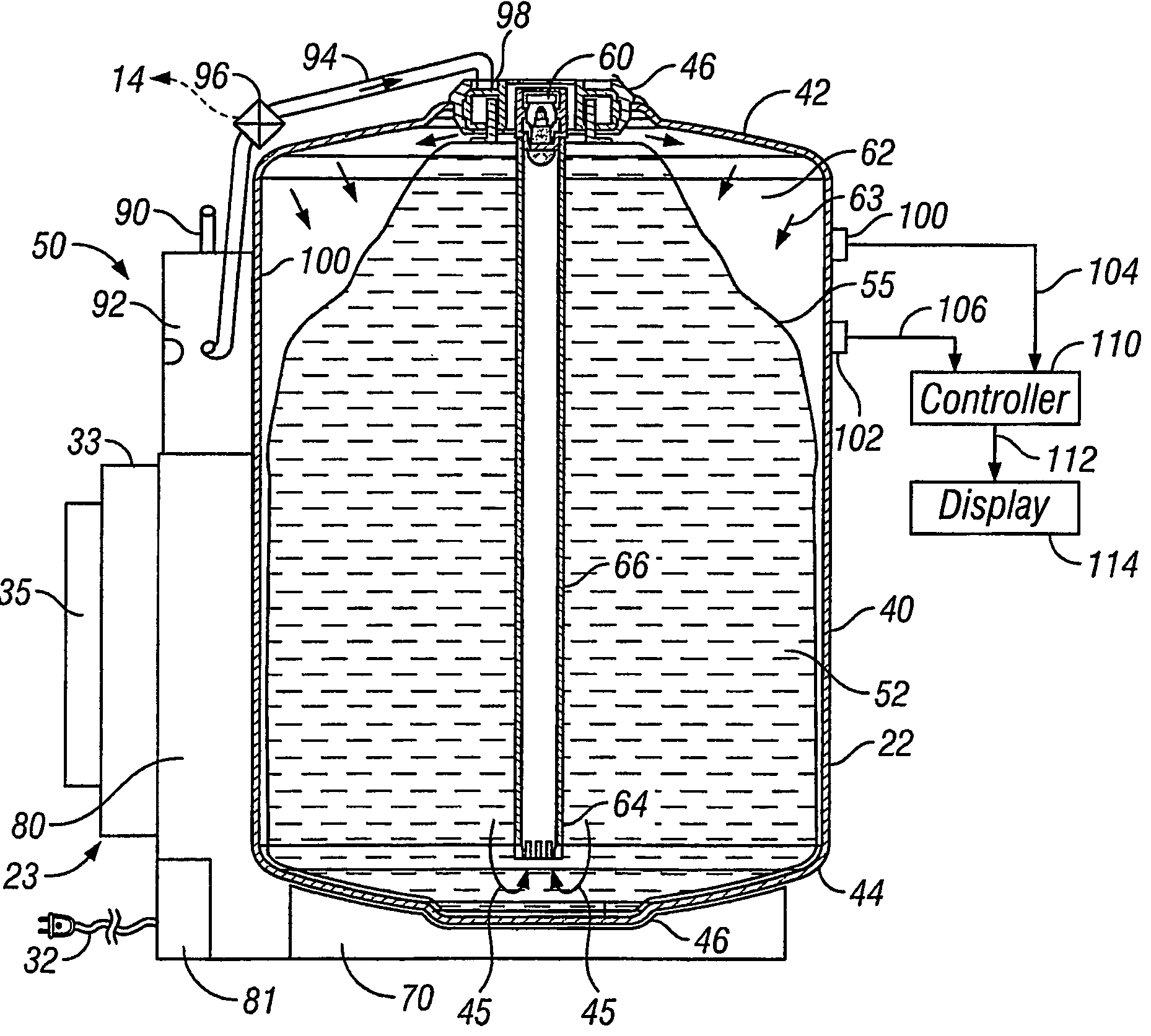

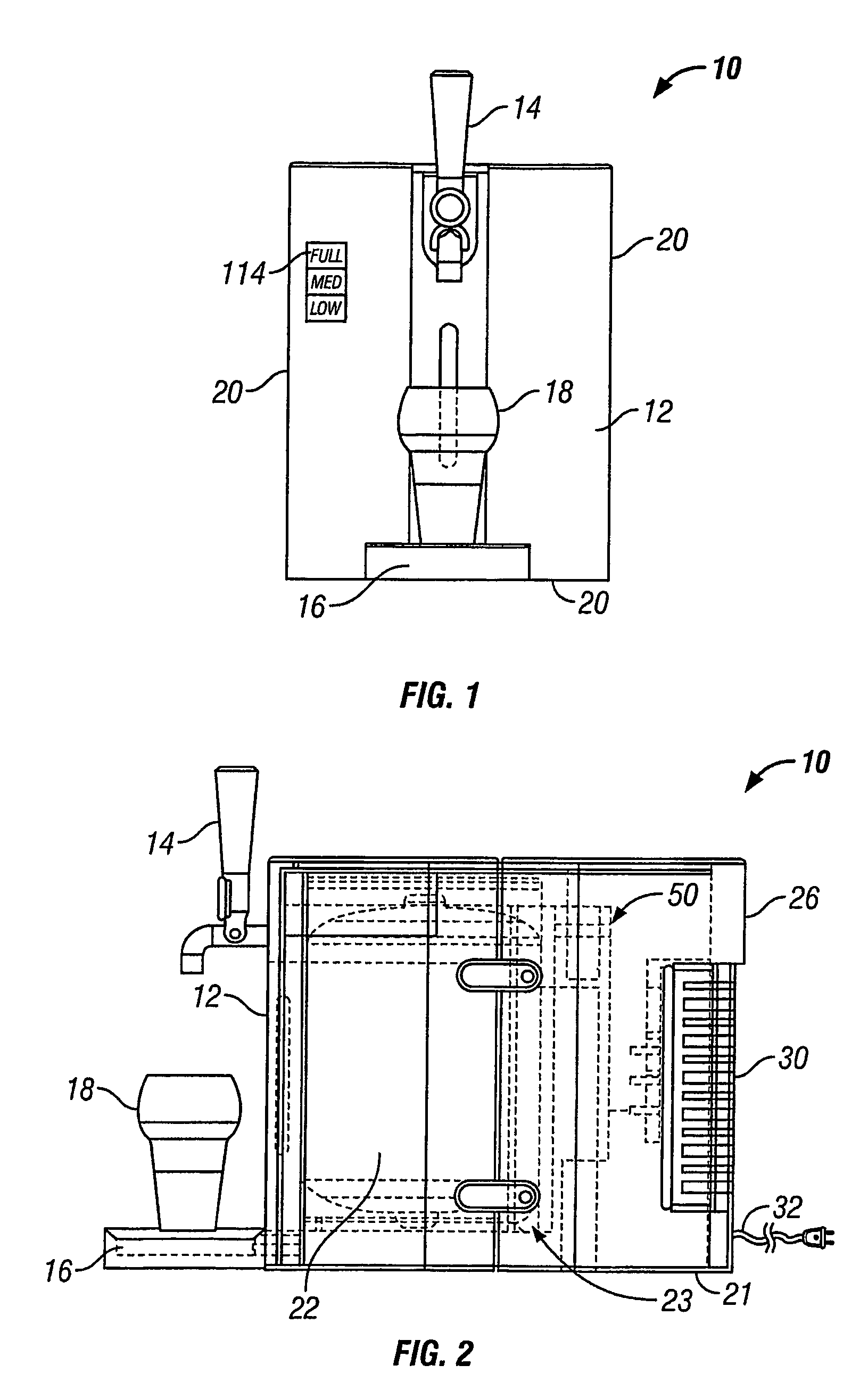

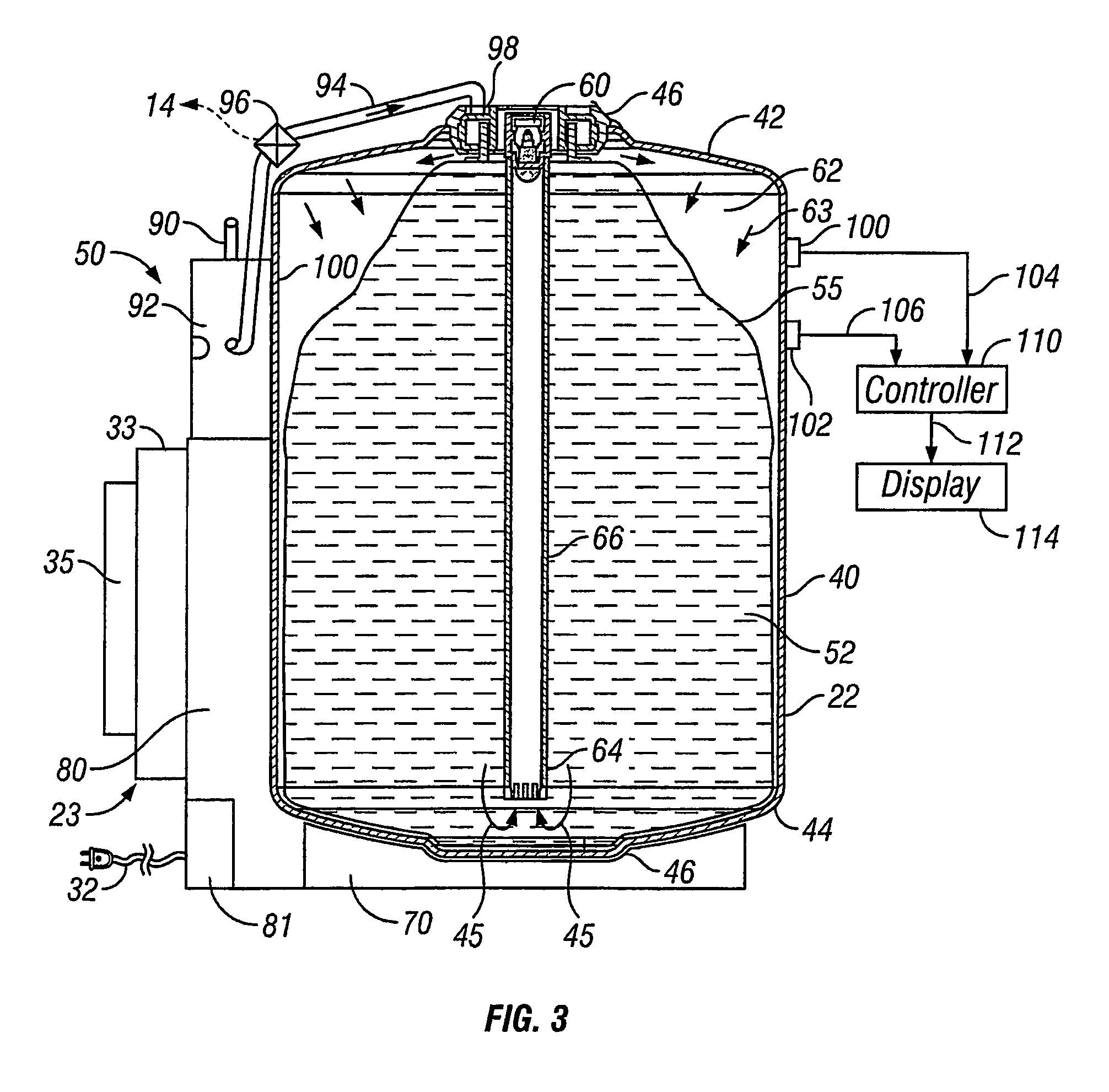

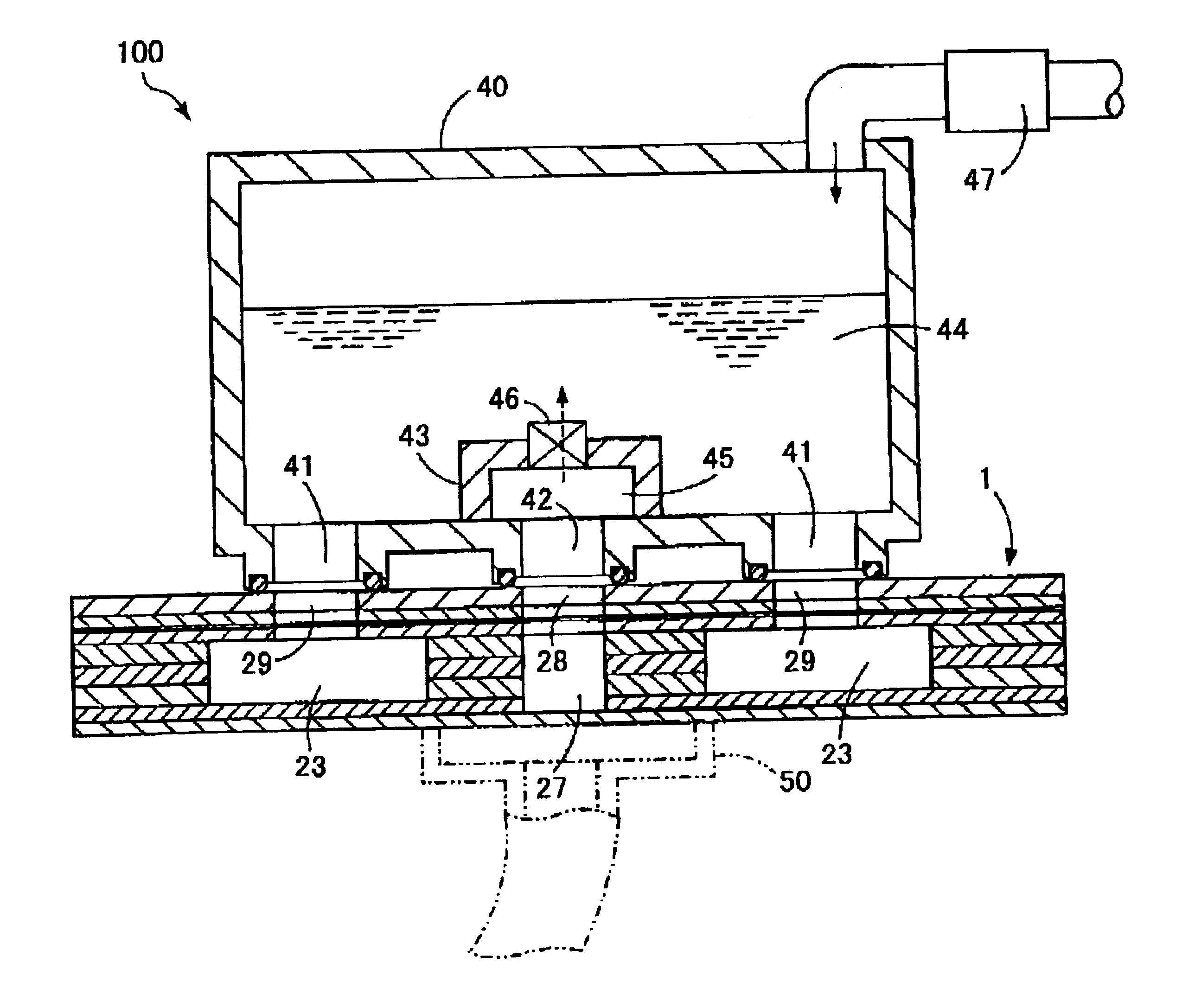

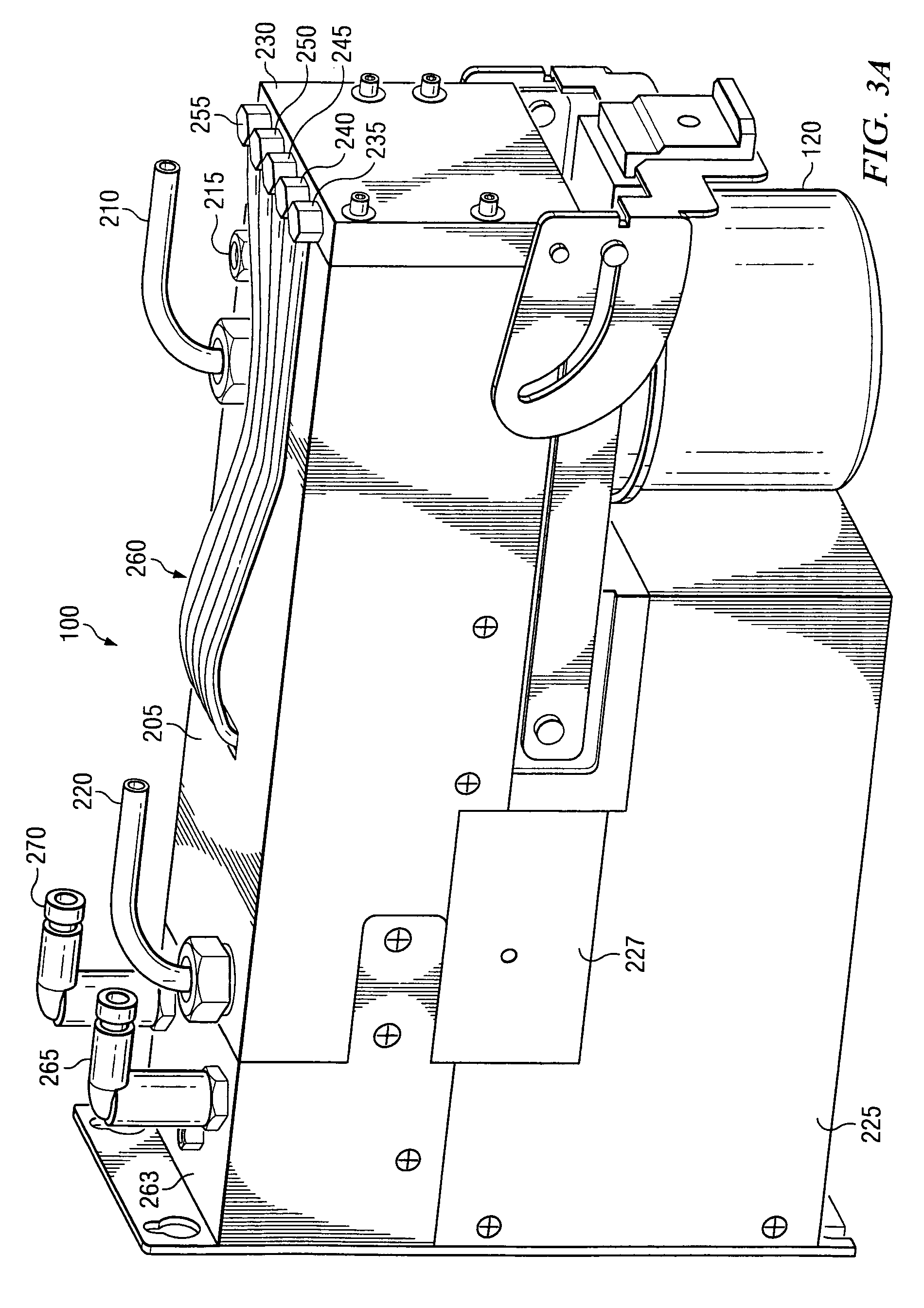

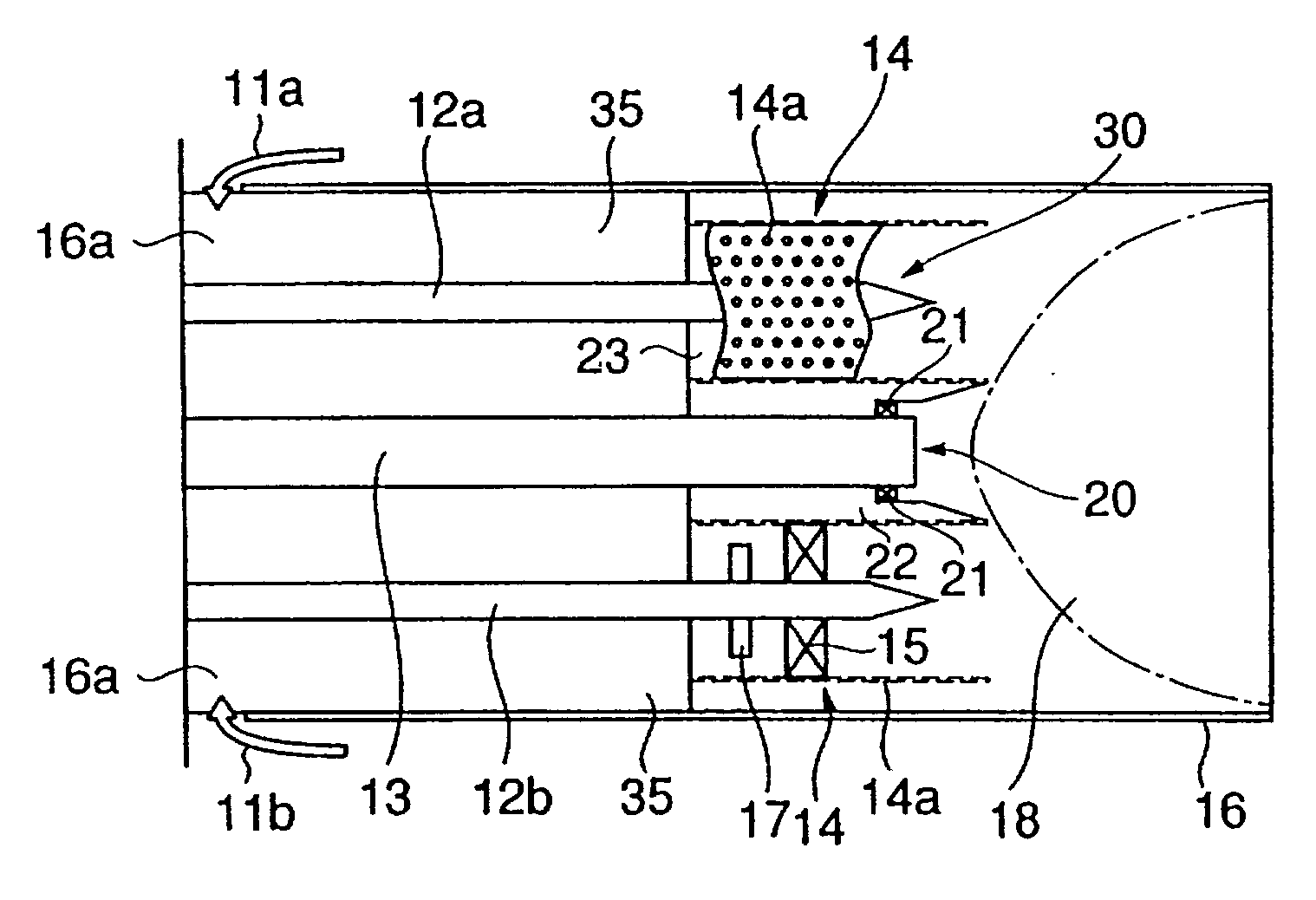

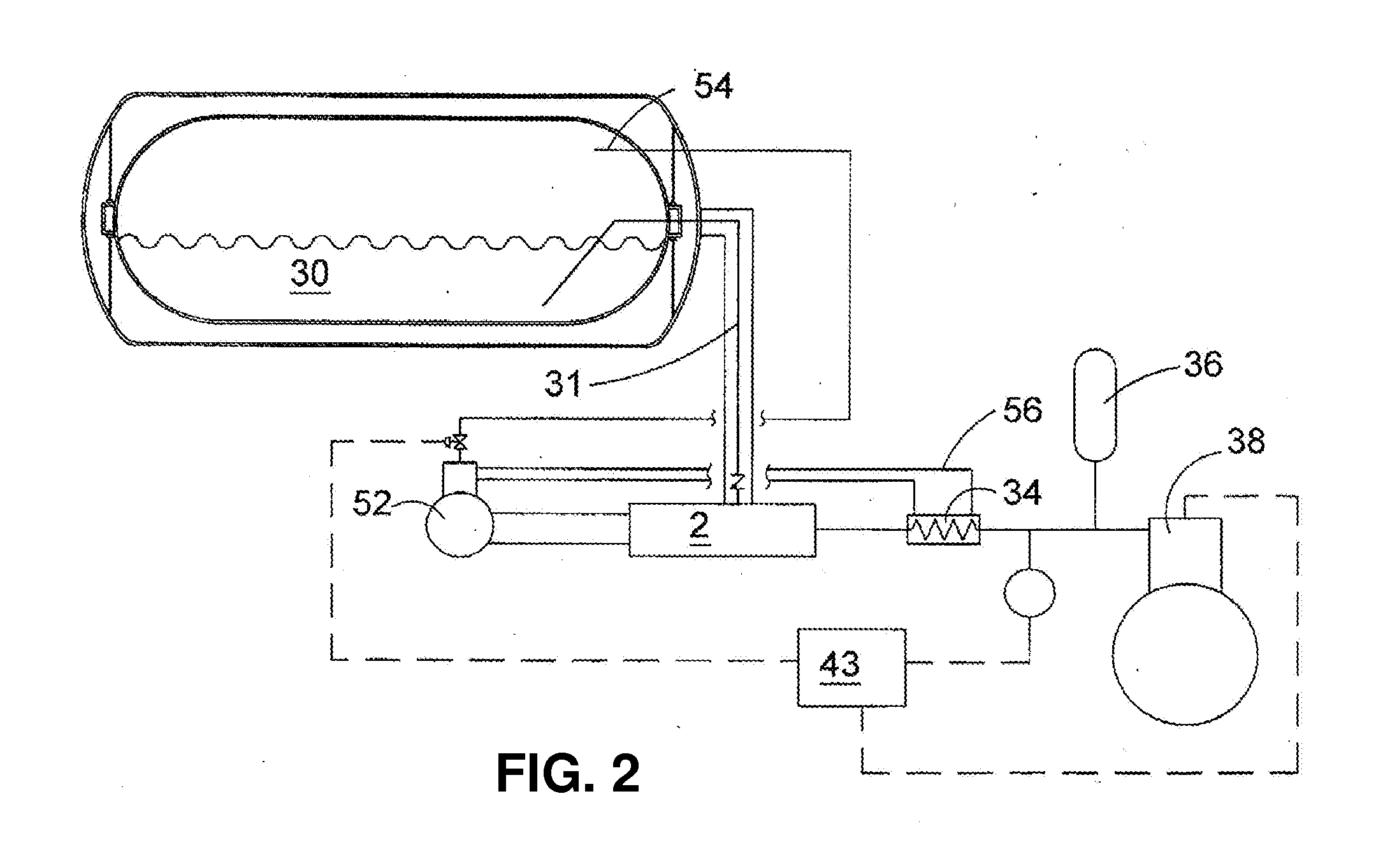

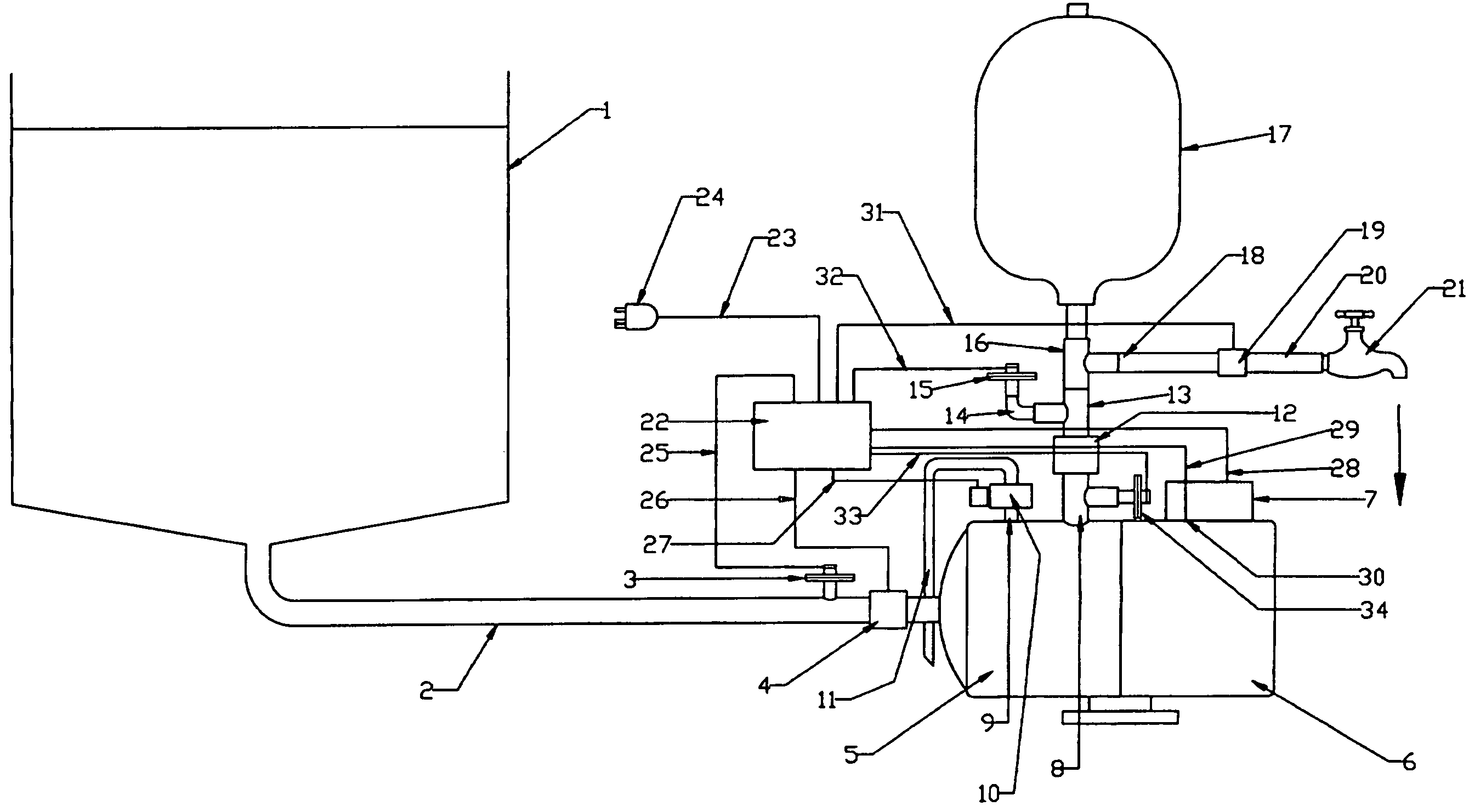

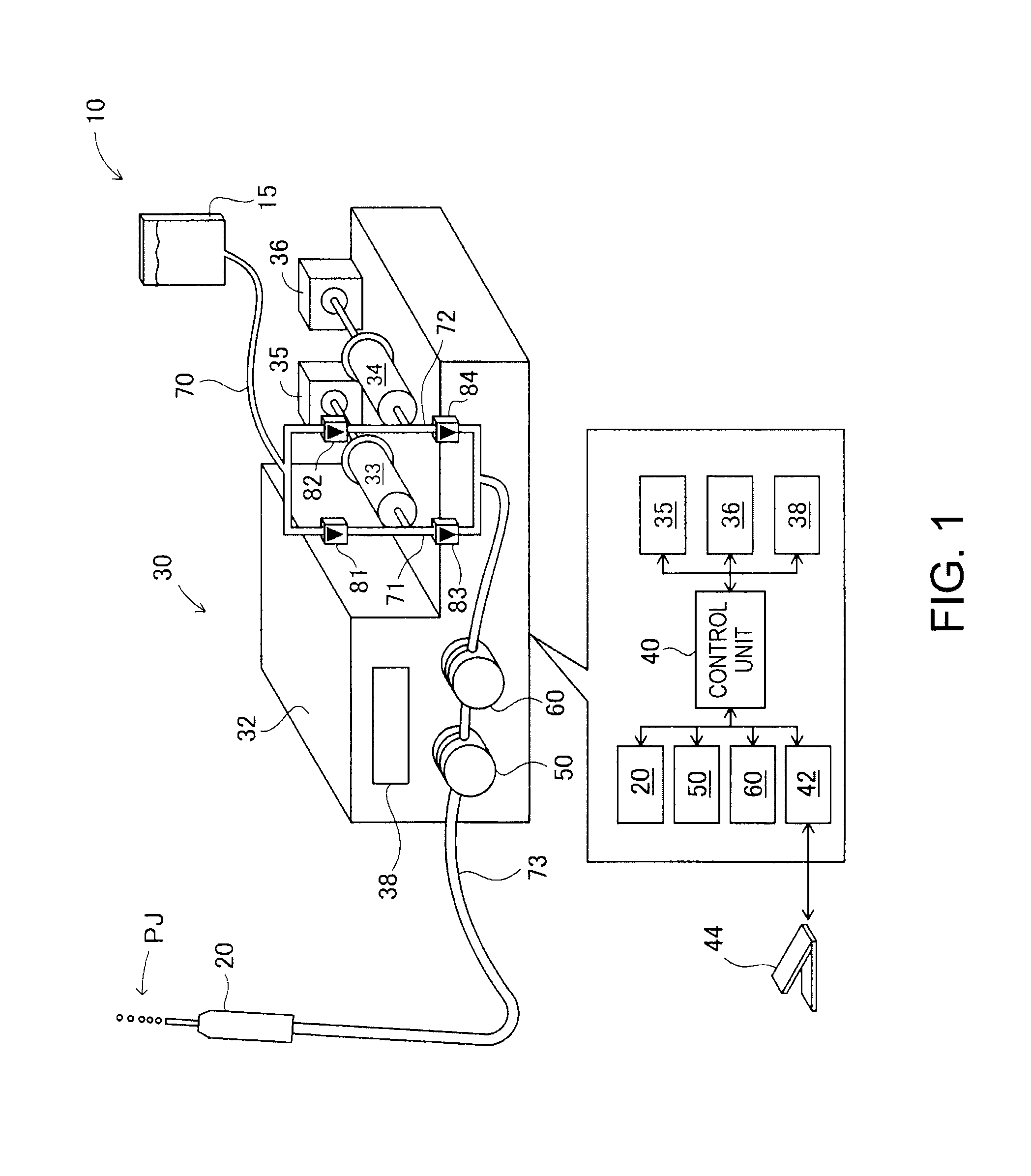

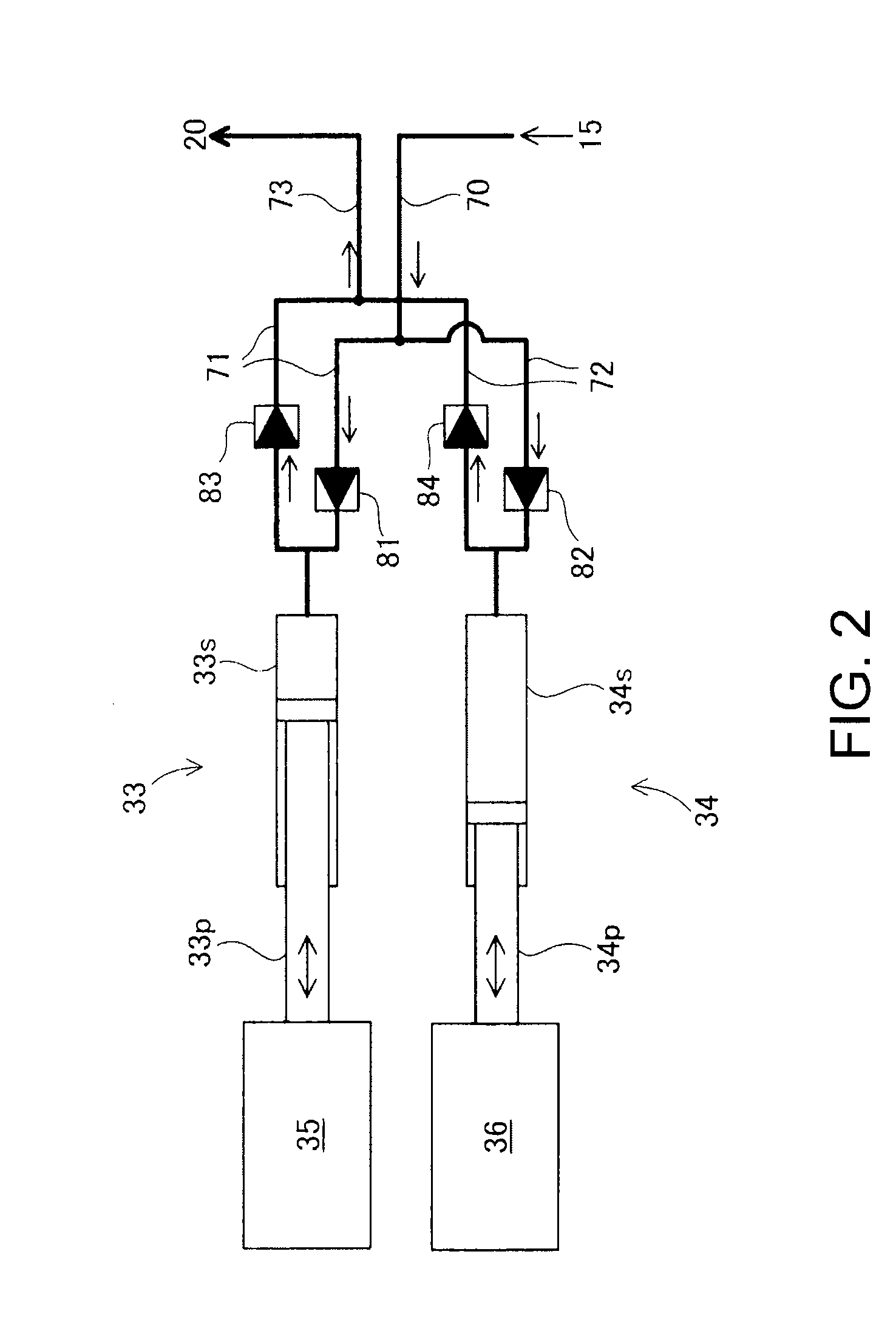

Beer dispensing system with gas pressure reservoir

ActiveUS20060138177A1Reduce dampening pressure fluctuationSufficient pressureLiquid transferring devicesVolume meteringPressure systemPressure sense

A home beer dispensing apparatus has a keg having a self-contained bag filled with a beer and a pressure system. The pressure system creates a pressurized air space between the keg inner walls and the bag to assist in the dispensing of the beer. The pressure system has a keg one-way air valve mounted to a top wall of the keg to permit entry of pressurized air into the keg. The pressure system has a pressure reservoir mounted in the dispensing apparatus outside the keg and in fluid flow communication with the keg one-way valve. The reservoir stores a charge of pressurized air and supplies at least a portion of this charge to the keg through the keg air valve when the dispensing apparatus is operated to dispense the beer. The reservoir provides a reserved charge of pressurized gas that is on hand to reduce dampening pressure fluctuations during beer dispensing which can result in beer frothing, especially during the early stages of beer dispensing when the air head space in the keg is small. Further, the apparatus may also have a pressure sensing system adapted to measure time rate of pressure change in the keg. The apparatus has a signaling device responsive to the time rate of pressure change in the keg to produce a signal related to volume of beer remaining in the bag. Preferably, the signal is displayed visually on the dispensing apparatus.

Owner:ANHEUSER BUSCH INBEV SA

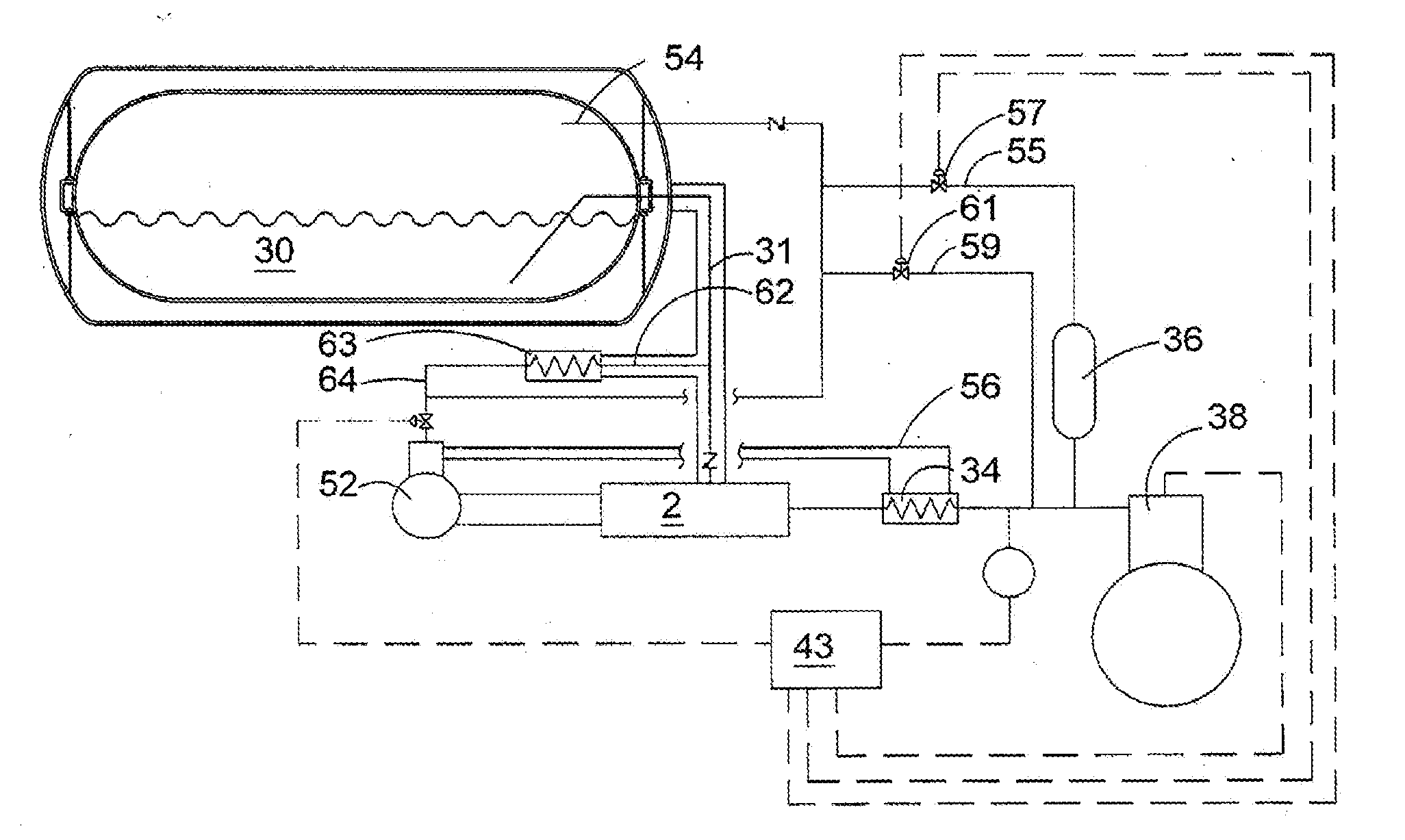

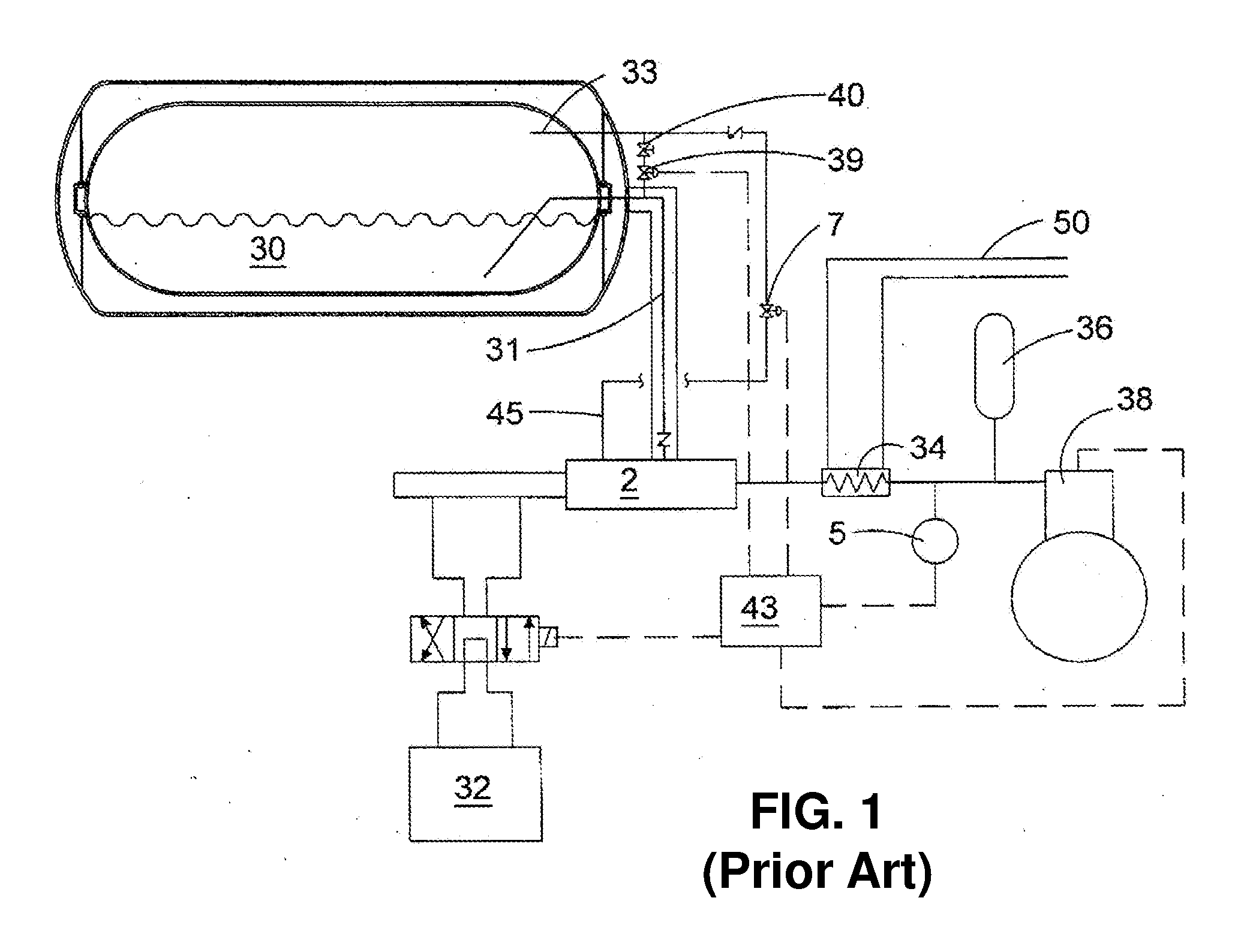

Beer dispensing system with gas pressure reservoir

ActiveUS7810679B2Suppress pressure fluctuationsReduces compressor ratingLiquid transferring devicesVolume meteringPressure systemPressure sense

A home beer dispensing apparatus has a keg having a self-contained bag filled with a beer and a pressure system. The pressure system creates a pressurized air space between the keg inner walls and the bag to assist in the dispensing of the beer. The pressure system has a keg one-way air valve mounted to a top wall of the keg to permit entry of pressurized air into the keg. The pressure system has a pressure reservoir mounted in the dispensing apparatus outside the keg and in fluid flow communication with the keg one-way valve. The reservoir stores a charge of pressurized air and supplies at least a portion of this charge to the keg through the keg air valve when the dispensing apparatus is operated to dispense the beer. The reservoir provides a reserved charge of pressurized gas that is on hand to reduce dampening pressure fluctuations during beer dispensing which can result in beer frothing, especially during the early stages of beer dispensing when the air head space in the keg is small. Further, the apparatus may also have a pressure sensing system adapted to measure time rate of pressure change in the keg. The apparatus has a signaling device responsive to the time rate of pressure change in the keg to produce a signal related to volume of beer remaining in the bag. Preferably, the signal is displayed visually on the dispensing apparatus.

Owner:ANHEUSER BUSCH INBEV SA

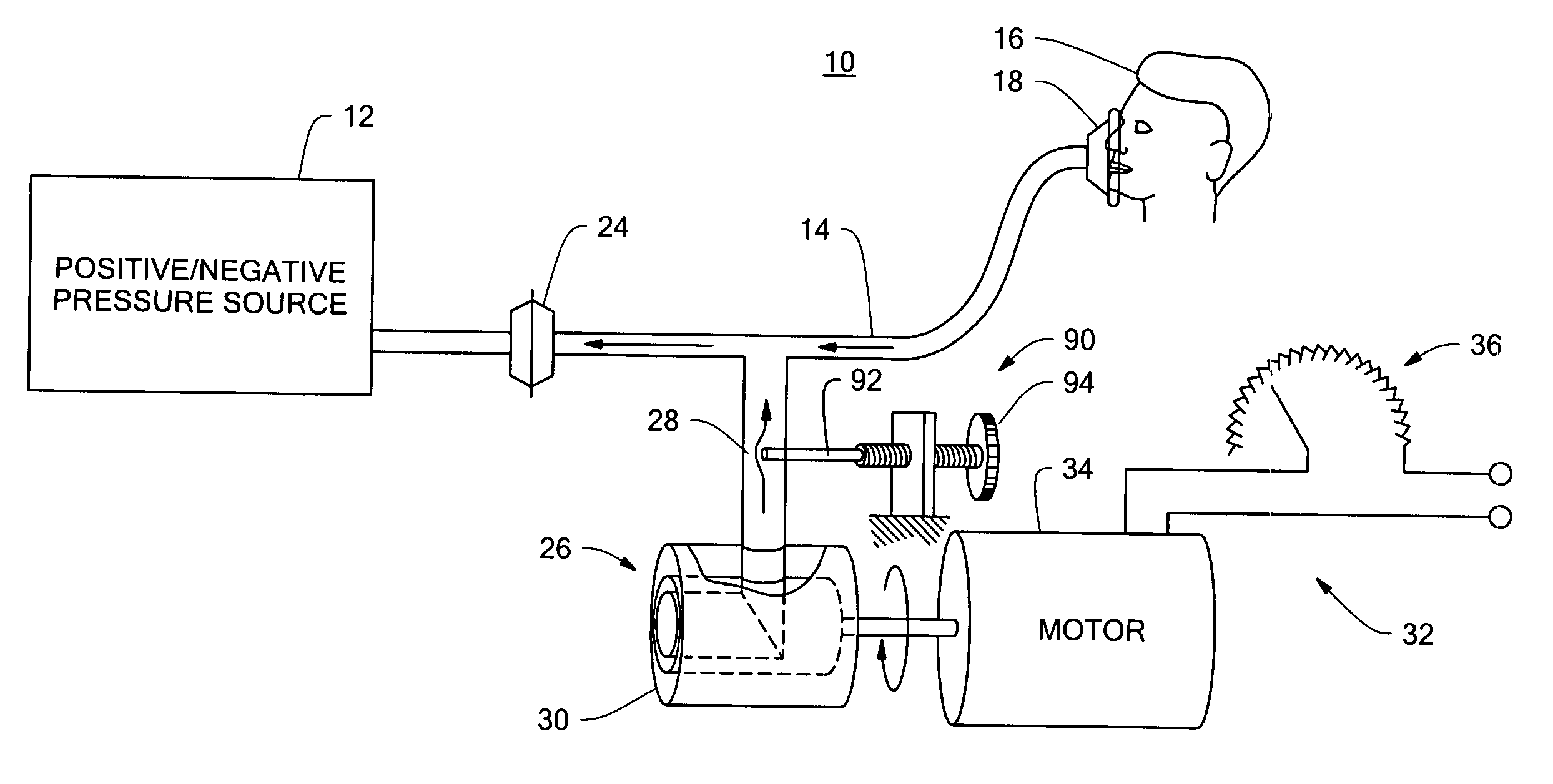

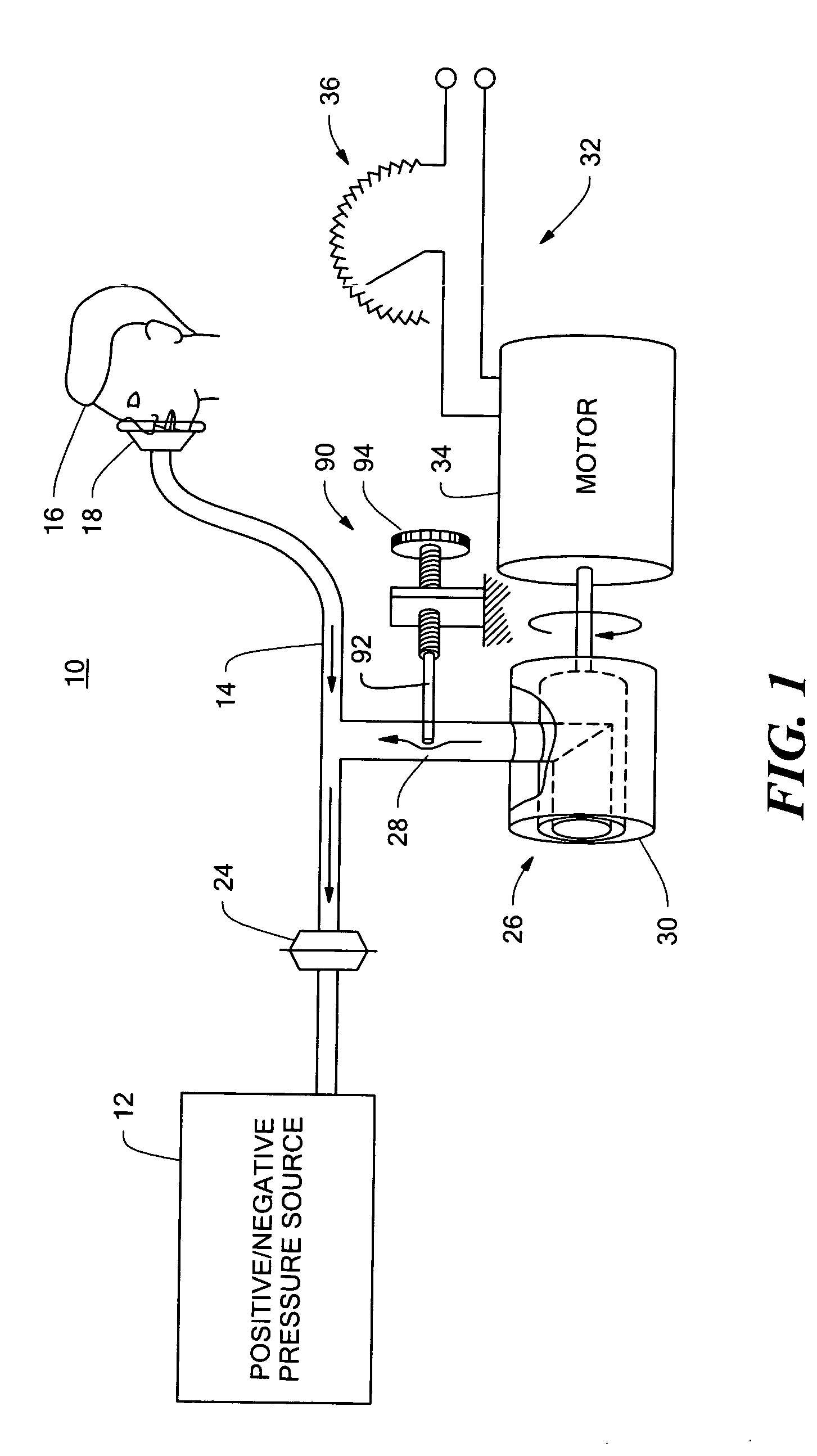

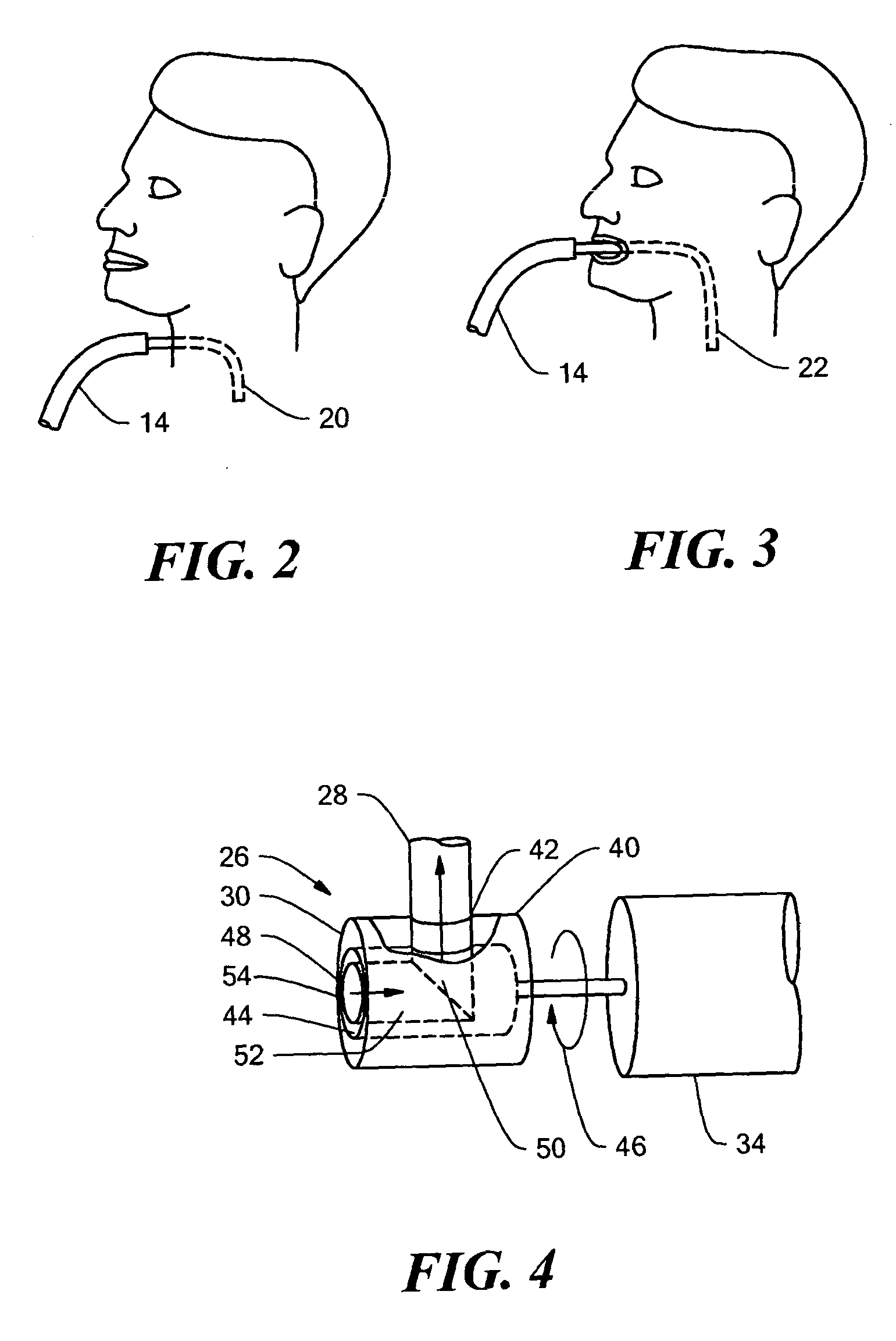

Insufflation-exsufflation system with percussive assist for removal of broncho-pulmonary secretions

ActiveUS6929007B2Small and portableEconomical of energyRespiratorsOperating means/releasing devices for valvesBroncho-pulmonaryHigh rate

Owner:RIC INVESTMENTS LLC

Retaining member

ActiveUS7267307B2Improve isolationSpring constantPipe supportsNon-rotating vibration suppressionEngineeringMechanical engineering

Owner:ITW AUTOMOTIVE PRODS

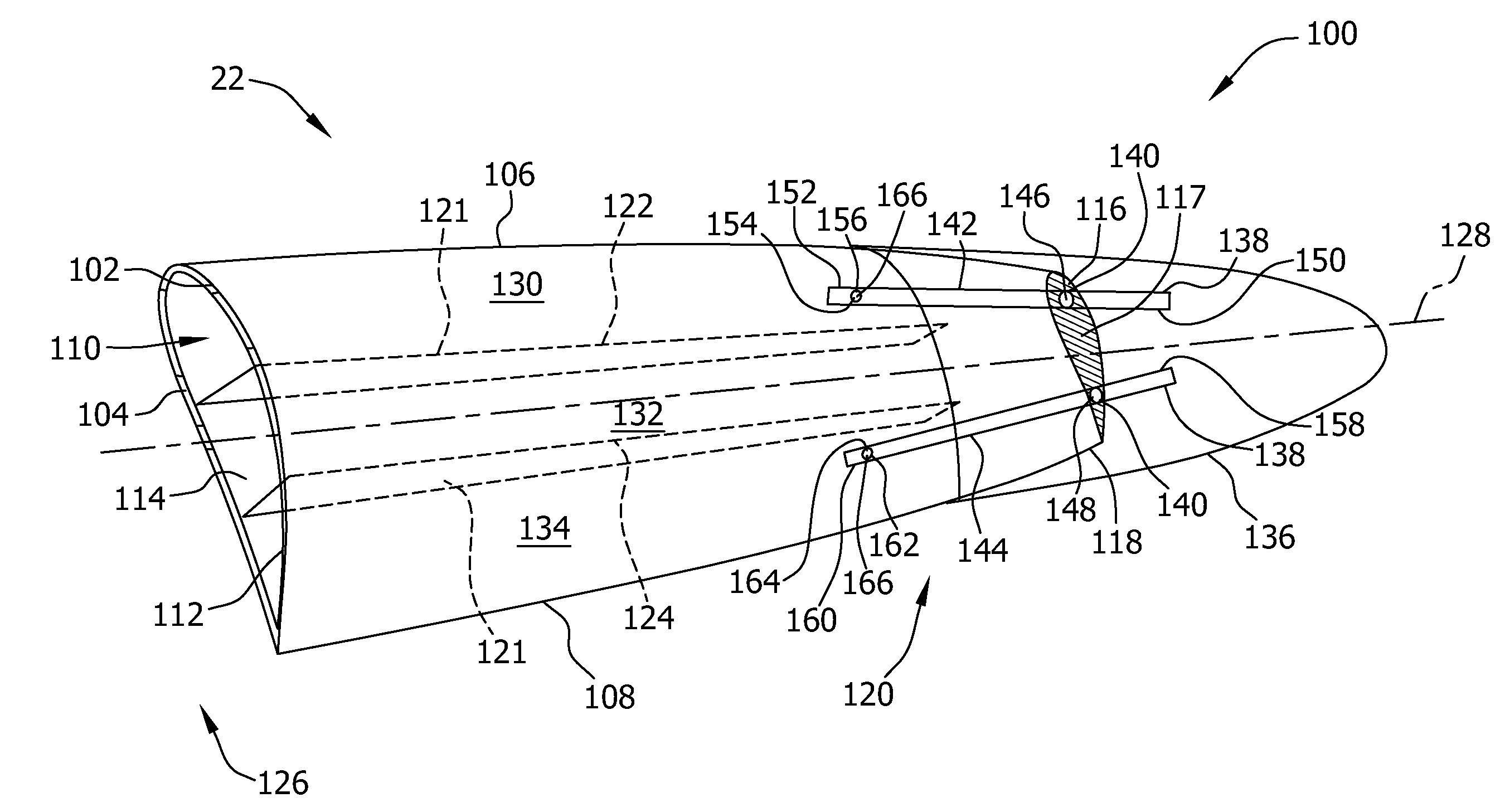

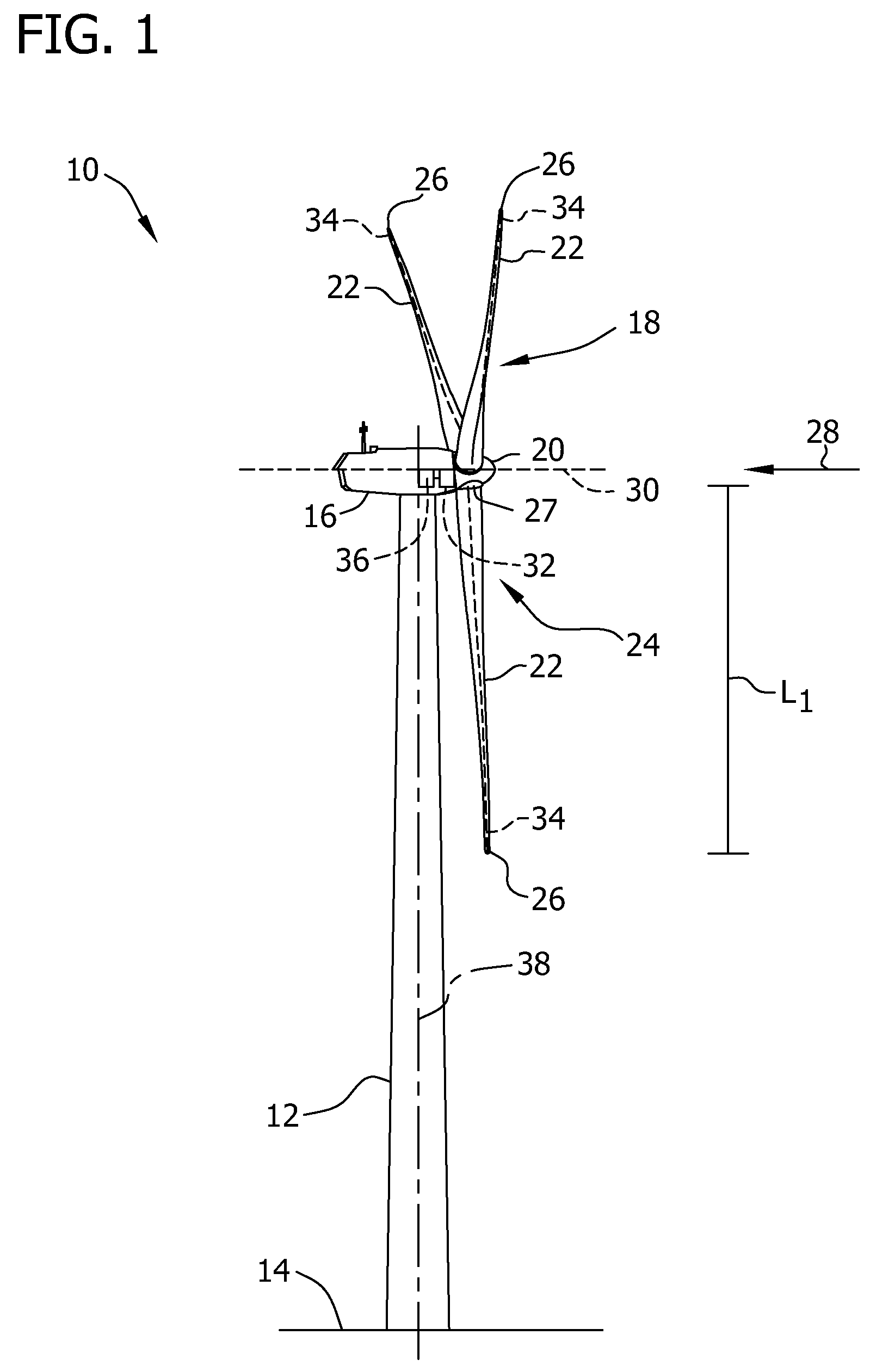

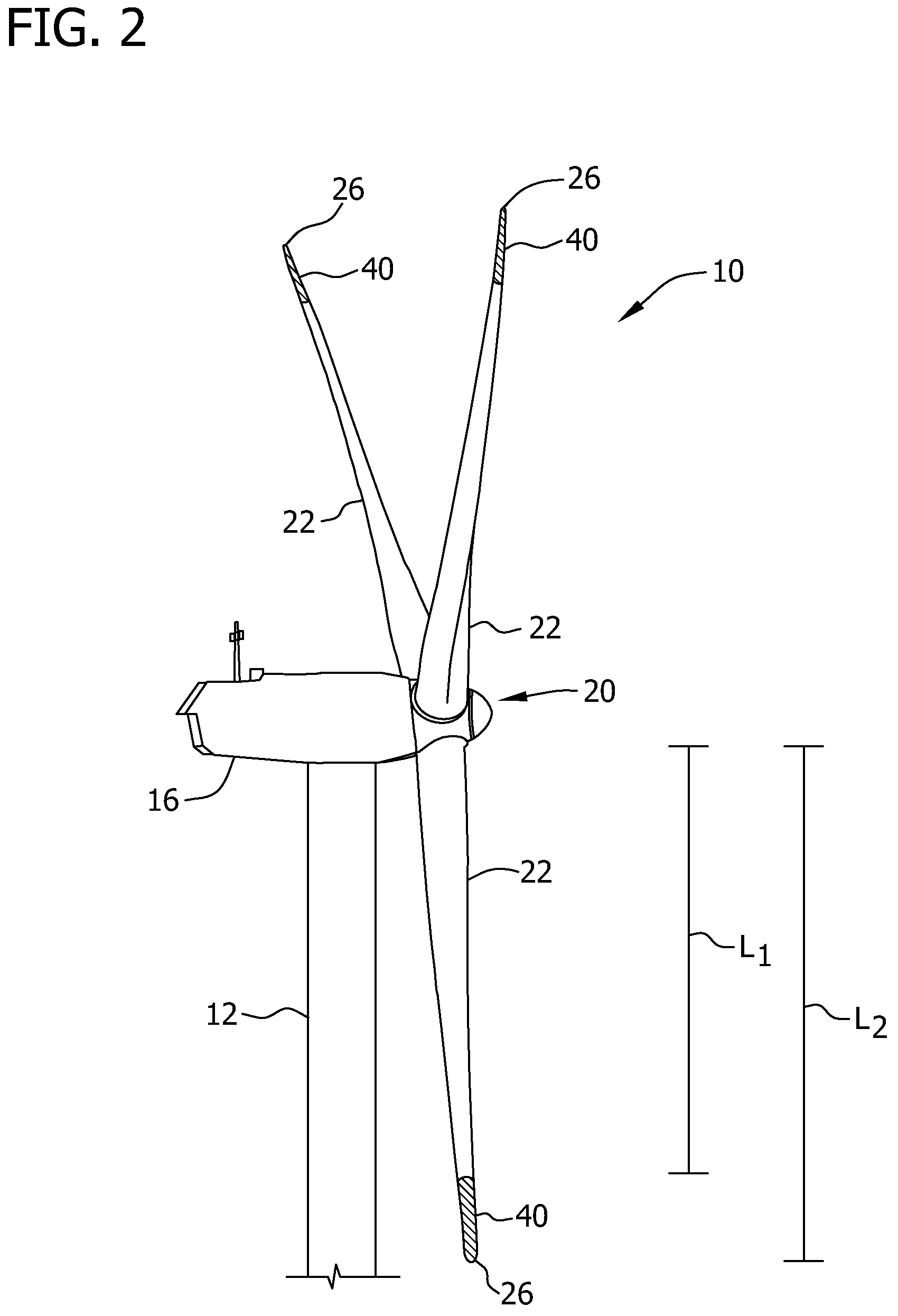

Systems and methods of assembling a rotor blade extension for use in a wind turbine

InactiveUS20110076149A1Improve powerIncrease the areaEngine manufactureEngine fuctionsTurbineEngineering

A method of assembling a blade extension assembly for use with a wind turbine. The method includes removing a tip end of a tip portion of a rotor blade and coupling a tip wall to the tip portion. The tip wall extends between a first sidewall and a second sidewall and includes a plurality of slots defined therein. A blade extension assembly is coupled to the tip portion.

Owner:GENERAL ELECTRIC CO

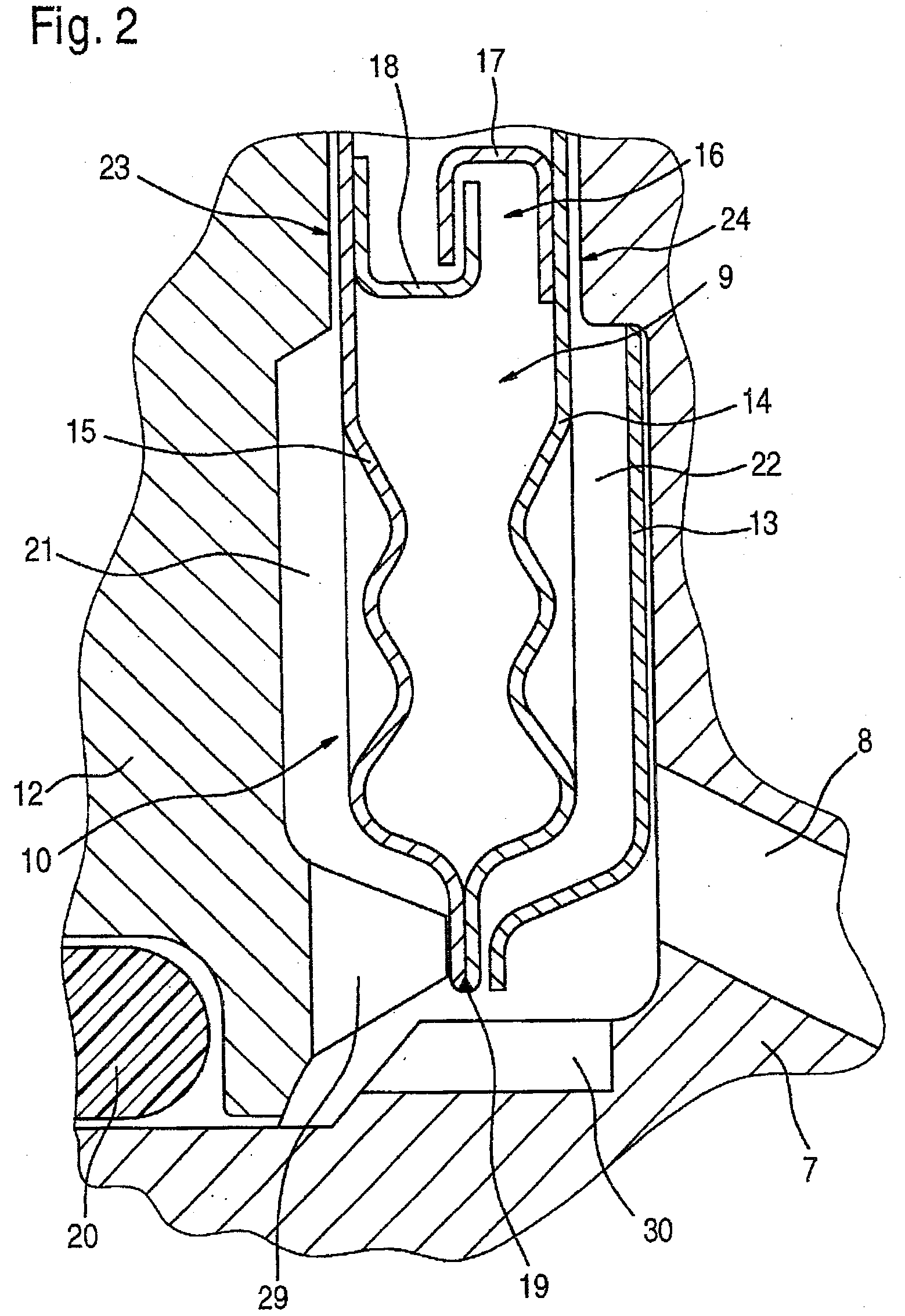

Submerged combustion glass manufacturing systems and methods

ActiveUS8707740B2Suppress pressure fluctuationsAvoid condensationGlass furnace apparatusGlass melting apparatusGlass manufacturingTemperature and pressure

Submerged combustion glass manufacturing systems include a melter having a floor, a roof, a wall structure connecting the floor and roof, and an exhaust passage through the roof. One or more submerged combustion burners are mounted in the floor and / or wall structure discharging combustion products under a level of material being melted in the melter and create turbulent conditions in the material. The melter exhausts through an exhaust structure connecting the exhaust passage with an exhaust stack. The exhaust structure includes a barrier defining an exhaust chamber having an interior surface, the exhaust chamber having a cross-sectional area greater than that of the exhaust stack but less than the melter. The barrier maintains temperature and pressure in the exhaust structure at values sufficient to substantially prevent condensation of exhaust material on the interior surface.

Owner:JOHNS MANVILLE CORP

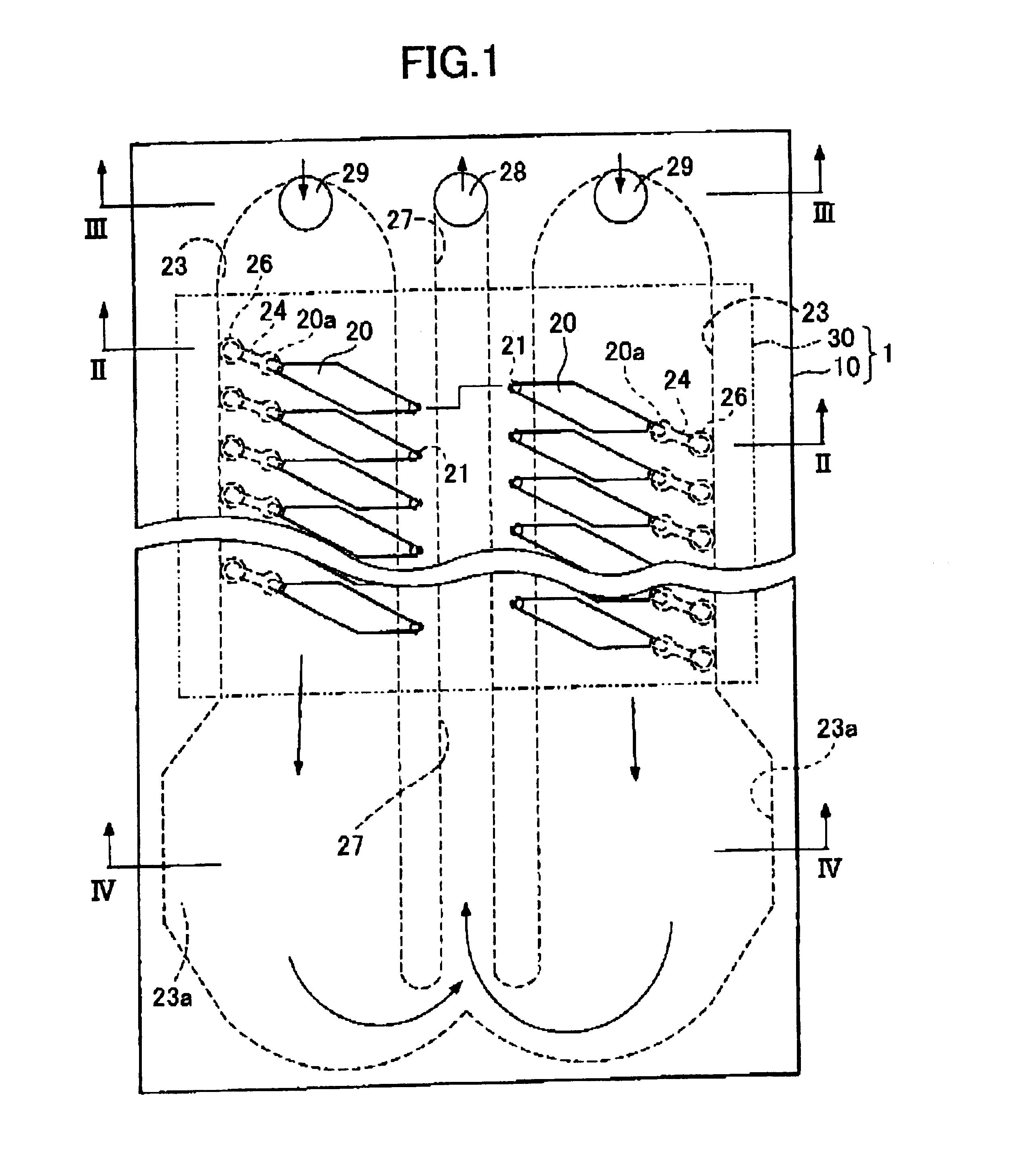

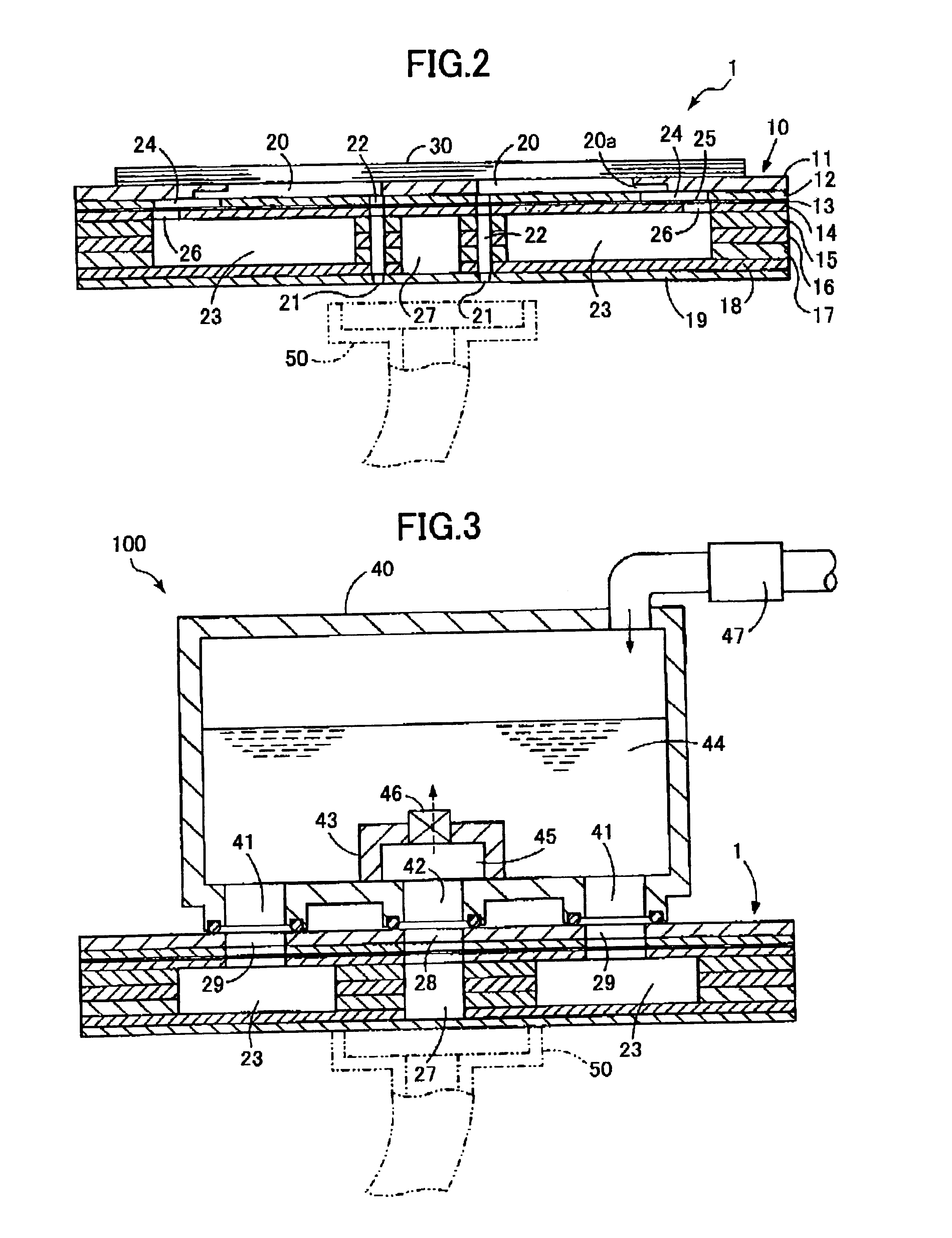

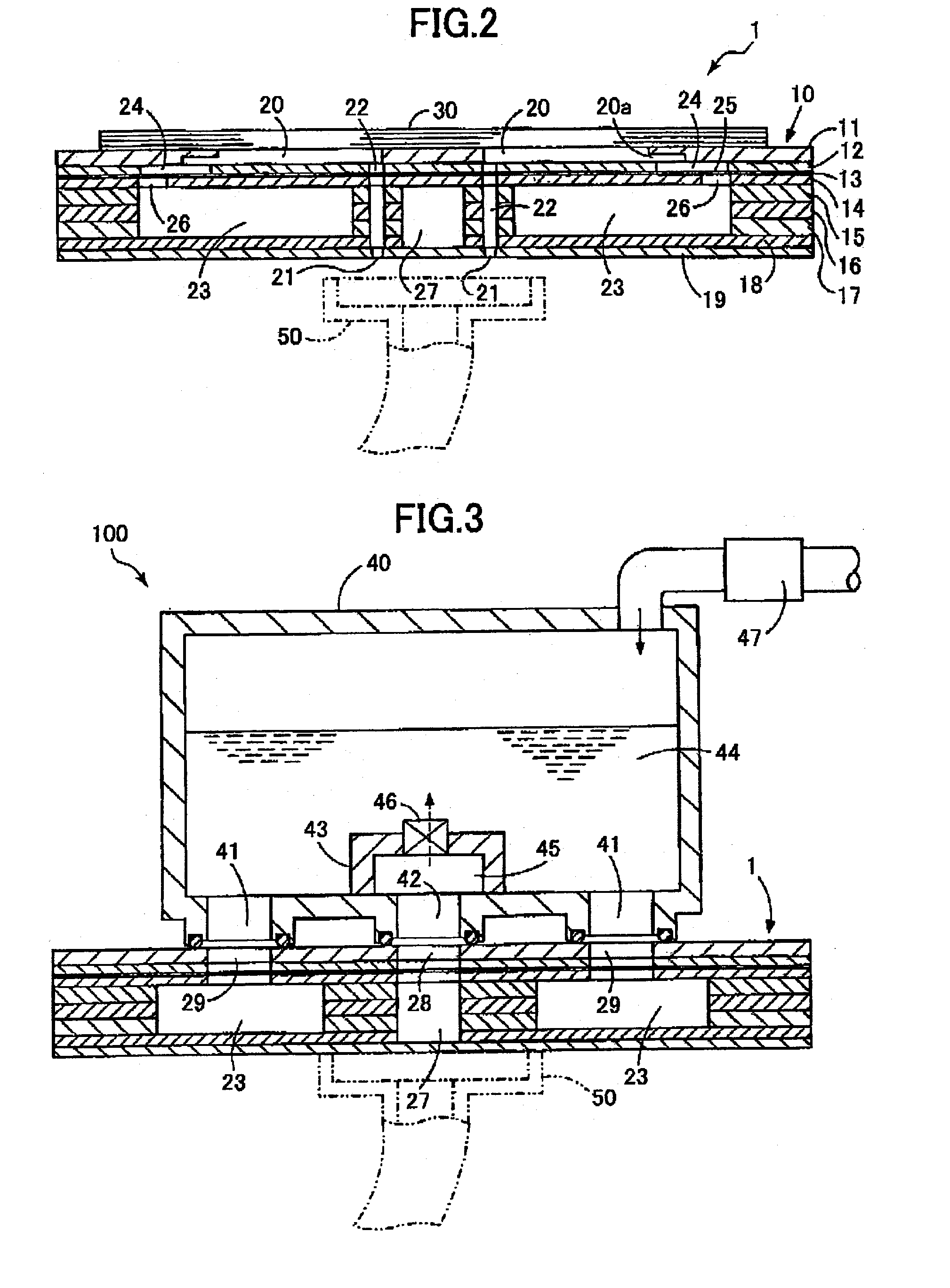

Ink jet head

InactiveUS6685299B2Improve featuresSimple configurationInking apparatusEngineeringMechanical engineering

Owner:BROTHER KOGYO KK

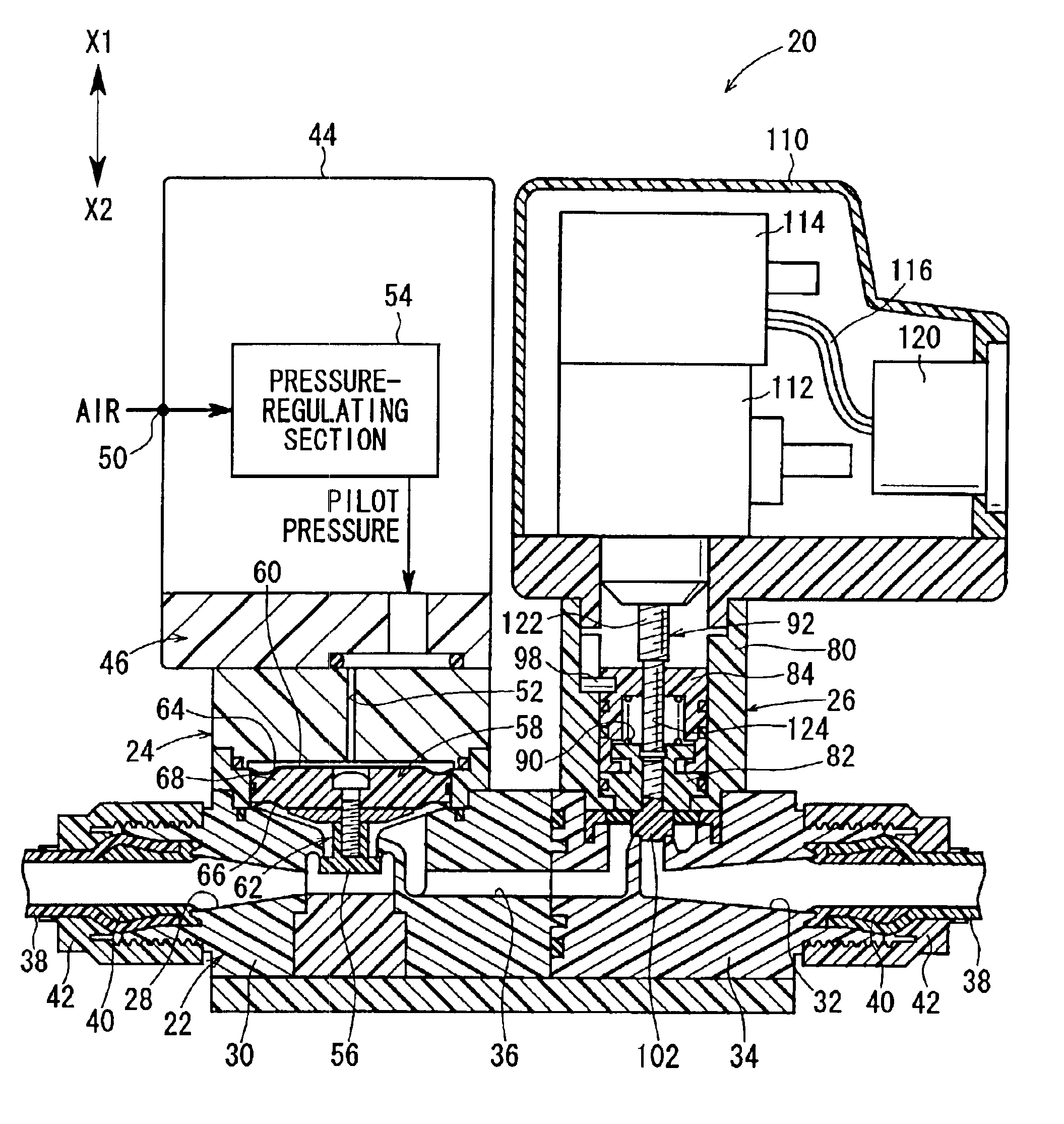

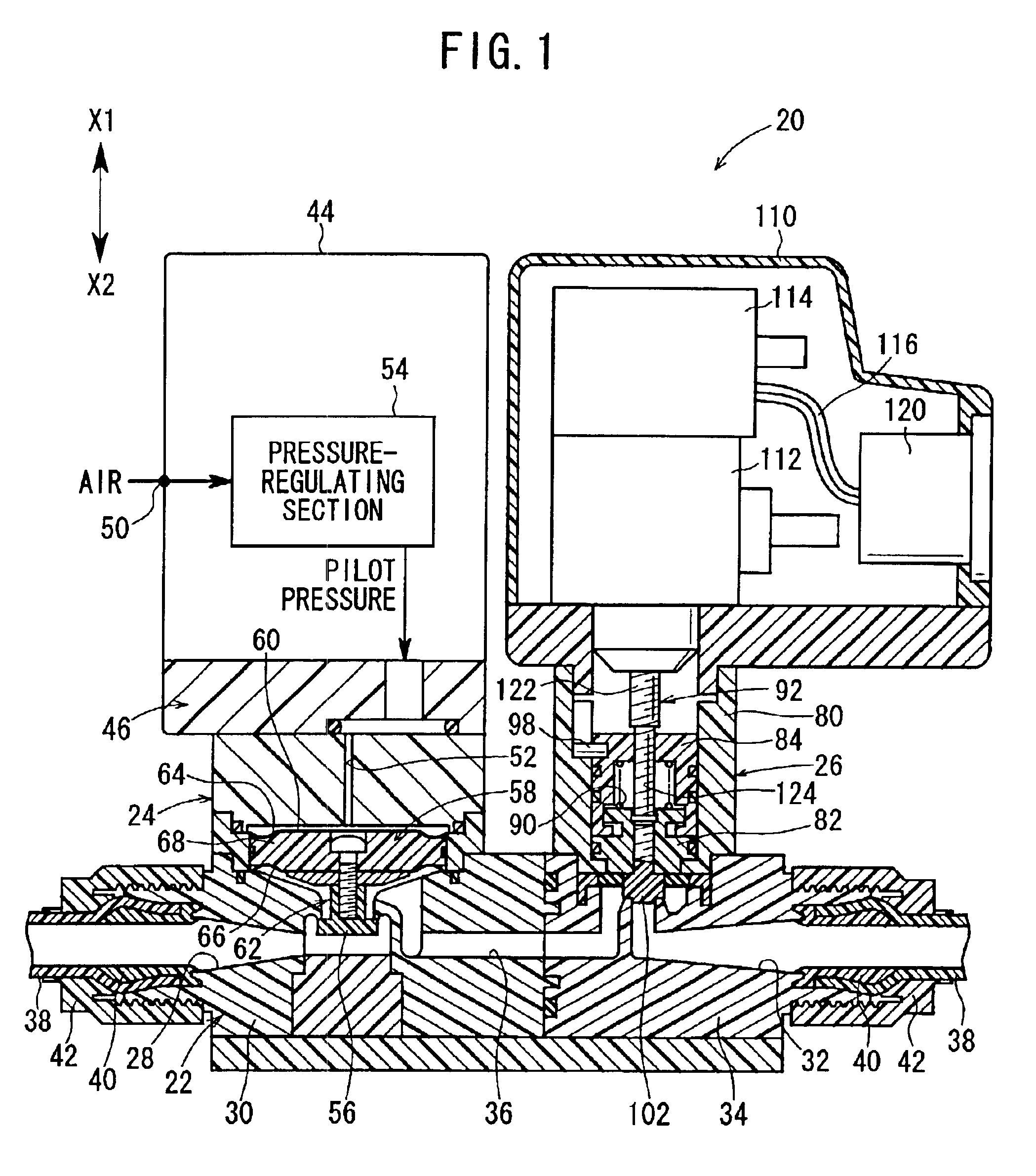

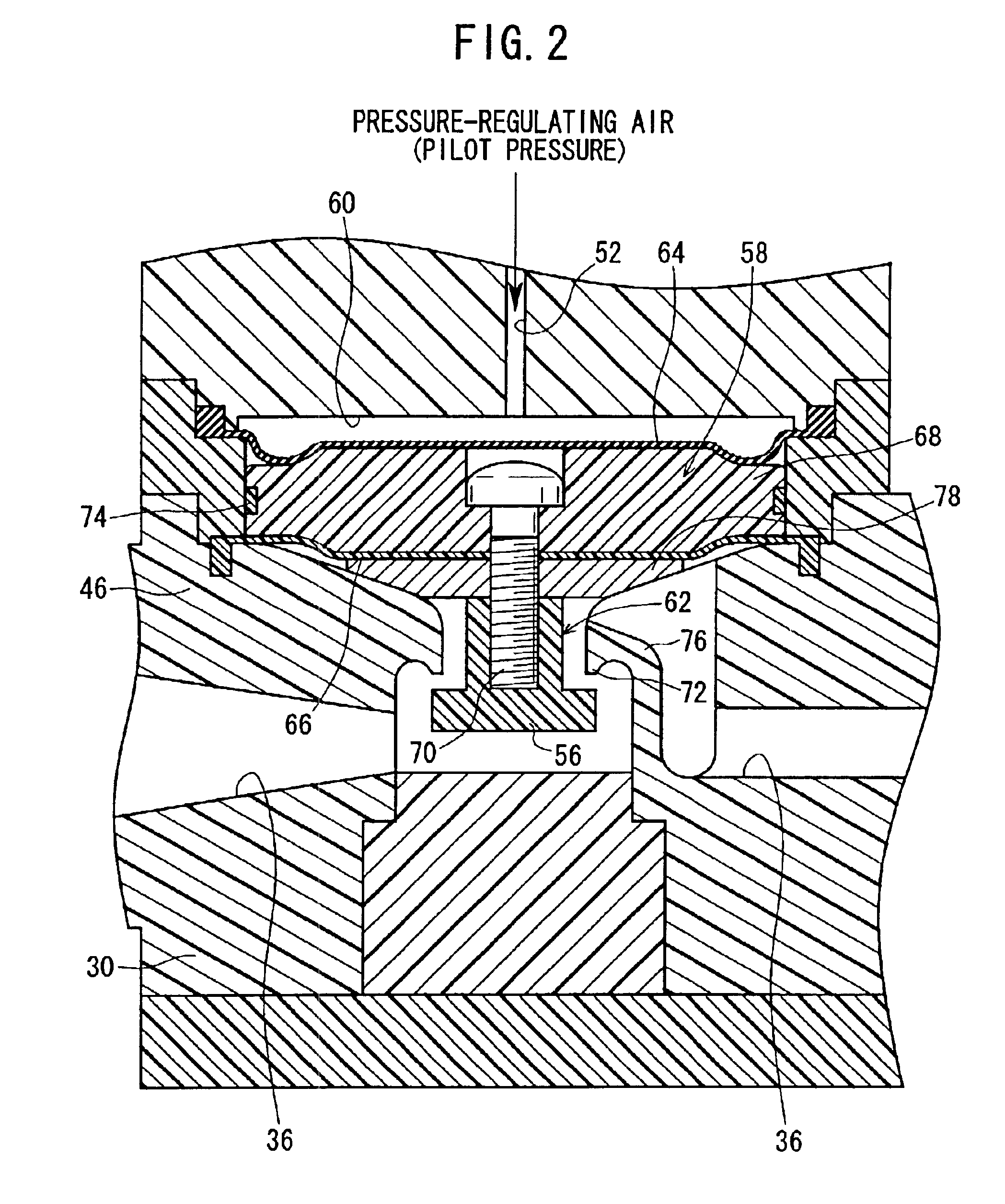

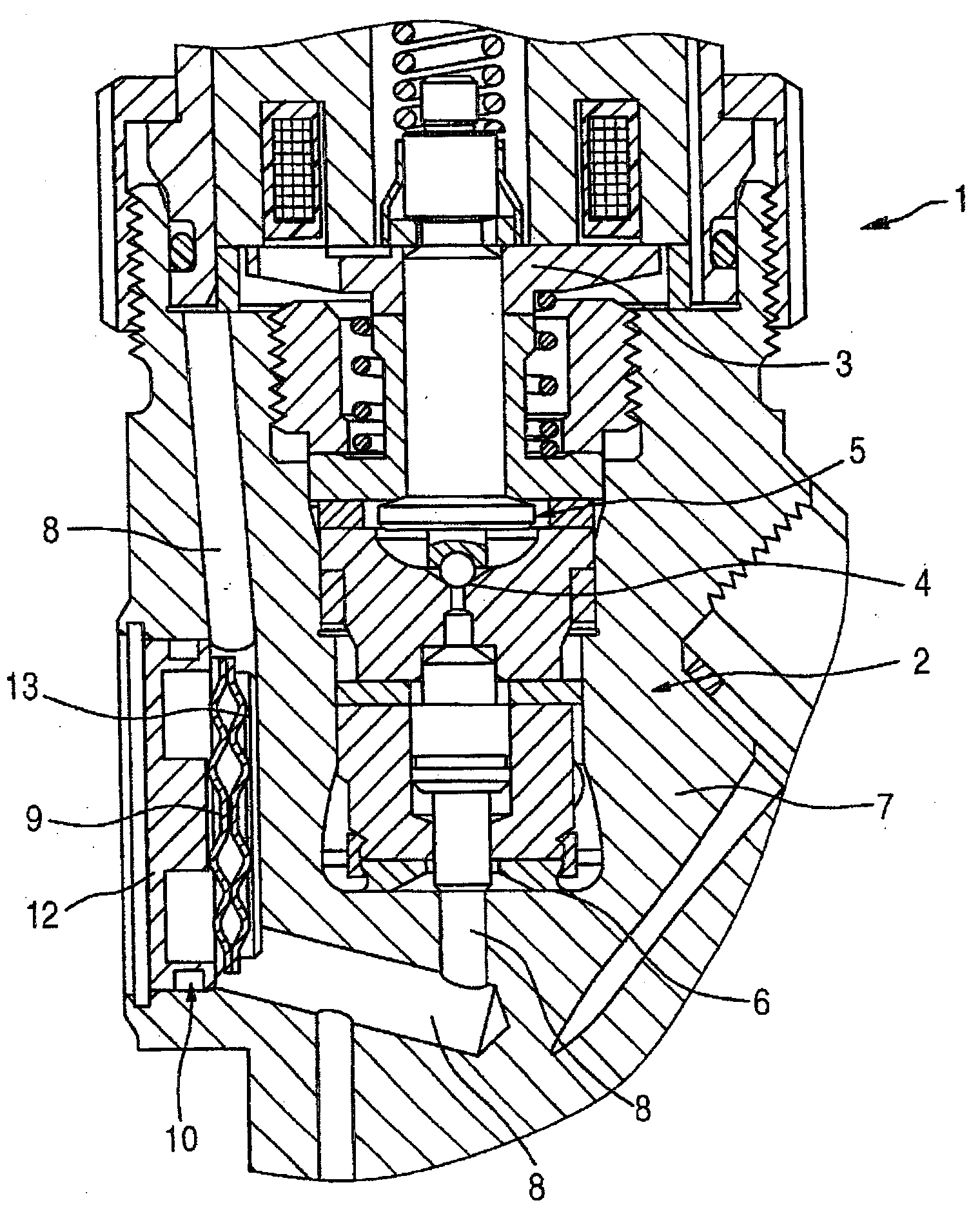

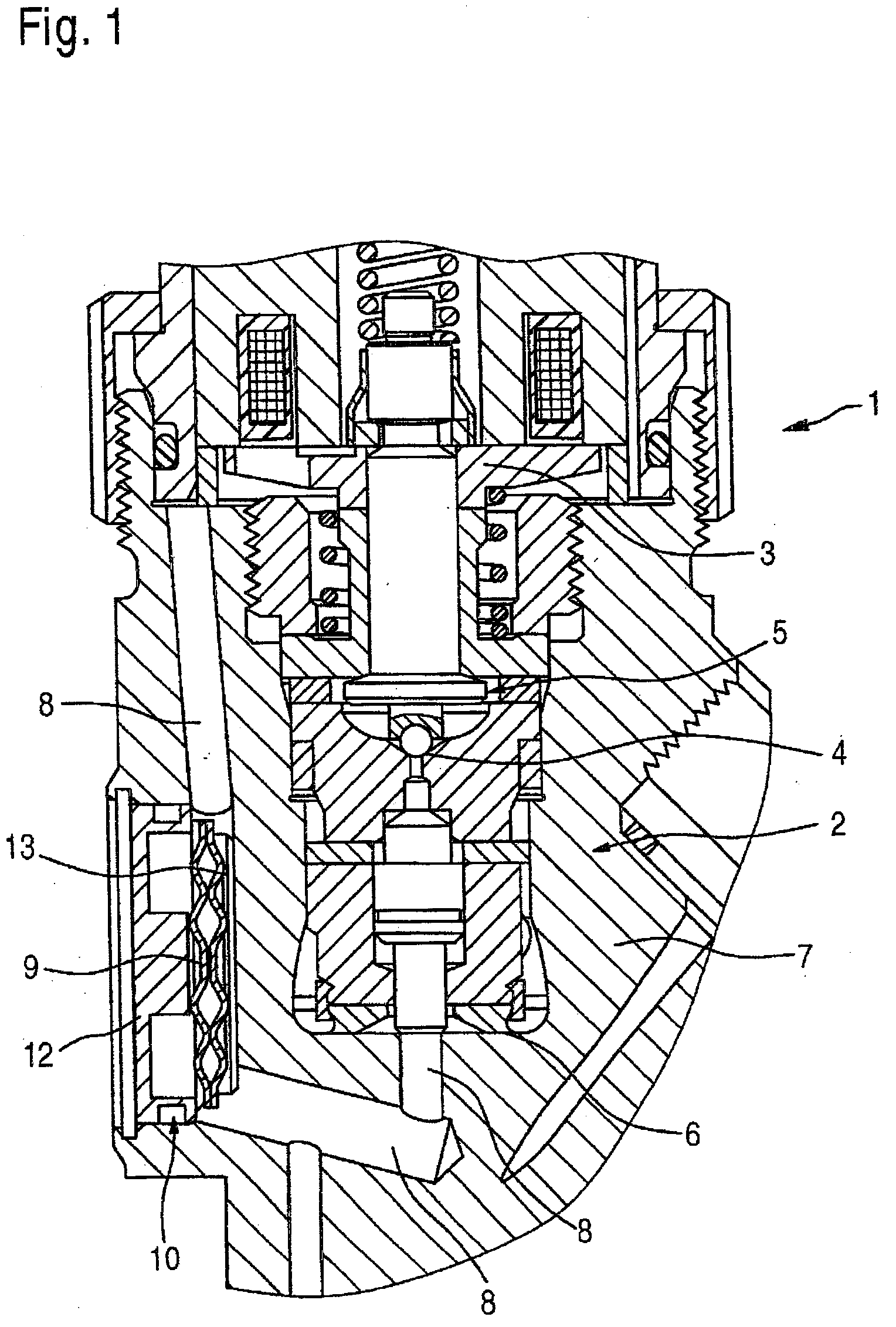

Flow rate control apparatus

InactiveUS6889706B2Eliminate delaysReduced installation spaceOperating means/releasing devices for valvesFlow control using electric meansLinear actuatorEngineering

A flow rate control apparatus is constructed by integrally assembling a pulsation-attenuating mechanism for balancing a regulated pilot pressure from a pressure-regulating section and a primary pressure of a pressure fluid flowing through a fluid passage to attenuate pressure fluctuation caused by pulsation of the pressure fluid, and a flow rate control mechanism for controlling a flow amount of the pressure fluid flowing through the fluid passage by adjusting a valve lift amount of a valve plug with a linear actuator controlled based on a rotary driving control signal from a controller.

Owner:SMC CORP

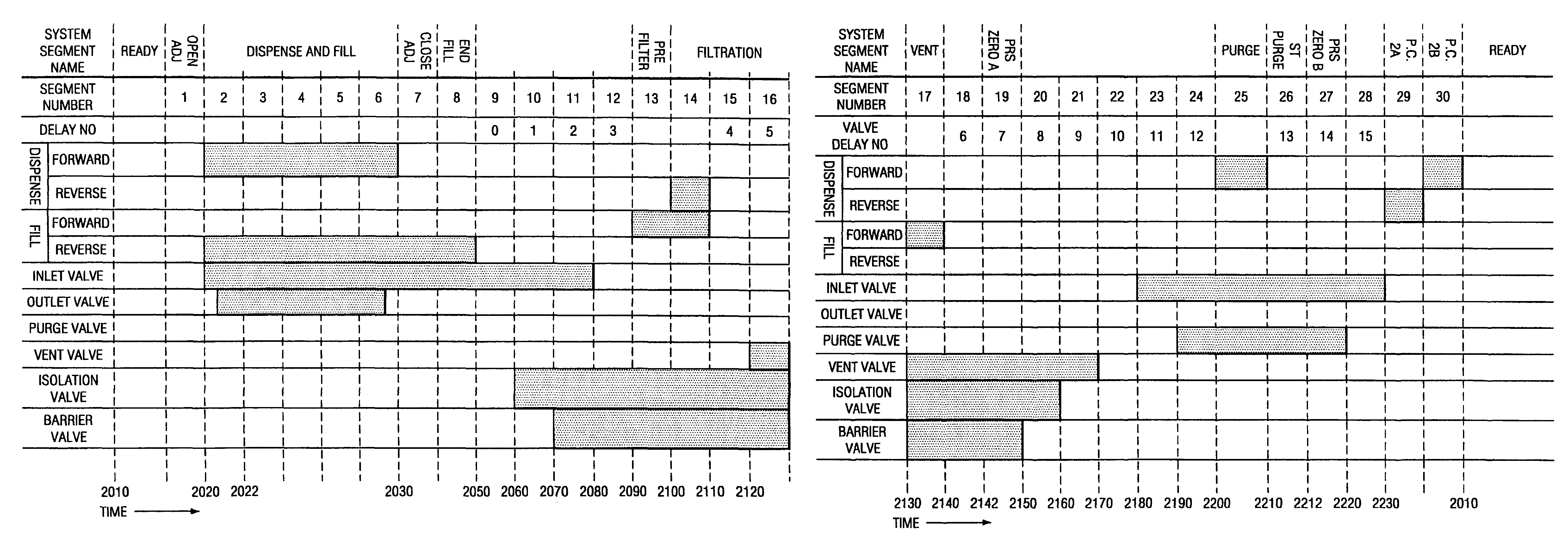

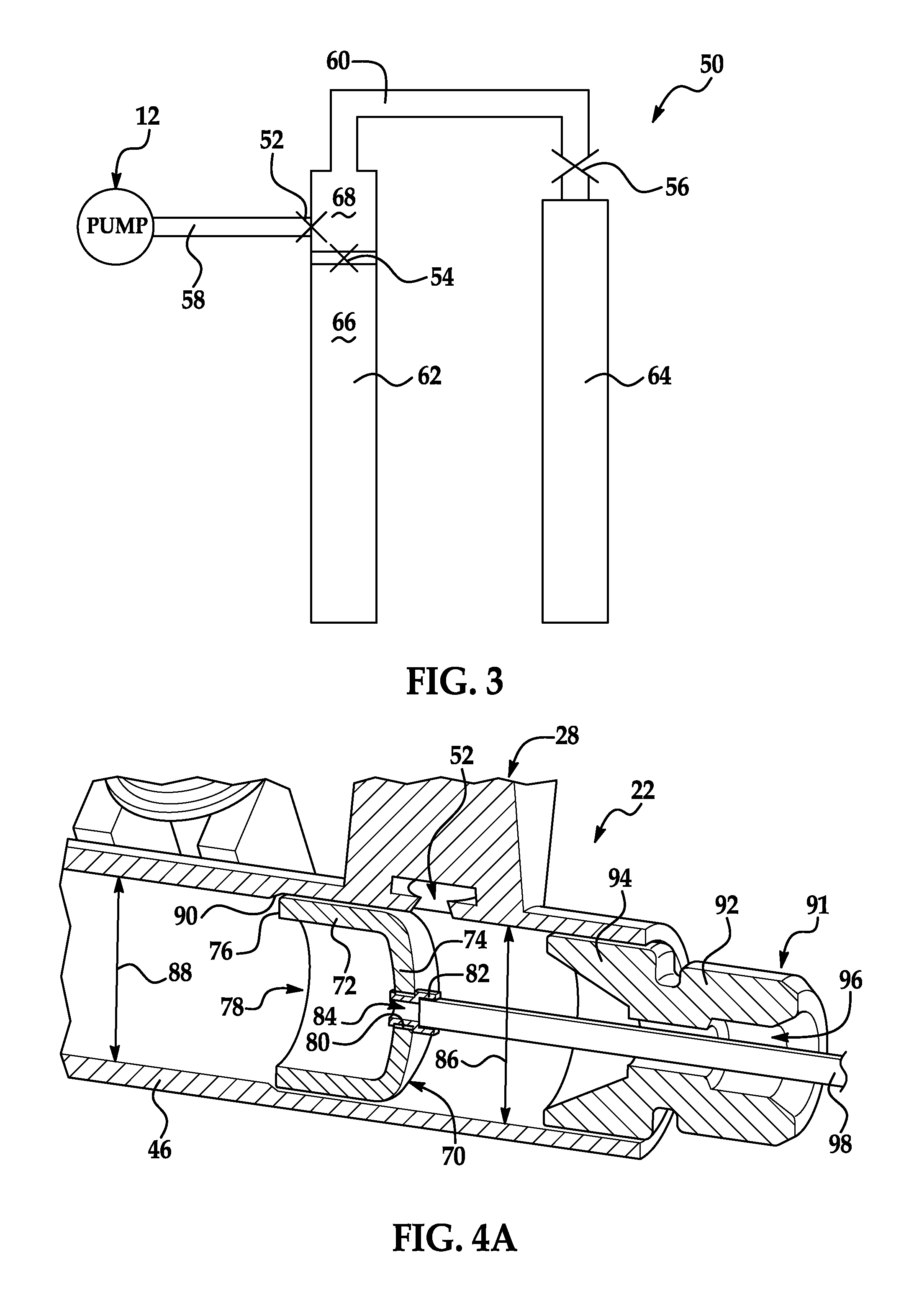

System and method for valve sequencing in a pump

ActiveUS8025486B2Minimizes pressure fluctuationReduce pressure changesServomotor componentsLarge containersEngineeringMechanical engineering

Systems and methods for minimizing pressure fluctuations within a pumping apparatus are disclosed. Embodiments of the present invention may serve to reduce pressure variations within a fluid path of a pumping apparatus by avoiding closing a valve to create a closed or entrapped space in the fluid path and similarly, avoiding opening a valve between two entrapped spaces. More specifically, embodiments of the present invention may serve to operate a system of valves of the pumping apparatus according to a valve sequence configured to substantially minimize the time the fluid flow path through the pumping apparatus is closed (e.g. to an area external to the pumping apparatus).

Owner:ENTEGRIS INC

Ink jet head

Owner:BROTHER KOGYO KK

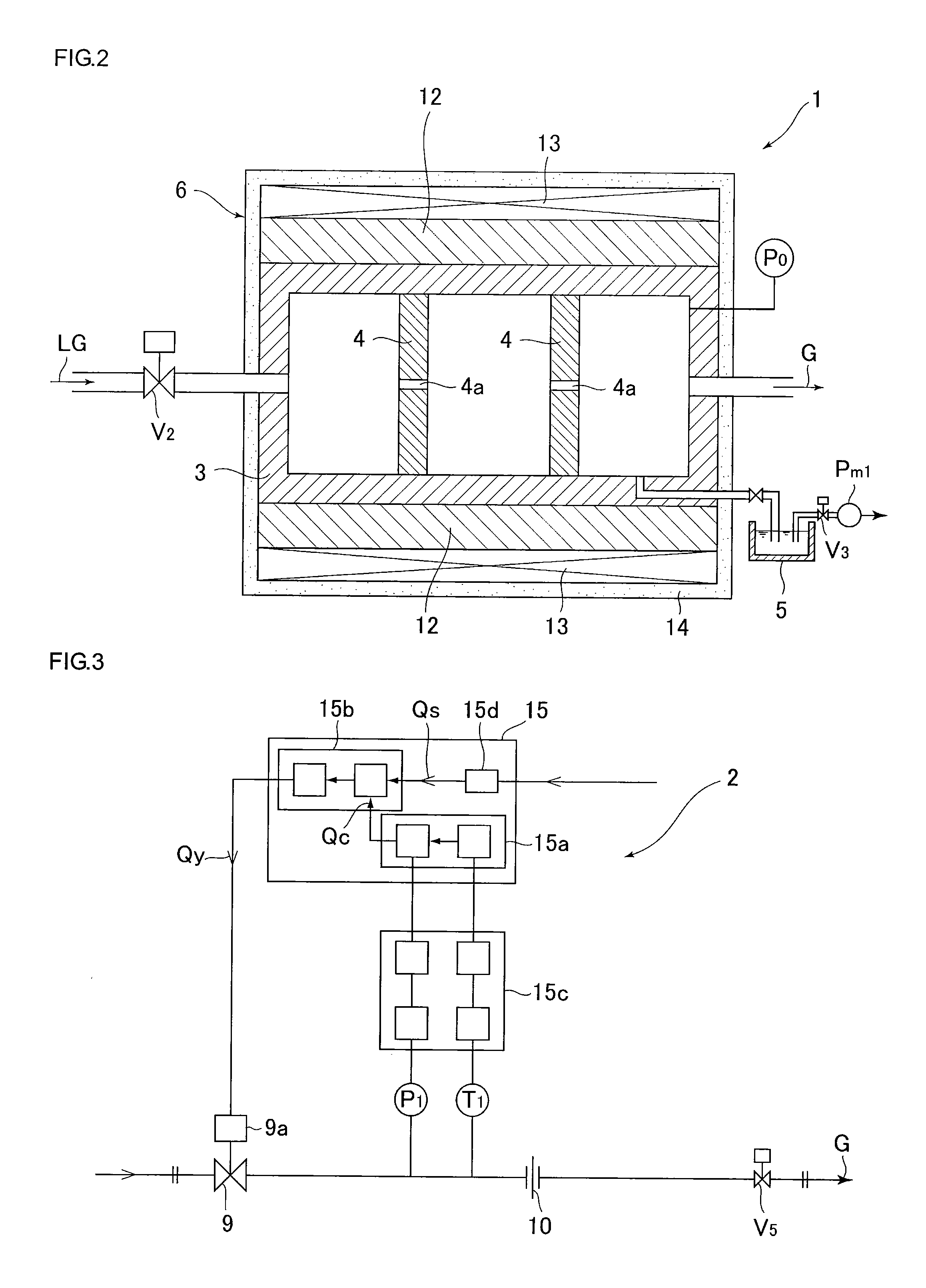

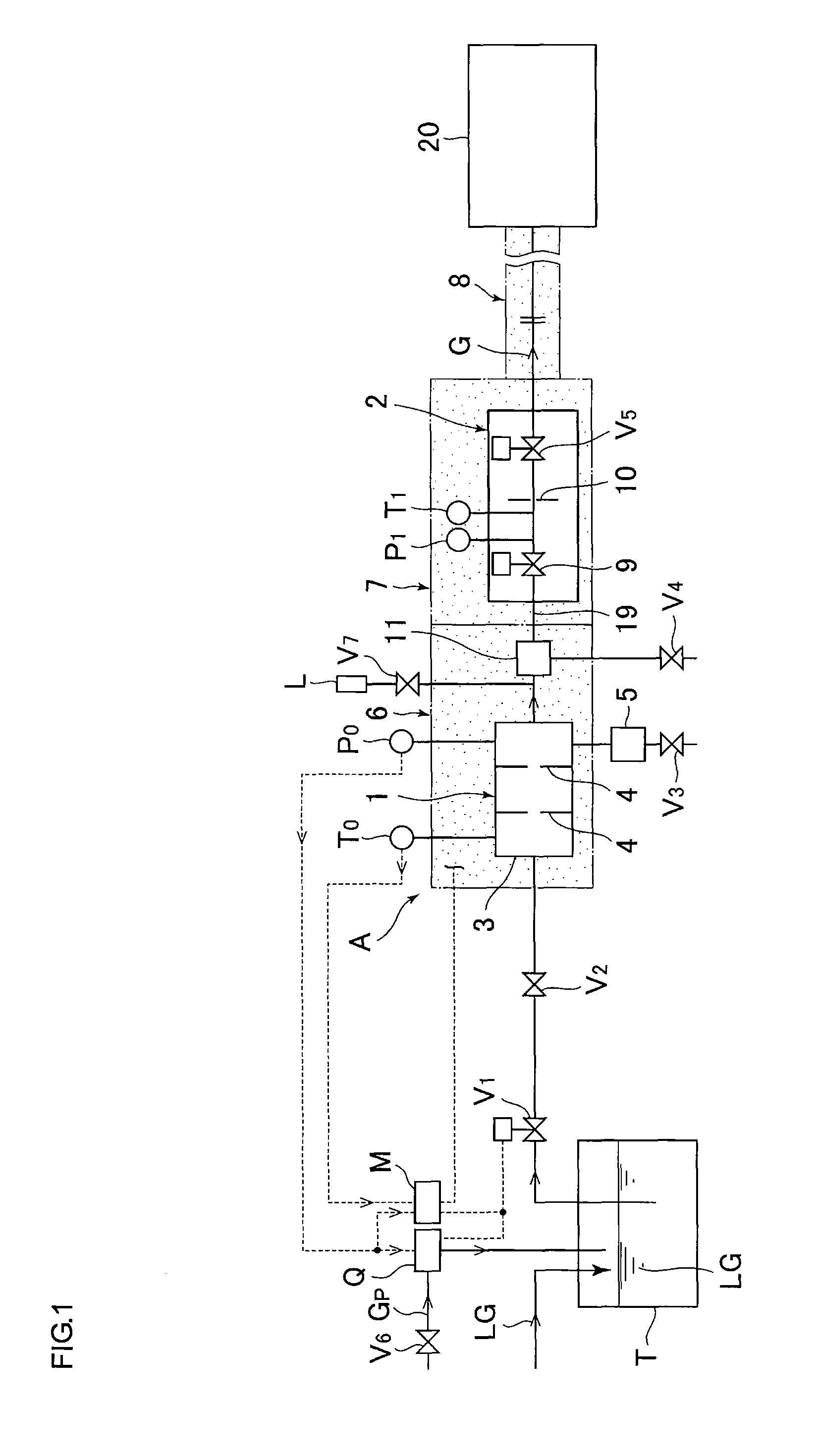

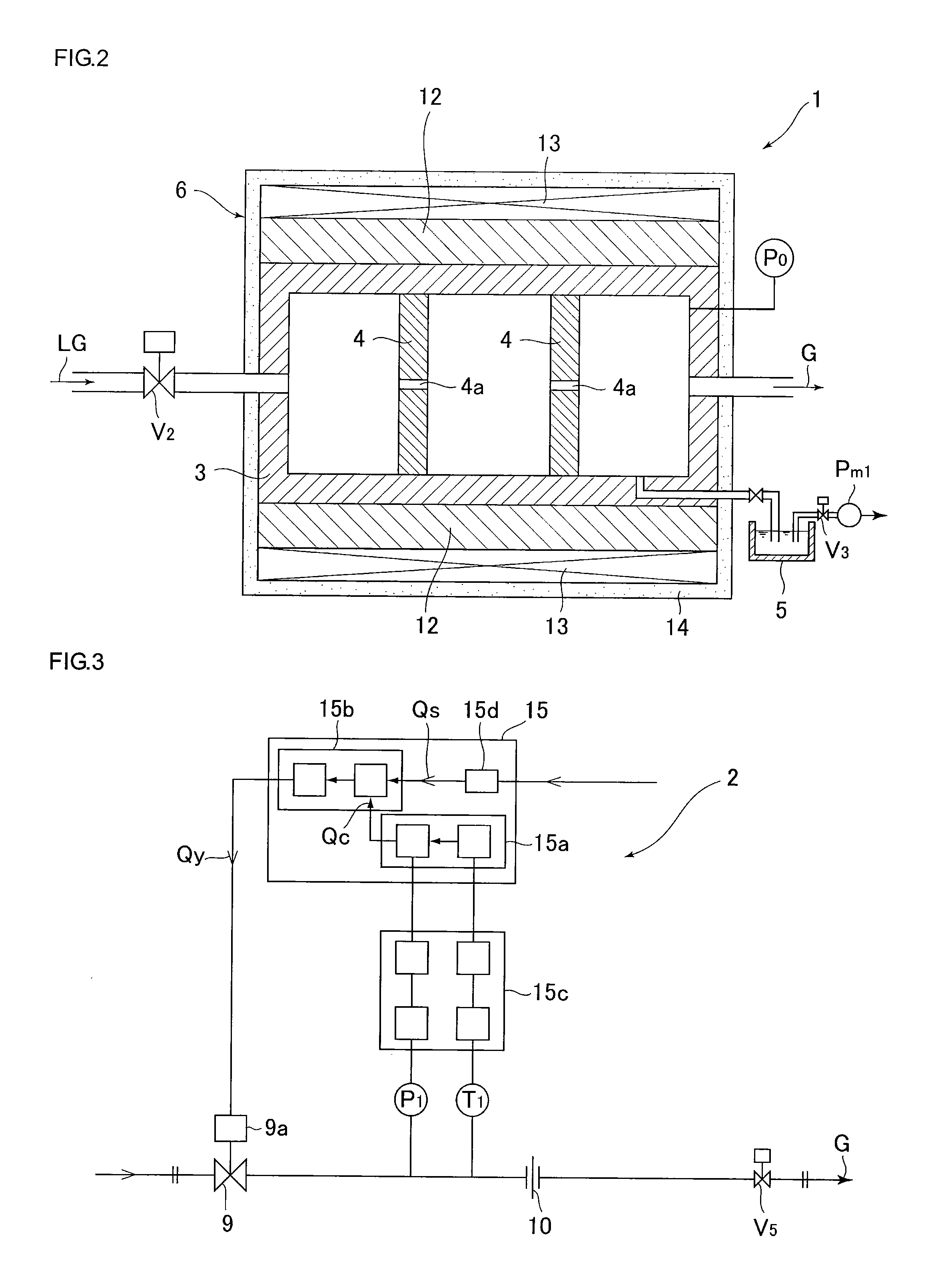

Gas supply apparatus equipped with vaporizer

ActiveUS20110100483A1Stable controlPrecise flow controlInternal combustion piston enginesValve members for heating/coolingTemperature controlEngineering

An energy-saving, downsized gas supply apparatus equipped with a vaporizer is provided, wherein the gas supply apparatus is capable of stably and easily performing highly accurate gas flow rate control without requiring rigorous temperature control on the vaporizer side. The present invention pertains to a gas supply apparatus equipped with a vaporizer that includes (a) a liquid receiving tank; (b) a vaporizer that vaporizes liquid; (c) a high-temperature type pressure type flow rate control device that adjusts a flow rate of a vaporized gas; and (d) heating devices that heat the vaporizer, the high-temperature type pressure type flow rate control device, and desired portions of pipe passages connected to the vaporizer and the high-temperature type pressure type flow rate control device.

Owner:FUJIKIN INC

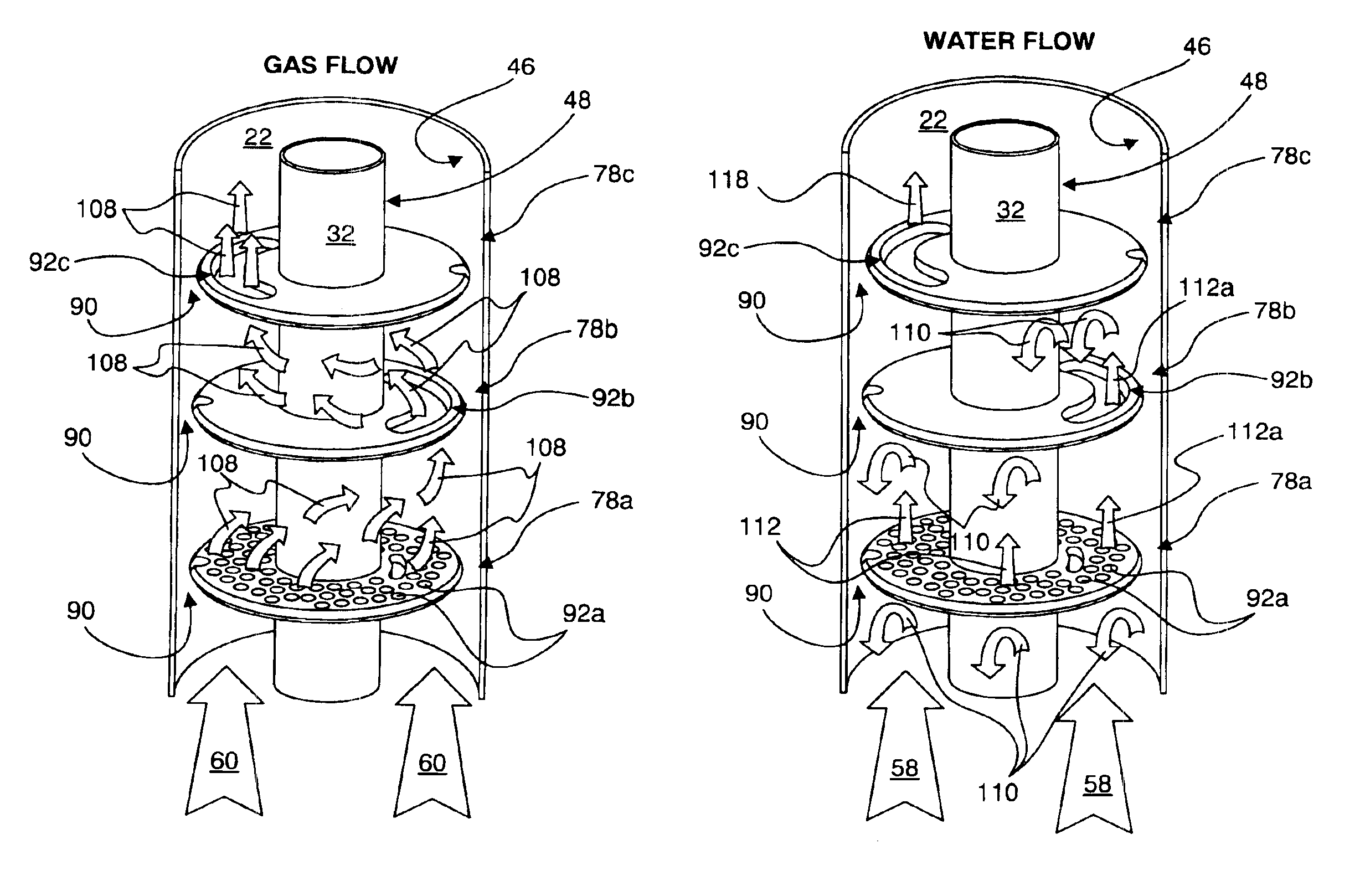

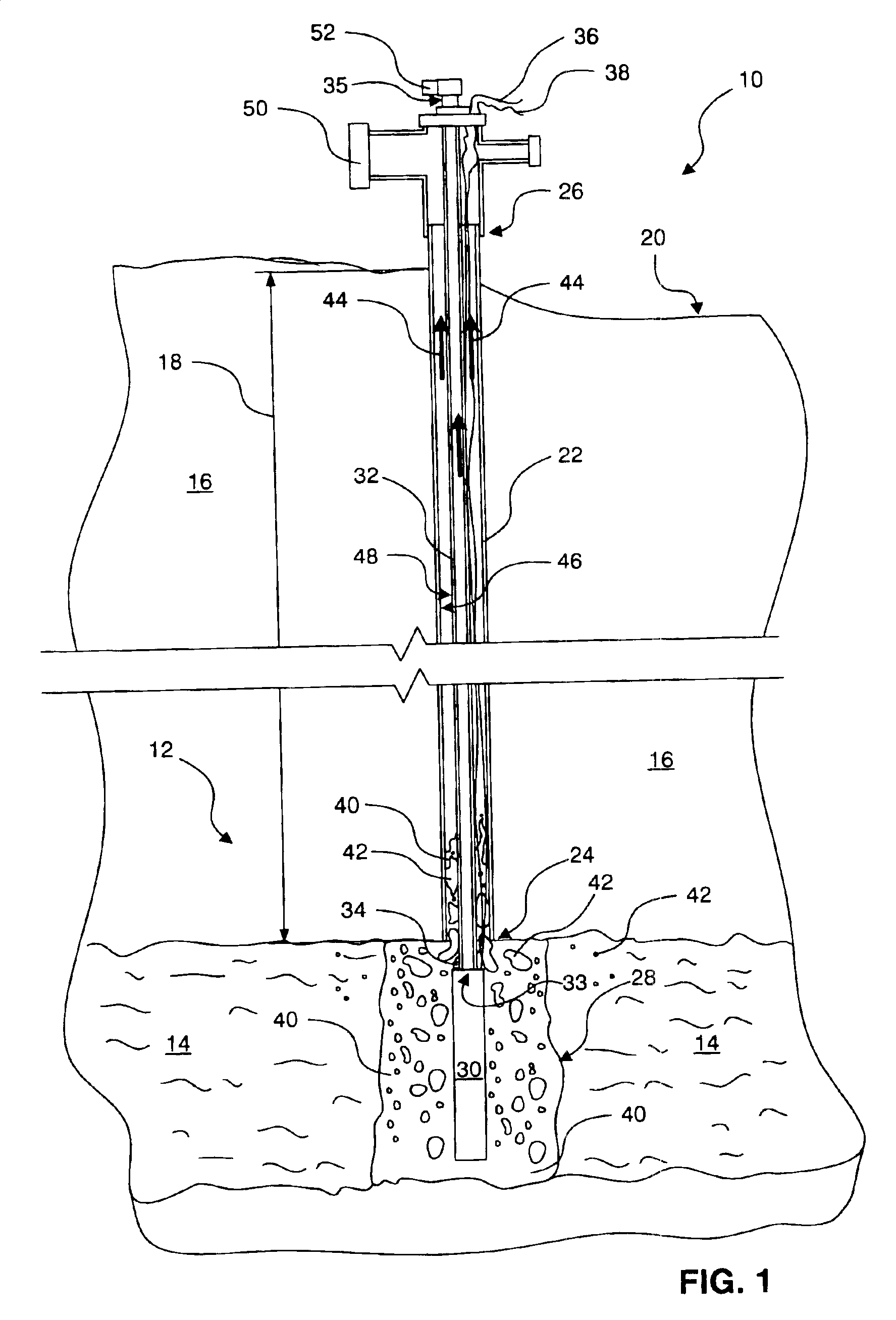

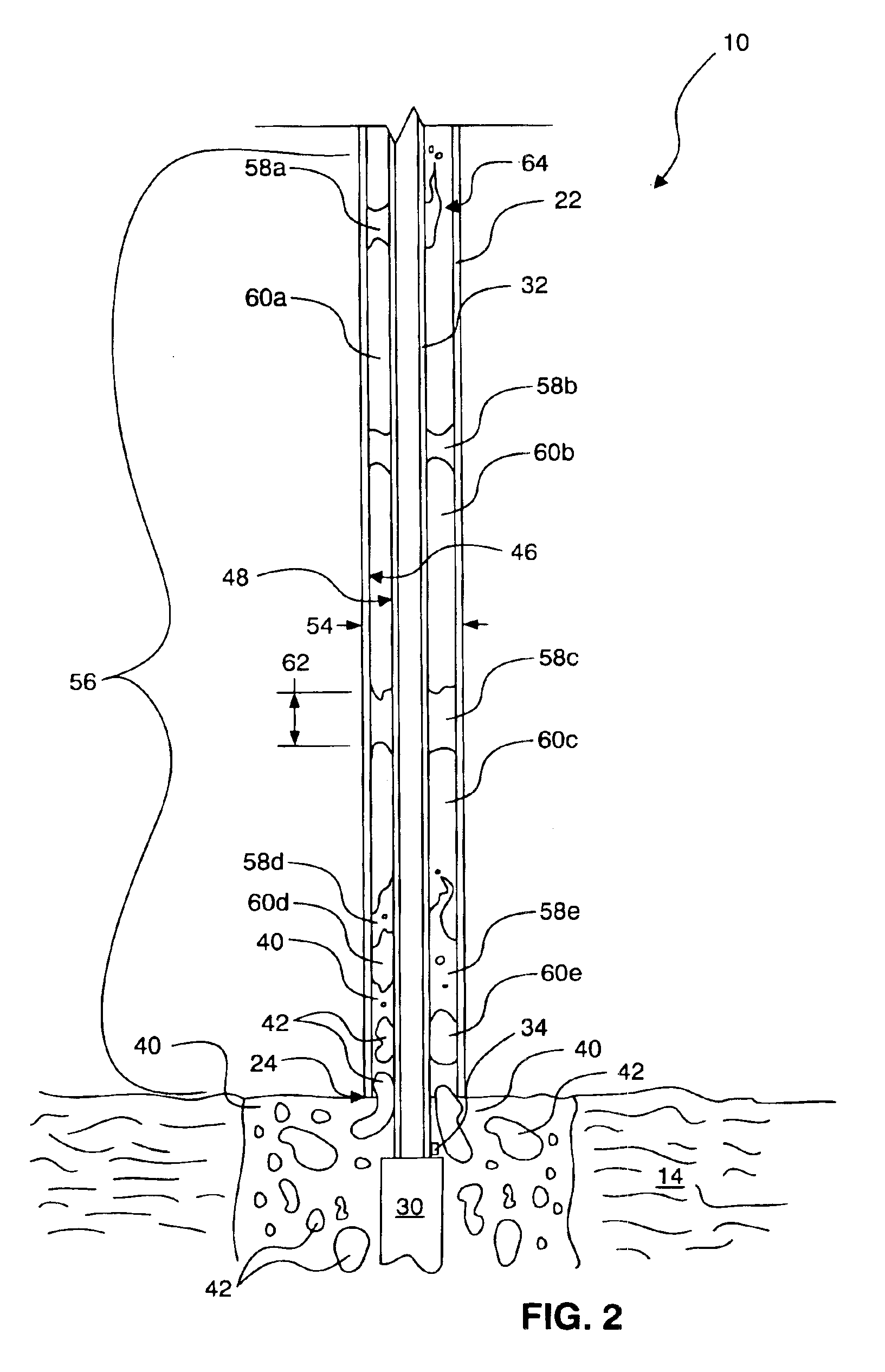

Baffle system for two-phase annular flow

An apparatus for promoting the flow of methane gas from a coal bed methane well. The apparatus may include a well casing extending into the earth to a cool seam aquifer. A conduit may be placed within the well and extend from the coal seam aquifer to the earth's surface. A pump may be connected to pump water from the coal seam aquifer through the conduit to the surface. A baffle may be placed in the gap formed between the interior surface of the well casing and the exterior surface of the conduit to the preferentially permit the flow of gas over the flow of water therethrough. The baffle may mitigate well bore pressure fluctuations, thus reducing the occurrence of pump gas lock and reducing well bore damage.

Owner:PRESTON YALE MATTHEW

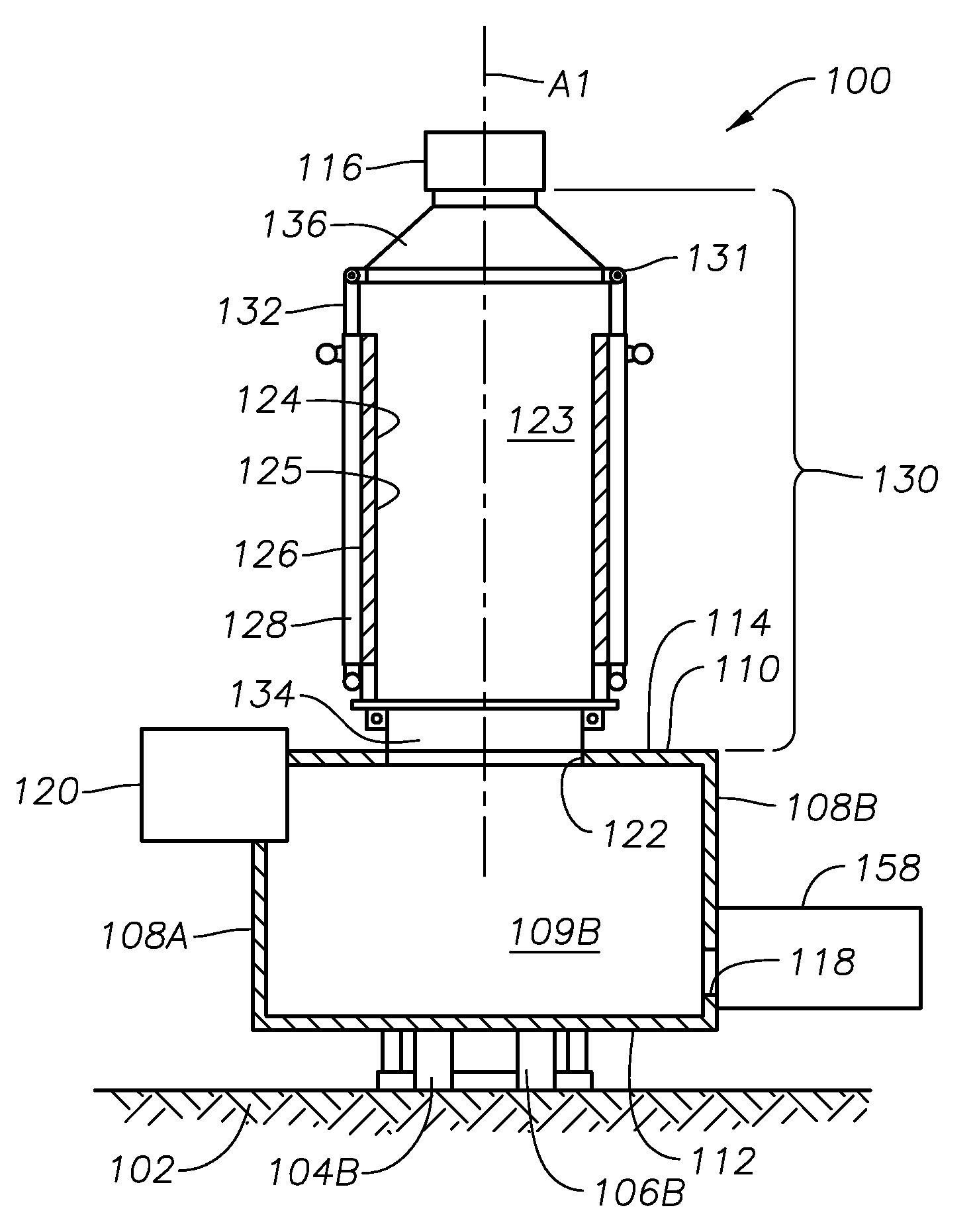

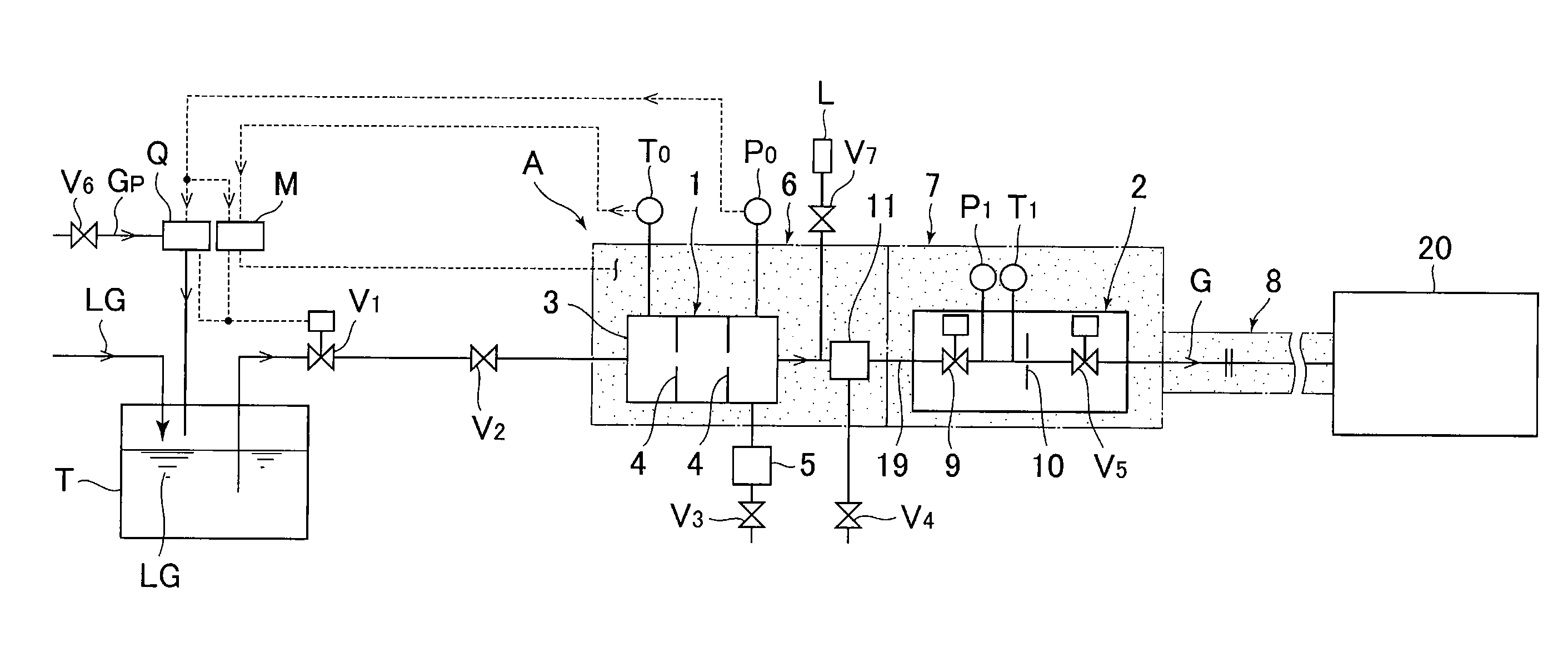

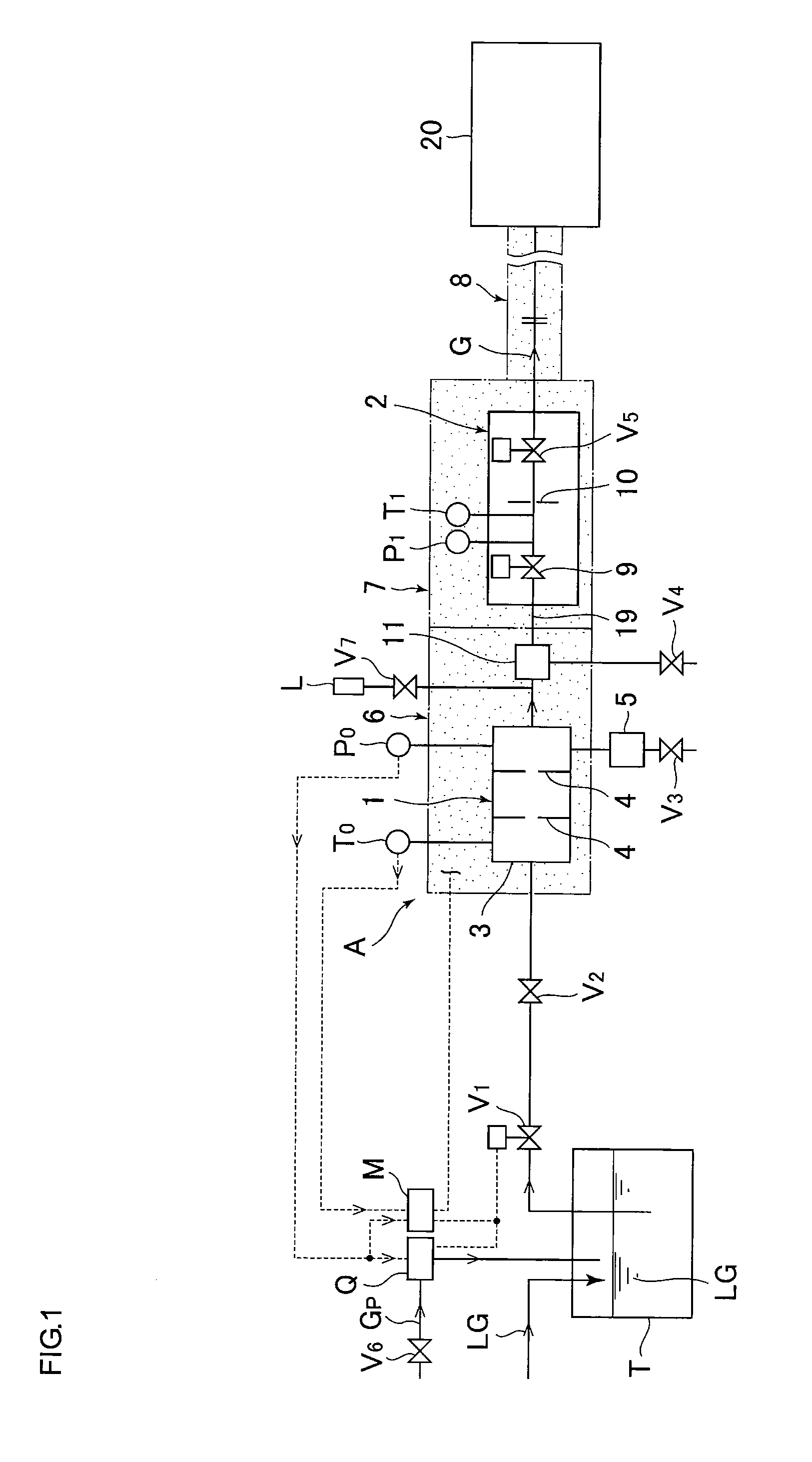

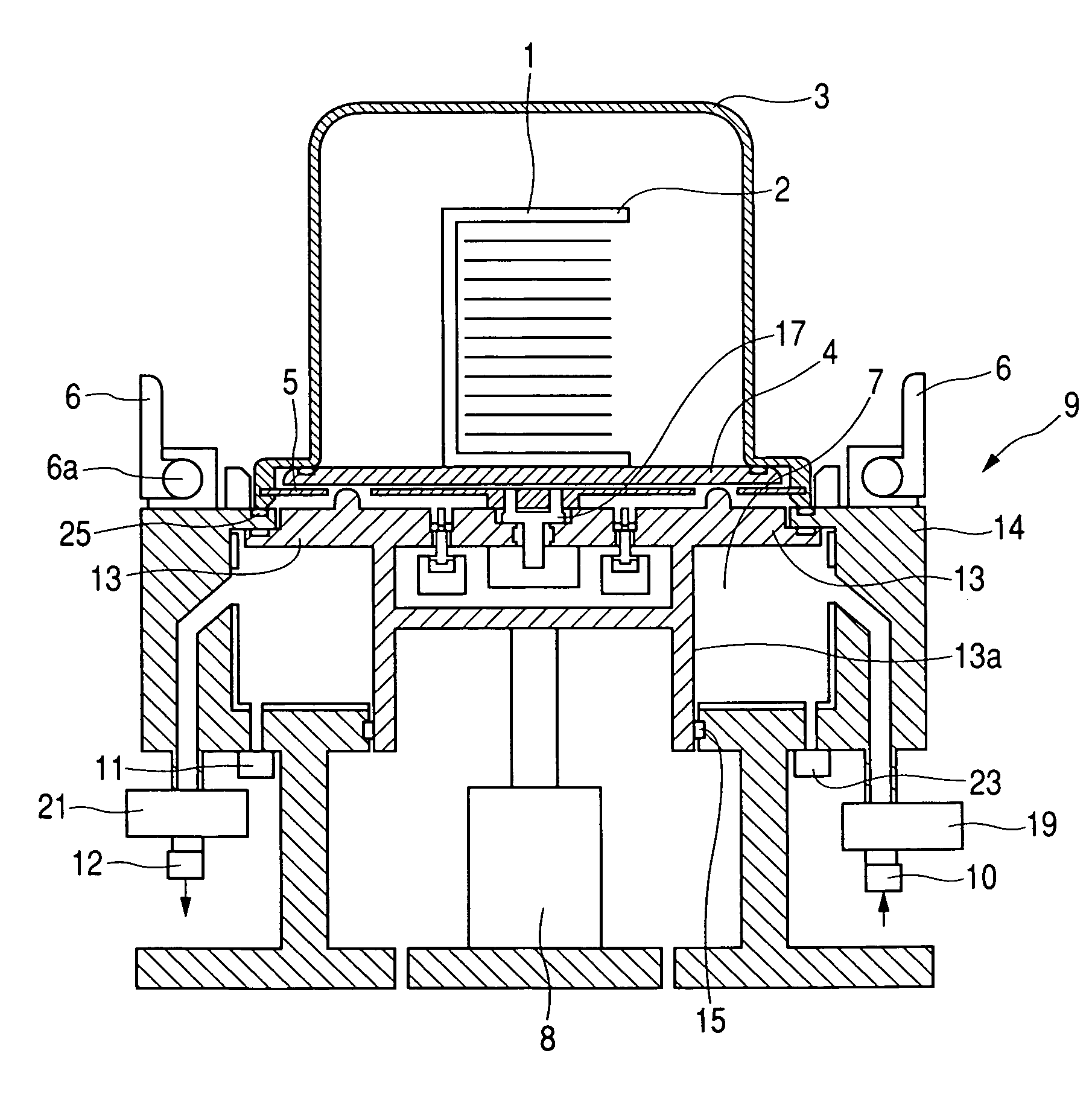

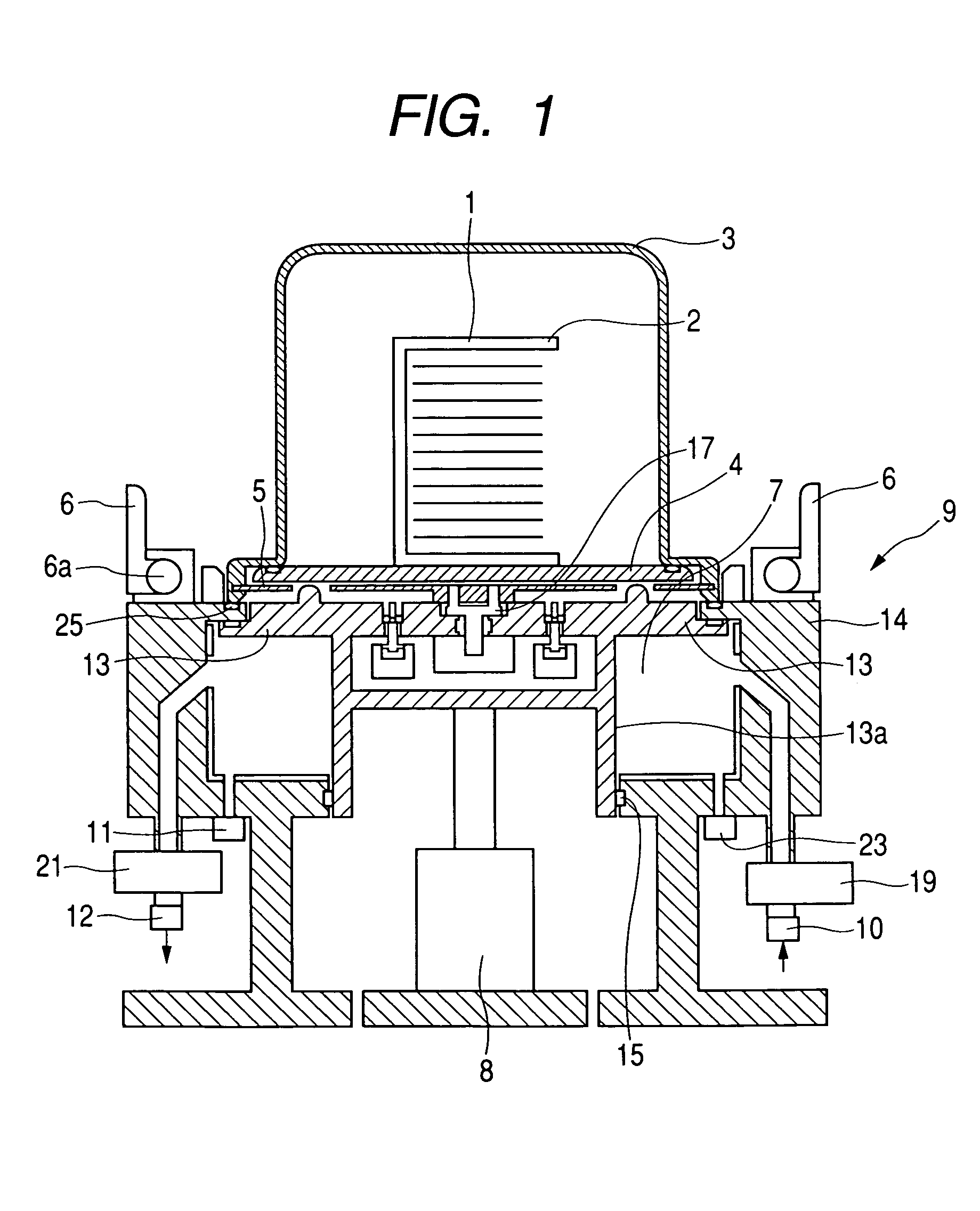

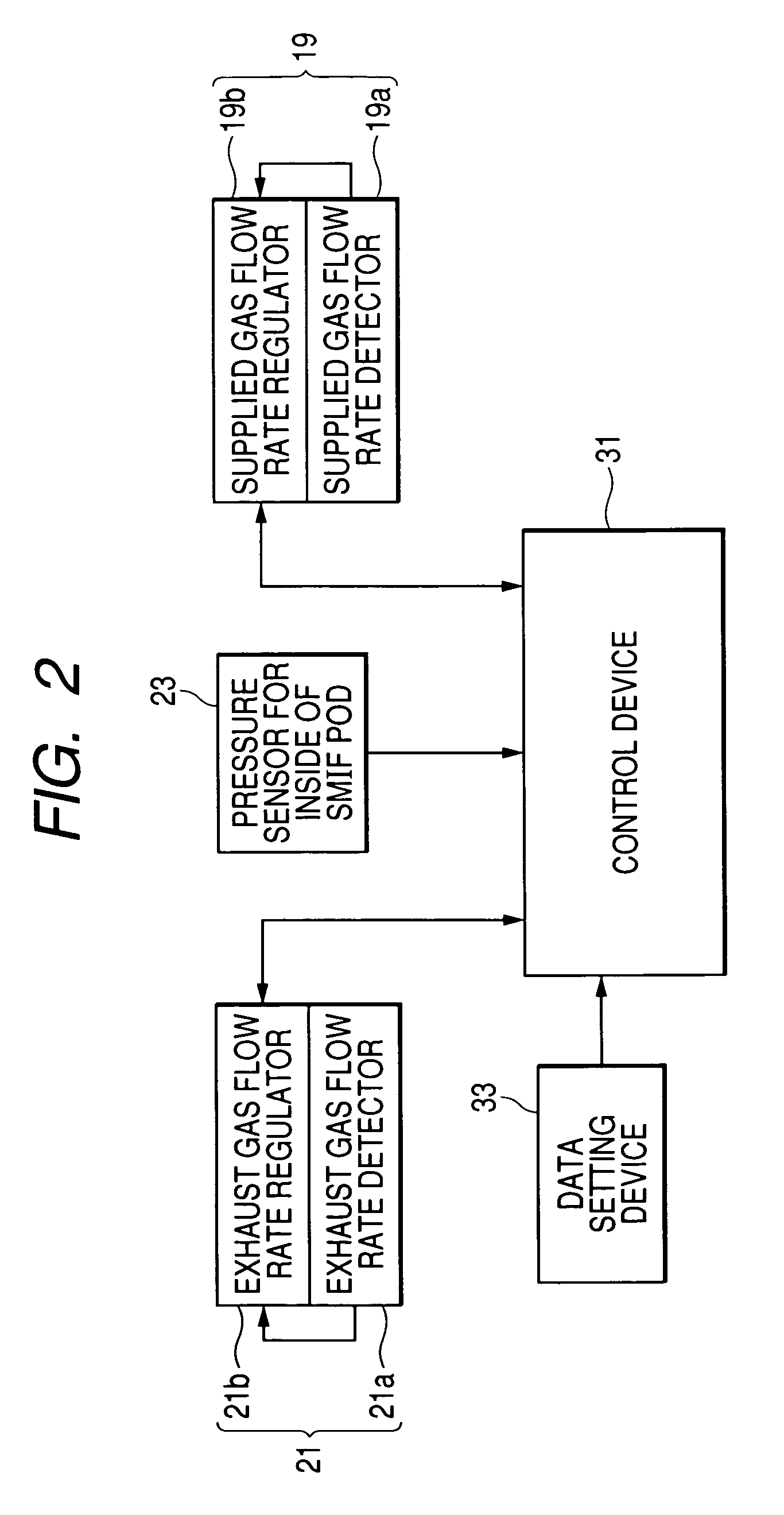

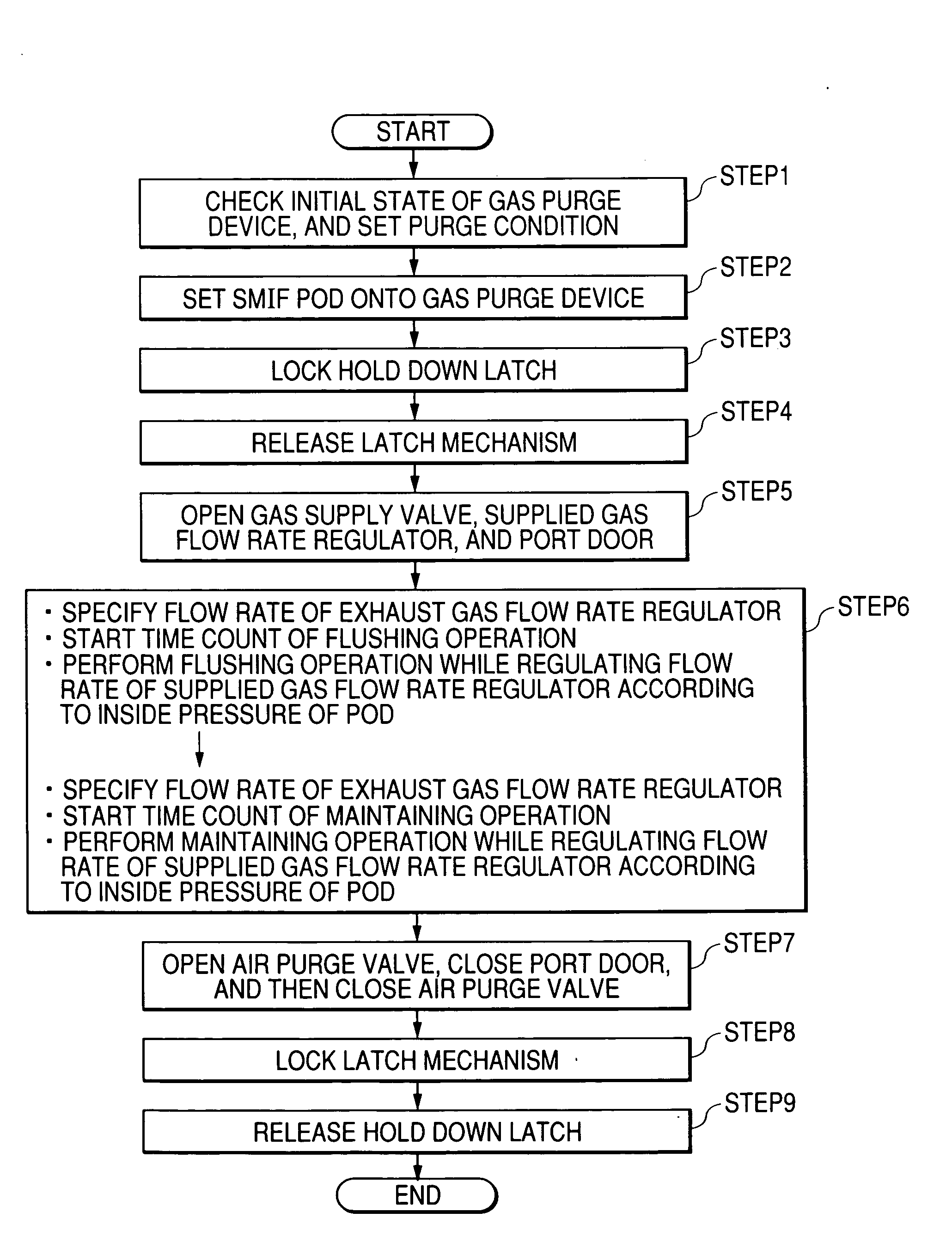

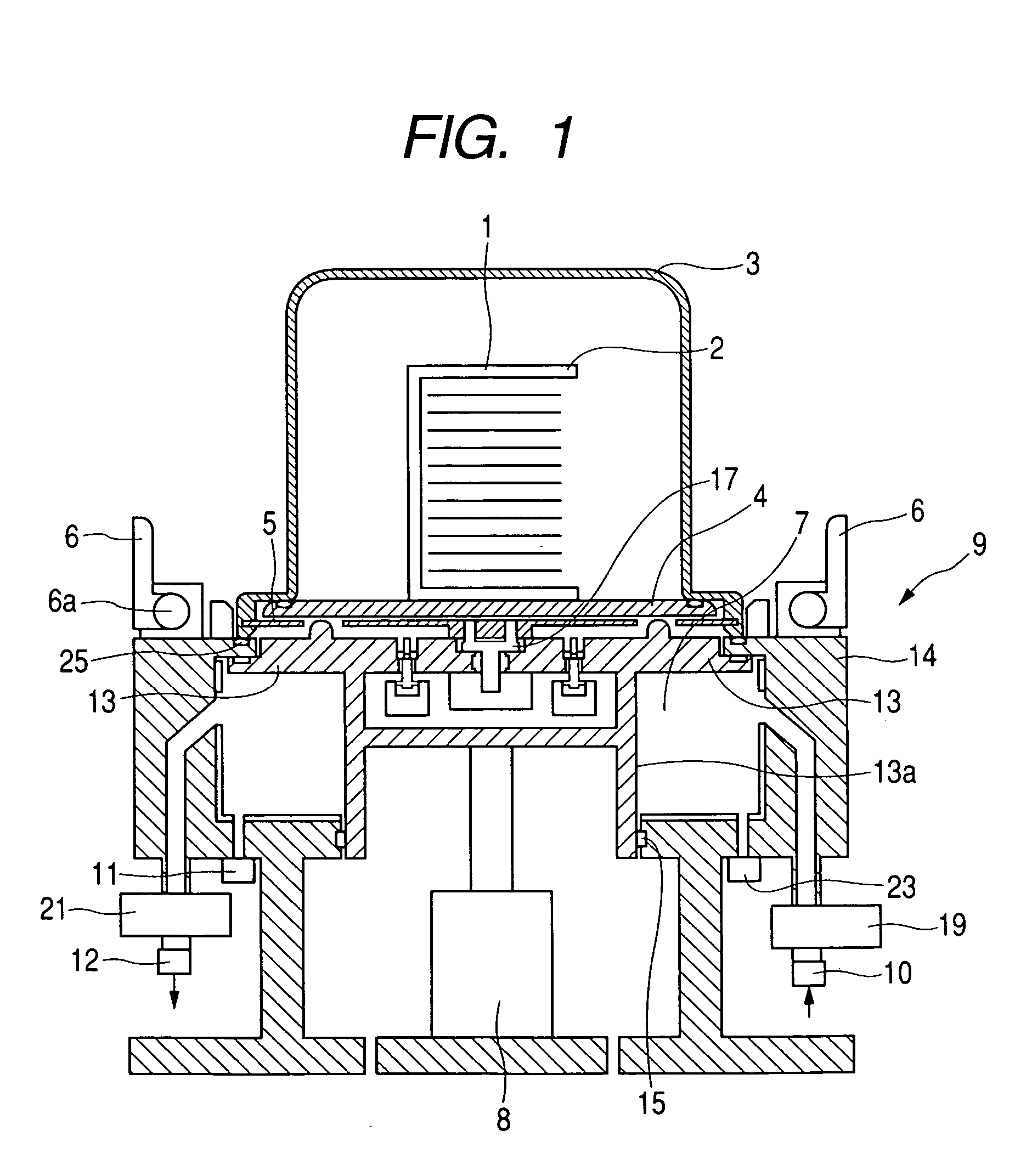

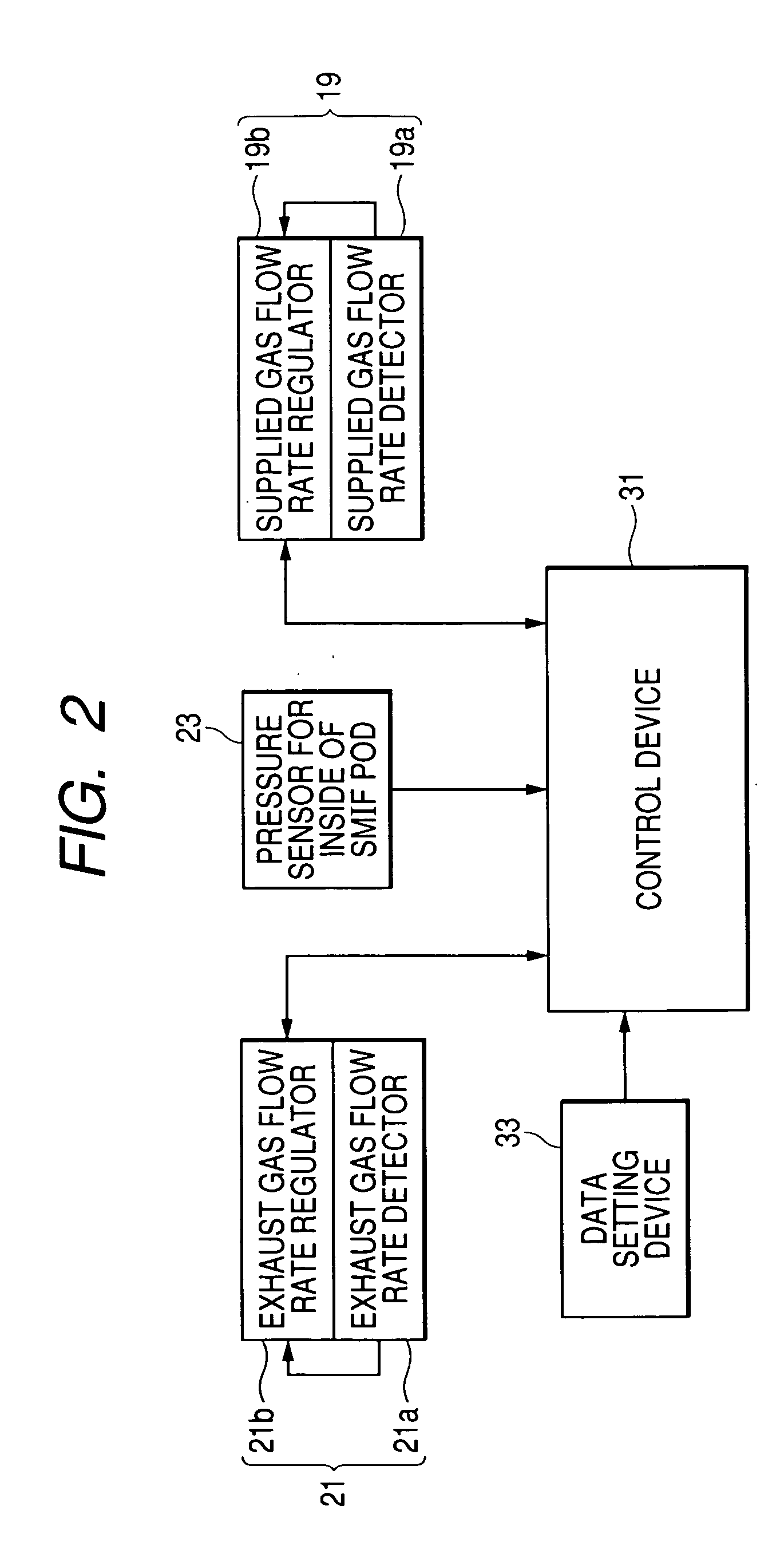

Purging system and purging method for the interior of a portable type hermetically sealed container

ActiveUS7360346B2Suppress pressure fluctuationsInhibit deteriorationLiquid fillingFlexible member pumpsHermetic sealProduct gas

A fine pressure fluctuation at short time intervals occurring when a portable type hermetically sealed container is purged is reduced to thereby prevent the deterioration or the like of a seal member due to the pressure fluctuation. In order to achieve this object, a gas flow rate regulating apparatus is disposed in a gas supplying system in a purging system, and pressure in the portable type hermetically sealed container during purge is measured and the result thereof is fed back to thereby control the flow rate of a supplied gas.

Owner:TDK CORPARATION

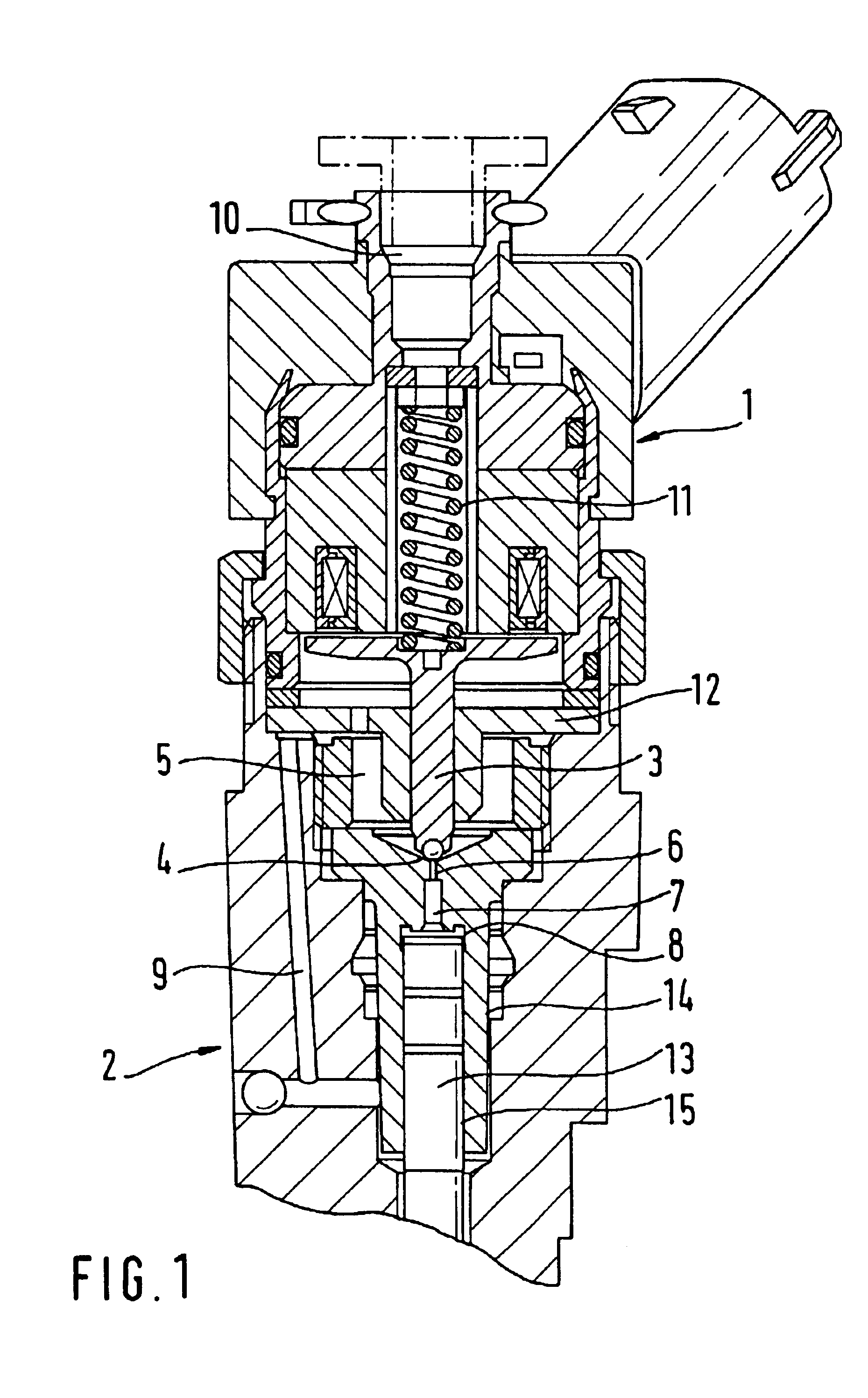

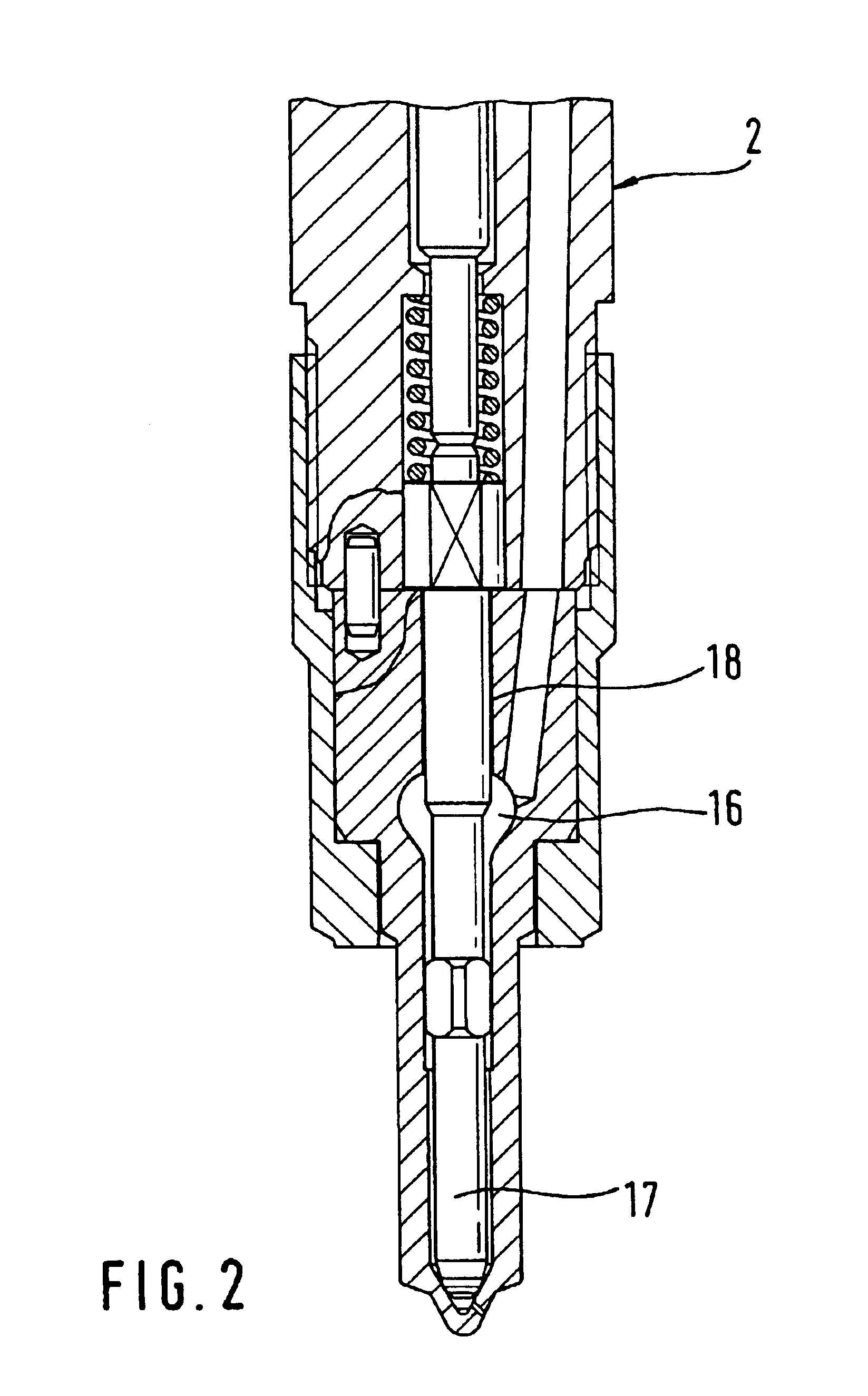

Fuel injector

InactiveUS20090127356A1Increase external pressureSafe and reliable functionOperating means/releasing devices for valvesSpray nozzlesCombustion chamberLine tubing

The invention relates to a fuel injector for injecting fuel into a combustion chamber, having a solenoid valve for controlling a mini-servo valve. A movable armature can be placed in a sealing fashion on a valve seat in a lower armature chamber, wherein in addition the mini-servo valve is held in an injector body and seals a control line against a flat seat. By means of the flat seat, during an actuation of the solenoid valve, the control line can be relieved of pressure from a high fuel pressure to a return pressure into at least one return line. A mechanism for reducing pressure oscillations are provided in the at least one return line, which includes at least one diaphragm cell which is held in a recess and which is placed in fluidic connection with the at least one return bore. A fuel injector with the mechanism for reducing pressure oscillations is therefore created in the at least one return line which operates without a leakage flow and has a simple and effective function.

Owner:ROBERT BOSCH GMBH

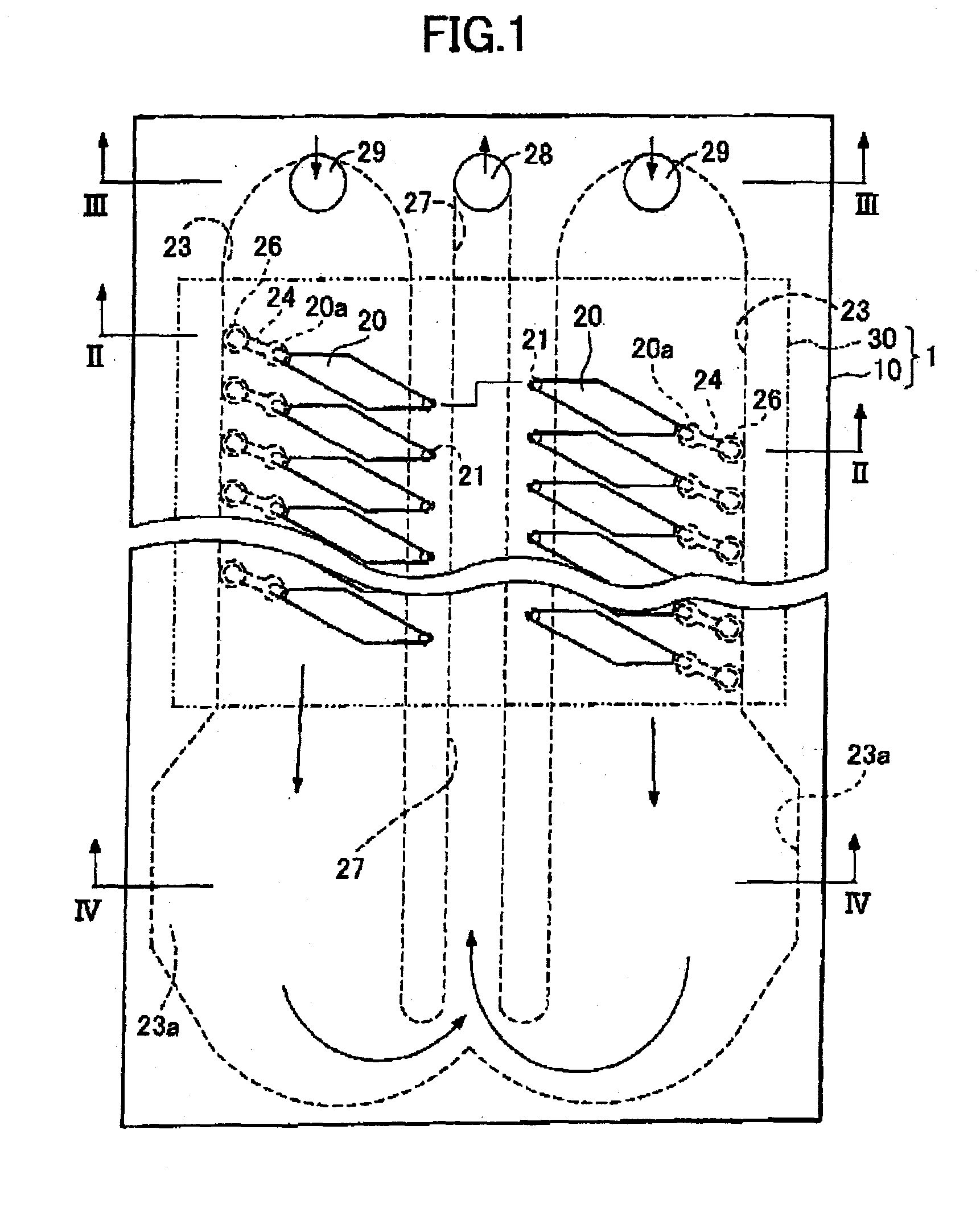

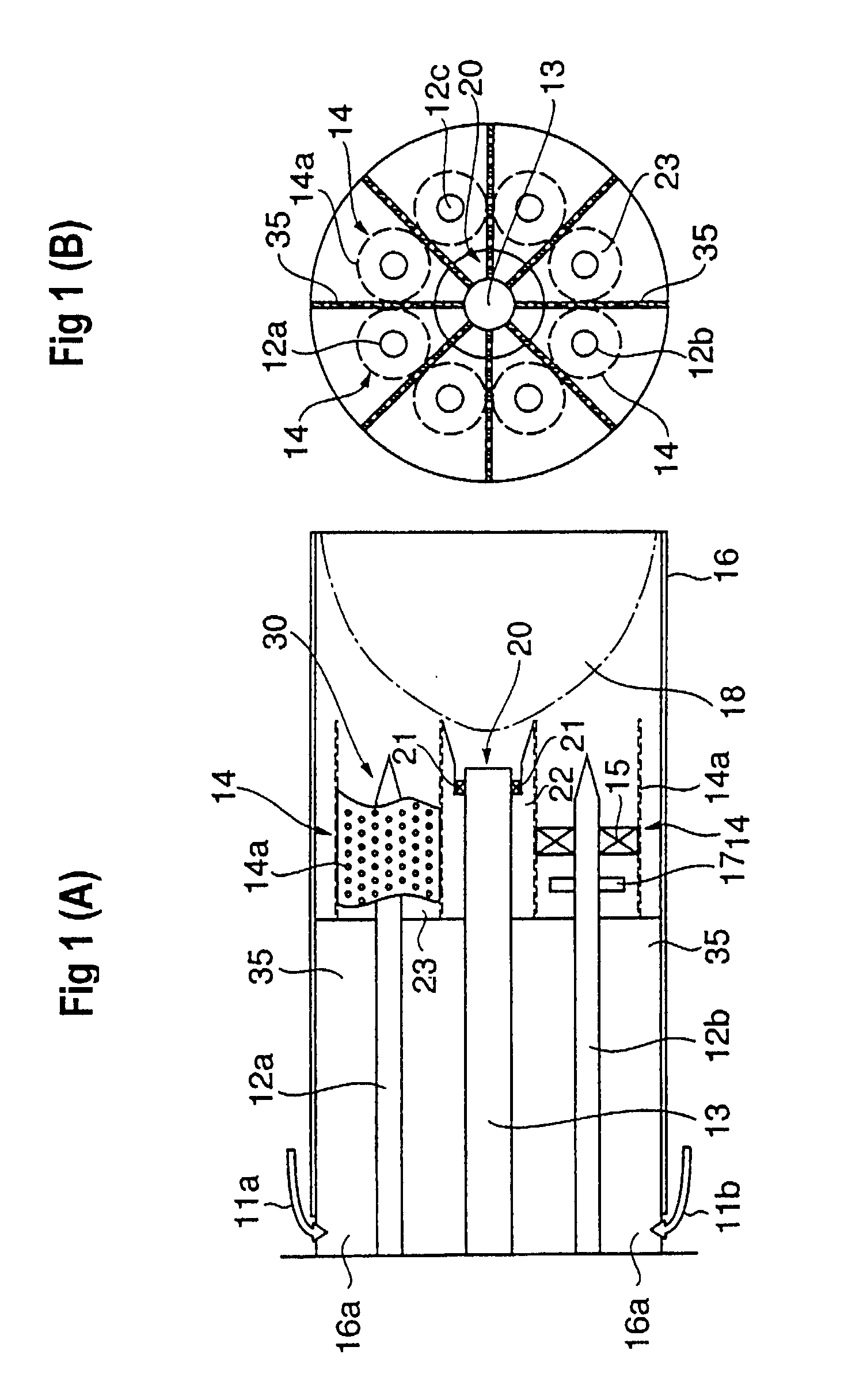

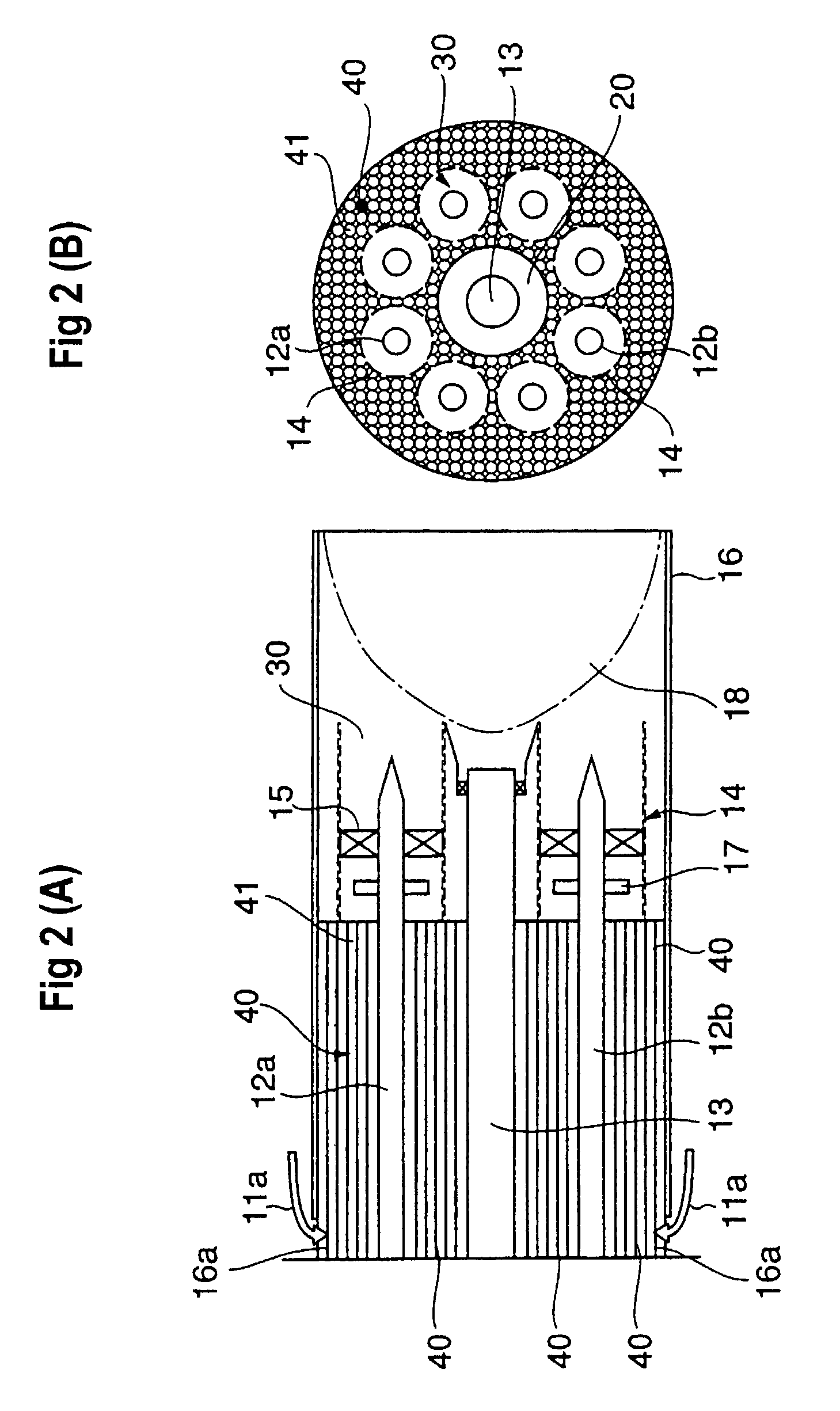

Gasturbine and the combustor thereof

InactiveUS20030051478A1Reduce the production of nitrogen oxidesSuppress pressure fluctuationsContinuous combustion chamberGas turbine plantsCombustorHoneycomb

The objective is to provide a gas turbine and the combustor thereof in which super high frequency combustion oscillation and the generation of NOx are reduced. The fluctuation in pressure which induces the fluctuation in heat liberation is suppressed in the gas turbine combustor comprising a plurality of main fuel supply nozzles, each having a premixing nozzle at the top end part thereof, by providing in the space upstream from the premixing nozzles partition elements for dividing the space along the axis of the combustor or a honeycomb element having air passages in the axial direction, or by providing premixing nozzles composed of cylindrical elements with many holes.

Owner:MITSUBISHI HEAVY IND LTD

Purging system and purging method for the interior of a portable type hermetically sealed container

ActiveUS20050069420A1Possible to executeHigh gas purityLiquid fillingFlexible member pumpsEngineeringGas supply

A fine pressure fluctuation at short time intervals occurring when a portable type hermetically sealed container is purged is reduced to thereby prevent the deterioration or the like of a seal member due to the pressure fluctuation. In order to achieve this object, a gas flow rate regulating apparatus is disposed in a gas supplying system in a purging system, and pressure in the portable type hermetically sealed container during purge is measured and the result thereof is fed back to thereby control the flow rate of a supplied gas.

Owner:TDK CORPARATION

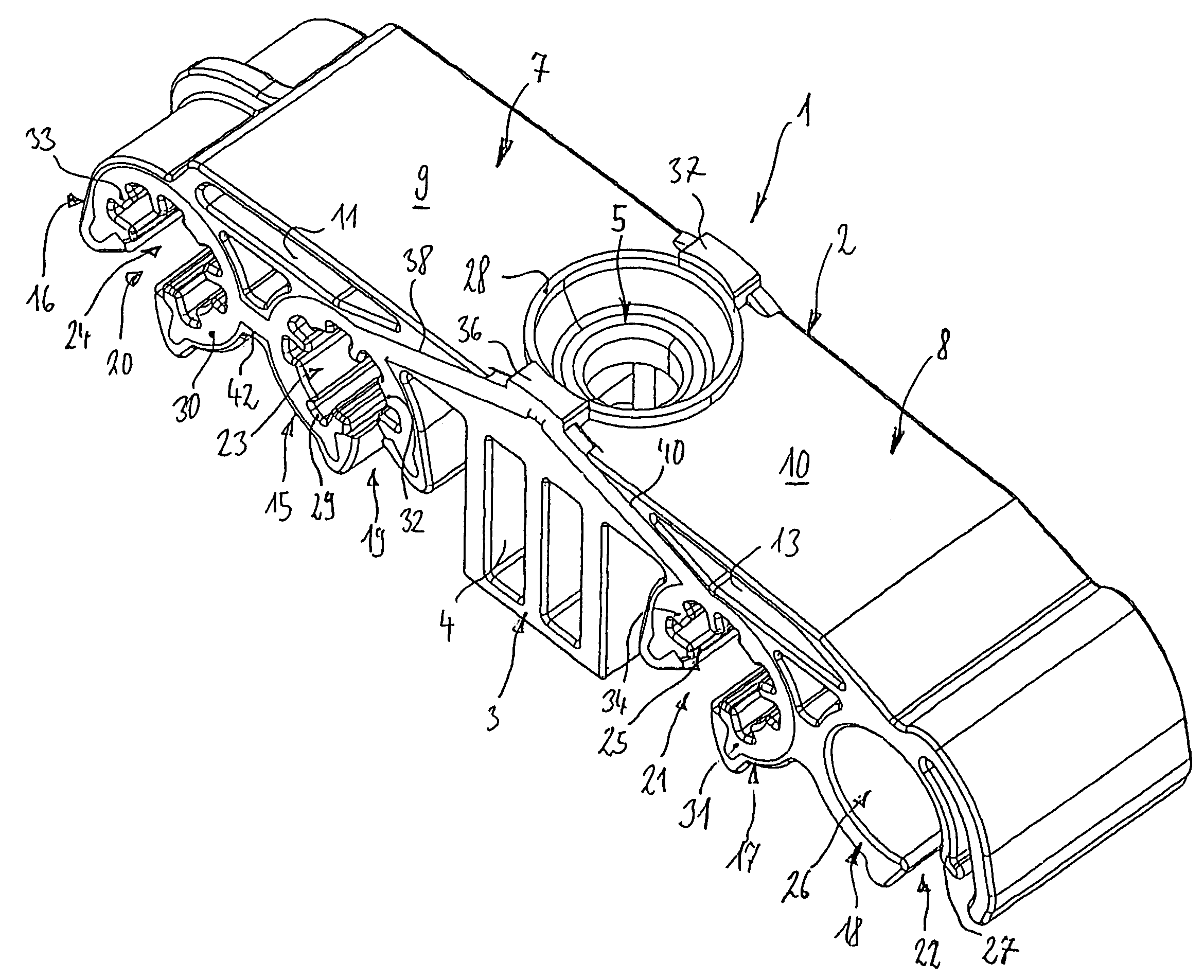

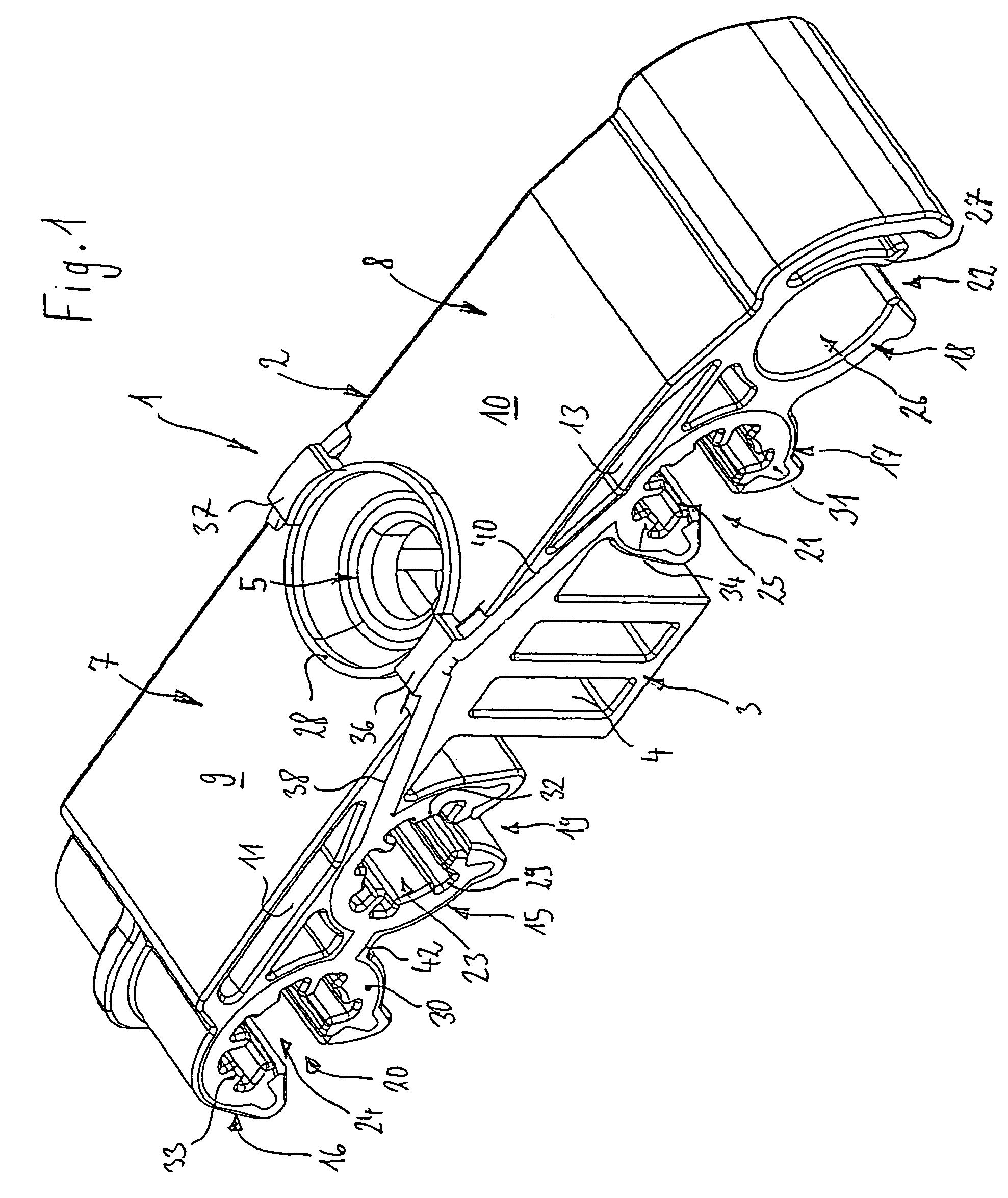

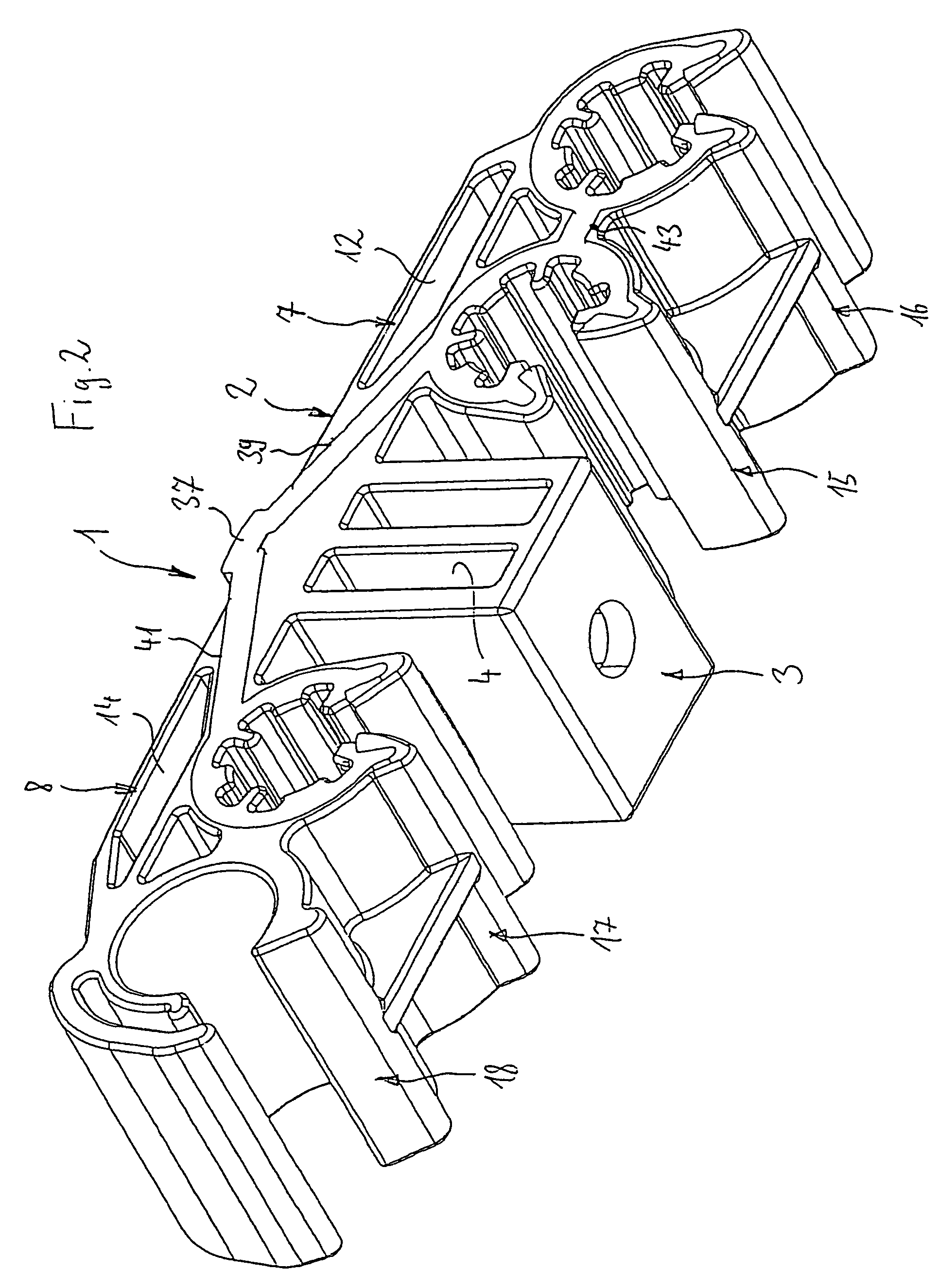

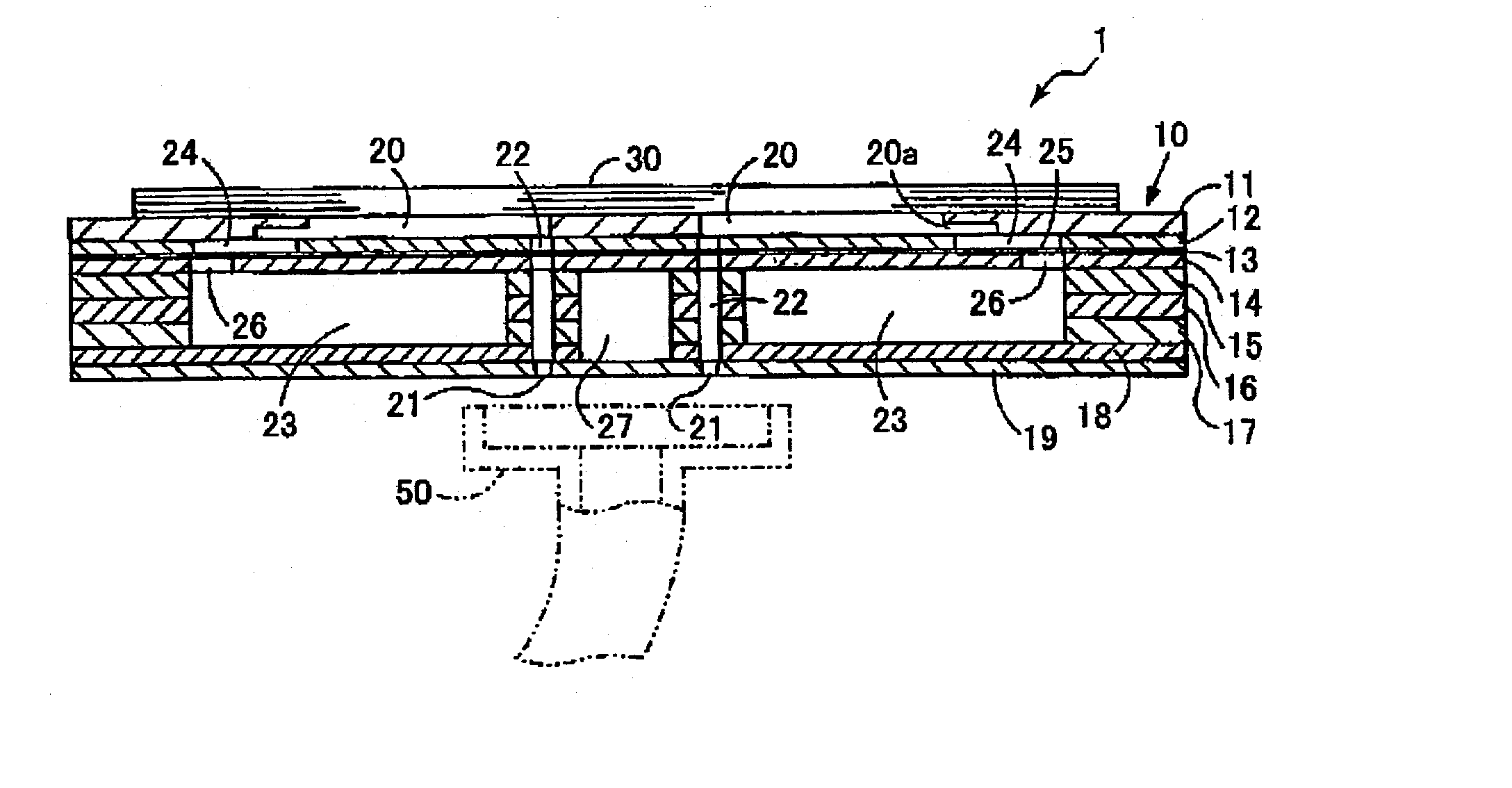

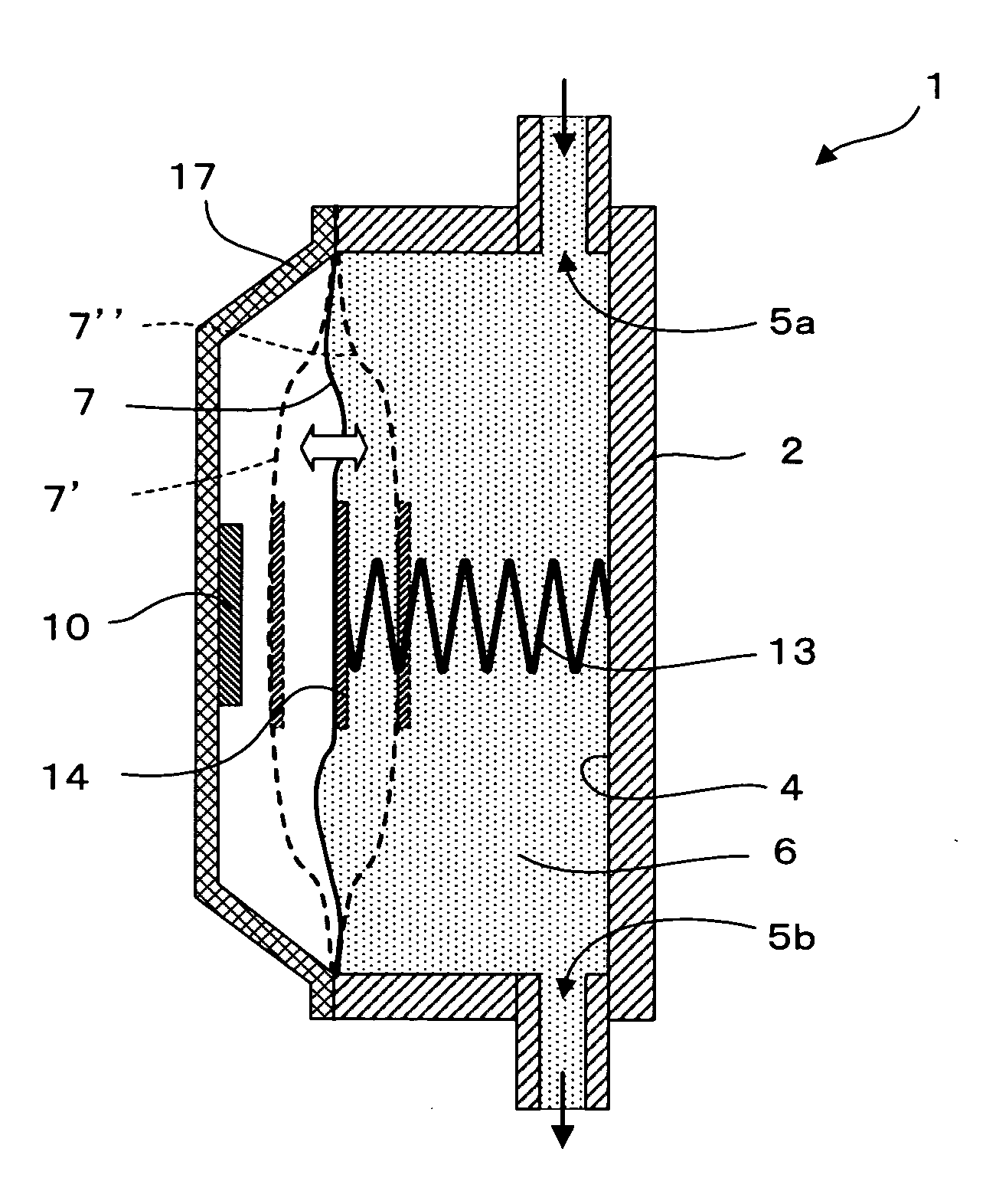

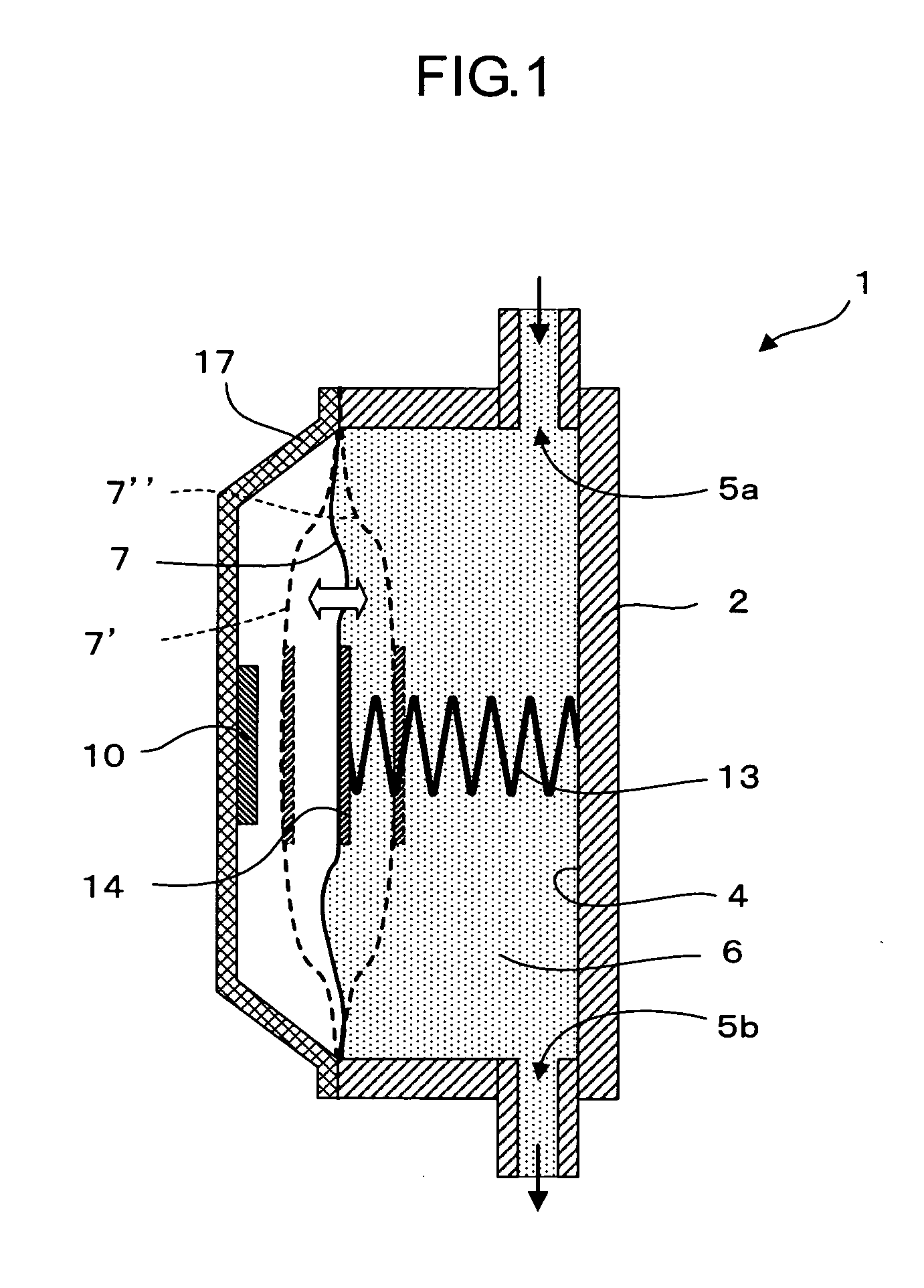

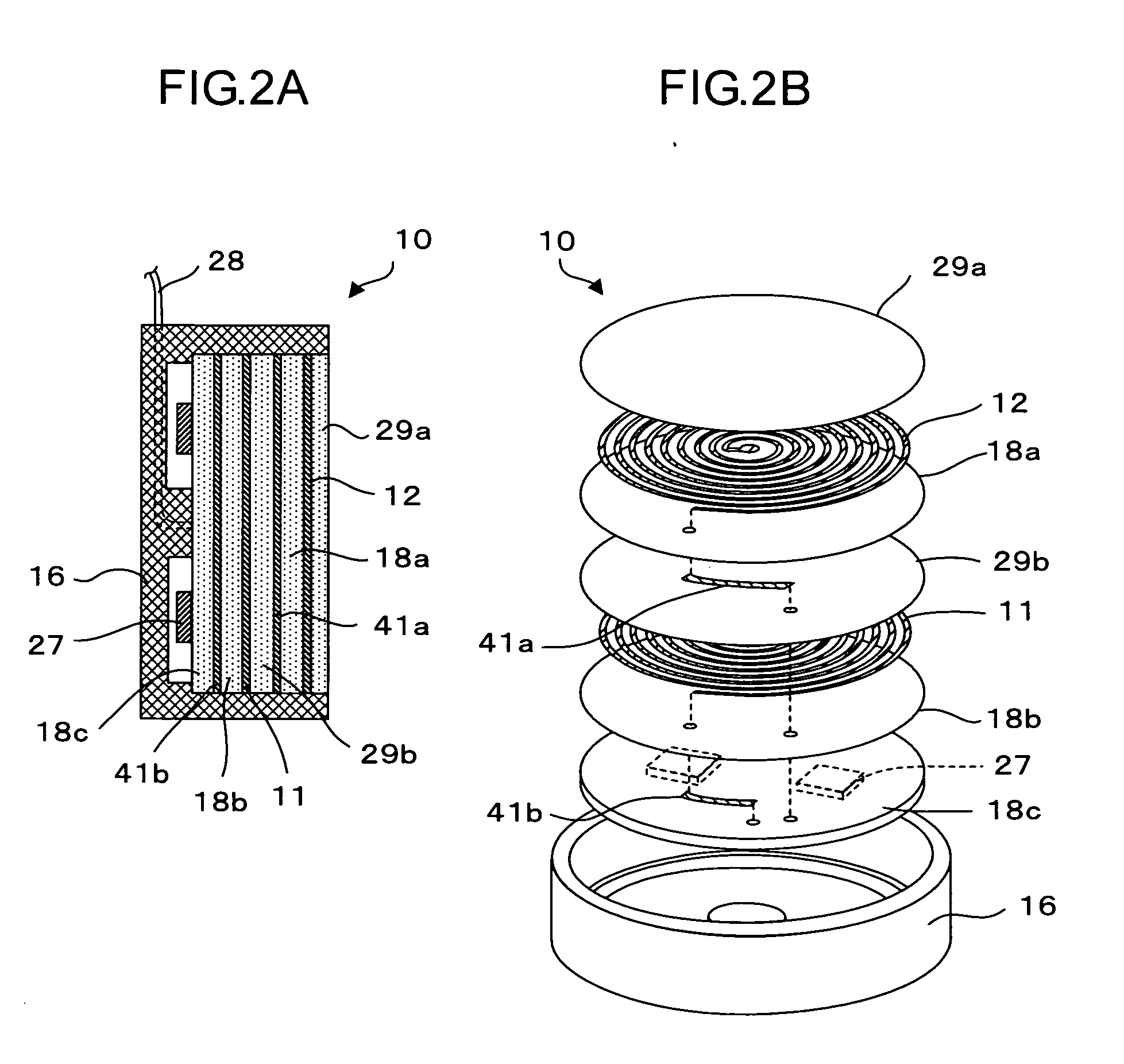

Pressure damper, liquid jet head, and liquid jet apparatus

InactiveUS20110205315A1Suppress pressure fluctuationsFunction increaseSpray nozzlesPrintingLiquid jetEngineering

Provided is a pressure damper reducing pressure fluctuations of liquid and detecting the pressure fluctuations of the liquid. The pressure damper (1) includes: a main body portion (2), the main body portion (2) including a recessed portion (4) with an opening and a communication hole (5) which is open to an inner surface of the recessed portion (4) and communicates to an external region; a flexible thin film (7) which closes the opening for reducing pressure fluctuations of fluid (6) included in the closed recessed portion (4); and a detecting portion (10) engaged with the main body portion (2) for detecting electromotive force generated by electromagnetic induction thereby detecting relative positional change between the flexible thin film (7) and the main body portion (2).

Owner:SII PRINTEK

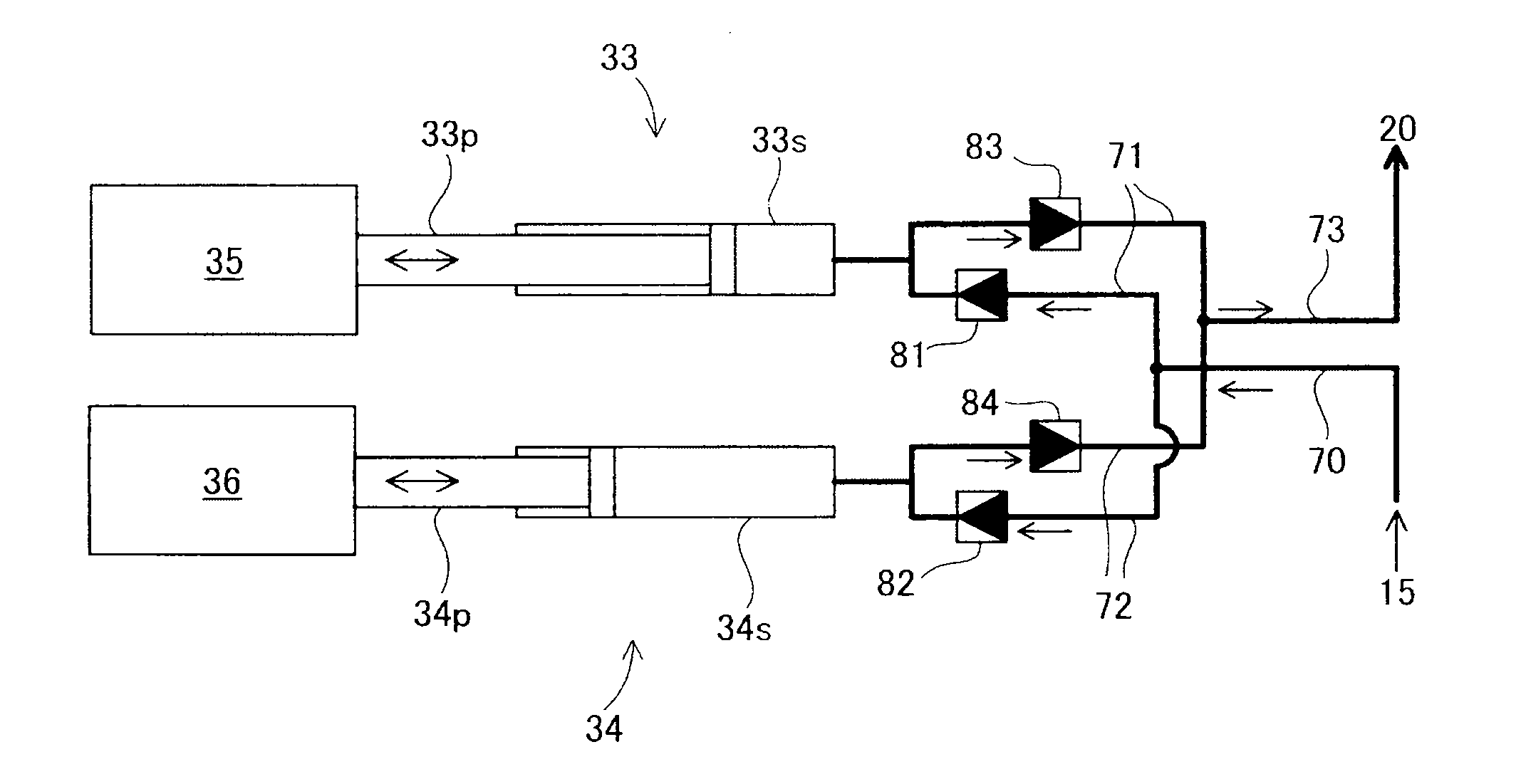

Two Engine System With A Gaseous Fuel Stored In Liquefied Form

ActiveUS20130228151A1Improve reliabilityLow efficiencyReciprocating combination enginesInternal combustion piston enginesFuel supplyProduct gas

A gaseous fuelled two-engine system comprises a high pressure direct injection engine as the main power source and an auxiliary fumigated engine that can be fuelled with vapor removed from a storage tank that stores the gaseous fuel in liquefied form at cryogenic temperatures. The fuel supply system comprises a cryogenic pump for raising the pressure of the fuel to the injection pressure needed for the high pressure direct injection engine, and the cryogenic pump is powered by the auxiliary fumigated engine.

Owner:WESTPORT FUEL SYST CANADA INC

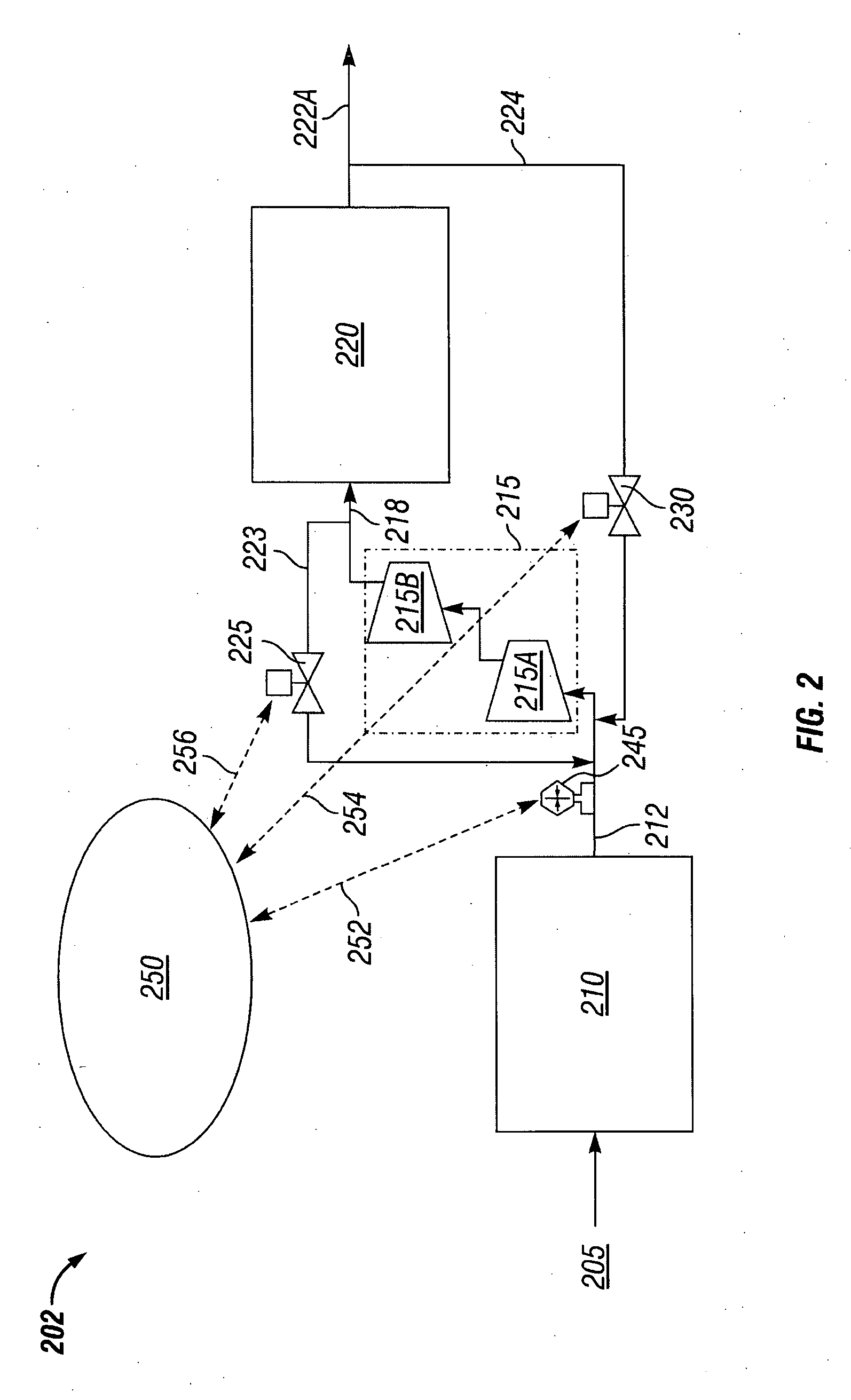

Apparatus and method for producing hydrogen

InactiveUS20060137245A1Reduce fluctuationPressure fluctuationLevel controlHydrogen separation using solid contactProcess engineeringStorage cell

An apparatus and method for producing a hydrogen-enriched reformate. The apparatus includes a fuel processor for converting a fuel to a reformate having fluctuations in pressure and or flow rate, means for reducing the fluctuations, a compression unit for compressing the reformate and one or more of a purification unit and a storage unit downstream of a compression unit. Means for reducing the fluctuations in the reformate can include one or more of a buffer and a conduit for providing a controlled flow of a supplemental fluid to an inlet of the compression unit. The supplemental fluid can include the compressed reformate, a hydrogen-enriched reformate, and mixtures thereof. The apparatus can include means for regulating power to the compression unit that can incrementally increase power to the compression unit particularly during start up. The purification unit can include one or more of a hydrogen selective membrane and a pressure swing adsorption unit. Methods for producing hydrogen are also disclosed.

Owner:TEXACO INC

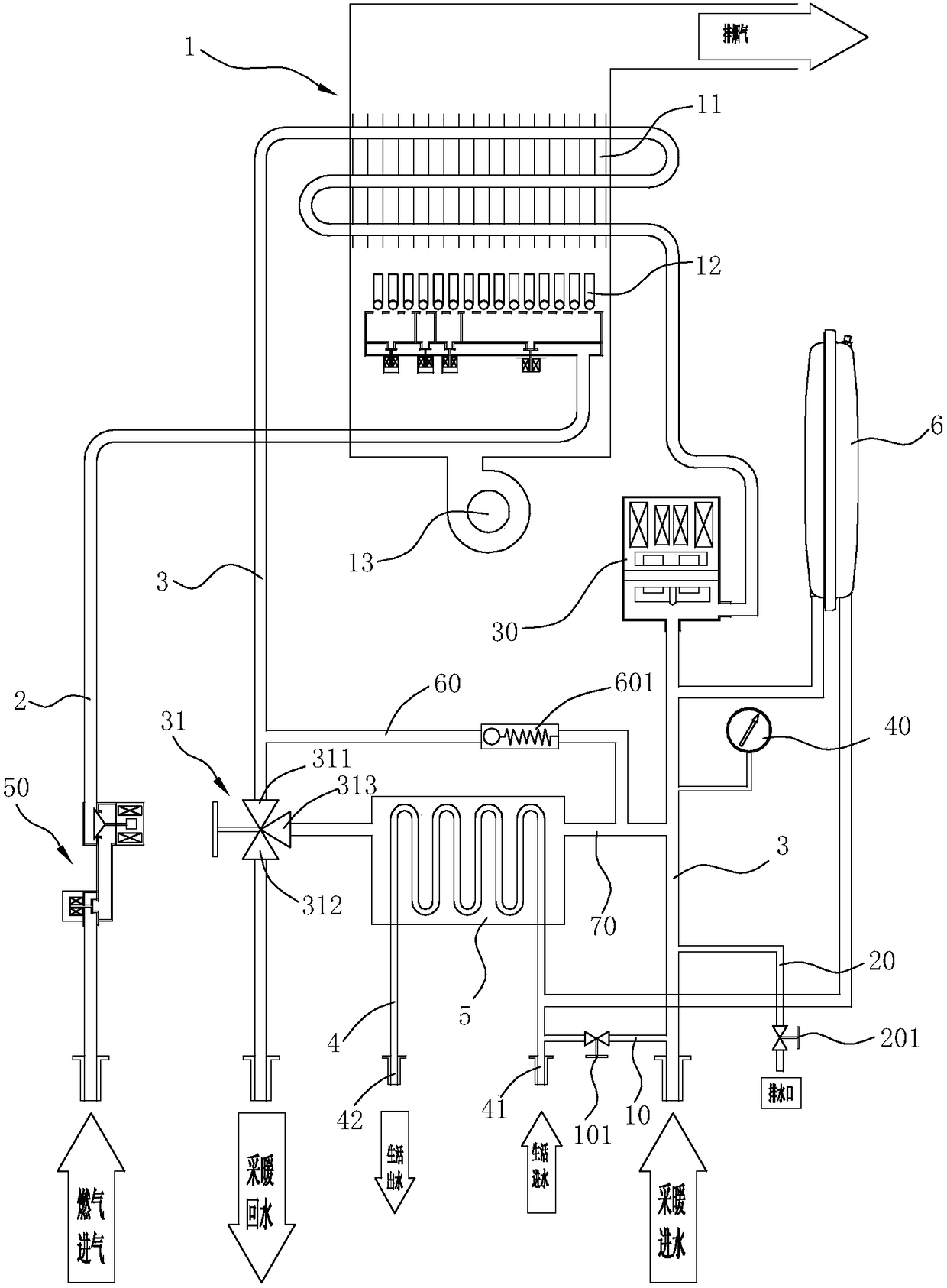

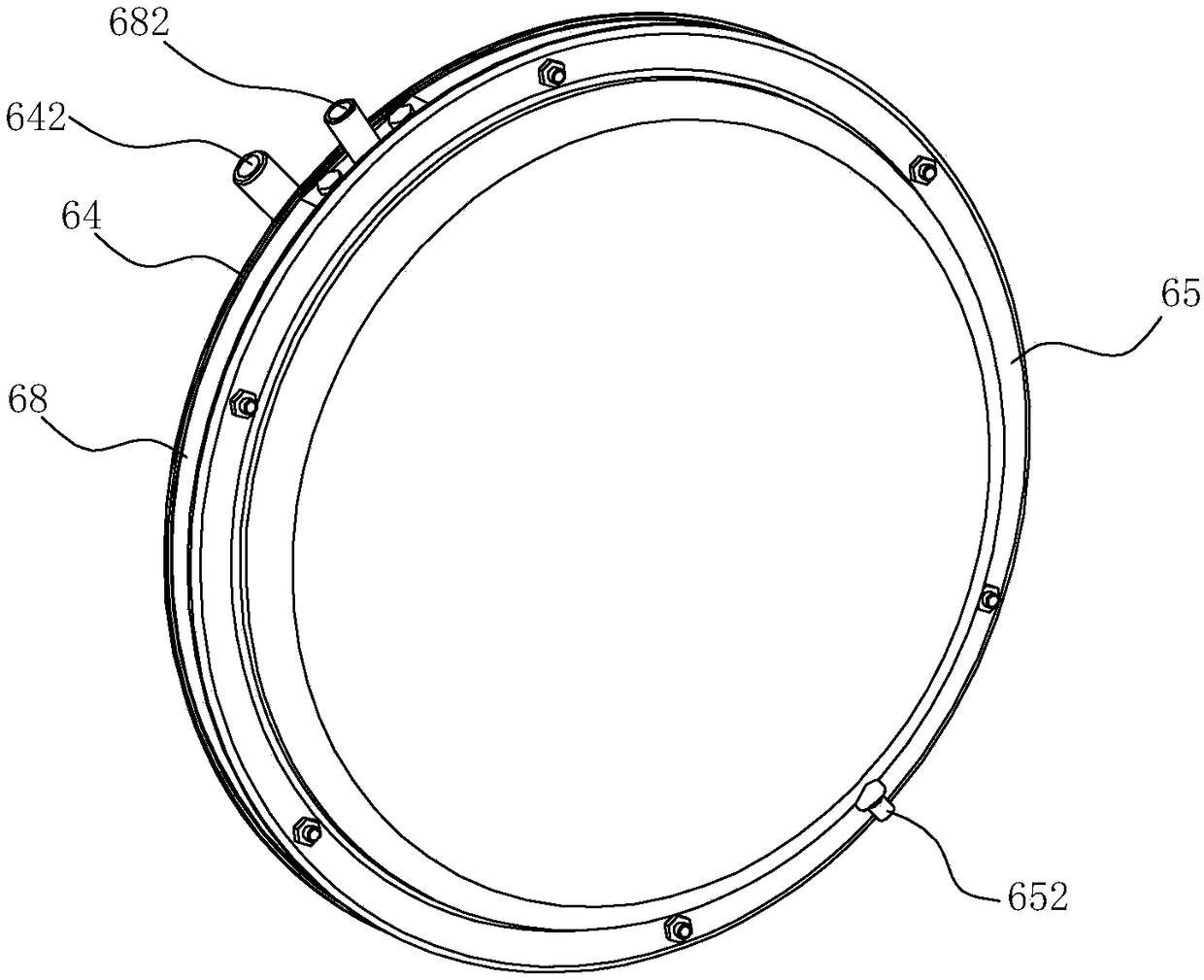

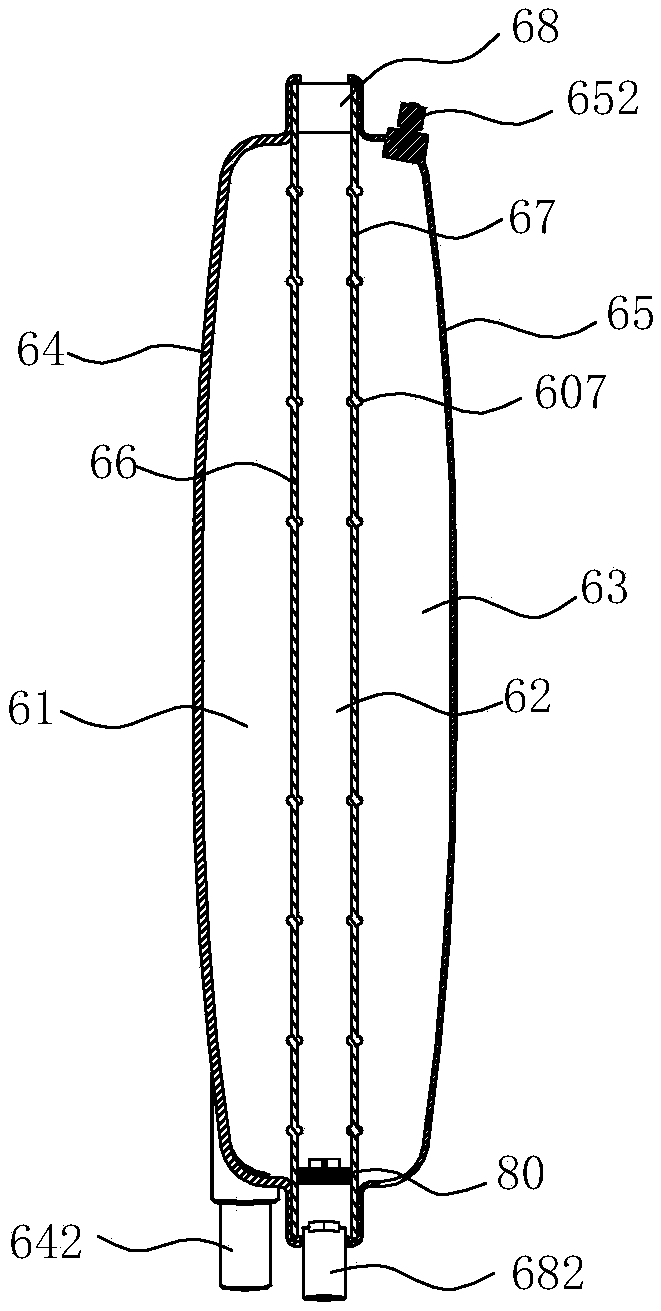

Dual-purpose furnace working system

PendingCN108061375AEfficient use ofSuppress pressure fluctuationsWater heatersExpansion tankWater source

The invention relates to a dual-purpose furnace working system which comprises a combustion heat-exchanging device, a fuel gas pipeline, a heating pipeline, a domestic water pipeline, a heat exchangerand an expansion water tank. The expansion water tank is provided with a first cavity, a second cavity and a third cavity. The first cavity communicates with the heating pipeline, the second cavity communicates with the domestic water pipeline, and the third cavity communicates with a balance air source. The dual-purpose furnace system can provide hot water sources for domestic water and heatingwater simultaneously, in the heating process, the domestic water is supplied as a priority, and energy is effectively utilized; two cavities of the expansion water tank are simultaneously connected toa heating waterway and a domestic waterway of a dual-purpose furnace in series, the expansion and shrinking quantity of circulating water in a heating loop and the expansion and shrinking quantity ofwater in the domestic waterway can be contained and supplemented, and pressure fluctuation of the heating loop and the domestic water can further be relieved; and stability of the water flow rate iskept, and the use comfort of the bathroom domestic water is improved while the heating function is ensured.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

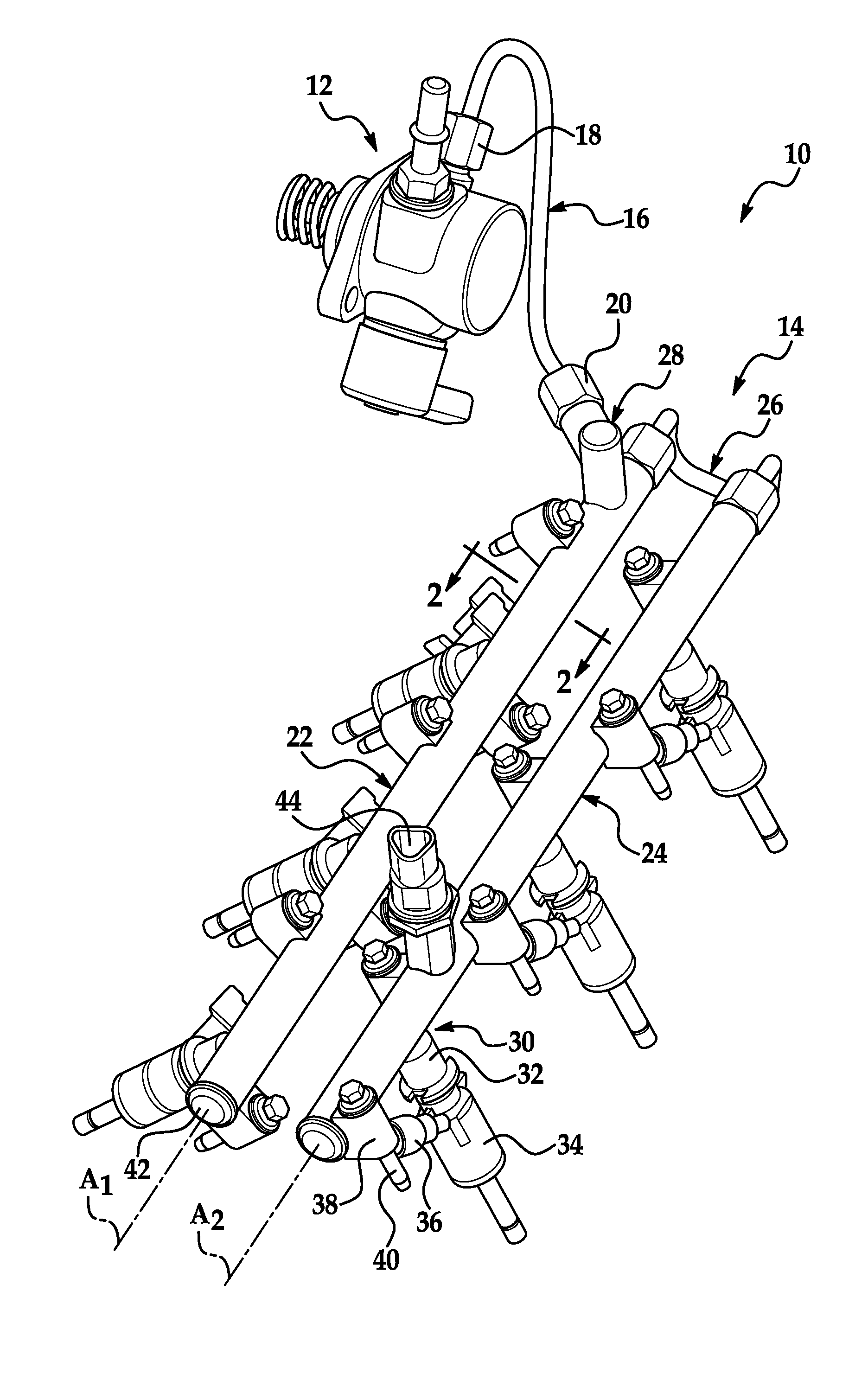

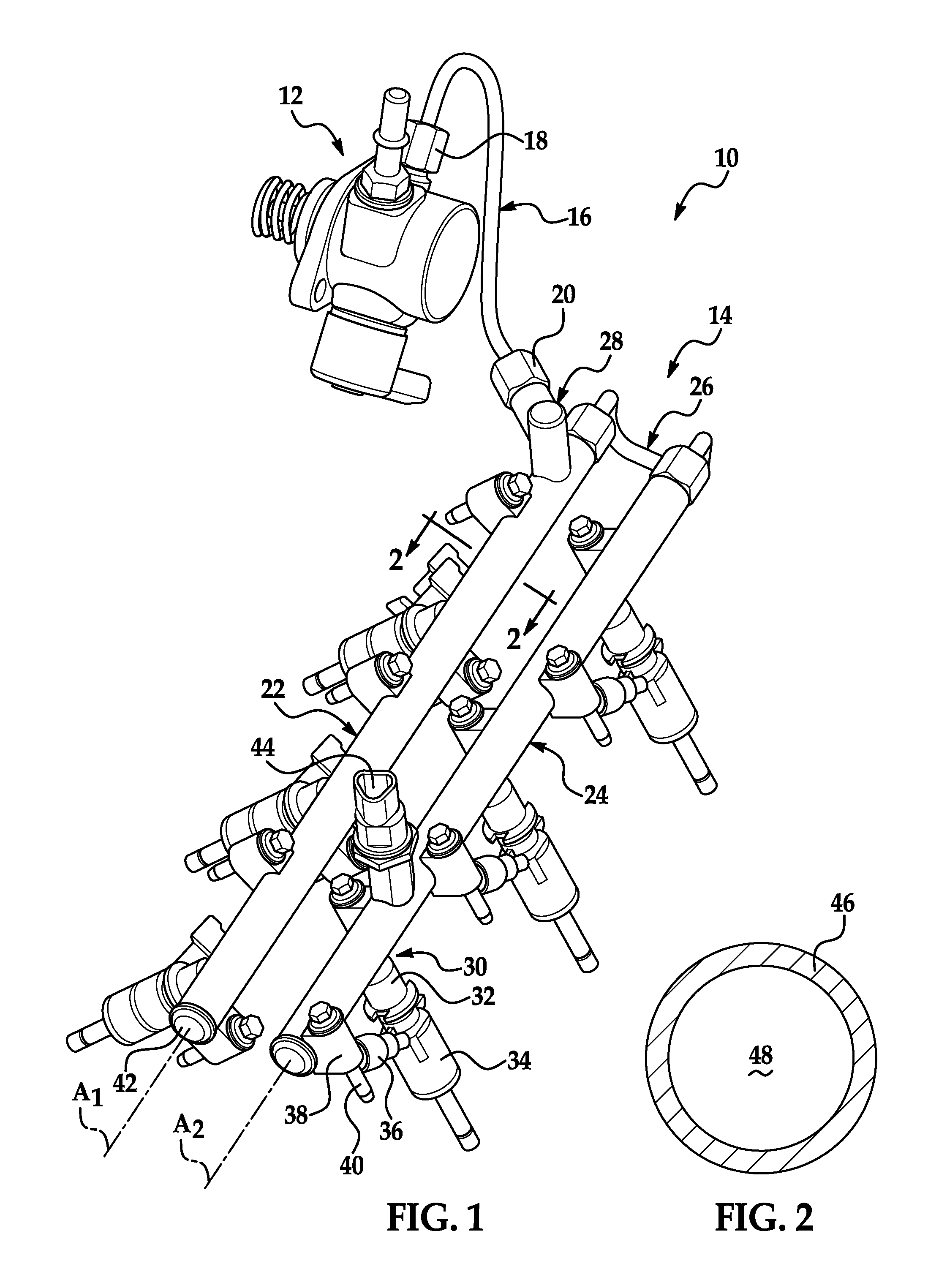

Internal secondary fuel rail orifice

InactiveUS20140261330A1Improve performanceSuppress pressure fluctuationsElectrical controlLow-pressure fuel injectionEngineeringHigh pressure

A fuel rail assembly configured for connection to an internal combustion engine includes a first fuel rail, a second fuel rail, and a crossover hose. The first fuel rail includes an inlet having a first flow restrictor and configured to be coupled to a high-pressure pump. The first fuel rail further includes a second flow restrictor disposed in an interior portion that divides the interior into a first rail volume and a remainder volume. The crossover hose includes a third flow restrictor near the end that is connected to the second fuel rail. A first pulsation control volume is defined between the pump and the inlet. A second pulsation control volume is defined to include the remainder volume and the volume in the crossover hose (i.e., between the first and second flow restrictors). The pulsation control volumes reduce pressure fluctuations produced by the high-pressure pump.

Owner:DOHERTY ROBERT J

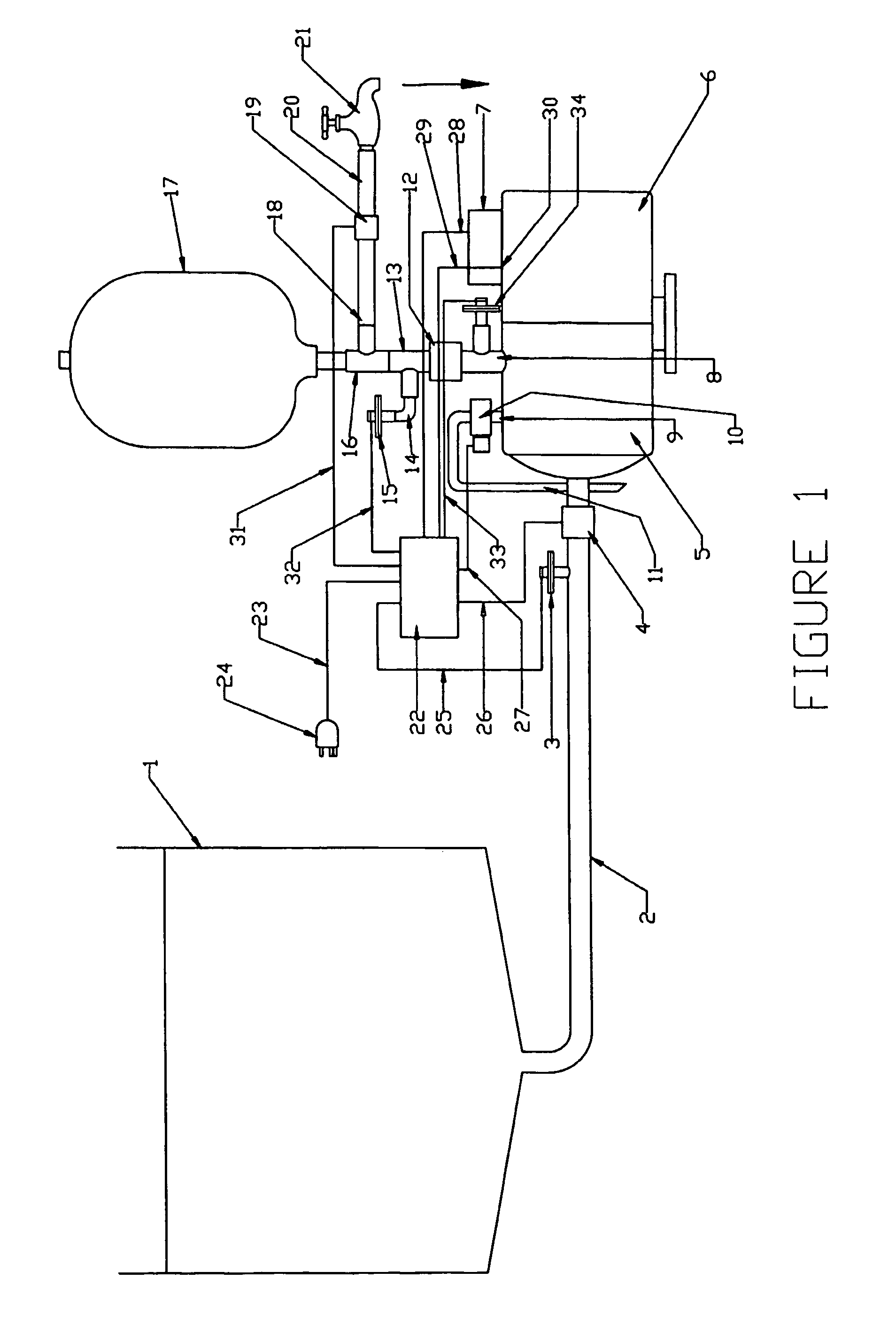

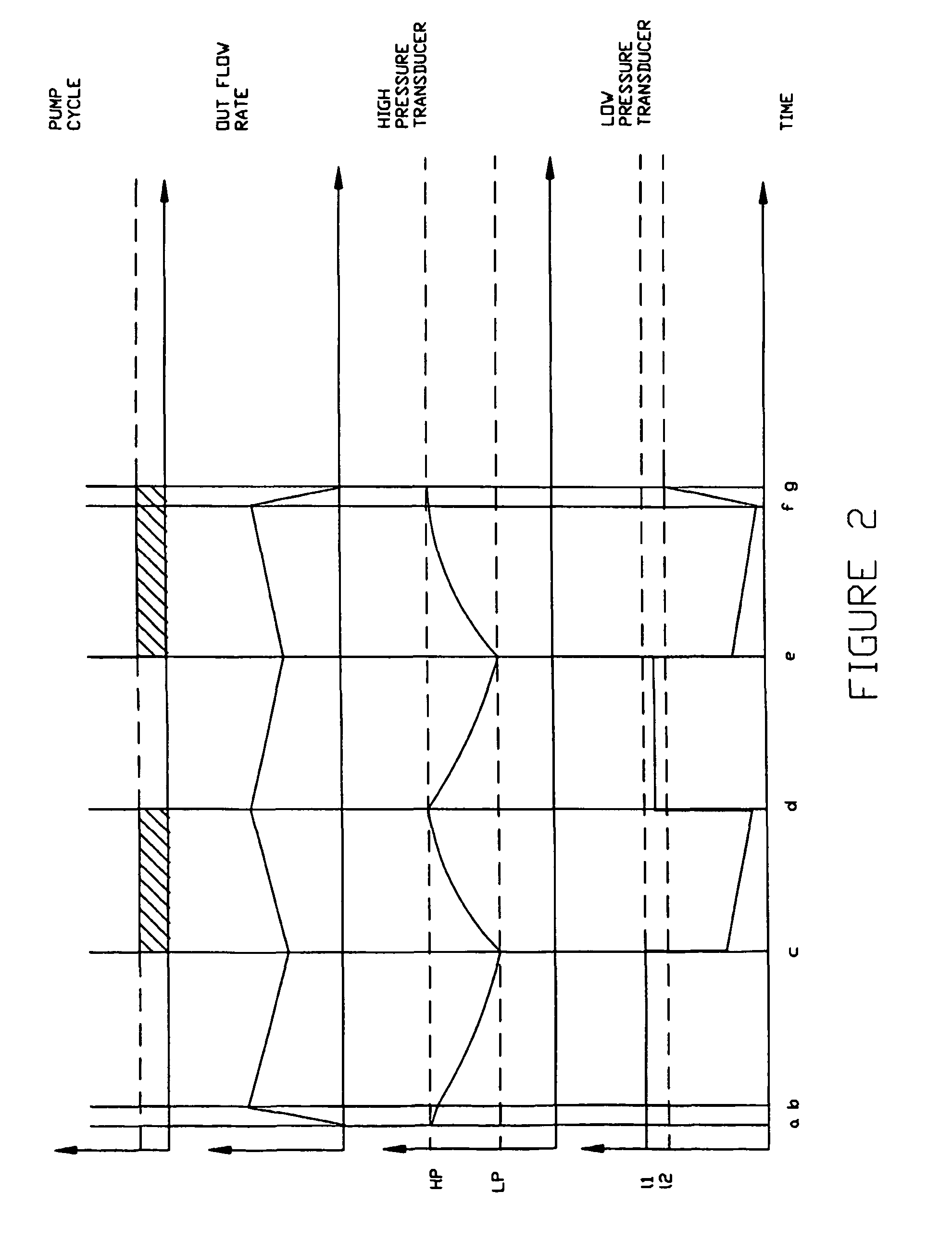

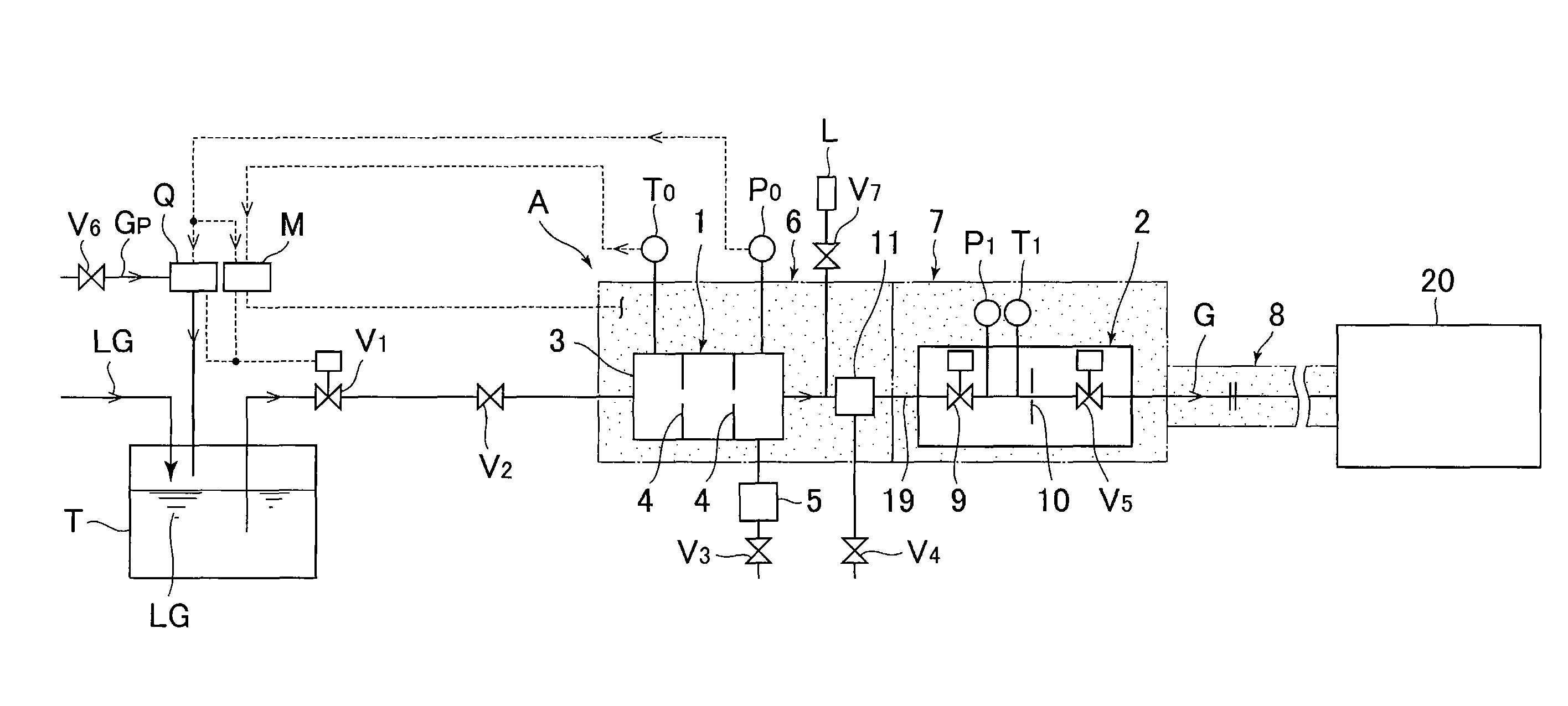

Pump control system

InactiveUS7901190B2Adequate determinationSignificant comprehensive benefitsPressure pumpsPump controlControl systemTransducer

A pumping system in which a pump (5) is controlled by a programmed controller (22) in response to input signals from an inlet pressure transducer (3) and an outlet pressure transducer (15) and in certain circumstances inputs from various flow sensors (4,19). The controller (22) can be programmed to allow the pump (5) to prematurely operate before an outlet pressure reaches a low pressure threshold, when usage of the liquid is high. The controller (22) can be programmed to detect a lack of prime of the pump (5), to restore prime once the pump (5) has lost prime, and to prevent successive on / off pump cycles when the outlet flow is continuous and at a moderate or low level.

Owner:GRAY

Gas supply apparatus equipped with vaporizer

ActiveUS8931506B2Stable controlPrecise flow controlInternal combustion piston enginesValve members for heating/coolingTemperature controlProduct gas

Owner:FUJIKIN INC

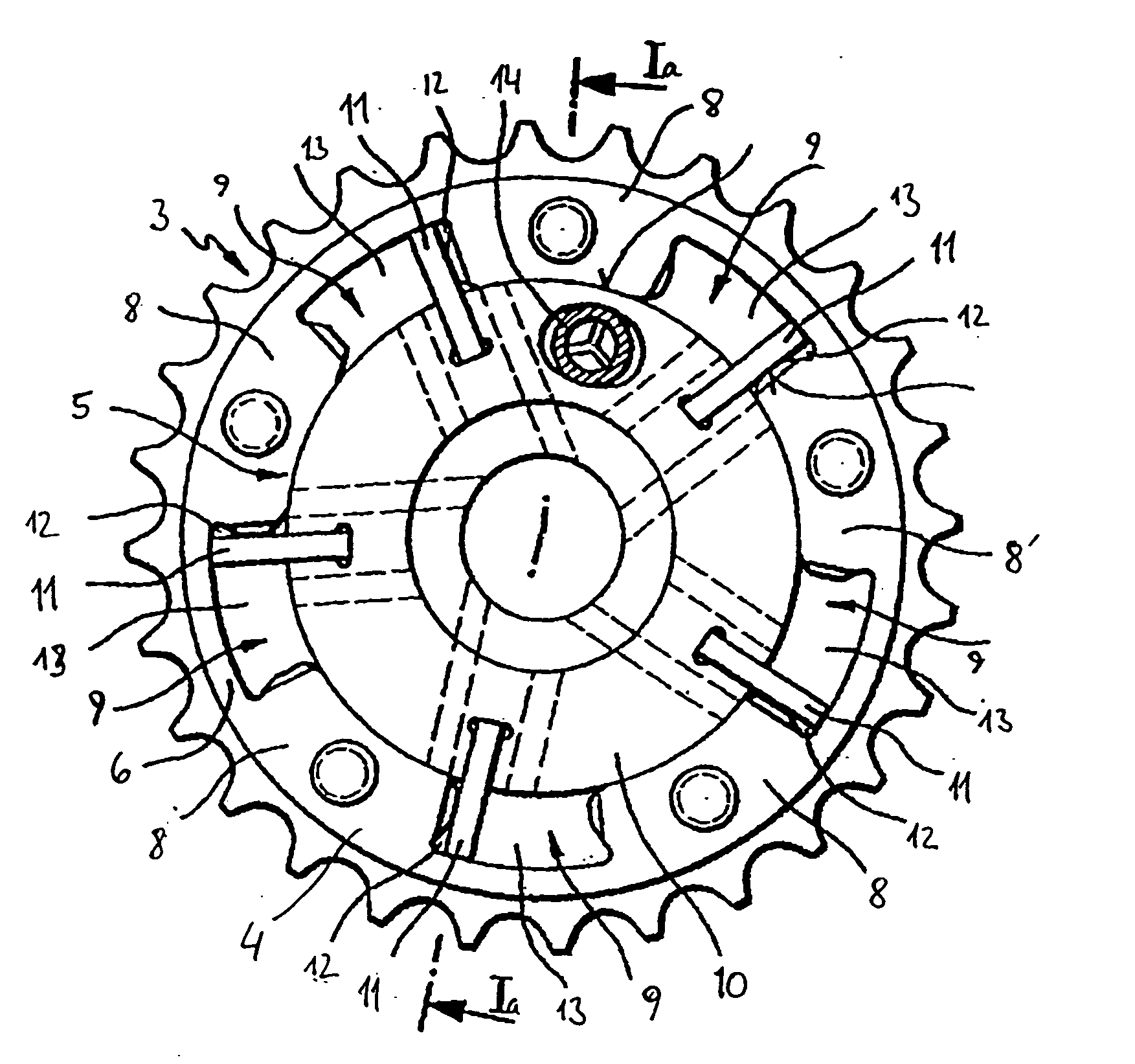

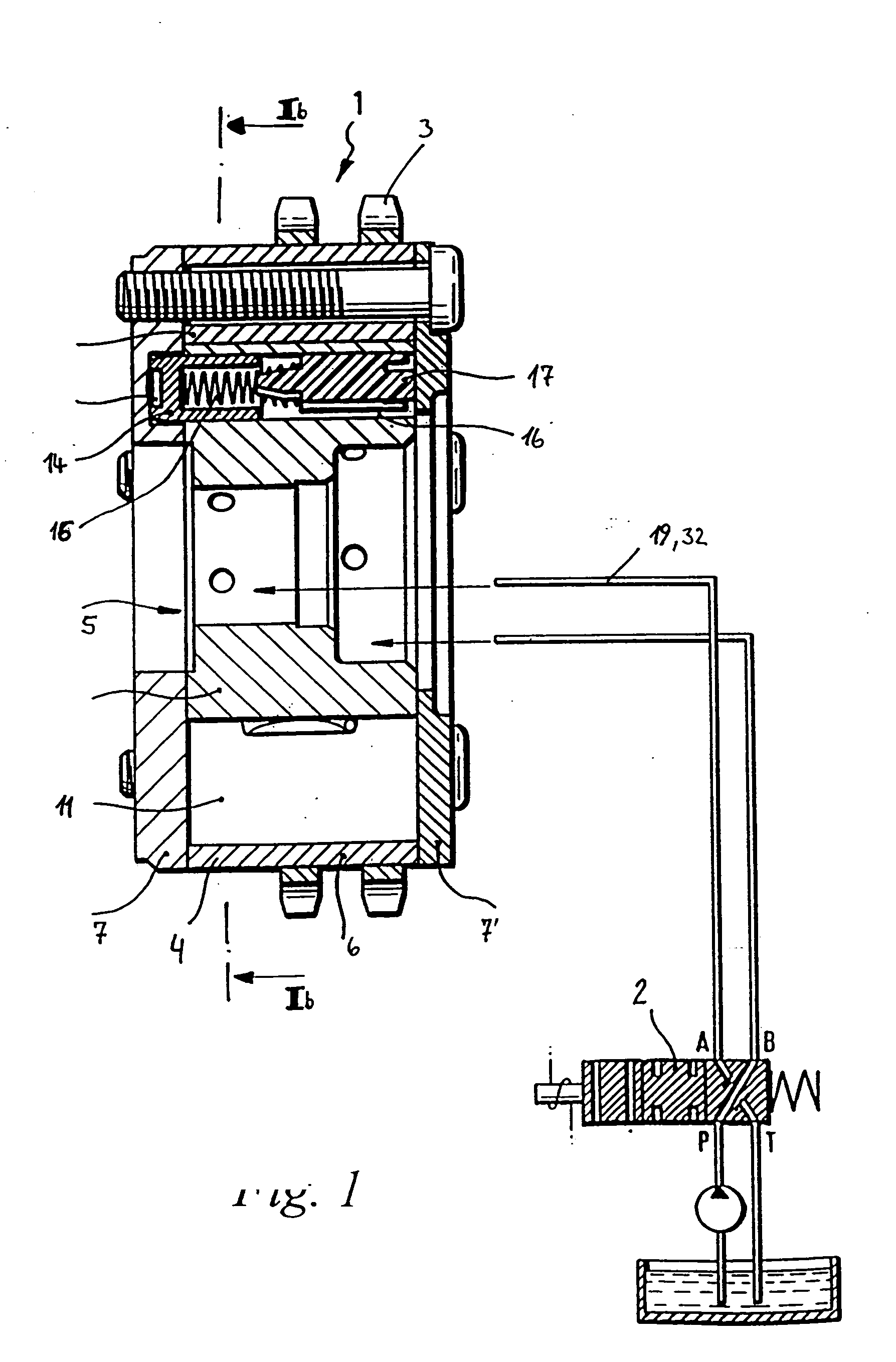

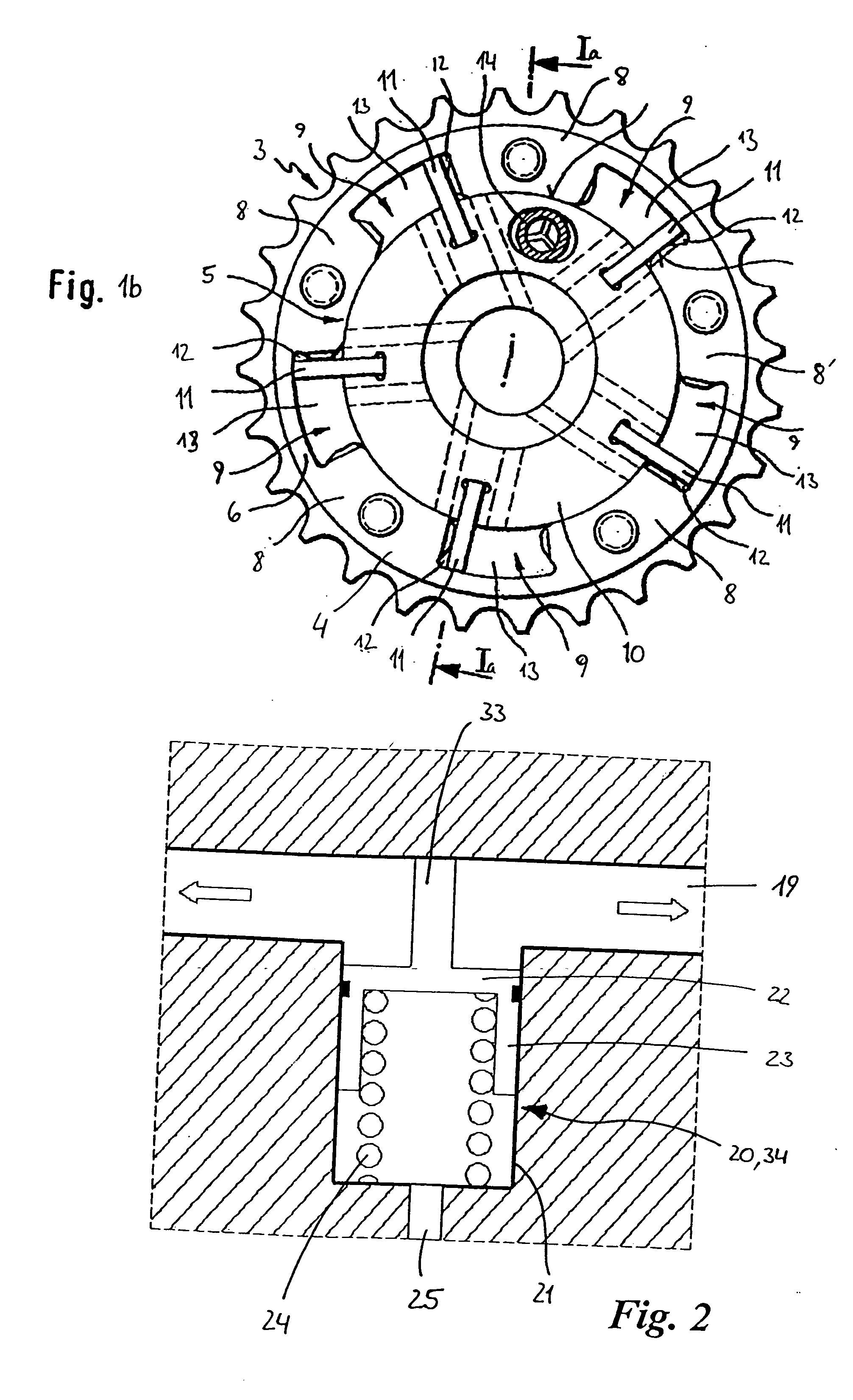

Internal combustion engine having a hydraulic device for adjusting the rotation angle of a camshaft relative to a cranks haft

ActiveUS20050274344A1Reduce pressure fluctuationEliminate pressure peakFluid couplingsValve drivesStatorEngineering

A hydraulic device for adjusting the rotation angle of a camshaft relative to a crankshaft in an internal combustion engine. The device has a rotor, with blades arranged around its periphery. A stator is connected in a rotationally secure manner to a drive wheel. The rotor and the stator together form pressure chambers, which can be filled with hydraulic fluid via a hydraulic fluid system, in which there is disposed a volume accumulator.

Owner:SCHAEFFLER TECH AG & CO KG

Fluid supply apparatus

InactiveUS20140127037A1Suppress pressure fluctuationsAvoid flow rateFlexible member pumpsMedical devicesInternal pressureEngineering

A fluid supply apparatus which supplies a fluid to a medical apparatus includes: a pump mechanism including a first pump capable of carrying out a intake operation of a fluid and a feeding operation of the fluid, and a second pump capable of alternately carrying out a intake operation of the fluid and a feeding operation of the fluid; a flow passage which includes an elastic member and which communicates with the pumps and supplies the fluid to the medical apparatus; a pressure fluctuation detecting unit capable of detecting fluctuation in internal pressure in the flow passage; and a flow passage deforming unit which deforms the flow passage according to the fluctuation in the internal pressure.

Owner:SEIKO EPSON CORP

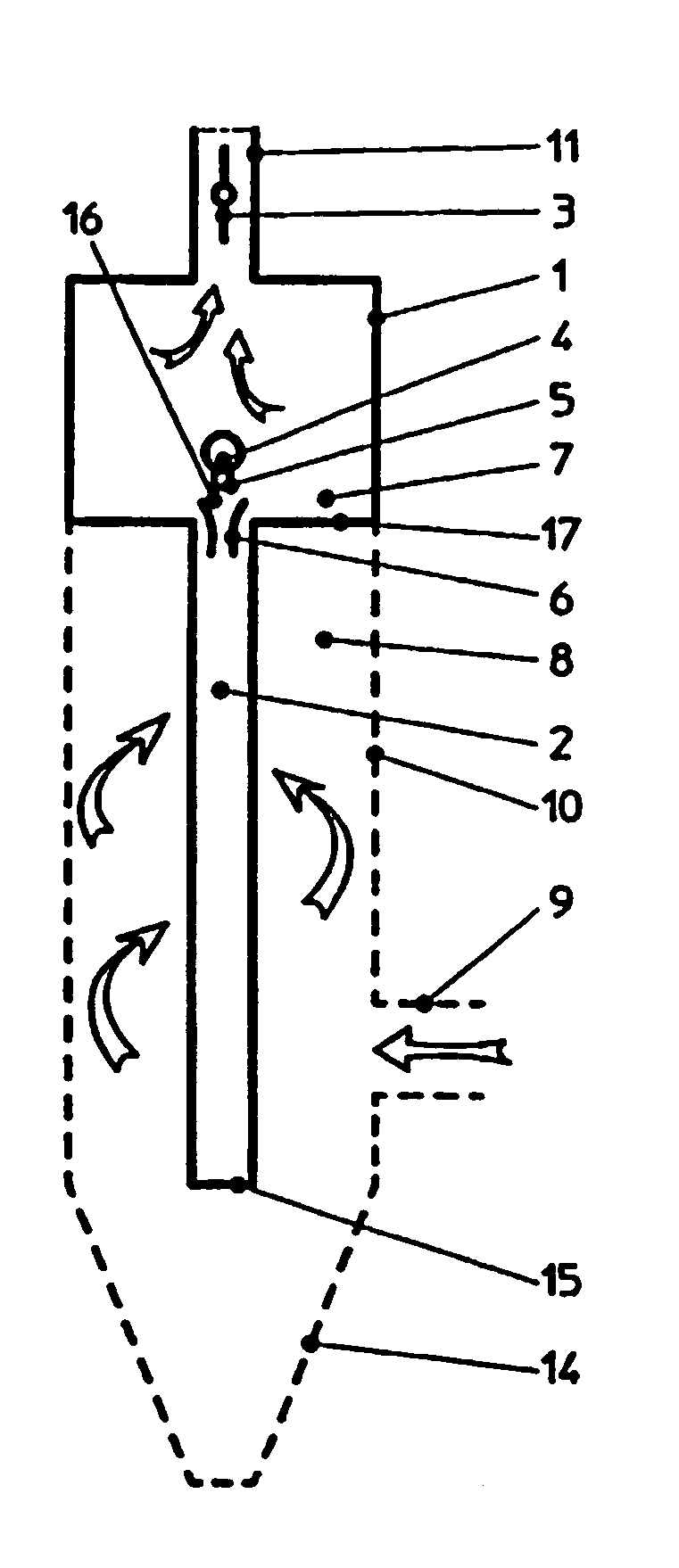

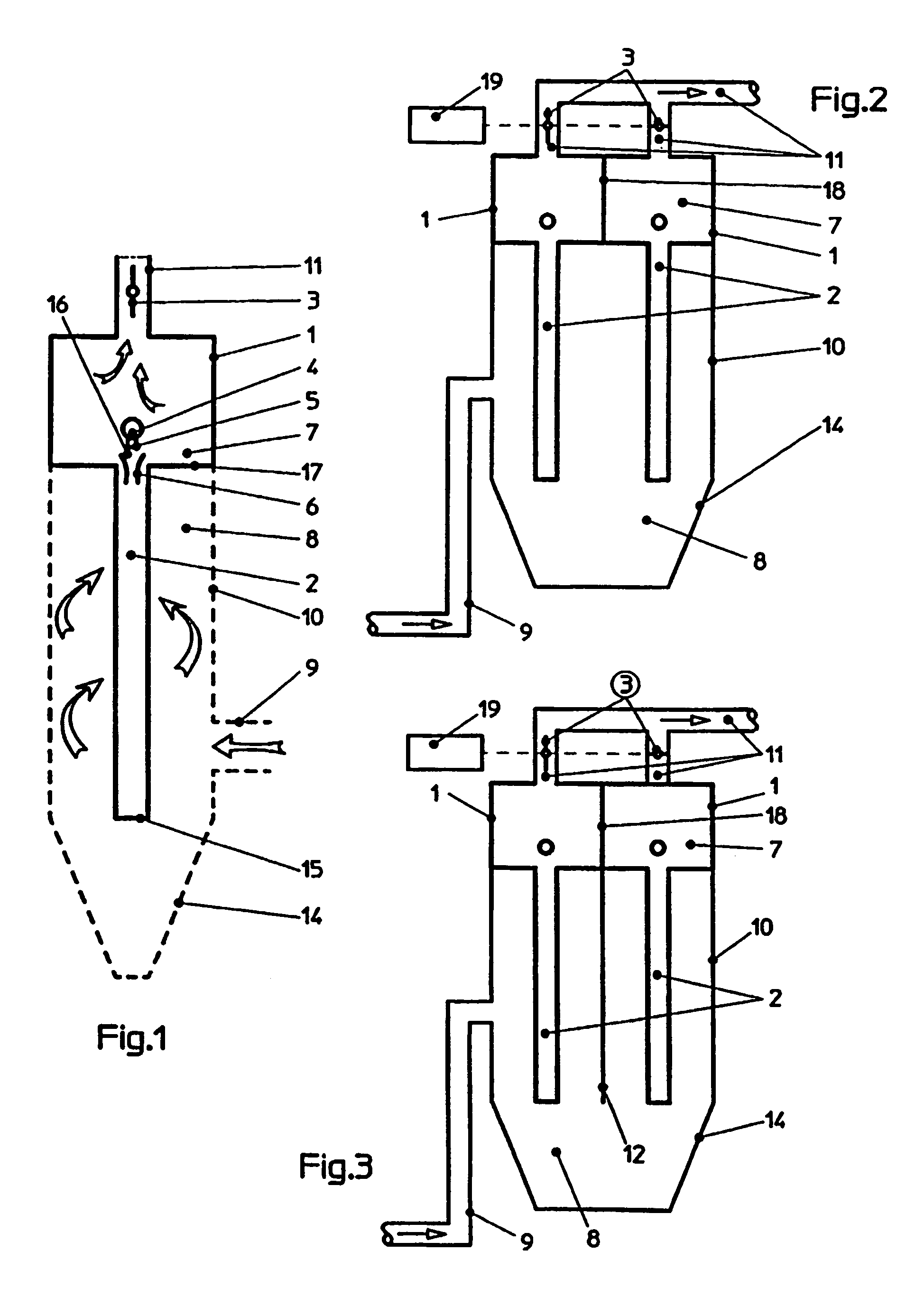

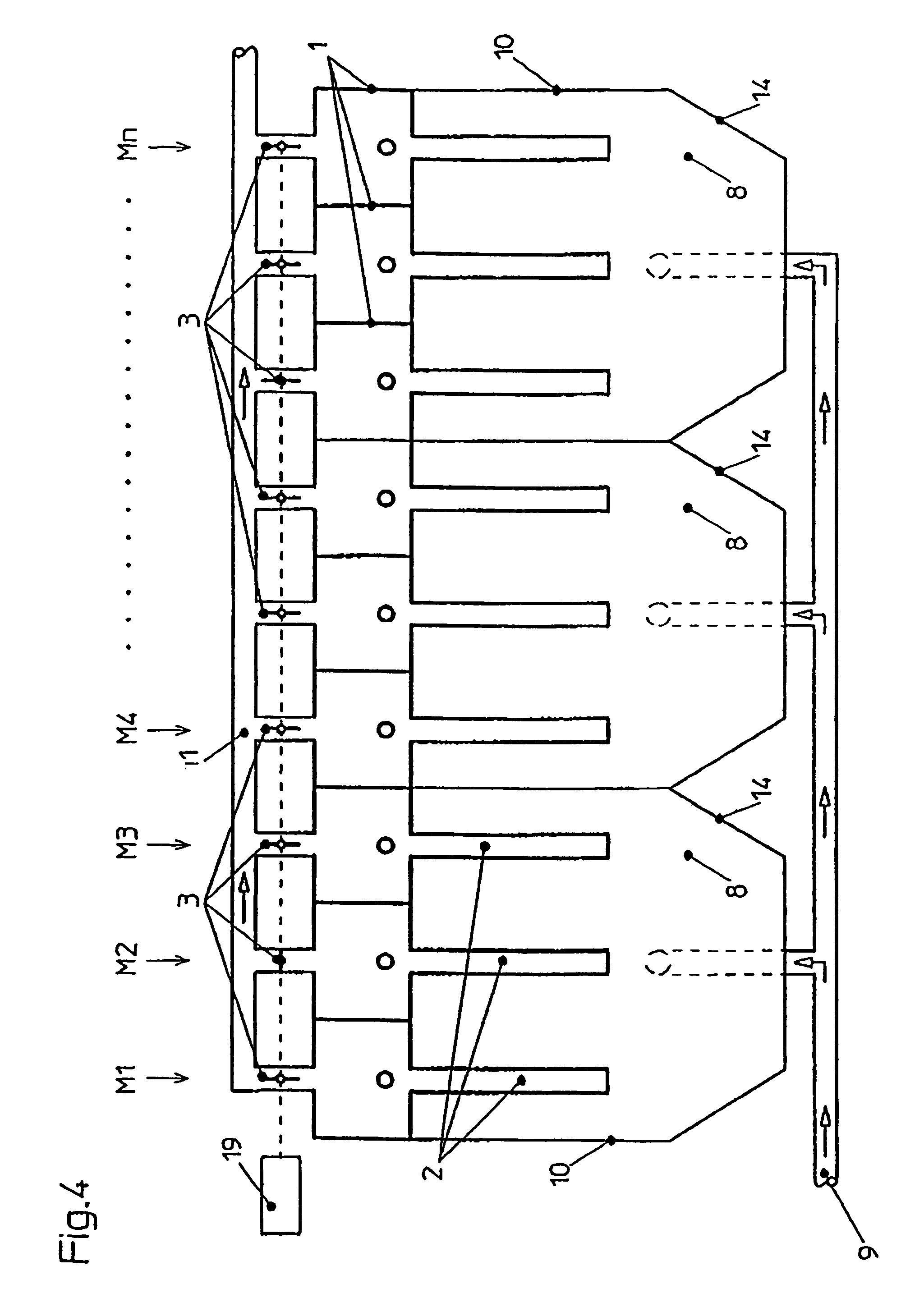

Method and device for cleaning filters for dust-laden waste gases

InactiveUS7300481B2Minimize installationMinimize productionCombination devicesAuxillary pretreatmentExhaust fumesFilter element

The invention relates to a method for cleaning filters for dust-laden waste gases, including several filter elements (2) which are arranged vertically in a filter housing (1) and which have an upper open end (16) and a lower closed end (15) with at least one feed line (9) for the dust-laden waste gases and at least one discharge line (11) for the cleaned waste gases, in addition to a device for injecting surges of compressed air into the open end (16) of the filter elements (2). In order to reduce pressure fluctuations in the filter and to provide efficient cleaning with pulsations of compressed air in the low pressure range i.e. from approximately 0.8 to 3 bars, the filter is divided into several filter modules (1) respectively including at least one filter element (2). At least two filter modules (1) are arranged in a filter housing (10) or a filter chamber. The filter modules (1) are cleaned alternately and each filter module (1) is associated with a discharge line (11) with a shut-off element (3) for the clean gas. A control device (19) is provided for the shut-off elements (3), whereby when the filter modules (1) which are to be cleaned are changed, the shut-off element (3) of the cleaned filter modules (1) is open and the shut off element (3) is closed in a diametrically opposed manner for the filter module (1) to be cleaned. As a result, any pressure fluctuations in the filter are minimised.

Owner:SCHEUCH GMBH

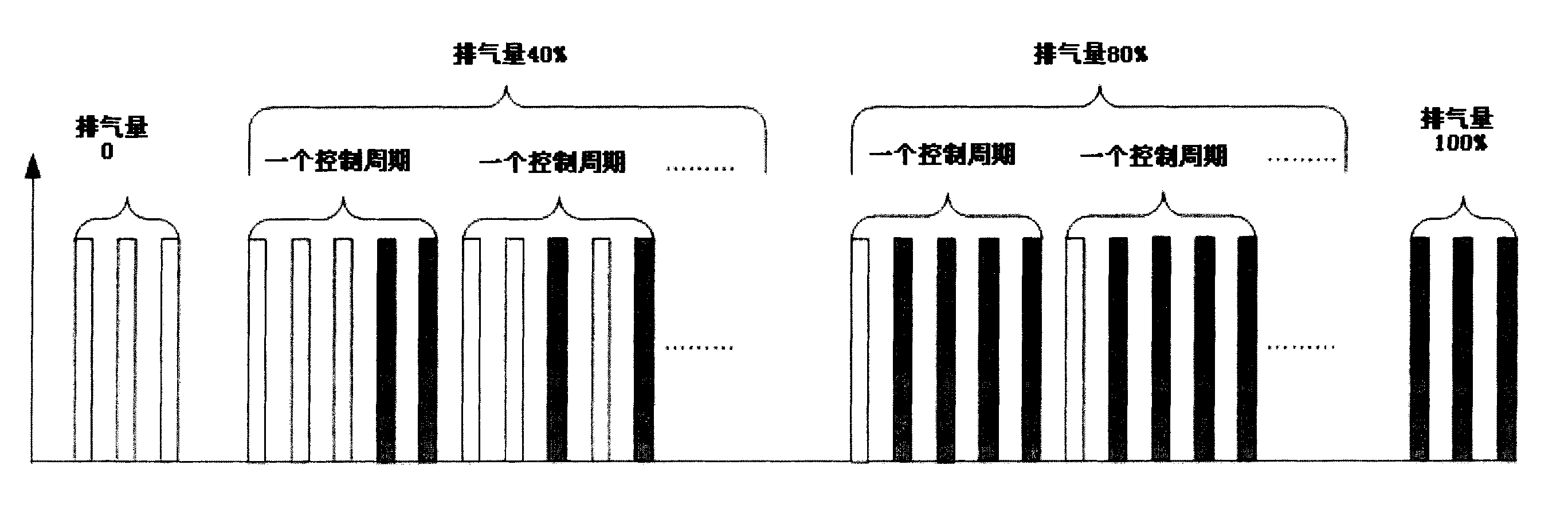

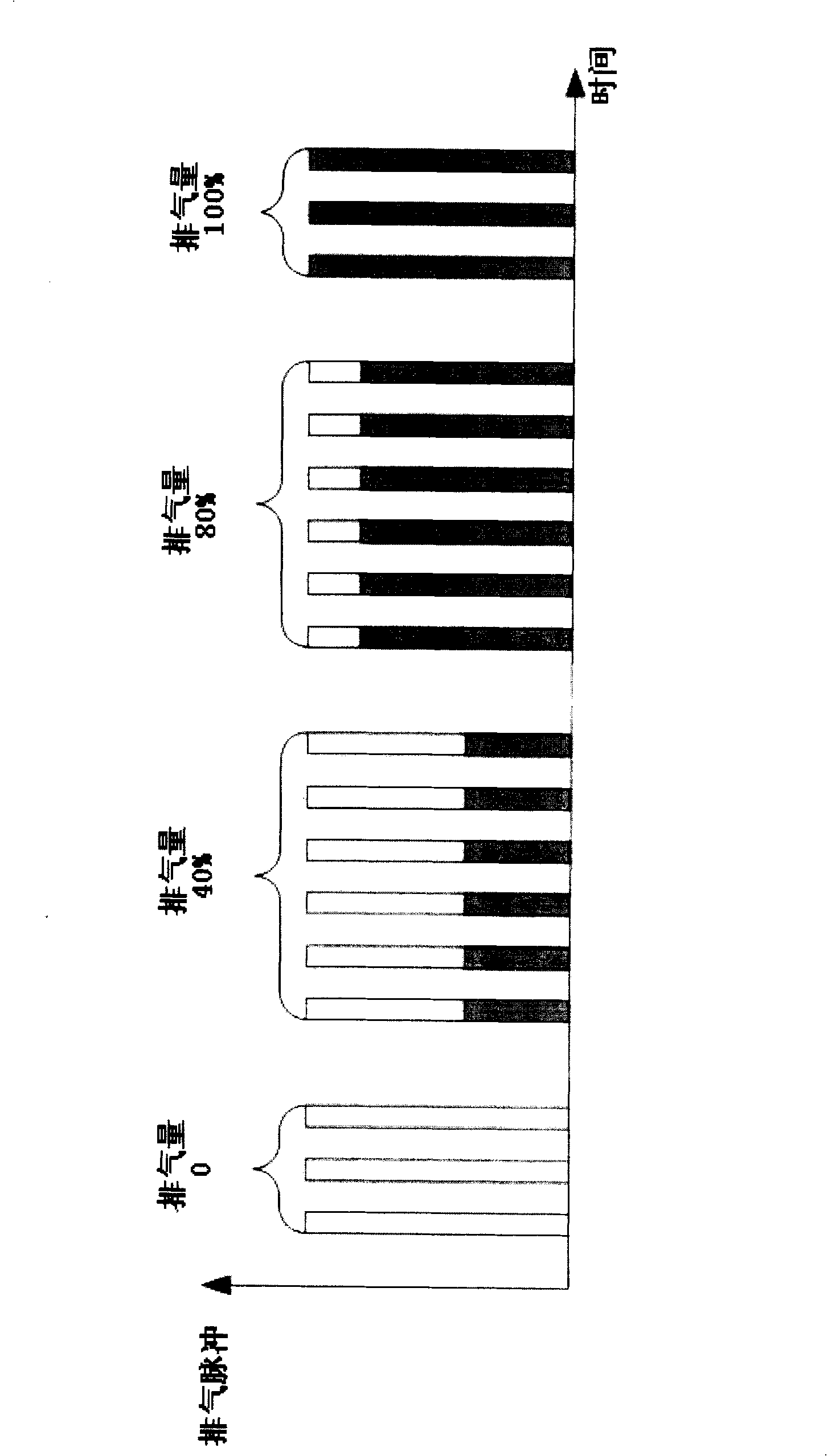

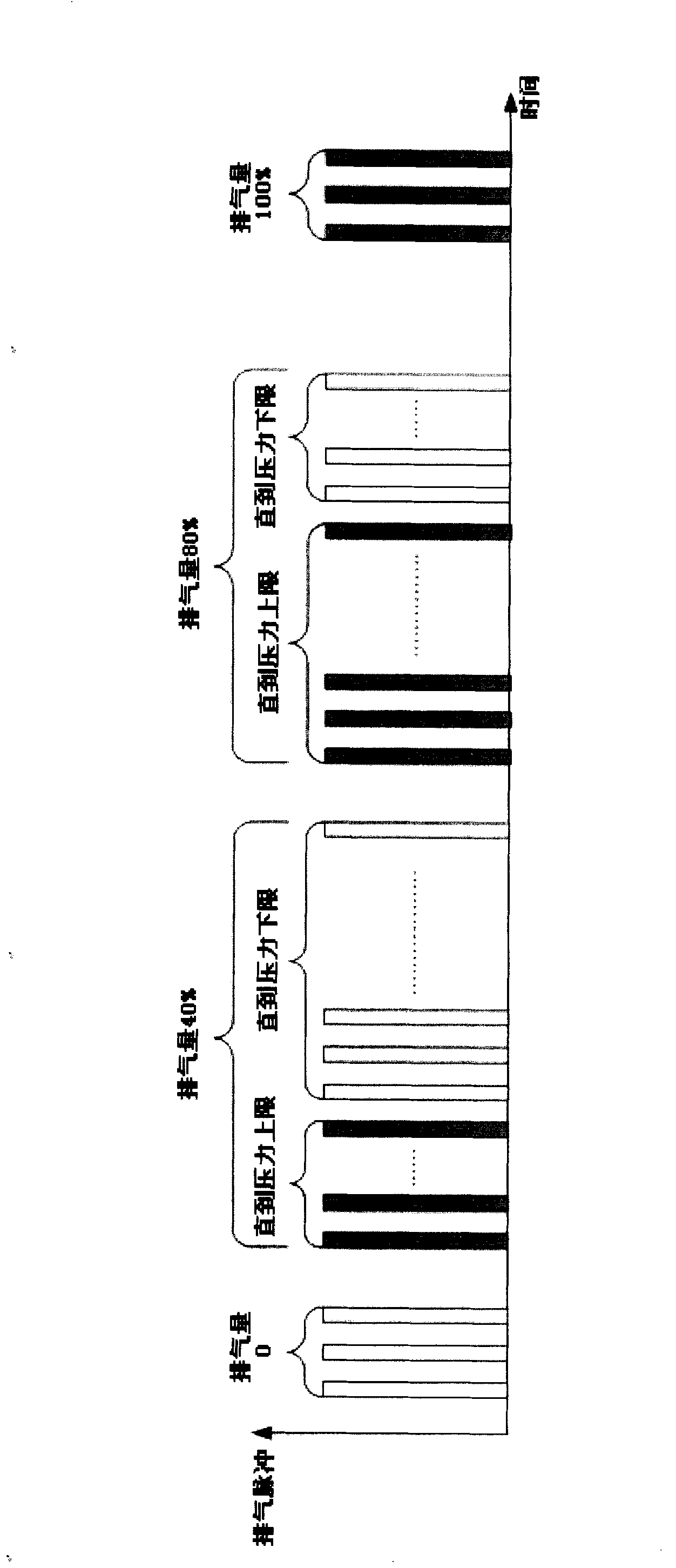

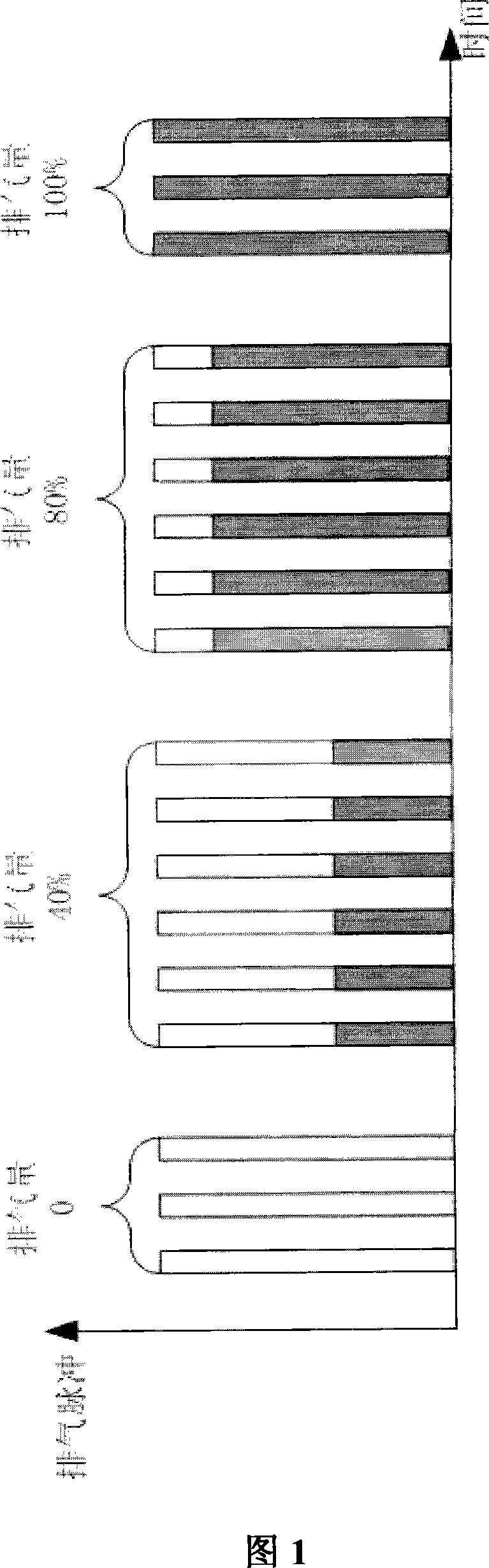

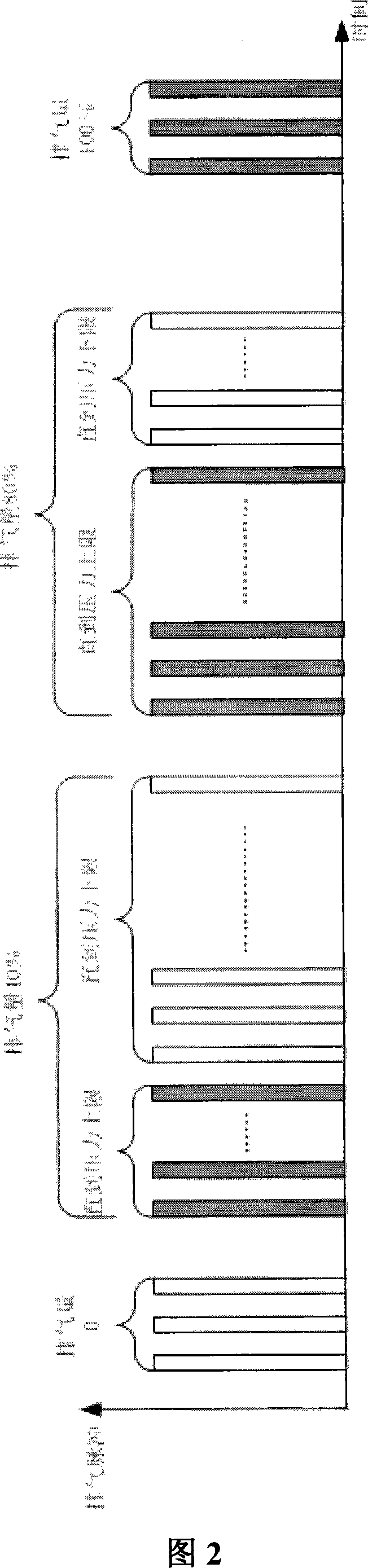

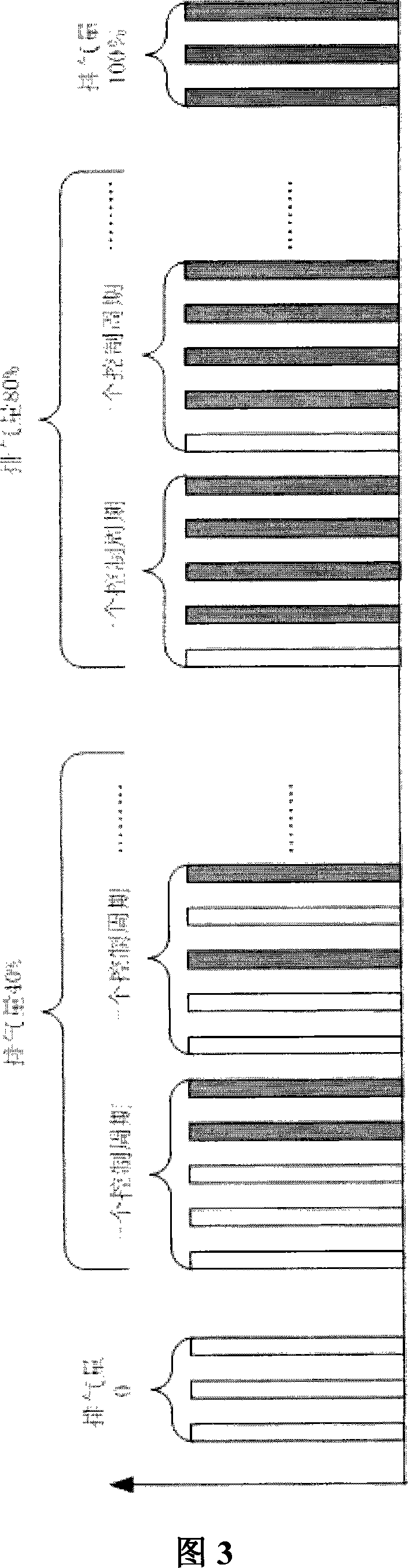

Air displacement stepless regulating method for reciprocating-piston compressor

InactiveCN101173658BUniform displacementThe method is simple and reliableSpace heating and ventilation safety systemsLighting and heating apparatusControl systemInhalation Valve

The invention discloses a stepless delivery regulation method of reciprocating-piston compressor, which is characterized in that duty cycle is determined using the maximum delivery and the actually required delivery of the compressor under full load; an inhalation valve is forced to open or freely closed through a control system and a or a plurality of executive device (s) for pressing the inhalation valve, enabling load circulation and non-load circulation to be alternatively distributed to comply with the duty cycle, thereby evenly supplying the required delivery. The invention has the advantages of capability of 0 to 100% continuous delivery regulation, less pressure fluctuation, saved energy, lowered noise, simple and reliable regulation effect.

Owner:XI AN JIAOTONG UNIV

Air displacement stepless regulating method for reciprocating-piston compressor

InactiveCN101173658AUniform displacementThe method is simple and reliablePump controlPositive-displacement liquid enginesLoad cycleValve actuator

The invention discloses a stepless adjustment method for the discharge volume of a reciprocating piston compressor. The method determines the duty ratio by the maximum discharge volume of the full-load operation of the compressor and the actual required discharge volume. Through a control system and a Or multiple actuators that can press open the suction valve to control the forced opening or free opening and closing of the compressor suction valve, so that the compressor loading cycle and no-load cycle are distributed at intervals and in line with the duty cycle, so as to uniformly provide all Exhaust volume required. The invention has the effect of realizing continuous adjustment of exhaust volume from 0 to 100%, small pressure fluctuation, energy saving and noise reduction, and simple and reliable adjustment.

Owner:XI AN JIAOTONG UNIV

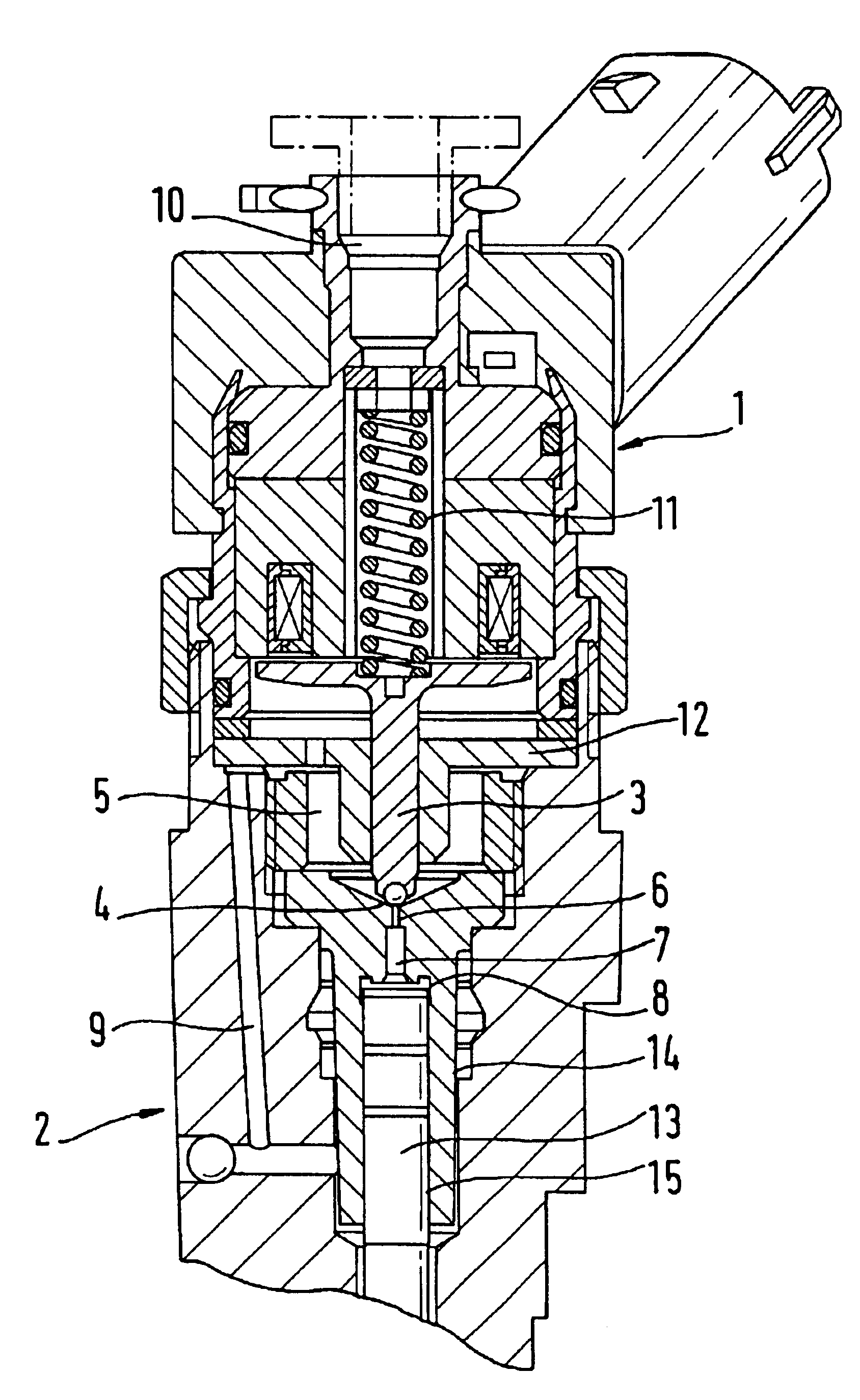

Injector with a magnet valve for controlling an injection valve

InactiveUS6877680B2Suppress pressure fluctuationsReduce intensitySpray nozzlesFluid pressure injection controlSolenoid valveFuel tank

Disclosed is an injector for fuel injection, with a magnet valve for controlling an injection valve, in which the magnet valve has a movable armature that can be moved onto a valve seat in the lower armature chamber. The lower armature chamber communicates fluidically with the control pressure chamber of the injection valve via bores. Via a return bore, incidental leak fuel quantities can be returned to a tank via the lower armature chamber. To prevent armature recoil upon closure of the valve seat by the armature, it is proposed that means be provided in the injector for reducing pressure fluctuations occurring in the lower armature chamber. Eliminating pressure fluctuations in the lower armature chamber leads to maximal elimination of armature recoil.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com