Patents

Literature

56results about How to "High gas purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

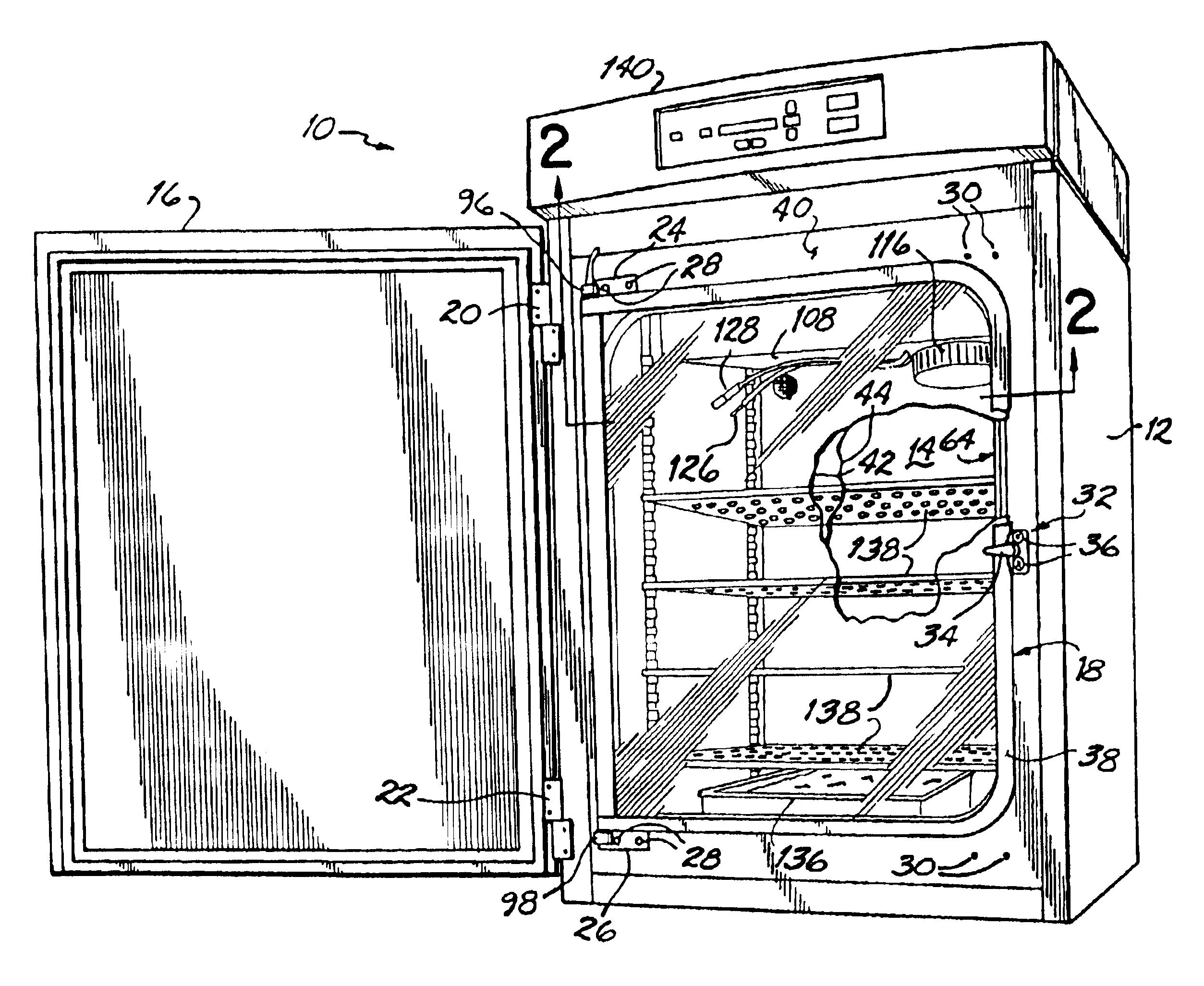

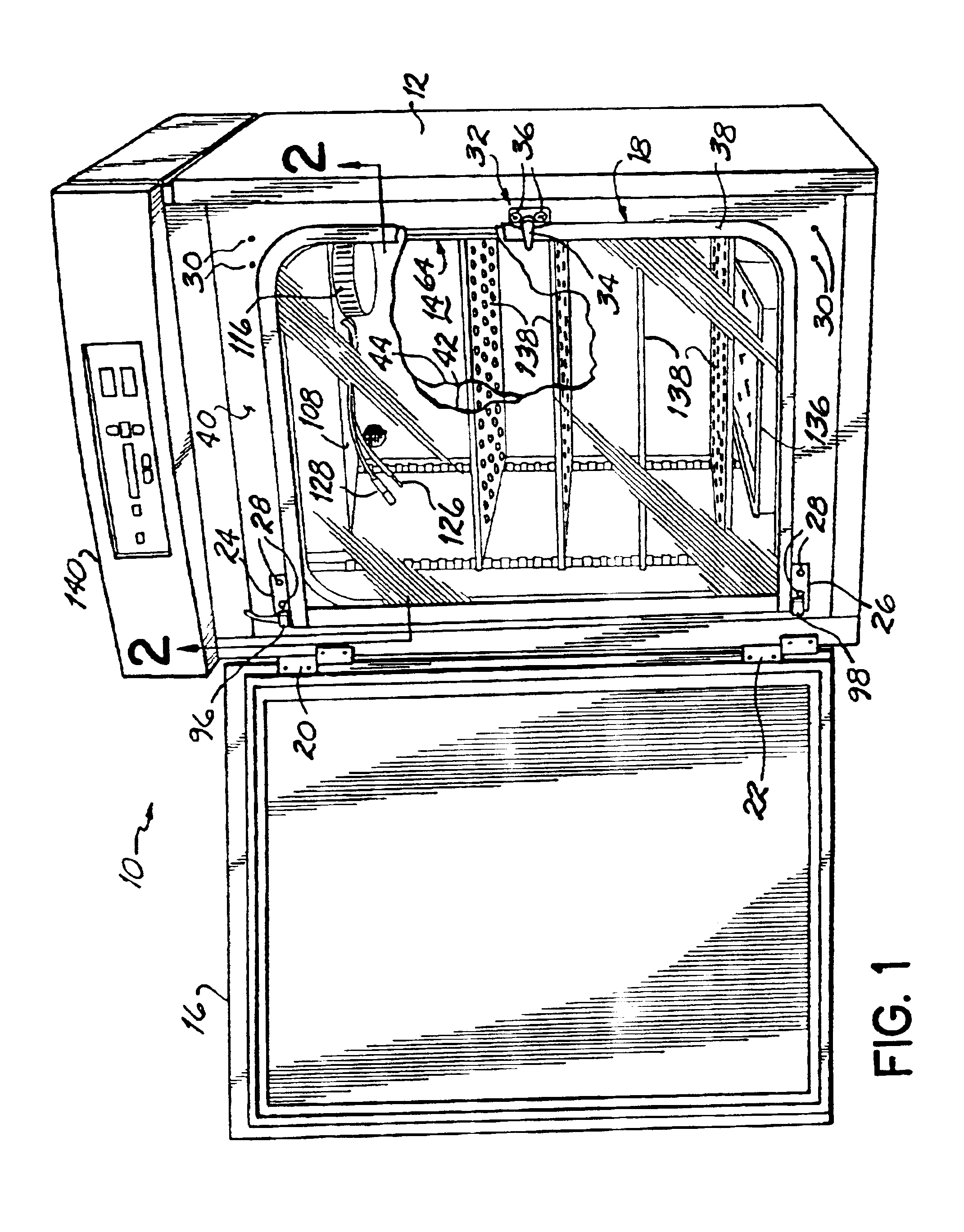

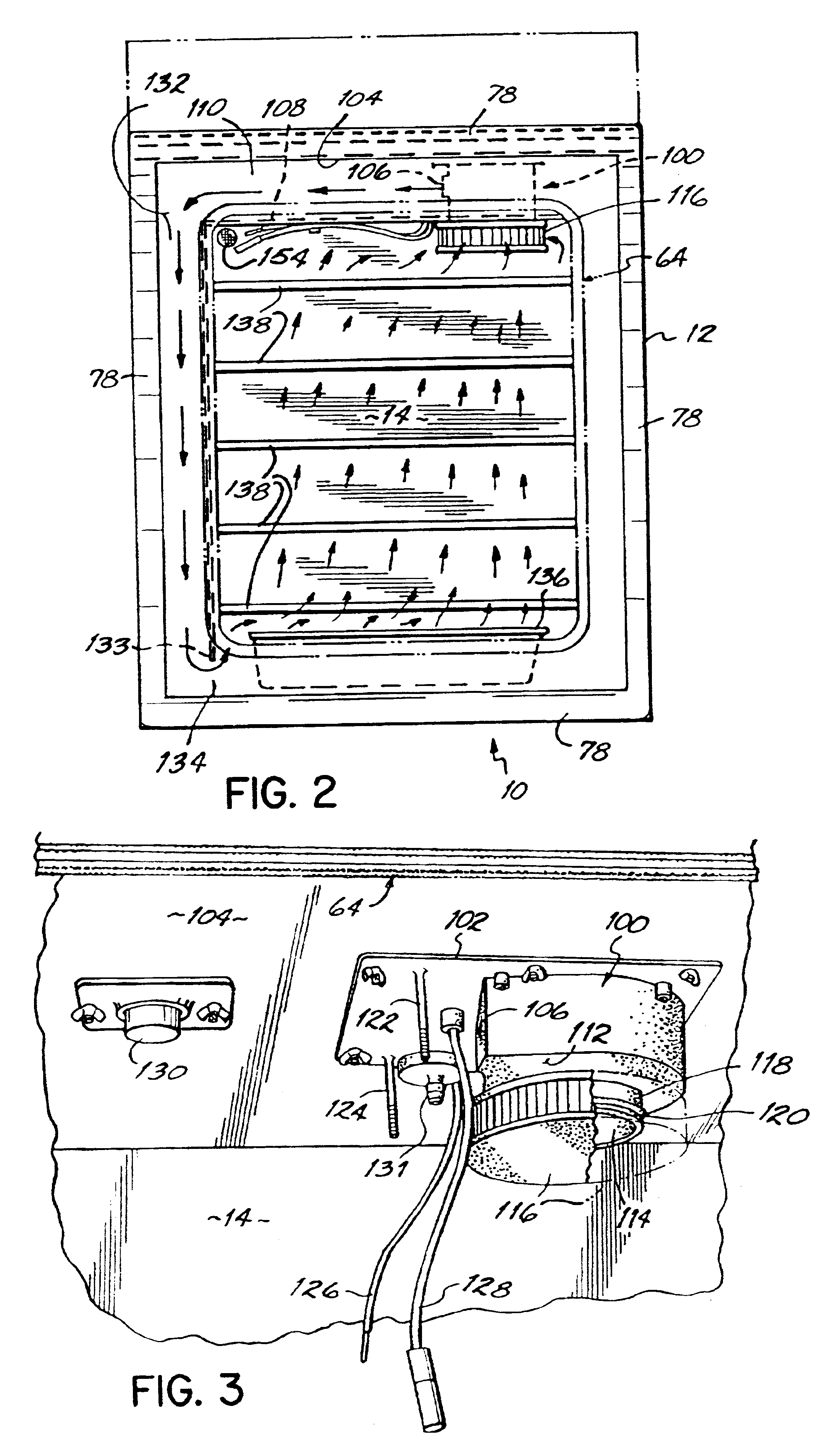

Incubator having combined HEPA and VOC filter

InactiveUS6878177B2Quickly and completely circulatedHigh gas purityCombination devicesBioreactor/fermenter combinationsHEPAControlled atmosphere

A controlled atmosphere incubator having an interior chamber adapted to be heated and humidified. An easily accessed blower is located within the gaseous environment of the incubator chamber and includes a HEPA filter and VOC filter readily replaceable by the user from within the chamber.

Owner:THERMO FISHER SCI ASHEVILLE

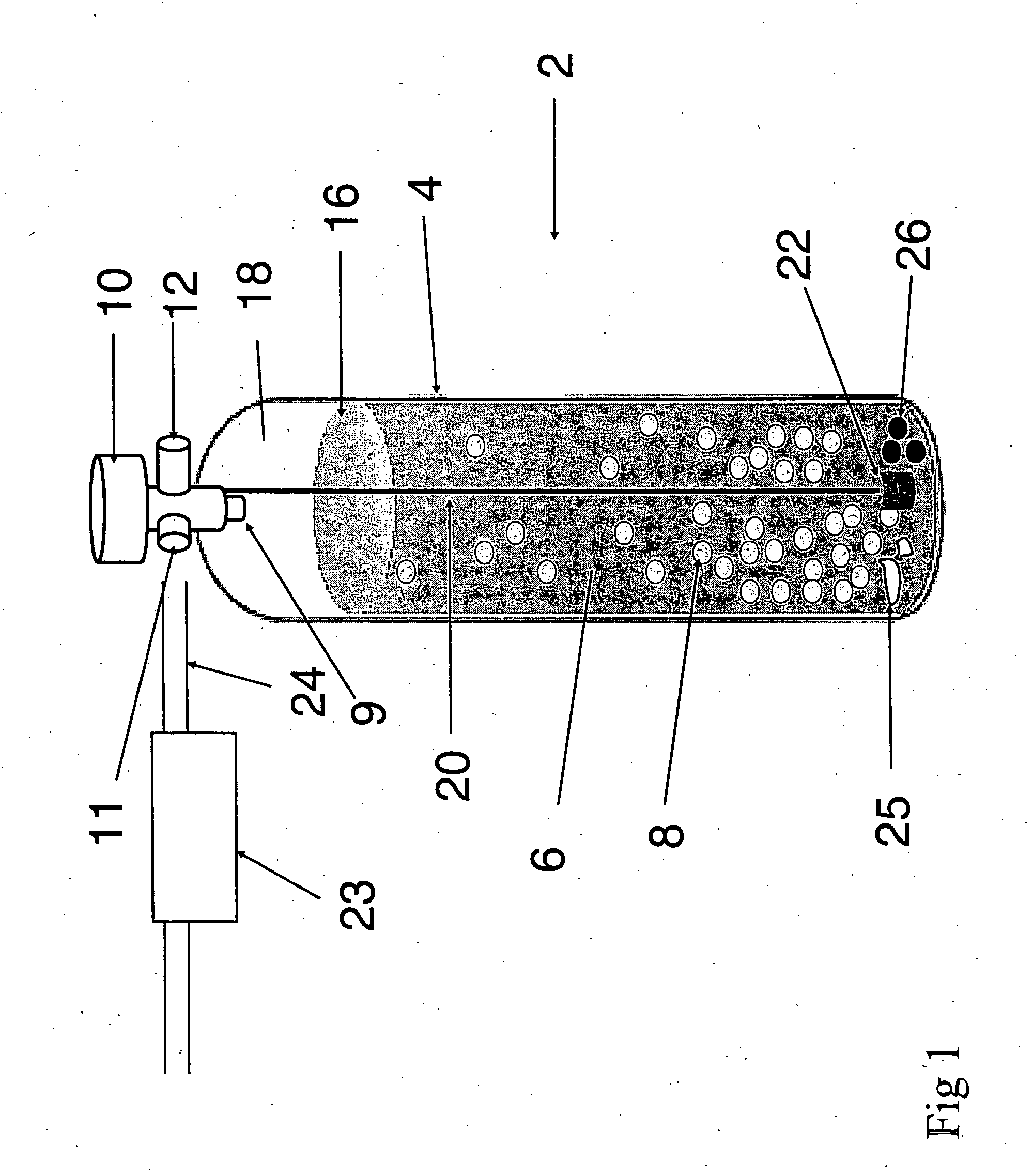

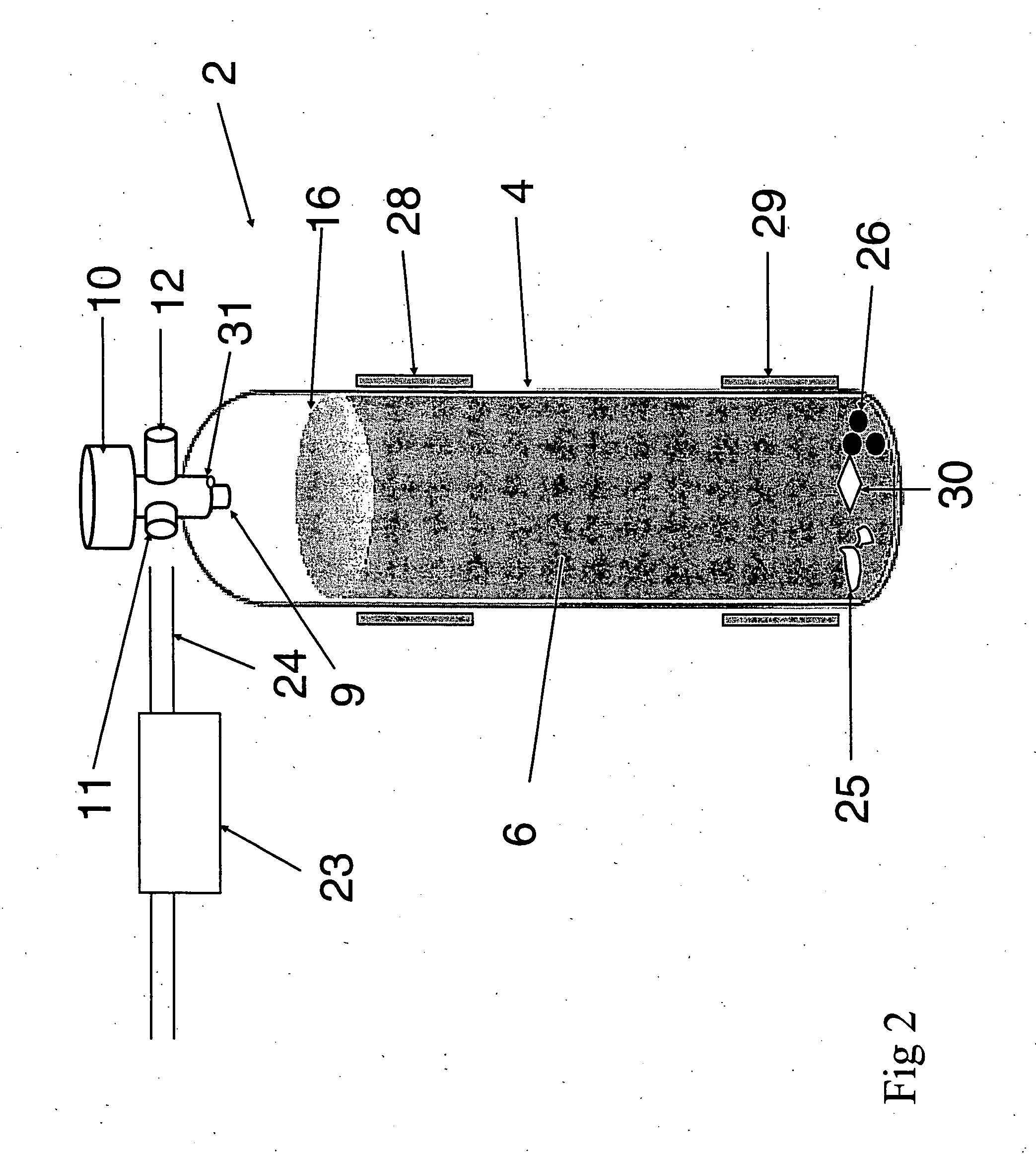

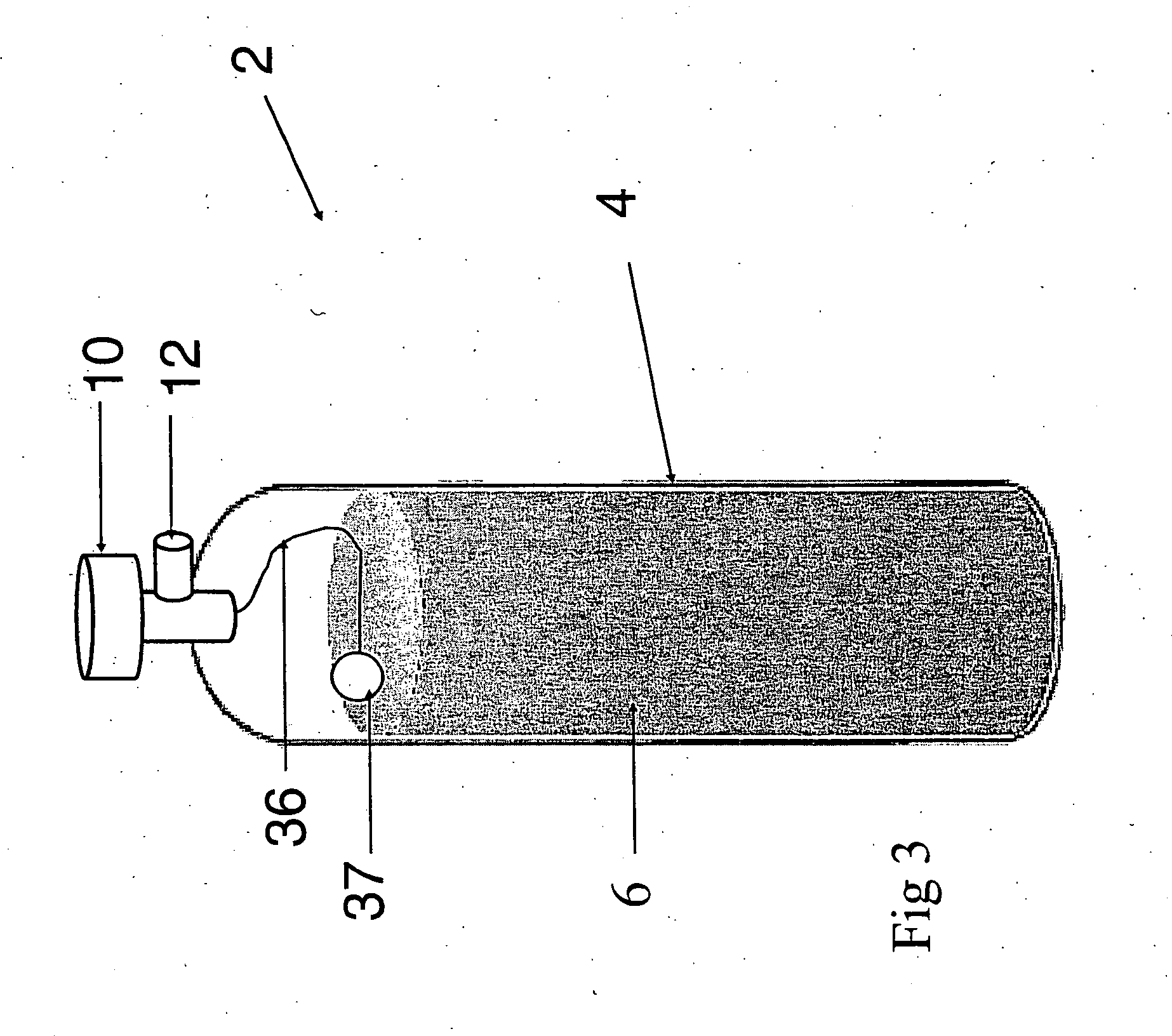

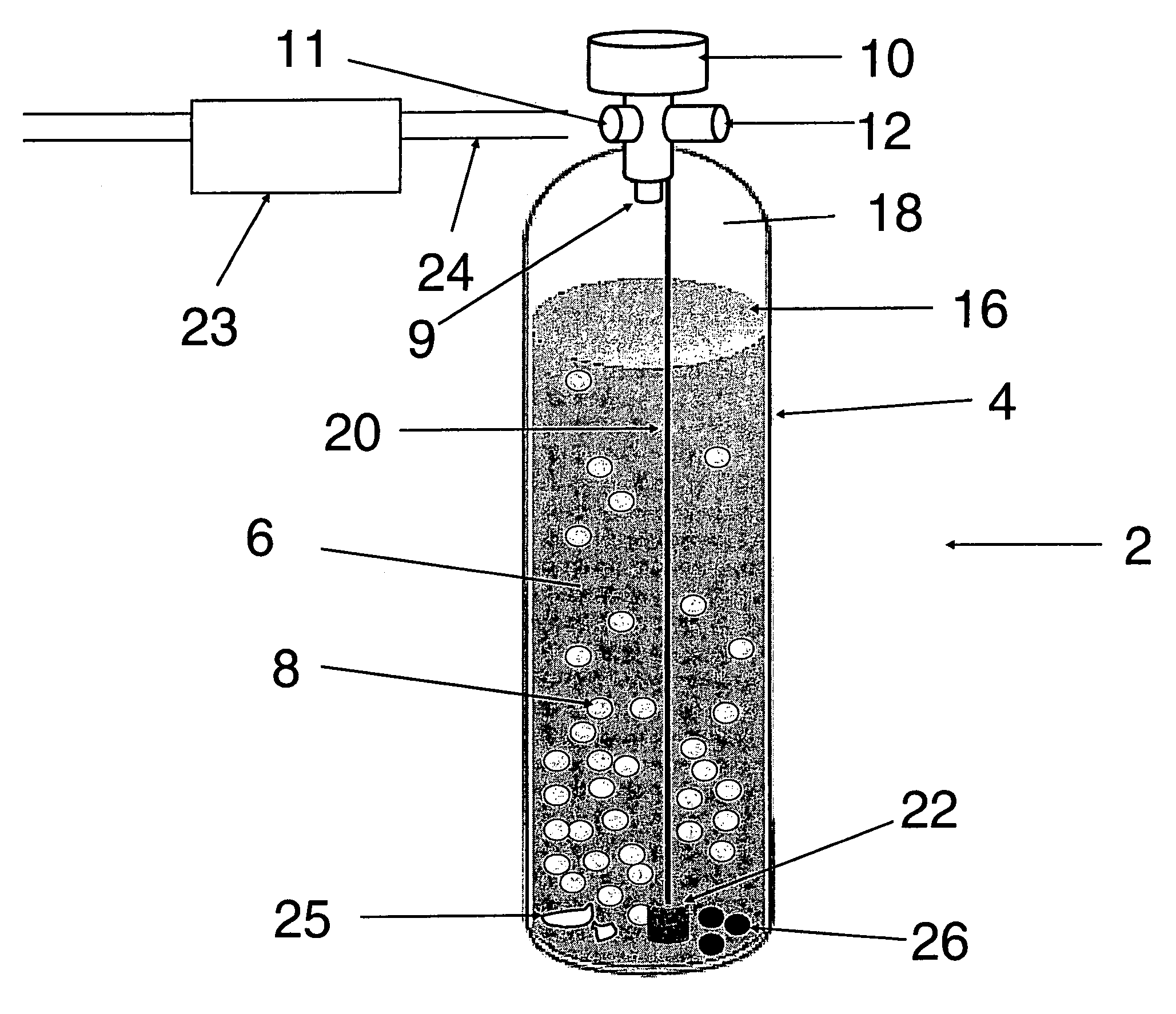

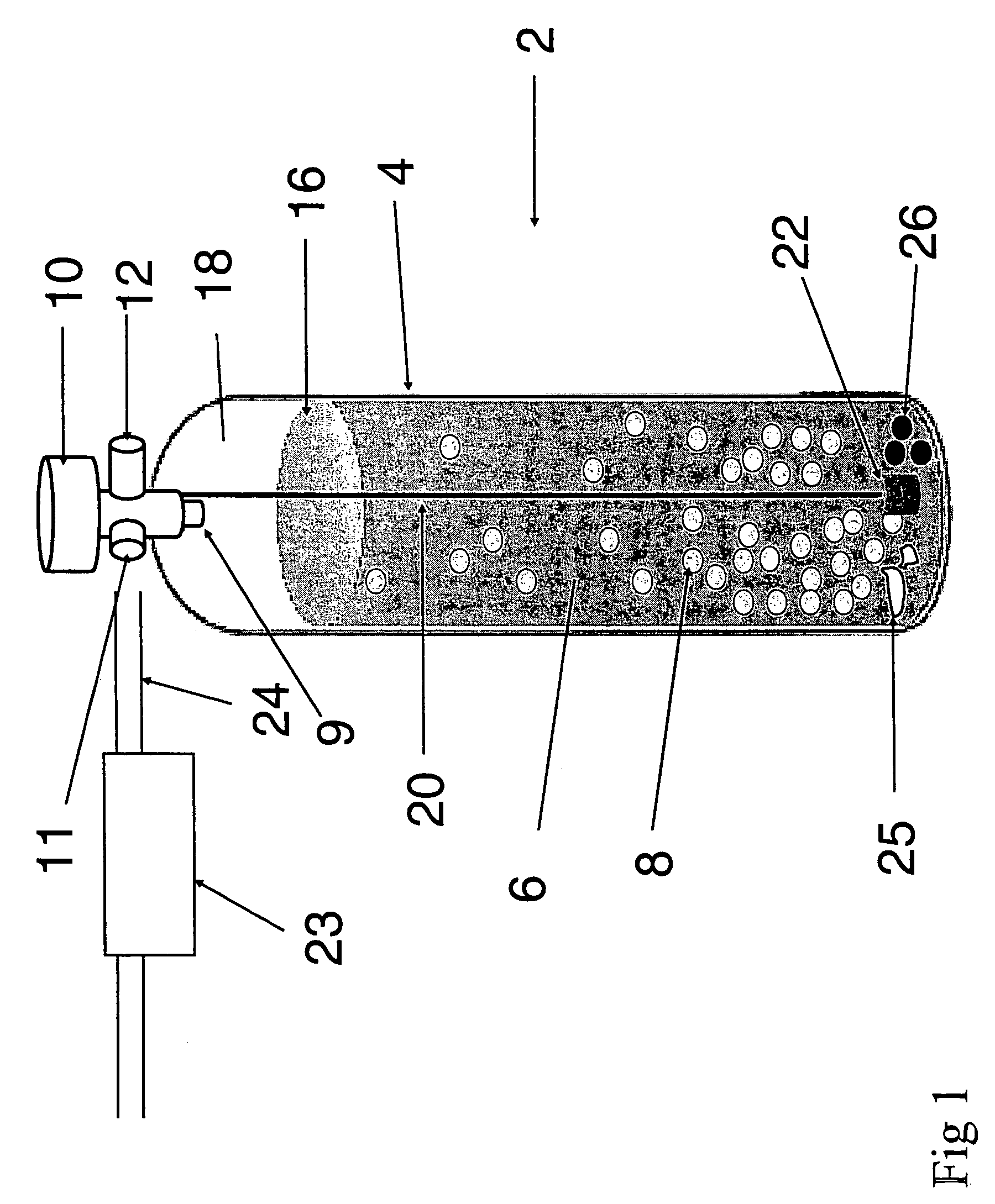

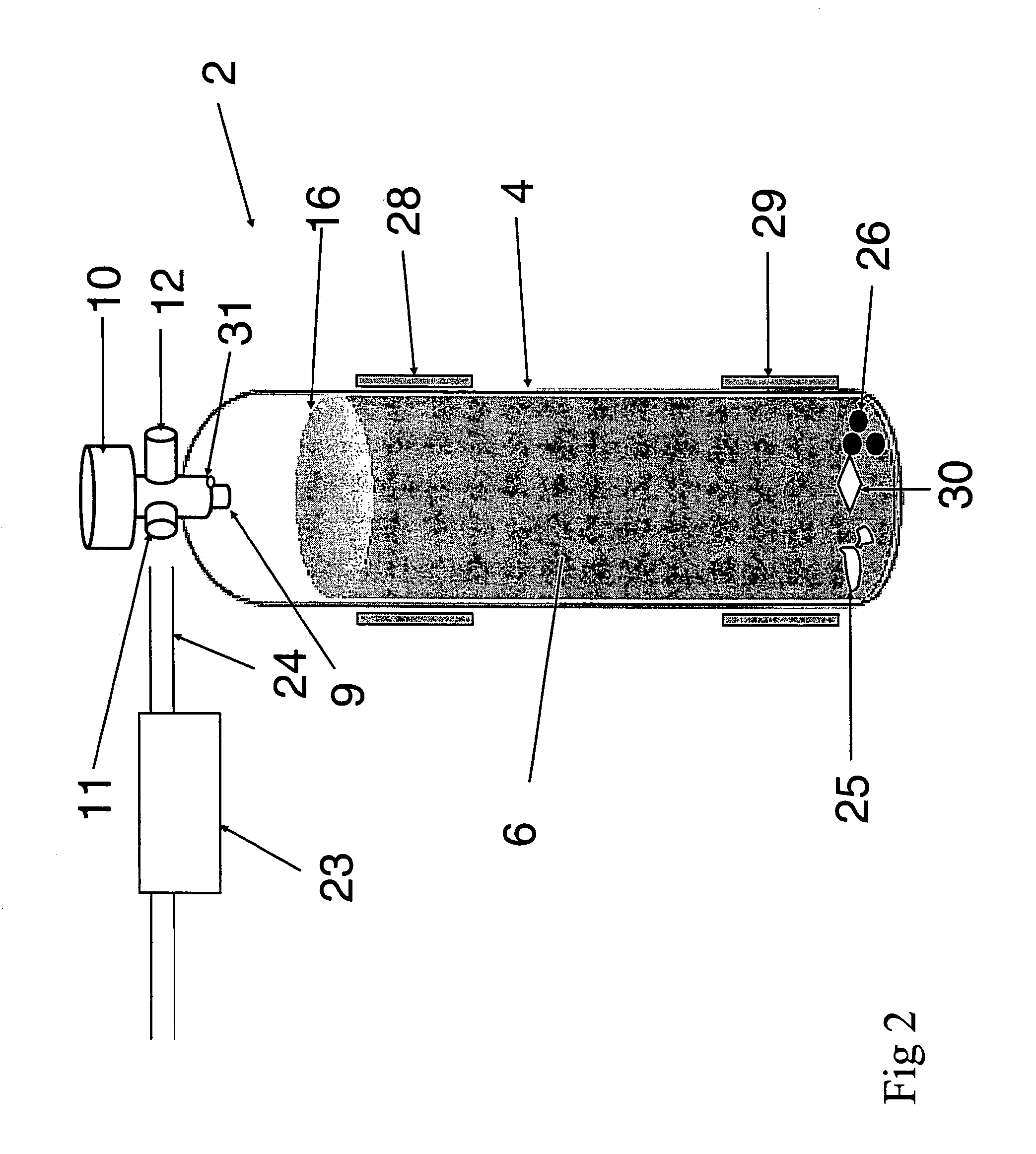

Storage and delivery systems for gases held in liquid medium

InactiveUS20060008392A1Shorten timeShorten the timeCombination devicesLiquid degasificationProduct gasFast filling

The present invention is directed to improvements in storage and delivery systems that allow for rapid fill and delivery of gases reversibly stored in a nonvolatile liquid medium, improvements in delivery and purity of the delivered gas. The low pressure storage and delivery system for gas which comprises: a container having an interior portion containing a reactive Lewis basic or Lewis acidic reactive liquid medium that is reversibly reacted with a gas having opposing Lewis acidity or basicity; a system for transferring energy into or out of the reactive liquid medium; or, a product gas purifier (e.g. a gas / liquid separator); or both.

Owner:VERSUM MATERIALS US LLC

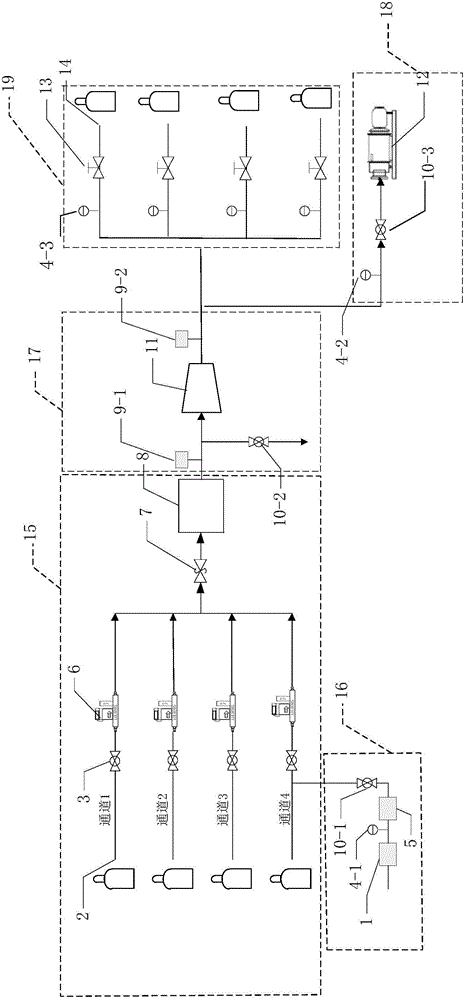

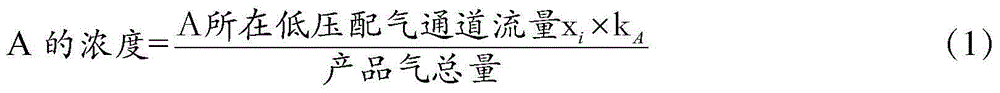

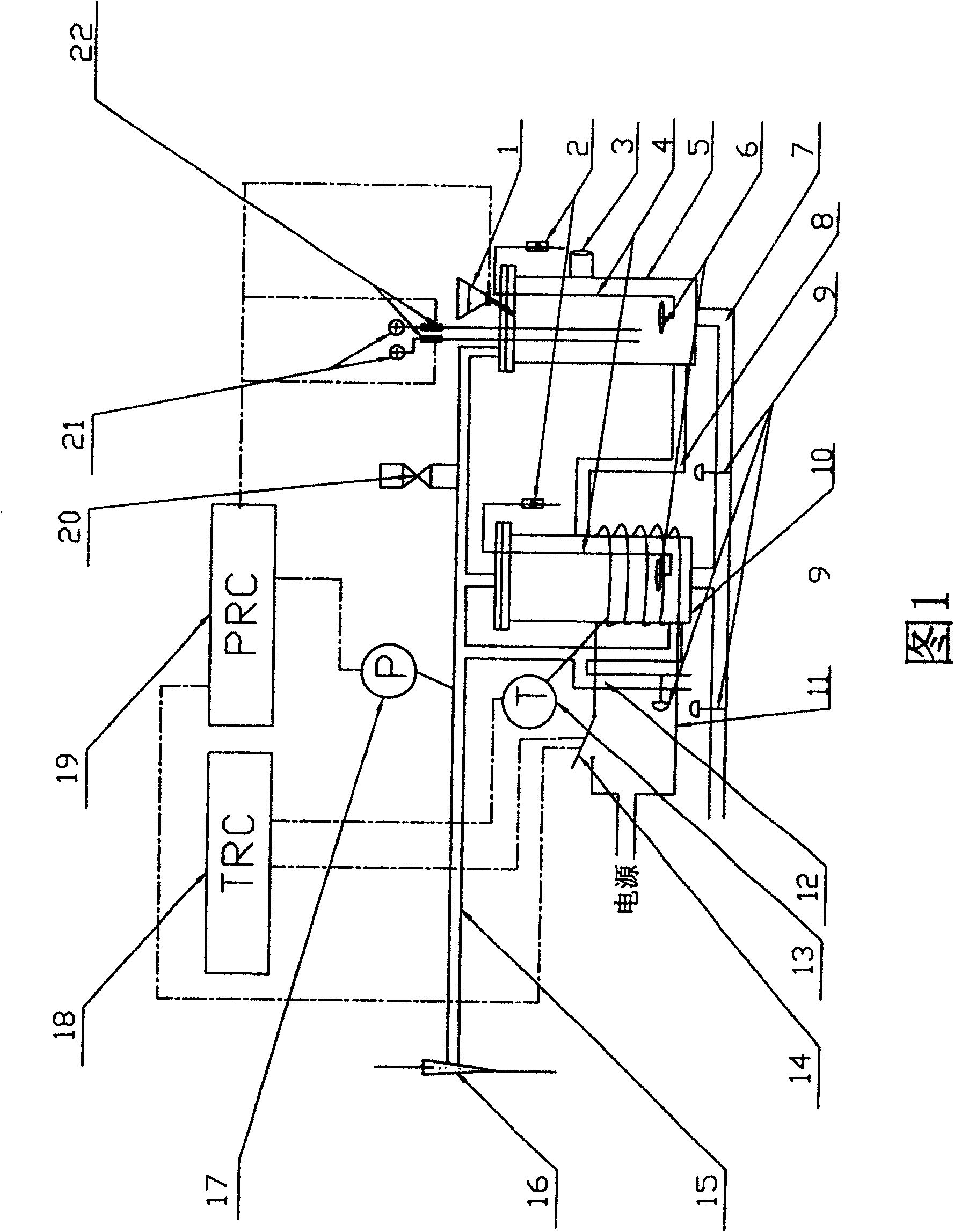

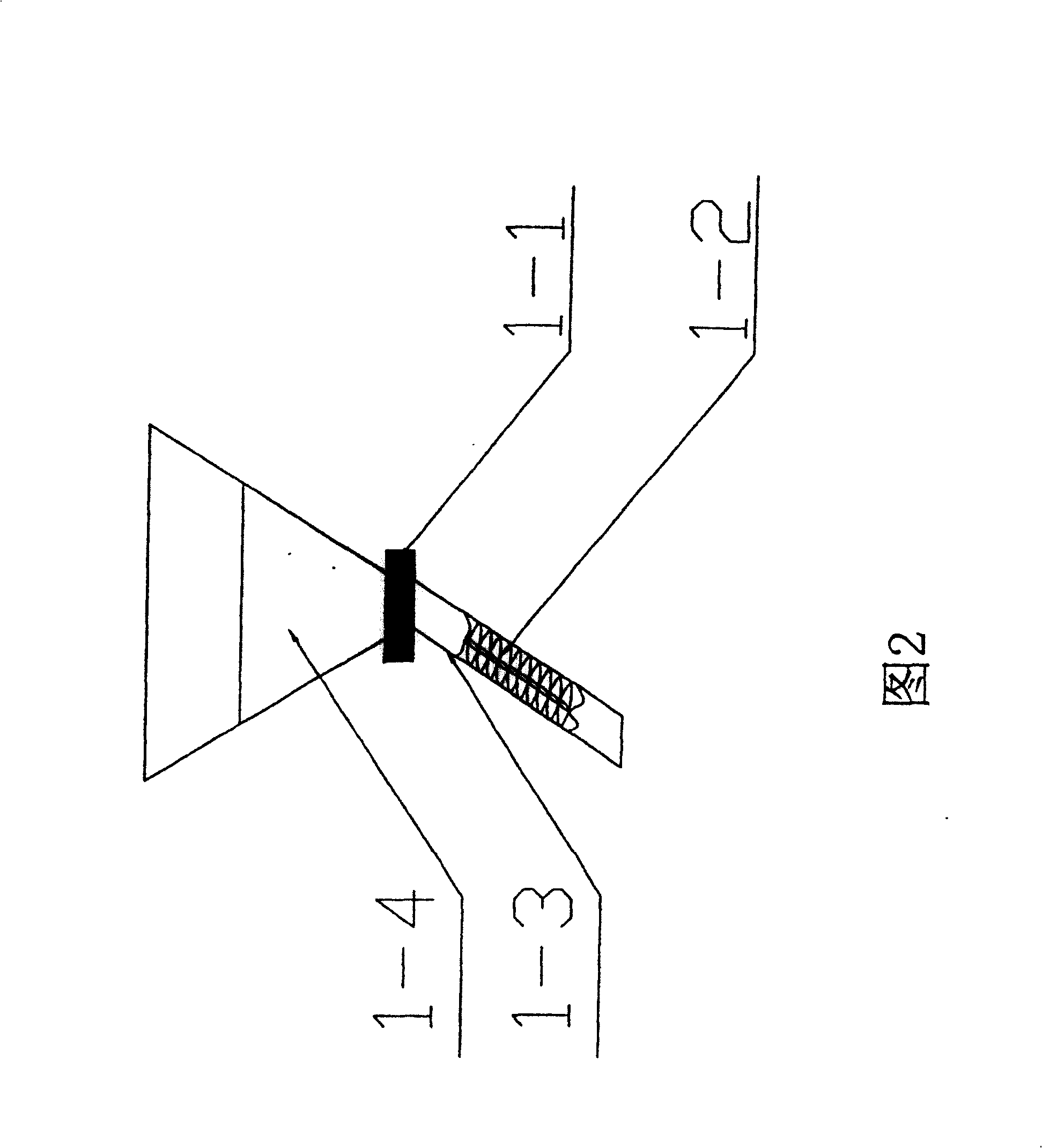

Anti-explosion multi-component dynamic air distribution device and method

ActiveCN104147948AStable pressureAnti-explosion effectMixer accessoriesMixing gases with gases/vapoursEngineeringAir compressor

The invention discloses an anti-explosion multi-component dynamic air distribution device and method. The device comprises a low-pressure air distribution system 15, an air compression generation device 16, a pressurization system 17, a vacuumization system 18 and a filling system 19. Through the adoption of a back pressure valve, the pressure of gas at the gas outlet end of the back pressure valve is stable before the gas enters a gas mixer, so that an anti-explosion effect is achieved; due to the adoption of a variable frequency diaphragm compressor, product gas is high in purity and free of impurity gas pollution; moreover, the pressure in the low-pressure air distribution channel is stabilized in a safe pressure range by adjusting the working frequency of the variable frequency diaphragm compressor to achieve the anti-explosion effect; flow control ranges of n mass flow controllers are distributed in a trapezoidal shape for real-time control on gas flow, so that the air distribution precision is improved; air generated by the air compressor is utilized as a diluent gas channel, so that the cost is saved; an alarm function can be performed in an air distribution process.

Owner:PERIC SPECIAL GASES CO LTD

Storage and delivery systems for gases held in liquid medium

InactiveUS7396381B2Shorten the timeEliminate and reduce liquid entrainmentCombination devicesLiquid degasificationLiquid mediumProduct gas

The present invention is directed to improvements in storage and delivery systems that allow for rapid fill and delivery of gases reversibly stored in a nonvolatile liquid medium, improvements in delivery and purity of the delivered gas. The low pressure storage and delivery system for gas which comprises:a container having an interior portion containing a reactive Lewis basic or Lewis acidic reactive liquid medium that is reversibly reacted with a gas having opposing Lewis acidity or basicity;a system for transferring energy into or out of the reactive liquid medium; or,a product gas purifier (e.g. a gas / liquid separator); or both.

Owner:VERSUM MATERIALS US LLC

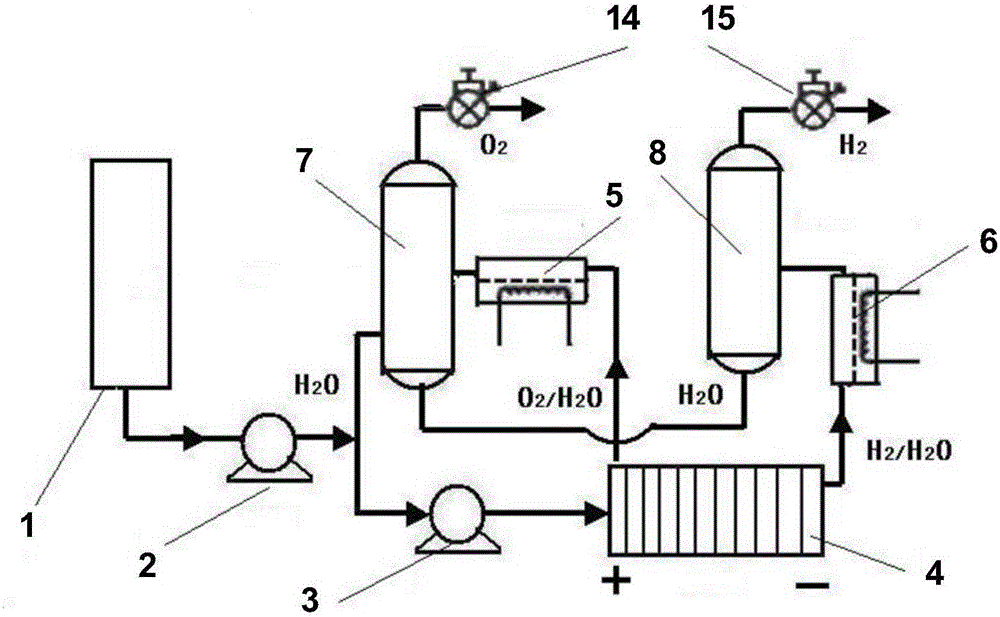

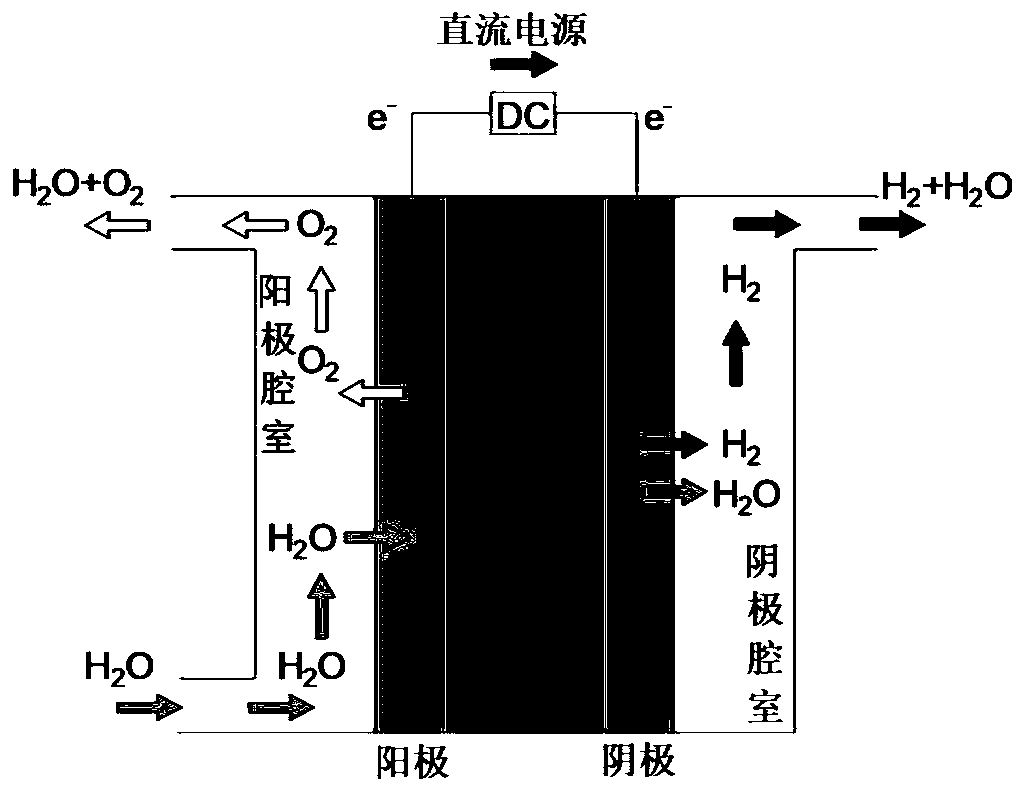

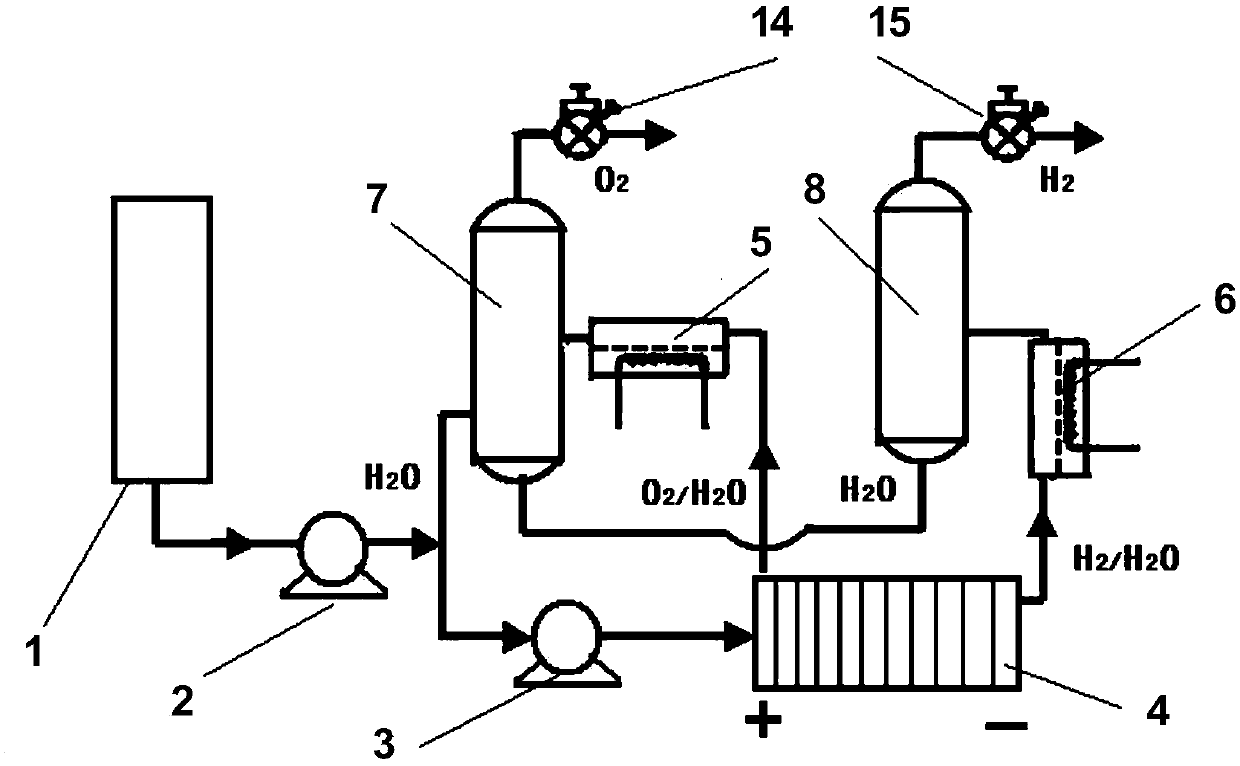

High pressure proton membrane water electrolysis device and method

ActiveCN105862066ANo incorporation of gasAvoid containingCellsDiaphragmsPolymer electrolytesHydrogen

The invention discloses a high pressure proton membrane water electrolysis device. The device comprises a water tank, a make up pump, an electrolytic cell stack, a first separator and a second separator, wherein the make up pump is used for communicating the water tank with a water inlet of the electrolytic cell stack; the first separator is communicated with an oxygen outlet of the electrolytic cell stack; the second separator is communicated with a hydrogen outlet of the electrolytic cell stack; and an electrolyte and proton exchange membrane is arranged in the electrolytic cell stack and is solid polymer electrolyte. The high pressure proton membrane water electrolysis device has the beneficial effects that the device avoids that the gases generated in traditional methods for electrolyzing water contain alkaline aerosol; and water and gas separation is carried out on the generated gases by the first and second separators, thus greatly improving the purity of the gases generated by electrolyzing water. The invention also discloses a high pressure proton membrane water electrolysis method.

Owner:淳华氢能源科技(湖南)有限公司

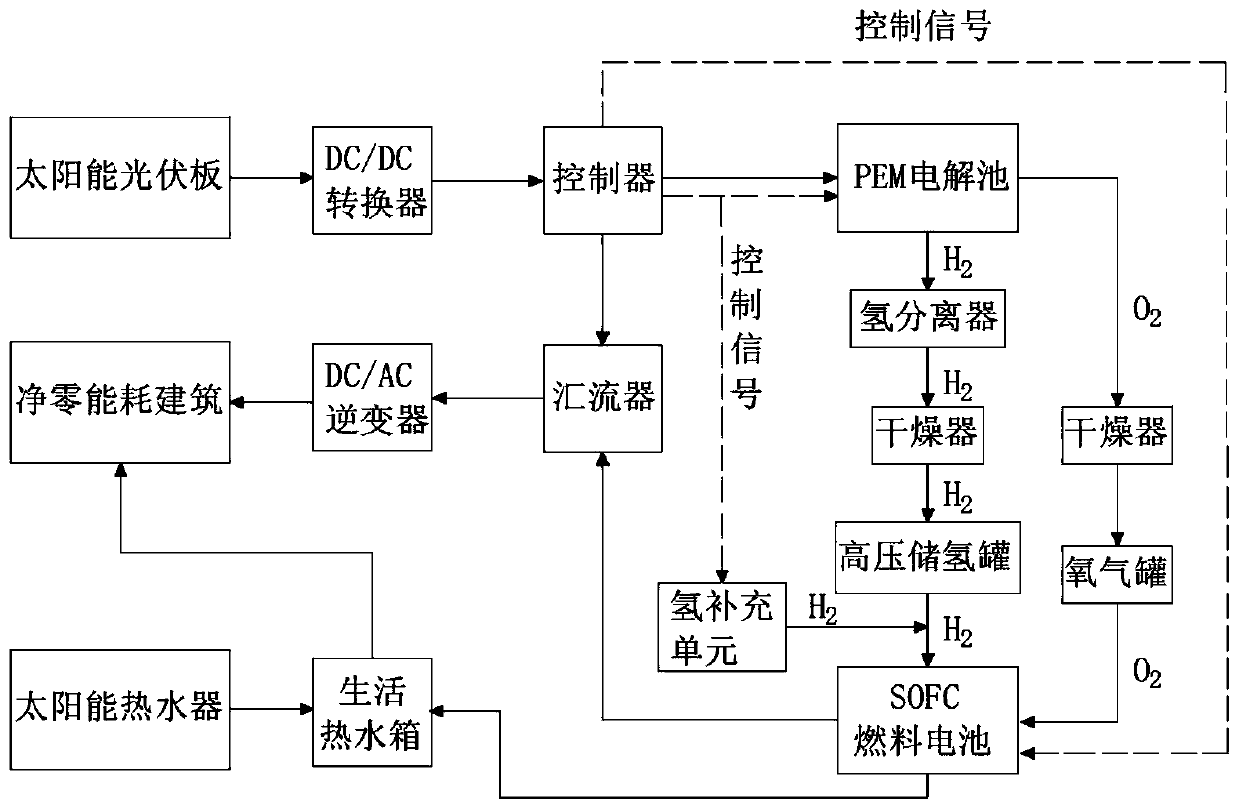

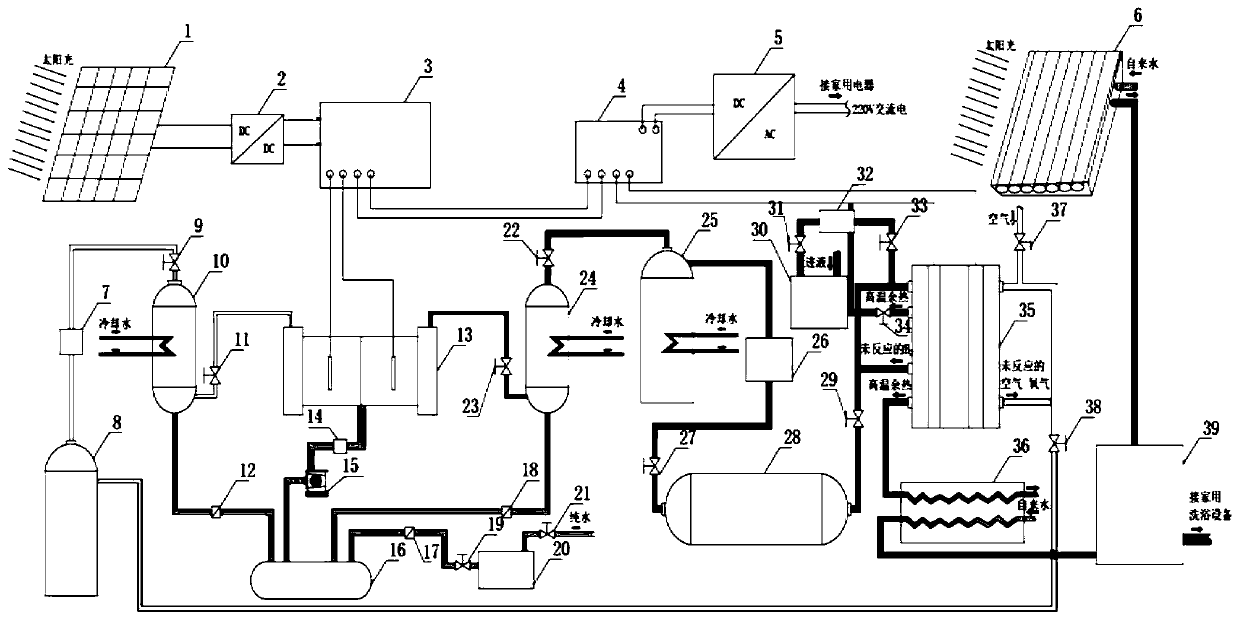

Novel net zero energy consumption building energy system based on hydrogen energy storage

PendingCN110690855AImprove power generation efficiencyReduce noiseFinal product manufacturePV power plantsSolar waterElectrolytic cell

The invention discloses a novel net zero energy consumption building energy system based on hydrogen energy storage. The system comprises two solar energy utilization devices of a solar photovoltaic panel and a solar water heater.The solar photovoltaic panel is connected with a DC / DC converter to perform voltage transformation of the power generated by the solar photovoltaic panel into the voltagesuitable for inversion of an inverter and electrolysis of an electrolytic cell and then connected to a controller. The controller is respectively connected with a hydrogen energy storage unit and a bus box, and part of the power generated by the solar photovoltaic panel is transmitted to the bus box through the controller for normal use of the net zero energy consumption building after being inverted by the inverter, and the excess electricity is used for electrolyzing water for hydrogen and storage. The intermittent and fluctuating problems existing in the solar photovoltaic power generationsystem can be solved, the net zero energy consumption building energy system is enabled to work normally in continuous rainy days and the utilization of waste heat in the SOFC fuel cell system is also realized so as to improve the efficiency of the SOFC fuel cell.

Owner:TIANJIN UNIV

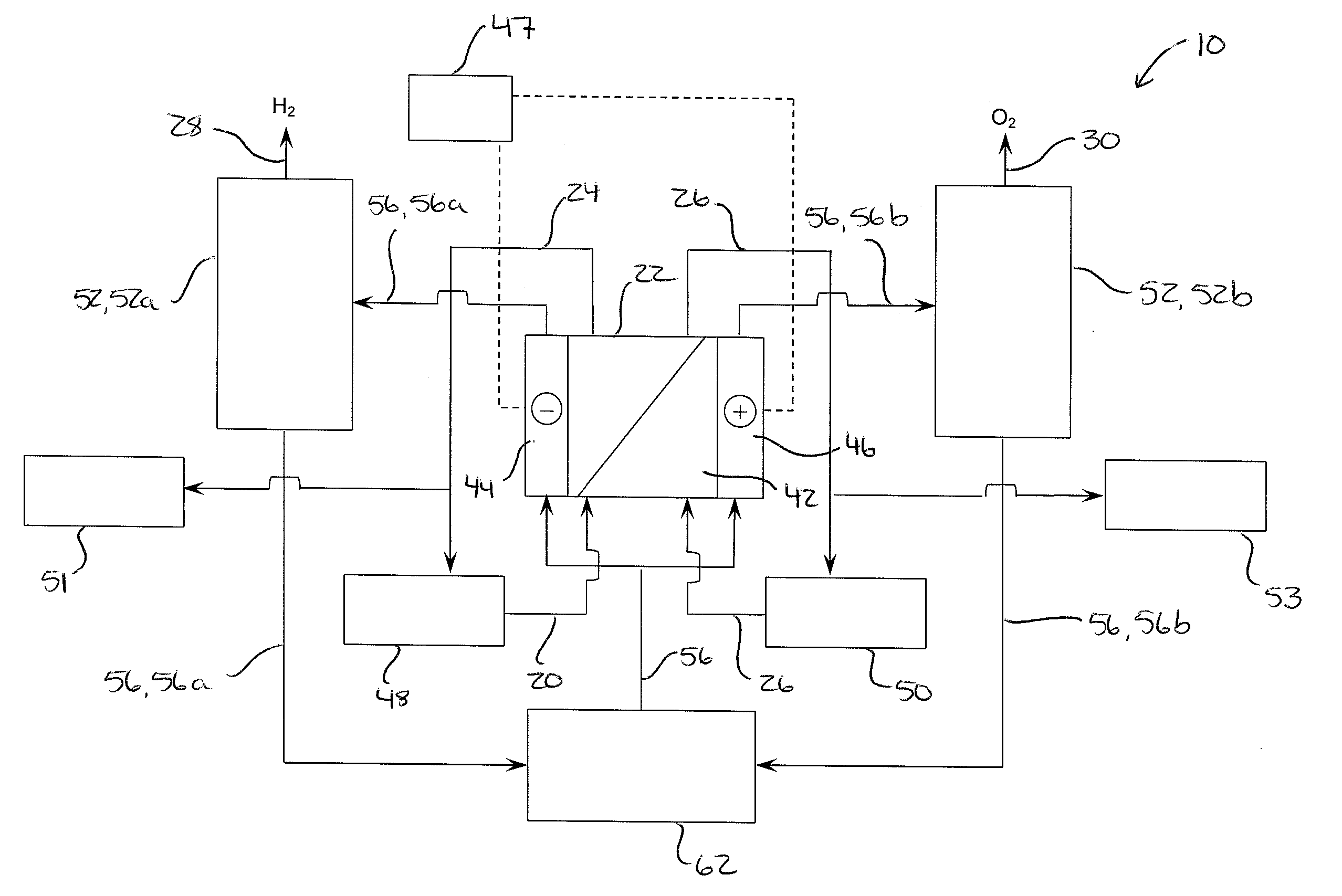

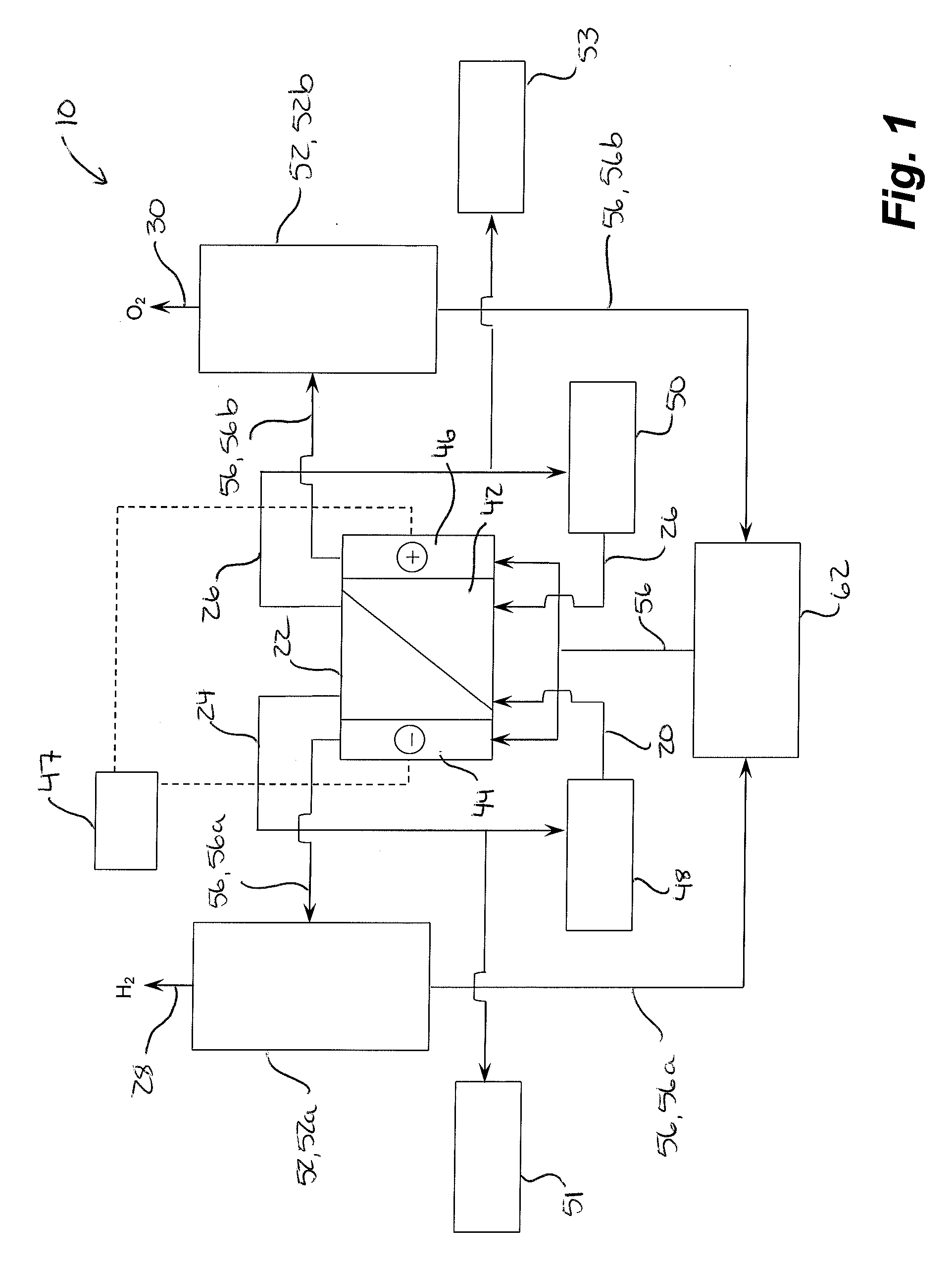

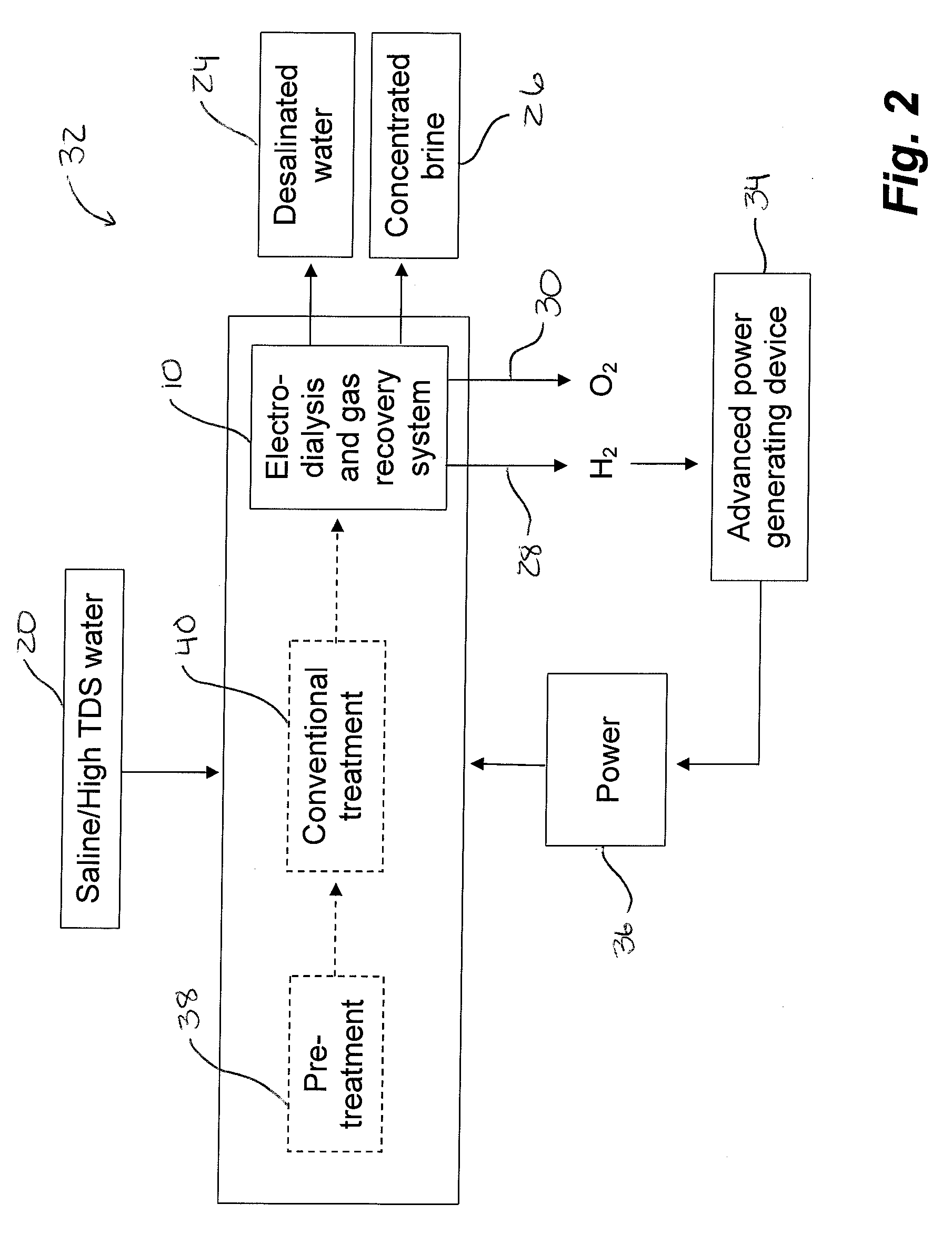

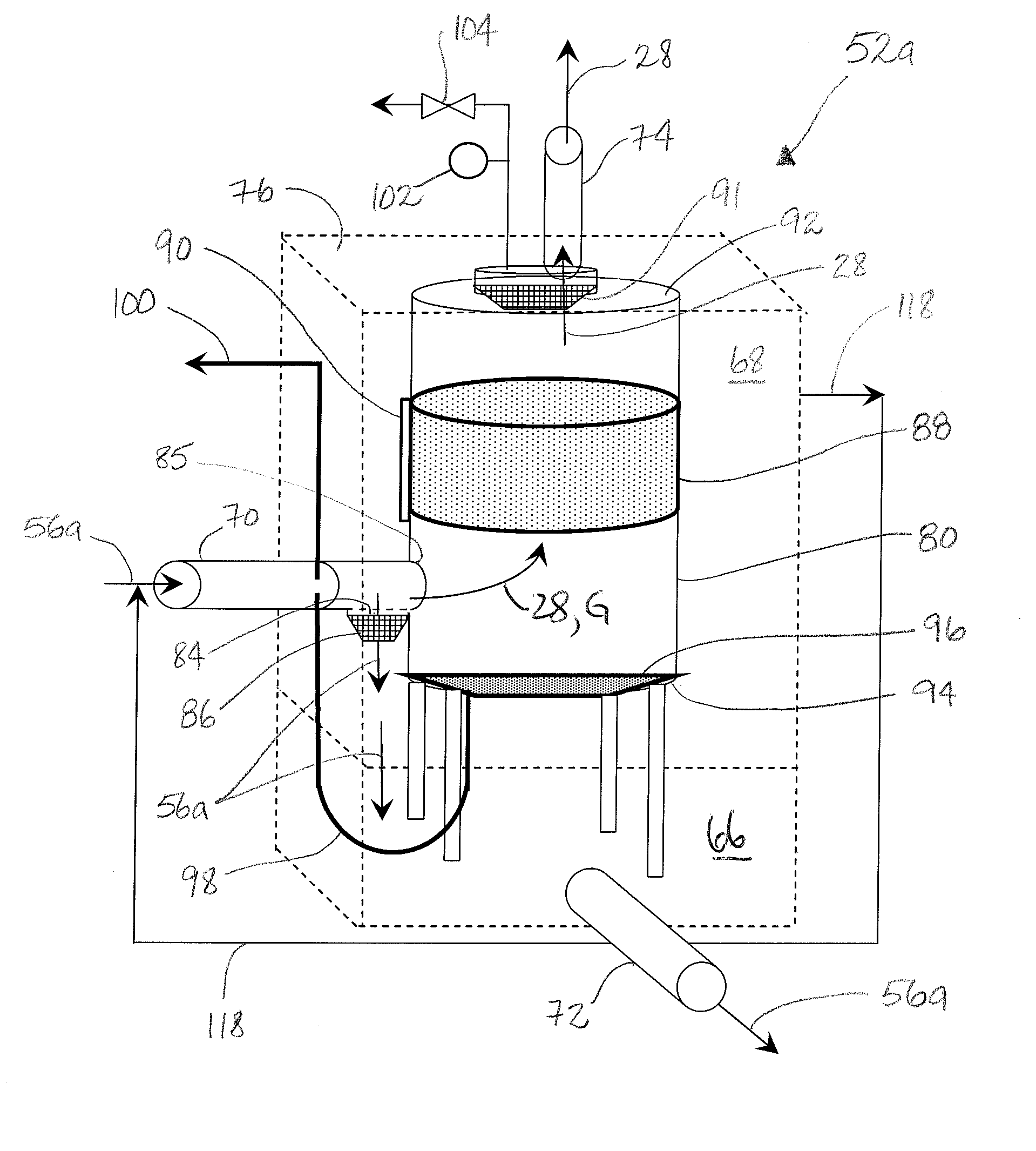

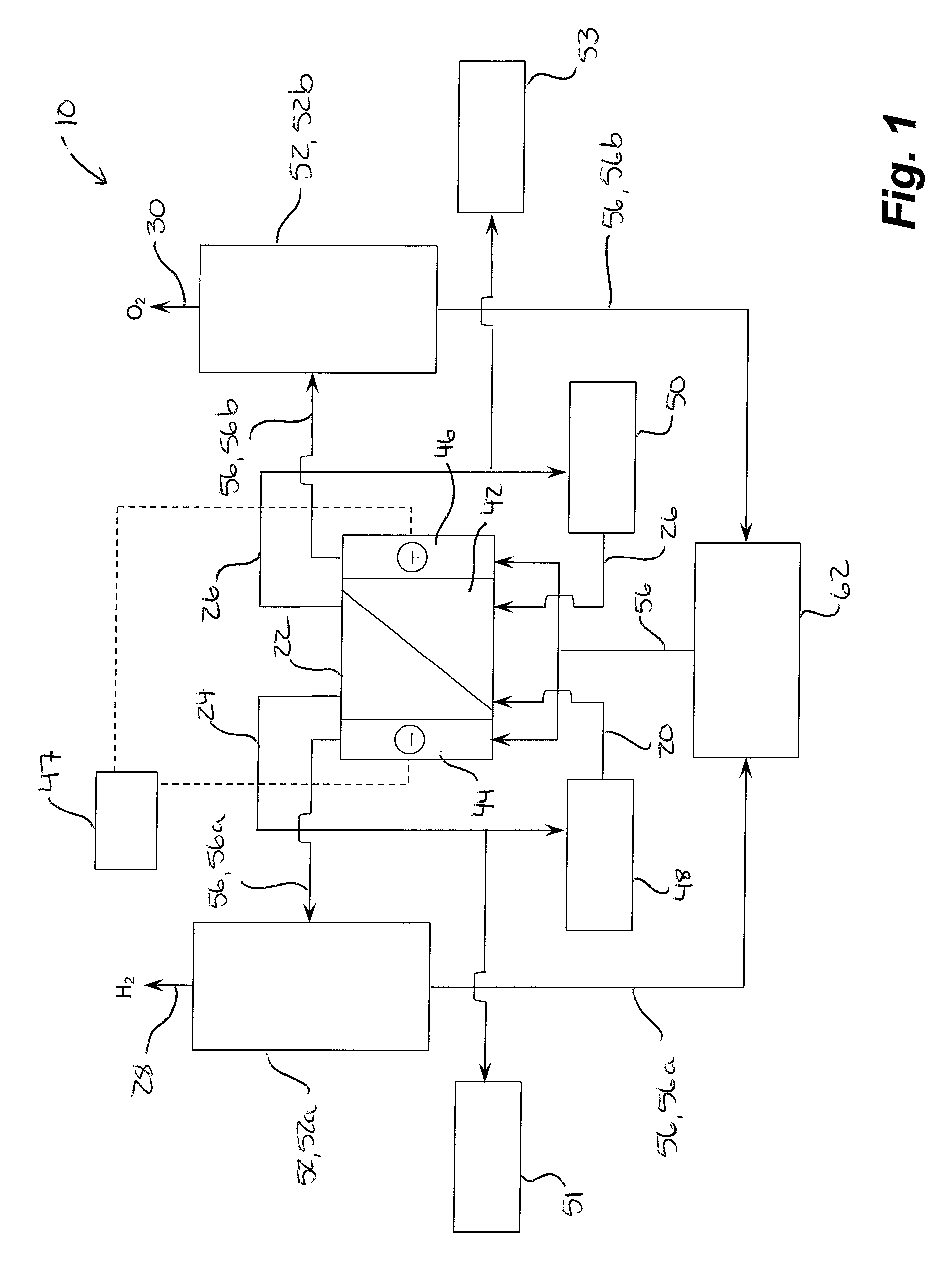

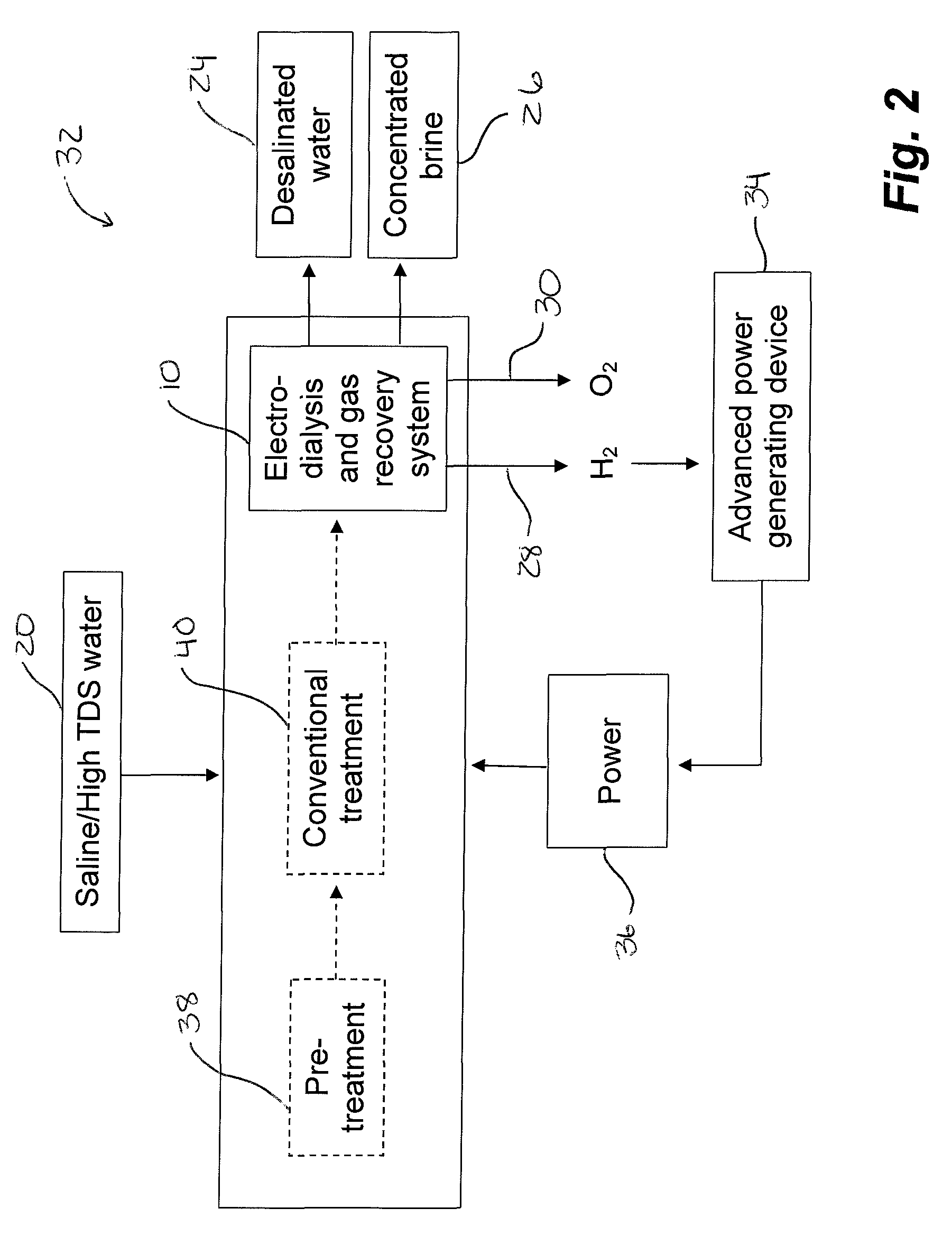

System for recovering gas produced during electrodialysis

ActiveUS20070084728A1Reduce energy consumptionRisk of explosion can be minimizedSludge treatmentGeneral water supply conservationUnit operationBiofuel

Disclosed is a system for recovering gas produced during electrodialysis of a saline solution, from gas entrained in an electrolyte solution circulating through anode and cathode compartments of an electrodialysis (ED) unit. In one embodiment, the system provides separate catholyte and anolyte towers within a closed, re-circulating loop between the cathode and anode compartments. Each tower comprises an inlet at which the entrained gas separates from the electrolyte solution and flows into the headspace. One can recover residual gases from the electrolyte solution in one more additional apparatus. Preferably, hydrogen gas is separated from the catholyte solution and, more preferably, further purified for use as a fuel source in alternative power generating devices, such as a fuel cell or bio-fuel generator, useful in the unit operations of a water treatment system.

Owner:VOLKER STEVIN CONTRACTING

A method for preparing high-purity deuterium gas by heavy water electrolysis

ActiveCN106342104BLess investmentQuick resultsElectrolysis componentsHydrogen isotopesNitrogen removalElectrolysis

The invention belongs to the technical field of special gas preparation, and relates to a method for preparing high-purity deuterium gas by electrolysis of heavy water. The method firstly heats and degasses heavy water with a deuterium oxide content of not less than 99.8%, and then electrolyzes the degassed heavy water to obtain deuterium gas and oxygen respectively after electrolysis. Evacuate the oxygen. Dry the deuterium gas to remove water. The dried deuterium gas is further deoxidized through a deoxidation catalyst. Deuterium deoxidation and nitrogen removal are performed on deuterium gas after deoxidation treatment. The deuterium gas after nitrogen removal is compressed to obtain high-pressure gas. The compressed deuterium gas is subjected to a pressure swing adsorption operation to further purify it. The resulting high-purity deuterium gas usually has a chemical purity of 99.999% and a deuterium isotopic purity of 99.9%.

Owner:PERIC SPECIAL GASES CO LTD

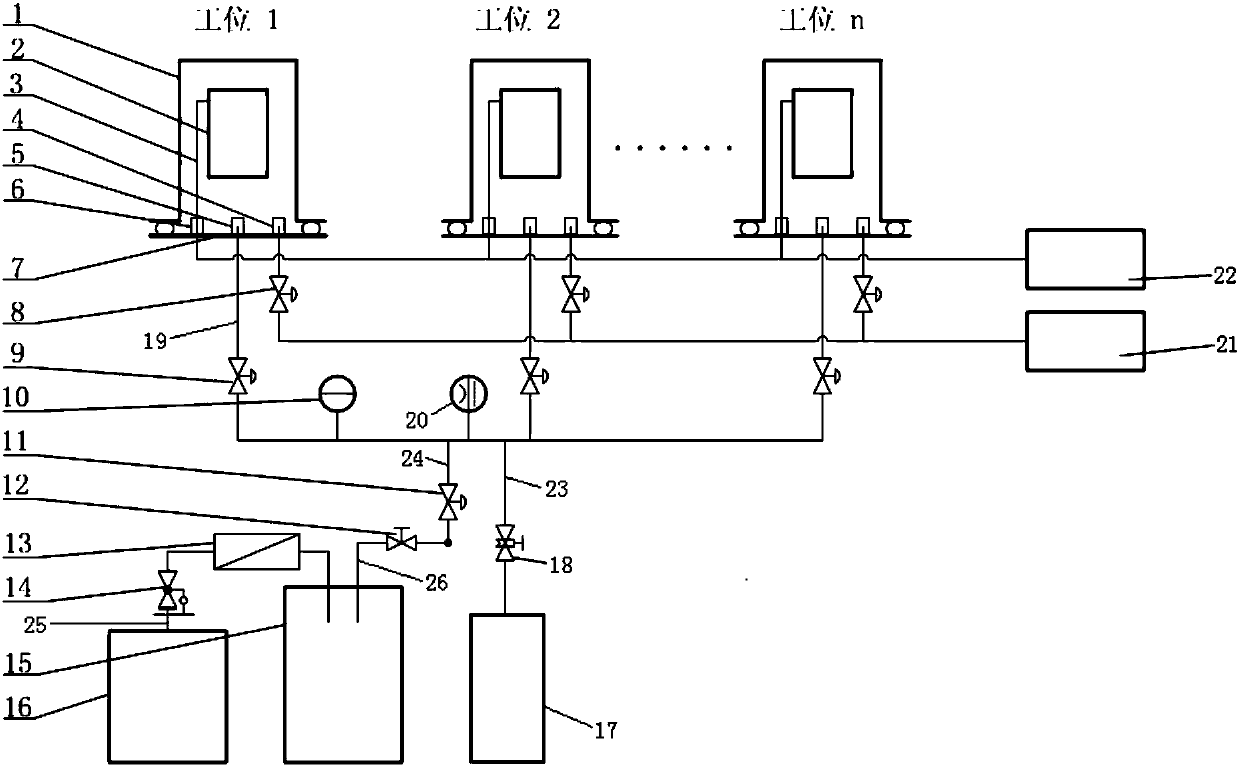

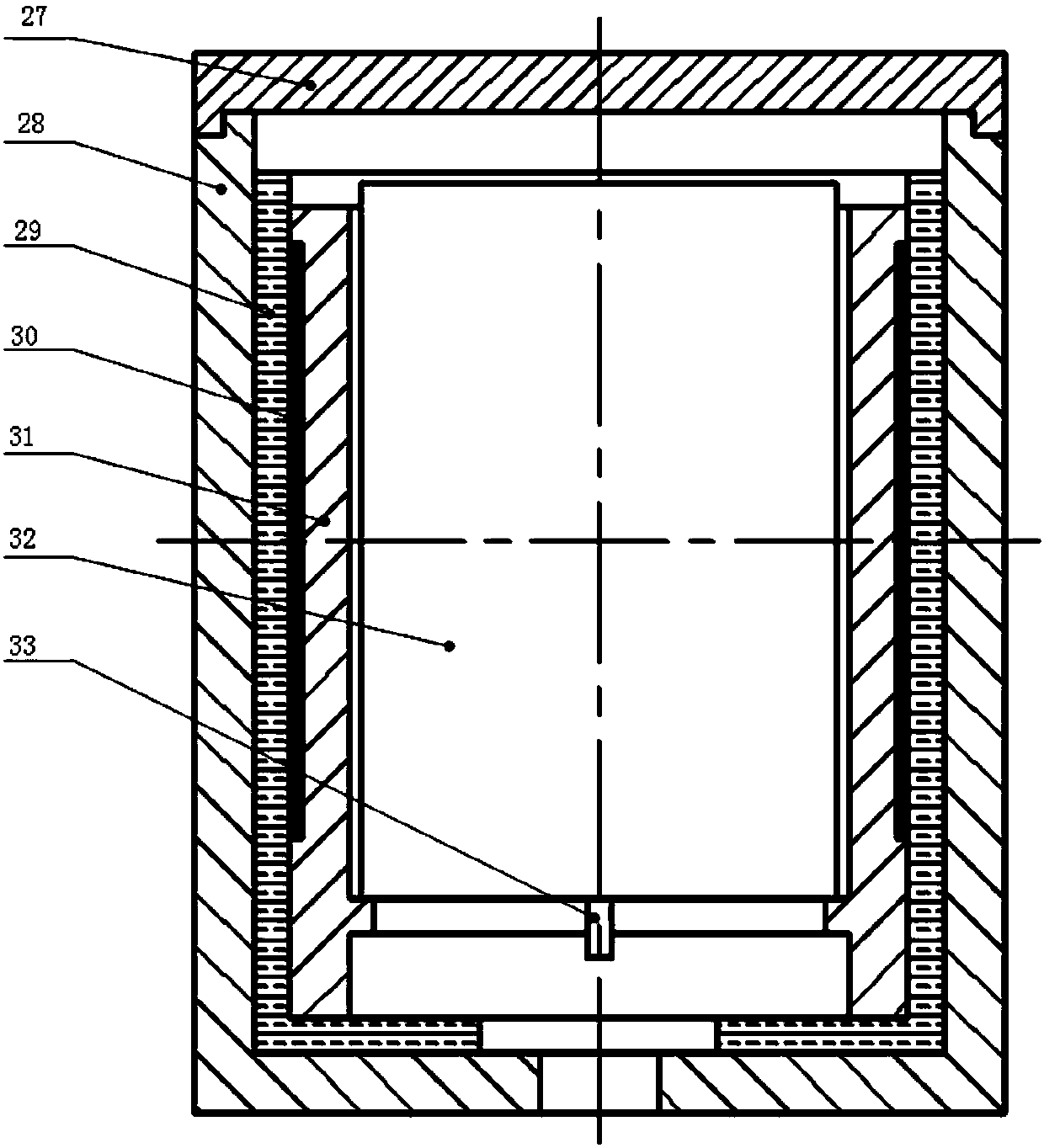

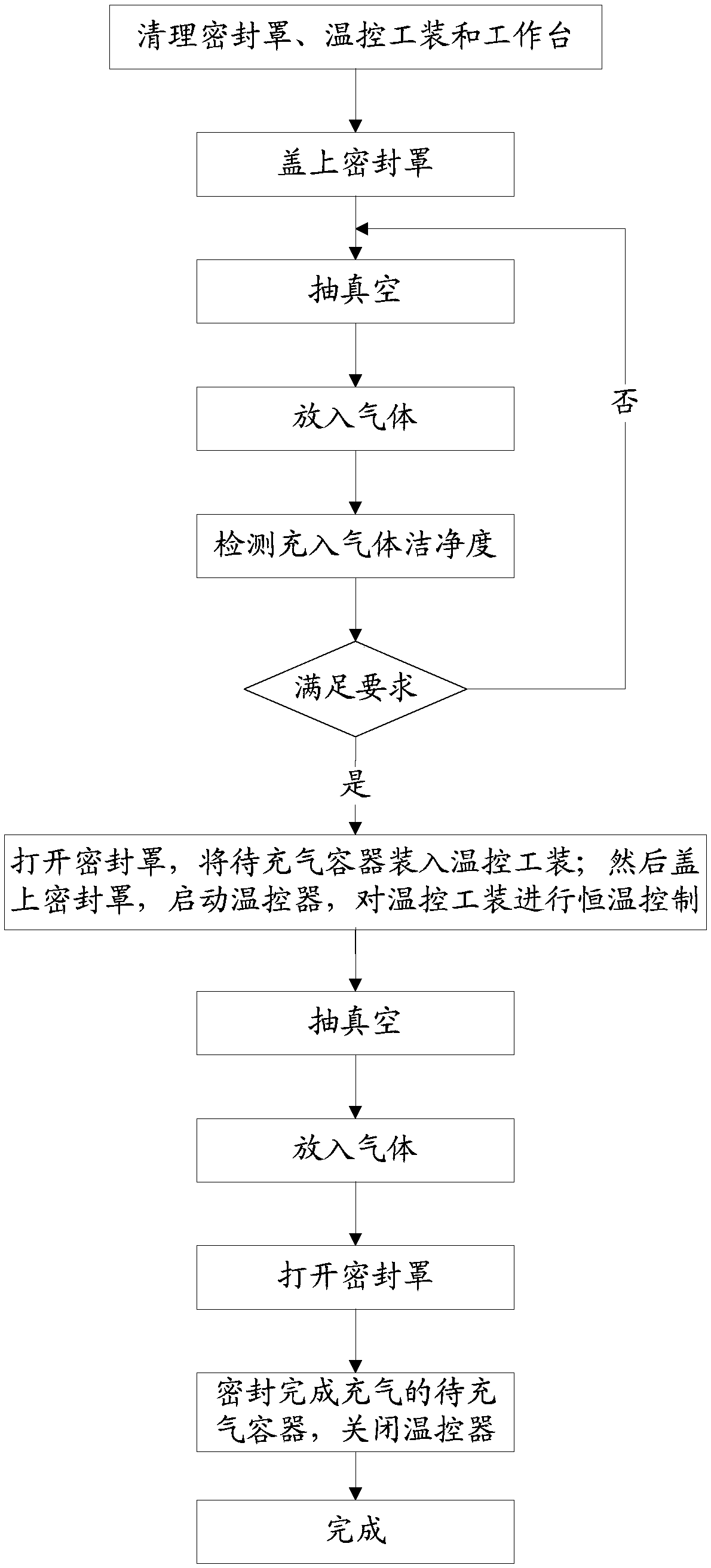

Vacuum inflating equipment and realizing method

ActiveCN107806565AImprove pumping efficiency and vacuumHigh gas purityFluid handledFluid handling accessoriesIonizationThin film gauge

The invention discloses vacuum inflating equipment and a realizing method. The vacuum inflating equipment comprises a sealing cover, a temperature-control tooling, a worktable, a temperature controller, a clean instrument, an inflating device and a molecular pump; an air pumping port, an air pumping and deflating port and a sealing socket are mounted on the worktable; the temperature-control tooling is mounted in a closed space formed by the sealing cover and the worktable; the air pumping and deflating port outward introduces an air pumping and deflating total pipeline which communicates withthe molecular pump and the inflating device; the air pumping and deflating total pipeline is further provided with a thin film gauge and an ionization gauge; the air pumping port outward introduces acleanliness measuring pipeline which is further connected with the clean instrument; and the temperature controller is connected with a temperature control circuit of the temperature-control toolingthrough the sealing socket. According to the vacuum inflating equipment, guarantee of purity, cleanliness, temperature and pressure of gas inflated into a sealing cavity of a precision instrument is achieved, the production quality and the efficiency of products are improved, and the service lives of the products are prolonged.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Method for fast preparing dimethyl ether steam reforming hydrogen production catalyst by virtue of alternate microwave

ActiveCN103551149AShort preparation timeReduce energy consumptionHydrogenMetal/metal-oxides/metal-hydroxide catalystsMetal nitrateSteam reforming

The invention discloses a method for fast preparing dimethyl ether steam reforming hydrogen production catalyst by virtue of alternate microwave. The method comprises the following steps: (1) preparing a mixed water solution of Cu(NO3)2 and M metal nitrate, wherein M metal is selected from iron, cobalt, nickel, manganese, lanthanum, chromium and zinc, the mol ratio of M:Cu in the mixed water solution is not less than 0 and not more than 1, and the total concentration range of Cu+M in the solution is 0.025mol / L-10.2mol / L; adding a carrier into the mixed water solution, and uniformly dispersing; (2) placing the mixed water solution in a microwave oven to alternatively heat; (3) drying the product obtained in the step (2), roasting to obtain a target catalyst. The method for preparing the dimethyl ether steam reforming hydrogen production catalyst is short in preparation time, low in energy consumption and easily controllable in process parameters; the prepared catalyst is high in reaction activity and good in selectivity; the prepared product is high in purity and good in quality; the catalyst can be used for in situ preparation of hydrogen.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

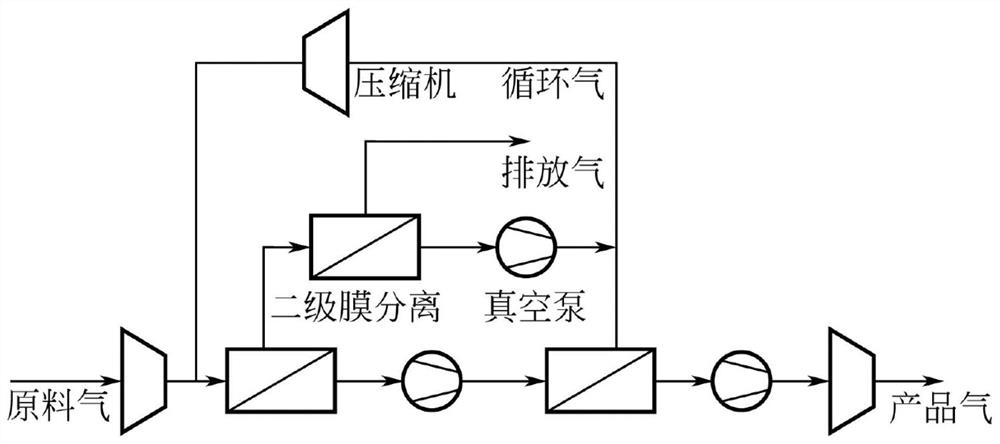

Method for purifying synthesis gas from methanol cracking

The invention provides a method for purifying synthesis gas from methanol cracking consists of, subjecting methanol cleavage synthesis raw material gas to 200-250 deg. C, 2.5-10 MPa, 2000-10000h#+[-1], removing H2S using ZnO as catalyst, then removing water and methanol through adsorbing with 5A molecular screen and mixture having a blue glue ration of 0-4:1.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

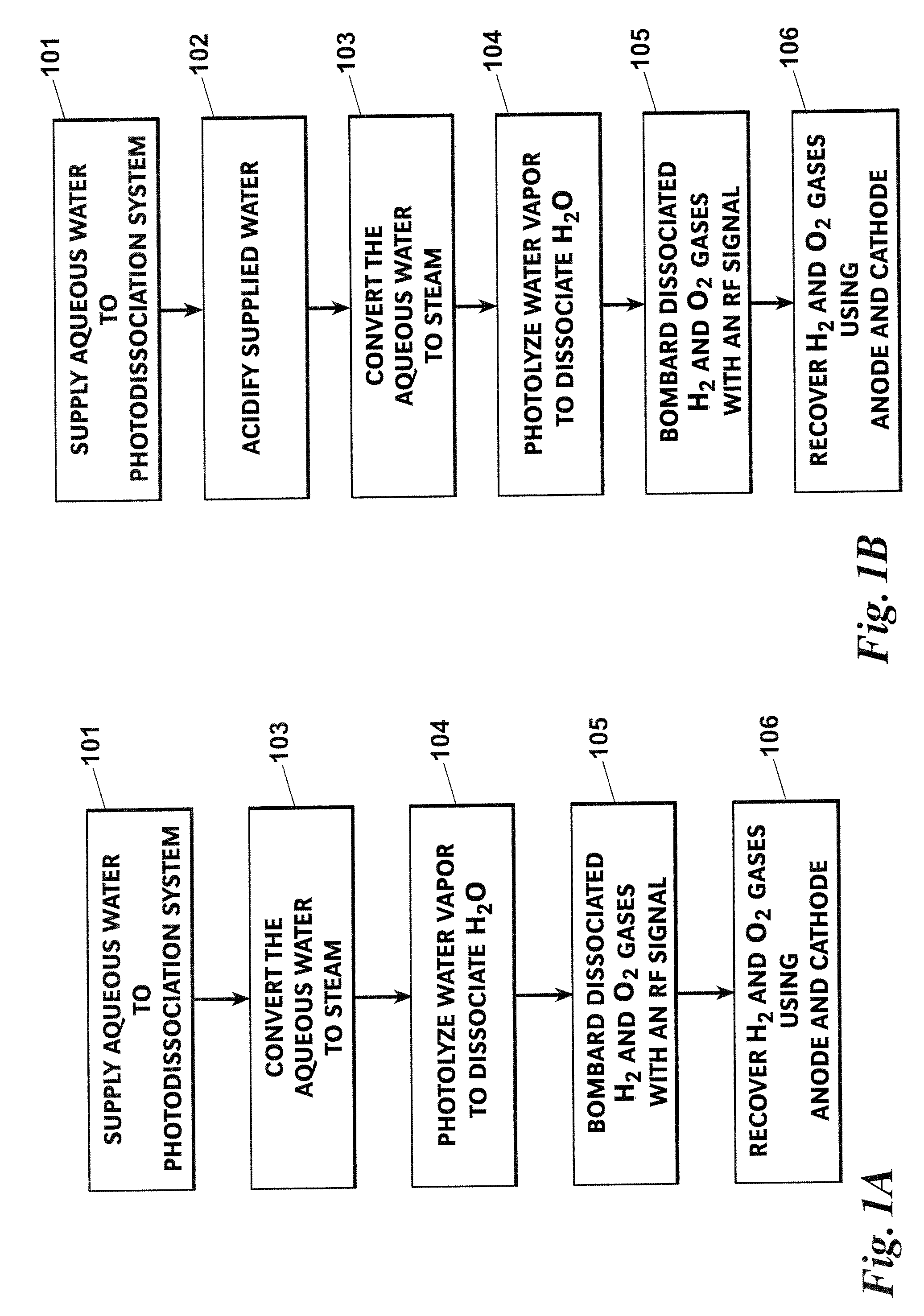

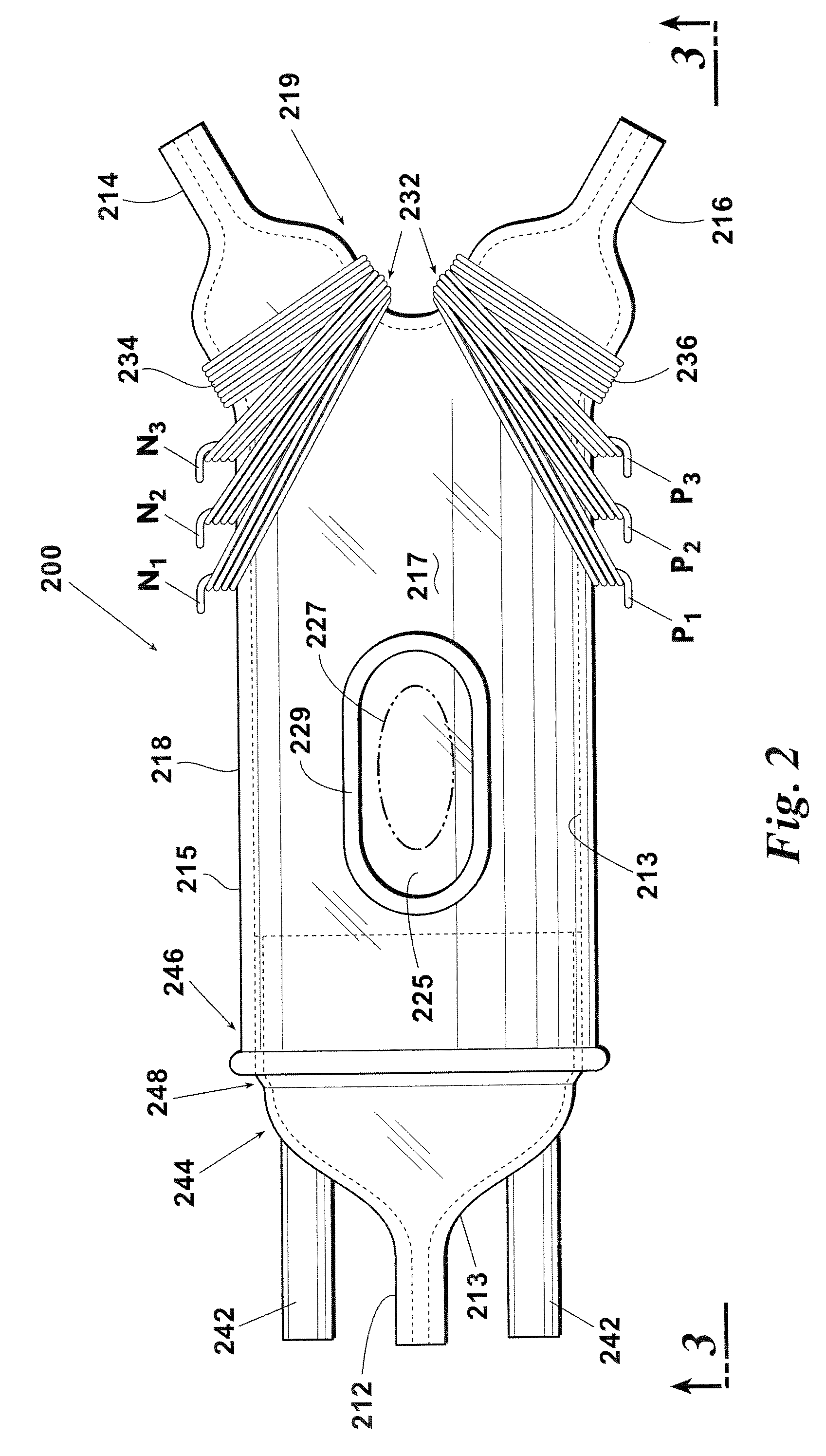

Reaction vessel including fielding apparatus

InactiveUS20070183942A1Easy to separateLow costHydrogenOxygen/ozone/oxide/hydroxideElectrical conductorWater vapor

The present disclosure provides a system and method to dissociate water molecules into H2 and O2 and includes a reaction vessel having at least one radiolysis apparatus, at least one photolysis apparatus, at least one catalyst apparatus, and at least one electromagnetic fielding apparatus. The reaction vessel has a body, a first end and a second end defining an interior reaction chamber, an inlet for receiving water vapor and at least two outlets. A plurality of windings of a contiguous electrical conductor are wound in a first direction adjacent the first outlet and plurality of windings of a contiguous electrical conductor wound in a second direction adjacent the second outlet such that the first direction is opposite the second direction. When a current is applied to the conductor, an electromagnetic field is generated to migrate the disassociated H2 and O2 molecules toward the respective first outlet or second outlet.

Owner:COASTAL HYDROGEN ENERGY

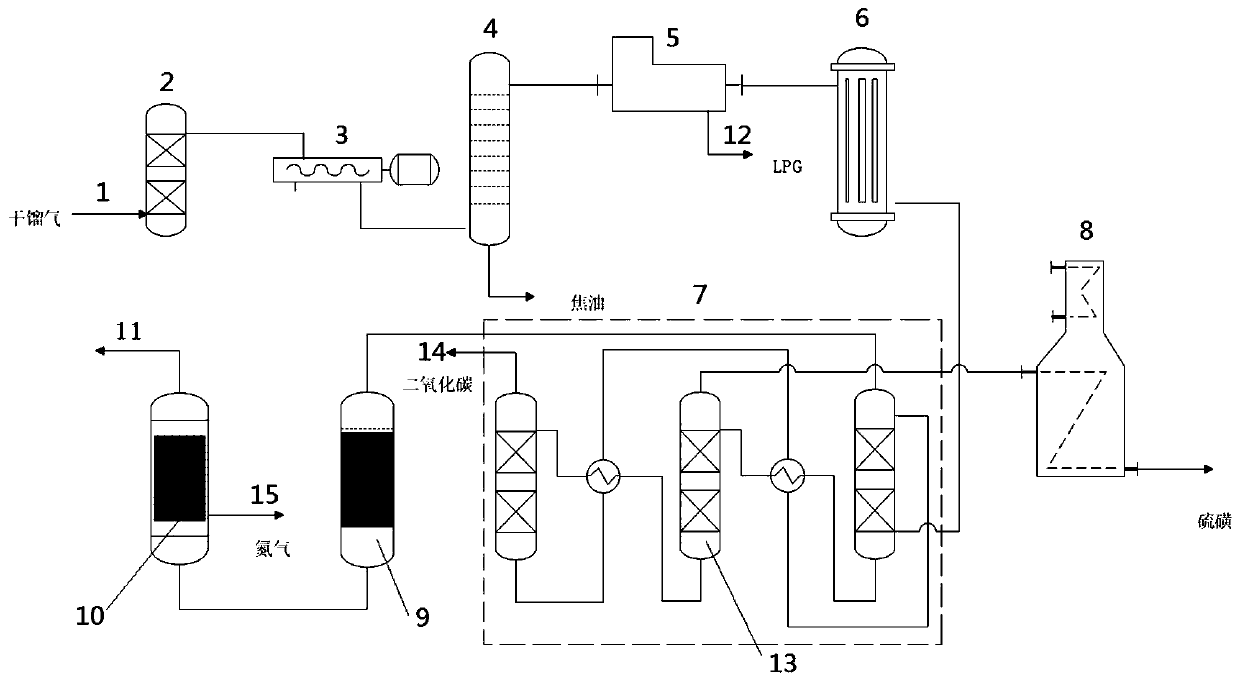

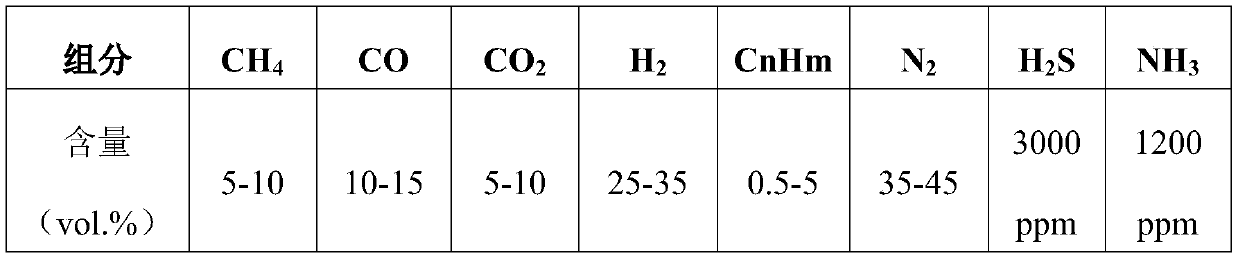

System and method for preparing LNG from medium and low temperature dry distillation raw coke oven gas through sulfur-resistant uniform-temperature methanation

PendingCN110655939AReduce carbon loadImprove thermal stabilityCombustible gas chemical modificationChemical industryMethanationProcess engineering

The invention discloses a system and method for preparing LNG from medium and low temperature dry distillation raw coke oven gas through sulfur-resistant uniform-temperature methanation, and belongs to the technical field of clean and efficient utilization of coal. Tar recovery is carried out after dedusting, deamination and purification on the dry distillation raw coke oven gas to obtain a high-value by-product; and advanced hydrocarbons such as propane, butane and the like are pressurized, liquefied and separated to directly prepare LPG. H2S gas desorbed by a desulfurization and decarburization device is high in purity, and sulfur can be recovered by adopting a Claus sulfur recovery process. The content of an LNG component CH4 obtained after cryogenic liquefaction separation is high andis greater than 95%, so that the requirements of a first-grade natural gas product are met. The system is easy and convenient to operate, clean and efficient utilization of low-rank coal is achieved through the low-temperature dry distillation poly-production technology of coal, liquefied natural gas with the high calorific value is produced, byproducts such as tar, LPG, sulfur and carbon dioxideare by-produced, energy is saved, and economic benefits are high.

Owner:CHINA HUANENG GRP CO LTD +1

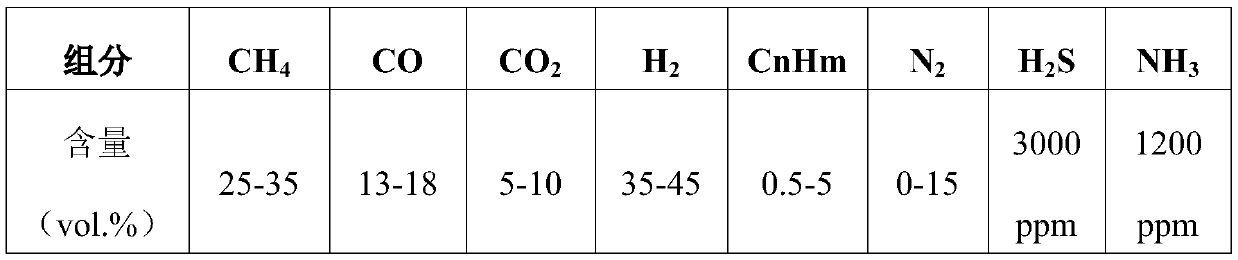

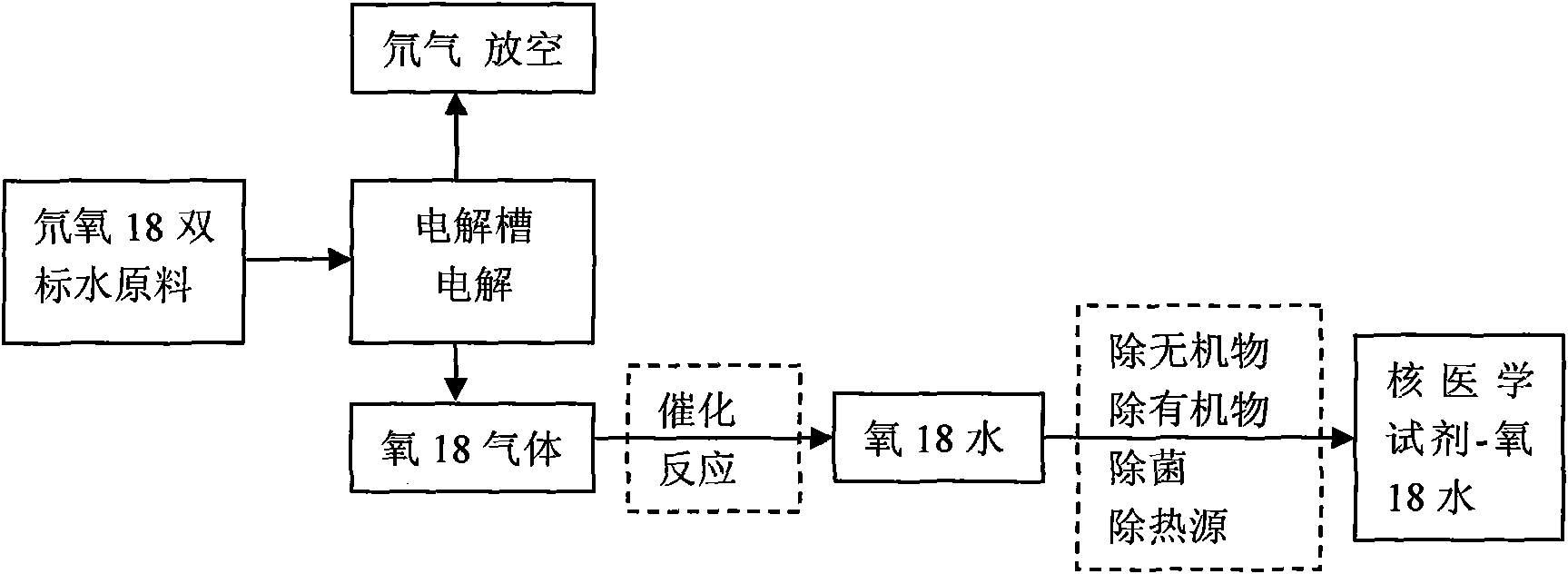

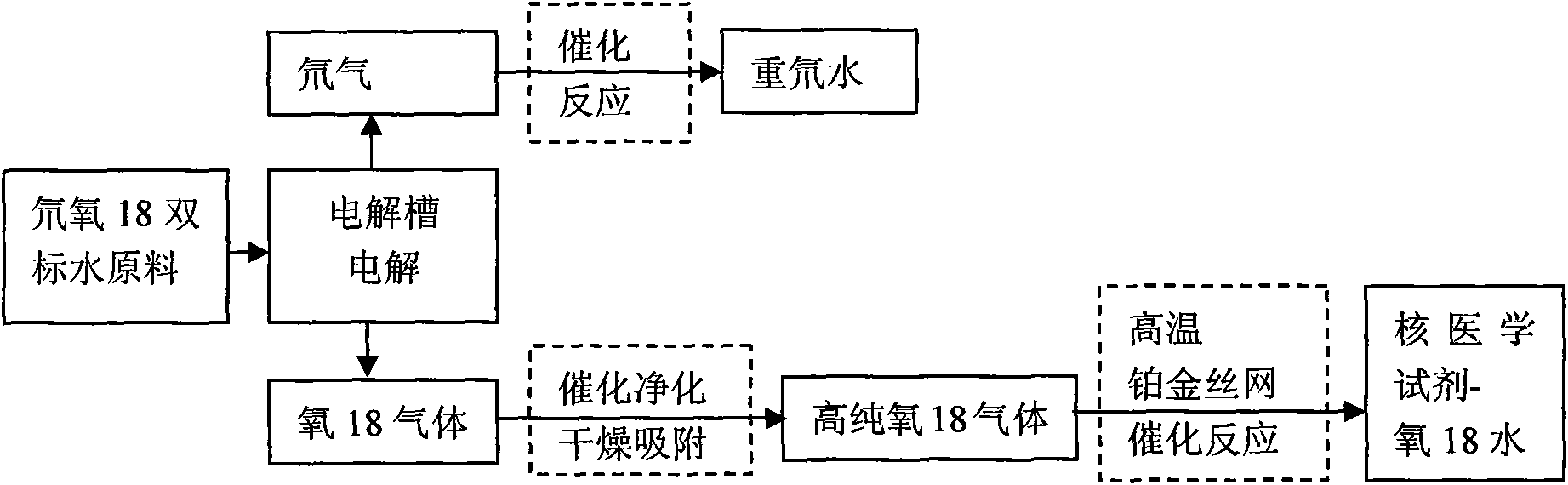

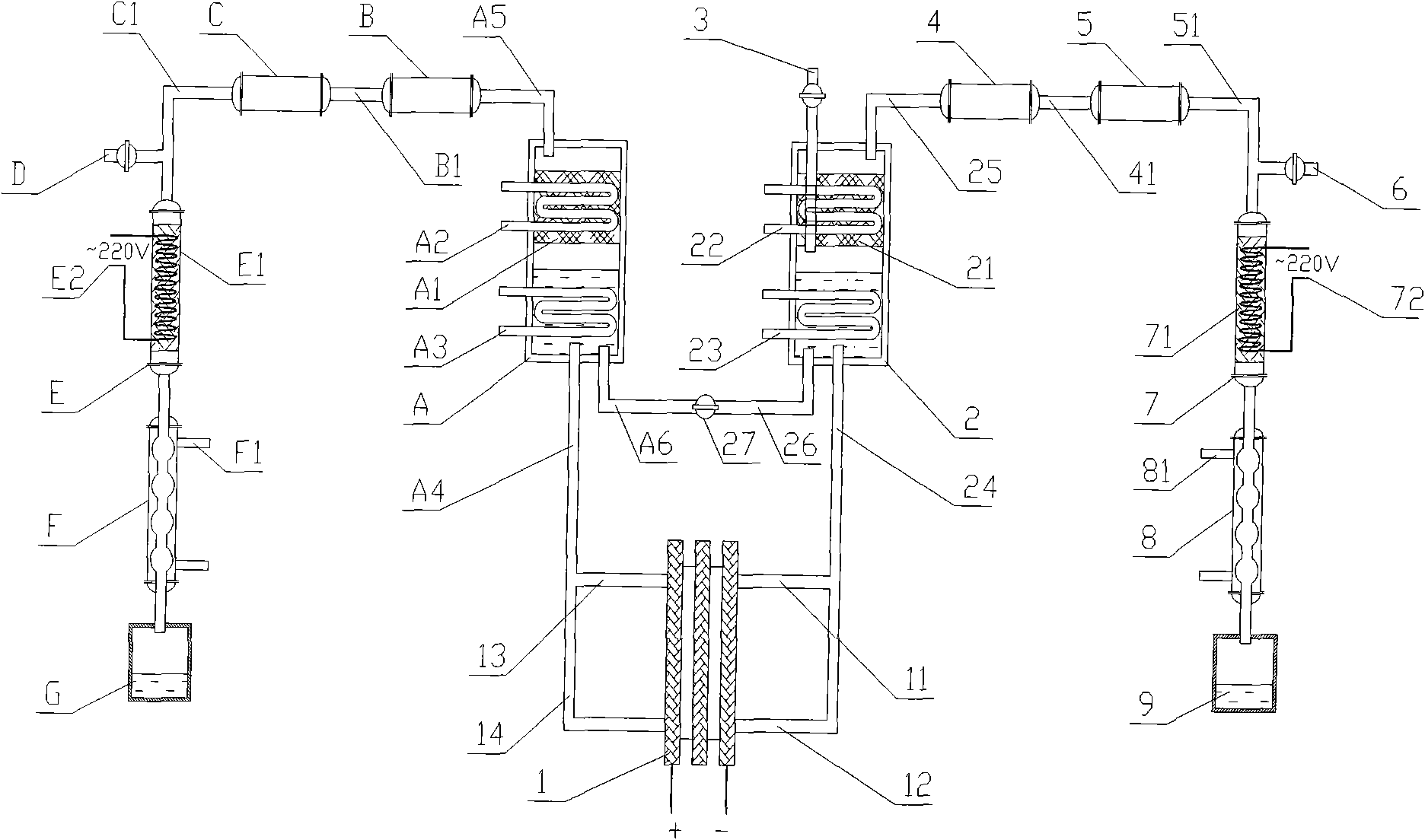

Method for preparing nuclear medicine diagnostic reagent oxygen-18 water and device thereof

ActiveCN101575086AImprove gas purityReduce running lossElectrolysis componentsWaterProduct gasRadiochemistry

The invention relates to a method for preparing nuclear medicine diagnostic reagent oxygen-18 water and a device thereof. The method comprises the steps of: utilizing an oxygen isotope water industrial rectifying separation device to obtain deuterium oxygen 18 doubly-labelled water as material; carrying out steps of electrolysis, purification and filtering to obtain high-purity deuterium and high-purity oxygen-18 gas; adopting a high-temperature platinum mesh to carry out catalyzing so as to lead the high-purity deuterium to react with the high-purity oxygen-18 gas at high temperature to generate deuterium water; and adopting the high-temperature platinum mesh to carry out catalyzing to lead the high-purity oxygen-18 gas to directly react with high-purity hydrogen to obtain the highly-purified oxygen-18 water adopted as the diagnostic reagent of nuclear medicine. Compared with the prior art, the invention which not only can make full use of the deuterium oxygen 18 doubly-labelled water to prepare the nuclear medicine diagnostic reagent oxygen-18 water and utilize by-product deuterium to prepare deuterium water but also can reduce process steps, enhance quality and yielding of oxygen-18 water of nuclear medicine and reduce product cost really has simple process and better effect.

Owner:SHANGHAI RES INST OF CHEM IND +1

Method for preparing sodium silicate by using sodium nitrate

InactiveCN110627077ALow reaction temperatureSave energyAlkali metal silicatesAlkali metal nitrate preparationNitrateReaction temperature

The invention provides a method for preparing sodium silicate. The method comprises the following steps: mixing sodium nitrate with a silicon raw material, carrying out a reaction under heating conditions, treating a solid phase after the reaction is completed to obtain a sodium silicate product, and collecting a gas generated by the reaction and performing treating to obtain nitric acid or nitrate by-products. According to the method, the sodium silicate products with different moduli can be selectively prepared by adjusting a ratio of sodium nitrate to quartz sand or other silicon-containingraw materials, and dilute nitric acid or nitrate by-products are produced. The method can also be applied to produce water glass or white carbon black. The method has the characteristics of low reaction temperature, short reaction time, and low energy consumption, the technological process is simple, the purity of the product is high, all the generated gas can be recycled, and thereby the methodhas a relatively good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Graded chlorine dioxide generator

The invention belongs to the field of environmental protection equipment. Specifically, it is an environmentally friendly chlorine dioxide generator that adopts special preparation technology, special structure, low cost, high conversion rate of raw materials and high purity of product. It is characterized in that it is equipped with a normal temperature reaction kettle and a heating reaction kettle. Concentration and temperature gradients are formed between each reaction kettle. The reaction is smoother and safer, and the raw material conversion rate is greatly improved. The sodium chlorate is metered and fed in solid form, which is very convenient. It greatly reduces the use of sulfuric acid, thereby reducing the amount of acidic waste liquid produced, and is more environmentally friendly; a pressure detector and a safety valve are installed on the discharge pipe, which are used in conjunction with the feed automatic controller to monitor and control the system pressure to ensure that The device is safe and reliable; a pressure balance tube is set up on the heated reaction kettle. When the liquid column pressure in the balance tube exceeds the system vacuum, the reaction residual liquid will automatically overflow and drain, which can achieve uninterrupted continuous operation and is conducive to industrial continuous production. .

Owner:NJTECH ENVIRONMENT TECH CO LTD

Movable water electrolysis hydrogen production hydrogenation device

The invention provides a movable water electrolysis hydrogen production hydrogenation device which comprises a rack, wherein a wheel set is arranged at the bottom of the rack; a proton exchange membrane electrolytic cell; a circulating pump which is connected with the proton exchange membrane electrolytic cell; a water-gas separation assembly which comprises a hydrogen-water separator and an oxygen-water separator, wherein the hydrogen-water separator is connected with the proton exchange membrane electrolytic cell, the oxygen-water separator is connected with the proton exchange membrane electrolytic cell and the circulating pump, and the oxygen-water separator is provided with a water supplementing port used for being connected with a water supplementing pump; and a control assembly which comprises a controller and two back pressure valves, wherein the two back pressure valves are connected to the hydrogen outlet of the hydrogen-water separator and the oxygen outlet of the oxygen-water separator respectively. According to the mobile water electrolysis hydrogen production hydrogenation device, the proton exchange membrane electrolytic cell is adopted, the reactant of the proton exchange membrane electrolytic cell is pure water, the proton exchange membrane electrolytic cell has a large working current density range of 0A / cm < 2 >-3A / cm < 2 > and a small volume so that the problems that the alkaline water electrolysis hydrogen production device has a small working current density range and a large volume and alkali liquor needs to be added are solved.

Owner:深圳市绿航星际太空科技研究院 +1

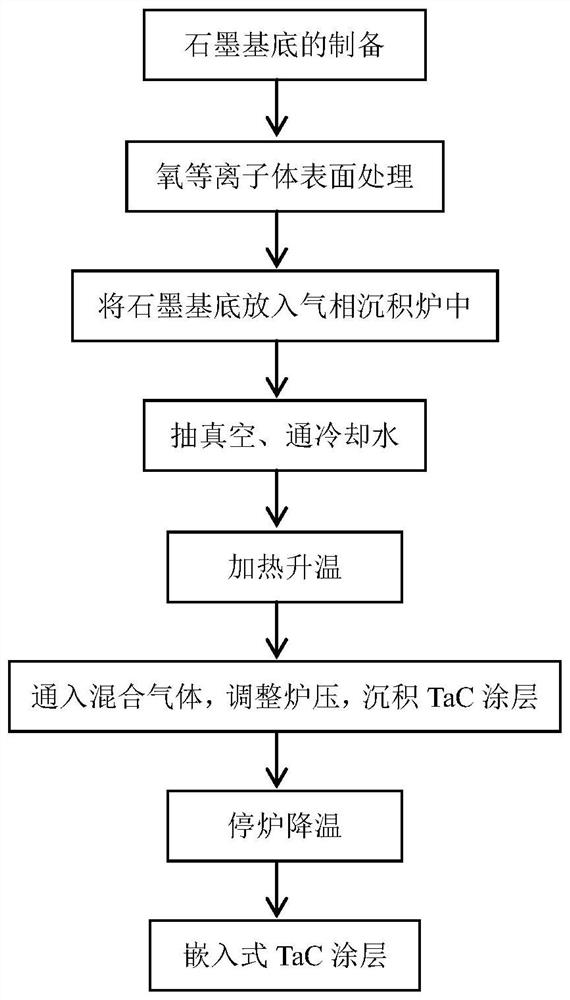

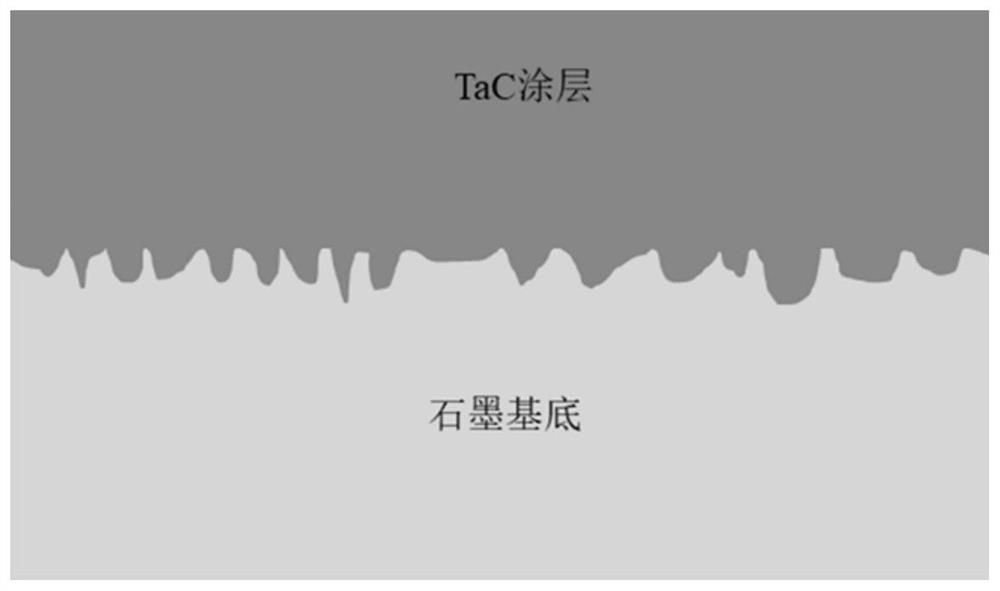

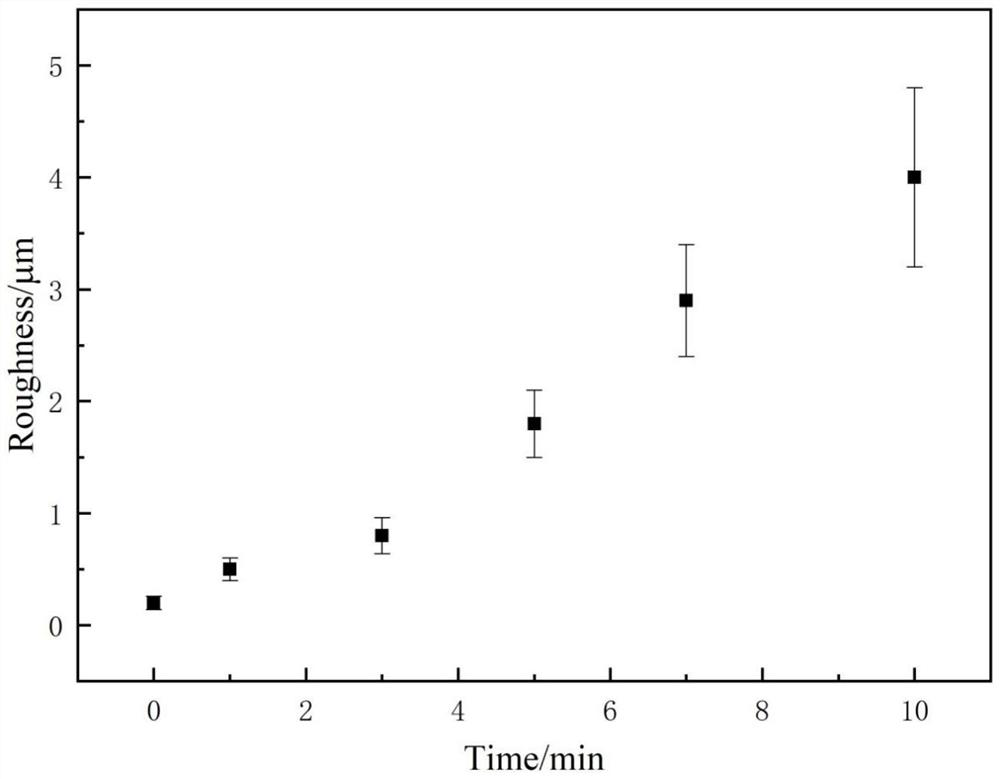

Surface treatment method of graphite substrate and preparation method of TaC coating

The invention discloses a surface treatment method of a graphite substrate and a preparation method of a TaC coating, and the surface treatment method comprises the following steps: cleaning and drying the graphite substrate, putting the graphite substrate into a reaction chamber of plasma modification equipment, closing an air inlet valve, vacuumizing the reaction chamber, and then introducing oxygen or argon to fill the reaction chamber; adjusting the air inlet valve to stabilize the vacuum degree of the reaction chamber at 10-100Pa, starting to discharge a radio frequency power supply, andperforming oxygen plasma or argon plasma to bombard the surface of the graphite substrate so as to increase the roughness of the surface of the graphite substrate and improve the activity of the surface of the graphite substrate; and performing TaC coating deposition after treatment by the method. The formed TaC coating can be tightly combined with a graphite substrate and is not easy to fall off,and the thermal shock resistance is greatly improved; and the process is simple, efficient, low in energy consumption, low in production cost and short in production period.

Owner:湖南中科顶立技术创新研究院有限公司 +1

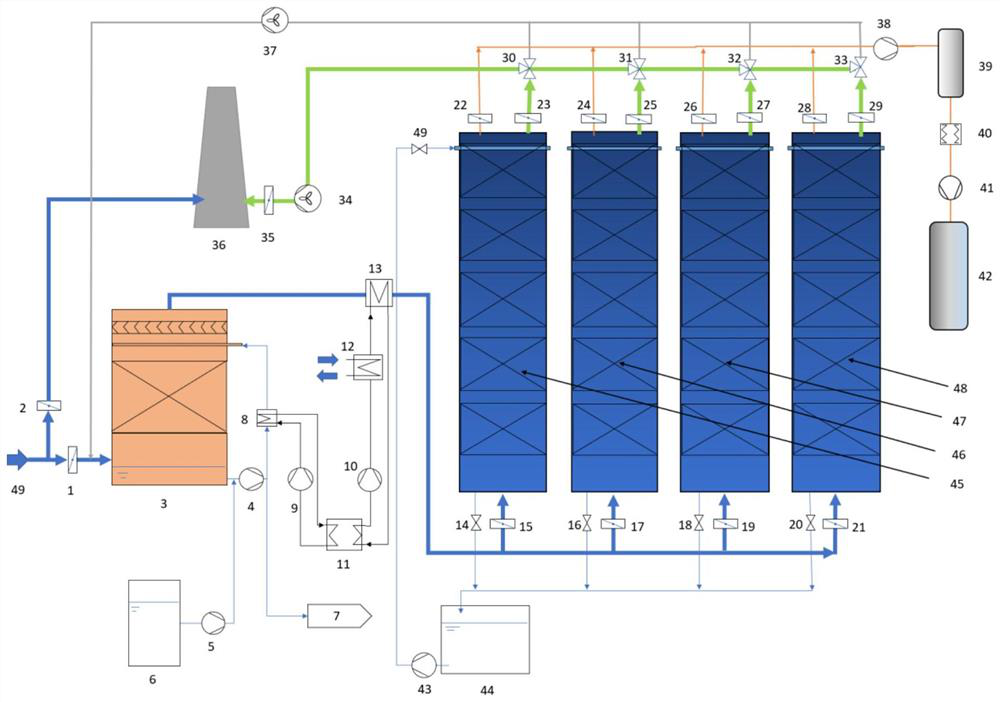

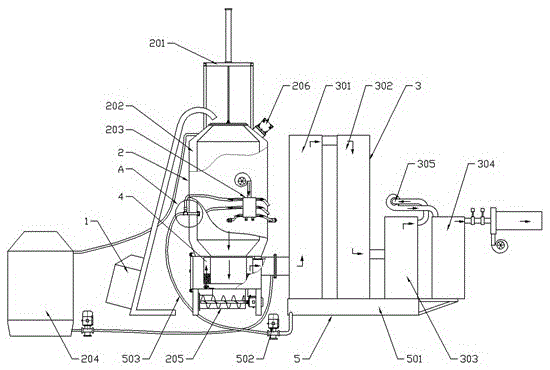

Biomass gasification unit

InactiveCN102703122AAvoid environmental pollutionImprove gas purityChemical industryCombustible gas productionTarProcess engineering

The invention discloses a biomass gasification unit which comprises a hay cutter (1), a closed conveyor (2), a gasification furnace (3), a purifier (4), an oil-gas separator (5), a Roots fan (6), a pressure adjusting bypass (7), a cyclone tar collecting device (8), a backflow pipe (9), a safe water seal (10), a wet gas holder (11), an emptying pipe (12), a flame arrester (13) and a user air supply pipe (14). The biomass gasification unit has the beneficial effects of running under a complete closed state during the processes from the preliminary processing of biomass to be used by the user, so that the environment pollution is avoided, due to layer-upon-layer purification, the gas purity is higher, the tar content is reduced to minimum, and the burning heat value approaches to a straw theoretic calorific value; and the biomass gasification unit is simple and convenient in operation, safe, environment-friendly, economic, energy-conservation and high-efficiency, and is suitable for concentrated air supply for multiple users.

Owner:山东长泰机械制造有限公司

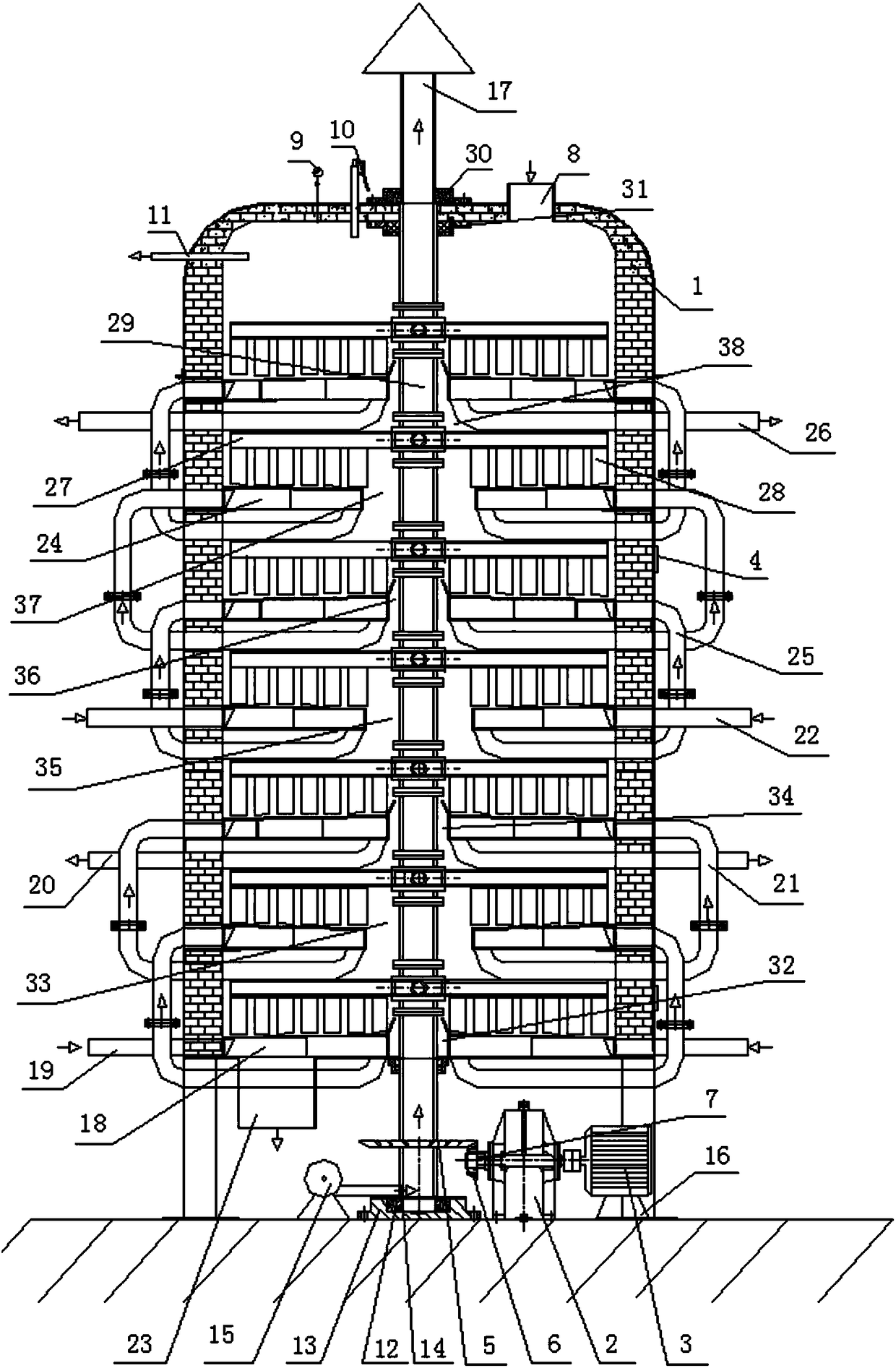

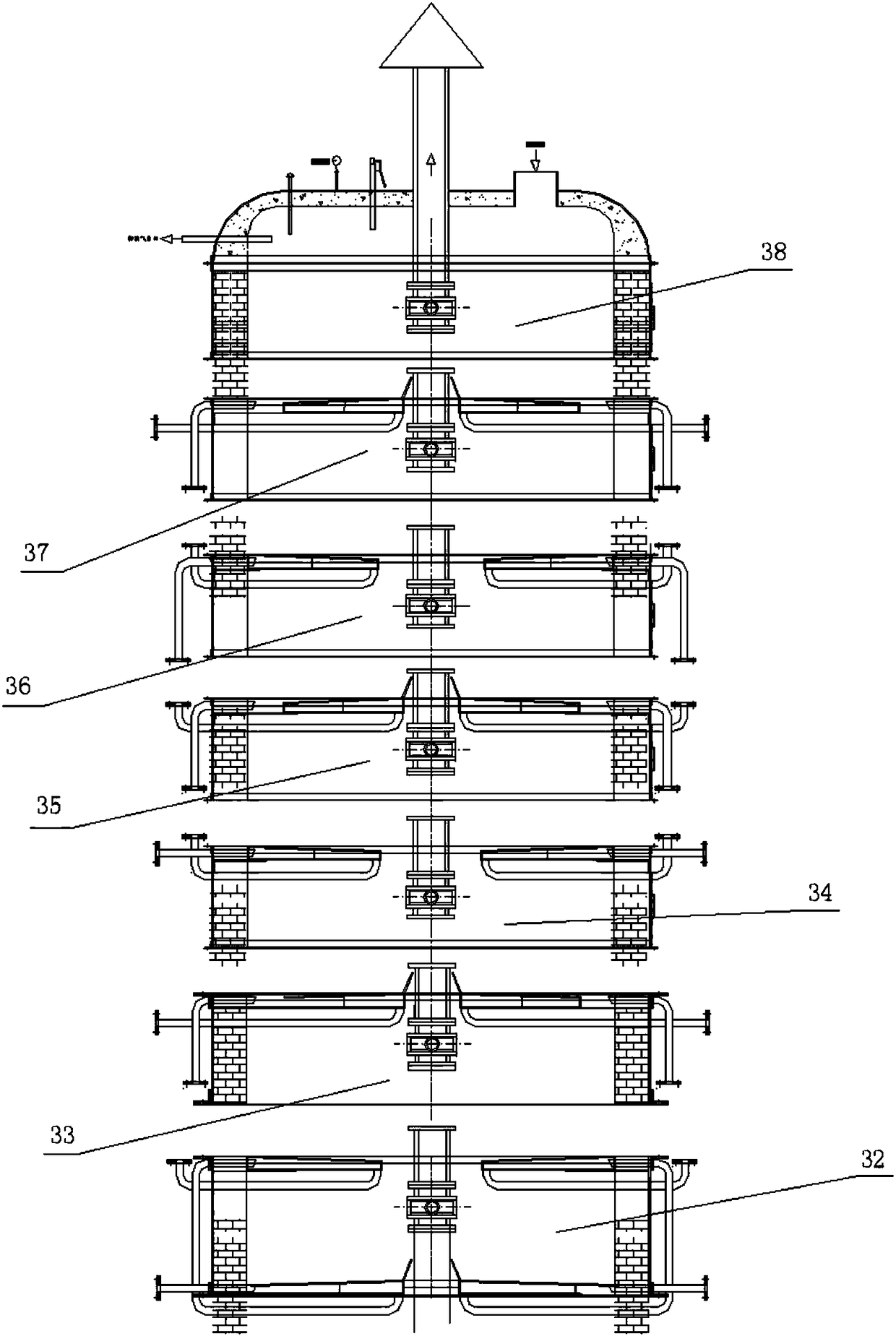

Multi-effect modular biomass gasification furnace and combustion method

PendingCN108624361AShorten the installation periodImprove efficiencyBiofuelsGasification processes detailsMulti effectEngineering

The invention provides a multi-effect modular biomass gasification furnace and a combustion method. The multi-effect modular biomass gasification furnace comprises a furnace body, wherein the interiorof the furnace body is sequentially equipped with first-stage to fifth-stage cooling chambers and first-stage to twelfth-stage carbonizing chambers, wherein a hollow combined central shaft is arranged in the first-stage to fifth-stage cooling chambers and the first-stage to twelfth-stage carbonizing chambers; sealing devices are arranged between the hollow combined central shaft and the furnace body; the hollow combined central shaft is connected with a gear set; the gear set is connected with a speed reducer; the speed reducer is connected with a motor; and the furnace body is connected witha furnace door. The combustion method provided by the invention is applied to the multi-effect modular biomass gasification furnace.

Owner:李佳纯

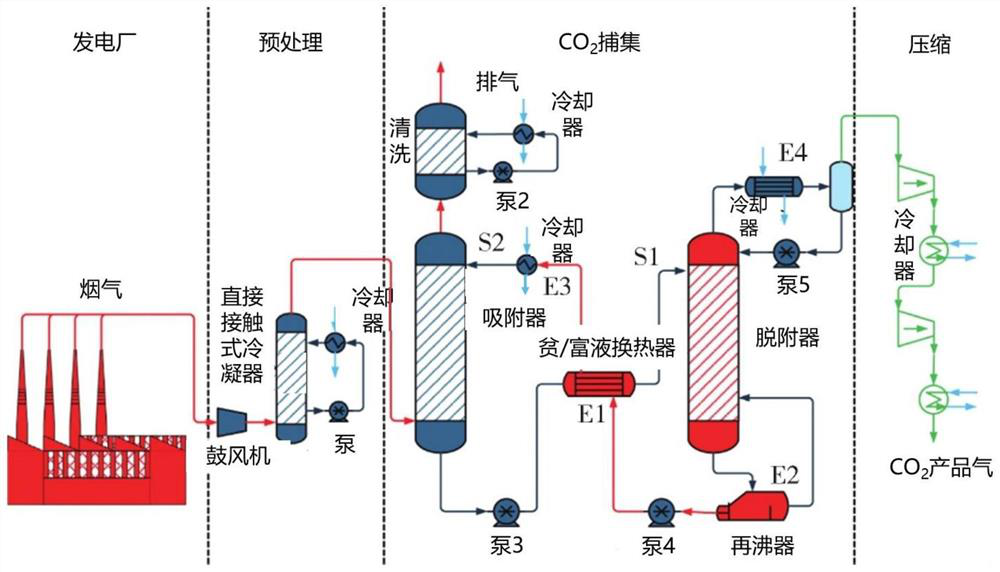

Method for decarburizing from concentrated carbon dioxide emission source based on wet-process regenerated carbon dioxide capture material

PendingCN114558414ADecarbonization achievedEasy to prepareProductsGas treatmentFlue gasProcess engineering

A method for decarburizing from a centralized carbon dioxide emission source based on a wet-process regenerated carbon dioxide capture material comprises the following steps: condensing and heating flue gas from the centralized carbon dioxide emission source, and respectively introducing the flue gas into a plurality of groups of carbon capture units connected in parallel to dry the wet-process regenerated carbon dioxide capture material in the carbon capture units; carrying out CO2 adsorption by adopting the dried wet-process regenerated CO2 trapping material, and then carrying out CO2 desorption on the wet-process regenerated CO2 trapping material subjected to CO2 adsorption in a water spraying manner; pumping the obtained CO2 into a buffer device by adopting a vacuum pump, and then sequentially dehumidifying and compressing to obtain CO2 gas for storage; and repeating the steps to continuously produce gas or intermittently produce gas through a plurality of groups of carbon capture units which are connected in parallel and are filled with wet-process regenerated CO2 capture materials, so as to realize decarburization from a centralized carbon dioxide emission source. According to the method, specific steps, conditions and parameters are adopted, overall good interaction is achieved, the material, equipment and operation cost can be reduced, the product gas purity is improved, and the method has wide application prospects.

Owner:霖和气候科技(北京)有限公司

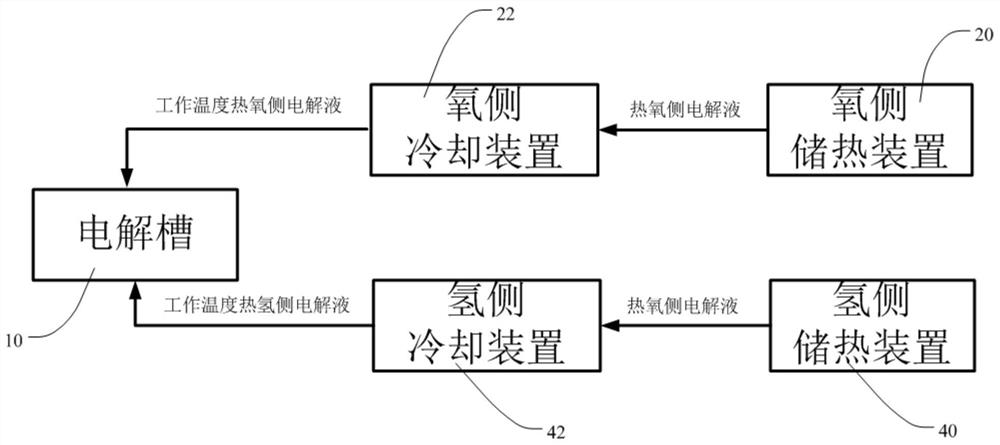

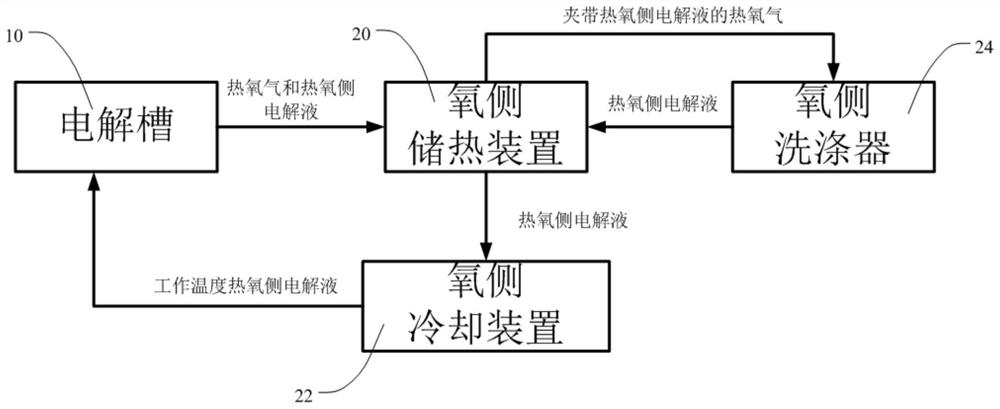

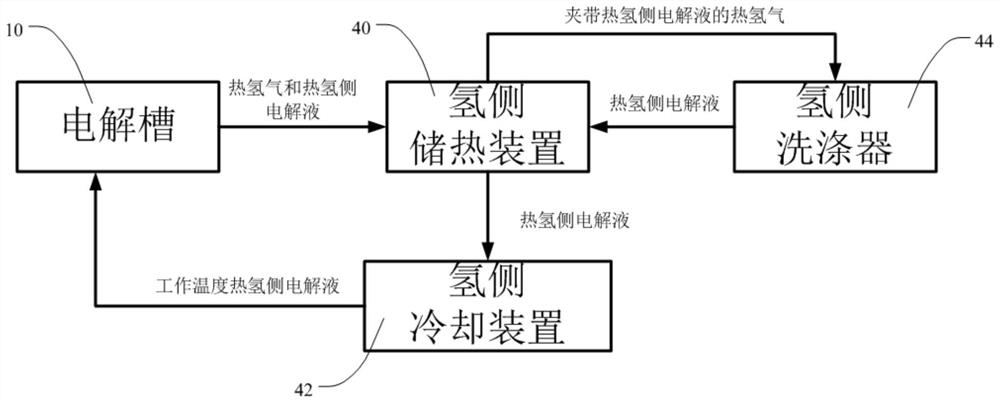

Hydrogen production method and hydrogen production system

The invention discloses a hydrogen production method and a hydrogen production system.The hydrogen production method comprises a hydrogen production electrolyte circulating method, and the hydrogen production electrolyte circulating method comprises the following steps that a gas-liquid mixture discharged from an electrolytic bath is subjected to heat preservation treatment, and layered hot gas and hot electrolyte are obtained after the gas-liquid mixture stands; carrying out at least one time of gas-liquid separation on the hot gas to obtain to-be-purified gas containing no thermal electrolyte, recycling the separated thermal electrolyte, and carrying out heat preservation treatment again; carrying out purification treatment on the gas to be purified; and the thermal electrolyte subjected to heat preservation treatment is circularly conveyed to the electrolytic bath to be subjected to an electrolytic reaction. According to the technical scheme, the hydrogen production efficiency can be improved.

Owner:阳光氢能科技有限公司

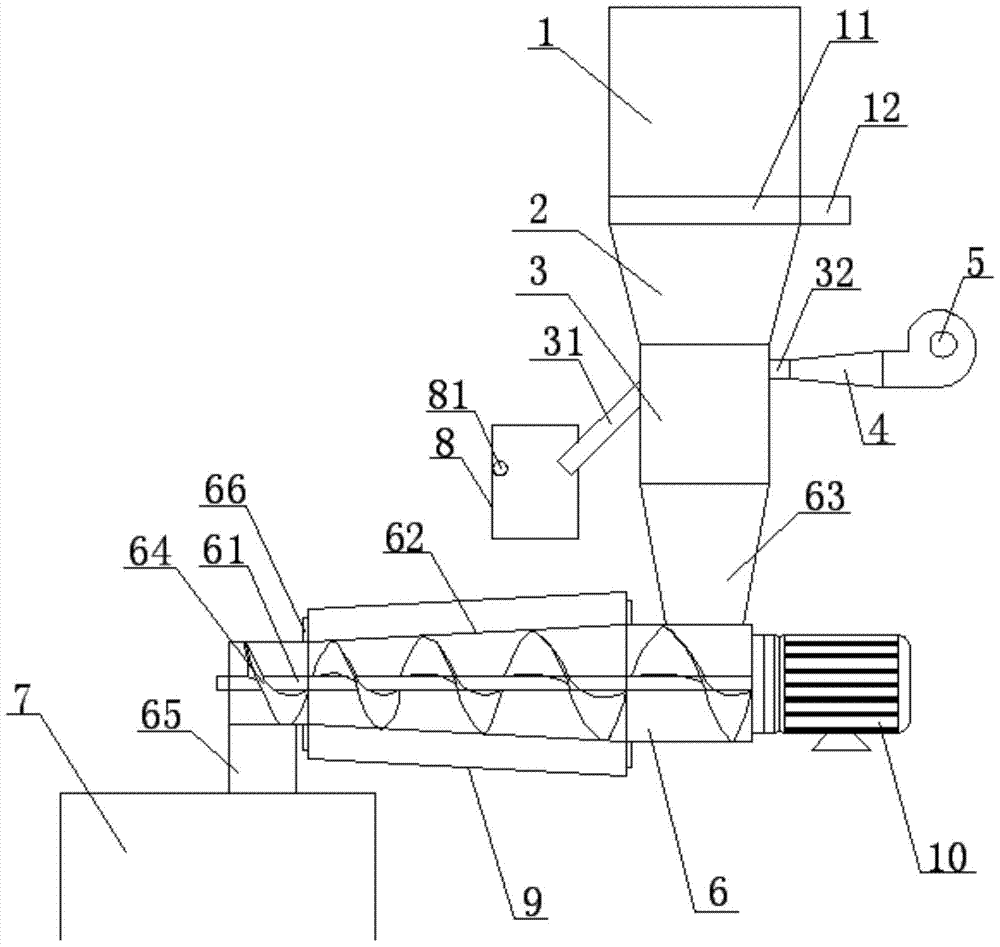

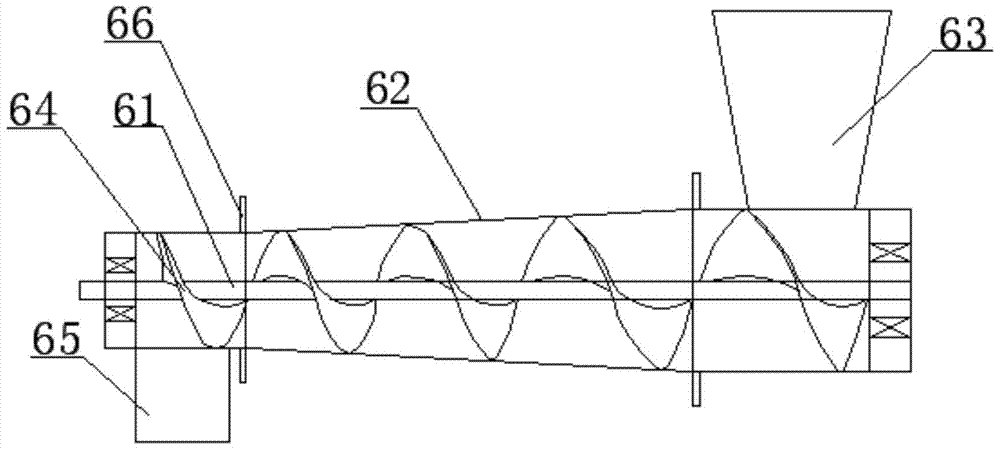

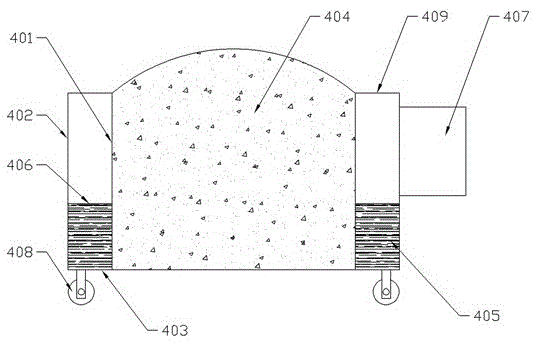

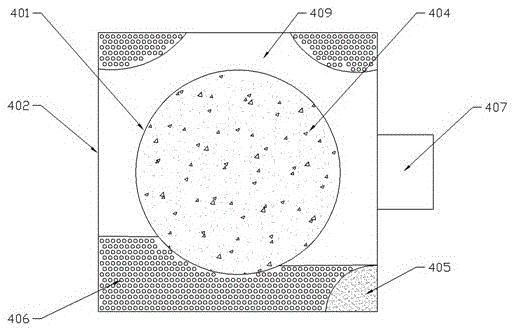

Feeding device for rice husk carbonization furnace

ActiveCN105062520BAchieve dust removalAchieve extrusionBiofuelsSpecial form destructive distillationHuskSpiral blade

The invention discloses an unloading device of a rice hull dry distillation furnace. The unloading device comprises a storage bin and a hopper, wherein a bottom valve and a bottom valve controller are arranged on the bottom of the storage bin; the bottom of the hopper is connected with a surrounding cover; an air outlet tube and a rectangular short tube are arranged on the side wall of the surrounding cover respectively; the rectangular short tube is connected with an air blower by an air hose; the bottom of the surrounding cover is connected with a spiral conveyor; the spiral conveyor comprises a main shaft and a machine enclosure; a spiral blade is arranged on the main shaft; the machine enclosure is divided into three sections; the machine enclosure sections at the two ends are cylindrical; the machine enclosure section on the middle part is conical; the spiral blade is also divided into three parts; the spiral blade parts at the two ends are distributed at an constant pitch; the spiral blade part on the middle part is distributed at a variable pitch; and the machine enclosure section on the middle part is uniformly provided with a plurality of radial fine holes within each pitch range; and the main shaft is connected with a drive motor on the side part at one side of the spiral conveyor. The unloading device is simple in structure, good in dust removal and gas exhaustion effect, and capable of improving purity of produced gas of the rice hull dry distillation furnace.

Owner:ANHUI UNIV OF SCI & TECH

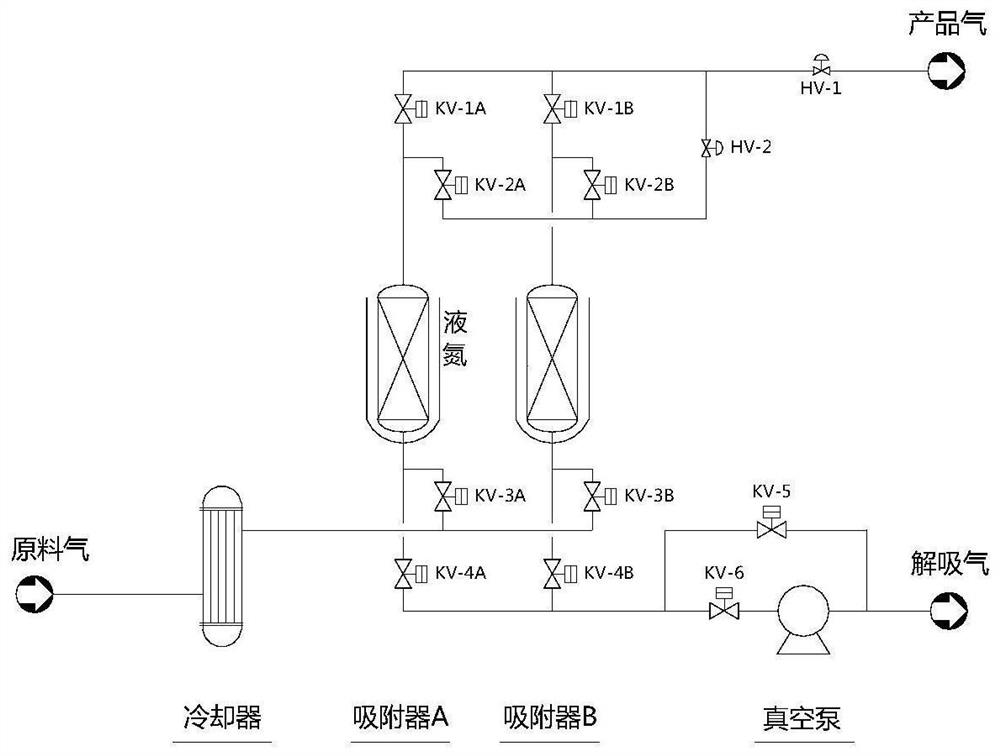

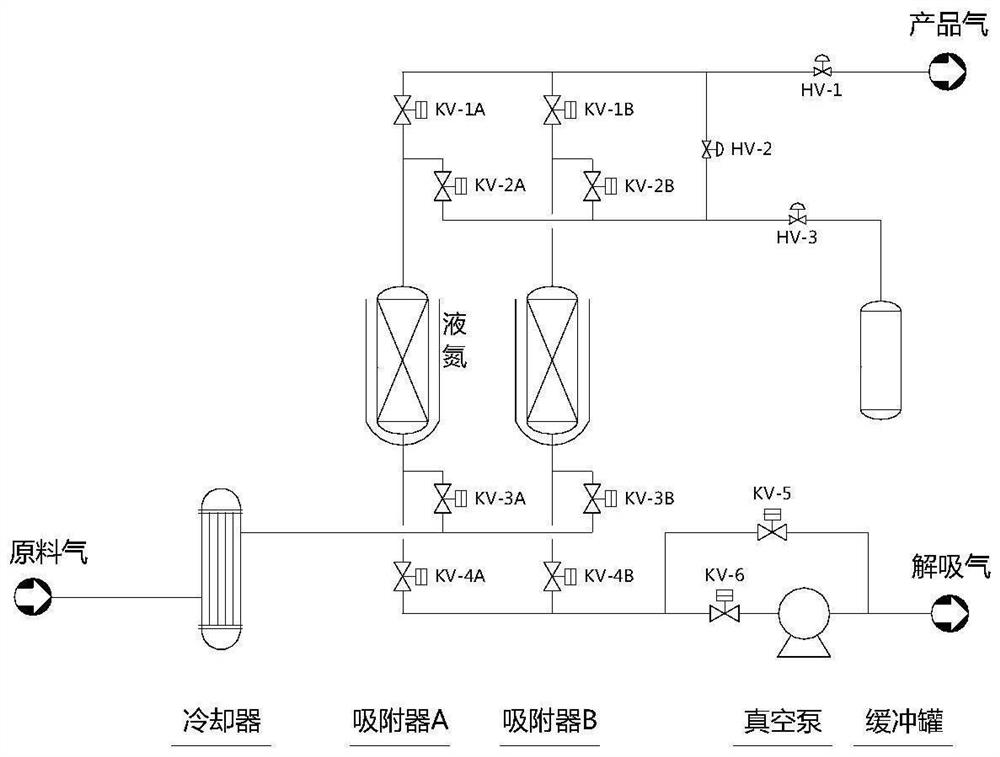

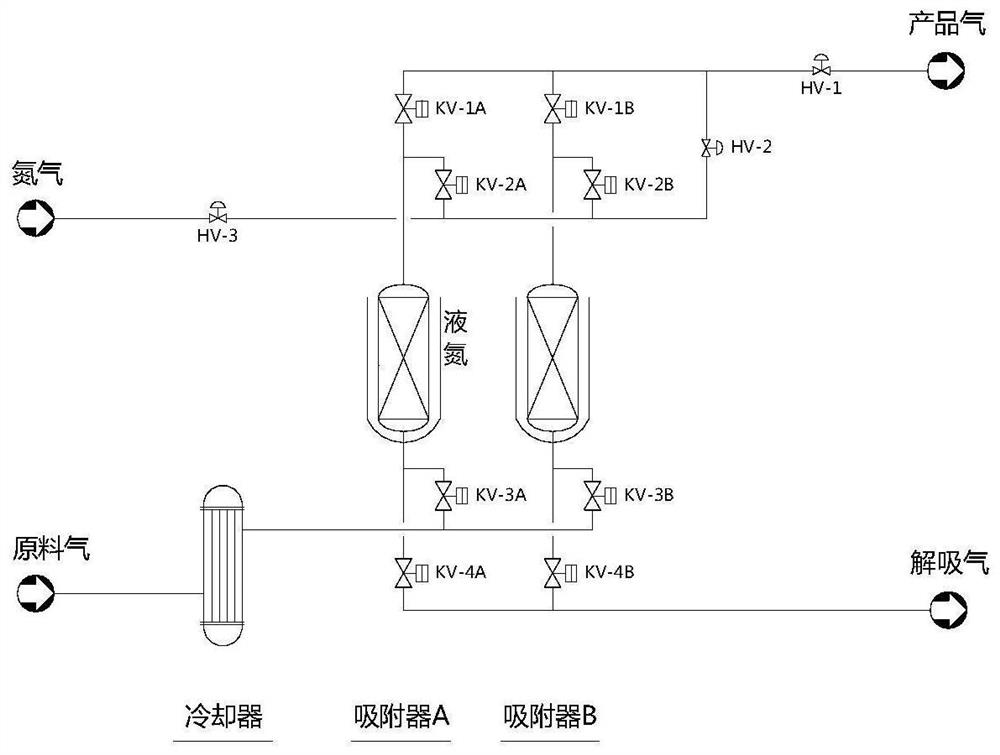

Method for low-temperature adsorption refining of high-purity and ultra-pure gas

ActiveCN114130155AAvoid consumptionReduce energy consumptionGas treatmentDispersed particle separationSorbentProcess engineering

The invention discloses a method for low-temperature adsorption and refining of high-purity and ultra-pure gas, which comprises the following steps: adsorbing and removing impurity gas in raw material gas at low temperature, preparing high-purity and ultra-pure product gas with the purity of higher than 99.99%, vacuumizing an adsorber by using a vacuum pump during regeneration, and feeding the high-purity and ultra-pure product gas into the adsorber while vacuumizing, thereby obtaining the high-purity and ultra-pure product gas with the purity of higher than 99.99%. A small amount of gas with low impurity component content is introduced into the adsorber to regenerate the adsorbent, and the temperature of the adsorber is not obviously increased during regeneration. According to the low-temperature adsorption method, the adsorber does not need to be deliberately heated in the regeneration process, consumption of a large amount of energy and materials caused by frequent heating and cooling of the adsorber is avoided, and the low-temperature adsorption method has the advantages that operation is easy, energy consumption is low, and the device is suitable for long-time continuous operation.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Fertilizer for protecting carbon dioxide gas on ground

InactiveCN100457689CCO2 release rate controlMeet the requirements of photosynthesisCarbon dioxide producing fertilisersFertilizer mixturesDipotassium hydrogen phosphateGreenhouse

This invention discloses a CO2 gaseous fertilizer, which can provide CO2 with a certain concentration to crops in greenhouses. The CO2 gaseous fertilizer is obtained by uniformly mixing ammonium bicarbonate 25-45%, potassium dihydrogen phosphate 40-60%, and dipotassium hydrogen phosphate 5-15%. When used, the CO2 gaseous fertilizer is added into an open container in protection soil, and then diluted with water. CO2 is rapidly released in the early stage, and slowly and stably released in the later stage to keep the CO2 concentration at 800-1200 ppm. The CO2 gaseous fertilizer has such advantages as abundant raw materials, simple preparation process, and convenient usage, and can increase the productivity by 15-20%, and shorten the mature period by 3-7 days.

Owner:HEFEI UNIV OF TECH +1

Gasification furnace built-in tar gasification circulating system

ActiveCN105482836AEmission reductionReduce pollutionGasifier mechanical detailsGasifier moving partsTarEngineering

The invention relates to a gasification furnace built-in tar gasification circulating system which comprises a feeder, a gasifier and a separation cooler which are sequentially connected, wherein the gasifier comprises a furnace body; the top of furnace body is provided with an automatic cover opening / closing mechanism; the outside of the furnace body is connected with an air intake mechanism and a cooling mechanism; the bottom of the furnace body is provided with an ash discharge mechanism; a tar gasifier is arranged above the ash discharge mechanism; the tar gasification mechanism comprises an inner liner and an outer liner; the top and bottom of the region between the inner liner and outer liner are respectively provided with a seal-structure upper cover and a bottom plate which is uniformly distributed with small holes; a gasifying agent is arranged on the bottom plate; wood charcoal generated by gasified biomass falls on the ash discharge mechanism and is accumulated in the inner liner; and the outer side of the outer liner is provided with a gas outlet pipe and the separation cooler. The gasification furnace built-in tar gasification circulating system is reasonable in design, simple to operate and convenient for maintenance, and has the advantages of high safety linkage coefficient, high automation degree, high continuous gas production capacity and high gas purity. The gasification furnace built-in tar gasification circulating system performs circulating gasification on the tar generated by the reaction, so the fume and tar emissions are low, thereby greatly lowering the environment pollution and especially air pollution.

Owner:ZHEJIANG JIUFAN NEW ENERGY TECH CO LTD

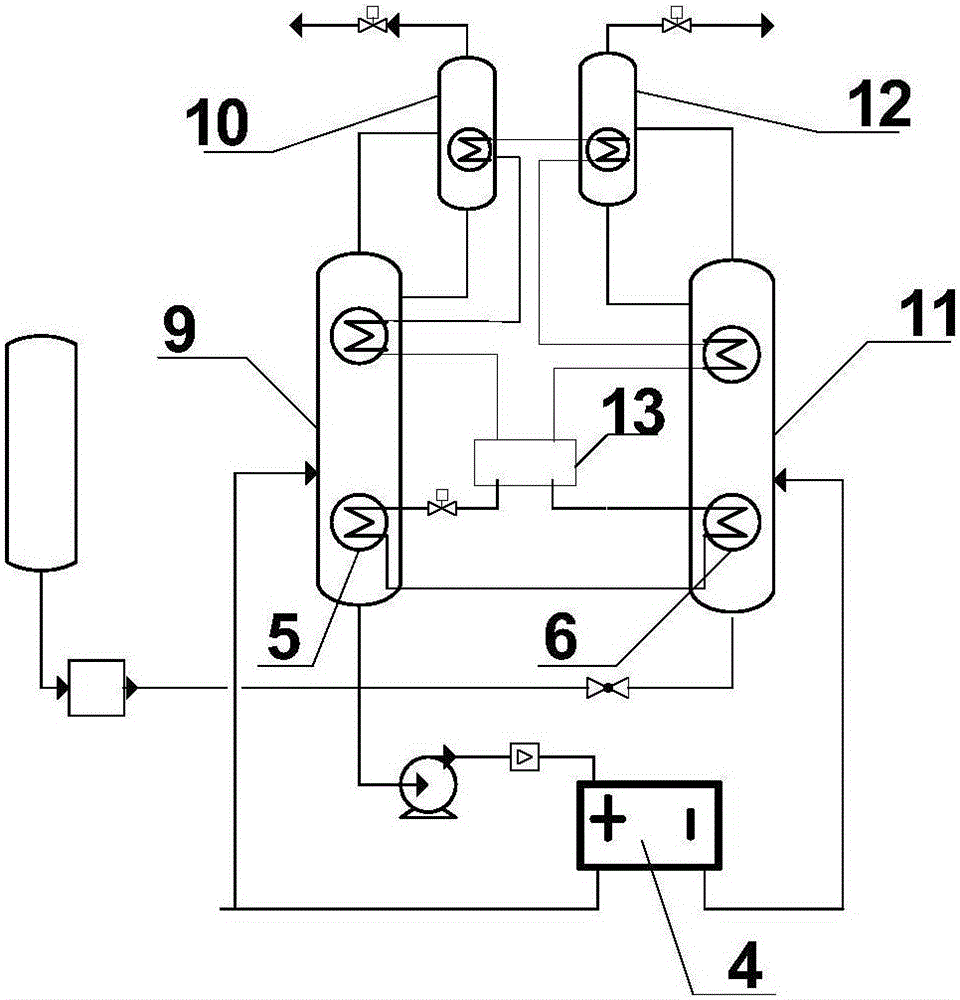

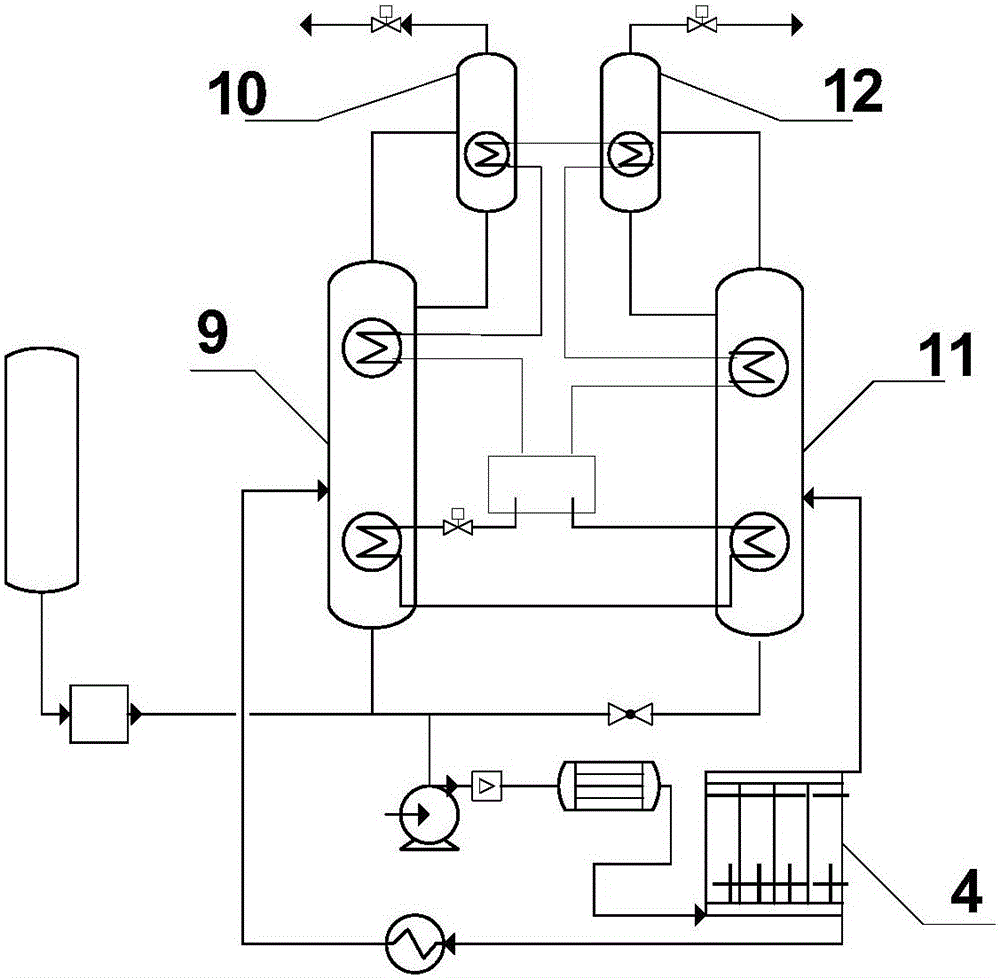

A high-pressure proton membrane water electrolysis device and method

ActiveCN105862066BNo incorporation of gasAvoid containingCellsDiaphragmsHigh pressure waterHigh pressure

The invention discloses a high pressure proton membrane water electrolysis device. The device comprises a water tank, a make up pump, an electrolytic cell stack, a first separator and a second separator, wherein the make up pump is used for communicating the water tank with a water inlet of the electrolytic cell stack; the first separator is communicated with an oxygen outlet of the electrolytic cell stack; the second separator is communicated with a hydrogen outlet of the electrolytic cell stack; and an electrolyte and proton exchange membrane is arranged in the electrolytic cell stack and is solid polymer electrolyte. The high pressure proton membrane water electrolysis device has the beneficial effects that the device avoids that the gases generated in traditional methods for electrolyzing water contain alkaline aerosol; and water and gas separation is carried out on the generated gases by the first and second separators, thus greatly improving the purity of the gases generated by electrolyzing water. The invention also discloses a high pressure proton membrane water electrolysis method.

Owner:淳华氢能源科技(湖南)有限公司

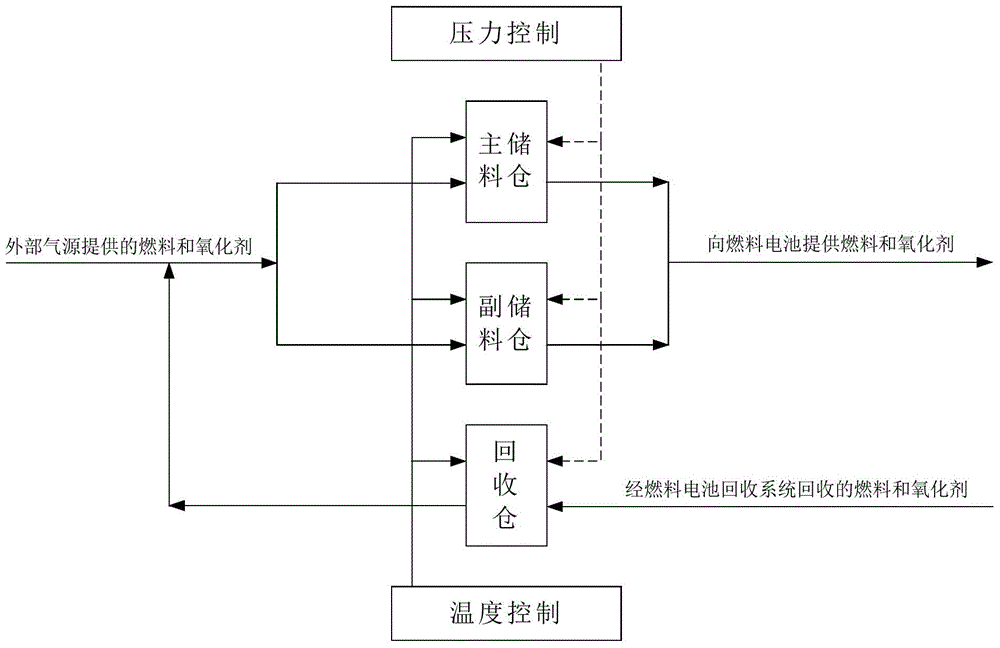

Control method for gas storage and release processes of fuel supply system employing solid-state storage materials

InactiveCN105047964AImprove control efficiencyMeets standard requirements for supply ratesReactant parameters controlFinal product manufactureSolid-state storageFuel cells

The invention relates to a control method for gas storage and release processes of a fuel supply system employing solid-state storage materials, and belongs to the field of application of fuel cell supply systems. The control method comprises a control method for gas storage and release processes of a primary storage bin, a secondary storage bin and a recovery bin. The gas storage and release processes of the fuel supply system are adjusted by changing kinetic parameters such as temperature, pressure and time of the primary storage bin, the secondary storage bin and the recovery bin to obtain fuel and an oxidant, which are high in gas purity and stable and controllable in gas supply rate; the fuel cell supply system is always kept in the optimal working state; safe operation of the system during the working period is kept; the control efficiency of the fuel cell supply system is improved; the process debugging cycle and the production cost are reduced; and the standard requirements on the supply rate of the fuel cell supply system in the industry are met.

Owner:TSINGHUA UNIV

System for recovering gas produced during electrodialysis

ActiveUS7909975B2Reduce energy consumptionRisk of explosion can be minimizedSludge treatmentGeneral water supply conservationElectricityHydrogen

Disclosed is a system for recovering gas produced during electrodialysis of a saline solution, from gas entrained in an electrolyte solution circulating through anode and cathode compartments of an electrodialysis (ED) unit. In one embodiment, the system provides separate catholyte and anolyte towers within a closed, re-circulating loop between the cathode and anode compartments. Each tower comprises an inlet at which the entrained gas separates from the electrolyte solution and flows into the headspace. One can recover residual gases from the electrolyte solution in one more additional apparatus. Preferably, hydrogen gas is separated from the catholyte solution and, more preferably, further purified for use as a fuel source in alternative power generating devices, such as a fuel cell or bio-fuel generator, useful in the unit operations of a water treatment system.

Owner:VOLKER STEVIN CONTRACTING

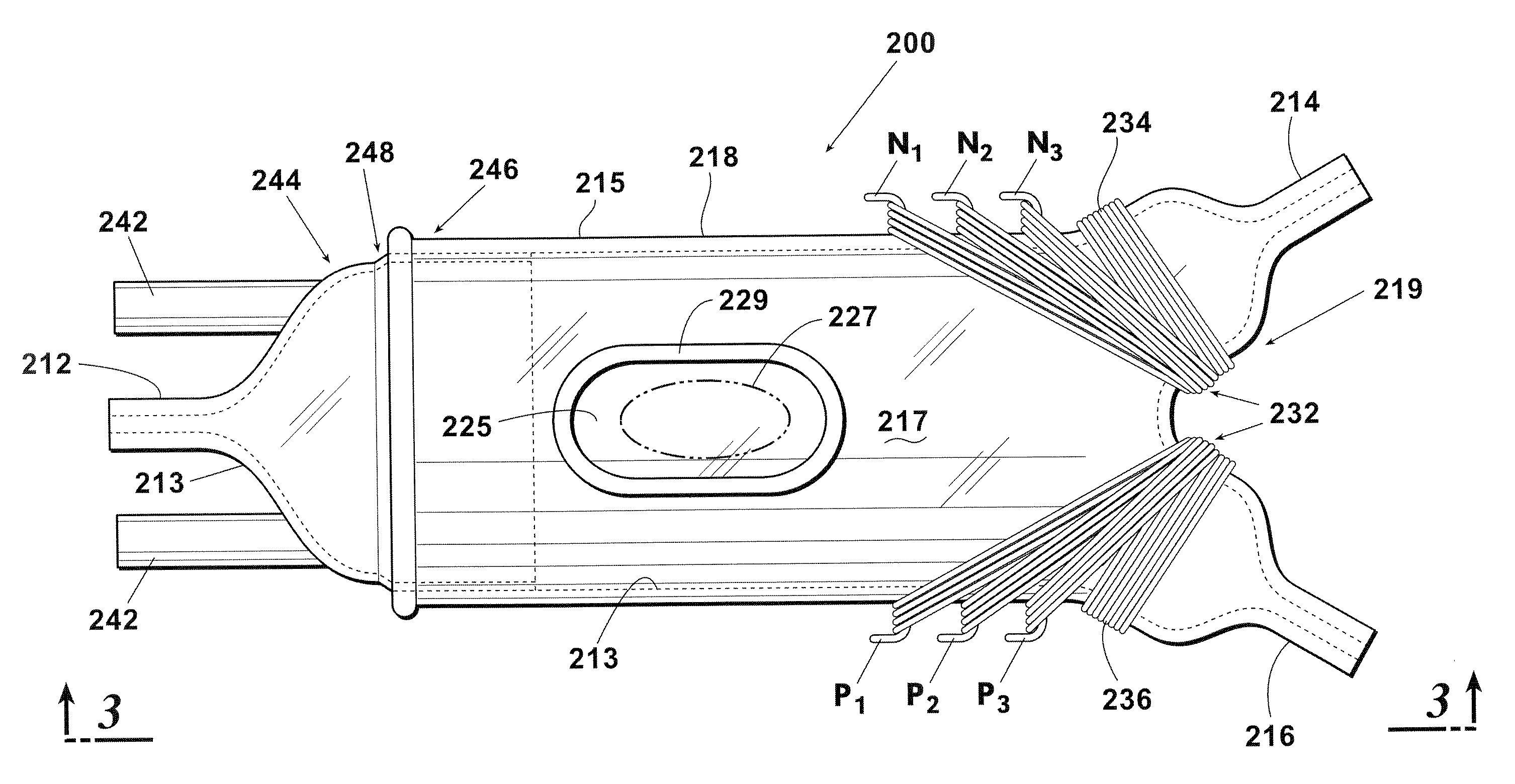

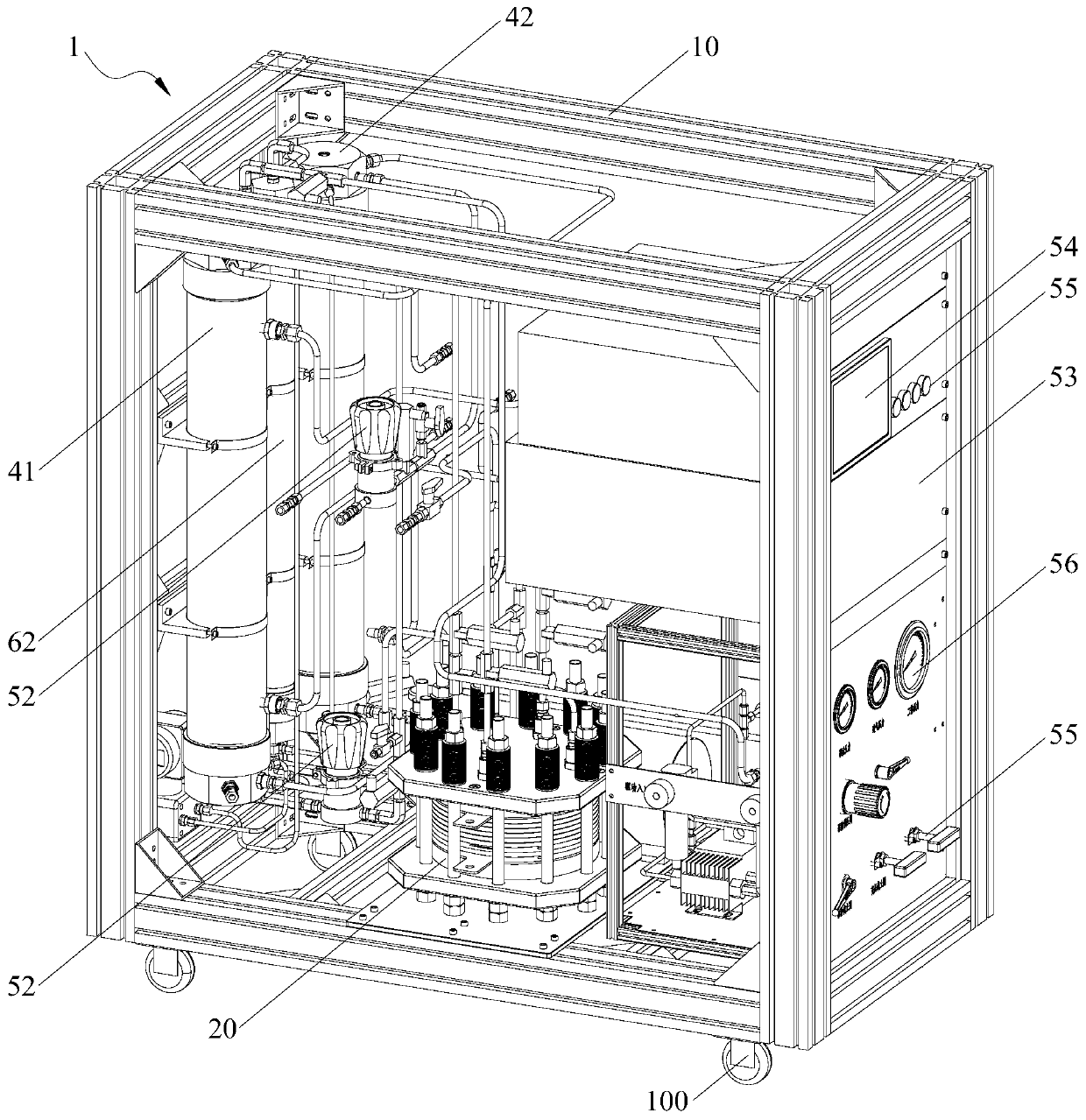

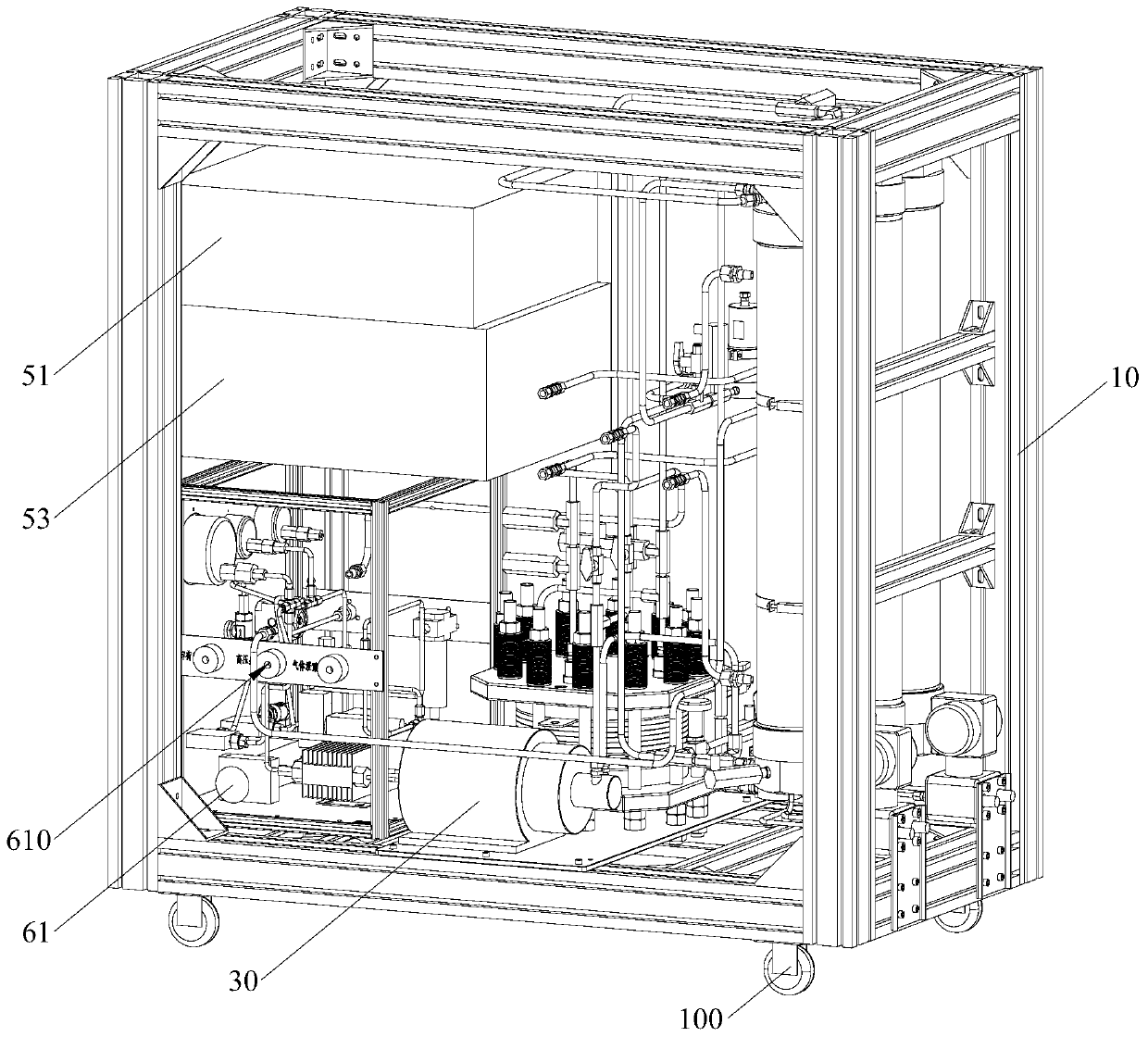

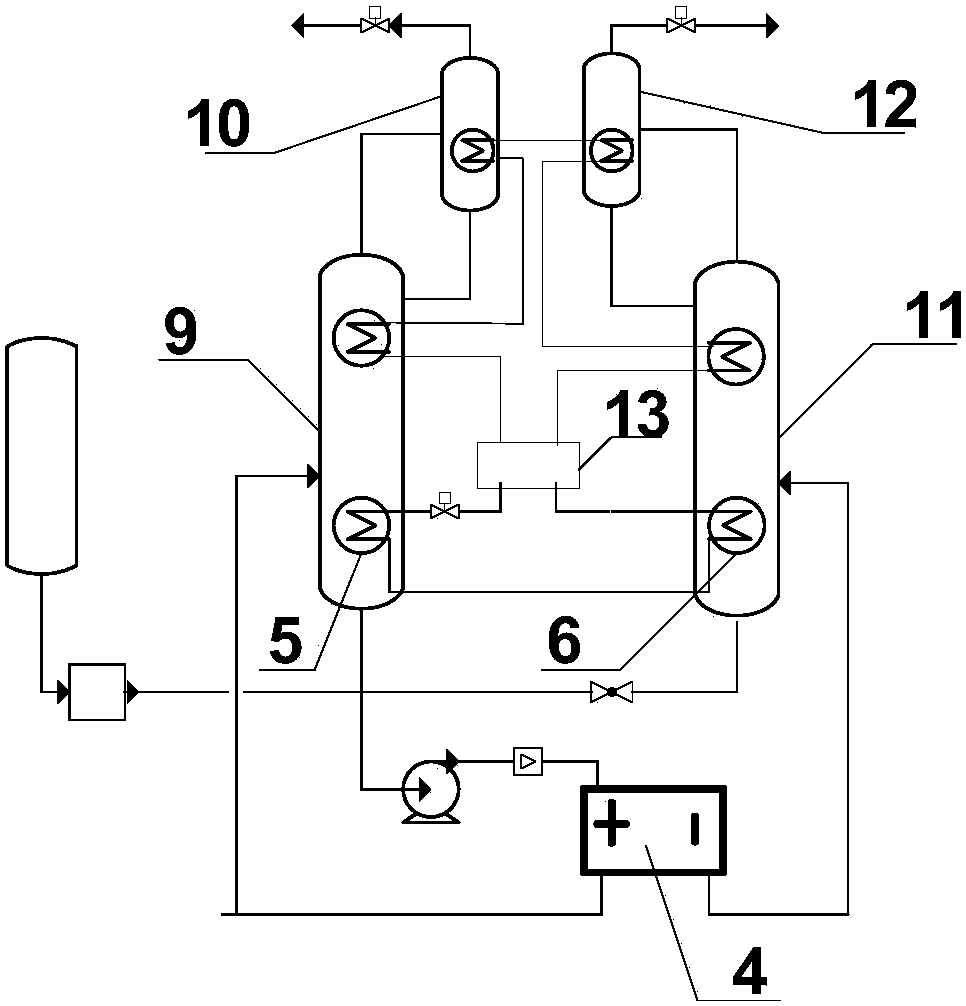

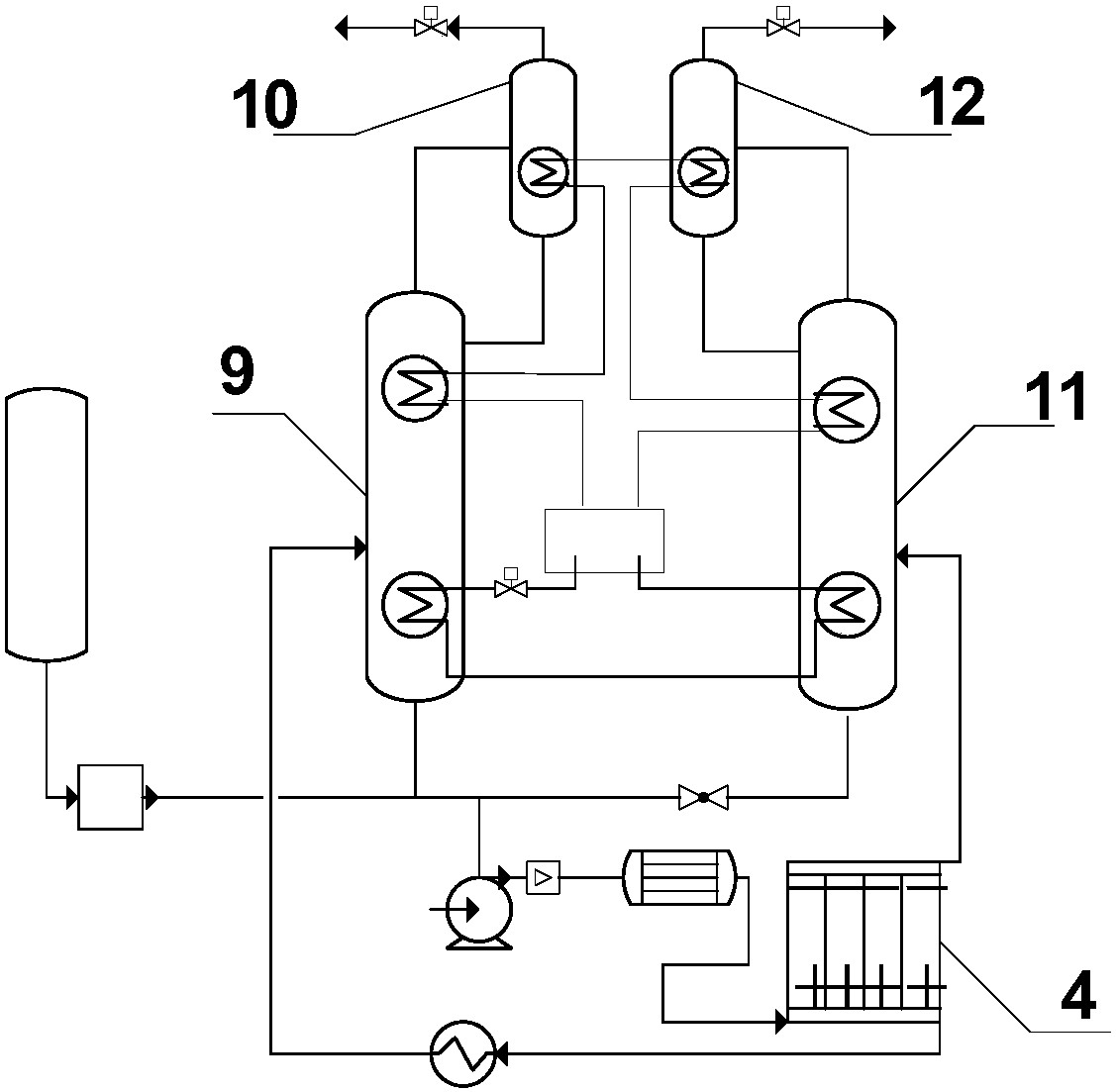

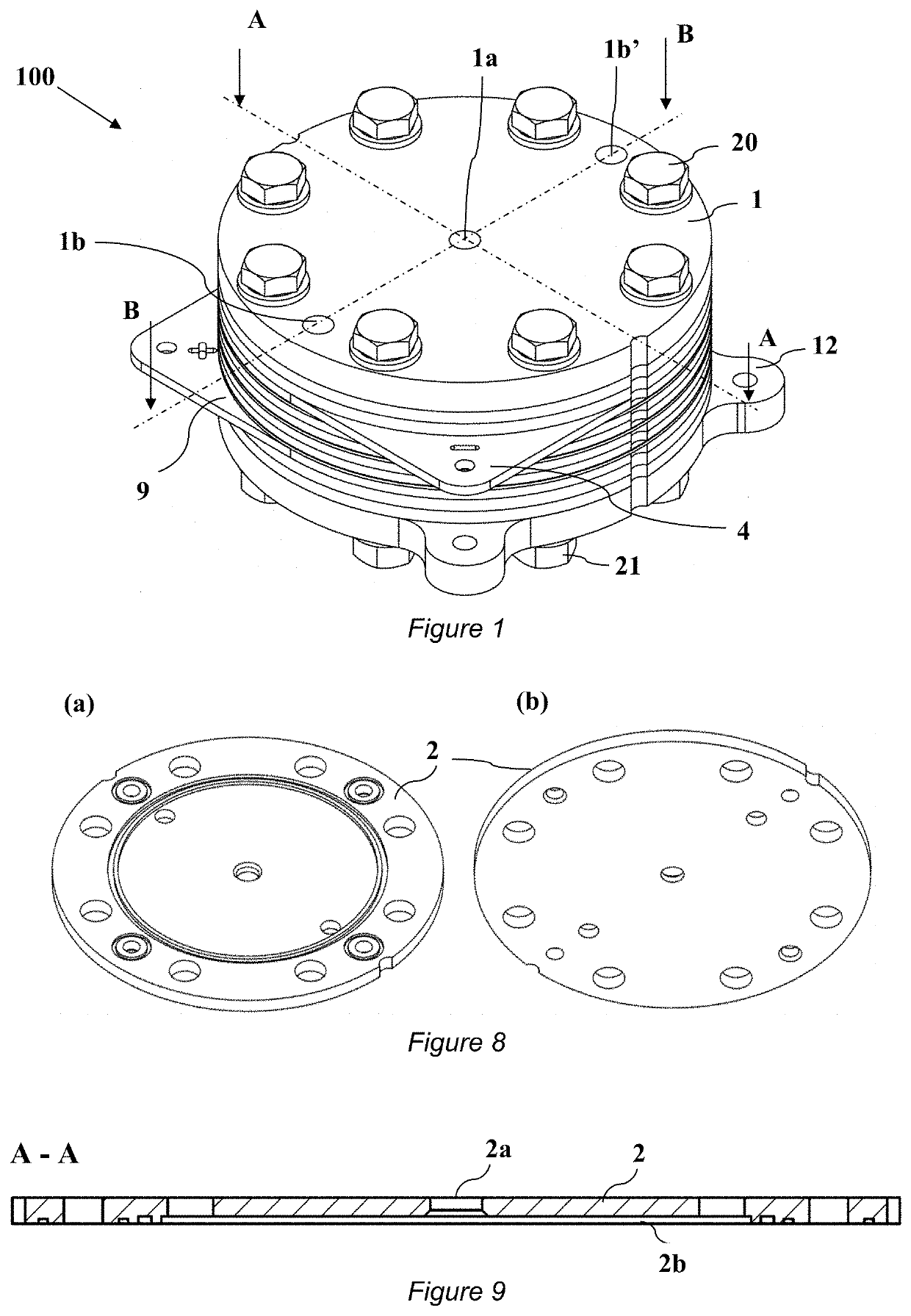

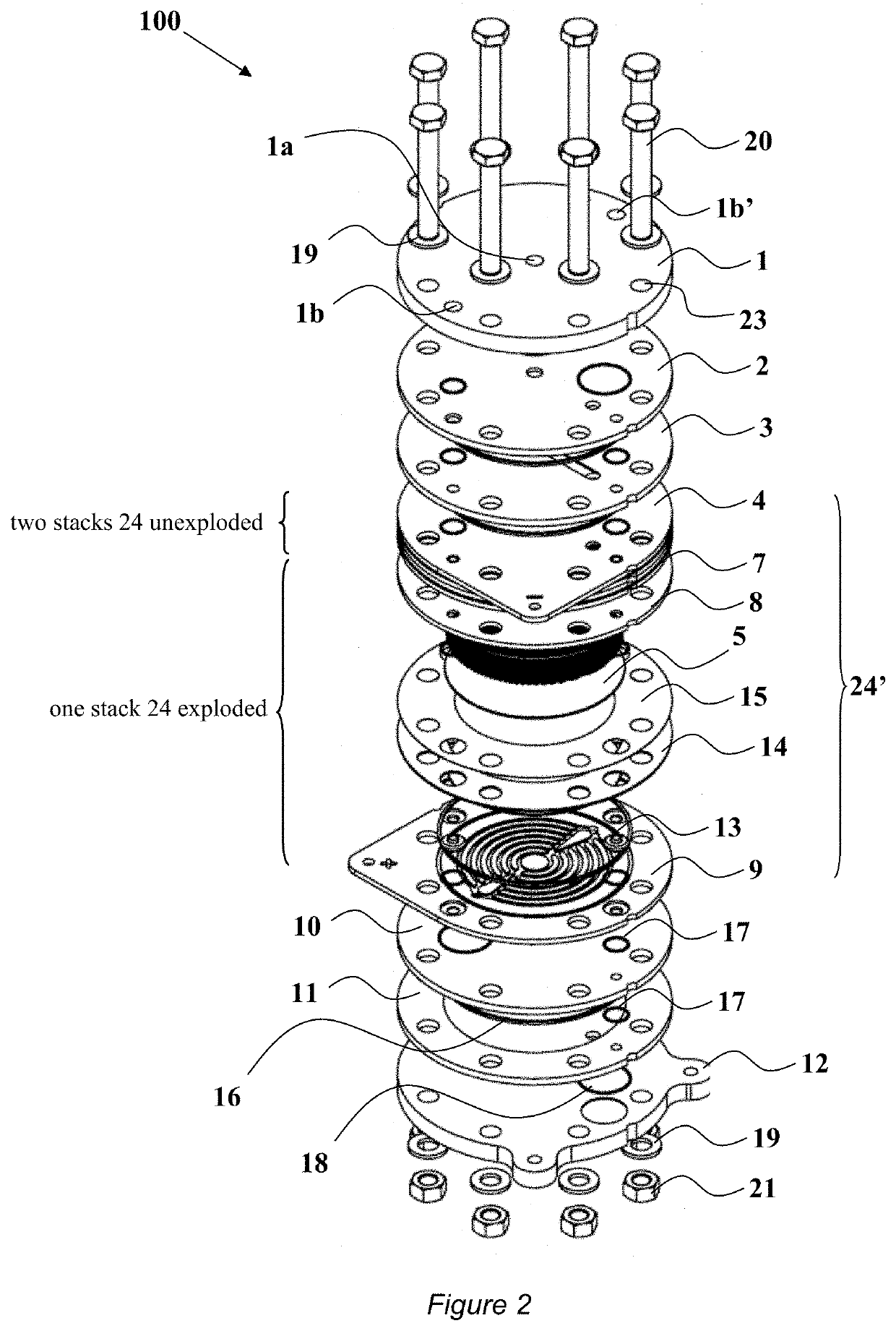

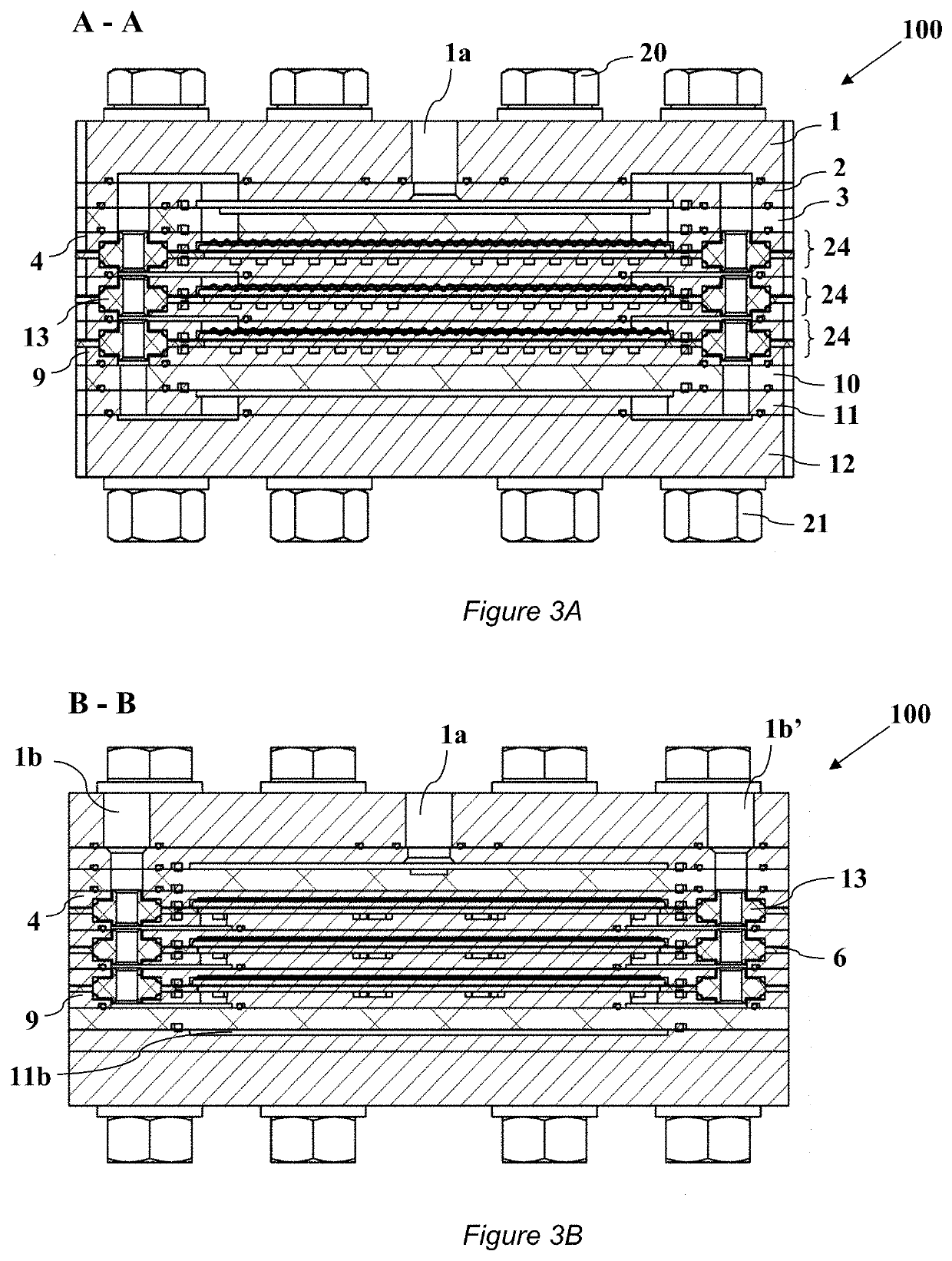

Modular electrolyzer unit to generate gaseous hydrogen at high pressure and with high purity

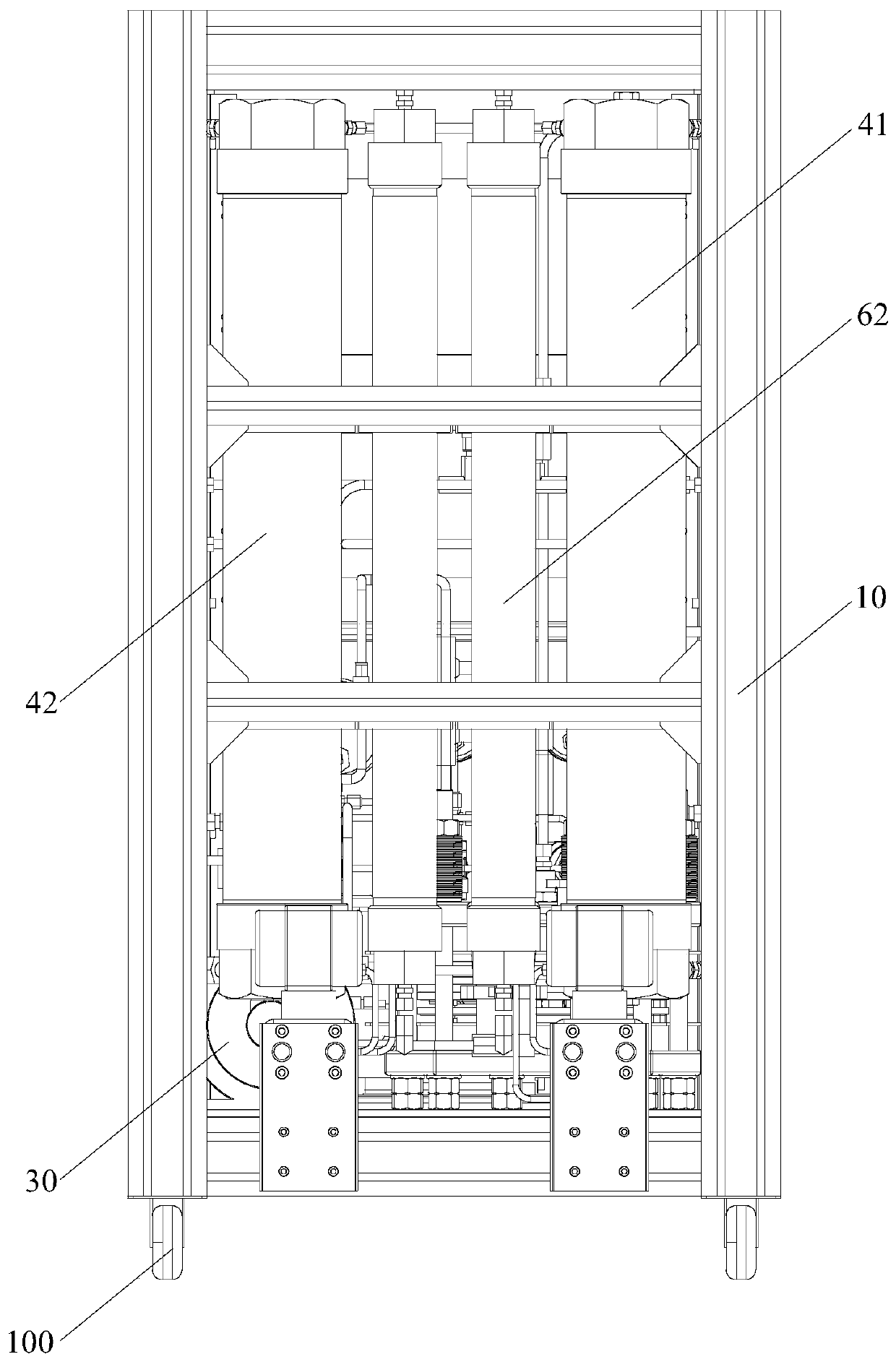

The present invention relates to the field of generating gaseous hydrogen at high pressures and with high purity via electrolysis of water by means of an electrolyzer unit (100) with a novel structure.

Owner:THALESNANO ZRT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com