Biomass gasification unit

A biomass and unit technology, applied in the chemical industry, the manufacture of combustible gas, climate sustainability, etc., can solve the problems of cumbersome structure, low manufacturing precision, low gas purity, etc., to avoid environmental pollution, easy operation, and gas purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

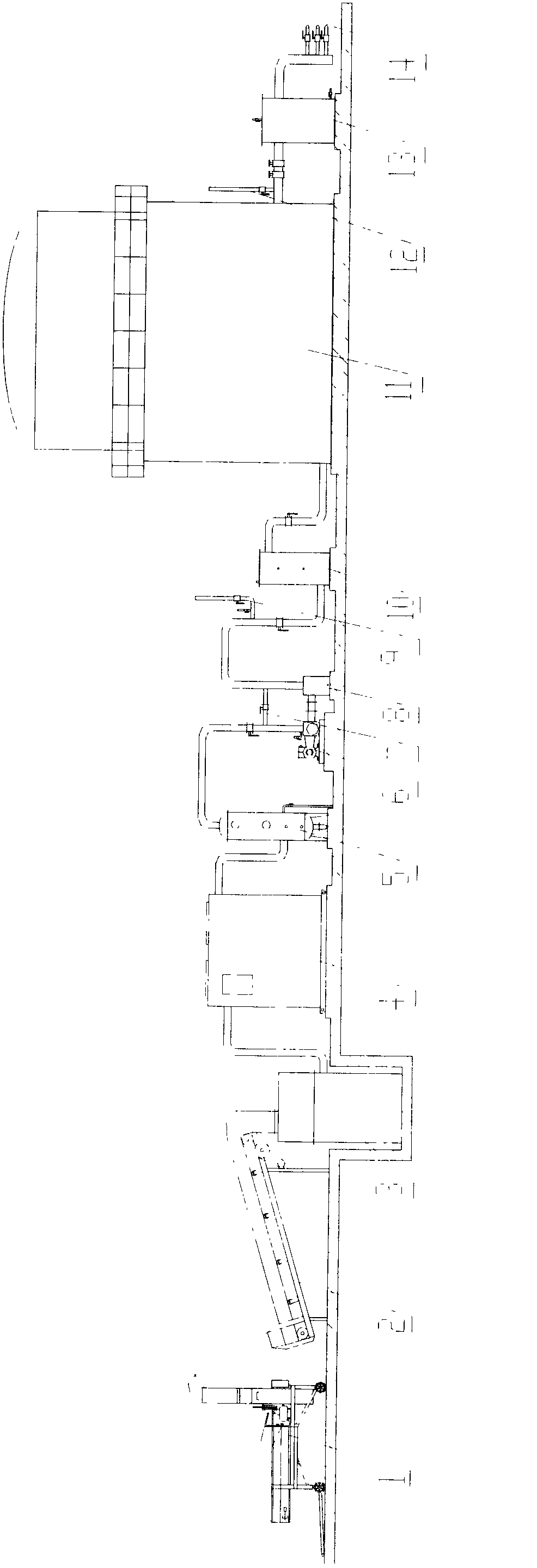

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0010] Such as figure 1 As shown, the biomass gasification unit includes hay cutter 1, closed conveyor 2, gasifier 3, purifier 4, oil-gas separator 5, Roots blower 6, pressure regulating bypass 7, cyclone coke collector 8 , return pipe 9, safety water seal 10, wet gas cabinet 11, emptying pipe 12, flame arrester 13, user air supply pipe 14, characterized in that: the hay cutter 1, the closed conveyor 2, and the gasifier 3 are sequentially Connection, the gasifier 3, the purifier 4, and the oil-gas separator 5 are successively connected through closed pipelines. The outlet pipeline of the oil-gas separator 5 is provided with a Roots blower 6, and one end of the pressure regulating bypass 7 is connected to the outlet pipeline of the oil-gas separator 5, and the other end Unicom cyclone focuser 8 outlet pipeline, cyclone focuser 8 and safety water seal 10 Unicom pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com