Multi-effect modular biomass gasification furnace and combustion method

A biomass and modular technology, applied in the direction of biofuel, gasification process, coke oven, etc., can solve the problems of lack of sufficient attention to products, difficult to guarantee economic efficiency, secondary pollution, etc., and achieve energy saving, environmental protection and safe production environment, Safer and more effective operation, high carbon yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

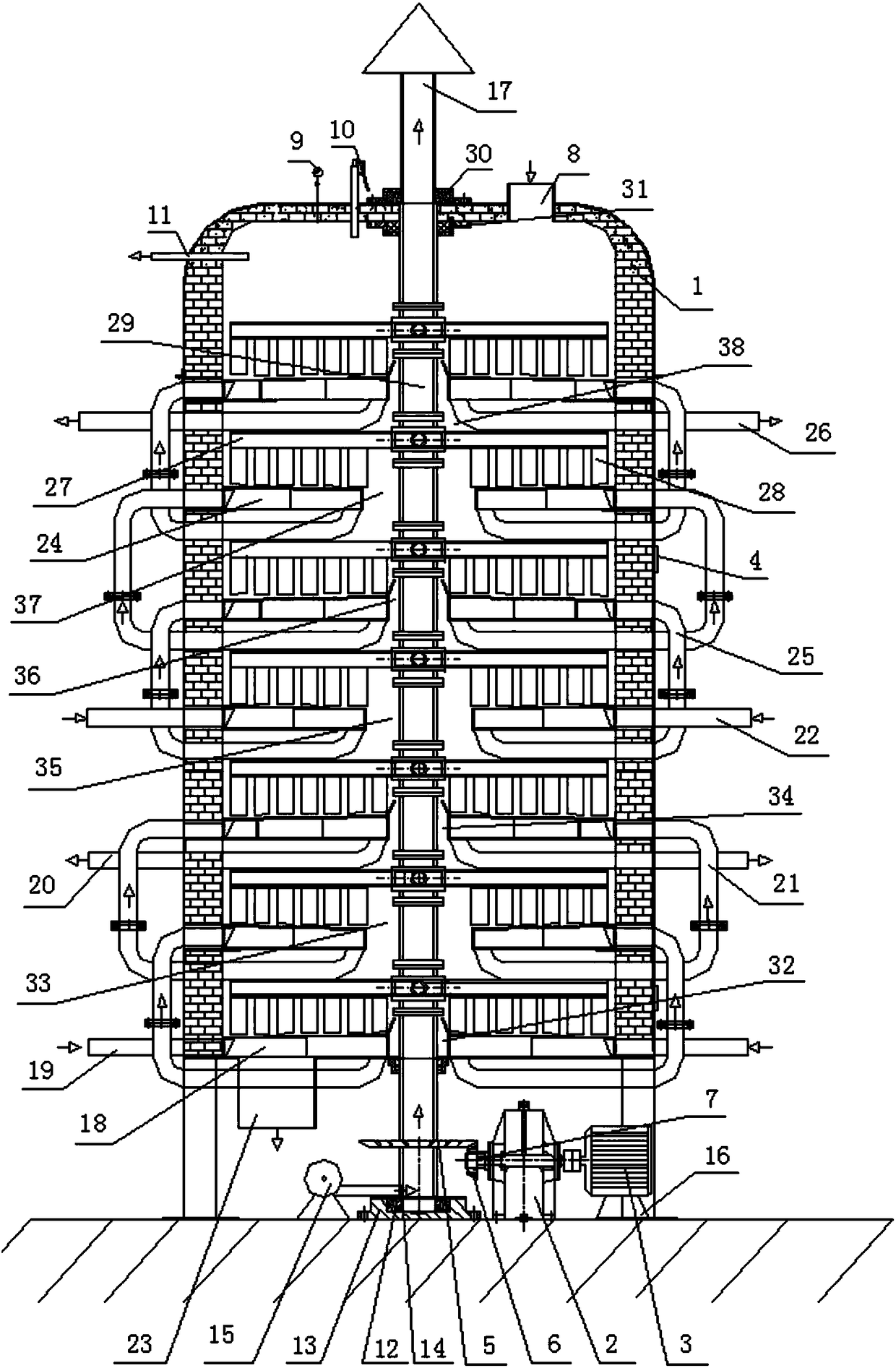

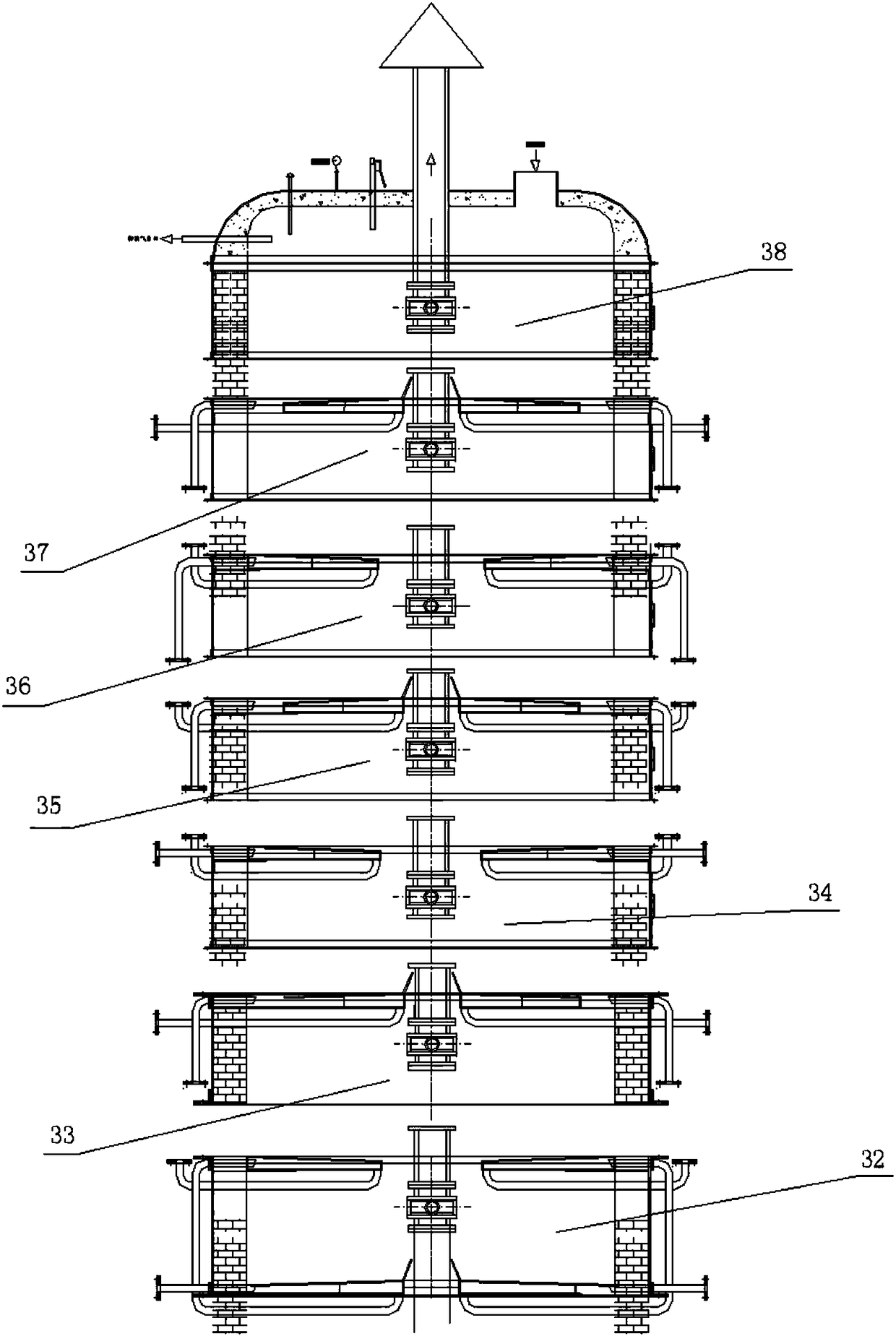

[0027] A kind of multi-effect modular biomass gasification furnace, its composition comprises: furnace body 1, described furnace body is equipped with 1-5 grade cooling chamber, 1-12 grade carbonization chamber sequentially, described 1-5 grade The cooling chamber and the 1-12-stage carbonization chamber are equipped with a hollow combined central shaft, and a sealing device is installed between the hollow combined central shaft and the furnace body, and the hollow combined central shaft is connected to the gear set , the gear set is connected to the reducer 2, the reducer is connected to the motor 3, the furnace body is connected to the furnace door 4, the furnace body is connected to the burner, and the furnace body can be made of refractory bricks .

Embodiment 2

[0029] In the multi-effect modular biomass gasifier described in Example 1, the gear set includes a bevel gear 5, the bevel gear meshes with the vertical bevel gear 6, and the vertical bevel gear is connected to the output shaft 7 of the reducer , the bevel gear is connected to the hollow combined central shaft.

Embodiment 3

[0031] In the multi-effect modular biomass gasification furnace described in Example 1, the top of the furnace body has a biomass feed port 8, and the top of the furnace body is connected with a pressure gauge 9 and a safety valve 10, and the There is a biomass gas outlet 11 at the upper end of one side of the furnace body, the bottom of the hollow combined central shaft is connected to the base 13 through a bearing 12, and an air inlet 14 is opened at the bottom of the hollow combined central shaft, and the air inlet The blower 15 is connected, the motor is connected to the bracket 16, and the top of the hollow combined central shaft is connected to the exhaust port 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com