Patents

Literature

209results about How to "Avoid containing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

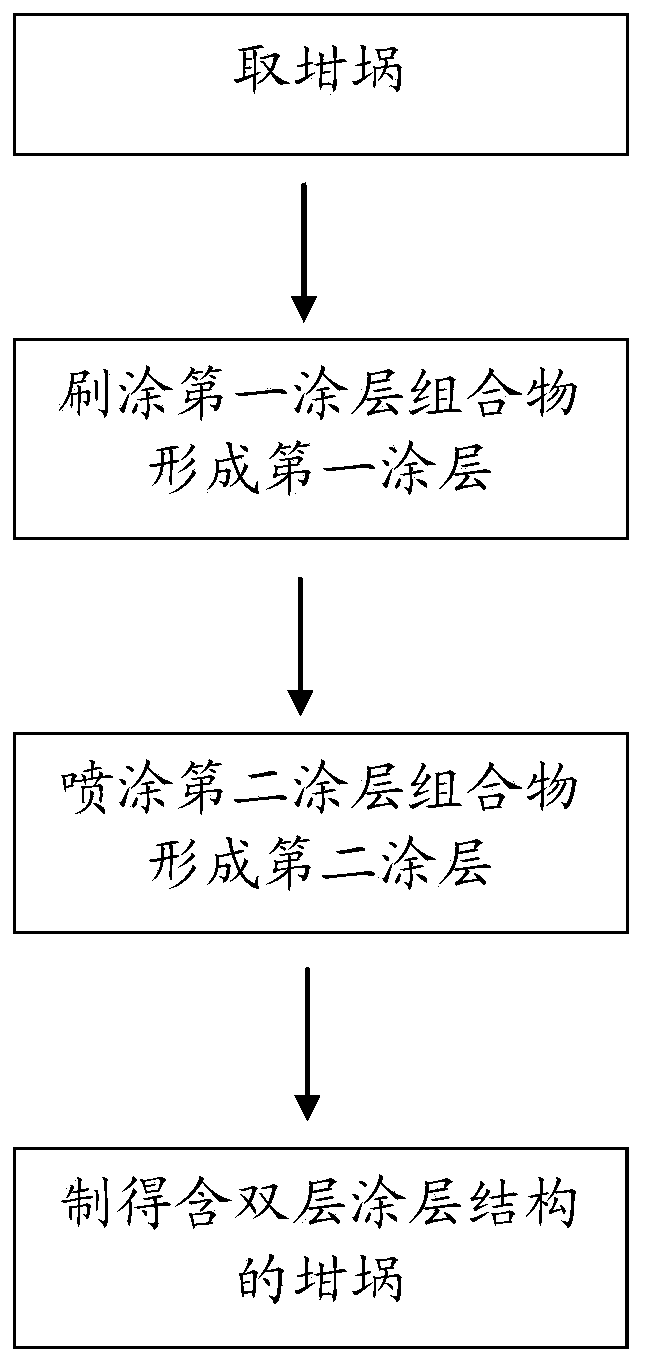

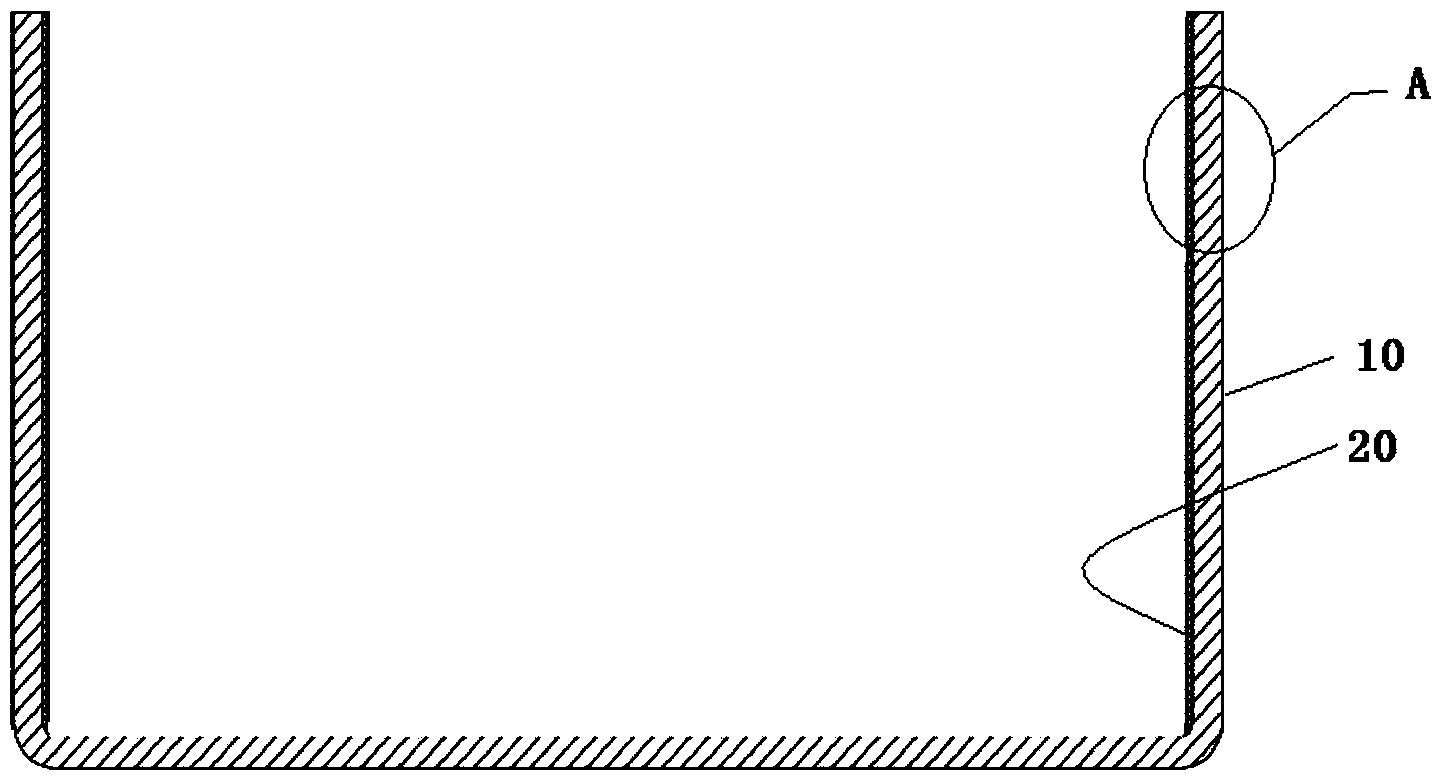

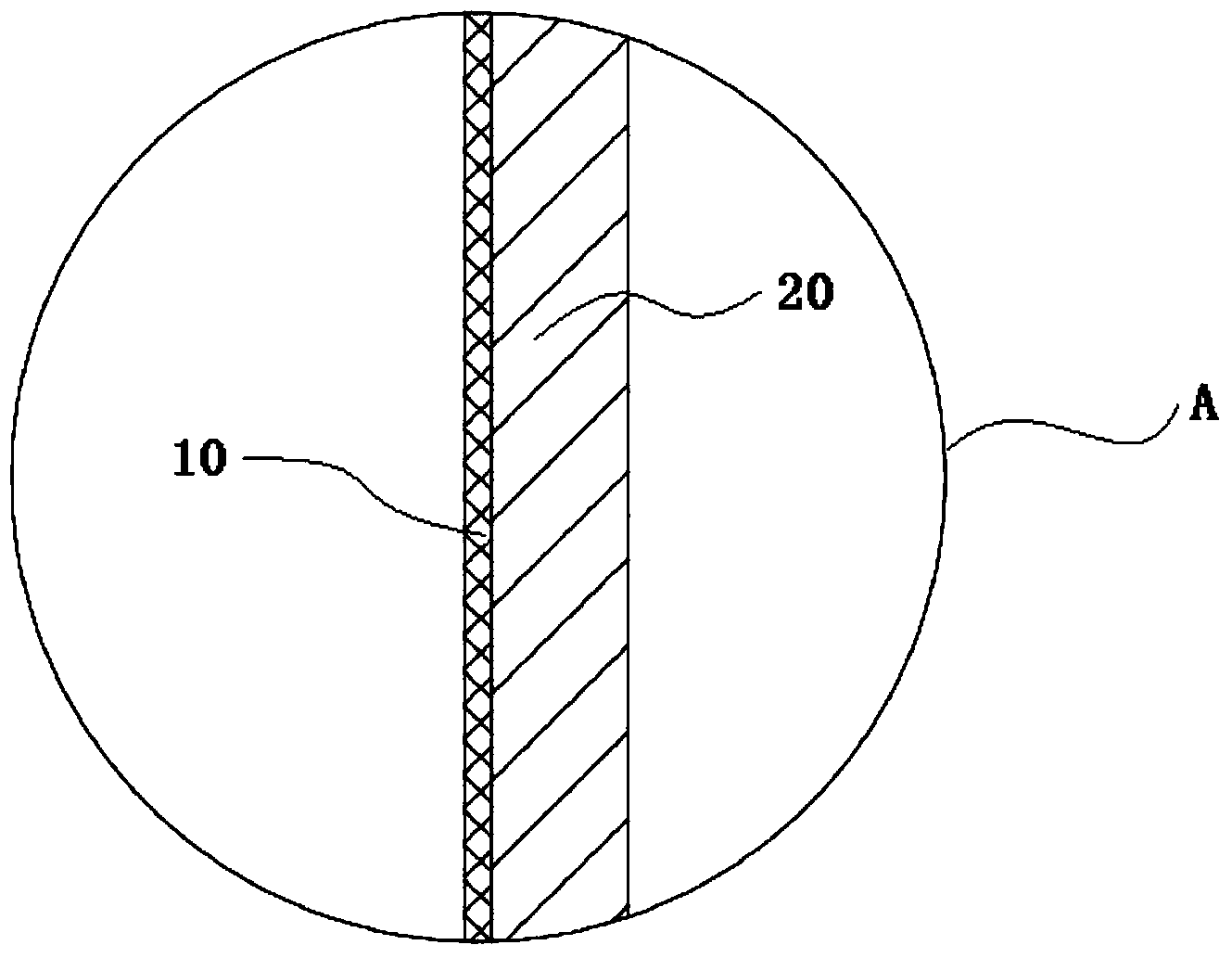

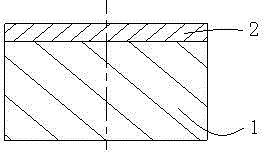

Crucible for polysilicon ingot casting, coating structure of crucible and coating preparation method

InactiveCN104109902AImprove bindingNot easy to fall offPolycrystalline material growthSingle crystal growth detailsCrucibleIngot casting

The invention provides a crucible for polysilicon ingot casting, a coating structure of the crucible and a coating preparation method. The coating structure of the crucible for polysilicon ingot casting comprises a first coating arranged on the inner side wall of the crucible and a second coating arranged on the first coating. The first coating is formed from a first coating composition by brush coating. The first coating composition comprises silicon nitride and a solvent. The second coating is formed from a second coating composition by spray coating. The second coating composition comprises silicon nitride and a solvent. The coating structure of the crucible for polysilicon ingot casting has uniform thickness, does not crack easily, has high bonding force to the inner wall of the quartz ceramic crucible, and strong bonding force between silicon nitride particles, does not spall easily in an ingot casting technology and has a low rate of adhesion to the crucible.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

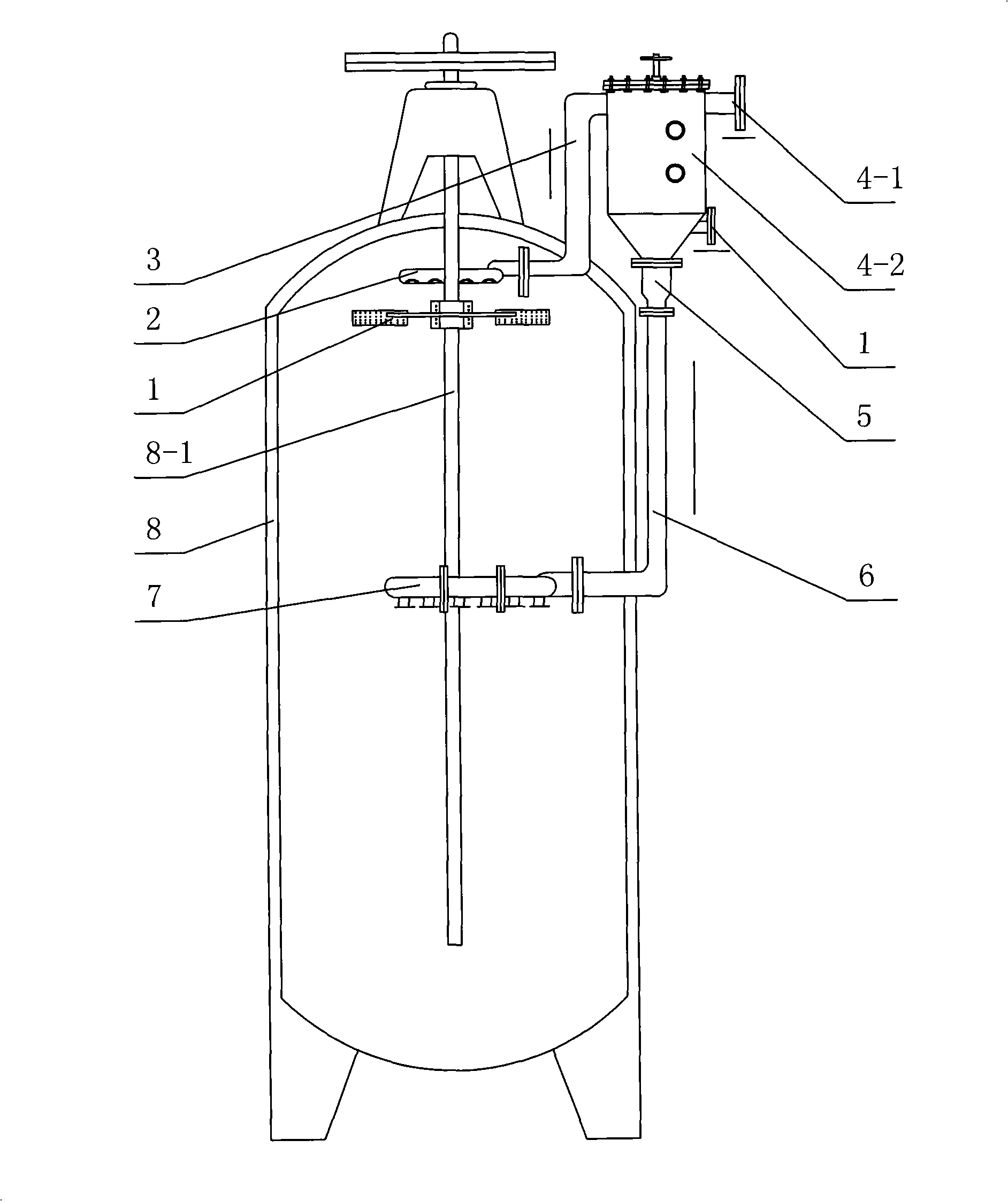

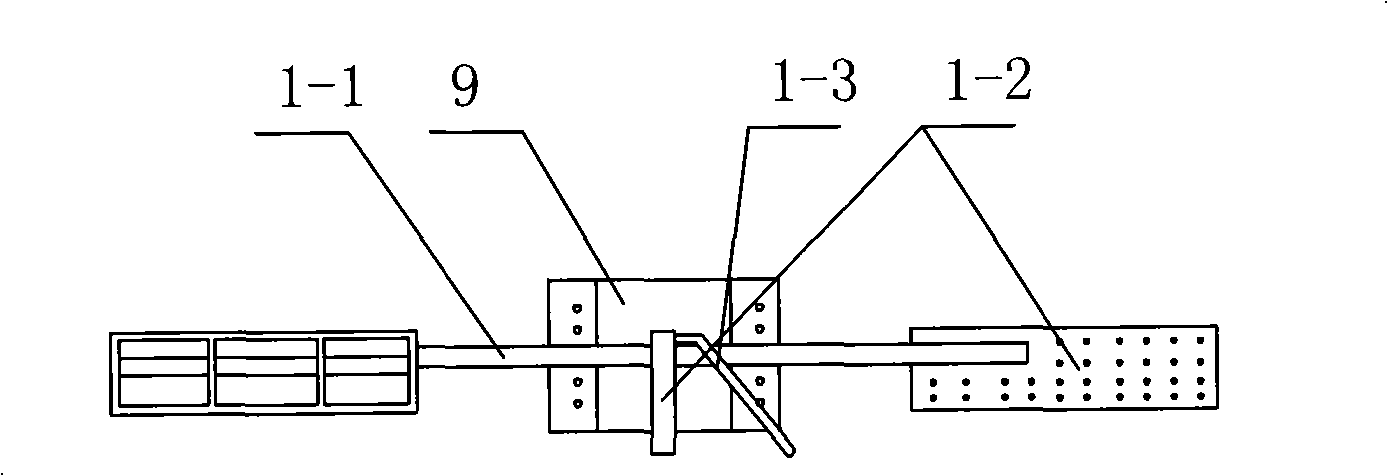

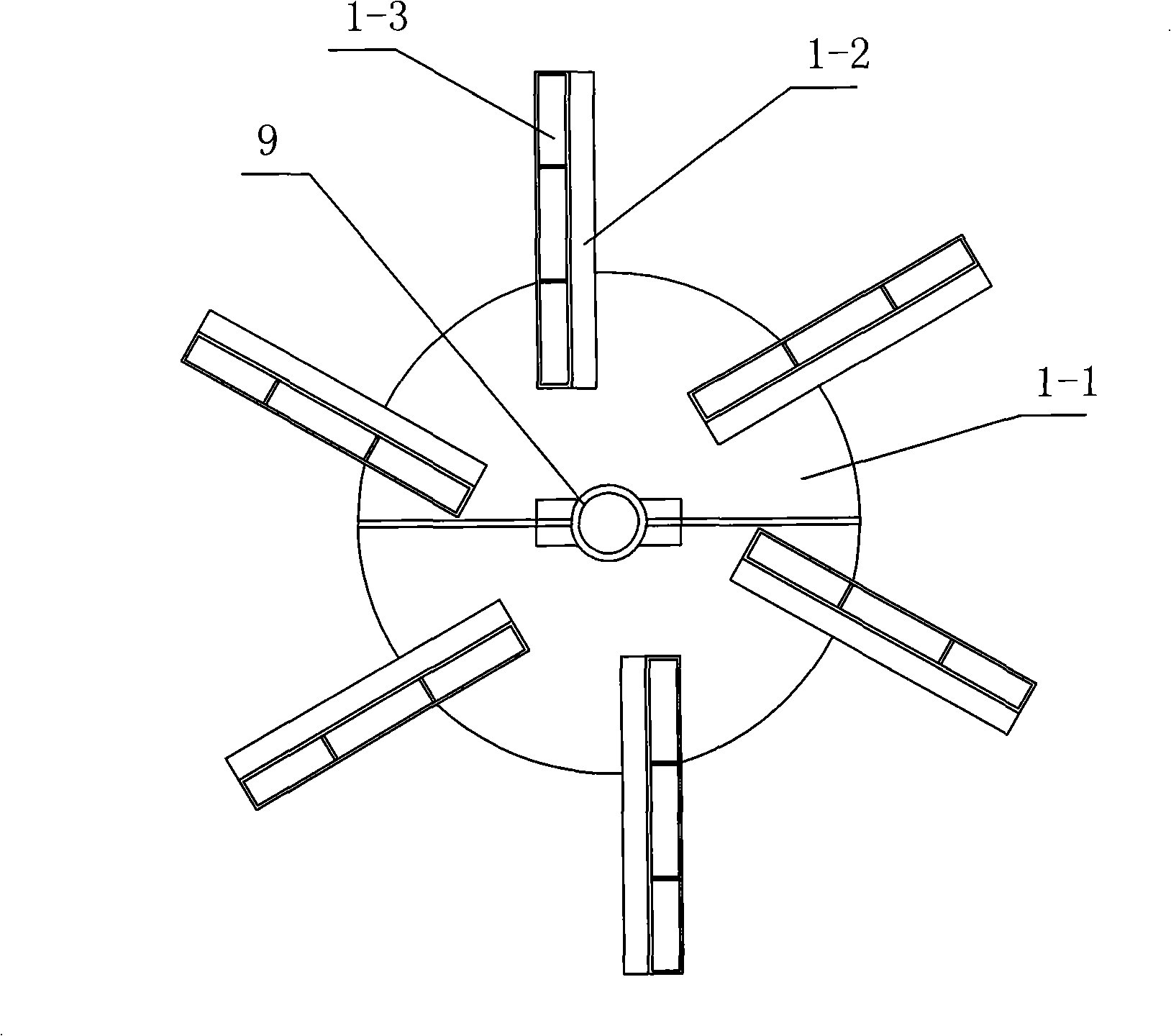

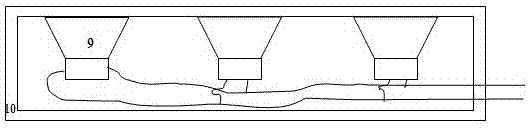

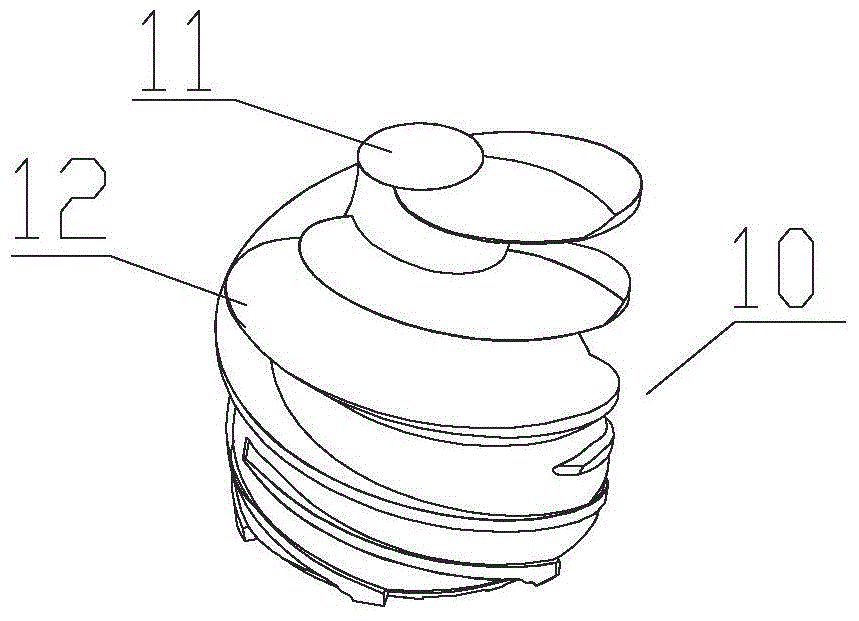

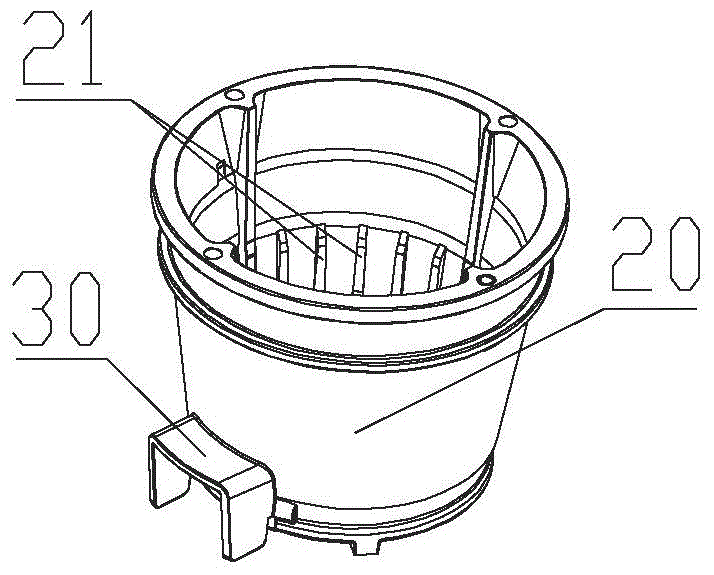

Multifunctional and composite type foam-preventing recovery device for biofermentation

InactiveCN101285034APrevent overflowPrevent fluid escapeBioreactor/fermenter combinationsBiological substance pretreatmentsSuppressorHigh energy

The invention relates to a multifunctional composite froth suppressing and recovering device used in biological fermentation. The invention is characterized in that the device comprises a novel foam suppressor, an exhaust internal drainage gas tray, a tank gas-liquid separation recoverer, a double L pipe and a recovered gas-liquid dispersing station, wherein, the devices are supported and communicated with one another in application, comprehensively solve three-high problems generally existed in the process of biological fermentation, namely the 'high froth' which affects yield, the 'high ventilation volume' which affects environment and the 'high energy consumption' which affects efficiency. When the device is matched with a bioreactor to use in fermenting production, overflow and liquid escape of a froth layer can be effectively prevented, and liquid loading volume and tank laying yield of fermentation liquid can be improved; meanwhile, environmental pollution is prevented, and obvious effects of energy economization and emission reduction are performed.

Owner:李明忠

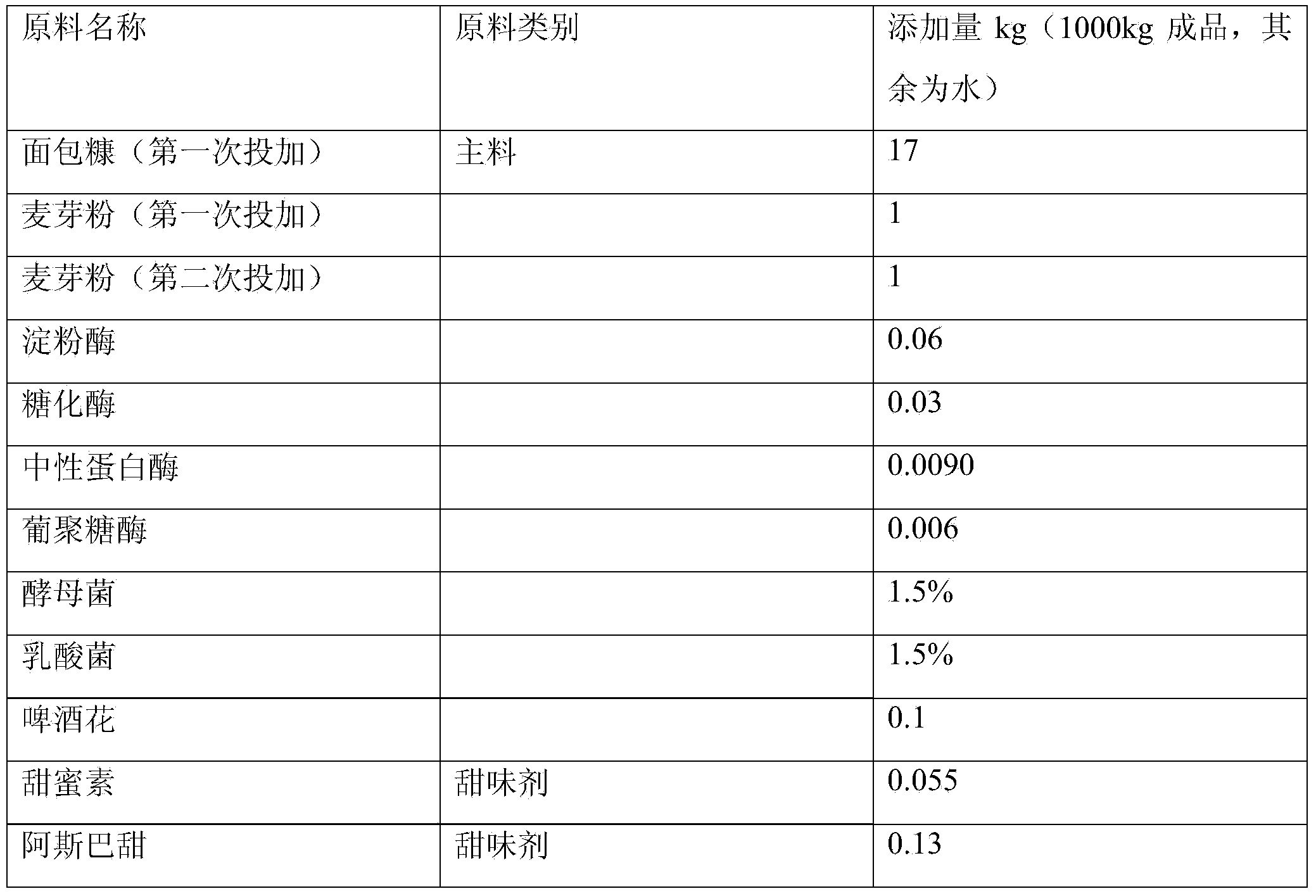

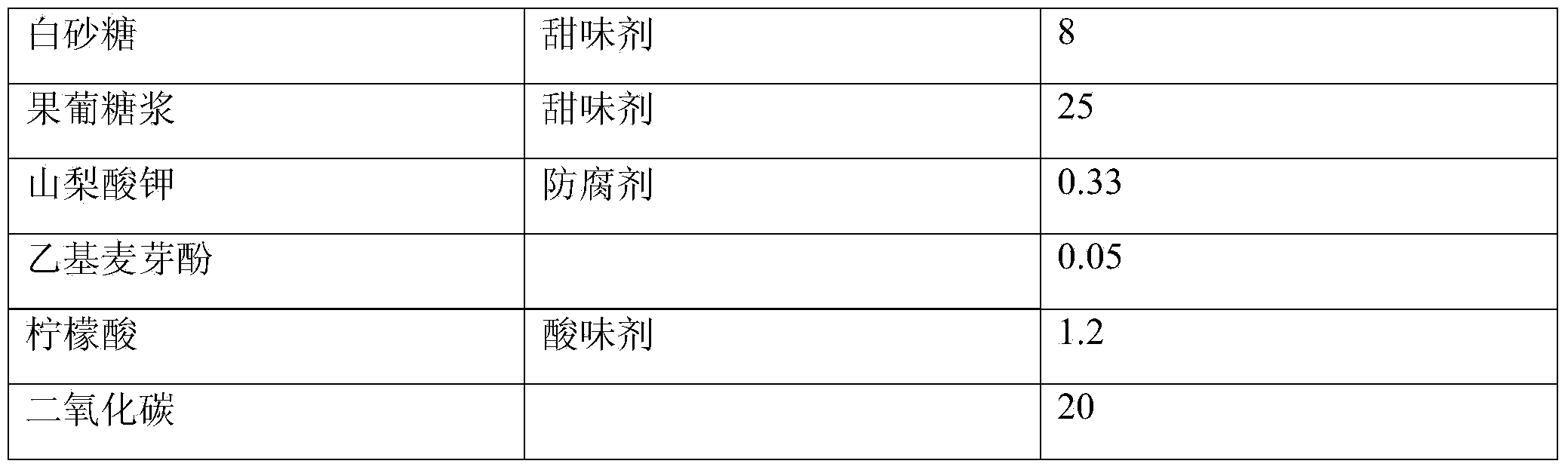

Method for preparing kbac beverage

InactiveCN103865728AReduce in quantityUniform particle sizeAlcoholic beverage preparationGlucanaseNeutral protease

The invention relates to a method for preparing a kbac beverage. The method comprises the following steps: adding water into a saccharifying tank, heating to be 35 DEG C, adding breadcrumbs, uniformly stirring, adding malt flour, heating to be 65 DEG C, adding alpha-amylase, heating to be 90 DEG C, stopping stirring, heating to be 100 DEG C, keeping the temperature for 20 minutes, cooling to be 52 DEG C, adding beta-glucanase, neutral protease and malt flour, keeping the temperature for 70 minutes, heating to be 60 DEG C, adding saccharifying enzyme, heating to be 63 DEG C, keeping the temperature for 40 minutes, heating to be 68 DEG C, keeping the temperature for 20 minutes, heating to be 78 DEG C, standing for 60 minutes to obtain a saccharification liquid, and filtering to obtain supernate. On the basis that the kbac fermented beverage prepared by using the method provided by the invention does not affect the original rich nutrition and health value, the biologic stability of a product is greatly improved, and the product is better in stability and taste within the expiration date. The product stability is that the nutrient substance can be separated for 180-200 days increased from 3-40 days.

Owner:TIANJIN QIULIN KWAS FOOD SCI & TECH

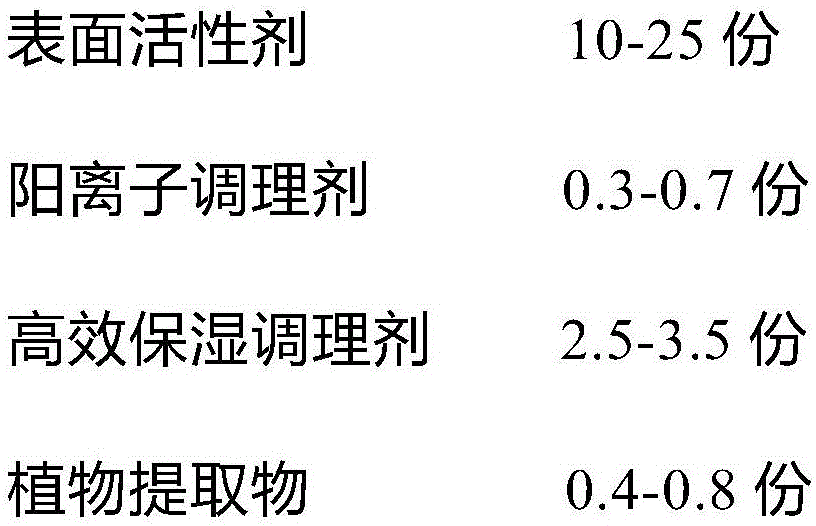

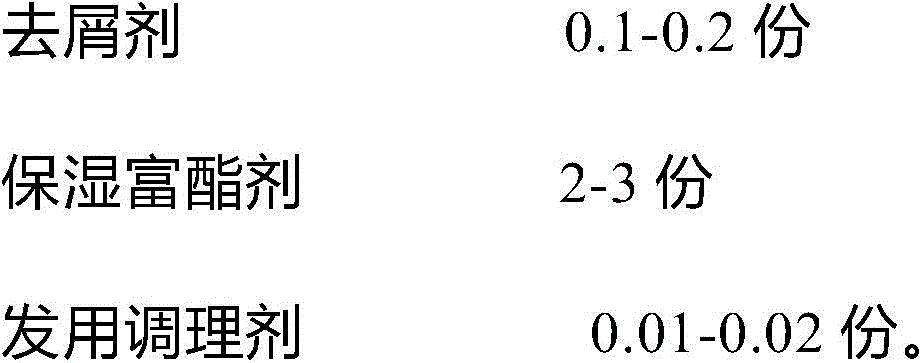

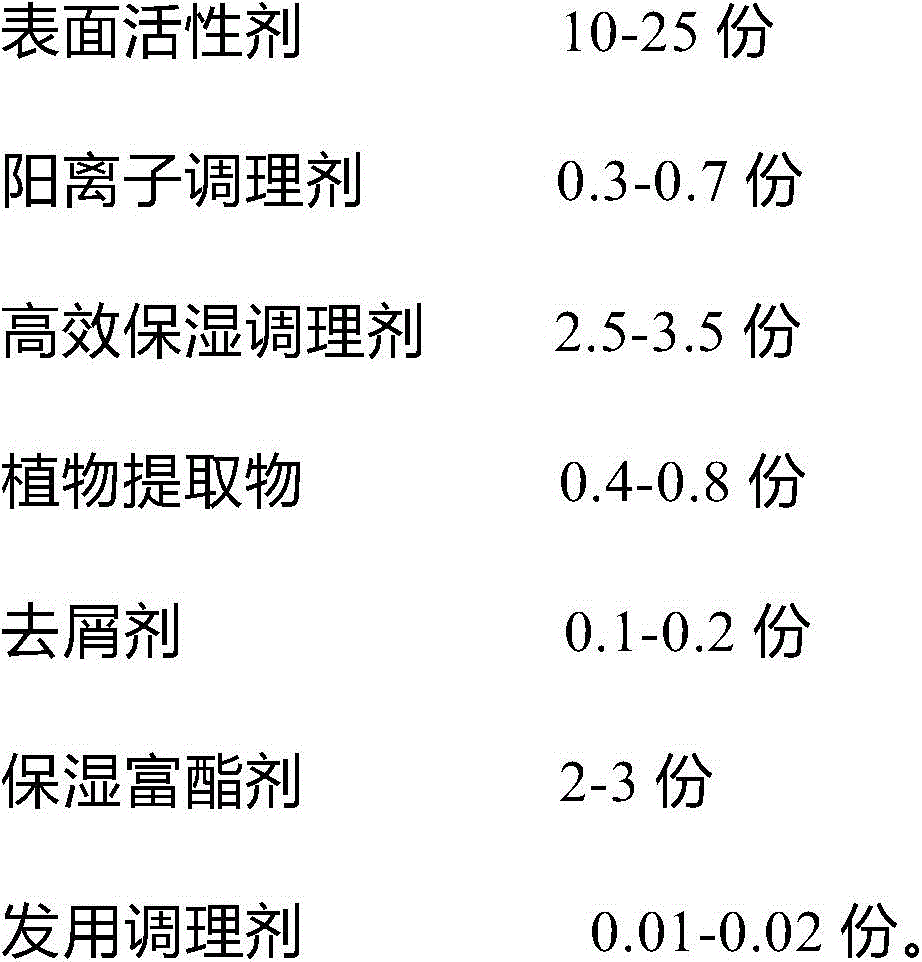

Silicon-oil-free balancing and repairing shampoo

InactiveCN105796421AImprove performancePerformance Broad SpectrumCosmetic preparationsHair cosmeticsSilicone oilGlycol distearate

The invention provides a silicon-oil-free balancing and repairing shampoo.The silicon-oil-free balancing and repairing shampoo is mainly prepared from, by mass, 20-28 parts of a surfactant, 0.2-0.4 part of polyquaternium-10, 0.2-0.4 part of cationic guar gum, 1-3 parts of glycol distearate and 0.3-0.8 part of dihydrogenated tallow phthalic acid amide.The silicon-oil-free balancing and repairing shampoo is mild in formula, contains no silicon oil, and is capable of being prepared into products suitable for crowds with oily, neutral and dry hair as needed and meeting the demands of different crowds.

Owner:PANROSA JIANGSU BIOTECH CO LTD

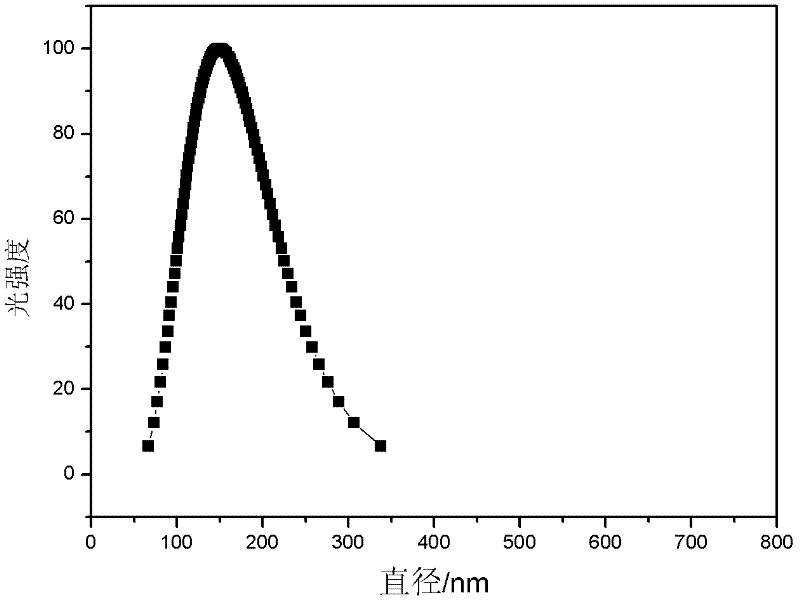

Method for preparing core-shell structured intelligent nano hydrogel

The invention relates to a method for preparing a core-shell structured intelligent nano hydrogel. The method comprises the following steps of: (1) preparing an aqueous solution of hydroxy-propyl cellulose (HPC); (2) dissolving the aqueous solution of HPC and acrylic monomers in deionized water, stirring, adding a crosslinking agent and an initiator, introducing nitrogen, adding an accelerator, stirring to obtain a polyacrylic nano hydrogel, dialyzing for 3 to 7 days, and regulating the pH value to be 3-4 to obtain a solution A; (3) dissolving acrylamide monomers and a crosslinking agent in deionized water, stirring, and introducing nitrogen to obtain a solution B; and (4) pouring the solution B into the solution A obtained in the step (2), introducing nitrogen to obtain a solution C, adding an initiator, heating, introducing nitrogen, and adding an accelerator finally. The preparation method has the advantages of mild reaction conditions and simple and easily controlled equipment; and the prepared nano hydrogel has controlled size, high stability, pH and temperature dual responsibility and high biosafety, and can be applied to the field of control release of medicines.

Owner:DONGHUA UNIV

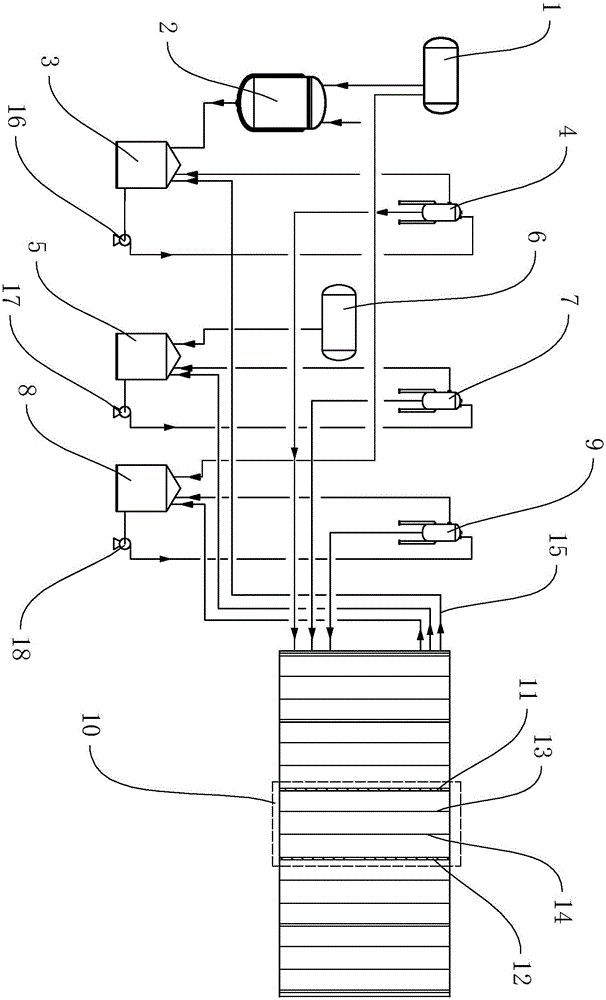

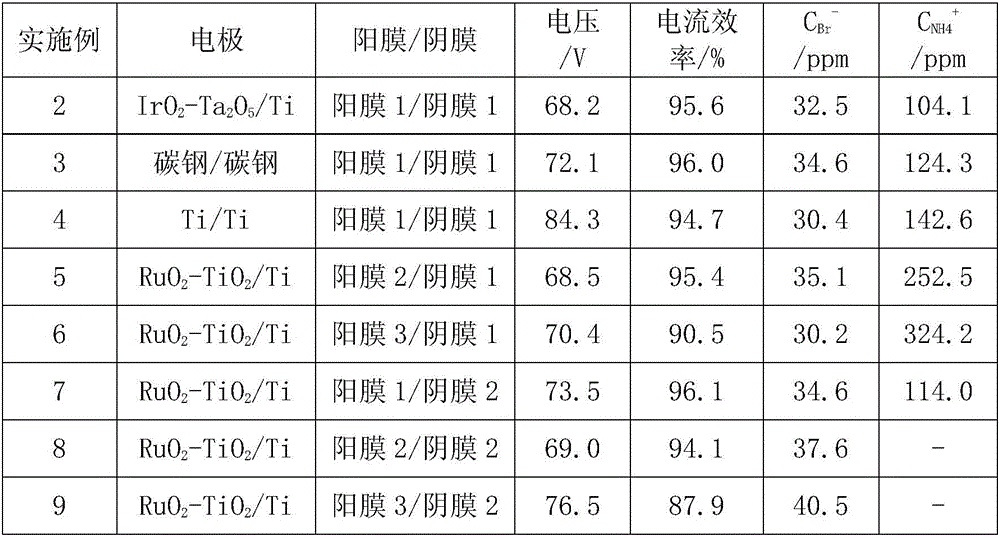

System and method for preparing high-purity tetrapropylammonium hydroxide through electrolysis method

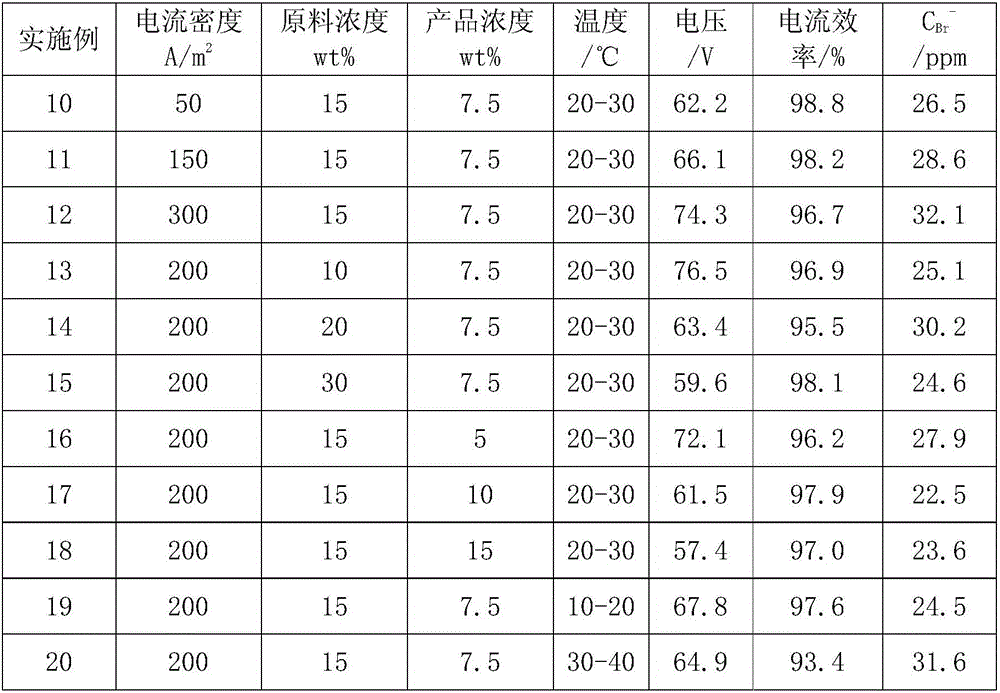

ActiveCN106801233AReduce contentAvoid containingCellsElectrolytic organic productionElectrolysisNitrogen gas

The invention provides a system and method for preparing high-purity tetrapropylammonium hydroxide through an electrolysis method. A 5wt%-25wt% tetrapropylammonium bromide solution serves as a raw material, a two-membrane three-chamber electrolyzer is adopted, tetrapropylammonium bromide in a middle chamber is dissociated to generate (CH3CH2CH2)4N+ and Br-, the cation (CH3CH2CH2)4N+ selectively penetrates a cation exchange film to form tetramethyl ammonium hydroxide together with hydroxyl in a cathode chamber; and the anion Br- selectively penetrates an anion exchange membrane to enter the cathode chamber to be oxidized to generate bromine, the bromine then reacts with ammonium hydroxide to generate ammonium bromide and nitrogen, and a 5wt%-15wt% high-purity tetrapropylammonium hydroxide solution is prepared through continuous current electrolysis according to a continuous or discontinuous method. The electrolysis process overcomes the defect that a product produced through an ion exchange method contains sodion, the beneficial effects of being low in energy consumption, high in product purity and high in current efficiency are achieved, and the bromide ion content in the product is smaller than 50 PPM.

Owner:ZHEJIANG UNIV OF TECH

Method for extracting essential oil from peony flowers

The invention discloses a method for extracting essential oil from peony flowers. The method comprises the following steps: (1) picking fresh peony petals, adding salt which is 20% to 30% of the peony petals by weight for 3-5 days' pickling; adding distilled water which is 3 to 5 times of the peony petals by weight for crushing of the peony petals; (2) extraction: adding purslane and an extraction agent which are respectively 1-3% and 3-5% of the peony petals by weight; adopting a probe-type ultrasonic generator for 30-50 minutes' ultrasonic extraction; carrying out filtering; collecting the filtrate; adding an ethyl alcohol solution with the mass concentration of 80-90% into the obtained filter residue; repeating ultrasonic extraction and filtration for two times; combining all the filtrates; (3) conducting separation on the mixed liquor with a centrifuge at 5000-6000 revolutions per minute; taking a supernatant; carrying out decompressing and removing of an organic solvent under a thermostatic water-bath condition to obtain the essential oil. The method provided by the invention has the advantages that the extracting time is short, the extraction efficiency is high, the situation that the extracted essential oil contains residual peony pollen is avoided to realize the hypoallergenic function, and reduce the harm to users of allergic constitution.

Owner:芜湖市丹洋现代农业科技发展有限公司

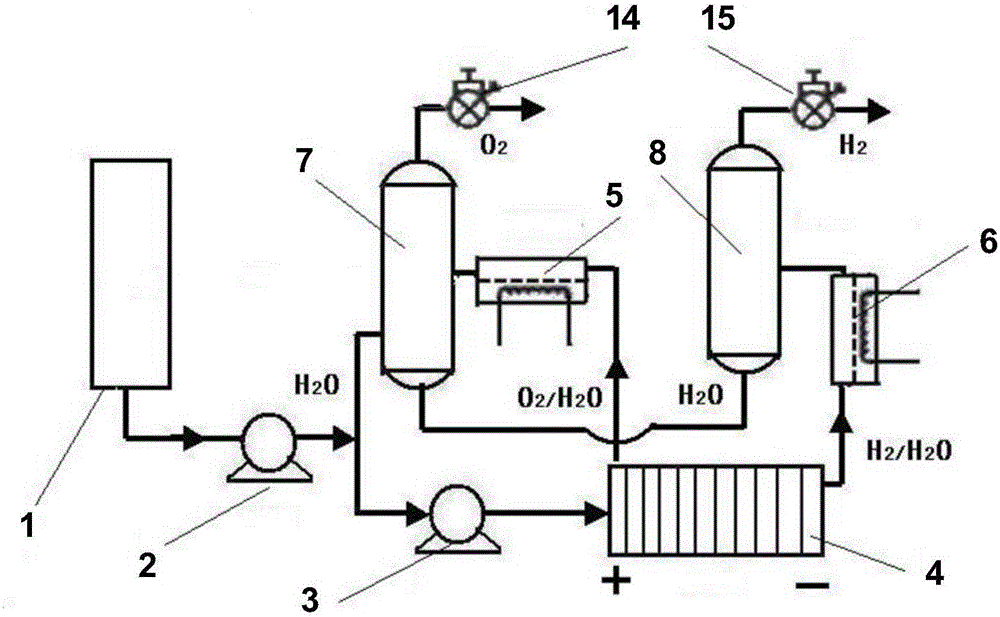

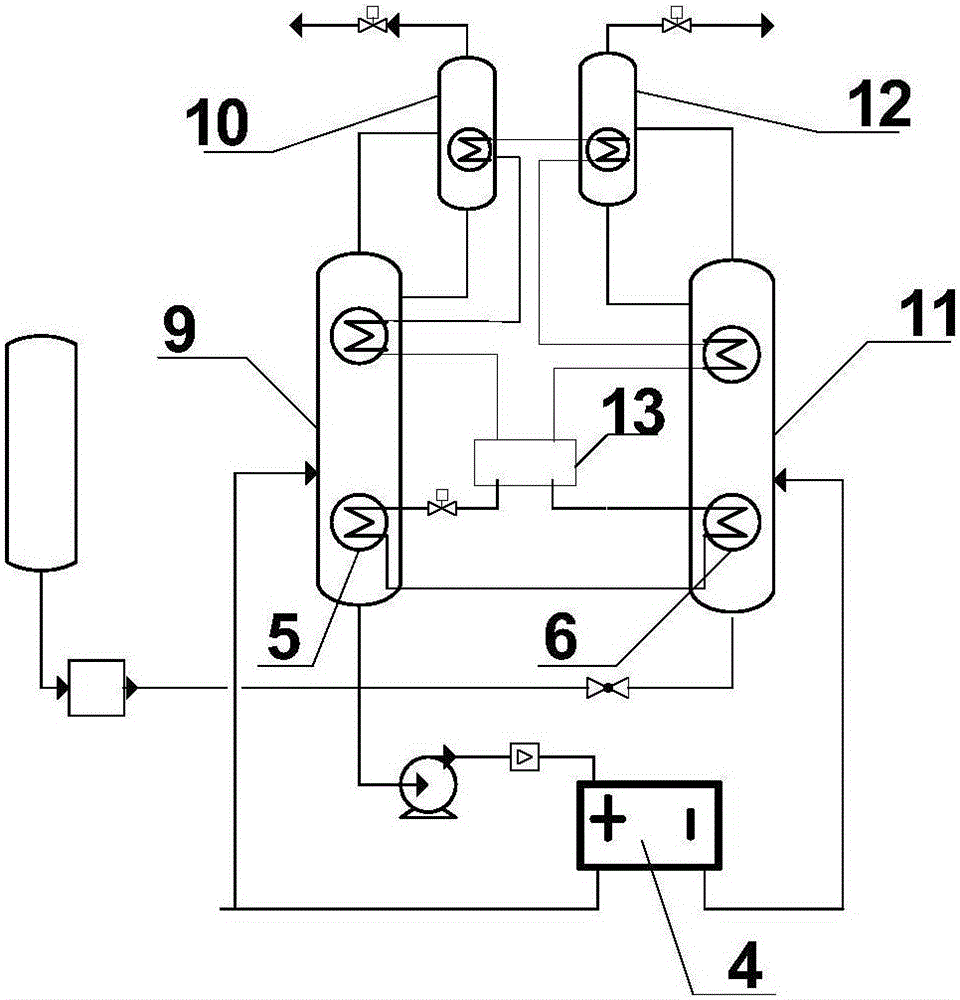

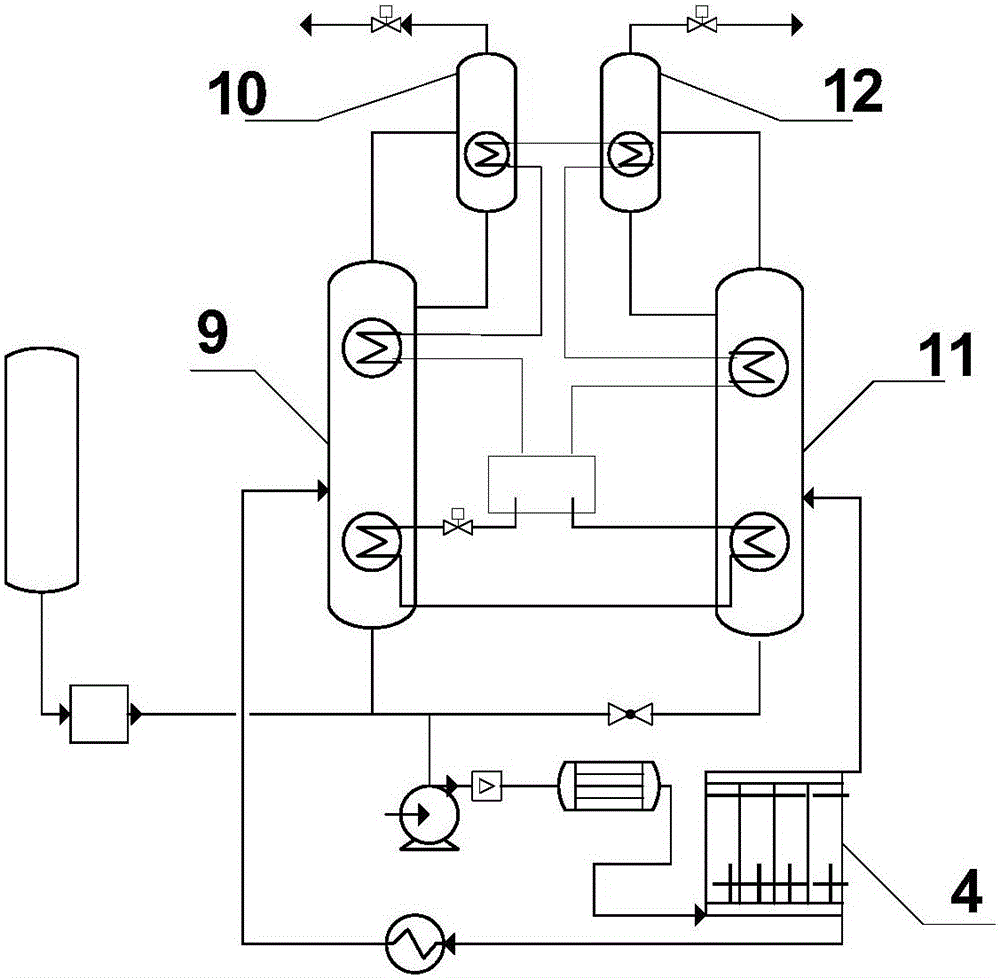

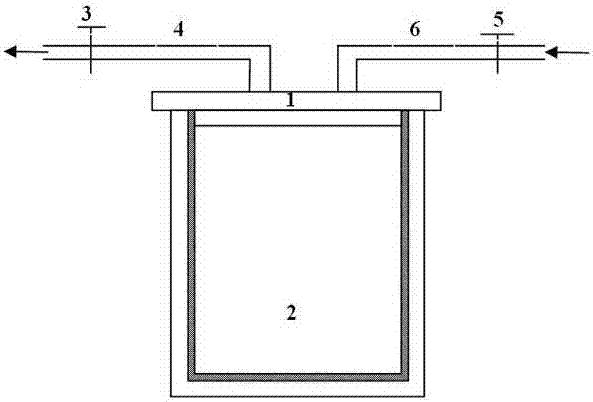

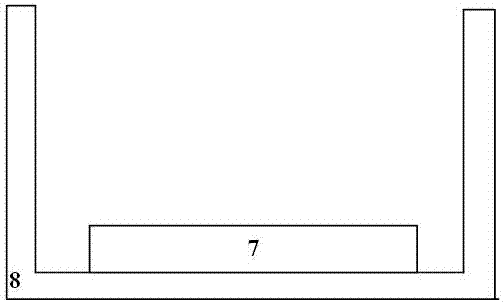

High pressure proton membrane water electrolysis device and method

ActiveCN105862066ANo incorporation of gasAvoid containingCellsDiaphragmsPolymer electrolytesHydrogen

The invention discloses a high pressure proton membrane water electrolysis device. The device comprises a water tank, a make up pump, an electrolytic cell stack, a first separator and a second separator, wherein the make up pump is used for communicating the water tank with a water inlet of the electrolytic cell stack; the first separator is communicated with an oxygen outlet of the electrolytic cell stack; the second separator is communicated with a hydrogen outlet of the electrolytic cell stack; and an electrolyte and proton exchange membrane is arranged in the electrolytic cell stack and is solid polymer electrolyte. The high pressure proton membrane water electrolysis device has the beneficial effects that the device avoids that the gases generated in traditional methods for electrolyzing water contain alkaline aerosol; and water and gas separation is carried out on the generated gases by the first and second separators, thus greatly improving the purity of the gases generated by electrolyzing water. The invention also discloses a high pressure proton membrane water electrolysis method.

Owner:淳华氢能源科技(湖南)有限公司

Pre-graphitized polycrystalline diamond compact

InactiveCN104563889AAvoid containingCobalt penetrationDrill bitsMetal layered productsPyrophylliteAlloy substrate

The invention provides a pre-graphitized polycrystalline diamond compact. A diamond single crystal polycrystalline layer covers a hard alloy substrate and is synthesized by a diamond single crystal and hard alloy at a high temperature under a high pressure. The process comprises the following steps: putting the diamond single crystal into a vacuum furnace, heating to 1350 to 1450 DEG C in a vacuum of 0.01 to 0.02Pa, and after pre-graphitizing the surface of the diamond single crystal, growing a polycrystalline diamond layer together with contacting single crystal graphite by use of the diamond single crystal and the hard alloy substrate while converting graphite into diamond under a pressure of 5 to 7GPa and at a temperature of 1000 to 1200 DEG C in a metal cup pyrophyllite synthesis cavity; and after growing the polycrystalline diamond layer, raising the temperature in the cavity to 1400 to 1500 DEG C, forming a surface adhesive layer which only has a bonding effect between the polycrystalline layer of the diamond single crystal and the hard alloy substrate, and bonding the polycrystalline diamond layer on the hard alloy substrate, thereby synthesizing the pre-graphitized polycrystalline diamond compact.

Owner:莱州市原野科技有限公司

Fabrication method for surface electroplating coating layer of NdFeB rare-earth permanent magnet

ActiveCN107039168AIncreased vacuum handlingContains to avoidPermanent magnet manufactureVacuum pumpingMetallurgy

The invention belongs to the technical field of corrosion-prevention surface processing, and particularly relates to a fabrication method for a surface electroplating coating layer of an NdFeB rare-earth permanent magnet. The fabrication method comprises the steps of firstly, pre-processing a surface of the NdFeB rare-earth permanent magnet; secondly, performing vacuum pumping on the NdFeB rare-earth permanent magnet; and finally, electroplating by employing an ultrasonic wave electroplating groove. By the fabrication method, expansion and bubbles of a plating layer caused by a hydrogen evolution effect are prevented, the corrosion prevention performance of the surface coating layer of the NdFeB rare-earth permanent magnet is improved, an existing NdFeB electroplating corrosion-prevention technology is expected to be substituted, and thus, the fabrication method has a very wide application prospect.

Owner:凉山稀土产业技术研究院

Method for extracting edible starch from oak seeds and obtaining byproduct tannin

InactiveCN104311676ASimple production processLow costEsterified saccharide compoundsSugar derivativesAmyrisTannin

The invention relates to the technical field of comprehensive utilization of oak seeds, and particularly relates to a method for extracting edible starch from oak seeds and obtaining byproduct tannin. The method comprises steps of preprocessing the oak seeds, firstly removing the tannin in the oak seeds so as to obtain crude extract of the tannin, taking the residue obtained in the preparation of the crude extract of the tannin as the raw material to prepare the starch, finally purifying the tannin. The yield of the prepared starch is 30-32%, the content of the starch is 71-73%, the content of the tannin in the starch is lowered to 0.5-0.58% from 7-8% in the raw material, wherein the 0.5-0.58% of tannin is safe and edible, furthermore, the yield of the extracted tannin is 5.83-5.98%, the purity of tannin is 83-84%, in the whole process, the recycling rate of the tannin in the raw material is 70-75%.

Owner:GUIZHOU LYUNONG BIOLOGICAL TECH CO LTD

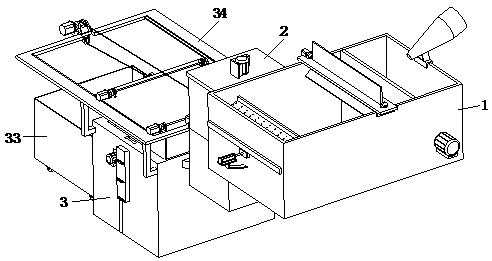

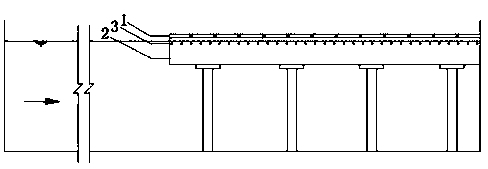

Papermaking wastewater pulp-water separation apparatus

ActiveCN110204099AAddressing technical inefficiencies in recyclingAvoid containingTreatment involving filtrationMultistage water/sewage treatmentFiberFlocculation

The invention discloses a papermaking wastewater paper-water separation apparatus, and belongs to the technical field of papermaking wastewater. The apparatus comprises a liquid pool, a flocculation tank and a separation device, the liquid pool is located beside the flocculation tank, the liquid pool is provided with a liquid pipeline extending into the flocculation tank, the flocculation tank isprovided with a liquid pipeline in overlapping fit with the separation device, the separation device comprises a sedimentation tank, a separation assembly and a collection assembly, the separation assembly is mounted at the top of the sedimentation tank, one end of the separation assembly extends to a position over the collection assembly, a defoaming assembly and a partition assembly are arrangedin the liquid pool, and the partition assembly is mounted in the liquid pool, and the defoaming assembly is in sliding fit with the top of the liquid pool. Two stretching members make a water filtering layer disengage from the sedimentation tank, a pulling motor drives a pulling wheel to rotate to make a pulling rope pull a sliding plate to move on a positioning plate, the sliding plate drives the water filtering layer to move into a collection box, and a plurality of air blowing nozzles blow paper pulp fibers on the water filtering layer into the collection box.

Owner:浙江弘安纸业股份有限公司

Mutton jerky and preparation method thereof

The invention relates to the technical field of food processing, in particular to mutton jerky and a preparation method thereof. The preparation method comprises the following steps: mutton and a mutton-smelling modifier are mixed according to a certain compounding ratio, so that the mutton-smelling is modified by the mutton-smelling modifier in the making process of the mutton jerky, the mutton-smelling of the mutton is removed or weakened to a larger degree, the flavor and the taste of the mutton are improved, and the quality of the mutton jerky is improved; then the mutton is limited to gigot meat, so that the quality of the meat from which the mutton jerky is made is ensured, and because the gigot meat is muscles capable of moving for a long time and higher in quality, the quality of mutton jerky products is improved; twelve kinds of raw materials of star aniseed, licorice roots, fennel, Chinese prickly ash, galanga, spice leaves, nard, red peppers, Chinese cinnamon, cardamom, fructus tsaoko, villous amomum fruits and the like and other raw materials are added to the gigot meat, so that the mutton-smelling modifier can improve the health-care effect during modifying and treating the gigot meat, appetite of a human body is improved, and the digestion is facilitated.

Owner:贵州麻阳河食品有限公司

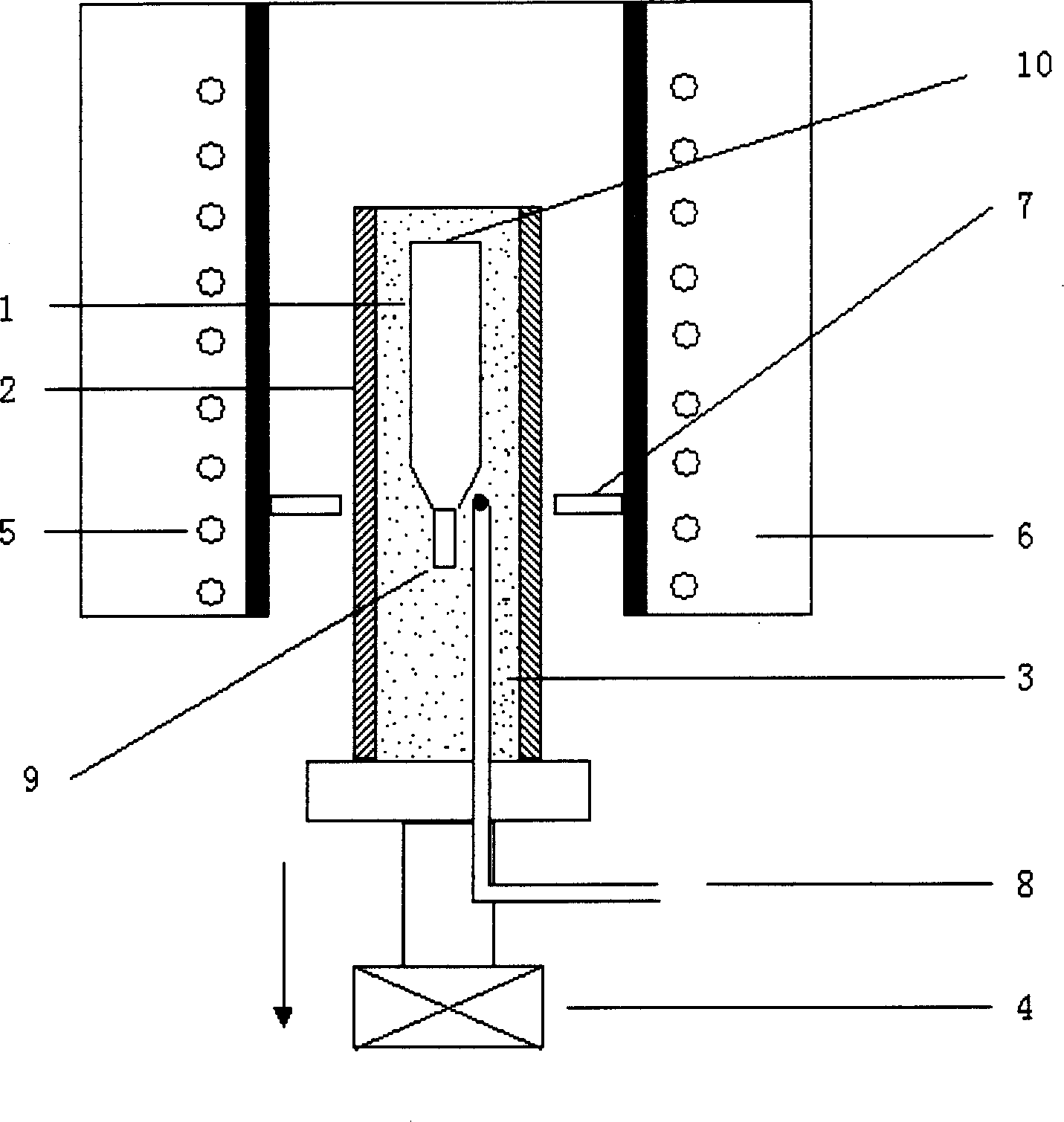

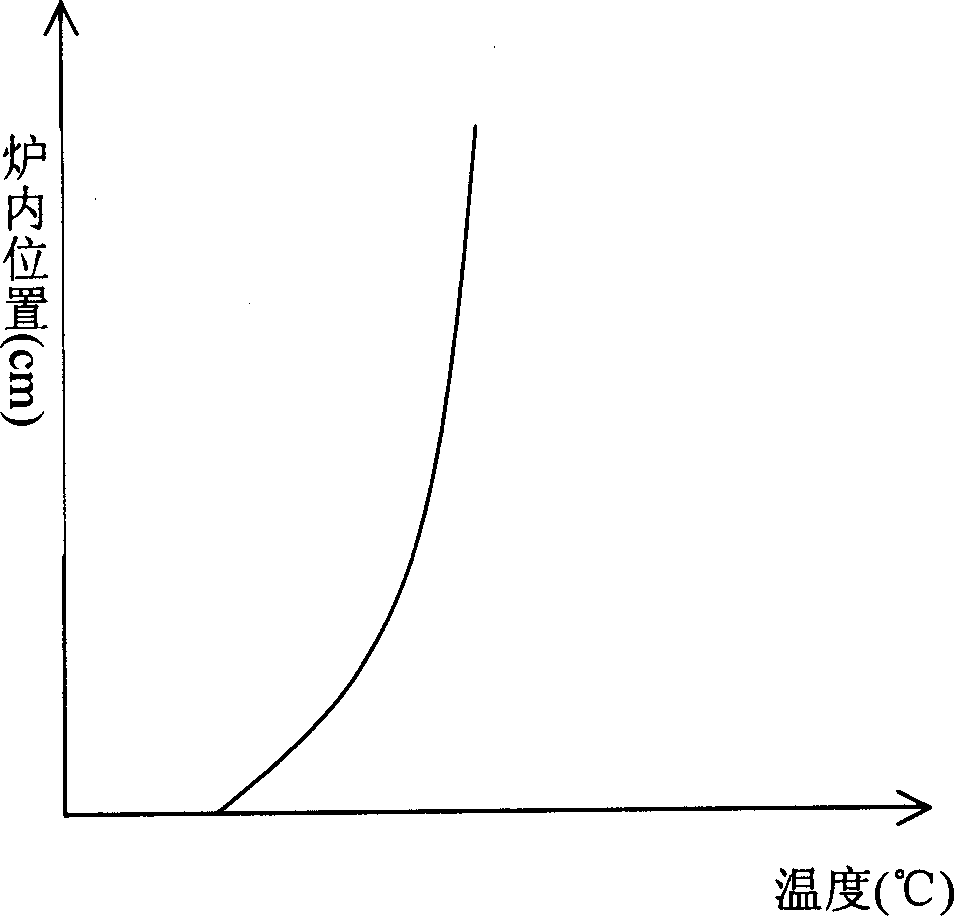

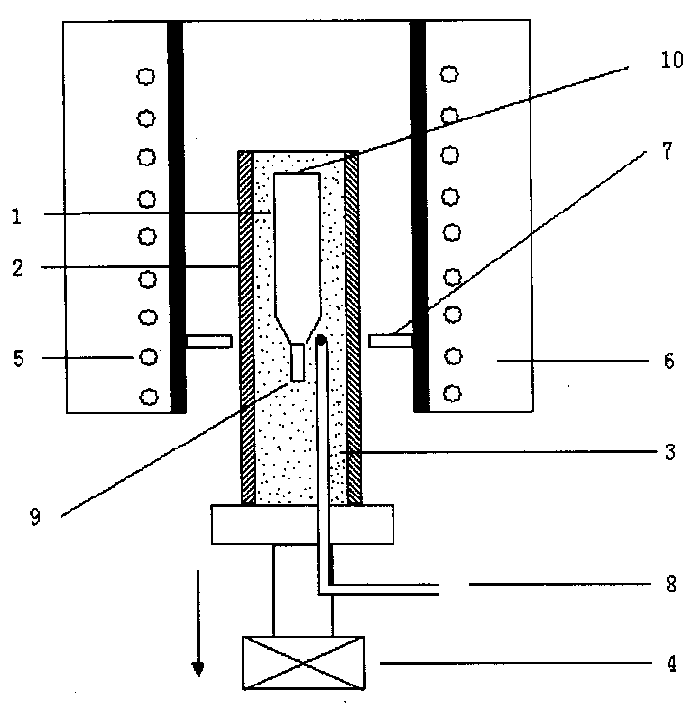

Method of growing near chemical gauge ratio lithium niobate monocrystal using crucible lowering method

InactiveCN1514046AAvoid hypoxiaOvercome the difficulty of volatilizationPolycrystalline material growthBy pulling from meltCrucibleLithium carbonate

A process for growing the lithium niobate monocrystal with near stoichiometric ratio by crucible lowering method includes putting orientational seed crystal in crucible, proportionally mixing Li2CO3 with Nb2O5, die pressing, putting it in said crucible, closing its cover, heating to 1160-1200 deg.C in resistance furnace to smelt and holding the temp for 2-6 hr, lowering the crucible at 0.1-1 mm / hr of speed to grow crystal, and cooling. Its advantages are simple equipment, large size and low cost.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

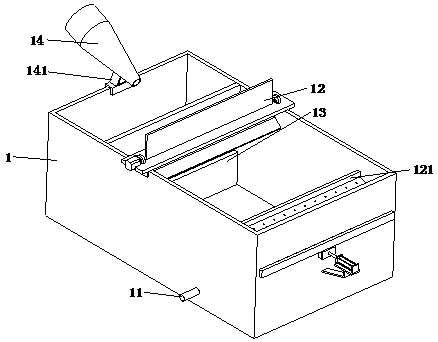

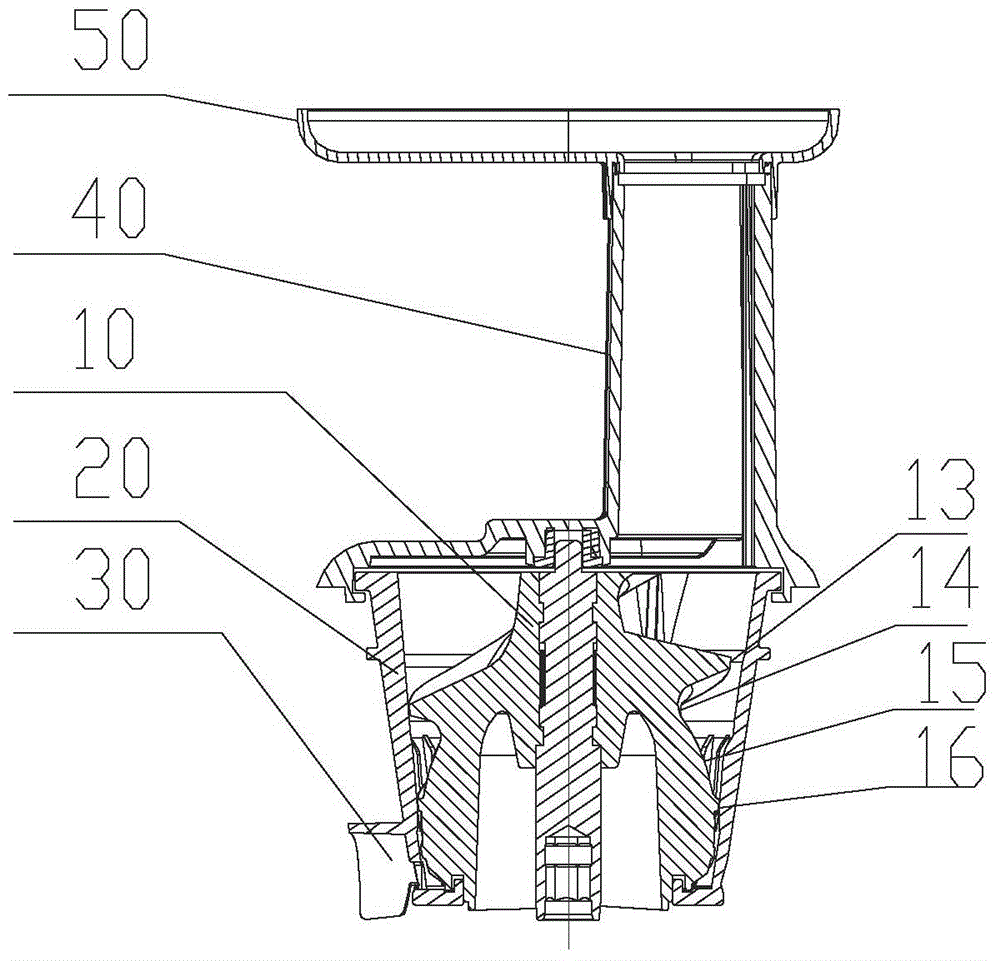

Device and method for preparing ice cream

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

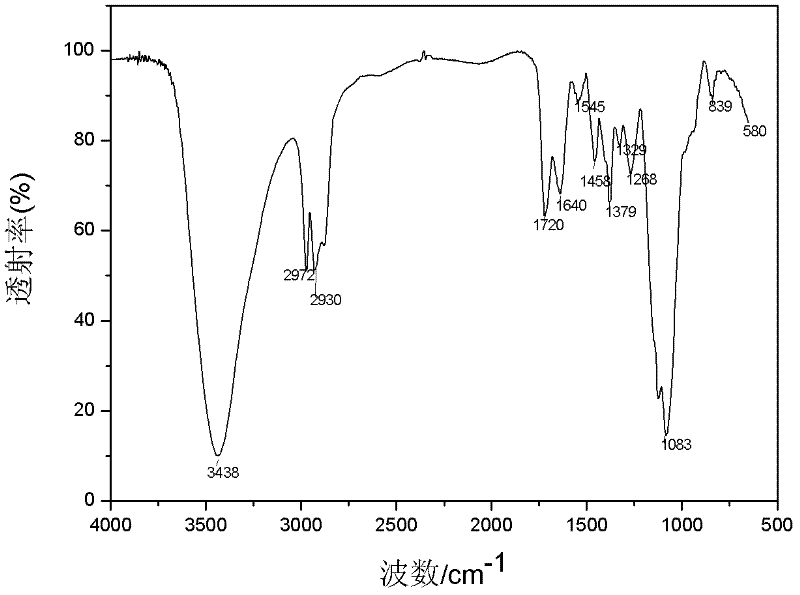

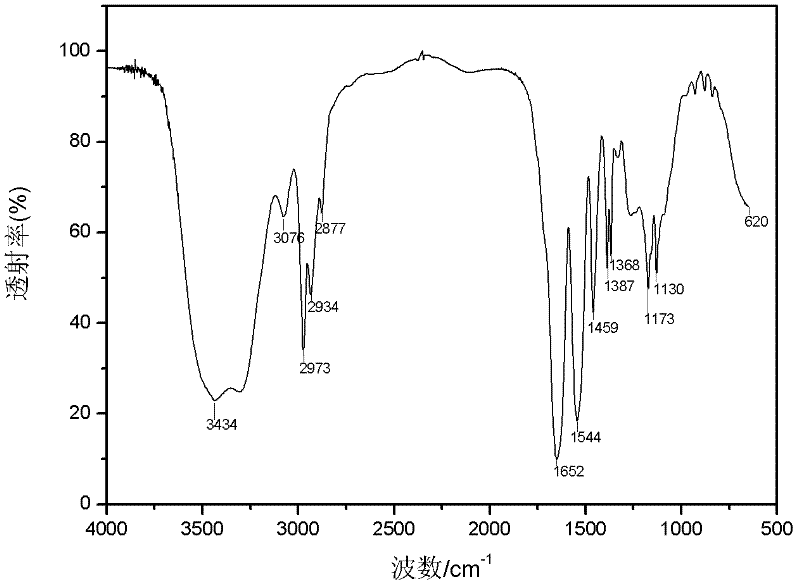

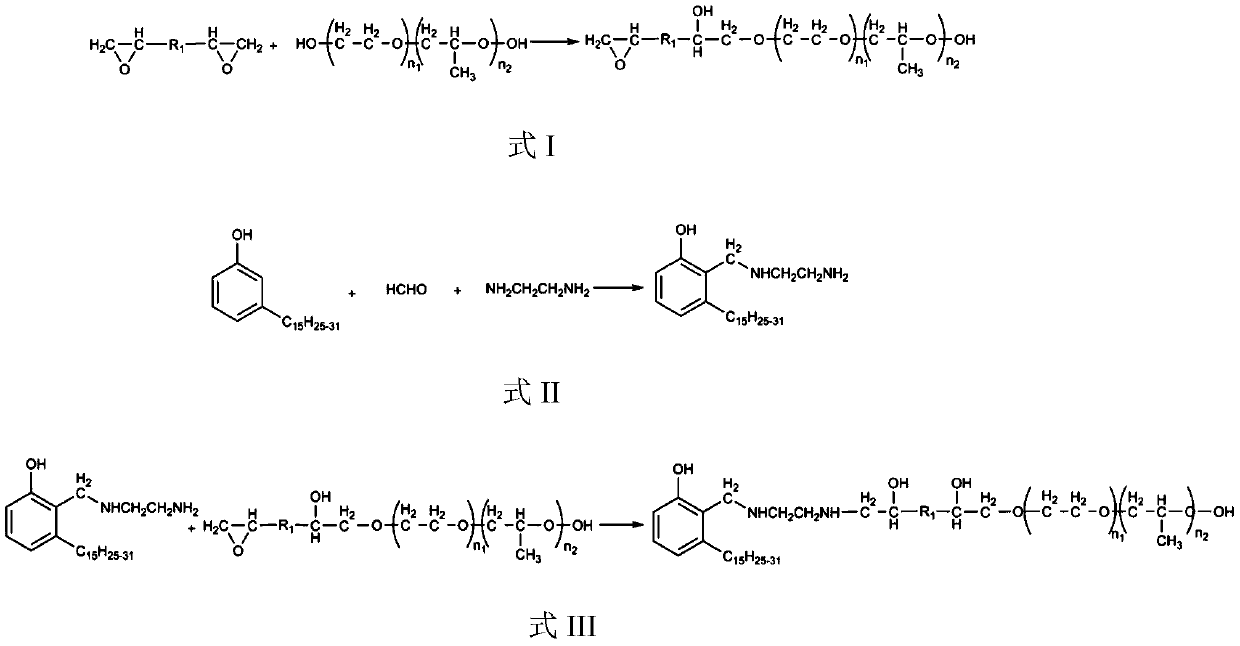

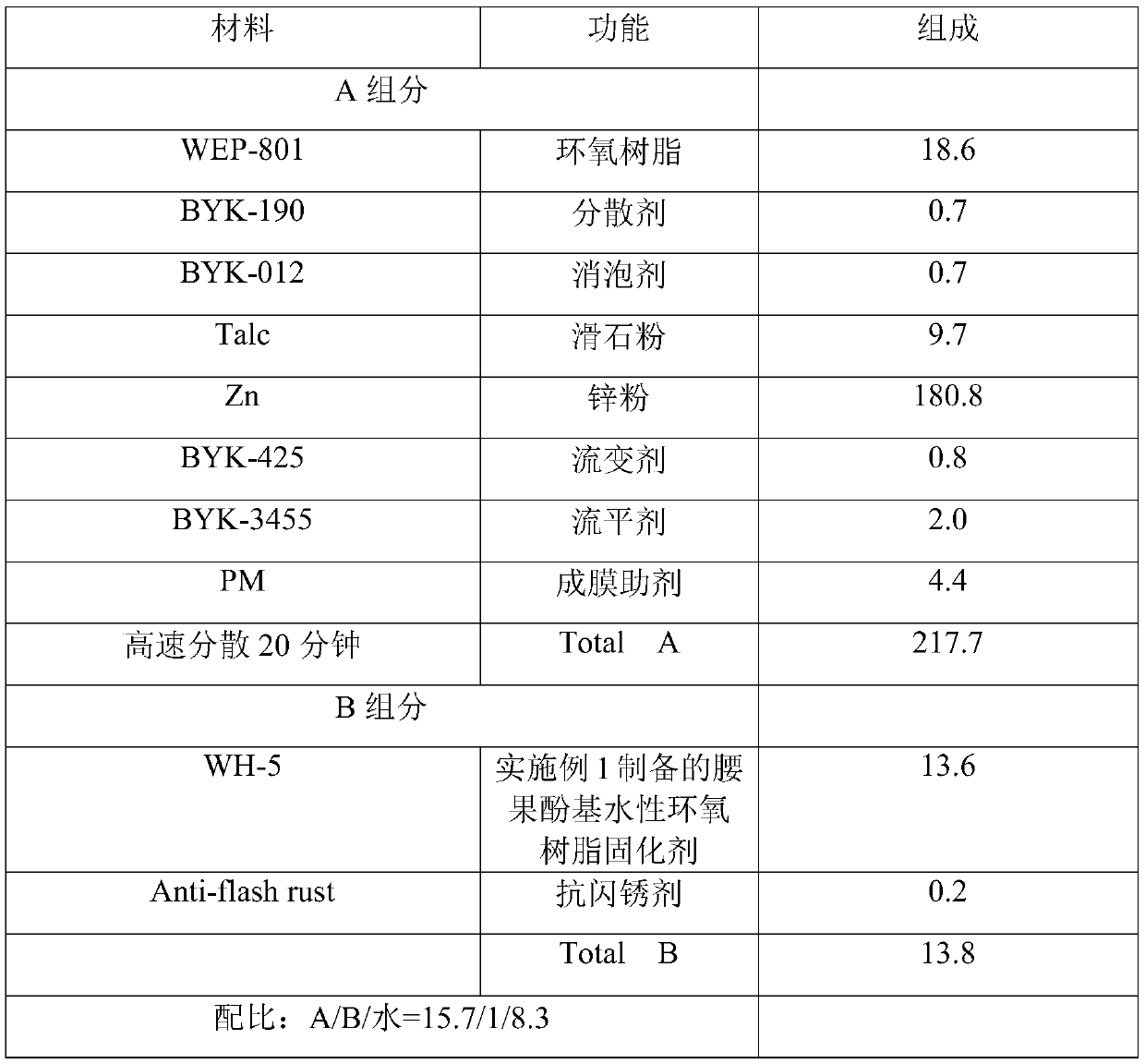

Preparation method and application of cardanol-based waterborne epoxy resin curing agent

The invention discloses a preparation method and application of a cardanol-based waterborne epoxy resin curing agent. The preparation method comprises the following steps: (1) mixing an epoxy resin and a polyether polyol, heating for melting, adding a catalyst at 50-100 DEG C, and carrying out condensation reaction to obtain an epoxy functional group emulsifier after the reaction is finished; (2)carrying out Mannich reaction on cardanol, a polyamine and formaldehyde to obtain a cardanol modified curing agent; and (3) adding the epoxy functional group emulsifier obtained in the step (1) into the cardanol modified curing agent obtained in the step (2), heating to 60-80 DEG C, and reacting to obtain the cardanol-based waterborne epoxy resin curing agent. The cardanol-based waterborne epoxy resin curing agent prepared by the preparation method disclosed by the invention is insensitive to the pH value and good in stability; the process is simple, amine does not need to be excessive, no organic solvent is added, and energy conservation and environmental protection are achieved.

Owner:岳阳中展科技有限公司

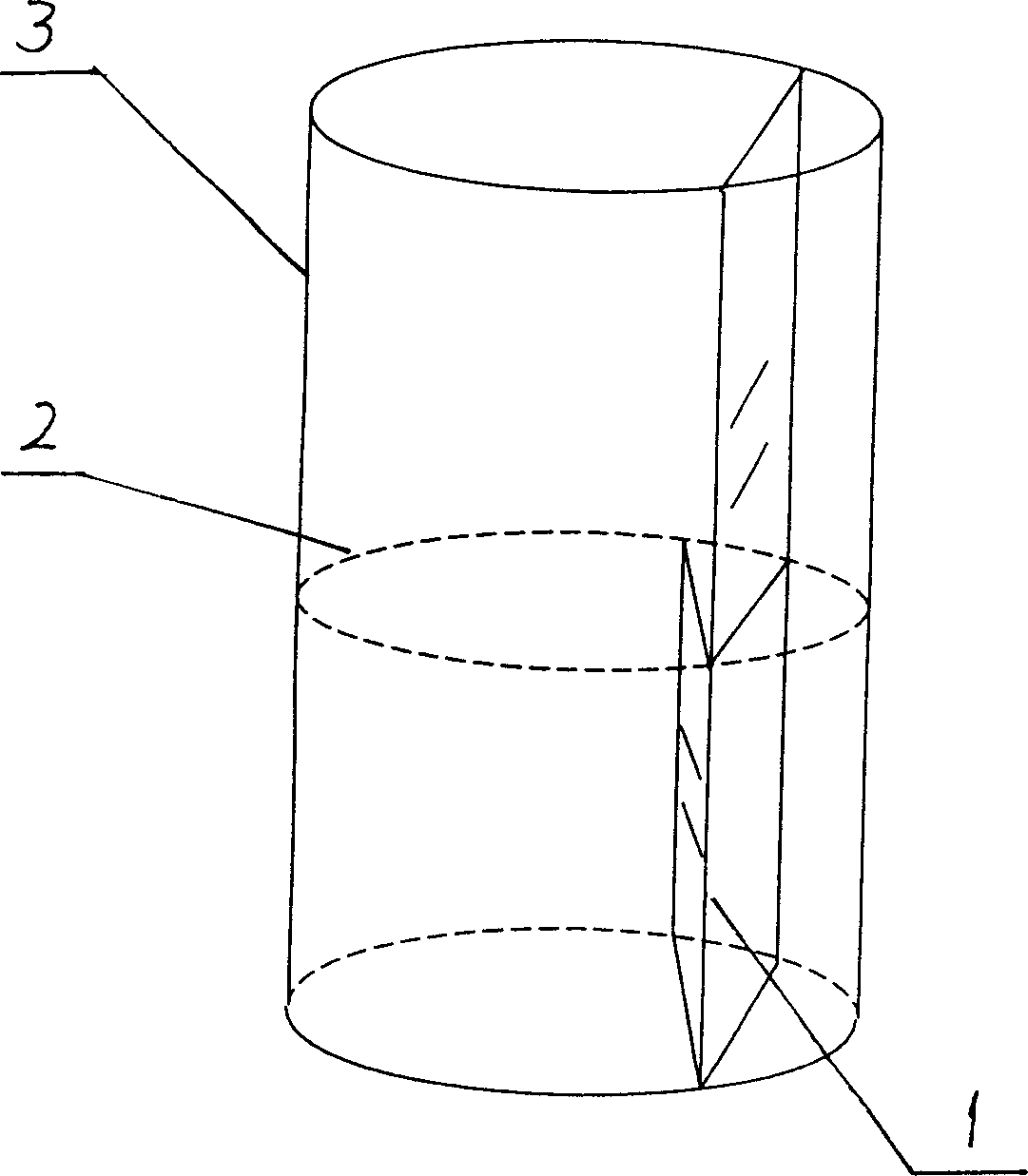

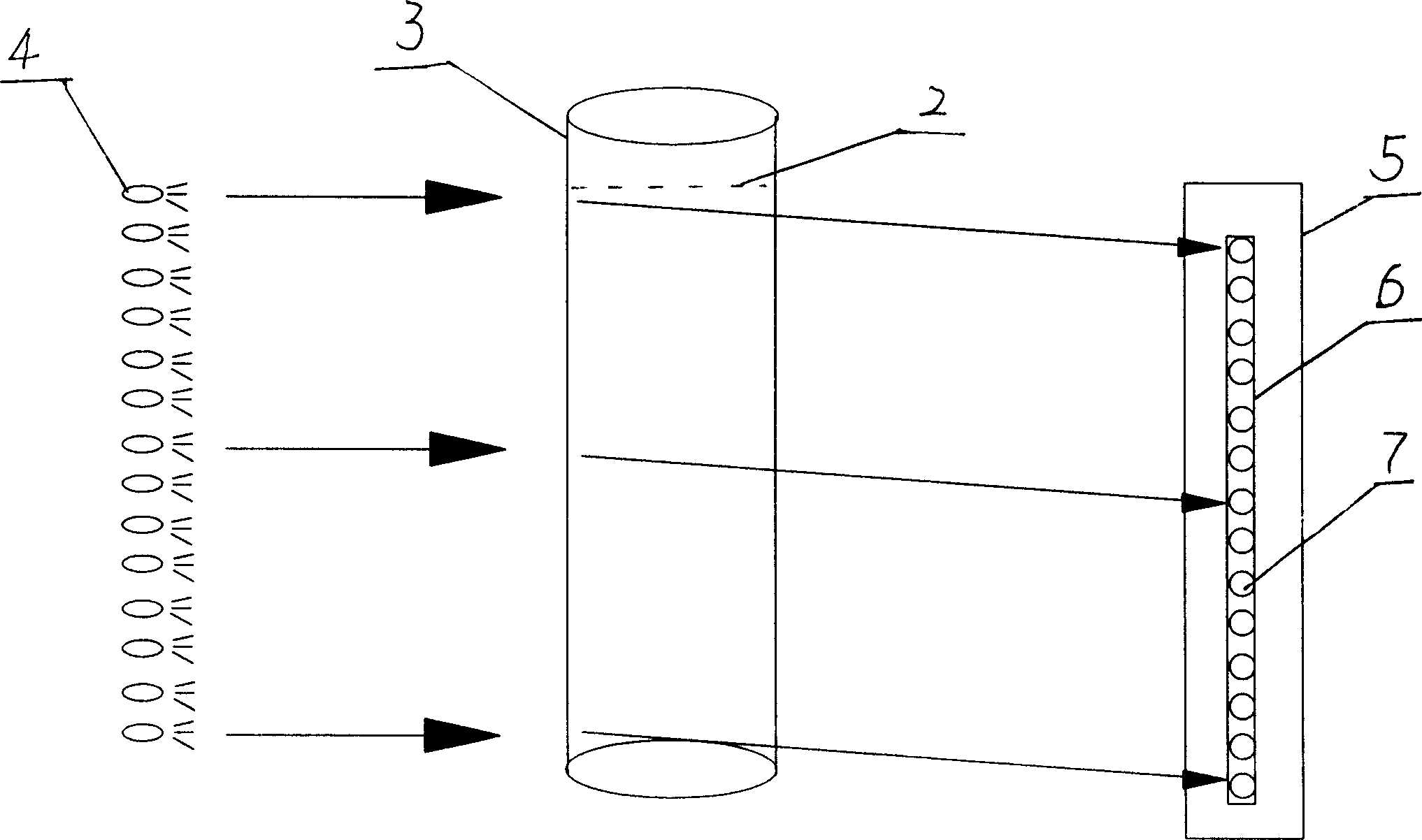

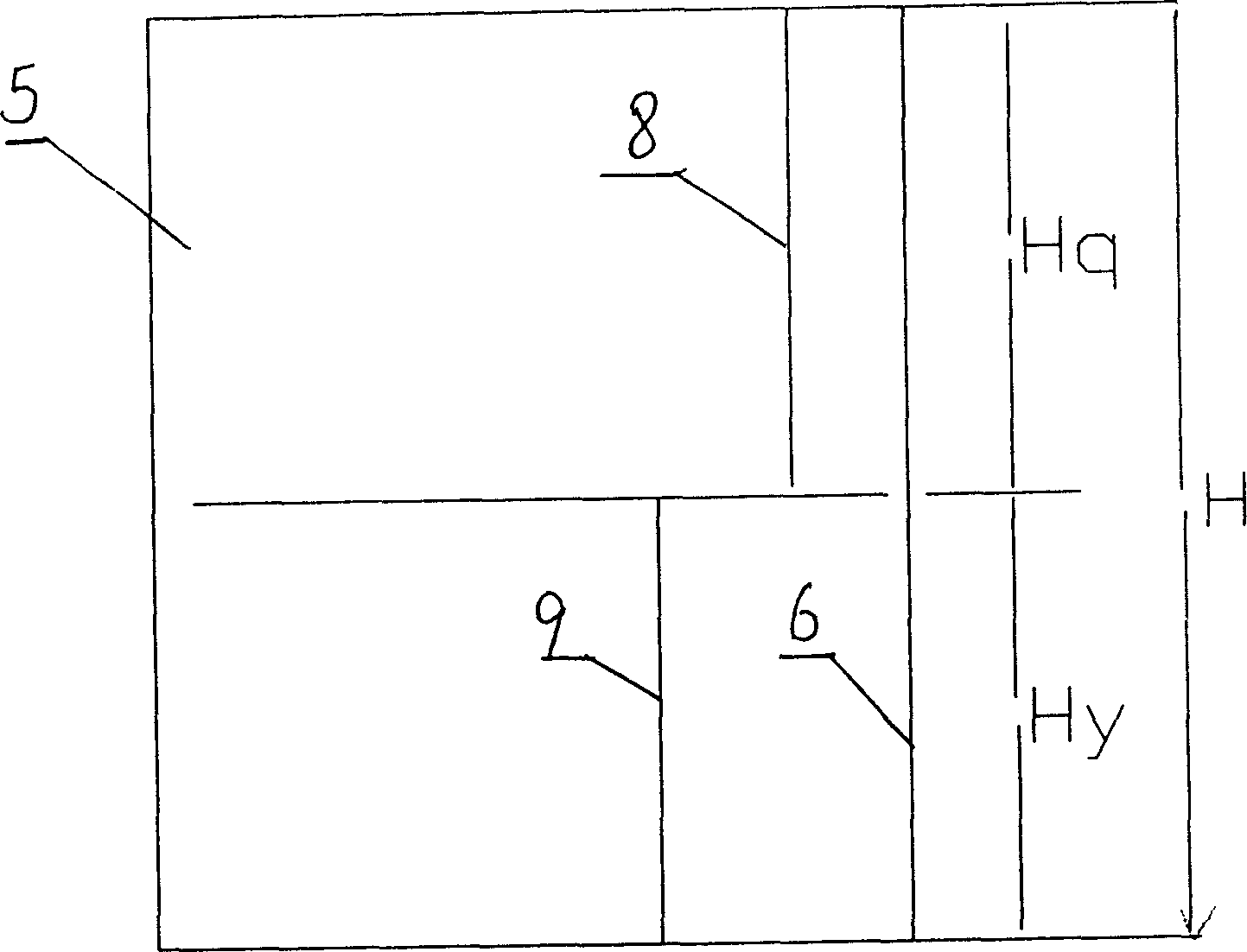

Digitized liquid level measuring method using laser conduction

InactiveCN1877267ASimple structureReduce usageMachines/enginesLevel indicatorsLevel measurementLaser light

Disclosed is a method for measuring laser conductive and digital quantizing liquid level. The method comprises setting laser diodes array along the axial of a cylindrical transparent connecting vessels, wherein the height of the laser diodes array is greater than the measuring range of the liquid level to be measured; setting a background on the opposite position of the cylindrical transparent connecting sampler to make the laser light beam emitted from the laser diodes array project on the background and form a vertical light striation, and defining the height of the liquid level according to the height of the light striation; setting photosensitive tubes array on the site of the light striation for receiving laser beam, wherein the height of the photosensitive tubes array corresponds to the laser diodes array and equals the measuring range of the liquid level to be tested, and the situation shown by the photosensitive tubes represents the real height of the liquid level.

Owner:田逸

High-activity tea pigment, and extraction method and application thereof

ActiveCN103478336AReduce dosageSimple extraction processTea extractionFood preparationThearubiginTea leaf

The invention relates to a high-activity tea pigment, and an extraction method and application thereof. The high-activity tea pigment comprises 50-90% of theabrownin, 7-30% of theaflavin and 3-20% of thearubigin. The extraction method comprises the following steps: A. crosslinking glucose oxidase to nano Fe3O4, and adding CO2 and inert material Al2O3 to form an enzyme mixture; B. pulverizing tea, adding water, heating to a boiling state, cooling by standing, and filtering to form tea soup; C. mixing the enzyme mixture and tea soup, and carrying out circular heating-cooling; D. after carrying out circular heating-cooling for 12-48 hours, putting a magnet in the container, absorbing the supernate, and filtering; and E. evaporating the filtrate to obtain a tea pigment crude extract, dissolving in an alcohol water solution, concentrating and drying to obtain the high-activity tea pigment. The high-activity tea pigment is applicable to food. The content of the high-activity theabrownin in the extract can reach 65-90%.

Owner:杭州茗褐生物科技有限公司

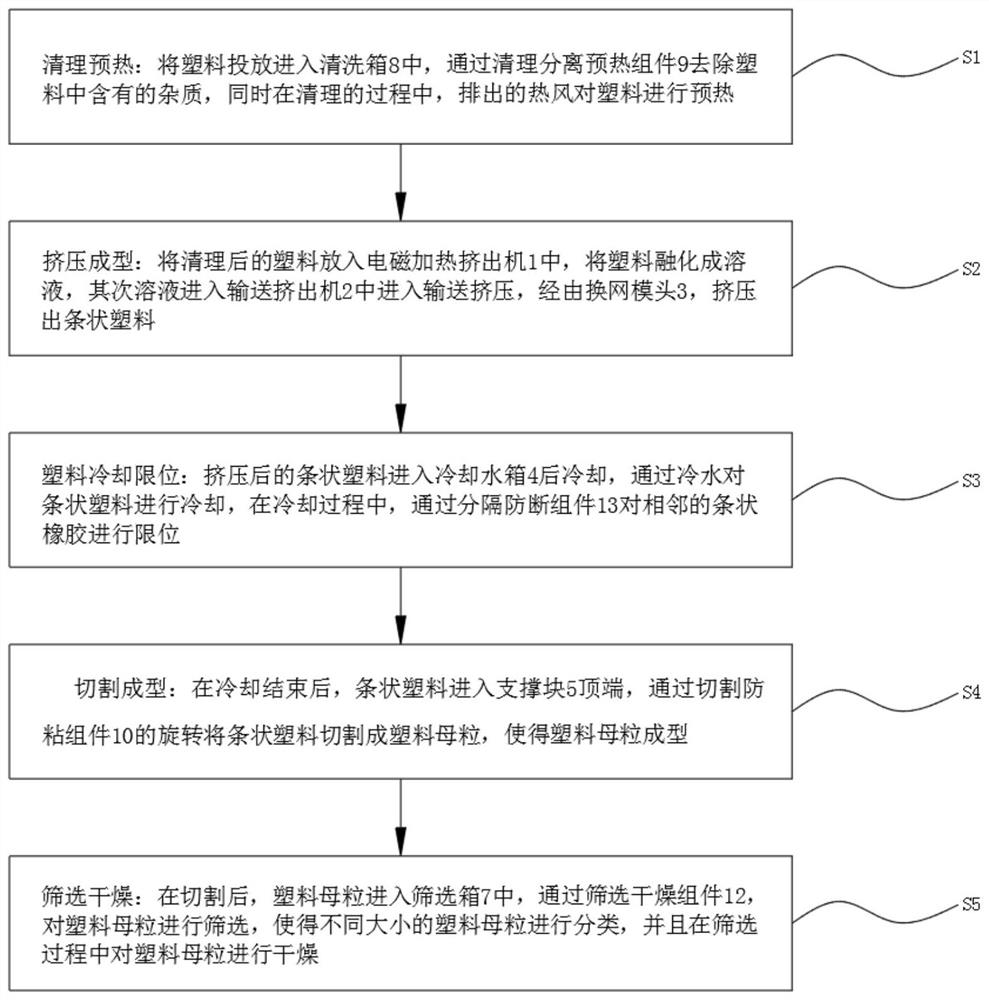

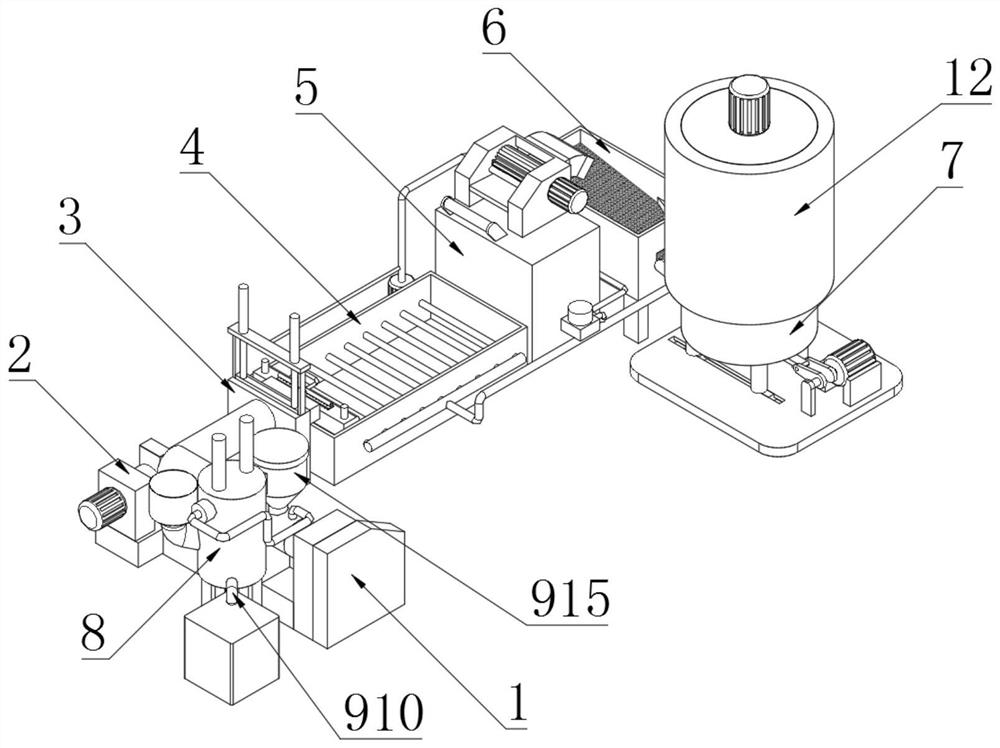

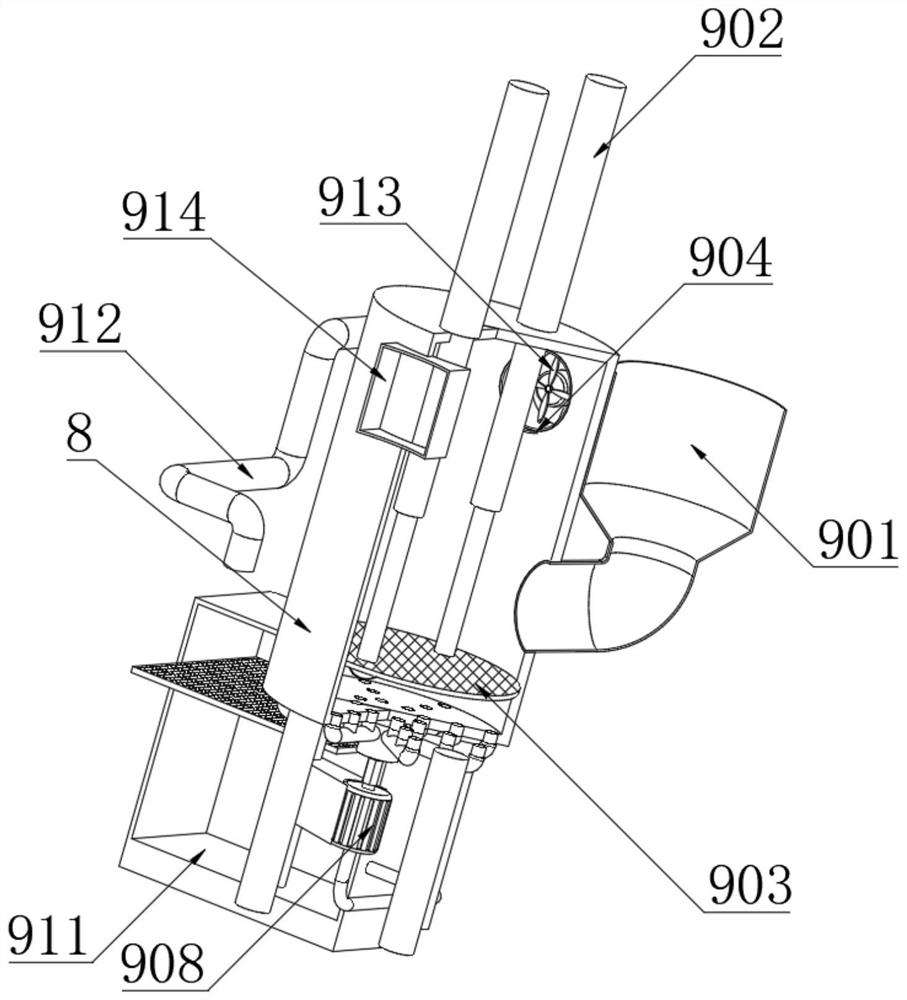

Efficient plastic master batch forming method

The invention discloses an efficient plastic master batch forming method. According to the forming method, a conveying extruder is placed at the end, away from a cleaning box, of an electromagnetic heating extruder, a net replacing die head is fixedly installed on the outer side of one end of the conveying extruder, a cooling water tank is placed at one end of the conveying extruder, a supportingblock is connected to one end of the cooling water tank, one end of the supporting block is connected with a backflow box, and one end of the backflow box is connected with a screening box. Accordingto the forming method, cyclic utilization of water resources is realized by an cleaning and separating preheating assembly, a cooling circulation assembly and a separation anti-breaking assembly, theutilization rate of the water resources is increased, the enterprise cost is reduced, then through the cleaning and separating preheating assembly and the separation anti-breaking assembly, multi-stepoperation on plastic through multiple production lines is not needed, the space utilization rate in an enterprise plant is increased, meanwhile, noise pollution caused by the multiple production lines is reduced, meanwhile, the cost of an enterprise is reduced, and more production benefits are made for the enterprise.

Owner:邓玉欣

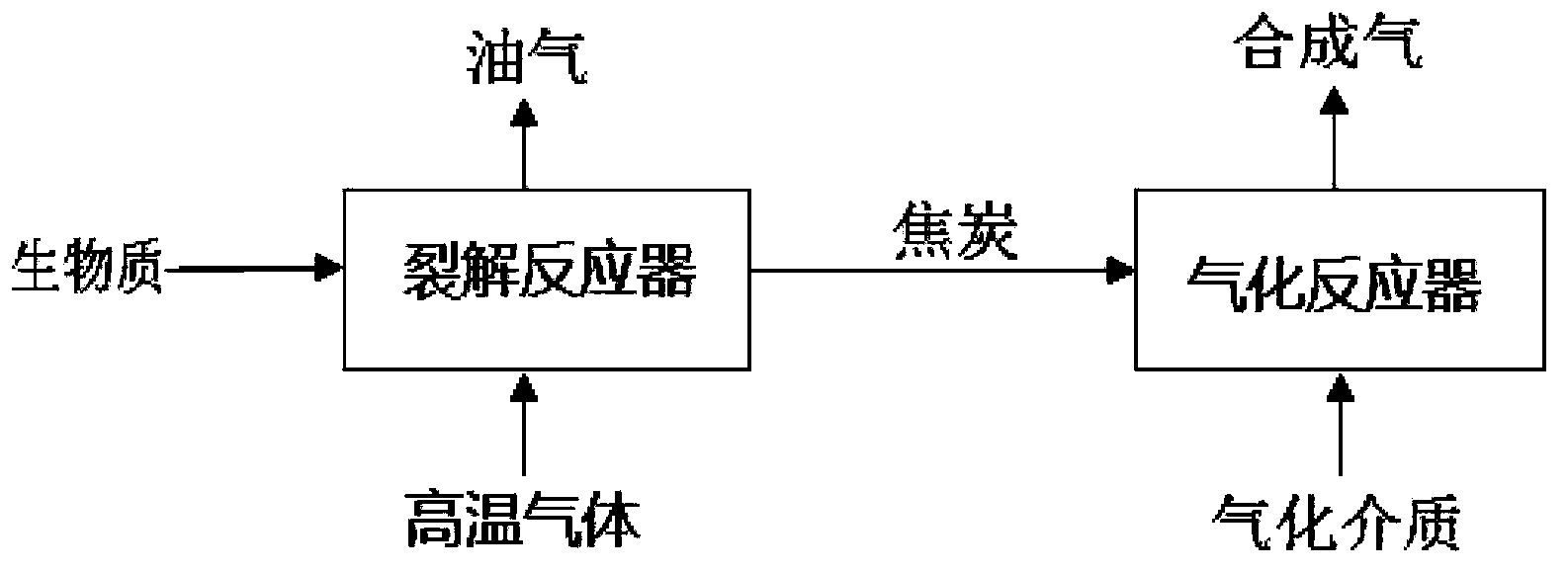

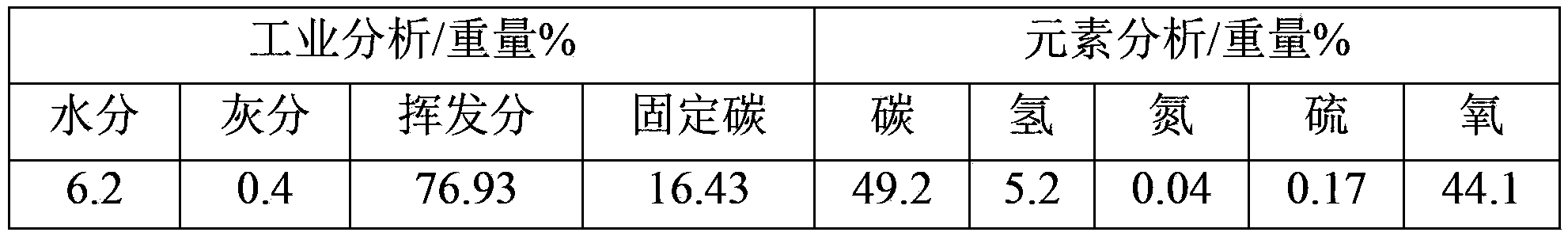

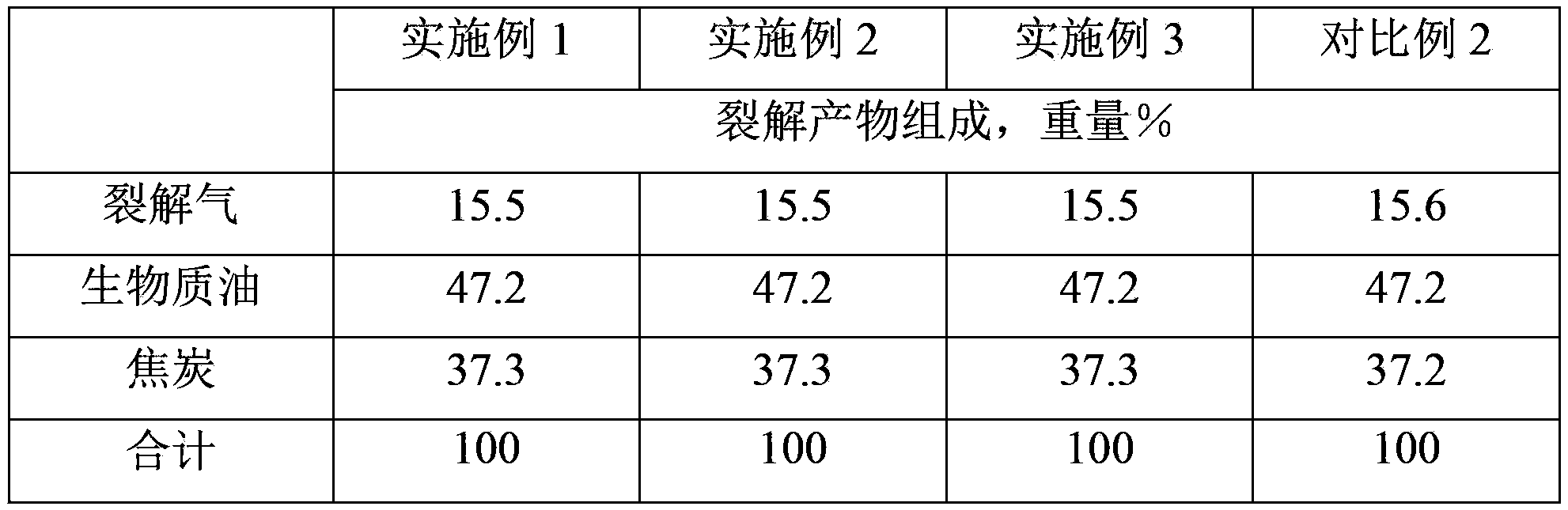

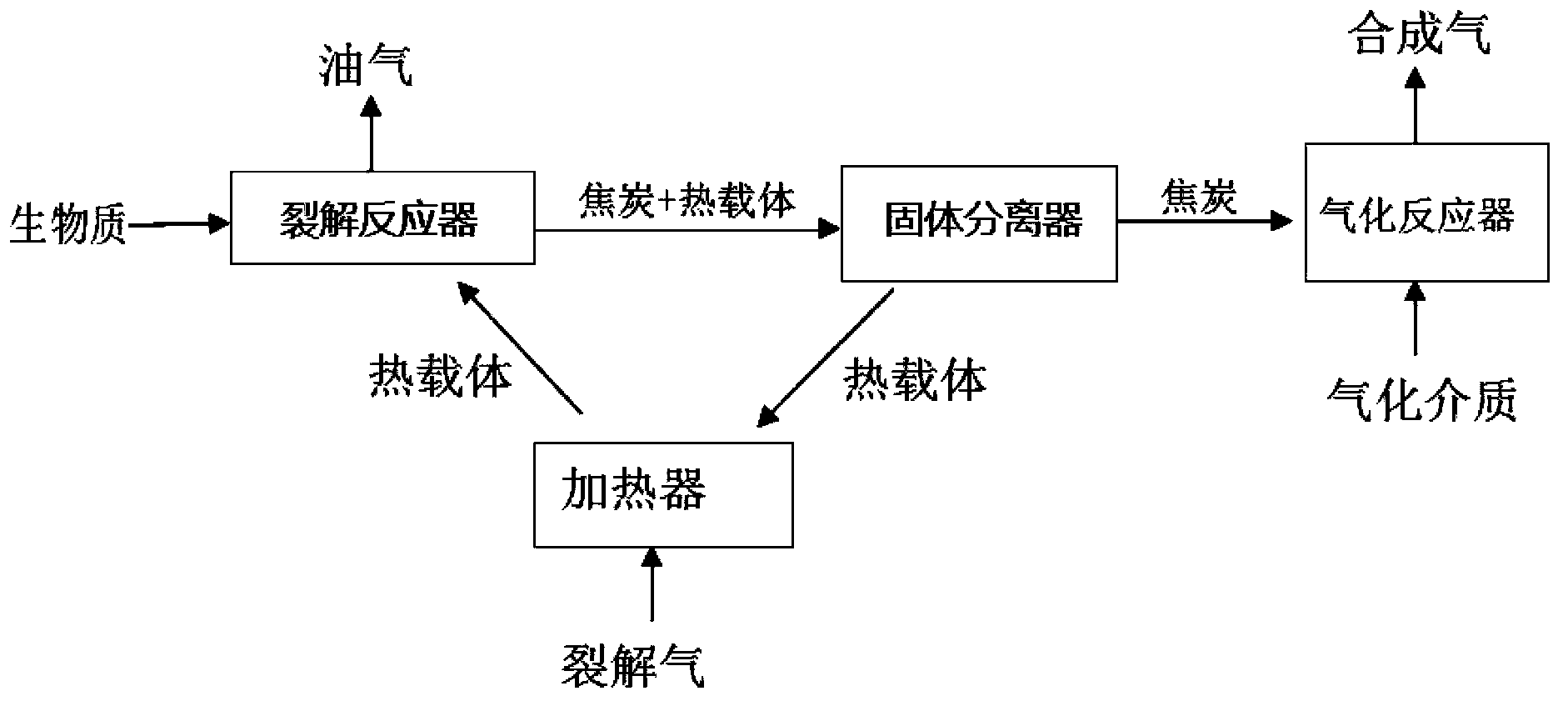

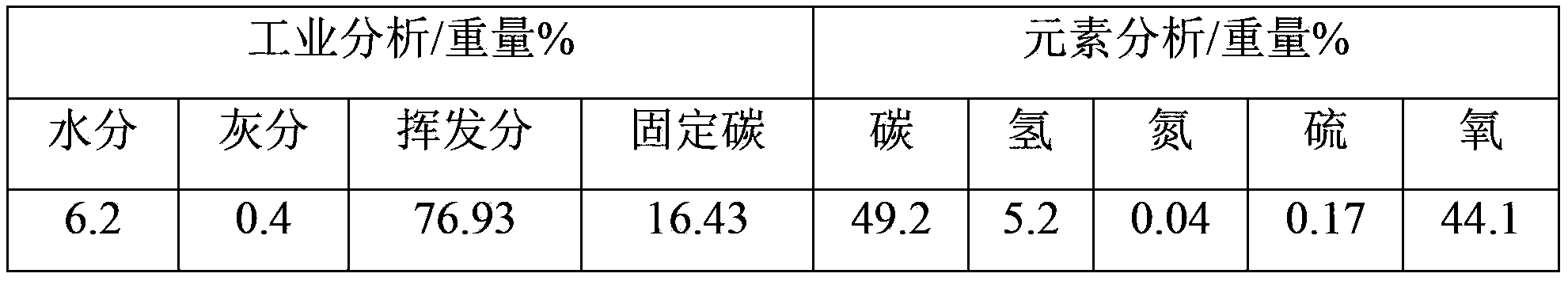

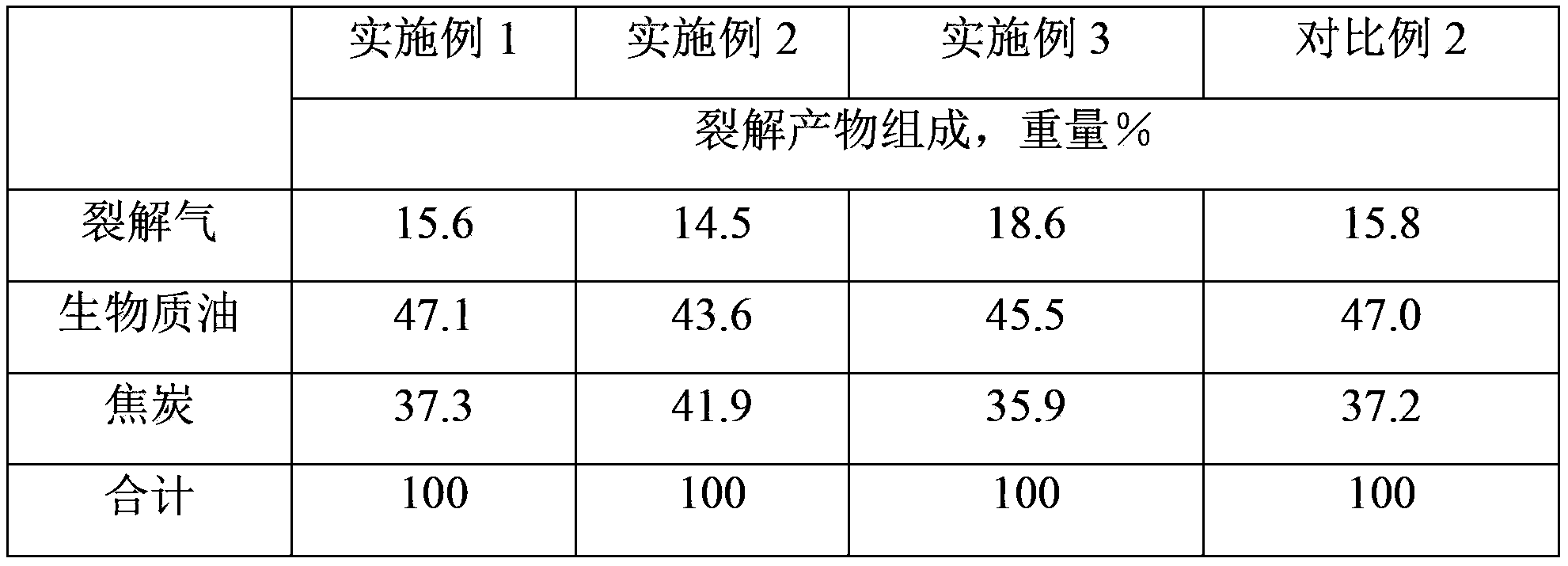

Method for preparing bio-oil and synthesis gas from biomass

InactiveCN104046372AAvoid containingReduce energy consumptionLiquid hydrocarbon mixture productionCombustible gas productionSyngasTar

The invention relates to a method for preparing bio-oil and synthesis gas from biomass. The method comprises the following steps: (1) under thermal cracking condition of biomass, biomass is subjected to a cracking reaction so as to obtain oil gas and coke; (2) oil gas undergoes oil-gas separation so as to separate pyrolysis gas from bio-oil; and (3) under conditions of gasification, the coke and a gasifying medium undergo a gasification reaction so as to separate synthesis gas from gasification reaction products. According to the method provided by the invention, bio-oil and synthesis gas can be simultaneously prepared by the use of biomass, and the prepared synthesis gas basically contains no tar.

Owner:CHINA PETROLEUM & CHEM CORP +1

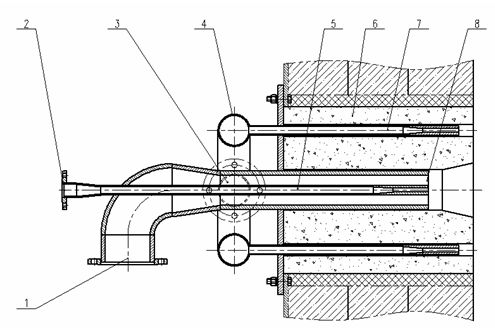

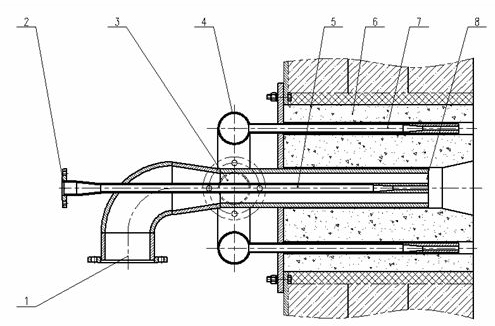

Pure-oxygen pulverized coal entraining combustor

InactiveCN102322633ASpread fastShorten the lengthPulverulent fuel combustion burnersCombustorFlue gas

The invention relates to a pure-oxygen pulverized coal entraining combustor, which comprises a pulverized coal nozzle arranged at the middle part of a combustor block, a pulverized coal feeding flue gas channel, a plurality of circular seam oxygen guns arranged at the circumference of the pulverized coal nozzle, a circular seam oxygen chamber connected to the outer ends of the plurality of circular seam oxygen guns, a central oxygen gun arranged in the pulverized coal flue gas channel and a circular seam oxygen inlet arranged on the central oxygen gun and communicated with the circular seal oxygen chamber. The length of flame of the combustor can be adjusted by adjusting flow adjusting valves on a central oxygen pipeline and a circular seam oxygen pipeline. Pulverized coal-containing flue gas is sprayed out from the pulverized coal flue gas channel, the central oxygen is sprayed out from the central oxygen gun positioned in the center of the pulverized coal flue gas channel, the pulverized coal flue gas and the central oxygen are premixed and burnt to form a stable root flame, therefore the fuel can be saved by 35 percent, the flue gas amount can be reduced by 70 percent, and nitric oxides contained in the flue gas are avoided.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

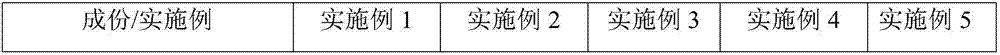

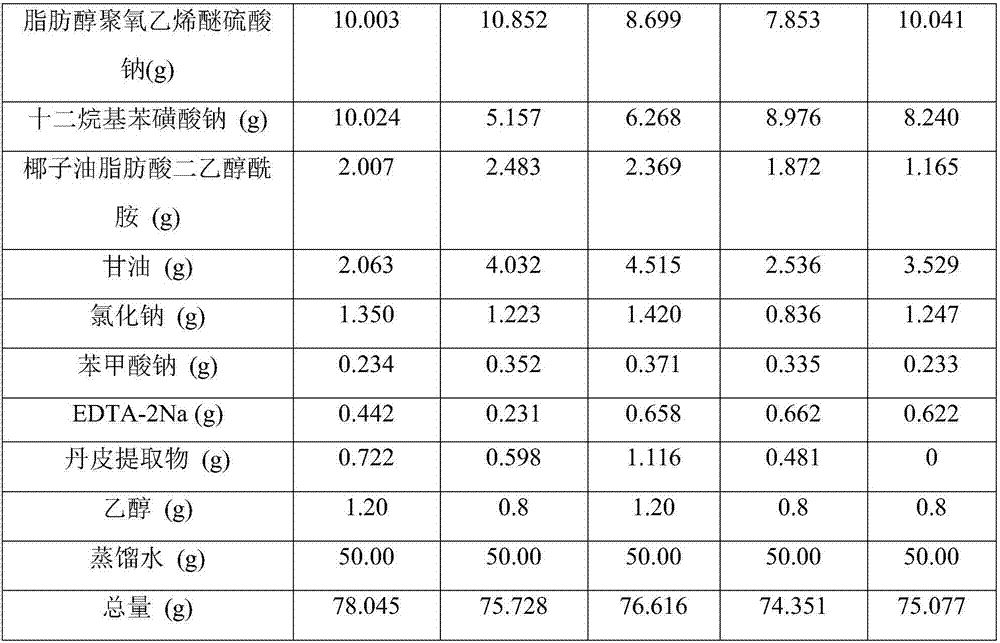

Hand sanitizer and preparation method thereof

InactiveCN107320392AImprove solubilityGood thickening effectCosmetic preparationsToilet preparationsGlycerolHand sanitizer

The invention discloses a hand sanitizer and a preparation method thereof. The hand sanitizer is composed of the following components in percentage by mass: 5%-15% of fatty alcohol polyoxyethylene ether sodium sulfate, 5%-15% of sodium dodecyl benzene sulfonate, 1.5%-3.5% of coconut oil fatty acid diethanolamide, 3.0%-6.0% of glycerol, 1.0%-2.0% of sodium chloride, 0.2%-0.5% of sodium benzoate, 0.2%-1.0% of EDTA-2Na, 0.5%-2.0% of a cortex moutan extract, 1.0%-1.5% of ethanol and the balance of distilled water, wherein the cortex moutan extract is prepared by adopting an ethanol-water-sodium chloride aqueous two phase method. The hand sanitizer is low in alkalinity and non-irritant, has the effects of relieving itching and stopping pain, can alleviate pain and itching sensations during cleaning of allergic-type and eczema-type skins and skin with mosquito bites and insect bites, has good decontamination effect, is simple to operate, and is low in cost.

Owner:CHONGQING UNIV

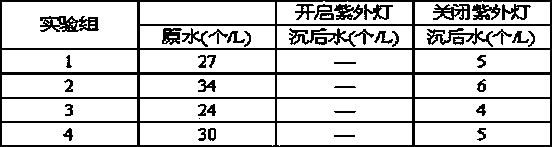

Method for removing cyclop type zooplanktons during treatment of drinking water

InactiveCN103723789AStable removal effectEasy to operateWater/sewage treatment by irradiationWater/sewage treatment by flocculation/precipitationWater collectionZooplankton

The invention provides a method for removing cyclop type zooplanktons during the treatment of drinking water. The method comprises a step of precipitating water source water by using a precipitation tank, wherein ultraviolet lamps are arranged in the water collecting sump area of the precipitation tank, and are arranged at the upper parts on the two sides of a water collecting sump in the length direction of the water collecting sump, and the cyclop type zooplanktons with negative phototaxis under certain radiation wavelengths can only move away from water collection holes. According to the method, stable removal effects can be achieved under the condition of not adding a chemical agent; the method is easy to operate, safe, reliable and low in input cost.

Owner:HOHAI UNIV

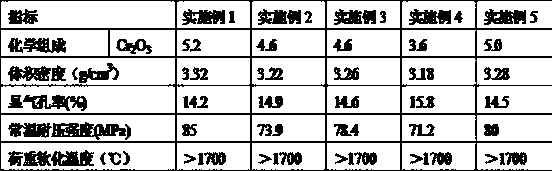

Low-chrome magnesite-chrome brick for glass kiln

The invention discloses a low-chrome magnesite-chrome brick for a glass kiln. The low-chrome magnesite-chrome brick is prepared from the following raw materials in percentage by mass: 10 to 25 percentof fused magnesite of which the granularity is 2 to 4 mm, 10 to 15 percent of fused magnesite of the which the granularity is 1 to 2 mm, 5 to 20 percent of fused magnesite-alumina spinel of which thegranularity is 1 to 2 mm, 10 to 30 percent of pre-synthesis magnesite-chrome clinker of which the granularity is 0 to 1 mm and 30 to 40 percent of fused magnesite of which the granularity is smallerthan 0.088 mm; in addition, an adhesive accounting for 3 to 5 percent of the total mass of all the raw materials is added. The low-chrome magnesite-chrome brick for the glass kiln, disclosed by the invention, has the property characteristics of low chrome content, high density, high strength, strong erosion resistance and good creep resistance. The low-chrome magnesite-chrome brick is used for a regenerative chamber of the glass kiln, is capable of reducing the chrome content of a refractory material to a large extent and effectively relieving the pollution of hexavalent chrome in a residual brick to environment, and is capable of prolonging the service life of the glass kiln and increasing the running rate of the glass kiln at the same time, so that good economic benefit and good social benefit can be obtained.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

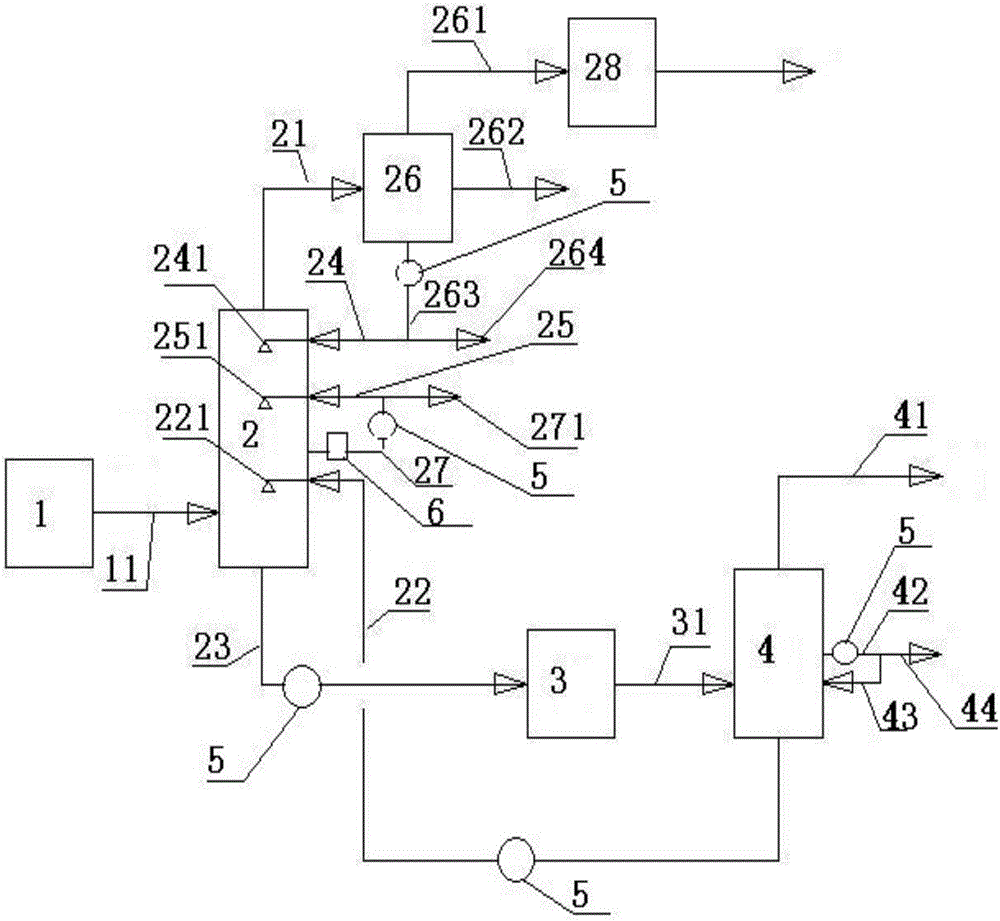

Method for preparing bio-oil and synthesis gas from biomass

ActiveCN104046373AAvoid containingRealize comprehensive utilizationLiquid hydrocarbon mixture productionSpecial form destructive distillationSyngasHeat carrier

The invention relates to a method for preparing bio-oil and synthesis gas from biomass. The method comprises the following steps: (1) in the presence of a heat carrier, biomass is subjected to a cracking reaction to obtain oil gas and solid products; (2) the oil gas undergoes oil-gas separation to separate pyrolysis gas from bio-oil; (e) the solid products undergo solid separation to separate coke from the heat carrier; and (4) the coke and a gasifying medium undergo a gasification reaction, and synthesis gas is separated from gasification reaction products. According to the method provided by the invention, bio-oil and synthesis gas can be simultaneously prepared by the use of biomass, and the prepared synthesis gas basically contains no tar.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal carbonization, oil-gas washing separation and delayed coking combined technology and device

InactiveCN105713630AImprove purification effectOmit the heating stepThermal non-catalytic crackingOven incrustations prevention/removalCarbonizationProcess engineering

The invention provides a coal carbonization, oil-gas washing separation and delayed coking combined technology. The technology comprises steps as follows: 1) oil gas produced during coal carbonization and pyrolysis in a carbonization reactor passes through a washing tower with fractionating tower bottom oil used as a spray medium for washing and dust removal treatment, and a first oil-gas mixture with dust removed and dust-containing tower bottom oil are obtained; 2) the dust-containing tower bottom oil is sent into a coke tower for delayed coking, a second oil-gas mixture is obtained from the top of the coke tower, and pitch coke is obtained from the tower bottom; 3) the second oil-gas mixture is sent to a fractionating tower for separation, a third oil-gas mixture is obtained from the top of the fractionating tower, hydrogenated raw oil is recovered from side lines of the fractionating tower, fractionating tower bottom oil is obtained from the fractionating tower bottom, and the fractionating tower bottom oil is sent into the washing tower to be used as the spray medium. The problems that coal carbonization, oil-gas separation and delayed coking combined technologies have complex steps and are low in efficiency and high in cost, energy waste is enormous and the like in the prior art are solved.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

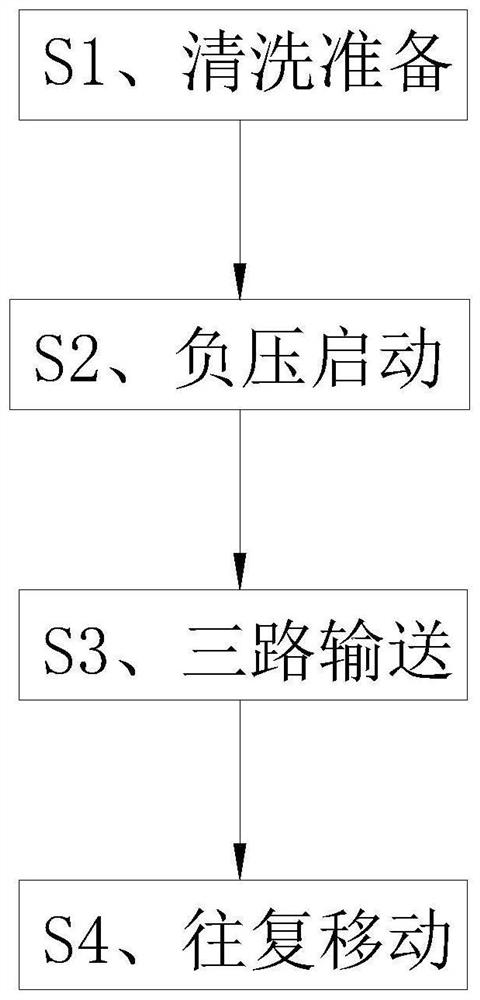

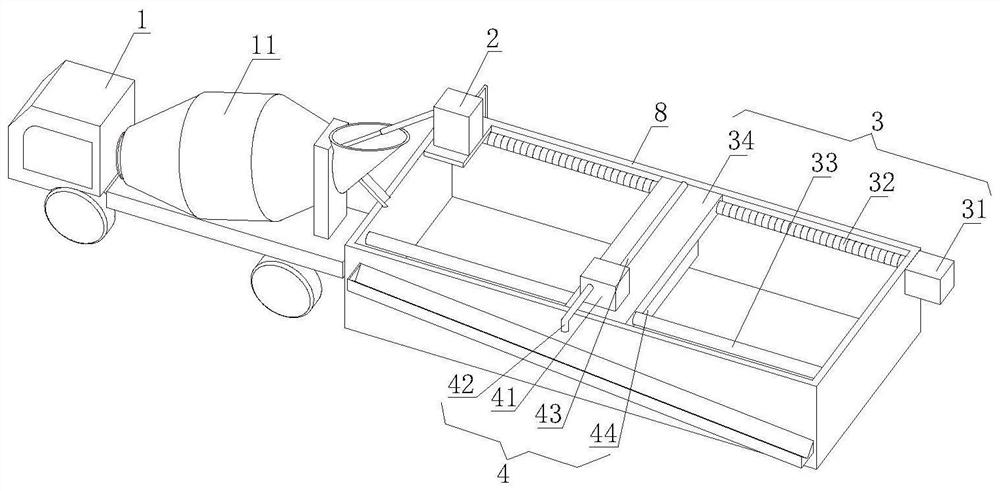

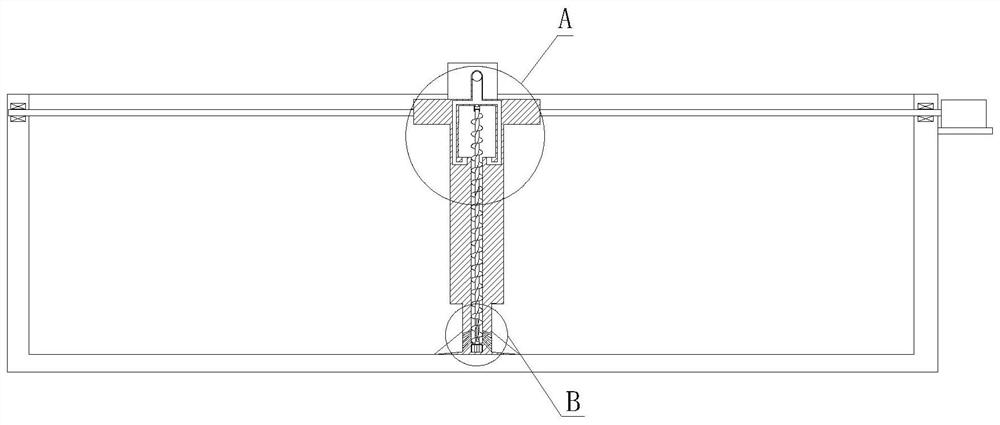

Concrete pond cleaning device and method

ActiveCN113351594AAvoid containingAvoid hard-to-pick problemsHollow article cleaningSuction forceSpiral blade

The invention discloses a concrete pond cleaning device and method. The concrete pond cleaning device comprises a concrete truck and a sedimentation pond, the concrete truck is provided with a stirring tank, a discharge port of the stirring tank is connected with a tailing cleaning pump, an outlet of the tailing cleaning pump is connected to the sedimentation pond, and the sedimentation pond is provided with a horizontal moving mechanism. When residues are sucked up through negative pressure holes in the bottom of the horizontal moving mechanism, materials near the negative pressure holes are rapidly lifted into a transferring cavity through cooperation with rotation of spiral blades, then the materials are sucked away through suction force of the horizontal moving mechanism, and by reducing the height of the horizontal moving mechanism and reducing the requirement for the suction force, energy consumption needed by the whole equipment is reduced, and the conveying amount is also increased; and the problem that air is contained in the negative pressure suction process and materials are difficult to directly rise is avoided. In the prior art, after the materials on the bottom surface are scraped up through a scraper, the materials are directly sucked up through negative pressure holes and conveyed to a spiral channel, and then the materials are lifted up through the spiral blades and continuously accumulated in the transferring cavity, and the problem that sucking is difficult to be performed due to the existence of air is solved.

Owner:浙江恒杰建材有限公司

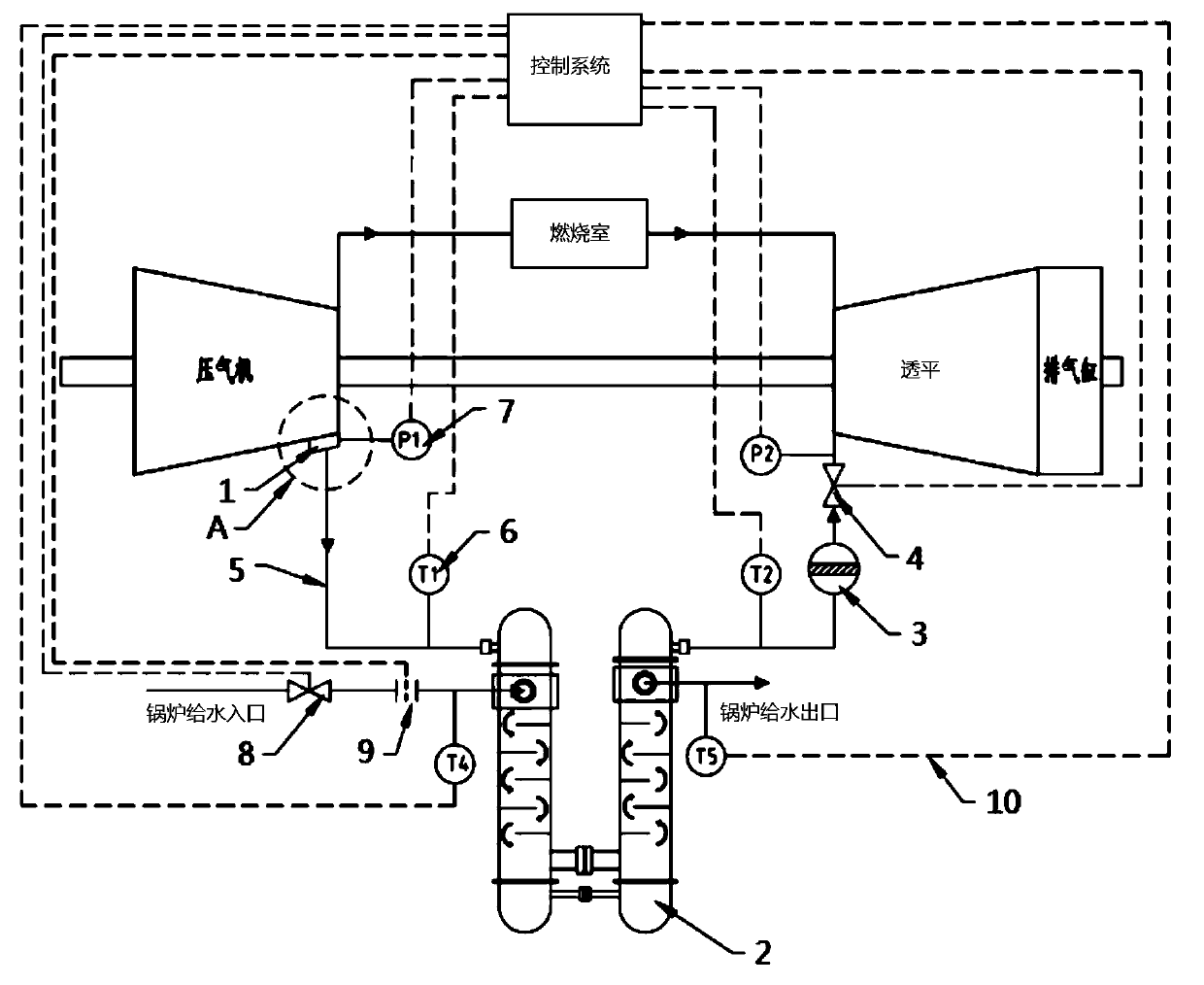

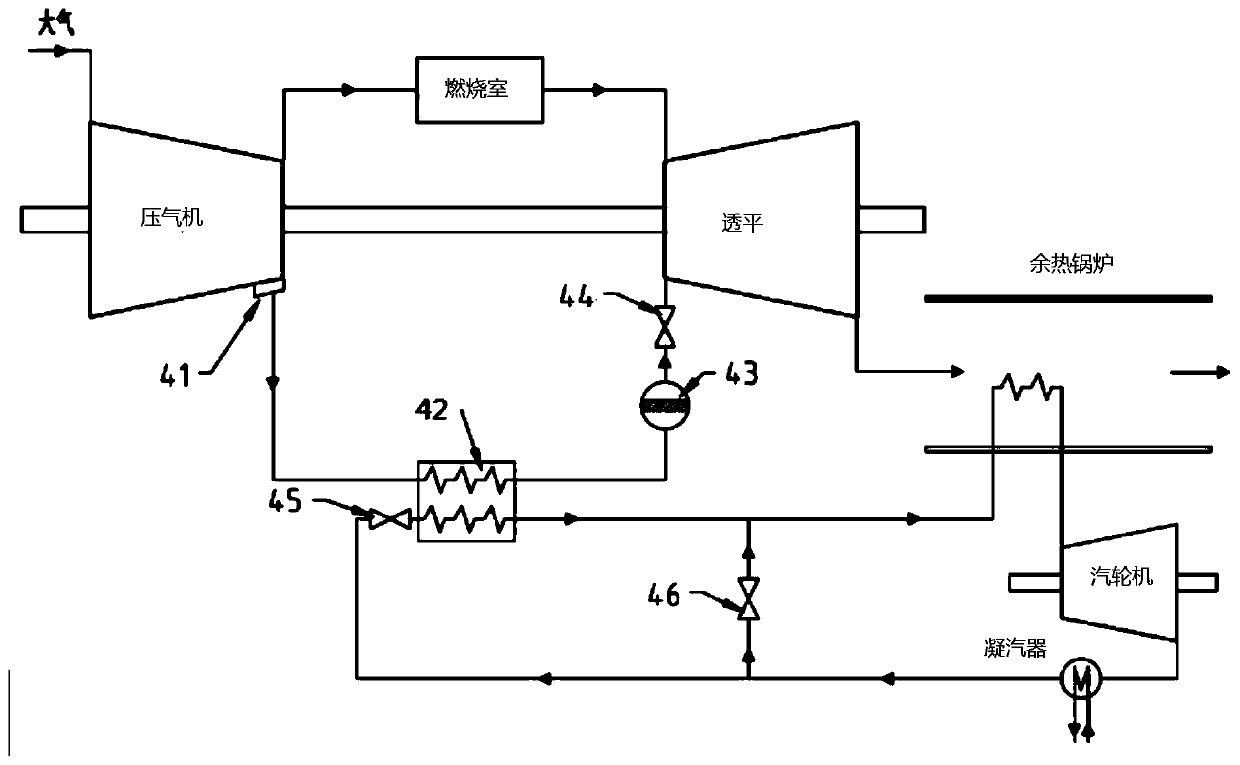

Cooling method of turbine rotor of combustion gas turbine and cooling gas system

ActiveCN109812299AImprove performanceImprove cooling effectDispersed particle filtrationBlade accessoriesGas turbinesTurbine blade

The invention discloses a cooling method of a turbine rotor of a combustion gas turbine and a cooling gas system. A gas pumping pipeline is connected between a gas compressor and a turbine, wherein agas pumping adjusting valve is arranged on the gas pumping pipeline; a temperature measuring device and a pressure measuring device are arranged at different points on the combustion gas turbine and are connected to a control system through signal circuits; the temperature measuring device and the pressure measuring device are used for transmitting detecting signals to the control system through the signal circuits; the control system is used for controlling the gas pumping adjusting valve and a water supplying adjusting valve to adjust to reach the temperature and flow rate required by gas tocool a turbine blade of the combustion gas turbine and a wheel disc; a water cooling temperature conditioning device for cooling gas is arranged between the gas compressor and the gas pumping adjusting valve on a gas pumping pipeline; the temperature T2 of cooling gas exhausted through the temperature conditioning device and fed into the turbine can be determined based on the gas temperature forcooling the turbine blade of the combustion gas turbine and the wheel disc; and the water inlet flow rate m1 of the temperature conditioning device is adjusted to control the temperature T2 of the cooling gas exhausted by the temperature conditioning device. The method and the system reach the best cooling effect with the least cooling gas volume.

Owner:HANGZHOU TURBINE POWER GRP

Refining method of active metallurgical lime

InactiveCN108191268AHigh activityImprove qualityGas purification with selectively adsorptive solidsGas contaminants removalGranularityCalcination

The invention provides a refining method of active metallurgical lime and relates to the field of production and preparation of lime. The method specifically comprises pretreatment, preheating treatment, calcination treatment and cooling treatment. According to the refining method of the active metallurgical lime, by controlling CaO content and granularity of raw materials, calcination temperatureof a reaction process and fuel, activity of the active lime is improved, sulfur content is reduced, and quality of the active lime is improved.

Owner:广西华洋矿源材料有限公司

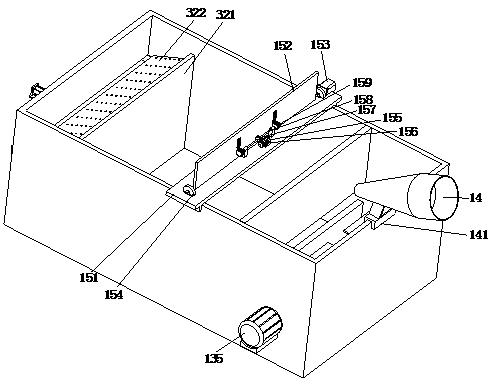

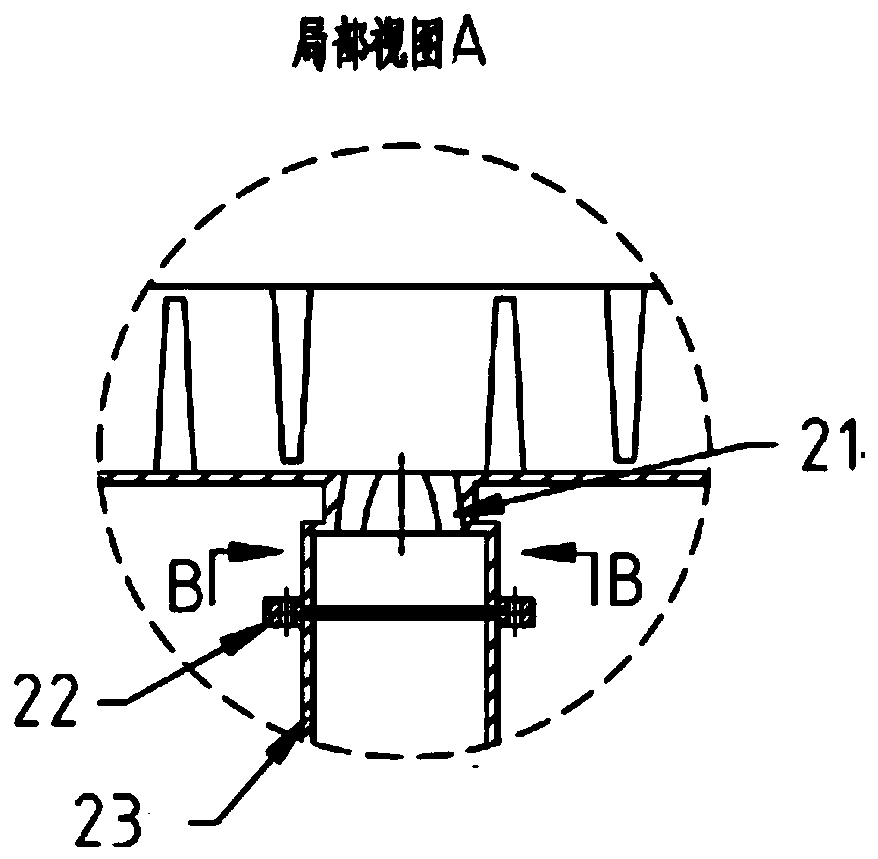

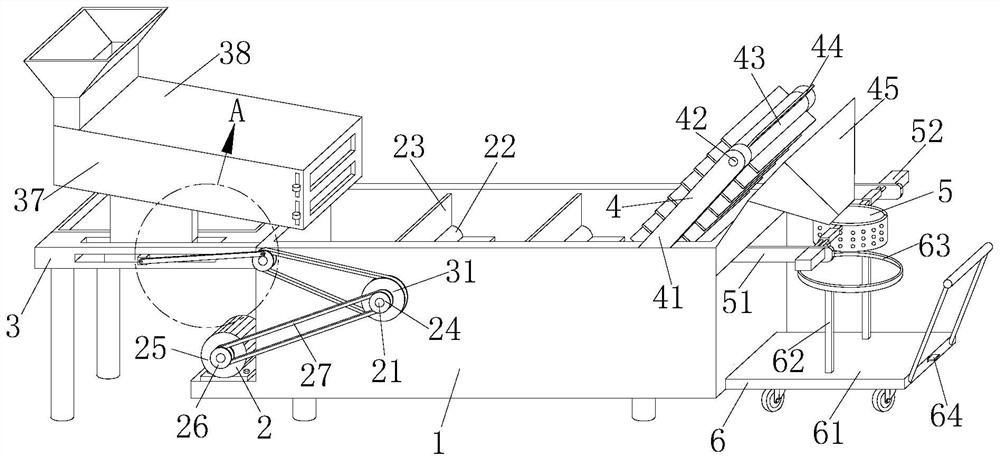

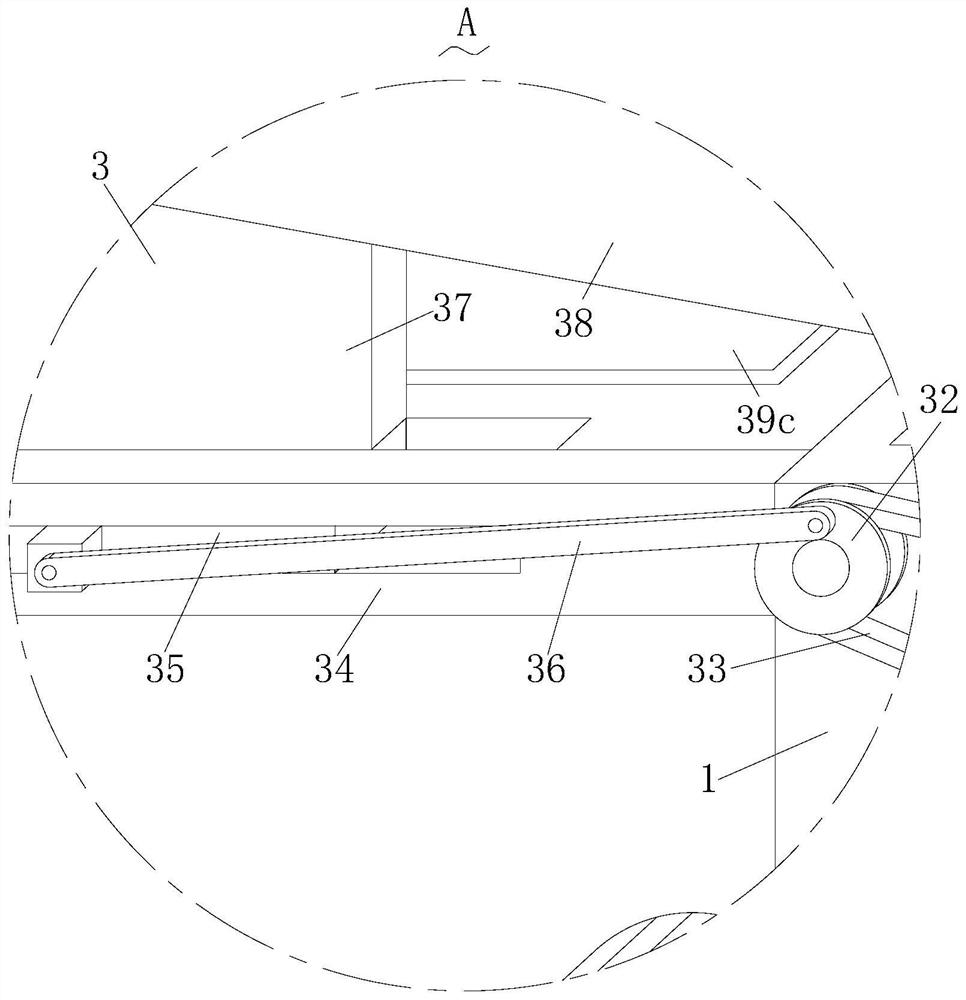

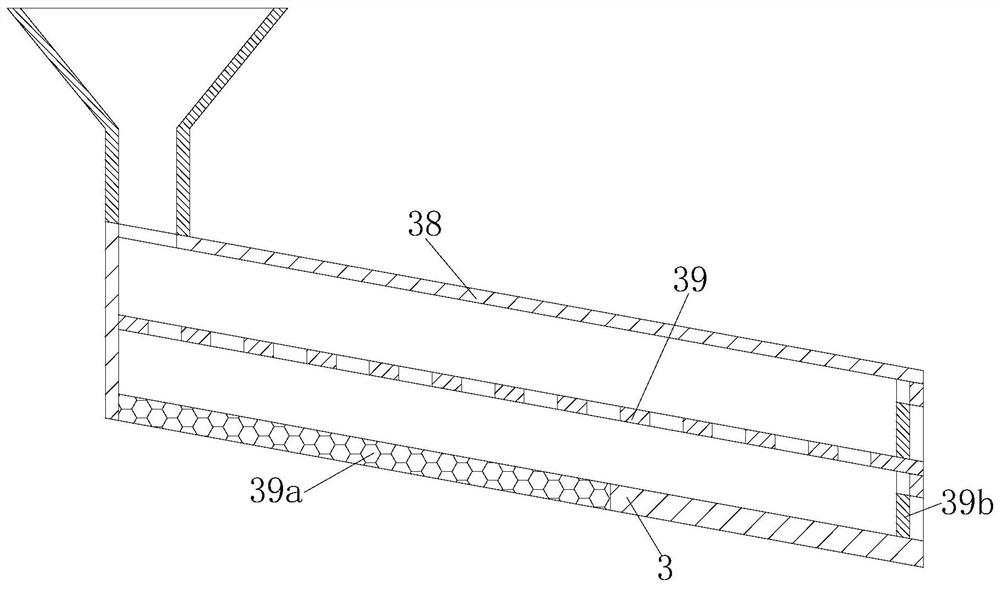

Multifunctional automatic fruit bagging device

InactiveCN112845036AGood cleaning effectConvenient feeding and fruit separationSievingScreeningHorticultureAgricultural engineering

Owner:合肥利晟科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com