Efficient plastic master batch forming method

A technology of plastic masterbatch and molding method, which is applied in chemical instruments and methods, filter screens, grids, etc., can solve the problems of easy adhesion of plastics to cutting blades, affecting the cutting of plastic masterbatches, and poor cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

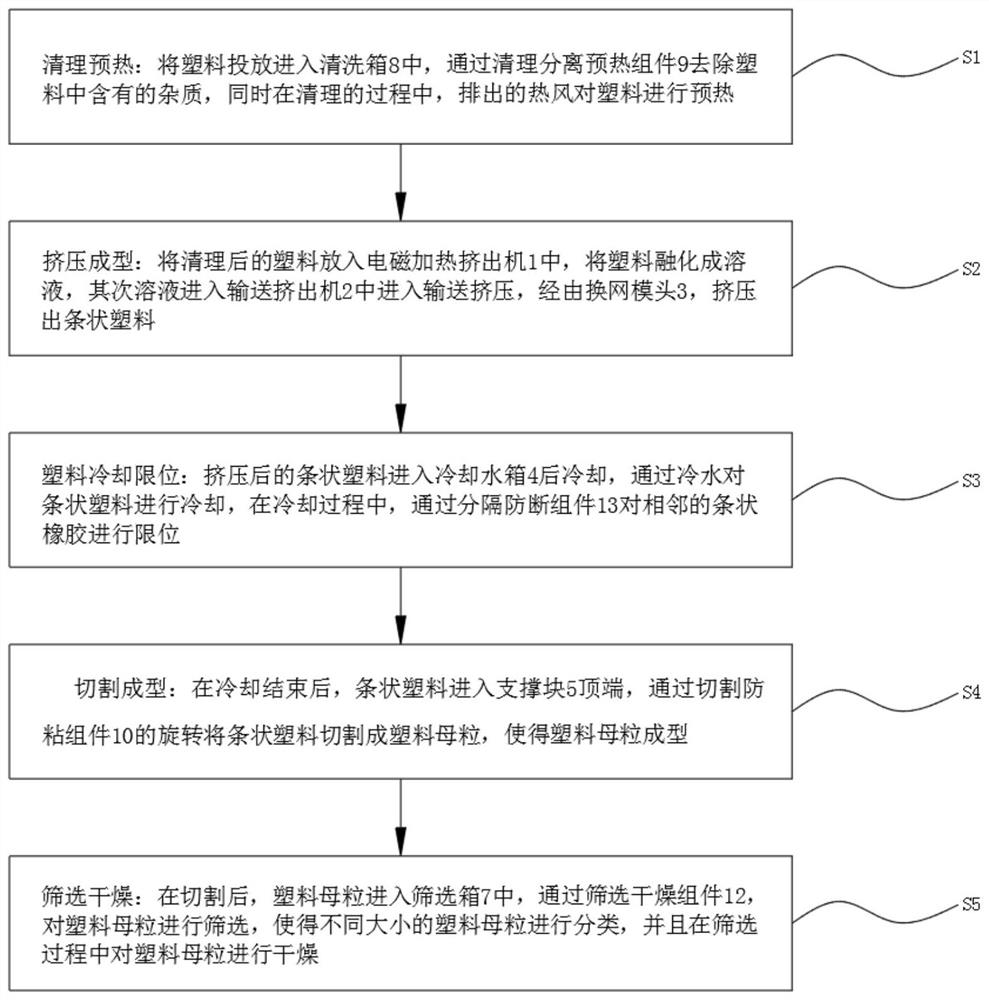

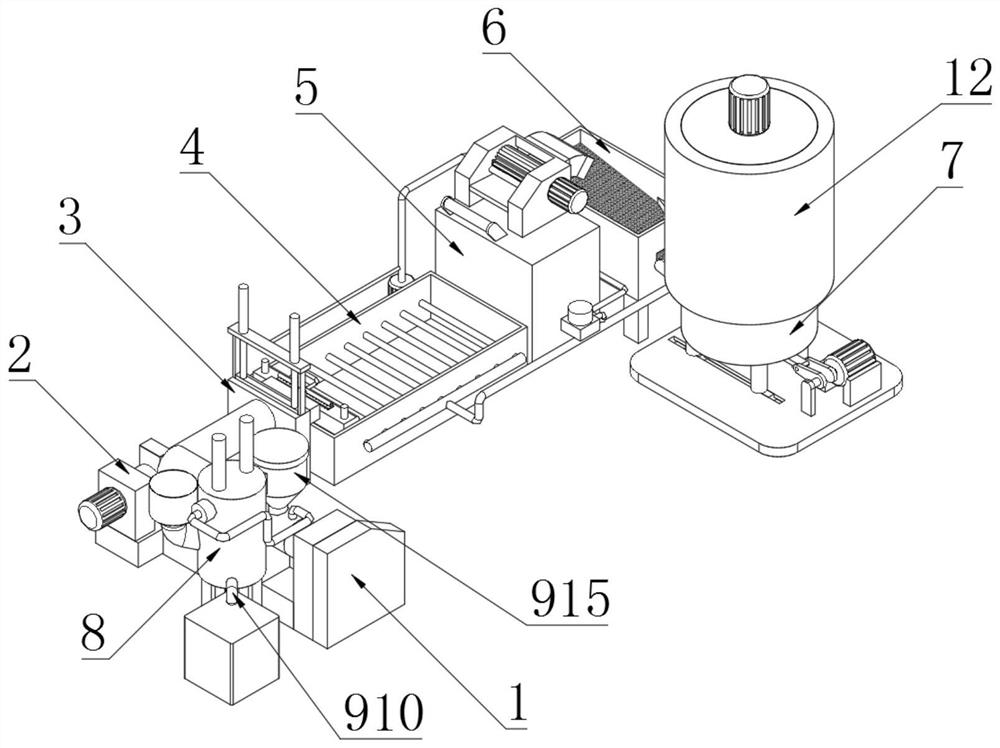

[0047] Example: such as Figure 2-15 As shown, the present invention provides a technical solution, a high-efficiency plastic masterbatch molding method, including an electromagnetic heating extruder 1, one end of the electromagnetic heating extruder 1 is connected with a cleaning box 8, and the electromagnetic heating extruder 1 is kept away from cleaning One end of the box 8 is placed with a conveying extruder 2, and the outer side of one end of the conveying extruder 2 is fixedly installed with a screen changing die 3, and one end of the conveying extruder 2 is placed with a cooling water tank 4, and one end of the cooling water tank 4 is connected with a support block 5, supporting One end of the block 5 is connected with a return box 6, and one end of the backflow box 6 is connected with a screening box 7;

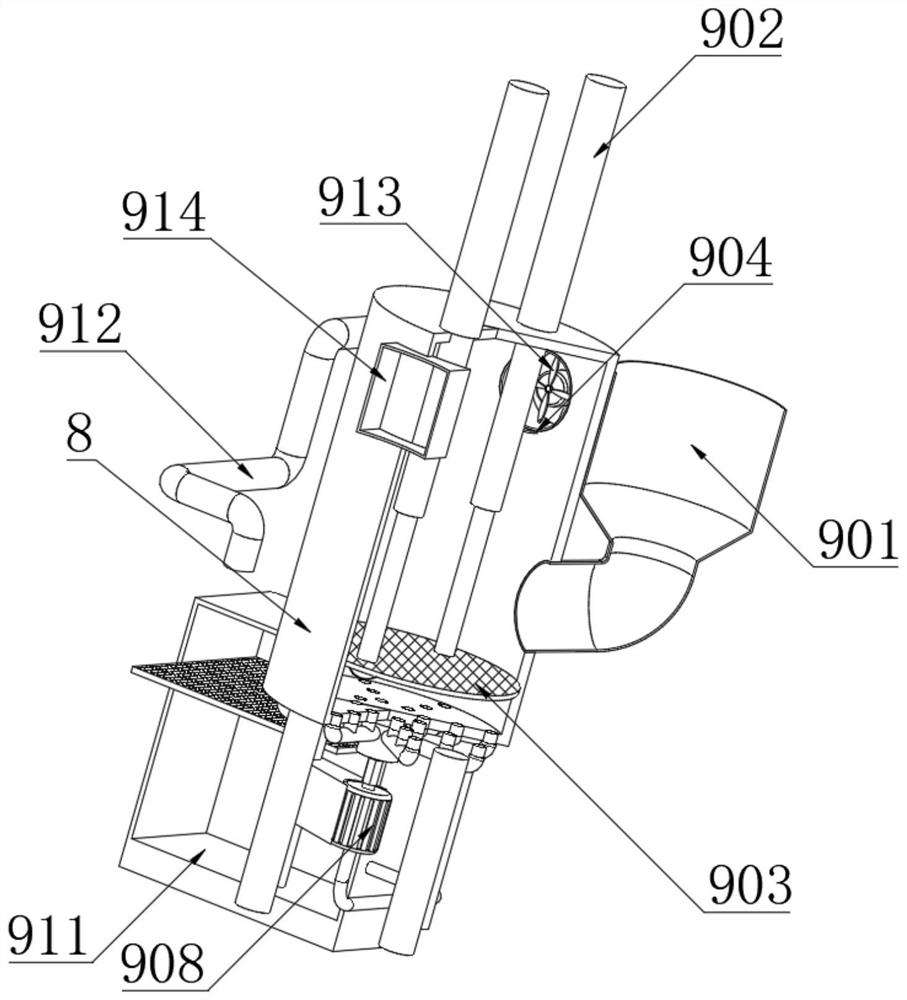

[0048] The cleaning box 8 is equipped with a cleaning and separation preheating component 9, which can quickly clean the plastic, improve the quality of the plastic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com