Patents

Literature

51results about How to "Solve dirty cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

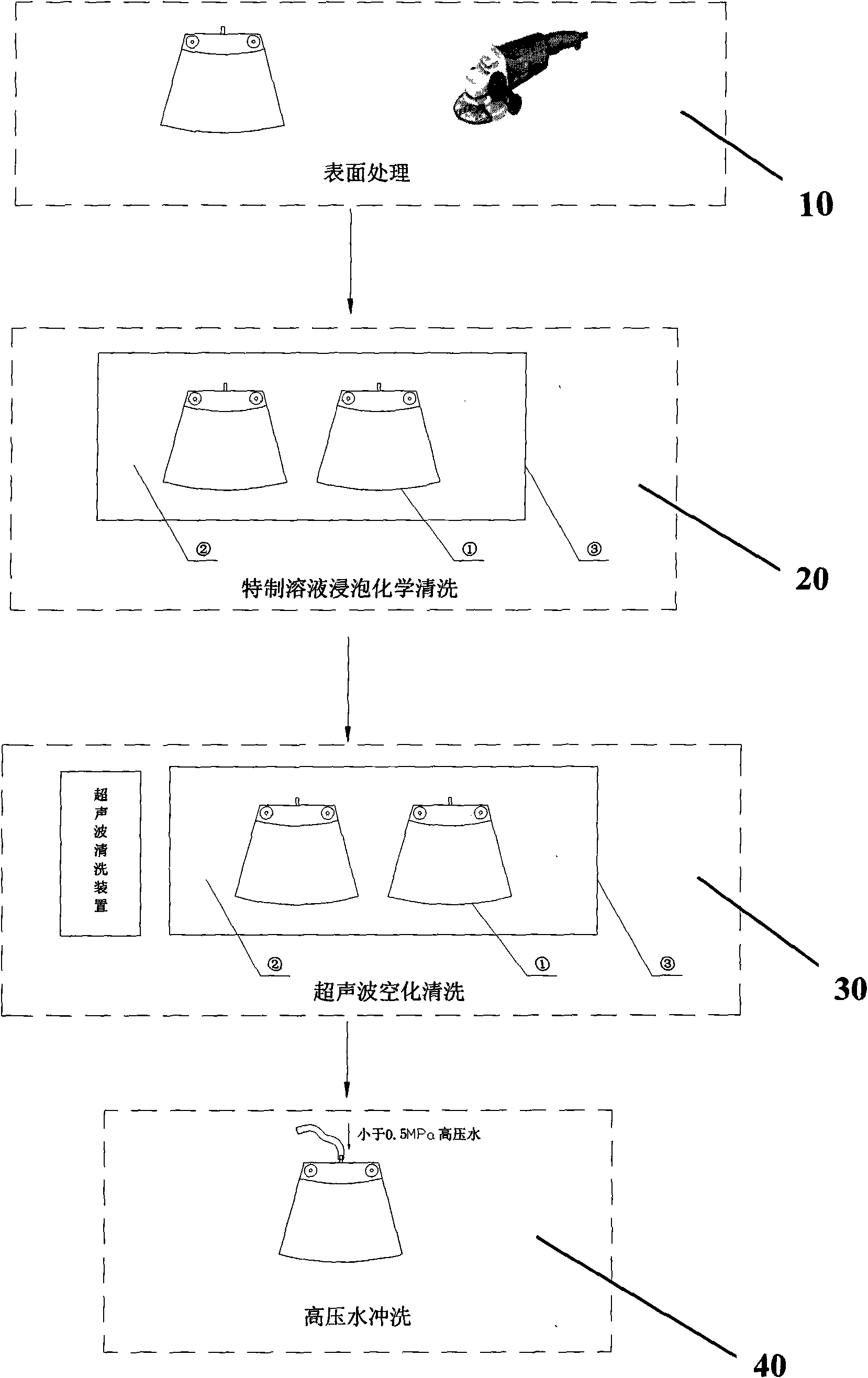

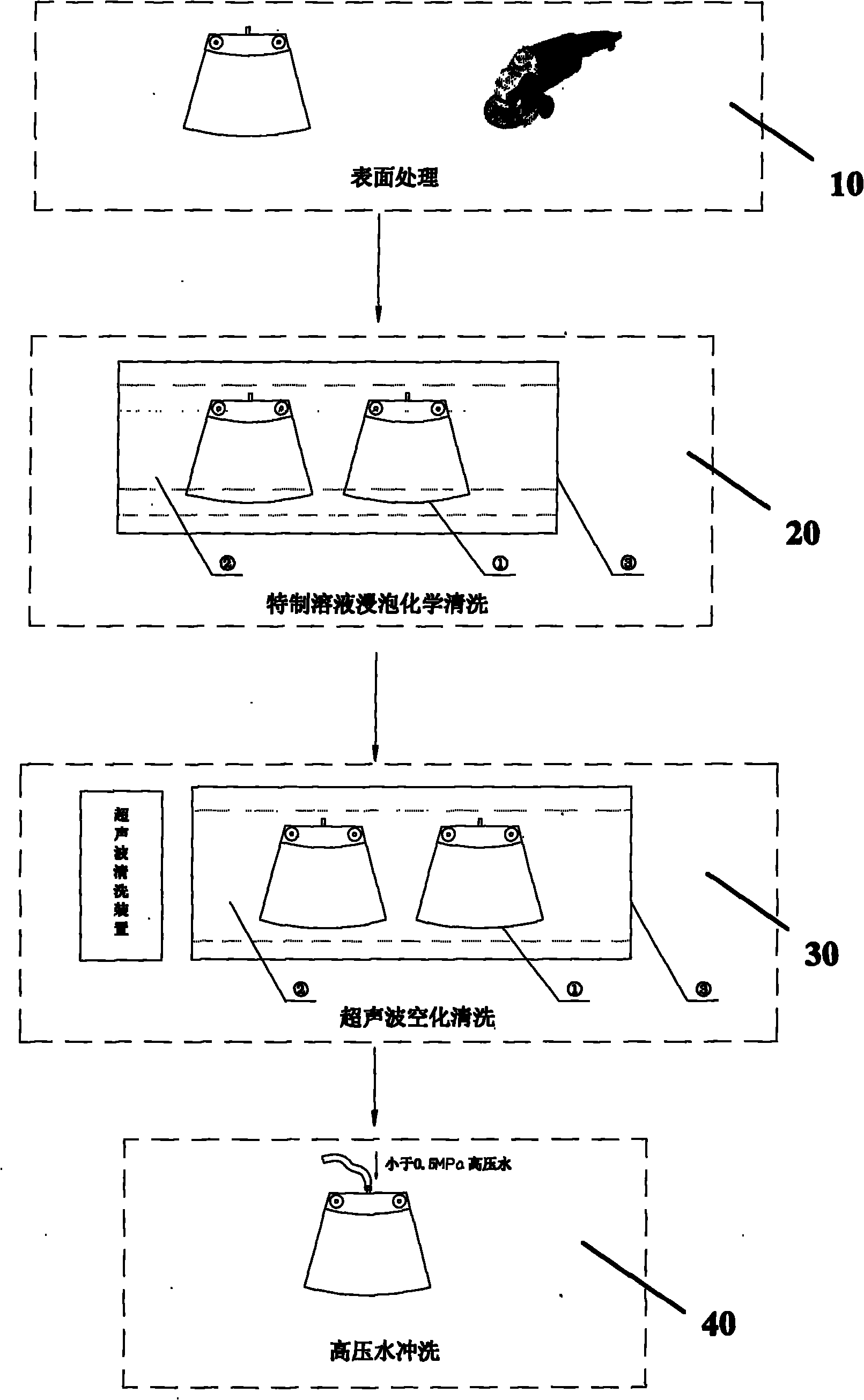

Method for cleaning ceramic filter plate of ceramic filter

InactiveCN101954226ASolve dirty cleaningExtended service lifeFilter regenerationVacuum ceramic filterMegasonic cleaning

The invention relates to a method for cleaning a ceramic filter plate of a ceramic filter. The cleaning method comprises a surface treatment step of the ceramic filter plate, wherein the surface treatment is surface polishing treatment of the ceramic filter plate. The cleaning method also comprises a chemical cleaning step, an ultrasonic cleaning step and a high-pressure water flushing step. The method has the advantages of simpleness in operation of the four steps and low cost, and greatly prolongs the service life of the ceramic filter plate; and the cleaning method can be reused, greatly reduces the operation cost of the ceramic filter, and can be popularized and applied to the filter plate of the ceramic filter.

Owner:宝钢集团上海梅山有限公司

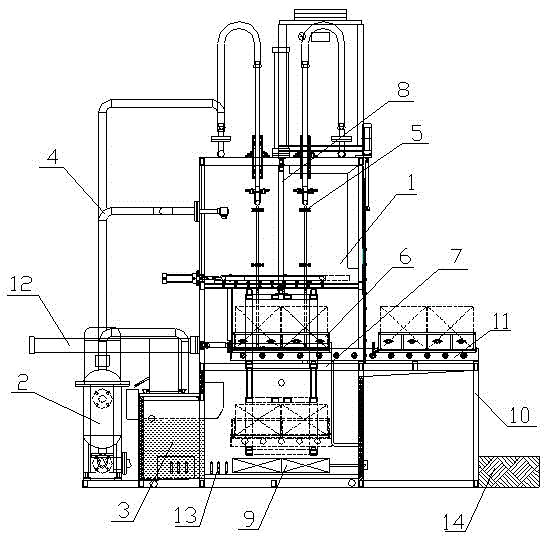

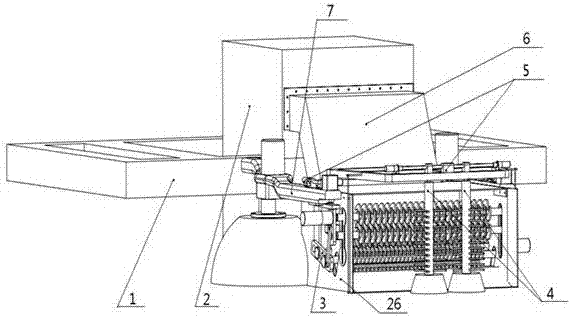

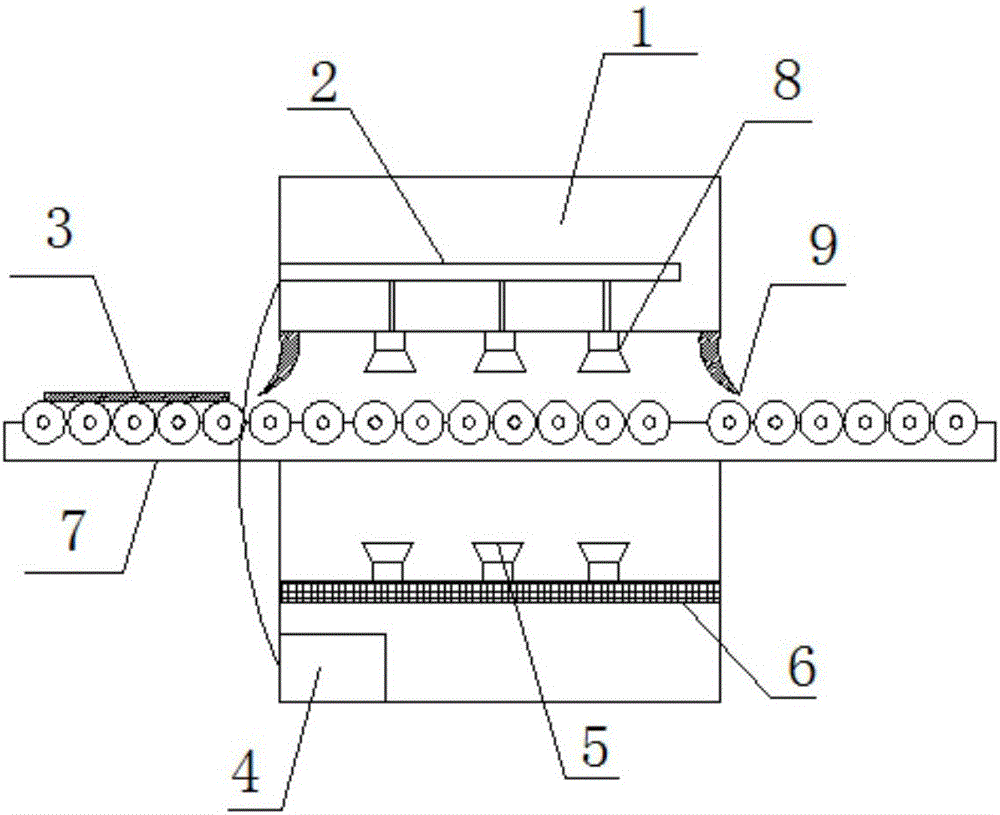

Ultrasonic cleaner

InactiveCN104368558ASolve dirty cleaningExtended service lifeCleaning using liquidsMegasonic cleaningEngineering

The invention aims to provide an ultrasonic cleaner comprising a body and a cleaning water pump. The cleaning water pump is disposed on the left of the body. A water tank is disposed between the cleaning water pump and the body. The cleaning water pump is connected to the body through a pipe. A moving spray pipe and a nozzle are disposed inside the body and are connected to the pipe. A basket is disposed right under the moving spray pipe and the nozzle and is disposed on a moving roller way; a lifting cylinder is disposed on the top of the body and controls the moving roller way to ascend and descend; an ultrasonic vibrating plate is disposed at the bottom of the body. The ultrasonic vibrating plate emits ultrasonic wave to clean a valve; the moving spray pipe and the nozzle are used to wash the valve with water, thus the valve is fully cleaned; the problem that the valve is insufficiently leaned is solved; a feeding rack and an incoming roller way rack allow convenient feeding, work efficiency is improved, and service life of the valve is prolonged.

Owner:安徽宝辉清洗设备制造有限公司

Pigment type blue ink

The invention relates to a blue ink and concretely to a water pigment blue ink which is easy to wash and can be used in fountain pen and sign pen. The said ink solves the problem in present blue ink which is of poor water resistance and sun resistance and can not be washed easily. The weight ratio of raw materials composition of the prepared ink is: 1.0 % -5 % of Berlin blue colorant, 0.2 % - 5 % of oxalic acid complexing agent, 0.01 % - 2 % of surface activator, 1 % - 10 % of water-loss reducer , 0.1 % - 1 % of binding agent, 0.1 % - 1 % of preservative agent, and the other is water. In relation to the present technology, the significance effect of this invention is: 1. in relation to the present blue ink, it has good water resistance and sun resistance but small diffusibleness; 2. in relation to the present writing ink of all kinds, it is erasable which solves the problem that clothes can not be washed cleanly when contaminated by the present ink; 3. the said ink and its catabolite is nontoxic, flavourless and can not pollute the environment.

Owner:SHANGHAI NNW NEW MATERIALS TECH

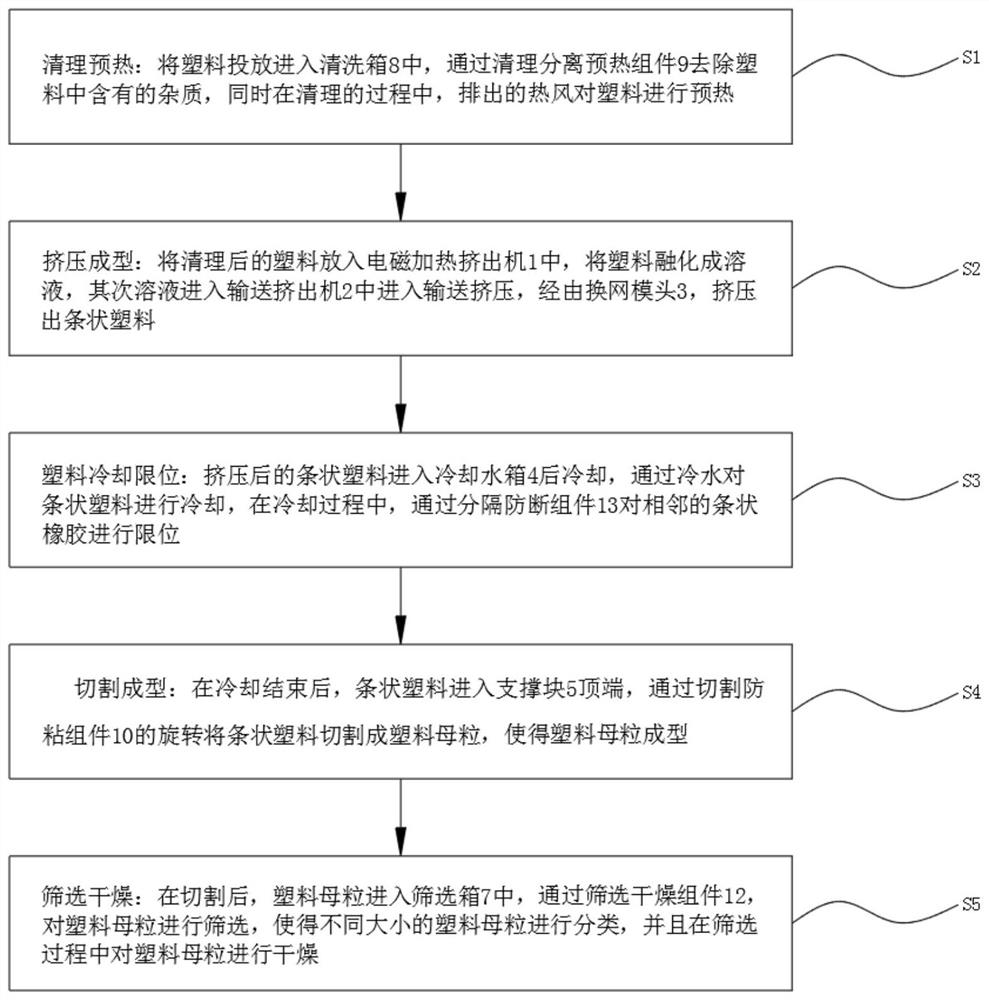

Efficient plastic master batch forming method

The invention discloses an efficient plastic master batch forming method. According to the forming method, a conveying extruder is placed at the end, away from a cleaning box, of an electromagnetic heating extruder, a net replacing die head is fixedly installed on the outer side of one end of the conveying extruder, a cooling water tank is placed at one end of the conveying extruder, a supportingblock is connected to one end of the cooling water tank, one end of the supporting block is connected with a backflow box, and one end of the backflow box is connected with a screening box. Accordingto the forming method, cyclic utilization of water resources is realized by an cleaning and separating preheating assembly, a cooling circulation assembly and a separation anti-breaking assembly, theutilization rate of the water resources is increased, the enterprise cost is reduced, then through the cleaning and separating preheating assembly and the separation anti-breaking assembly, multi-stepoperation on plastic through multiple production lines is not needed, the space utilization rate in an enterprise plant is increased, meanwhile, noise pollution caused by the multiple production lines is reduced, meanwhile, the cost of an enterprise is reduced, and more production benefits are made for the enterprise.

Owner:邓玉欣

Dual rolling brush device

The invention discloses a dual rolling brush device. The dual rolling brush device comprises a rolling brush device comprises a rolling brush bracket, wherein a front rolling brush and a rear rolling brush are installed below the rolling brush bracket, the rear rolling brush is driven by a motor to move in an anti-clockwise direction, the front rolling brush is tangent to the rear rolling brush, the front rolling brush is driven by the rear rolling brush to rotate in an opposite direction, the motor is installed above the rolling brush bracket, and a dustbin is further arranged behind the rear rolling brush. According to the dual rolling brush device, the dual rolling brush device is used for power-driven drive type scrubbers; compared with a traditional dish brush or a single rolling brush device, the dual rolling brush device has the advantages that the cleaning effect is several times better, so that cleaning efficiency is greatly improved, and the problem of uncleanness is thoroughly solved.

Owner:WUHU AIRUITE ENVIRONMENTAL TECH

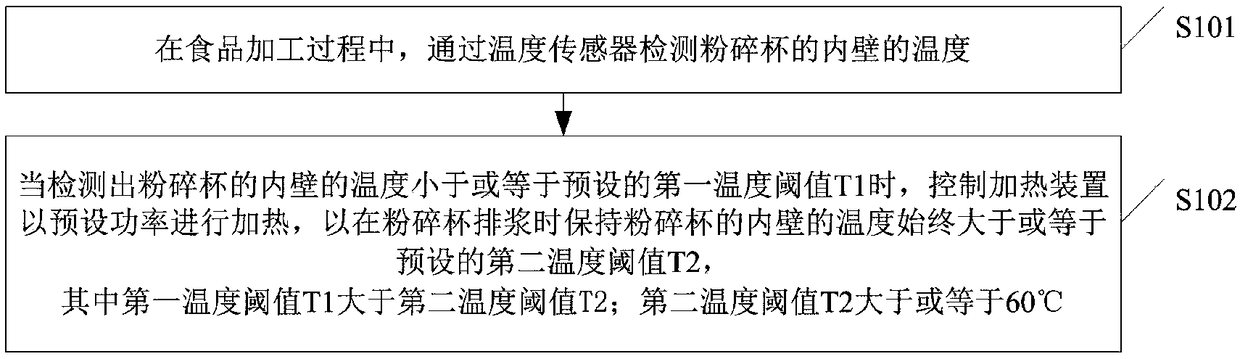

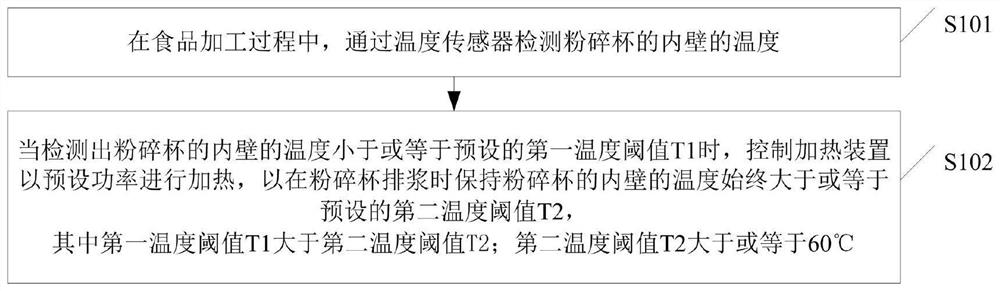

Control method of food processing machine

The embodiment of the invention discloses a control method of a food processing machine. The food processing machine can comprise a pulverizing cup, a heating device, a motor and a temperature sensor.The method can comprise the following steps: detecting the temperature of the inner wall of the pulverizing cup by the temperature sensor in the food processing process; and when detecting that the temperature of the inner wall of the pulverizing cup is less than or equal to a preset first temperature threshold value T1, controlling the heating device to perform heating according to preset powerso as to maintain the temperature of the inner wall of the pulverizing cup to be still more than or equal to a preset second temperature threshold value T2 when the pulverizing cup discharges pulp, wherein the first temperature threshold value T1 is more than the second temperature threshold value T2, and the second temperature threshold value T2 is more than or equal to 60 DEG C. Through the scheme of the embodiment, the temperature of the inner wall of the pulverizing cup still maintains above at least 60 DEG C, the problem that food adhesion on a food processing cup is solved and the cleaning effect is improved.

Owner:JOYOUNG CO LTD

Chemical pipeline cleaning device

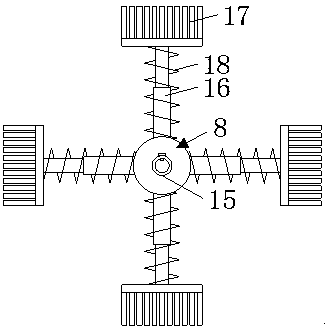

InactiveCN109622527AAvoid rotation relative to the pipe wallPrevent rotationHollow article cleaningElectric machineryCompound (substance)

The invention discloses a chemical pipeline cleaning device. The chemical pipeline cleaning device comprises a bracket; the surface of the bracket is connected with a driving device through a first extension rod; a first spring sleeves the surface of the first extension rod; a battery and a cleaning motor are mounted in the bracket; and the cleaning motor is connected with the cleaning brush through a rotating shaft. The chemical pipeline cleaning device is provided with the driving device; the driving device drives a rubber track to rotate for driving through a driving motor; as the contact area between the rubber track and pipe walls is large, the rotation of the bracket relative to the pipe walls in the cleaning process by the cleaning device is prevented; through track driving, the cleaning motor is guaranteed to be not rotated relative to the pipe walls, so that the cleaning brush can be rotated relative to the pipe walls for cleaning, the cleaning efficiency is improved, and thecleaning is more thorough; and through cooperation among the driving device, the cleaning motor and the cleaning brush, the problem of weak cleaning caused by the slip phenomenon easily generated by atraditional automatic cleaning device is solved.

Owner:温州兴南环保科技有限公司

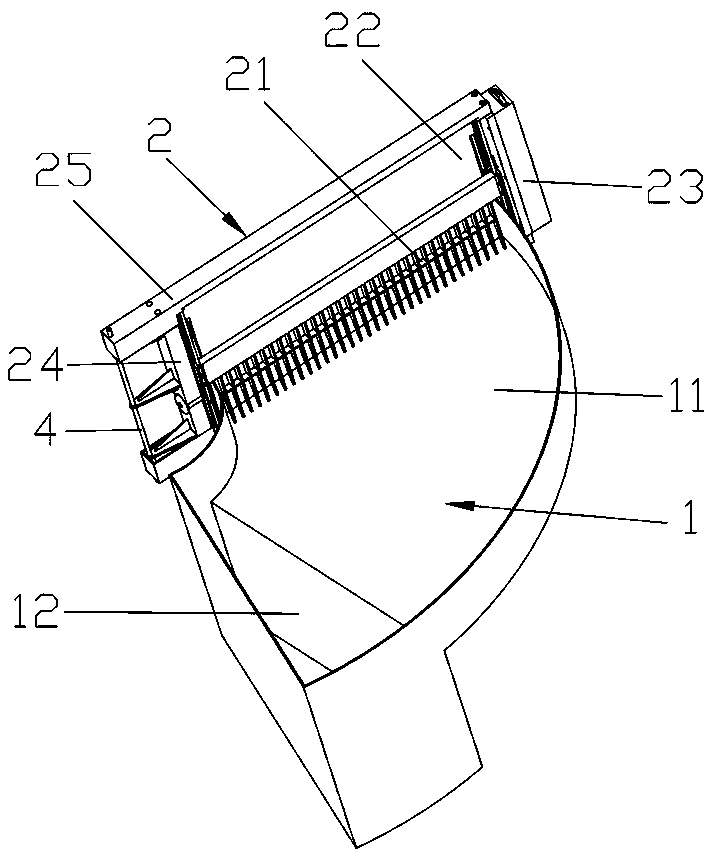

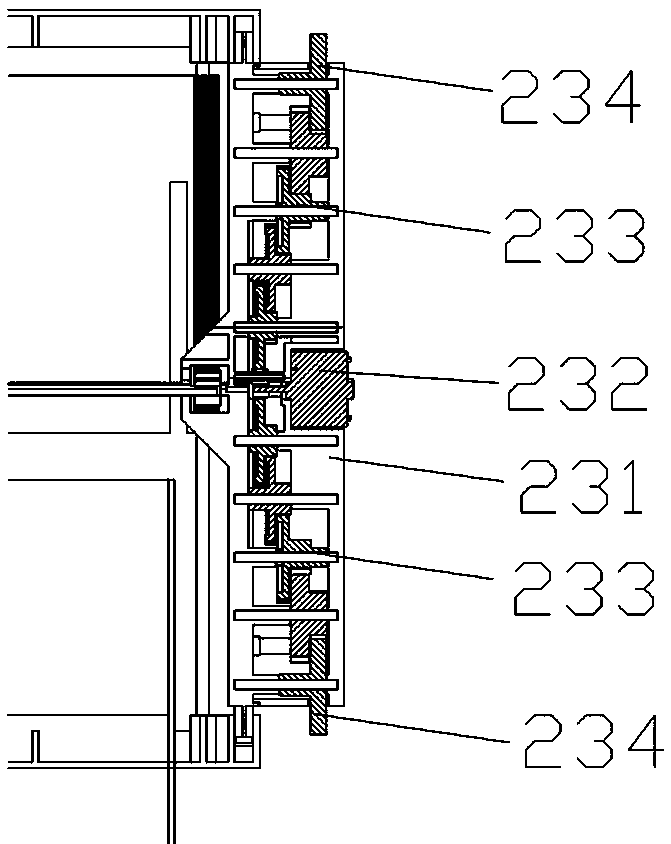

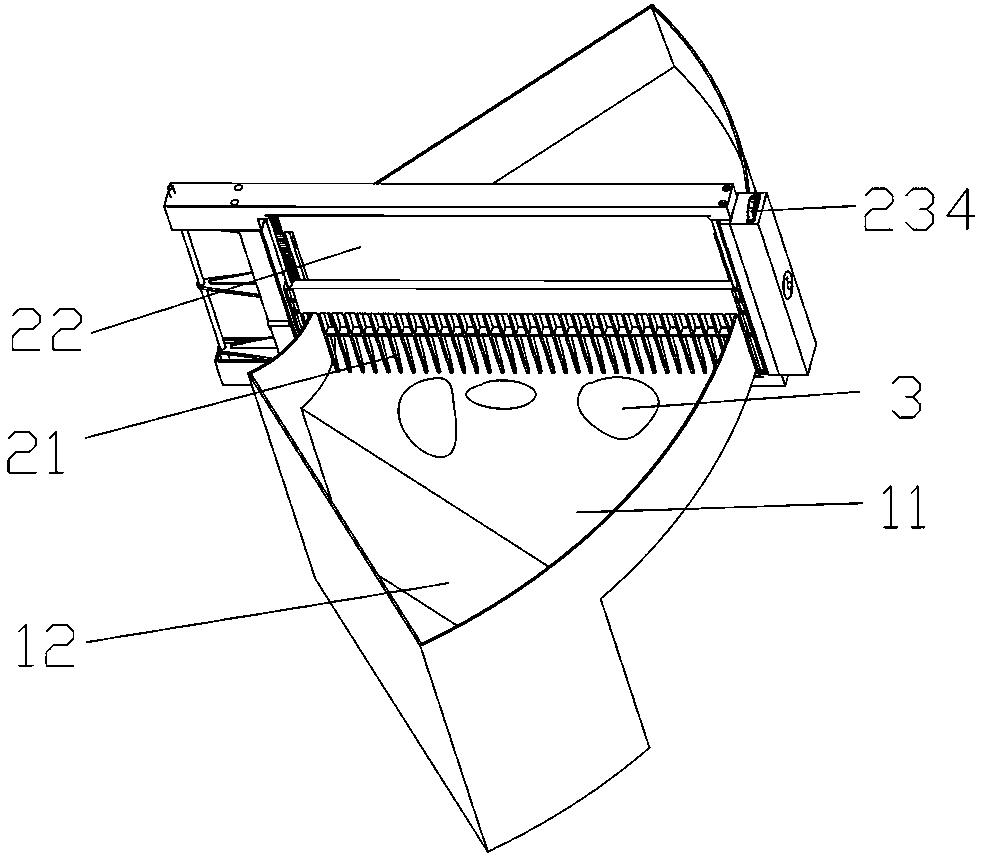

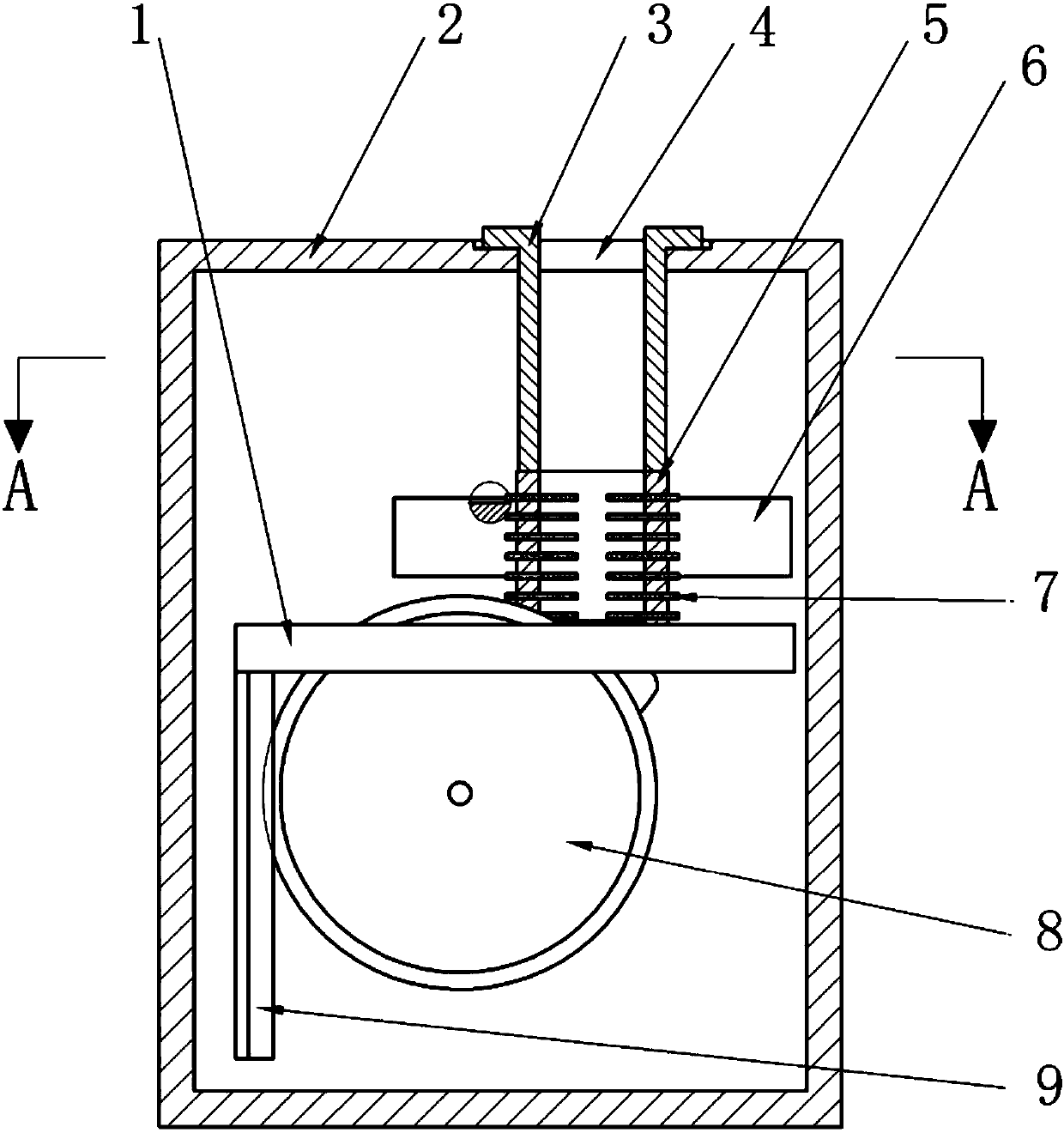

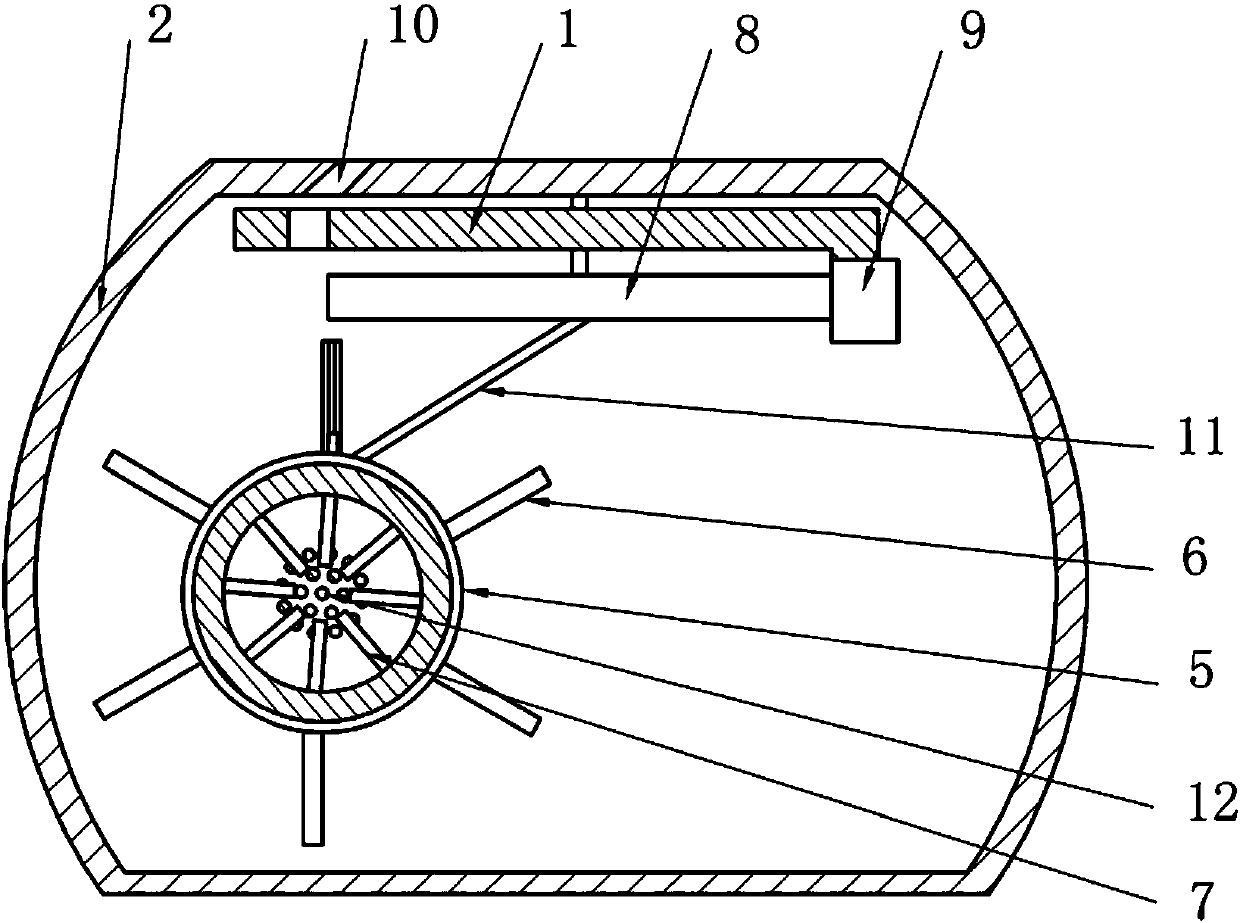

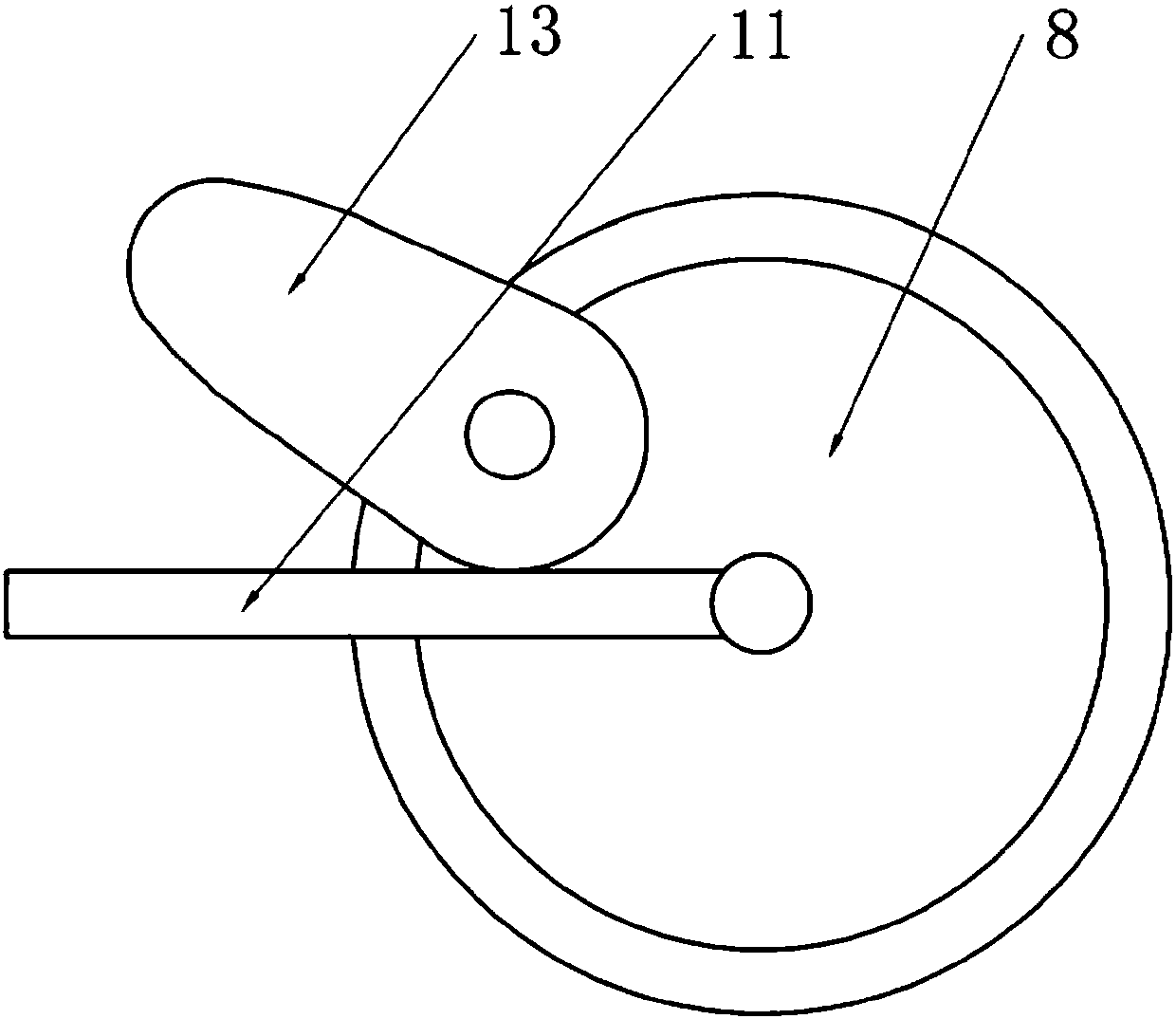

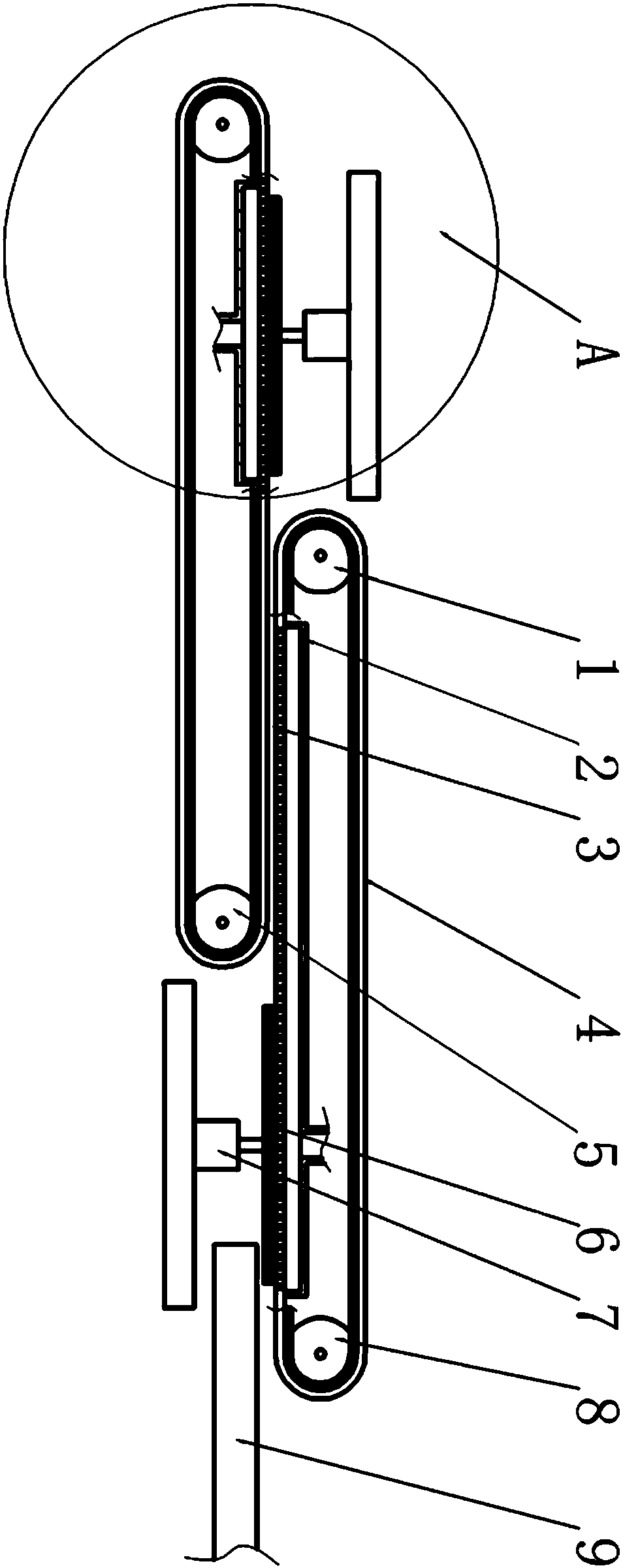

Automatic excrement shoveling and litter removing cat litter basin

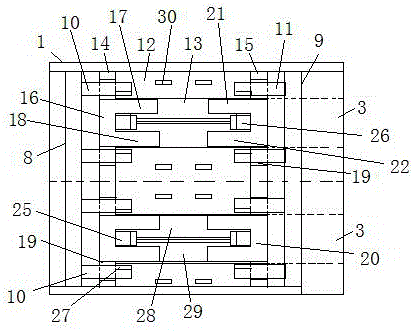

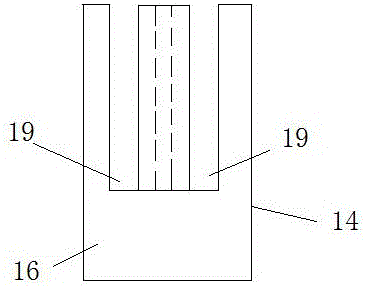

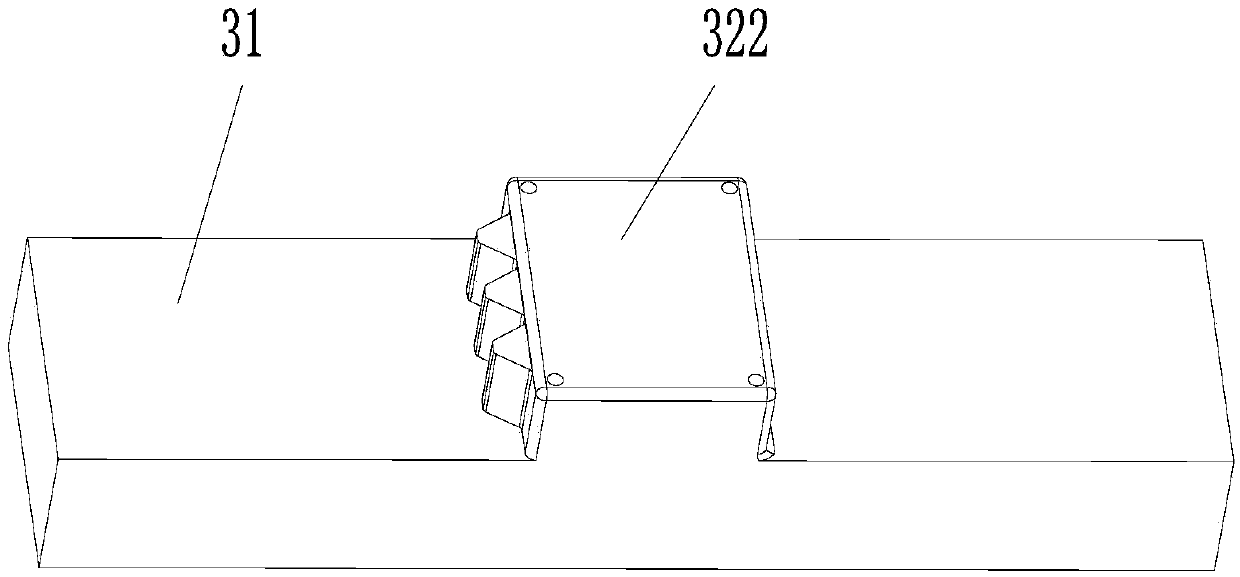

PendingCN111587795ASolve the problem of large-scale pollutionSolve dirty cleaningAnimal housingAnimal scienceLitter

The invention relates to the technical field of cat litter basins, in particular to an automatic excrement shoveling and litter removing cat litter basin which comprises a cat litter basin body and aswing rod assembly. The swing rod assembly comprises a feces shoveling grid plate, a sand cleaning plate, a swing rod driving assembly, a sand cleaning plate driving assembly and a swing rod support,and the swing rod assembly is installed on the cat litter basin body through a rotating shaft and is driven by the swing rod driving assembly to rotate with the rotating shaft as the center. And the feces shoveling grid plate is used for filtering and separating cat feces from cat litter and shoveling out the cat feces. The sand cleaning plate is used for shoveling out all cat litter, and the litter cleaning plate driving assembly moves up and down. Specifically, the swing rod driving assembly drives the swing rod assembly to rotate to drive the feces shoveling grid plate and the litter removing plate to rotate, and therefore cat feces and cat sand are removed. The cat litter basin has the following beneficial effects that the structure is simple, the automatic litter removing function isachieved, the action is small, the structure is simple, the weight is light, and the cost is low.

Owner:SHANGHAI TOWNEW INTELLIGENT TECH CO LTD

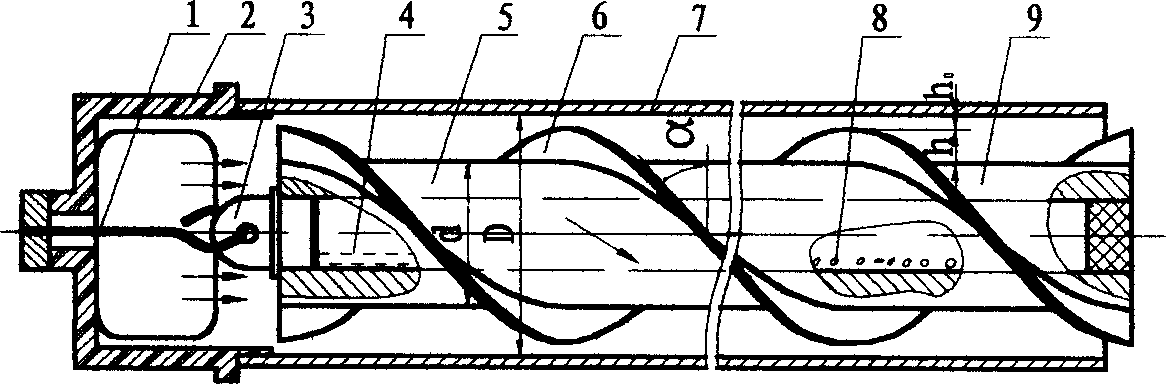

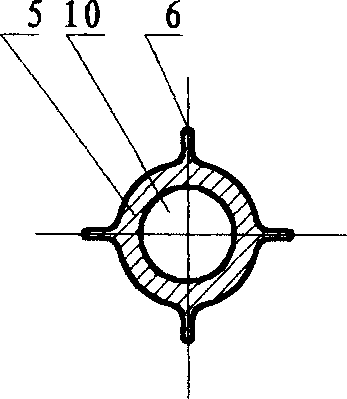

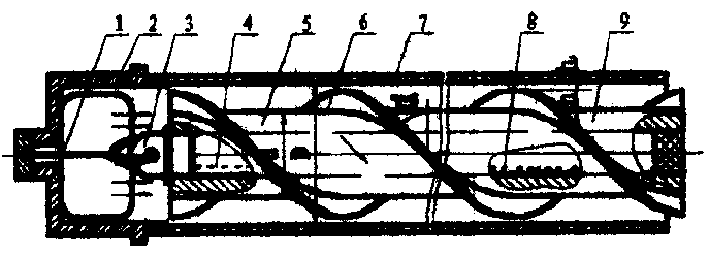

An inner tube spinning type purification and thermal conduction reinforced spiral -curved tooth tube

InactiveCN1485595AReduce the effective flow areaSolve wear and tearRotary device cleaningHelical lineEngineering

A inner tube rotating type purification and heat transfer reinforcement plastic helical tooth tube, wherein free rotating plastic helical tooth tube can be arranged in the heat transfer tube, whose inner chamber is stuffed by liquid or balls having good fluidity and an same integral density as that of the heat-transfer fluid in the tube, thus keeping the suspended state constantly. The tube by the invention effective reinforces the convective heat transfer, the heat transfer coefficient is increased by over 55%, thus can be widely used in the automatic purification and scale prevention for various type of low flow rate column tubes type heat transfer equipment.

Owner:株洲工学院帅科机械清洗研究所

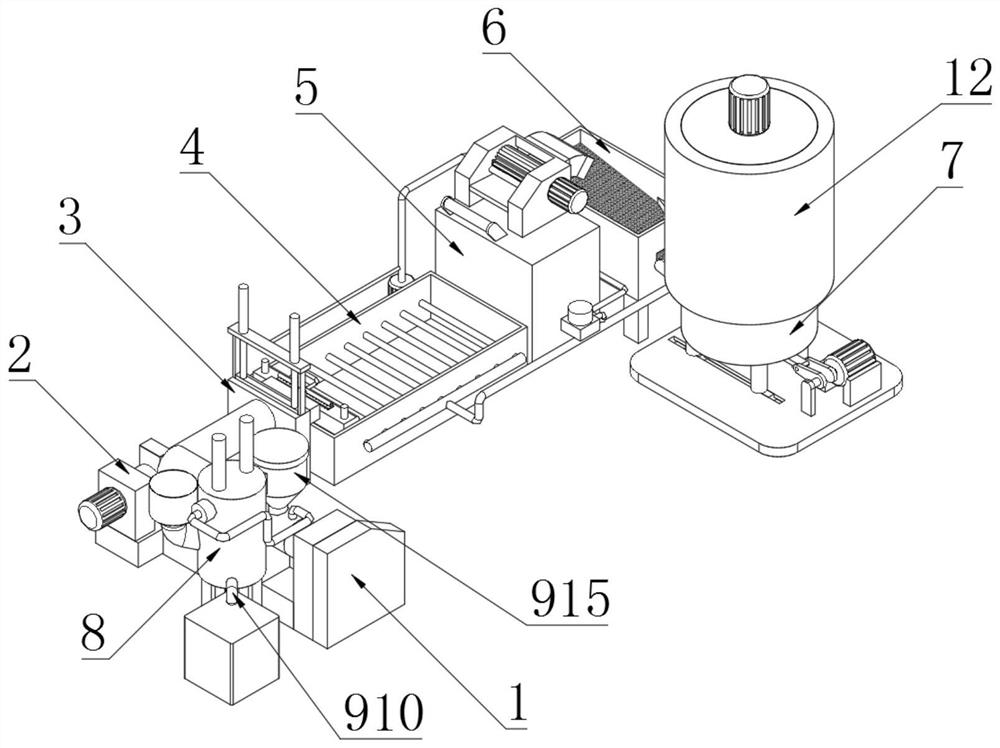

Full-automatic cleaning machine for large-batch fruits

The invention relates to a full-automatic cleaning machine for large-batch fruits, comprising a shell, a feeding hole and a discharge hole, wherein the shell is internally provided with a cleaning mechanism and a transmitting mechanism; the cleaning mechanism comprises a bottom plate; the bottom plate is provided with a fixing mechanism, a first cleaning brush and a second cleaning brush; the first cleaning brush is arranged at the left end of the fixing mechanism, and the second cleaning brush is positioned at the right end of the fixing mechanism; the fixing mechanism comprises a filter plate, a baffle, a first fixing device and a second fixing device; the first fixing device comprises a first fixing rod, and the second fixing device comprises a second fixing rod; the baffle is arranged between the first fixing rod and the second fixing rod; the transmitting mechanism is arranged at the lower end of the baffle. The full-automatic cleaning machine for the large-batch fruits is simple in structure, safe, reliable, convenient to use and low in cost, and can be used for cleaning large numbers of fruits in a full-automatic way in all directions, so that the fruit cleaning efficiency is effectively improved.

Owner:盐城市白桦林园林有限公司

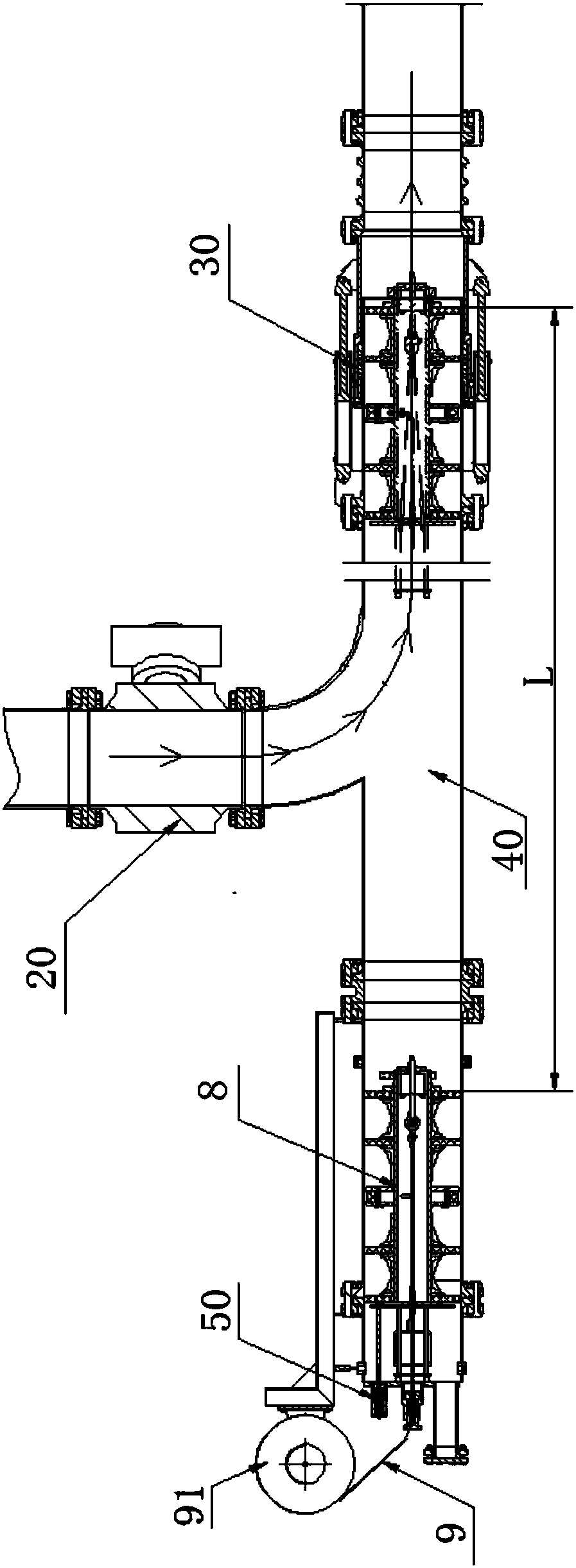

Rubber pneumatic bag type mud pipeline clearing top-plug device for shield tunneling machine

The invention provides a rubber pneumatic bag type mud pipeline clearing top-plug device for a shield tunneling machine, and belongs to the field of underground tunneling construction equipment. The rubber pneumatic bag type mud pipeline clearing top-plug device comprises a tube plug inner tube, a rubber pneumatic bag and two pneumatic bag clamping plates, wherein the tube plug inner tube is of ahollow cylinder structure; one end cover of the tube plug inner tube is equipped with a clamping plate supporting frame, and the end cover and the clamping plate supporting frame are arranged in a sealing mode; two pneumatic bag clamping plates are arranged on the middle part of the outer ring of the tube plug inner tube in a parallel mode; the pneumatic bag clamping plates and the outer ring of the tube plug inner tube are arranged in a sealing mode; the rubber pneumatic bag is fixedly arranged between the two pneumatic bag clamping plates and is away from one end of the tube plug inner tube;a rubber air cylinder and the pneumatic bag clamping plates are arranged in a sealing mode; a gas-filled tube is arranged inside the tube plug inner sleeve; one end of the gas filled tube passes through the tube plug inner sleeve and is arranged in the rubber pneumatic bag, and the other end of the gas filled tube passes through the clamping plate supporting frame and is connected with an external gas supply device; a control valve is arranged on the gas filled tube; and one end, away from the rubber pneumatic bag, of the gas filled tube is equipped with a cart rope. The rubber pneumatic bagtype mud pipeline clearing top-plug device solves the problem that deposits cannot be cleared, prevents the top plug from being blocked, and avoids a difficult pull-back phenomenon.

Owner:辽宁三三工业有限公司

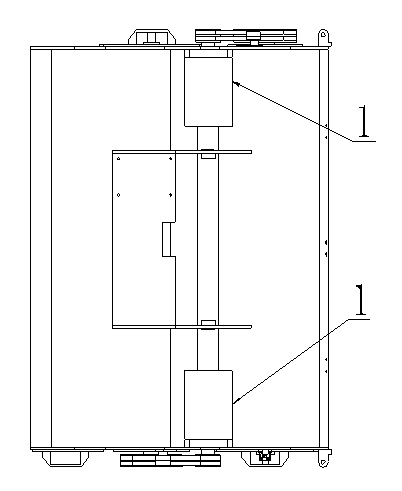

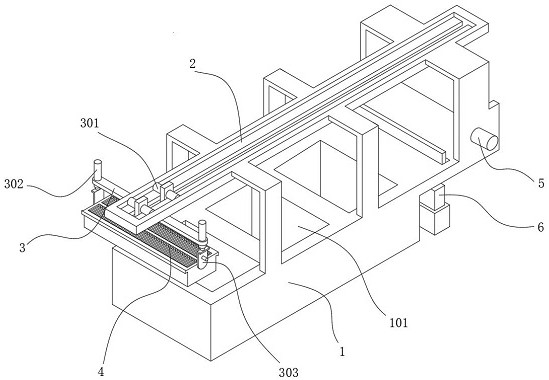

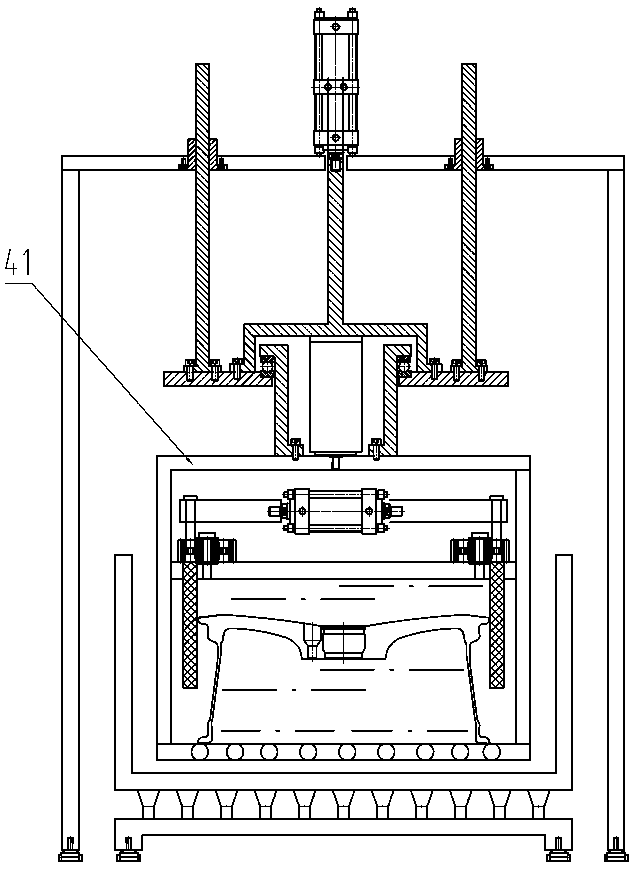

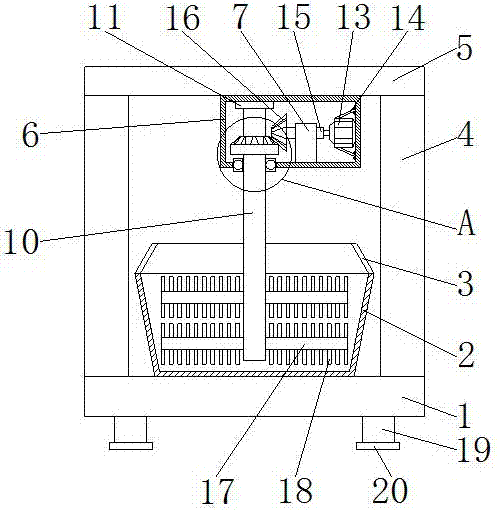

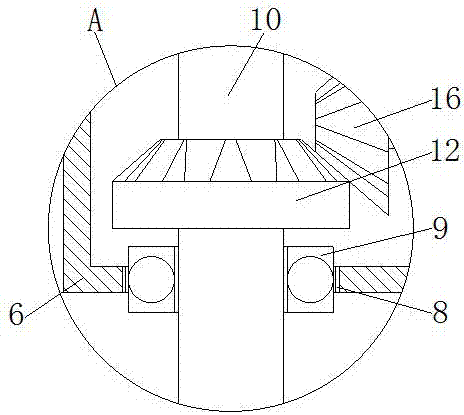

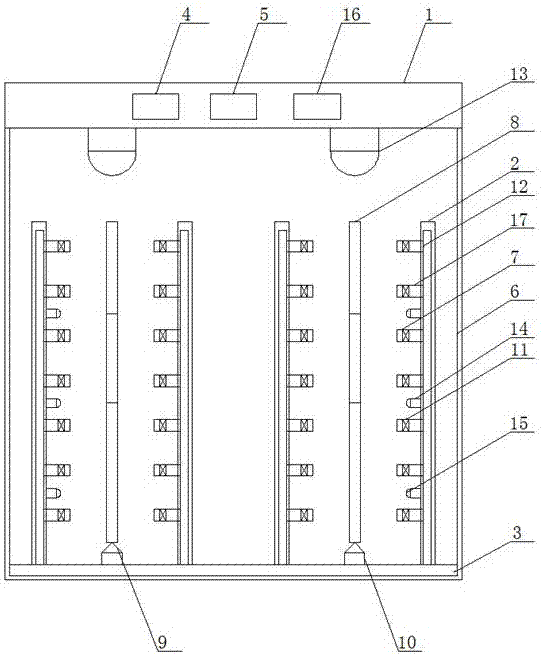

Full-automatic silicon wafer cleaning and spin-drying equipment

PendingCN114334732ASolve dirty cleaningImprove cleaning efficiencySemiconductor/solid-state device manufacturingWaferingElectric machinery

The invention discloses full-automatic silicon wafer cleaning and spin-drying equipment, and relates to the field of silicon wafer production. Comprising a cleaning box, a plurality of cleaning bins are formed in the cleaning box, a water spraying mechanism is installed in each cleaning bin, a sliding rail is connected to the upper portion of the cleaning box, a moving mechanism is arranged below the sliding rail, and a hanging basket is connected to the bottom end of the moving mechanism in a hanging mode. According to the silicon wafer cleaning device, through the arrangement of the hanging basket, the motor and the mounting column, after silicon wafers in the hanging basket are cleaned, the hanging basket is moved to the position near the mounting column through the moving mechanism, the hanging basket is clamped to the mounting column through the fixing rod, the motor is started, and the motor drives the hanging basket to rotate through the mounting column; when the hanging basket rotates, water in the hanging basket is discharged through the water discharging inclined opening under the action of centrifugal force, when the hanging basket rotates, the hanging basket drives outside air to enter the air groove formed in the hanging basket through the first air inlet and the second air inlet formed in the two sides, and airflow is discharged through the intercepting net to air the outer side of the silicon wafer.

Owner:王鹏

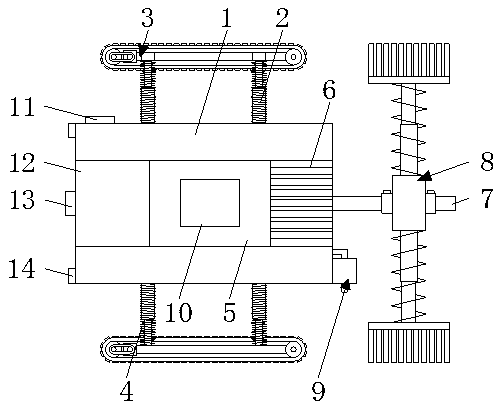

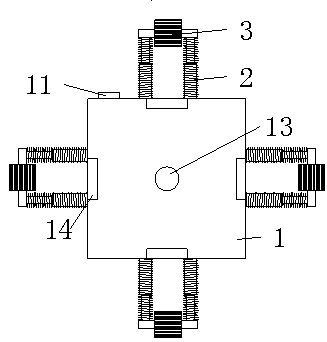

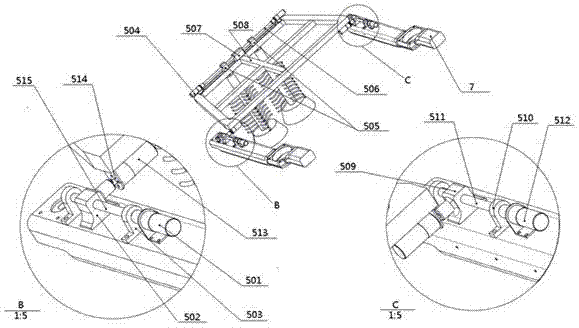

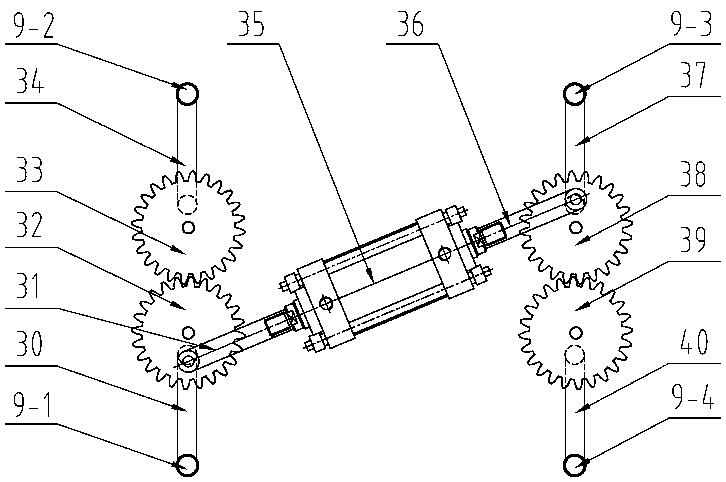

Composite sweeping device and method for gardening electronic sweeper

ActiveCN107268499AFlexible working methodsSolve cleaning difficultiesRoad cleaningGrain treatmentsVehicle frameSmall branch

The invention relates to a composite sweeping device and method for a gardening electronic sweeper. The composite sweeping device comprises a garbage pretreatment device and garbage aftertreatment devices; the garbage pretreatment device comprises composite smashing boxes installed on two longitudinal beams at the outer end of a vehicle frame, trapezoidal frames installed at the upper ends of the composite smashing boxes, two sets of cutter rollers installed in each composite smashing box body, position adjusting devices installed on the trapezoidal frames, composite rake sweeping brushes installed on the position adjusting devices of the trapezoidal frames and delivering devices connected with the composite smashing boxes; the garbage aftertreatment devices are installed at the two longitudinal beams at the outer end of the vehicle frame, and are located at the rear end of the composite smashing box. The composite sweeping device and method for the gardening electronic sweeper can achieve separate work and composite work of the garbage pretreatment device and the garbage aftertreatment devices, the garbage pretreatment device can gather, smash and recycle long branches, and the garbage aftertreatment devices suck and sweep dust and fine and small branches and leaves. The composite sweeping device and method for the gardening electronic sweeper are flexible in work mode, and solves the problems that long branches and leaves are difficult to sweep and not thoroughly cleaned.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

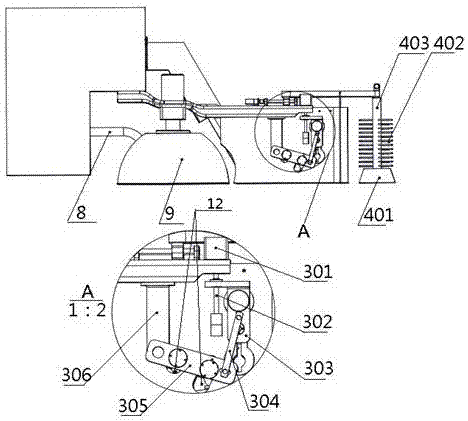

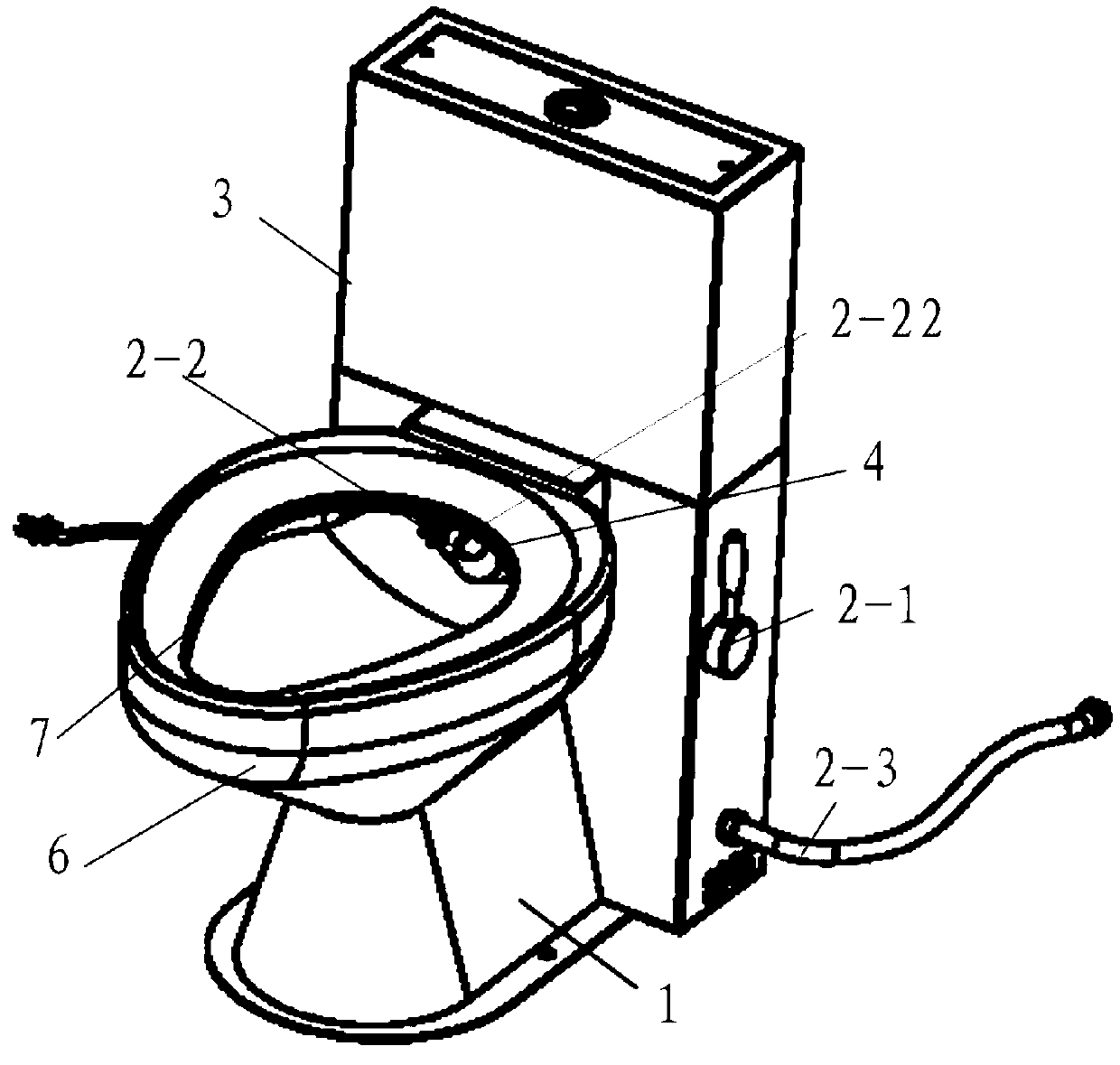

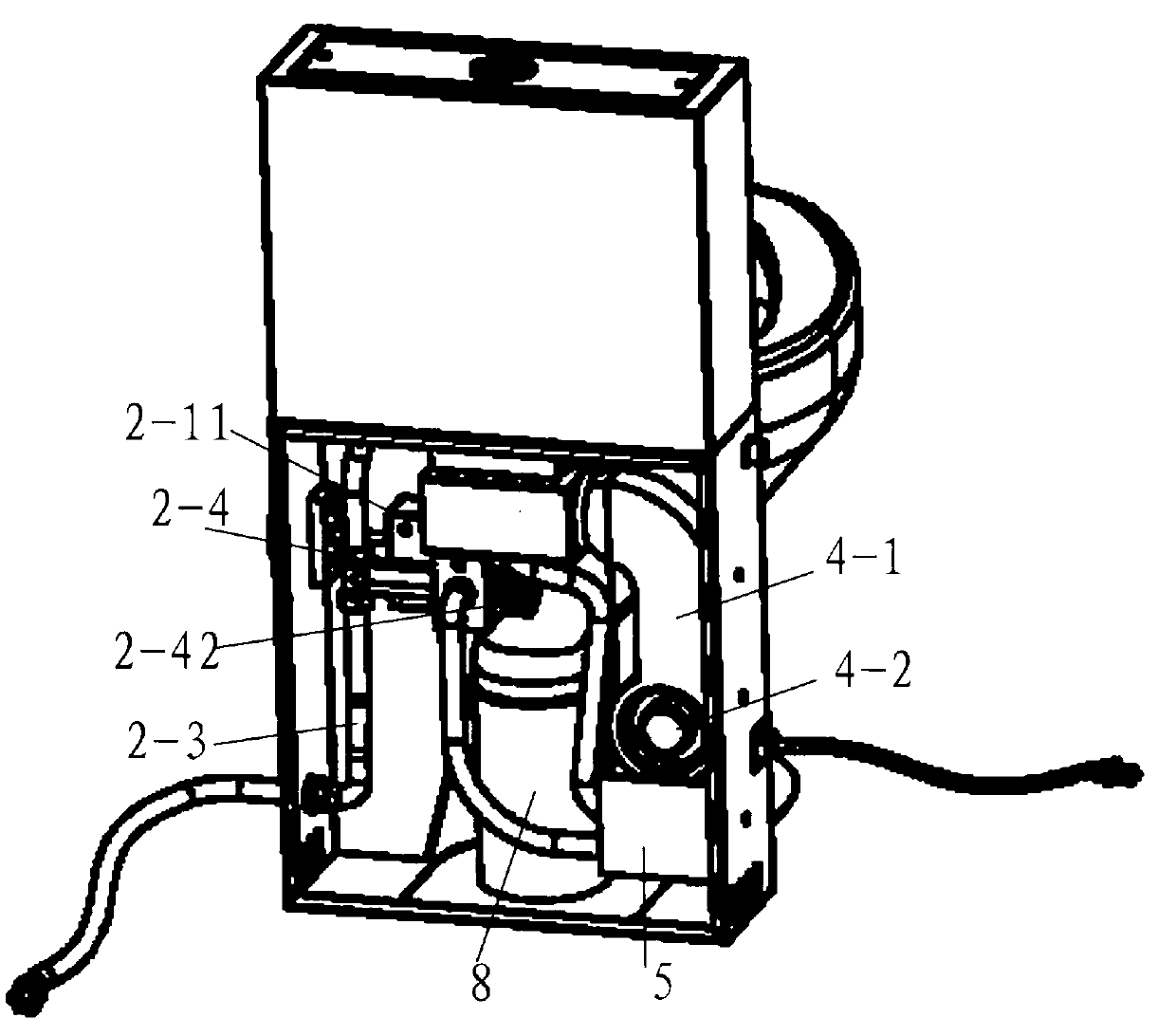

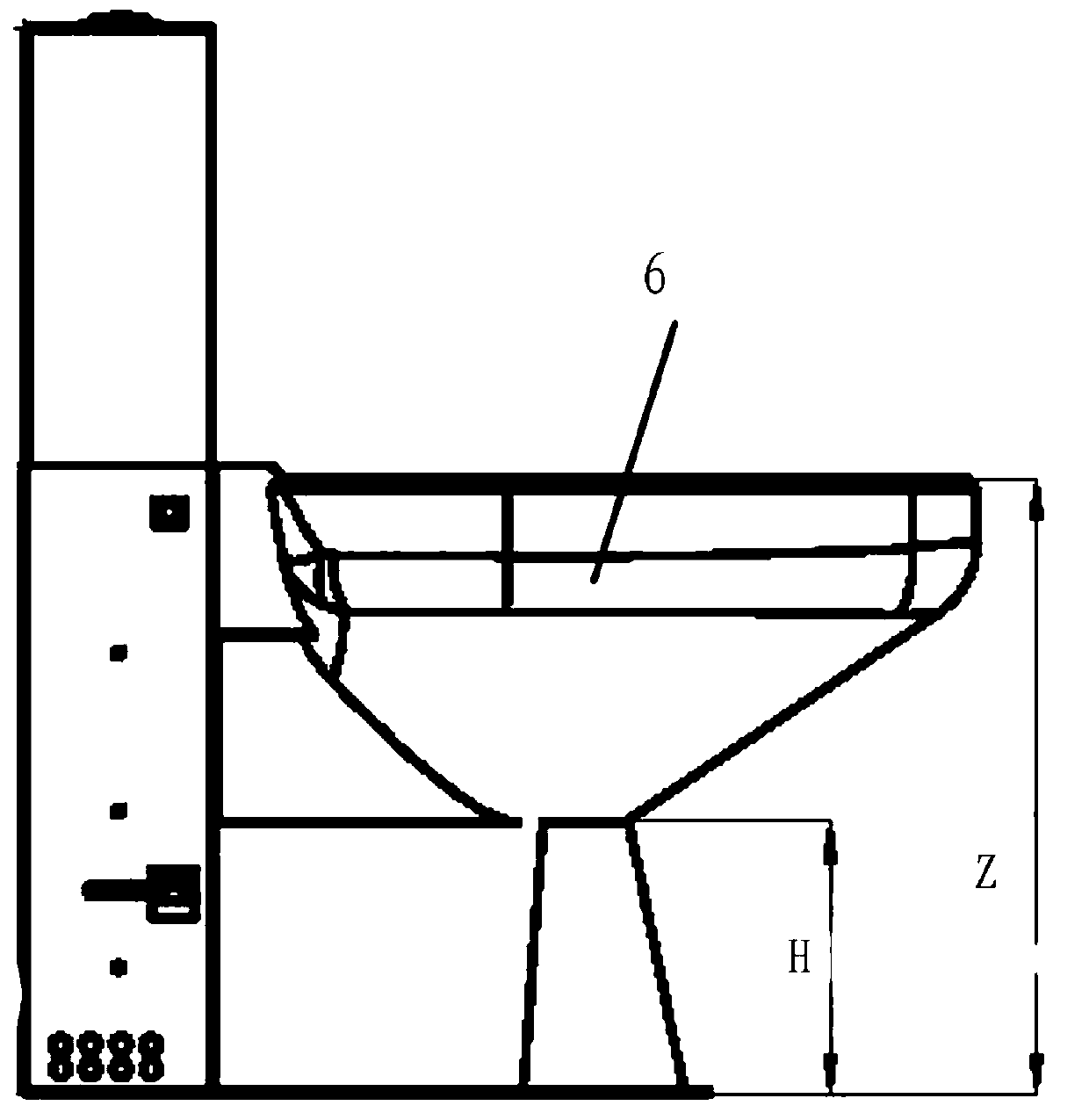

Multifunctional toilet bowl

ActiveCN103343566ASolve dirty cleaningAvoid fixed patternsLavatory sanitoryEngineeringControl switch

The invention discloses a multifunctional toilet bowl which comprises a toilet bowl body and a hip cleaning device which is arranged on the toilet bowl body, wherein a toilet bowl basin, a flushing channel and a sewage discharge channel are arranged on the toilet bowl body. The multifunctional toilet bowl is characterized in that the hip cleaning device comprises a rotating control switch, a water spraying extensible moving mechanism, a water inlet pipeline which is connected with a water spraying nozzle and a water valve which is arranged on the water inlet pipeline, a valve core rod which controls a valve core to be closed and opened is arranged in the water valve, the water spraying extensible moving mechanism comprises a moving rod which is movably arranged on the inner wall of the toilet bowl basin of the toilet bowl body, and a water spraying nozzle which is fixed on the movable rod, the moving rod and the valve core rod are synchronously driven by the rotating control switch, the moving rod is driven by the rotating control switch to move frontward and backward, and the opening degree of the water valve is controlled by the rotating control switch at the same time. The multifunctional toilet bowl is simple in structure, convenient to use, low in cost and good in practicability.

Owner:佛山市三水创兴不锈钢制品有限公司

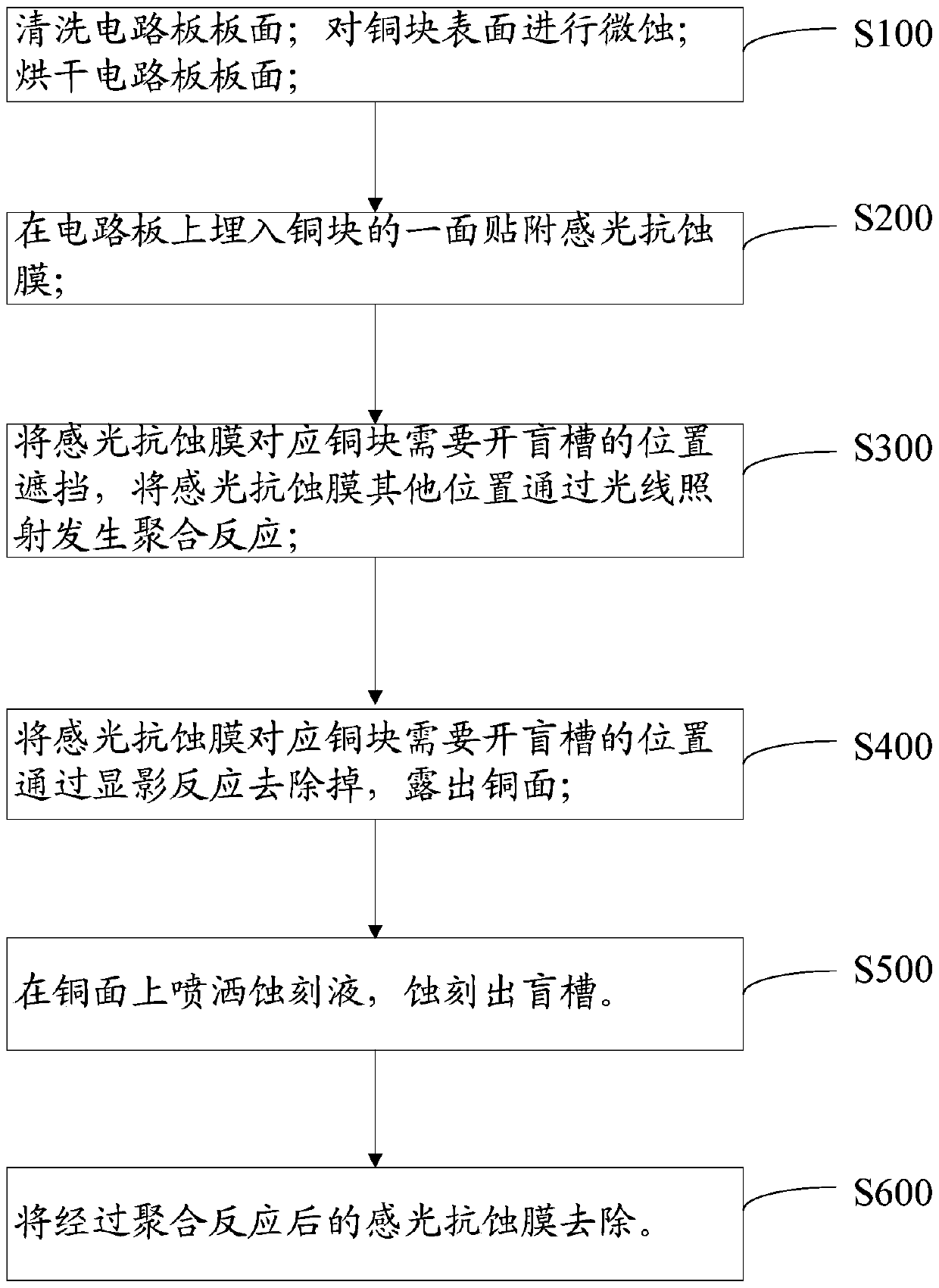

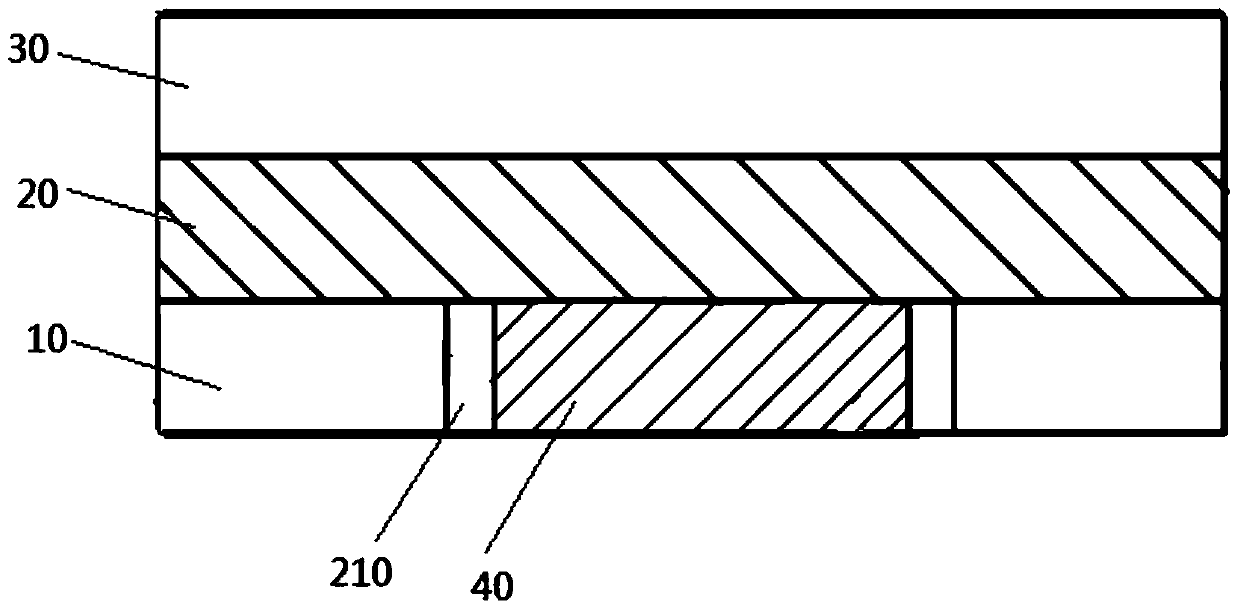

Method for making blind slots of buried copper blocks in circuit boards

ActiveCN104797085BControl depthSolve the problem of milling cutter printingPrinted circuit manufactureSurface coolingResist

The invention discloses a method for manufacturing blind grooves embedded in copper blocks of circuit boards, comprising the following steps: attaching a photosensitive resist film to one side of the circuit board where the copper blocks are embedded; The position is blocked, and the other positions of the photosensitive resist film are polymerized by light irradiation; the position of the photosensitive resist film corresponding to the copper block that needs to open a blind groove is removed by developing reaction, and the copper surface is exposed; the etching solution is sprayed on the copper surface to etch out Blind slot. By using the photosensitive resist film after polymerization to protect the part of the circuit board that does not need to open the blind slot, the depth of the blind slot can be well controlled by etching, and the uniformity of the etching is used to make the wall of the blind slot after etching flat, thereby solving the problem. It solves the problem of milling cutter printing on the bottom of blind slots traditionally processed by CNC machine tools, improves the heat dissipation effect of heating components in the later stage, and completely solves the problem of unclean cleaning of copper PCB surface cooling oil and coolant after milling slots.

Owner:GCI SCI & TECH

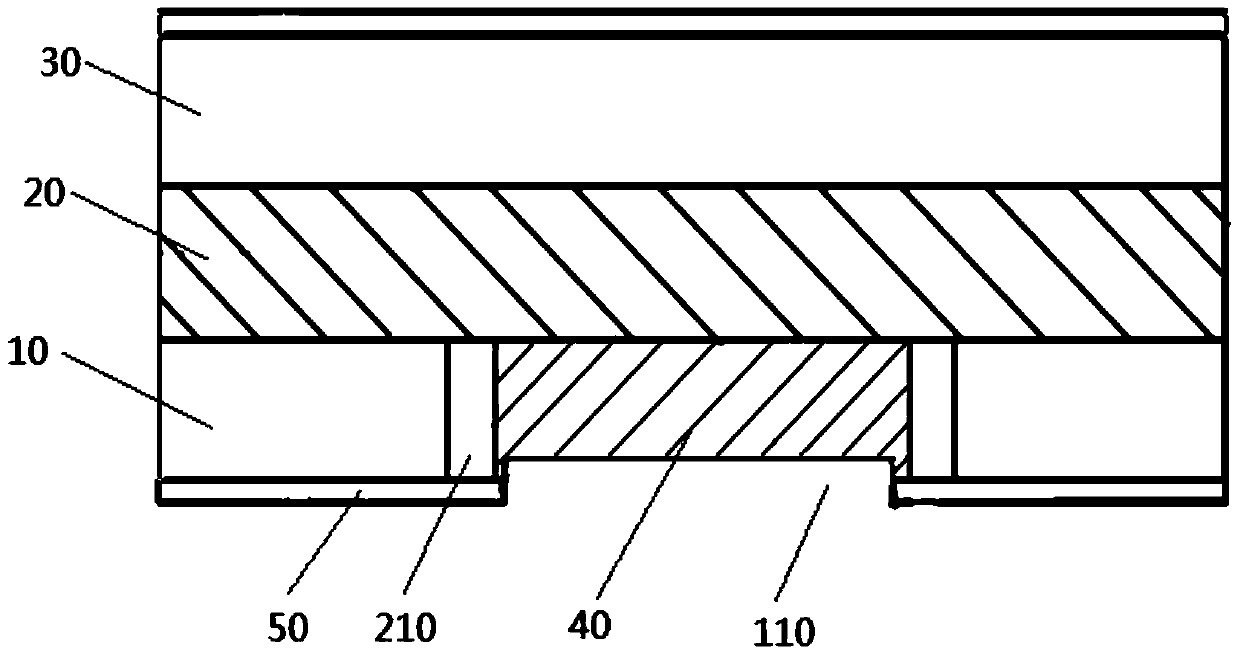

Cleaning device for coated glass

Owner:WUHU VACUUM TECH

Pigment type blue ink

The invention relates to a blue ink and concretely to a water pigment blue ink which is easy to wash and can be used in fountain pen and sign pen. The said ink solves the problem in present blue ink which is of poor water resistance and sun resistance and can not be washed easily. The weight ratio of raw materials composition of the prepared ink is: 1.0 % -5 % of Berlin blue colorant, 0.2 % - 5 % of oxalic acid complexing agent, 0.01 % - 2 % of surface activator, 1 % - 10 % of water-loss reducer , 0.1 % - 1 % of binding agent, 0.1 % - 1 % of preservative agent, and the other is water. In relation to the present technology, the significance effect of this invention is: 1. in relation to the present blue ink, it has good water resistance and sun resistance but small diffusibleness; 2. in relation to the present writing ink of all kinds, it is erasable which solves the problem that clothes can not be washed cleanly when contaminated by the present ink; 3. the said ink and its catabolite is nontoxic, flavourless and can not pollute the environment.

Owner:SHANGHAI NNW NEW MATERIALS TECH

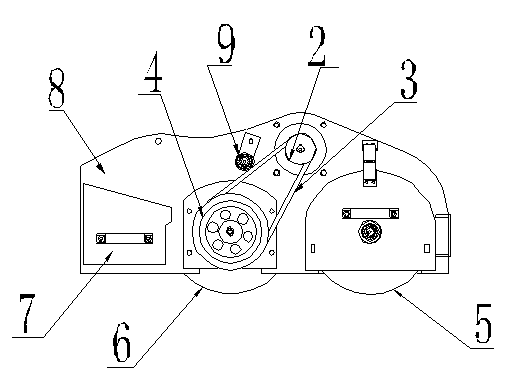

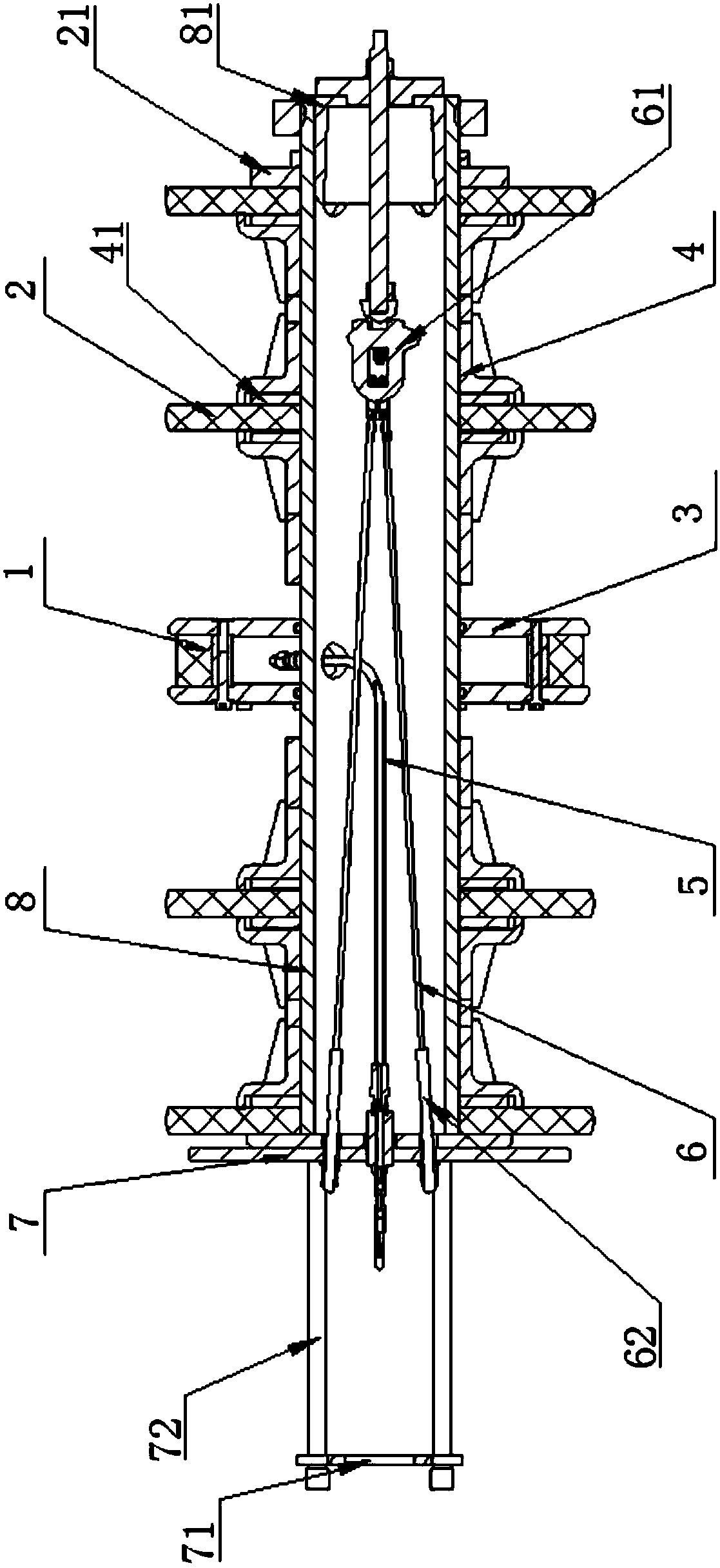

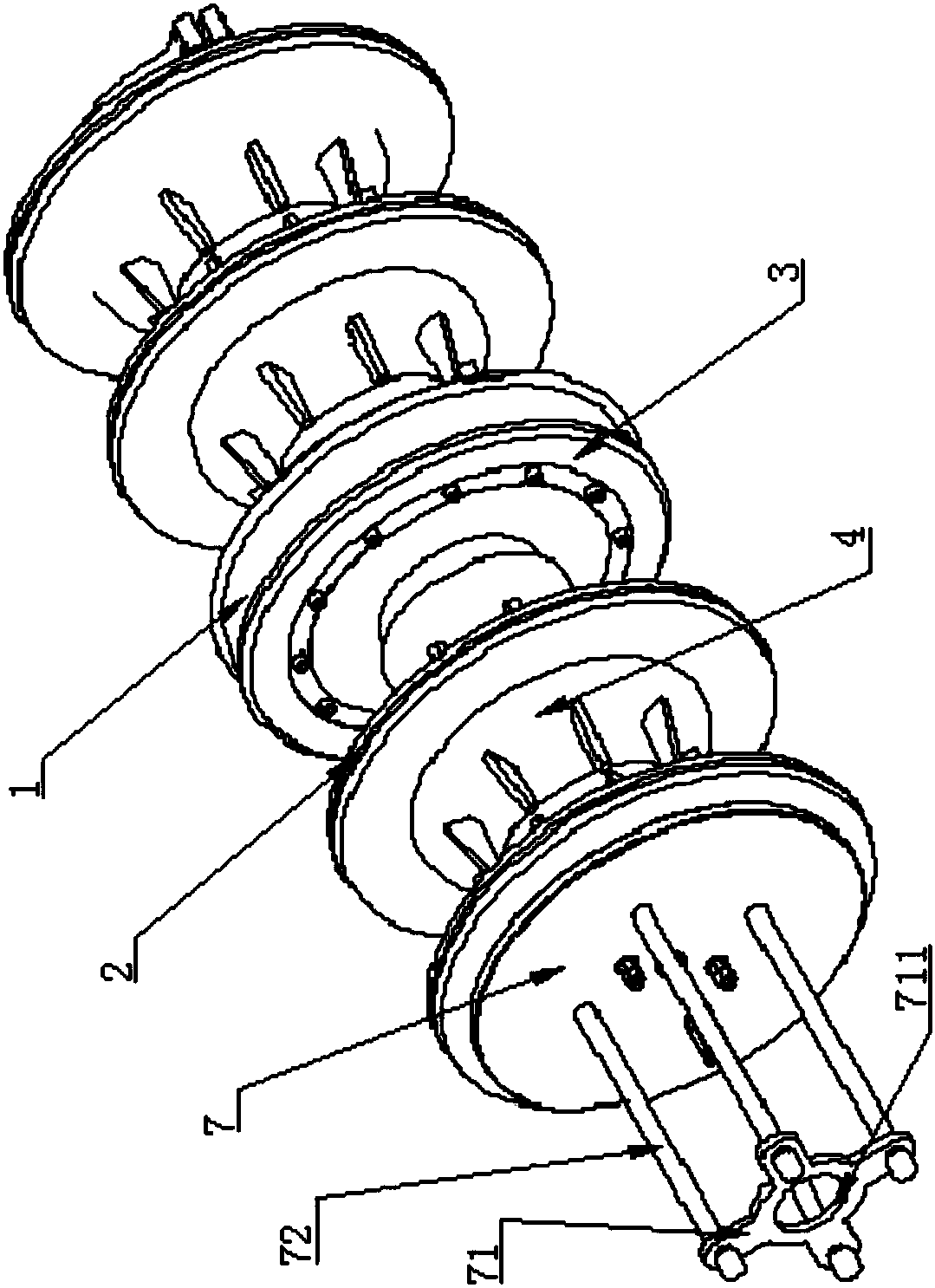

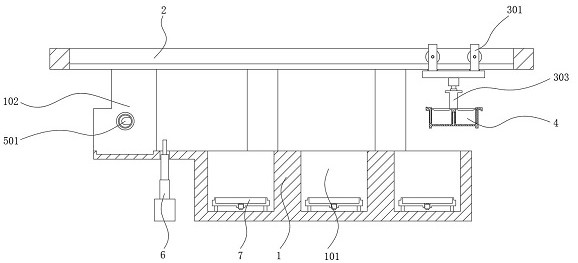

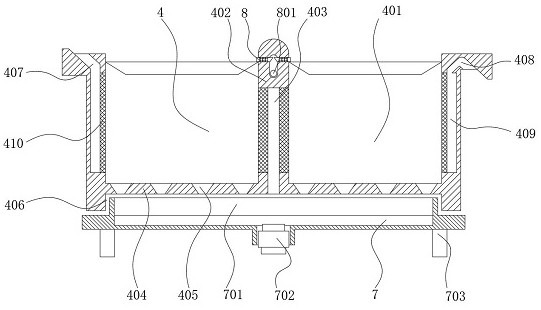

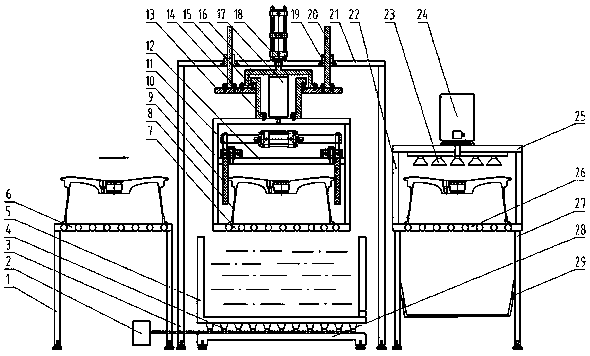

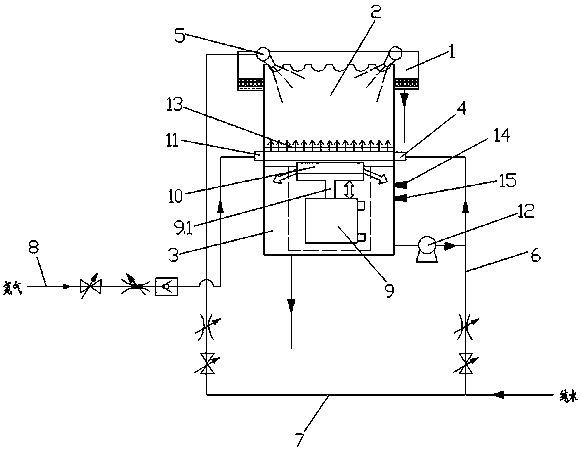

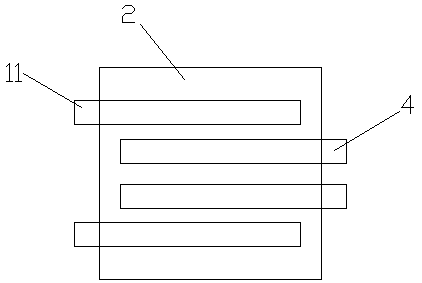

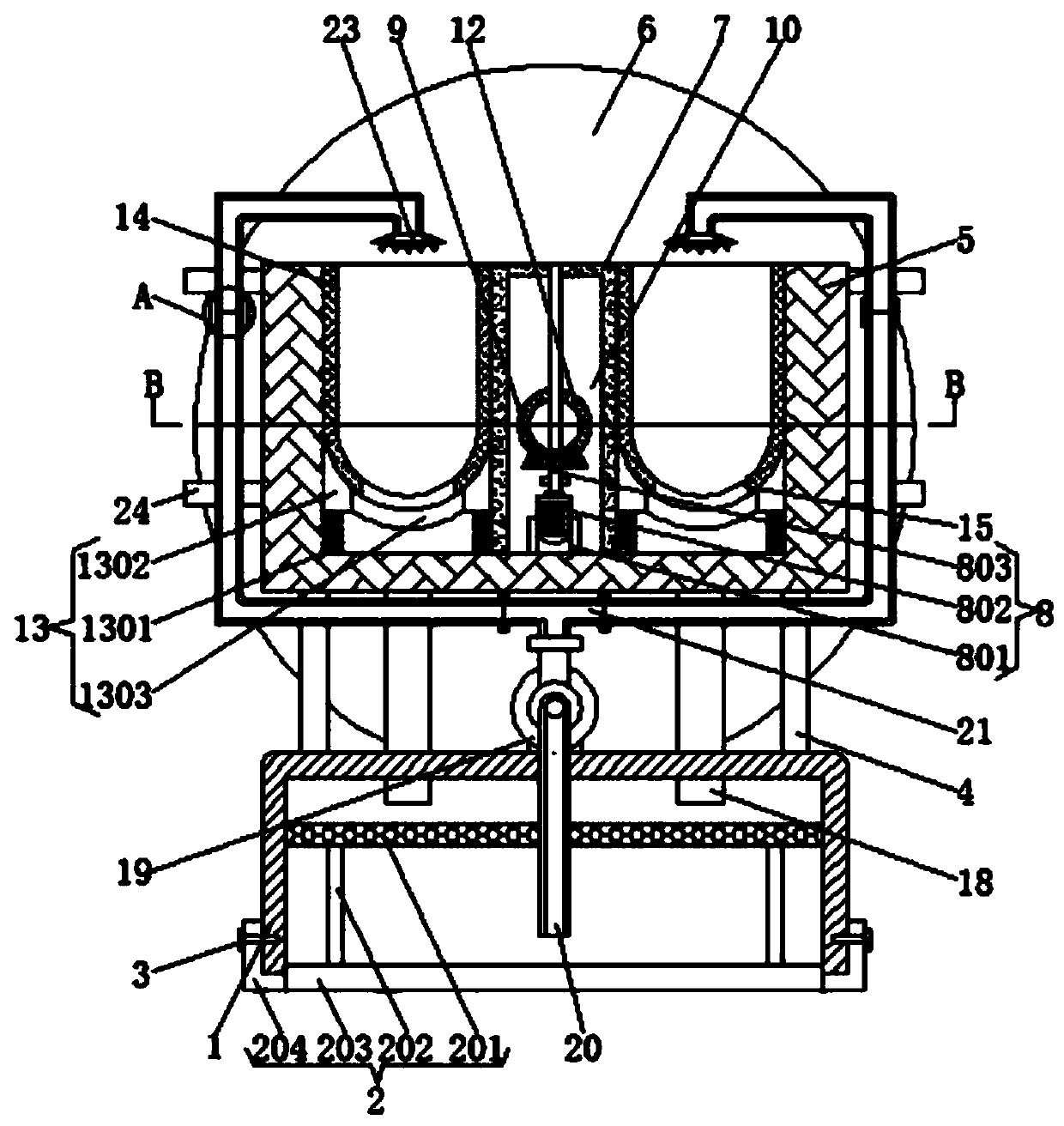

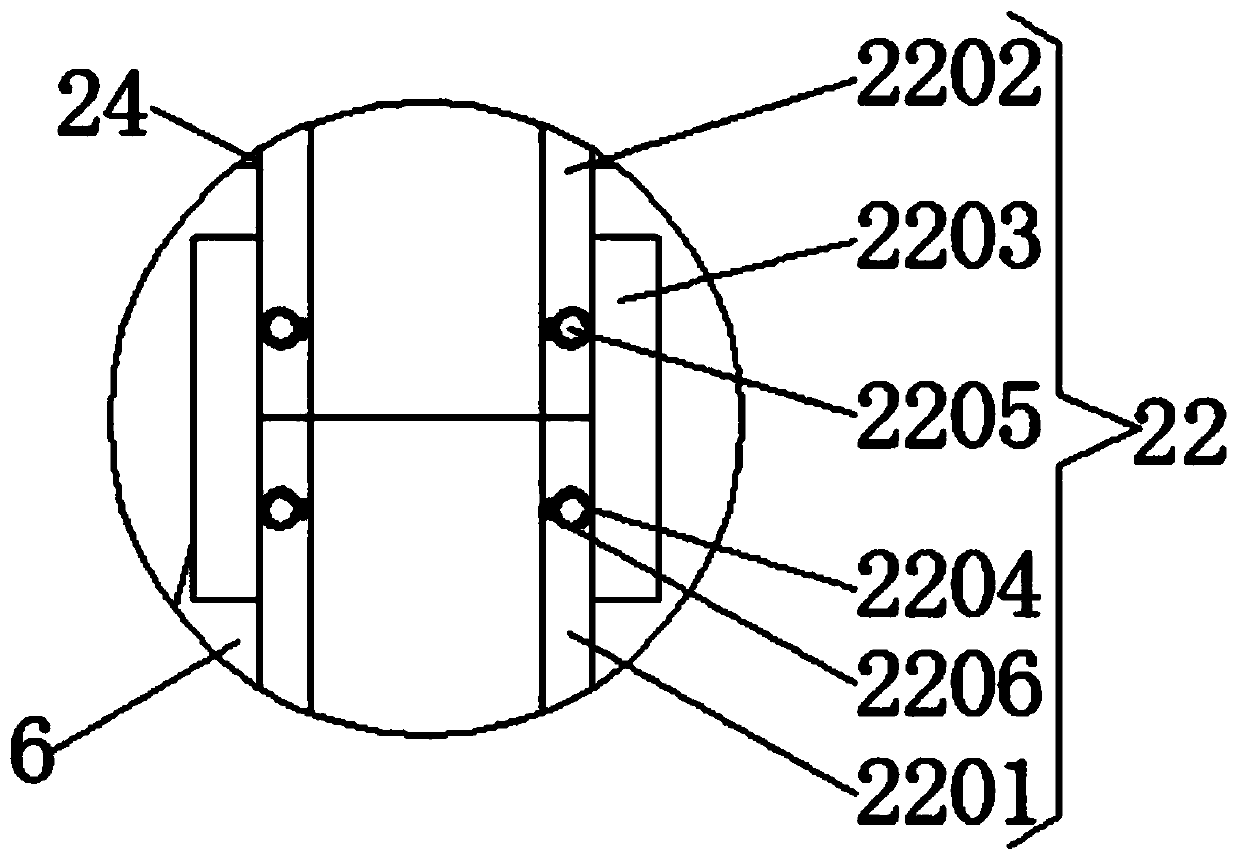

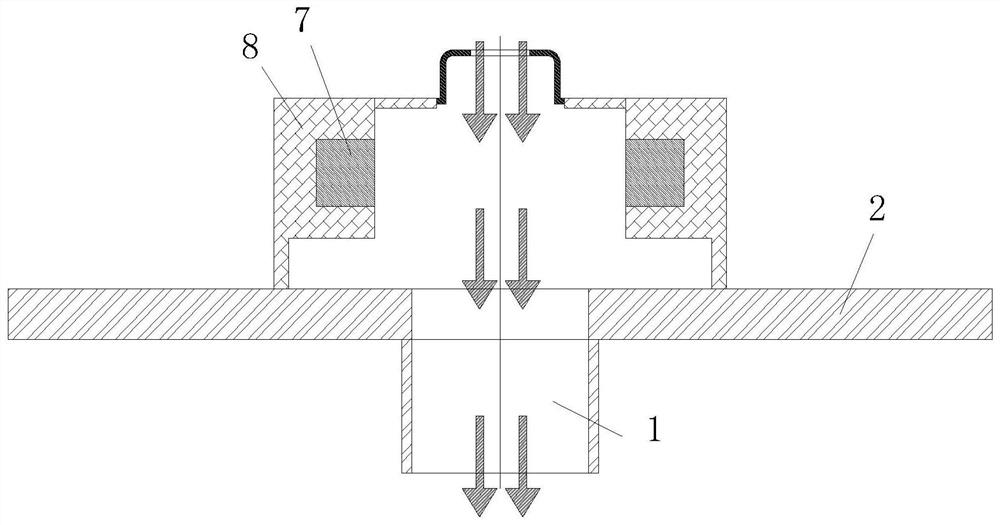

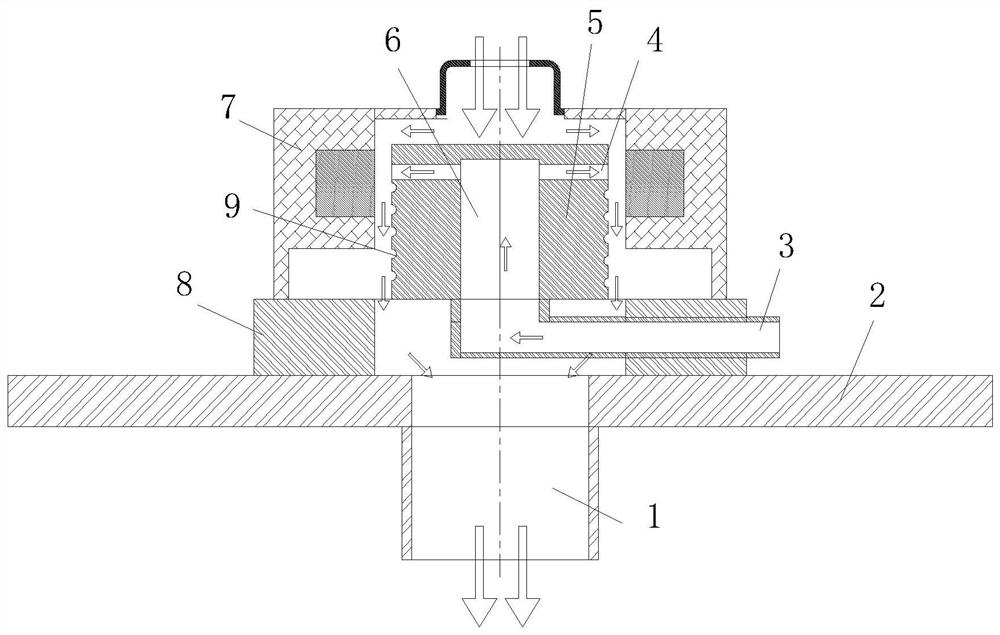

Online hub cleaning system

PendingCN110756514AImprove cleaning effectSolve dirty cleaningDrying gas arrangementsCleaning using liquidsProcess engineeringContinuous production

The invention relates to the technical field of hub cleaning, in particular to an online hub cleaning system. The online hub cleaning system comprises an input roller way module, a hub cleaning deviceand an output roller way module; the hub cleaning device comprises a lifting module, a rotating module, a clamping module and an ultrasonic cleaning module; hubs can be rotated in the cleaning process; the cleaning effect is further improved by using a cavitation effect of an ultrasonic device; the surface state of the cleaned subs is guaranteed to meet subsequent procedure requirements; and theonline hub cleaning system can be used for automatic continuous production, and solves the problem of halfway cleaning in the traditional hub industry.

Owner:CITIC DICASTAL

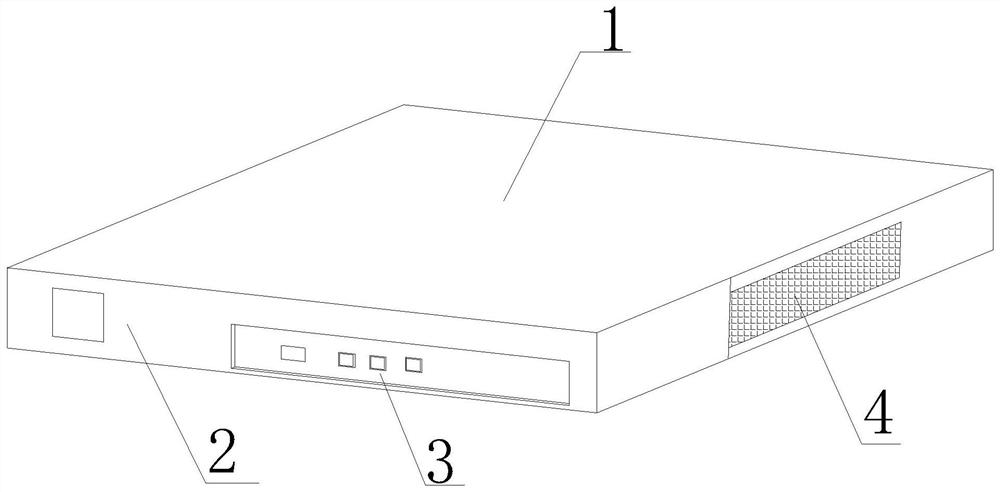

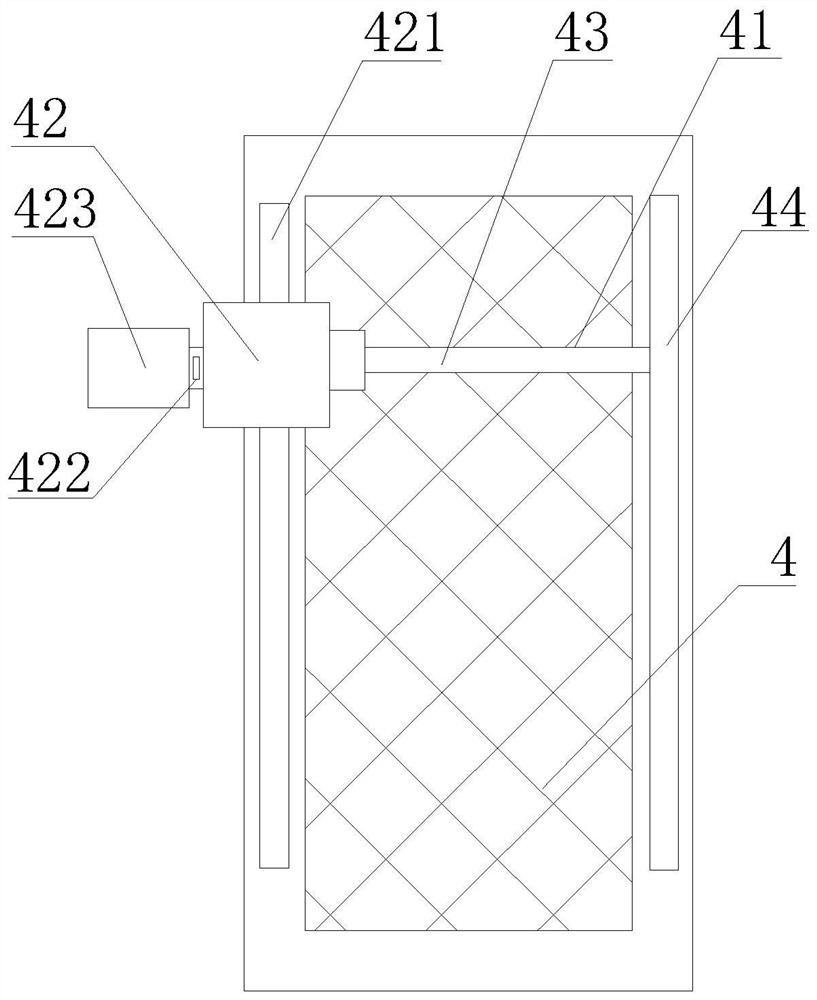

Portable network safety equipment

PendingCN113597210AImprove cleanlinessSolve dirty cleaningCleaning using toolsSupport structure mountingElectric machineryElectronic component

The invention discloses portable network safety equipment, and relates to the technical field of network safety equipment. The portable network safety equipment comprises a safety equipment main body, an equipment shell, a wiring port and a heat dissipation net. The equipment shell is fixedly mounted on the outer side of the safety equipment main body, the wiring port is formed in the front surface of the equipment shell, and the heat dissipation net is arranged on the side surface of the equipment shell; and a dust removal mechanism is fixedly mounted on the inner side, close to the equipment, of the heat dissipation net. A power motor is connected with a power source to drive a cleaning column to rotate, then a moving block and a moving groove are matched with each other to enable the cleaning column to move to sweep dust on the heat dissipation net, and then a pressing rod and a pull rope are matched with each other so that the cleanliness of a dust removal mechanism is improved, and the problems that the dust removal capacity in equipment is poor, and the dust can not be cleaned during dust cleaning are solved; and the cleaning degree of the equipment is increased so that the heat dissipation effect in the equipment is improved, and efficient operation of electronic elements in the equipment is increased.

Owner:曹欣欣

Automatic cleaning device of sweet potatoes

Owner:耒阳市耒兴薯业发展有限公司

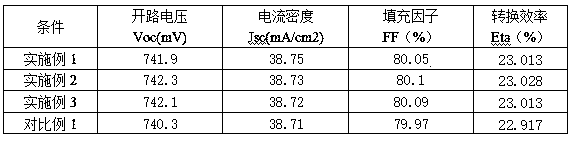

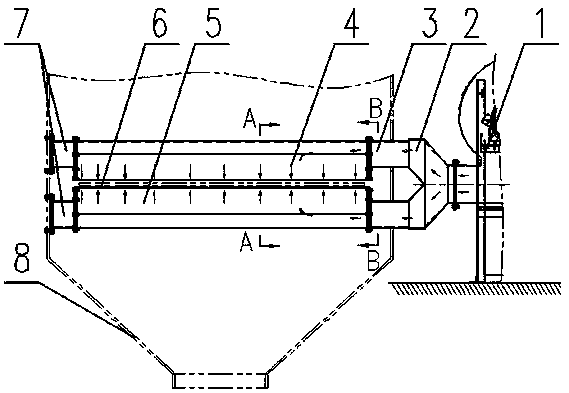

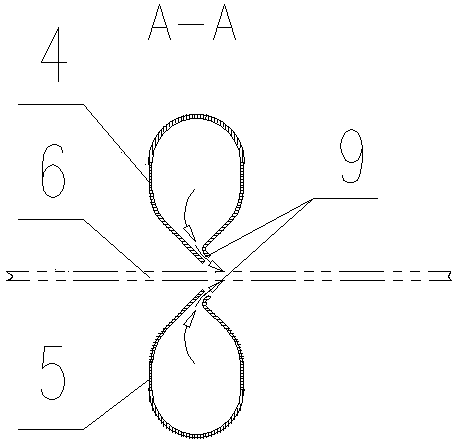

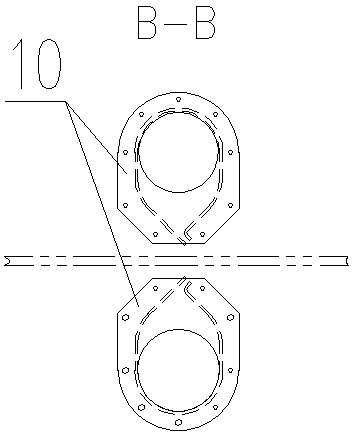

High-efficiency crystalline silicon heterojunction solar cell silicon wafer cleaning device and method

PendingCN110534463AImprove photoelectric conversion efficiencyReduce water consumptionSemiconductor/solid-state device manufacturingCrystalline siliconWaste management

The invention relates to a high-efficiency crystalline silicon heterojunction solar cell silicon wafer cleaning device and method. The device comprises an overflow tank, and upper and lower tanks which are arranged above and below. A liquid inlet pipe and an air inlet pipe are arranged at the lower part of the upper tank. A pure water spray is arranged at the top. Pure water enters an overflow pipe and a spray pipe. Nitrogen enters a nitrogen pipe. The nitrogen pipe is connected with the inlet pipe. The overflow pipe is connected with the liquid inlet pipe. The spray pipe is connected with thepure water spray. A fast-discharging cylinder is arranged in the lower tank. The piston rod of the fast-discharging cylinder is connected with a fast-discharging cover. The upper tank is provided with a fast-discharging opening corresponding to the fast-discharging cover. According to the invention, water washing is divided into two steps of pure water overflow and spraying, so that the last water contacted by a silicon wafer is clean new pure water; the problem of uncleaned silicon wafer surface in an HJT cell is solved; the photoelectric conversion efficiency of the HJT solar cell is improved; and the stable process is more suitable for mass production.

Owner:SUZHOU AIKANG LOW CARBON TECH INST

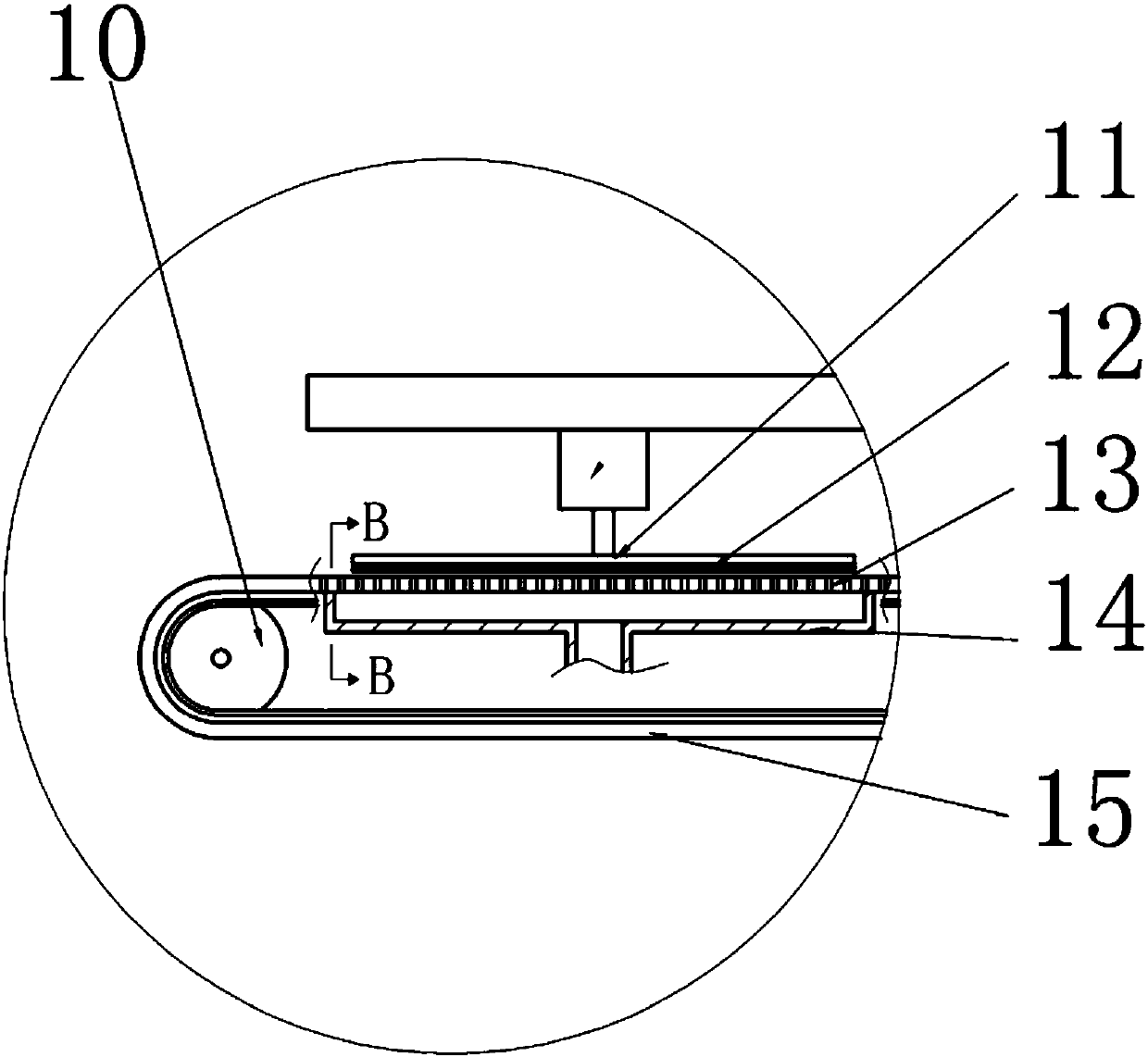

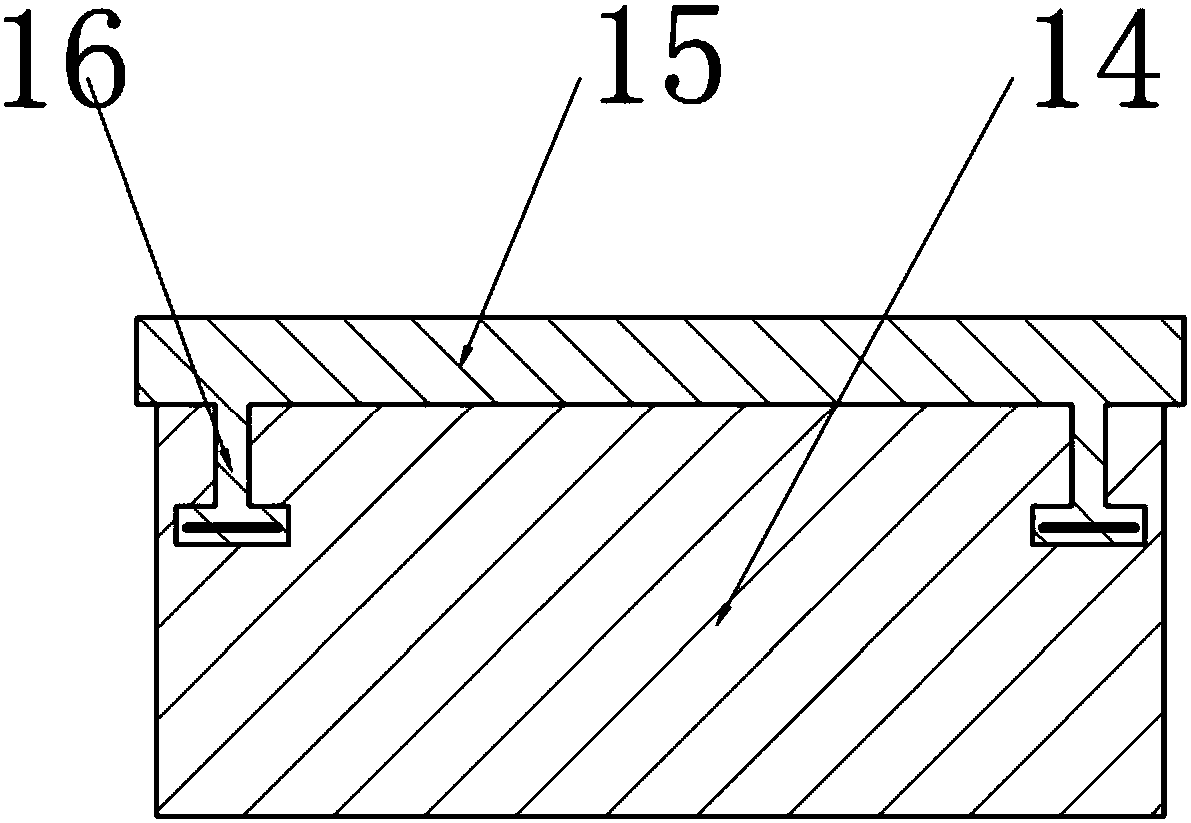

Air cushion belt type conveyor sweeper

PendingCN107600966AWill not affect service lifeWon't cause deviationCleaningEngineeringHigh pressure

The invention discloses an air cushion belt type conveyor sweeper. A high-pressure centrifugal fan is connected with an air distributing box through a flange and bolts, assembling holes allowing two transition air pipes to penetrate are formed in the side wall of a hopper, close to the air distributing box, at the head of a conveyor, one ends of the two transition air pipes penetrate into the assembling holes and are welded to special-shaped flanges, and the other ends of the two transition air pipes are welded to the air distributing box. One ends of an upper strong wind pipe and a lower strong wind pipe are welded on the special-shaped flanges, the special-shaped flanges are connected through bolts, the other ends of the upper strong wind pipe and the lower strong wind pipes are welded to another special-shaped flange, one end of a supporting pipe is welded to the corresponding special-shaped flange, and the special-shaped flanges are connected through bolts and welded to the side wall of a discharging hopper of the conveyor. A wind nozzle is arranged at the upper end of each of the upper strong wind pipe and the lower strong wind pipe, and the wind nozzles are spaced from a conveyor belt by a certain distance and form certain angles with the conveyor belt. The pneumatic sweeper involved in the technical scheme does not make contact with the conveyor belt, and dust and residual materials attached to the upper and lower belt surfaces of the conveyor belt are swept cleanly.

Owner:河南天隆输送装备有限公司

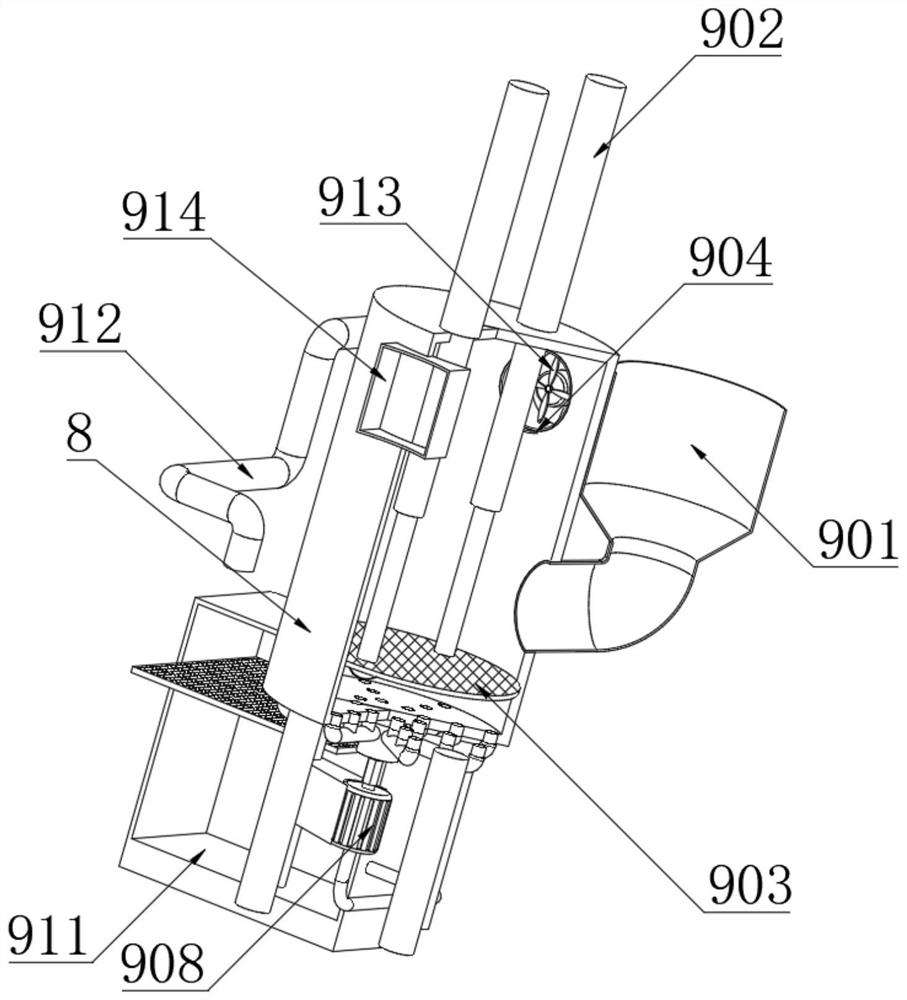

In-out-factory palm disinfection method for aquatic product processing factory

InactiveCN108030425ASolve dirty cleaningSmooth rotationBathroom accessoriesMedical applicatorsPolyethylene oxideDisinfectant

The invention belongs to the field of disinfection of food processing factories and particularly discloses an in-out-factory palm disinfection method for an aquatic product processing factory. Benzalkonium bromide and polyethylene oxide are mixed according to the volume ratio of (15-25):(1-1.5), clear water is added to the mixed solution for dilution to prepare a disinfectant, and the microorganism inhibition effect is improved. Meanwhile, a hand washing device for the aquatic product processing factory is used in the method, the disinfection cleaning effect is improved, and the situation is avoided that in the prior art, operation personnel cannot clean the two hands completely by themselves.

Owner:重庆市念湖食品有限公司

Negative-pressure transportation waste glass cleaning device

InactiveCN107695062ASolve the problem of easy movement and unclean cleaningSolve dirty cleaningCharge manipulationFlexible article cleaningEngineeringMechanical engineering

Owner:CHONGQING HECHUAN JINXING GLASS PROD CO LTD

Power-shaking-based and water-washing-combined circulating reciprocating type clam cleaning device and method

ActiveCN111557334ASolve dirty cleaningAvoid enteringBivalves processingReciprocating motionEngineering

The invention discloses power-shaking-based and water-washing-combined circulating reciprocating type clam cleaning device and method. The device comprises a water tank, wherein the surface of the water tank is sleeved with a filtering device, fixing screws are arranged on the inner wall of the filtering device, the surfaces of the fixing screws are in threaded connection with the inner wall of the water tank, and supporting rods are connected to the upper surface of the water tank. The invention discloses a circulating reciprocating type concha cleaning device based on power shaking and combined water washing. Under the action of the connecting block, the shaking frame reciprocates and shakes front and back; then the push rod pushes the cleaning box to reciprocate back and forth, so thatthe force for shaking the nail is constant, the force for shaking the nail is prevented from being too large or too small, and therefore the problems that at present, in a hand cranking process, the force is difficult to control, the shell of the nail is prone to being broken due to the too large force, the amount of spit sediment is small due to the small force, and the interior of the nail cannot be cleaned thoroughly are effectively solved.

Owner:山东未来城建筑工程有限公司

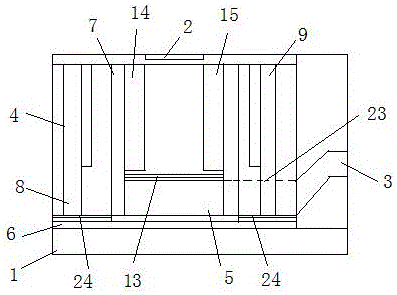

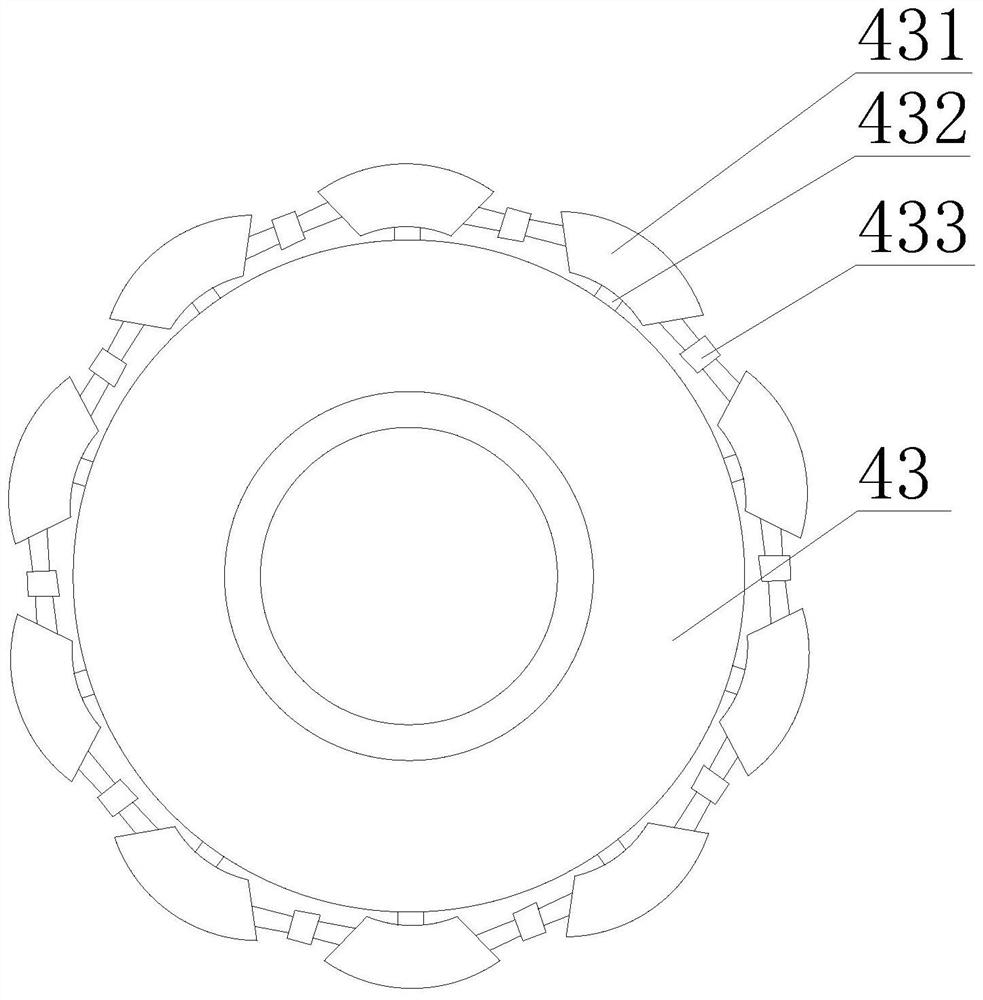

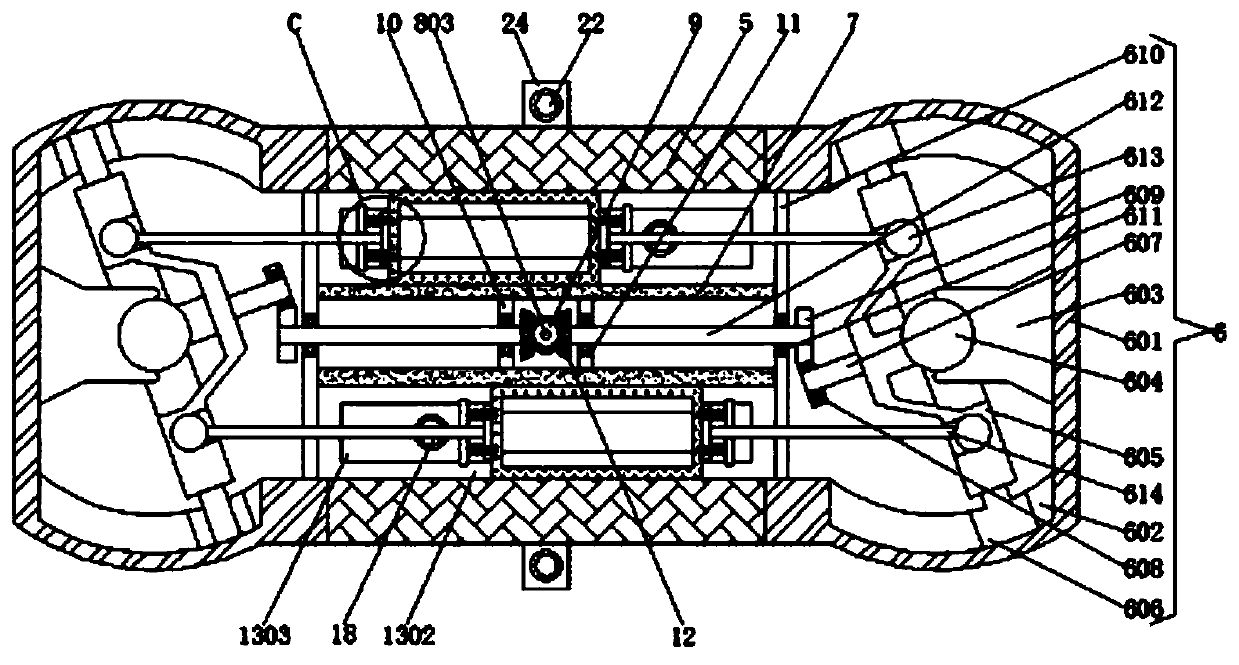

A structure of a motor stator inner cavity dust removal device

ActiveCN110548727BReduce friction sound failure rateSolve dirty cleaningDirt cleaningManufacturing stator/rotor bodiesElectric machineDust control

Owner:合肥市通得力电气制造有限公司

Intelligent cleaning mechanism of domestic cleaning equipment

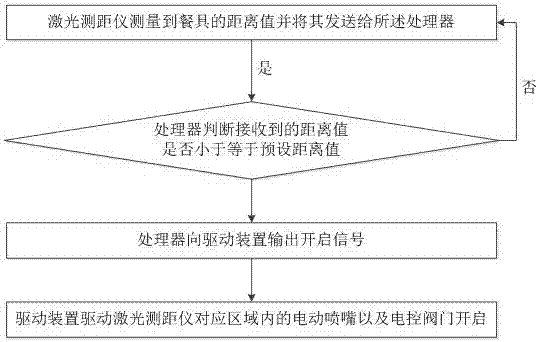

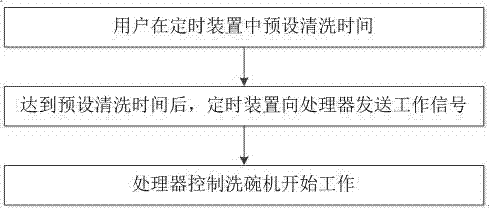

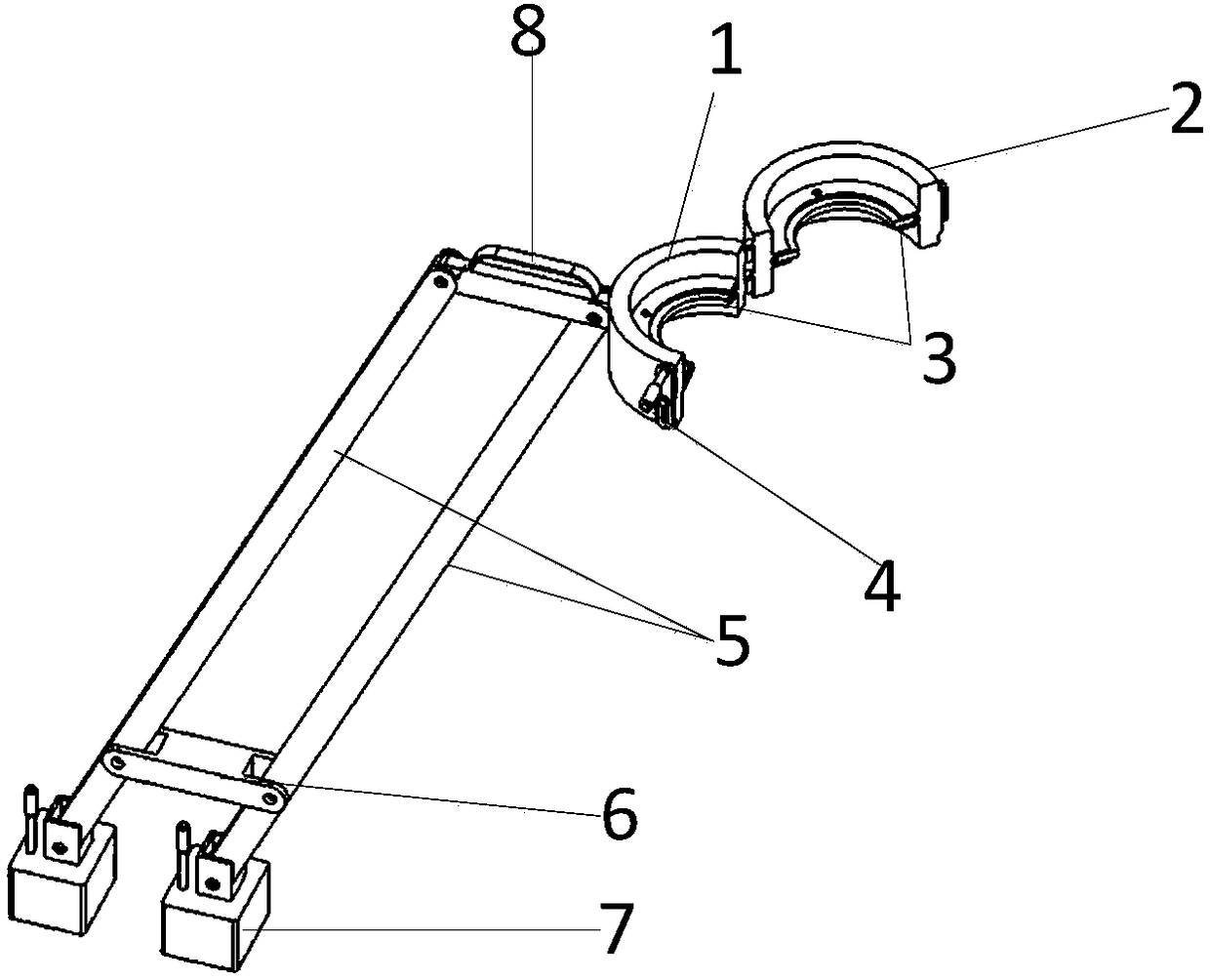

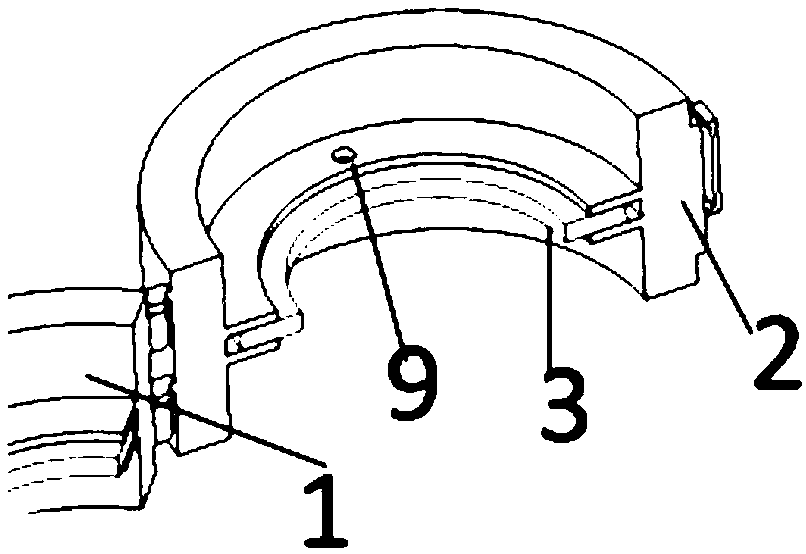

InactiveCN107320040AImprove energy efficiencySolve dirty cleaningTableware washing/rinsing machine detailsWater pipeEngineering

The invention discloses an intelligent cleaning mechanism of domestic cleaning equipment and is applied to dish washing machines. The intelligent cleaning mechanism includes a box, a plurality of cleaning devices and a base, the box includes a processor and a drive device, the processor is connected with the drive device, the cleaning devices are arranged on the base, each cleaning device includes two left-and-right symmetrical independent structures, the interior of the box includes the cleaning devices, each cleaning device includes a water pipe and an electric nozzle, the water pipes are connected with a water source, the electric nozzles are connected with the drive device, a shelf is arranged between the two symmetrical structures of each cleaning device, the shelves are of vertical multi-layer structures, electric sliding blocks are arranged at the bottoms of the shelves and are connected with the drive device, the base includes straight guide rails which are located below the shelves, and the shelves are connected with the straight guide rails through the electric sliding blocks.

Owner:TAICANG BOXUAN INFORMATION TECH

Upright pure mechanical drilling rod mud scrapping device

PendingCN108708691ASolve dirty cleaningReduce labor intensityCleaning apparatusLocking mechanismDrill floor

The invention discloses an upright pure mechanical drilling rod mud scrapping device. The device comprises two powerful magnet suction plates, the powerful magnet suction plates are provided with upright rods, working grippers are arranged on the tops of the upright rods, semicircular left housings are arranged on the working grippers, semicircular right housings are connected with the ends of theleft housings, locking pin mechanisms which can buckle the left housings with the right housings are arranged at the other ends, and circular rubber mud scrapping pieces are arranged in the left andright housings. When the device is used, the two powerful magnet suction plates adhere to a steel drilling well platform, the locking pin mechanisms are switched on to separate the left and right housings, the grippers on the edges of the left housings are held by hands, the left housings are moved to allow the rubber mud scrapping pieces installed in the left housings to be completely in contactwith the outer walls of drilling rods before the right housing are gathered up, the locking mechanisms are used, and after the upper portions of the drilling rods are in positions, the locking pin mechanisms are switched on again to draw back the left housings to wait for the next repeated movement. The device has the advantages of being time saving, strength saving, and capable of improving the safety of the drilling platform and reducing the labor intensity of drilling well workers.

Owner:XI'AN PETROLEUM UNIVERSITY

A method for controlling a food processing machine

The embodiment of the present invention discloses a method for controlling a food processor. The food processor may include a crushing cup, a heating device, a motor, and a temperature sensor. The temperature of the inner wall; when it is detected that the temperature of the inner wall of the crushing cup is less than or equal to the preset first temperature threshold T1, the heating device is controlled to heat with a preset power, so as to maintain the temperature of the inner wall of the crushing cup when the crushing cup is discharged Always greater than or equal to the preset second temperature threshold T2; wherein, the first temperature threshold T1 is greater than the second temperature threshold T2; the second temperature threshold T2 is greater than or equal to 60°C. Through the solution of this embodiment, the temperature of the inner wall of the crushing cup is kept at least above 60° C., which solves the problem of food sticking on the food processing cup and improves the cleaning effect.

Owner:JOYOUNG CO LTD

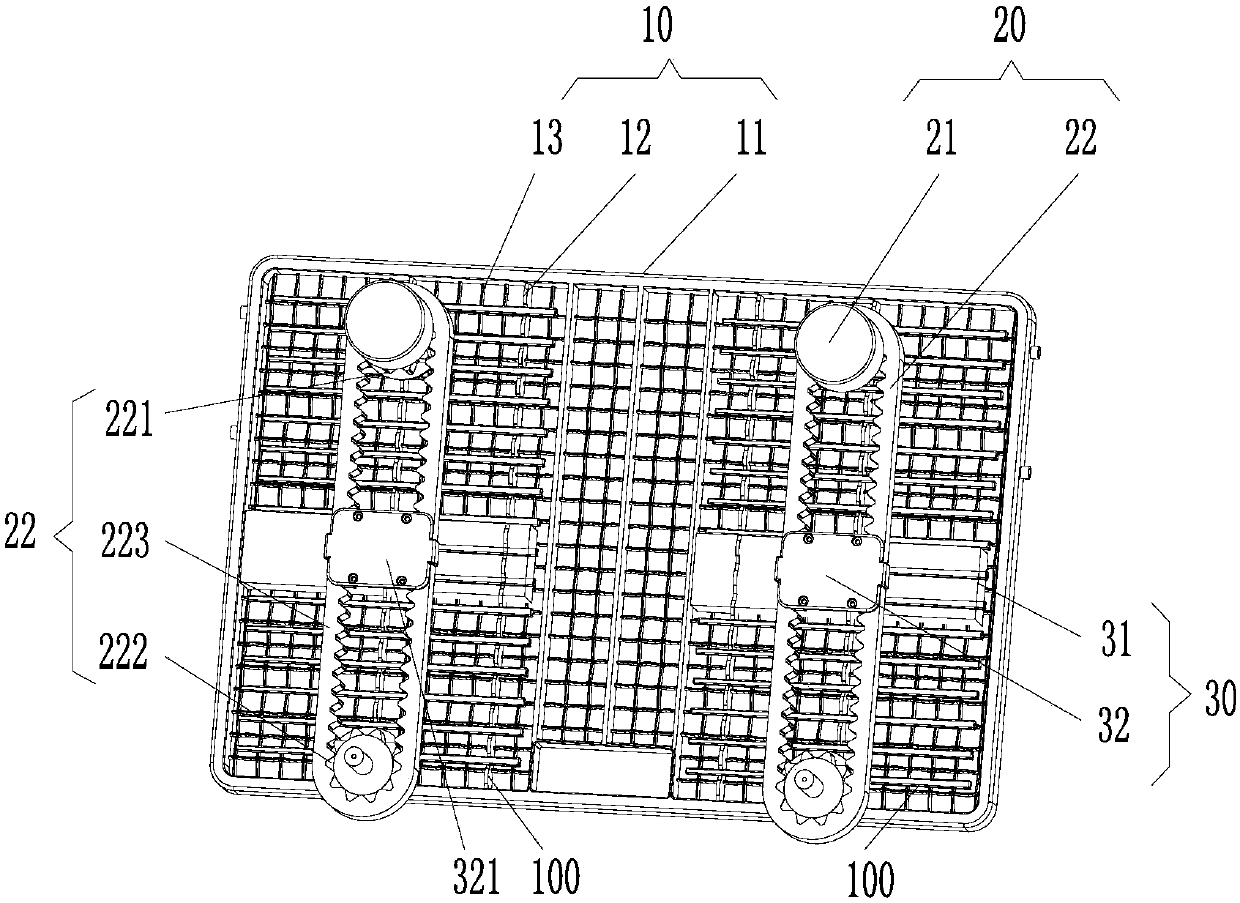

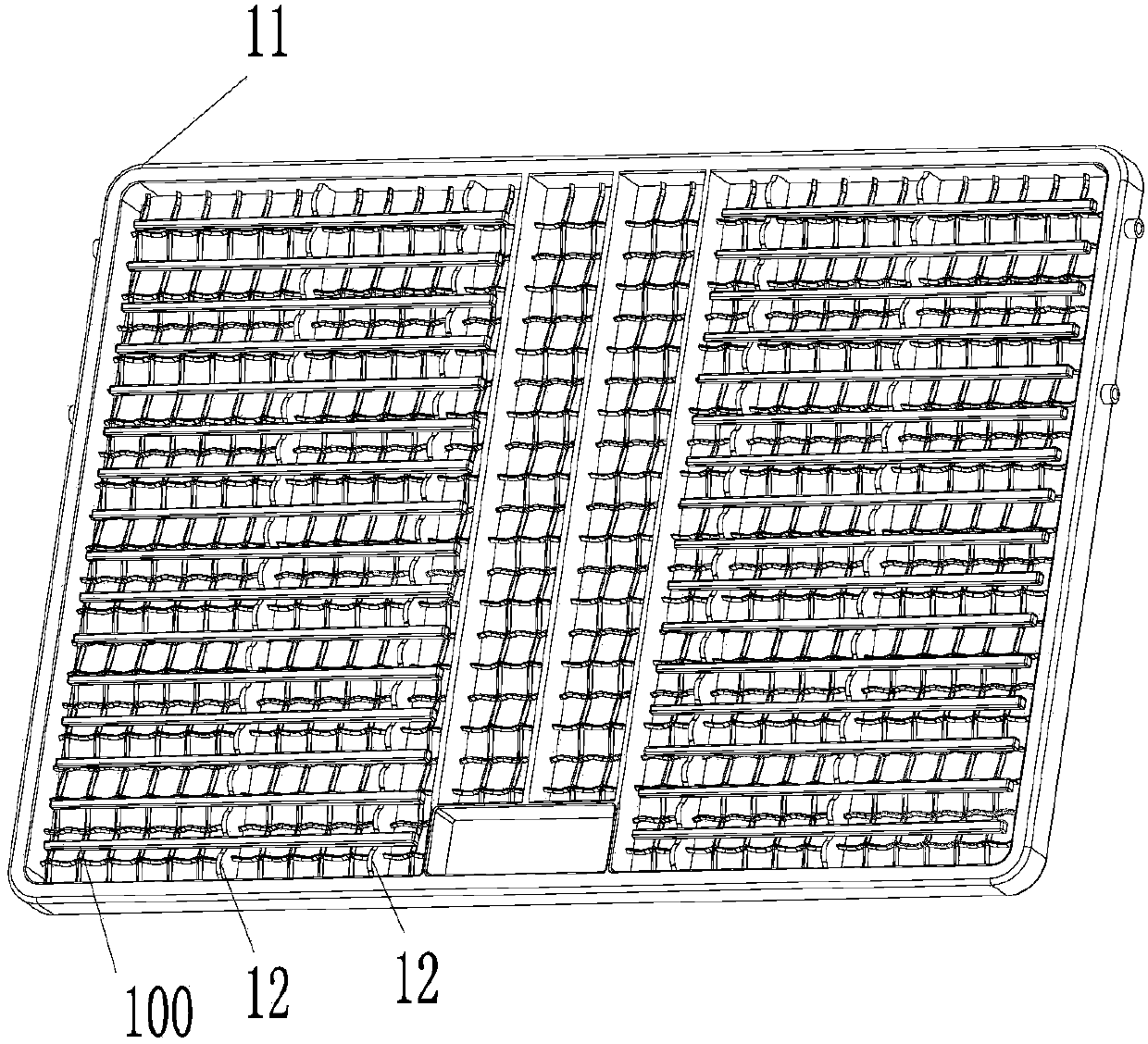

Chopstick cleaning component and dishwasher having same

ActiveCN106214096BClean thoroughlySolve dirty cleaningTableware washing/rinsing machine detailsMechanical engineering

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com