A method for controlling a food processing machine

A technology of a food processor and a control method, which is applied in the direction of kitchen utensils, home utensils, applications, etc., can solve problems that affect user experience, easy adhesion, automatic cleaning is not clean, etc., and achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

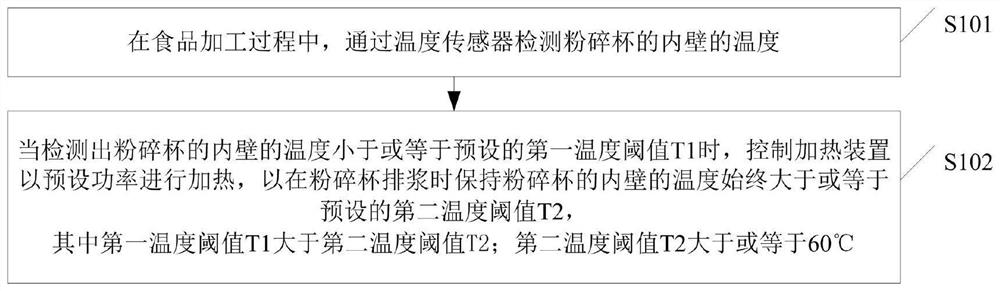

[0033] An embodiment of the present invention provides a method for controlling a food processor, which may include a crushing cup, a heating device, a motor, and a temperature sensor, such as figure 1 As shown, the method may include S101-S102:

[0034] S101. During food processing, the temperature of the inner wall of the crushing cup is detected by a temperature sensor;

[0035] S102. When it is detected that the temperature of the inner wall of the crushing cup is less than or equal to the preset first temperature threshold T1, control the heating device to heat with a preset power, so as to keep the temperature of the inner wall of the crushing cup always greater than or equal to the preset second temperature threshold T2;

[0036] Wherein, the first temperature threshold T1 is greater than the second temperature threshold T2; the second temperature threshold T2 is greater than or equal to 60°C.

[0037] In the embodiment of the present invention, in the process of food...

Embodiment 2

[0042] This embodiment provides a specific embodiment of a blending pulping process on the basis of the first embodiment.

[0043] Optionally, the blending and pulping process may include: heating the mixture of water and ingredients in the crushing cup to a first preset temperature and crushing; discharging the slurry obtained after crushing, and pouring water into the crushing cup to heat to a second temperature; The temperature is preset, and heated water is added to the slurry to blend the slurry with a preset volume.

[0044]In the embodiment of the present invention, blending and pulping treatment is generally required for large-capacity pulping in small-space crushing. The pulping process may include: the first step: water injection into the crushing cup; the second step: preheating to the set temperature and Complete the crushing; Step 3: Open the slurry discharge valve to discharge the slurry; Step 4: Fill the crushing cup with water and heat it to the set temperature...

Embodiment 3

[0049] In this embodiment, on the basis of the first or second embodiment, the second temperature threshold T2 is limited.

[0050] In the embodiment of the present invention, the above-mentioned blending and pulping process is taken as an example for illustration. Since there are pulping and water injection processes in the blending process, there may be a risk of dry burning when the temperature is controlled too high, and the residual slurry may be burnt. When it is low, some organic matter in the residual slurry, especially starch in rice, is easy to adhere to the inner wall of the crushing cup, and the expected effect cannot be achieved. Generally, it is preferable to control the temperature of the inner wall of the crushing cup above 60°C, which is the second temperature threshold. T2 is greater than or equal to 60°C, preferably T1≥70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com