Patents

Literature

45results about How to "Ensure no residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

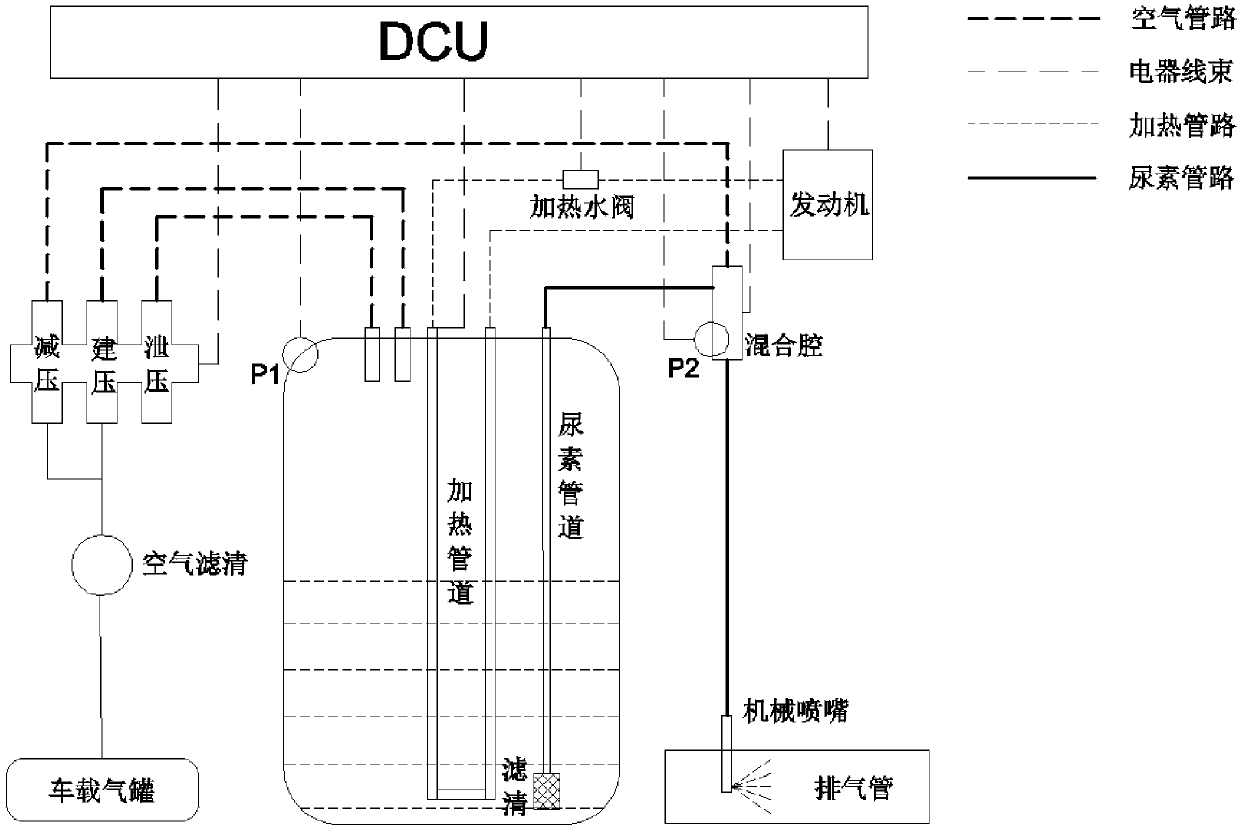

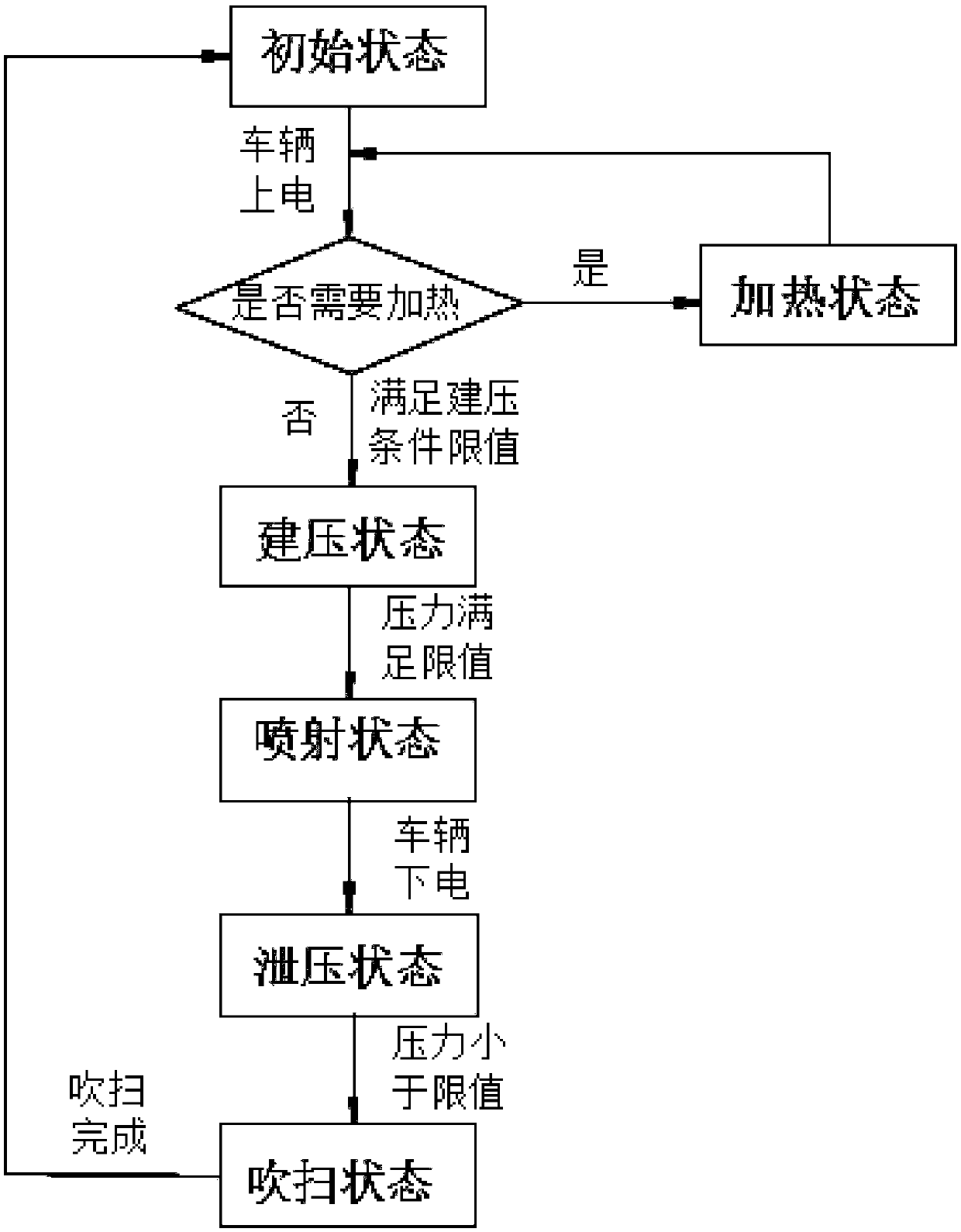

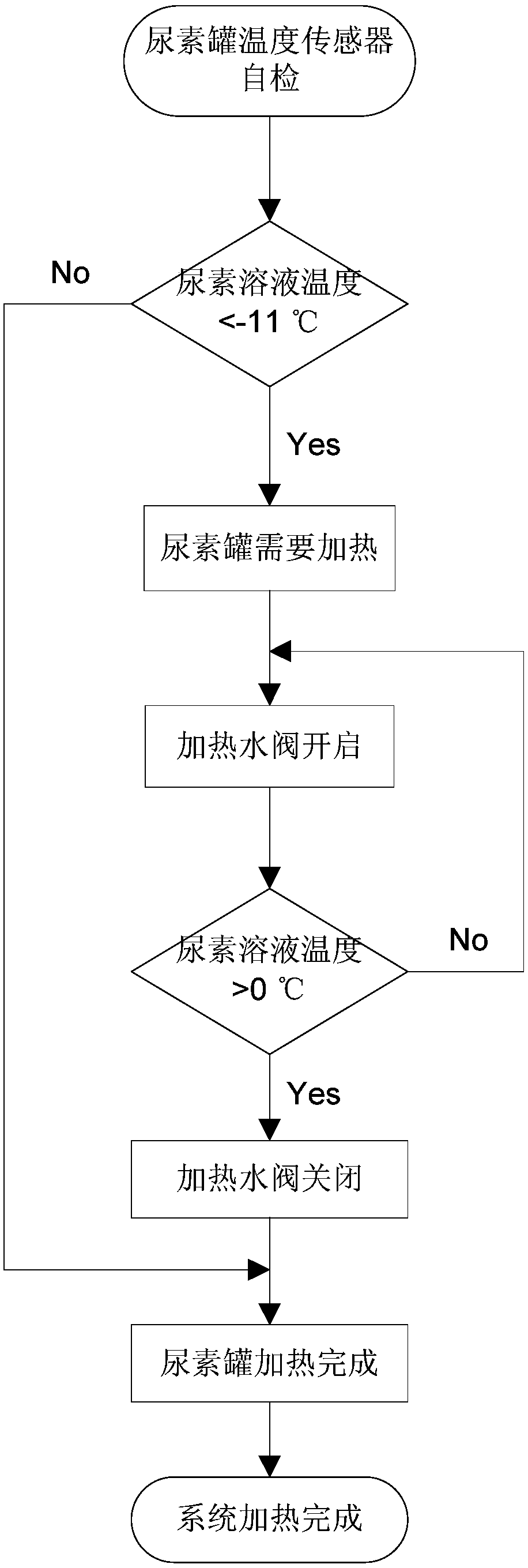

Control method for air assisting type gas drive SCR system

InactiveCN107687358AGuaranteed accuracyClear control logicInternal combustion piston enginesExhaust apparatusChemical reactionProcess engineering

Owner:广州贻谷环保科技有限公司

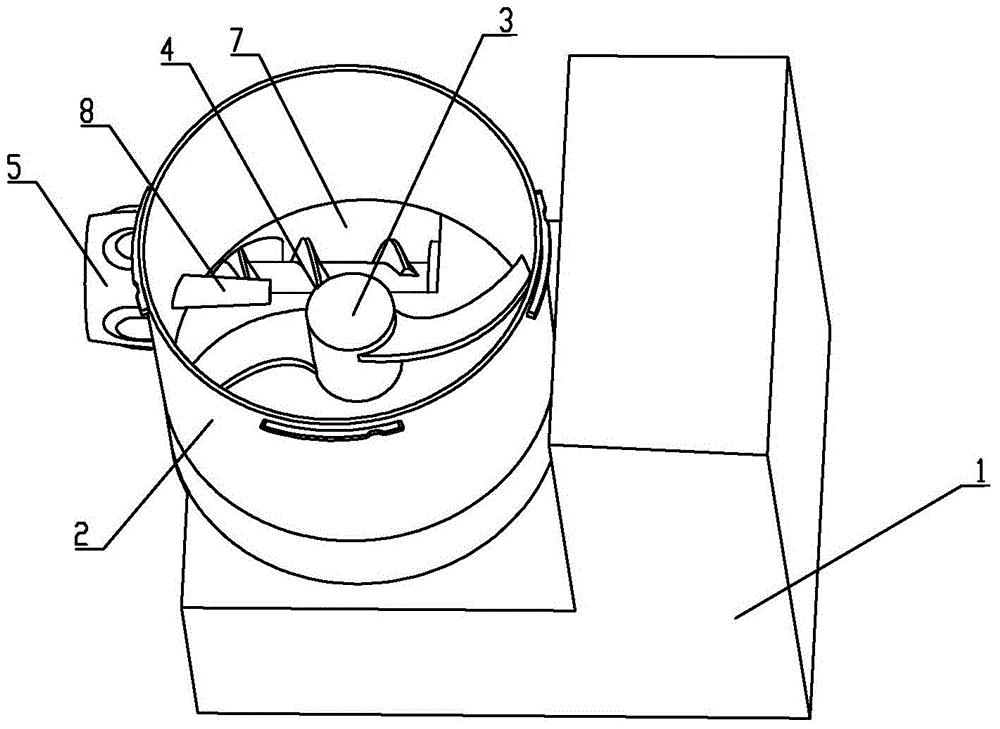

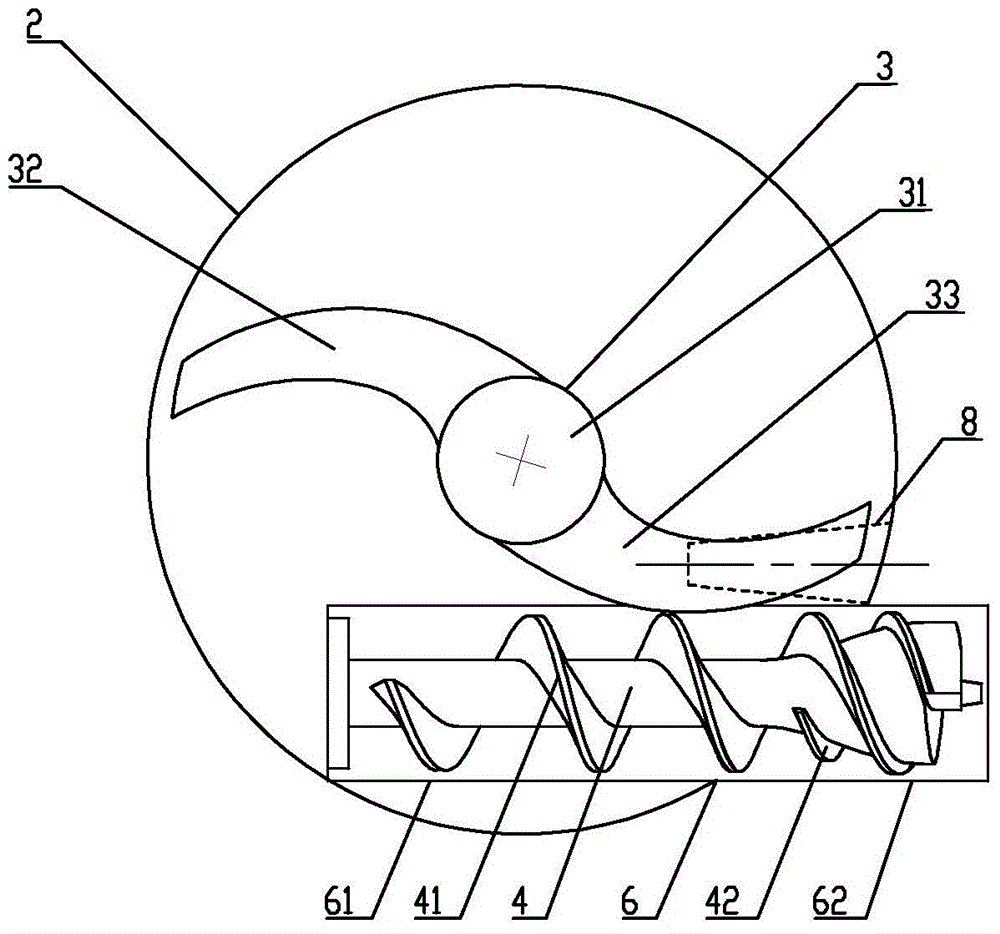

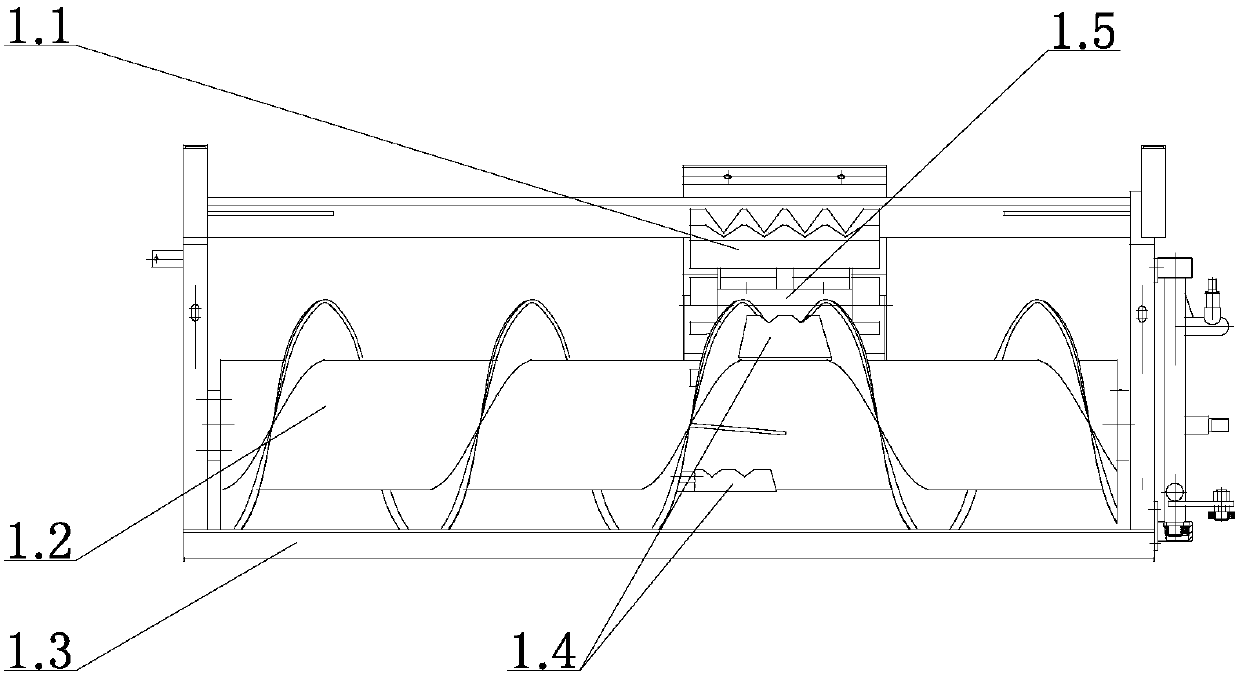

High-efficiency noodle making method of household noodle maker

ActiveCN104542789AStir wellImprove kneading effectMixing/kneading with vertically-mounted toolsDough extruding machinesPulp and paper industryExtrusion

The invention discloses a high-efficiency noodle making method of a household noodle maker. The noodle maker comprises a motor base with a motor, a stirring cup connected with the motor base, a stirring rod, a dough extruding cylinder, a screw rod, a die head and a control unit, wherein the stirring rod is longitudinally arranged in the stirring cup and consists of a rod body and upper stirring teeth and lower stirring teeth arranged on the rod body, the dough extruding cylinder is horizontally arranged on one side below the stirring cup, the screw rod is arranged in the dough extruding cylinder, the motor drives the stirring rod and the screw rod to rotate, a dough inlet is formed in the position at which the stirring cup and the stirring cup are communicated, and a noodle cutting rod is arranged on the inner wall of the stirring cup. The noodle making method comprises a dough kneading step and an extrusion forming step, the mutual shearing action of the upper and lower stirring teeth and the noodle cutting rod is added during the dough kneading step and the extrusion forming step, so that the dough is blended sufficiently and evenly, in addition, the dough is shorn or torn off to form a dough easily entering the dough inlet and facilitate dough feeding, the dough extrusion efficiency can be promoted, and no dough residue in the stirring cup can also be guaranteed.

Owner:JOYOUNG CO LTD

Removal process for aflatoxin and benzopyrene in peanut oil

ActiveCN107008226AQuality improvementGood removal effectOther chemical processesFatty-oils/fats refiningBenzopyrenesChemistry

The invention belongs to the technical field of grease and discloses a removal process for aflatoxin and benzopyrene in peanut oil. The process comprises the following steps: S1) preparing an adsorbent; S2) performing adsorption and centrifugalization; and S3) regenerating the adsorbent. The process disclosed by the invention can effectively remove aflatoxin and benzopyrene, is simple and feasible in operating step and suitable for being industrially popularized and used.

Owner:SHANDONG YUHUANG GRAIN & OIL FOOD

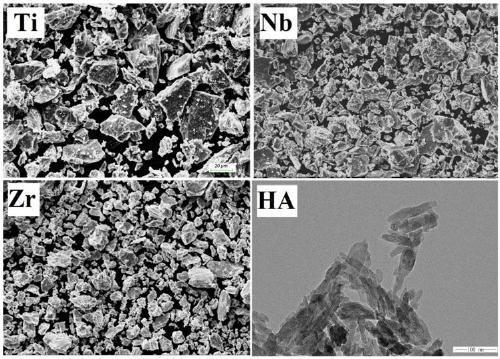

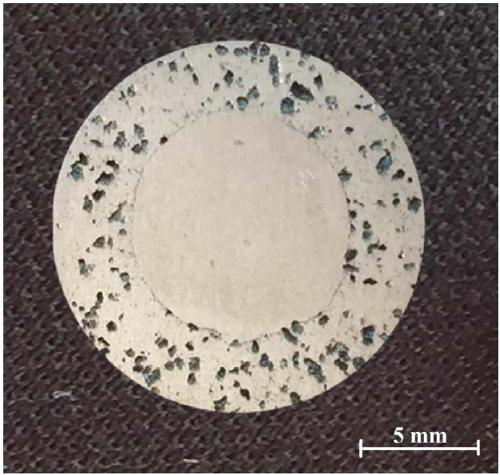

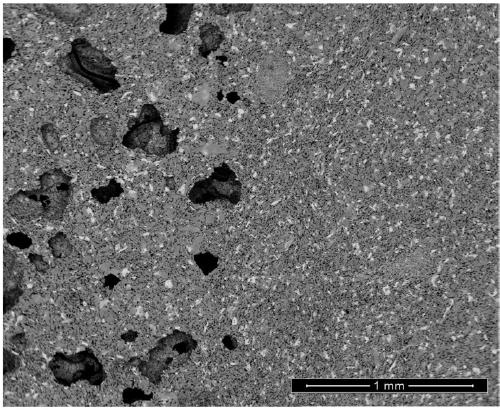

Outer-layer porous orthopedic hard implant material with integrated radial structure and function and preparation method and application thereof

InactiveCN109666820AImprove corrosion resistanceGood modulus of elasticityTissue regenerationProsthesisImplant materialNiobium

The invention discloses an outer-layer porous orthopedic hard implant material with integrated radial structure and function and a preparation method and application thereof. The preparation method comprises the following steps of mechanical ball milling titanium, niobium and zirconium powder according to the proportion to obtain the Ti-Nb-Zr composite powder, mechanical ball milling titanium, niobium, zirconium and HA powder to obtain the Ti-Nb-Zr -HA powder, then mixing with the pore-forming agent ammonium bicarbonate powder to obtain the composite powder B, pre-compression molding the Ti-Nb-Zr composite powder and the composite powder B to obtain the cylinder pressed blank of the radial grading structure, and finally sintering by utilizing a pulse plasma activated sintering furnace to obtain the orthopedic hard implant material. The orthopedic hard implant material not only has a porous structure due to the outer layer, the bioactive ceramic HA is added, so that the composite material has good bone bonding, the bone integration performance and the low elastic modulus suitable for matching with bone, the orthopedic hard implant material also has excellent compression resistance due to the compact structure of the core part, can be used as a good artificial bone tissue replacement material.

Owner:YUNNAN UNIV

Removing method for benzopyrene in edible vegetable oil

The invention discloses a method for removing benzopyrene from edible vegetable oil, which specifically includes the following steps: (1) degumming; (2) deacidification; (3) preparing an adsorbent; (4) preparing a mixed adsorbent; (5) decolorizing, Deodorization; (6) Filtration. The invention does not destroy any beneficial components in the edible oil through degumming first, has no influence on the quality of the edible oil, and does not cause loss of the edible oil, and the degumming effect is good; because it works under high vacuum, the heating time of the material is short, and the oil Nutrients will not be destroyed. This method is especially suitable for deodorization and deacidification of oils with high content of unsaturated fatty acids and easy oxidation. In addition, it is a large-pore particle adsorption material with large specific surface area and strong adsorption capacity, which ensures that there is no residue in the oil and can be reused. The removal effect of benzopyrene is good, which greatly improves the quality of the oil and eliminates potential safety hazards. .

Owner:青岛天祥食品集团有限公司

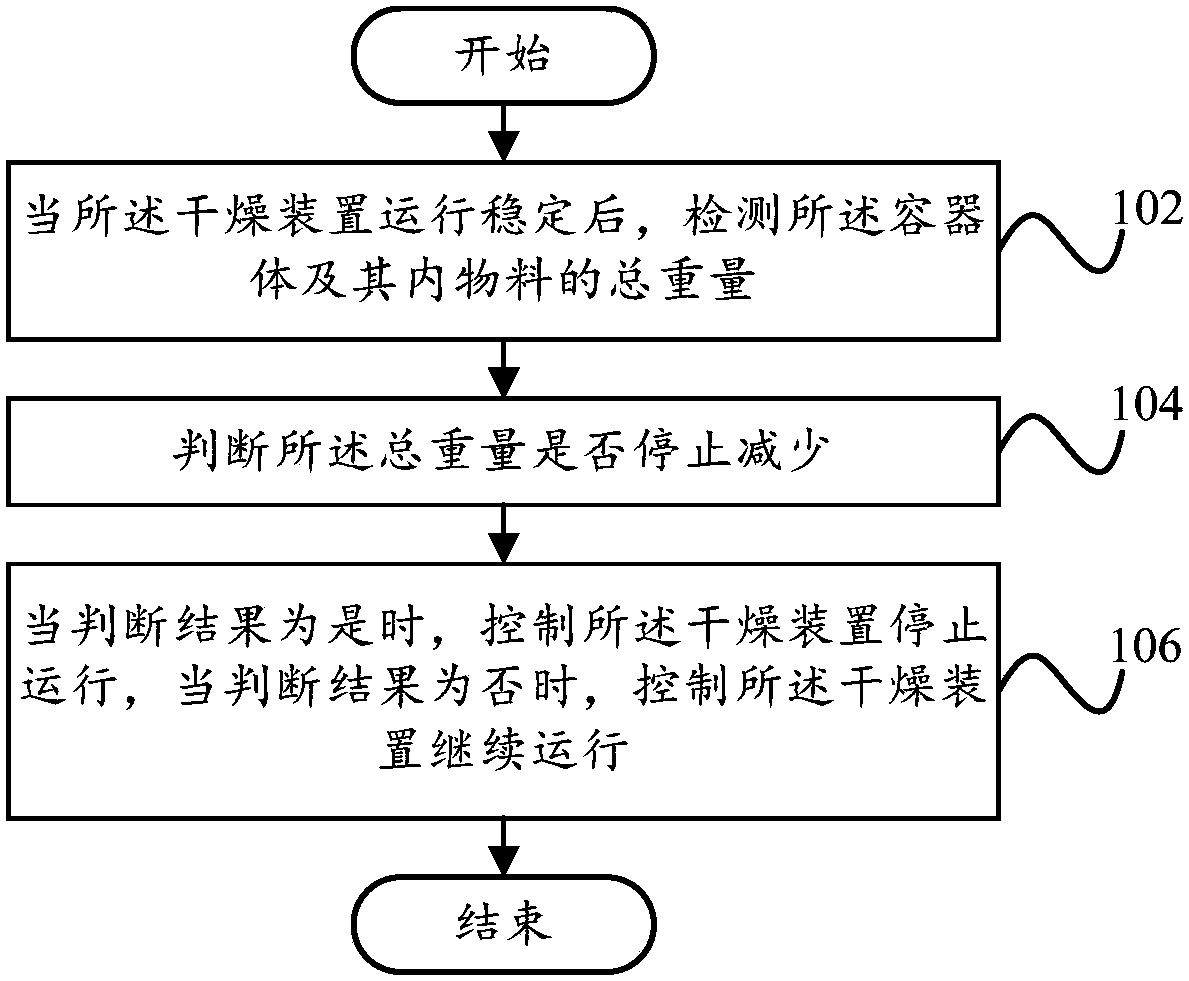

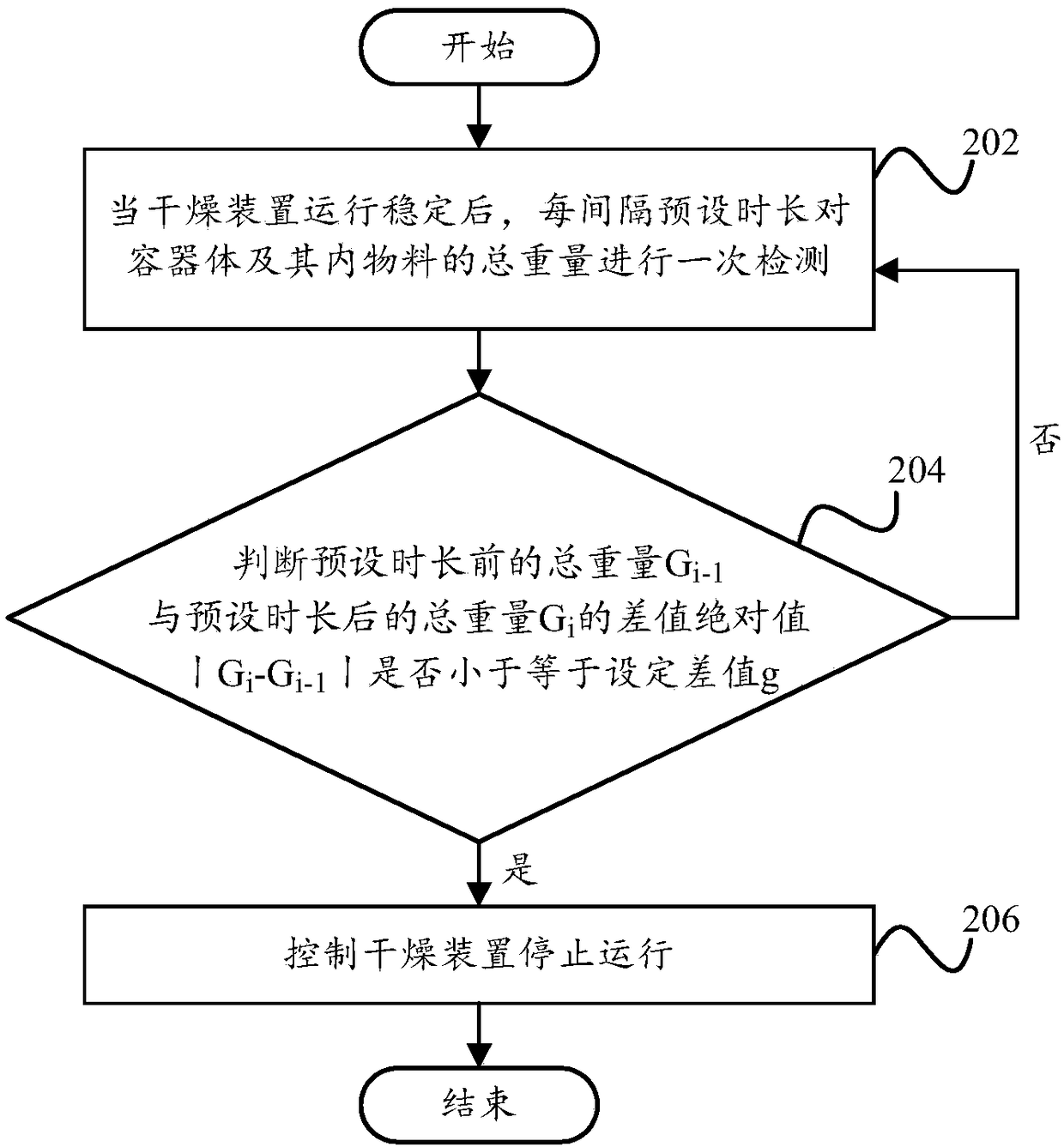

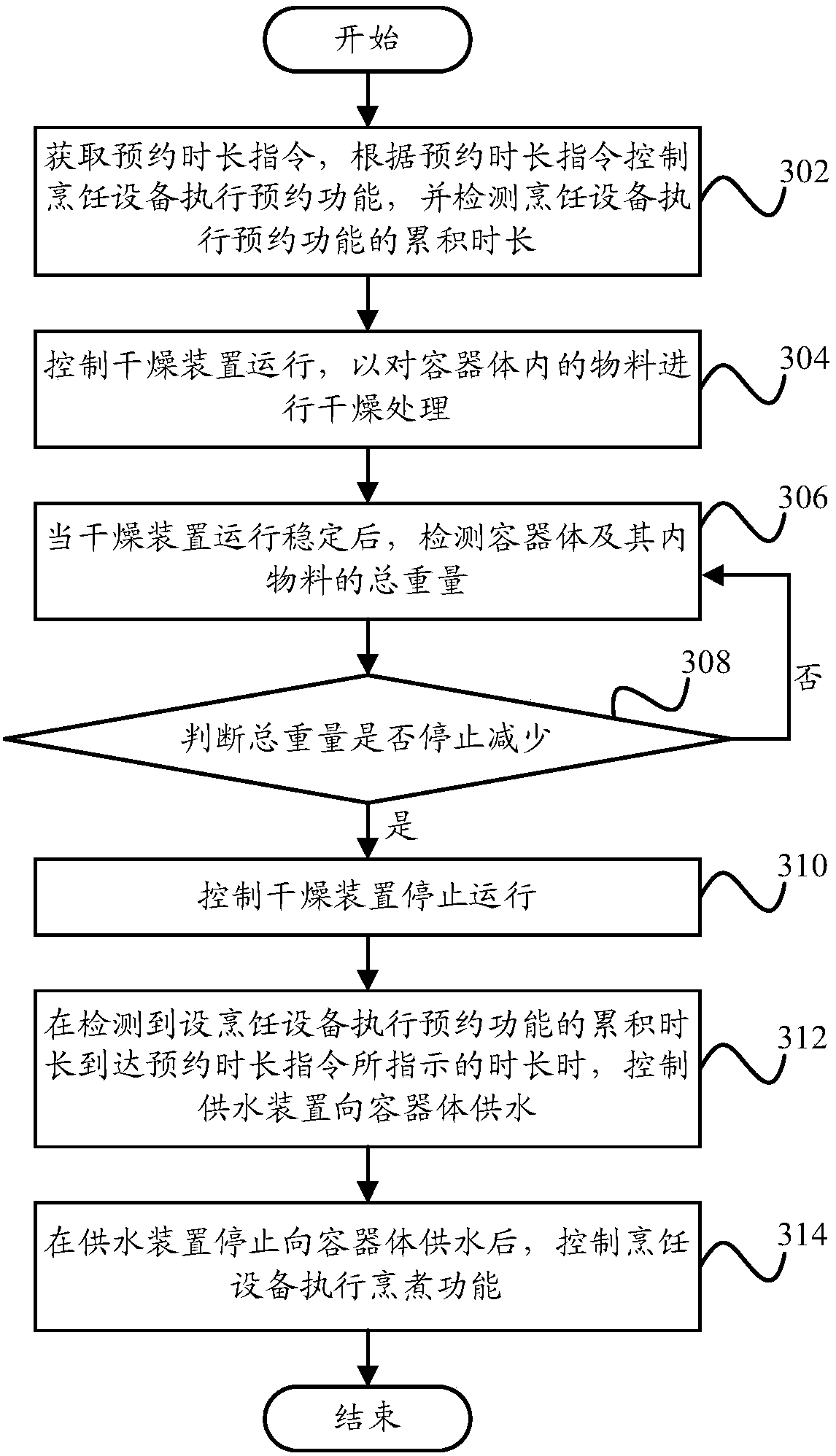

Cooking equipment, control method thereof and control device thereof

ActiveCN108113450AEasy dischargeEasy to drainBeverage vesselsSteam cooking vesselsInterference factorEngineering

The invention provides cooking equipment, a control method thereof and a control device thereof. The control method of the cooking equipment comprises the steps that a container body and the total weight of materials in the container body are detected after a drying device is stable in operation; whether or not the total weight stops decreasing is determined; when a judgment result is YES, the drying device is controlled to stop operation, and when a judgment result is No, the drying device is controlled to continue to operate. The method has accuracy of determining whether or not the materials reach the drying target, and suffers from less interference factors to ensure that the drying target of the materials is achieved, so that the problems that the materials are excessively dried or drying is not up to standard are avoided, and the cooking taste of the materials are ensured.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

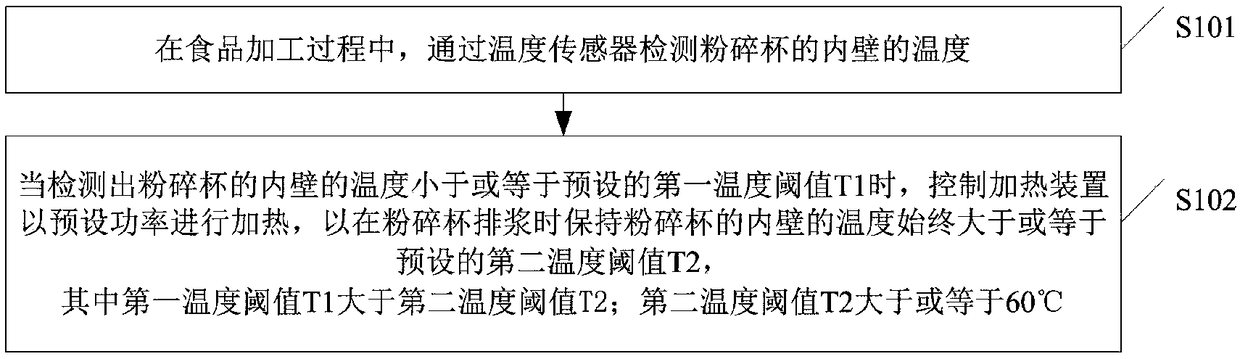

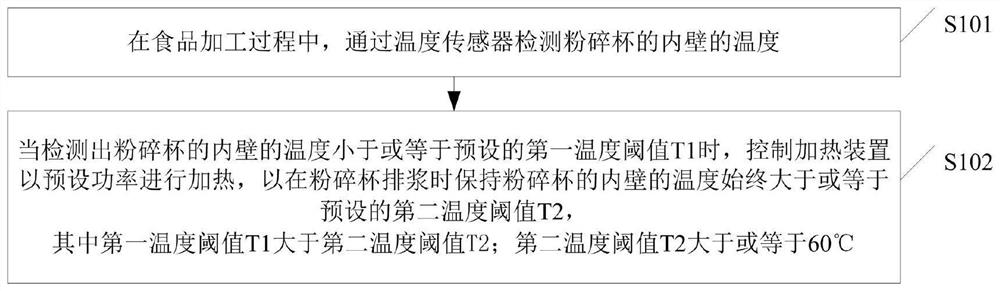

Control method of food processing machine

The embodiment of the invention discloses a control method of a food processing machine. The food processing machine can comprise a pulverizing cup, a heating device, a motor and a temperature sensor.The method can comprise the following steps: detecting the temperature of the inner wall of the pulverizing cup by the temperature sensor in the food processing process; and when detecting that the temperature of the inner wall of the pulverizing cup is less than or equal to a preset first temperature threshold value T1, controlling the heating device to perform heating according to preset powerso as to maintain the temperature of the inner wall of the pulverizing cup to be still more than or equal to a preset second temperature threshold value T2 when the pulverizing cup discharges pulp, wherein the first temperature threshold value T1 is more than the second temperature threshold value T2, and the second temperature threshold value T2 is more than or equal to 60 DEG C. Through the scheme of the embodiment, the temperature of the inner wall of the pulverizing cup still maintains above at least 60 DEG C, the problem that food adhesion on a food processing cup is solved and the cleaning effect is improved.

Owner:JOYOUNG CO LTD

Method for removing pigments and metal ions from vegetable oil

InactiveCN107022413AEfficient removalReduce oil contentOther chemical processesFatty-oils/fats refiningVegetable oilFood safety

The invention belongs to the technical field of physics and chemistry and discloses a method for removing pigments and metal ions from vegetable oil. The method comprises the following steps: adding 1% to 2% of decoloring adsorbent into the vegetable oil, heating the temperature of the mixture to 75 DEG C to 80 DEG C, carrying out stirring for 30 to 60 minutes at the rate of 100rpm under heat-preserving conditions, then, carrying out standing for 30 to 60 minutes, and then, carrying out centrifugation, so as to obtain precipitates. The method disclosed by the invention is simple and feasible, the pigments and the metal ions can be effectively removed, and thus, the wasting of oils is avoided; the quality of the vegetable oil cannot be damaged, so that food safety is guaranteed.

Owner:SHANDONG YUHUANG GRAIN & OIL FOOD

Adsorbent for removing pigment, aflatoxin and metal ions from corn oil

InactiveCN106902793AIncrease spacingImprove hydrophobicityOther chemical processesFatty-oils/fats refiningSorbentMetal

The invention belongs to the technical field of oil adsorbent, and discloses an adsorbent for removing pigment, aflatoxin and metal ions in corn oil, which is prepared according to the following process: step 1) diatomite modification, step 2) Crushing and grinding, step 3) granulation, step 4) sintering, step 5) amino acid modification. The inventive adsorbent can effectively adsorb pigment, aflatoxin and metal ions.

Owner:SHANDONG YUHUANG GRAIN & OIL FOOD

Separation and purification technology of glucose

InactiveCN109136305ASave investment and land occupationHigh degree of system automationFermentationGlucose productionIon exchangeIon

The invention belongs to the field of separation and purification of sugar and discloses a separation and purification technology of glucose. The technology comprises the following steps of preparation of an adsorbent, liquefaction and saccharification, microfiltration, decoloration and impurity removal, nanofiltration and concentration and crystallization. According to the separation and purification technology, by adopting multi-membrane filter treatment and adsorption treatment, the steps such as ion exchange are omitted, the technology is simple and feasible, and the yield and purify of prepared products are high.

Owner:卢松

Mobile filling machine

The invention provides a mobile filling machine. The mobile filling machine comprises a longitudinal moving mechanism, a moving platform slidingly connected with the longitudinal moving mechanism, a transverse moving mechanism fixed with the moving platform, and a filling mechanism slidingly connected with the transverse moving mechanism, wherein the filling mechanism comprises a box, a conveying belt and a filling motor; the conveying belt is arranged in the box, and is driven to operate through the filling mechanism; a feeding port is formed in one side of the top end of the box; a filling port is formed in one side opposite to the feeding port at the bottom end of the box; the transverse moving mechanism comprises a transverse guide rail and a guide groove; the transverse guide rail is fixed with the box; the guide groove is fixed with the moving platform; and the filling mechanism slides in the guide groove through the transverse guide rail. The mobile filling machine can realize no residue of coals in filling, and is free of raise dust and pollution.

Owner:海城市祥程矿业有限公司

Decolorizing agent capable of decreasing aflatoxin content in peanut oil

ActiveCN107413300AImprove hydrophobicityLarge specific surface areaOther chemical processesFatty-oils/fats refiningChemistryAcid treatment

The invention belongs to the technical field of decolorizing agents, and discloses a decolorizing agent capable of decreasing aflatoxin content in peanut oil. The decolorizing agent is prepared by the following processes: step (1), performing acid treatment and ultrasonic treatment; step (2), performing crushing and grinding; step (3), performing stirring and granulation; and step (4) performing drying and sintering. The decolorizing agent provided by the invention can effectively remove pigment and aflatoxin, can be used repeatedly, and saves costs for enterprises.

Owner:SHANDONG YUHUANG GRAIN & OIL FOOD

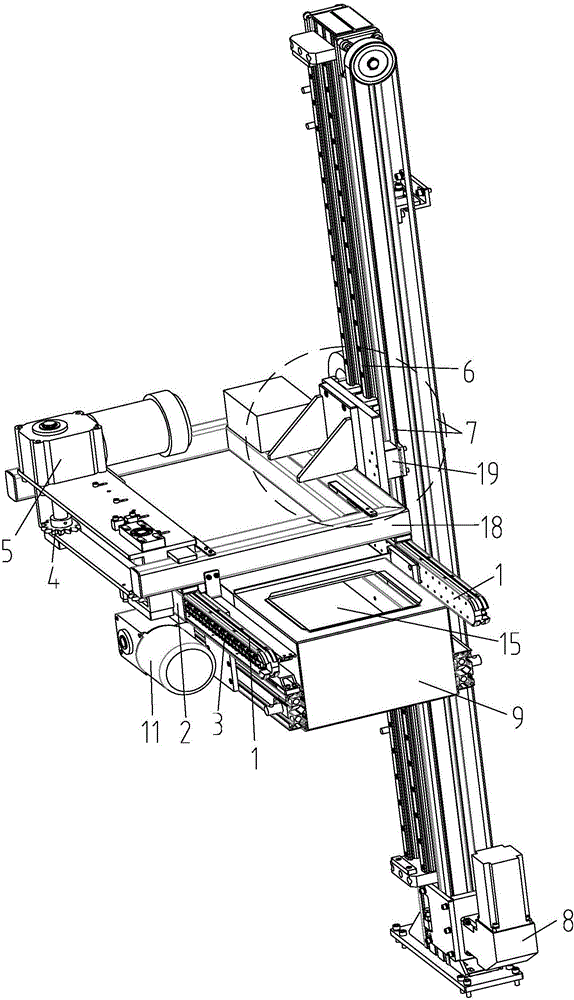

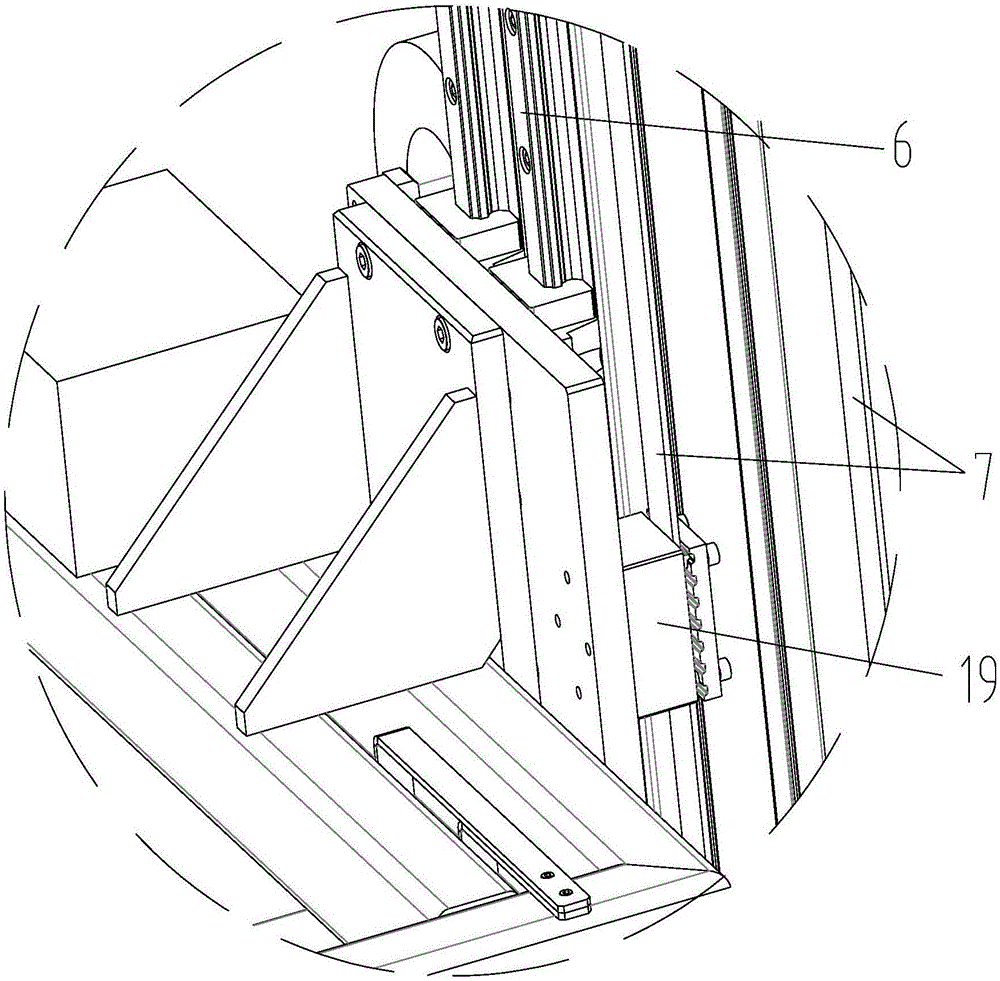

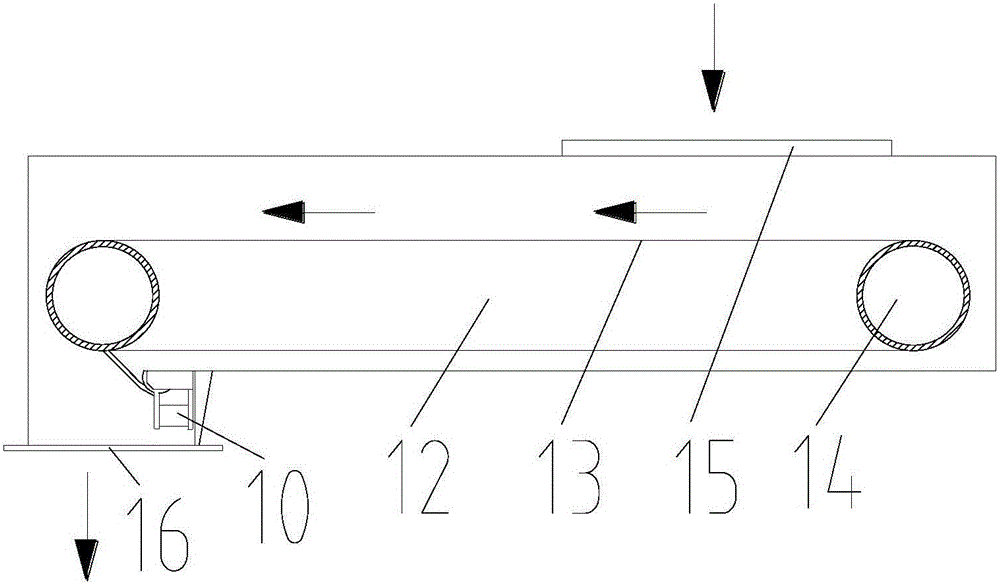

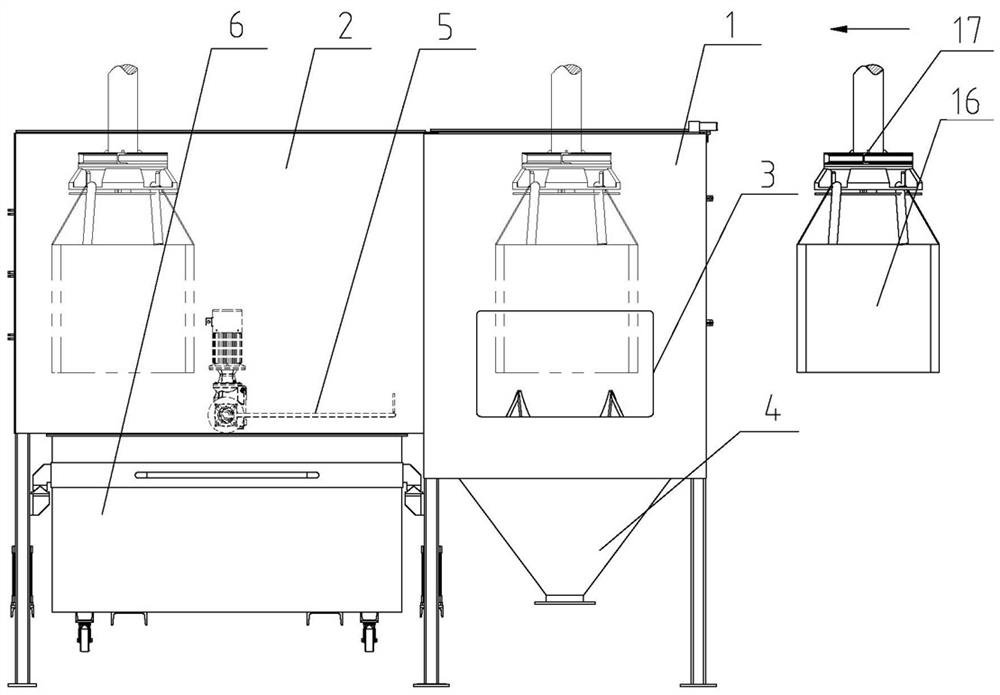

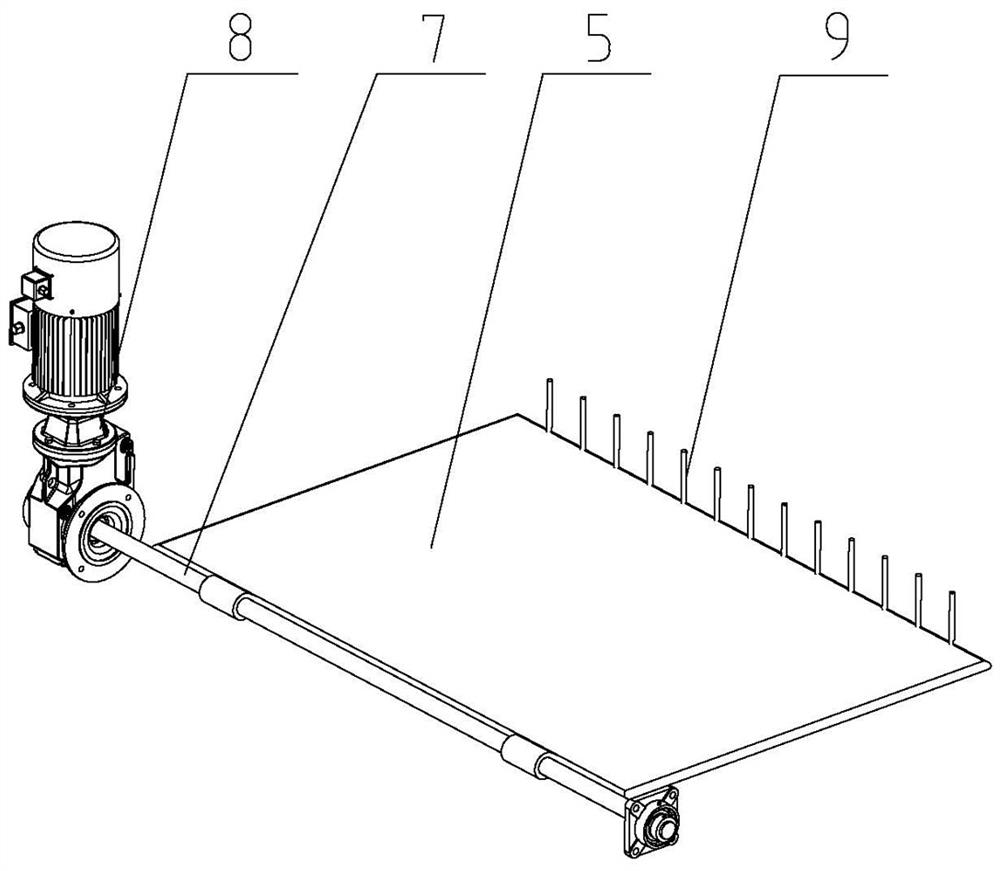

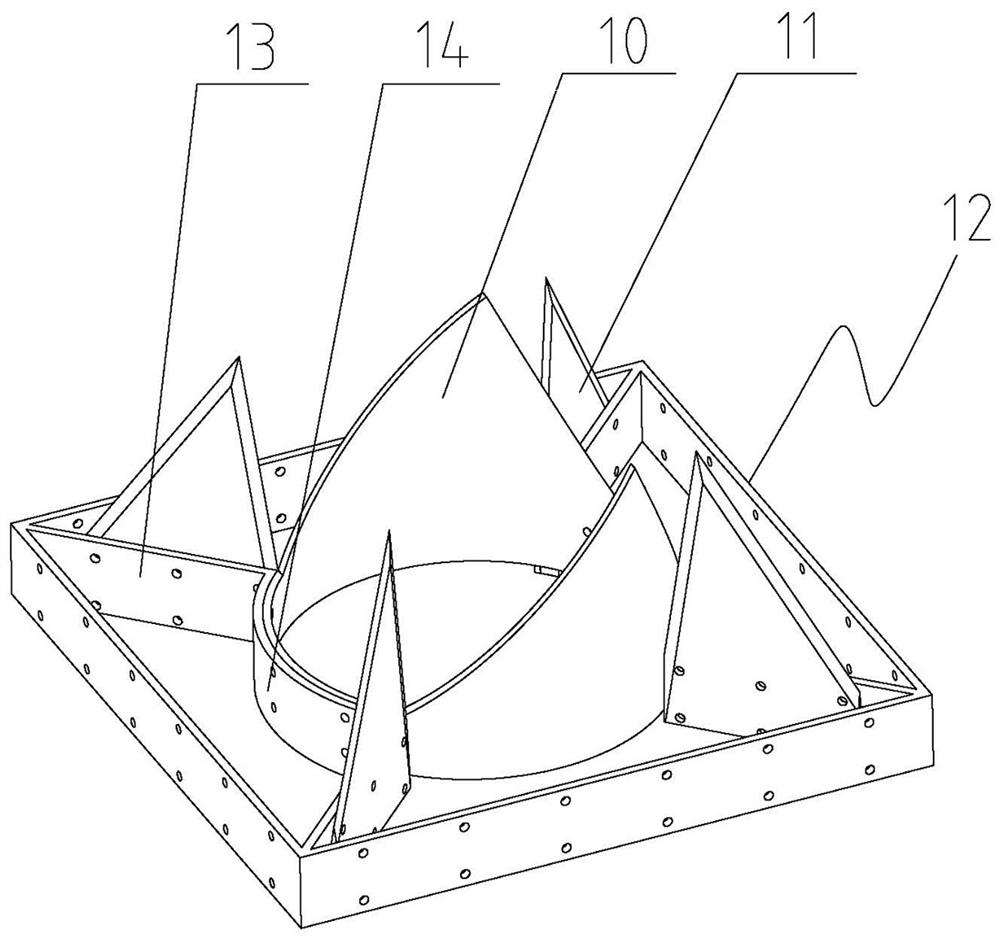

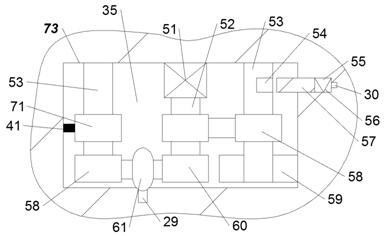

Automatic ton bag opening machine

PendingCN113955259ASmooth entryEnter the discharge bin, the spreader hangs the waste bag and enters smoothlyLoading/unloadingUnpacking by cuttingElectric machineryEngineering

The invention relates to the technical field of ton bag opening and blanking, in particular to an automatic ton bag opening machine which can achieve automatic ton bag opening and collecting, reduce labor intensity and improve efficiency and safety. The machine comprises a bag breaking cutter and a lifting appliance used for hanging ton bags, and is characterized by further comprising a bag opening bin and a bag collecting bin which are arranged side by side and integrated into a whole. The bag breaking cutter is installed in the bag opening bin, the bottom of the bag opening bin is connected with a discharging bin, a turnover pressing plate is installed in the bag collecting bin, one end of the pressing plate is connected with a driving motor through a rotating shaft, a row of teeth is installed at the other end of the pressing plate, and a waste bag collecting mechanism is arranged at the bottom of the bag collecting bin.

Owner:WUXI RICH INTELLIGENT EQUIP CO LTD

Method for manufacturing panels of color touch screens

InactiveCN104182085AAvoid pollutionAvoid corrosionInput/output processes for data processingHigh volume manufacturingEngineering

The invention discloses a method for manufacturing panels of color touch screens. The method includes steps of providing substrates; coating positive photoresist layers on the substrates; exposing, developing and solidifying the positive photoresist layers, removing exposed portions of the positive photoresist layers by means of developing and reserving unexposed portions of the positive photoresist layers; forming optical film layers on the reserved portions of the positive photoresist layers and certain regions on the substrates; removing films on the reserved portions of the positive photoresist layers so as to remove first certain portions of the optical film layers, and reserving second certain portions of the optical film layers; forming nontransparent insulating layers on the reserved portions of the optical film layers. The certain regions on the substrates correspond to the portions, which are removed by means of developing, of the positive photoresist layers. The first certain portions of the optical film layers cover the reserved portions of the positive photoresist layers. The second certain portions of the optical film layers cover the regions, which correspond to the certain portions of the positive photoresist layers, of the substrates, and the certain portions of the positive photoresist layers are removed by means of developing. The method has the advantages that problems of environmental pollution and corrosion on substrates made of glass materials due to hydrofluoride can be solved, accordingly, the yield can be increased, manufacturing procedures are easy to control, and the method is suitable for large-scale production.

Owner:凯盛科技股份有限公司

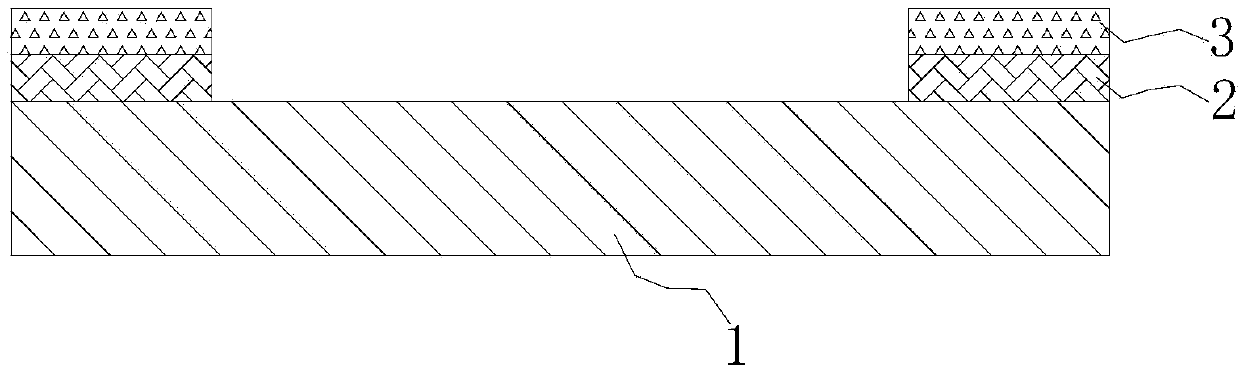

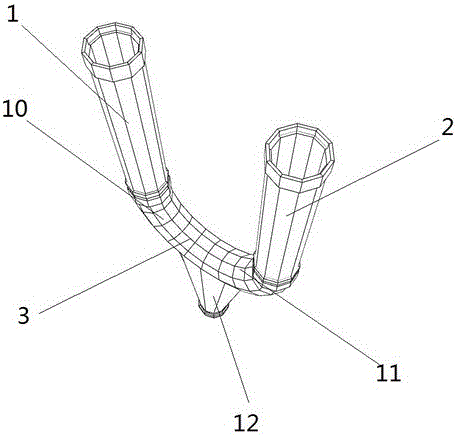

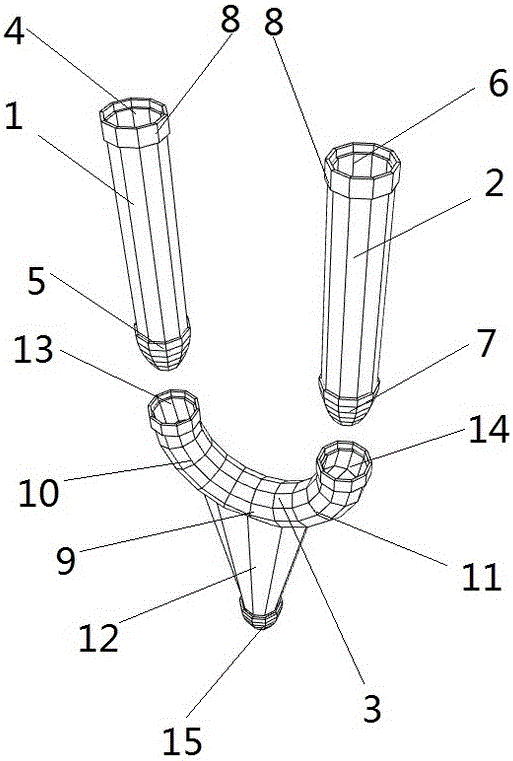

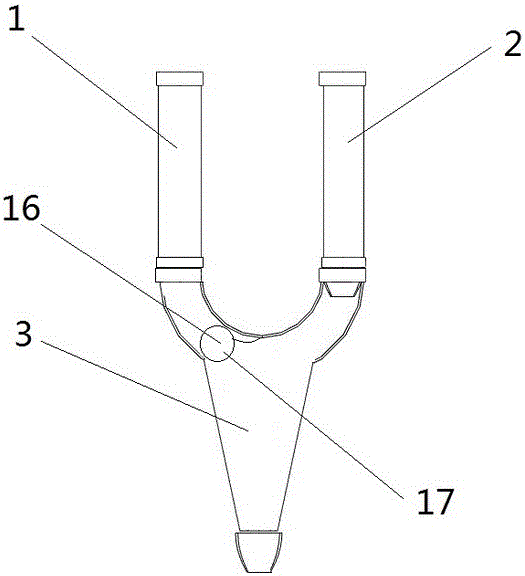

Head joint dual-way joint for rapidly flushing inner wall of nasal feeding pipe

InactiveCN106726611AEnsure no residueIncrease cleaning workMedical devicesCatheterInjection portJunction point

The invention belongs to the field of medical apparatuses and instruments, and provides a head joint dual-way joint for rapidly flushing the inner wall of a nasal feeding pipe. The head joint dual-way joint comprises a nasal feeding pipeline (1), a flushing pipeline (2) and a three-way pipeline (3). The nasal feeding pipeline (1) comprises a nasal feeding pipe injection port (4) and a nasal feeding pipe three-way connection port (5). The flushing pipeline (2) comprises a flushing pipe injection port (6) and an injection pipe three-way connection port (7). The nasal feeding pipe injection port (4) and the flushing pipe injection port (6) are each fixedly provided with a syringe adapter (8); the three-way pipeline (3) comprises a front-way pipeline (10), a back-way pipeline (11) and a liquid outlet pipeline (12) which are connected at the junction points (9); the front-way pipeline (10) comprises a nasal feeding pipe insertion joint (13), the back-way pipeline (11) comprises a flushing pipe insertion joint (14), and the liquid outlet pipeline (12) comprises a liquid outlet joint (15). Compared with the prior art, the dual-way joint has the advantage that rapid cleaning work can be performed after the nasal feeding action is completed so as to ensure that no residue remains on the inner wall of the nasal feeding pipe which is used for a long time.

Owner:CHENGDU XUNDE SCI & TECH

Cleaning and washing method of laser drilled aluminum nitride ceramic plate

ActiveCN110918548AReduce damageImprove cleaning efficiencyDrying gas arrangementsCleaning using liquidsIsopropyl alcoholMegasonic cleaning

The invention discloses a cleaning and washing method of a laser drilled aluminum nitride ceramic plate. The cleaning and washing method comprises the following steps that firstly, a drilled aluminumnitride ceramic sheet is soaked with acid, oxide in molten slags reacts with the acid, the molten slags bonded on the aluminum nitride ceramic plate generate holes to be soft, and the molten slags onthe surface of the ceramic plate can be removed only by gently wiping with cloth, so that the damage to the ceramic sheet caused by a scraper is reduced; in the middle of the cleaning, the large softmolten slags can fall off through the multiple times of ultrasonic cleaning and washing, so that the acid can conveniently react with the inner layer molten slags, the cleaning and washing process isaccelerated, and the cleaning and washing efficiency is improved; and low-concentration alkali is used for soaking for short time, the alkali slightly reacts with the surface of the aluminum nitride ceramic sheet, then the molten slags in micro-holes can be completely cleared and washed, the phenomena that the surface of the aluminum nitride ceramic plate is corroded with pits and the roughness isexcessive due to too high alkali washing concentration and too long time are avoided, and no residue of the molten slags in the micro-holes is guaranteed. All the ultrasonic cleaning and washing is performed by placing the aluminum nitride ceramic plate in absolute ethyl alcohol or isopropanol for the ultrasonic cleaning and washing, and the aluminum nitride plate is free of reaction with the absolute ethyl alcohol and the isopropanol, so that the production process is better controlled.

Owner:GUANGDONG GASTIGHT HERMETICAL COMPONENT

Removal Technology of Aflatoxin and Benzopyrene from Peanut Oil

ActiveCN107008226BQuality improvementGood removal effectOther chemical processesFatty-oils/fats refiningBenzopyrenesChemistry

The invention belongs to the technical field of grease and discloses a removal process for aflatoxin and benzopyrene in peanut oil. The process comprises the following steps: S1) preparing an adsorbent; S2) performing adsorption and centrifugalization; and S3) regenerating the adsorbent. The process disclosed by the invention can effectively remove aflatoxin and benzopyrene, is simple and feasible in operating step and suitable for being industrially popularized and used.

Owner:SHANDONG YUHUANG GRAIN & OIL FOOD

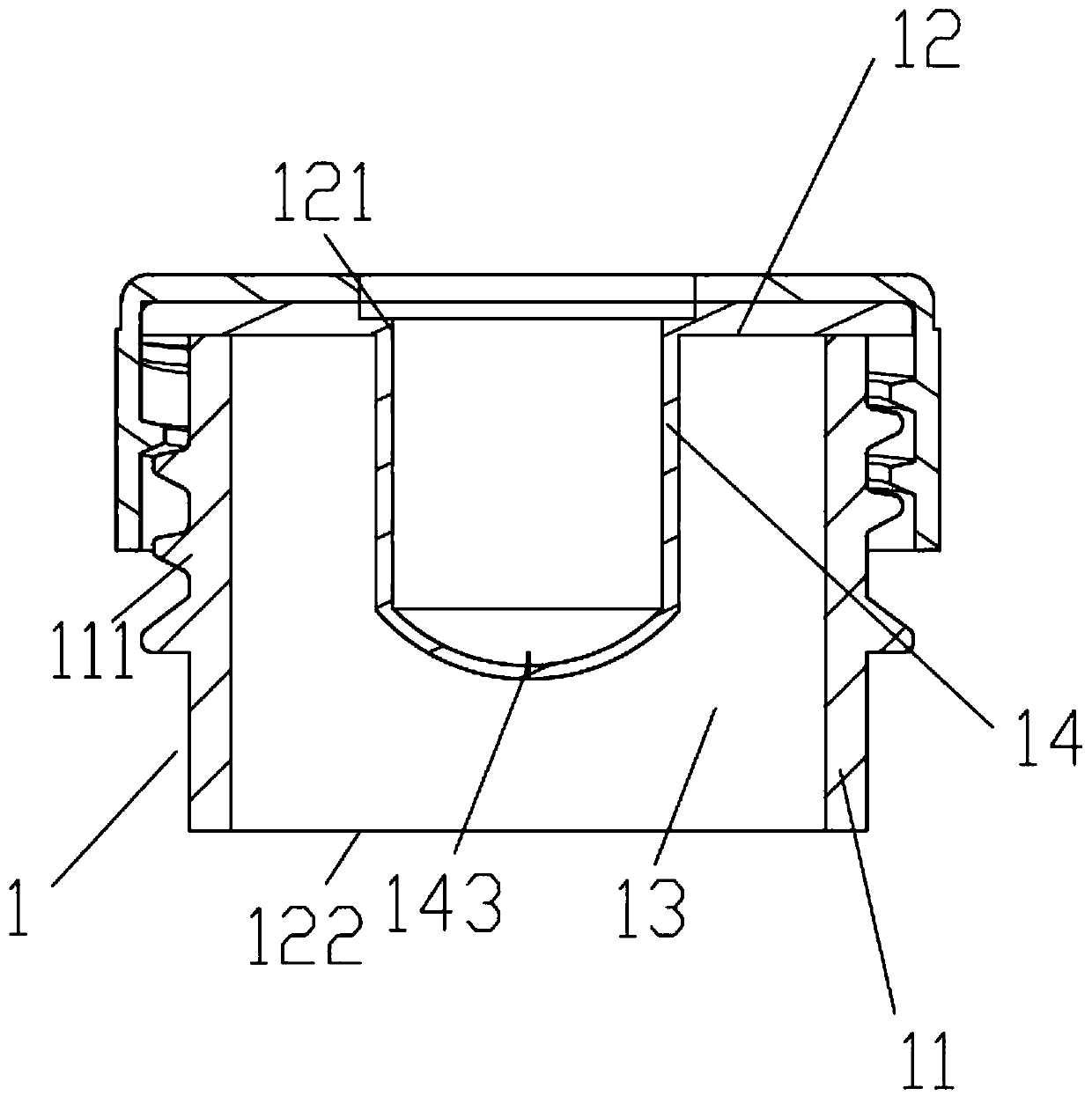

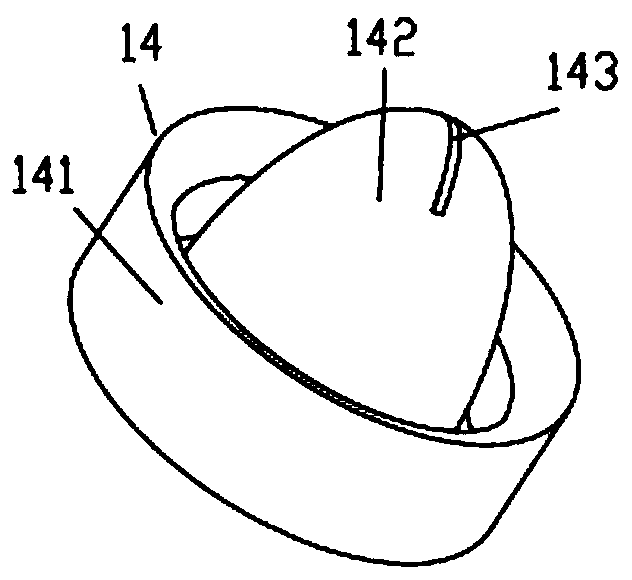

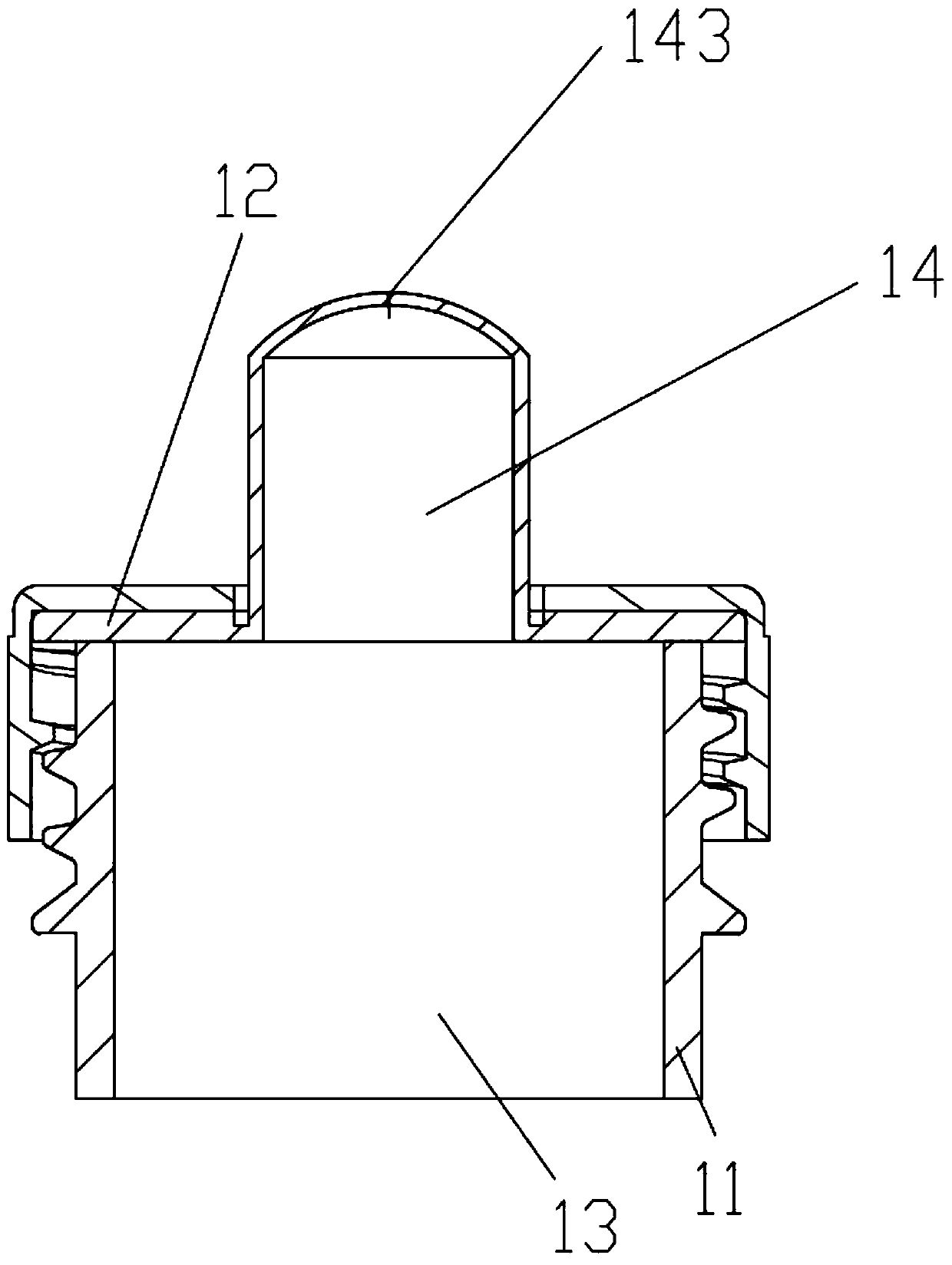

Pinching-type stretchable cover

The invention relates to the field of container cover structures, and particularly discloses a pinching-type stretchable cover. The pinching-type stretchable cover comprises a base. The base is provided with a side wall. A matched connection part is arranged on the side wall and is used for being connected to an external container in a matched mode. A base plate is arranged at the upper end of thebase. The pinching-type stretchable cover is provided with a liquid outlet. A container cover inlet is formed in the lower end of the base, and liquid in the external container flows towards the liquid outlet through the container cover inlet. The pinching-type stretchable cover is further provided with an elastic stretchable valve. The stretchable valve comprises a valve seat and a valve body. The valve seat is connected to the liquid outlet. The valve body is made of an elastic material. A notch is formed in the valve body. According to the pinching-type stretchable cover, when liquid is discharged out of the external container, the liquid outlet stretches out of a container opening; after the liquid discharged, the liquid outlet retreats into the container opening, so that residues atthe container opening are avoided, cleanliness and sanitation are guaranteed, and operation is easy and convenient; and the safety is ensured, and the pinching-type stretchable cover is more sanitary.

Owner:李红彪

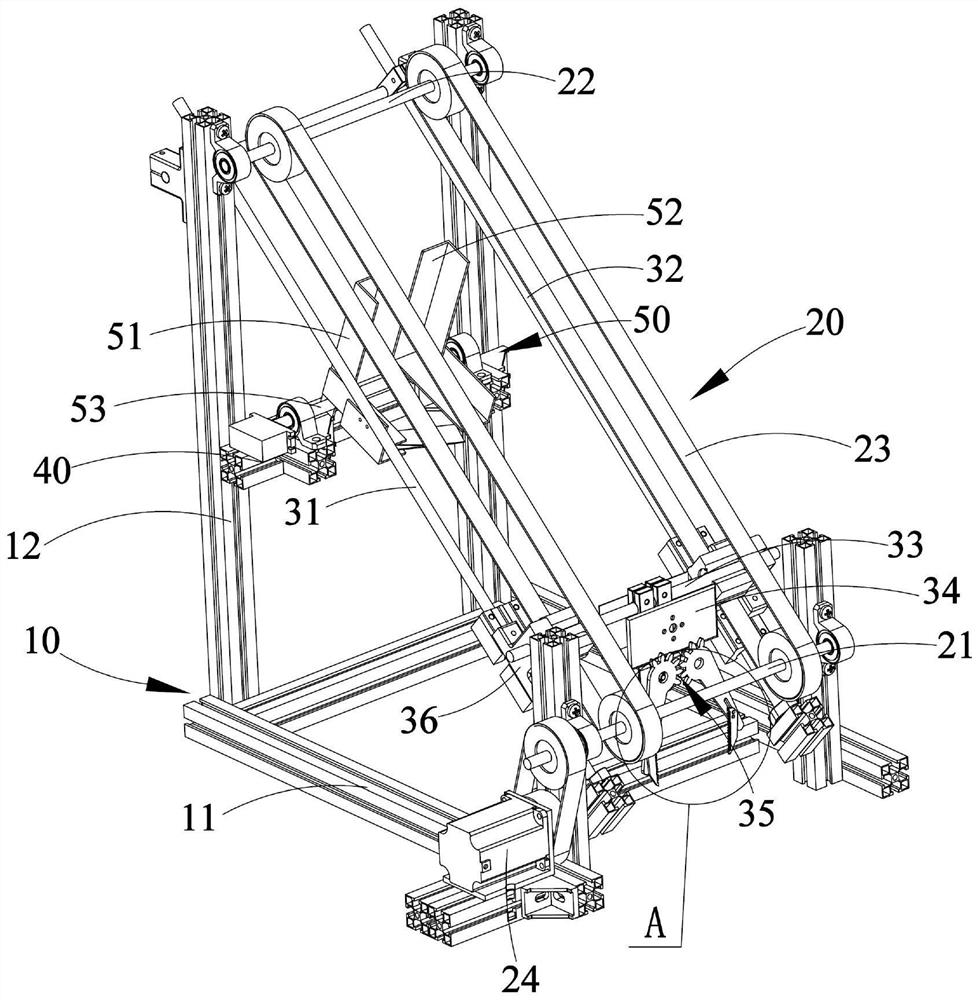

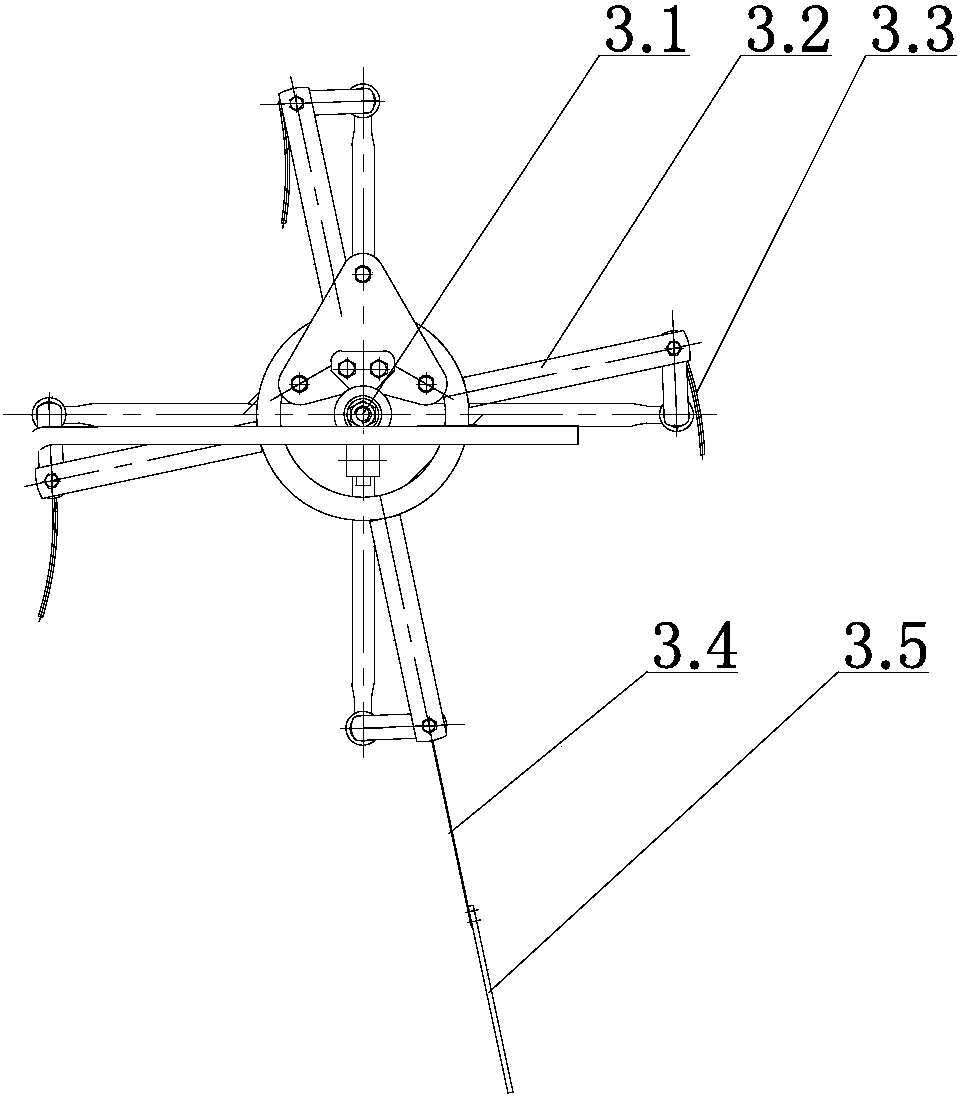

Semi-automatic barreled raw material pouring device for chemical industry

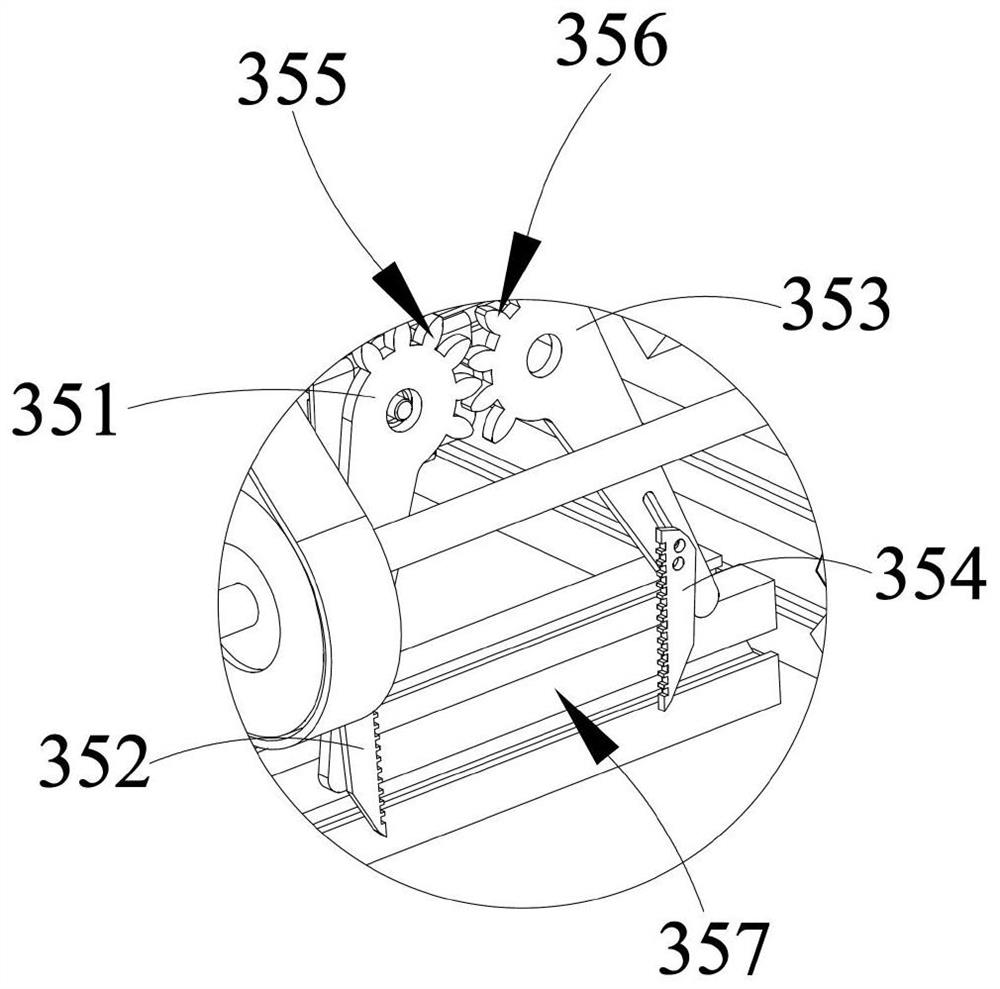

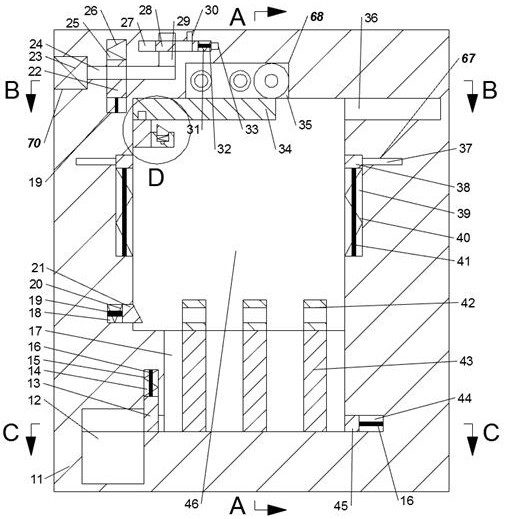

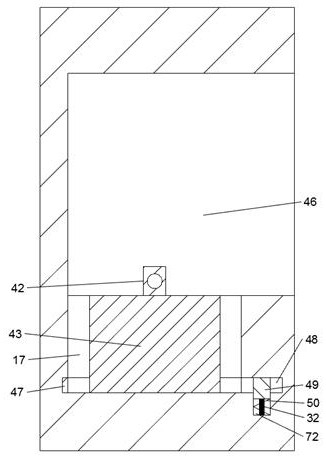

ActiveCN112027710AEnsure no residueImprove efficiencyConveyorsLoading/unloadingChemical industrySemi automatic

The invention discloses a semi-automatic barreled raw material pouring device for a chemical industry. The semi-automatic barreled raw material pouring device comprises a mounting support, a lifting assembly and a grabbing assembly, wherein the mounting support comprises first supports and second supports, the first ends of the first supports are connected with the first ends of the second supports, the first end of the lifting assembly is connected with the second end of the first support, the second end of the lifting assembly is connected with the second ends of the second supports, the first supports are perpendicularly connected with the second supports so to enable the mounting support to be in an L shape, a height difference exists between the first end and the second end of the lifting assembly, the grabbing assembly is arranged on the lifting assembly, the grabbing assembly is used for grabbing a raw material barrel, and the lifting assembly is used for driving the grabbing assembly to move in the extending direction from the second ends of the first supports to the second ends of the first supports. According to the semi-automatic barreled raw material pouring device forthe chemical industry, the raw material barrel can be poured very conveniently, and the pouring efficiency of the semi-automatic barreled raw material pouring device is improved.

Owner:诸城市五洲化工涂料有限公司

A decolorizing agent capable of reducing the content of aflatoxin in peanut oil

ActiveCN107413300BIncrease spacingImprove hydrophobicityOther chemical processesFatty-oils/fats refiningPigmentChemistry

The invention belongs to the technical field of decolorizing agents, and discloses a decolorizing agent capable of decreasing aflatoxin content in peanut oil. The decolorizing agent is prepared by the following processes: step (1), performing acid treatment and ultrasonic treatment; step (2), performing crushing and grinding; step (3), performing stirring and granulation; and step (4) performing drying and sintering. The decolorizing agent provided by the invention can effectively remove pigment and aflatoxin, can be used repeatedly, and saves costs for enterprises.

Owner:SHANDONG YUHUANG GRAIN & OIL FOOD

Cleaning device for conducting pickling derusting on surfaces of metal mechanical and electrical products

The invention discloses a cleaning device for conducting pickling derusting on the surfaces of metal mechanical and electrical products. The cleaning device comprises a box body. A cleaning cavity communicating with the outer portion is formed in the box body. A pickling cavity with an upward opening is formed in the lower inner wall of the cleaning cavity, three pickled treatment blocks are connected in the pickling cavity in a sliding manner, and a hook is fixedly connected to the upper end of each treatment block. A waste material cavity communicating with the pickling cavity is formed in the left inner wall of the pickling cavity. A movement mechanism used for taking the treatment blocks is arranged in the box body. The device is simple in structure and convenient to use, the mechanical and electrical products subjected to pickling treatment can be automatically grabbed and washed with clear water, pickling liquid attached to the surfaces of the products and rust which is not separated from the surfaces of the products are removed, it is ensured that no residues are left on the surfaces of the products, in addition, iron rust residues and wastewater can be automatically treated, and pretreatment is conducted for pickling of the next batch of products.

Owner:广州莹冲涡轮增压器有限公司

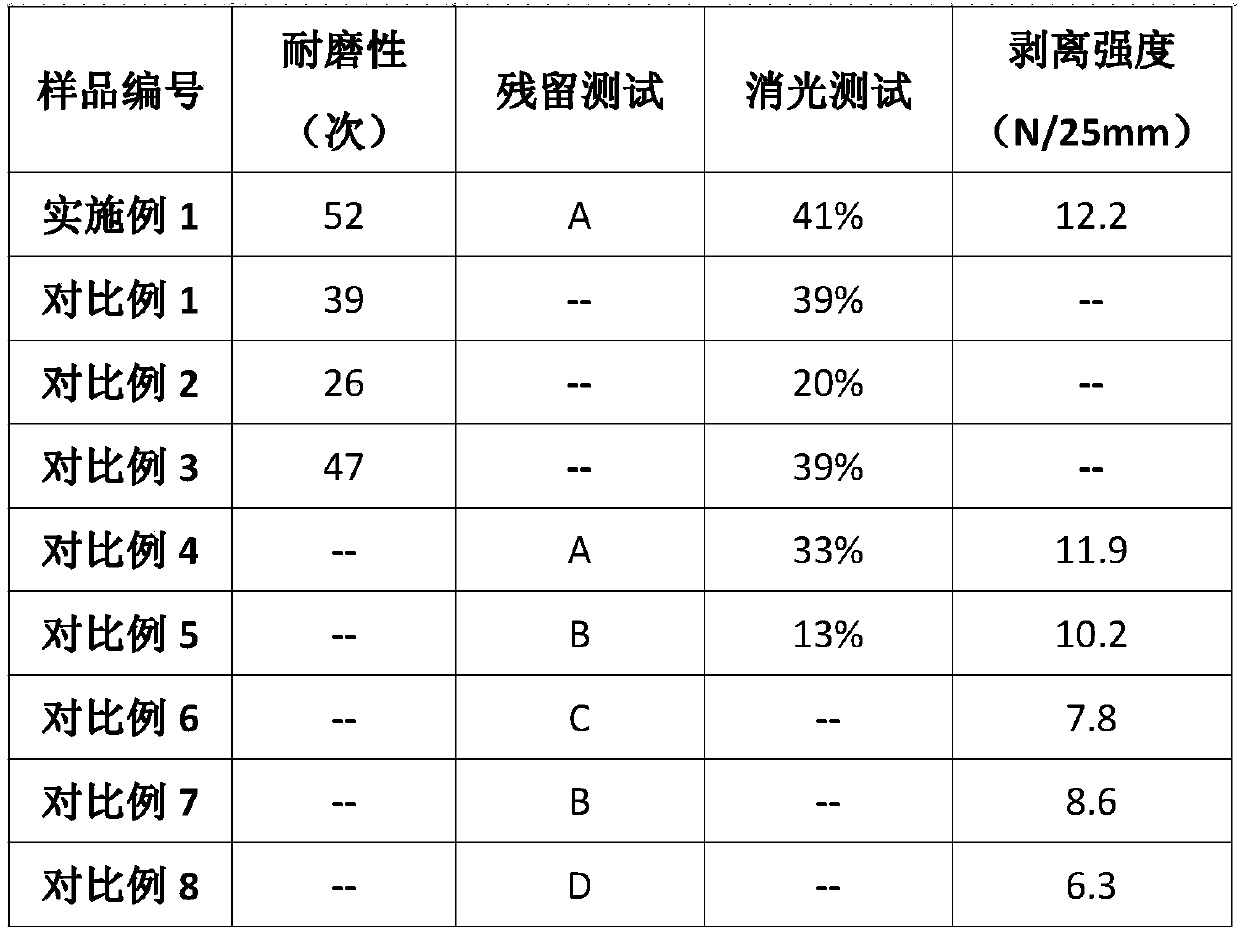

Super-hydrophobic micro-extinction surface protecting film and preparation method and application method thereof

ActiveCN107760215AImprove hydrophobicityGood optical performanceFilm/foil adhesivesOrganic non-macromolecular adhesiveAdhesiveLiving free-radical polymerization

The invention provides a super-hydrophobic micro-extinction surface protecting film and a preparation method and an application method thereof. The super-hydrophobic micro-extinction surface protecting film comprises a hydrophobic layer, a micro-extinction layer and an adhesive layer. The adhesive layer is an acrylic acid series adhesive, the micro-extinction layer is compound filler comprising silicon dioxide and titanium dioxide, and the hydrophobic layer is a fluorine-containing silane coupling agent treatment layer; the acrylic acid series adhesive is polymerized by adopting active free radicals, and the polydispersity index is smaller than 2.5; by matching silicon dioxide and titanium dioxide for the micro-extinction layer, the adhesive is selection of special composition. By means ofthe selection, effects of excellent comprehensive performances with hydrophobic property, micro-extinction, adhesiveness and without residues are achieved.

Owner:상보신재료(소주)유한공사

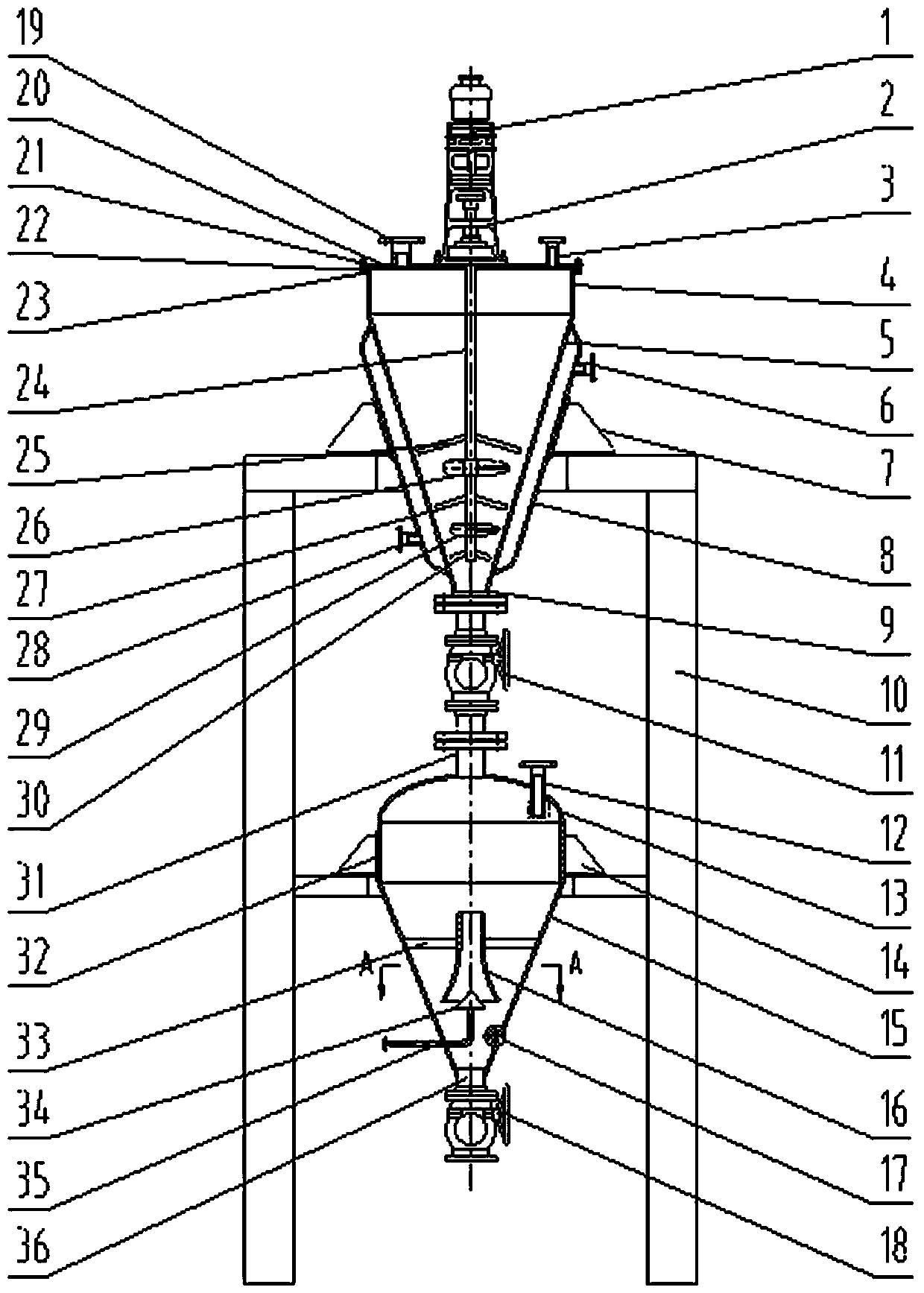

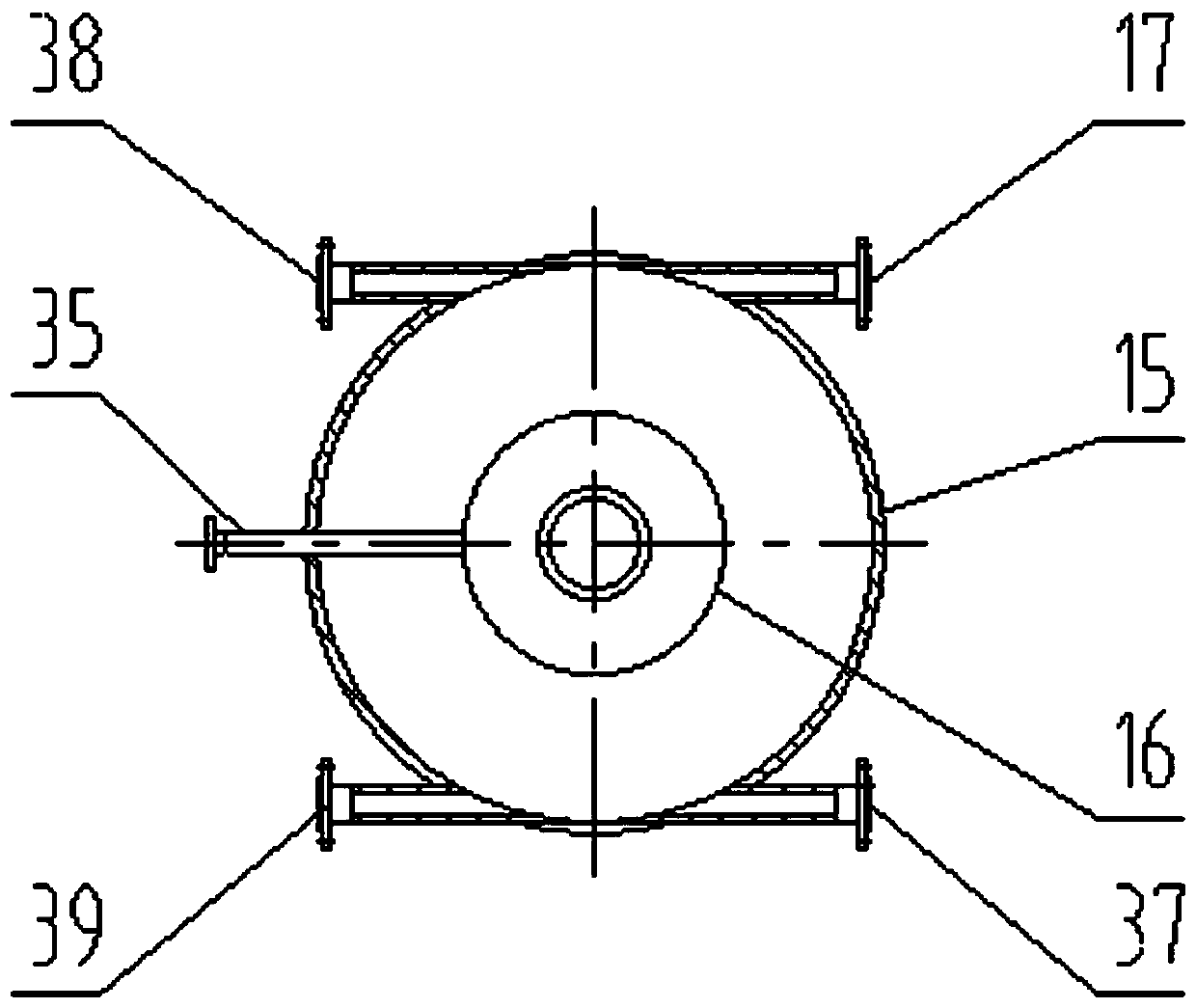

Drying, crushing and mixing all-in-one machine

PendingCN107790052AReduce the risk of contaminationEnsure no residueTransportation and packagingDrying gas arrangementsChemical industrySize difference

The invention discloses a drying, crushing and mixing all-in-one machine, comprising a drying and crushing device and a mixing device, wherein the drying and crushing device is connected with the mixing device by means of an upper end discharge valve; the mixing device sequentially comprises an elliptical head, a lower end straight tube and a lower end taper tube from top to bottom, wherein the lower end taper tube is connected with the lower end straight tube, the side wall of the lower end taper tube is provided with a middle air inlet, a lateral air inlet A, a lateral air inlet B, a lateralair inlet C and a lateral air inlet D, and an umbrella-shaped cap is installed on the top of the middle air inlet; an air lifting cylinder is installed in the lower end taper tube. After the drying,crushing and mixing all-in-one machine is used, three operation units, i.e., a drying operation unit, a crushing operation unit and a mixing operation unit are realized in the same equipment, so thatthe mixing time of materials is shortened, and the particle size difference between the materials is further reduced in a mixing process; the drying, crushing and mixing all-in-one machine is stable in structure and convenient to assemble and disassemble, and can be widely applied to the fields such as chemical industry, medicines and food.

Owner:THE FOURTH INST OF NUCLEAR ENG OF CNNC

A cleaning method for laser perforated aluminum nitride ceramic plate

ActiveCN110918548BAvoid damageAvoid corrosionDrying gas arrangementsCleaning using liquidsMegasonic cleaningMolten slag

The invention discloses a method for cleaning a laser perforated aluminum nitride ceramic plate. The perforated aluminum nitride ceramic plate is first soaked in acid, and the oxides in the molten slag react with the acid to bond the aluminum nitride ceramic plate. The slag is hollow and soft, and the slag on the surface of the ceramic plate can be removed by gently wiping with a cloth to reduce the damage to the ceramic plate caused by the scraper; multiple ultrasonic cleaning in the middle can make large pieces of soft slag fall off, which is convenient for acid and Inner layer slag reaction, adding block cleaning process to improve cleaning efficiency; short-term soaking with low-concentration alkali, the alkali reacts slightly with the surface of the aluminum nitride ceramic sheet, and the slag in the micropores can be completely cleaned to avoid alkali If the cleaning concentration is too high and the time is too long, it will cause corrosion pits and excessive roughness on the surface of aluminum nitride ceramics, so as to ensure that there is no residue of slag in the micropores; all ultrasonic cleaning is to put the aluminum nitride ceramic plate into absolute ethanol or Ultrasonic in isopropanol, the aluminum nitride plate has no reaction with absolute ethanol and isopropanol, and the production process is better controlled.

Owner:GUANGDONG GASTIGHT HERMETICAL COMPONENT

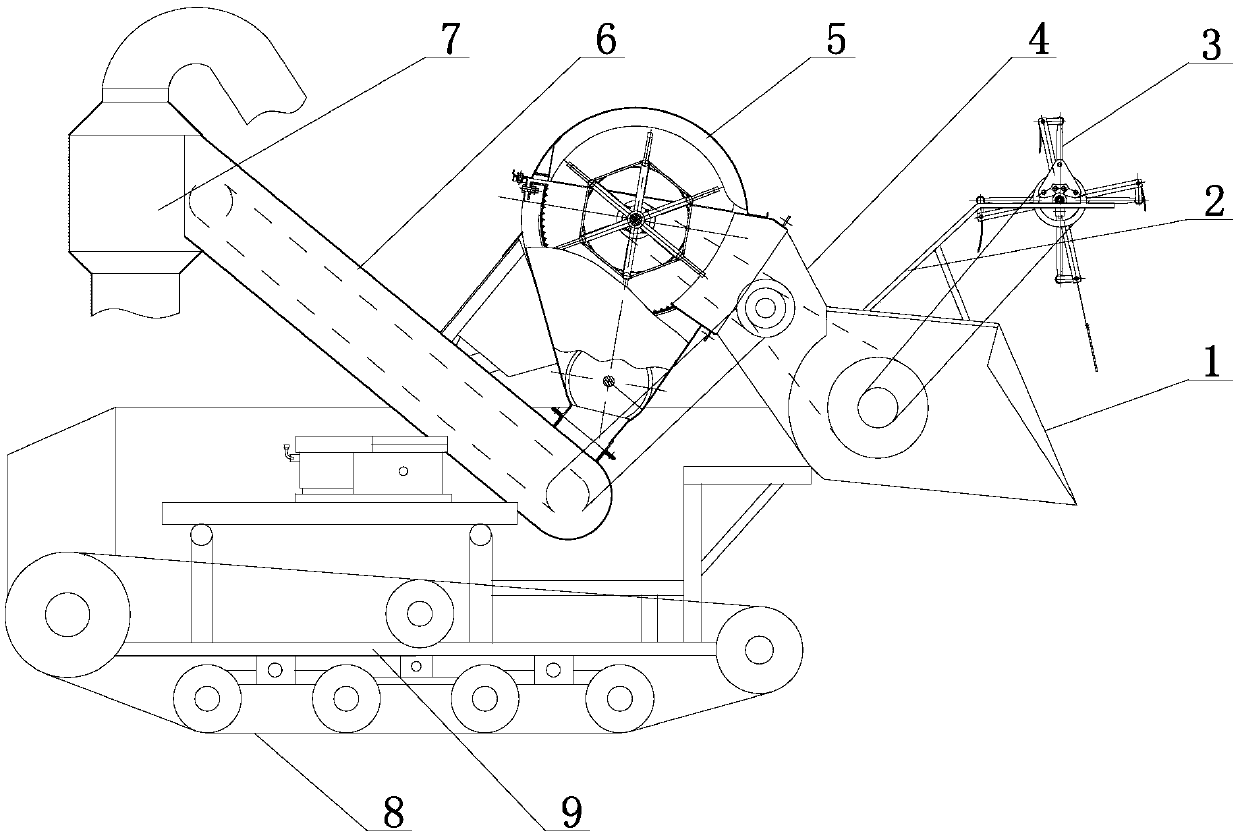

Harvester for strain cultivation

InactiveCN107810704AEnsure no residueGuaranteed collection rateMowersThreshersMicrochiropteraAgricultural science

The invention belongs to the technical field of strain cultivation, and in particular relates to a harvester for strain cultivation, especially suitable for harvesting crops during the cultivation of crop strains such as wheat and rice. The structural design of the present invention is ingenious and reasonable. In the actual application process, through the unique designs of the feeding mechanism and reeling mechanism in the cutting platform, the discharging auger in the threshing mechanism and the belt conveying device in the lifting and discharging mechanism, From crop harvesting, threshing, transportation to final bagging and collection, the crop seeds are guaranteed to be free of residues to the greatest extent, thus greatly improving the harvesting rate of crop seeds, and at the same time avoiding the problem of intermixing of different strains of crop seeds 1. The purity of the seeds is ensured, and the manual harvesting and peeling operations in the strain cultivation process are replaced by this harvester. On the premise of ensuring the harvest rate and purity of crop seeds, it saves manpower and improves the efficiency of harvesting and threshing. .

Owner:曹成峰

Wear-resisting and semi-matted handle door bowl sticker and application method thereof

ActiveCN107815258AImprove wear resistanceImprove aging resistanceFilm/foil adhesivesEster polymer adhesivesPolymer scienceAdhesive

The invention provides a wear-resisting and semi-matted handle door bowl sticker and an application method thereof. The door bowl sticker structurally comprises a wear-resisting layer, a semi-matted layer and an adhesive layer, wherein the adhesive layer is an acrylic acid adhesive; the acrylic acid adhesive is polymerized by adopting active free radicals, and a polydispersity index is less than 2.5; the wear-resisting layer is prepared by matching corundum and graphite powder; the semi-matted layer is prepared by matching a benzotriazole ultraviolet absorbent and titanium dioxide; by selecting the material, the effect of excellent comprehensive performance including wear resistance, matting property, no residues, binding property and the like is realized.

Owner:绍兴市侨陆智能科技有限公司

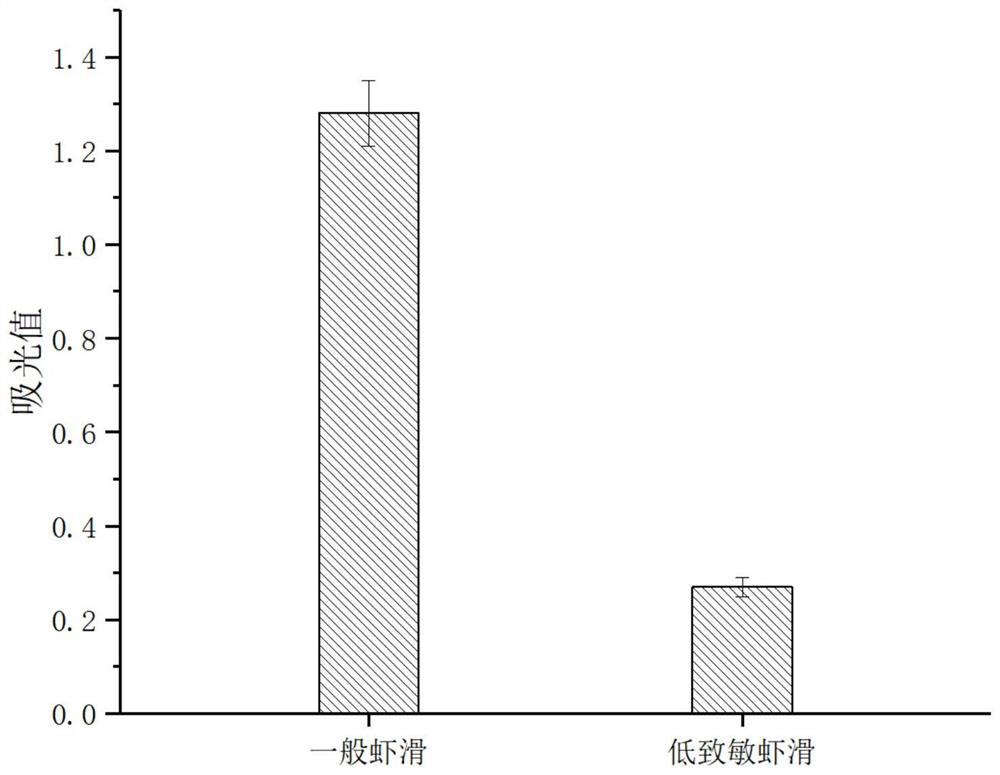

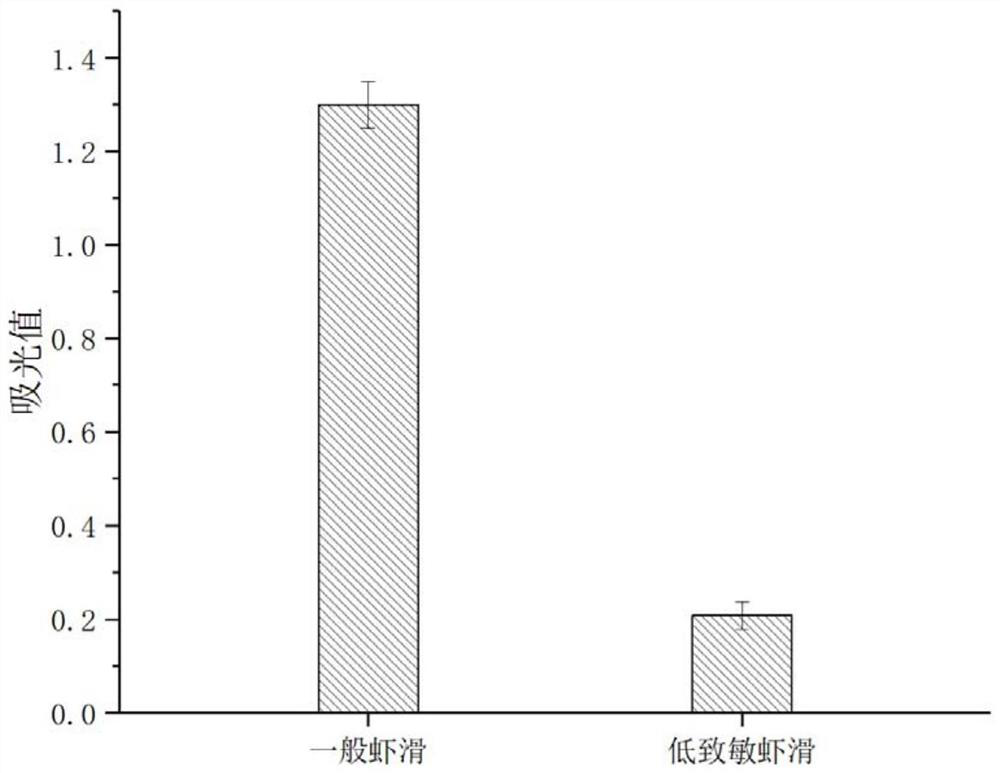

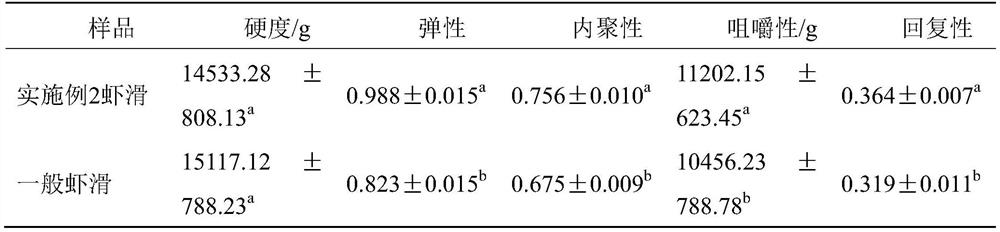

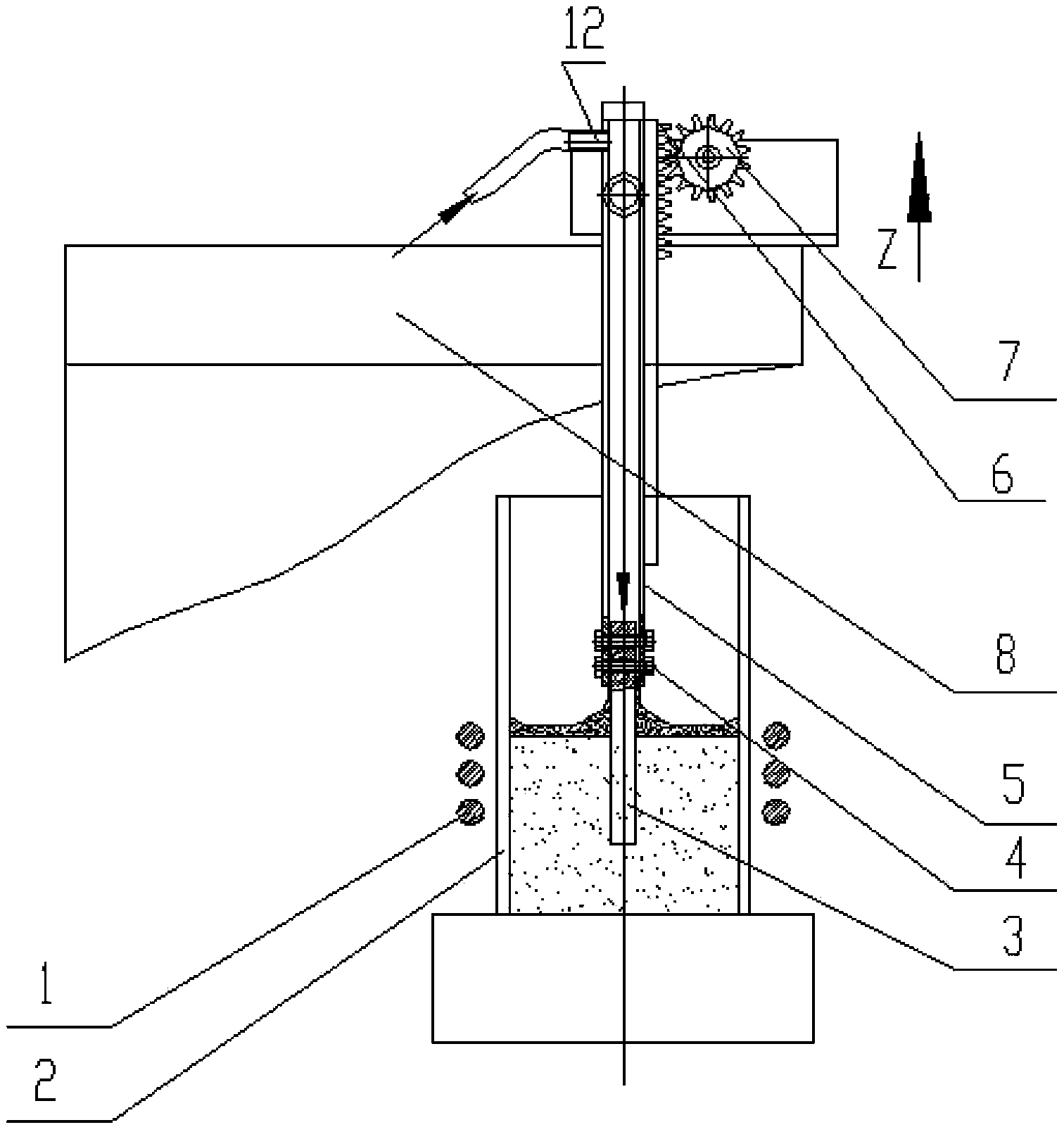

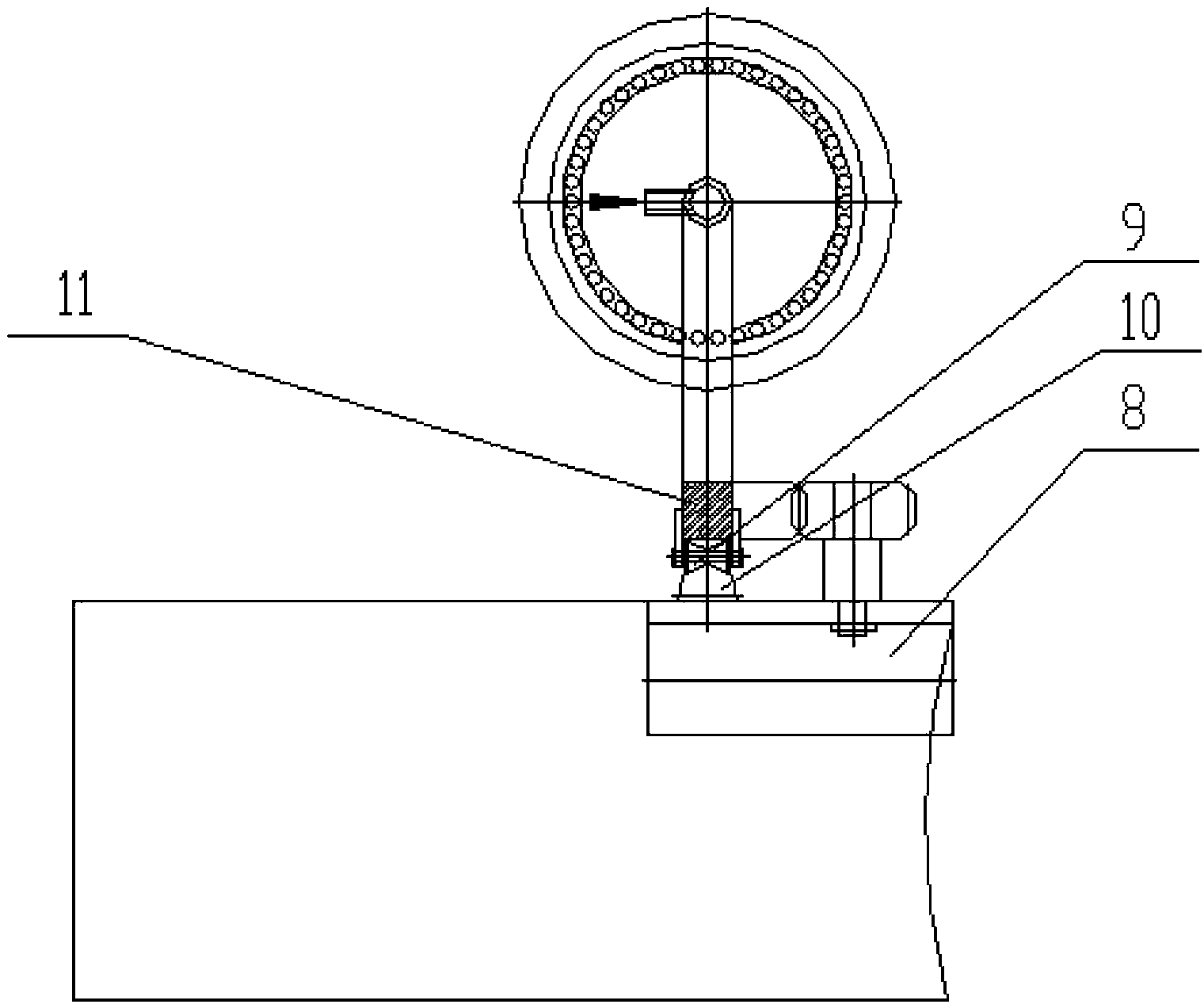

Low-sensitization and high-elasticity mashed shrimp and preparation method thereof

The invention discloses a low-sensitization and high-elasticity mashed shrimp and a preparation method thereof, and the method comprises the following steps: adding shrimp meat into a desensitization solution, and mincing to obtain shrimp homogenate; carrying out ultrasonic treatment on the obtained shrimp homogenate, adding a shaping liquid, mincing again to obtain shrimp paste, and kneading and shaping the shrimp paste to obtain shrimp paste; the desensitization liquid is a trehalose solution with the concentration of 0.8-1.2%, and is prepared by treating the trehalose solution through medium barrier plasma processing equipment. According to the method disclosed by the invention, the sensitization protein is treated by adopting an ultrasonic synergistic plasma technology, so that the sensitization of the protein can be efficiently reduced, the reduction of food quality caused by excessive treatment by a single technology can be avoided, and the gel property of the shrimp protein can be enhanced to a certain extent, so that the shrimp protein has a more elastic and refreshing taste.

Owner:SOUTH CHINA UNIV OF TECH

Coating for die forging, film and manufacturing process

PendingCN112143305APlay a lubricating rolePlay a role in heat preservationCoatingsMetallurgyHeat conservation

The invention discloses a coating for die forging, a film and a manufacturing process. The coating for die forging comprises a base material and glass powder dispersed in the base material. Accordingto the film for die forging, the coating for die forging is applied on a base material through coating. According to the film for die forging, vaporization is started at the using temperature, the vaporization point is high, and no peculiar smell exists in the vaporization process; and in the die forging process, deformation metal flows at high temperature, meanwhile, the film is gradually vaporized, the heat preservation effect can be achieved, it can be guaranteed that no residue exists on the surface of the vaporized forging, and the beneficial effects of being safe and environmentally friendly are achieved.

Owner:德阳市鸿澳润滑材料科技有限责任公司

Start melting device and method for preparing high-purity metallic oxide by using cold crucible

The invention relates to a start melting device and method for preparing high-purity metallic oxide by using a cold crucible. The start melting device comprises a crucible, a electro-magnetic induction arranged along the circumference of the crucible, a graphite rod, an alumina ceramic tube and a lifting system, wherein the alumina ceramic tube is connected to the lifting device, the graphite rod is inserted into the high-purity alumina ceramic tube, a gap is reserved between the alumina ceramic tube and the graphite rod, and the alumina ceramic tube and the graphite rod are connected by an alumina ceramic bolt. According to the method, the alumina ceramic tube and the lifting system act on the high-purity graphite rod so as to carry out start melting on high-purity metal oxide, the high-purity graphite rod is protected by using argon gas so as to prevent the high-purity graphite rod from being in direct contact with oxygen, and the high-purity graphite rod is taken out of the cold crucible by using the automatic lifting system after ignition so as to ensure that the start melting material has no residue in raw materials and can be reused, therefore no pollution is caused to the molten high-purity metal oxide.

Owner:RUIWEI TECH TIANJIN

A method for controlling a food processing machine

The embodiment of the present invention discloses a method for controlling a food processor. The food processor may include a crushing cup, a heating device, a motor, and a temperature sensor. The temperature of the inner wall; when it is detected that the temperature of the inner wall of the crushing cup is less than or equal to the preset first temperature threshold T1, the heating device is controlled to heat with a preset power, so as to maintain the temperature of the inner wall of the crushing cup when the crushing cup is discharged Always greater than or equal to the preset second temperature threshold T2; wherein, the first temperature threshold T1 is greater than the second temperature threshold T2; the second temperature threshold T2 is greater than or equal to 60°C. Through the solution of this embodiment, the temperature of the inner wall of the crushing cup is kept at least above 60° C., which solves the problem of food sticking on the food processing cup and improves the cleaning effect.

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com