Method for manufacturing panels of color touch screens

A touch screen and panel technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of product scrapping, large environmental pollution of hydrofluoride, high scrap rate, etc., and achieve suitable mass production, The manufacturing process is easier to control and the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] This section generally describes the materials and test methods used in the experiments of the present invention. While many of the materials and manipulations which are employed for the purposes of the invention are well known in the art, the invention has been described here in as much detail as possible. It will be clear to those skilled in the art that in the following, unless otherwise specified, the materials, equipment and operation methods used in the present invention are well known in the art.

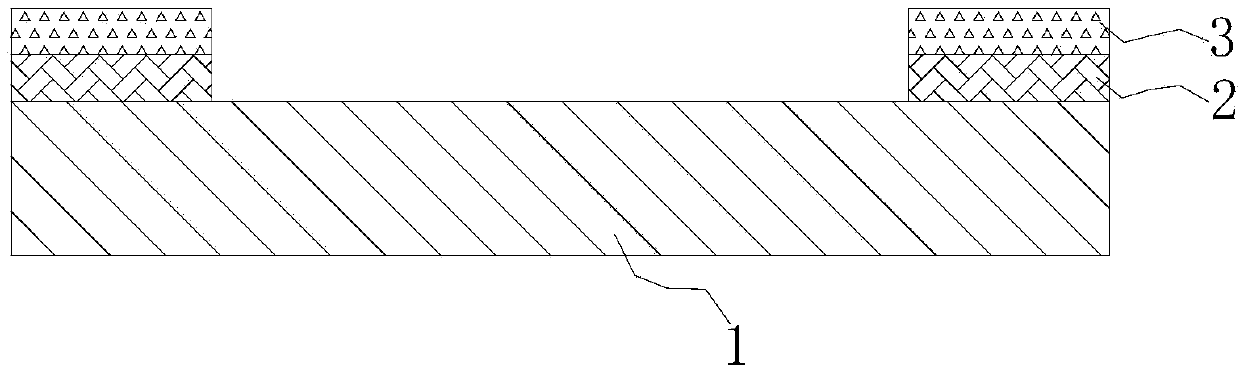

[0019] see figure 1 , the color touch screen panel prepared by the existing preparation method and the preparation method of the color touch screen panel of the present invention includes a substrate 1 , an optical film layer 2 covering the substrate 1 and an opaque insulating layer 3 covering the optical film layer 2 .

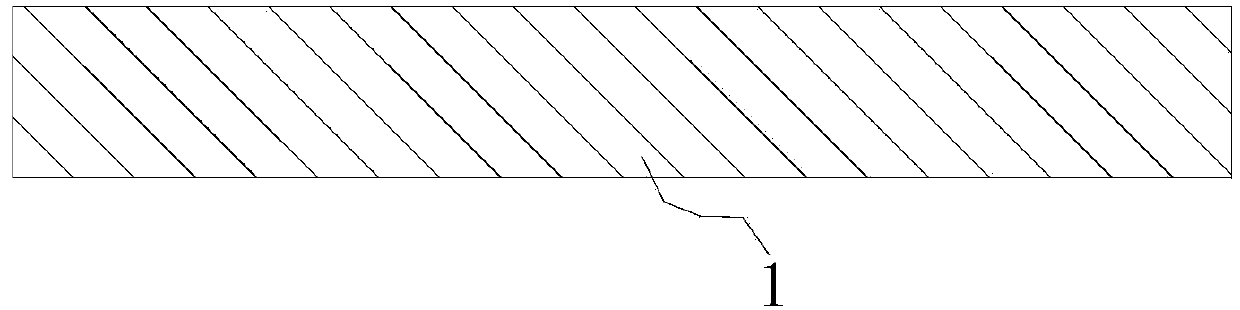

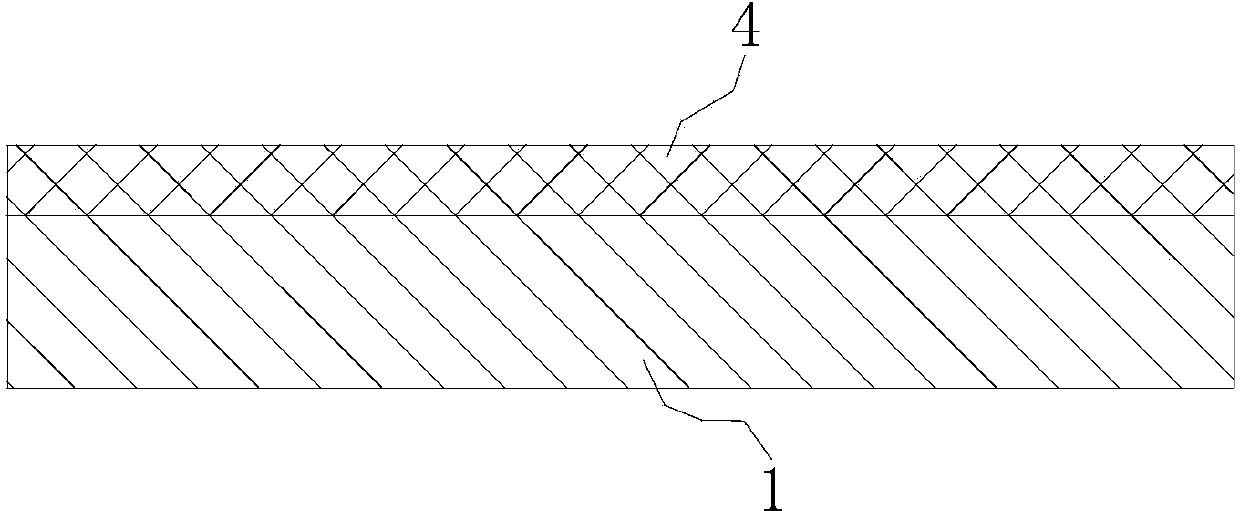

[0020] see Figure 2 to Figure 7 , the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com