Control method for air assisting type gas drive SCR system

An SCR system, air-assisted technology, applied in air quality improvement, exhaust treatment, exhaust devices, etc., can solve problems such as large time consumption, pressure shock, urea solution pressure shock, etc., to achieve clear status functions and clear control logic , the effect of improving reliability and maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

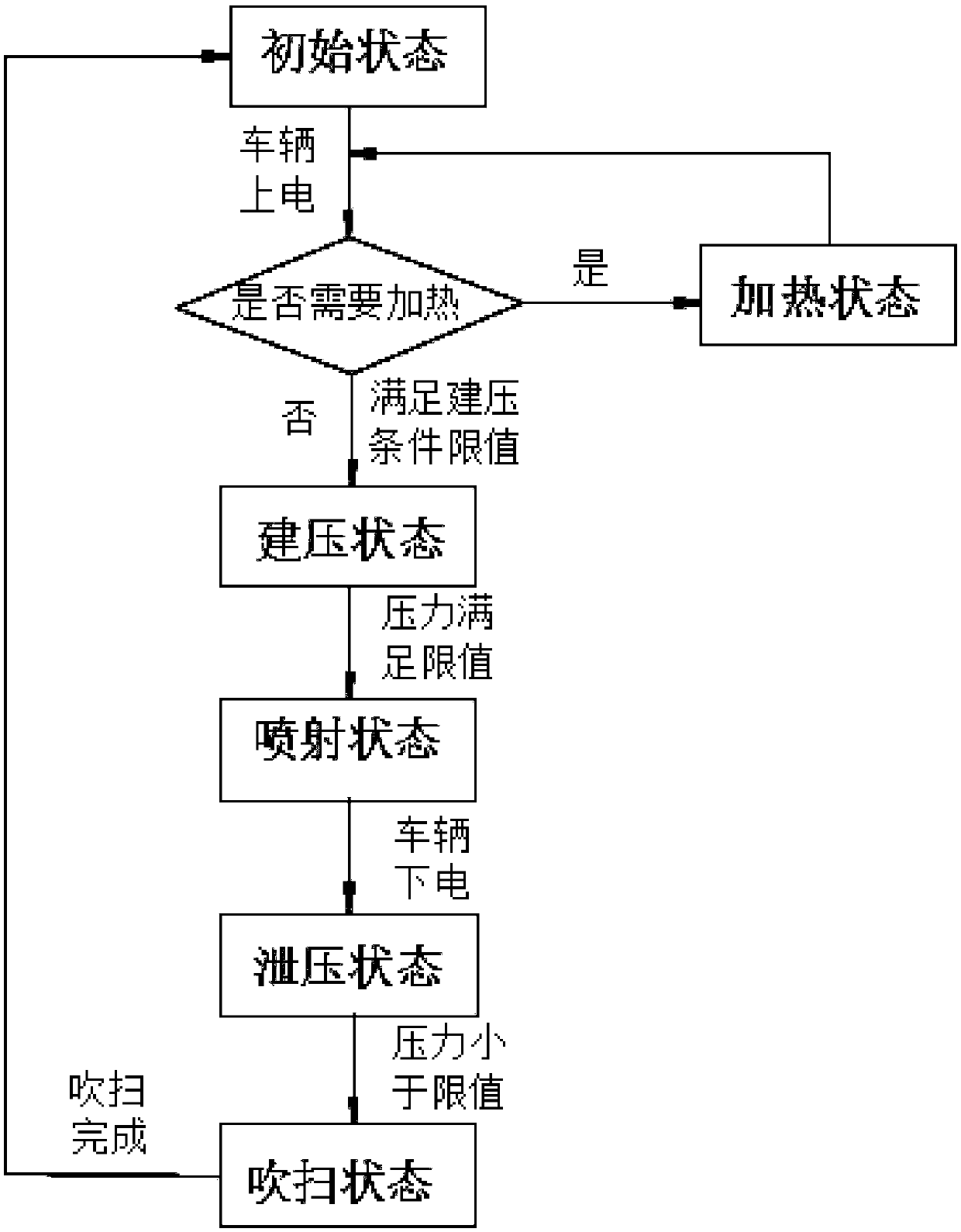

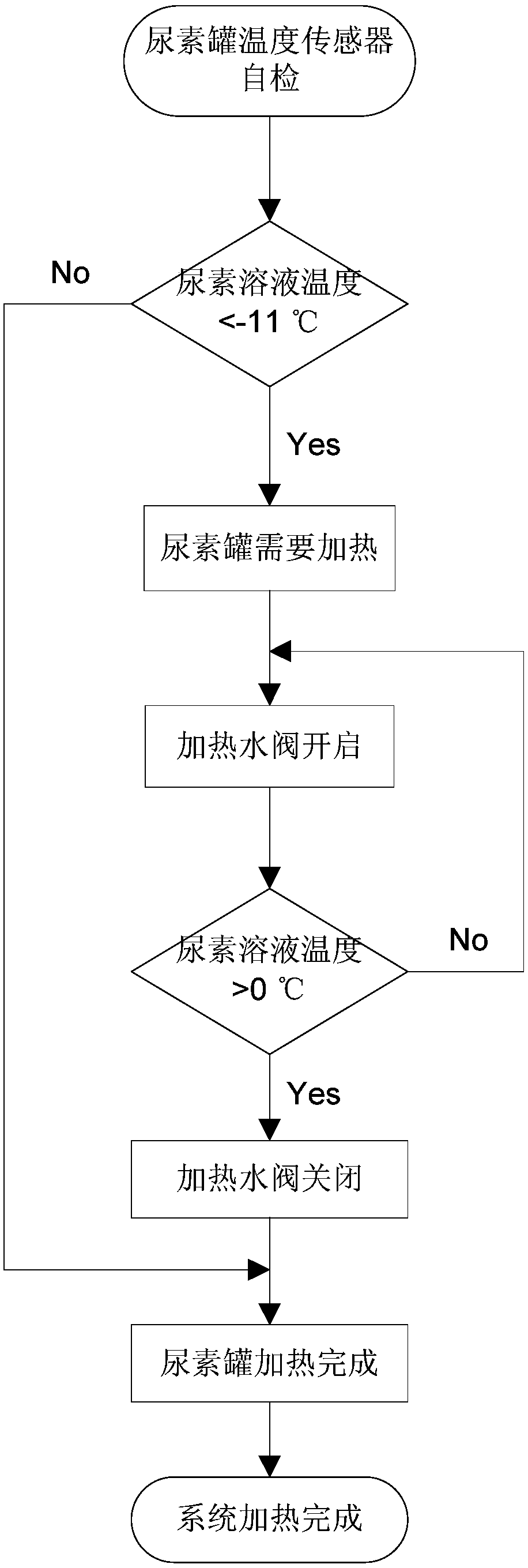

[0030] The technical solution of the control method of the air-assisted gas drive SCR system involved in the present invention will be described in further non-limiting detail below in conjunction with preferred embodiments and accompanying drawings.

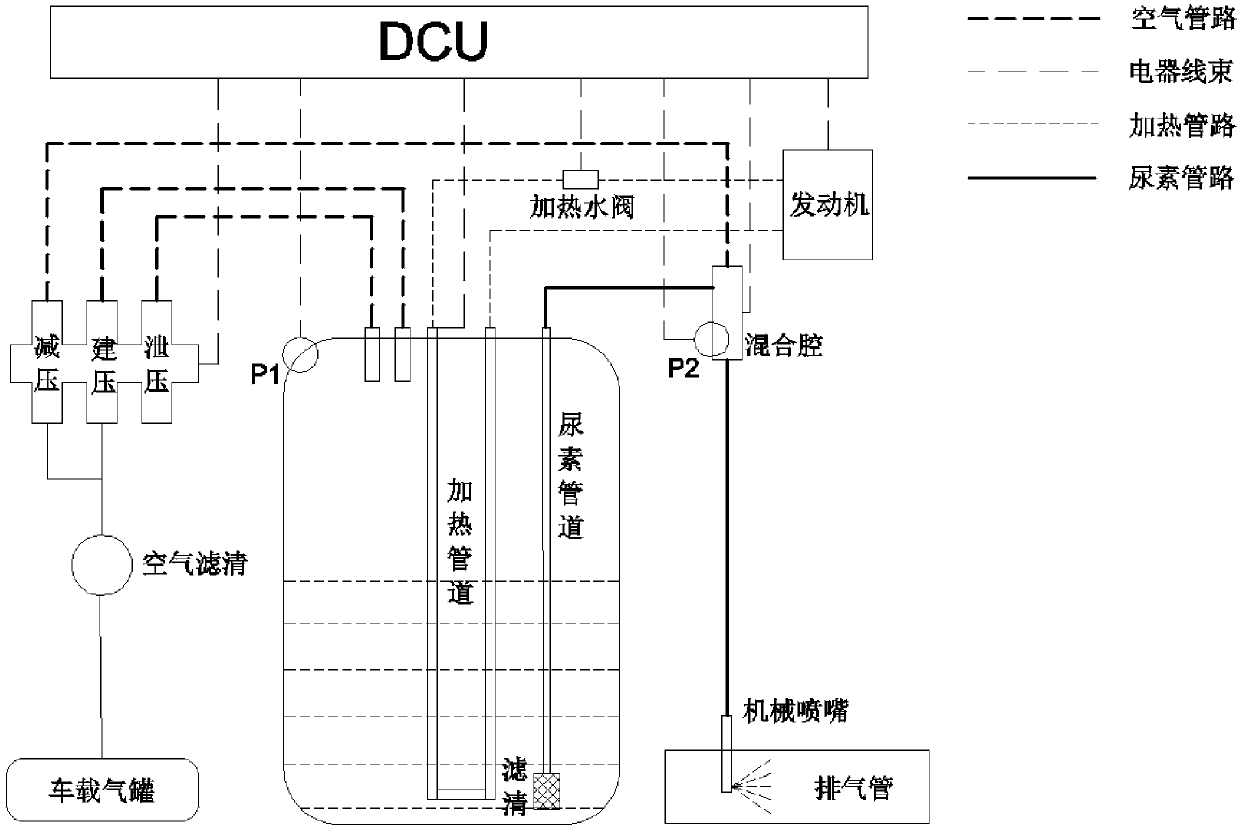

[0031] see figure 1 As shown, the air-assisted gas-driven SCR system (hereinafter referred to as "the system") involved in the present invention is an SCR system that uses compressed air as the power source of the system, replacing the urea pressure building pump in the traditional sense. The whole system is mainly composed of a urea tank assembly, a mixing chamber and an air solenoid valve assembly, and has a simple structure, and uses the control method involved in the present invention to achieve better functions.

[0032] In the system, the vehicle-mounted air tank is used as the compressed air source, and the function of the air filter is to filter the compressed air to ensure its cleanliness. The air solenoid valve assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com