Patents

Literature

255results about How to "Improve kneading effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum nitride powders

ActiveUS20150353355A1Large particle sizeUnique shapeNitrogen compoundsSynthetic resin layered productsOctahedronOragene

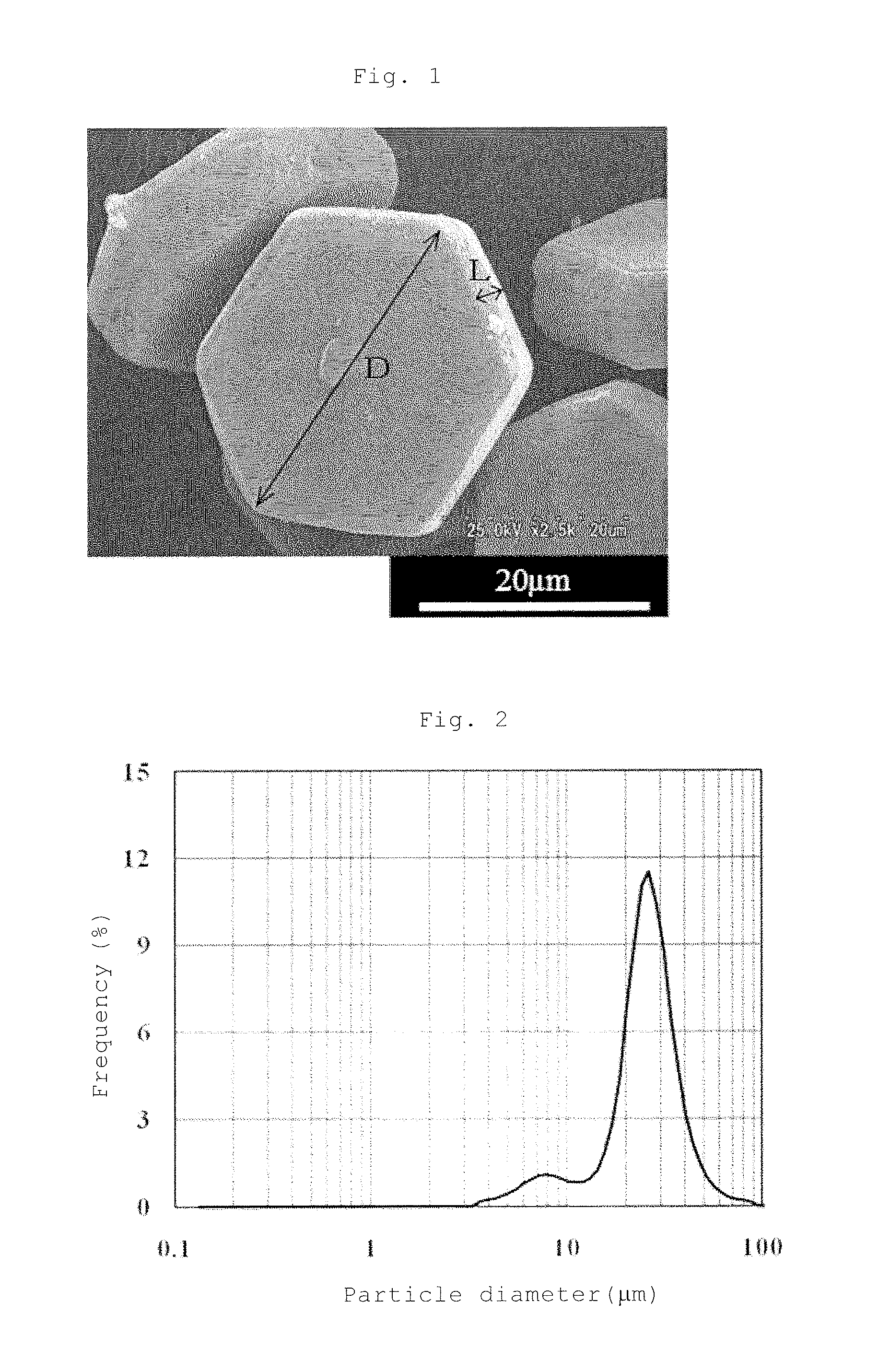

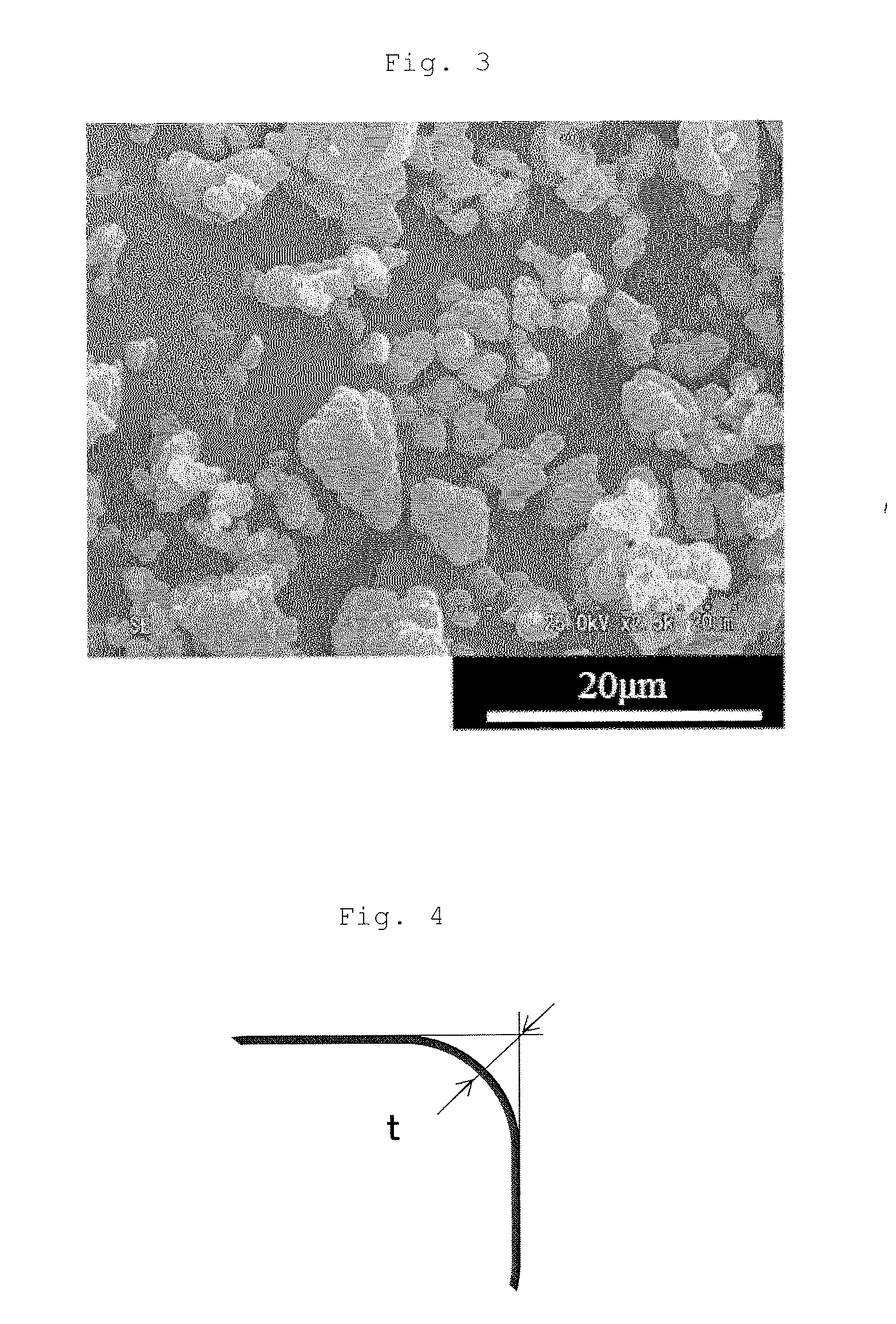

Aluminum nitride crystal particles, aluminum nitride powders containing the same, production processes for both of them, an organic polymer composition comprising the aluminum nitride crystal particles and a sintered body.Each of the aluminum nitride crystal particles has a flat octahedral shape in a direction where hexagonal faces are opposed to each other, which is composed of two opposed hexagonal faces and 6 rectangular faces, in whichthe average distance “D” between two opposed corners of each of the hexagonal faces is 3 to 110 μm, the length “L” of the short side of each of the rectangular faces is 2 to 45 μm, and L / D is 0.05 to 0.8; each of the hexagonal faces and each of the rectangular faces cross each other to form a curve without forming a single ridge; and the true destiny is 3.20 to 3.26 g / cm3.

Owner:TOKUYAMA CORP

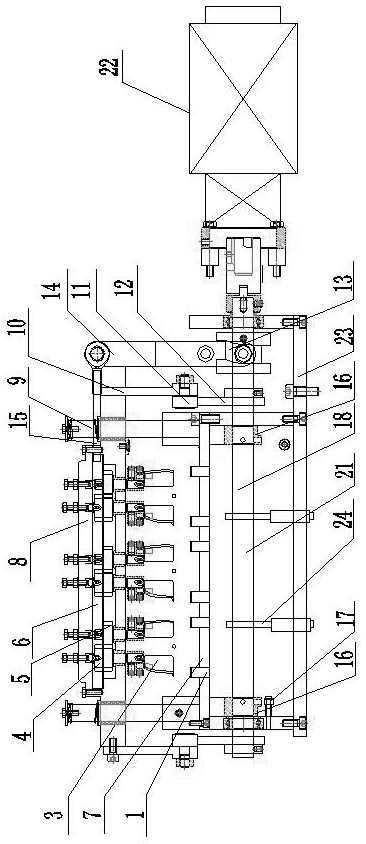

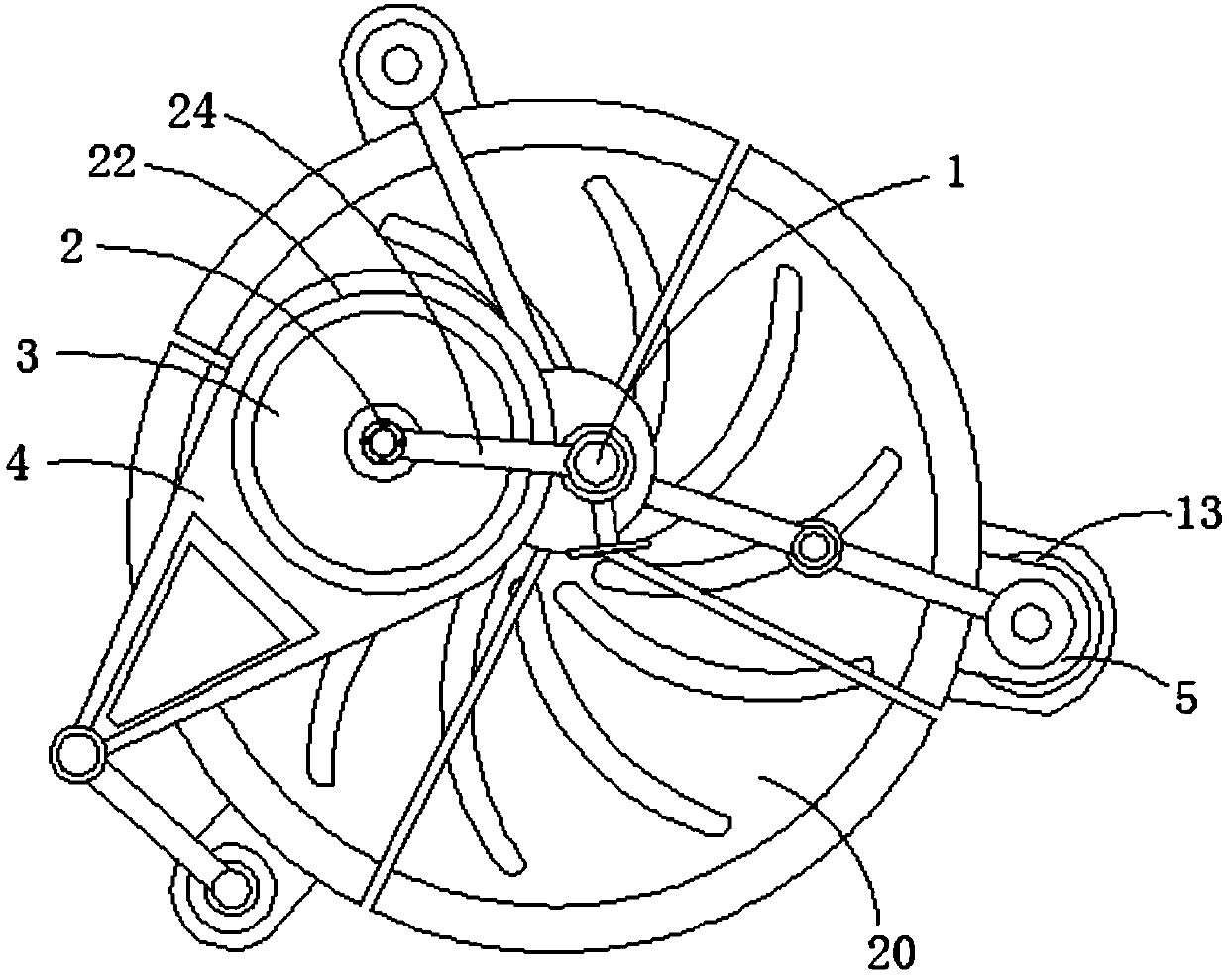

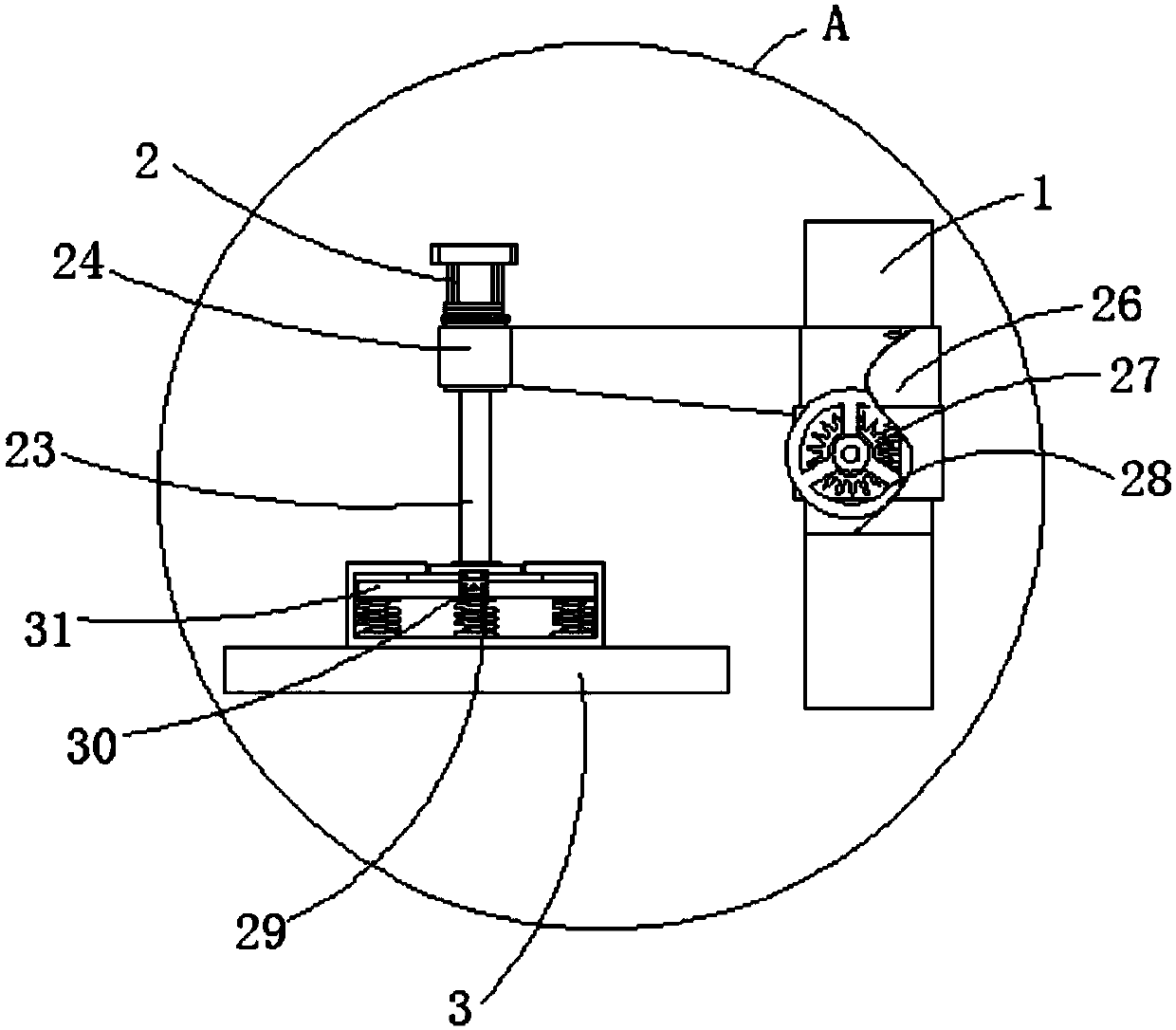

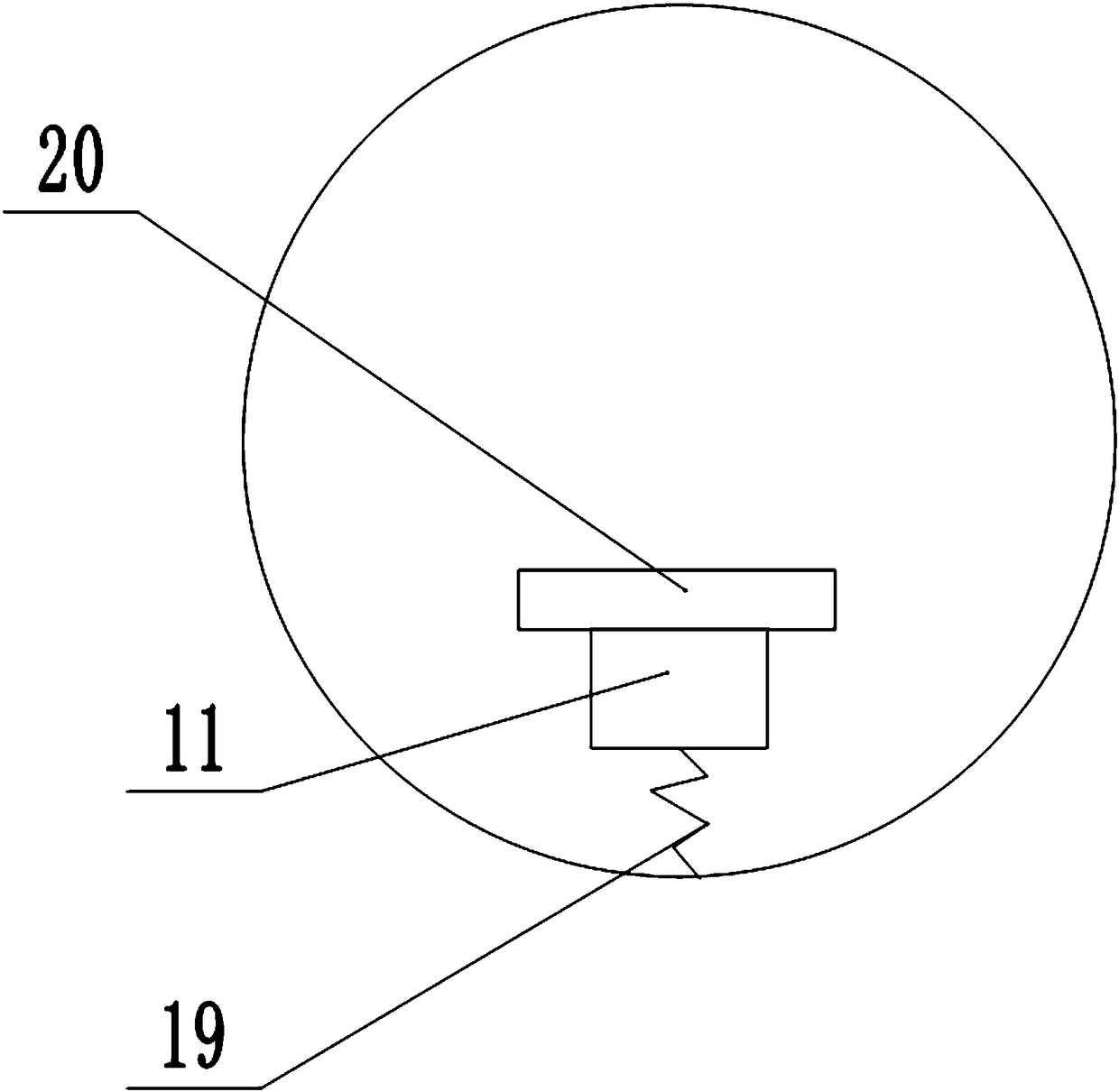

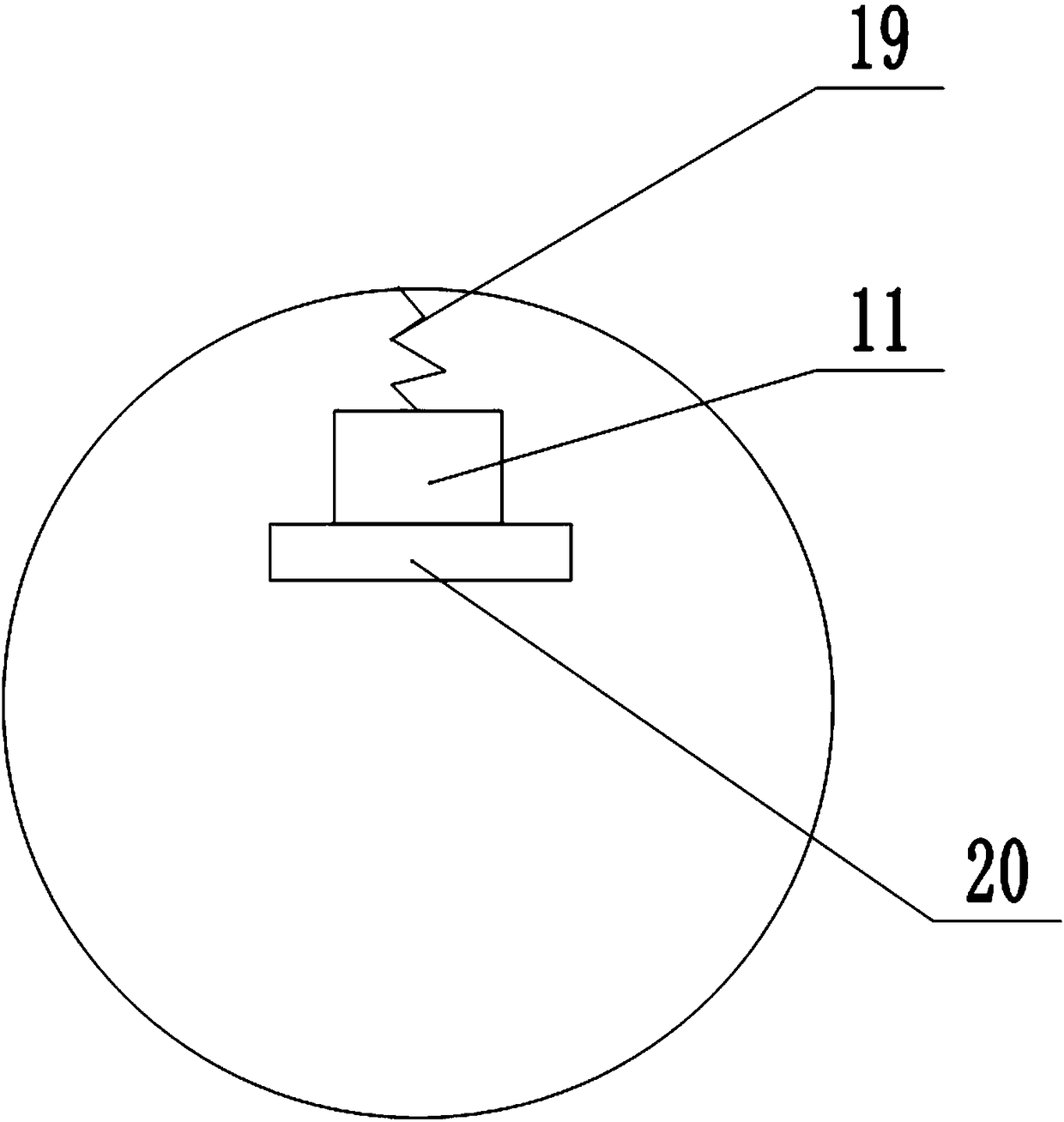

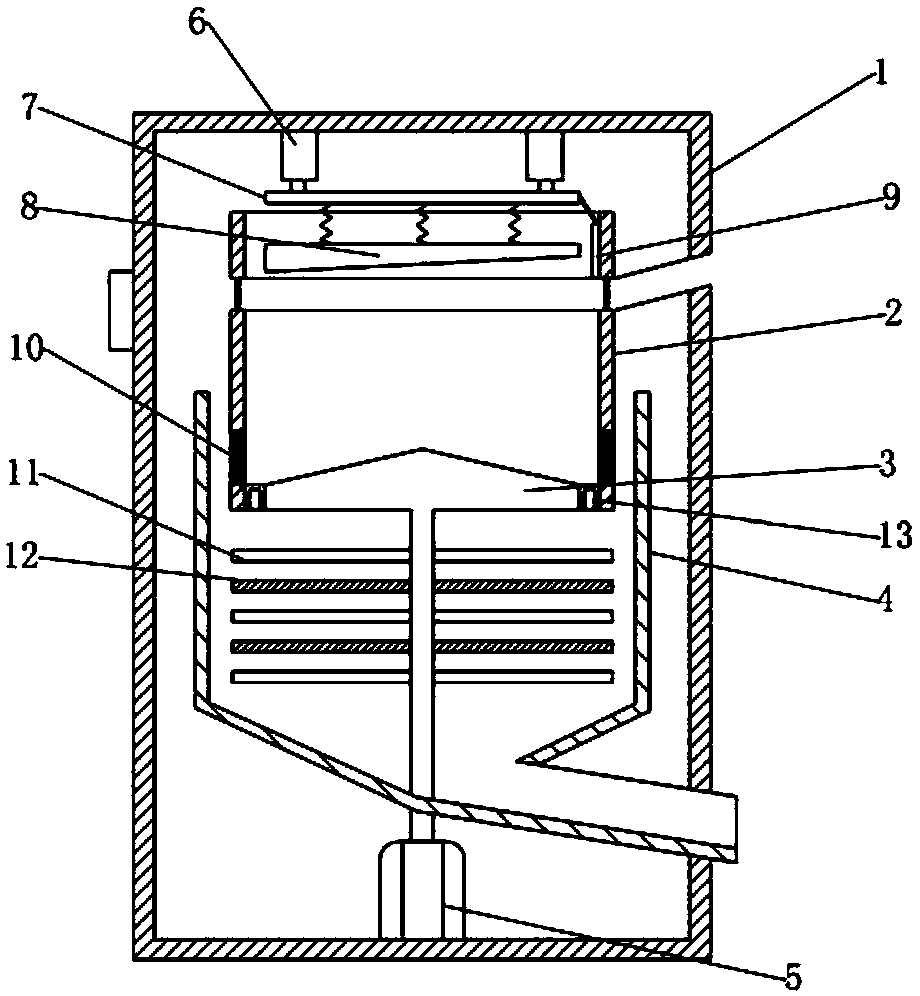

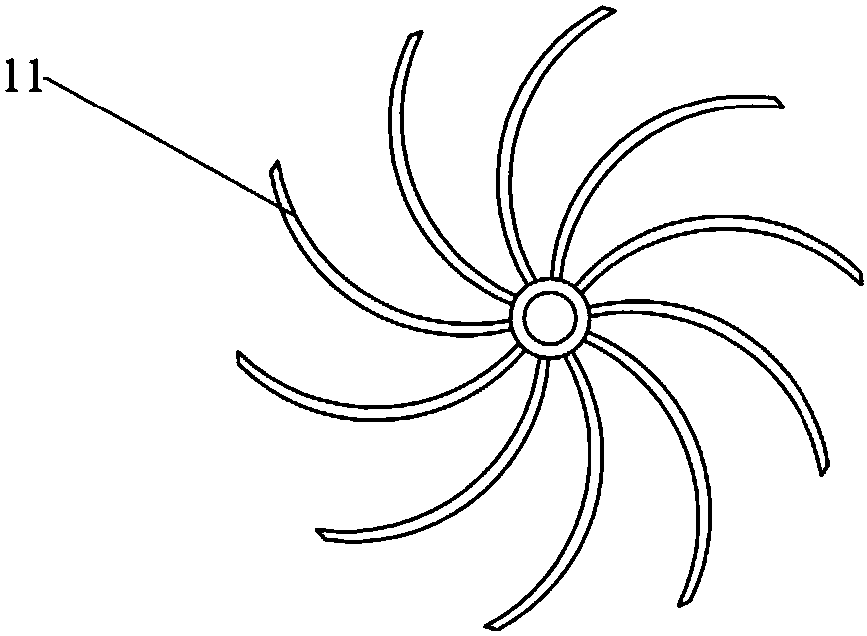

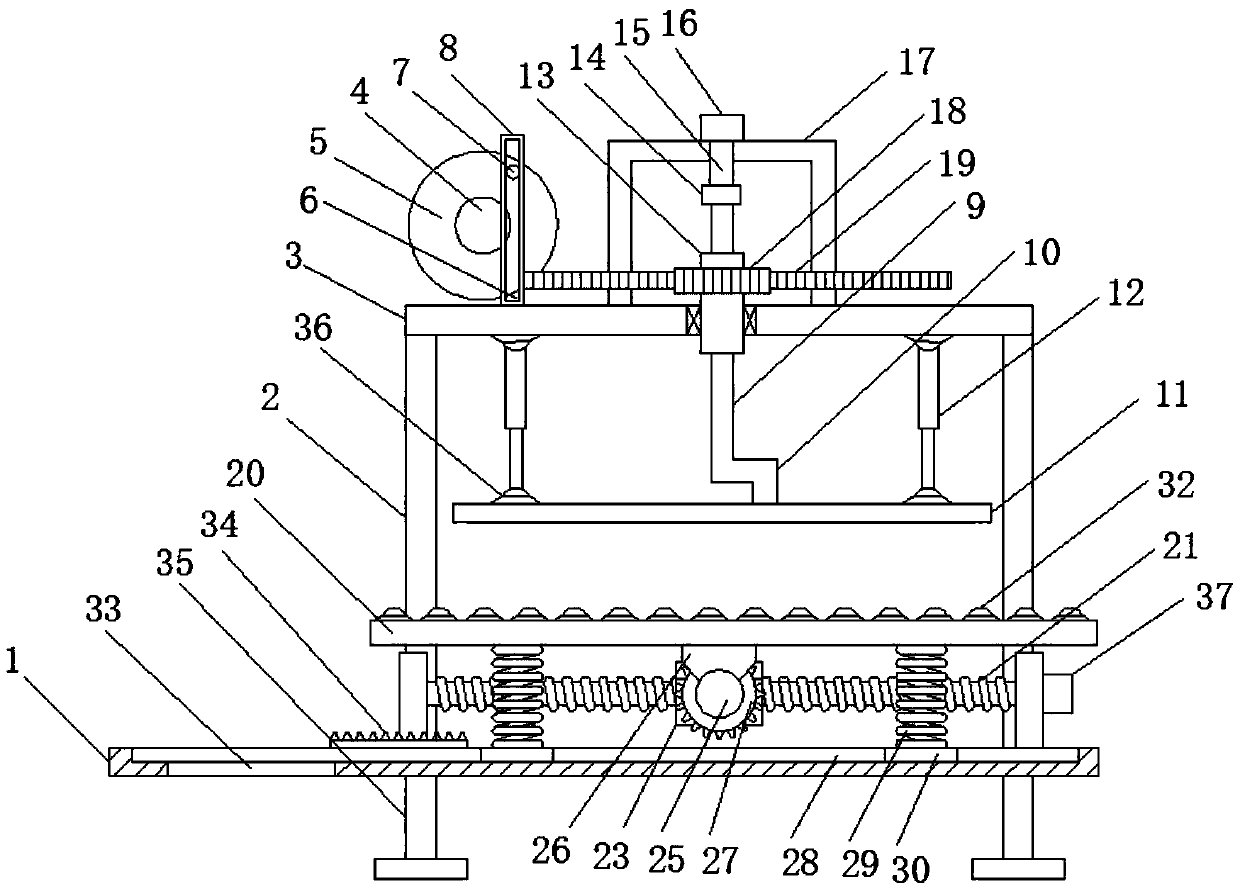

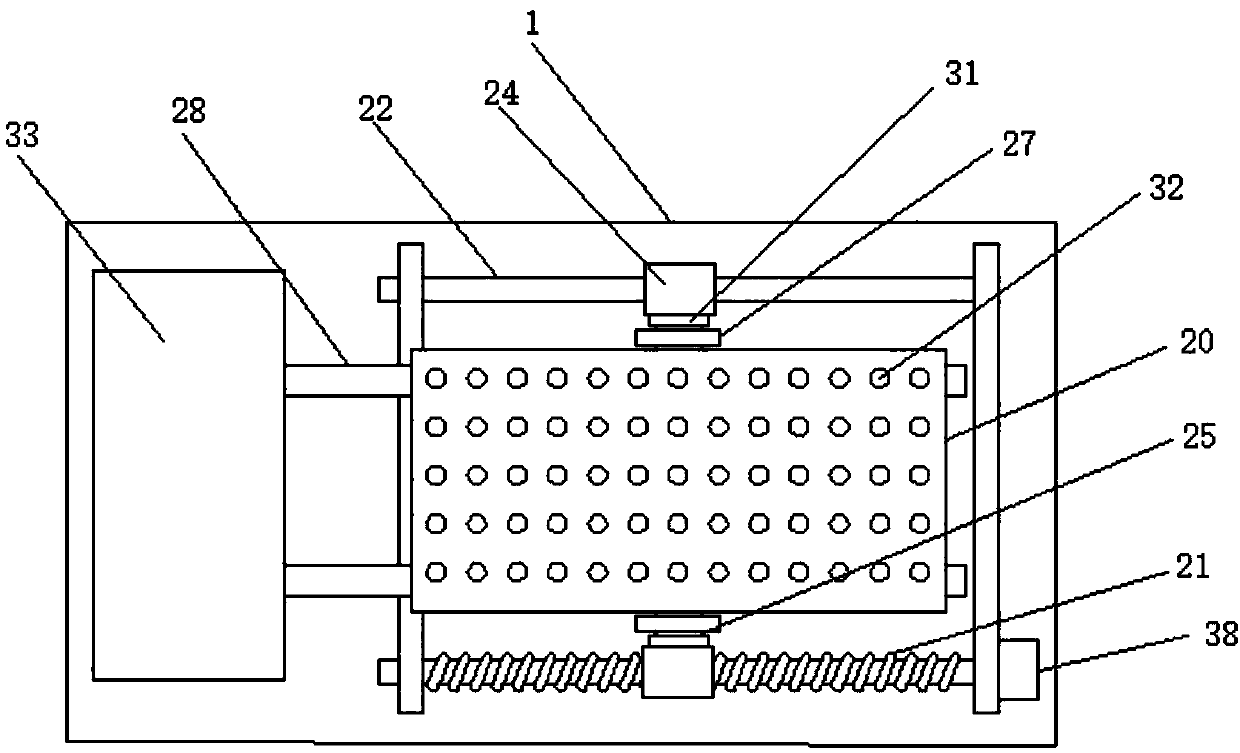

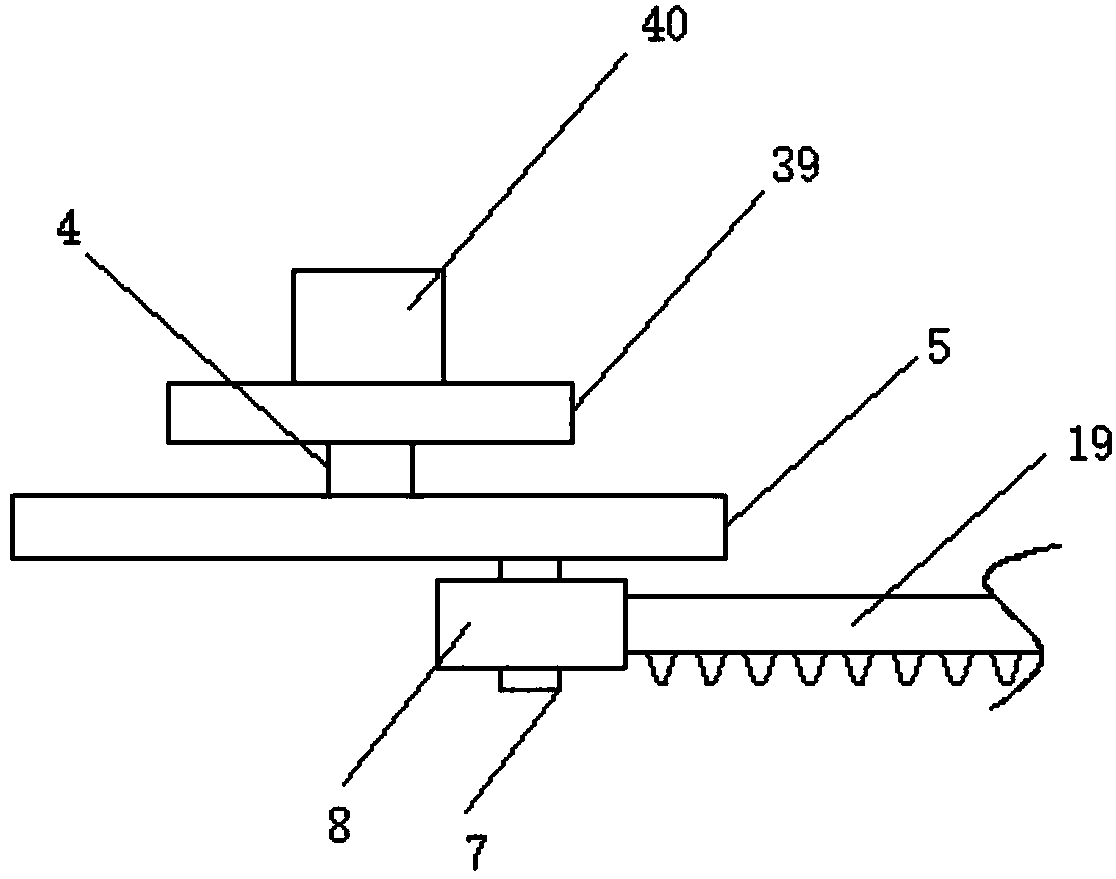

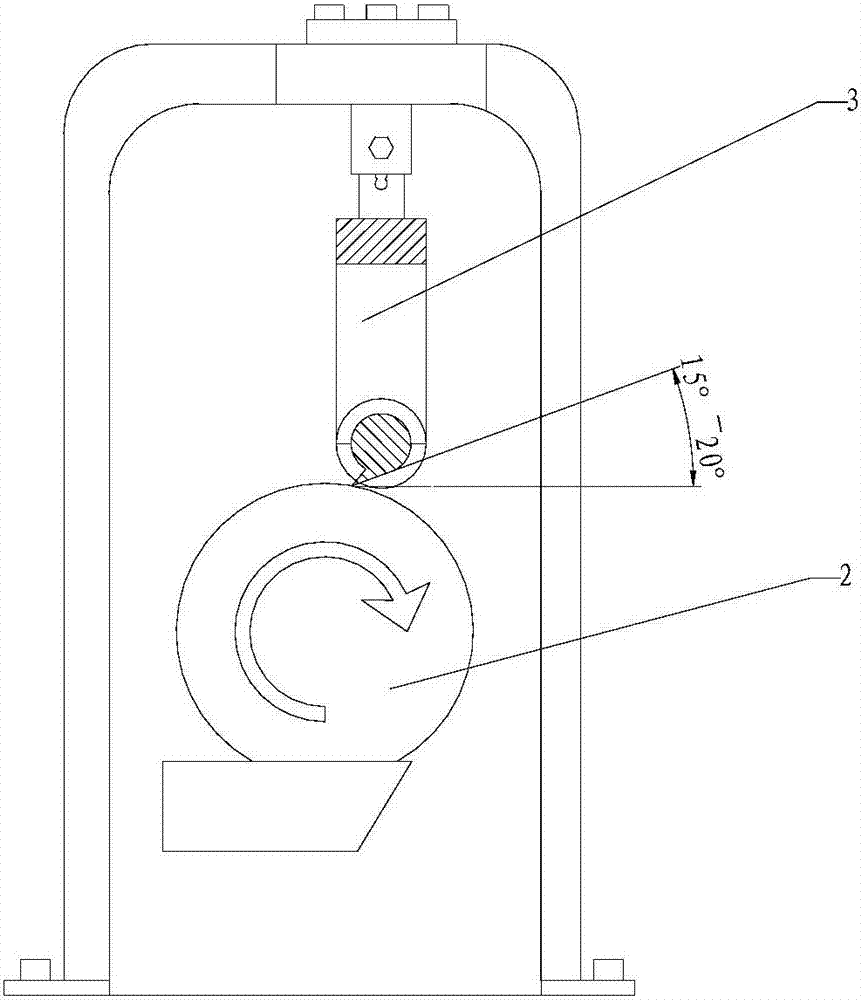

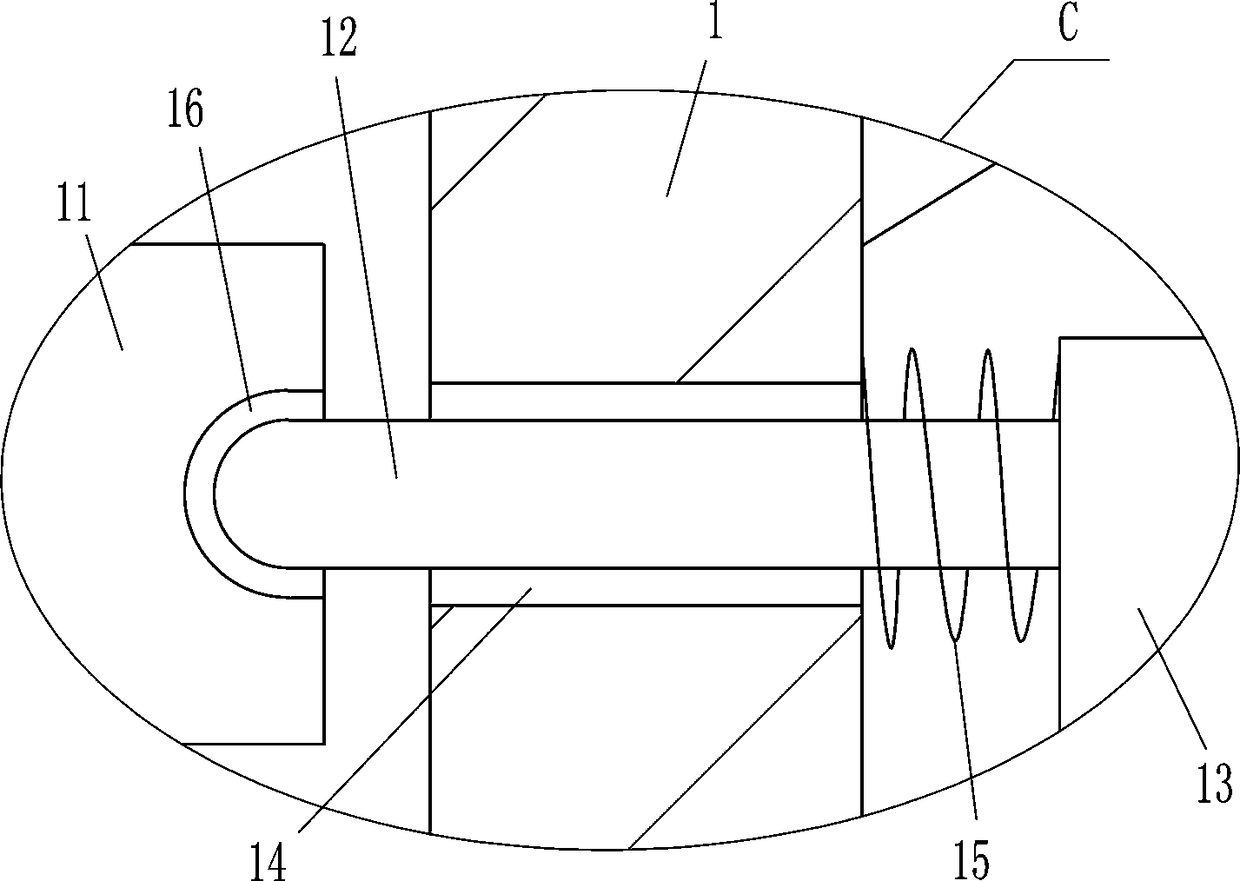

Efficient kneading device for traditional Chinese medicine processing

ActiveCN107694676AImprove kneading effectSimple structureGrain treatmentsEngineeringChinese herbology

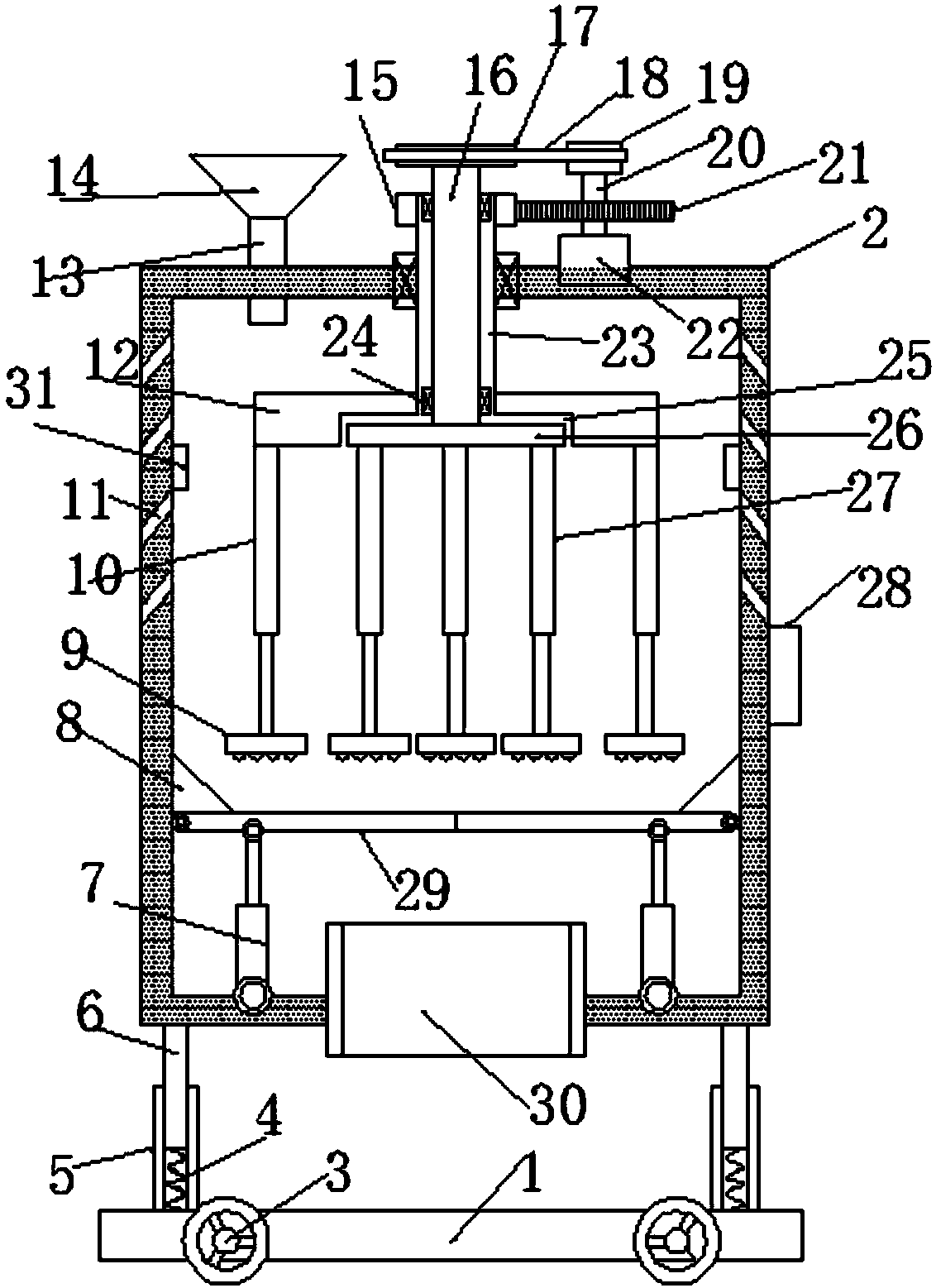

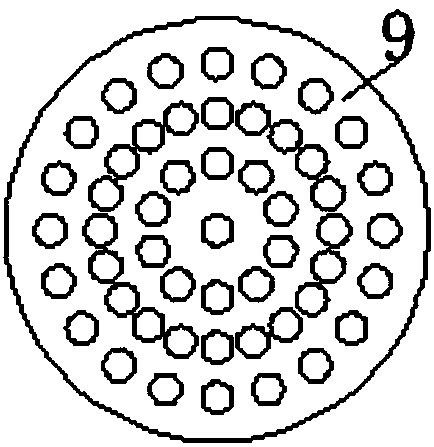

The invention discloses an efficient kneading device for traditional Chinese medicine processing. The efficient kneading device comprises a base and a processing box, wherein roller wheels convenientfor carrying are arranged at the left side and the right side of the base; the processing box is arranged above the base; supporting rods are symmetrically arranged at the two sides of the lower end of the processing box; the lower ends of the supporting rods are sleeved by supporting sleeves in a sliding mode; the lower ends of the supporting sleeves are connected and fixed with the base; dampingsprings are arranged inside the supporting sleeves; the supporting sleeves are connected and fixed with the supporting rods through the damping springs, and this buffer mechanism is beneficial for improving anti-seismic property of the device; an unloading tube is arranged at the left upper side of the processing box; and an unloading hopper is arranged at the upper end of the unloading tube. Theefficient kneading device is simple and reasonable in structure, is convenient to carry, and is good in buffer performance; and a pushing rod motor I and a pushing rod motor II drive a kneading plateto move up and down, so that the materials are kneaded, and the materials are reversed for being kneaded, and therefore, the kneading effect of the materials is further improved, and the practicability is high.

Owner:江苏惠淳农业科技发展有限公司

Preparation method of high-quality prebaked anode for 500KA electrolytic cell

The invention relates to a preparation method of a high-quality prebaked anode for a 500KA electrolytic cell. The method comprises the following steps of: (1) storing petroleum coke at different storage locations according to different producing areas; (2) crushing the petroleum coke blocks having the granularity greater than 200mm with a sledge hammer, sieving the petroleum coke blocks with the granularity less than 200mm, delivering the petroleum coke with the granularity less than 70mm into a petroleum coke conveyer belt, recrushing the petroleum coke with the granularity greater than 70mm so as to deliver the petroleum coke with the granularity less than 70mm into the petroleum coke conveyer belt; (3) feeding different petroleum cokes into a specified blending cabin, wherein the petroleum coke of one producing area is placed in each of the four blending cabins, and a belt weigher is arranged at the bottom of each blending cabin; (4) preparing calcined coke; (5) preparing rough coke, middle coke, fine coke and powdery coke; (6) preparing boiler-out thickeners; (7) preparing cooled thickeners; (8) preparing green bodies; (9) feeding the green bodies into a stacking storeroom for stacking; and (10) roasting the green bodies to obtain a prebaked anode. By using the preparation method, the electrolysis preparation requirement can be met, and safe and sable operation of the electrolytic cell is ensured.

Owner:嘉峪关索通预焙阳极有限公司

Method for improving rheological property of coal pitch and increasing coking value of coal pitch and modifier thereof

InactiveCN101812235AWide variety of sourcesNo toxicityBituminous material adhesivesBuilding insulationsFlue gasGranularity

The invention relates to a method for improving rheological property of coal pitch and increasing a coking value of coal pitch and a modifier thereof. The method achieves the purpose of improving the rheological property of pitch at the kneading temperature of 160 to 180 DEG C under the premise of ensuring the high-temperature coking value of the pitch by adding the multicomponent modifier into molten pitch under the premise of the existing preparation technique of carbon anode for aluminium. The modifier consists of oleic acid or dibutyl phthalate and ultrafine graphite powder or carbon powder with the granularity of not more than 40mum. The introduction of the multicomponent modifier can enhance the reactivity of anode impedance air and CO2, can reduce the mixing quantity of pitch in the kneading procedure properly and achieve the purpose of improving the anode quality and reducing the flue gas emission of the pitch.

Owner:CENT SOUTH UNIV

Processing technology of black tea by utilizing bacterial strain fermentation

InactiveCN107467234AAccelerated destructionUniform qualityPre-extraction tea treatmentFlavorBlack tea

The invention provides a processing technology of black tea by utilizing bacterial strain fermentation, and relates to the technical field of tea processing. The processing technology of the black tea by utilizing bacterial strain fermentation comprises the following steps of withering fresh tea leaves until the water content reaches 55-65% so as to obtain withered tea leaves; freezing the withered tea leaves at 50-30 DEG C below zero for 2.5-4 hours, taking the frozen tea leaves out, sprinkling a mixed enzyme solution onto the tea leaves, carrying out standing for 20-40 minutes, and carrying out rolling until 75-85% of cells are broken so as to obtain rolled tea leaves; and then, sprinkling a fermentation solution onto the rolled tea leaves, carrying out fermentation at 30-55 DEG C for 6-12 hours so as to obtain fermented tea leaves, wherein the fermentation solution is a mixture of aspergillus oryzae fermentation broth and bacillus subtilis fermentation broth, and drying the fermented tea leaves. By performing bacterial strain fermentation treatment on the tea leaves by utilizing the aspergillus oryzae and the bacillus subtilis, nutrients in the tea leaves can be effectively decomposed by fermentation; moreover, the prepared black tea has a unique flavor.

Owner:青田峰之润茶业有限公司

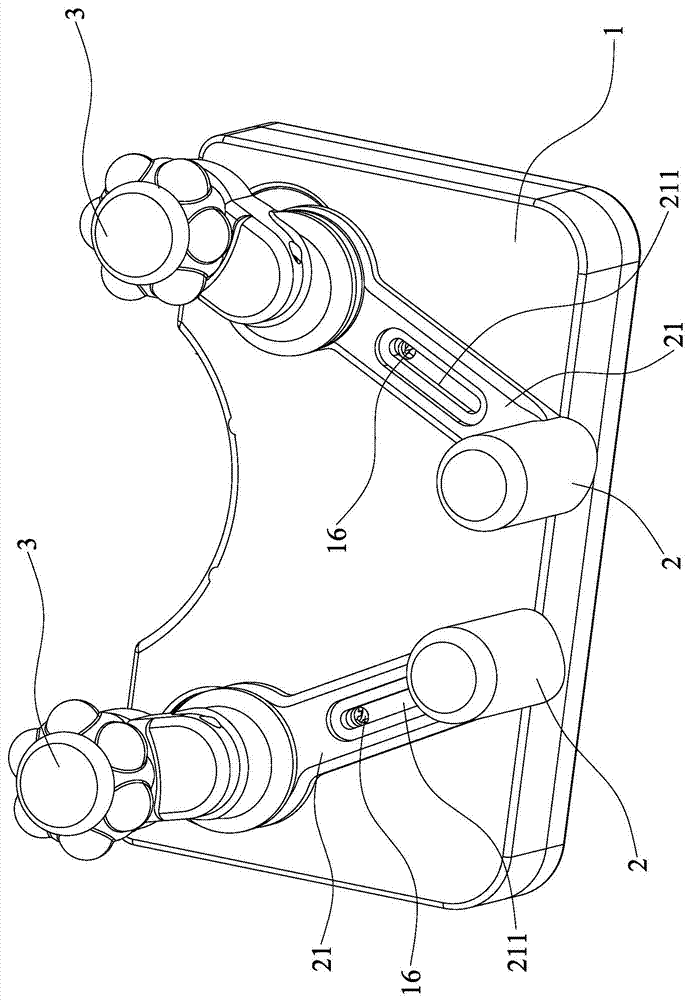

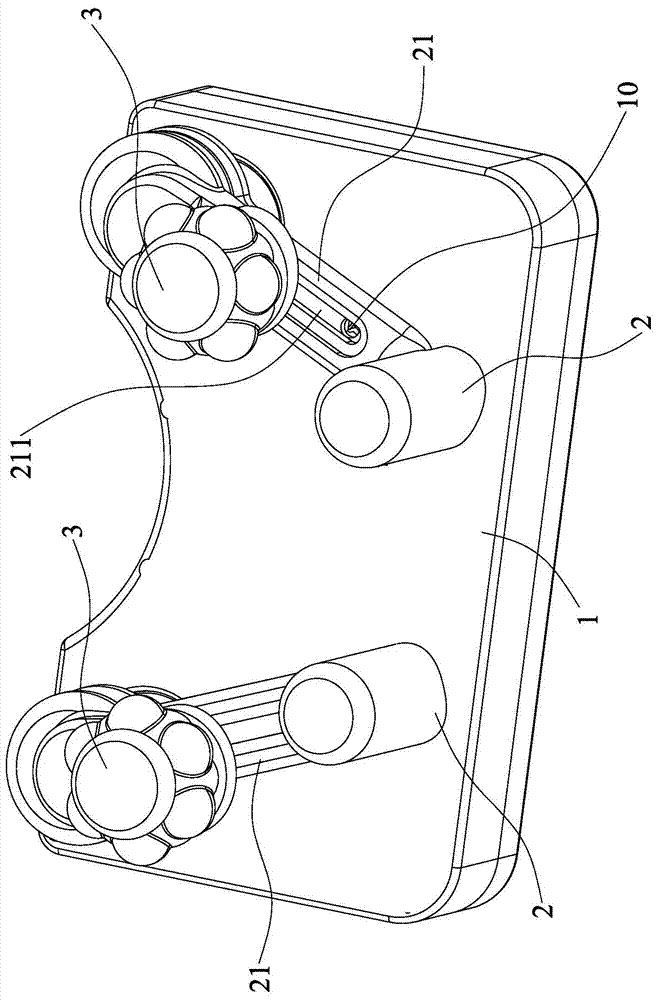

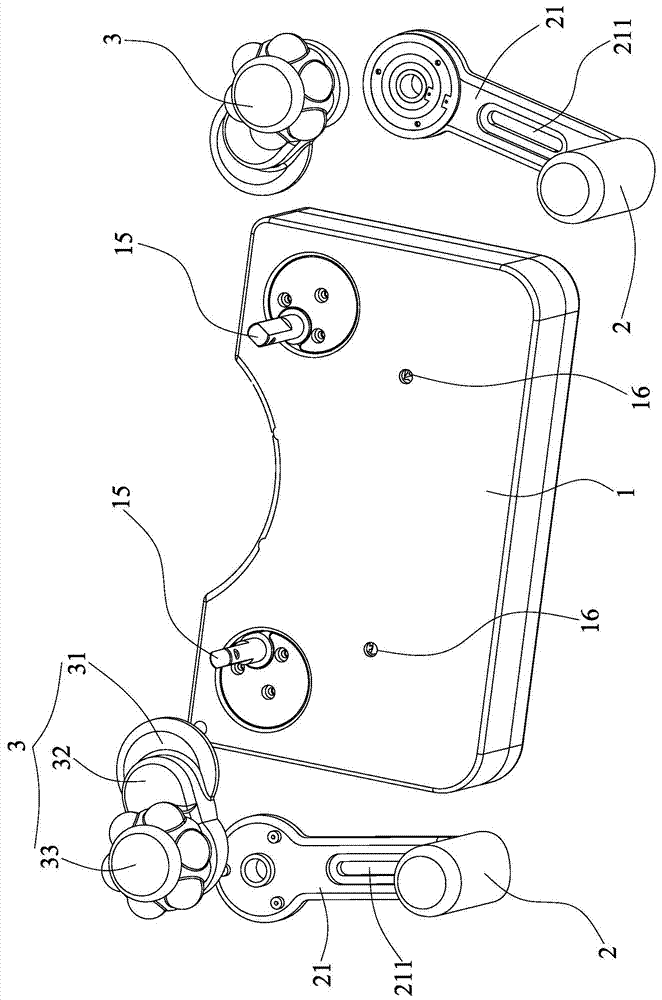

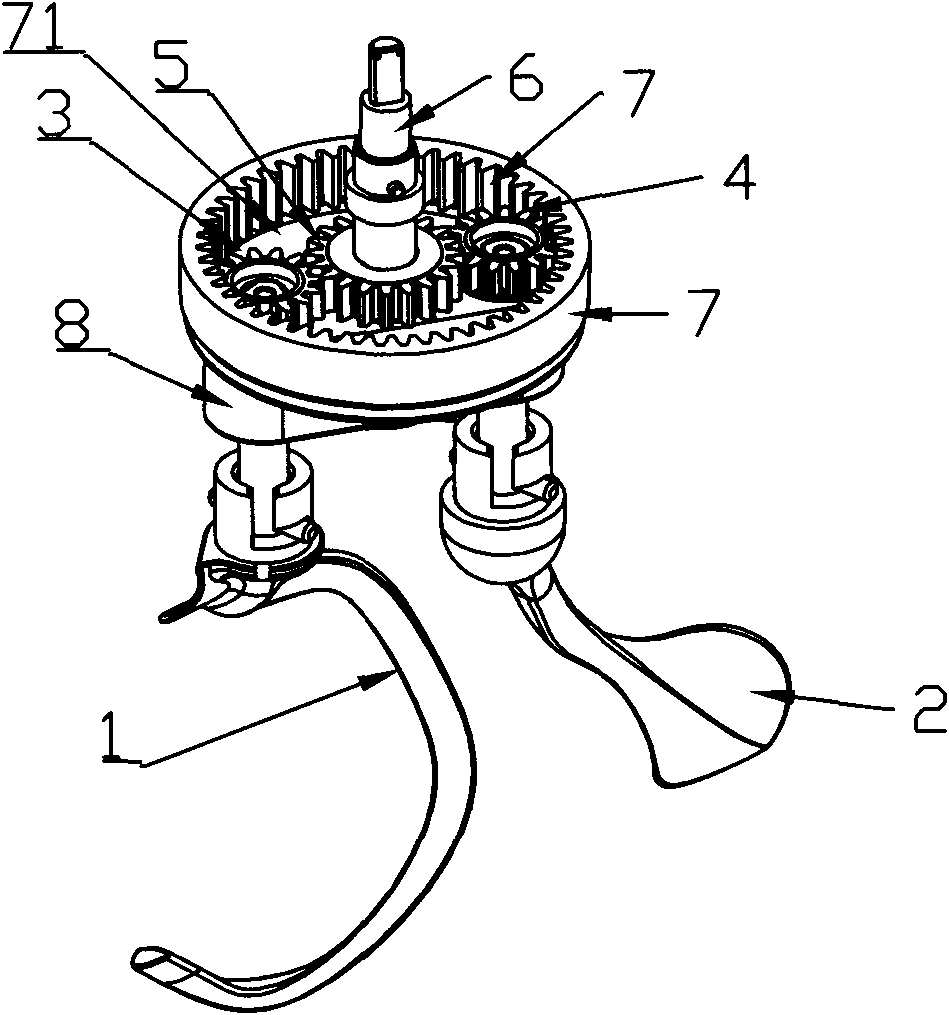

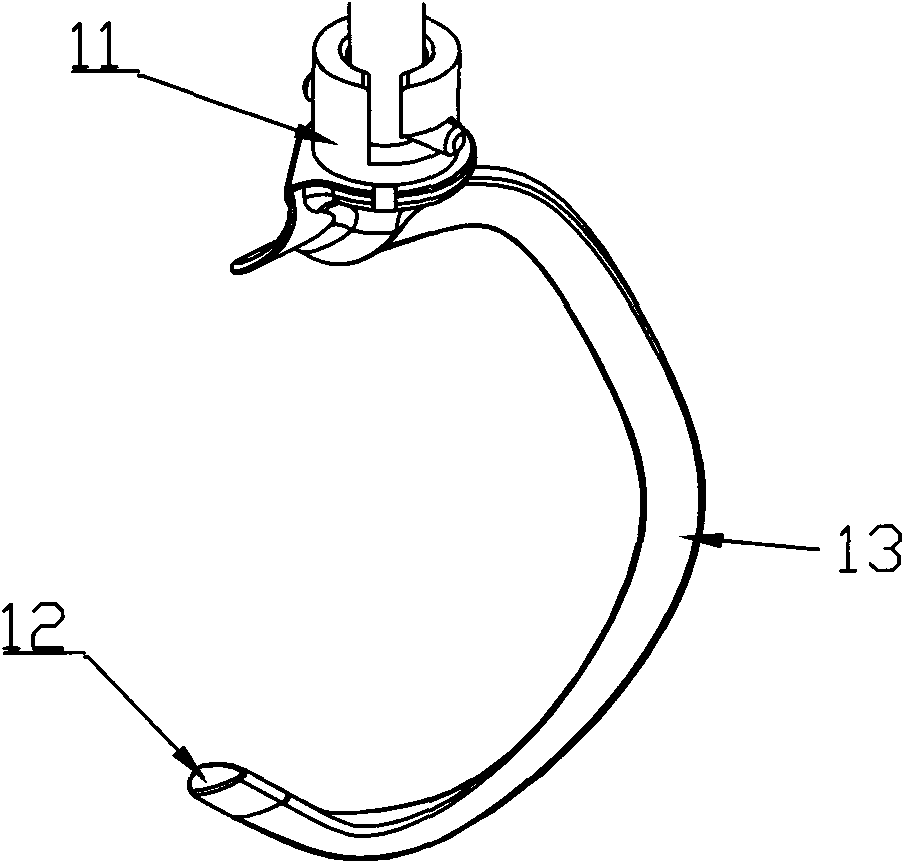

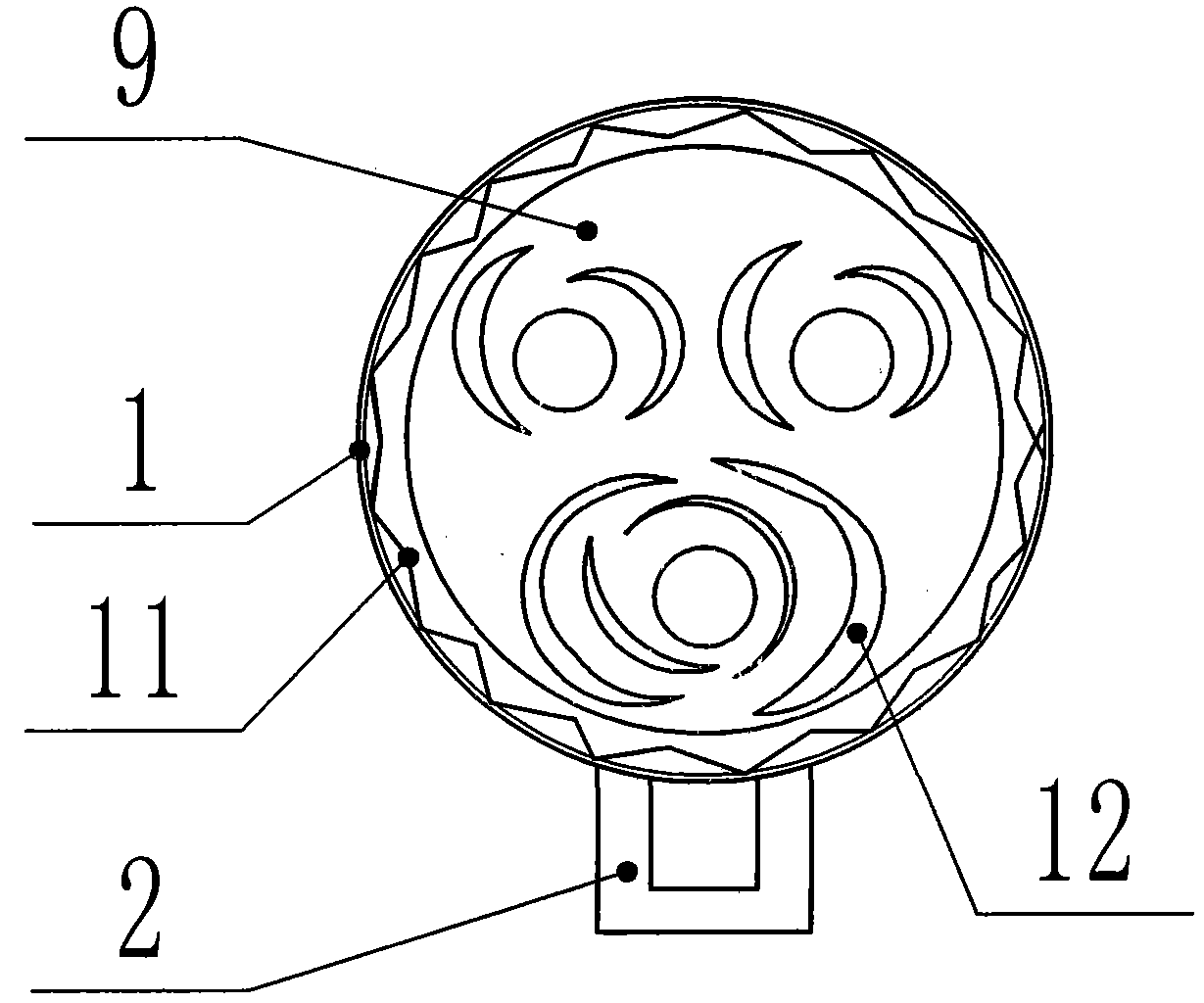

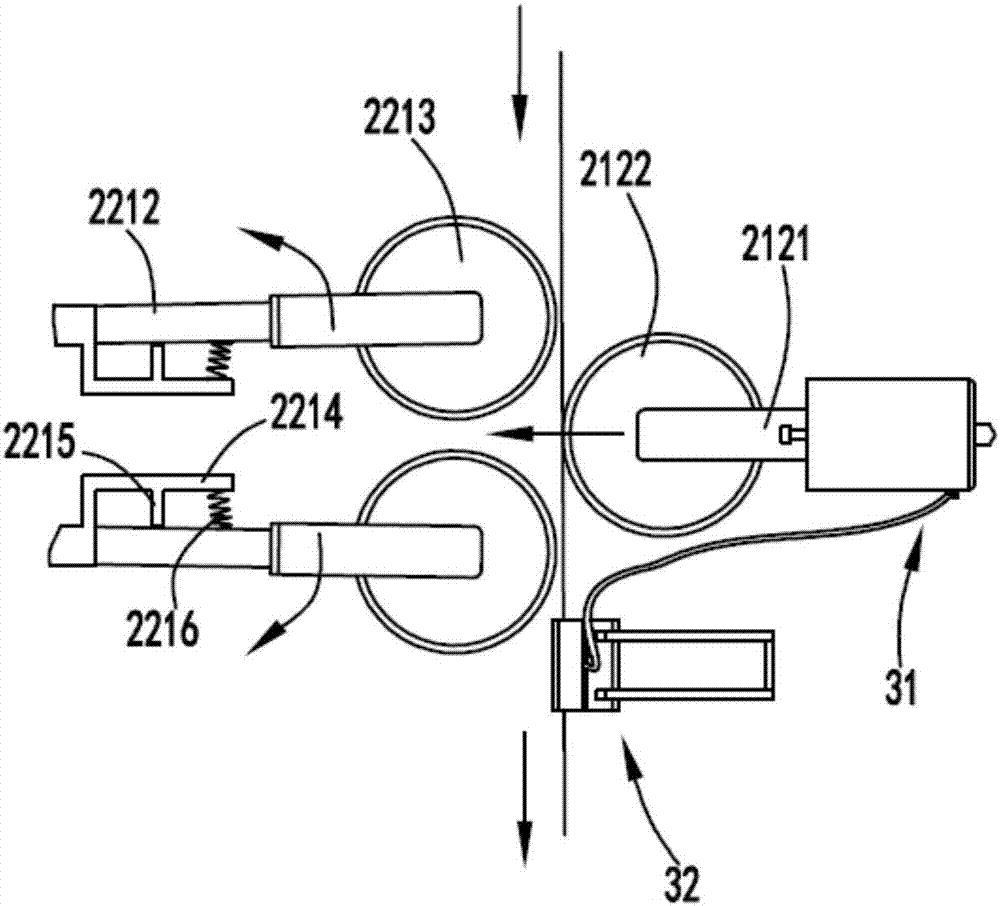

Shoulder massaging machine core

PendingCN107397663AAchieving a kneading effectIncrease the kneading strokeSuction-kneading massagePhysical medicine and rehabilitationGear wheel

The invention discloses a shoulder massaging machine core, which comprises two groups of massaging head groups which are arranged on a machine core main body; each massaging head group comprises a first massaging head and a second massaging head; a motor is arranged in the machine core main body; worm wheels at two ends are driven by virtue of a worm on the motor; each worm wheel is in transmission with one kneading gear; an eccentric shaft is arranged on each kneading gear; each first massaging head is arranged at the tail end of a corresponding connecting arm, and the other end of the connecting arm sleeves the eccentric shaft; a strip-shaped sliding groove, which is limited in a limiting nail on the machine core main body, is formed in each connecting arm; the first massaging heads, under the action of the eccentric shafts, can drive the connecting arms to rotate and the first massaging heads, which are limited by the limiting nails, can do compound motions of longitudinal swinging and back-and-forth moving; the second massaging heads are fixed to the eccentric shafts; and the second massaging heads are rotated around the kneading gears when the kneading gears rotate. With the application of the shoulder massaging machine core provided by the invention, shoulder massaging and kneading can be simultaneously implemented; and a massaging area and a kneading travel can be increased, so that shoulders, which are pressed, can feel more comfortable.

Owner:XIAMEN COMFIER TECH CO LTD

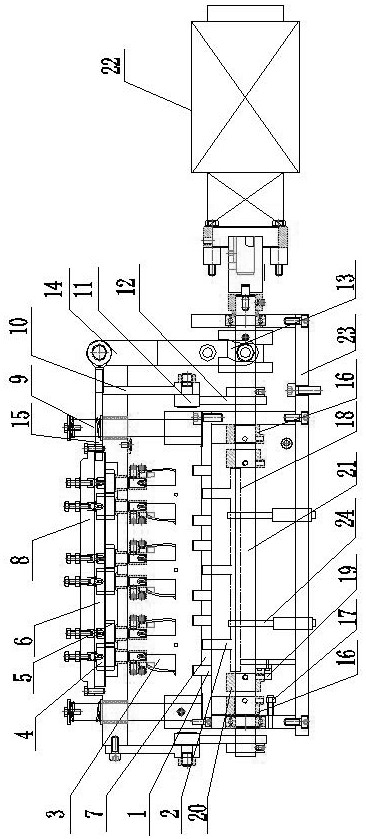

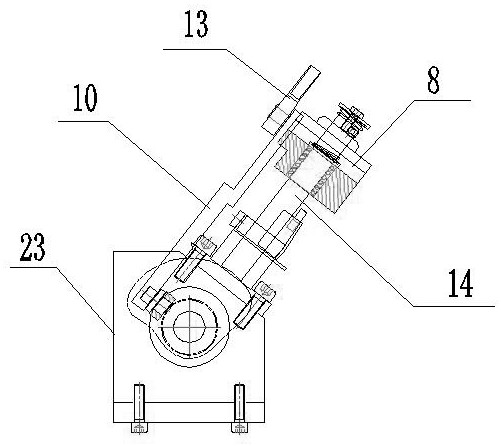

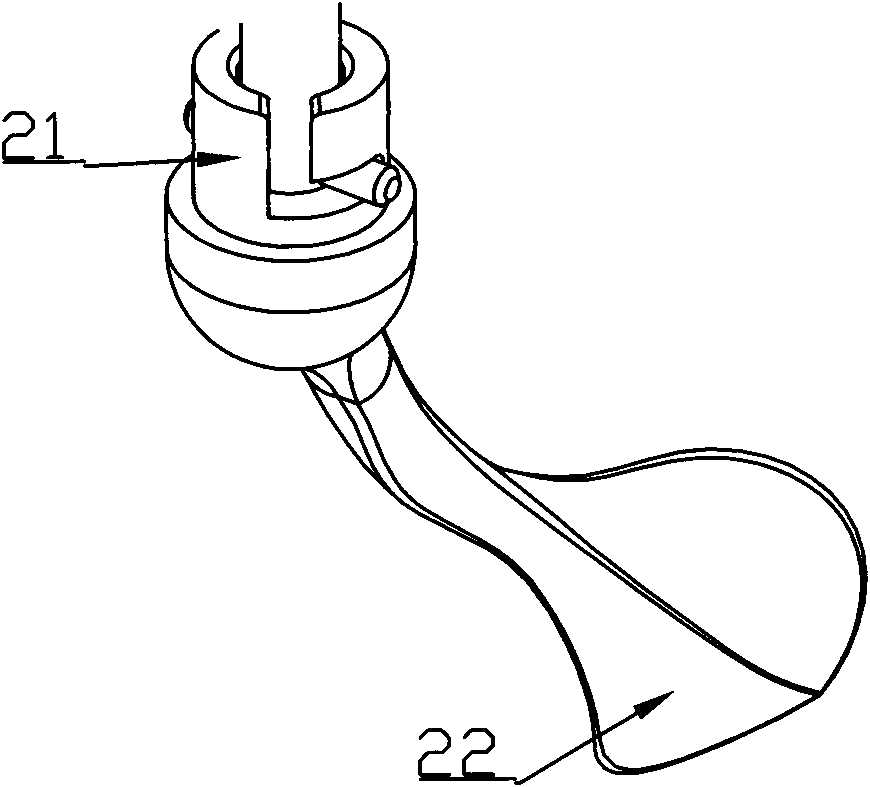

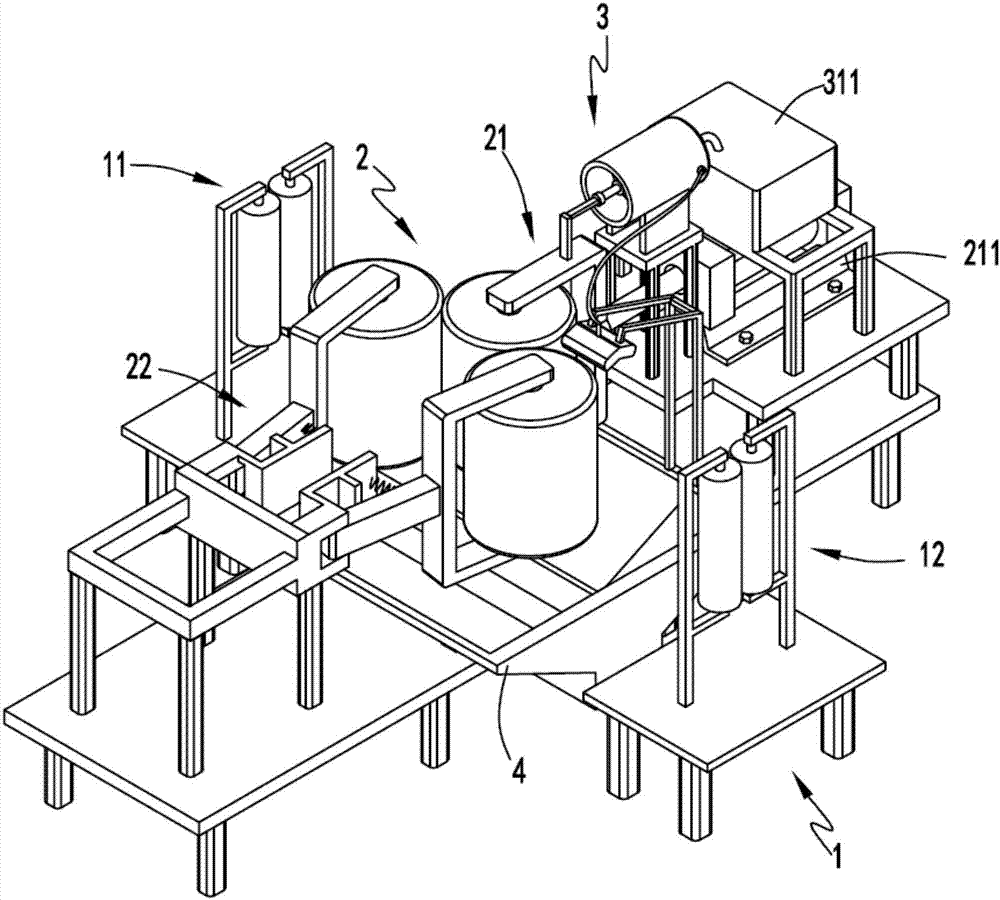

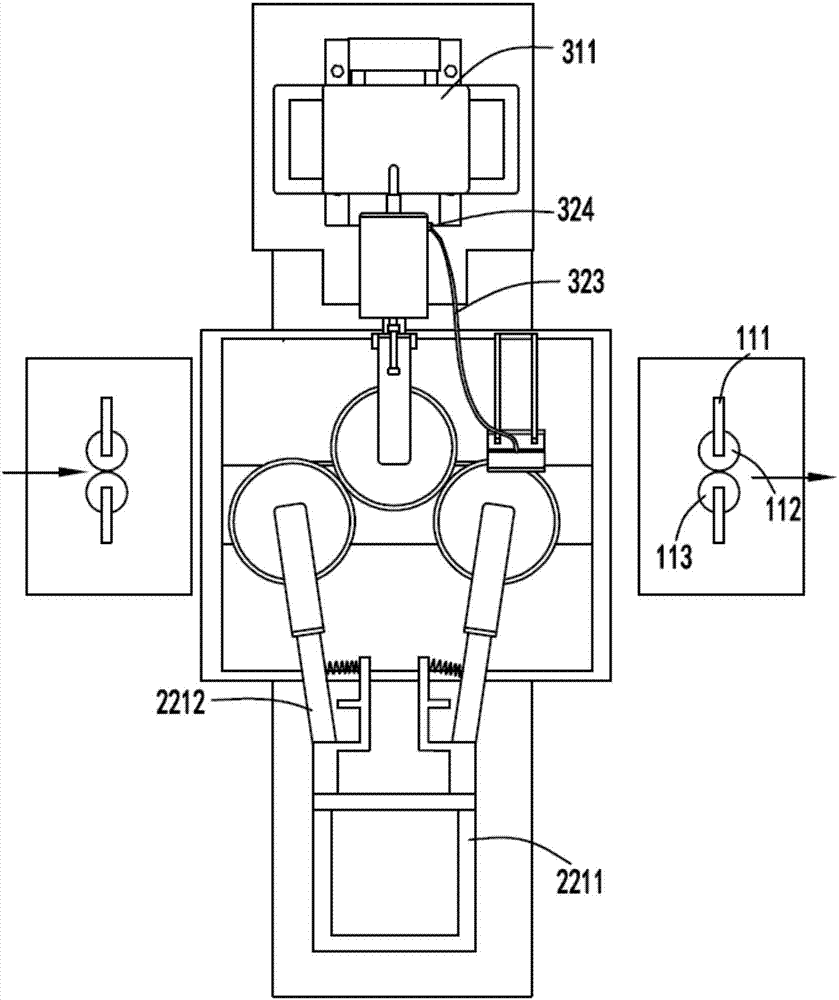

Wonton forming device

PendingCN111820256ARealize kneading automationRealize full automation of productionDough processingStructural engineeringIngot

The present invention relates to a wonton forming device including a locating frame plate, a forming supporting plate and a forming claw; the forming supporting plate is used for placing a wonton dough sheet, is disposed at the rear side of the locating frame plate capable of moving up and down and is matched with the locating frame plate to fix the wonton dough sheet; the forming claw is disposedabove the locating frame plate and the forming supporting plate and is capable of moving up and down to knead the wonton dough sheet fixed by the locating frame plate and the forming supporting plate; and all the locating frame plate, the forming supporting plate and the forming claw are coaxially driven and connected by a power mechanism. The wonton forming device provided by the present invention does not need to be manually operated so that the making efficiency of wontons shaped like shoe-shaped gold ingots is greatly increased; the wonton forming device is suitable for large-scale mass production of the wontons shaped like shoe-shaped gold ingots, the sizes and shapes of the wontons shaped like shoe-shaped gold ingots, which are industrially produced on a large scale, are very consistent, the manpower and time consumption may be greatly reduced, production processes of the wontons may be simplified, so that the cost of the wontons is reduced, and the yield of the wontons is increased.

Owner:CHANGYHI KAIXING MECHANICAL MFG CO LTD +1

Dough kneading hook structure

ActiveCN102973171ABalance vibrationIncrease contactKitchen equipmentEngineeringMechanical engineering

The invention relates to an automatic dough kneading machine, in particular to a dough kneading hook structure of the automatic dough kneading machine. The dough kneading hook structure comprises a first dough kneading hook. The top of the first dough kneading hook is installed on a first drive structure. The dough kneading hook structure further comprises a second dough kneading hook. A second drive structure is connected with the top of the second dough kneading hook. According to the dough kneading hook structure, the second dough kneading hook is additionally arranged based on the original first dough kneading hook, contact of a dough with the dough kneading hooks is enhanced in the stirring process, and dough kneading effect is improved. In addition, after the second dough kneading hook is added, vibration generated by rotation of the first dough kneading hook is balanced, the dough kneading machine is more stable in the working process, noise generated by the vibration is reduced, and product working stability is improved.

Owner:SHENZHEN MUREN APPLIANCE

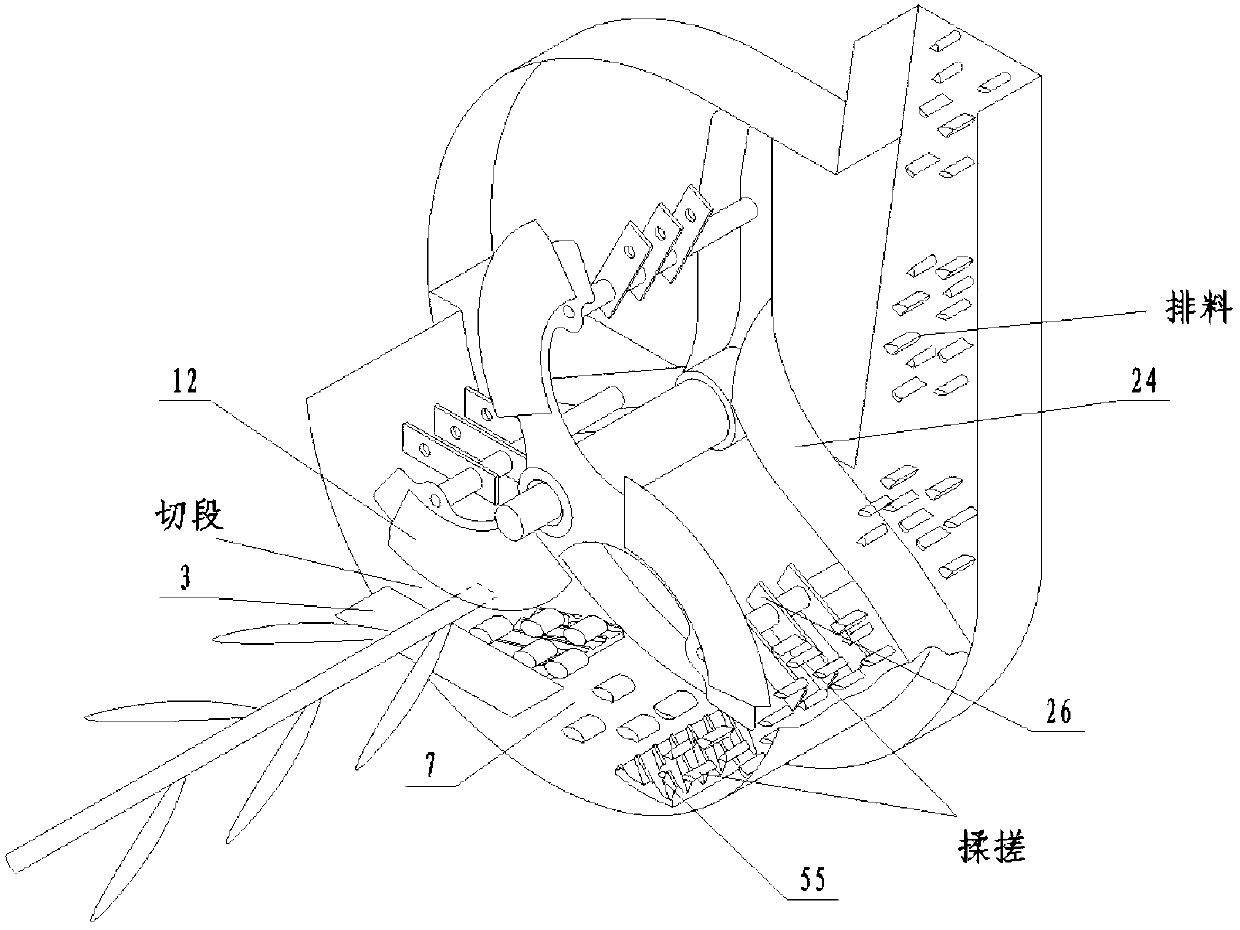

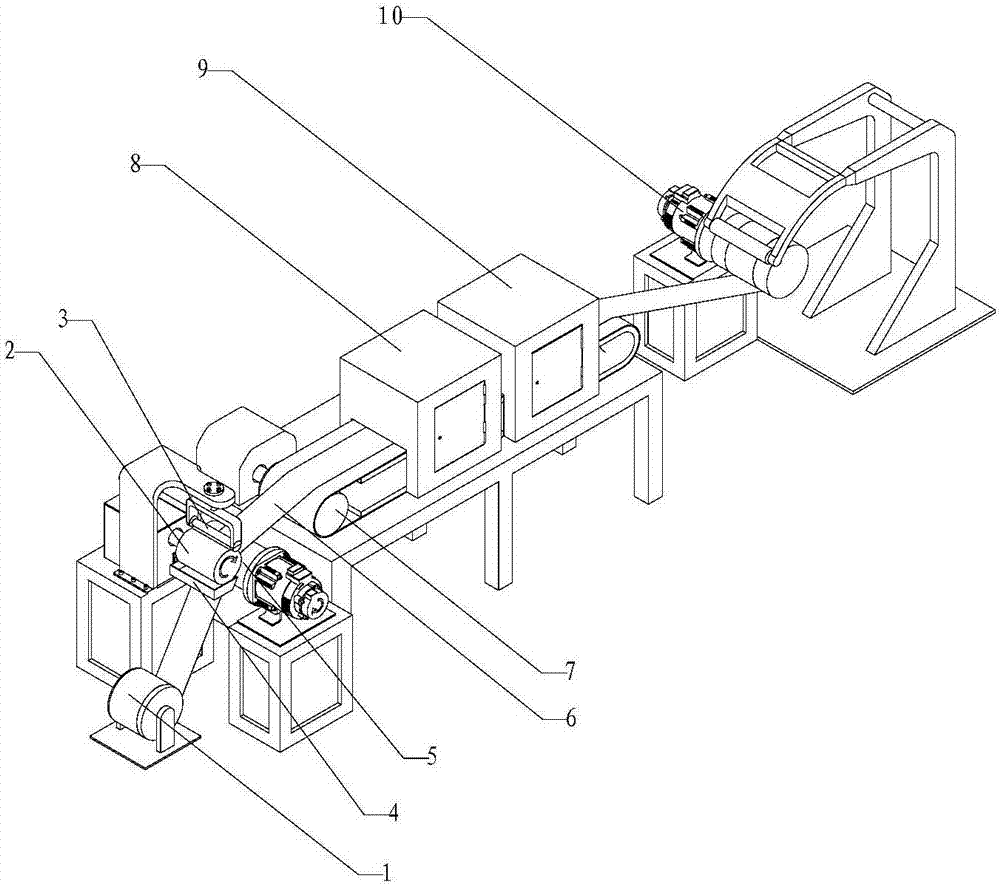

Method and machine for cutting and rubbing forage grass

InactiveCN103125219AEasy to use electricityIncrease the rate of broken stem nodesFeeding-stuffCrop conditionersLivestock breedingEngineering

The invention relates to the field of agricultural machinery, in particular to a method and a machine for cutting and rubbing forage grass used for ensiling and machining of the livestock breeding industry. The machine for cutting and rubbing the forage grass is composed of a rack (19), a gearbox (16), an automatic feeding device (6), a cutting and rubbing chamber (7), a thrower shell (11) and a discharge port (9). The machine can be used for cutting or rubbing operation on all kinds of dry (fresh) forage grass, crop straw and the like. When feed blocking happens in the operating process, a first operating arm (33) on the gearbox (16) is placed into a neutral gear, a second operating arm (31) is placed into a reverse gear, then automatic feed returning can be achieved, and the accident is removed. The machine is easy to operate and high in safety. In the rubbing operation, the breaking ratio of stem joints of materials is promoted, the rubbing effect is good, the rubbed forage grass is convenient to eat for animals, and the ingestion ratio is promoted.

Owner:CHINA AGRI UNIV

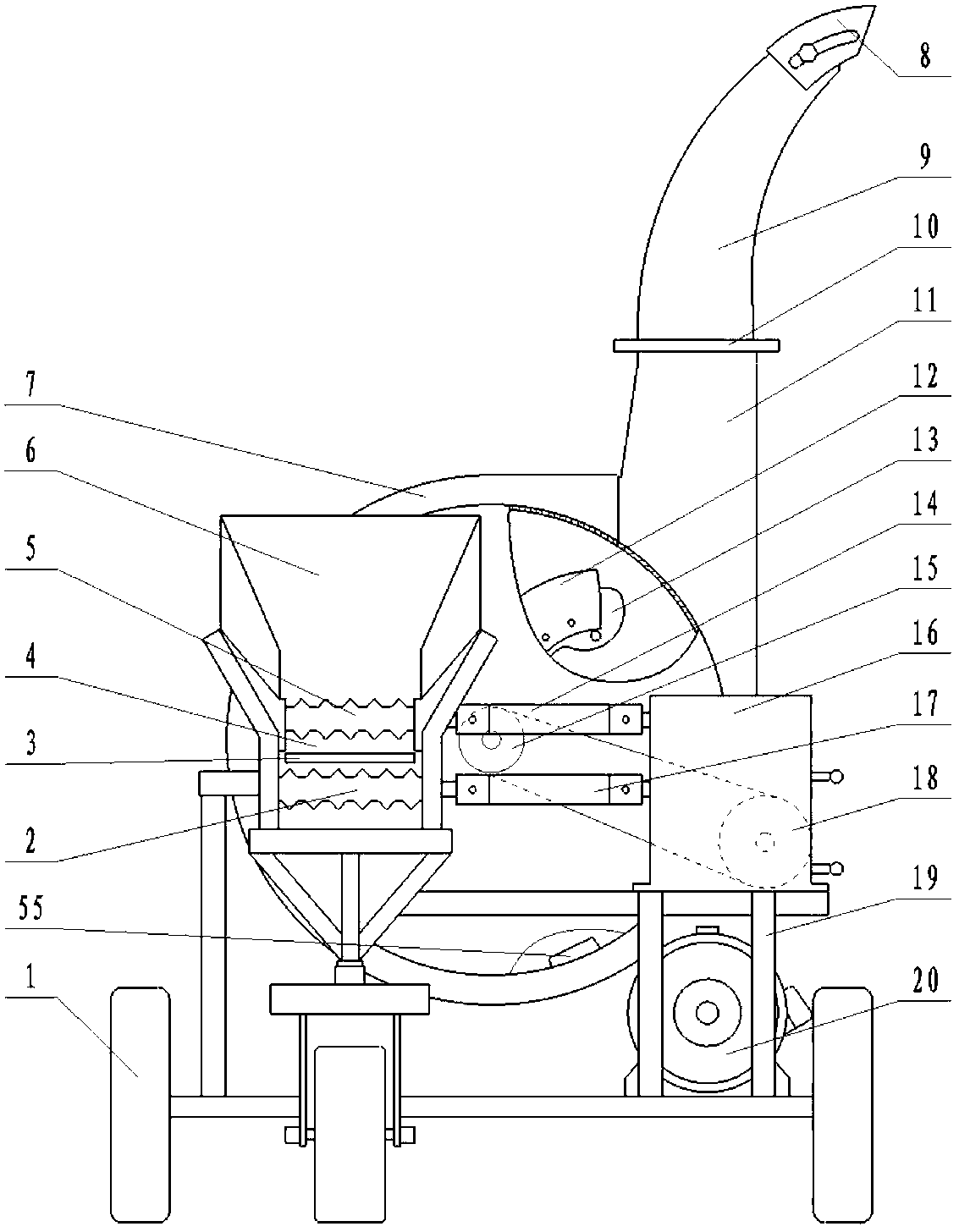

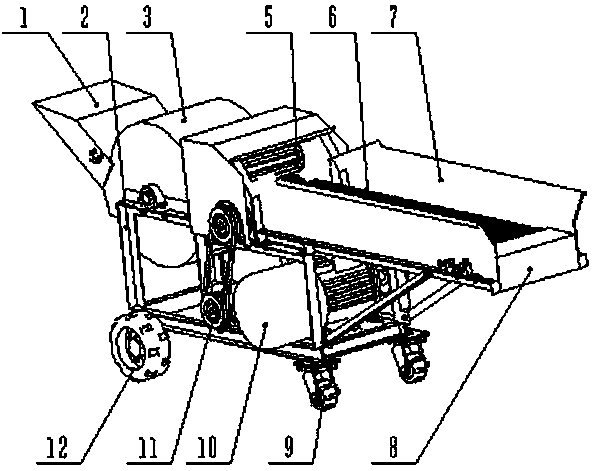

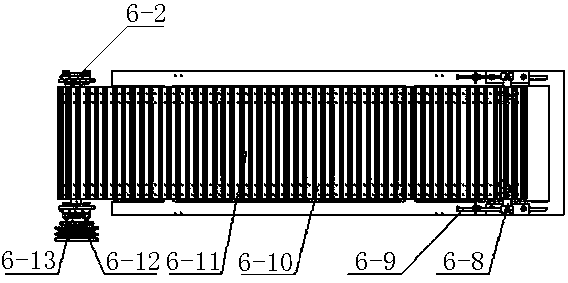

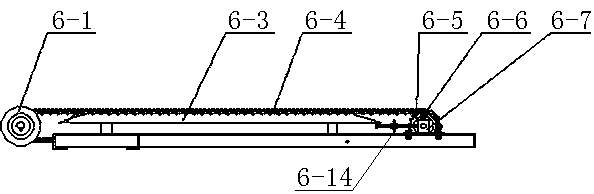

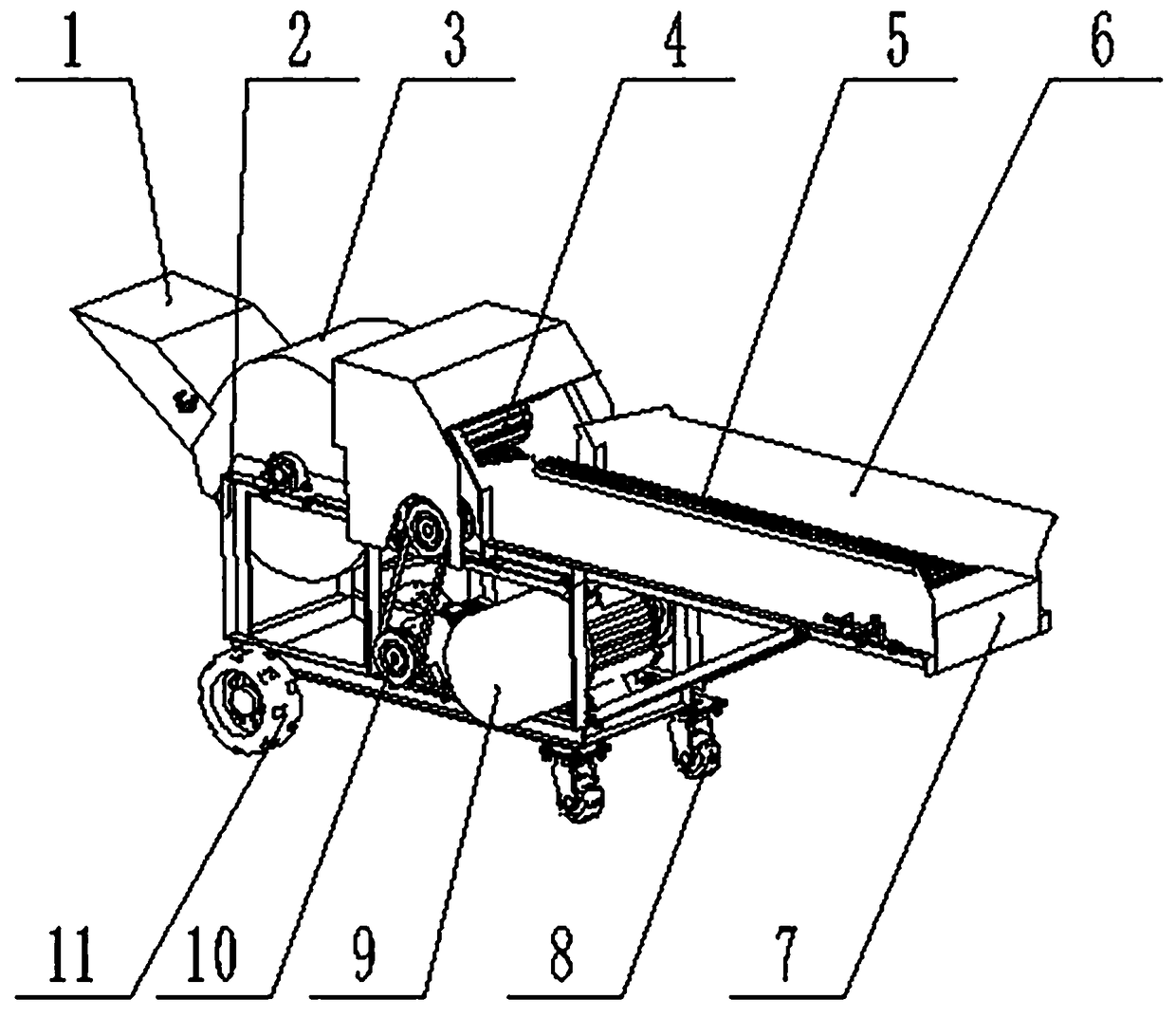

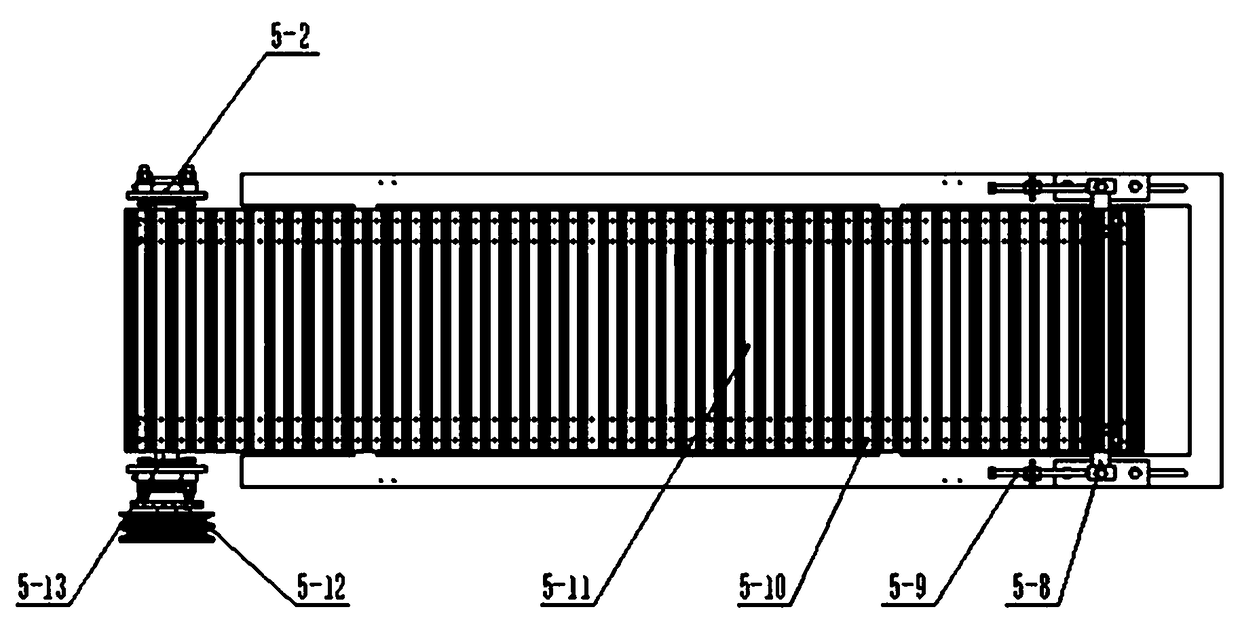

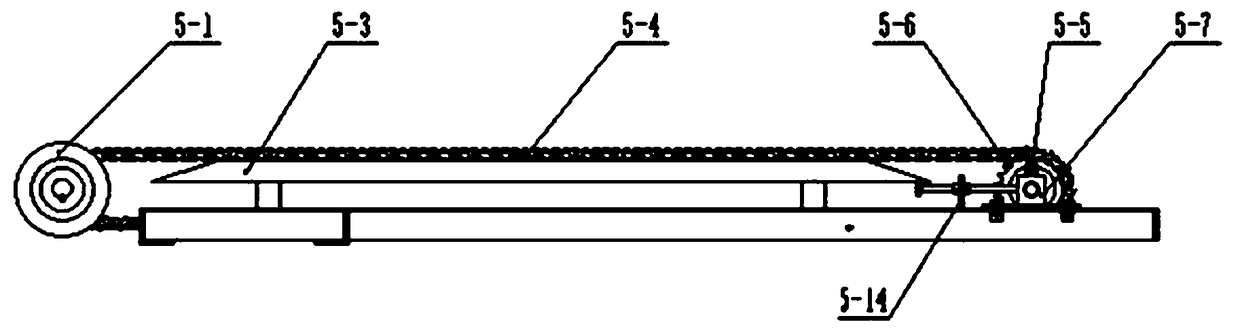

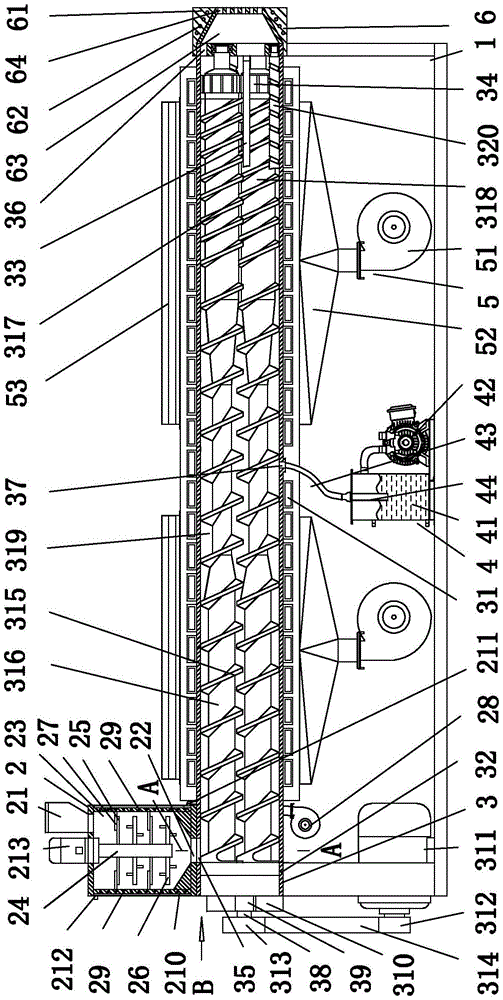

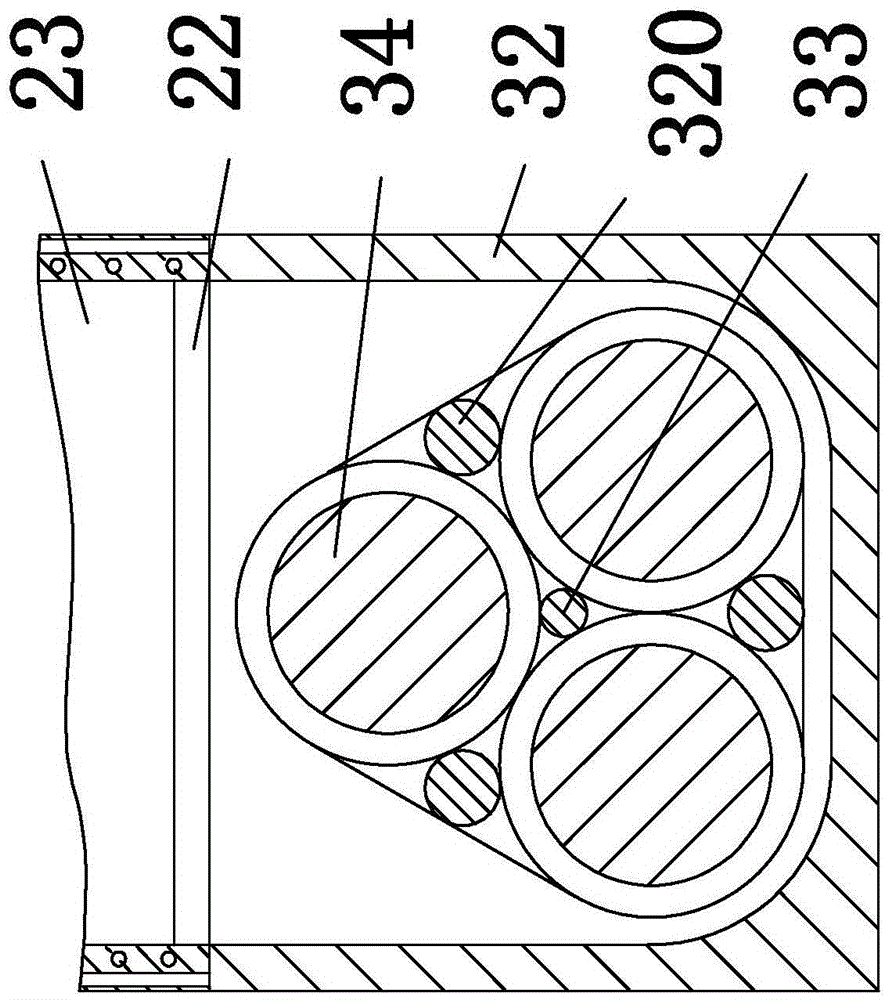

Silage feed fine strip kneading machine

PendingCN108450983AImprove kneading effectPromote digestion and absorptionFeeding-stuffCuttersAfter treatmentEngineering

The invention discloses a silage feed fine strip kneading machine. The silage feed fine strip kneading machine comprises a machine frame, wherein a conveying device, a feeding device, a crushing device and a power device are arranged on the machine frame; an outlet of the conveying device is connected with an inlet of the feeding device; an outlet of the feeding device is connected with an inlet of the crushing device; the crushing device comprises a crushing supporting frame which is fixed to the machine frame; a main shaft is mounted on the crushing supporting frame; a crushing chamber is arranged under the main shaft; a plurality of toothed plates are fixed to the bottom of the crushing chamber; a plurality of rotor web plates are axially mounted on the main shaft; each of pin shafts isarranged in each rotor web plate; and a plurality of hammer pieces are mounted on each pin shaft in a sleeving manner. According to the silage feed fine strip kneading machine disclosed by the invention, forage is automatically transported to the feeding device through the conveying device; after treatments of extruding, flattening and the like are performed on the forage by the feeding device, the forage is further transported to the crushing device by the feeding device to be subjected to treatments of kneading, crushing and the like, and the kneading effect of the forage is greatly improved; and the forage can be crushed into the fine strip-shaped forage of which the length is 100-250mm, and the fine strip-shaped forage is directly subjected to silage to be eaten by livestock.

Owner:GANSU AGRI UNIV

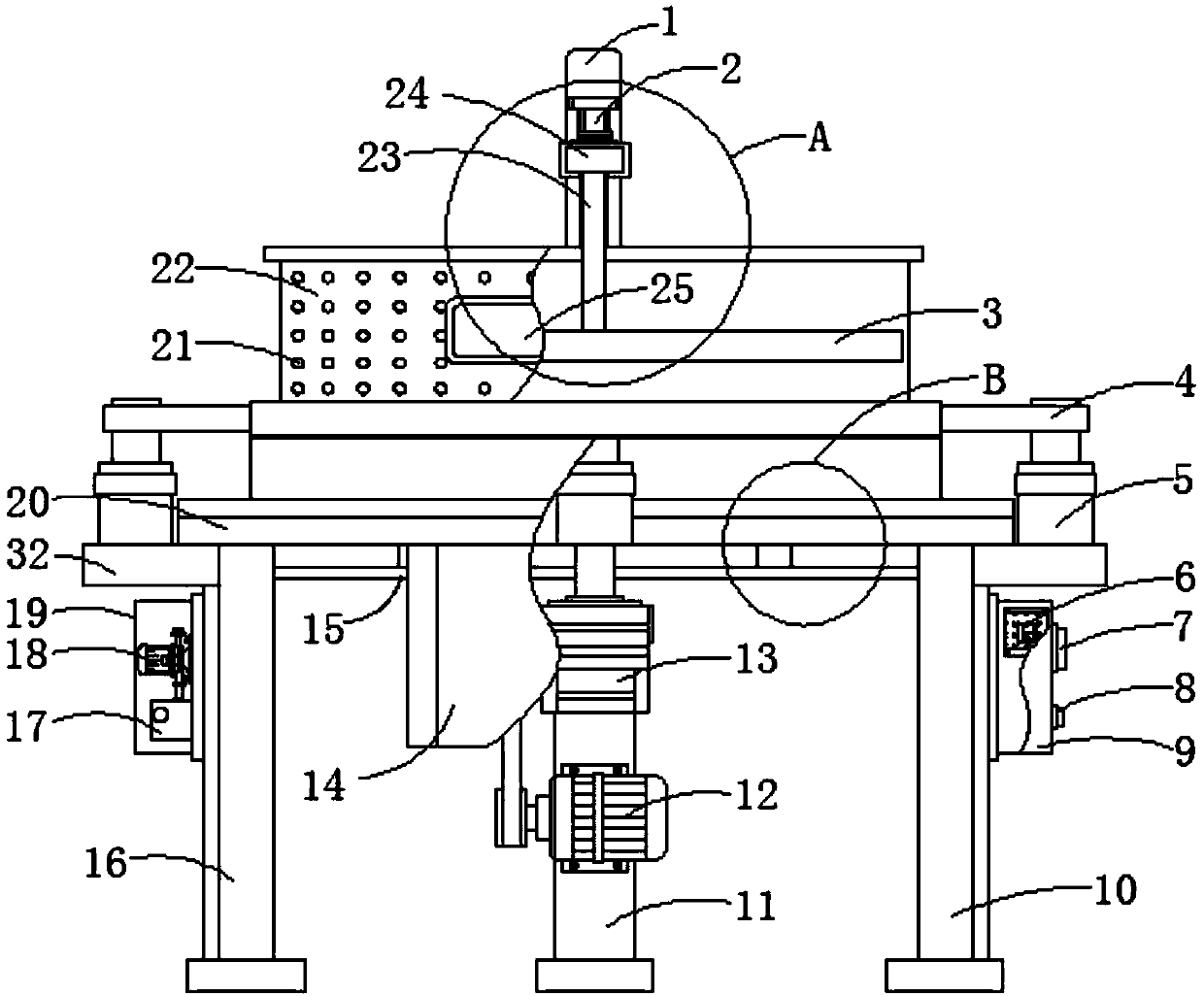

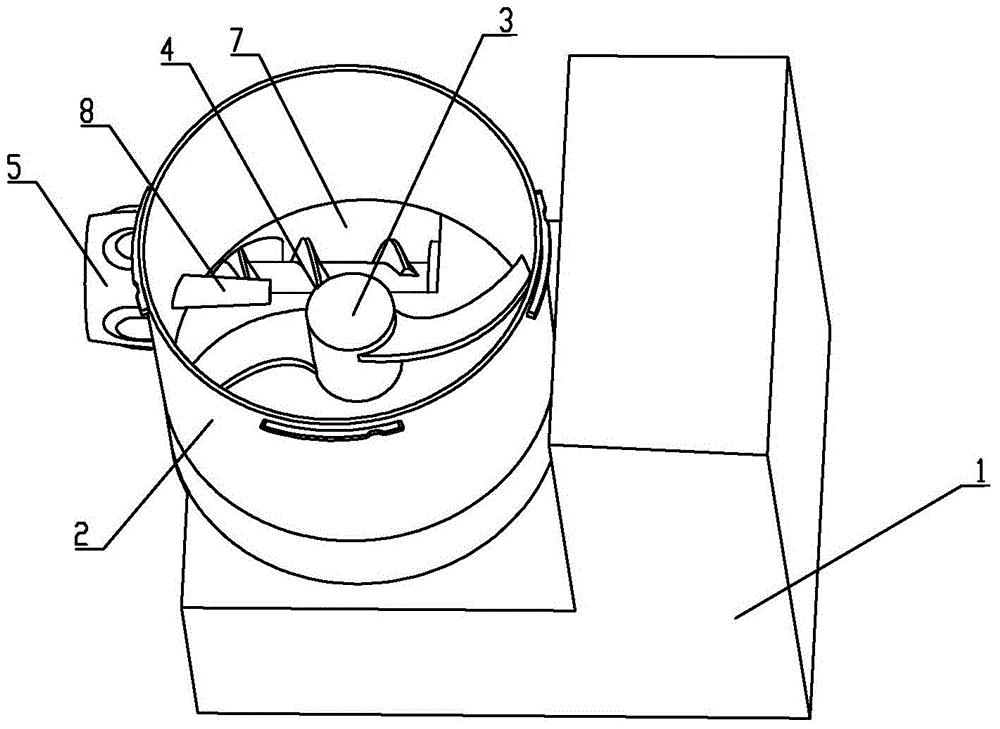

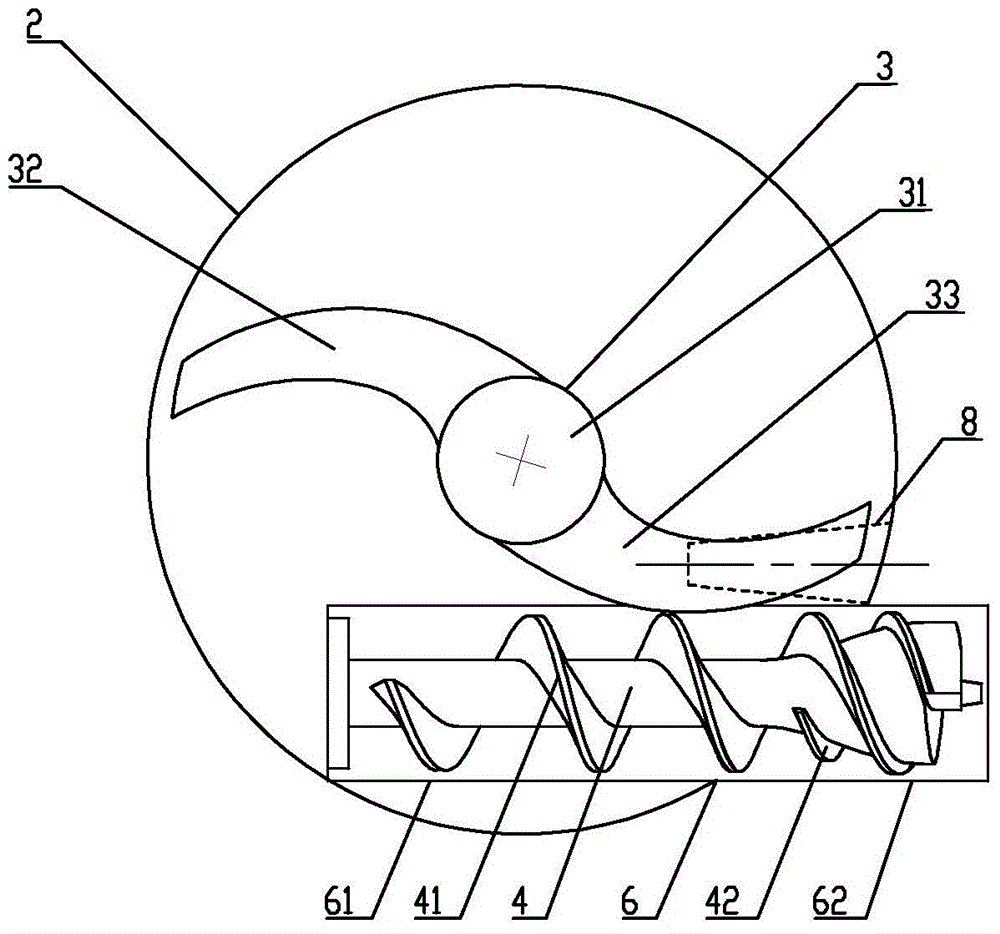

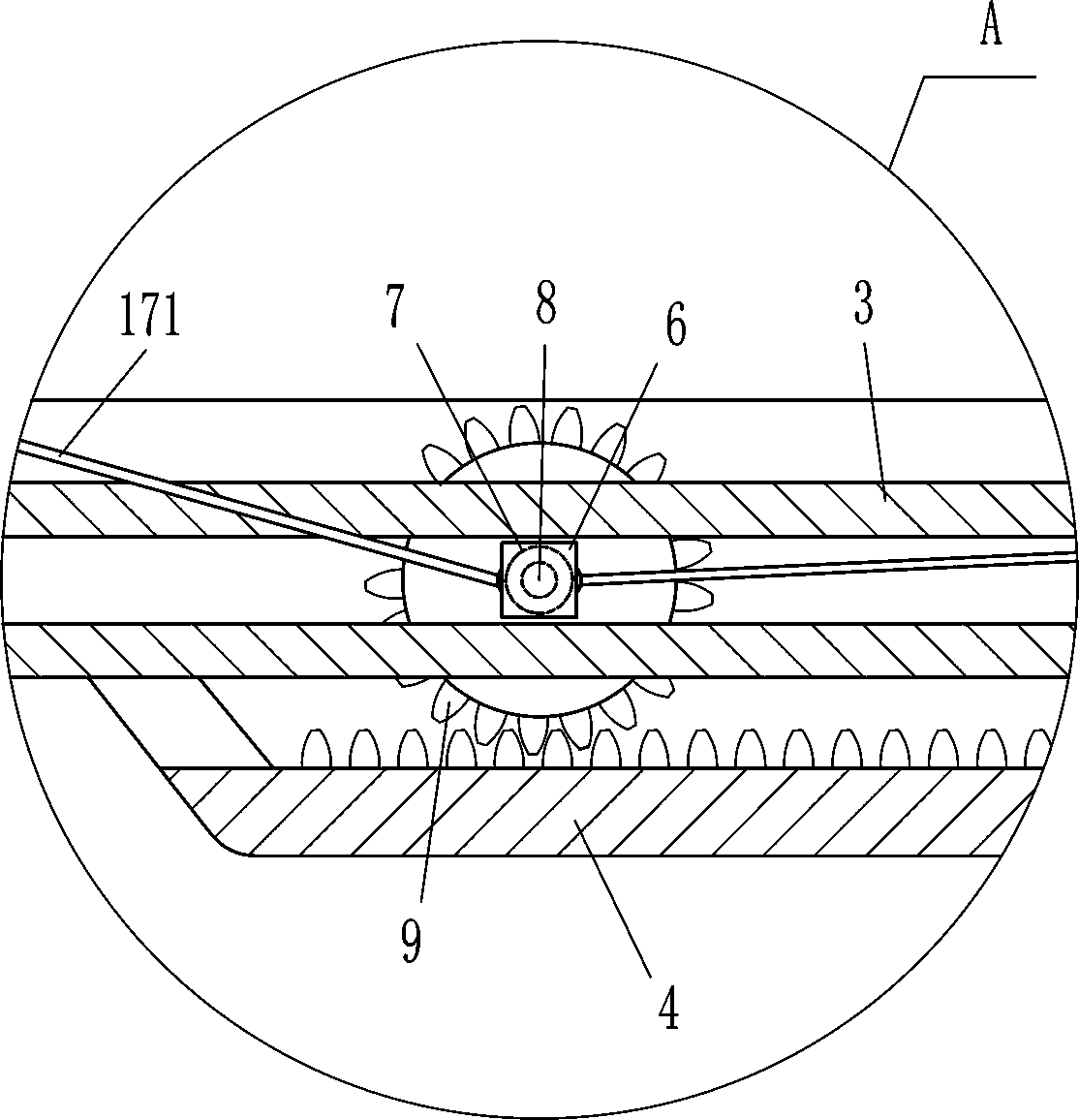

Tea leaf rolling machine capable of automatically controlling rolling pressure

InactiveCN107624914AImprove kneading effectGuaranteed tastePre-extraction tea treatmentHydraulic cylinderAutomatic control

The invention discloses a tea leaf rolling machine capable of automatically controlling rolling pressure. The tea leaf rolling machine comprises a working platform, wherein a stand column and a rolling plate are arranged at the top of the working platform; the rolling plate is located on one side of the stand column; a rolling plate supporting frame is connected to the bottom of the rolling platethrough a sliding groove and a sliding block in a sliding manner; a sliding seat is arranged on the outer wall of the stand column in a sleeving manner; a gear is arranged in the sliding seat; a handwheel is connected to the outer wall of one side of the gear through a rotating shaft in a rotating manner; a cross arm is welded to the outer wall of one side, adjacent to the hand wheel, of the sliding seat; and a hydraulic cylinder is fixedly connected to the top of the cross arm through a bolt. According to the tea leaf rolling machine disclosed by the invention, a KS02Y controller, a timing adjusting knob, a hydraulic pump, a hydraulic oil tank, a hydraulic cylinder, a hydraulic rod, a gland, a spring and a PT124G pressure sensor are arranged, by automatic control of the rolling force, the rolling force is "light, heavy and light" and the best rolling force of the tea leaves is guaranteed at the early stage, the middle stage and the late stage, so that the rolling effect of the tea leaves is improved and the mouth feel of the tea leaves is guaranteed.

Owner:长兴丰收园茶叶专业合作社

High-efficiency noodle making method of household noodle maker

ActiveCN104542789AStir wellImprove kneading effectMixing/kneading with vertically-mounted toolsDough extruding machinesPulp and paper industryExtrusion

The invention discloses a high-efficiency noodle making method of a household noodle maker. The noodle maker comprises a motor base with a motor, a stirring cup connected with the motor base, a stirring rod, a dough extruding cylinder, a screw rod, a die head and a control unit, wherein the stirring rod is longitudinally arranged in the stirring cup and consists of a rod body and upper stirring teeth and lower stirring teeth arranged on the rod body, the dough extruding cylinder is horizontally arranged on one side below the stirring cup, the screw rod is arranged in the dough extruding cylinder, the motor drives the stirring rod and the screw rod to rotate, a dough inlet is formed in the position at which the stirring cup and the stirring cup are communicated, and a noodle cutting rod is arranged on the inner wall of the stirring cup. The noodle making method comprises a dough kneading step and an extrusion forming step, the mutual shearing action of the upper and lower stirring teeth and the noodle cutting rod is added during the dough kneading step and the extrusion forming step, so that the dough is blended sufficiently and evenly, in addition, the dough is shorn or torn off to form a dough easily entering the dough inlet and facilitate dough feeding, the dough extrusion efficiency can be promoted, and no dough residue in the stirring cup can also be guaranteed.

Owner:JOYOUNG CO LTD

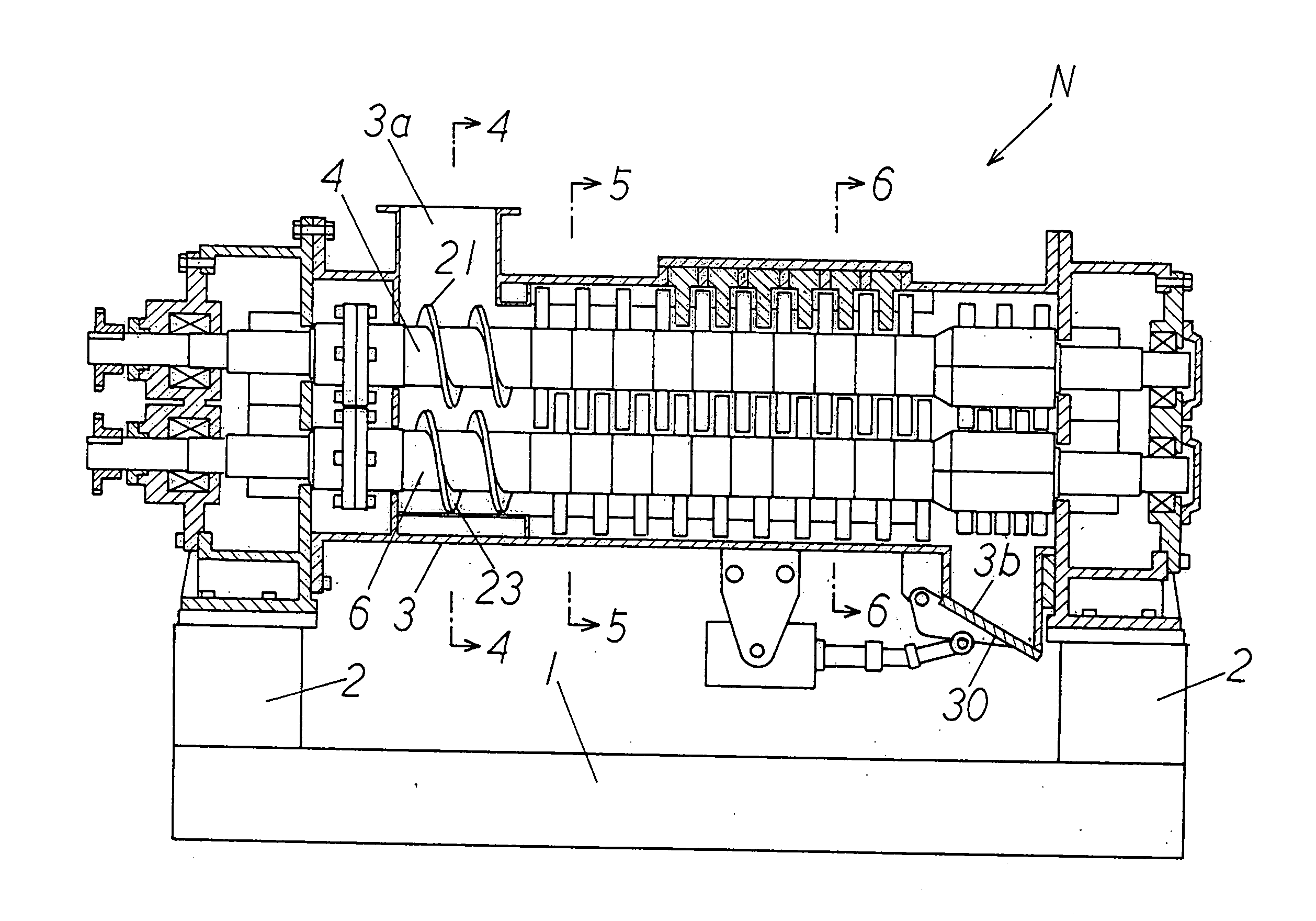

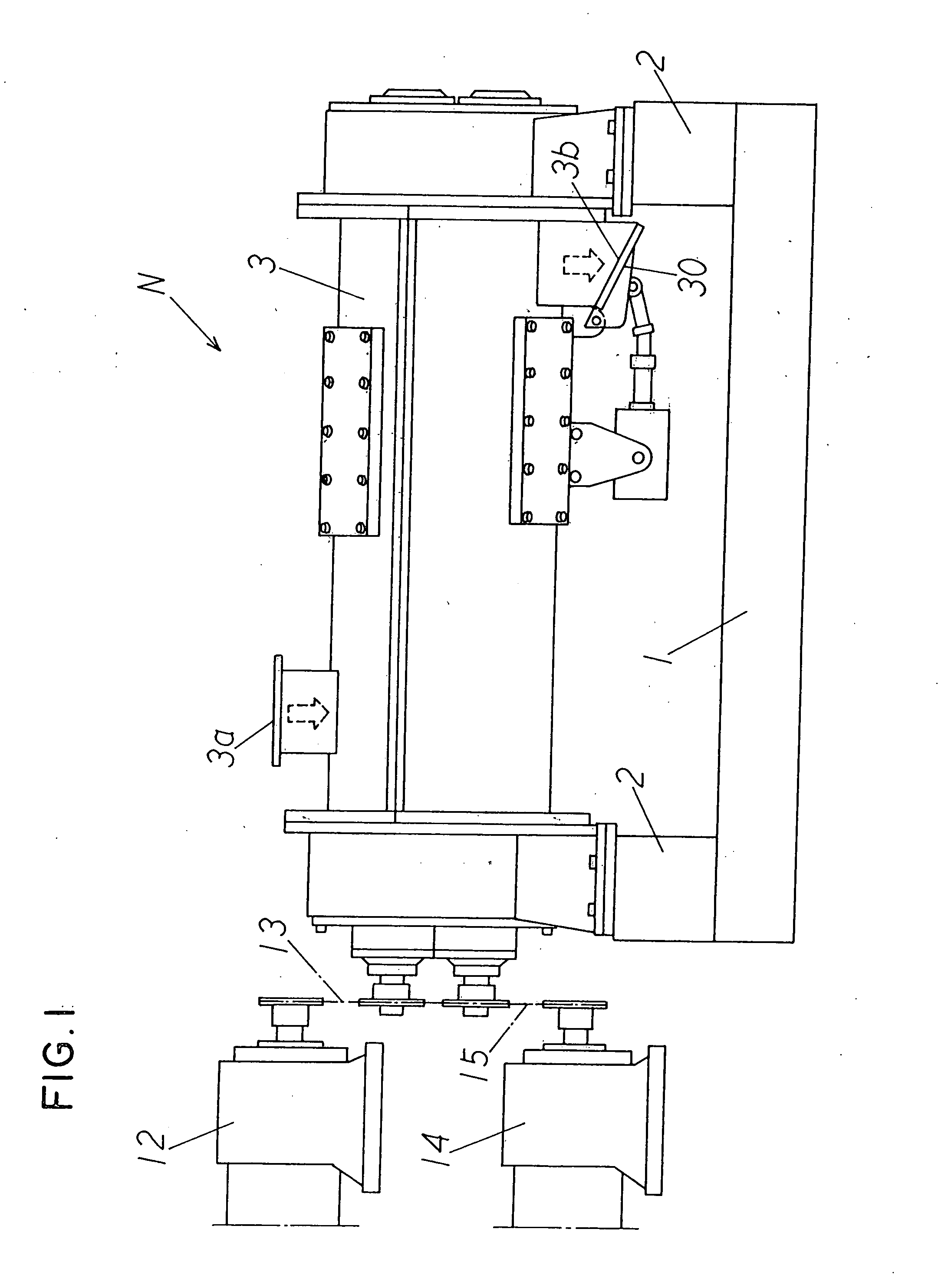

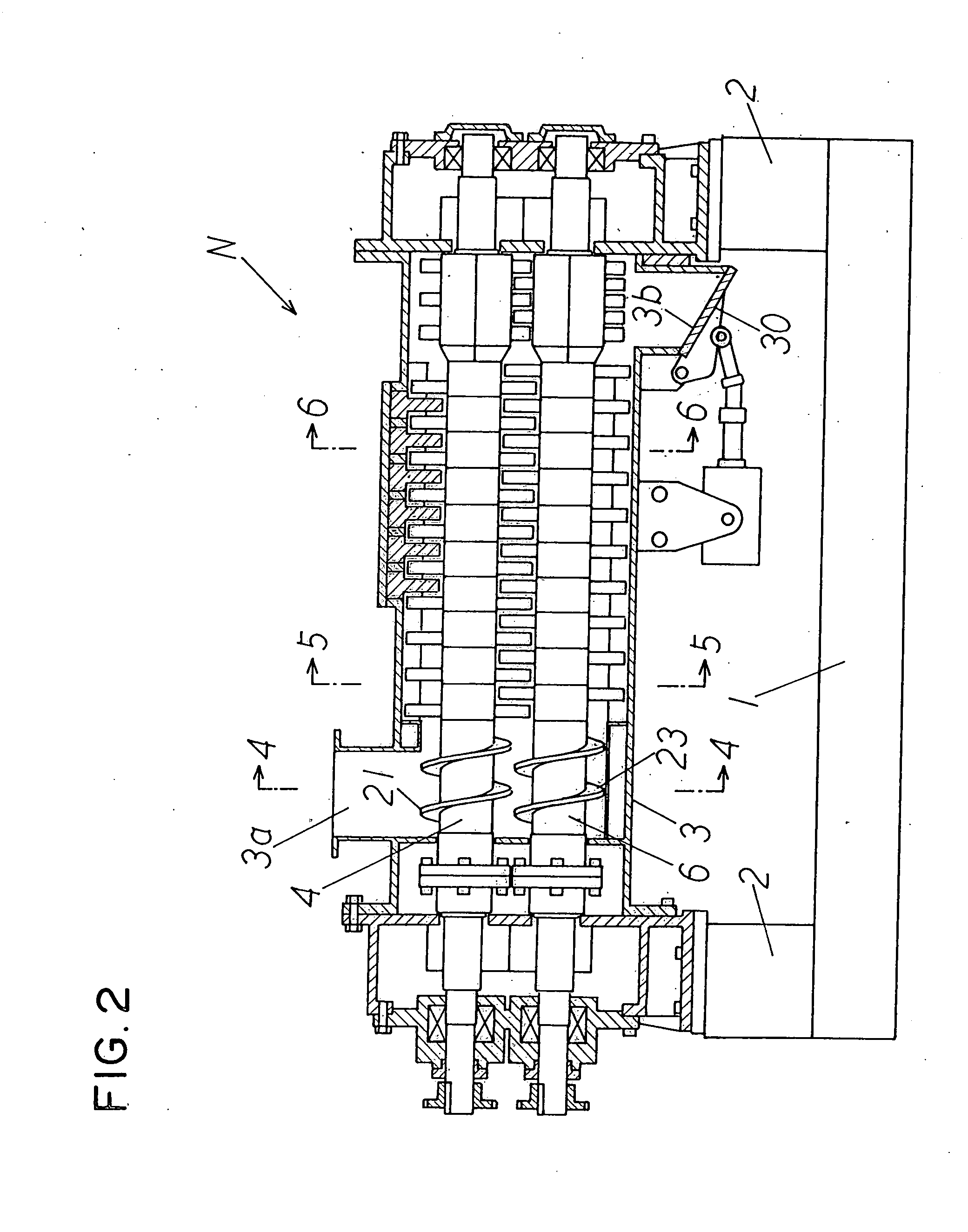

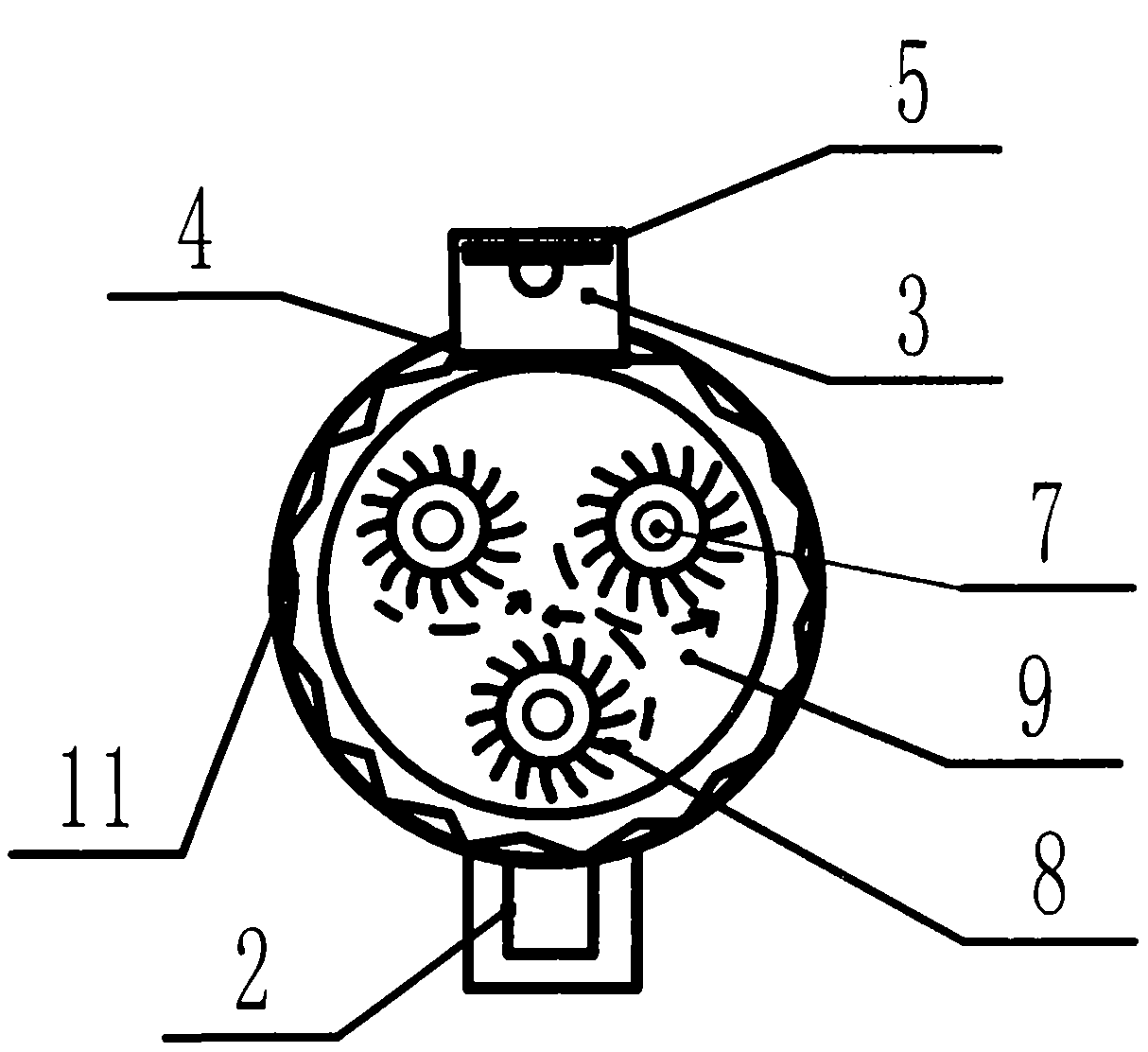

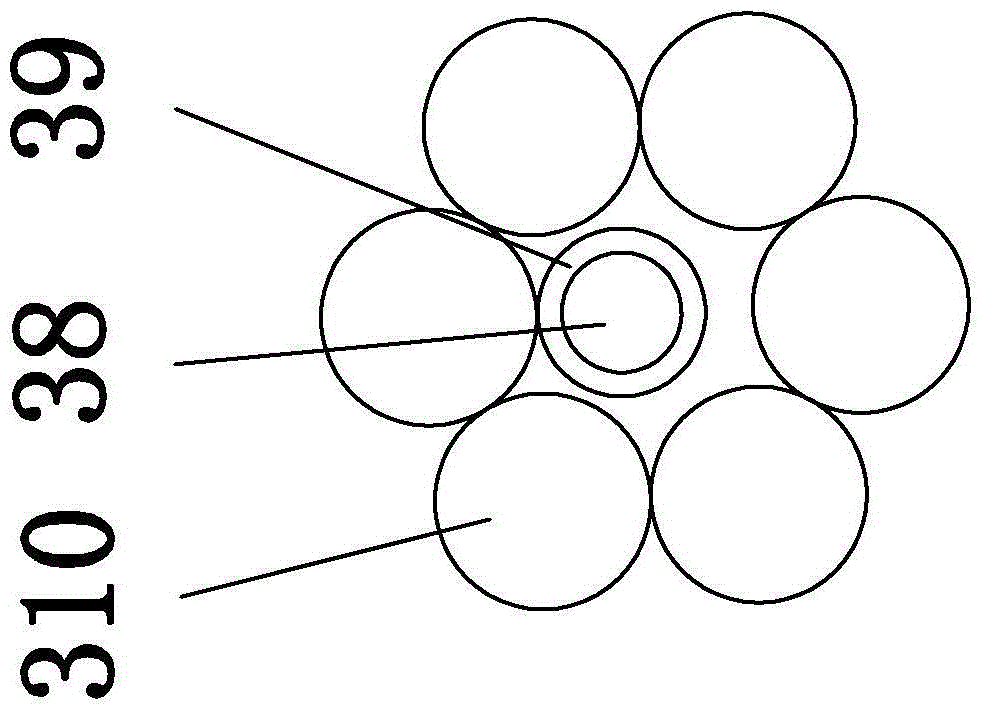

Kneader

InactiveUS20080078853A1Increase space volumeImprove kneading effectRotary stirring mixersTransportation and packagingPulp and paper industryMaterial supply

A kneader includes a casing with a papermaking material supply opening and a papermaking material outlet located below the papermaking material supply opening; at least first, second, third and fourth rotational shafts provided inside the casing; first blades attached to the first rotational shaft; second blades attached to the second rotational shaft; third blades attached to the third rotational shaft; and fourth blades attached to the fourth rotational shaft. The first rotational shaft and the second rotational shaft are located at the same height and are arranged parallel to each other, and the third rotational shaft and the fourth rotational shaft are located at the same height and are arranged parallel to each other. The third rotational shaft is located under the first rotational shaft and the fourth rotational shaft is located under the second rotational shaft, respectively.

Owner:NIPPON PAPER IND CO LTD +1

Tea water-removal rolling device

InactiveCN108450583AExtended stayFully contactedPre-extraction tea treatmentRolling diskAmmonium chloride mixture

The invention belongs to the field of tea processing, and particularly discloses a tea water-removal rolling device. A water removal unit and a rolling unit are arranged on a rack. The water-removal unit consists of a roller rotatably connected to the rack and a hot-air fan fixedly arranged on the rack for driving the roller. One end of the roller, close to the rolling unit, is sleeved with a convex disk. The inner wall of the roller is fixedly connected with spiral conveying blades. One end of the roller, close to the rolling unit is provided with a discharge hole. An inclined feeding table is arranged at the discharge hole; the rolling unit comprises a rolling disc and a rolling roller arranged above the rolling disc. Projections are arranged on the rolling roller in the circumferentialdirection; the upper end of the rolling disk is fixedly connected with the lower end of the feeding table. An air bag layer is arranged at the upper end of the rolling disc. A second Y-shaped tube isarranged on the rack. The three terminals of the second Y-shaped tube are respectively communicated with an air outlet, the rolling roller and the air bag layer. Ammonium chloride crystal is placed atone end of the second Y-shaped tube, close to the roller. According to the invention, the device meets the requirements of mechanized conveying of tea in the process of water-removal and rolling.

Owner:贵州省凤冈县浪竹有机茶业有限公司

Tea rolling machine

PendingCN107593959AMeet different pressure needsGuaranteed qualityPre-extraction tea treatmentElectric machineryEngineering

The invention relates to the field of tea equipment, in particular to a tea rolling machine. The tea rolling machine comprises a casing, a first rolling barrel, a rolling disc, a second rolling barreland a motor, wherein a feeding opening and a discharging opening are formed in the casing; an air cylinder is also arranged on the top in the casing; a press plate is arranged under the air cylinder,and is connected with a press disc through a spring; the first rolling barrel is arranged in the casing; a material inlet opening corresponding to the feeding opening is formed in the first rolling barrel; a baffle plate is also arranged in the material inlet opening position and is connected with the air cylinder; the rolling disc is arranged under the first rolling barrel; the rolling disc is connected with the motor arranged at the bottom of the casing through a connecting shaft; the second rolling barrel is arranged under the rolling disc; radial rolling blades are arranged inside the second rolling barrel; a controller is also arranged outside the casing; the controller is connected with the air cylinder. The rolling process is performed in two rolling barrels, so that the twisted and formed tea at the bottom of the first rolling barrel leave to enter the secondrolling barrel to be twisted; the problem of insufficient rolling of the tea in the rolling barrels is solved; the tea quality is ensured.

Owner:湄潭县渝乾茶叶有限公司

Rubber vibration insulator having ultra-low hardness

InactiveUS20020019478A1Improve kneading effectGood oil retentionSpecial tyresRubber-like material springsCompression setEngineering

The present invention provides a rubber vibration insulator for use in a vibration insulation device integrated into precision instruments such as acoustic, computer-associated and game instruments, which insulator has a low hardness, a small compression set, a large loss tangent and a small temperature dependence. The insulator can be prepared by crosslinking and curing a rubber composition comprising 100 parts by weight of a partially crosslinked butyl rubber and 50 to 200 parts by weight of an extender component.

Owner:YAMAUCHI CORP

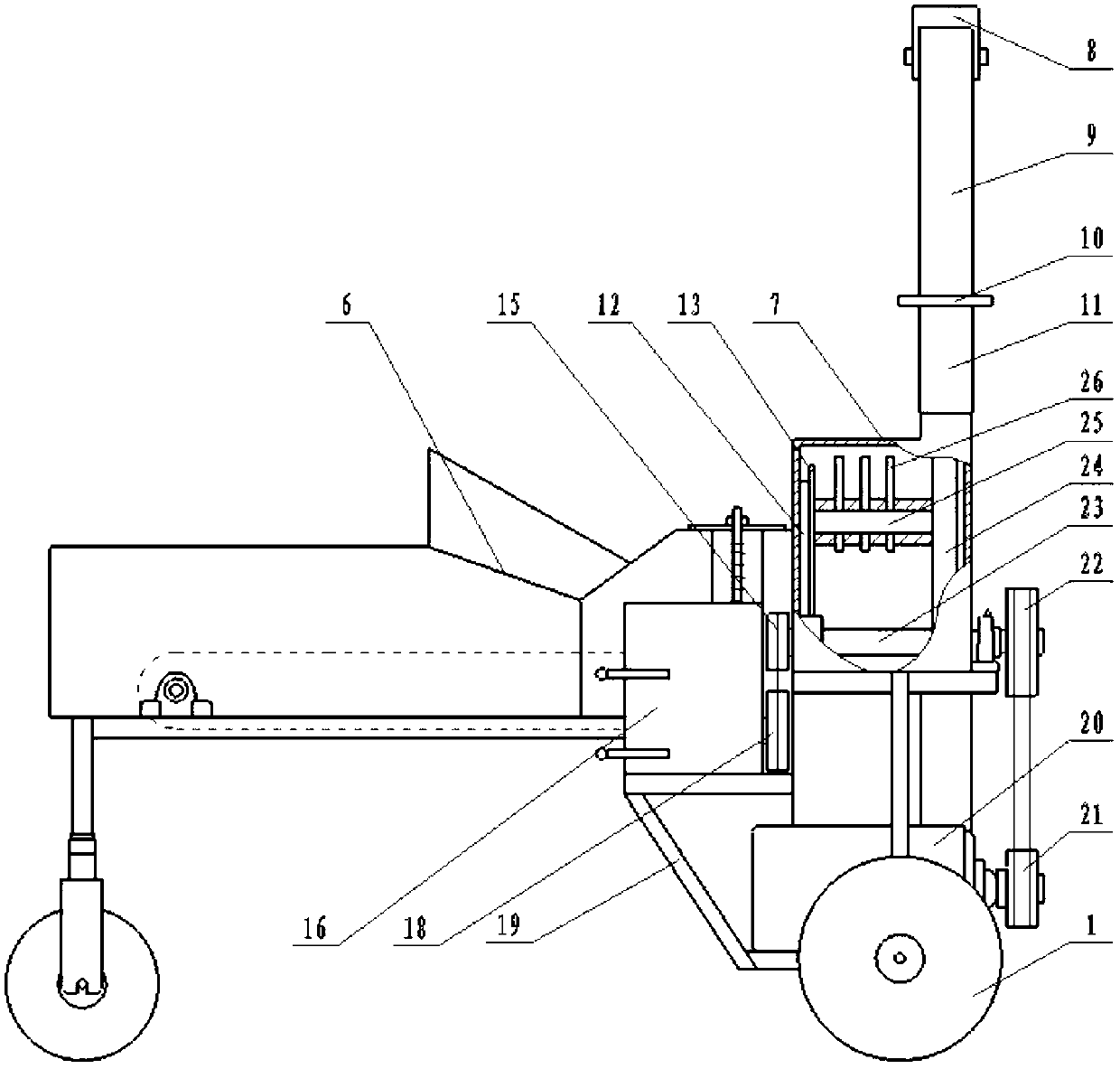

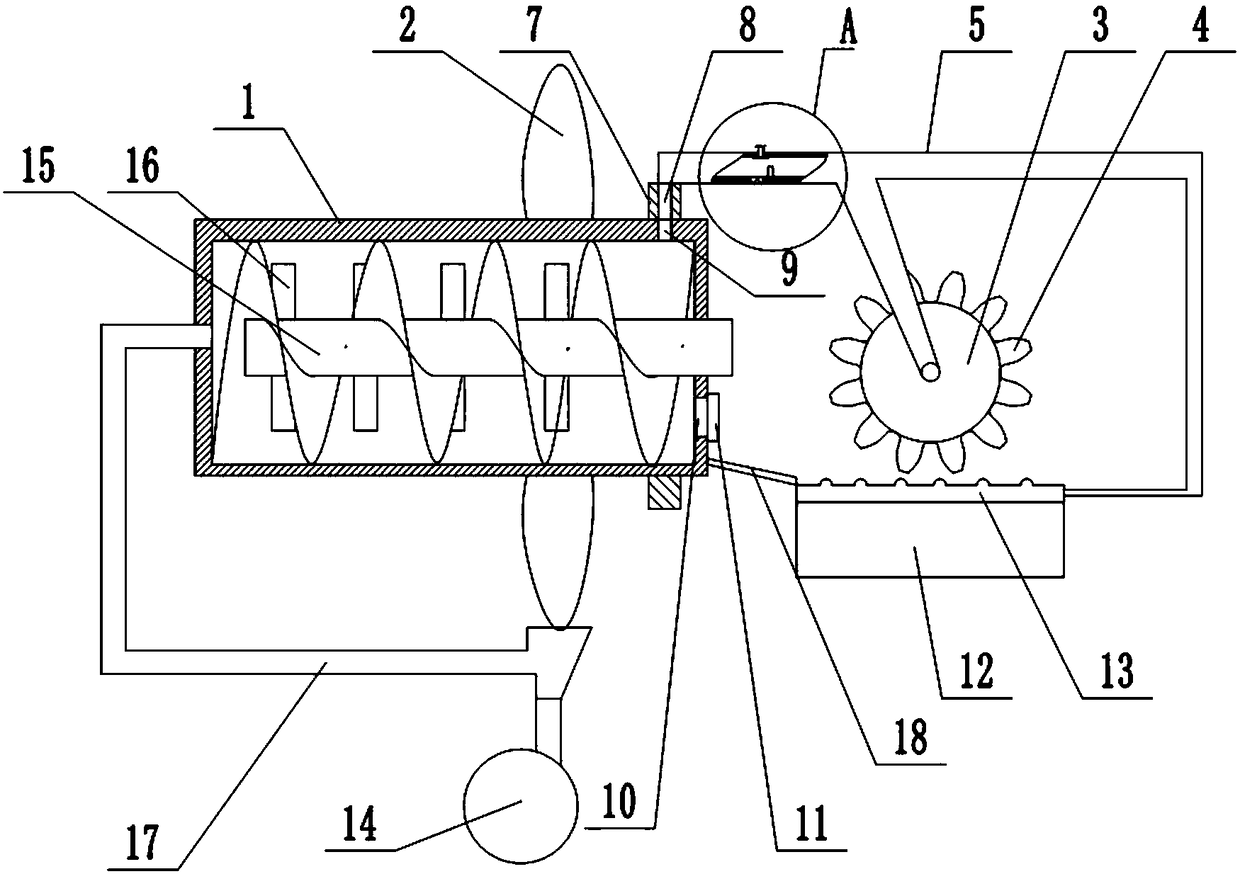

Silage rubbing filament machine

ActiveCN109005961AImprove kneading effectAvoid stacking and jammingCuttersGrain treatmentsReciprocating motionEngineering

The invention discloses a silage rubbing filament machine, which comprises a rack, a conveying device, a feeding and cutting device, a pulverizing device and a power device. The feeding and cutting device comprises a grass feeding roller upper roller assembly, a grass feeding roller lower roller assembly and a cutting assembly. The grass feeding roller upper roller assembly comprises an upper roller movable support, an upper roller bearing seat and a grass feeding roller upper roller. Since the upper roller movable support is movably mounted on a feeding mechanism rack, the distance between the grass feeding roller upper roller and a grass feeding roller lower roller can be adjusted up and down according to the amount of forage, which avoids the phenomenon of accumulation and jamming during the conveying process. At the same time, a moving blade in the cutting assembly realizes the up and down reciprocating motion under the action of an eccentric wheel and a connecting rod, and the moving blade and a fixed blade are engaged to cut the forage cut into desired short sections before entering the pulverizing device, which can greatly improve the rubbing effect of the forage. In addition, the length of the cut forage can be adjusted by adjusting the rotation speed of a cutting shaft, and the cut forage can be processed into the required short filament forage by the pulverizing device and directly stored for feeding the livestock after silaging.

Owner:GANSU AGRI UNIV

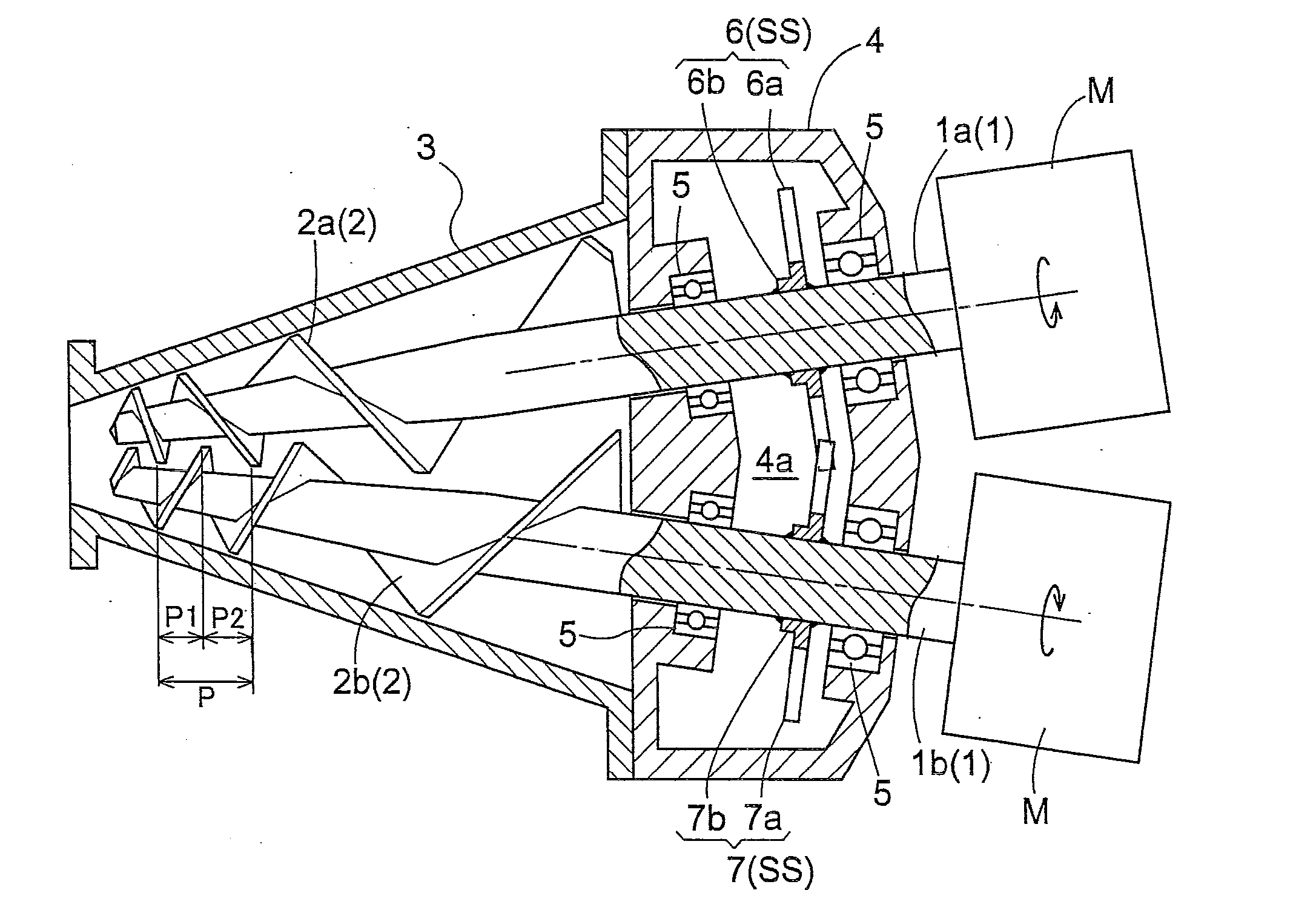

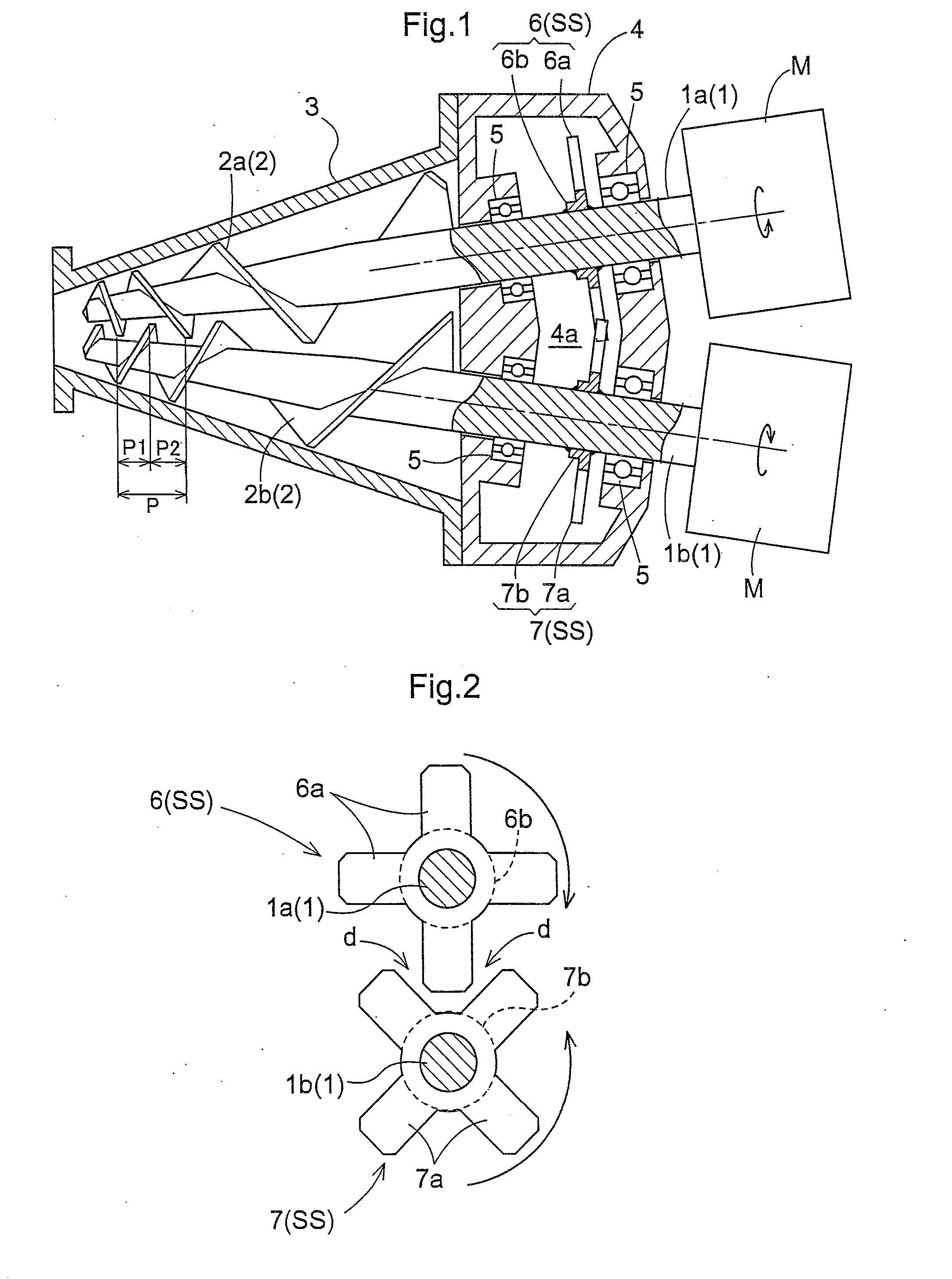

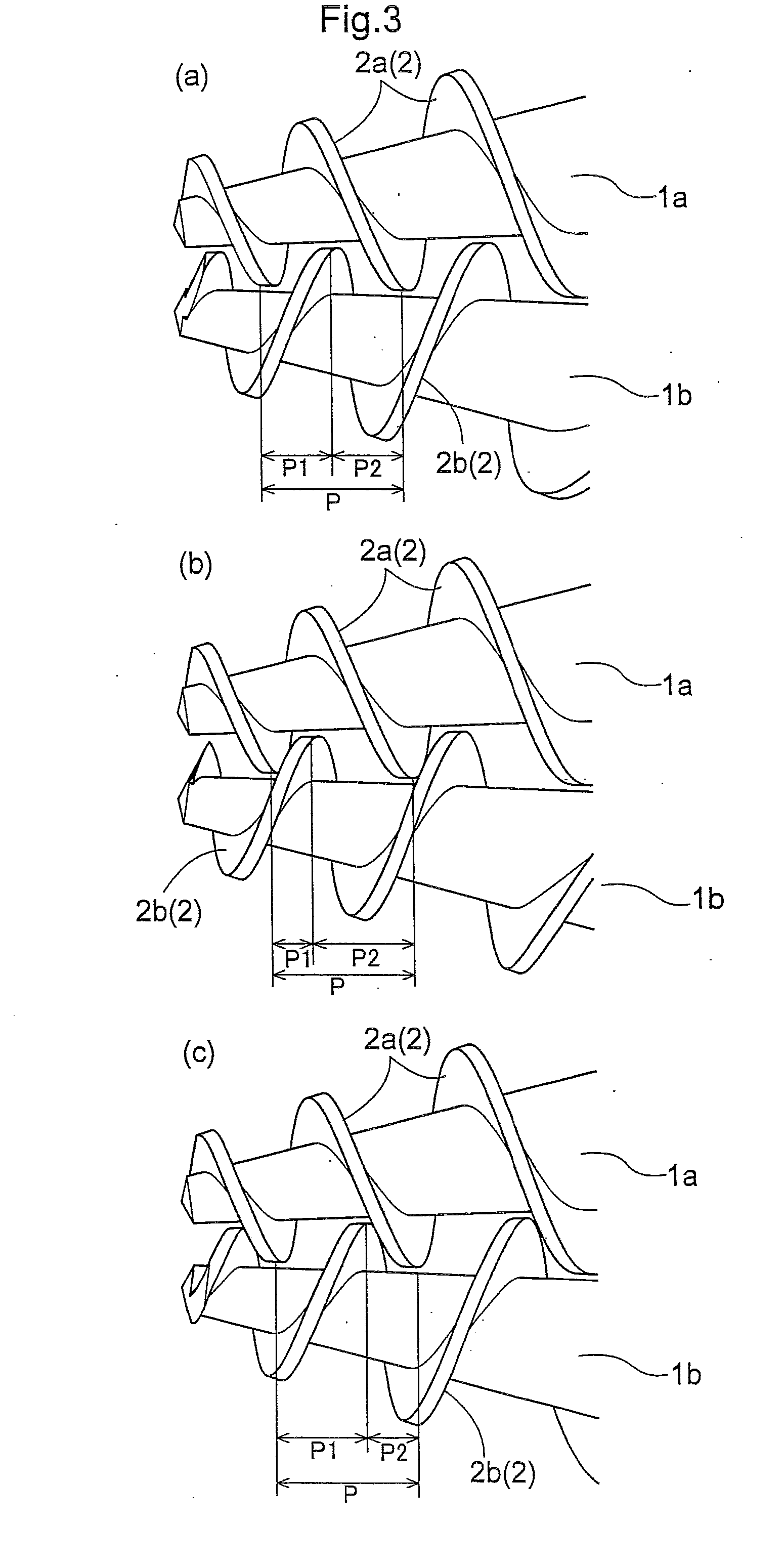

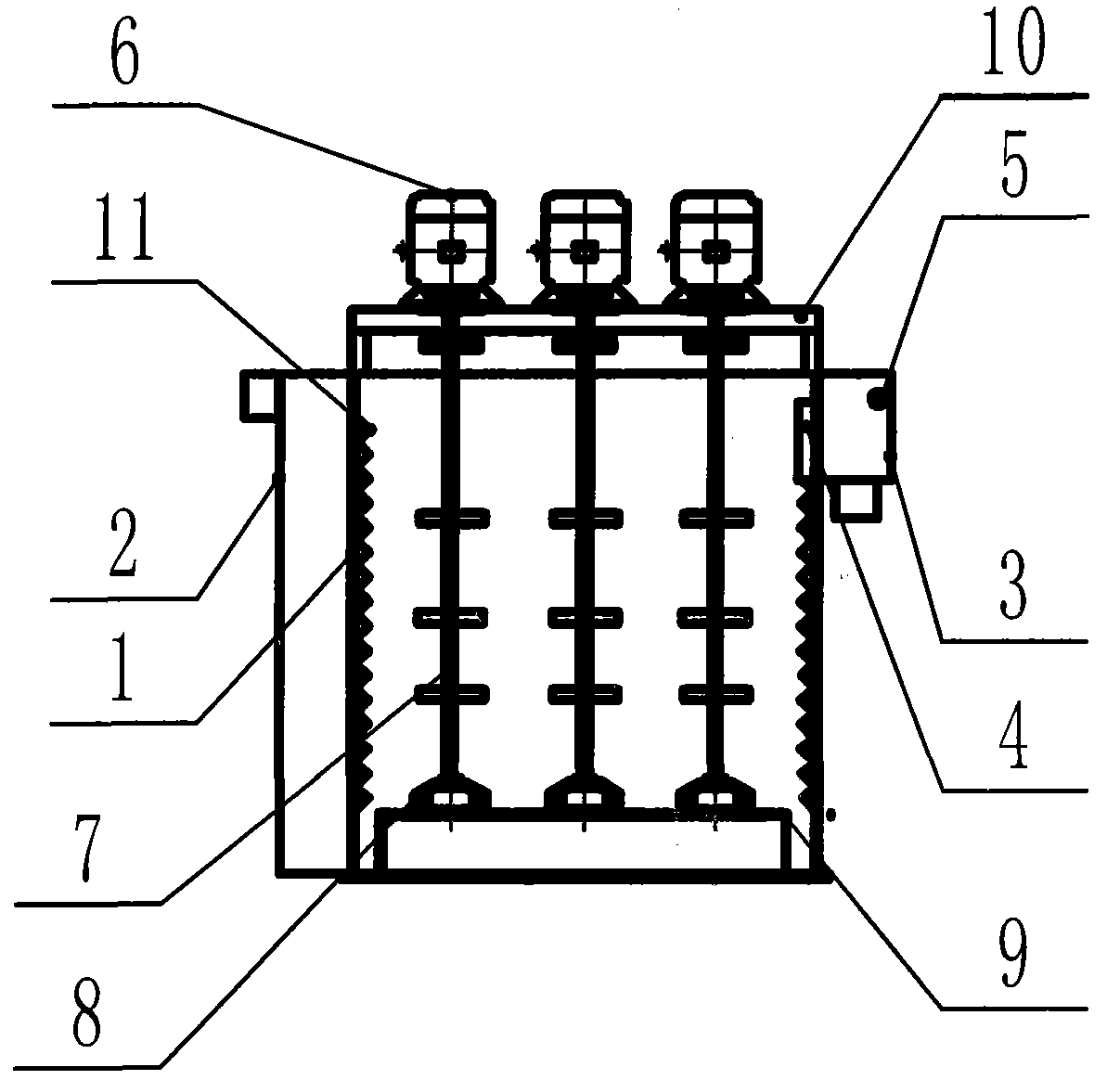

Two-shaft extruder

InactiveUS20110091596A1Position be quite differentImprove kneading effectConfectioneryCeramic shaping apparatusPhase differenceEngineering

In a two-shaft extruder, a pair of rotor shafts (1) is rotatably arranged such that the closer to the head end of the pair, the smaller the distance between the pair. The pair of rotor shafts (1) is respectively provided with screw blades (2) mounted on the head end side of the pair. The rotor shafts (1) are adapted such that one screw blade (2a) enters gaps of the other screw blade (2b). Drive devices (M) for rotationally driving the pair of rotor shafts (1) are mounted on the respective base ends of the pair. The extruder has a screw blade contact prevention mechanism (SS) which, when the pair of rotor shafts (1) is driven, prevents the pair from having a phase difference greater than a predetermined level.

Owner:MORIYAMA

Vibration insulator from partially crosslinked butyl rubber

InactiveUS6489402B2Improve kneading effectGood oil retentionNon-rotating vibration suppressionSpecial tyresHardnessEngineering

A rubber vibration insulator for use in a vibration insulation device integrated into precision instruments such as acoustic, computer-associated and game instruments, which insulator has a low hardness, a small compression set, a large loss tangent and a small temperature dependence and can be prepared by curing a rubber composition comprising 100 parts by weight of a partially crosslinked butyl rubber and 50 to 200 parts by weight of an extender component as well as a vulcanizing agent.

Owner:YAMAUCHI CORP

Three-shaft scattering device of viscous slurry

InactiveCN103521111AReduce the effect of negative pressureNegative pressure effect guaranteeRotary stirring mixersImpellerSlurry

The invention relates to a three-shaft scattering device of viscous slurry. The three-shaft scattering device comprises a round cylinder, a master stirring apparatus, a slave stirring apparatus, a guide blade, a pressure stabilizing plate, a waveform shear plate, a feeding hole, a discharge hole, a round hole sieve plate, a high-pressure water pipe and the like. According to the scattering device of the viscous slurry, the pressure stabilizing plate is arranged at the bottom and can automatically suck ore slurry into the round cylinder by pressure difference; a cylindrical rotary zone in the cylinder is eliminated by the shear plate arranged at the inner wall; the shear performance of the material is also improved; the stirring intensity of each stirring apparatus is effectively increased by the guide plate and three groups of mixing impellers arranged on stirring bearings; namely, the kinematic velocity of the material in the round cylinder is increased. Thus, effective dispersing of a viscous material is achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Profile extrusion molding resin composition and profile extrusion resin molded product

InactiveUS20130023618A1Improve kneading effectNice appearanceAlkaline-earth metal silicatesHeat resistanceShell molding

The present invention provides a profile extrusion molding resin composition capable of forming a profile extrusion resin molded product which is excellent in strength, impact resistance, heat resistance, scratch resistance, surface appearance and shaping property. The profile extrusion molding resin composition of the present invention comprises an aromatic vinyl-based resin component which comprises a rubber-reinforced aromatic vinyl-based resin (A) having the following definition (1) and an ultrahigh molecular weight aromatic vinyl-based resin (B) having the following definition (2) at specific proportions, said resin composition further comprising a lubricant (C) and an inorganic filler (D) in specific amounts based on the aromatic vinyl-based resin component: (1) A resin which is constituted from a graft polymer (a1) obtained by graft-polymerizing an aromatic vinyl compound in the presence of a rubber polymer and, if required, a polymer (a2) obtained by polymerizing an aromatic vinyl compound (with the proviso that a content of the component (a2) is not more than 90% by mass based on a total amount of the components (a1) and (a2)), and which has an acetone-soluble component having a weight-average molecular weight of not more than 1,000,000; and (2) a resin which is obtained by polymerizing a monomer component comprising an aromatic vinyl compound, and which has an acetone-soluble component having a weight-average molecular weight of not less than 2,000,000.

Owner:TECHNO POLYMER CO LTD

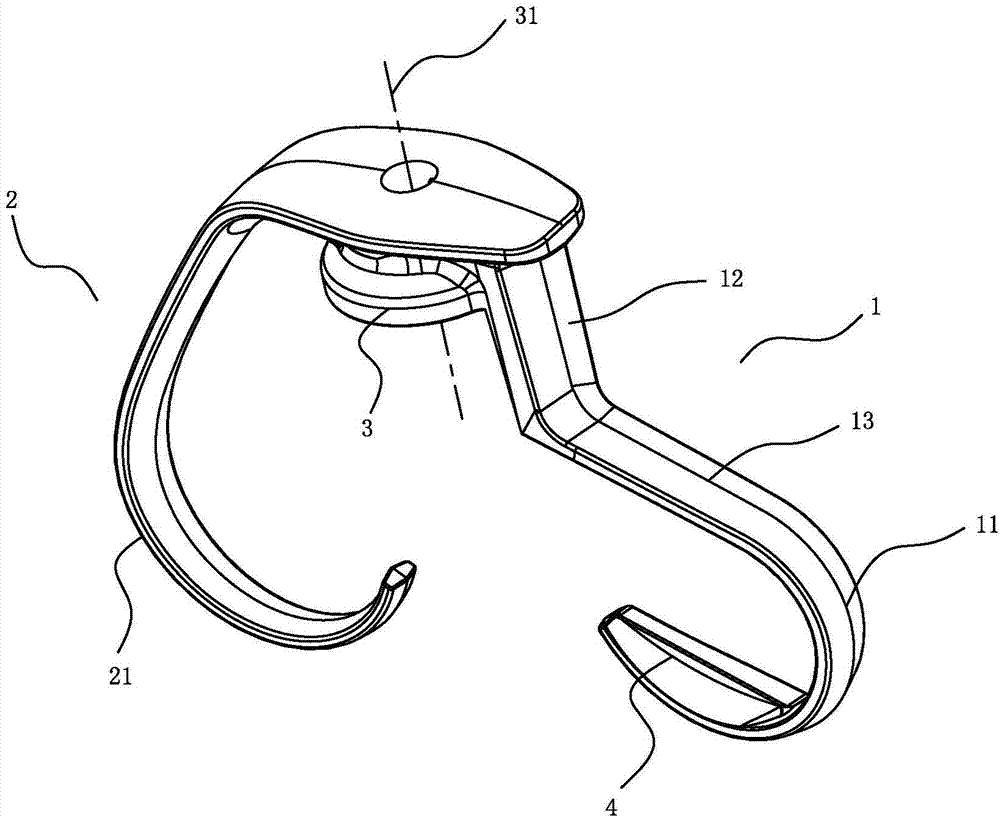

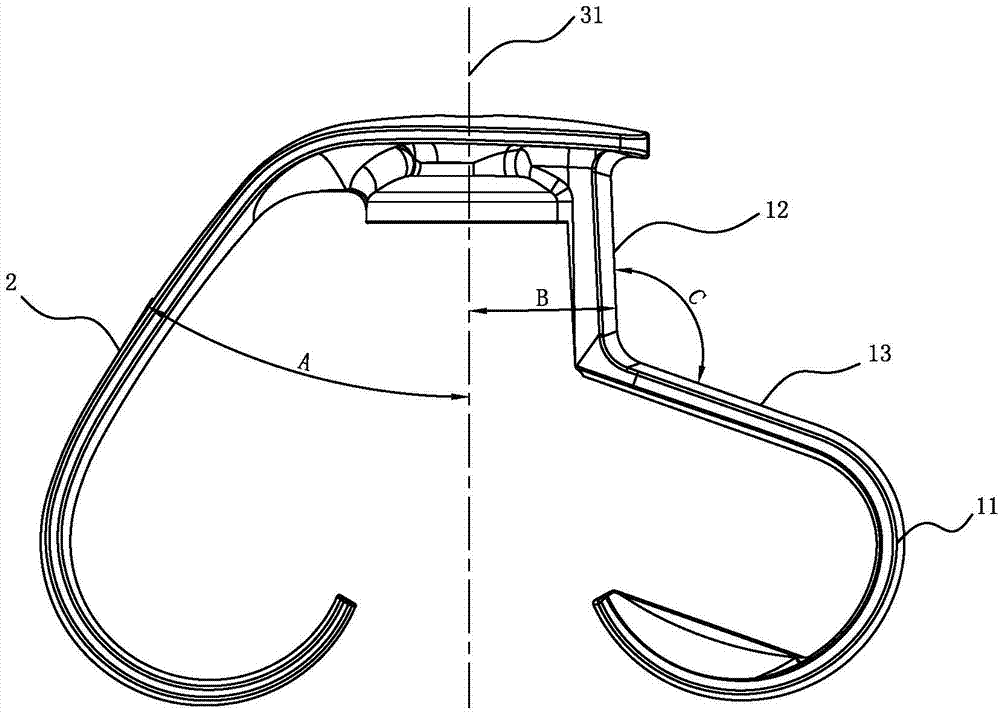

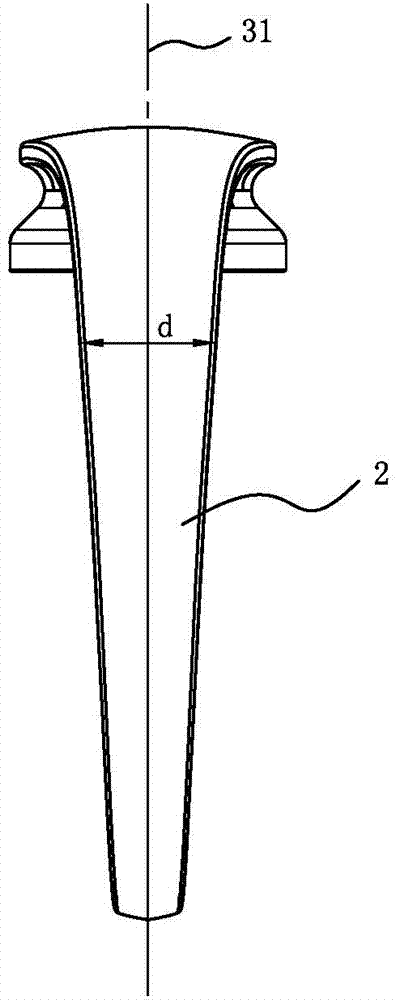

Double-hook type dough kneading hook

ActiveCN103478184AOvercome the shockReduce noiseMixing/kneading with vertically-mounted toolsDrive motorEngineering

The invention discloses a double-hook type dough kneading hook which comprises a dough kneading hook body, wherein the dough kneading hook body comprises a first dough kneading part and a second dough kneading part which are integrally formed; a connecting part connected with a driving device is arranged between the first dough kneading part and the second dough kneading part; the first dough kneading part and the second dough kneading part are distributed circumferentially and uniformly around the rotary central line of the dough kneading hook body; the first dough kneading part and the second dough kneading part are respectively provided with a first hook part and a second hook part which can knead dough on the edge of and at the bottom of a dough kneading cup simultaneously; and at least one of the two hook parts bends towards the connecting part. The double-hook type dough kneading hook performs dough kneading by rotating the first dough kneading part and the second dough kneading part which are integrally formed, so that vibration of a single dough kneading hook structure is effectively overcome, the noise in the dough kneading process is reduced, the dough kneading aging is improved, and the dough kneading effect is excellent; and the first dough kneading part and the second dough kneading part are integrally formed, so that the double-hook type dough kneading hook are not required to drive the two dough kneading parts to perform autorotation and revolution simultaneously, the load of a driving motor is reduced, and the reliability is improved.

Owner:JIANGMEN HOUSOEN ELECTRIC MFG

Convenient-to-blank weaving processing cotton kneading machine

InactiveCN107761248AImprove the effectEvenly distributedFabric breaking/softeningNon-woven fabricsEngineeringScrew thread

The invention discloses a convenient-to-blank weaving processing cotton kneading machine, which comprises a transverse plate, an upper kneading plate and a lower kneading plate, wherein the middle part of a support top plate is provided with a vertical rotating shaft; the lower end of the rotating shaft is provided with a folding bending rod; the lower end of the folding bending rod is eccentrically and fixedly connected with the upper end surface of the upper kneading plate; a lead screw shaft and a guide rod which are parallel are also arranged at the upper side of the transverse plate; thetwo ends of the lead screw shaft and the guide rod are respectively fixed on the transverse plate through a support frame; a moving block connected with the lead screw shaft through screw threads is also arranged on the lead screw shaft; a guide sleeve glidingly connected with the guide rod is arranged on the guide rod; a support rotating shaft is arranged between the moving block and the guide sleeve; the two ends of the support rotating shaft are respectively connected with the moving block and the guide sleeve through a rotating sleeve; the side wall of the support rotating shaft is fixedlyconnected with the middle part of the lower end surface of the lower kneading plate through a fixing block. The convenient-to-blank weaving processing cotton kneading machine has the advantages thatthe structure is simple; the operation is simple and convenient; the cotton kneading effect is sufficient; the blanking is convenient; the efficiency is higher; the practicability is higher.

Owner:杭州恒迅纺织品有限公司

Production method of membrane electrode diffusion layer for fuel cell

InactiveCN107403939AIncrease viscosityEasy transferFinal product manufactureCell electrodesCold airFuel cells

The invention belongs to the field of fuel cell membrane electrodes, and concretely relates to a production method of a membrane electrode diffusion layer for a fuel cell. The production method comprises the following steps: 1, cleaning carbon paper with ethanol, drying the cleaned carbon paper, impregnating the dried carbon paper in a polytetrafluoroethylene emulsion, and sintering the impregnated carbon paper to obtain polytetrafluoroethylene supported carbon paper; 2, coating the carbon paper obtained in step 1 with a carbon powder slurry prepared from acetylene black, water and a binder; 3, sequentially carrying out hot air box drying and cold air box cooling on the carbon paper obtained in step 2; and 4, drying the carbon paper obtained in step 3 in a drying box to obtain the carbon paper which is the membrane electrode diffusion layer. A dispersant used in the invention is water, is cheap, has a good kneading effect with the binder, does not generate irritating smell in the production workshop, and is highly safe; and the produced diffusion layer has the advantages of uniform thickness, flat surface, improvement of the performances of a membrane electrode, large coating area, simplicity in production, and greatly improved production efficiency.

Owner:FUJIAN FUAN MINDONG YANAN ELECTRICAL MACHINE

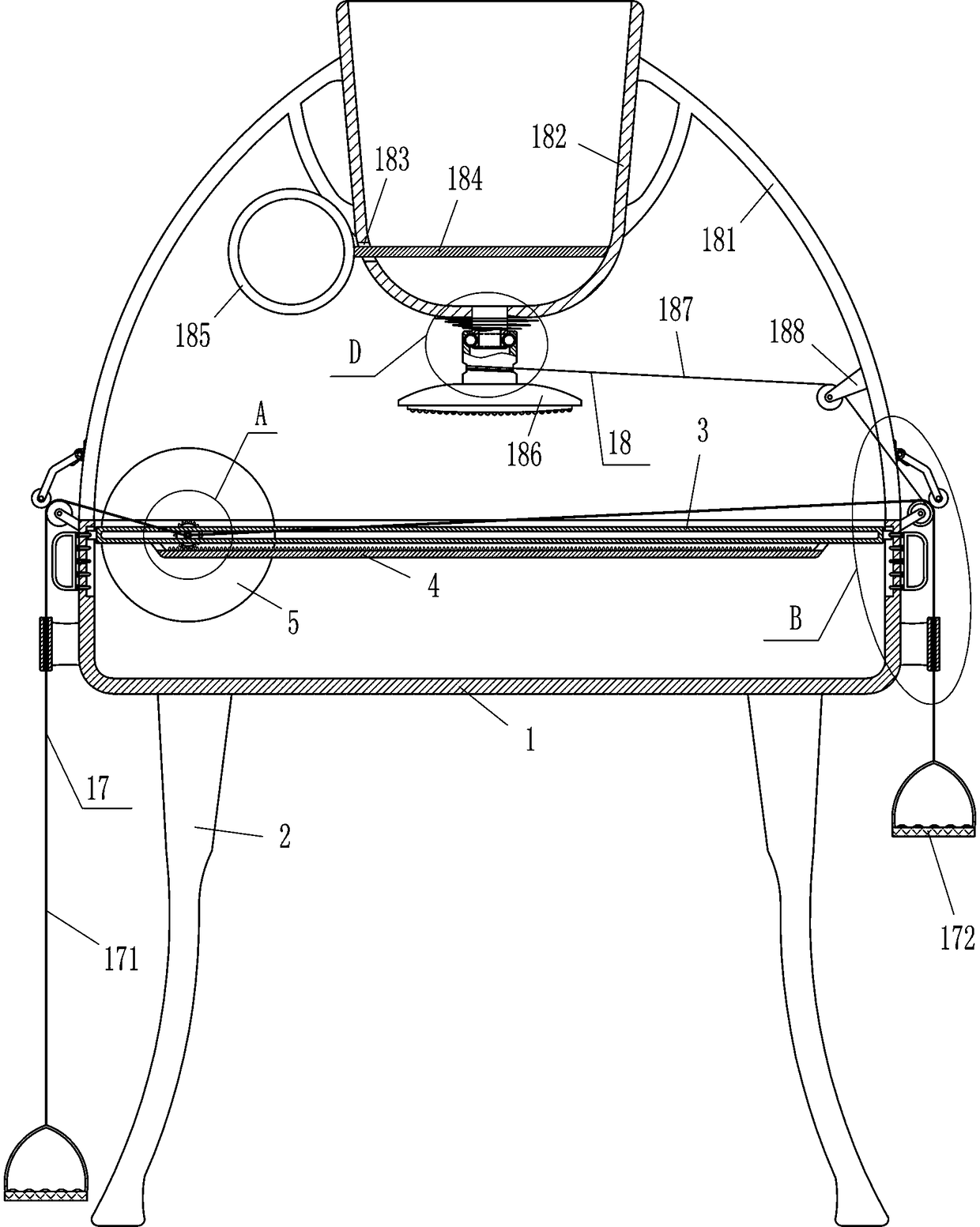

Pedal type dough kneading machine

ActiveCN109392971AProtection against mobile effectsImprove kneading effectMixing/kneading structural elementsEngineering

The present invention relates to a dough kneading machine and particularly relates to a pedal type dough kneading machine. A technical problem is to provide the pedal type dough kneading machine whichcan enable people to more conveniently conduct dough kneading, is good in dough kneading effects, can also conduct the dough kneading and adds flour at the same time. A technical scheme is as follows: the pedal type dough kneading machine comprises a frame body, support legs, a horizontal hole plate, a rack, a roller, horizontal sliding blocks, bearing seats, rotating shafts, gears, vertical sliding blocks, clamping rods, handles, etc.; and the support legs are symmetrically fixedly connected at the left and right sides of the outer bottom part of the frame body, vertical sliding grooves witha guiding function are arranged in the front and rear sides of an upper part of the left and right side surfaces of the frame body, and the vertical sliding grooves are internally provided with thevertical sliding blocks in a sliding manner. Dough is put into the frame body, feet are used to move pedals up and down, so that the roller move left and right and at the same time rotate front and back alternately to conduct dough kneading, people do not need to conduct the dough kneading using a rolling pin, and the dough kneading machine is convenient and quick, and can also enable the dough kneading effect to be better.

Owner:灵璧县浩翔信息科技有限公司

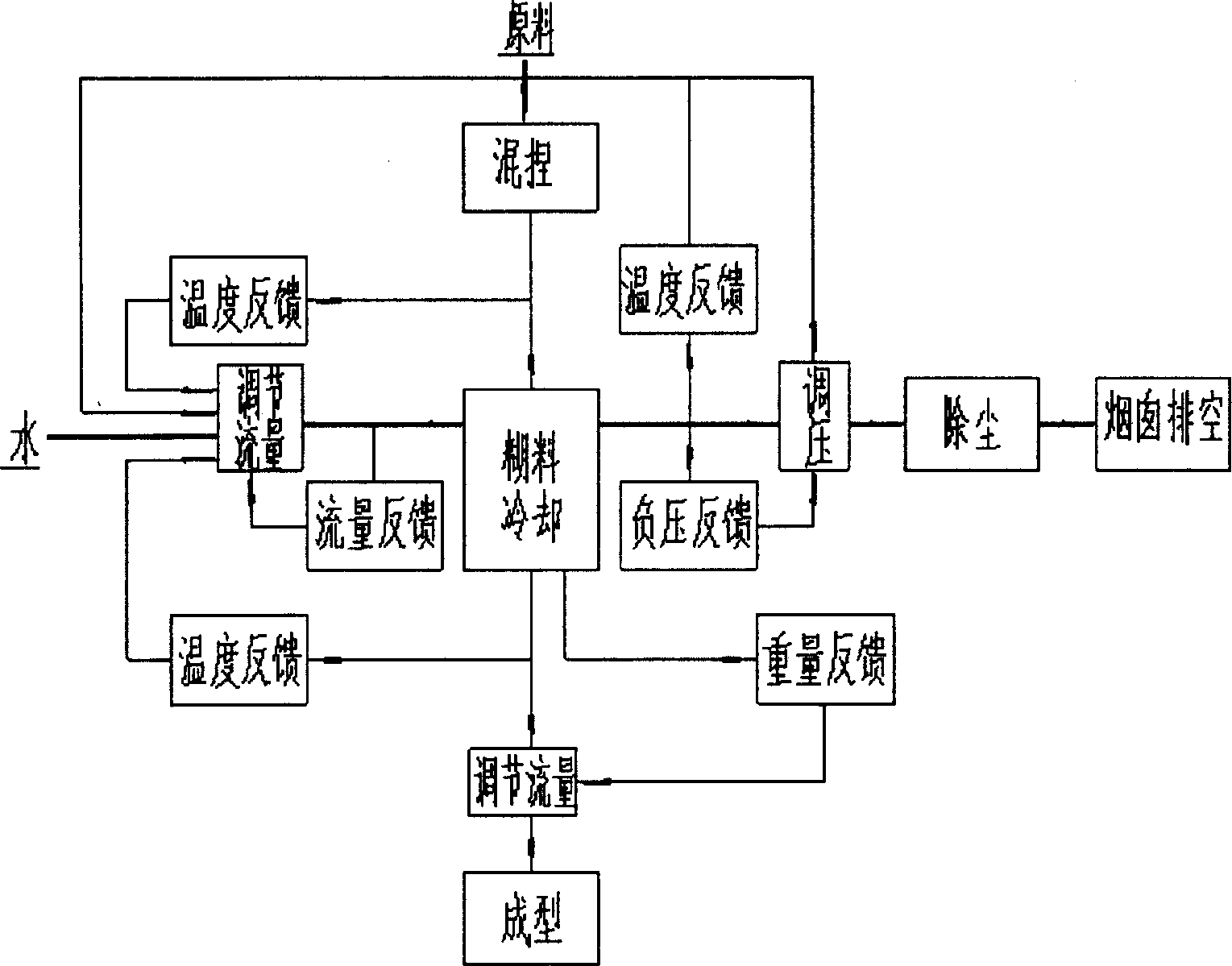

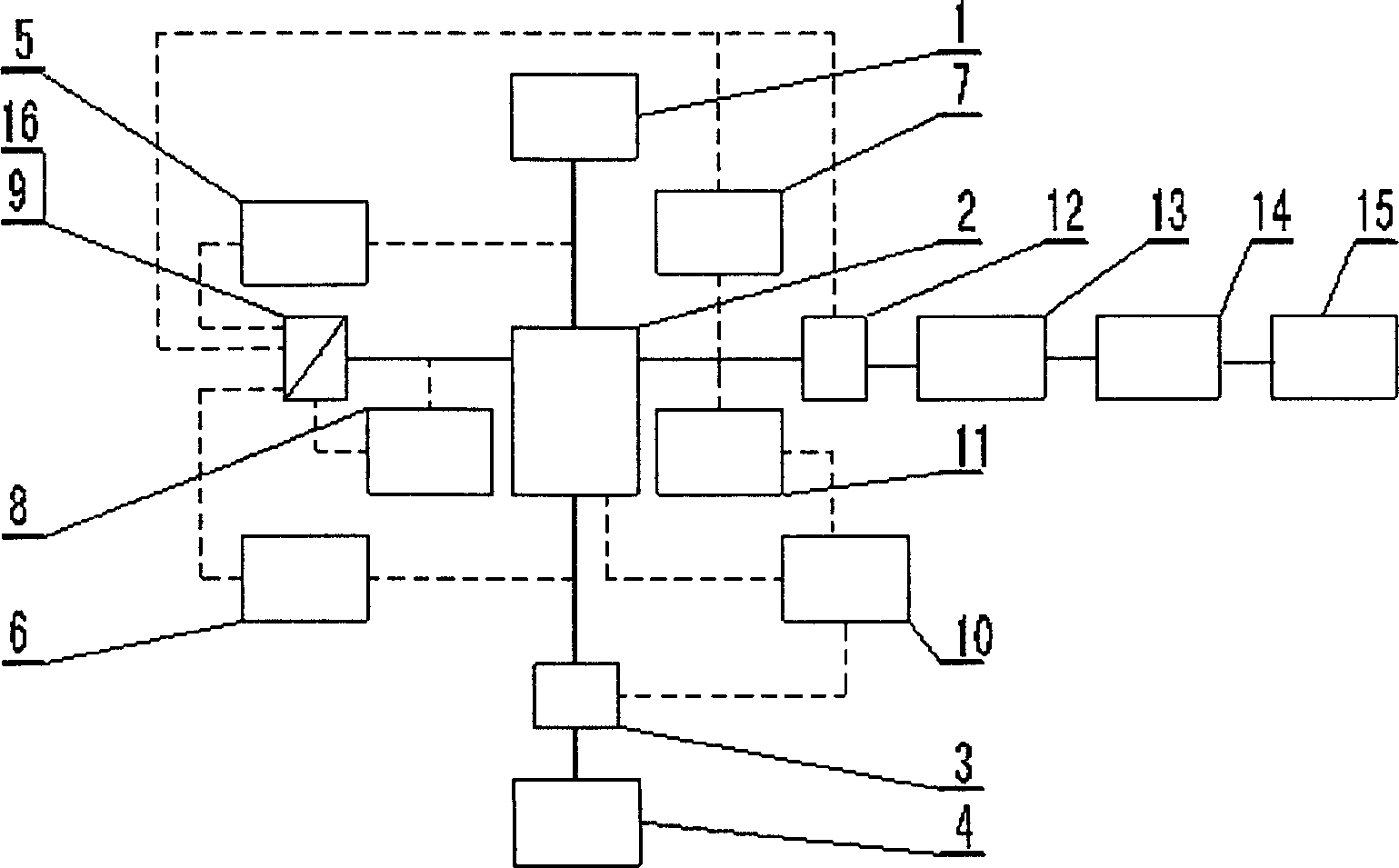

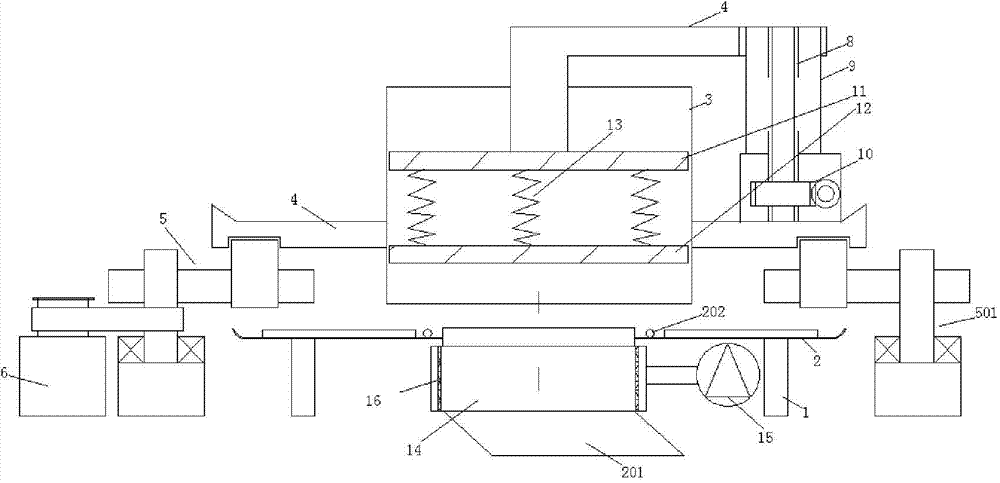

Process for producing anode paste by direct water spraying and continuous cooling and complete equipment set

This invention discloses the productive technology of directed spray, continuous cooling to anode thickeners and the equipment. The method and equipment is following: by continuous mixer, discharging continuously anode thickeners produced into the thickeners cooler, making cooling water flowing from the penstock and into the cooler, which directly spraying water to anode thickeners and making them cool, the anode thickeners after cooling shaping in shaping machine; the smoke gas discharged by the thickeners cooler discharges into air after passing bugdusters, fans and chimneys. The temperature sensor and the flowmeter input gauged data into a computer, and the computer analyses it and emits instruction to adjust the mount of cooling water, which makes the temperature of thickeners dischareged from thickeners cooler to be a set value. Adjusting the dam board of discharging thickeners at the bottom of thickeners cooler, making the mass or weight of anode thickeners in thickeners cooler be stable, making the mass or weight of anode thickeners entering shaping machine be a set value; according negative pressure value measured by the negative pressure sensor, adjusting thickeners cooler to keeping a right negative pressure value.

Owner:GUIYANG AL-MG DESIGN & RES INST

Equipment for cleaning sizing agent on surface of fabric

InactiveCN107217412ASimple structureEasy to cleanFabric breaking/softeningTextile treatment by spraying/projectingTextile fiberTransfer procedure

The invention relates to a fabric surface slurry cleaning equipment, comprising a conduction part, the conduction part includes an introduction device and an outlet device for conducting textile fibers; a kneading part, the kneading part is arranged between the introduction device and the outlet device, the kneading part includes The pushing mechanism and the rolling mechanism respectively arranged on both sides of the textile fiber during the transmission process, the pushing mechanism is used to push the textile fiber to move towards the direction of the rolling mechanism, and the rolling mechanism is used to cooperate with the pushing mechanism to move forward and backward simultaneously The surface of the textile fiber is rolled in the direction; the cleaning part, the cleaning part includes a water supply mechanism set above the pushing mechanism and a water supply mechanism set on the side of the rolling mechanism for spraying the water in the water supply mechanism to the rolled textile fiber The spray mechanism on the surface; the present invention overcomes the problems of incomplete cleaning, low cleaning efficiency and large amount of water resources used when cleaning the surface of the fabric with residual slurry.

Owner:CHANGXING JIAPU YIHANG TEXTILE FACTORY

Soft-extrusion tea twisting machine

InactiveCN104738228AImprove qualityPlay a buffer rolePre-extraction tea treatmentDrive motorEngineering

The invention discloses a soft-extrusion tea twisting machine which comprises a bracket, a twisting plate and a twisting device, wherein the twisting device comprises a twisting barrel and a press cover; the press cover has a buffer structure; the periphery of the lower end part of the twisting roller is connected with a plurality of support arms; a crank-rocker mechanism is arranged at the lower end of each support arm; a connection drive device is arranged on each crank-rocker mechanism; a connecting rod is arranged at the upper end of the press cover; adjusting screw rods are arranged in upright posts; the lower ends of the upright posts are fixedly arranged on the support arms; worm and gear transmission mechanisms are arranged at the lower ends of the adjusting screw rods; a receiving hopper is arranged on the upper end surface of the press cover; a rotary closing switch is arranged at the lower end of the receiving hopper; a feeding channel is arranged above the receiving hopper; and a discharge channel is arranged at the lower end of the twisting plate. According to the soft-extrusion tea twisting machine, the defects of the prior art are overcome; the soft-extrusion tea twisting machine is reasonable in design, and compact in structure; a drive motor is started through a PLC, and is used for controlling a reasonable distance between the press cover and the twisting plate; and meanwhile, the press cover has a buffer structure, so that pressure release on tea twisting is facilitated; and the twisted tea quality is improved.

Owner:ANHUI GUOKANG AGRI CO LTD

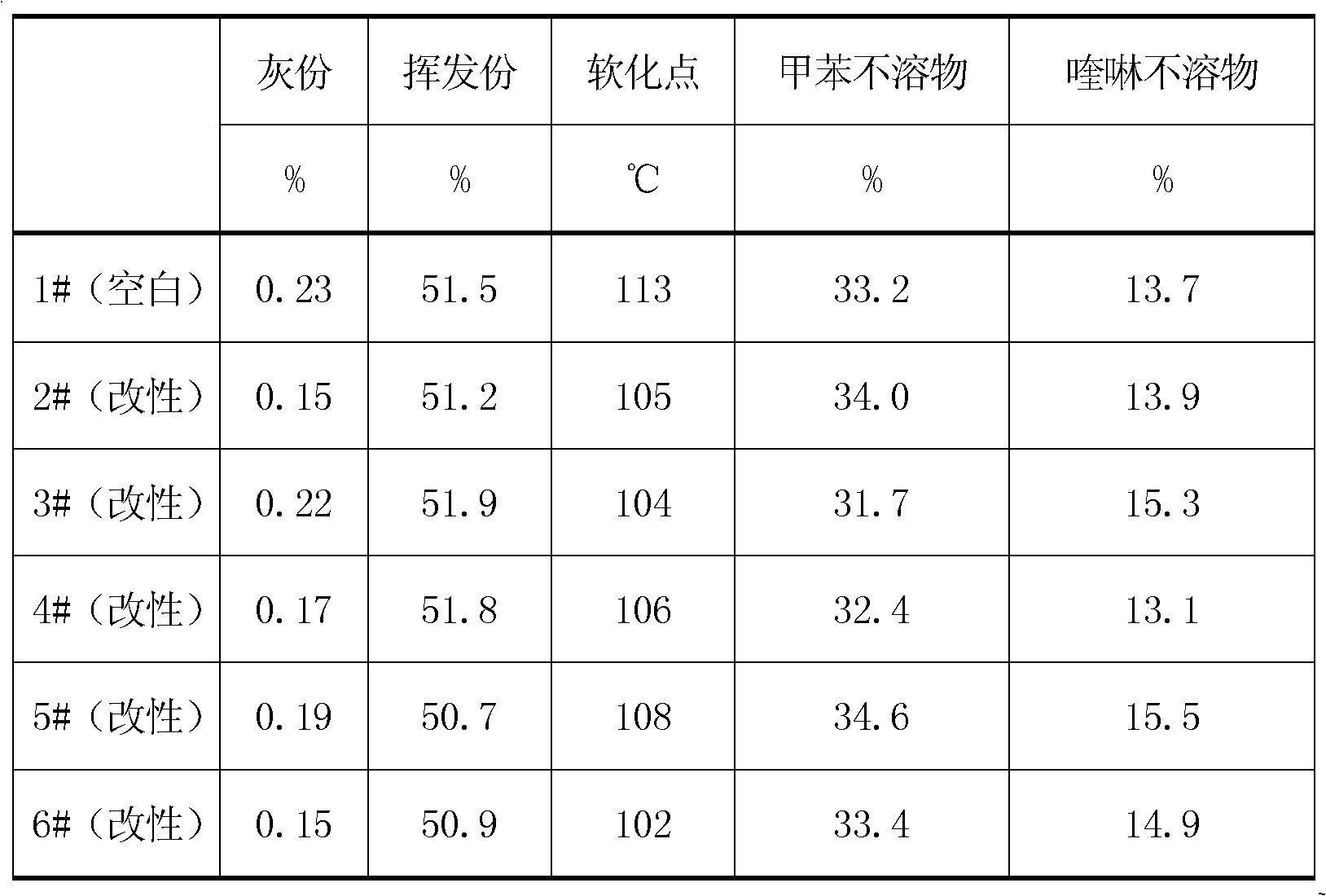

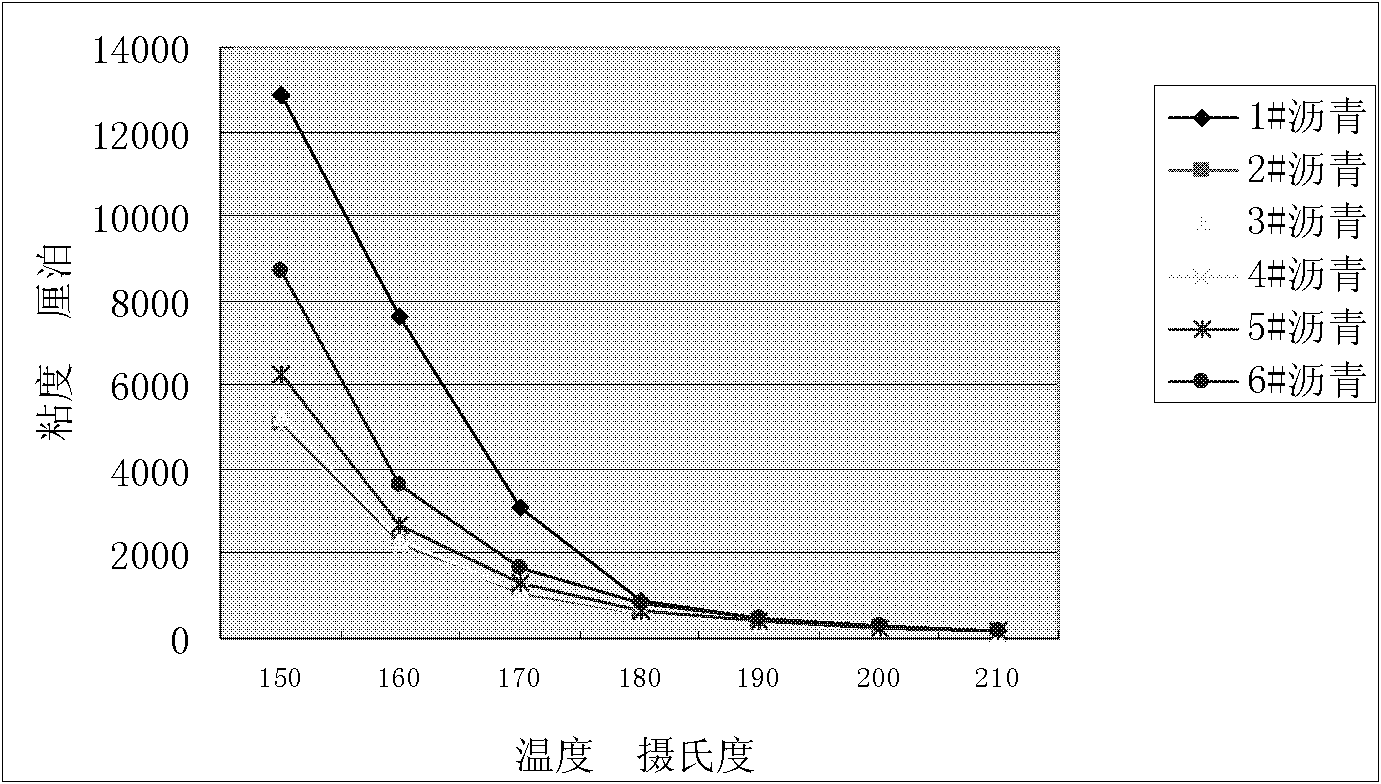

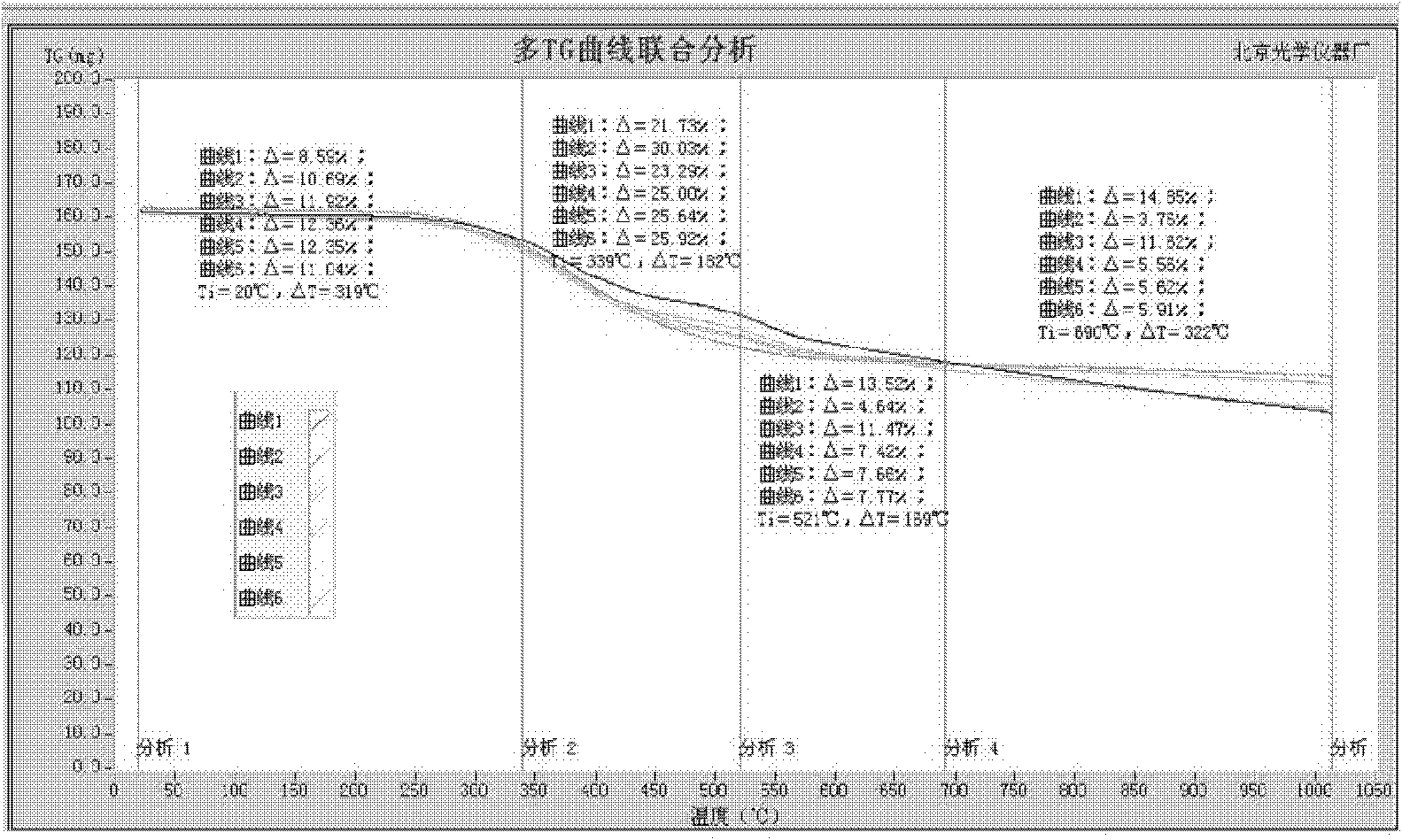

Method for determining electrolytic aluminum carbon paste kneading temperature

InactiveCN101308104AImprove liquidityImprove permeabilityFlow propertiesInvestigating phase/state changeAdditive ingredientQuinoline

The invention relates to a method for mixing and kneading carbon paste used in electrolytic aluminum, which is characterized in that when kneading ingredients for the carbon paste, asphalt is added with a softening point controlled at between 90 and 120 DEG C, percentage of toluene insoluble is controlled at between 25 percent and 35 percent and quinoline insoluble at between 6 percent and 15 percent; and the optimal range of asphalt viscosity is between 285 and 700-centipoise, and the mixing and kneading temperature range of the paste is at between 150 and 200 DEG C. The method figures out the relation between the rheologic property and the softening point of the coal asphalt and the relation between the rheologic property and the main components of the asphalt including the toluene insoluble, the quinoline insoluble through analysis of the softening point of coal asphalt and rheologic property of main components of the asphalt including the toluene insoluble, the quinoline insoluble and the coal asphalt, and researches, and determines the optimal range of viscosity, so as to determine the optimal mixing and kneading temperature of the paste. As a result, the asphalt achieves good fluidness and can fully penetrate into pore space of aggregate, and the paste achieves sound plasticity, thereby being favorable for mixing, kneading and forming as well as improving the quality of carbon products.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Broken plastic regeneration plasticizer

ActiveCN105711055AReduce gapEasy dischargePlastic recyclingMechanical material recoveryVacuum pumpingPlasticizer

The invention relates to the field of waste plastic recycle, and aims at providing a broken plastic regeneration plasticizer. The broken plastic regeneration plasticizer comprises a machine base, a cutting-mixing pre-plasticizing device, a main plasticizing device and a vacuum suction filter device, wherein the cutting-mixing pre-plasticizing device is provided with a feeding hopper and a discharging port; the main plasticizing device comprises a cylinder which is provided with a cylinder heating device and connected with the machine base, a middle rod, two ends of which are connected with the cylinder, a plurality of main spiral push rods, two ends of which are pivoted with the cylinder, and a push rod driving device; an auxiliary spiral push rod is arranged in the interspace outside every two adjacent main spiral push rods; two ends of the auxiliary spiral push rods are pivoted with the cylinder; and the cylinder is provided with a plasticizing inlet which is arranged at the rear part of the side of the cylinder and communicated with the discharging port, a plasticizing outlet which is located at the front end of the cylinder, and an exhaust vent which is communicated with the inlet of the vacuum suction filter device.

Owner:NINGBO LVHUA RUBBER & PLASTIC MACHINERY IND & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com