Process for producing anode paste by direct water spraying and continuous cooling and complete equipment set

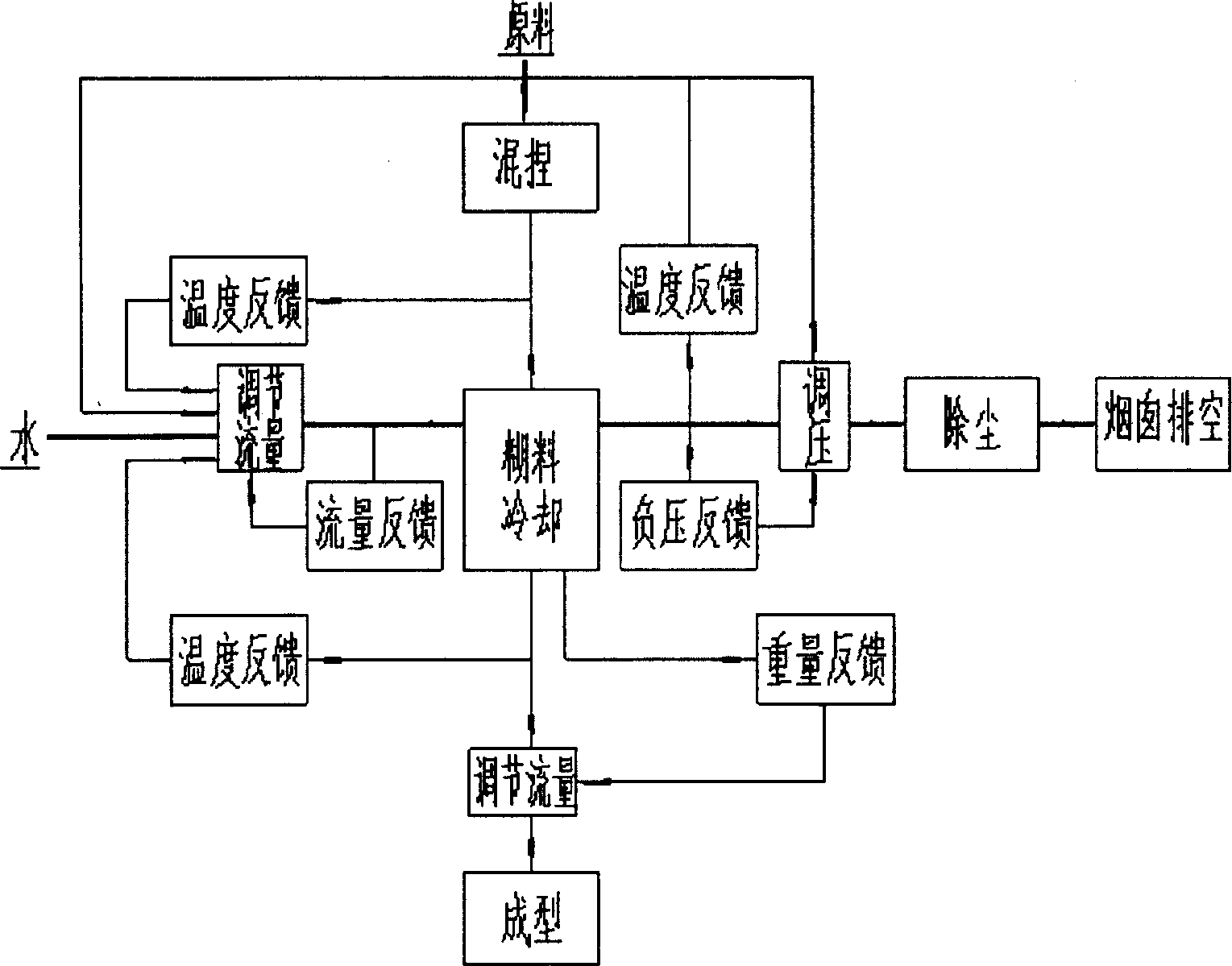

A complete set of equipment and production process technology, applied in the field of continuous cooling production process and equipment of anode paste, can solve the problems of large area of direct air cooling equipment, difficulty in collecting cooling flue gas, unsatisfactory cooling effect, etc., so as to improve the mixing and kneading effect. effect, lowering temperature, improving fluidity and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

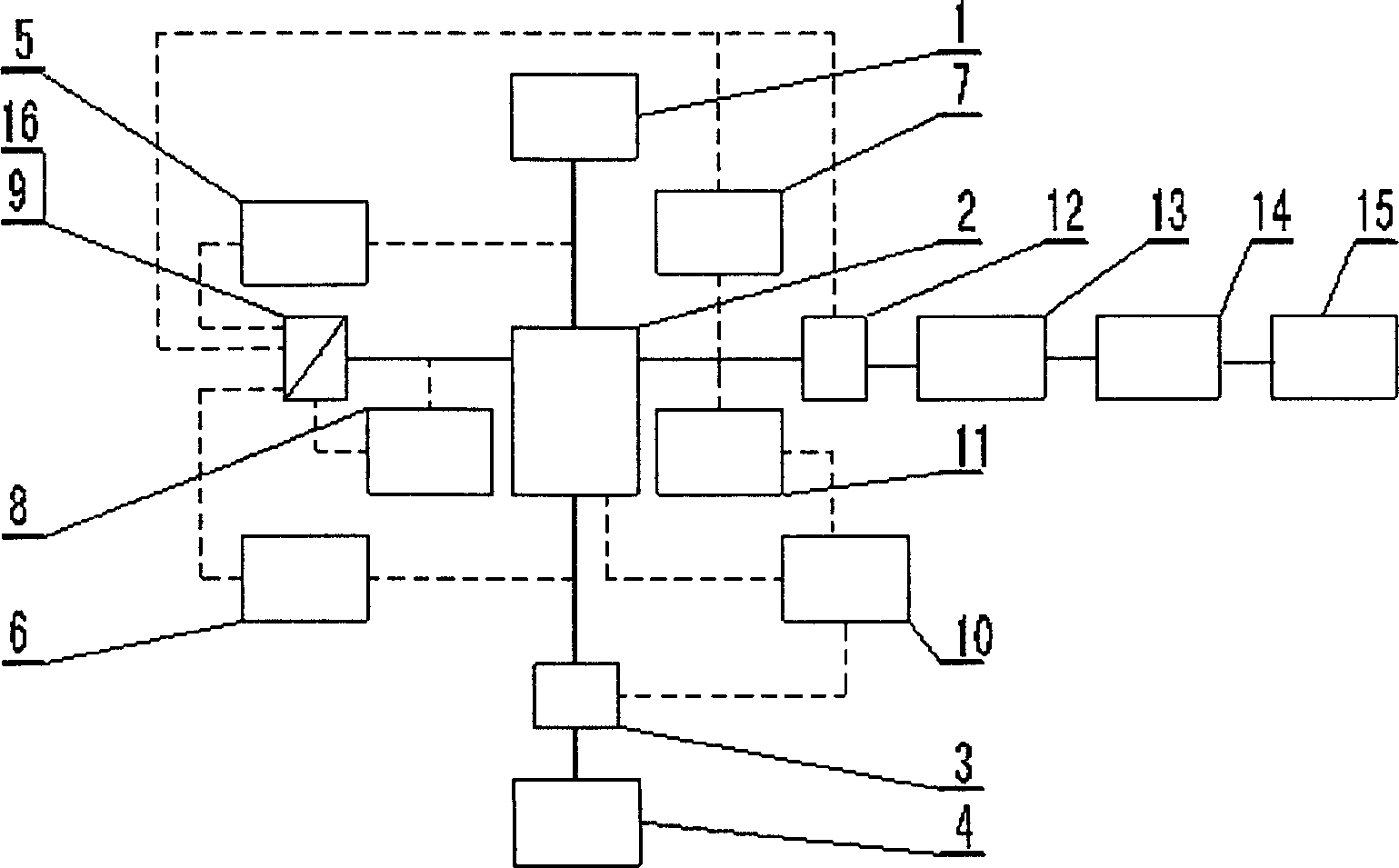

[0019] Embodiment of the present invention: according to the output requirements of the continuous kneading machine 1, the optional configuration, the paste cooler 2 (including various sensors, discharge baffles, water supply valves, water flow meters and computer control systems, etc.), And make connecting parts, connect according to the relationship shown in the figure. Firstly, connect the continuous kneader 1 with the paste cooler 2, and connect the paste cooler 2 with the water valve 9, the discharge baffle 3, and the forming machine 4 respectively; secondly, connect the paste cooler 2 with the valve 12, dust removal The dust remover 13 is connected with the fan 14 and the chimney 15; then, the temperature sensors 5, 6, 7 are respectively connected to the paste inlet, the paste outlet and the flue gas outlet of the paste cooler 2, and the flowmeter 8 Connect between the water valve 9 and the paste cooler 2, connect the weight sensor 10 with the paste cooler 2 and the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com