Double-hook type dough kneading hook

A kneading hook and hook-type technology, which is applied in the direction of mixing/kneading with vertical installation tools, can solve the problems of large vibration and shaking range, large drive motor load, overheating of the drive motor, etc., to achieve good kneading effect, Effect of reducing load and overcoming vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

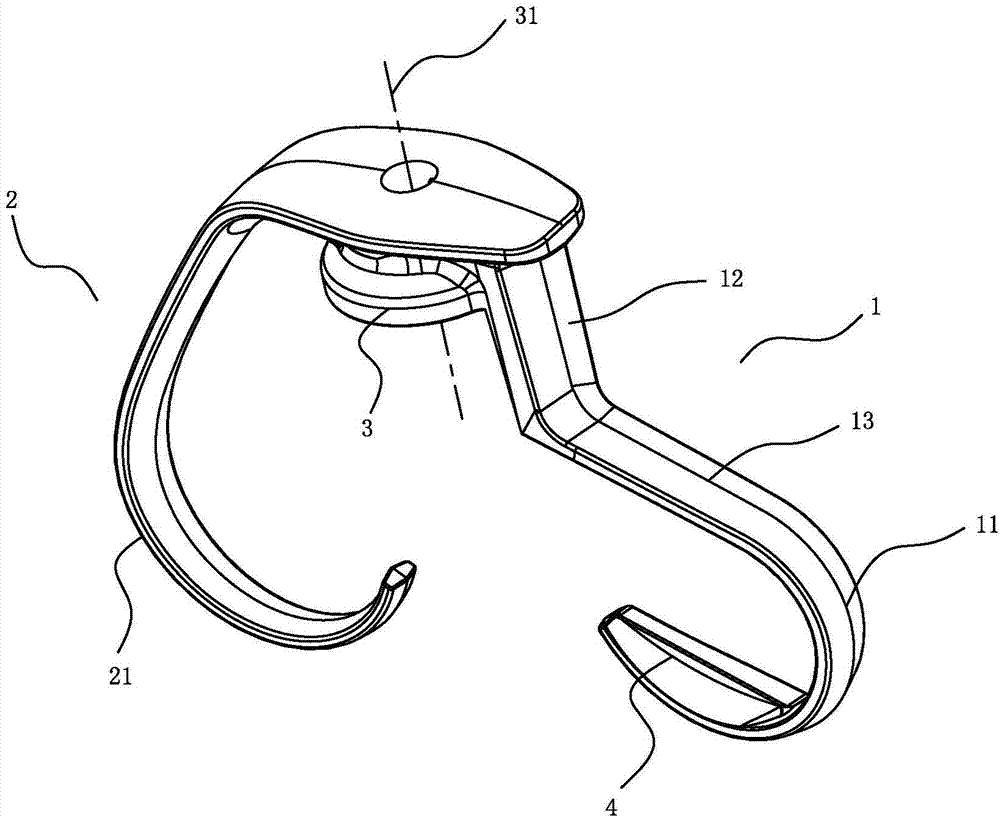

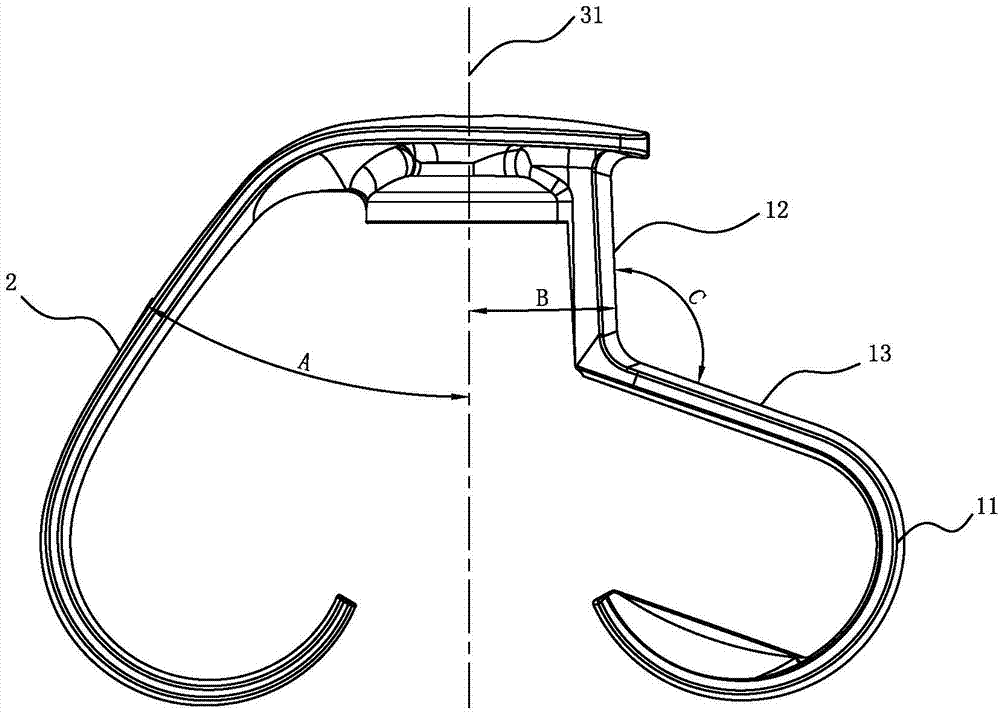

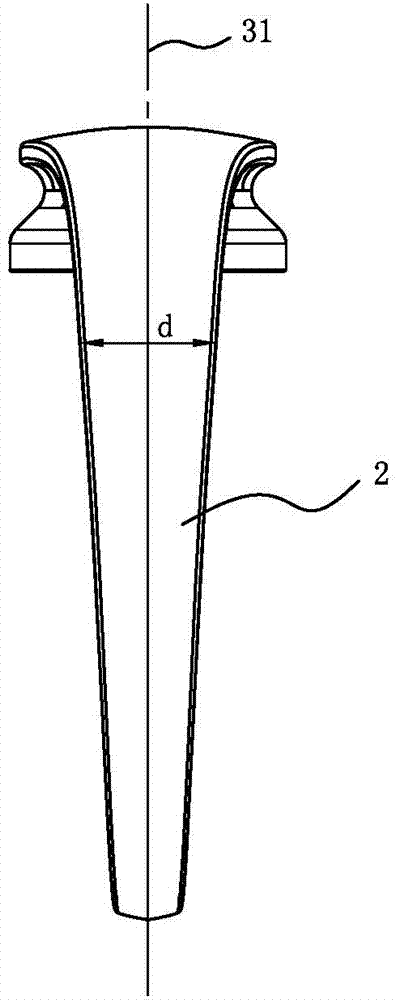

[0024] Reference Figure 1 to Figure 4 , A double-hook kneading hook of the present invention includes a kneading hook body placed in a kneading cup 10, the kneading hook body includes a first kneading portion 1 and a second kneading portion 2 integrally formed. Between the kneading portion 1 and the second kneading portion 2 is provided a connecting portion 3 connected to the driving device 20 that drives the kneading hook body to rotate. The first kneading portion 1 and the second kneading portion 2 surround the rotation center line of the kneading hook body 31 are evenly distributed in the circumferential direction. The first kneading part 1 and the second kneading part 2 are respectively provided with first hook parts 11 and second hook parts 21 at the end away from the connecting part 3 that can simultaneously knead the edge and bottom dough of the kneading cup 10, At least one of the two hooks is bent toward the connecting portion 3. When kneading the dough, the integral...

Embodiment 2

[0034] Reference Figure 5 , A double-hook type kneading hook, which is different from Embodiment 1 in that: the shape and structure of the second kneading portion 2 are different. In this embodiment, the second kneading portion 2 is in a "C" shape, which is The cantilever 22 connected to the connecting portion 3 and the inclined "J"-shaped hook 23 are composed. In order to enhance the connection strength between the cantilever 22 and the connecting portion 3, a reinforcing rib 5 is provided between the cantilever 22 and the connecting portion 3, "C" The second kneading surface of the font can be used to knead the middle and upper part of the kneading cup 10. Compared with the "J"-shaped structure, the kneading area is larger, but its strength is lower.

Embodiment 3

[0036] Reference Image 6 , A double-hook type kneading hook, which is different from Embodiment 1 in that: the shape and structure of the first kneading portion 1 are different. In this embodiment, the first kneading portion 1 is in a "J" shape, and the first The first hook portion 11 of the kneading portion 1 is curved toward the inner surface of the kneading cup 10. Compared with the structure of Example 1, although the strength of the first kneading portion 1 is poor, it can be improved by increasing its cross-sectional area. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com