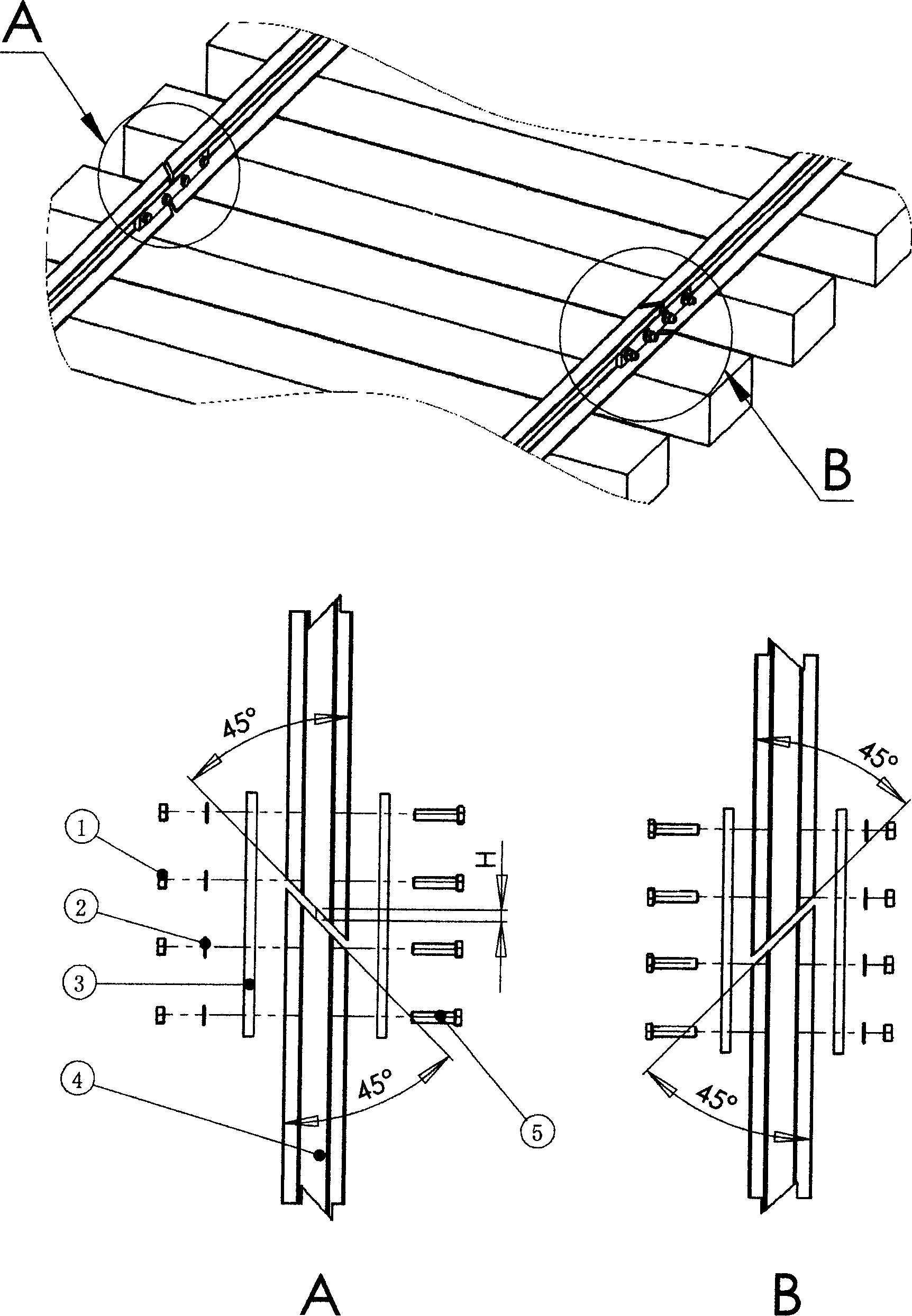

Joint technique for 45 degree sloping railway track

A technology of rail and inclination, applied in the joints of rails, roads, tracks, etc., can solve the problems of vibration and noise, easy wear at joints, wheel impact, etc., and achieve the effect of overcoming vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] New construction: After transporting the rails produced according to the improved drawings to the construction site, follow the traditional installation method. There are two points to note here: 1) The inclination angles of the left and right rails should be symmetrical. 2) The gap H between the seams of the front and rear rails refers to the distance in the direction of train travel, and should be equal to the gap calculated by the road section design department when splicing the rails by the traditional method.

[0012] Reconstruction project: During the allowed construction period, the construction locomotive is driven onto the railway, and each rail is continuously cut and punched in a retreating manner, and then the processed rails are spliced one by one with a track laying machine in sequence. The seam gap remains consistent with the original seam gap (referring to the distance in the direction of train travel). It is suggested that for each construction, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com