Patents

Literature

371results about "Rail joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

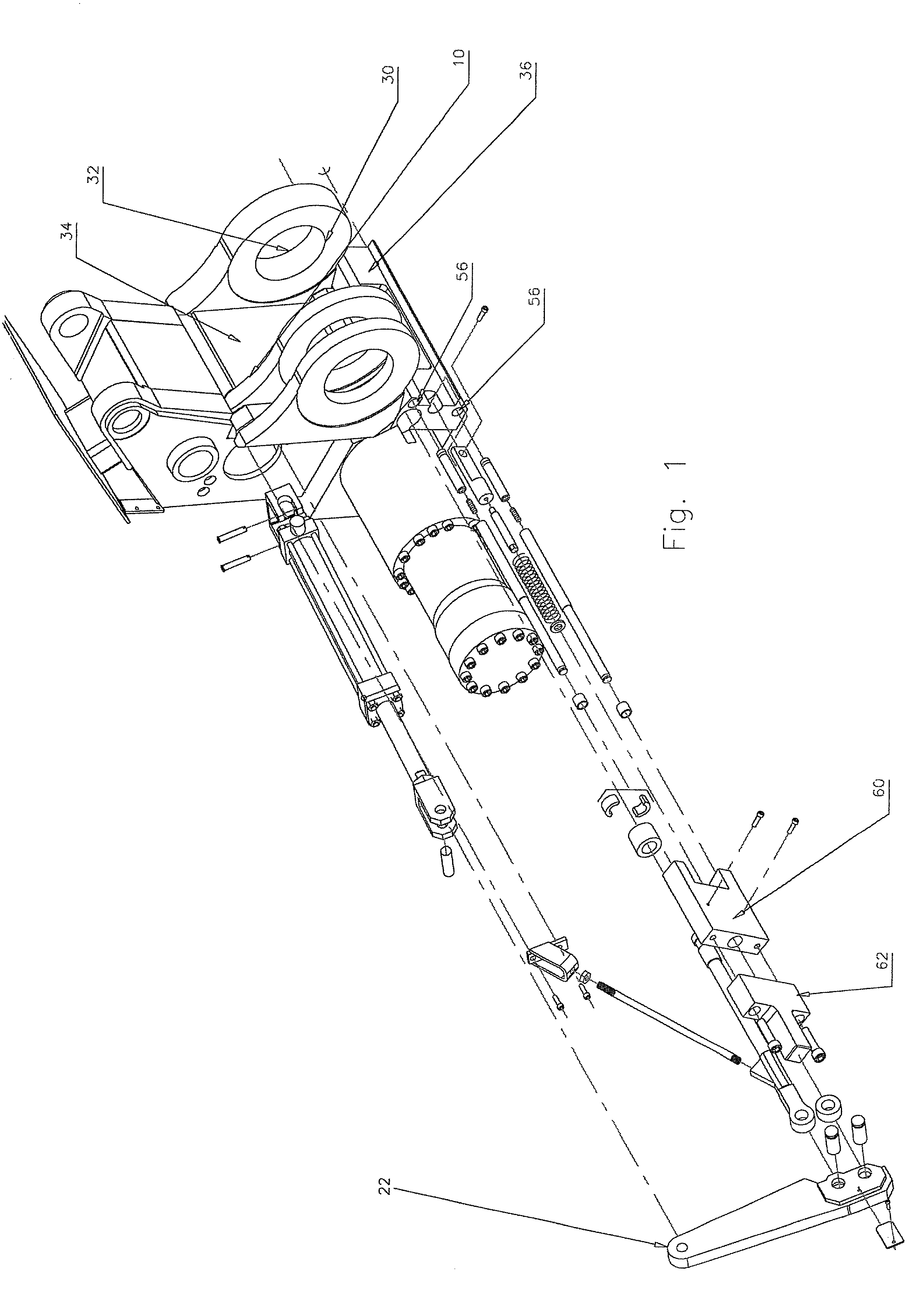

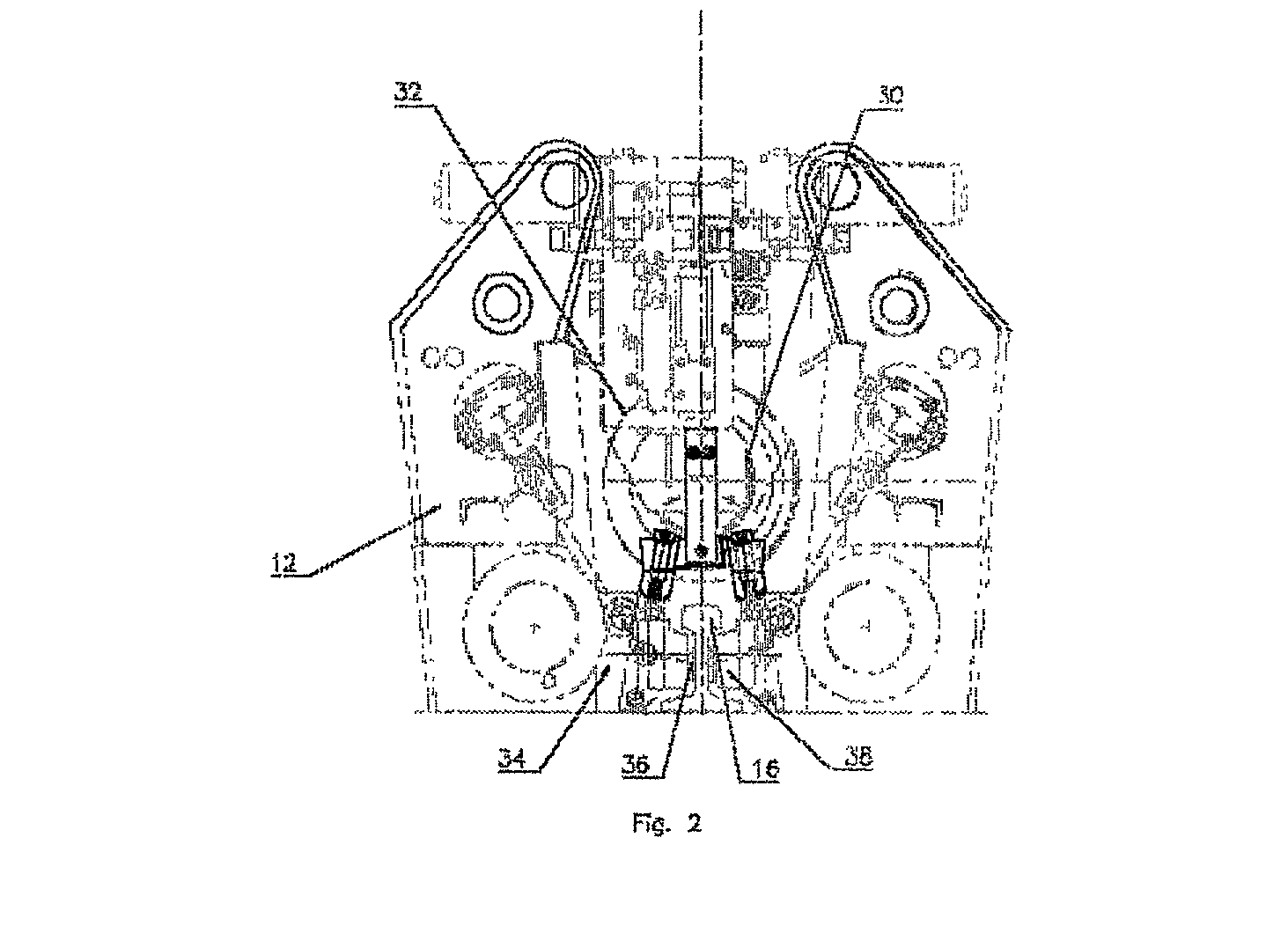

Rail welderhead shear apparatus

A flash butt rail welding welderhead combines in a single unit, the ability for the three functions of rail pulling, flash butt forging and maintaining the "after forged" displacement without any change in platen position such that shearing may be accomplished in three stages, a single stage, multiple stages or a progressive stage, all while maintaining clamping and stretching force on the rails.

Owner:HOLLAND CO

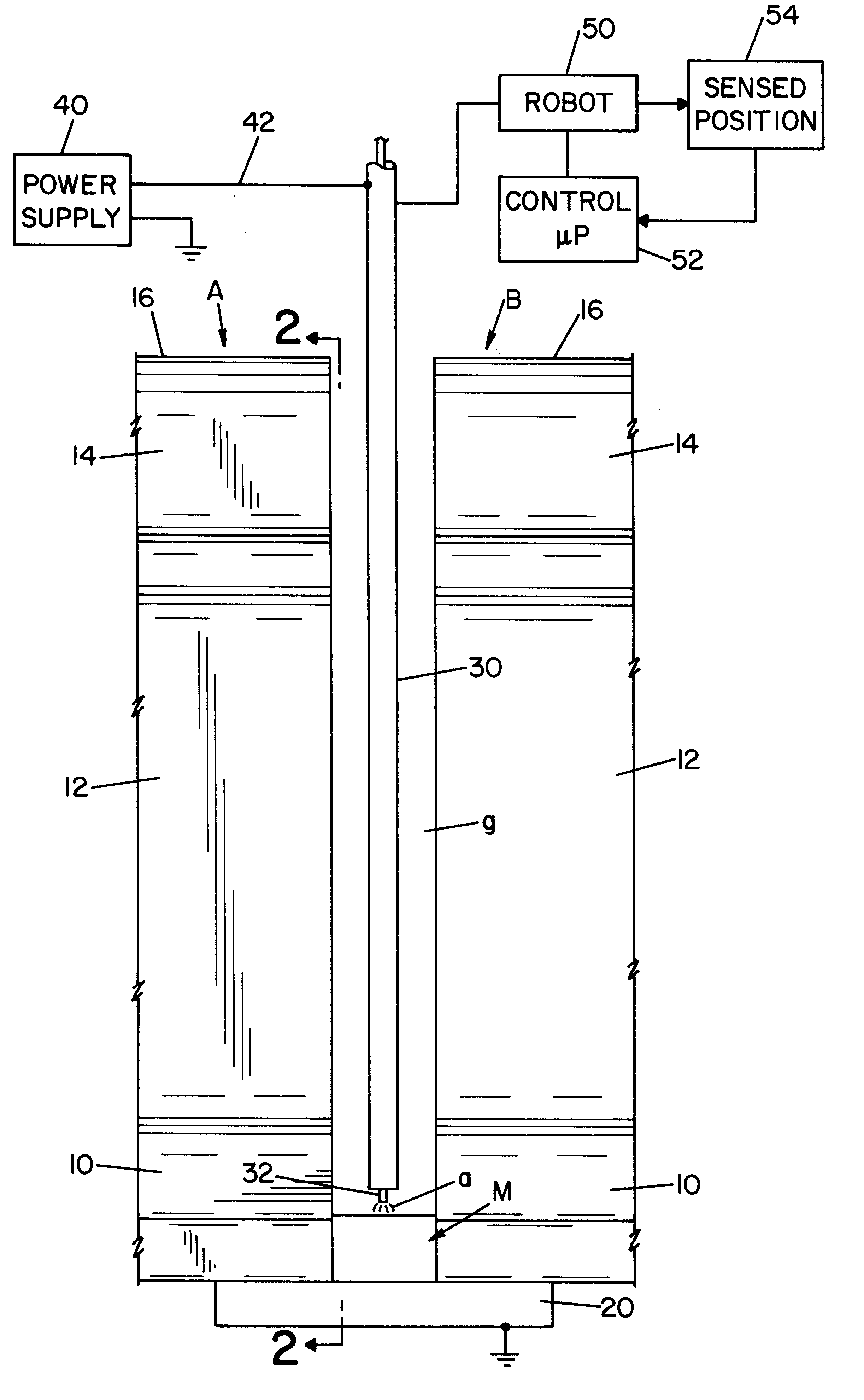

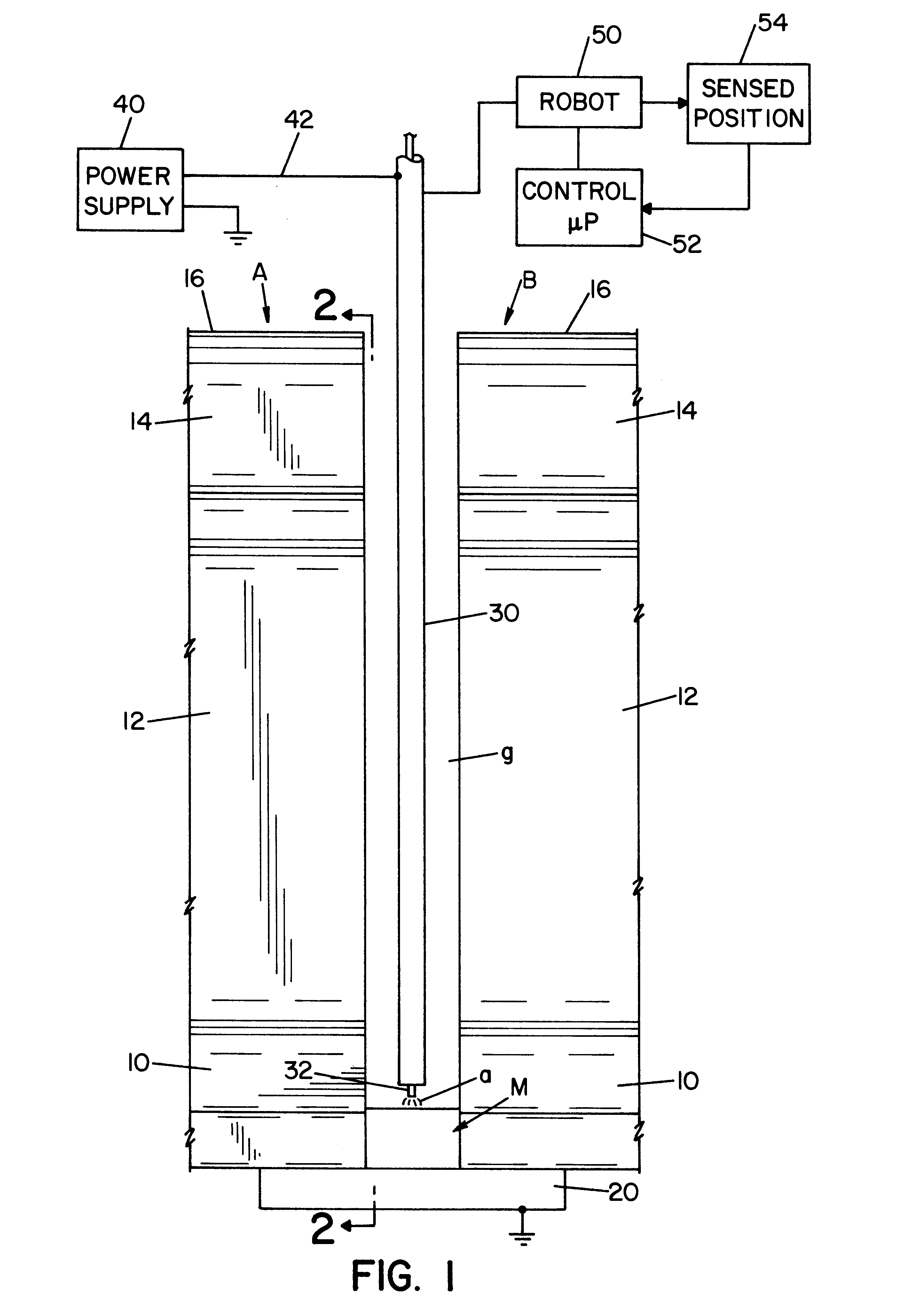

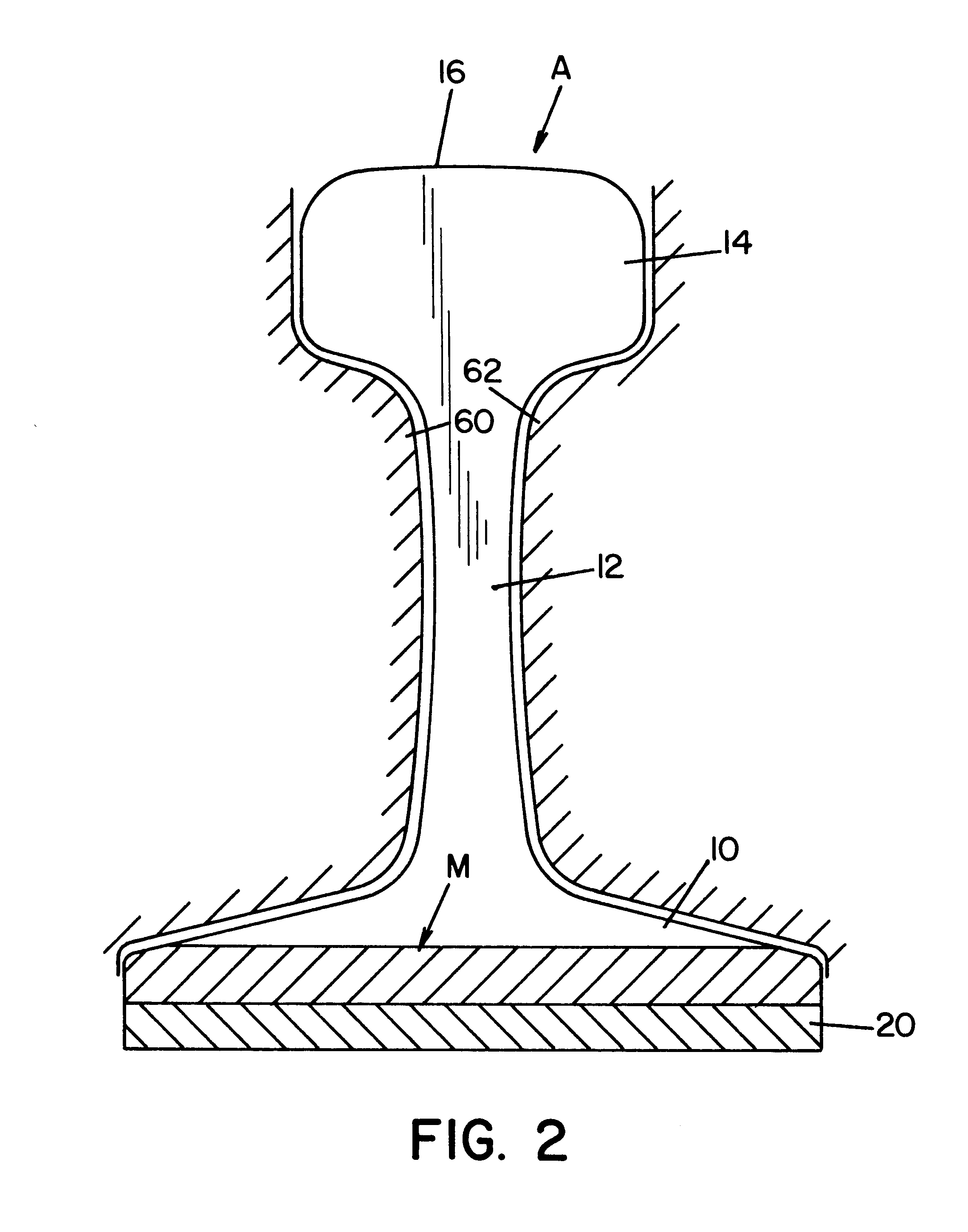

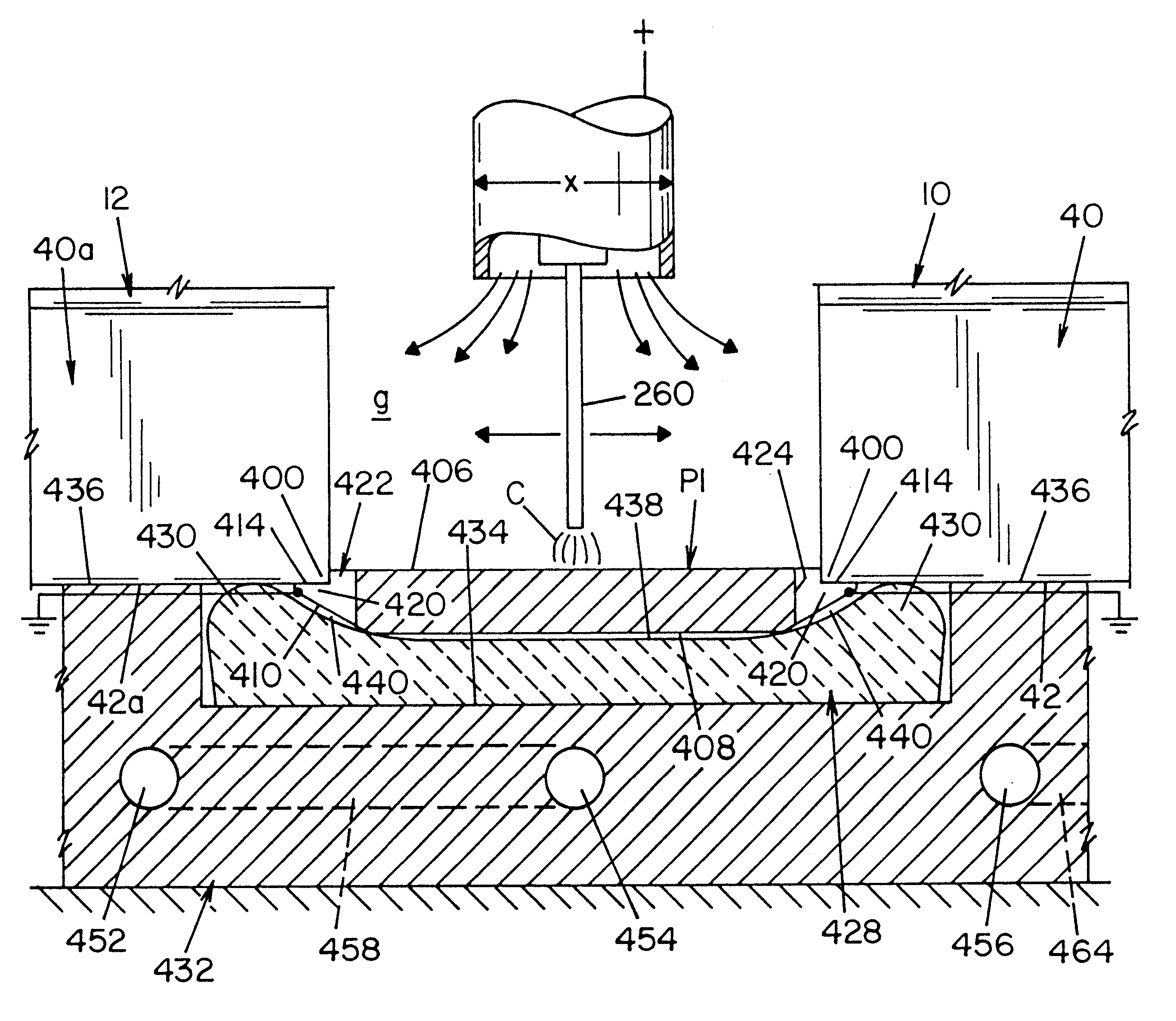

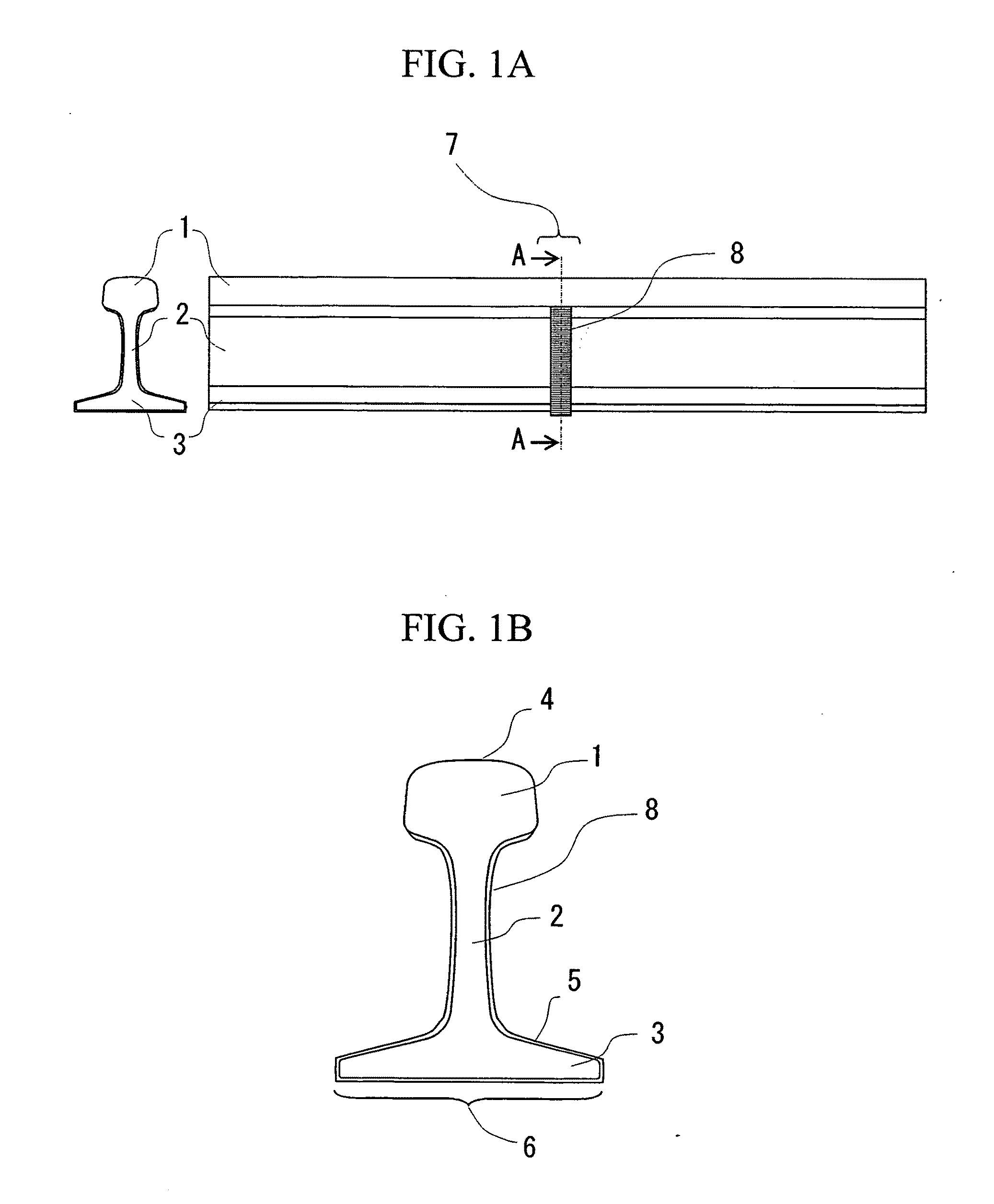

Method and system for welding railroad rails

A method and system for automatically filing the narrow gap between facing end walls of adjacent first and second railway rails by depositing vertically spaced layers of molten metal in the gap with an electric arc welding torch using a robotic mechanism that moves the torch in a pattern controlled by a low level robotic execute program from a spatial position to a next spatial position, said method and system comprising: constructing a data array for a specific gap, said array constituting a series of positions making up an idealized progression of said torch to fill said gaps in vertically spaced layers made up of multiple positions, each of said fixed positions identified by at least four coordinates, including (1) at least x, y and z, (2) the layer in which said position is a part and (3) the welding parameters to be executed while said torch moves toward the next position; outputting data relating to a specific position from said data array; processing said welding parameters associated with said outputted data using said robotic execute program; then, outputting the new fixed data relating to the next position in said series of points; processing said welding parameters associated with said new data using said robotic execute program; and, repeating said outputting and processing acts until said positions in said data array relating to a specific layer have been processed. Thereafter the method or system repeats the layer or processes the next layer comprising multiple stored positions.

Owner:LINCOLN GLOBAL INC

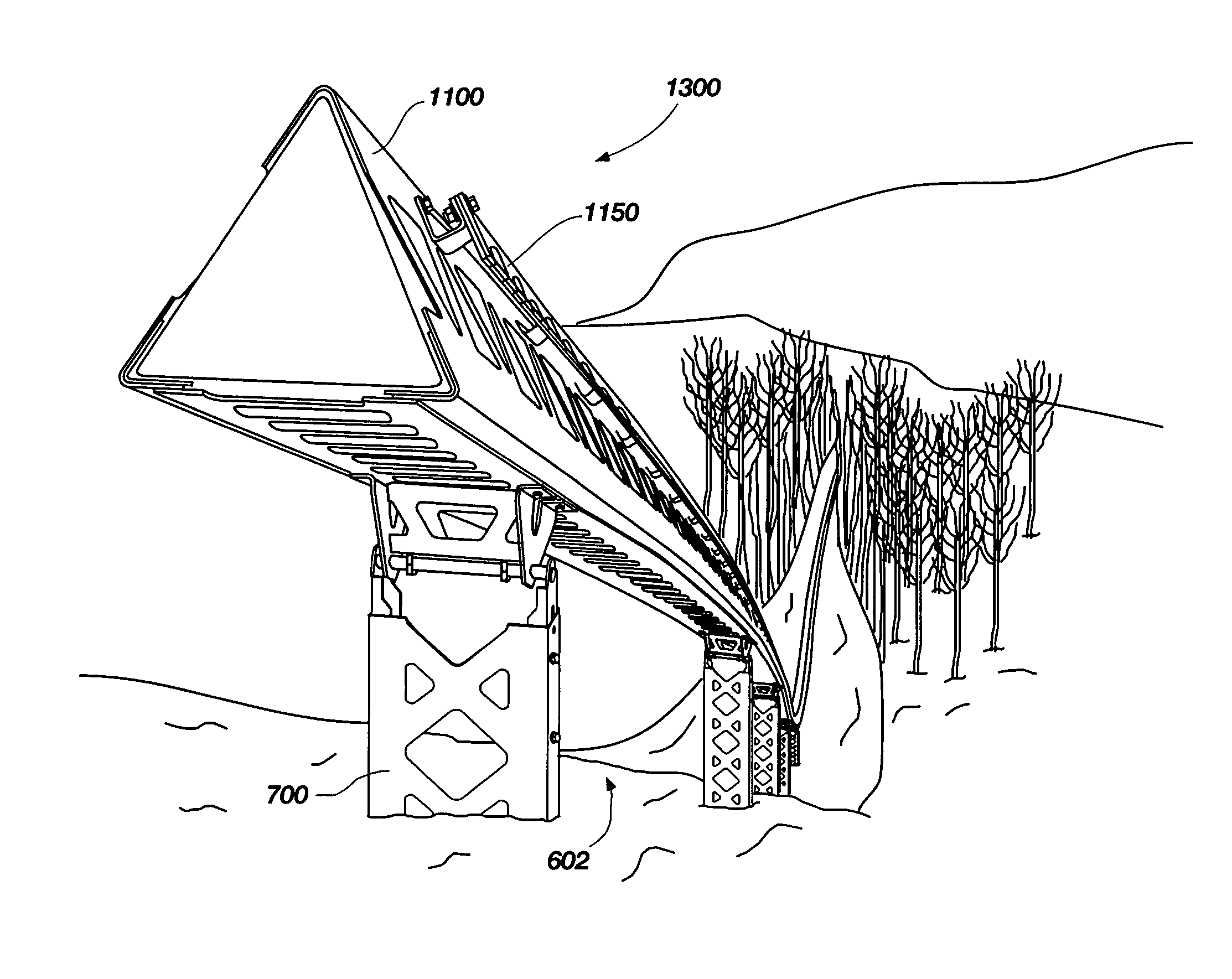

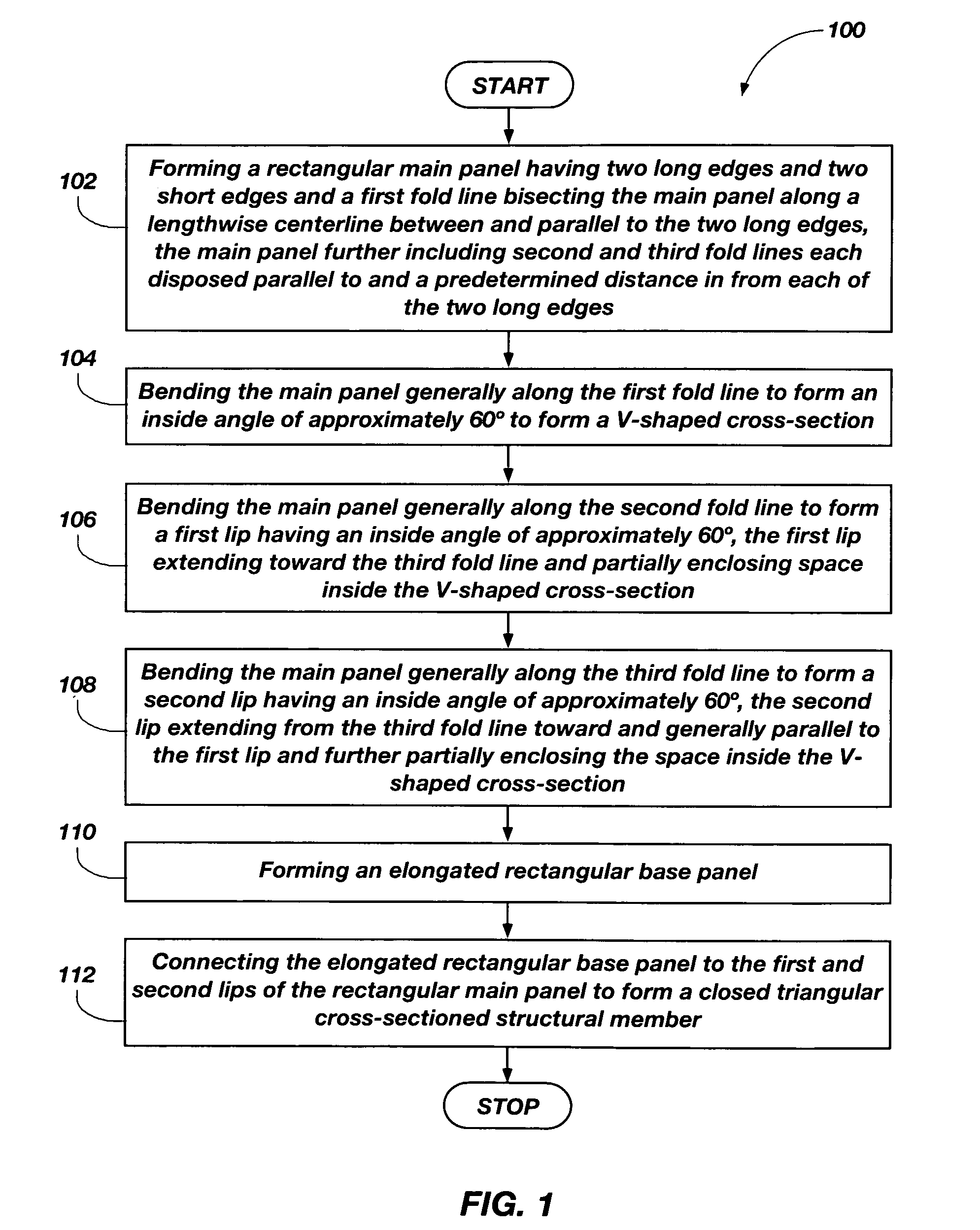

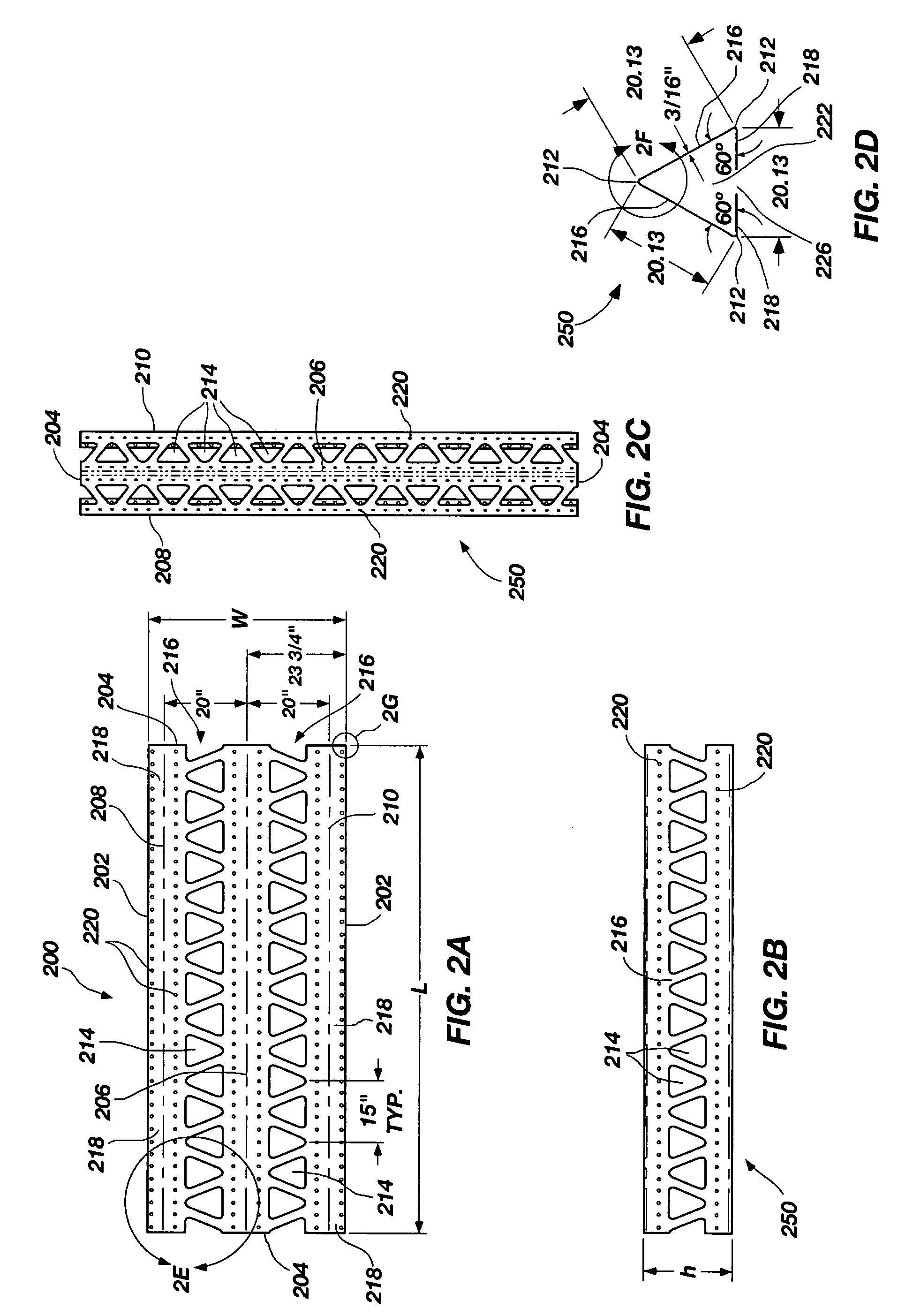

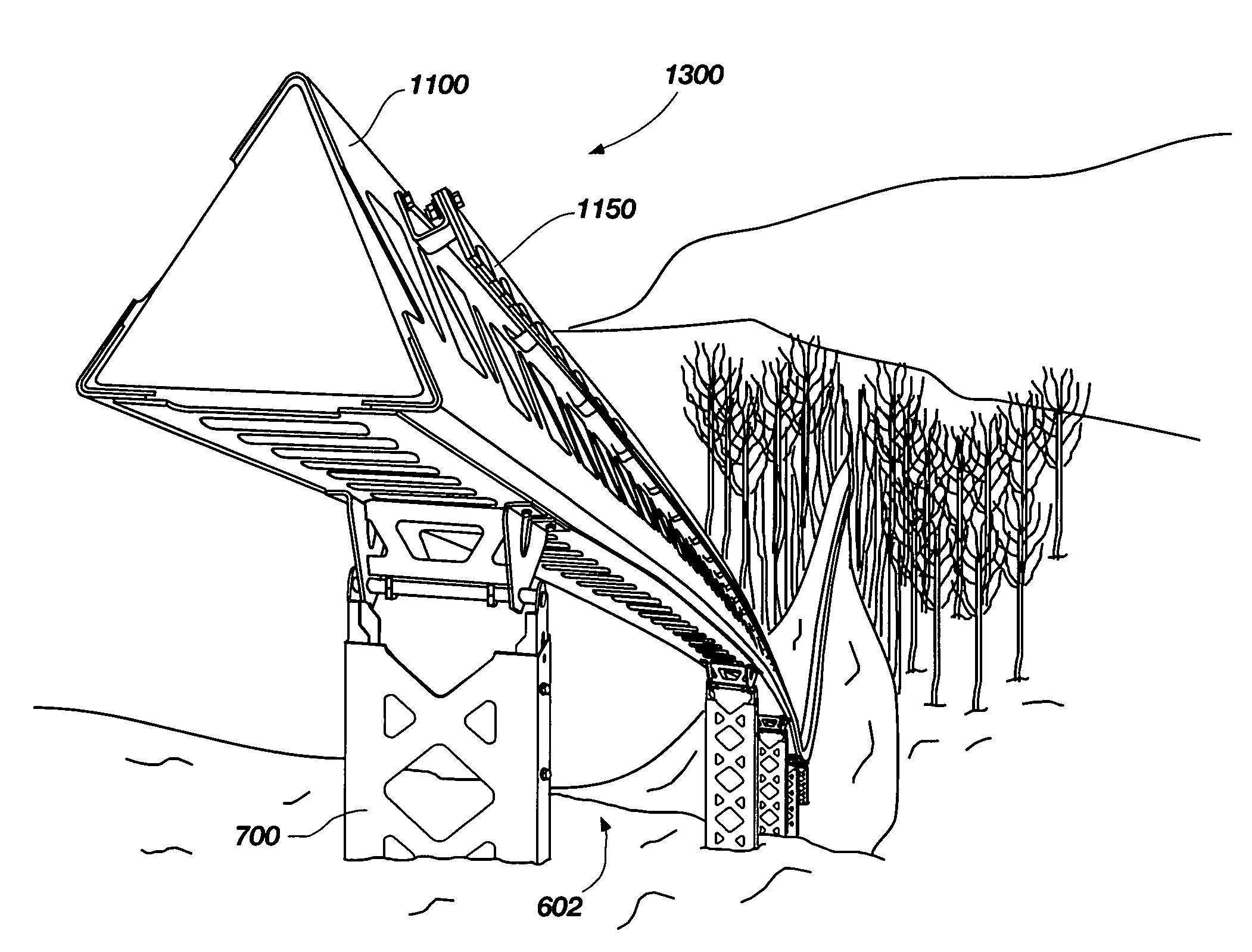

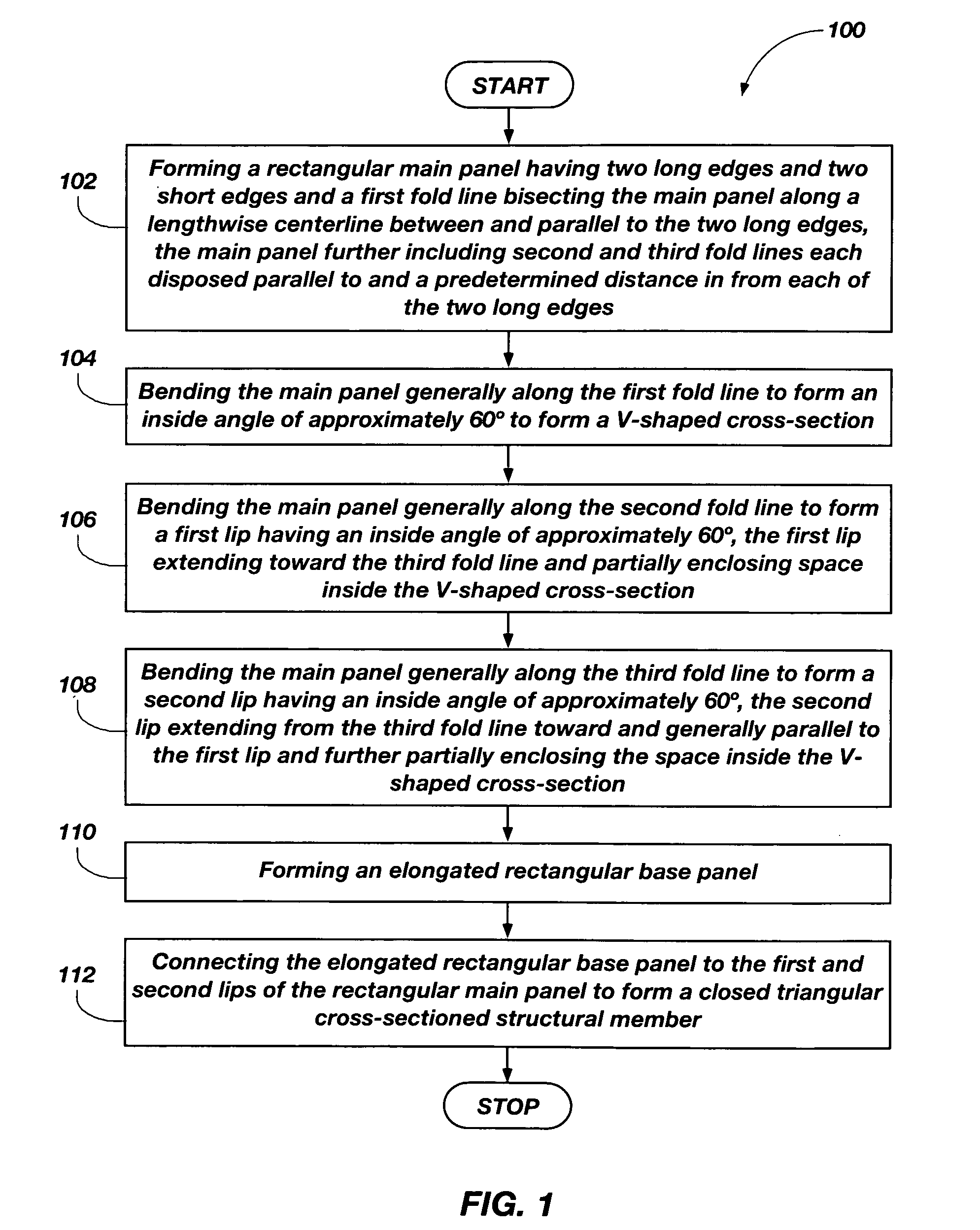

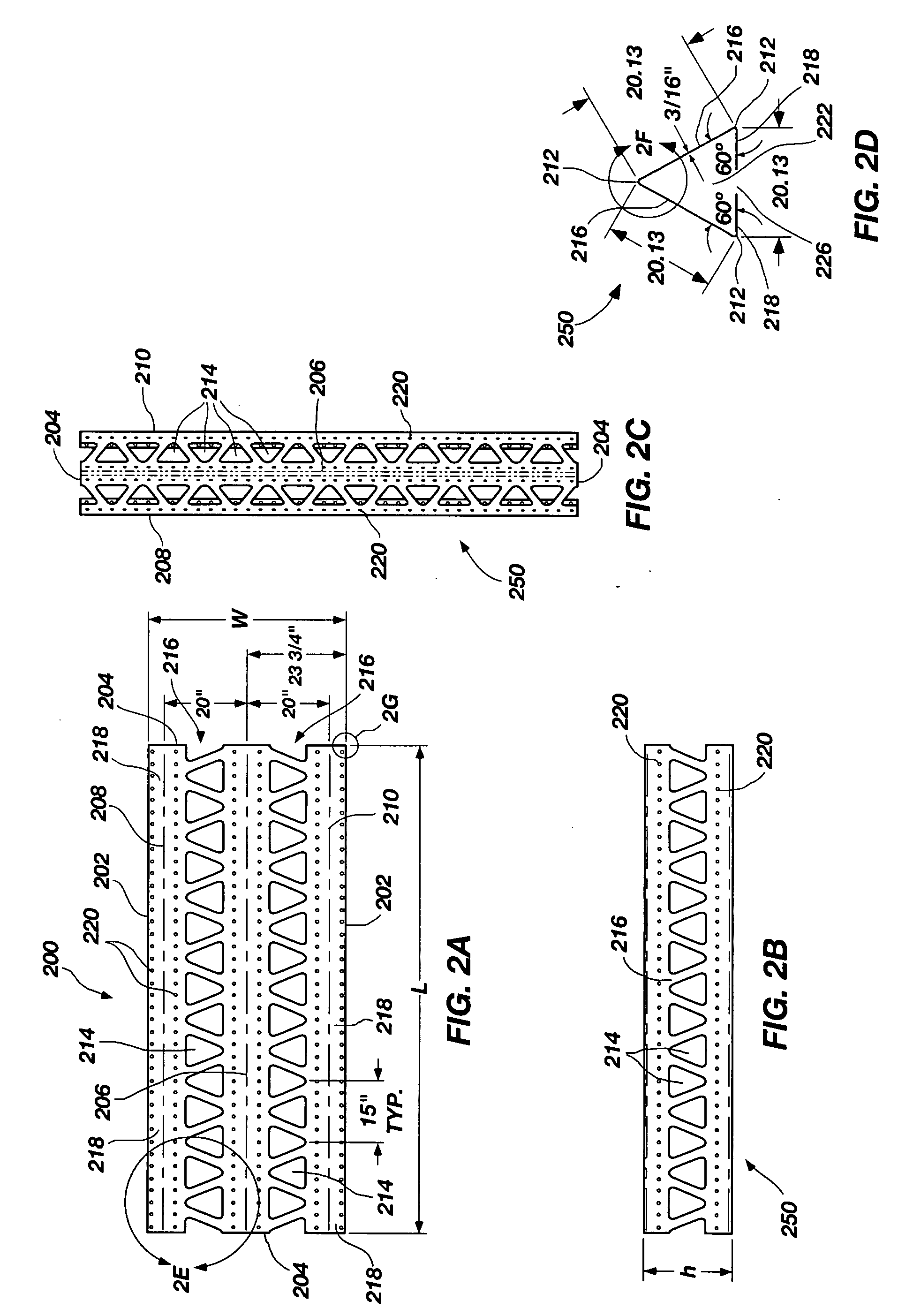

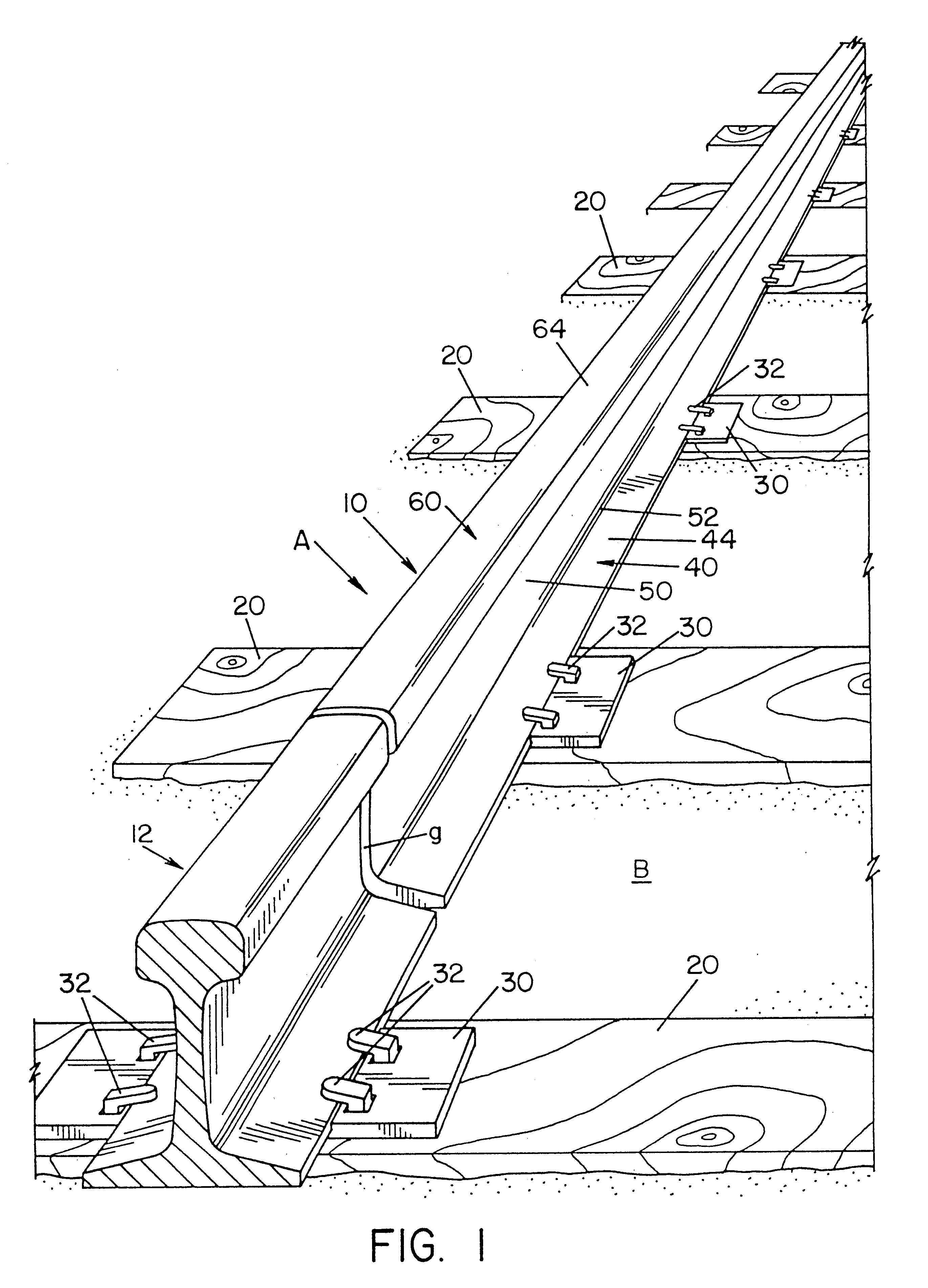

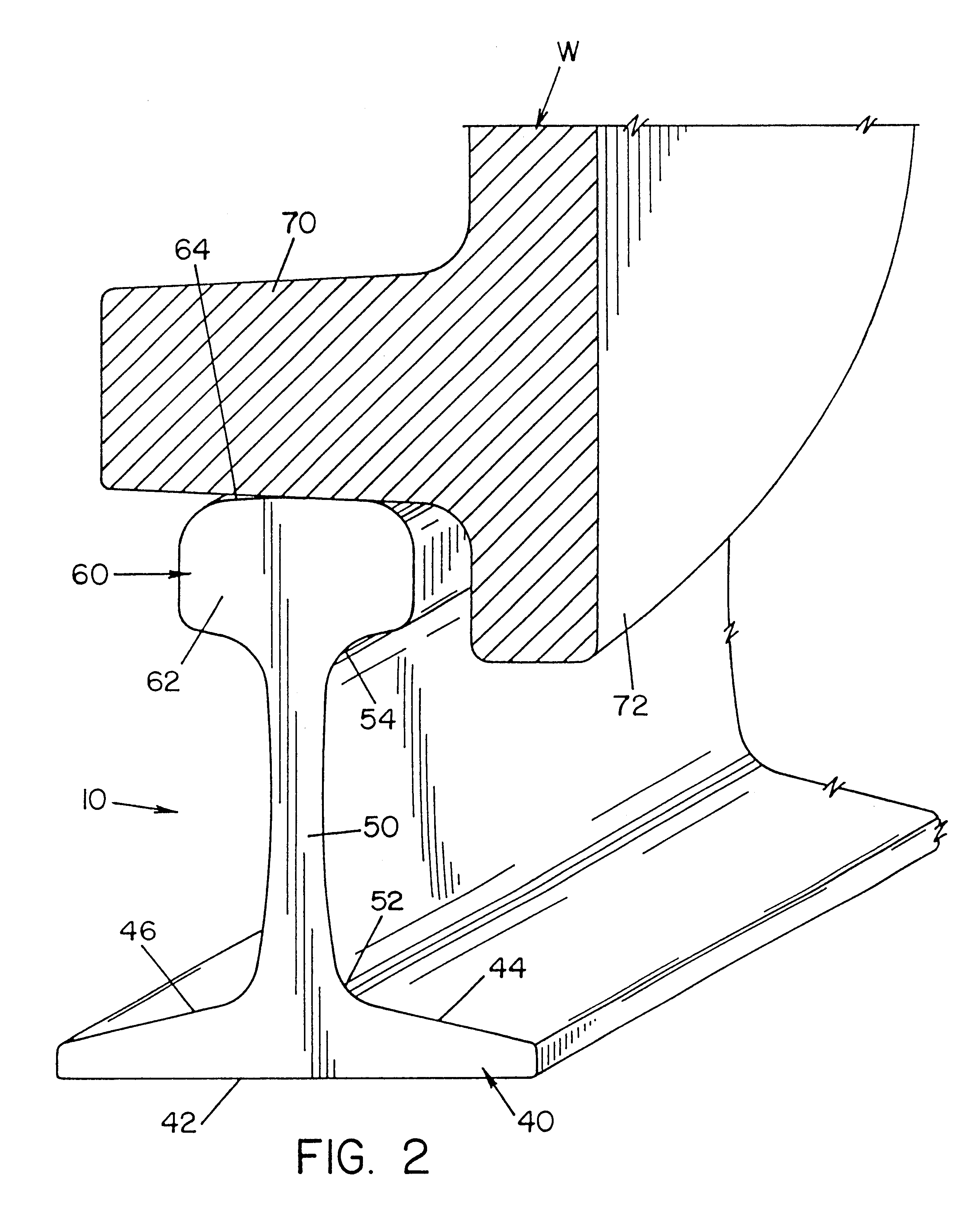

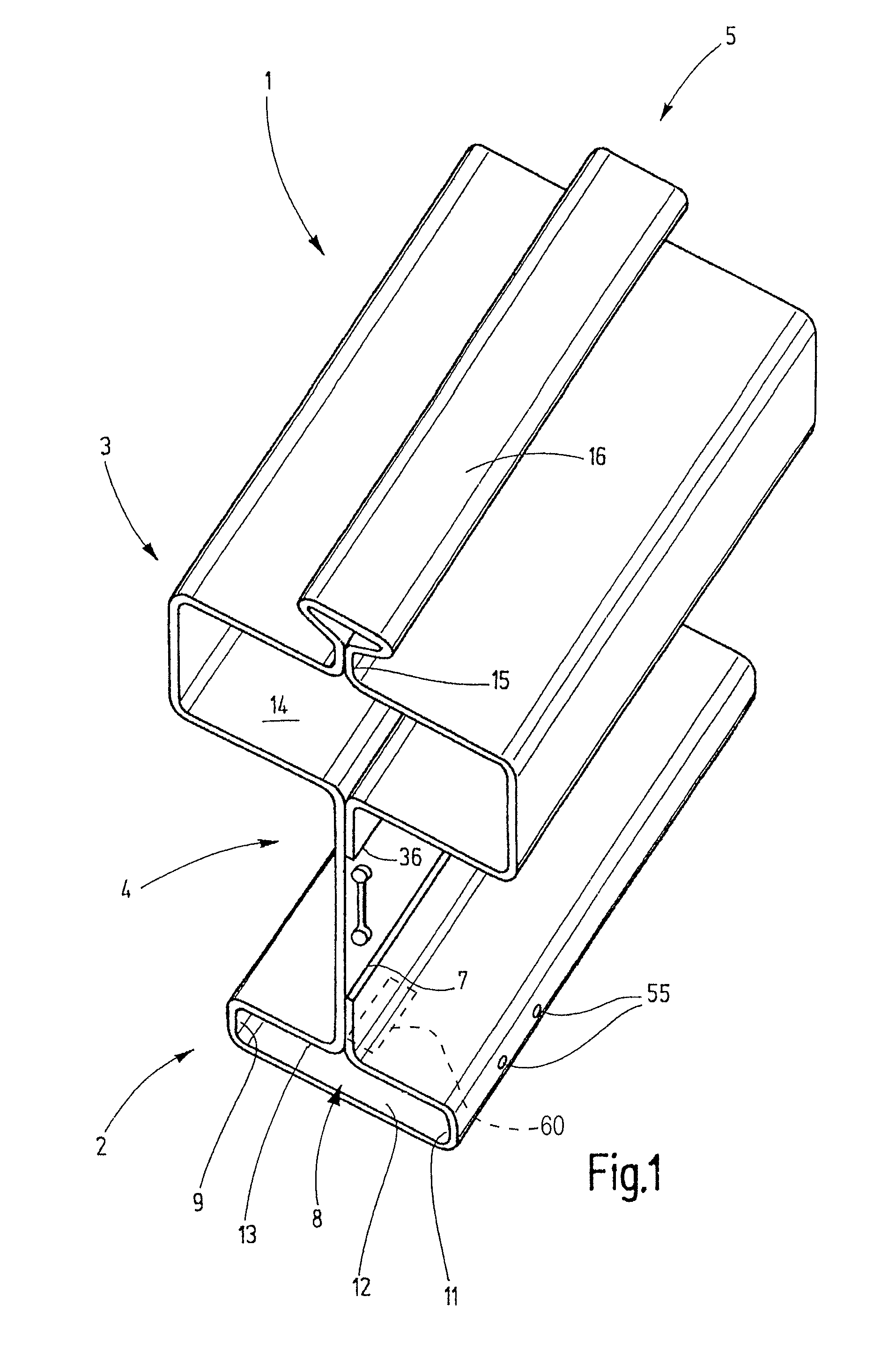

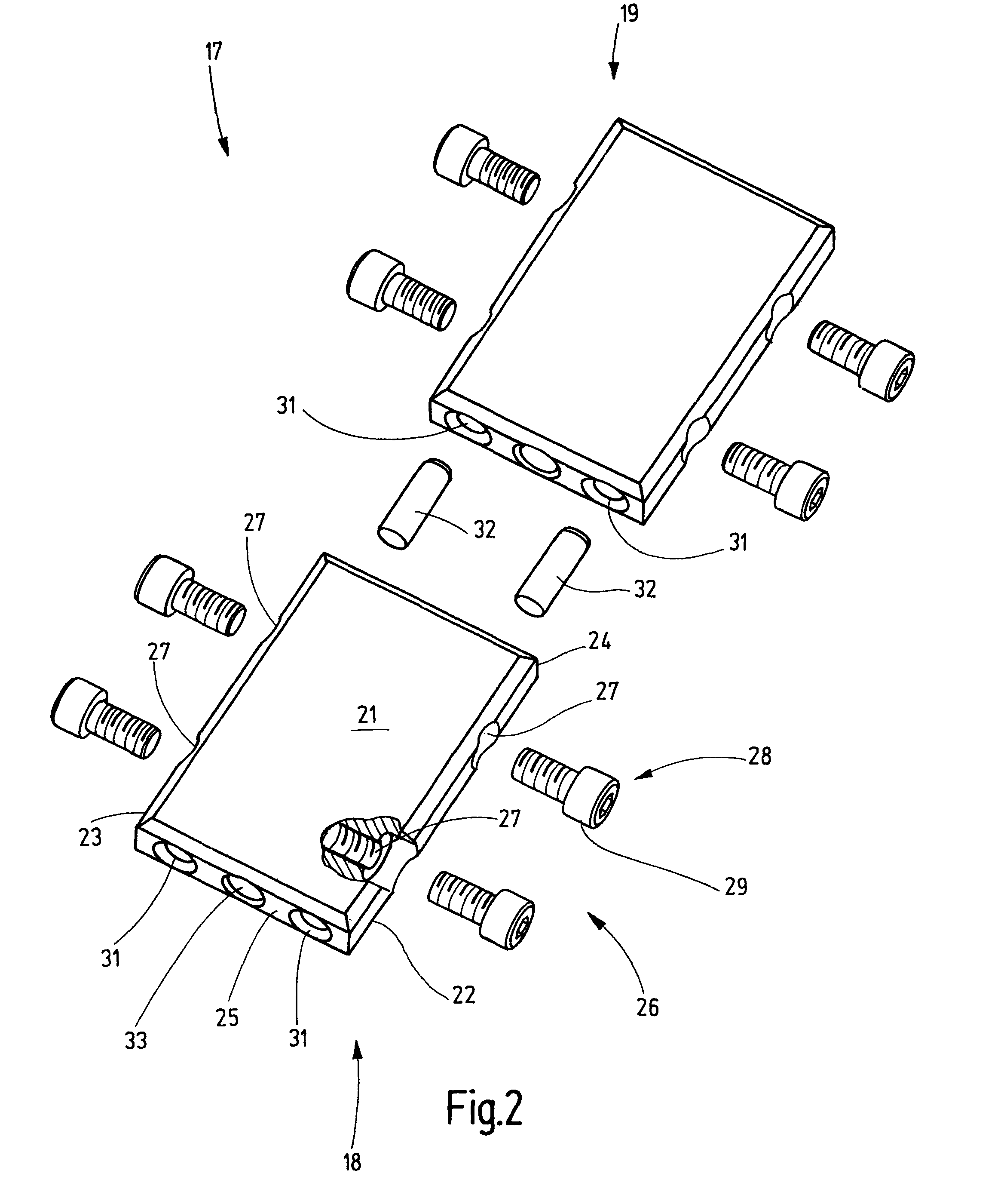

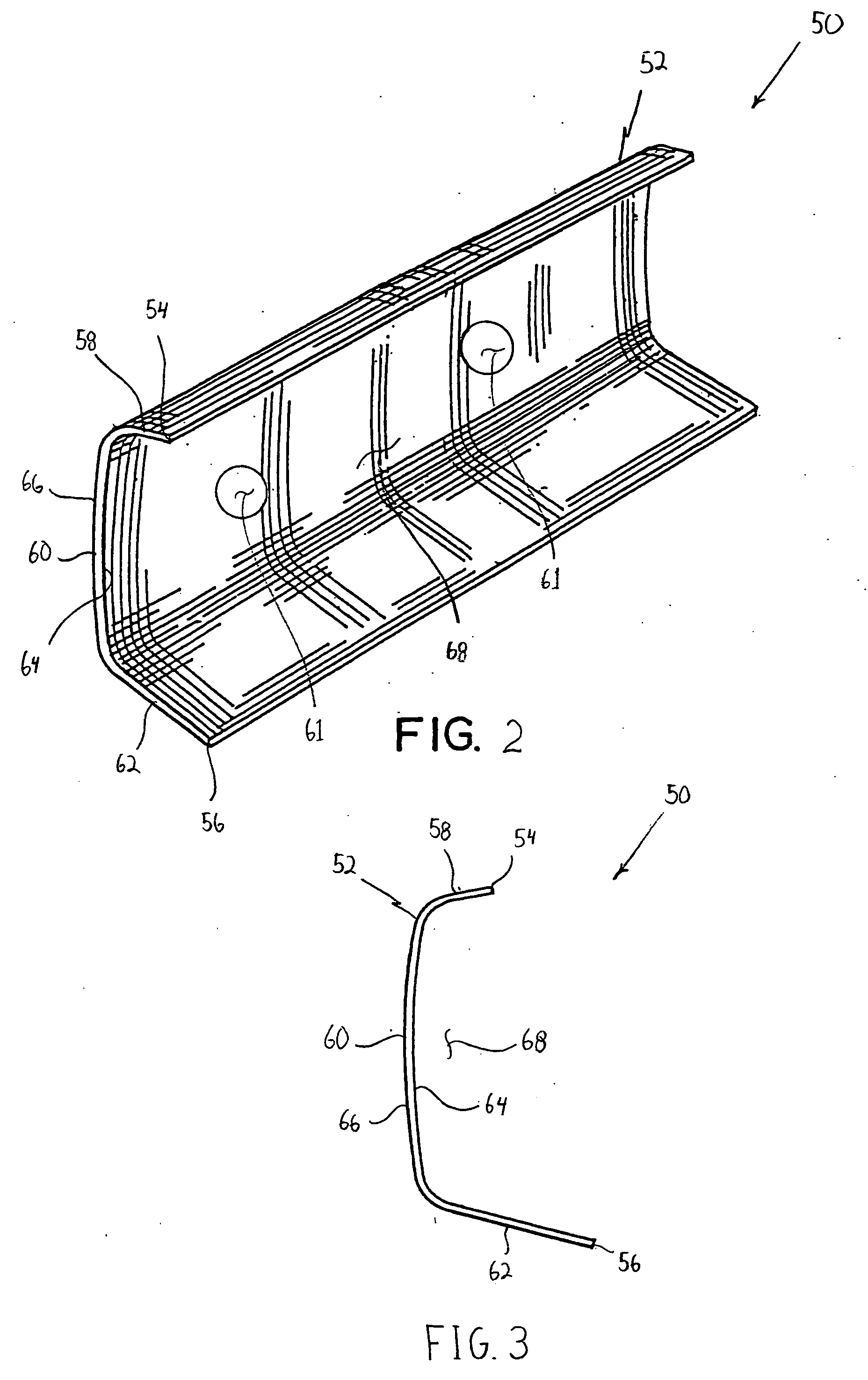

Hollow structural members, a rail system and methods of manufacturing

The invention is hollow structural members, a rail system based thereon and method of manufacturing such hollow structural members. Embodiments of the structural members may be hollow triangular prism-shaped with a cross-section that is triangular, isosceles, hexagonal or otherwise. Embodiments of rail systems based on hollow structural members are also disclosed. Embodiments of the rail systems disclosed herein may also include reaction assemblies for local dissipation of stresses due to thermal expansion of track materials.

Owner:HILLTRAC

Hollow structural members, a rail system and methods of manufacturing

The invention is hollow structural members, a rail system based thereon and method of manufacturing such hollow structural members. Embodiments of the structural members may be hollow triangular prism-shaped with a cross-section that is triangular, isosceles, hexagonal or otherwise. Embodiments of rail systems based on hollow structural members are also disclosed. Embodiments of the rail systems disclosed herein may also include reaction assemblies for local dissipation of stresses due to thermal expansion of track materials.

Owner:HILLTRAC

Method and system for welding railroad rails

InactiveUS6207920B1Avoid lostAvoid overall overheatingRailsWelding/cutting auxillary devicesMolten steelMechanical engineering

A method of gas shielded arc welding steel rails spaced from each other to define a longitudinal gap therebetween comprises the steps of providing an elongated steel barrier plate across the gap at the bottom of the spaced rails, and filling the gap above the barrier plate with a molten steel from an advancing filler metal electrode by a gas shielded electric arc welding process. The barrier plate has a central portion received in the gap and longitudinally extending recesses laterally outwardly adjacent to the central portion and which underlie the bottoms of the rails at the bottom of the gap.

Owner:LINCOLN GLOBAL INC

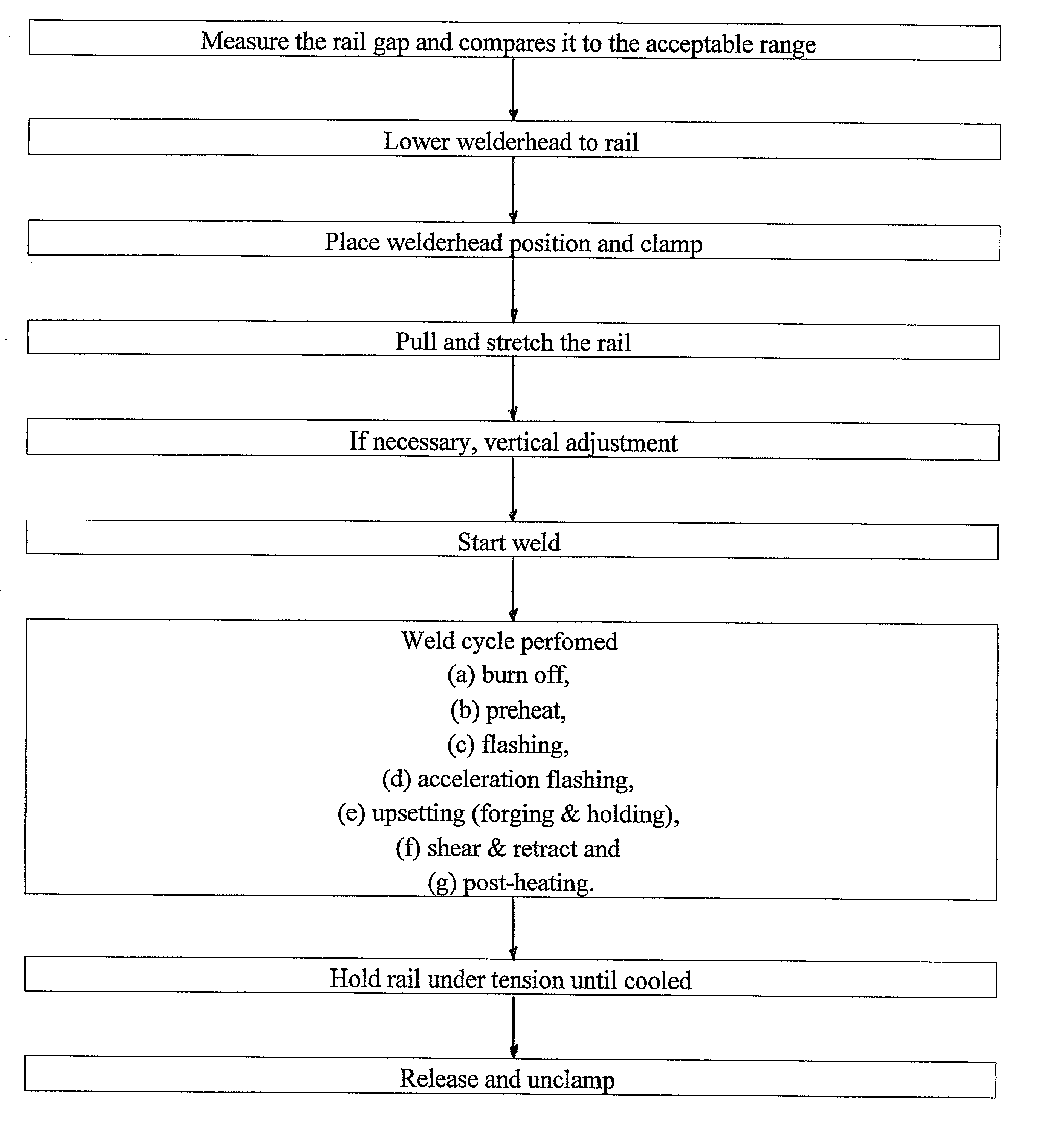

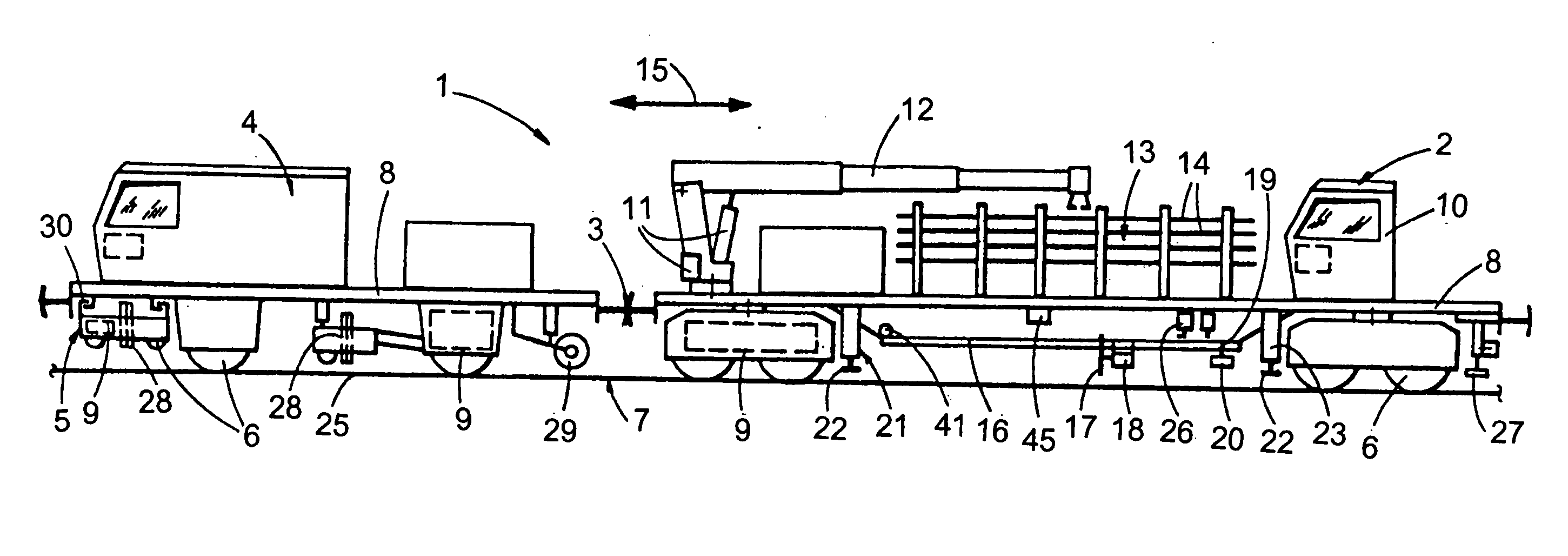

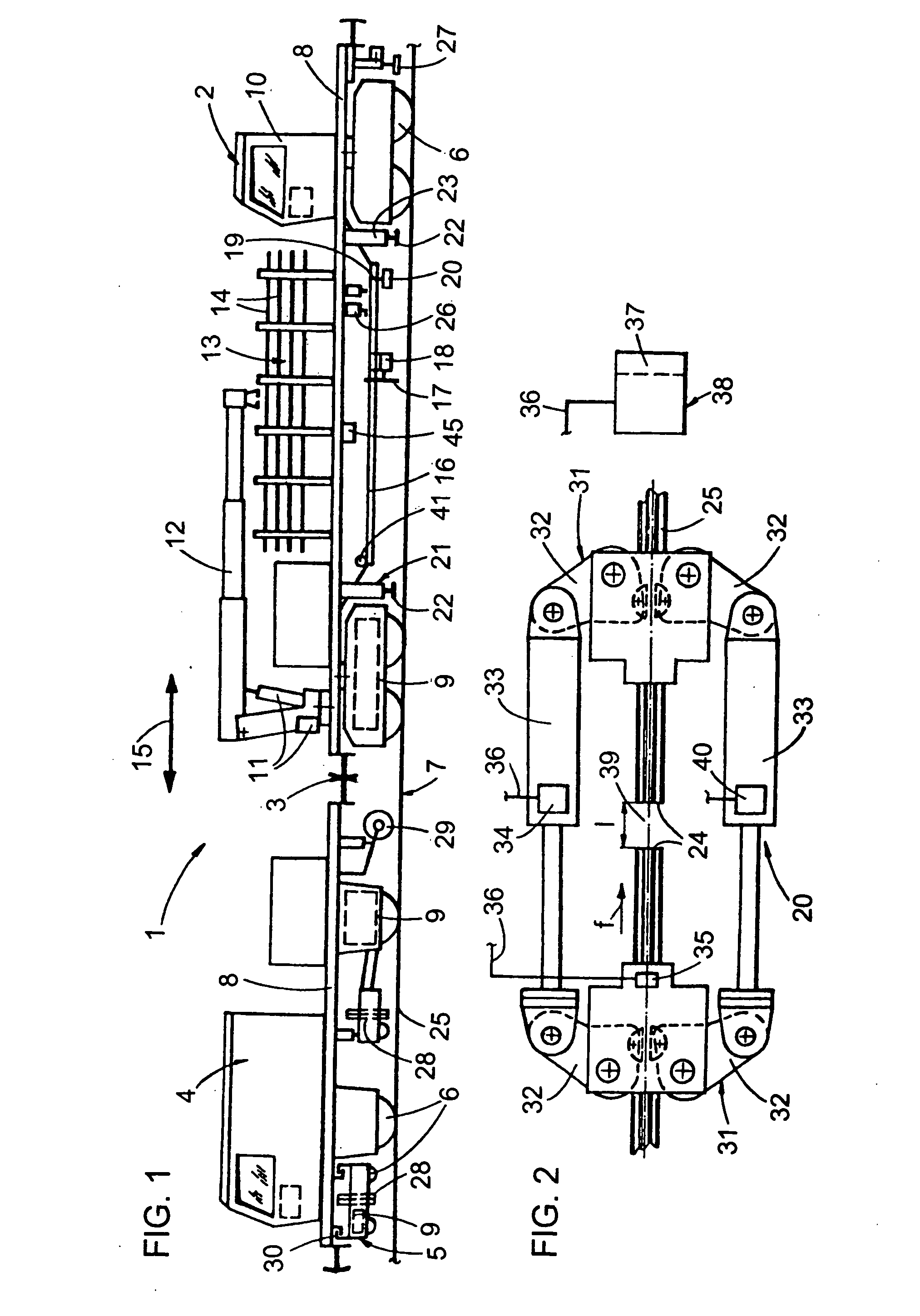

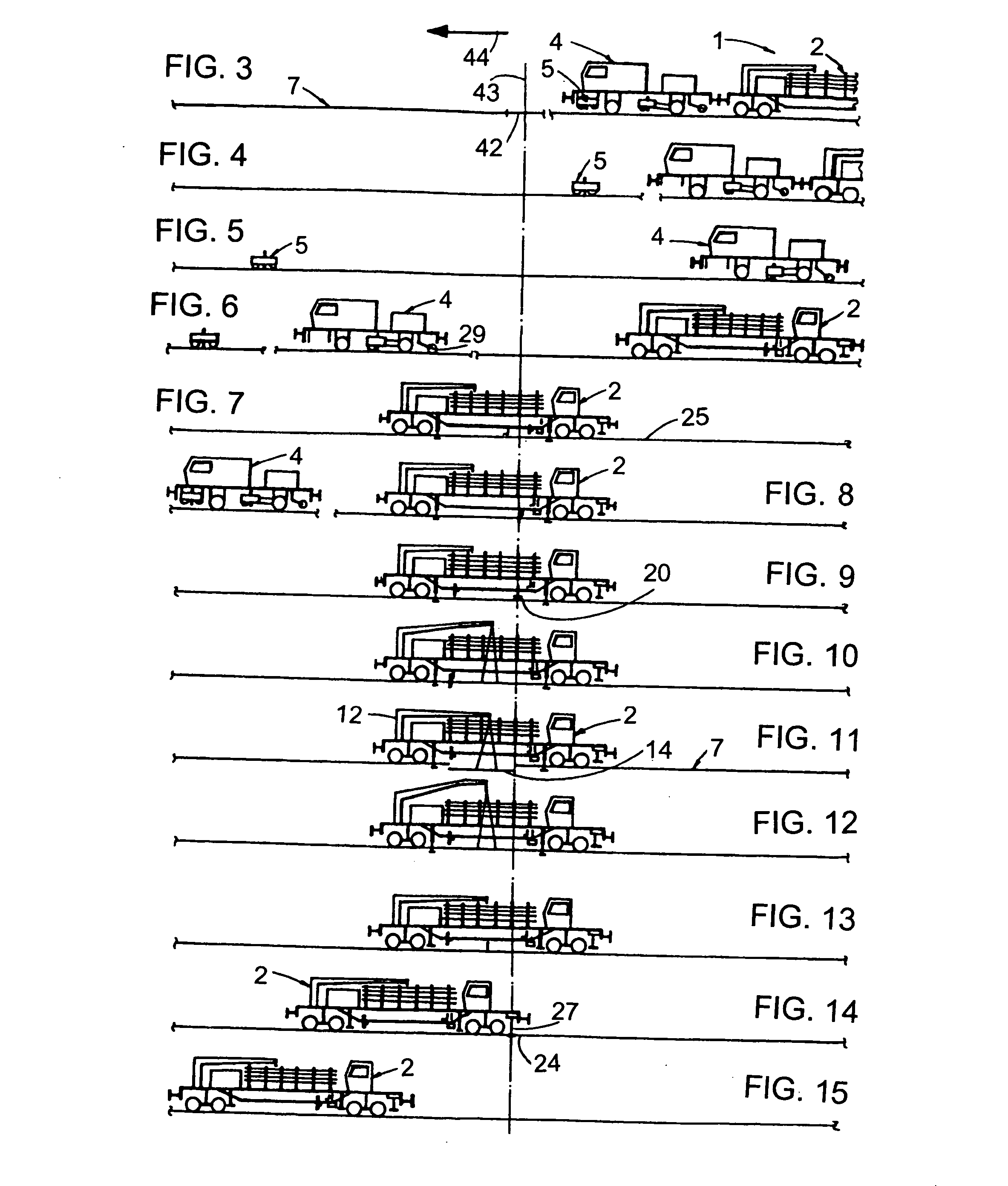

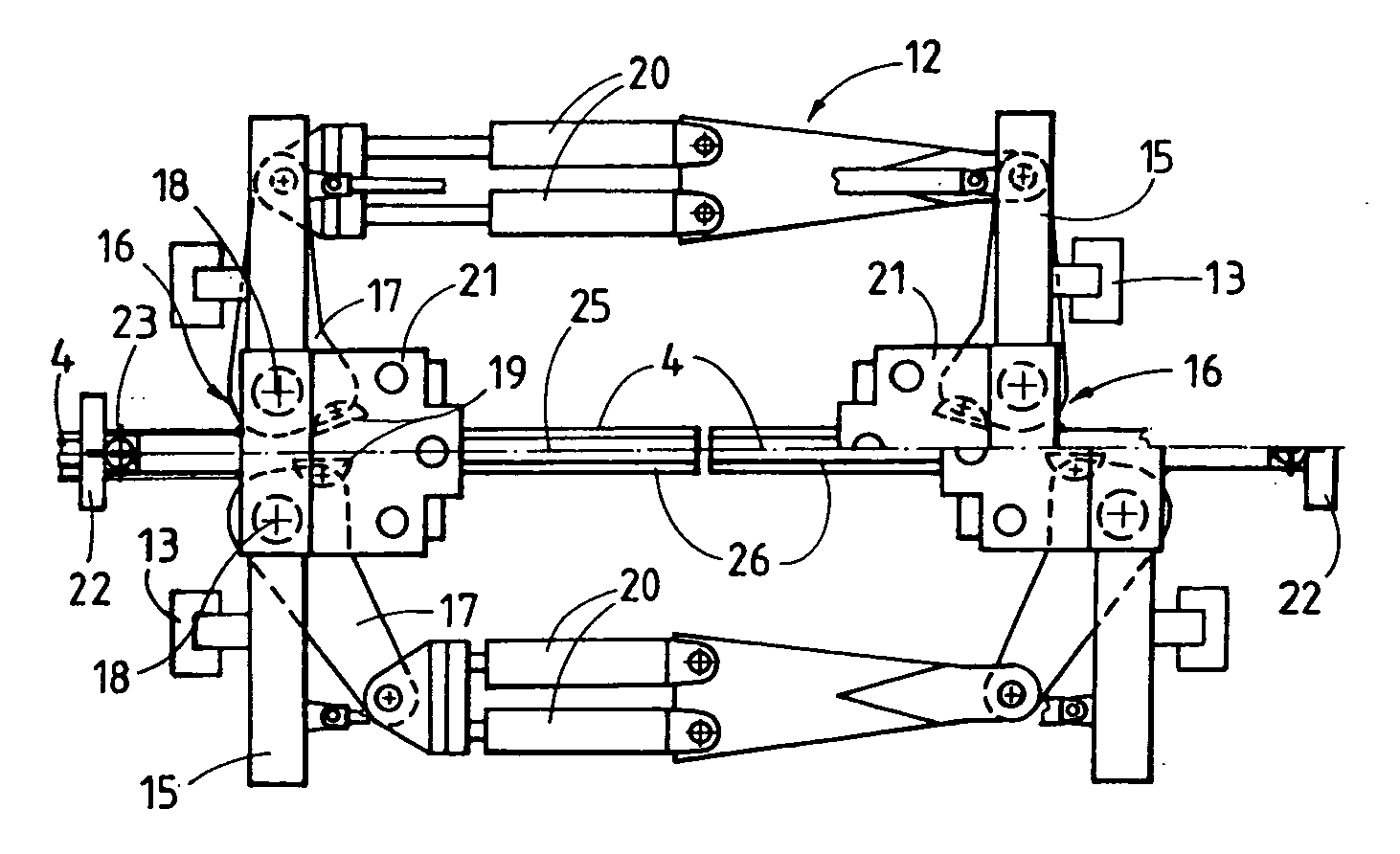

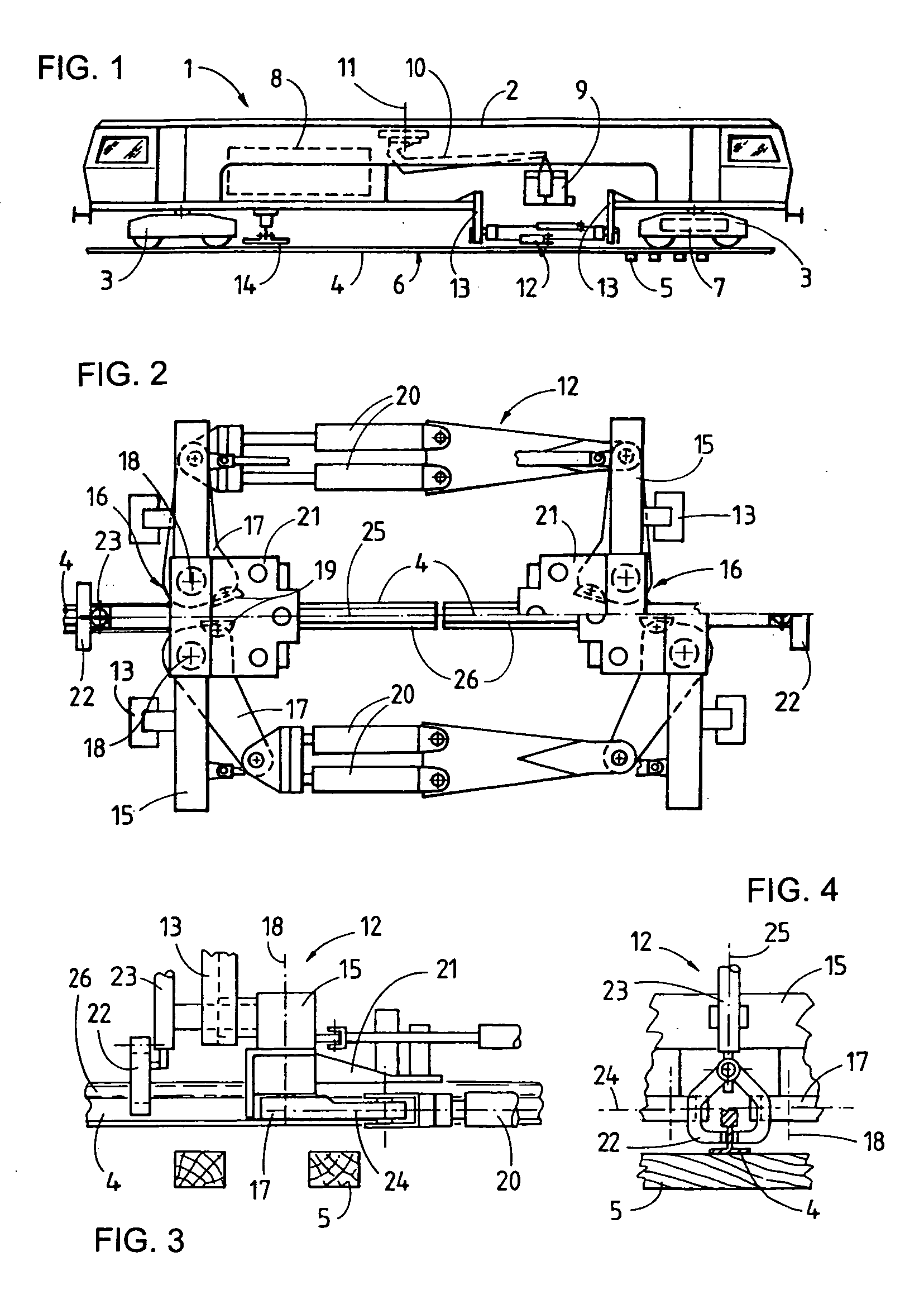

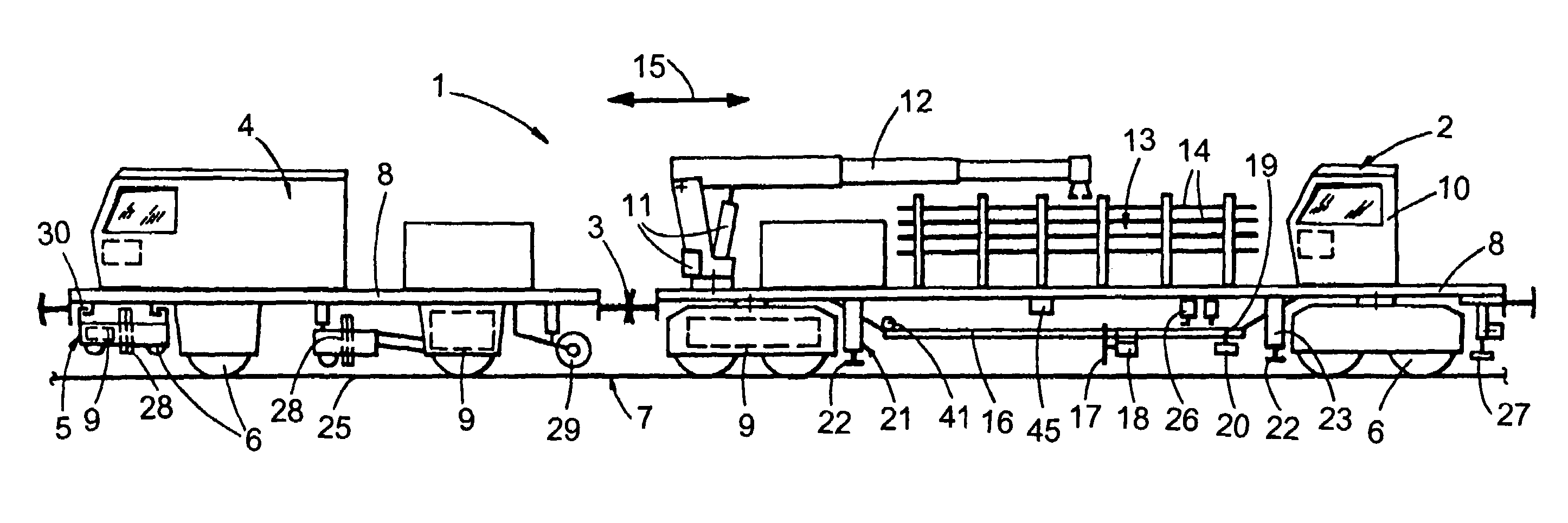

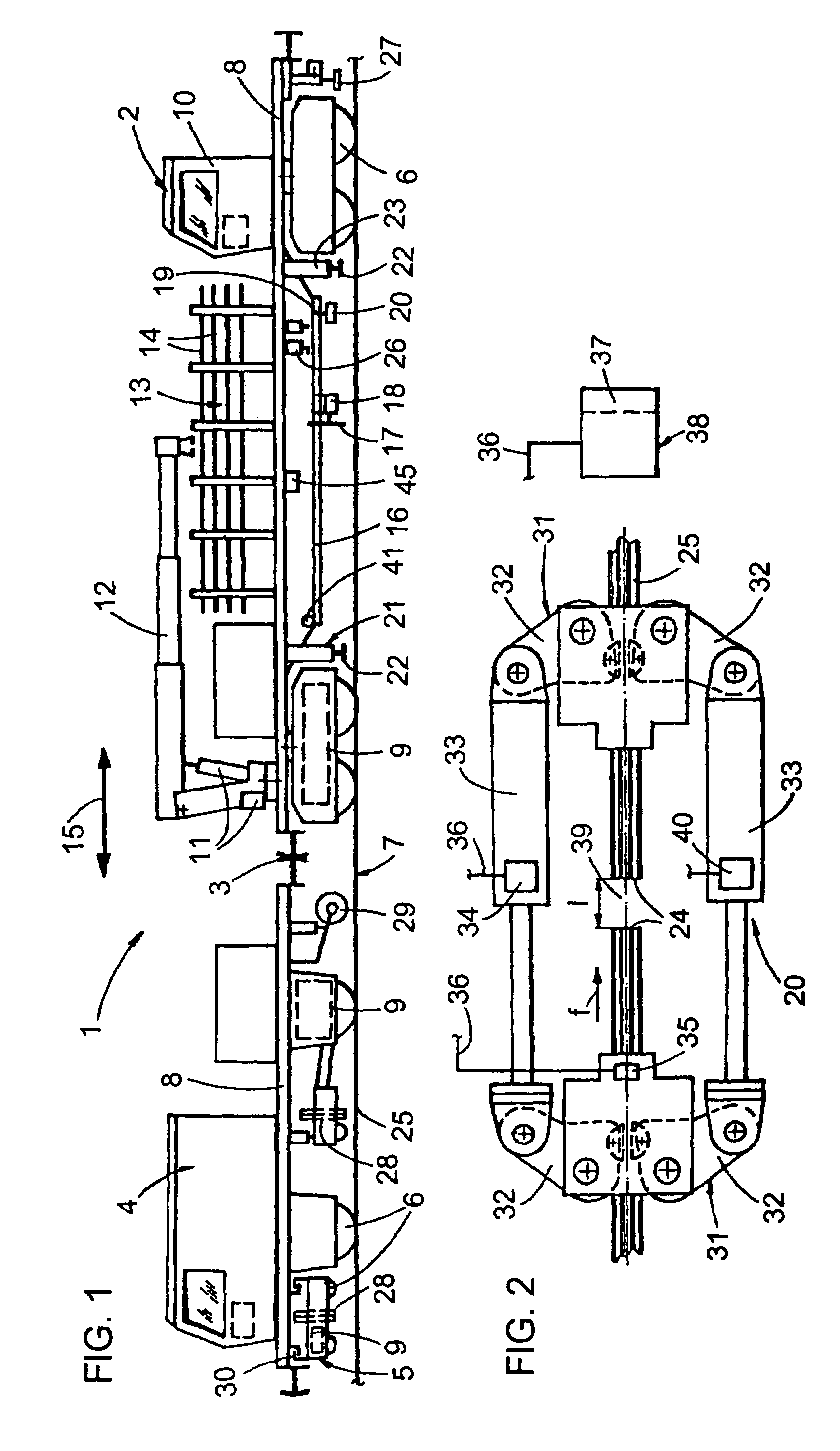

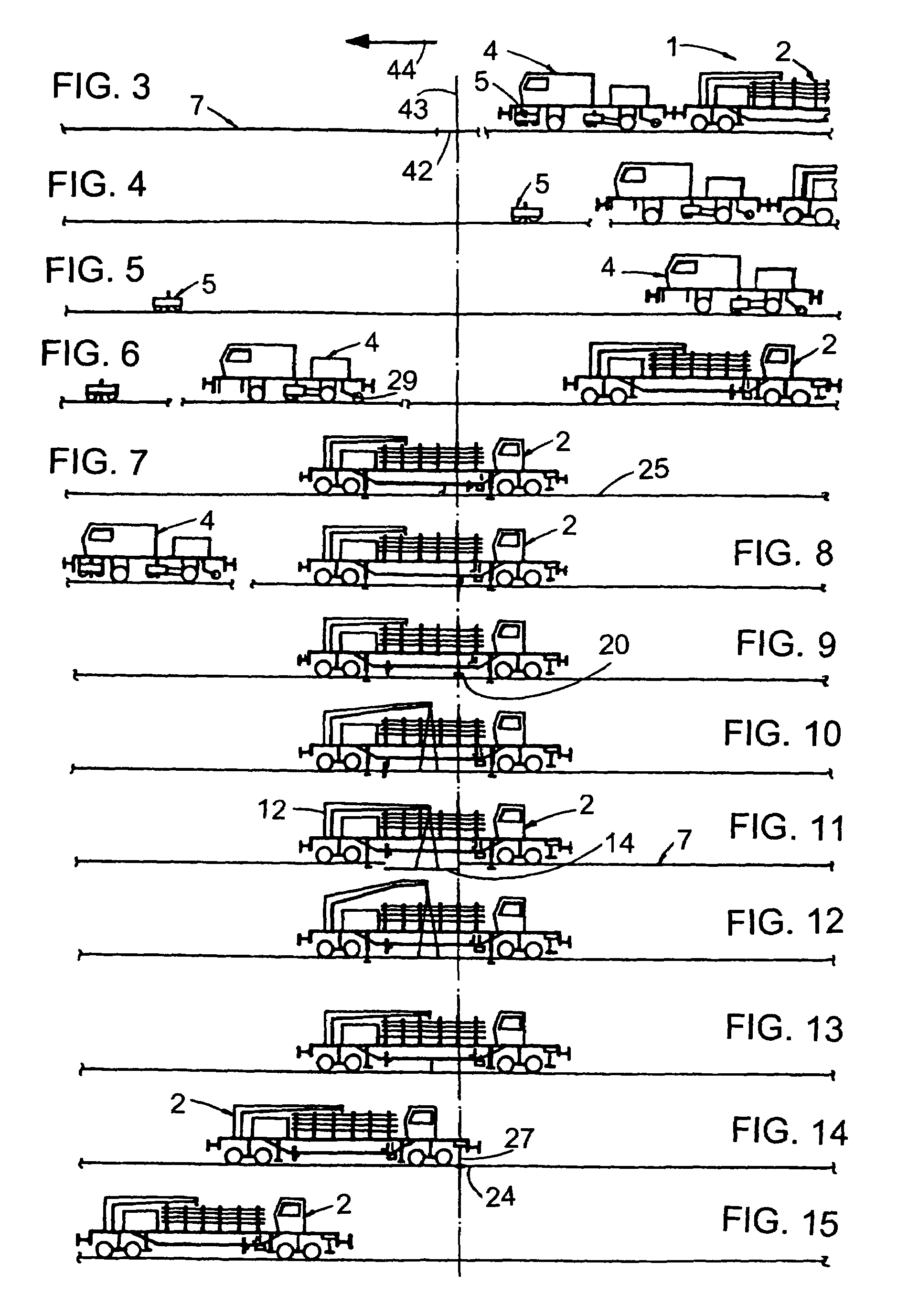

Method and machine for replacing damaged rail sections of a track

InactiveUS20060219123A1Desired rail tensionExact lengthRail jointsRailway track constructionPull forceEngineering

In a method for efficiently removing a great number of damaged rail sections, after a first separating cut, the severed free rail ends are gripped by a rail pulling device connecting the rail ends to one another, and are pulled towards one another. The pulling force required for the pulling-together as well a current rail temperature are registered for calculation of that length of a replacement rail which is required for producing a desired rail tension. A second separating cut is carried out—with corresponding path measurement—spaced at a distance from the first separating cut as calculated on the basis of the selected length of the replacement rail.

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

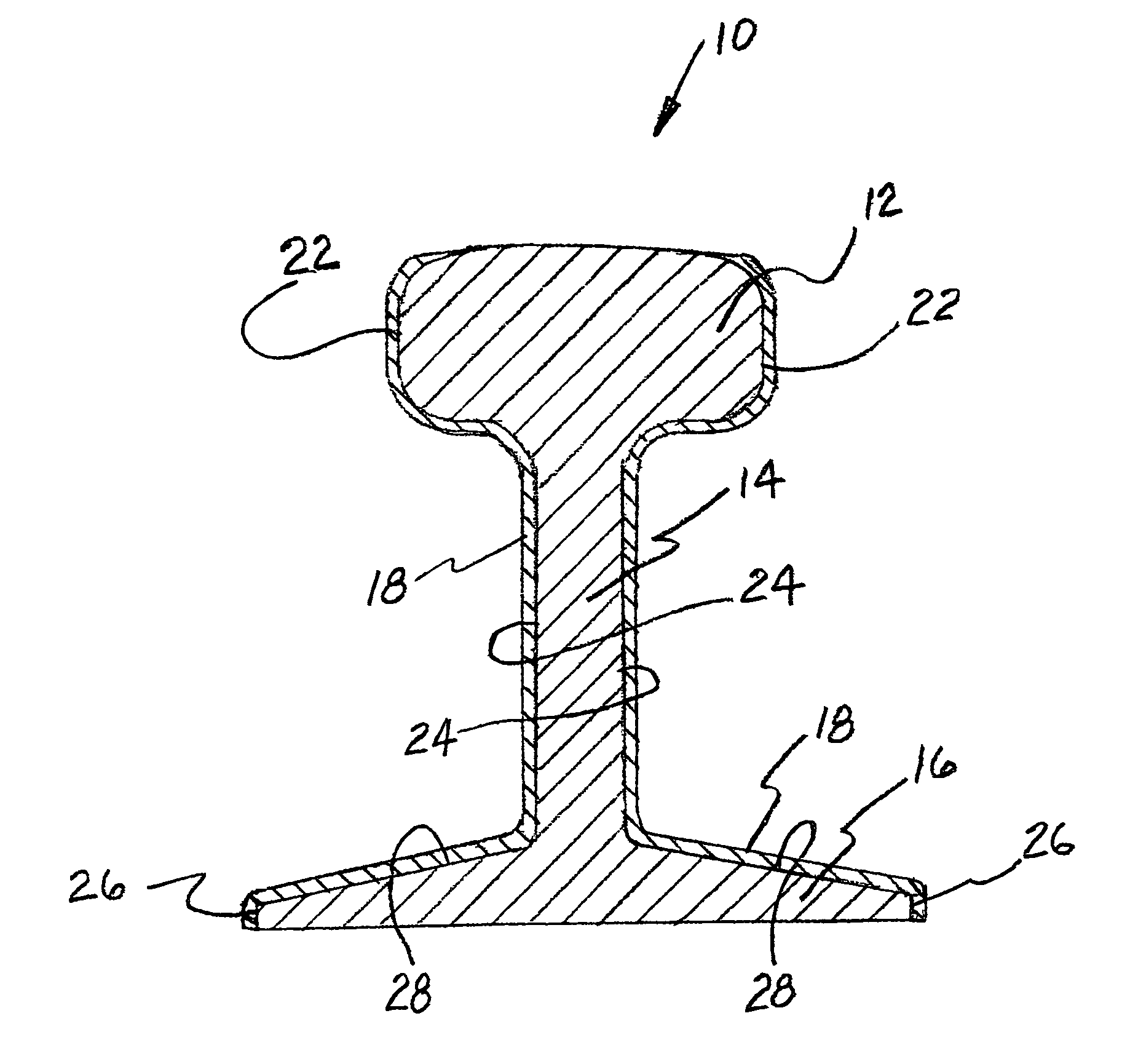

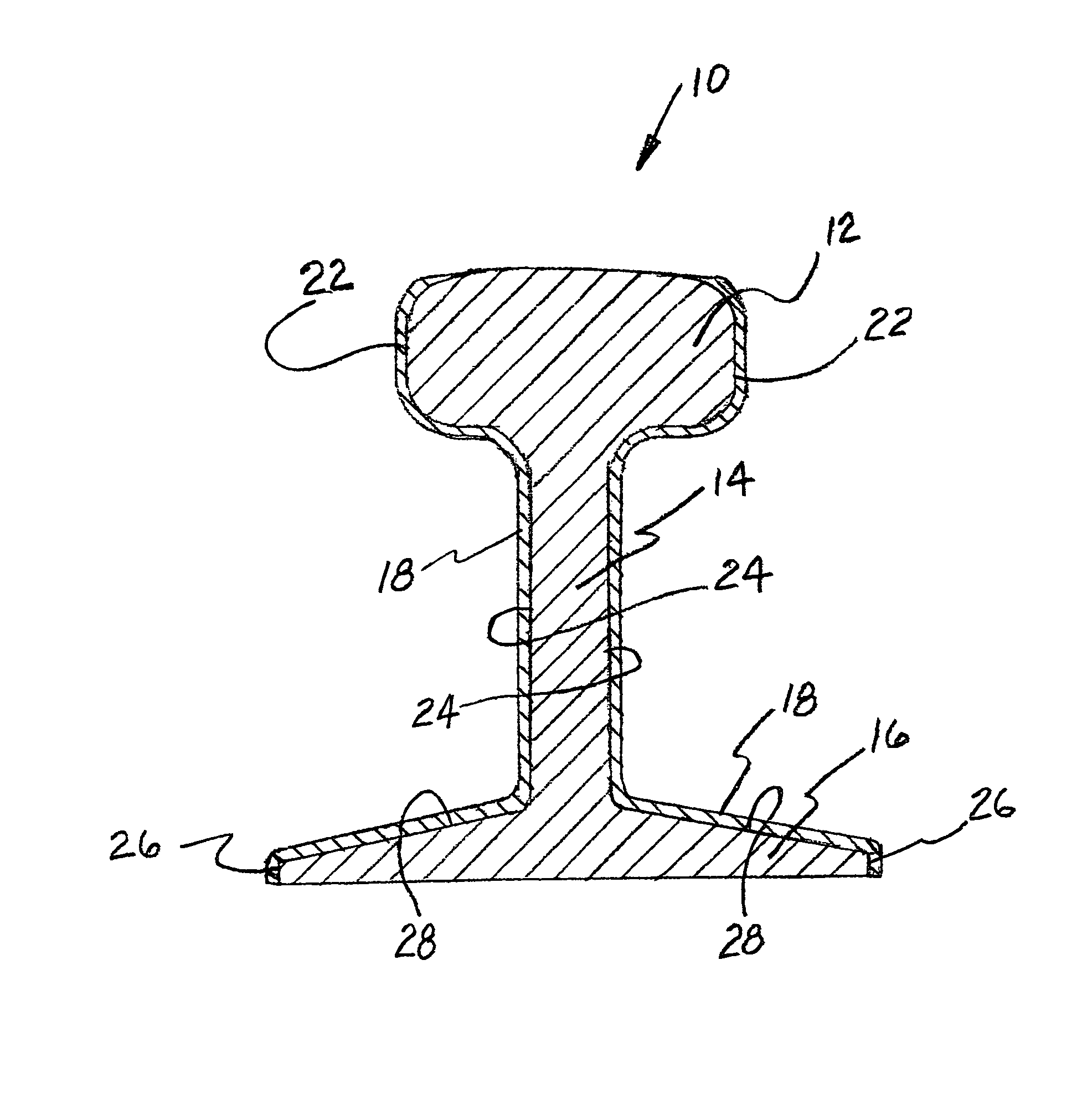

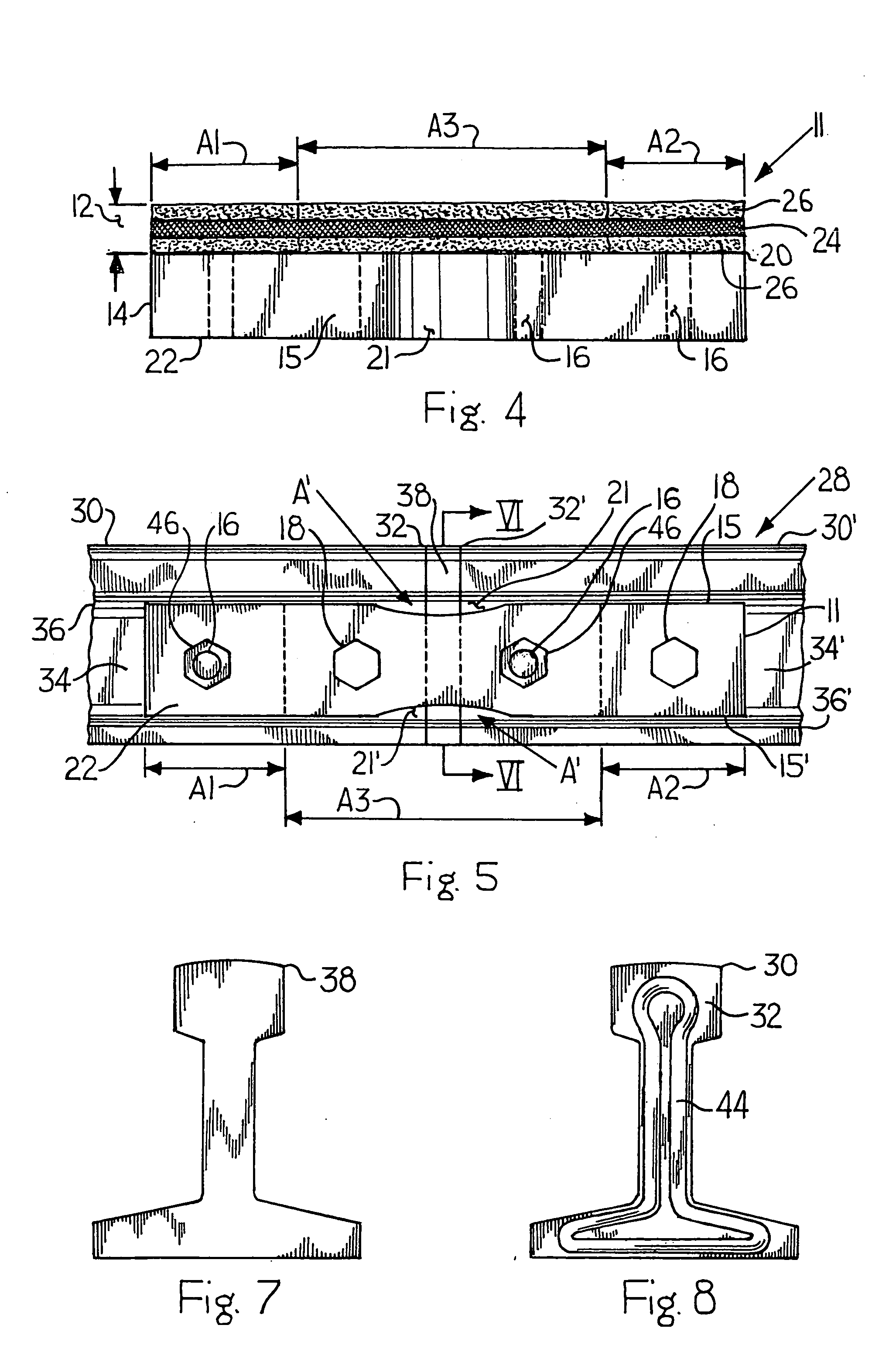

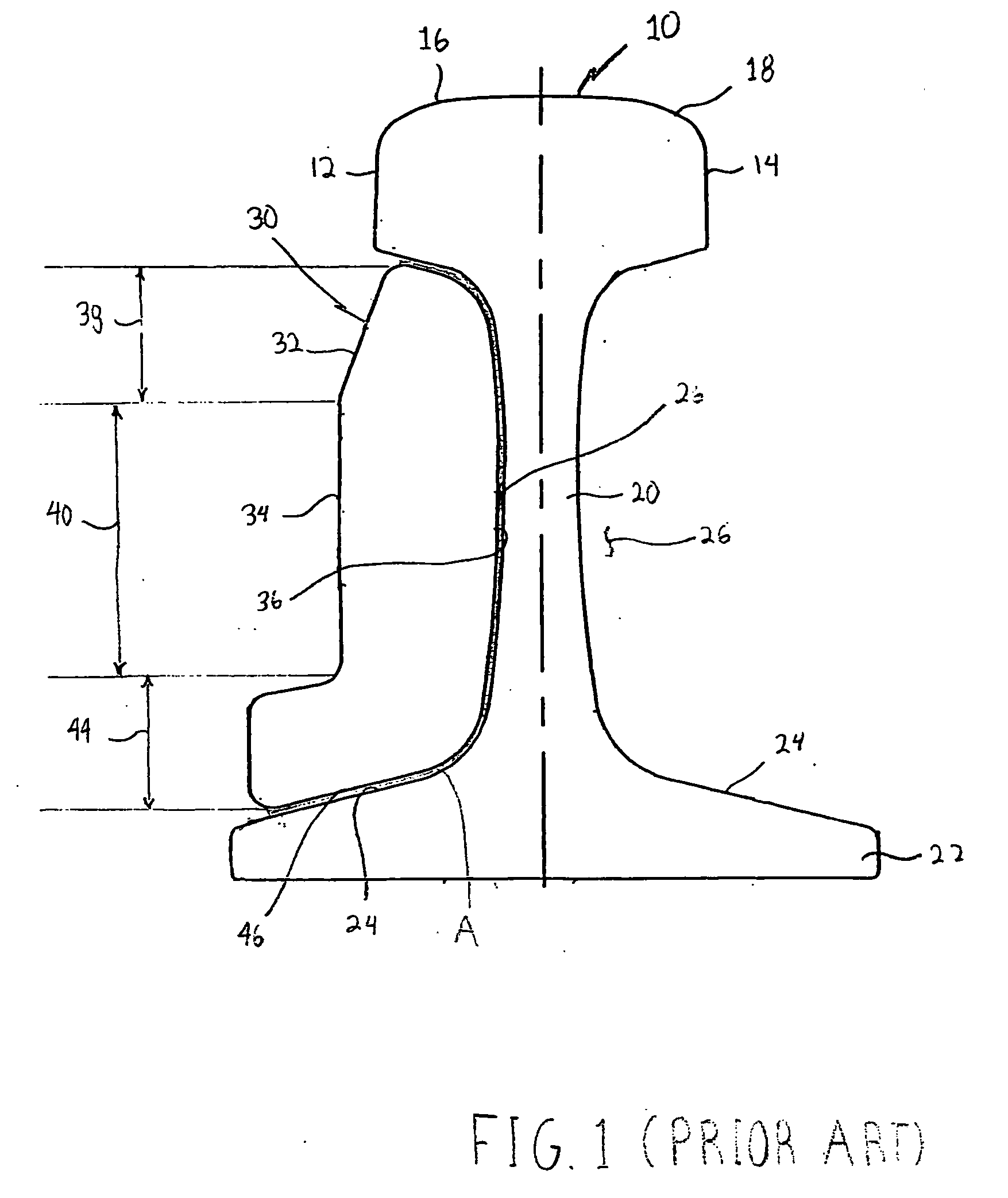

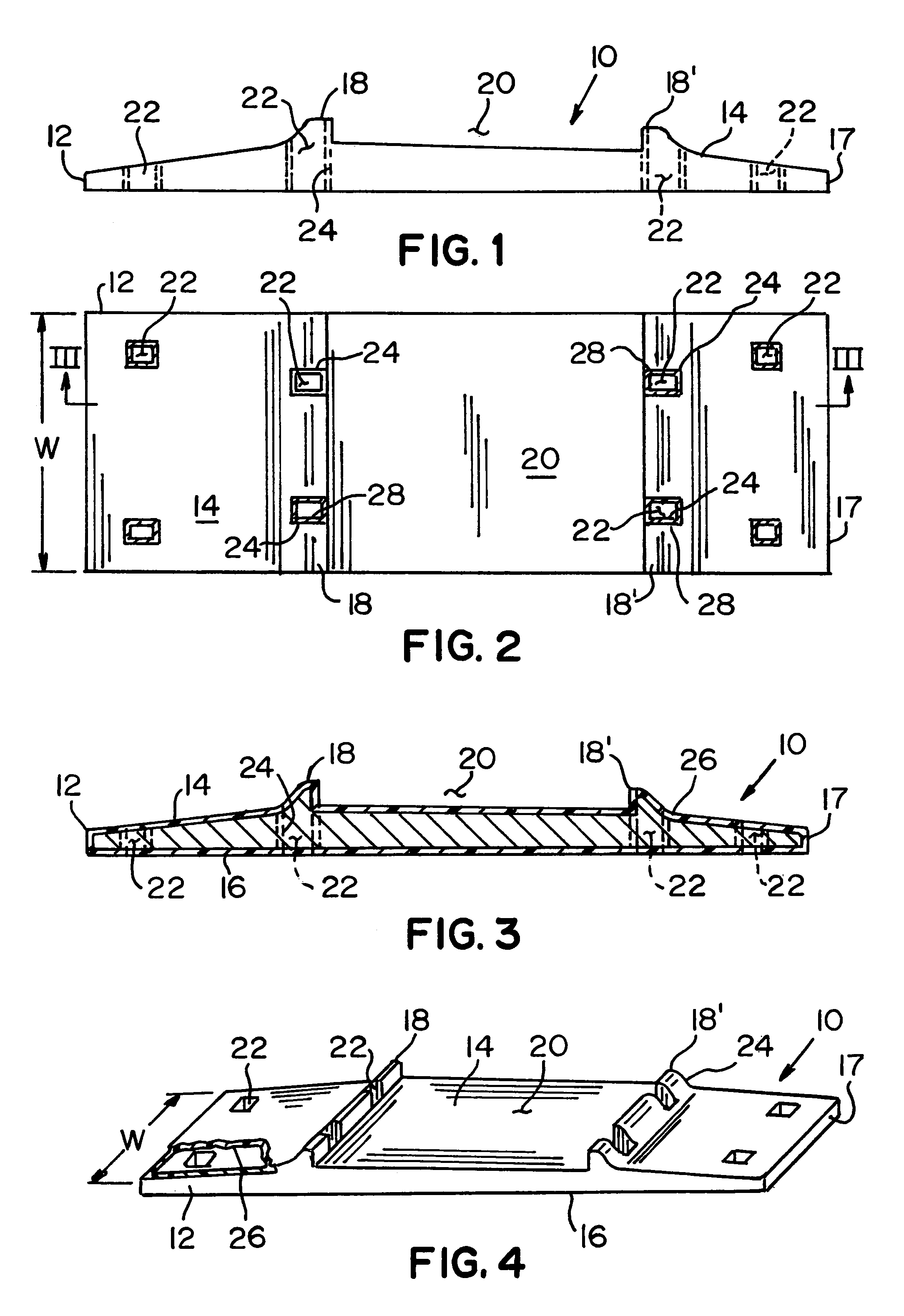

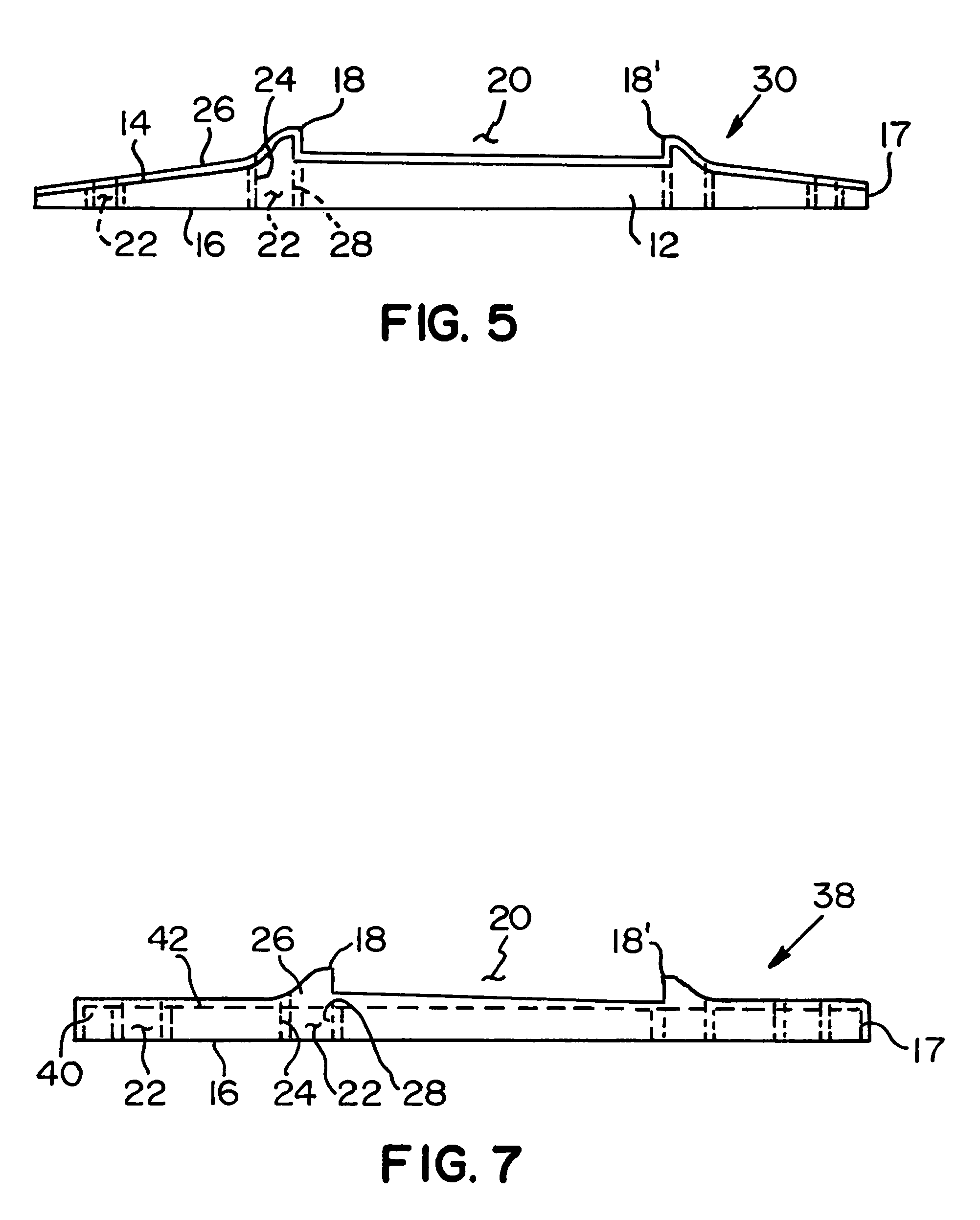

Insulated rail joint assembly

ActiveUS20070272762A1High strengthEasy constructionRail devicesRail jointsCross connectionEngineering

An insulated rail joint assembly comprises a rail with a thick web section, held in place by joint bars and secured with electrically isolated fasteners. The joint bars have non-uniform cross-sections, being shaped with a thicker midsection area and thinner ends. Electrically non-conductive shear pins through the rail and the joint bars provide shear resistance and prevent glue bond failure. High strength cloth between the rail ends and between the rail and the joint bars strengthens the joint, as does an insulating rail clip resiliently fastened to an insulating tie plate, which itself may be supported on a cross tie of increased width.

Owner:VOESTALPINE RAILWAY SYST NORTRAK LLC

Magnetic rail bond

InactiveUS20100219256A1Rail devicesCoupling device detailsMagnetic tension forceConductive materials

Magnetic means and apparatus for implementing rail bonds and rail feeds. A rail bond embodiment comprises an electrical conductor. Mechanically and electrically coupled to each end of the electrical conductor is a magnet that comprises a magnetic material that is plated with an electrically conductive material. In an alternative embodiment, the magnet comprises a magnetic material that is disposed between two pieces of steel or other metal. In operation, the two magnets are attached to two rail sections, across a joint separating the rails, via the attractive magnetic force between each magnet and its associated rail. In this way, the electrical circuit comprising the rails is maintained.

Owner:WILLIAMS MARK A

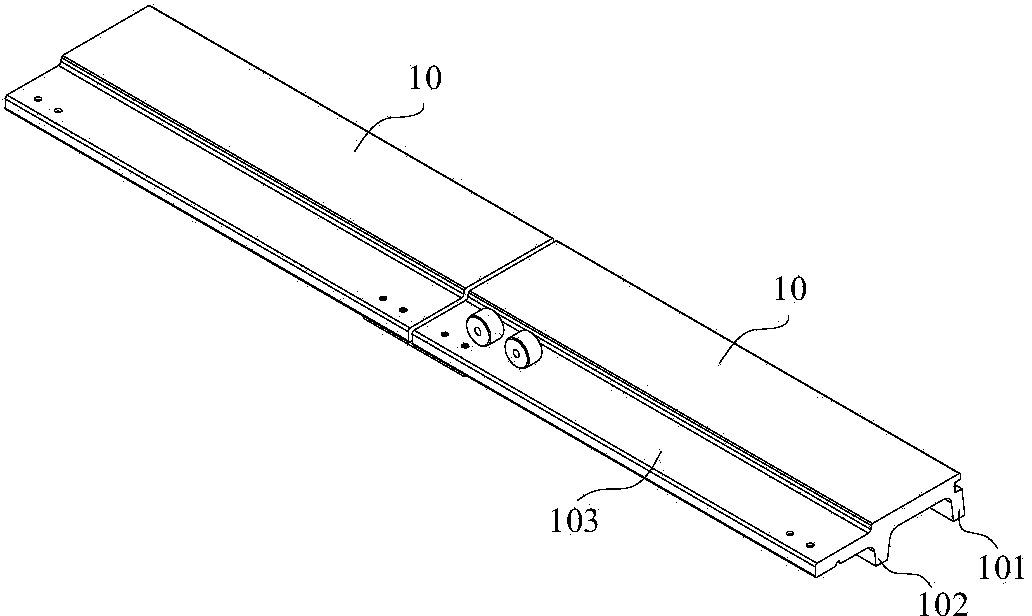

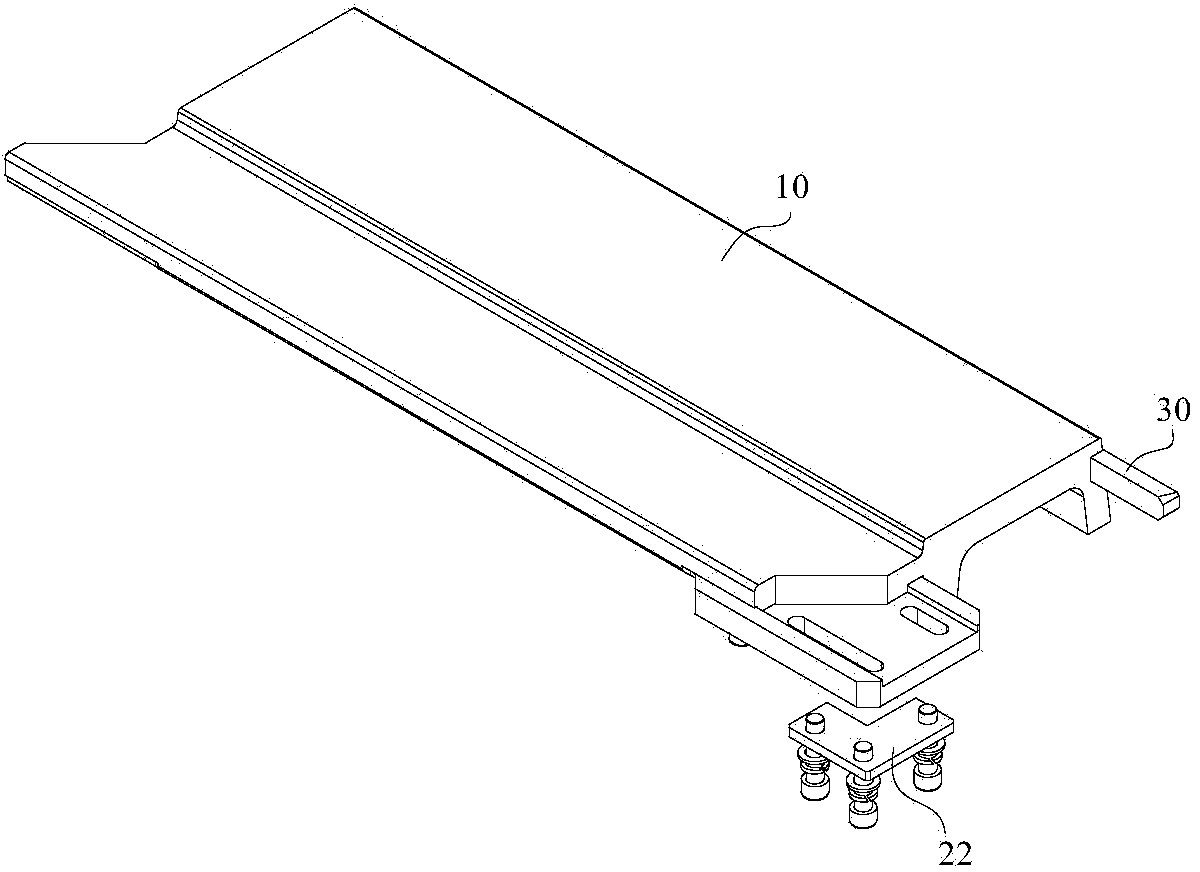

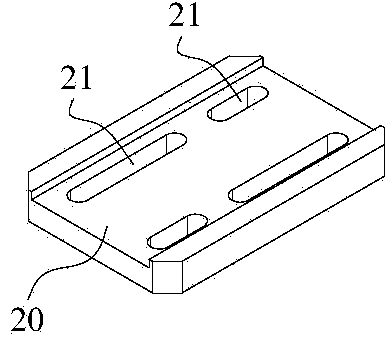

F rail connector structure of medium-and-low-speed magnetic suspension system rail

ActiveCN103966928AAchieve connectionIncrease stiffnessRail jointsMagnetic suspension systemEngineering

An F rail connector structure of a medium-and-low-speed magnetic suspension system rail aims to improve torsional stiffness and the altitude difference misalignment prevention ability of an F rail connector, and improve mounting precision of the rail. An inner guiding and limiting groove and an outer guiding and limiting groove which longitudinally extend are formed in the inner bottom and the outer side wall of a wing rail at the connecting end of each of two adjacent F rails respectively, the opening end of a U-shaped connecting plate is embedded into the inner guiding and limiting grooves and the outer guiding and limiting grooves, long slotted holes are formed in the U-shaped connecting plate in the longitudinal direction and the horizontal direction at intervals, and bolt connecting components which penetrate through the long slotted holes enable the U-shaped connecting plate and the two adjacent F rails to be detachably connected.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

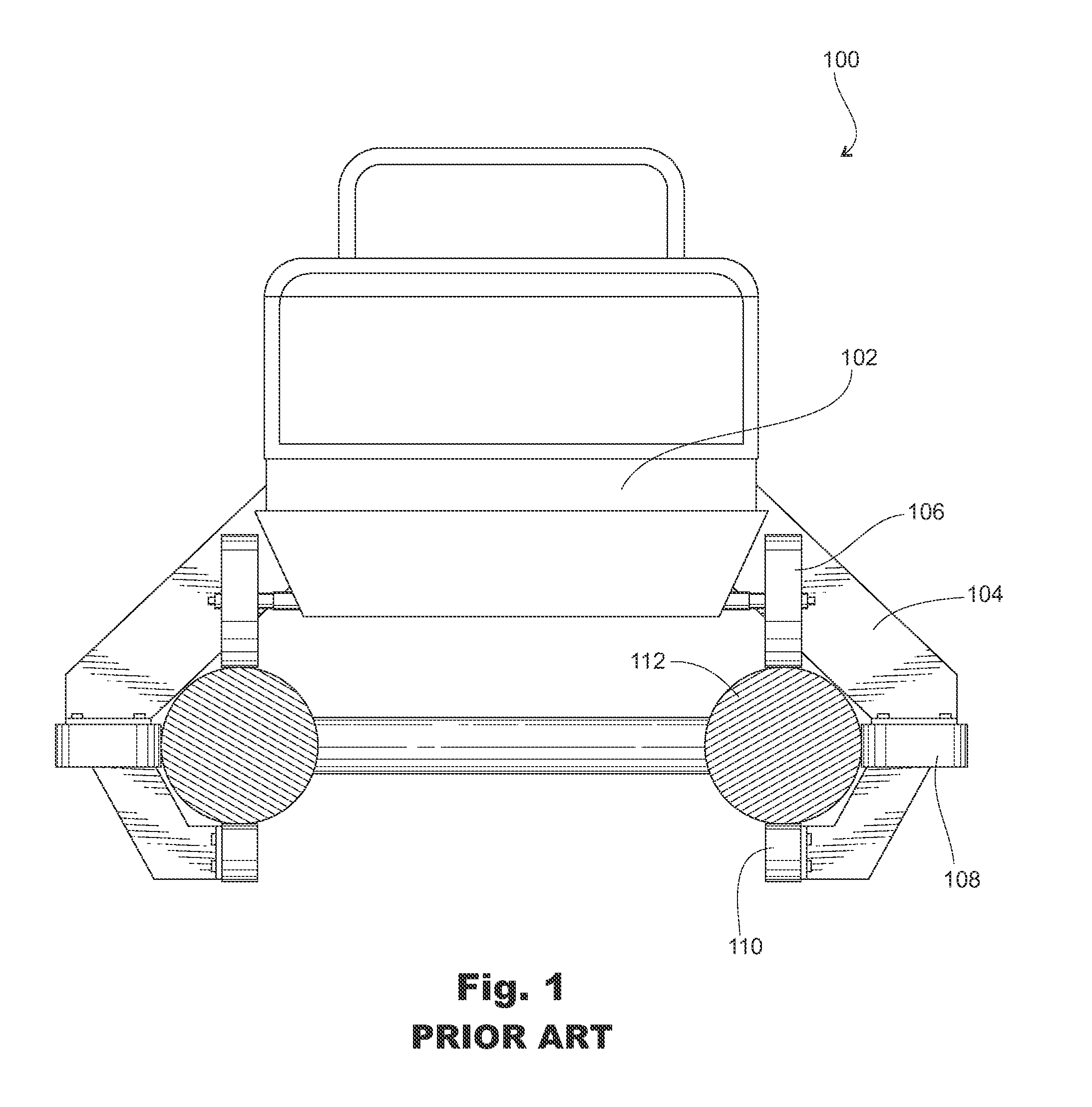

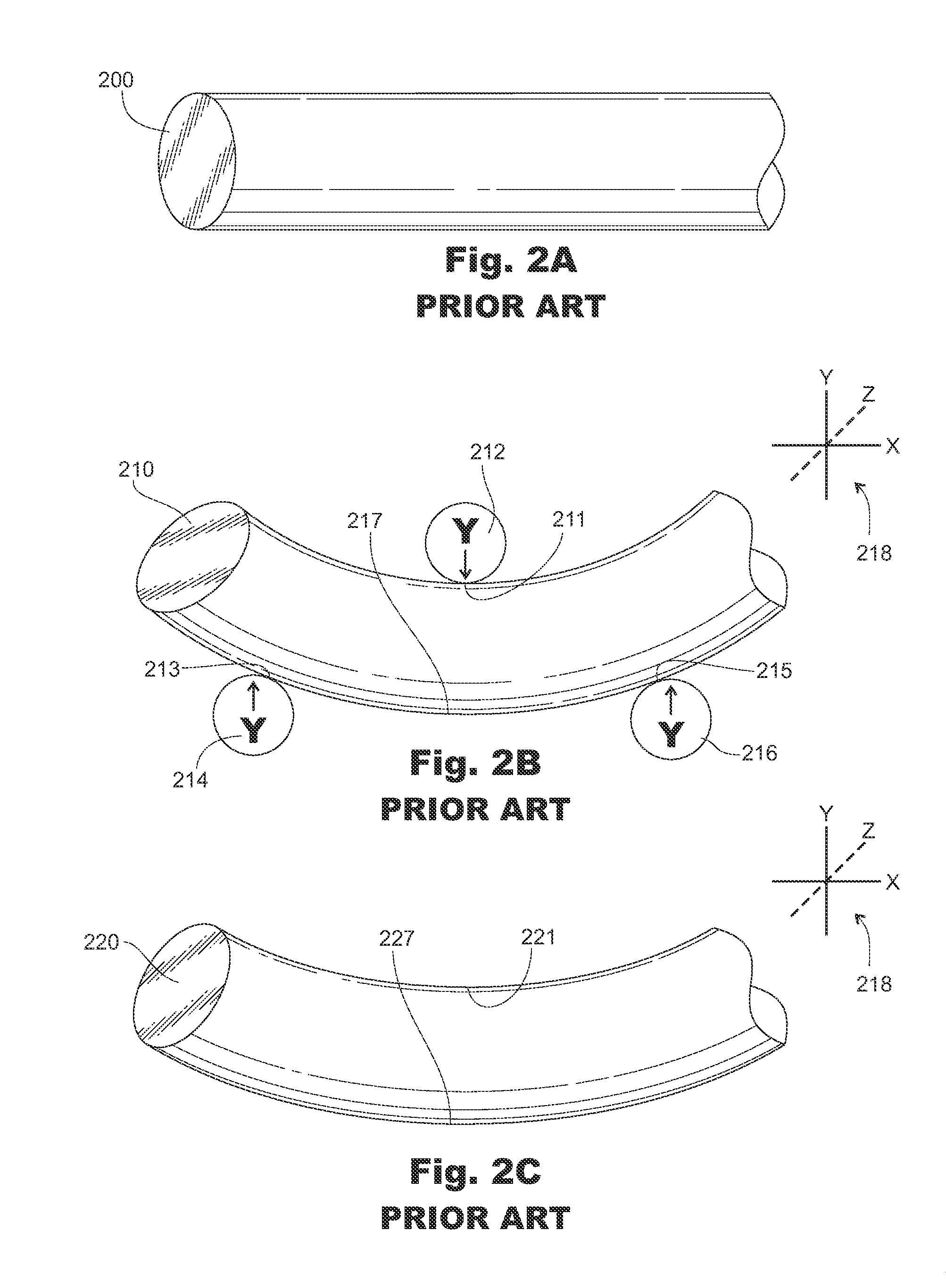

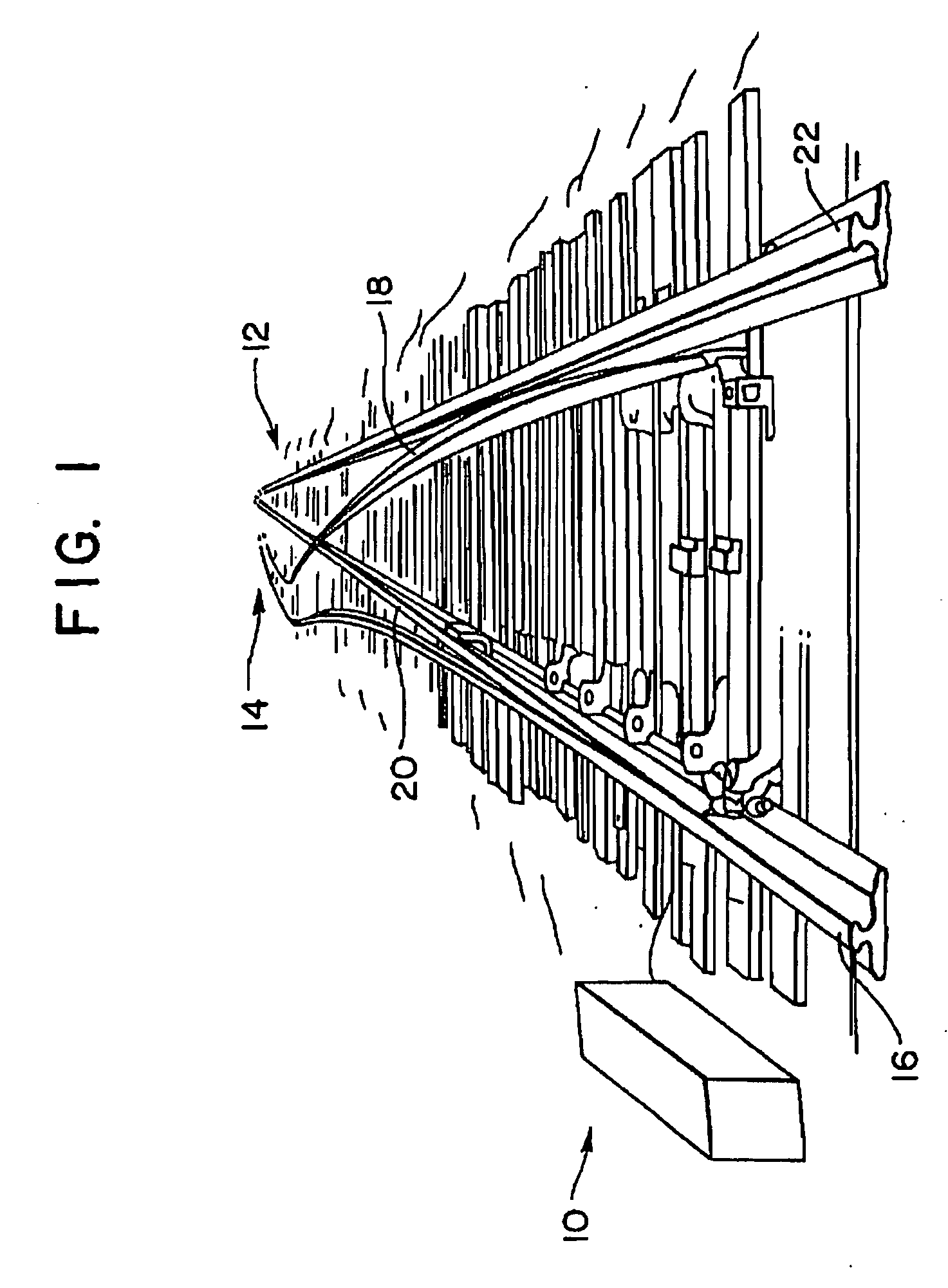

Rolling Vehicle Track

A method of fabricating an amusement park ride track utilizing stock, planar materials, namely comprising of creating elongated, curved structures from planar materials. A roller coaster track capable of being fabricated from multiple planar pieces without heating or bending. Other embodiments are described which utilize elongated, curved structures such as ski lifts, people movers, staircases and architectural structures. A jig is disclosed for providing for ease of manufacture of the elongated, curved structures.

Owner:ROCKY MOUNTAIN COASTERS

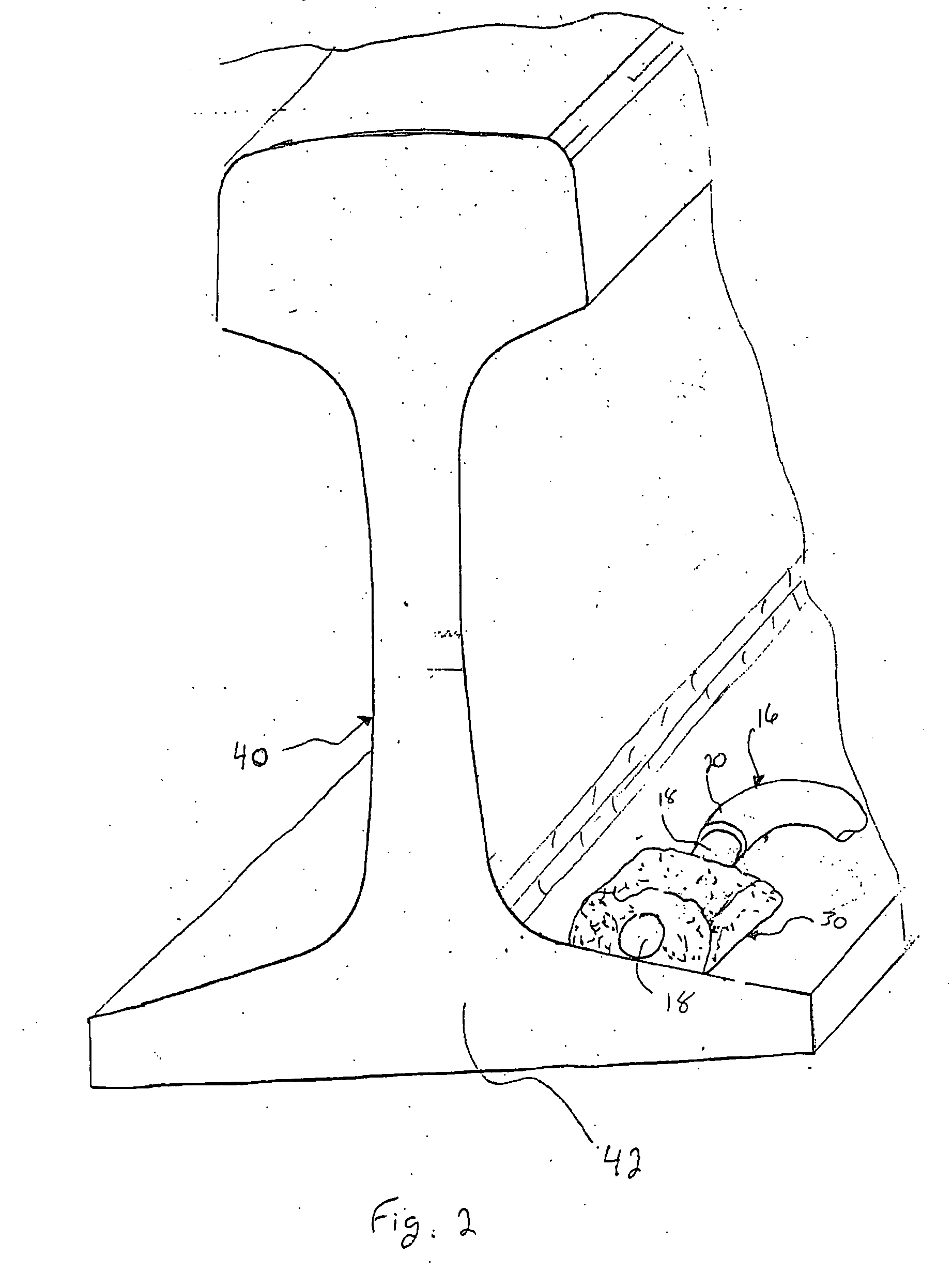

Railroad rail having thermal insulation below the railhead either coated in the field or at the rail production facility

Owner:JONES PAUL

High-strength resin-based composite material track insulating components

ActiveCN101229815ASuitable mechanical propertiesIncrease production costPlastic/resin/waxes insulatorsRail jointsShear formingResin-Based Composite

The invention relates to a fastener used by a railway track, which comprises a track pitch baffle, a baffle base and an insulation track pitch block. The technical proposal is that: prepreg of thermoplastic resin composite is taken as the base material and is cut to be shaped; after being preheated, pulled, pressed, solidified and shaped, the material is made into insulation components of the track. The prepreg of thermoplastic resin composite refers to prepreg composite obtained by combining the thermoplastic resin and nemaline reinforced material; the thickness of the prepreg of thermoplastic resin composite is ranging between 0.1 mm-0.6mm, and the proportion of the reinforced material inside the prepreg of thermoplastic resin composite is 20-40 percent of that of the thermoplastic resin. The invention is characterized by great strength and modulus, good size stability, lasting static resistance, small friction coefficient, wear resistance, long service life, etc.

Owner:NINGBO SHUXIANG NEW MATERIAL

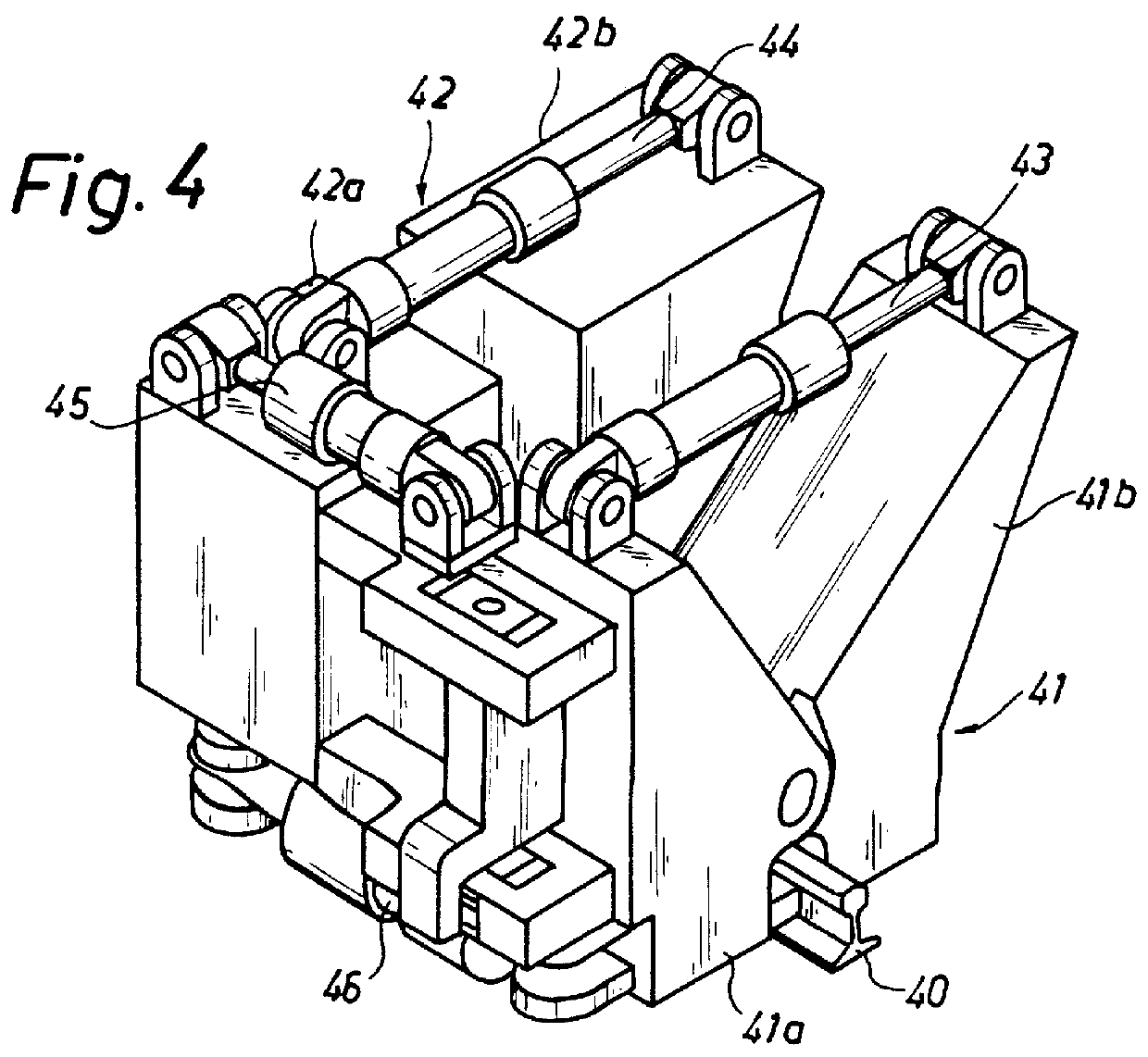

Resistance rail welding device with alignment mechanism

PCT No. PCT / SE96 / 01597 Sec. 371 Date Jun. 5, 1998 Sec. 102(e) Date Jun. 5, 1998 PCT Filed Dec. 4, 1996 PCT Pub. No. WO97 / 21514 PCT Pub. Date Jun. 19, 1997A device for welding together elongated work pieces such as railroad track, is provided with controls to eliminate pre-existing angles that exist between each work piece prior to joining.

Owner:ESAB AB

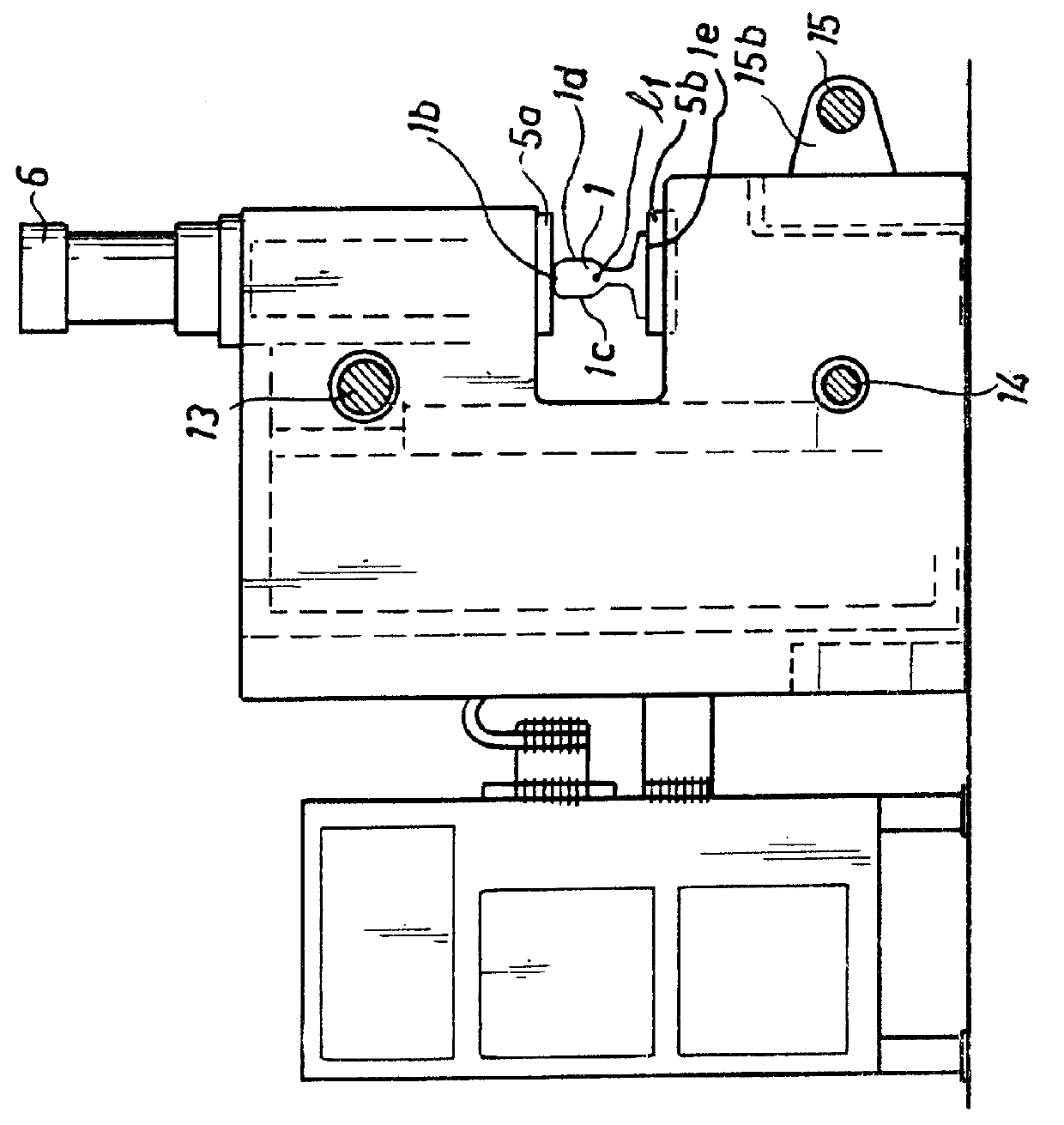

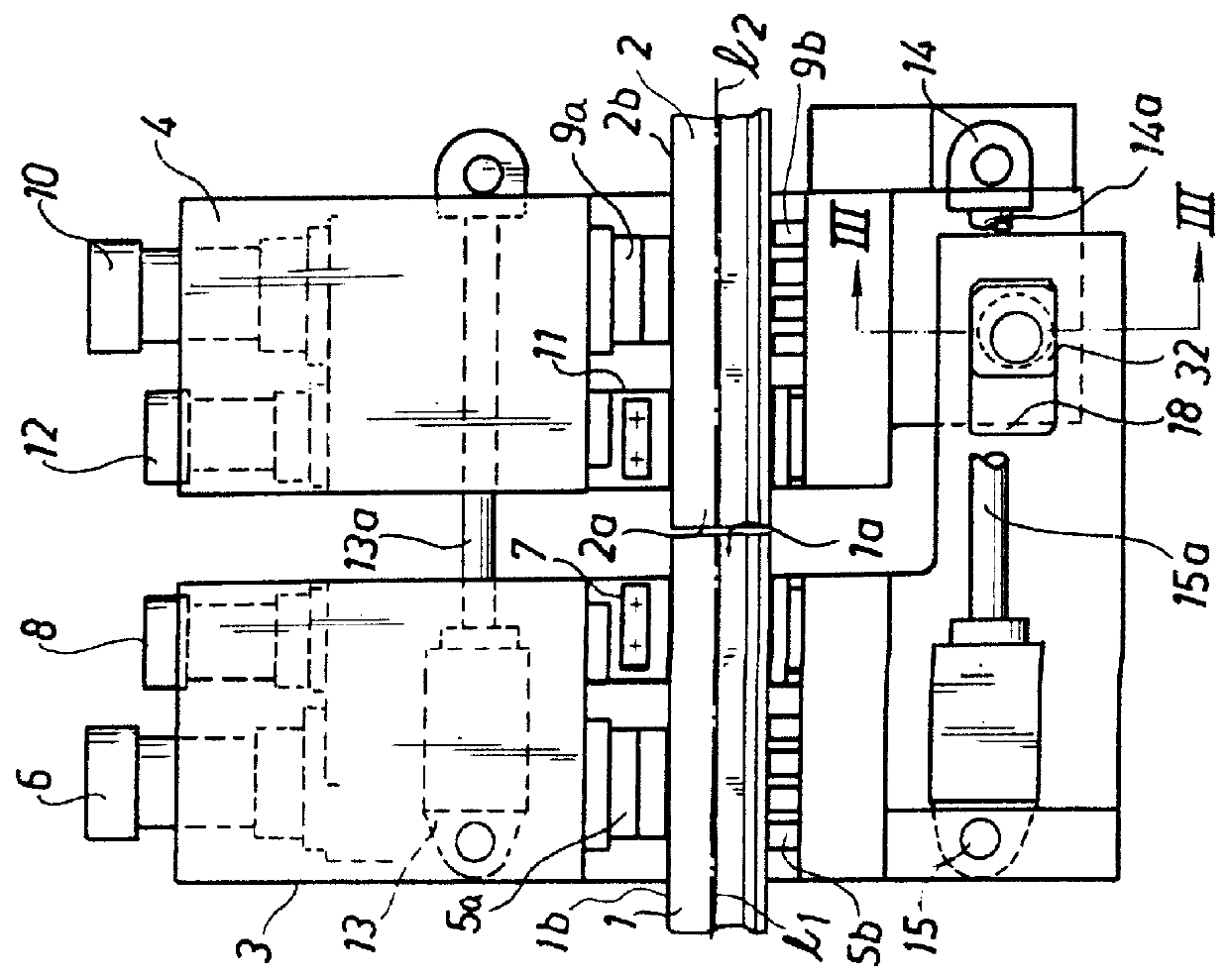

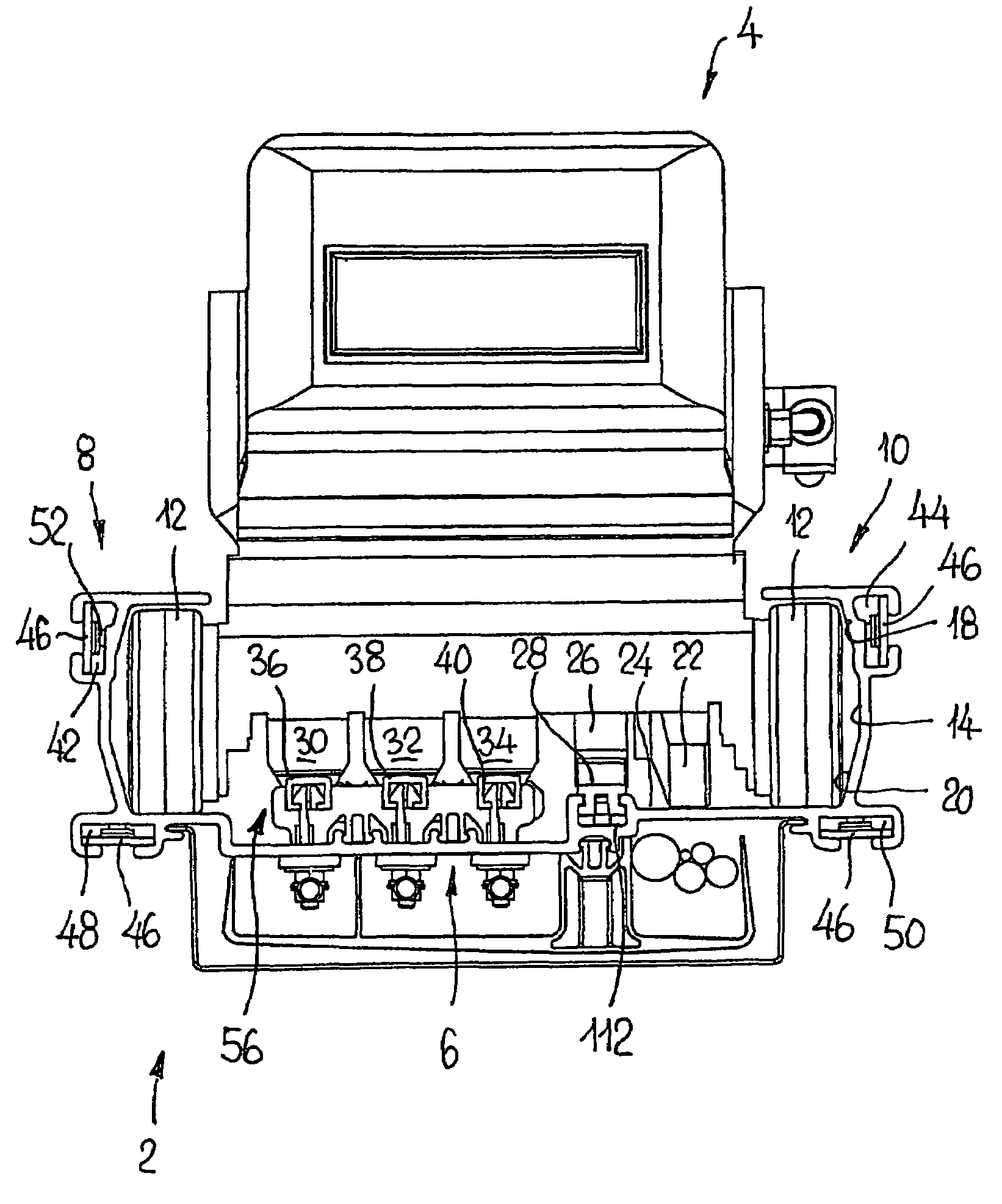

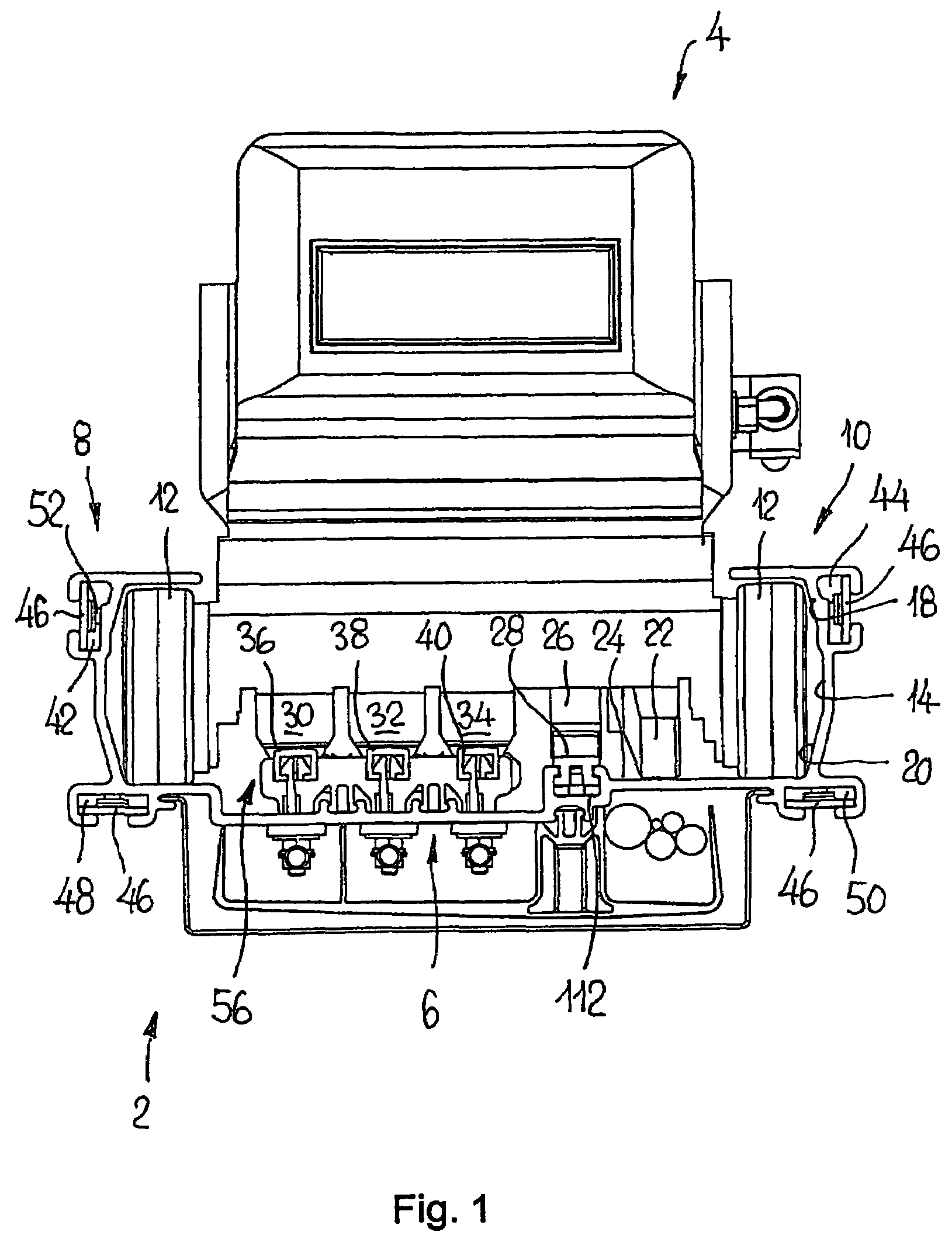

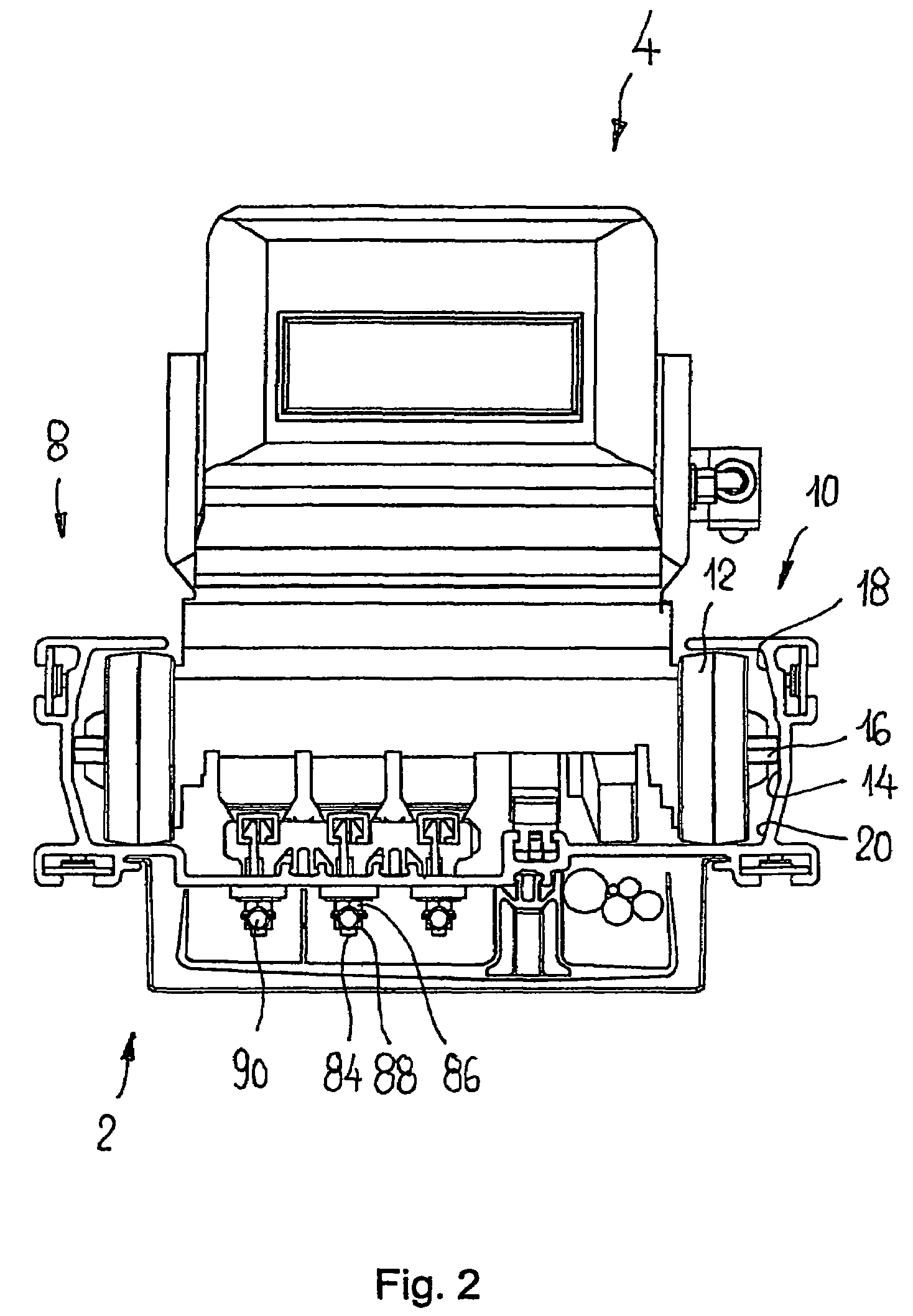

Machine and method for welding rails of a track

InactiveUS20060261044A1Simplify mannerQuick and precise and automatically executable grippingRailsBallastwayEngineeringMechanical engineering

A machine for welding the rails of a track includes a rail pulling device that grips the rail ends and pulls them together so that they can be welded to one another. Two rail clamps provided for gripping the rails are fastened to the rail pulling device. The rail clamps are each vertically adjustable in their position relative to the rail pulling device by way of a respective adjustment drive in a direction extending perpendicularly to a pulling device plane formed by hydraulic drives of the rail pulling device. With this, the rails can be lifted from ties in a simple manner in order to enable the clamping members of the rail pulling device to grip the rails.

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

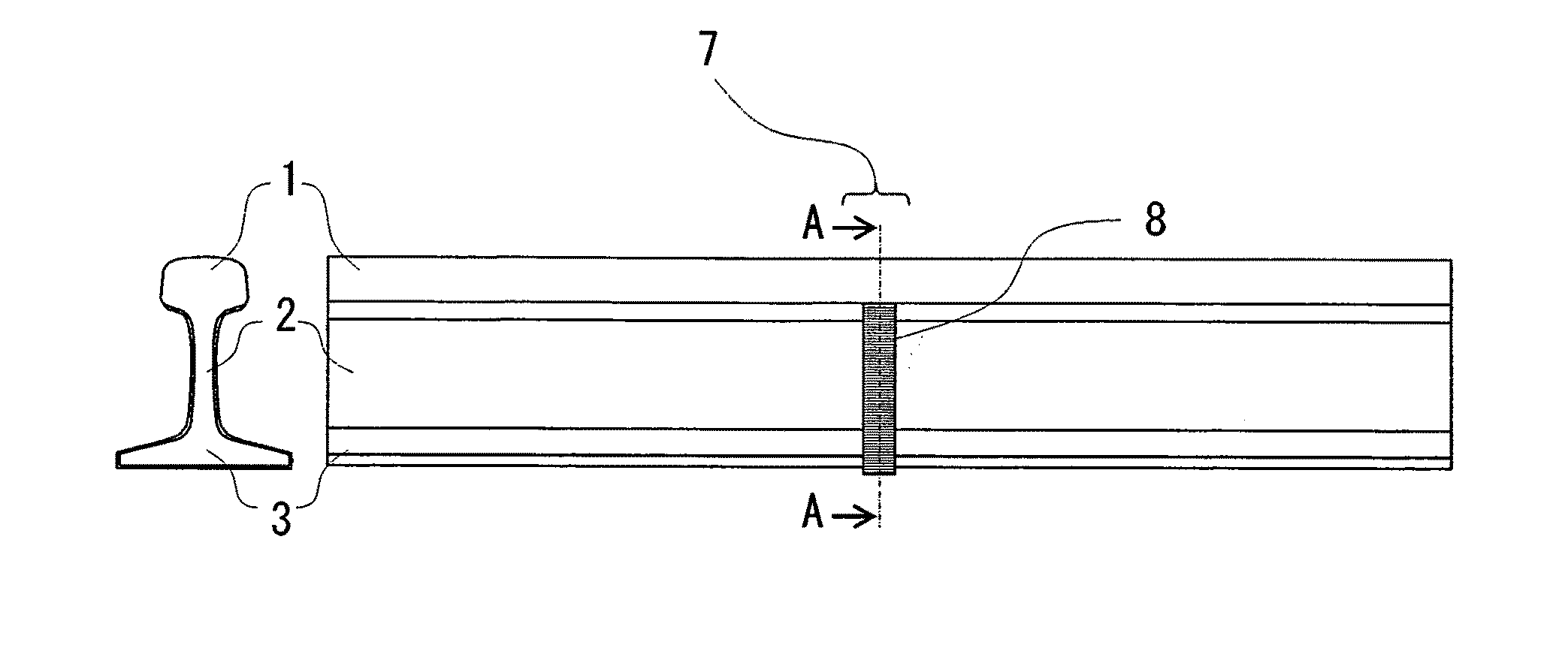

Method of cooling rail weld zone, device for cooling rail weld zone, and rail weld joint

InactiveUS20120015212A1Improve residual stressAvoid fatigue crackingRailsFurnace typesEngineeringMechanical engineering

The invention provides a method of cooling a rail weld zone. The method includes a first rail web portion cooling process of cooling a rail web portion cooling region of the rail weld zone in a part of a temperature range until the completion of transformation from austenite to pearlite, a second rail web portion cooling process of cooling the rail web portion cooling region after the entire rail web portion of the rail weld zone is transformed to pearlite, a foot portion cooling process of cooling a foot portion of the rail weld zone, and a head portion cooling process of cooling a head portion of the rail weld zone. When cooling time of the first and second rail web portion cooling processes is t minute, a k value satisfies an expression represented as −0.1t+0.63≦k≦−0.1t+2.33.

Owner:NIPPON STEEL CORP

Rail heater clip

A rail clip for securing a strip heater to a rail that resists removal when subjected to intense vibration, such as when rail cars are passing overhead. The rail clip is configured with a U-shaped rail flange receiving area wherein the opposite sides of this receiving area are configured with at least one tooth each for securing the rail therebetween. For greater securement, multiple teeth on each side of this U-shaped receiving area would be employed and with at least one tooth on each side thereof being in alignment with the other. Furthermore, the teeth on at least one side of this receiving area would include multiple teeth, both pointed and elongated.

Owner:THOMAS & BETTS INT INC

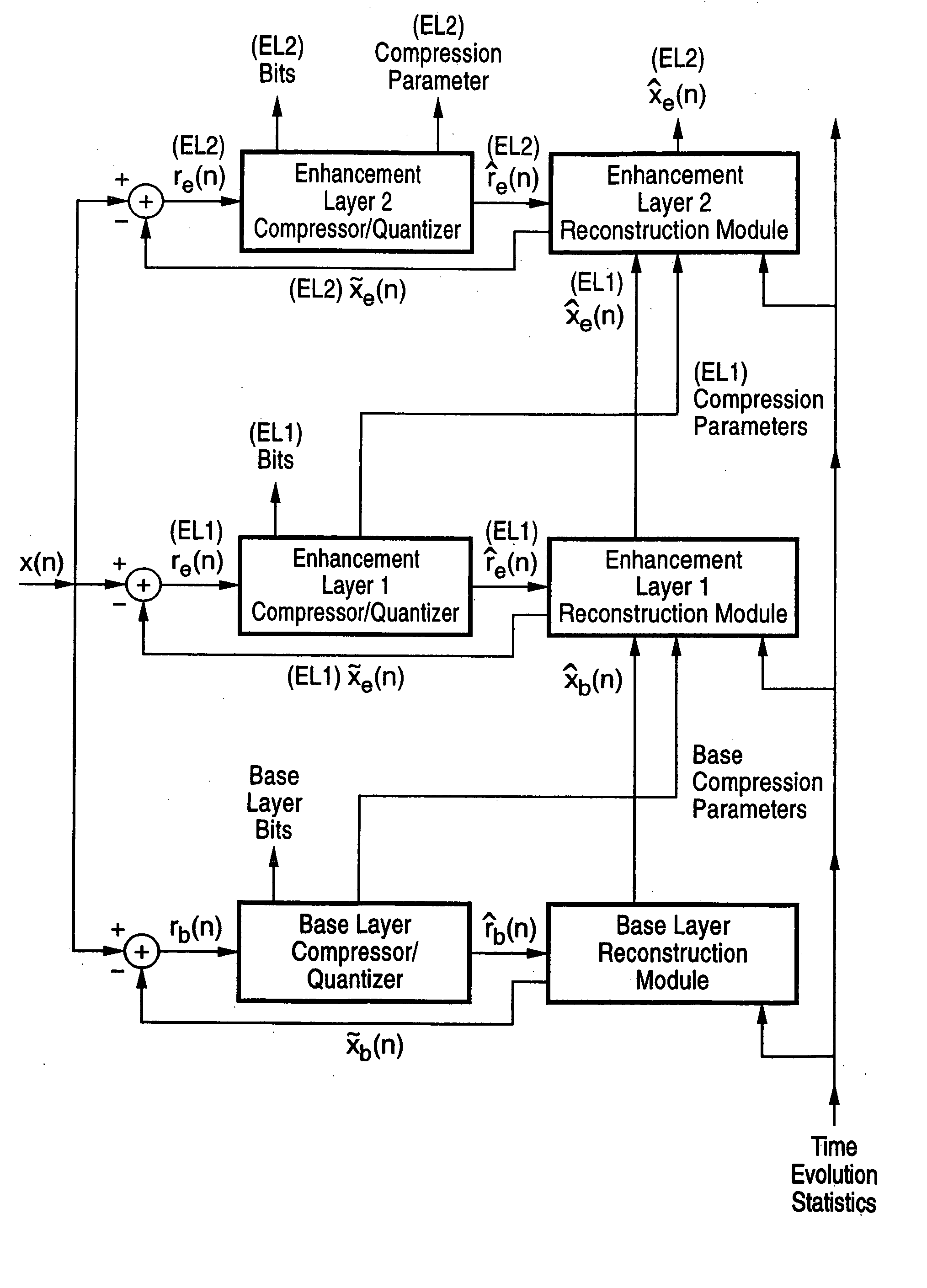

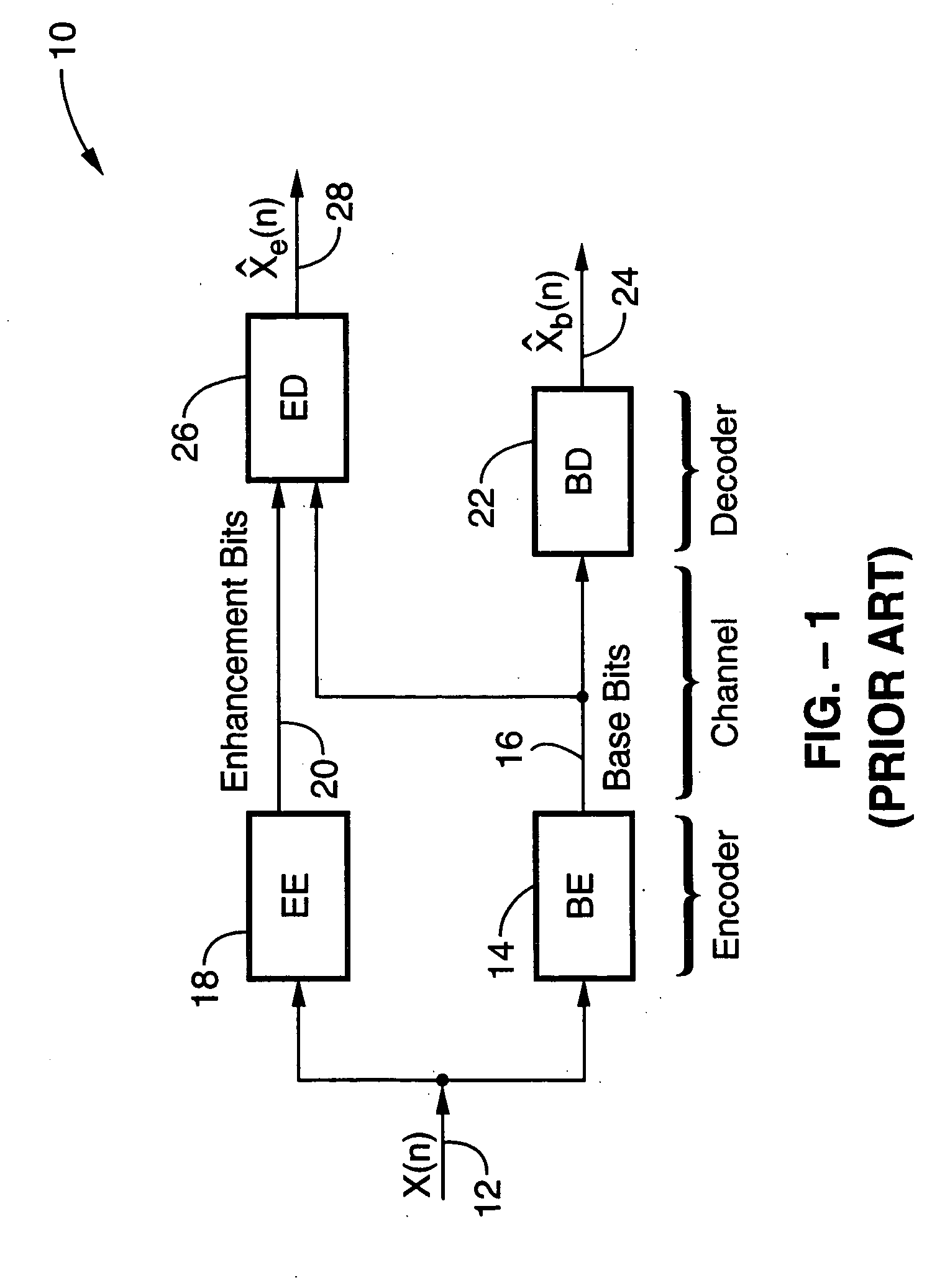

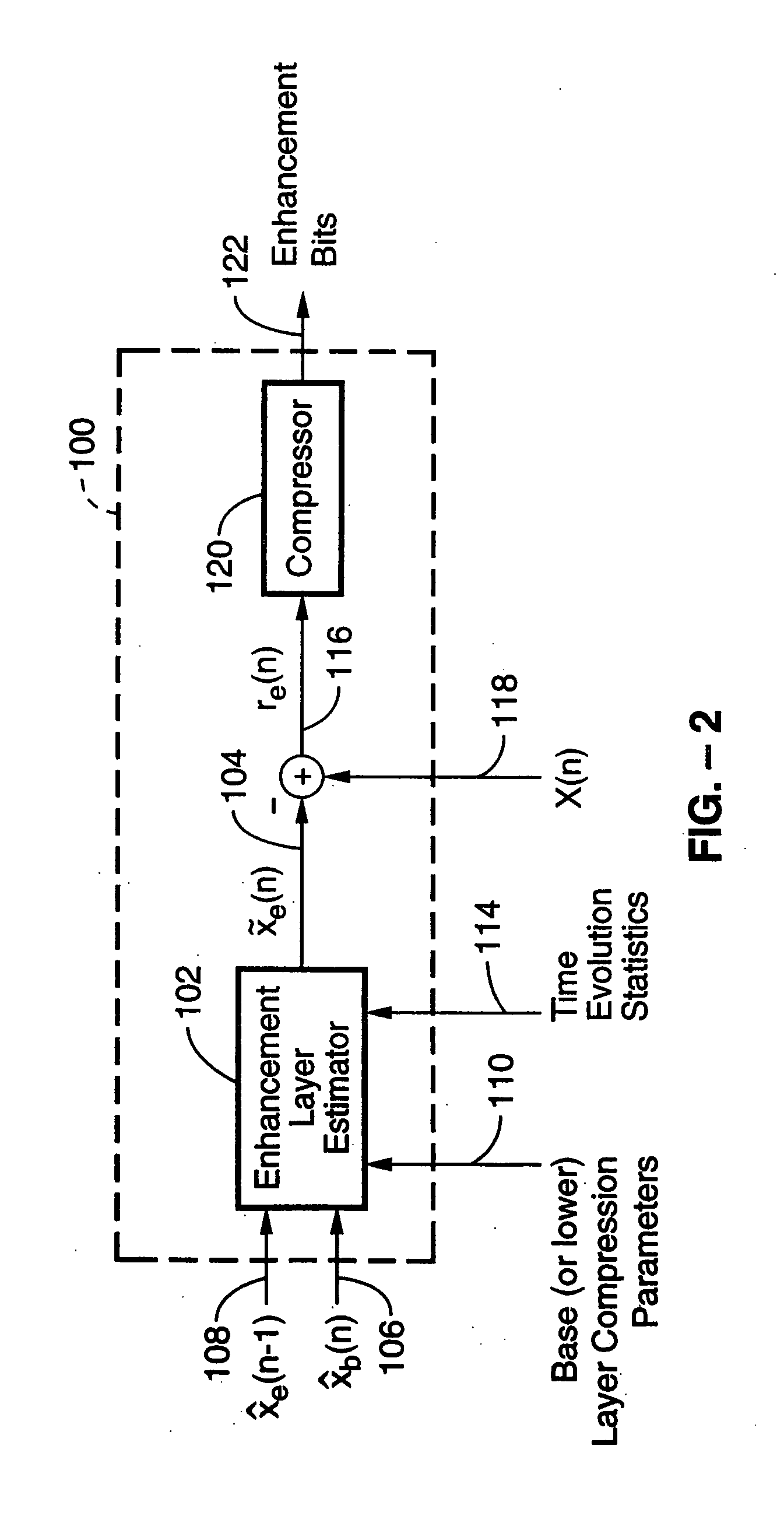

Scalable predictive coding method and apparatus

InactiveUS20050265616A1Efficient scalabilityQuality improvementCharacter and pattern recognitionRail jointsCombining rulesAlgorithm

A scalable predictive coder in which the current frame of data is predicted at the enhancement-layer by processing and combining the reconstructed signal at: (i) the current base-layer (or lower layers) frame; and (ii) the previous enhancement-layer frame. The combining rule takes into account the compressed prediction error of the base-layer, and the parameters used for its compression.

Owner:NORDIC INTERACTIVE TECH LLC

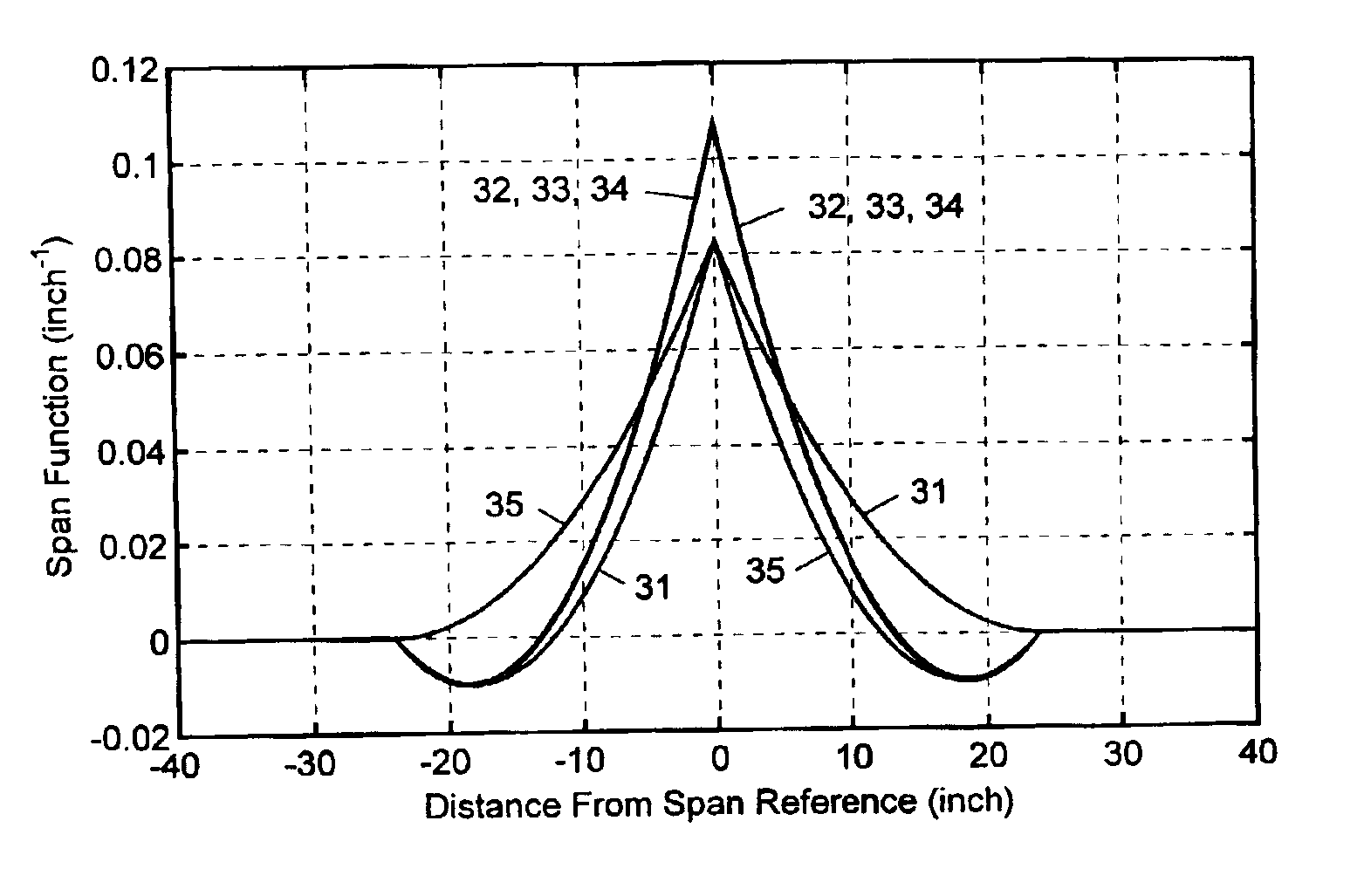

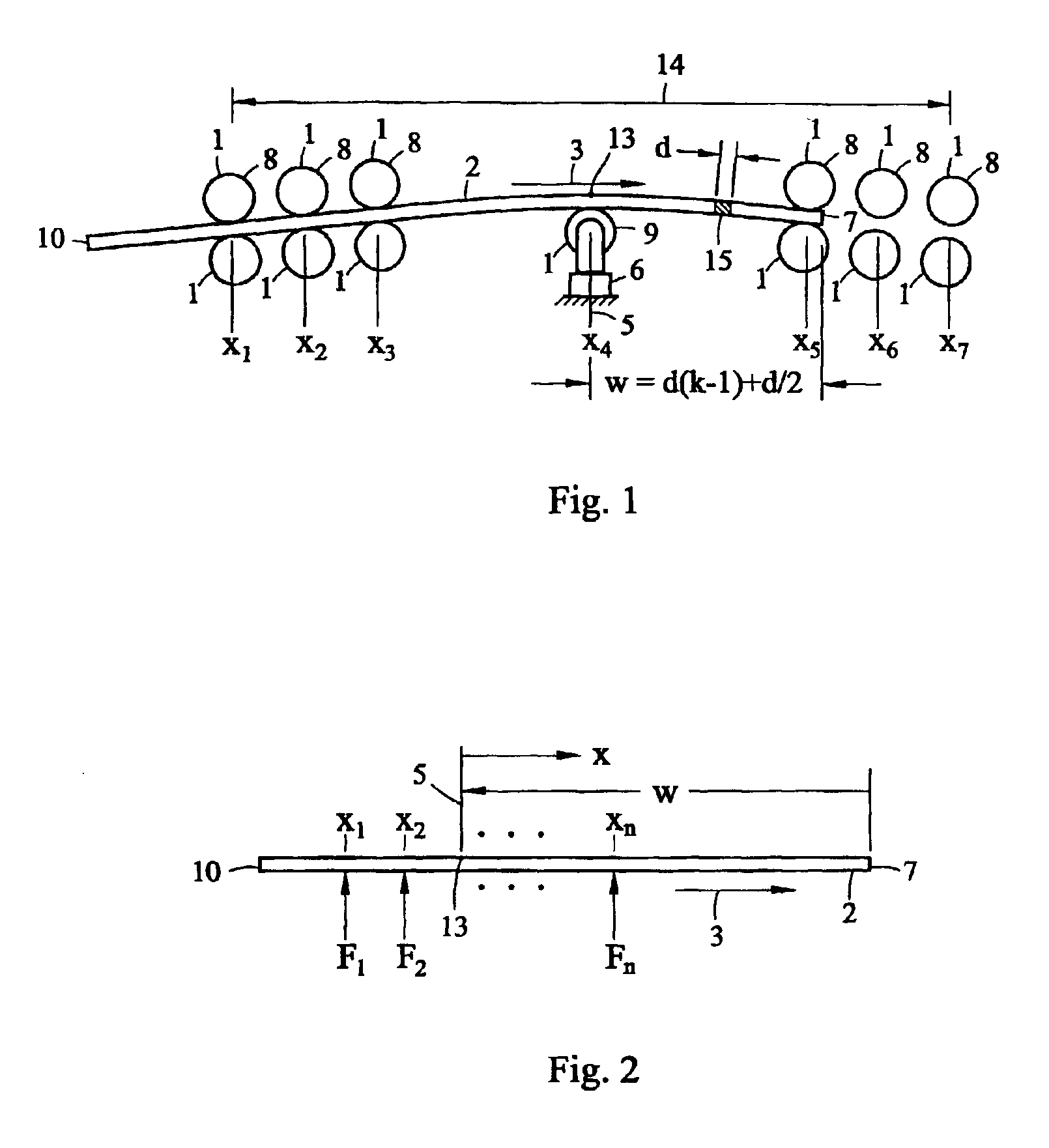

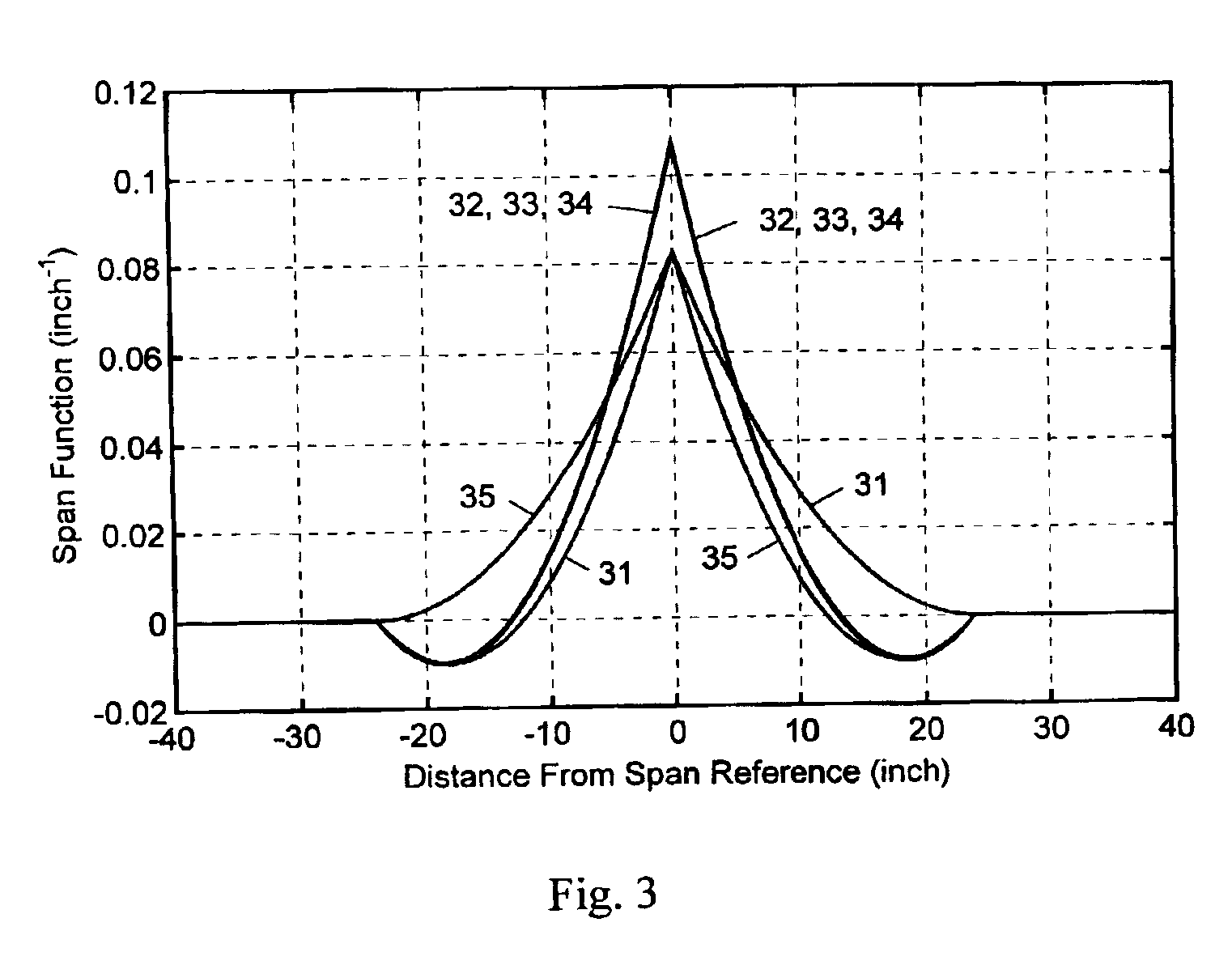

Method for estimating compliance at points along a beam from bending measurements

InactiveUS7047156B1Good estimateEstimation quality is reducedAnalysing solids using sonic/ultrasonic/infrasonic wavesForce measurementKaiman filterState variable

The inherent smoothing in bending stiffness measurement of wood boards as occurs in the machine grading of lumber can mask the effect of knots and other local characteristics affecting structural value. Improved estimates of local (pointwise) stiffness will be useful in decisions about further processing and use of a tested board. Measured compliance is reciprocally related to measured stiffness and is the convolution of local compliance and a “span function”. Span function is specific to the bending span configuration used and can change during measurement of a board. A general procedure for computing span function, which heretofore has been known only for simple bending spans, is disclosed. A Kalman filter uses this and other available information to optimally estimate local compliance from an observed relationship between local compliance and state variables of a state-space model. Method for linear algebraic determination of local compliance also depends on span functions and is disclosed.

Owner:KIERSTAT SYST

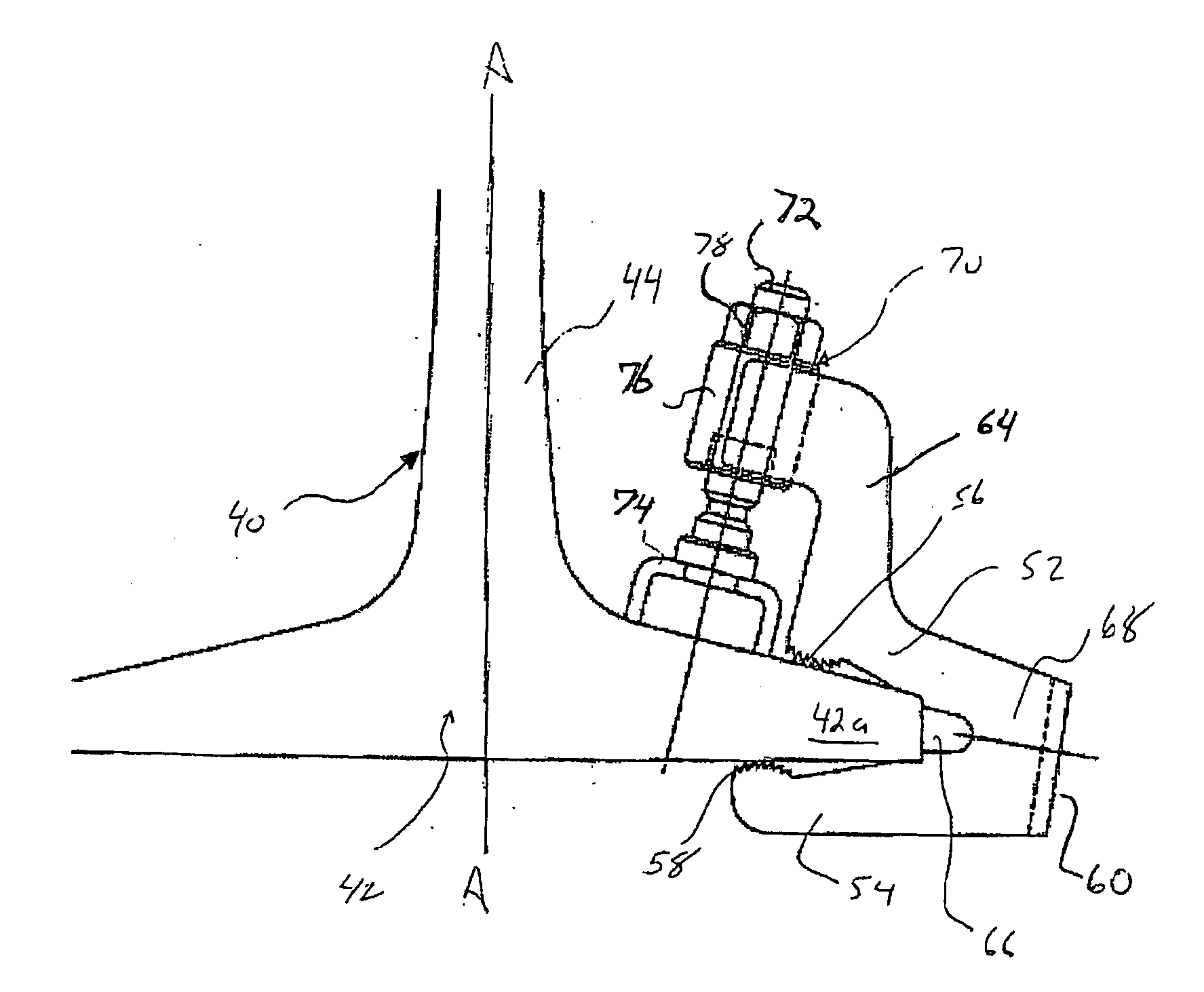

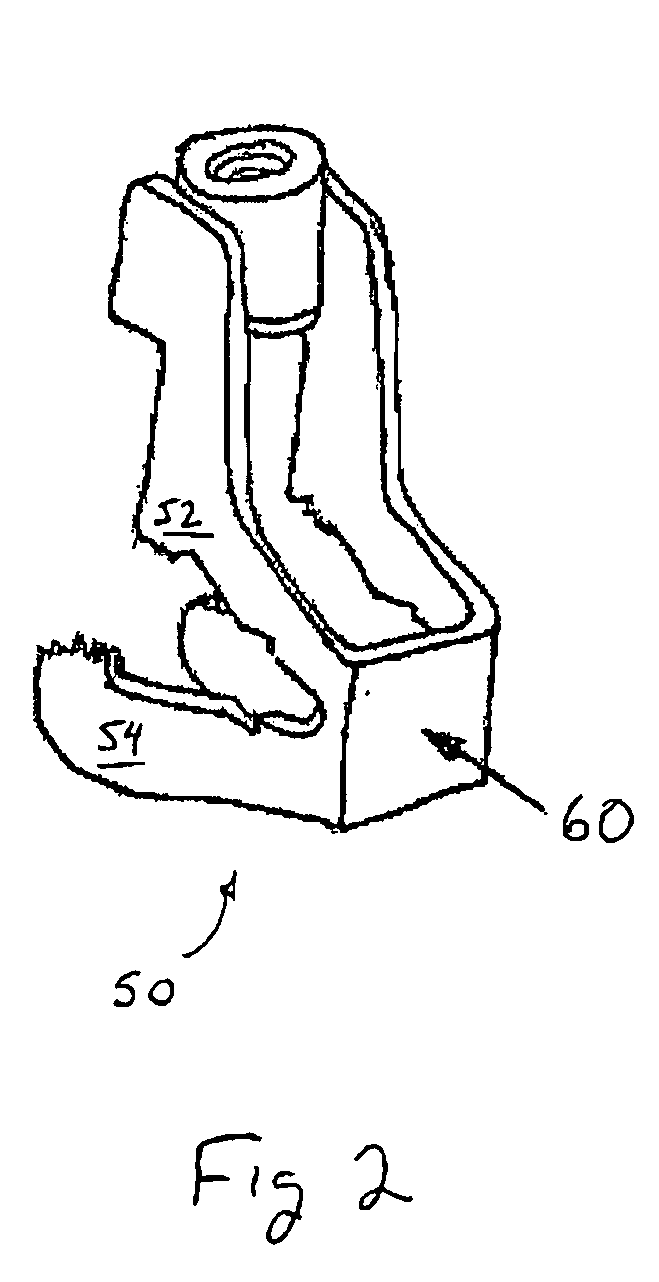

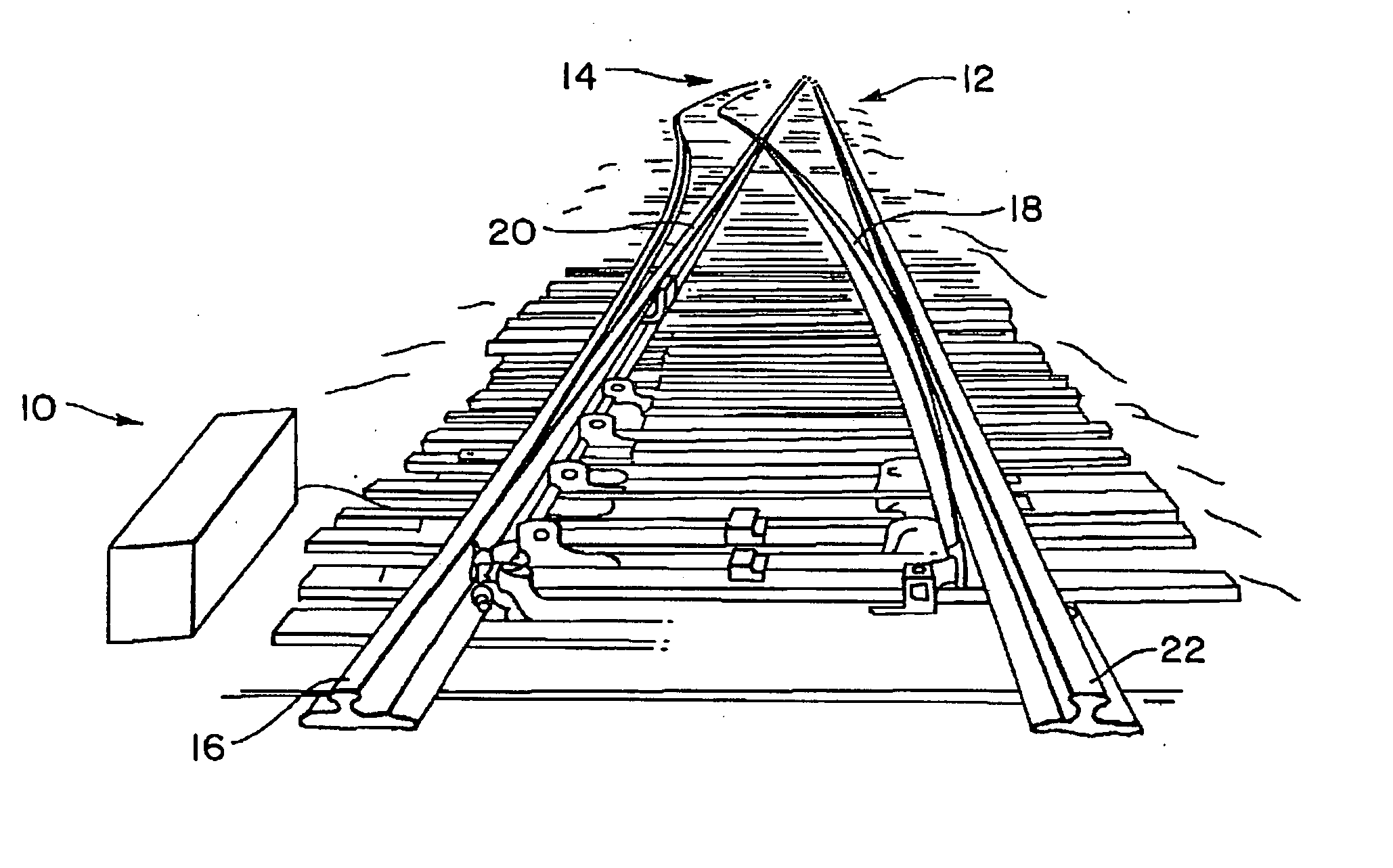

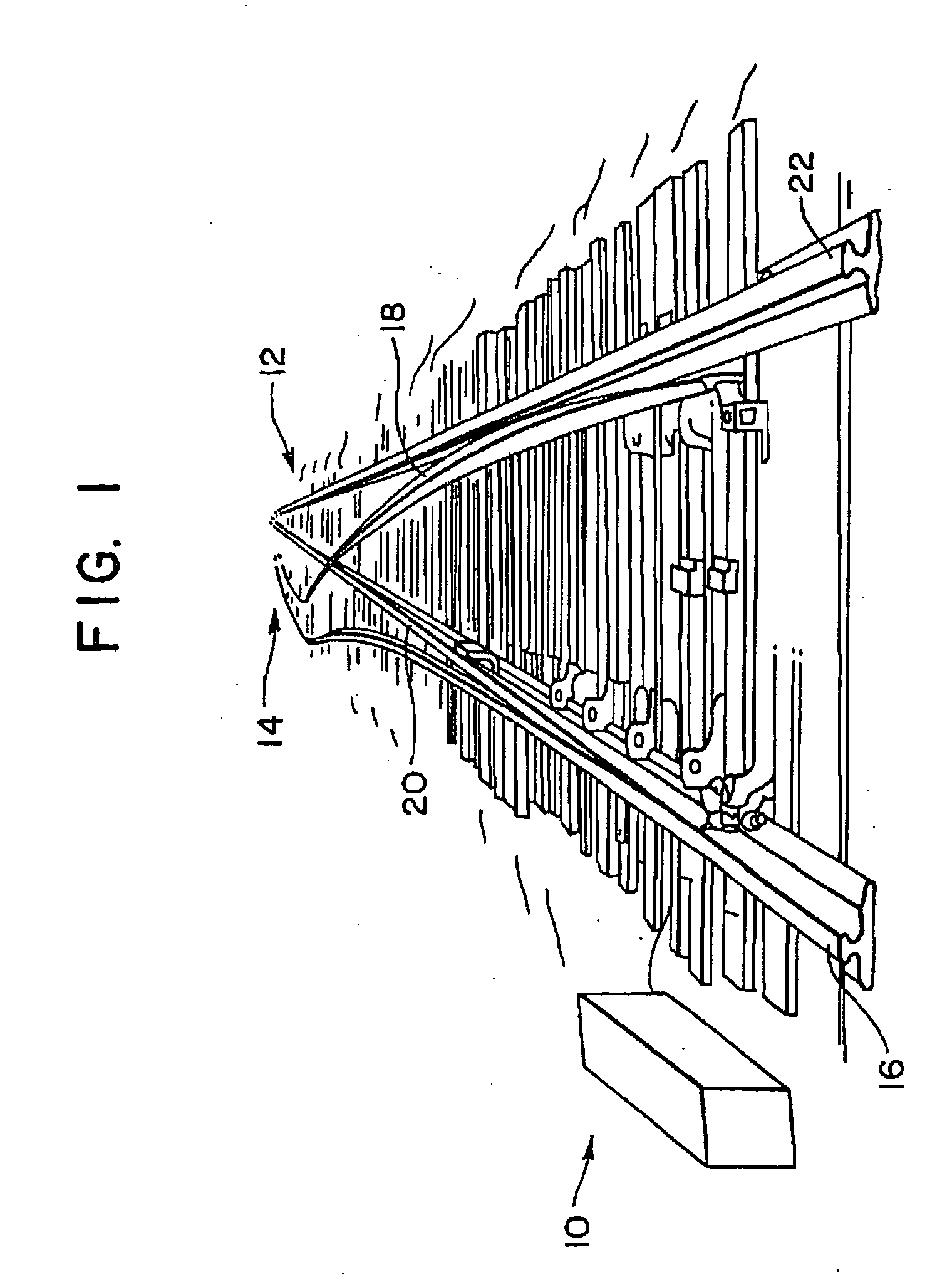

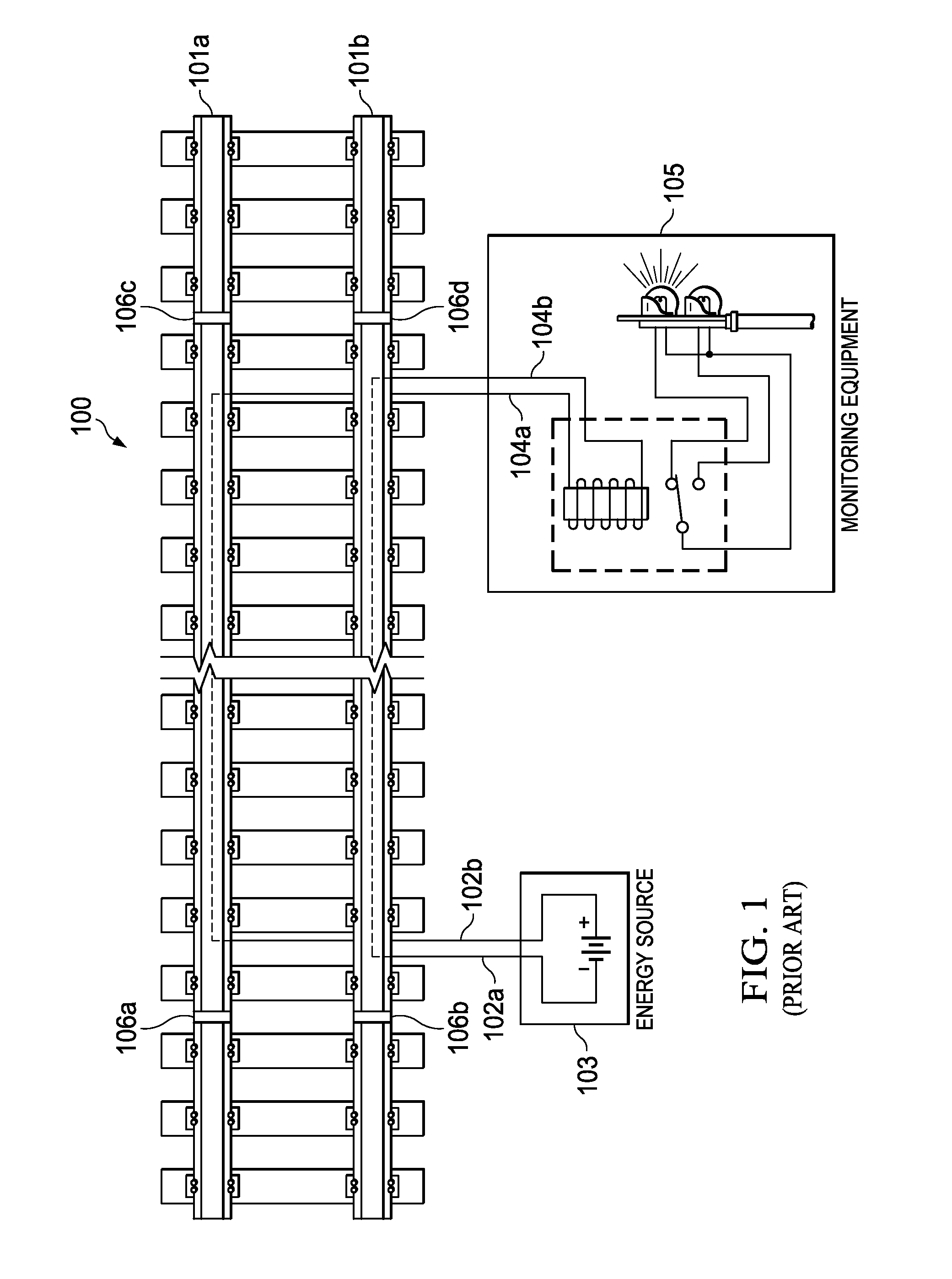

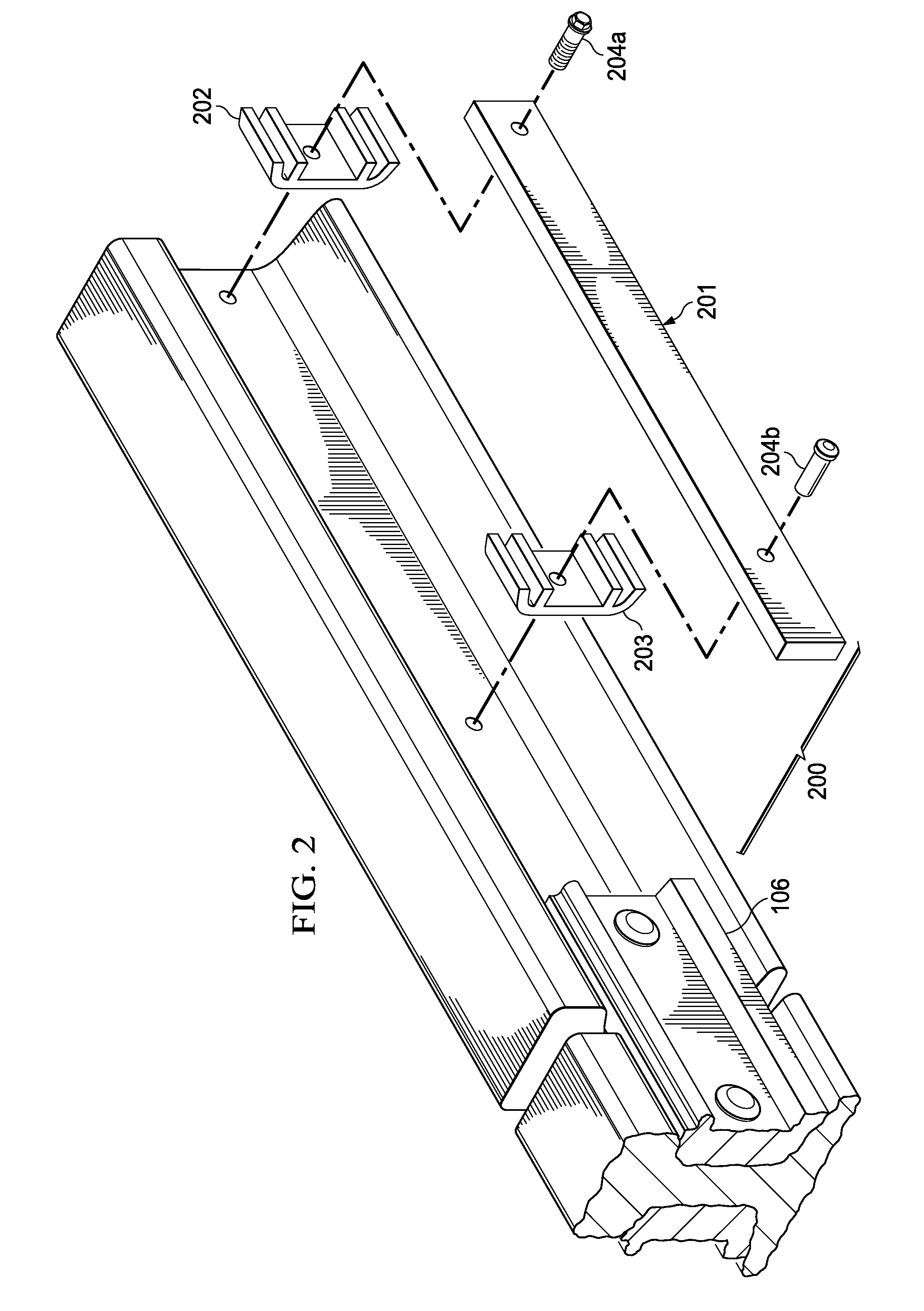

Non-invasive railroad attachment mechanism

InactiveUS20060032934A1Facilitate biasingEasy to compressRail devicesRail jointsEngineeringNon invasive

The present invention relates to a system and method for non-invasively attaching components to railroad track rails. More specifically, an anchor is provided that securely fastens to the track rail in a non-invasive manner for holding one or more components relative to a surface of the track rail. In one embodiment, the non-invasive anchor utilizes a compressive force to clamp to a flange portion of the track rail. Once securely clamped to the track rail, an adjustable track engaging member is utilized to hold a component relative to the surface of the track rail. In this regard, the track engaging member may be advanced toward the track rail to compress the component between a portion of the anchor and a surface of the track rail. In another embodiment, the anchor is adhesively attachable to a surface of the track rail.

Owner:FASTRAX INDS

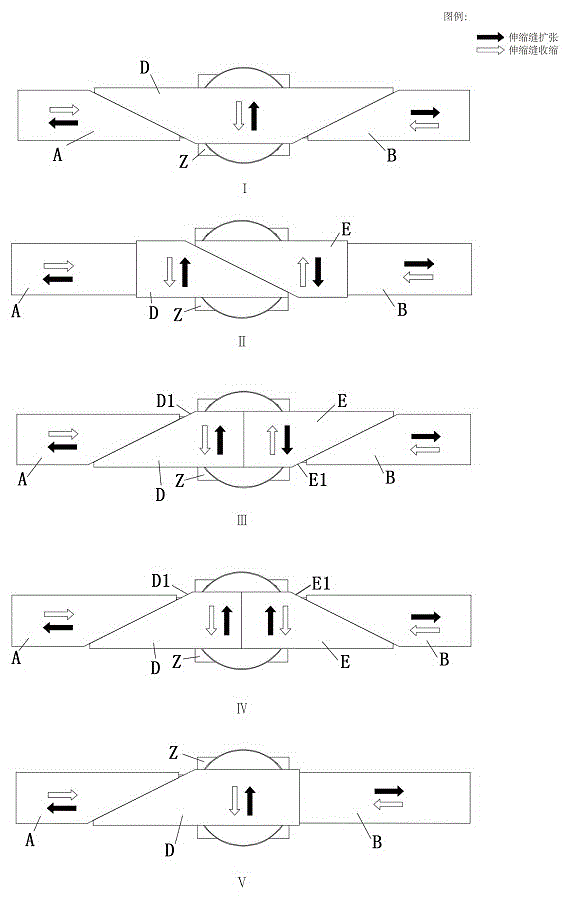

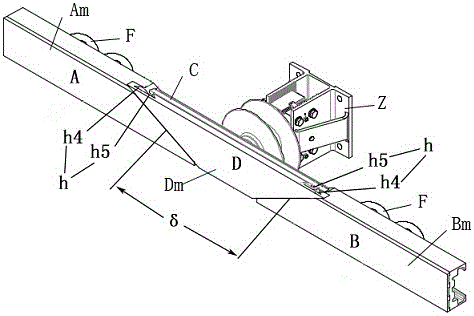

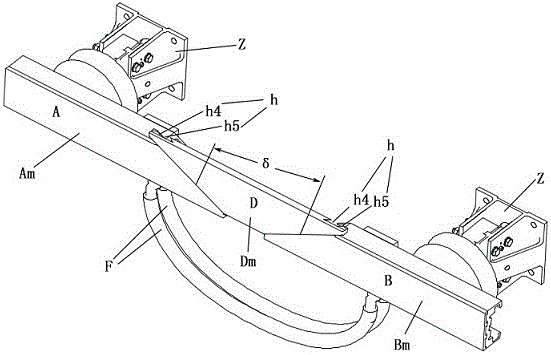

Jointless telescopic connector with contact rails

ActiveCN105742840ARun fastGuaranteed cooperationCoupling device connectionsNon-rotary current collectorElectrical conductorEngineering

The invention relates to a jointless telescopic connector with contact rails. The jointless telescopic connector with the contact rails comprises two contact rail segments, a limiting guide body, a contact surface slide block and an electrical conductor, wherein the two contact rail segments are in connecting fit with sliding clearances through the limiting guide body; at least one contact surface slide block is arranged on the limiting guide body or substrates of the contact rail segments; the external contact surface of the contact surface slide block and the external contact surfaces of the contact rail segments are located on the same working surface; the contact surface slide block partially or completely covers a telescopic gap between the two contact rail segments; at least one edge of the contact surface slide block is a bevel edge; the included angle of the sideline of the bevel edge and the telescopic direction of the contact rail segments is smaller than 90 degrees; when the two contact rail segments displace in the length direction to cause a change of the telescopic gap, the contact surface slide block correspondingly displaces along the direction vertical to the telescopic direction of the contact rail segments to adapt to the change of the telescopic gap on the contact working surface; and meanwhile, at least one electrical conductor is connected with the limiting guide body or / and the two contact rail segments to achieve electrical conduction.

Owner:HUNAN HUAPIN RAIL TRANSIT CO LTD

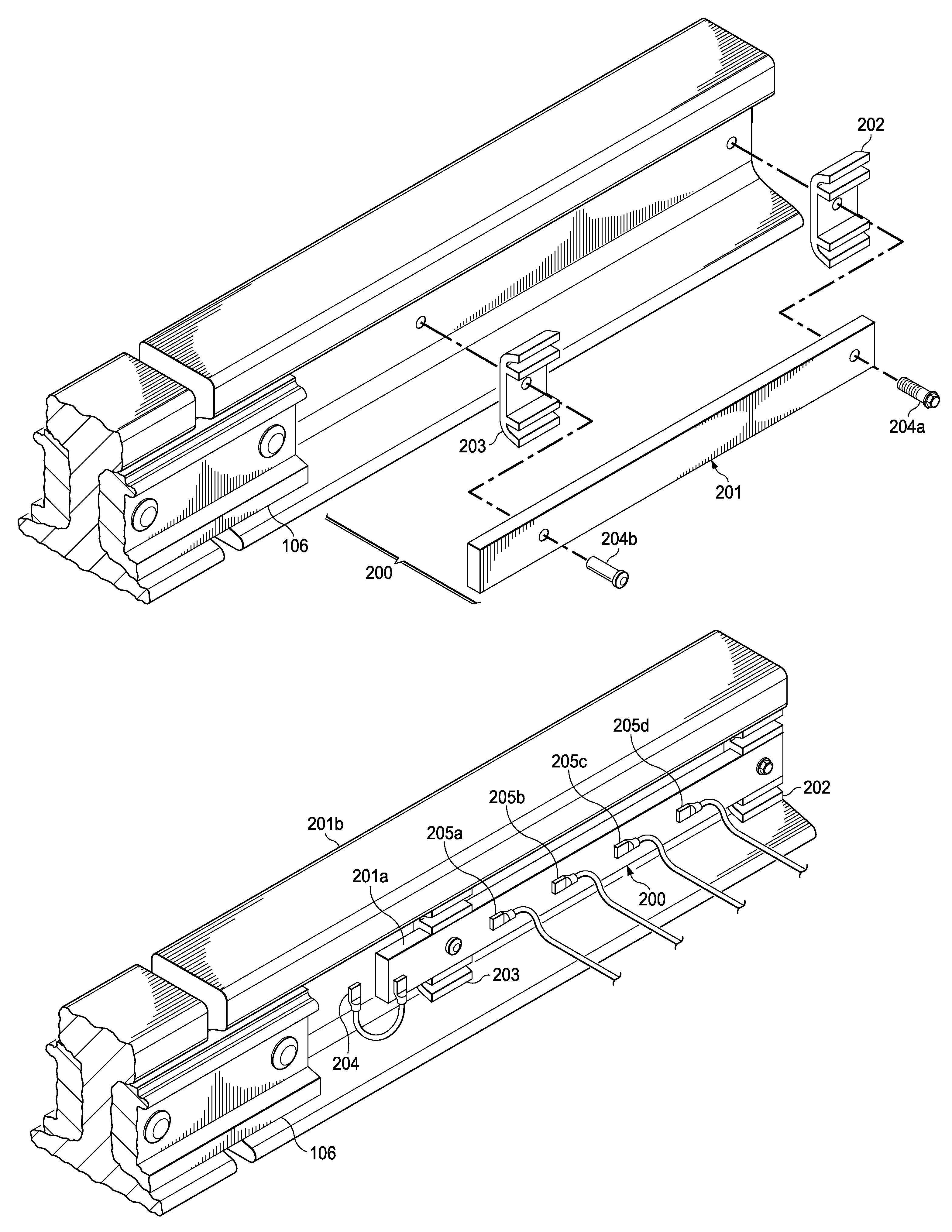

Conductive railroad attachment

ActiveUS20060032933A1Eliminate resistancePoor electrical connectionPrinted circuit assemblingRail devicesElectricityElectrical connection

Disclosed is a method for forming electrical interconnections between railroad track components and signal conductors / lines. In one arrangement, an electrically conductive adhesive is utilized to electrically interconnect a signal conductor to a railroad track component. In another arrangement, a clamp is utilized in conjunction with the electrically conductive adhesive that forms the electrical interconnection. The clamp maintains the signal conductor in direct contact with the surface of the railroad track component while the electrically conductive adhesive cures. In these arrangements, the use of the electrically conductive adhesive allows for making an electrical connection with a railroad component without penetrating the structure of that component. In a further arrangement, a hollow tubular connector is utilized to electrically connect two signal conductors associated with railroad track components. An interior of the tubular connector is at least partially filled with an electrically conductive adhesive prior to inserting the ends of the signal conductors therein.

Owner:CCI THERMAL TECH INC

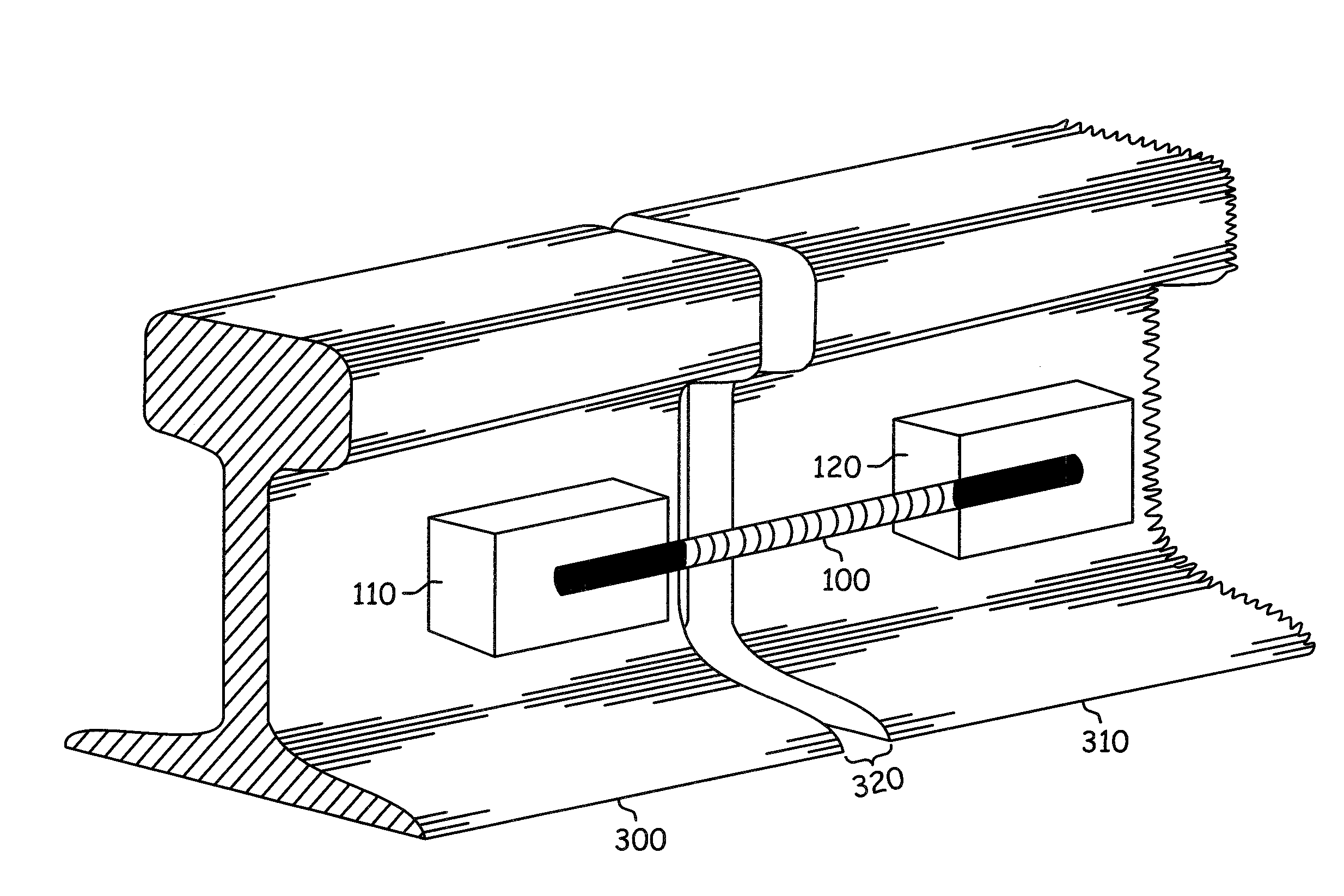

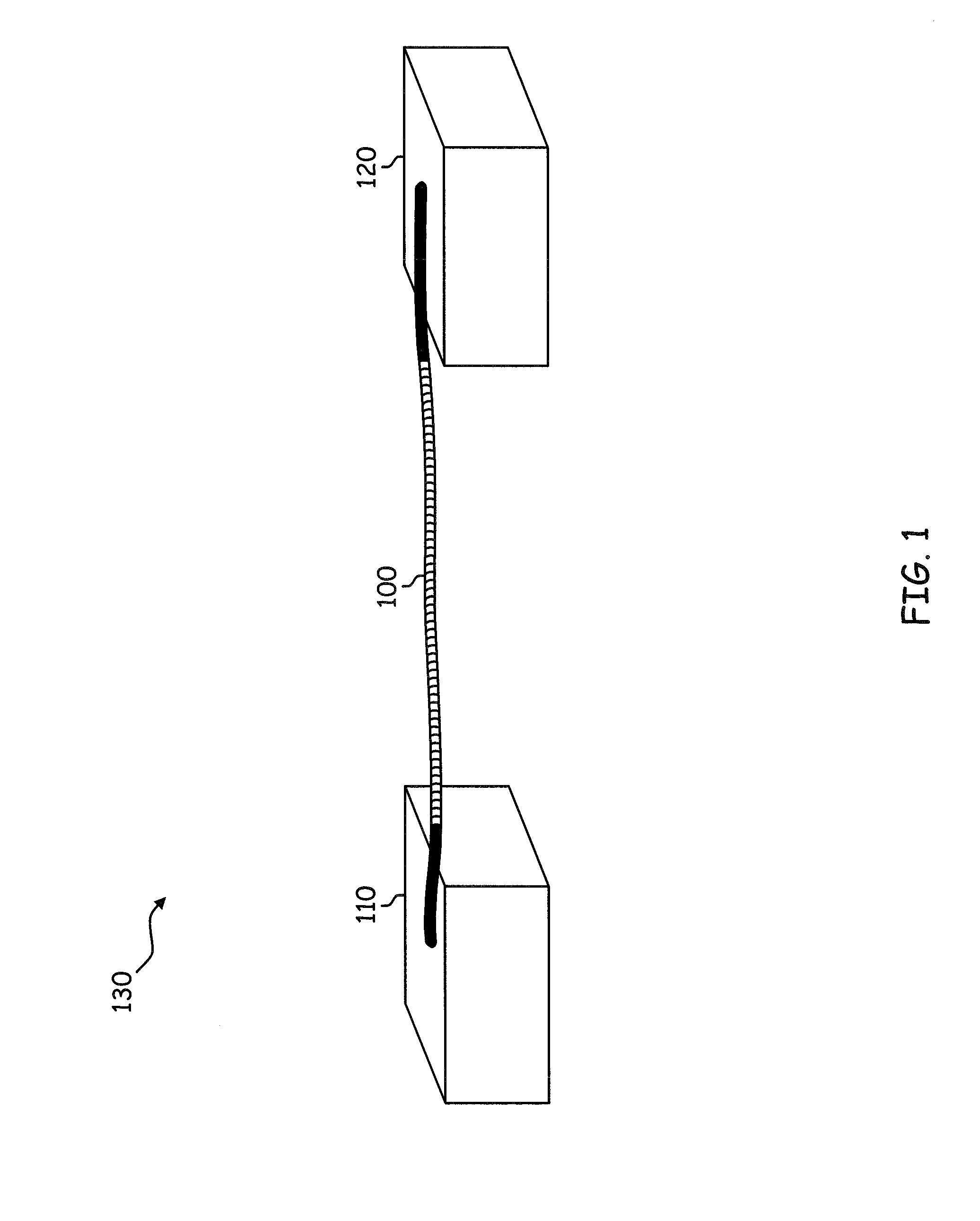

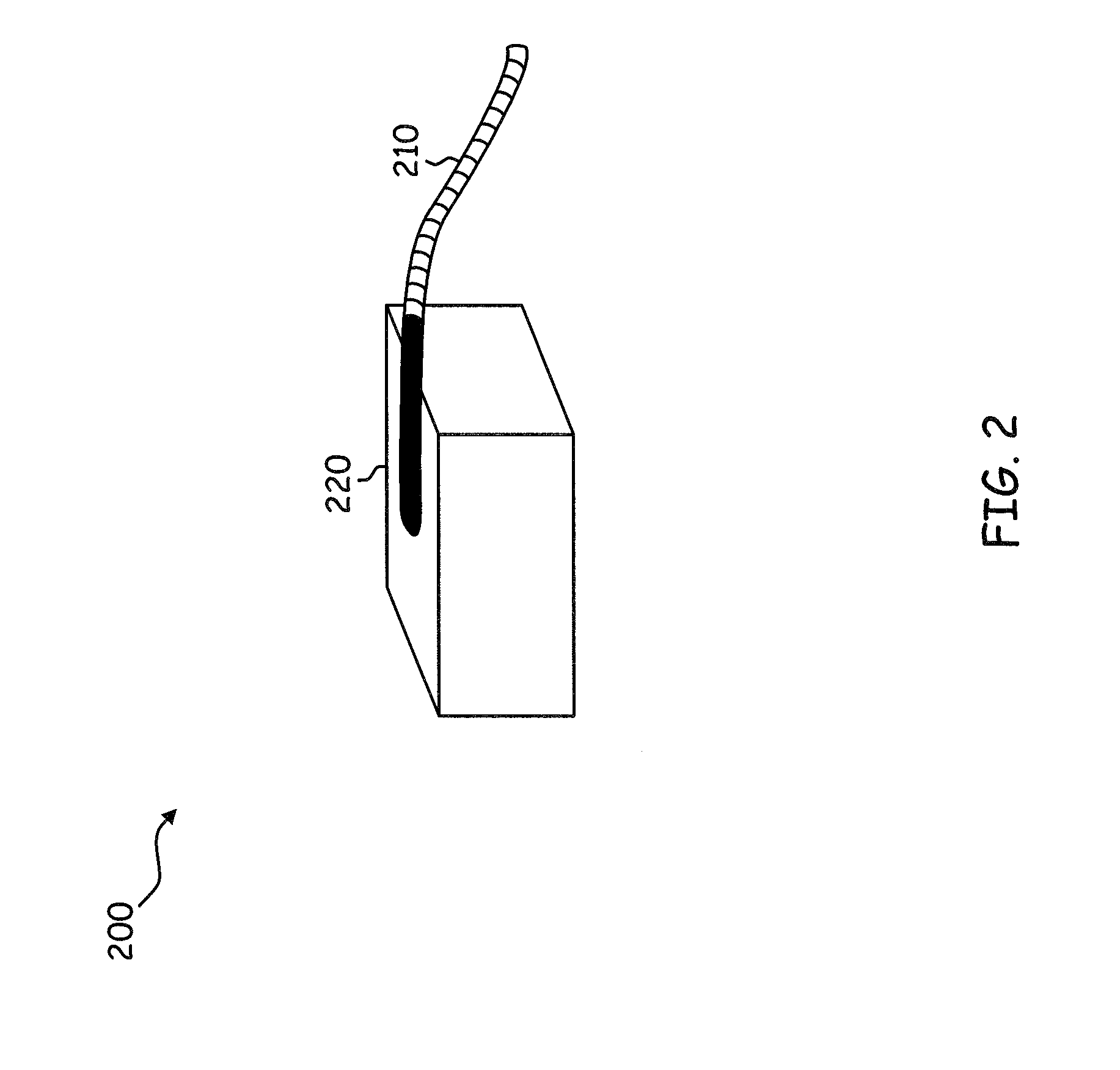

Methods and apparatus for establishing electrical connections to a railroad rail

ActiveUS8939380B1Reduce harmEasy and less-expensive to replaceRail devicesRail jointsElectrical connectionEngineering

A method of making an electrical connection to a railroad rail includes fastening a wire bonding assembly to a railroad rail, the wire bonding assembly including first and second spaced apart washer plates contacting the rail and a metal bar supported by the washer plates. The metal bar is electrically connected with the rail with a first conductive lead contacting a selected point on the rail and a selected point on the metal bar. A second conductive lead is connected to another selected point on the metal bar for establishing an electrical connection to the rail from an electrical device.

Owner:BNSF RAILWAY

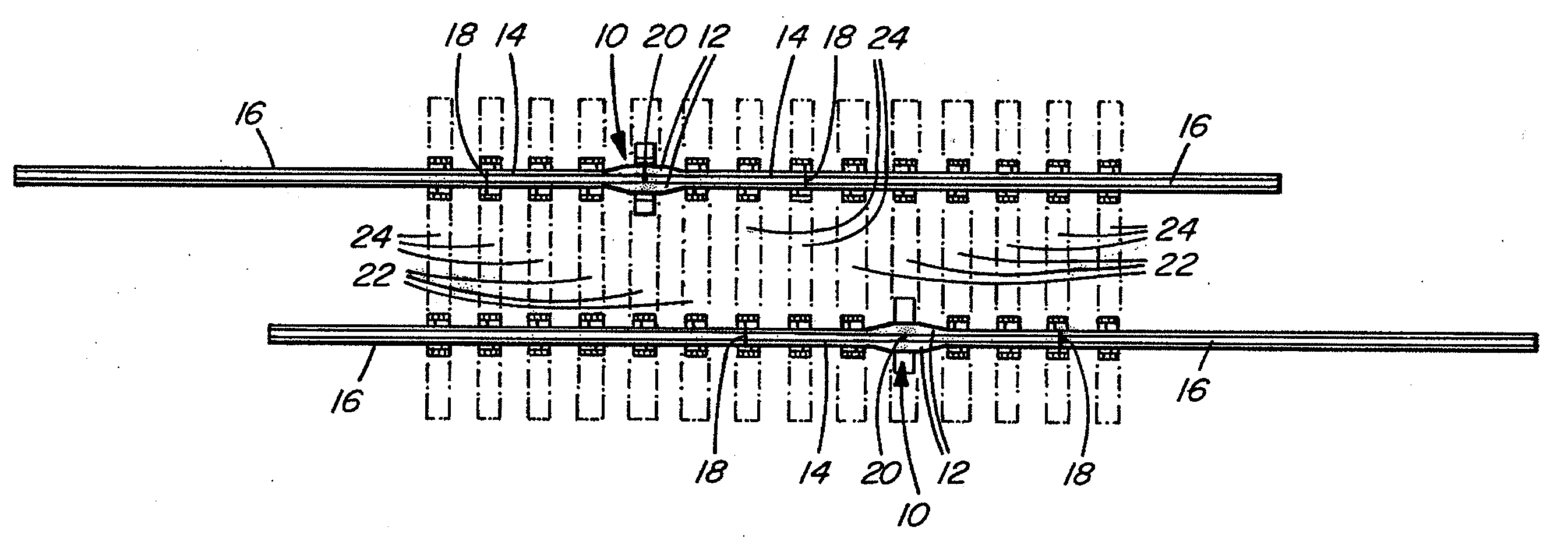

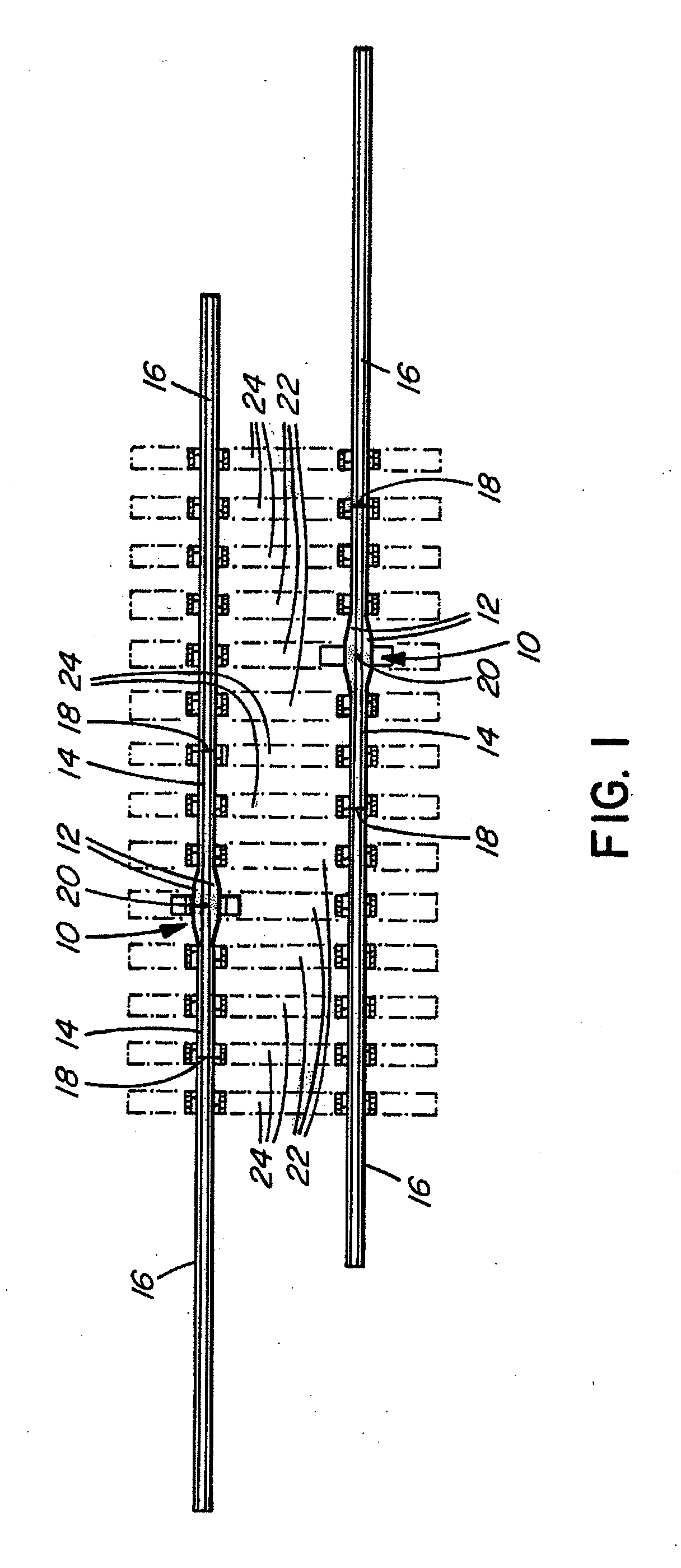

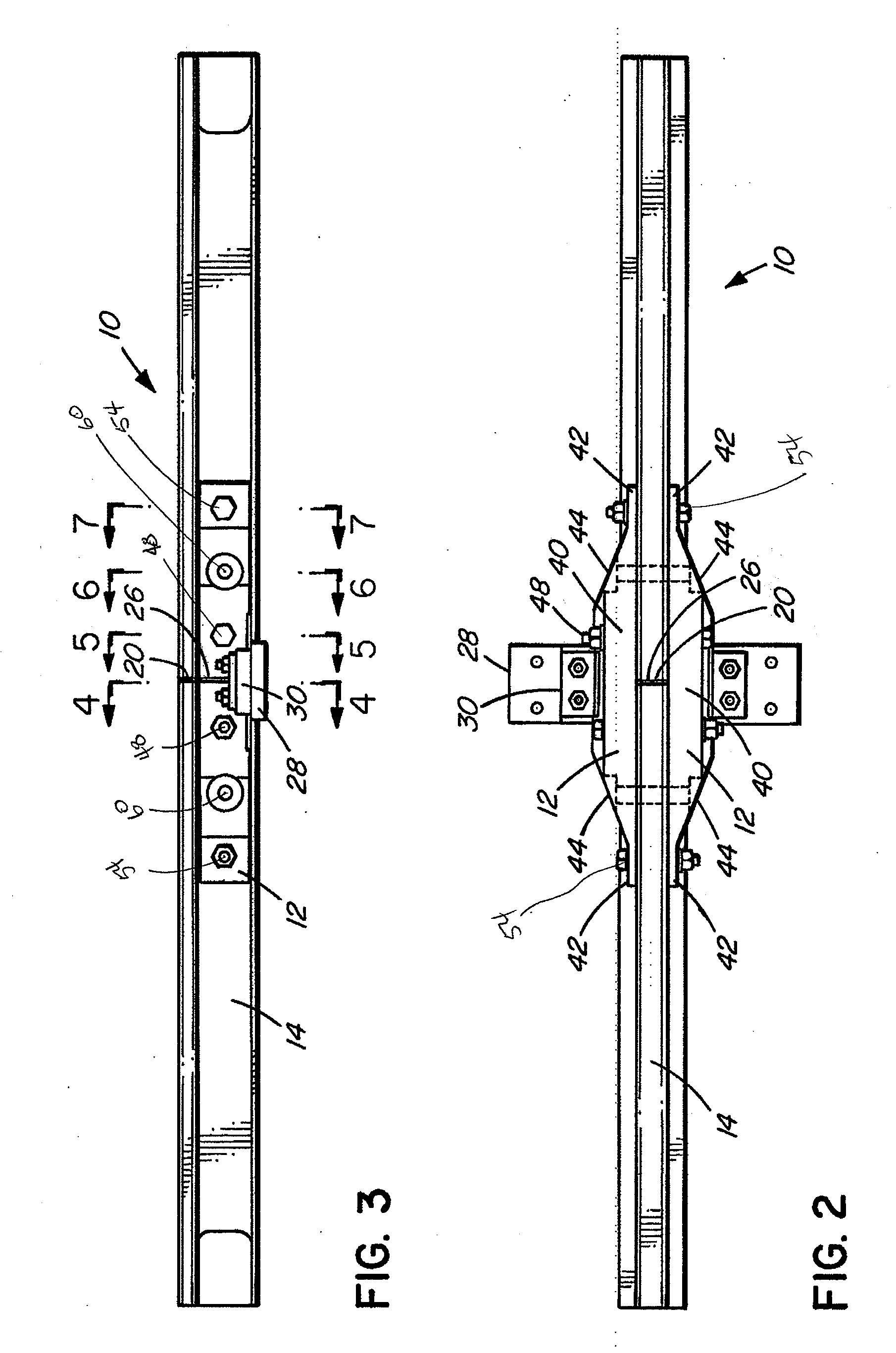

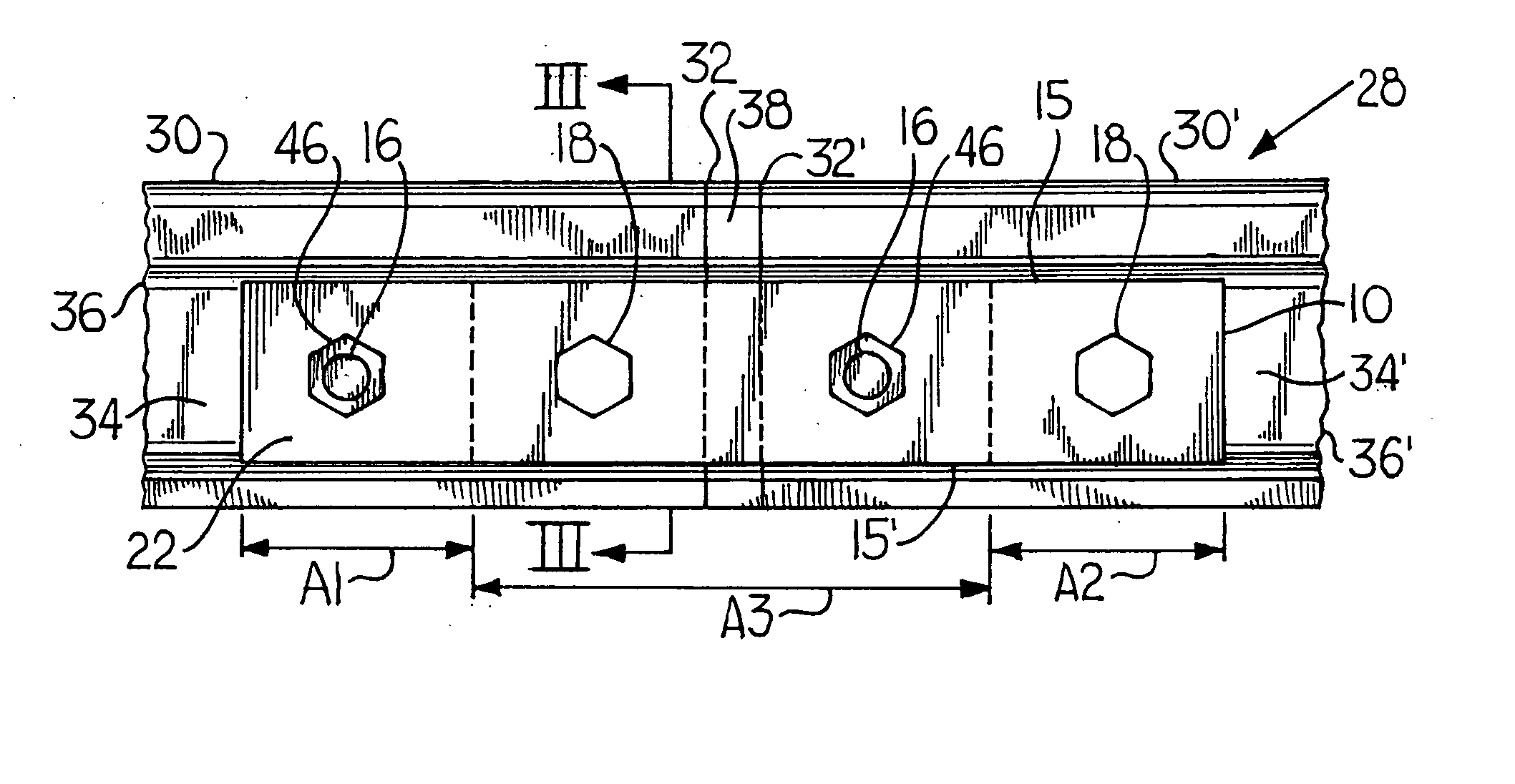

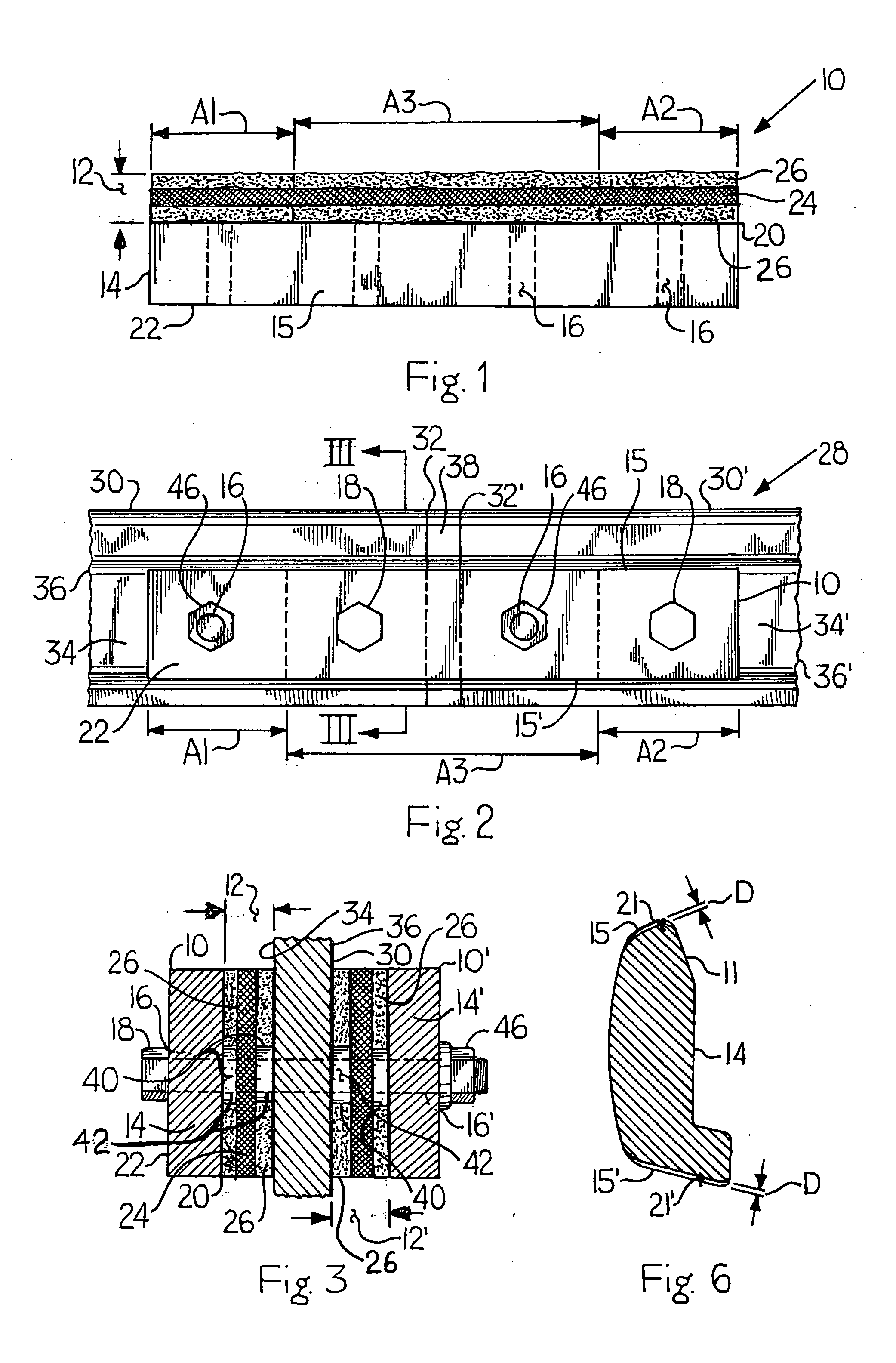

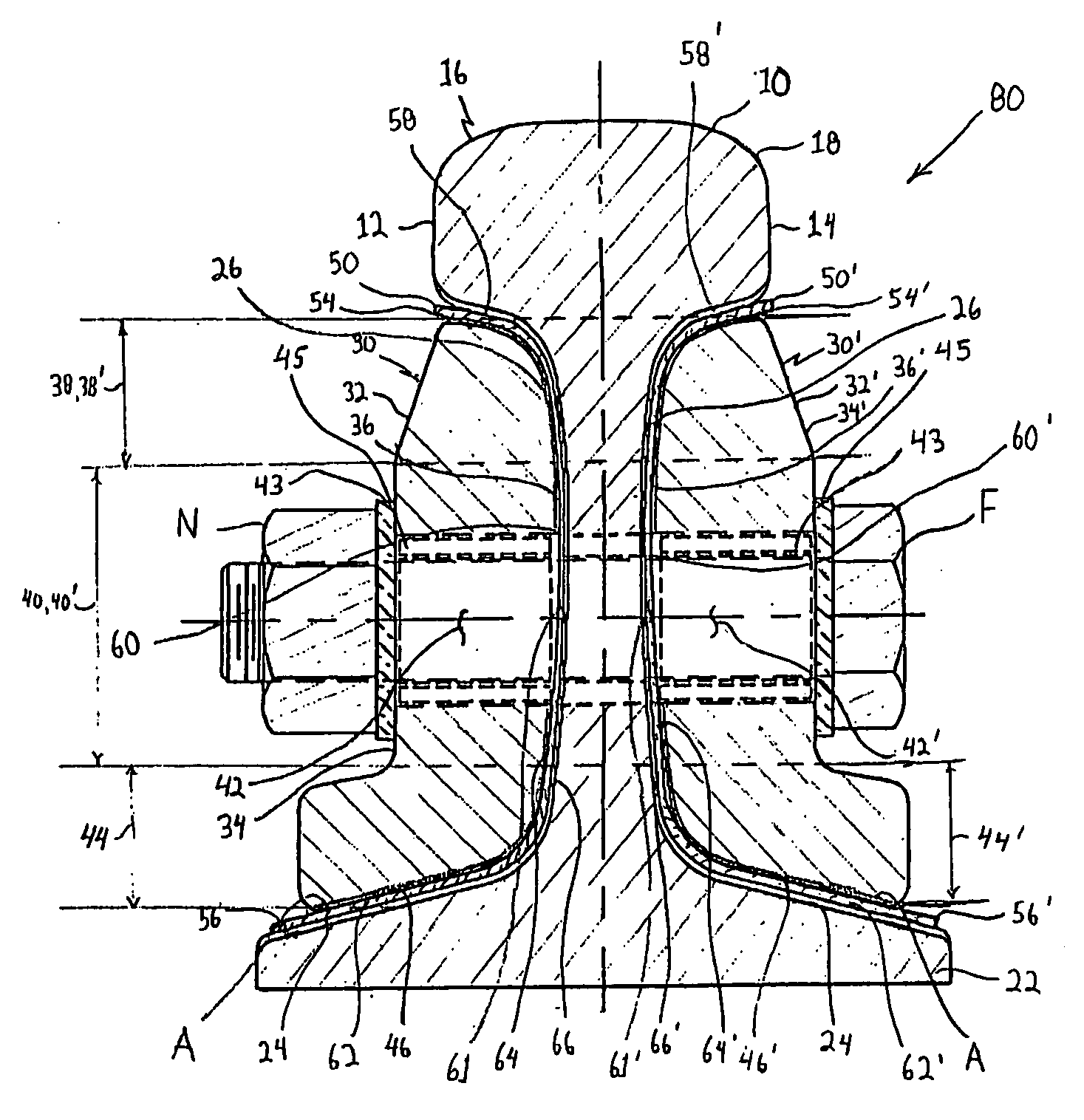

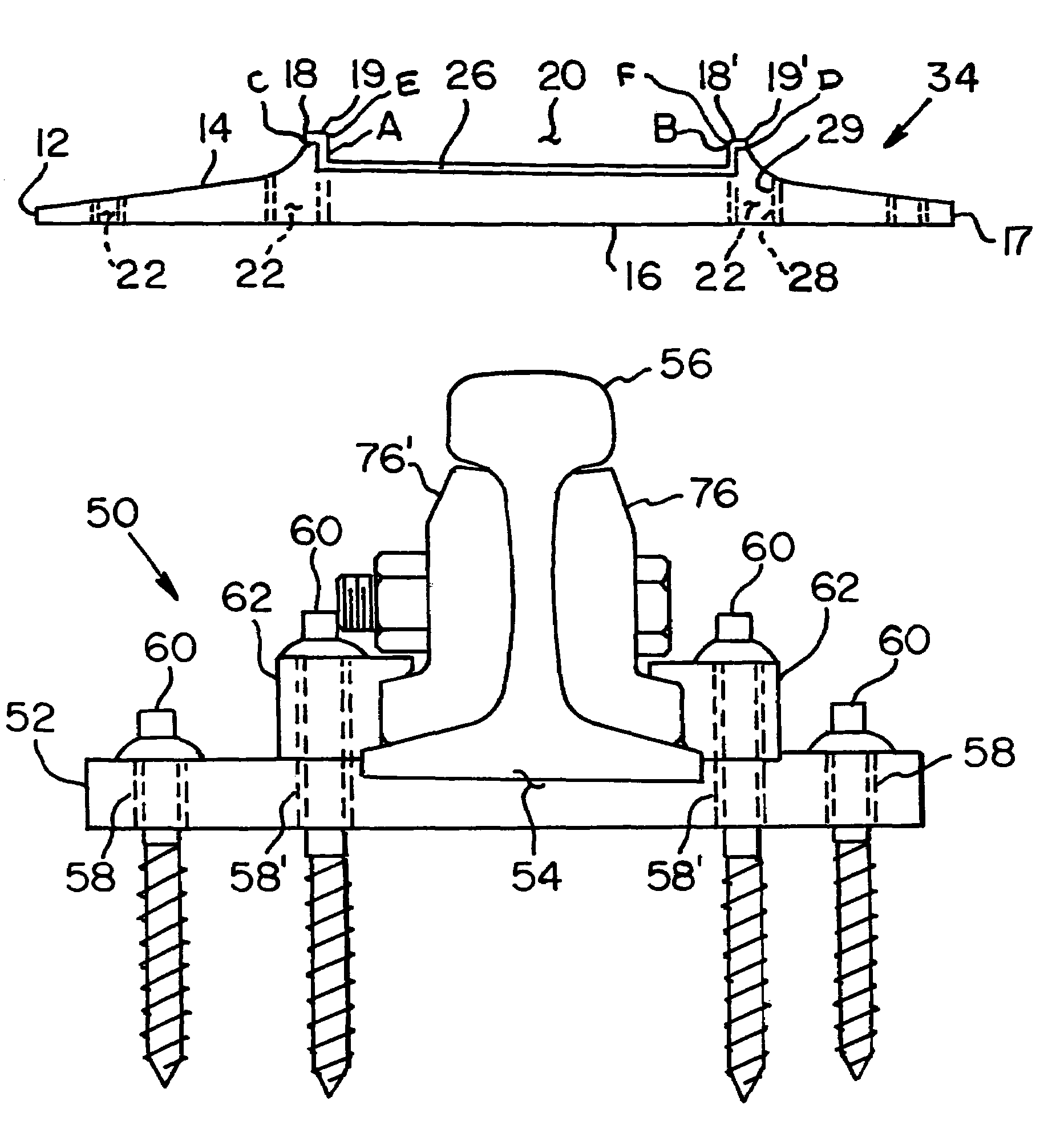

Rail joint bars and rail joint assemblies

A rail joint assembly is provided for joining abutting railroad rails with an electrically-insulated joint. The rail joint assembly comprises abutting railroad rails compressing an insulating gasket therebetween and rail joint bars secured through a plurality of holes by fasteners to the adjacent railroad rails. The rail joint bars comprise a body and an insulating spacer comprising a porous mesh screen and washer. A layer of epoxy is sandwiched between a rail joint bar and railroad rail and comprises a rigid epoxy on lateral portions of a first side of a rail joint bar and a flexible epoxy placed on a central portion of the first side of a rail joint bar. Rail joint bars are rectangular shaped and may have a cutout.

Owner:KOPPERS DELAWARE INC

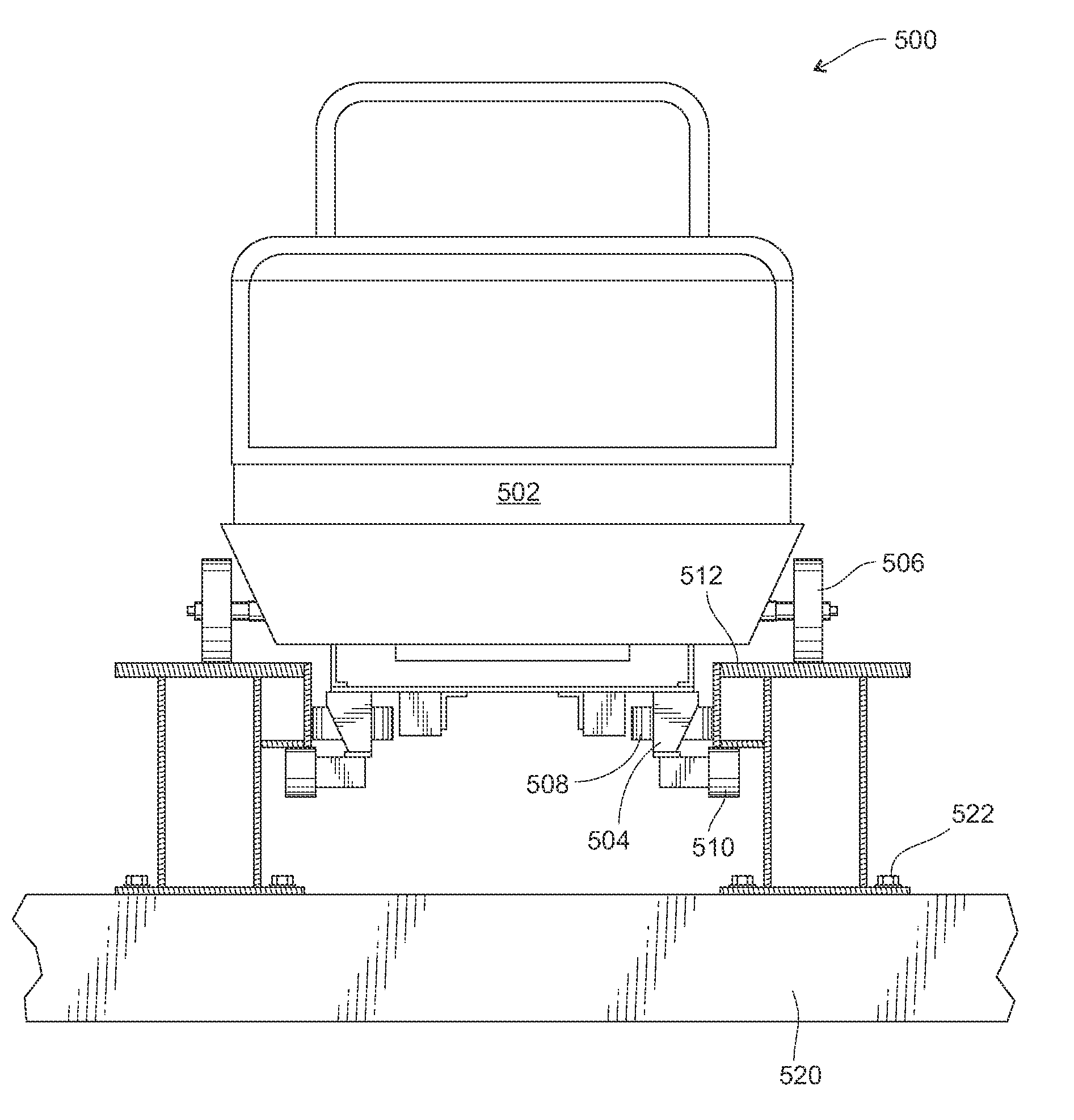

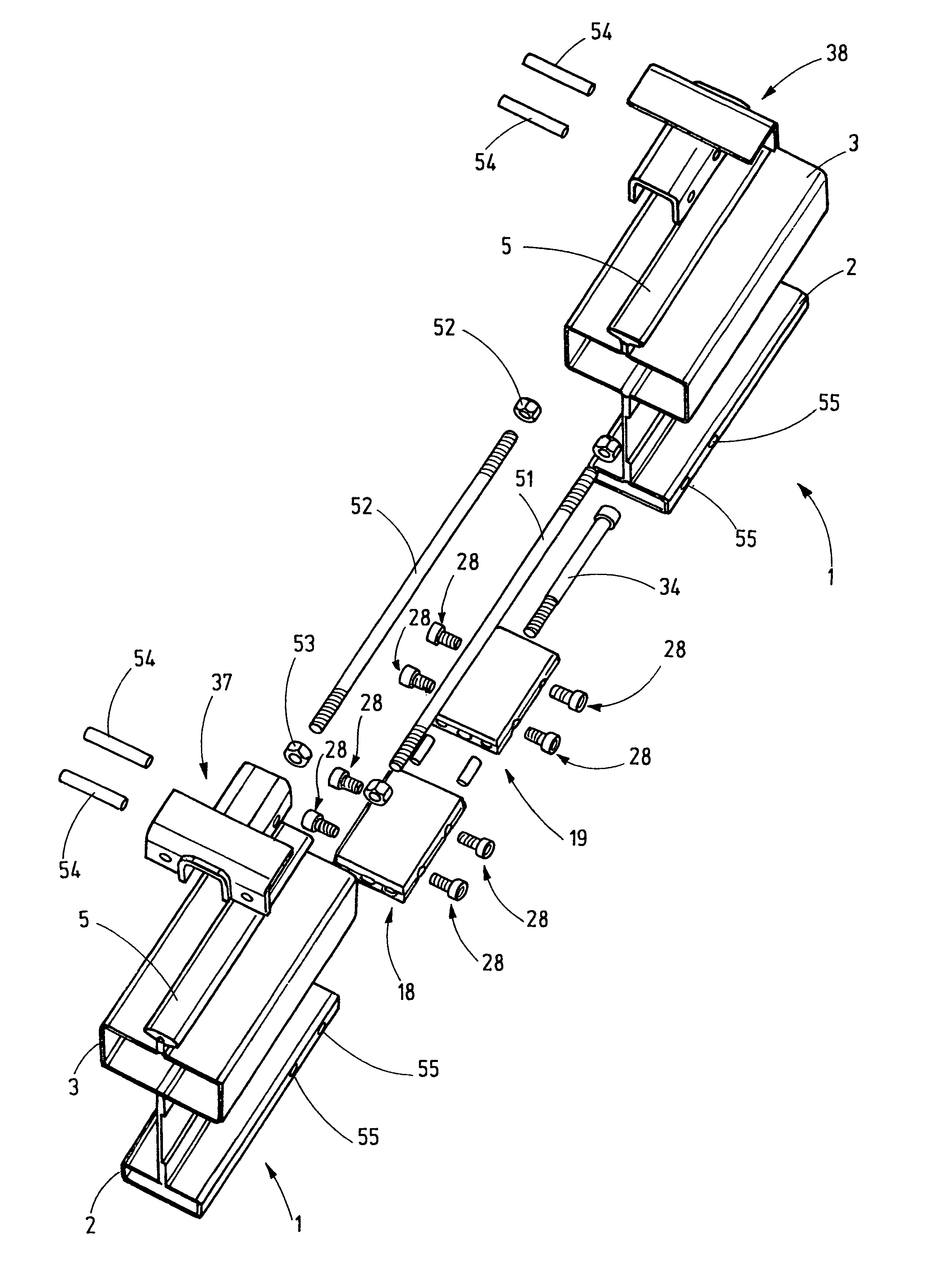

Railway joint connection arrangement

InactiveUS7997207B2Efficient arrangementReduce gapRail jointsRope railwaysTransverse forceEngineering

A joint connector for the lower flanges of adjoining running rails is assembled from two abutment pieces that each is seated in a lower flange of a respective rail that forms the joint. By use of centering devices, the correctly aligned positioning of the two abutment pieces is assured, wherein the abutment pieces transfer their aligned positioning to the lower flanges that meet each other without offset at the joint and the positioning cannot be negatively affected by transverse forces. The connection also provides a positive-fit in a transverse direction of the rails. Another joint connector arrangement connects the two running rails in the region of the top side. Abutment pieces in this case are seated as riders on a support rib and are connected to each other by tension rods.

Owner:STAHL CRANESYSTEMS GMBH

Method and machine for replacing damaged rail sections of a track

In a method for efficiently removing a great number of damaged rail sections, after a first separating cut, the severed free rail ends are gripped by a rail pulling device connecting the rail ends to one another, and are pulled towards one another. The pulling force required for the pulling-together as well a current rail temperature are registered for calculation of that length of a replacement rail which is required for producing a desired rail tension. A second separating cut is carried out—with corresponding path measurement—spaced at a distance from the first separating cut as calculated on the basis of the selected length of the replacement rail.

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

Center supported bond joint

Owner:PORTEC RAIL PRODS

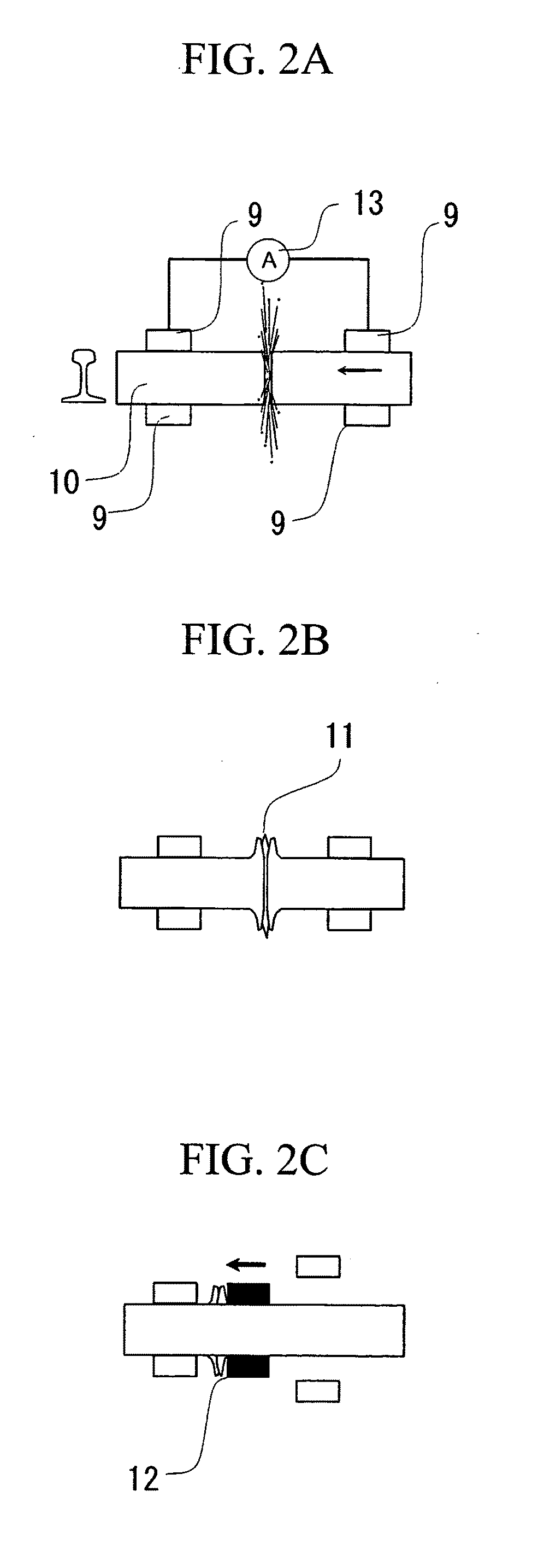

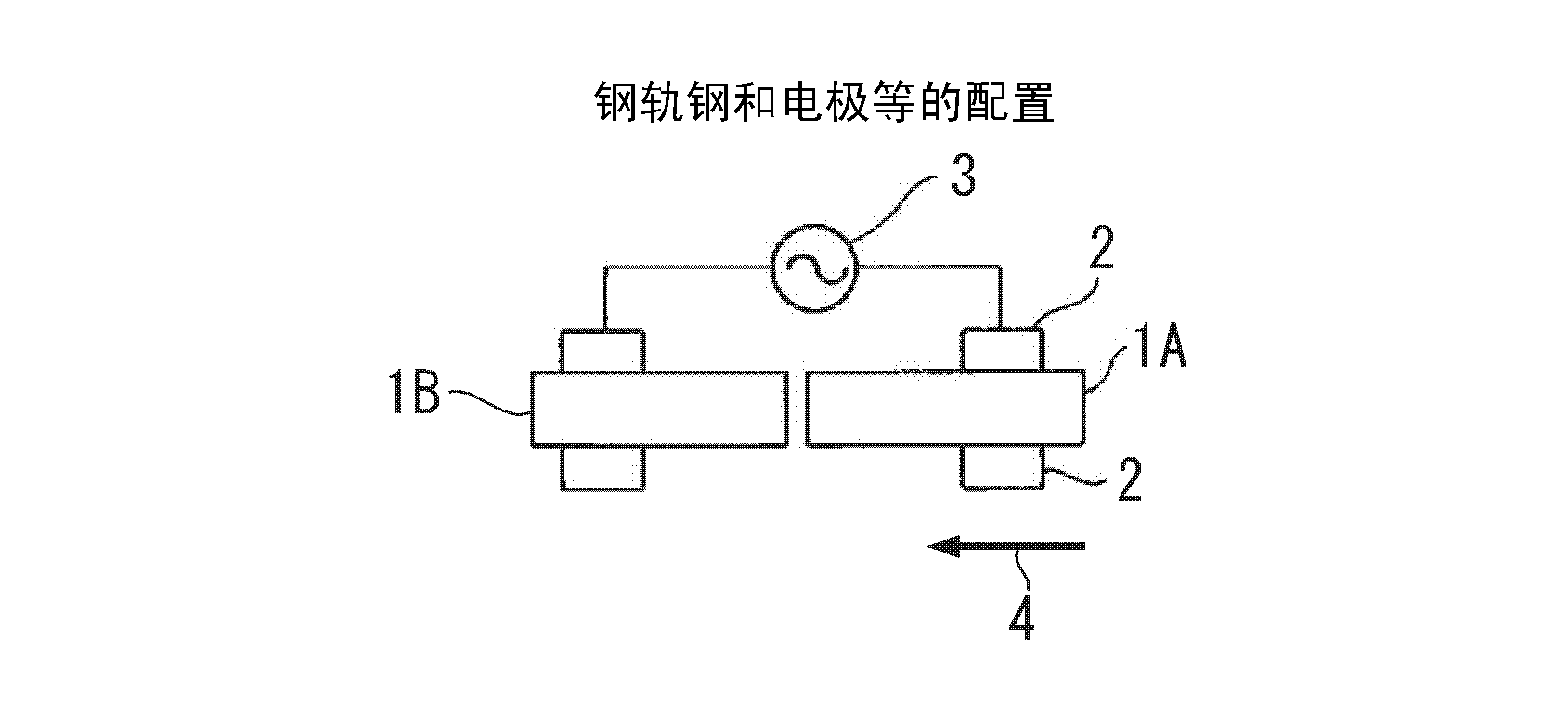

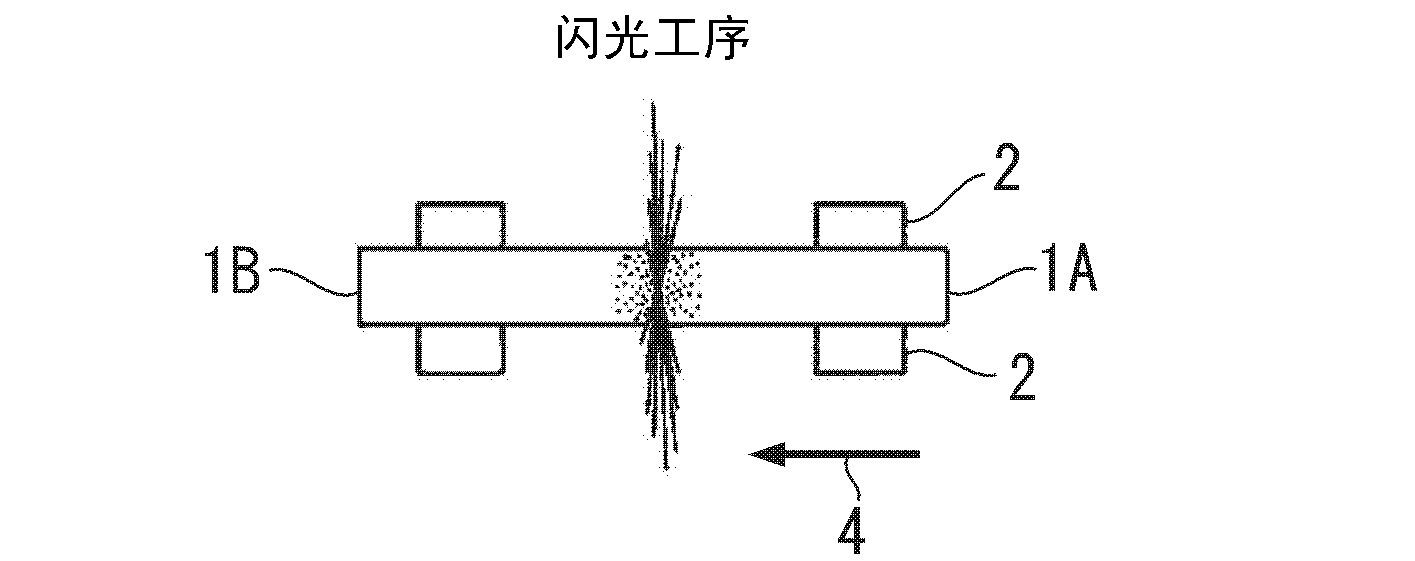

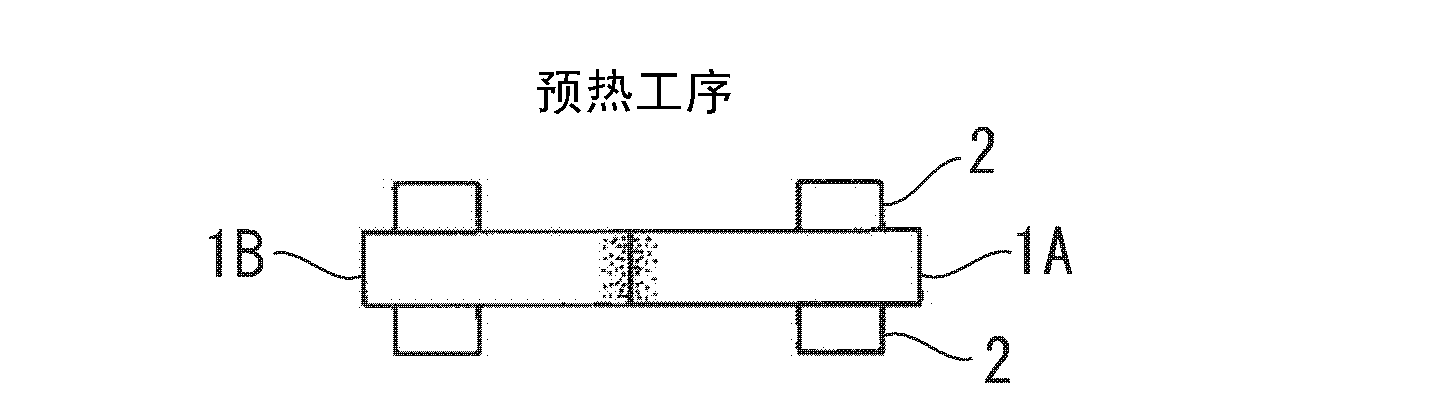

Flash-butt welding method for rail steel

InactiveCN102665994ASteep heat distributionExtend the exchange cycleRailsWelding electric supplyElectrical resistance and conductancePower flow

The invention relates to a welding method. The method is for subjecting a pair of track rail steels to flash- butt welding, which is provided with a preheating step for causing a current to flow for a predetermined time period in a state in which the welding surfaces of the pair of the track rail steels are forced into contact with each other, and heating the vicinity of the welding surfaces by means of resistance heating, a previous flash step for partially generating flash on the welding surfaces, and heating the welding surfaces by means of the resistance heating and electric-arc heating of the flash, and a later flash step for further generating the flash on the entire welding surfaces, and uniformly applying heat to the entire welding surfaces by means of the resistance heating and electric-arc heating of the flash, wherein the later flash speed in the later flash step is 2.1-2.8 mm / sec inclusive.

Owner:NIPPON STEEL CORP

Tie plate

An electrically-insulated tie plate for electrically isolating parts of a railroad rail system from each other. The electrically-insulated tie plate includes a base plate having a recessed area for receiving a railroad rail and a layer of electrically-insulating material covering portions of the base plate.

Owner:KOPPERS DELAWARE INC

Rail for self-propelled electric trucks

Owner:TELEELEVATOR

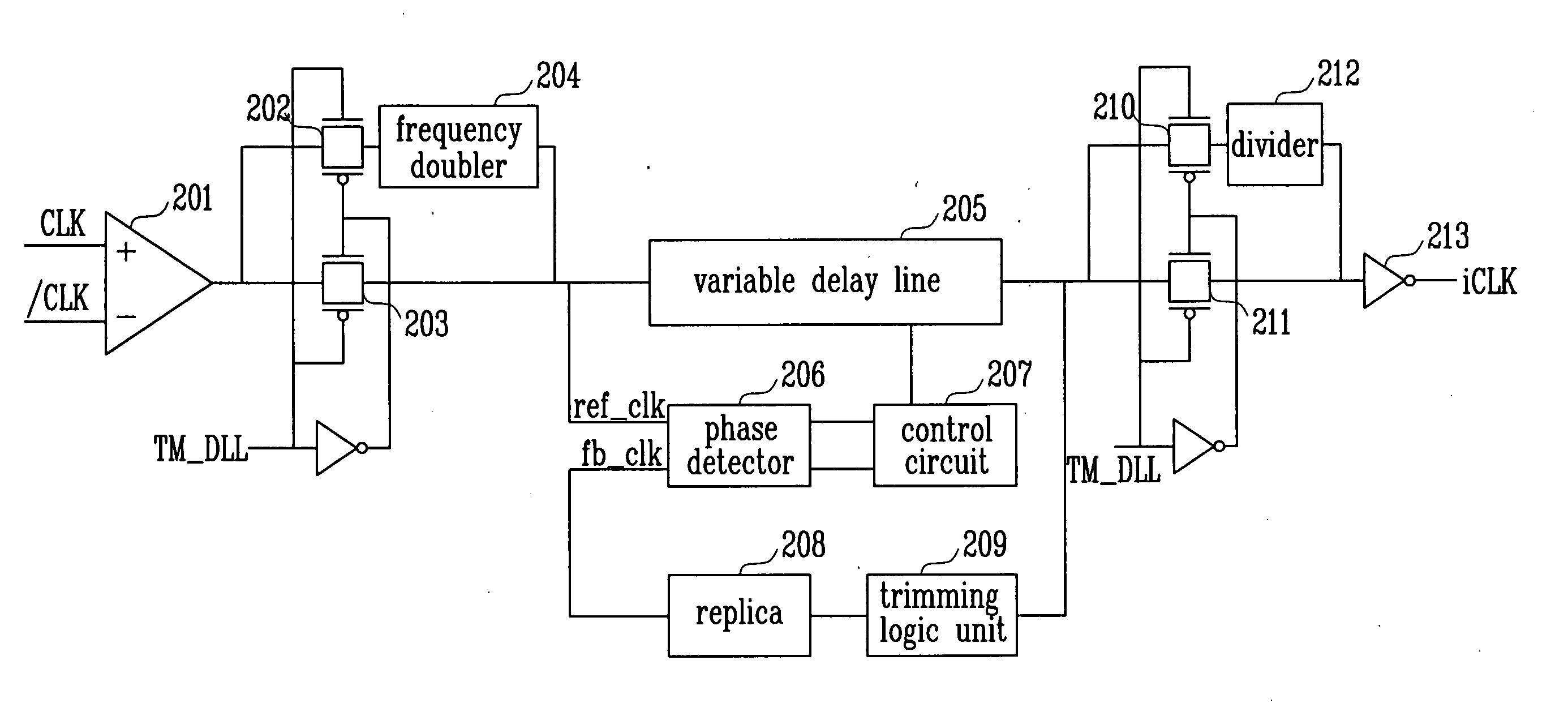

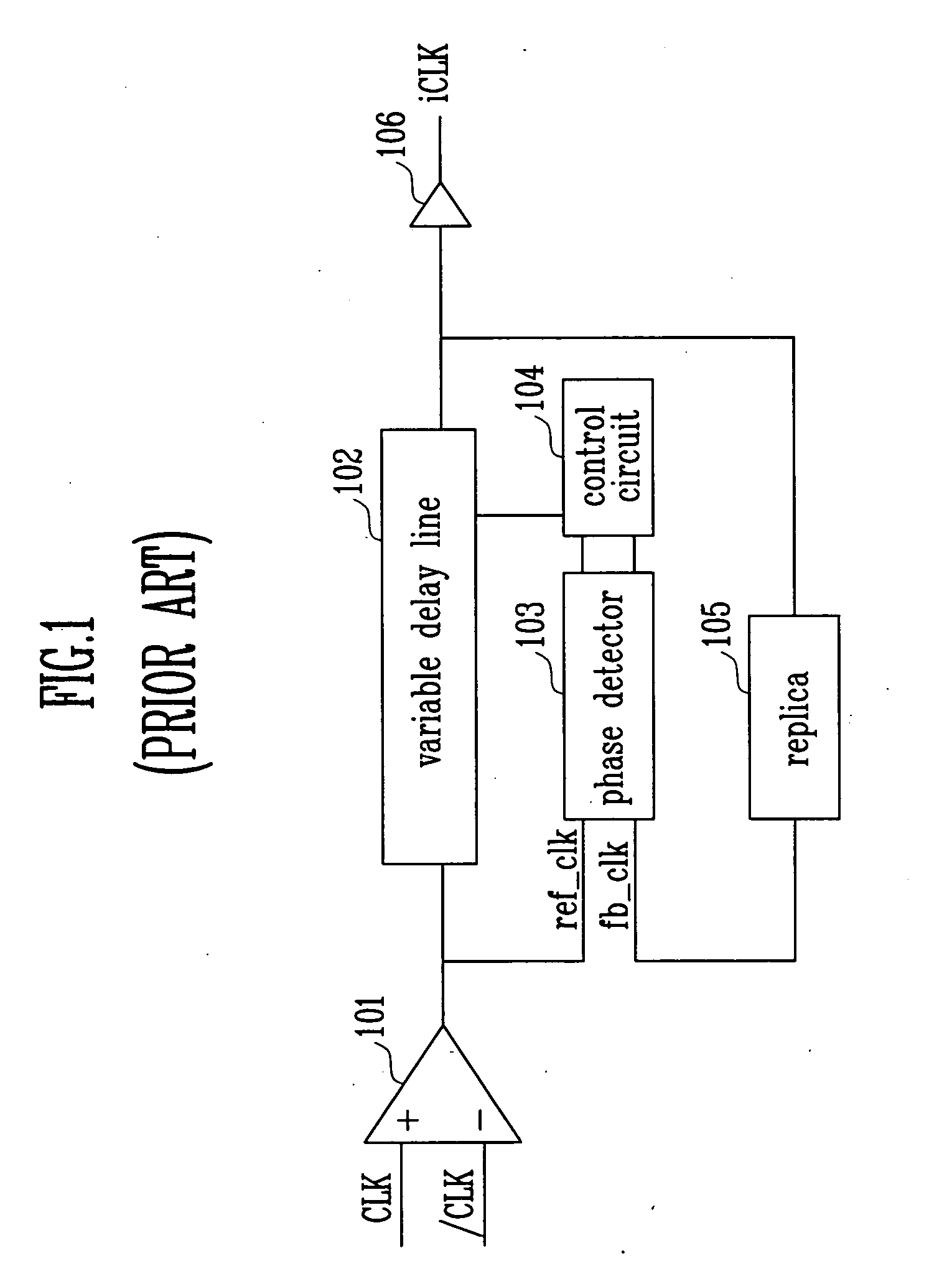

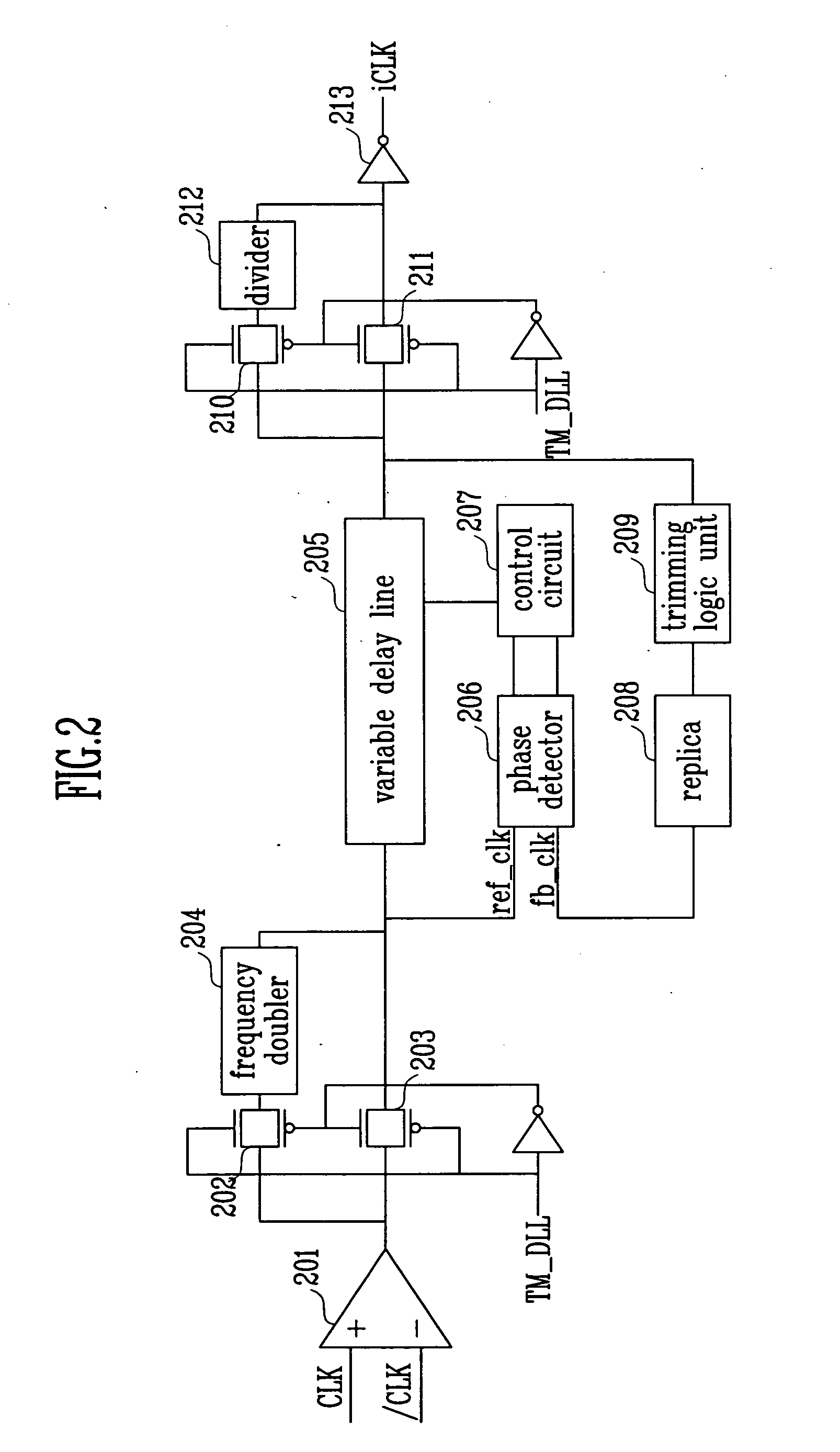

Delay locked loop

InactiveUS20050231247A1Low frequency operationPulse automatic controlPulse train pattern monitoringPhase detectorPhase difference

The present invention discloses a delay locked loop including: a frequency doubler for increasing the output frequency from an input buffer for buffering a clock; a variable delay line for delaying the output from the frequency doubler; a divider for restoring the output frequency from the variable delay line to the frequency of the clock by dividing the output frequency; an output buffer for buffering the output from the divider; a replica for delaying the output from the variable delay line; a phase detector for detecting a phase difference between the output from the replica and the output from the frequency doubler; and a control circuit for determining a delay amount of the variable delay line according to the output from the phase detector.

Owner:INTELLECTUAL DISCOVERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com