Jointless telescopic connector with contact rails

A technology of contact rails and connectors, which is applied in the direction of connection, conductive connection, rail joints, etc., can solve the problems of current collector slipper and related connection mechanism damage, unfavorable current collection, instability, etc., so as to improve the working life and The effect of vehicle running speed, elimination of abnormal impact noise and unstable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

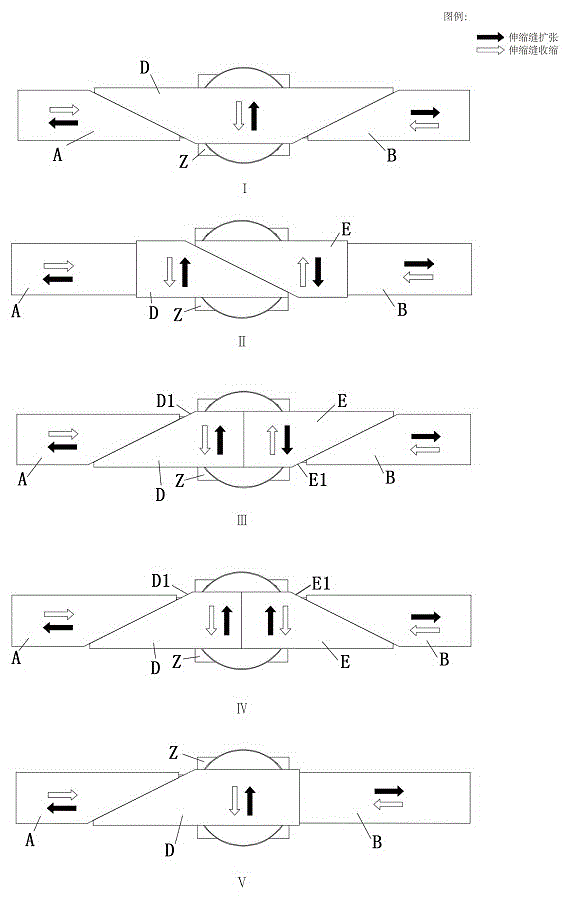

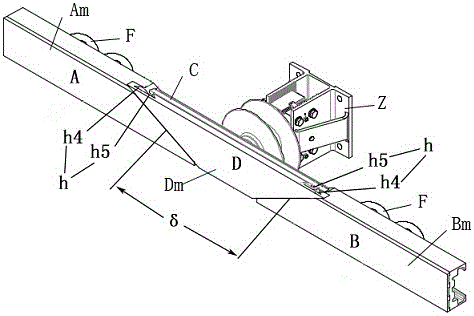

[0026] Embodiment one: according to figure 1 (I) and figure 2 As shown, a C-shaped contact rail adopts a telescopic connector with a slide rail chute transmission mechanism without expansion joints, and the limit guide (C) is respectively inserted into the C-shaped grooves of two C-shaped contact rail segments (A, B). , there is a sliding gap between the contact rail segment and the limit guide body, the two contact rail segments (A, B) can only slide along the length of the contact rail; a contact surface slider (D), the slider partially or completely Cover the telescopic gap (δ), and the outer contact surfaces (Am, Bm) of the two contact rail segments (A, B) and the outer contact surface (Dm) of the contact surface slider (D) are always in the same plane in three-dimensional space , so that the current collector passes through without impact; the transmission mechanism (h) is composed of the guide rail (h4) set on the contact surface slider (D) and the guide dovetail groov...

Embodiment 2

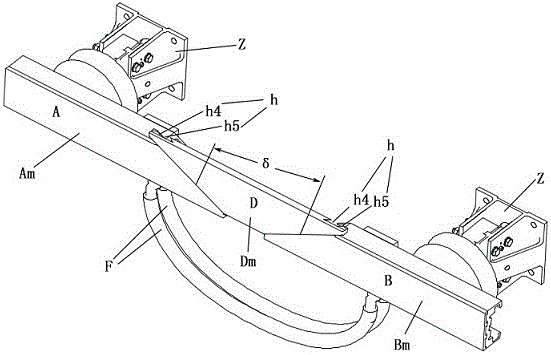

[0027] Embodiment two: according to figure 1 (I), image 3 As shown, a C-shaped contact rail adopts a telescopic connector with no expansion joints in the slide rail chute transmission mechanism, and has a limit guide (C) (insulator upper accessory chuck) respectively snapped into the C-shaped grooves of the two C-shaped contact rail sections (A, B), and the two contact rail sections (A, B) can freely expand and slide in the direction of their length; There is a contact surface slider (D) which completely or partially covers the telescopic gap (δ) and the outer contact surfaces (Am, Bm) of the two contact rail segments (A, B) and The outer contact surface (Dm) of the contact surface slider (D) is always in the same plane in three-dimensional space, so that the current receiver can pass through without impact; the transmission mechanism (h) is controlled by the guide rail (h4) set on the contact surface slider (D) ) and the guide dovetail groove (h5) set on the guide limit bo...

Embodiment 3

[0028] Embodiment three: according to figure 1 (Ⅲ), Figure 4As shown, a C-shaped contact rail adopts a telescopic connector with no expansion joints in the rack and pinion transmission mechanism. The two ends of the limit guide (C) are inserted into the two contact rail segments (A, B) and maintain an appropriate sliding gap. , the two contact rail sections (A, B) can freely stretch and slide in their long direction; two contact surface sliders (D, E) are installed on the limit guide body (C), and two contact surface sliders ( D, E) Cover the telescopic gap (δ), and always maintain an adjoining relationship with the two contact rail segments (A, B), and the outer contact surfaces (Am, Bm) of the two contact rail segments (A, B) and the contact The outer contact surfaces (Dm, Em) of the surface sliders (D, E) are always in the same plane in three-dimensional space, so that the current collector can pass through without impact; the contact surface slider (D) and the limit guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com