Patents

Literature

86results about How to "Avoid fatigue cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

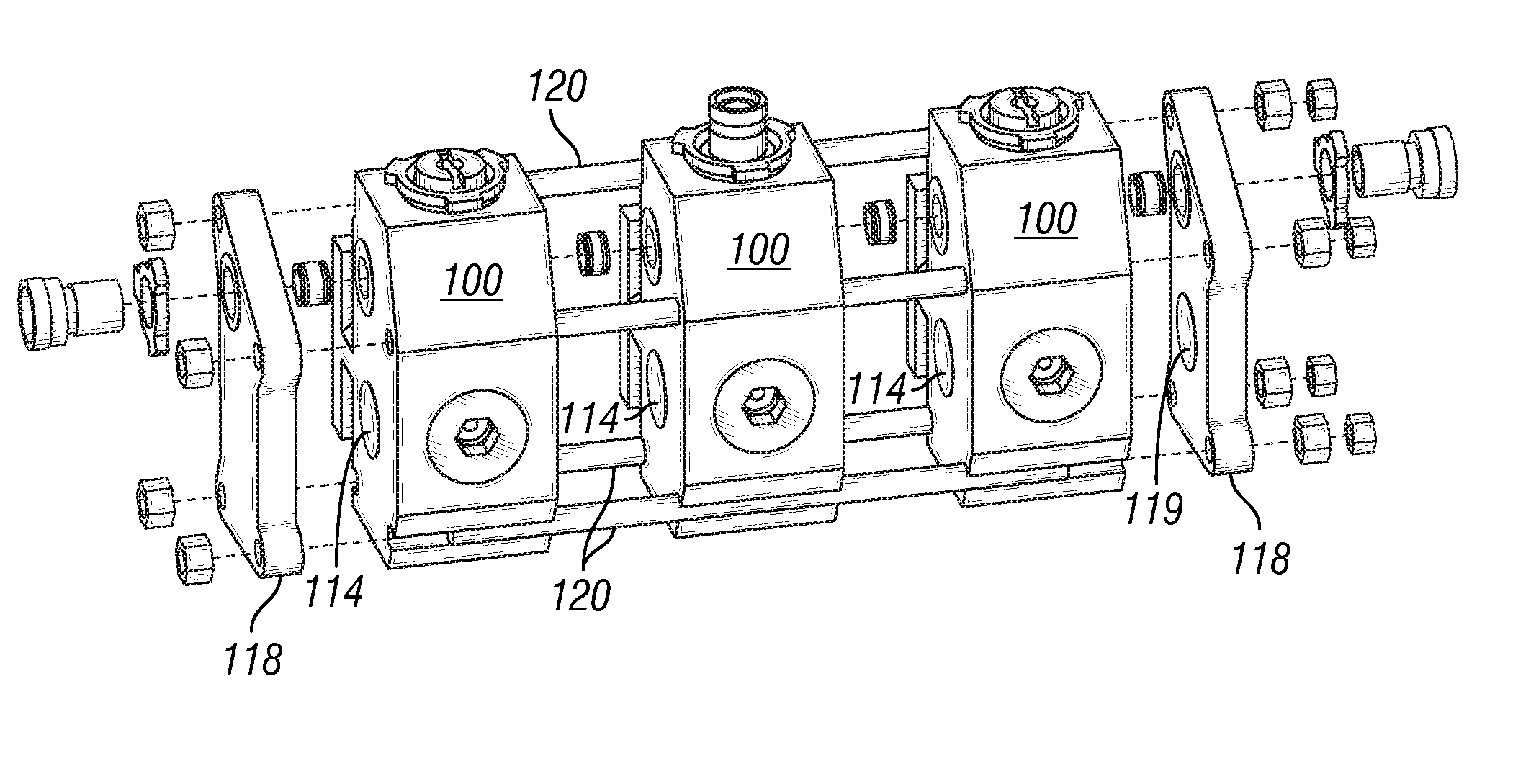

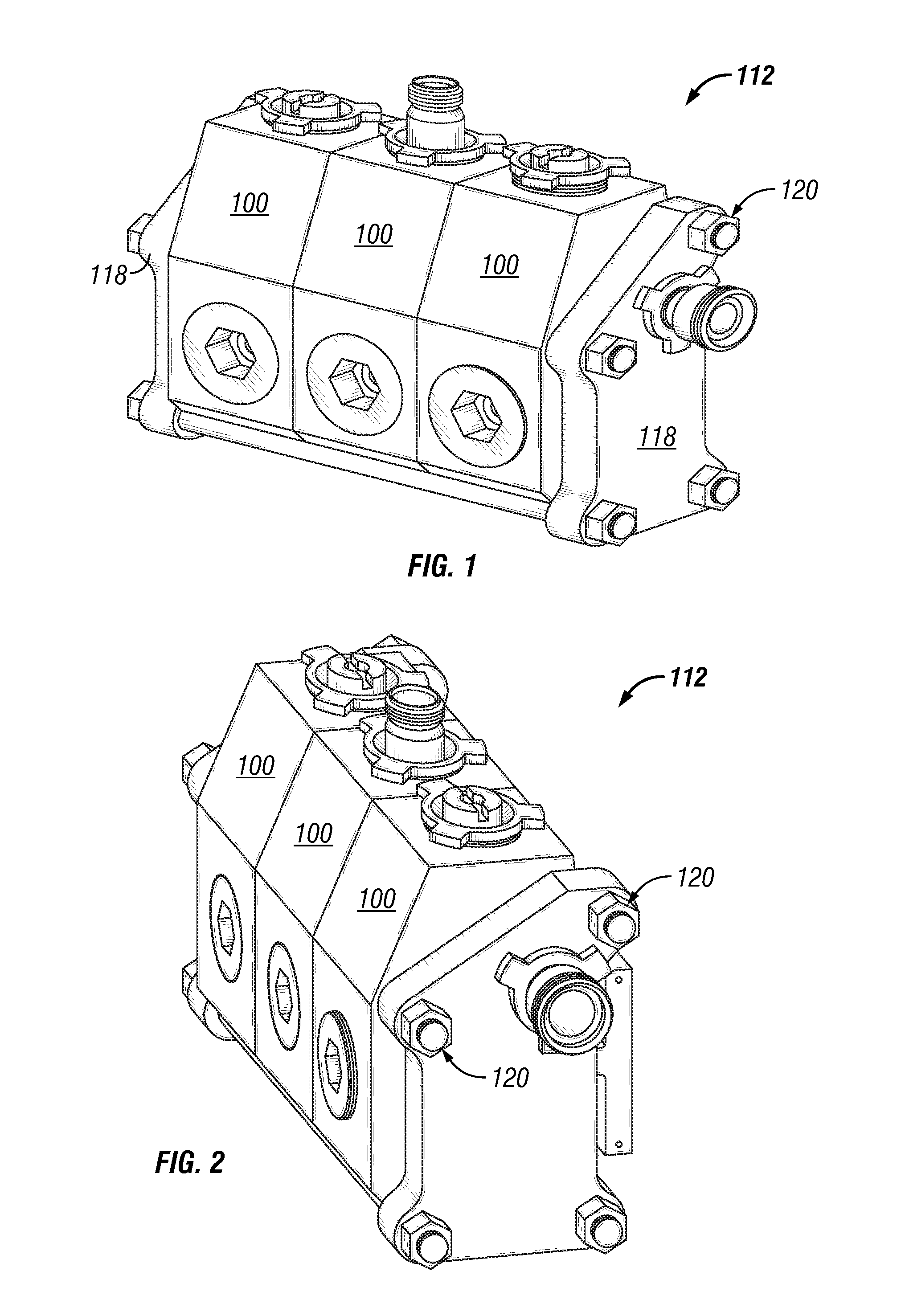

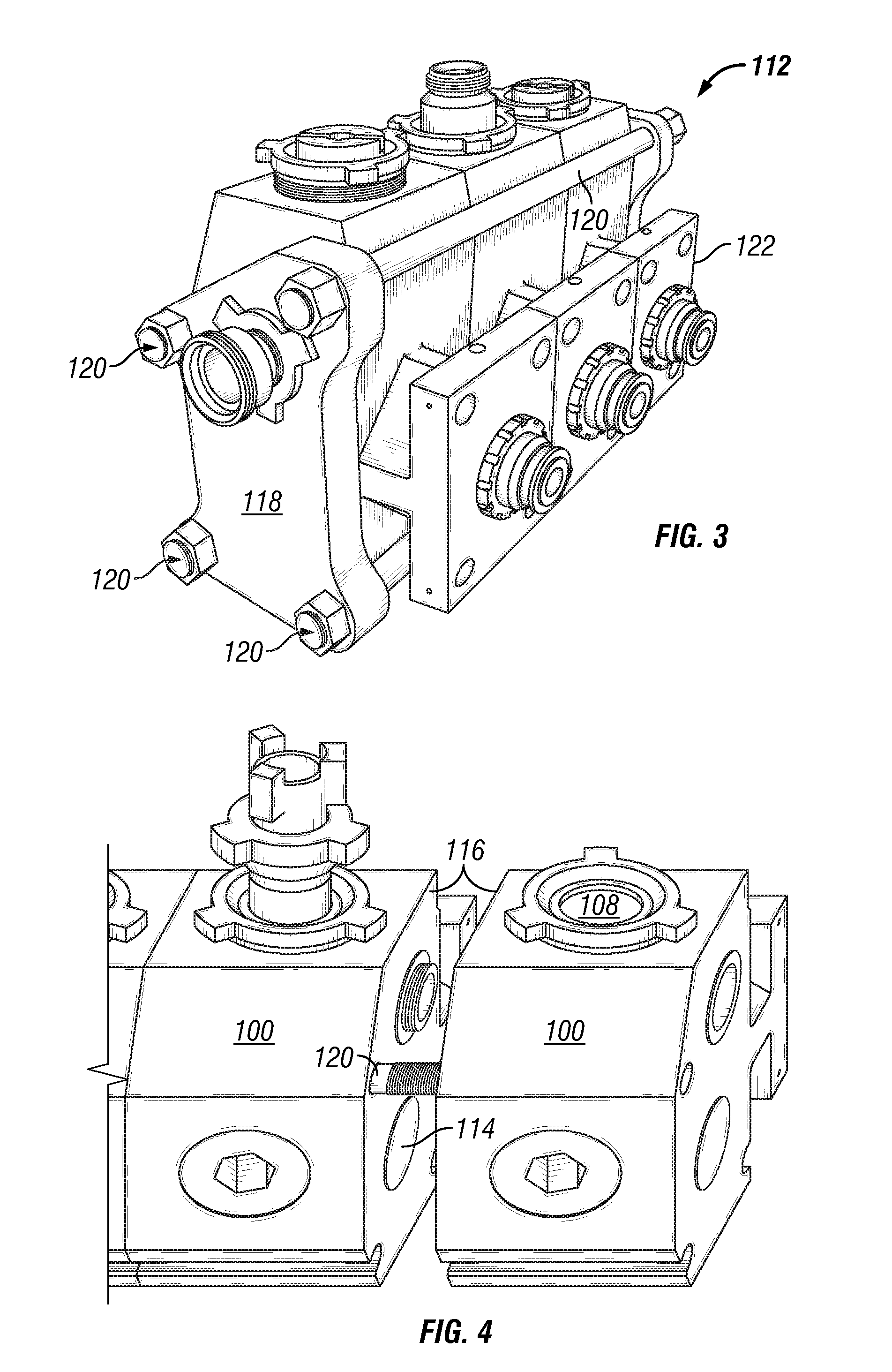

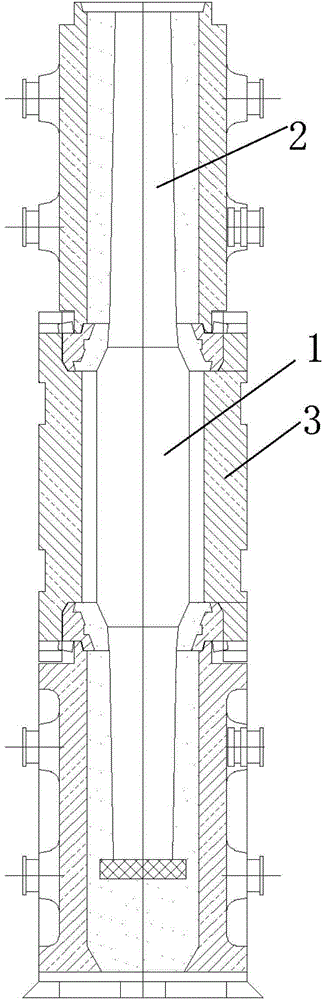

Pump body

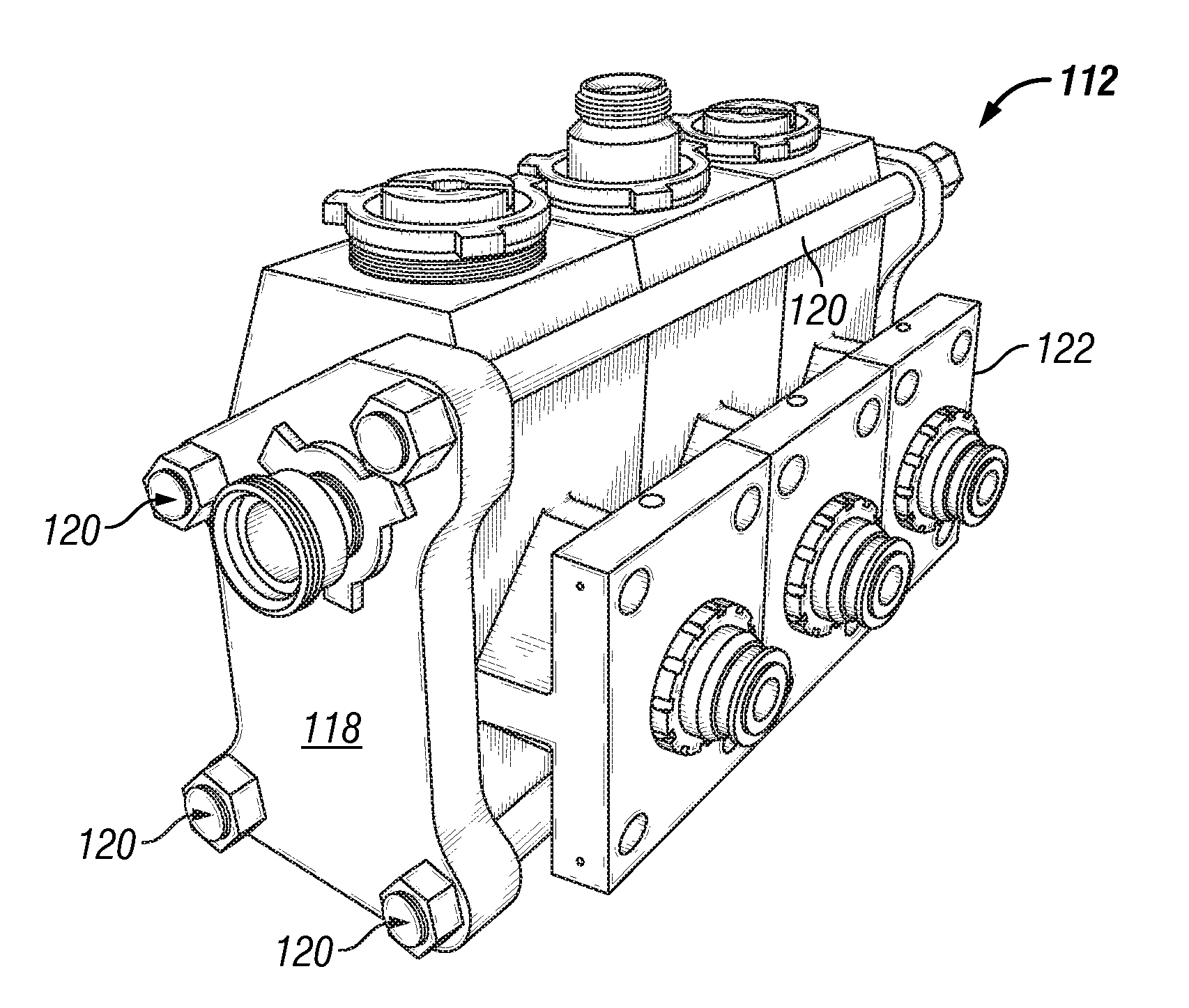

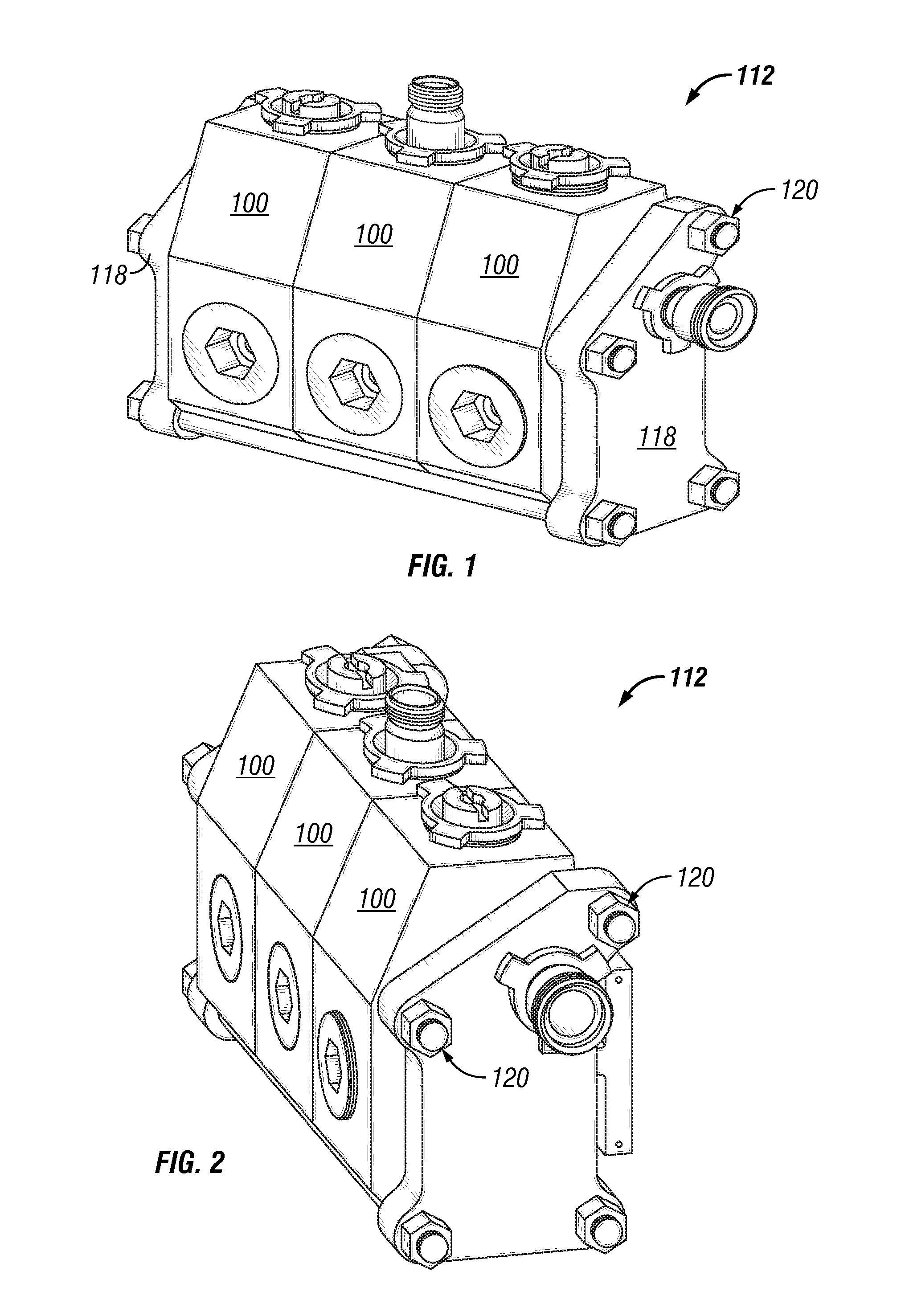

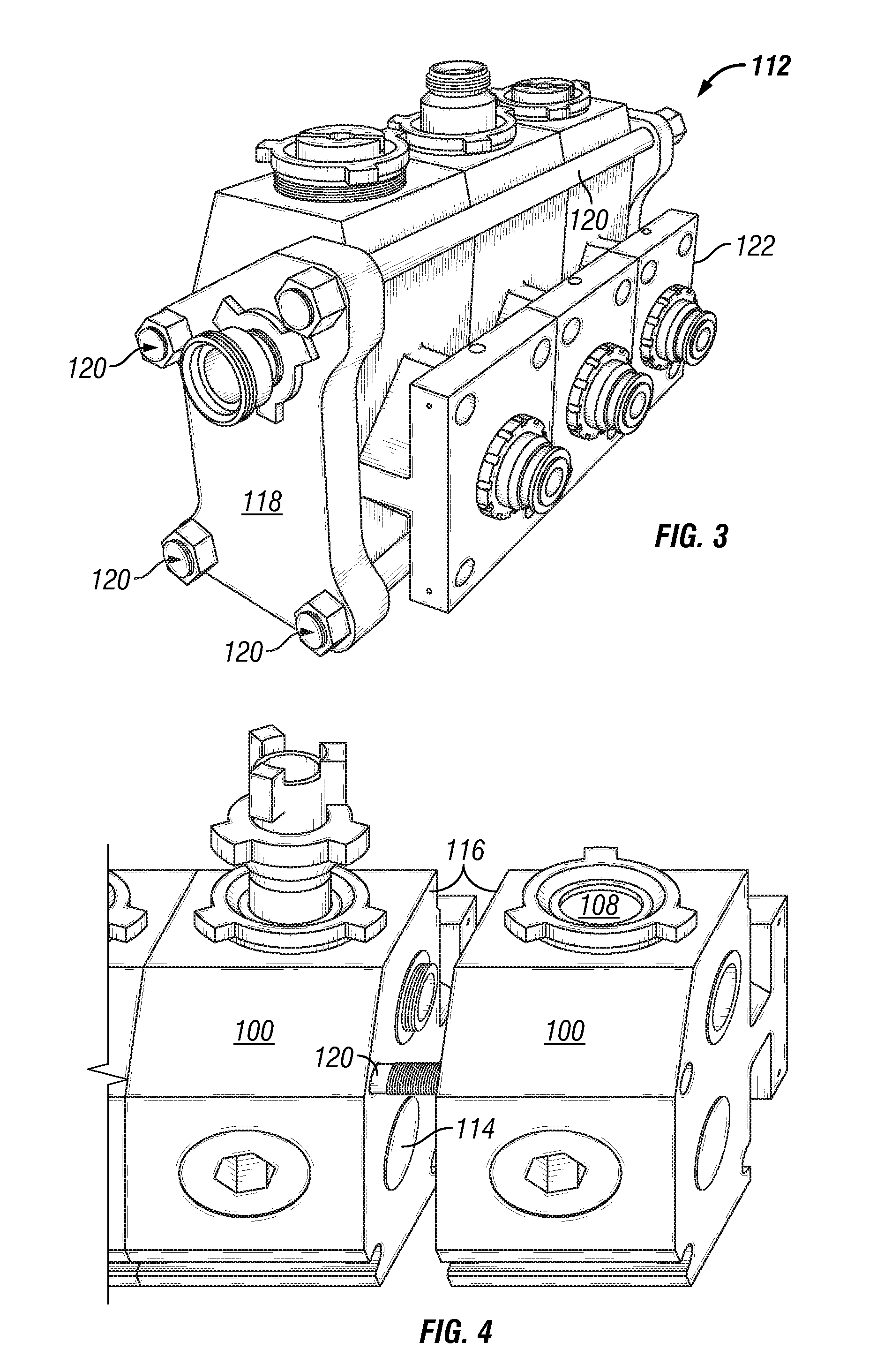

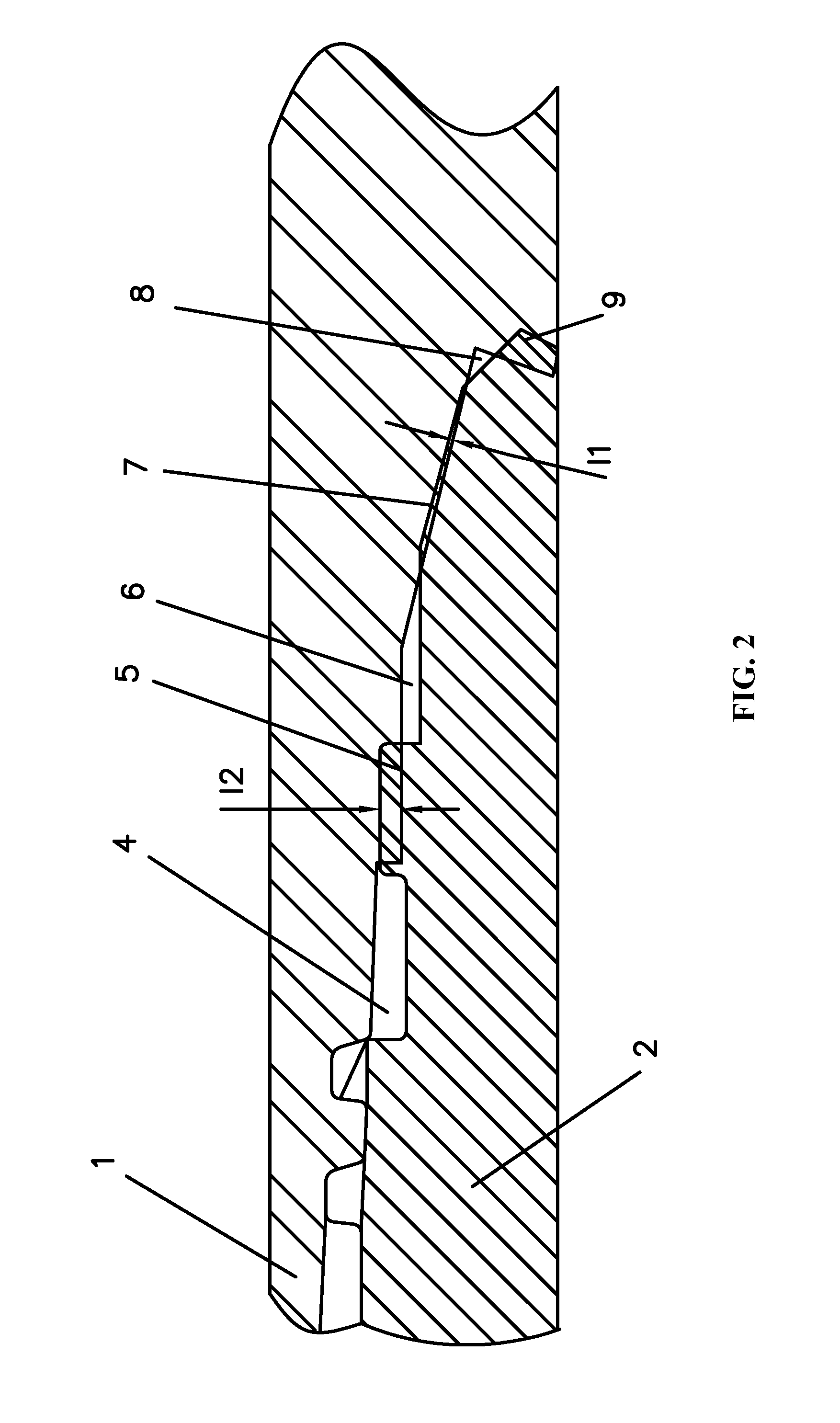

ActiveUS20110081268A1Preventing initiationAvoid fatigue crackingPortable framesValve arrangementsEngineeringFatigue cracking

A multiplex fluid pump assembled from a plurality of pump bodies connected side by side between opposing end plates with a plurality of fasteners tightened to compress the pump bodies between the end plates. Raised surfaces on opposite exterior side surfaces of each pump body are engaged with an adjacent end plate or an adjacent pump body to apply a pre-compressive force at the raised surfaces and thereby inhibit the initiation of fatigue cracks.

Owner:LIBERTY OILFIELD SERVICES LLC

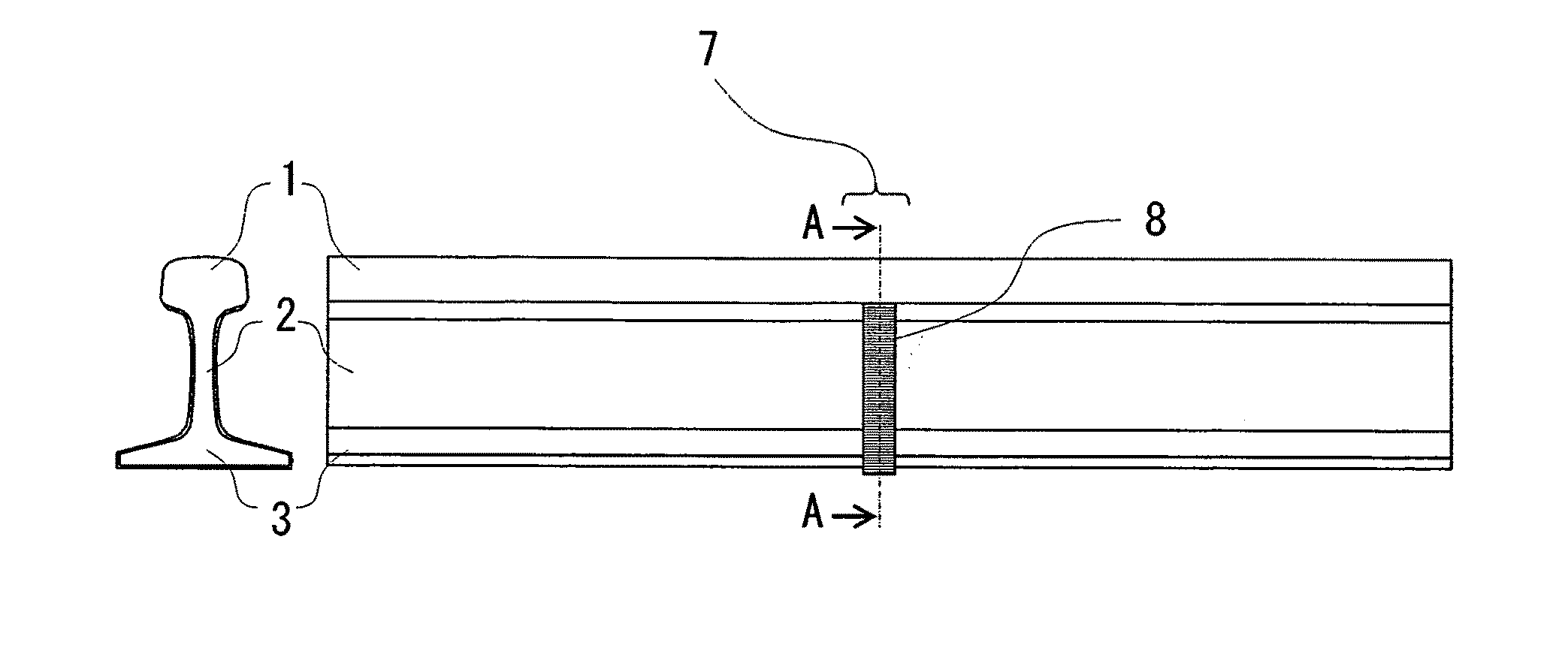

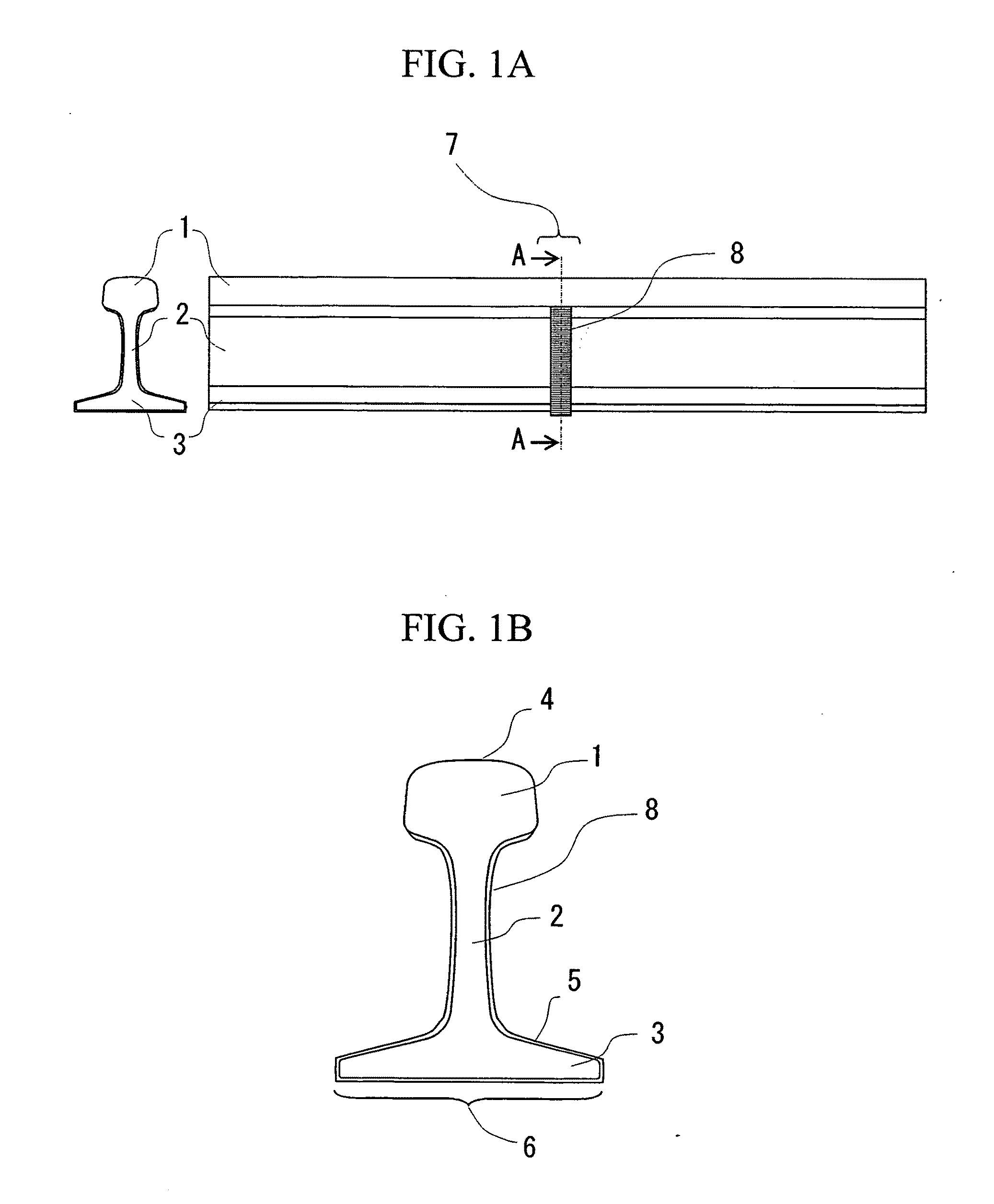

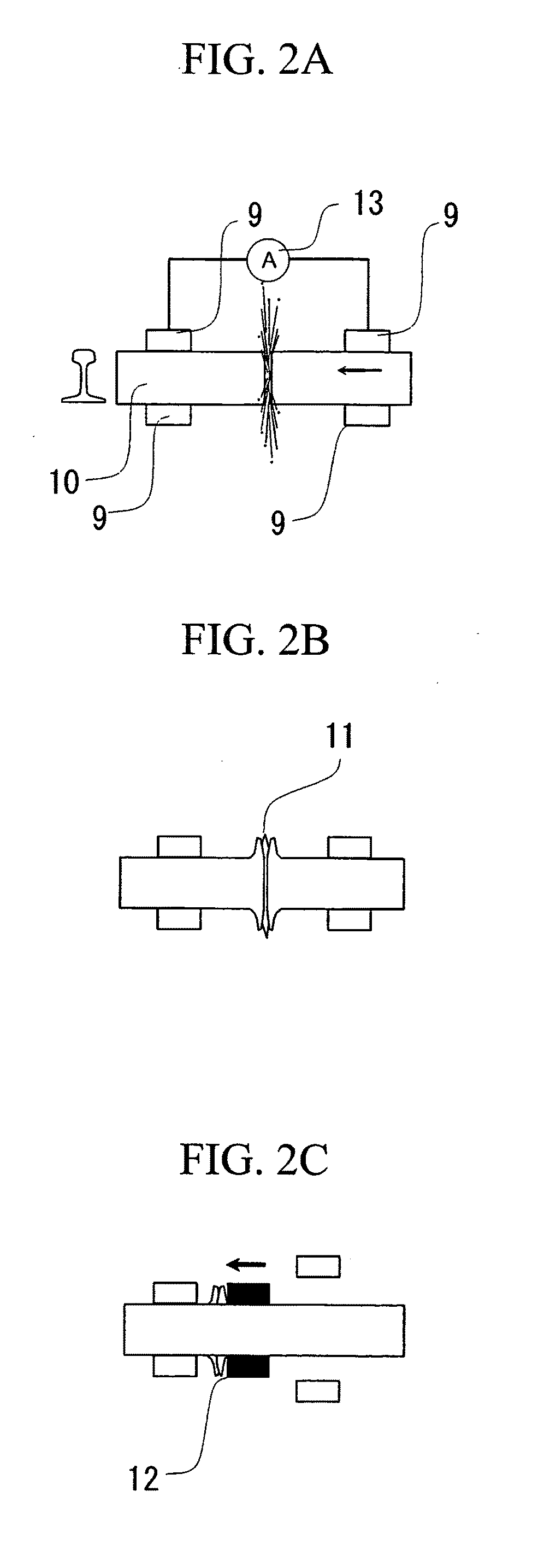

Method of cooling rail weld zone, device for cooling rail weld zone, and rail weld joint

InactiveUS20120015212A1Improve residual stressAvoid fatigue crackingRailsFurnace typesEngineeringMechanical engineering

The invention provides a method of cooling a rail weld zone. The method includes a first rail web portion cooling process of cooling a rail web portion cooling region of the rail weld zone in a part of a temperature range until the completion of transformation from austenite to pearlite, a second rail web portion cooling process of cooling the rail web portion cooling region after the entire rail web portion of the rail weld zone is transformed to pearlite, a foot portion cooling process of cooling a foot portion of the rail weld zone, and a head portion cooling process of cooling a head portion of the rail weld zone. When cooling time of the first and second rail web portion cooling processes is t minute, a k value satisfies an expression represented as −0.1t+0.63≦k≦−0.1t+2.33.

Owner:NIPPON STEEL CORP

Pump body

ActiveUS8601687B2Preventing initiationAvoid fatigue crackingPortable framesValve arrangementsEngineeringFatigue cracking

A multiplex fluid pump assembled from a plurality of pump bodies connected side by side between opposing end plates with a plurality of fasteners tightened to compress the pump bodies between the end plates. Raised surfaces on opposite exterior side surfaces of each pump body are engaged with an adjacent end plate or an adjacent pump body to apply a pre-compressive force at the raised surfaces and thereby inhibit the initiation of fatigue cracks.

Owner:LIBERTY OILFIELD SERVICES LLC

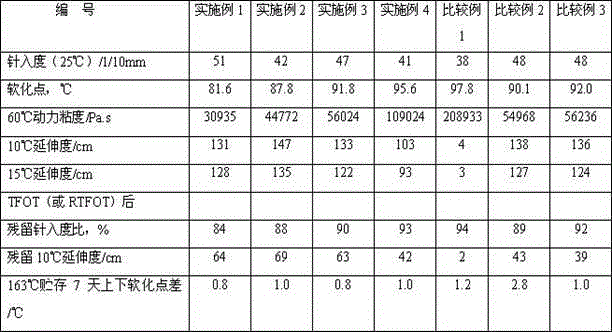

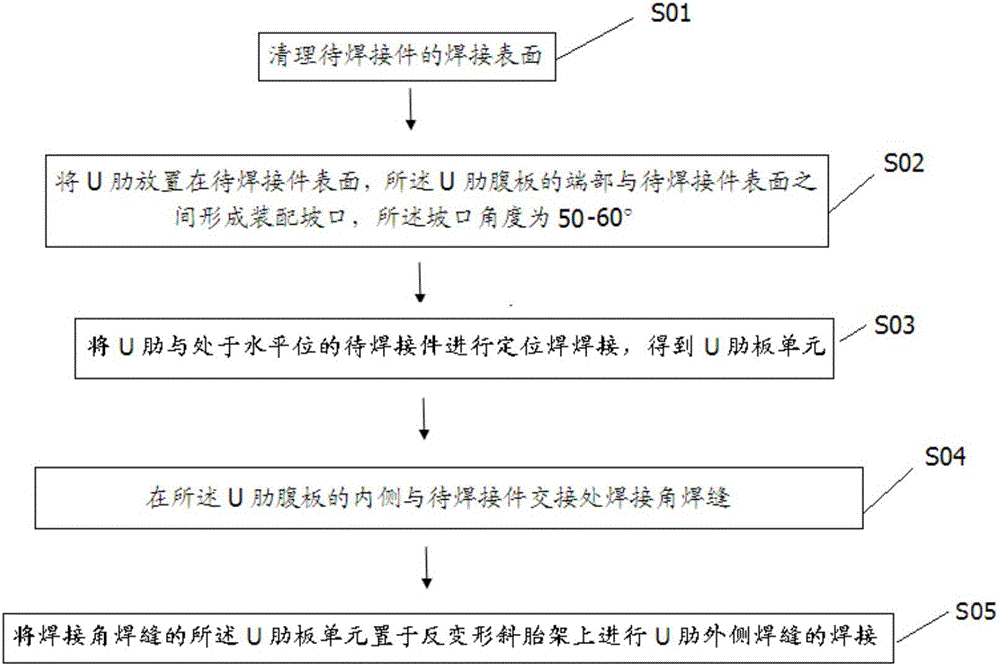

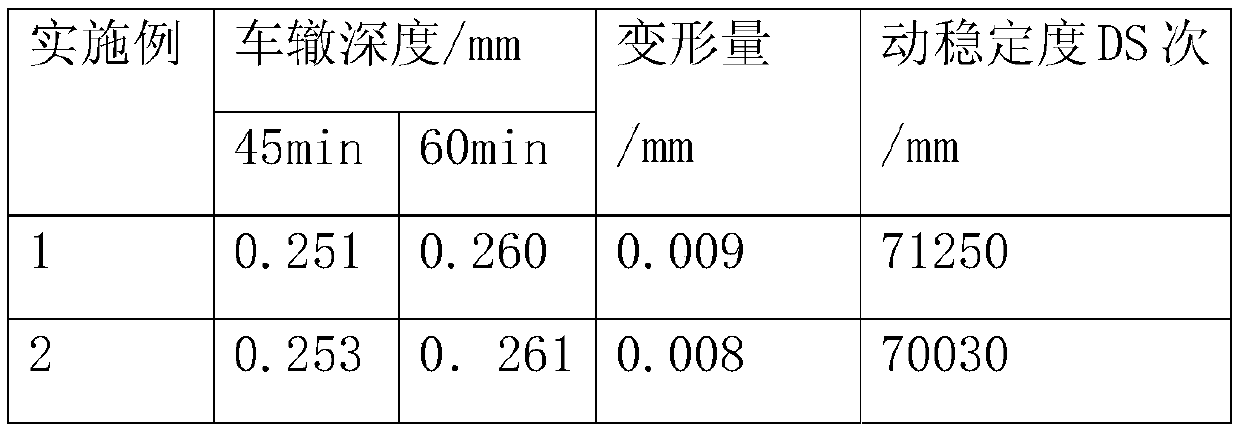

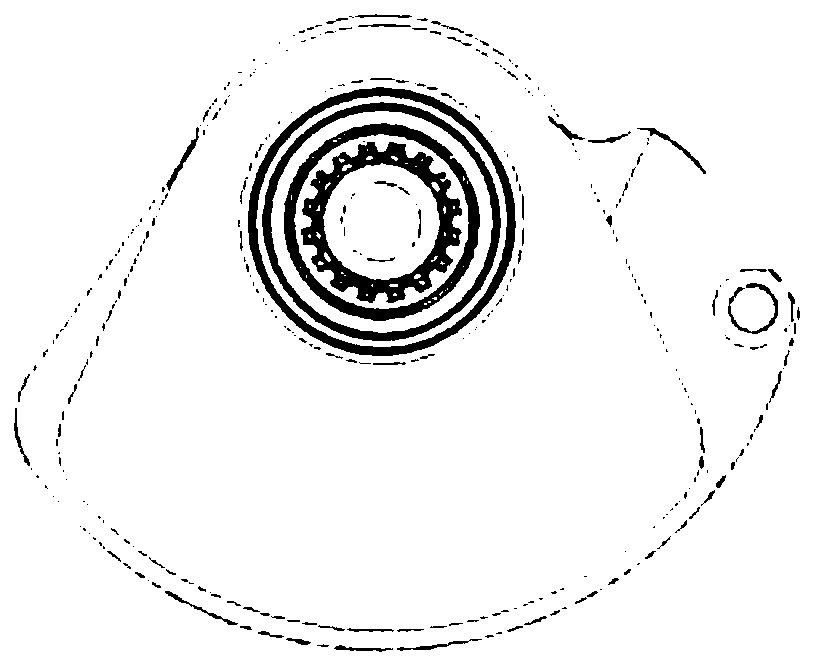

Novel high viscosity asphalt and preparation method thereof

ActiveCN104559235AHigh softening pointRaise the reaction temperatureBuilding insulationsPhosphoric acidRoad surface

The invention discloses novel high viscosity asphalt and a preparation method thereof. The novel high viscosity asphalt comprises the following raw materials in parts by weight: 100 parts of base asphalt with high asphaltene content, 0.1-1.2 part of polyphosphoric acid, 2-12 parts of a ductility improver mother liquid, 1-8 parts of a dispersant, and 0.2-0.5 part of a coupling agent. The preparation method comprises the following steps: adding the polyphosphoric acid in the molten base asphalt to perform a chemical modification reaction, then adding the ductility improver mother liquid, continuing to react, and finally adding the dispersant and the coupling agent to continue to react for a period of time to prepare high viscosity asphalt, wherein the whole process is performed under a highs-speed stirring condition. The high viscosity asphalt is high in 60-degree dynamic viscosity, high in softening point, high in low-temperature ductility, stable to store, and good in adhesion to aggregates, has excellent high temperature stability, excellent low temperature anti-cracking performance, excellent anti-fatigue performance and excellent water resistance, is especially suitable for high-temperature humid areas, areas with relatively high diurnal temperature difference, and paving of heavy-duty roads and drainable pavements, effectively prevents common pavement damages such as pavement rutting, pavement upheaval, pavement fatigue cracking, pavement cold cracking and water encroachment on pavements, and prolongs the service life of the pavement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chemically-modified hard asphalt and preparation method thereof

ActiveCN104559232AImprove low temperature performanceHigh viscosityBuilding insulationsCrack resistancePhosphoric acid

The invention discloses chemically-modified hard asphalt and a preparation method thereof. The chemically-modified hard asphalt comprises the following components in parts by weight: 100 parts of basic asphalt, 0.5-3.0 parts of polyphosphoric acid, 2-12 parts of ductility increasing agent mother liquor and 0.2-0.4 part of a surfactant. The preparation method comprises the following steps: adding polyphosphoric acid into the melted basic asphalt for chemically-modified reaction, then adding the ductility increasing agent mother liquor for further reaction, and finally adding the surfactant for further reaction for a period of time to prepare the chemically-modified hard asphalt. The whole process is implemented under a high-speed stirring condition. The chemically-modified hard asphalt prepared by the preparation method disclosed by the invention is high in flow resistance, high in softening point, high in low-temperature ductility, high in bonding property with aggregate, and excellent in high temperature stability, low temperature cracking resistance, fatigue resistance and water invasion resistance; the chemically-modified hard asphalt is particularly suitable for areas with high temperature, wet areas and areas with large diurnal temperature difference and can be used for paving a pavement of a traffic road, so that common pavement damage phenomena such pavement rutting, upheaval, fatigue cracking, low-temperature cracking and water invasion of the pavement are effectively prevented, and the service life of the pavement is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

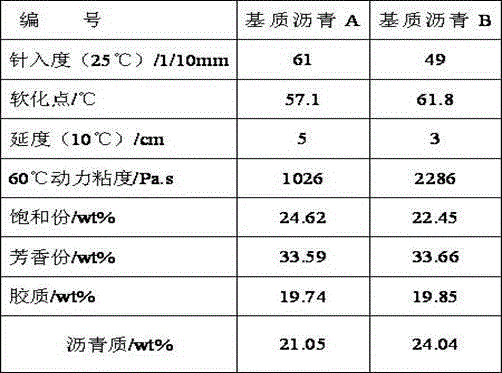

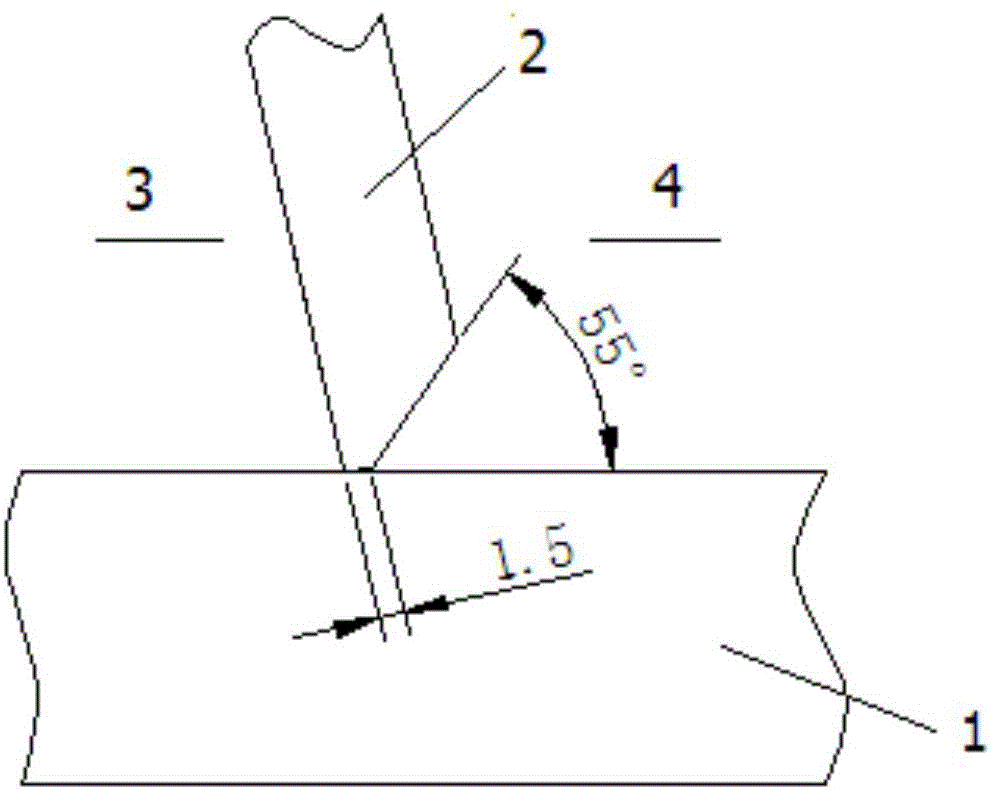

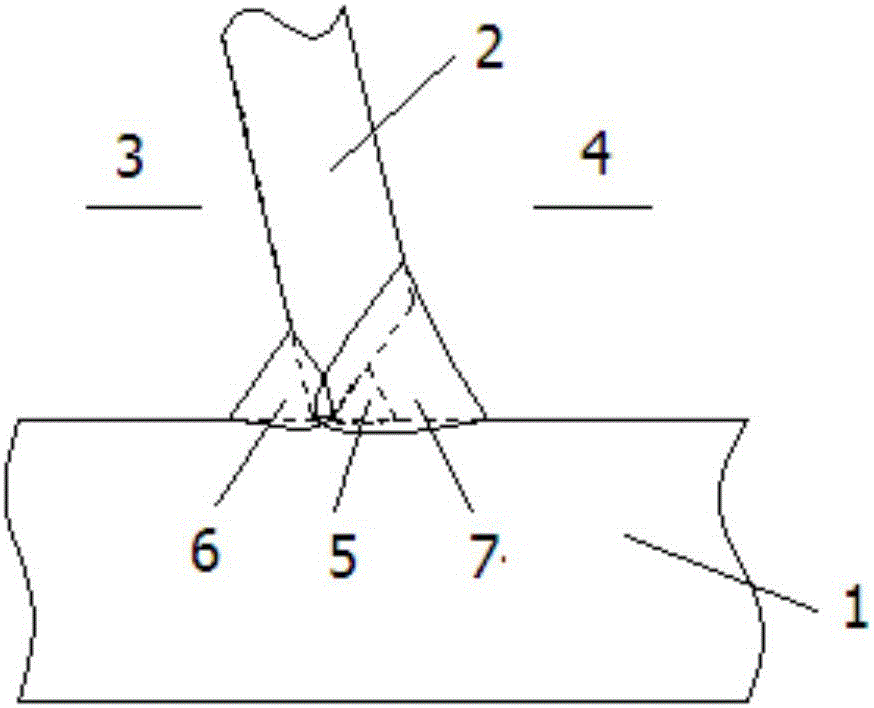

Two-sided welding method for U-shaped ribbed slab unit welding seam

InactiveCN106563868AReduced stress amplitudeAvoid Fatigue Cracking ProblemsArc welding apparatusSubmerged arc weldingEngineering

The invention provides a two-sided welding method for a U-shaped ribbed slab unit welding seam. The two-sided welding method comprises the following steps: cleaning the welding surface of a piece to be welded; placing a U-shaped rib on the surface of the piece to be welded, wherein an assembly groove is formed between the end part of a U-shaped ribbed web plate and the surface of the piece to be welded, and the groove angle is 50-60 degrees; carrying out positioning welding on the U-shaped rib and the piece to be welded in the horizontal position to obtain a U-shaped ribbed slab unit; welding a fillet welding seam at the jointing position of the inner side of the U-shaped ribbed web plate and the piece to be welded; and placing the U-shaped ribbed slab unit welded with the fillet welding seam on an anti-deformation slanting tension bed to carry out welding of an outer side welding seam, wherein a process of twin-wire submerged arc welding with single power supply is adopted. According to the two-sided welding method, a jointing welding seam between the U-shaped rib and the piece to be welded is changed into a two-sided fillet welding seam form from a single-sided fillet welding seam form in the prior art, so that stress amplitudes at a weld root and a weld toe are greatly lowered, the problem of initiation of fatigue cracks of the welding seam at the weld root is solved, and the fatigue performance at the weld toe is also improved.

Owner:WUCHUAN HEAVY ENG

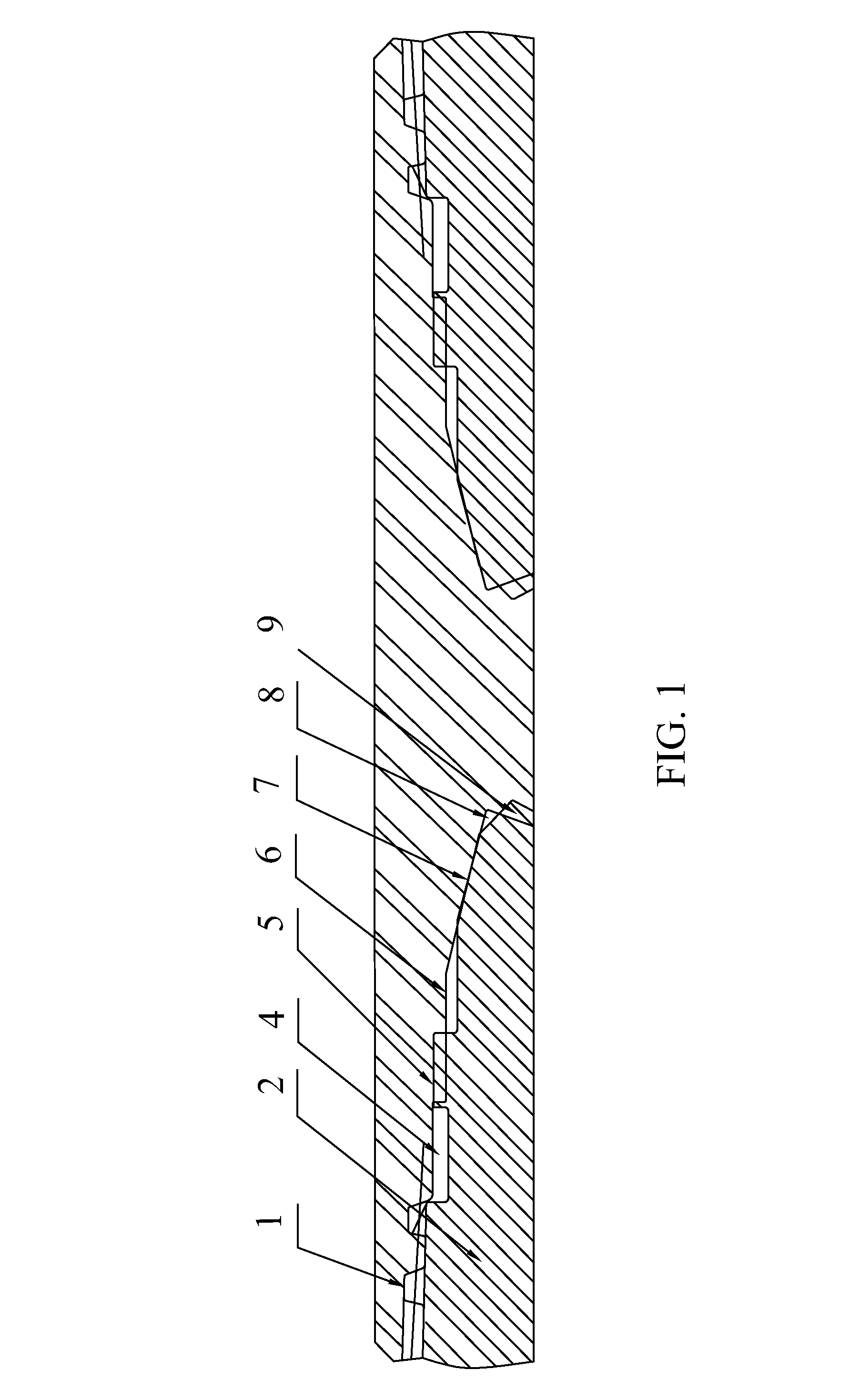

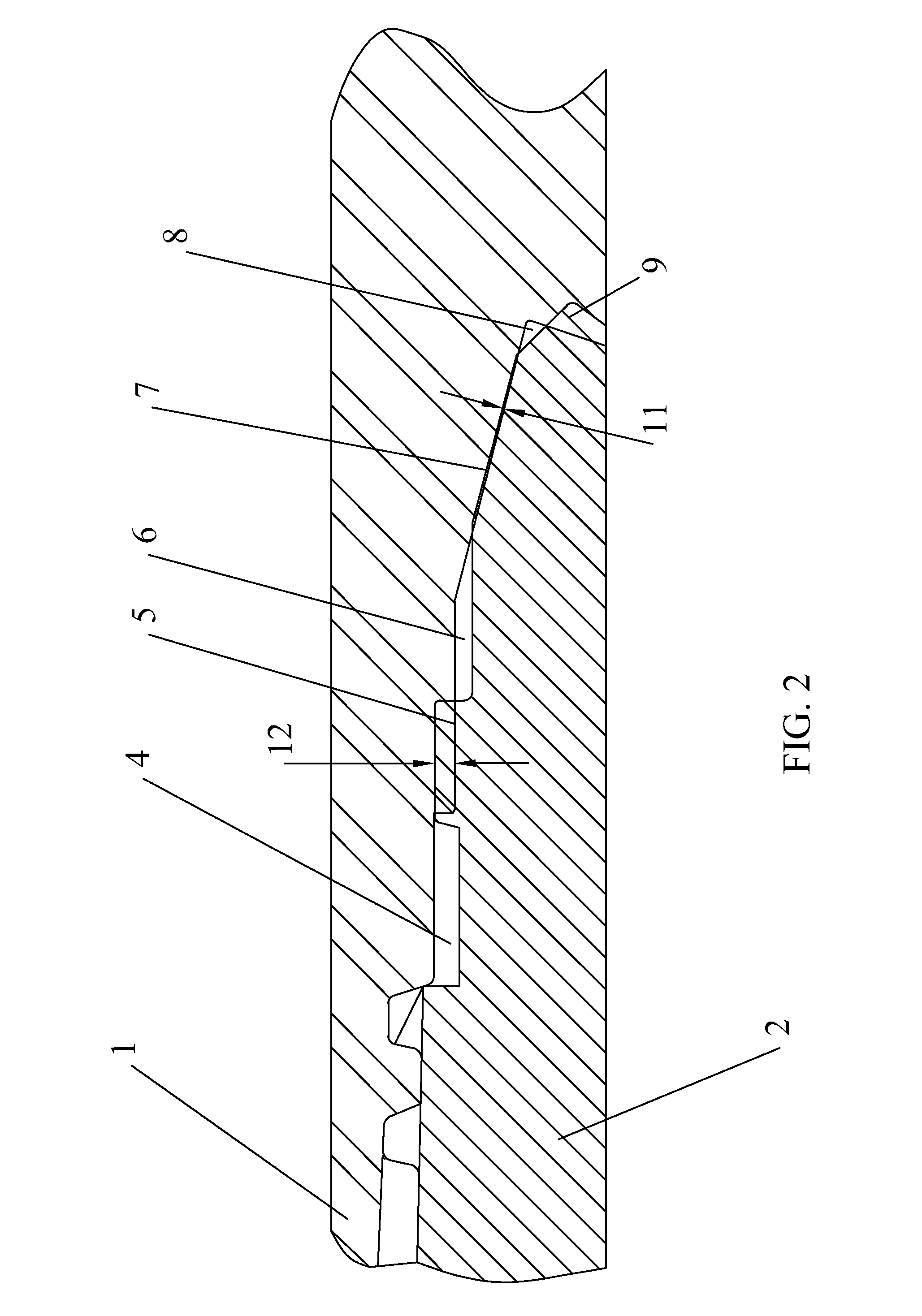

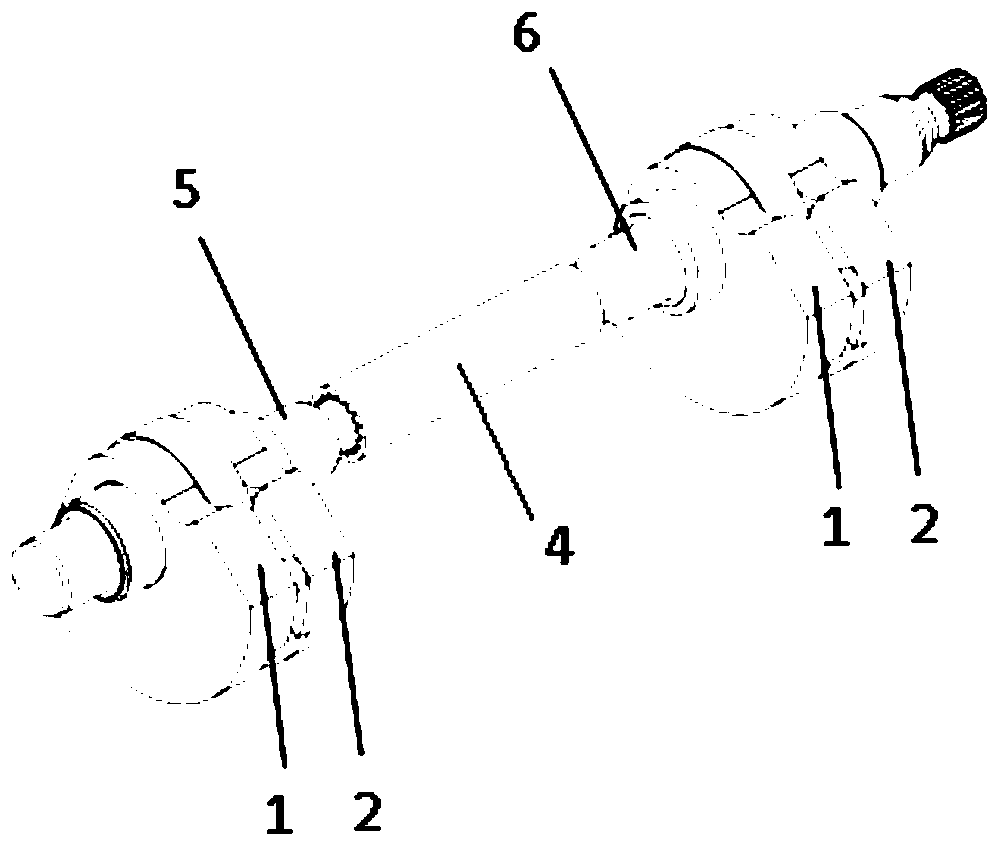

Threaded pipe connector

ActiveUS20130119657A1Good sealing effectImprove connection strengthDrilling rodsHose connectionsThreaded pipeCoupling

A threaded pipe connector, including: a pipe body including an external thread on one end; and a coupling including an internal thread on a corresponding end. Both the external thread and the internal thread are buttress threads capable of matching with each other. A ratio of thread height to pitch is 0.25-0.35, bearing surface angle is −15-3°, and guide surface angle is 10-50°. A clearance is provided between a thread crest and a thread root after engagement of the external and internal threads. A sealing area between the pipe body and the coupling includes in sequence a first cylindrical transitional area, a cylindrical sealing area, a secondary cylindrical transitional area, a conical sealing area, and a conical transitional area. Tapers of both sides of the conical sealing area are the same. One end of the conical transitional area is connected with a torque shoulder.

Owner:TIANJIN TIANGANG SPECIAL PETROLEUM PIPE MFR

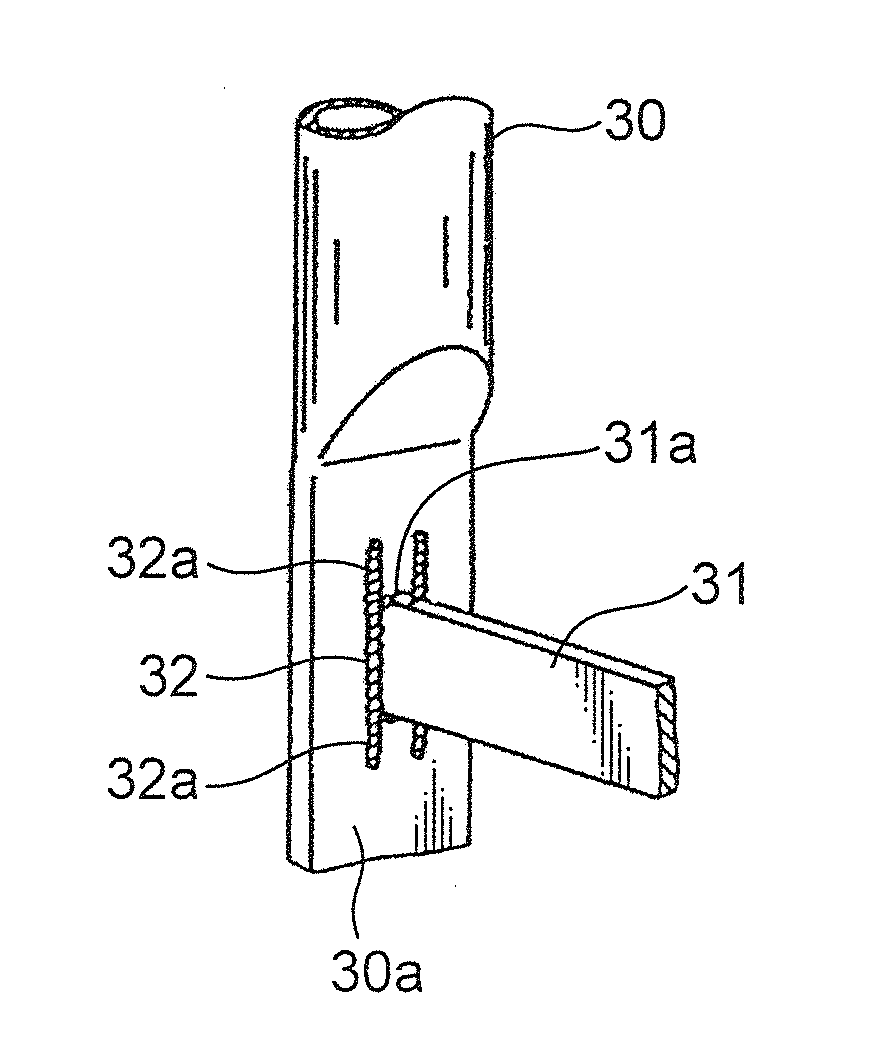

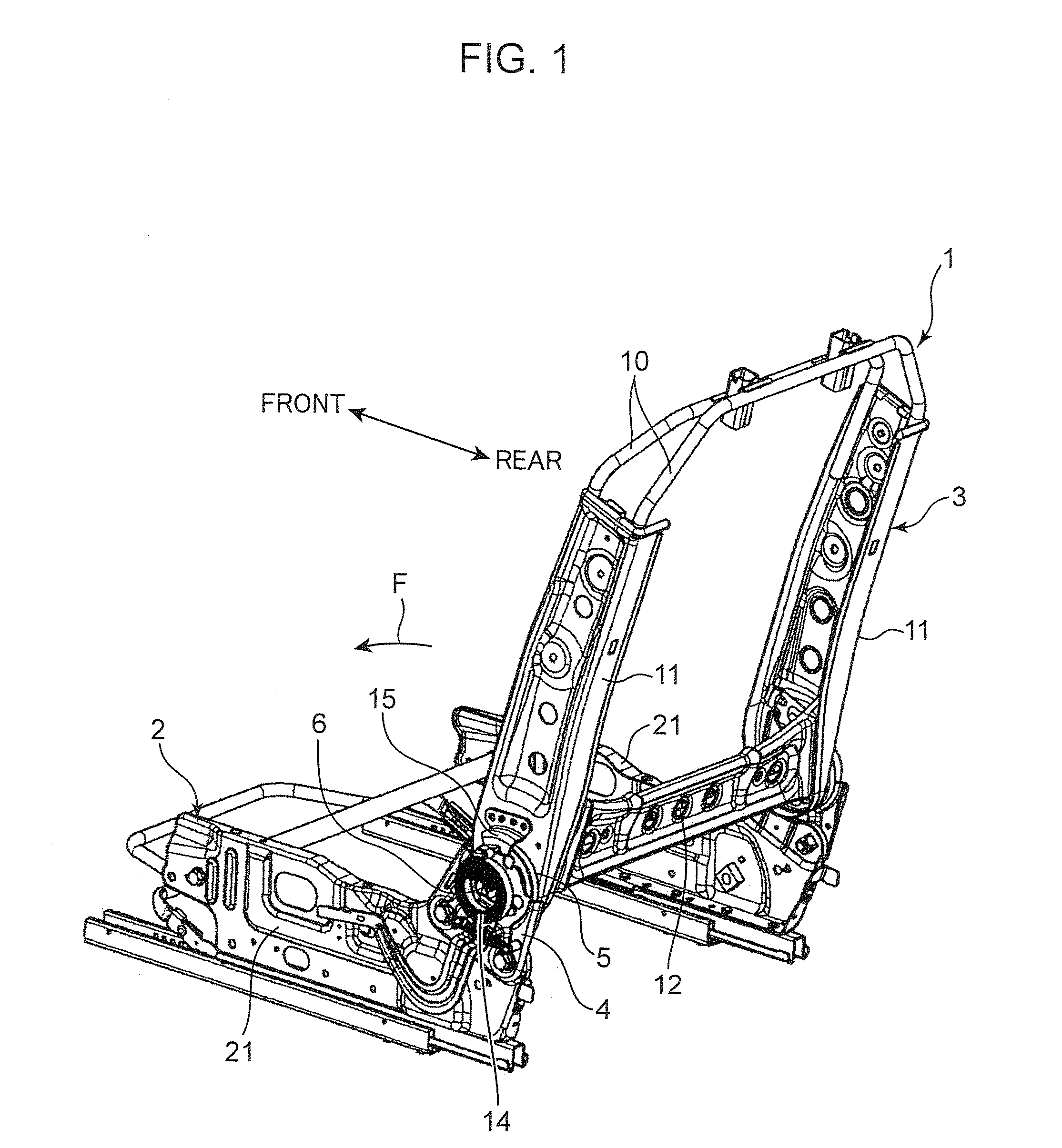

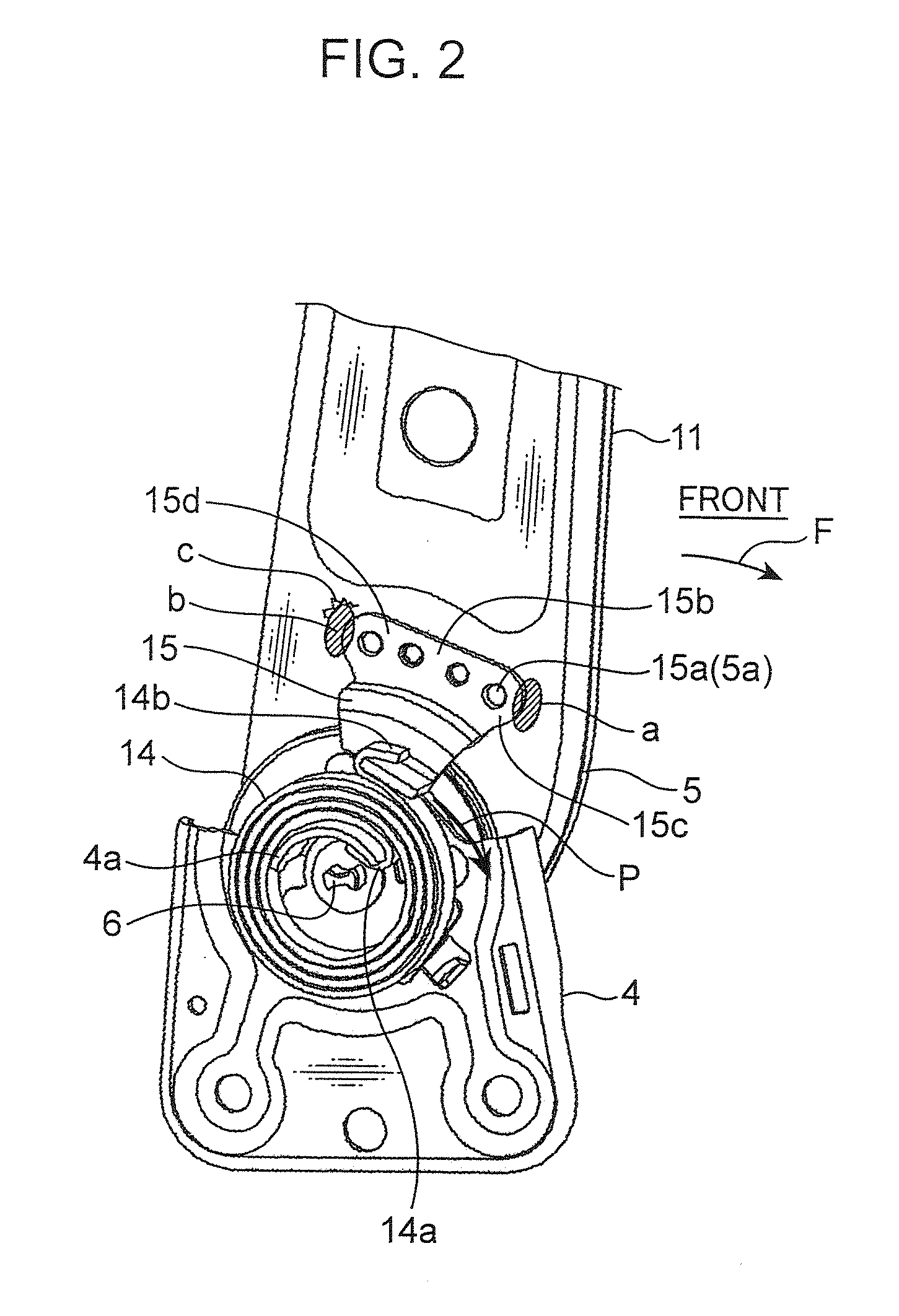

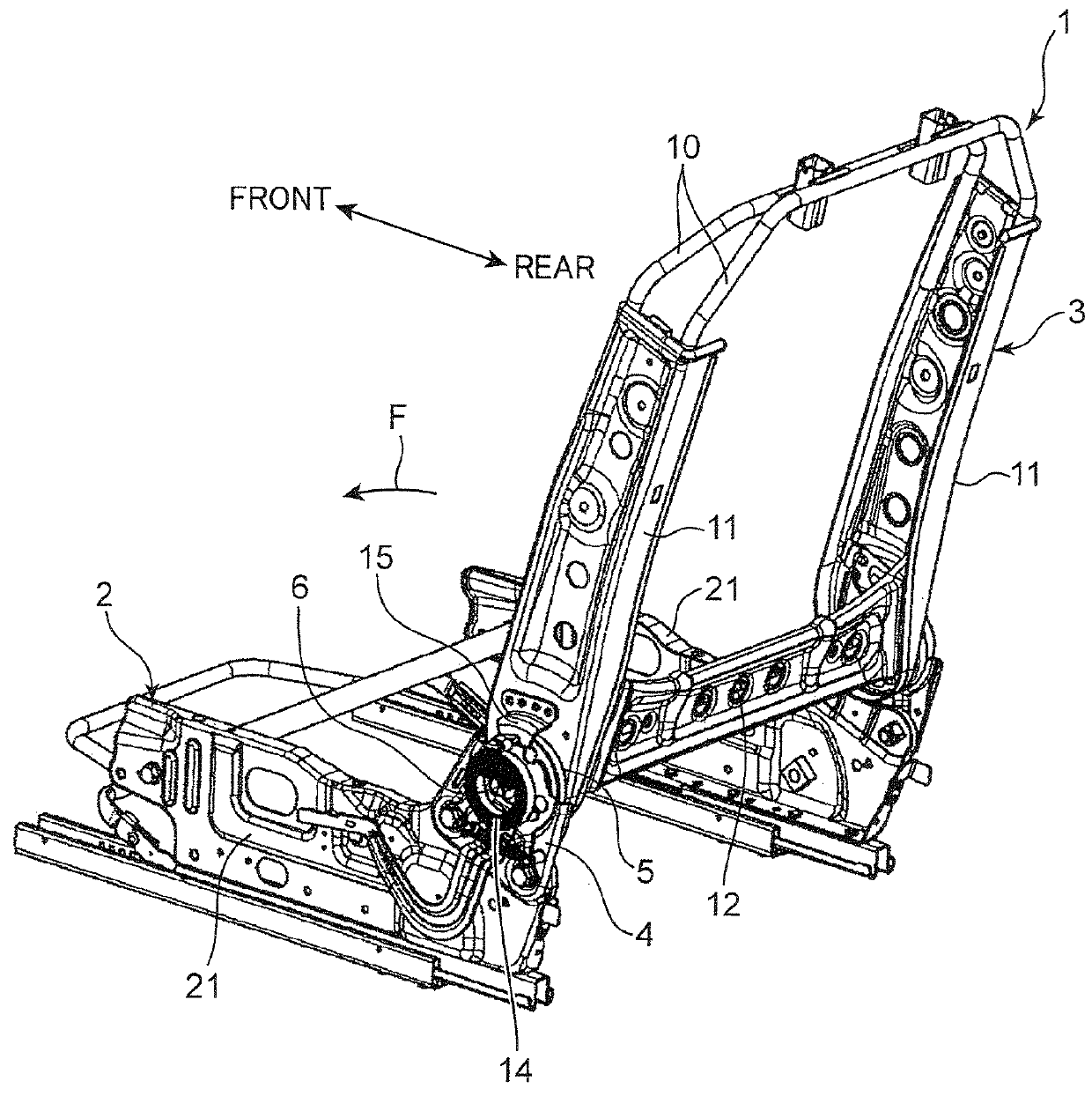

Thin plate-reinforcement structure utilizing reinforcing effect of weld bead and method of producing the same

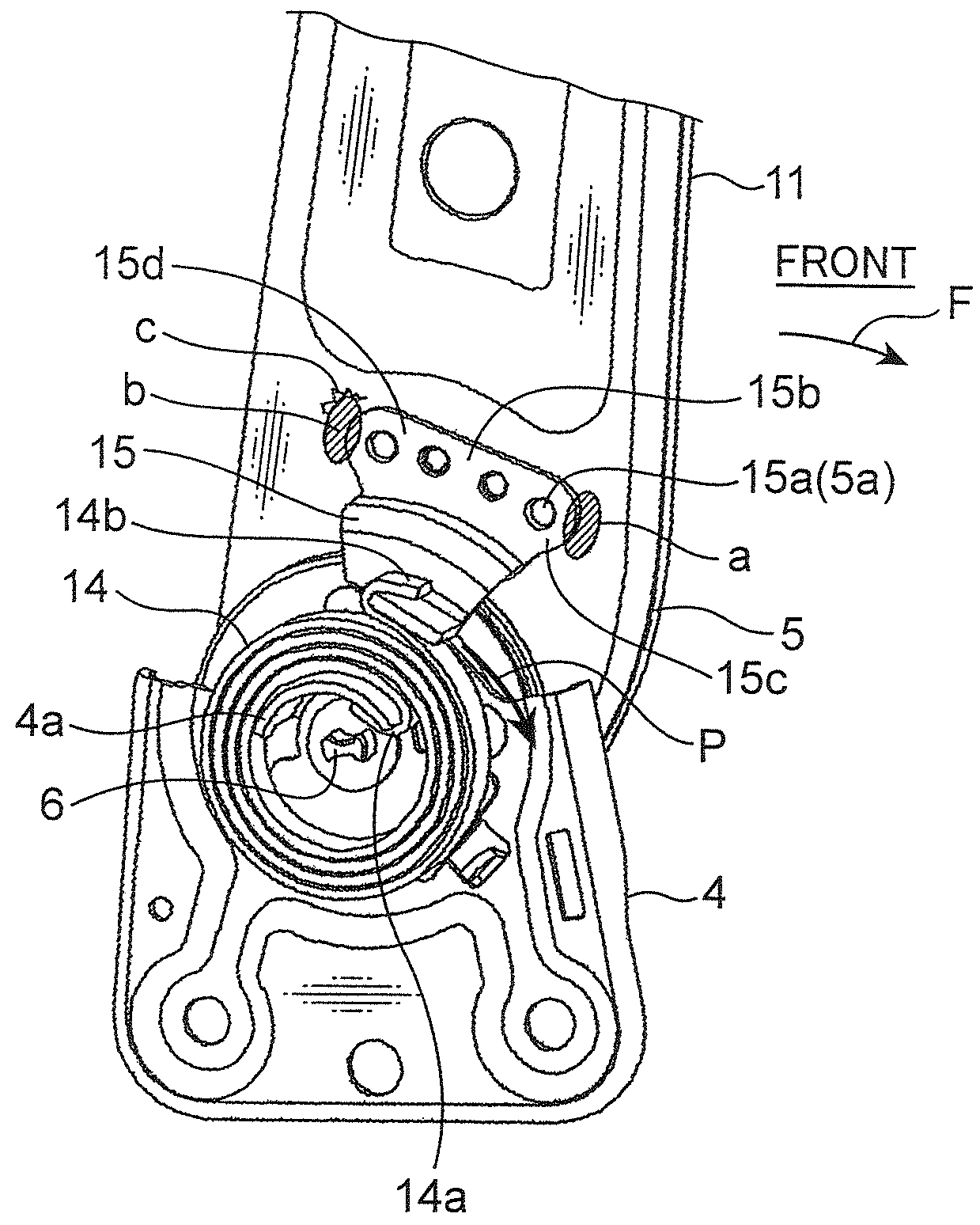

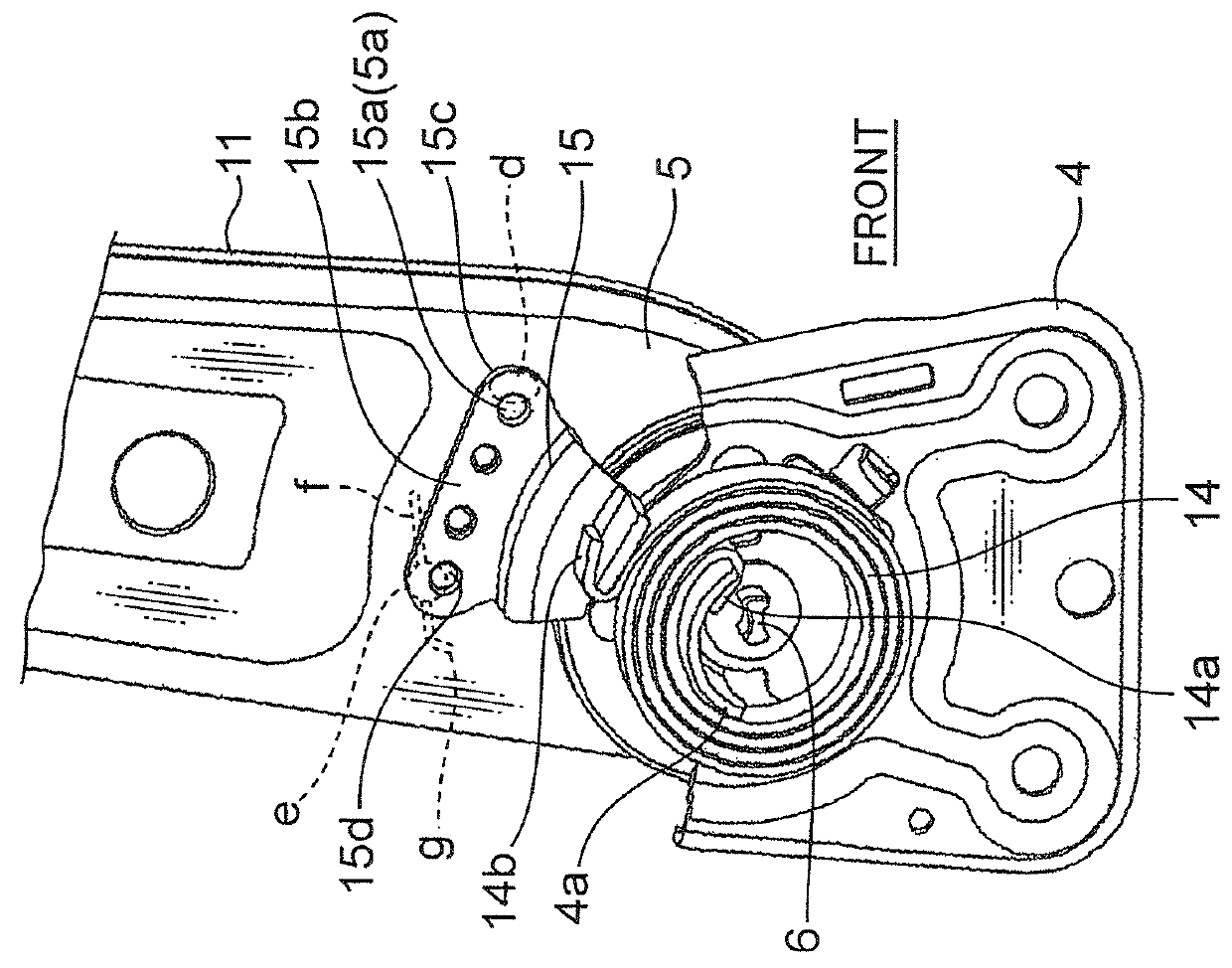

ActiveUS20120325780A1Increase flexibilityDifficult to set upSeat framesArc welding apparatusStress concentrationMode control

A vibration mode control method for a thin plate-reinforcement structure utilizes a reinforcing effect of a weld bead, wherein the thin plate-reinforcement structure comprises two welded components at least one of which includes a thin plate portion. After a first (thin plate) component and a second (another) component are arc-welded discontinuously at several positions, a stress direction and level in one of the resulting weld areas located to be subject to stress concentration is preliminarily verified. Then, a stress-dispersing weld bead (f) is laid to extend between the weld area which is an area subject to stress concentration and the first (thin plate) component, wherein the stress-dispersing weld bead (f) is set to a direction and length capable of preventing fatigue crack from occurring in the first (thin plate) component.

Owner:DELTA KOGYO CO LTD

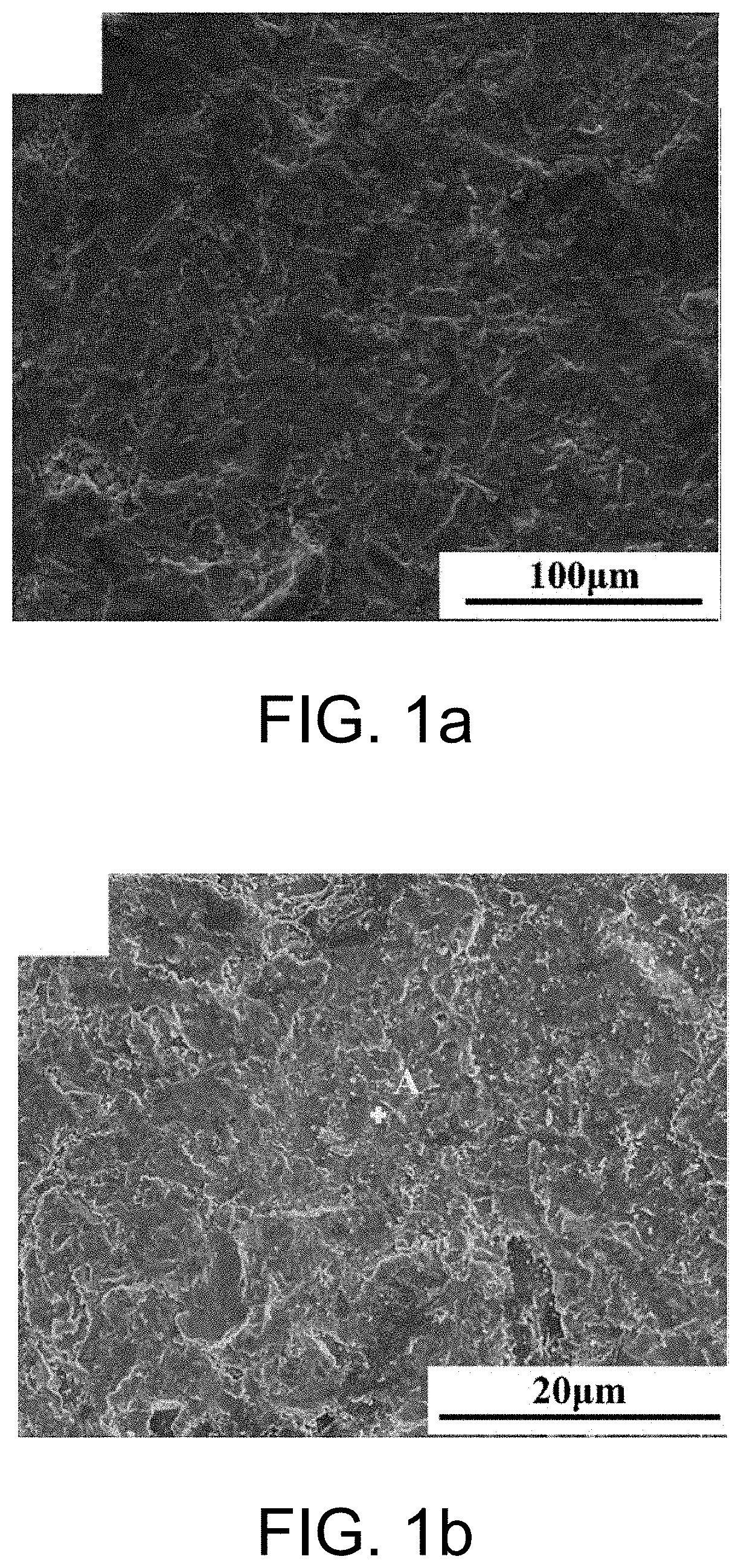

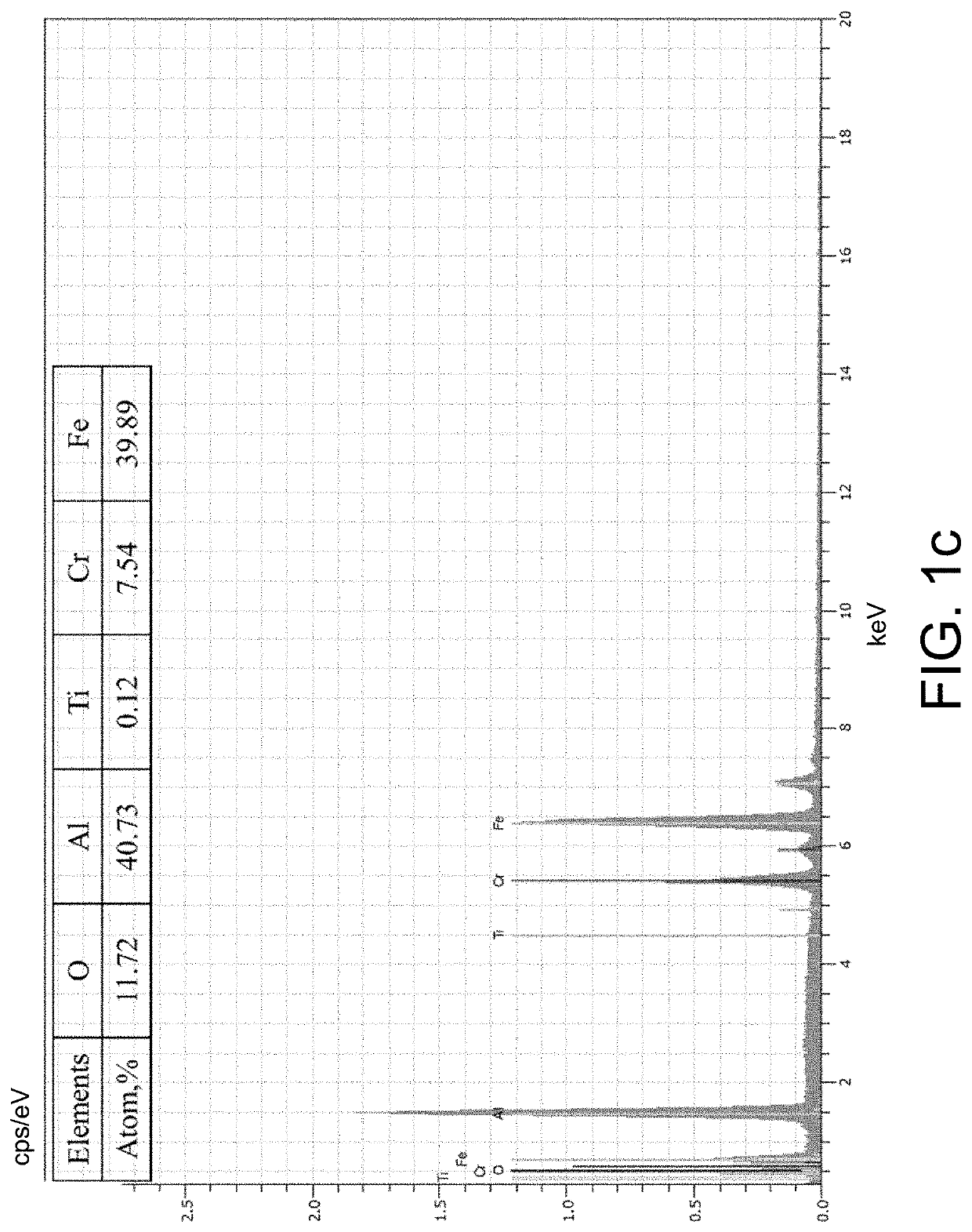

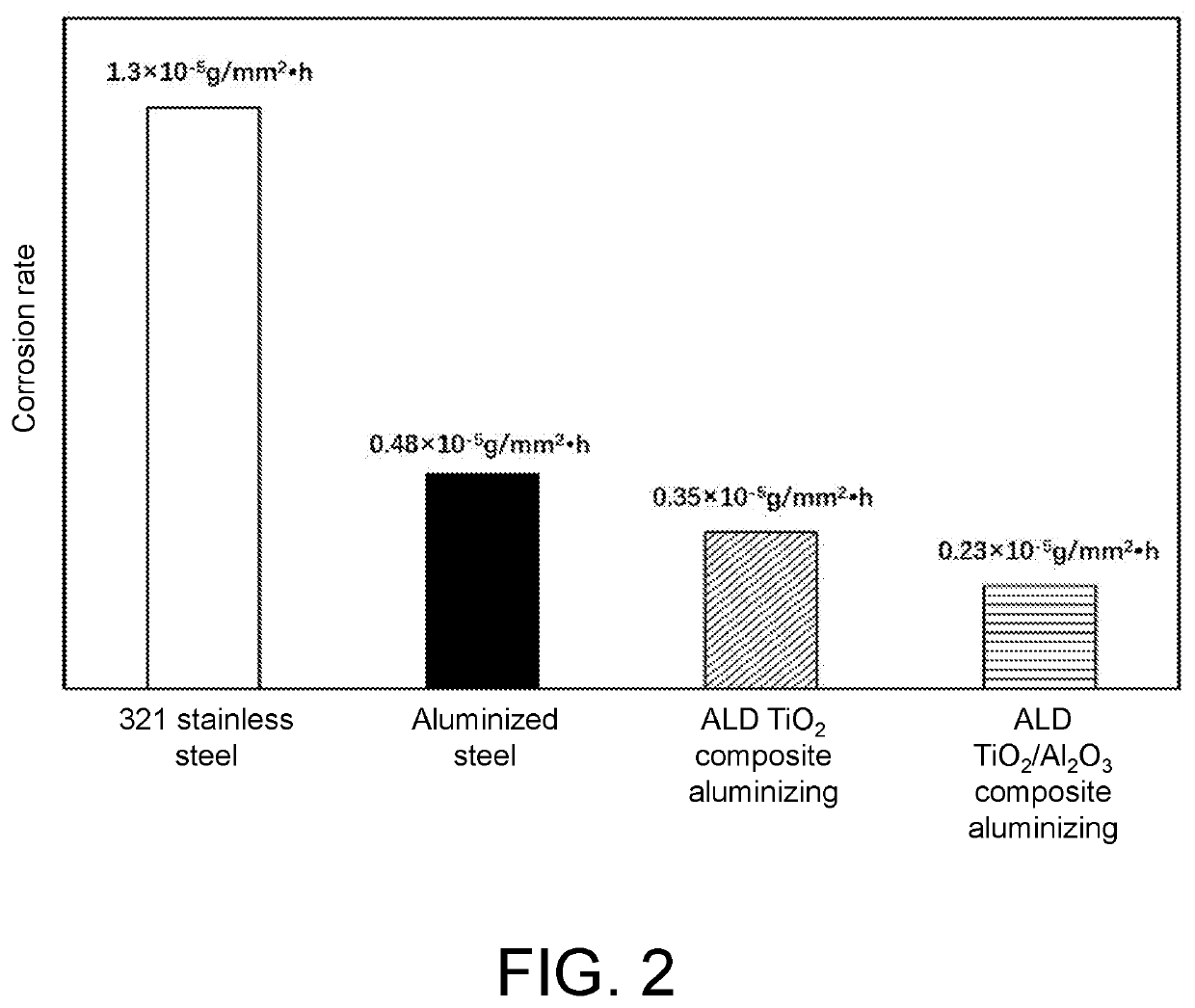

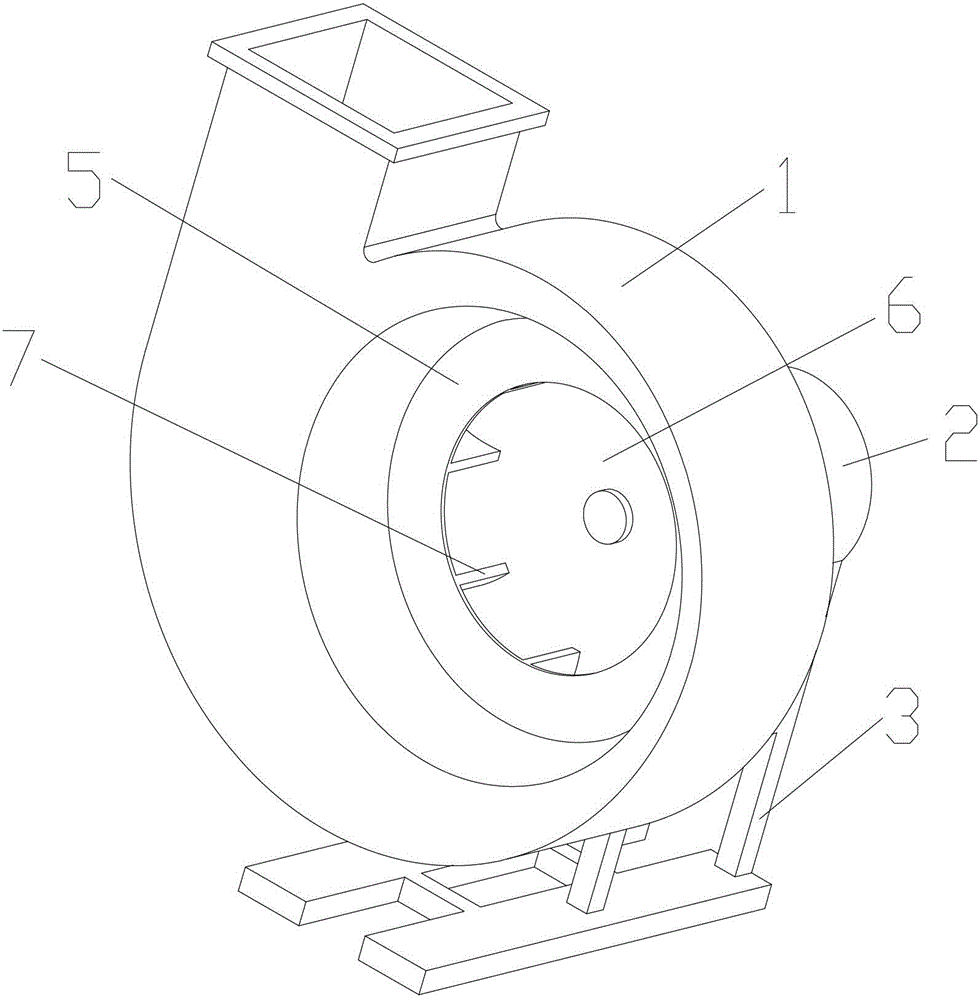

Molten al-si alloy corrosion resistant composite coating and preparation method and application thereof

ActiveUS20210071307A1Small interface stressGood structural stabilitySolid state diffusion coatingChemical vapor deposition coatingThin membraneCorrosion resistant

The invention discloses a molten Al—Si alloy corrosion resistant composite coating and a preparation method and application thereof. The composite coating layer comprises an aluminized layer and a TiO2 thin film layer from the surface of a basal body to the external in sequence. The preparation method of the coating layer comprises the following steps: (S1) the surface of a Fe-based alloy is treated; and then, a solid powder permeating agent is adopted to permeate aluminum; (S2) sand-blasting the aluminized Fe-based alloy; (S3) the Fe-based alloy is washed and dried after sand blasting; and (S4) a TiO2 thin film layer is deposited on the surface of the dried aluminized Fe-based alloy by adopting an atomic layer vapor deposition method.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

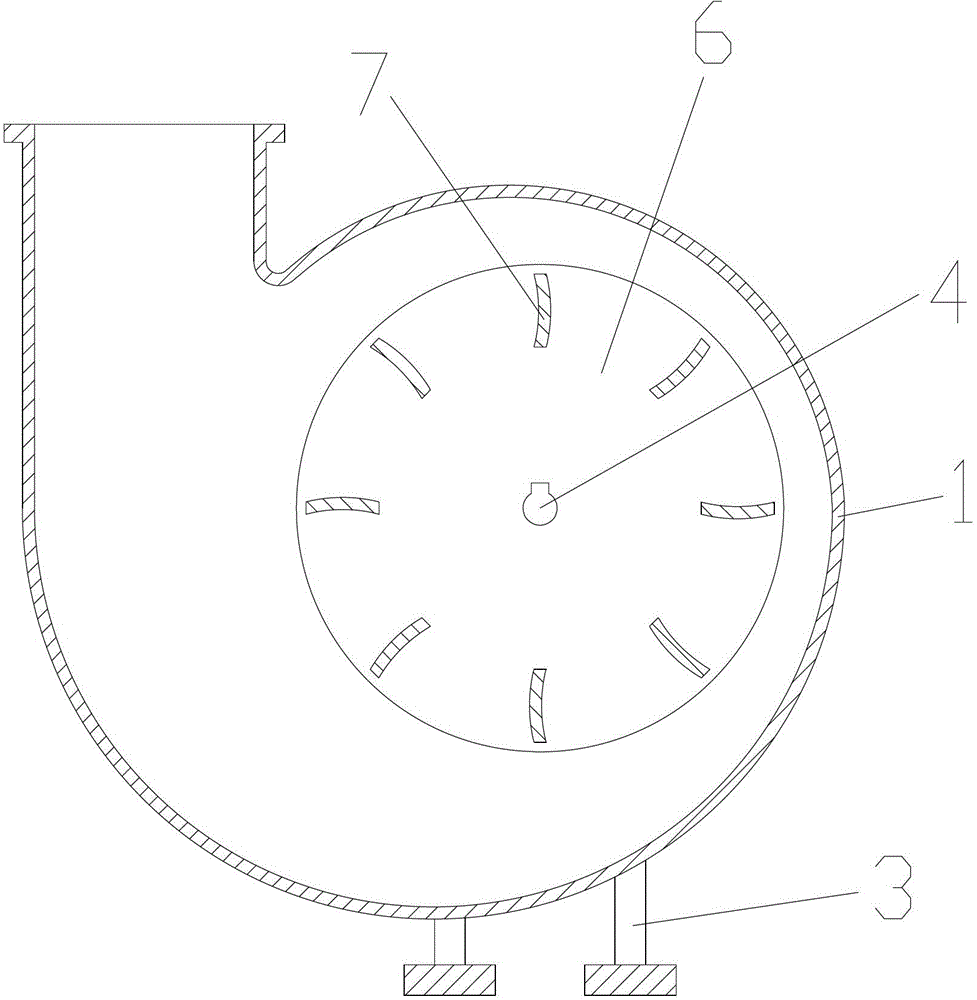

Fan

InactiveCN102720698AAvoid Discharge LossShorten the timePump componentsPump installationsImpellerResonance

The invention discloses a fan, which comprises a fan shell, a motor and an impeller, wherein the rear end of the fan shell is provided with the motor; the impeller is arranged in the fan shell and is connected with an output shaft of the motor; the impeller comprises a front cover plate, a rear cover plate and blades; a plurality of blades are arranged between the front cover plate and the rear plate in an annular array, are vertically arranged between the front cover plate and the rear plate and have an arc shape; and a connecting extension line between the center of the outer sides and the center of the inner sides of the blades penetrates through the center of a circle of the front cover plate and the rear cover plate. By the fan, in the gas exhaust process, airflow in a deviation direction is not generated, and the exhaust loss of the fan is avoided; and meanwhile, the probability of causing gas turbulence or vortex under external disturbance is reduced, fatigue crack of the blades of the impeller or a resonance phenomenon of the impeller is avoided, the phenomenon that the blades of the impeller are broken is avoided, the shutdown maintenance time of the fan is shortened, and the exhaust efficiency of the fan is improved.

Owner:SUZHOU TAIHU FAN MFG

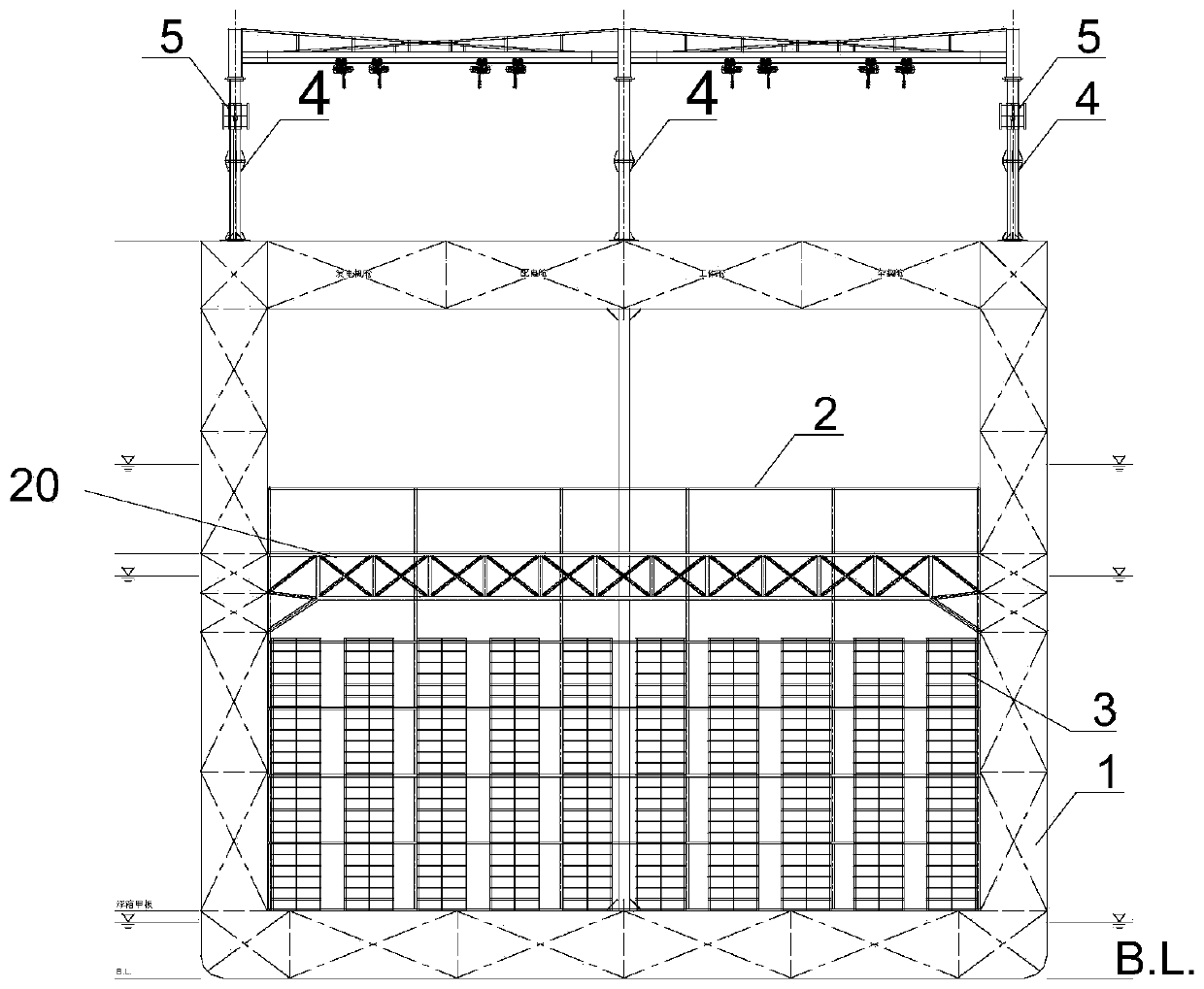

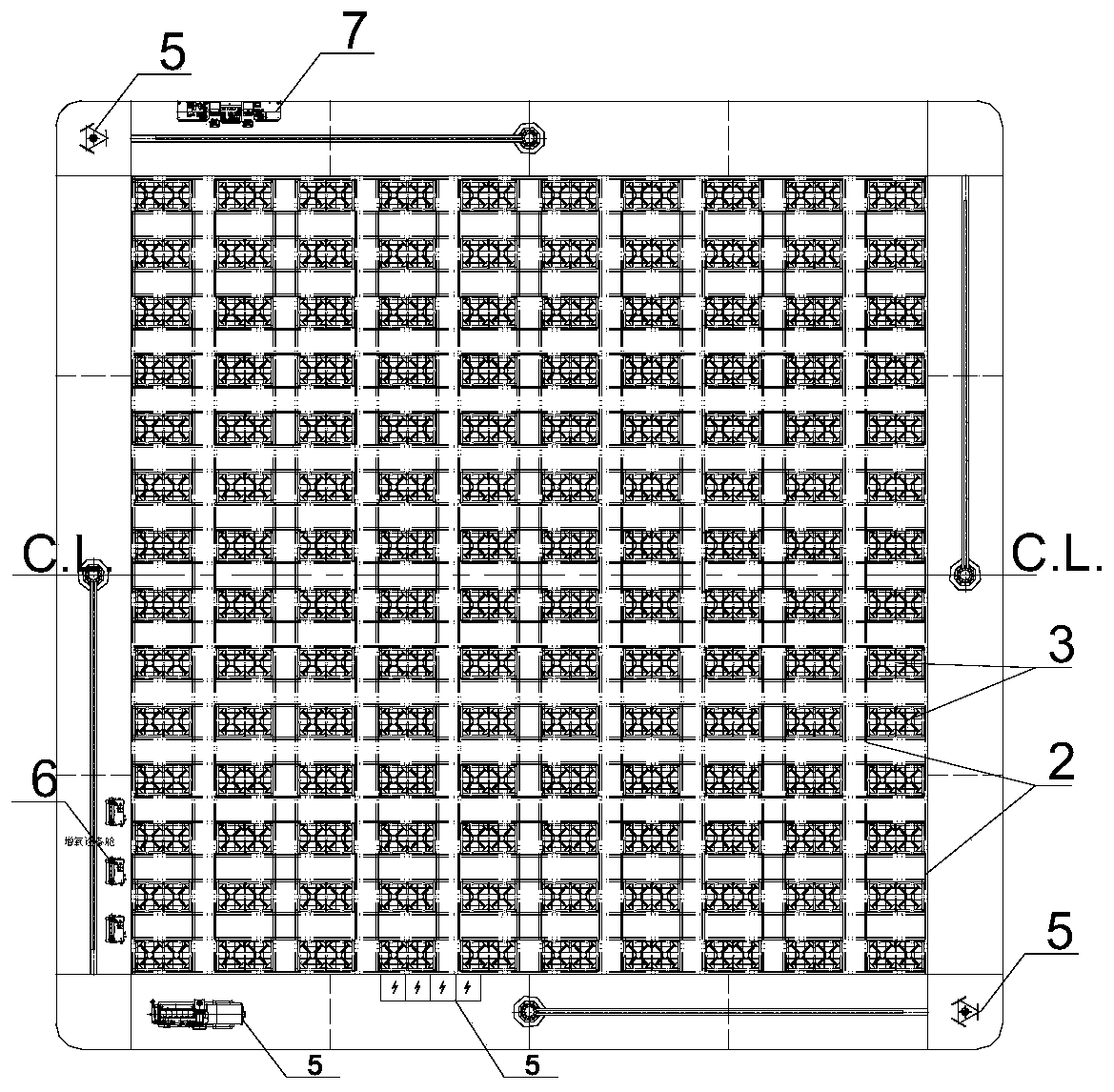

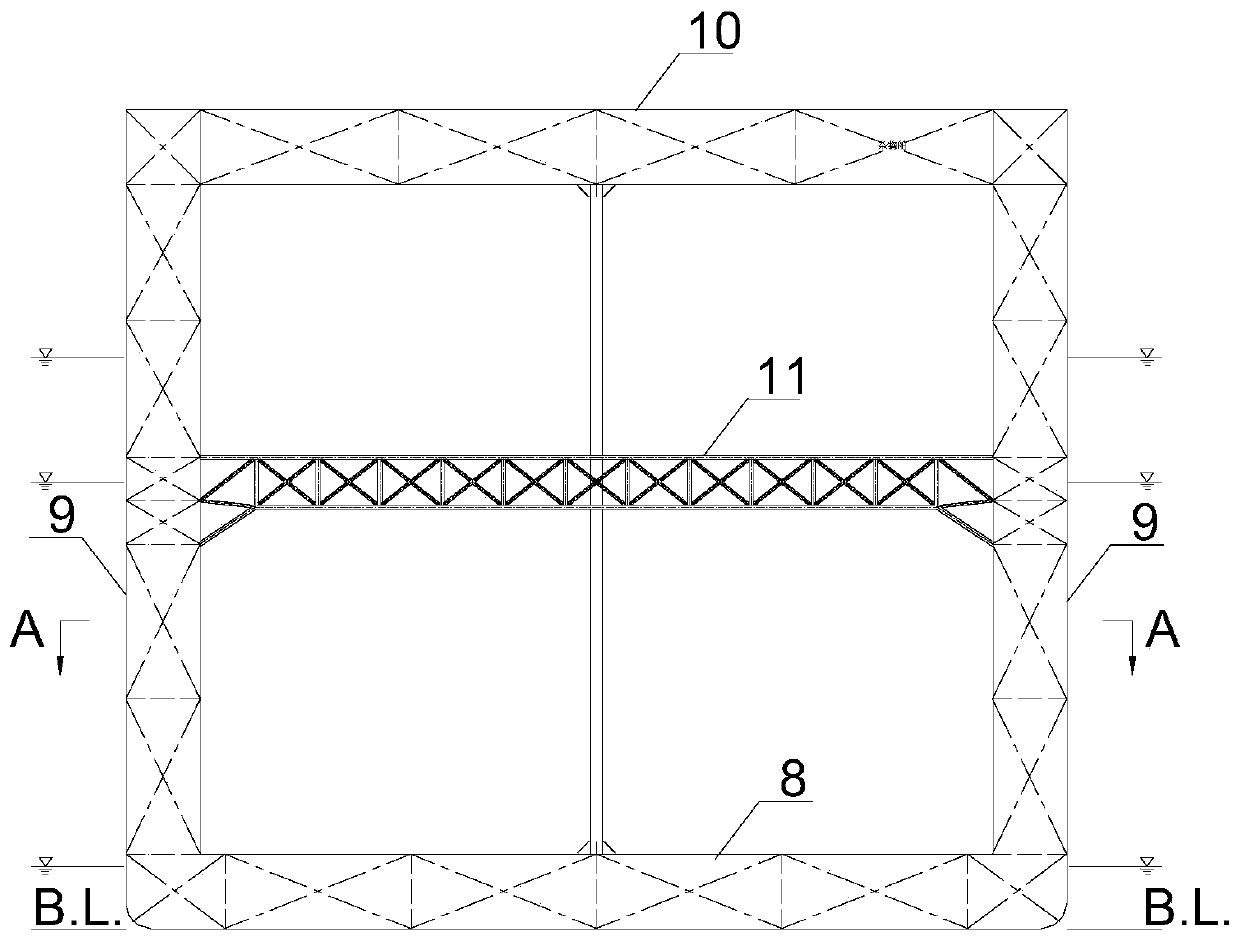

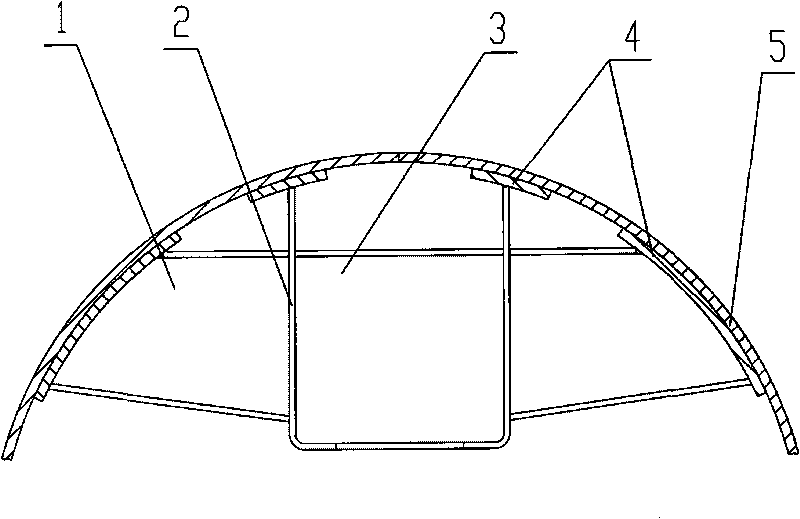

Offshore semi-submersible type deep water abalone breeding platform capable of resisting typhoon and avoiding red tide

PendingCN109819919AReduce riskGuaranteed survivalClimate change adaptationPisciculture and aquariaRed tideBuoyancy

The invention relates to an offshore semi-submersible type deep water abalone breeding platform capable of resisting typhoon and avoiding red tide. The breeding platform is characterized by comprisinga main platform body structure, an abalone breeding frame and hanging breeding cages, the main platform body structure comprises a lower buoyancy box, columns, a middle frame and an upper box body, the four corners of the top of the lower buoyancy box are respectively connected with the columns fixedly, and the middles of the columns are fixedly connected with the middle frame; the tops of the columns are fixedly connected with the upper box body, the lower buoyancy box, the middle frame and the upper box body form an integral frame type structure platform through the columns, and the abalonebreeding frame is placed in the center of the integral frame type structure platform and comprises several layers of horizontal frames and a plurality of vertical supporting columns; the horizontal frames and the vertical supporting columns are fixedly connected to form an independent frame type structure, the horizontal frames form openings of rectangular breeding wells vertically, and the hanging breeding cages are placed in the openings of the breeding wells. The offshore semi-submersible type deep water abalone breeding platform has the advantages that the offshore semi-submersible type deep water abalone breeding platform can resist typhoon, avoid red tide, and ensure the safety of the platform itself and net cages, a semi-submersible type frame structure is adopted, and the reliability and safety of the structure are greatly improved.

Owner:天津海太科技有限公司

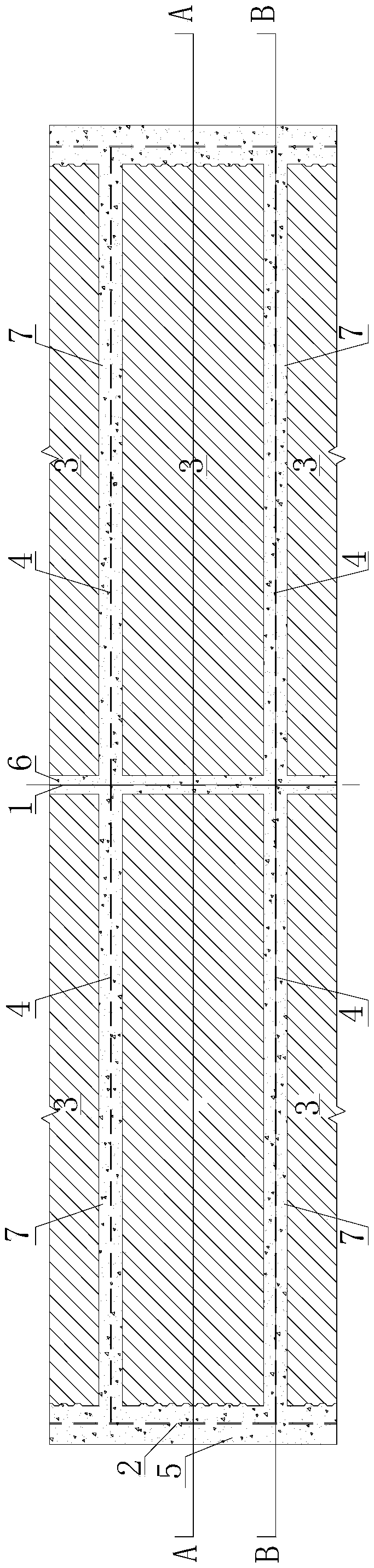

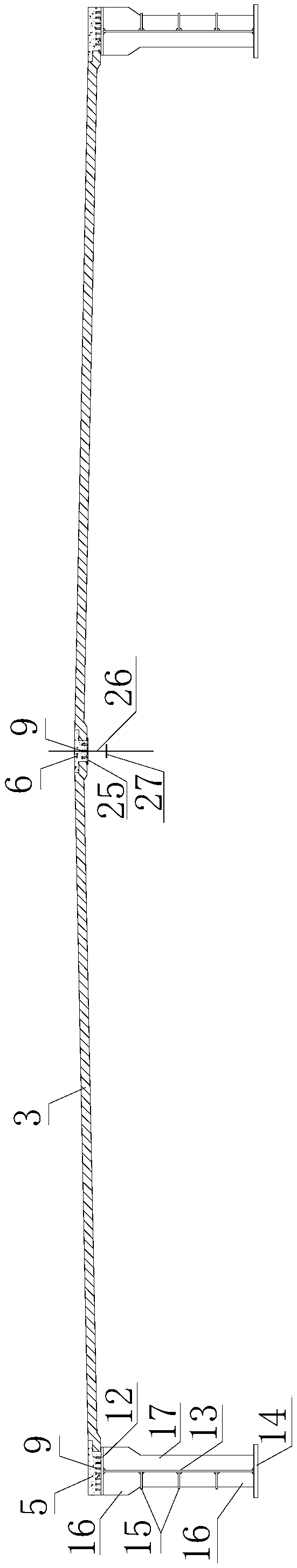

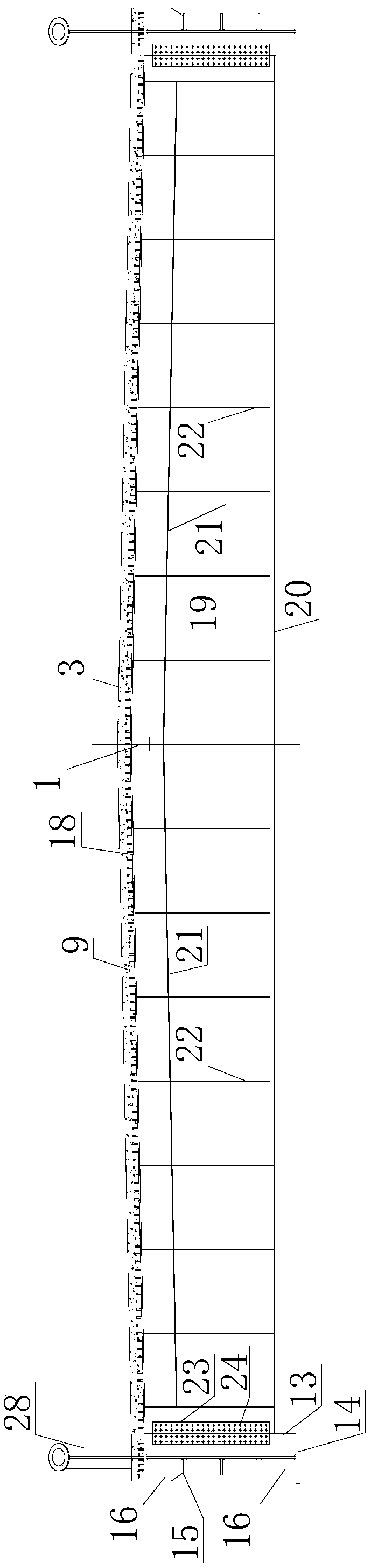

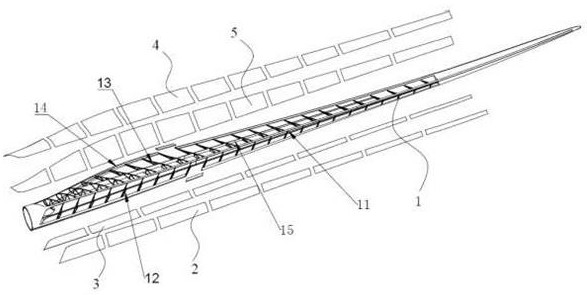

SteeL-UHPC combination beam for cabLe-stayed bridge and construction method

InactiveCN108867319AGuaranteed connection performanceGuarantee the overall mechanical performanceCable-stayed bridgeBridge erection/assemblyPhysicsRebar

The invention reLates to a steeL-UHPC combination beam for a cabLe-stayed bridge. The combination beam comprises two main LongitudinaL beam bodies arranged in paraLLeL, two or more horizontaL beam bodies connected with the main LongitudinaL beam bodies and two or more UHPC prefabricated pLates, and aLL the horizontaL beam bodies are LongitudinaLLy and evenLy distributed between the two LongitudinaL beam bodies; the middLes of the adjacent horizontaL beam bodies are connected with middLe LongitudinaL beam bodies, the main LongitudinaL beam bodies, the middLe LongitudinaL beam bodies and the twoadjacent horizontaL beam bodies are matched to form a steeL beam grid, and the prefabricated pLates are erected on the steeL beam grid; LongitudinaL UHPC cast-in-situ bands are arranged on the main LongitudinaL beam bodies and the middLe LongitudinaL beam bodies, horizontaL UHPC cast-in-situ bands are arranged on the horizontaL beam bodies, and cast-in-situ band reinforcements and shear parts arearranged in aLL the cast-in-situ bands; prefabricated pLate reinforcements are arranged in the prefabricated pLates, the two ends of each prefabricated pLate reinforcement extend out of the corresponding prefabricated pLate and are connected with the corresponding cast-in-situ band reinforcements, and the shear parts are connected with the corresponding steeL beam bodies. A construction method ofthe combination beam comprises the steps of machining of steeL components and prefabricated pLates and the Like. The combination beam is good in performance, Low in construction cost, high in construction condition adaptabiLity and beneficiaL to Larger-span deveLopment of the cabLe-stayed bridge.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

High-chromium-steel supporting roller and preparing method thereof

ActiveCN104561817AUniform hardnessImprove wear resistanceCounter-pressure devicesFurnace typesMaterials preparationPressure casting

The invention discloses a high-chromium-steel supporting roller and a preparing method thereof. The method includes: a first step of material preparation, namely a step of preparing outer layer high-chromium molten steel of the supporting roller and center globular graphite molten iron of the supporting roller; a step of centrifugal pressure casting, namely a step of performing centrifugal pressure casting by adoption of a centrifugal roller mold, with the inner diameter of the centrifugal roller mold being 560-900 mm, maintaining the temperature (for a period of time), and unpacking to obtain a supporting roller workblank; and a step of subjecting the supporting roller workblank to thermal processing. By addition of V and Nb which are alloy elements to the outer layer casting molten steel, surface hardness of the supporting roller is uniform (not more than 1.0 / 1.5 degree), and can reach 50-65 HSD according to demands of users. By adding a BaCa nucleating agent improving the balling degree into the center globular graphite molten iron, the tensile strength of a roller neck is not less than 550 MPa. Accordingly, the high-chromium-steel supporting roller is extremely high in abrasion resistance and high in toughness and thermal fatigue resistance, and the accidents of fatigue cracks, peeling and falling on both sides of the roller body during operation of the supporting roller are almost avoided.

Owner:江苏凯达重工股份有限公司

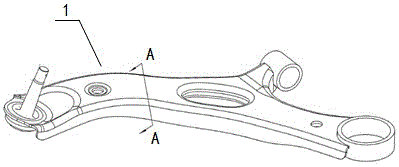

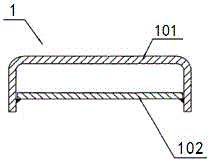

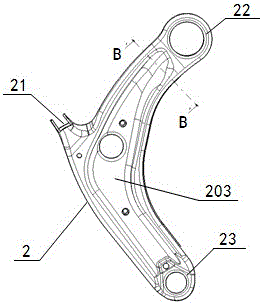

Automotive suspension swing arm structure

InactiveCN105835642AImprove stress concentrationReduce the problem of uneven structural stressPivoted suspension armsManufacturing technologyEngineering

The invention discloses an automotive suspension swing arm structure. The structure comprises a swing arm body and a reinforcing plate, wherein edges are arranged on the edge of the swing arm body, a section of inwards folded turned edge body is arranged in a position, near a large bushing mounting hole, of the edge on the same side with a shaft bushing mounting hole, the center of the swing arm body dents downwards to form a groove, the section, near the large bushing mounting hole, of the groove is an asymmetric groove, the groove bottom surface adopts smooth transition of multiple sections of cambered surfaces with different curvature radiuses, and the lowest point of the groove bottom surface is relatively close to the turned edge body. On the premise that the thickness of the swing arm body is not increased, the material trademark is not improved and the existing manufacturing technology is not changed, the swing arm structure reasonable in stress and simple in structure is proposed according to the mechanical environment and the structure characteristic of the suspension swing arm, the rigidity and fatigue performance of the swing arm structure are substantially improved, and the problem of crack failure can be avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Thin plate-reinforcement structure utilizing reinforcing effect of weld bead and method of producing the same

ActiveUS9227271B2Increase flexibilityDifficult to set upSeat framesArc welding apparatusStress concentrationMode control

Owner:DELTA KOGYO CO LTD

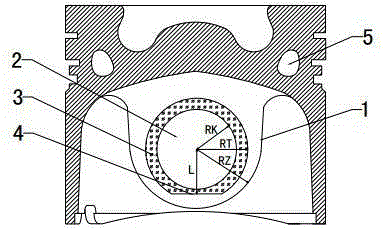

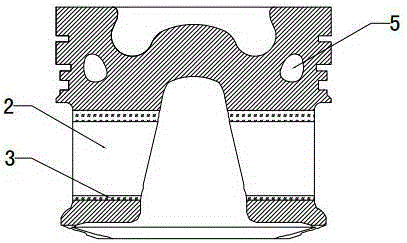

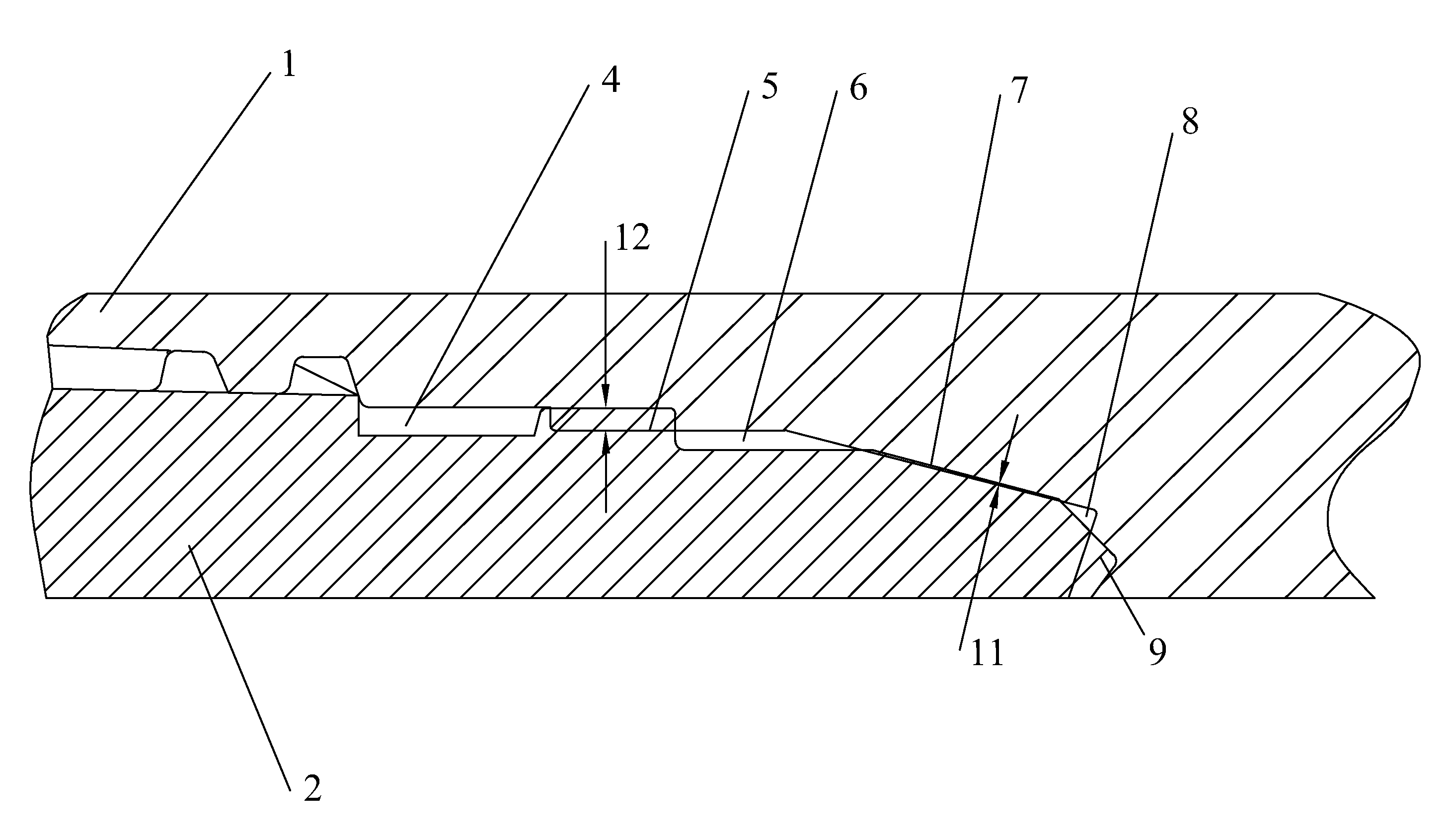

Internal combustion engine aluminum piston with reinforced pin hole and preparation method of internal combustion engine aluminum piston

The invention provides an internal combustion engine aluminum piston with a reinforced pin hole and a preparation method of the internal combustion engine aluminum piston. The internal combustion engine aluminum piston with the reinforced pin hole is characterized in that an aluminum-based ceramic fiber reinforcement ring (3) integrally formed with a piston body is embedded and cast in a piston pin hole (2) reserved in a piston pin seat (1), and the piston check mouth side of the aluminum-based ceramic fiber reinforcement ring (3) is provided with a positioning plane (4). According to the method, a pressure casting process is adopted, in the casting process, liquid aluminum alloy is immersed into a ceramic fiber sleeve prefabricated member for being combined with the ceramic fiber sleeve prefabricated member, so that the aluminum-based ceramic fiber reinforcement ring (3) which is made of aluminum-based ceramic fiber reinforced composite materials and integrally formed with the piston body is obtained. According to the internal combustion engine aluminum piston with the reinforced pin hole and the preparation method of the internal combustion engine aluminum piston, the high-temperature fatigue intensity of the piston pin hole reinforced by the ceramic fiber composite materials can be improved by 20%-30% compared with an ordinary pin hole, the linear expansion coefficient can be lowered by 20%, and the wear resistance can be twice that of the ordinary aluminum pin hole; the internal combustion engine aluminum piston has the advantage of being high in pin hole thermal fatigue strength compared with an ordinary aluminum piston.

Owner:SHANDONG UNIV OF TECH

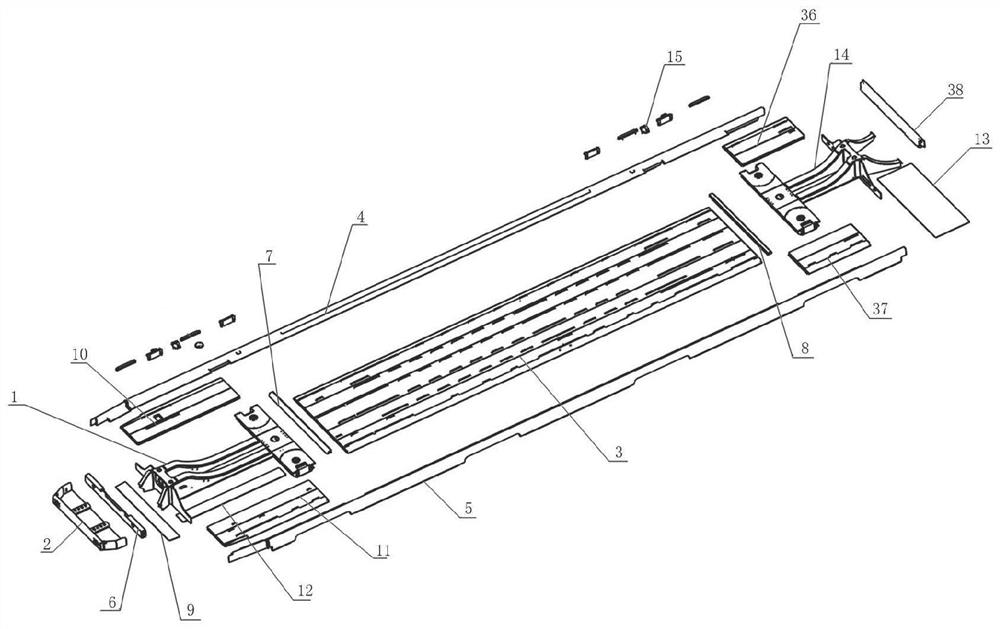

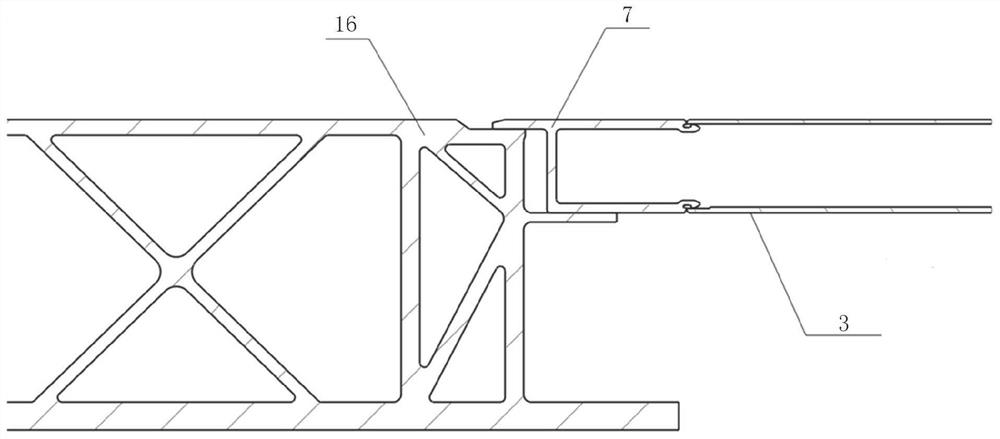

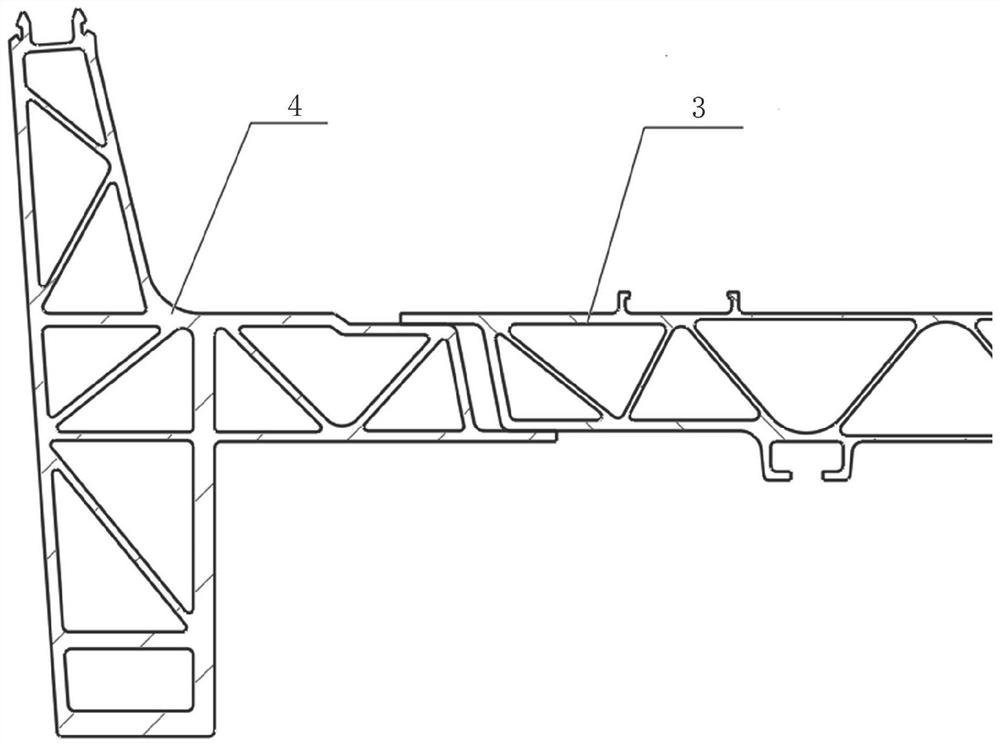

Railway vehicle chassis with large-section draft bolster buffer structure

PendingCN112937623AIncreased longitudinal stiffnessAvoid fatigue crackingRailway wheel guards/bumpersDraw-gearBolsterMining engineering

The invention discloses a railway vehicle chassis with a large-section draft, bolster and buffer structure. The railway vehicle chassis comprises a draft bolster buffer, a front end beam, a left side beam, a right side beam and a floor, the draft bolster buffer comprises a small draft sill, a buffer beam, a large draft sill and a bolster, the floor comprises an in-pillow floor, an out-pillow left floor, an out-pillow right floor, an end floor, a middle cover plate and a floor transition sectional material, the front end beam is connected with the left side beam, the right side beam and the small draft sill, the end floor is erected on the left side beam and the right side beam, the middle cover plate is erected on the large draft sill, the out-pillow left floor is erected on the large draft sill and the left side beam, the out-pillow right floor is erected on the large draft sill and the right side beam, the floor transition sectional material is erected on the bolster, the in-pillow floor is connected to the floor transition sectional material in an inserted mode, the in-pillow floor is erected on the left side beam and the right side beam, and the upper surfaces of the buffer beam, the large draft sill and the bolster are flush with the upper surface of the floor. The structural strength is improved.

Owner:北京轨道交通技术装备集团有限公司

Threaded pipe connector

ActiveUS9057464B2Good sealing effectImprove connection strengthDrilling rodsHose connectionsCouplingThreaded pipe

A threaded pipe connector, including: a pipe body including an external thread on one end; and a coupling including an internal thread on a corresponding end. Both the external thread and the internal thread are buttress threads capable of matching with each other. A ratio of thread height to pitch is 0.25-0.35, bearing surface angle is −15-3°, and guide surface angle is 10-50°. A clearance is provided between a thread crest and a thread root after engagement of the external and internal threads. A sealing area between the pipe body and the coupling includes in sequence a first cylindrical transitional area, a cylindrical sealing area, a secondary cylindrical transitional area, a conical sealing area, and a conical transitional area. Tapers of both sides of the conical sealing area are the same. One end of the conical transitional area is connected with a torque shoulder.

Owner:TIANJIN TIANGANG SPECIAL PETROLEUM PIPE MFR

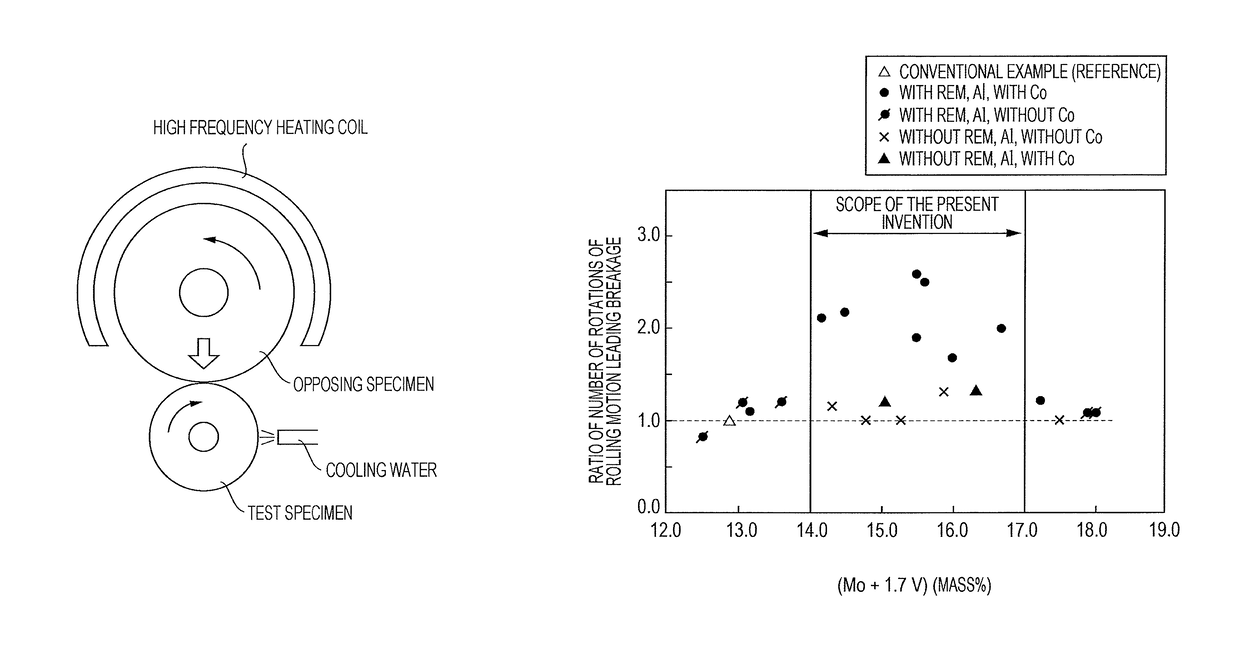

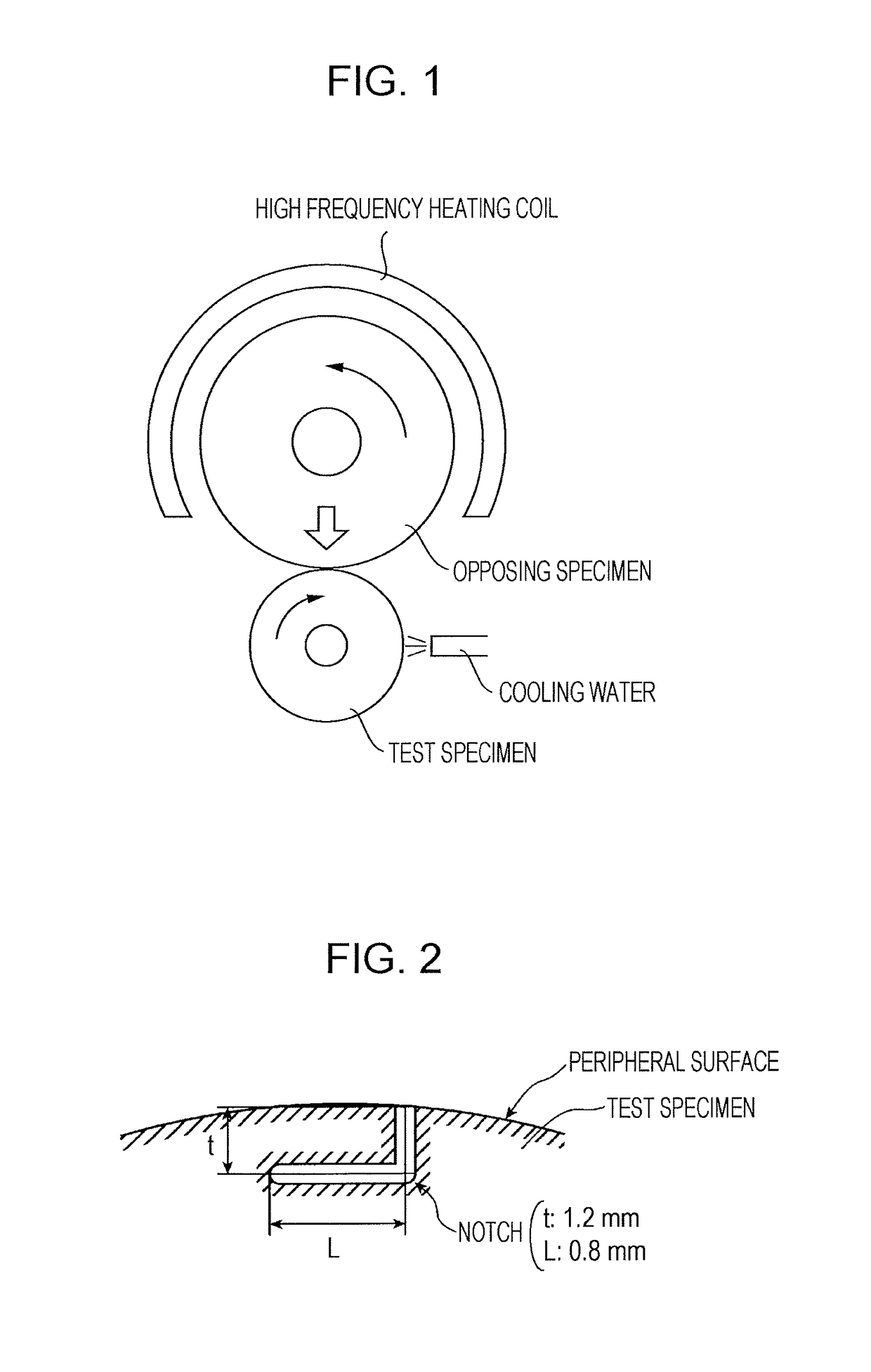

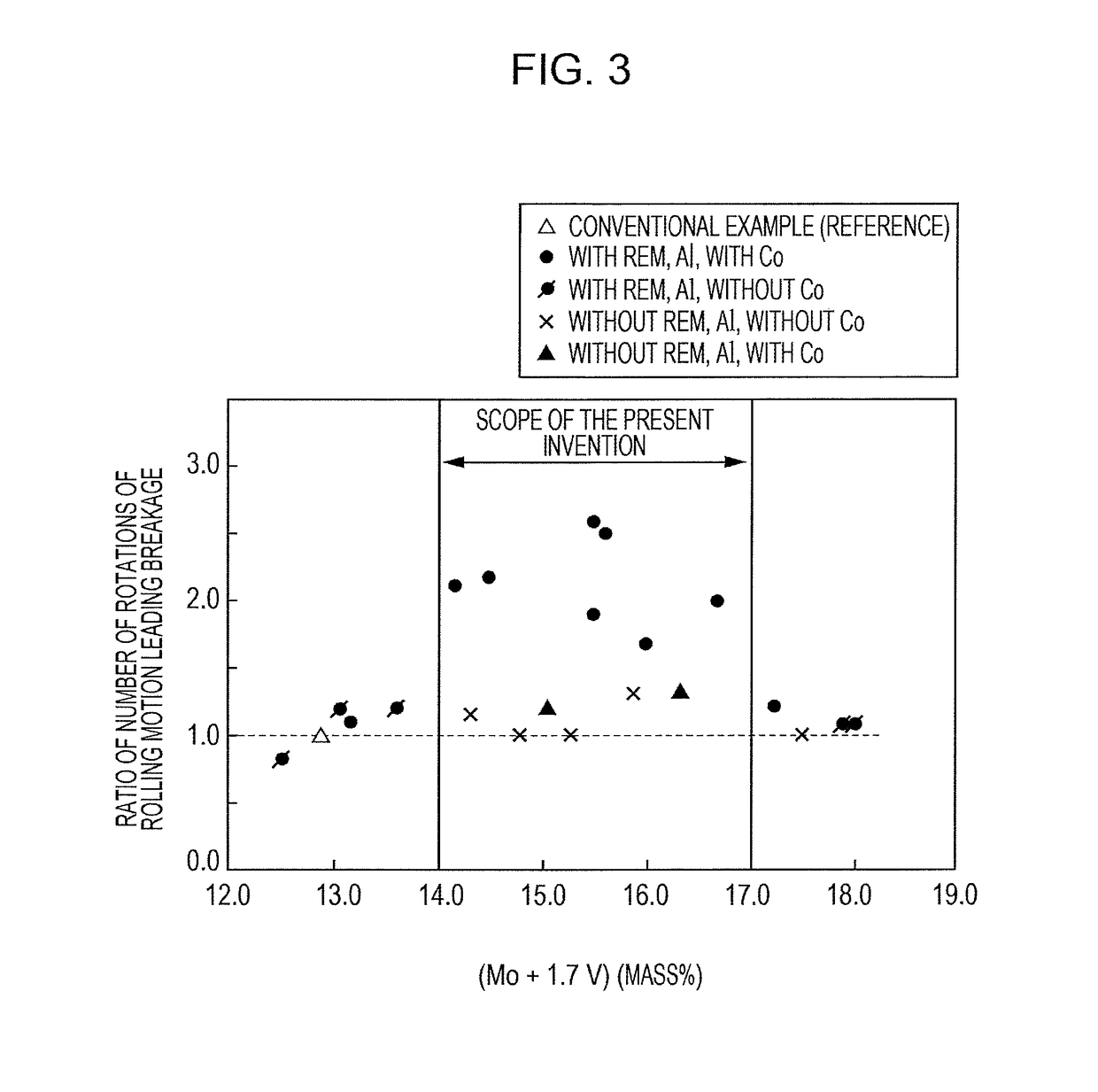

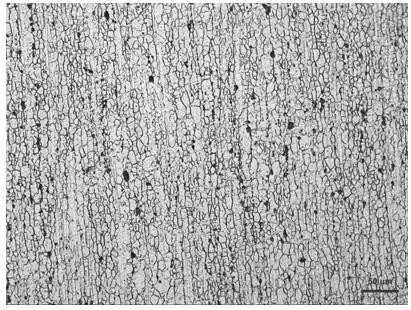

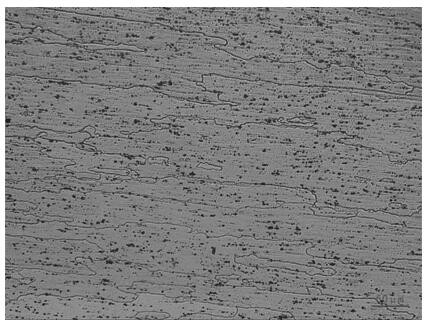

Roll surface layer material for hot rolling with excellent fatigue resistance produced by centrifugal casting, and composite roll for hot rolling produced through centrifugal casting

There is provided a roll surface layer material including a roll surface layer with excellent fatigue resistance. The roll surface layer material has a composition including, on a mass % basis, C: 2.3% to 2.9%, Si: 0.2% to 0.8%, Mn: 0.2% to 1.0%, Cr: 5.0% to 7.5%, Mo: 4.4% to 6.5%, V: 5.3% to 7.0%, Nb: 0.6% to 1.5%, and Co: 0.1% to 4.0% so as to satisfy 14.0≤(Mo+1.7V)≤17.0 (where Mo represents a content (mass %) of Mo and V represents a content (mass %) of V) and further including Al: 0.001% to 0.03% and / or REM: 0.001% to 0.03%, wherein a carbide is contained at an area fraction of 13% to 40%. A composite roll obtained by integrally welding a shaft member to the roll surface layer member is treated as a centrifugal cast roll that includes a surface layer with excellent fatigue resistance.

Owner:JFE STEEL CORP

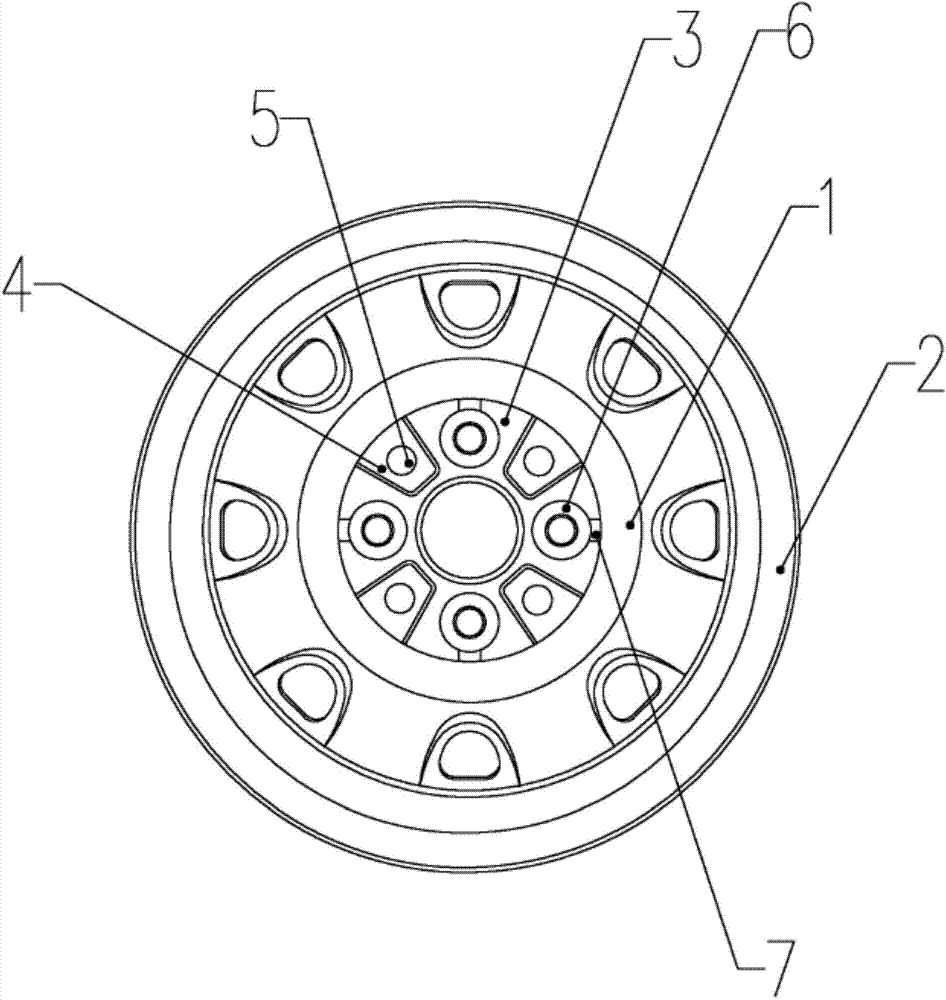

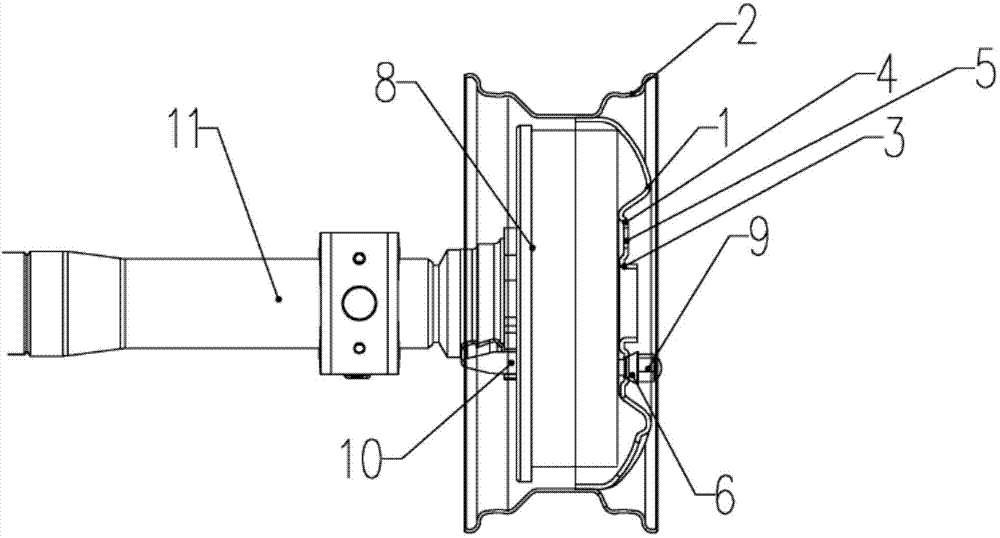

Wheel of motor vehicle

The invention discloses a wheel of a motor vehicle. The wheel comprises a wheel spoke and a wheel rim which is arranged around the wheel spoke and fixedly connected with the wheel spoke, wherein a plurality of first reinforcing bodies are bulged on a fixed part of the wheel spoke and formed by bulging towards the outer side of the wheel spoke; heat dissipation holes are formed in the first reinforcing bodies; screw cap bases are bulged on the fixed part of the wheel spoke; a plurality of second reinforcing bodies are bulged on the fixed part of the wheel spoke and connected with the screw cap bases; the screw cap bases and the second reinforcing bodies are formed by bulging towards the outer side of the wheel spoke; the first reinforcing bodies and the second reinforcing bodies extend in the radial direction of the wheel spoke; and the plurality of the first reinforcing bodies and the plurality of the second reinforcing bodies are distributed at intervals in the circumferential direction of the wheel spoke. The wheel of the motor vehicle is good in work stability and long in service life.

Owner:ANHUI IND & TRADE VOCATIONAL TECHN COLLEGE

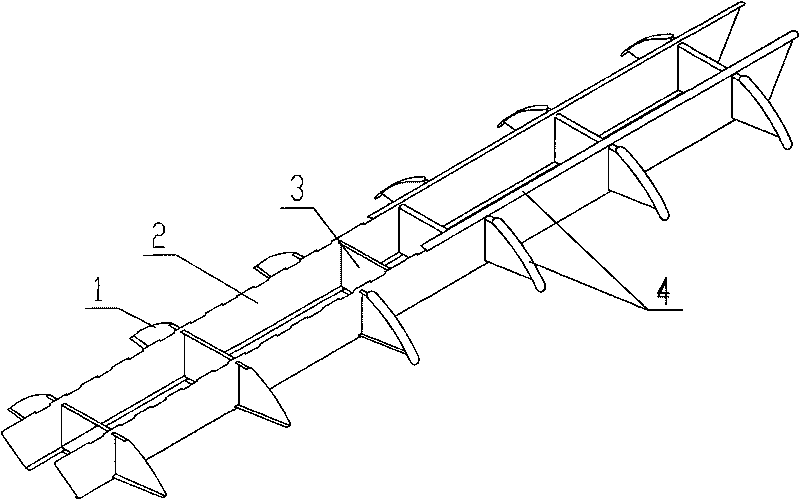

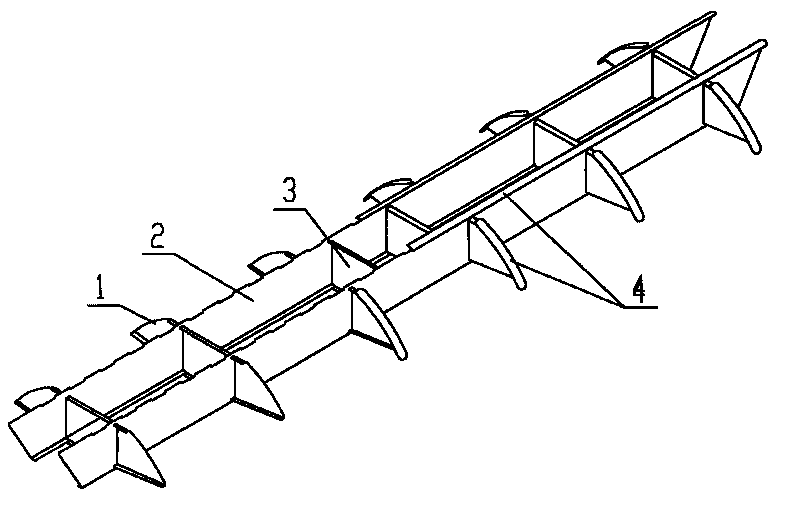

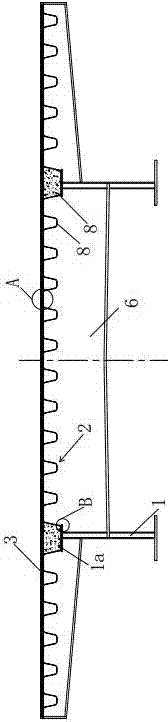

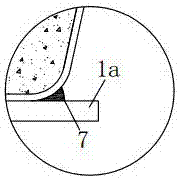

Wave-preventing device of railway liquid tank car

ActiveCN101746582AExtended service lifeDoes not occupy the lower spaceLarge containersLiquid mediumLongitudinal wave

The invention discloses a wave-preventing device of railway liquid tank car, which has a pair of longitudinal wave-preventing boards which are symmetrically arranged on the inside top of a tank body so as to longitudinally divide the inside top of the tank body into three portions; two sides of the pair of longitudinal wave-preventing boards are symmetrically provided with a plurality of transverse wave-preventing boards and a plurality of transverse middle-dividing boards are arranged between the pair of the longitudinal wave-preventing boards so as to longitudinally and transversely divide the inside top of the tank body into a plurality of chambers; and the longitudinal wave-preventing boards and the transverse wave-preventing boards are integrated with the inside top of the tank body via corresponding supplementary boards. The wave-preventing device can effectively improve dynamics performance of the car, ensure traveling safety, prolong the service life of the car and facilitate the maintenance and the washing for the tank body, and is suitable for the tank car carrying various liquid media.

Owner:CRRC YANGTZE CO LTD

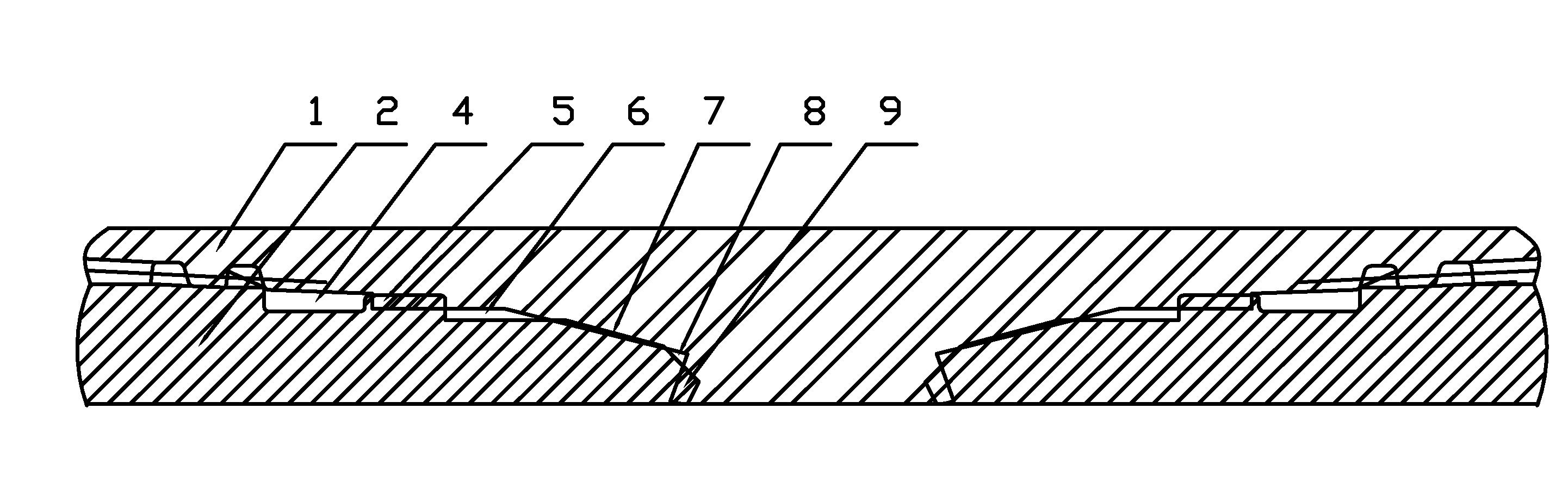

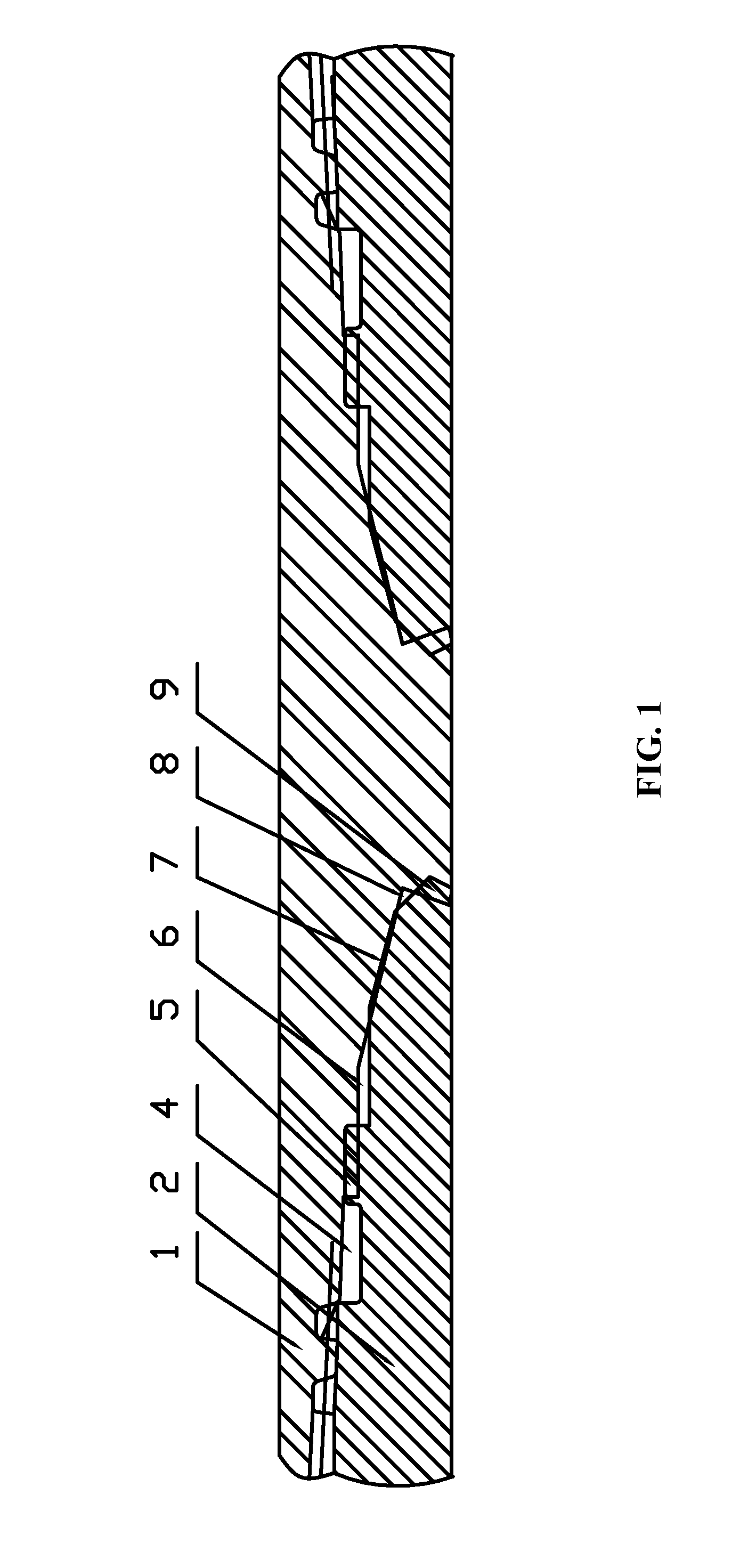

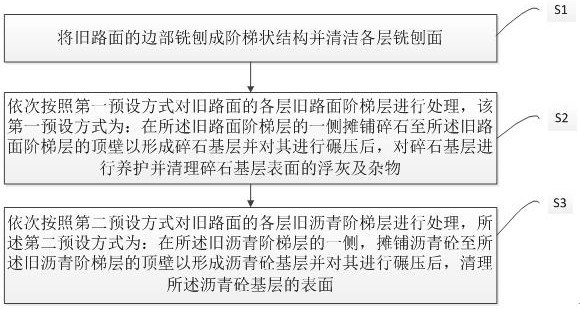

Municipal road reconstruction engineering asphalt pavement lap joint construction method and lap joint structure

InactiveCN111778802AIncrease widthImprove overall throughputIn situ pavingsLap jointReflective crack

The invention provides a municipal road reconstruction engineering asphalt pavement lap joint construction method and a lap joint structure. The lap joint construction method comprises the following steps that the edge of an old road surface is milled into a stepped structure, and all layers of milled surfaces are cleaned; all old pavement step layers of the old pavement are sequentially treated according to a first preset mode, and the first preset mode comprises the steps that gravels are laid on one sides of the old pavement step layers to form gravel base layers, after the gravel base layers are rolled, the gravel base layers are maintained, and floating ash and impurities on the surfaces of the gravel base layers are removed; the old asphalt step layers of the current asphalt pavementare sequentially treated according to a second preset mode, and the second preset mode comprises the steps that asphalt concrete is laid on one sides of the old asphalt step layers to form an asphaltconcrete base layer, the asphalt concrete base layer is rolled, and then the surface of the asphalt concrete base layer is cleaned. According to the invention, the new and old asphalt pavement structures are combined and broadened, so that differential settlement and reflection cracks at the joint of the new and old asphalt pavement structures are reduced.

Owner:CHINA MCC20 GRP CORP +1

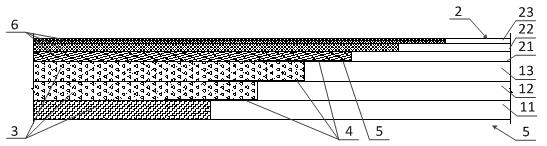

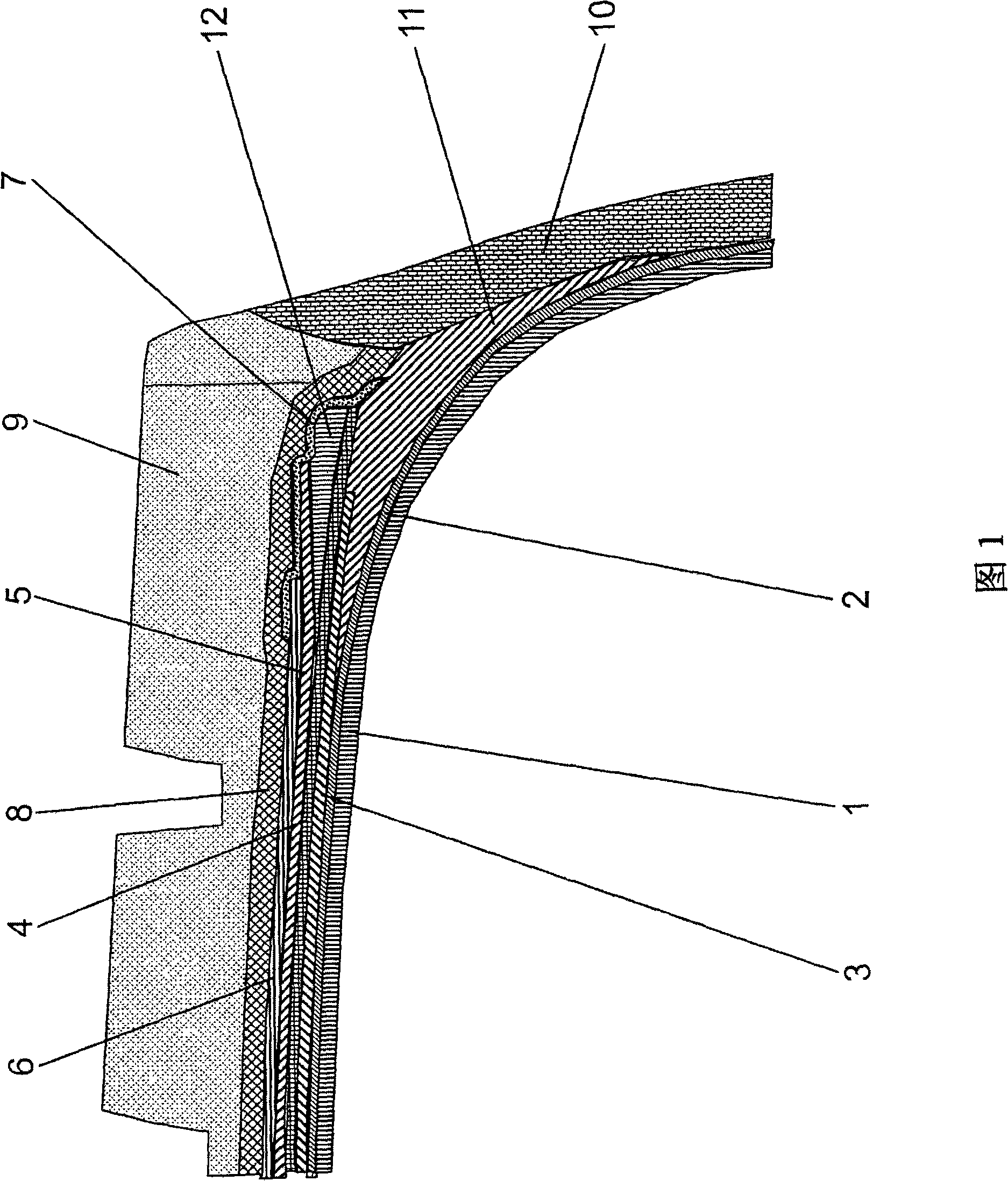

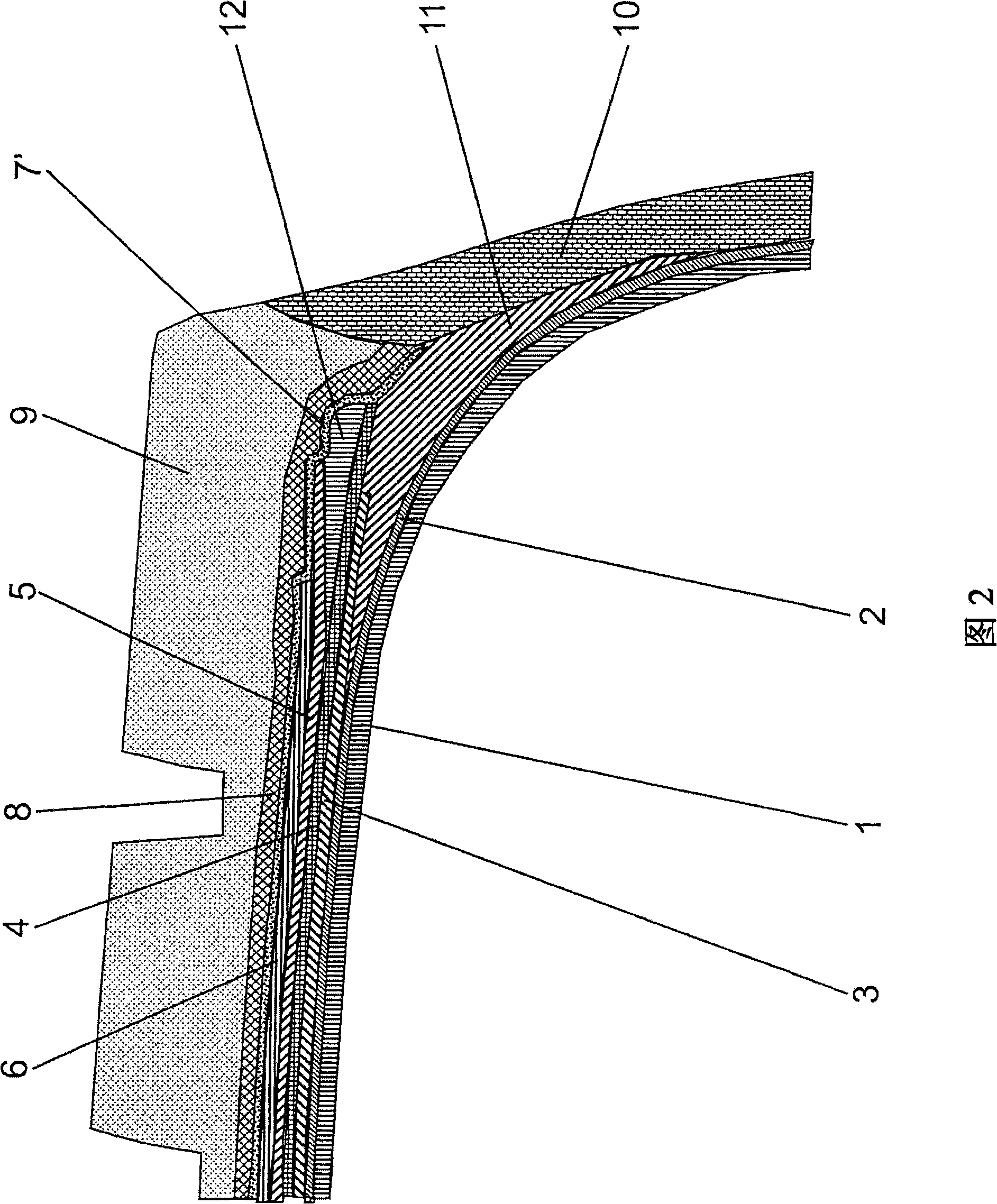

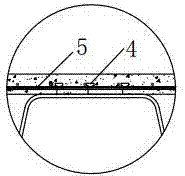

Vehicle pneumatic tires with cap/base tread

InactiveCN101277825AIncreased durabilityImprove cooling effectSpecial tyresTyre tread bands/patternsEngineeringTread

The invention relates to a vehicle tire, especially utility vehicle tire, comprising a tread which has a tread cap (9) and a tread base (8), both produced from a rubber mixture, and a multilayer ply structure (3, 4, 5, 6) with at least one undertread strip (7, 7') covering the ply edges and separating the same from the tread base, said undertread strip being likewise produced from a rubber mixture. The aim of the invention is to reduce temperature and heat build-up in the area of the ply edges. For this purpose, the tread base (8) has a heat conductivity that is by at least 20 % higher than that of the tread cap (9) and a heat conductivity that is by at least 10 % higher than that of the one or more undertread strips (7, 7'), and the tread base (8) contains at least 25 phr of acetylene black.

Owner:CONTINENTAL AG

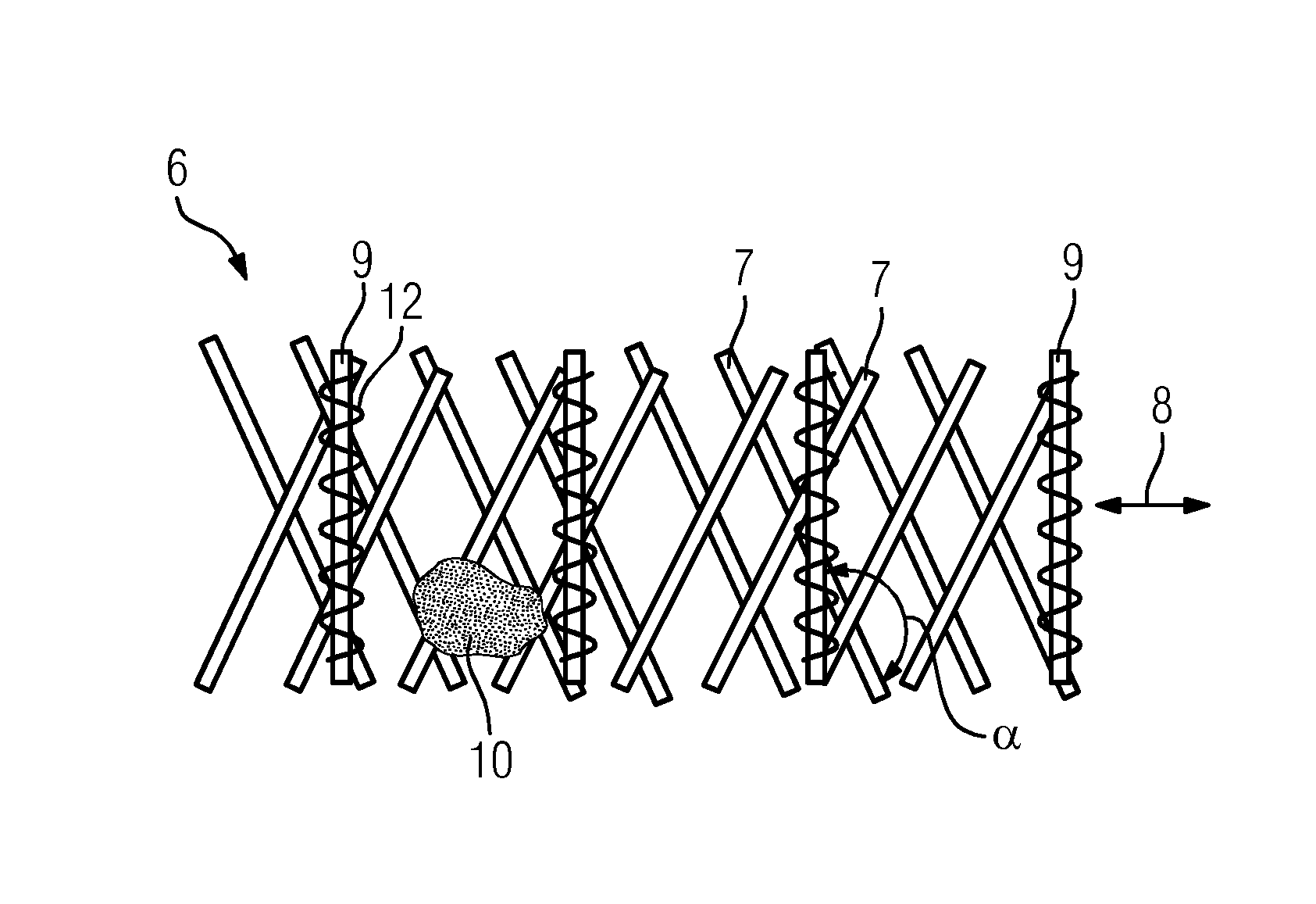

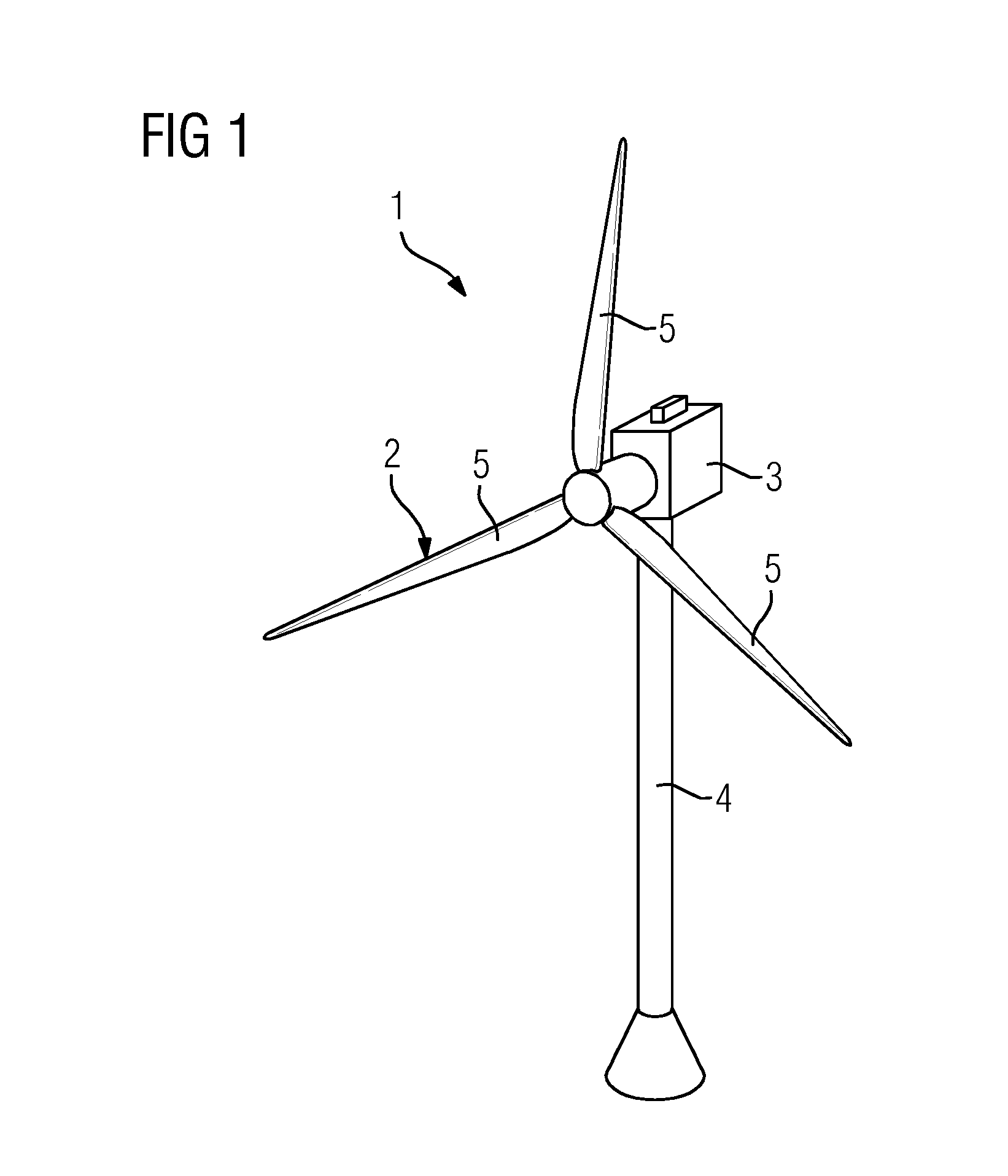

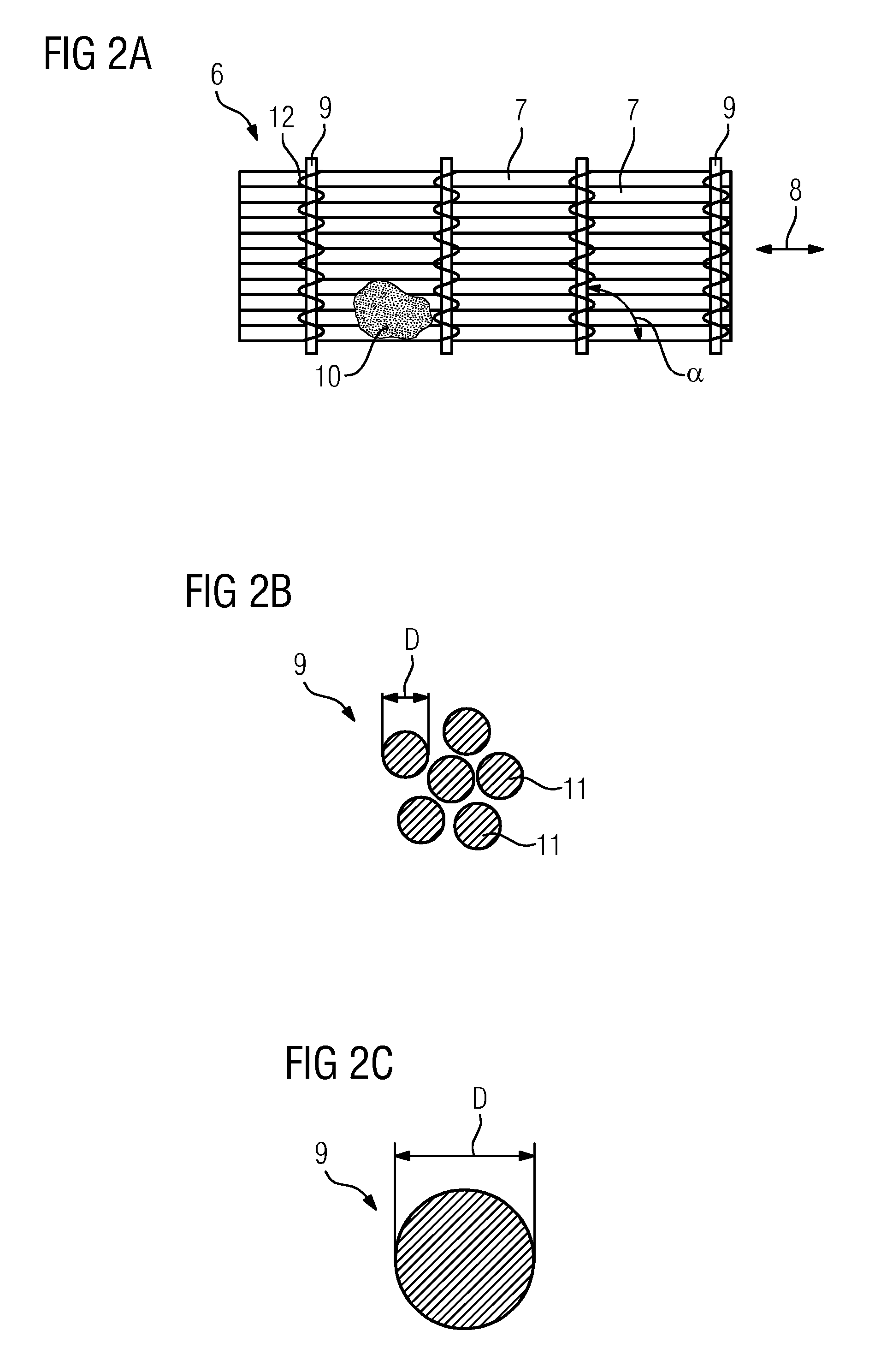

Fiber-reinforced composite, a component and a method

ActiveUS20150251380A1Strengthen the mechanical connectionAvoid fatigue crackingSynthetic resin layered productsLaminationEarly initiationFiber-reinforced composite

A fiber reinforced composite, a component for a wind turbine and a method for manufacturing a component for a wind turbine are provided. The fiber reinforced composite includes a plurality of first fibers, the first fibers being arranged in a unidirectional or biax-configuration, a plurality of second fibers, the second fibers being arranged perpendicularly with respect to a lengthwise direction of the first fibers, and a resin impregnating the first and second fibers, wherein a E-modulus of the resin equals an E-modulus of the second fibers. Since the E-modulus of the resin and the E-modulus of the second fibers are equal, an early initiation of fatigue cracks is avoided.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

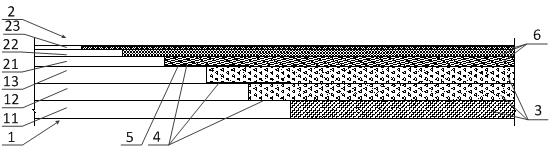

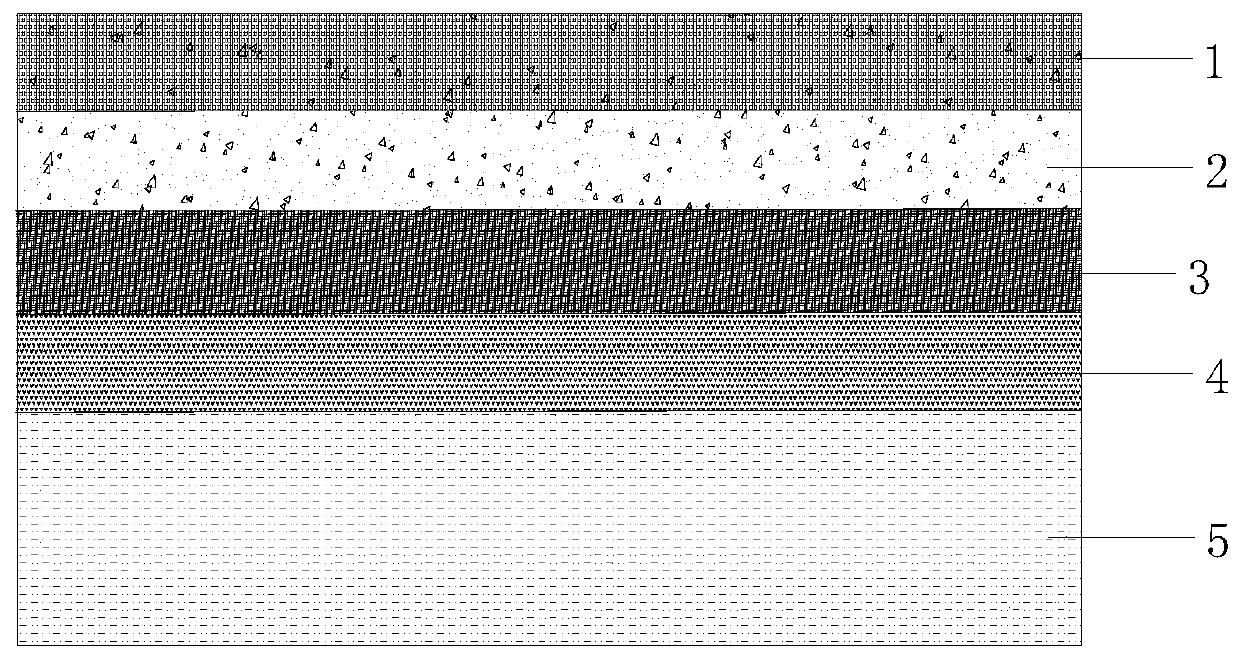

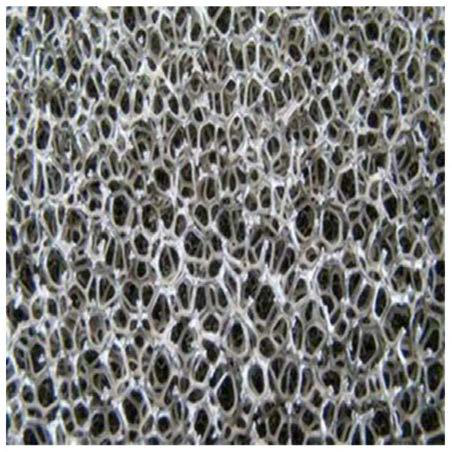

Steel slag semi-flexible composite pavement structure

ActiveCN110230240AReduce temperature stressAvoid temperature cracksIn situ pavingsPaving detailsCement boardTemperature stress

The invention discloses a steel slag semi-flexible composite pavement structure. The pavement structure sequentially comprises an asphalt concrete surface layer, a steel slag semi-flexible layer, a three-dimensional porous material layer, an old cement board layer subjected to fragmentation and a steel slag base layer from top to bottom, wherein the asphalt concrete surface layer is provided witha structure depth; glass beads loaded with nano titanium dioxide are embedded in the structure depth; three-dimensional communication structures are formed among pores of the three-dimensional porousmaterial, wherein the communication porosity is 50-99%, and the pore diameter is 0.1-20 mm; a specific composite structure layer is adopted, therefore, the shrinkage caused by cooling is relatively small, and relatively small temperature stress is generated to avoid temperature cracks; meanwhile, through interaction of different structural layers of all the layers, mutual tensile stress exists among all the layers, and fatigue cracking can be relieved by combining with use of specific functional materials; and the steel slag semi-flexible composite pavement has excellent high-temperature stability, low-temperature crack resistance, fatigue durability and water stability.

Owner:河北迁曹高速公路开发有限公司 +1

Prefabricating construction method of steel and superhigh performance concrete combined beam of steel rib plate type bridge floor

ActiveCN107447676AHigh strengthIncreased durabilityMouldsBridge erection/assemblyStress concentrationUltimate tensile strength

The invention relates to the technical field of combined beams, in particular to a prefabricating construction method of a steel and superhigh performance concrete combined beam of a steel rib plate type bridge floor. The method includes the following steps of firstly, machining, manufacturing and installing a steel main beam; secondly, machining and installing a zigzag-form steel plate; thirdly, pouring a superhigh performance concrete bridge floor plate; fourthly, curing superhigh performance concrete, drawing out an air bag or a foam plate before high-temperature curing and after superhigh performance concrete reaches the demolding strength; fifthly, installing a combined bridge floor plate; sixthly, connecting transverse seams of the combined bridge floor plate; seventhly, constructing a fence or an anti-collision wall; eighthly, paving the constructed bridge floor. The combined beam formed through the prefabricating construction method can effectively reduce the stress concentration degree of a fatigue sensitive part and improve the fatigue performance of the orthotropic steel bridge floor plate.

Owner:FUZHOU UNIV

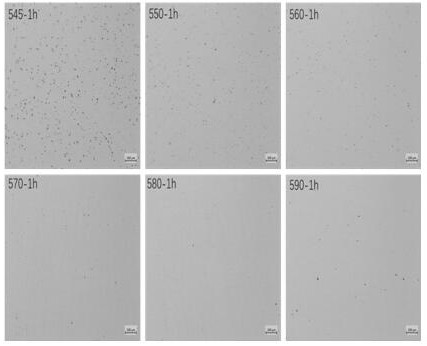

Anti-fatigue and corrosion-resistant forged Al-Mg-Si-Zr aluminum alloy wheel and preparation method thereof

PendingCN114875281AImprove fatigue resistanceHigh hardnessSpecial tyresMetallic material coating processesAlloy wheelCorrosion resistant

The invention belongs to the technical field of forged aluminum alloy, and particularly relates to an anti-fatigue and corrosion-resistant forged Al-Mg-Si-Zr aluminum alloy wheel and a preparation method thereof. The aluminum alloy wheel is composed of Si, Mg, Cu, Fe, Mn, Cr, Ti, Zr and the balance Al. The aluminum alloy material is forged by optimizing alloy components, carrying out graded homogenization treatment on a cast rod and adopting an optimized aluminum rod heating process and a solid solution and aging process after die forging, the fatigue performance can be circulated for about 7 * 107 weeks under the pressure of 200 Mpa, and the stripping corrosion resistance reaches the PA level. In addition, the tumbling process and the surface treatment process are added, the fatigue resistance and the corrosion resistance of the aluminum alloy wheel are further enhanced, the requirement of a wheel biaxial fatigue test is met, and the requirement of an international first-class main engine plant is met.

Owner:山东骏程金属科技有限公司 +1

An impact-resistant road roller steel wheel excitation structure

PendingCN109853336AImprove reliabilityIncrease contact areaRoads maintainenceEngineeringElectrical and Electronics engineering

The invention discloses an impact-resistant road roller steel wheel excitation structure. A group of excitation structures comprises two fixed eccentric blocks and a movable eccentric block which arearranged on a rotatable excitation shaft in a sleeving manner; the fixed eccentric blocks are fixedly connected with the excitation shaft; the movable eccentric block can relatively rotate around theexcitation shaft; at least one of the opposite faces of the two fixed eccentric blocks is provided with a boss limiting structure capable of limiting the position of the movable eccentric block; the side face, facing the face of the movable eccentric block, of the boss limiting structure forms two limiting faces, and when the large vibration limiting face makes surface contact with one side face of the movable eccentric block, the fixed eccentric blocks and the movable eccentric block are overlapped. When the small vibration limiting face makes contact with the other side face of the movable eccentric block, the fixed eccentric block and the movable eccentric block are located on two opposite faces of the excitation shaft respectively. The limiting structure and the fixed eccentric blocksare integrally formed, a large contact area is provided for the movable eccentric block, the contact stress of the contact surface is reduced, and repeated impact of the movable eccentric block can beborne.

Owner:XCMG CONSTR MACHINERY

A kind of chemically modified hard asphalt and its preparation method

ActiveCN104559232BImprove low temperature performanceHigh viscosityBuilding insulationsPolymer scienceCrack resistance

The invention discloses chemically-modified hard asphalt and a preparation method thereof. The chemically-modified hard asphalt comprises the following components in parts by weight: 100 parts of basic asphalt, 0.5-3.0 parts of polyphosphoric acid, 2-12 parts of ductility increasing agent mother liquor and 0.2-0.4 part of a surfactant. The preparation method comprises the following steps: adding polyphosphoric acid into the melted basic asphalt for chemically-modified reaction, then adding the ductility increasing agent mother liquor for further reaction, and finally adding the surfactant for further reaction for a period of time to prepare the chemically-modified hard asphalt. The whole process is implemented under a high-speed stirring condition. The chemically-modified hard asphalt prepared by the preparation method disclosed by the invention is high in flow resistance, high in softening point, high in low-temperature ductility, high in bonding property with aggregate, and excellent in high temperature stability, low temperature cracking resistance, fatigue resistance and water invasion resistance; the chemically-modified hard asphalt is particularly suitable for areas with high temperature, wet areas and areas with large diurnal temperature difference and can be used for paving a pavement of a traffic road, so that common pavement damage phenomena such pavement rutting, upheaval, fatigue cracking, low-temperature cracking and water invasion of the pavement are effectively prevented, and the service life of the pavement is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

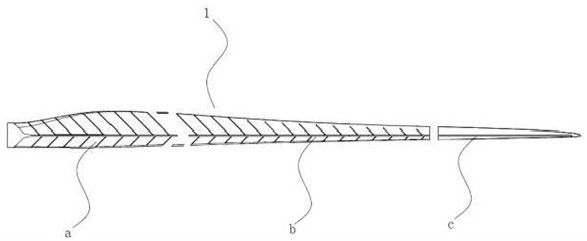

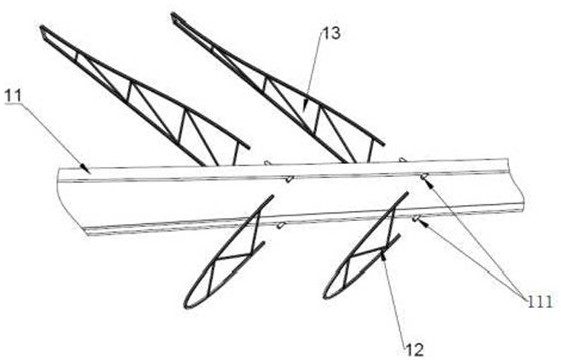

Truss type modular wind power blade

ActiveCN113775471AImprove stabilityGuaranteed safe operationFinal product manufactureMachines/enginesEngineeringFront edge

The invention relates to the technical field of wind power generation equipment, in particular to a truss type modular wind power blade. The truss type modular wind power blade comprises a blade truss frame, a front edge shell module and a rear edge shell module; the blade truss frame comprises a main beam, a plurality of front edge supporting trusses and a plurality of rear edge supporting trusses, the front edge supporting trusses and the rear edge supporting trusses are distributed in the length direction of the main beam in a staggered mode, and rear edge beams and rear edge small I-shaped beams are arranged on the corresponding sides of the rear edge trusses; the front edge shell module comprises PS front edge shells arranged on the windward sides of the front edge supporting trusses and SS front edge shells arranged on the leeward sides of the front edge supporting trusses; and the rear edge shell module comprises PS rear edge shells arranged on the windward sides of the rear edge supporting frames and SS rear edge shells arranged on the leeward sides of the rear edge supporting frames. The front and rear edge shell modules are connected with the main beam through the front and rear edge supporting trusses, the front and rear edge supporting trusses and the main beam are designed to form a certain angle, internal force borne by the main beam is transmitted to the trusses and released to the front edge and the rear edge, finally, the force is transmitted to the blade root, an overall stable structure is formed, and the overall stability of the wind power blade is improved.

Owner:NEWTECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com