Vehicle pneumatic tires with cap/base tread

A technology for pneumatic vehicles and pneumatic vehicles, applied in the direction of tire tread/tread pattern, special tires, tire parts, etc., which can solve problems such as wear, affecting wet adhesion, dry adhesion, and changing properties of cured mixtures , to achieve the effect of improving thermal conductivity, improving thermal conductivity and good tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

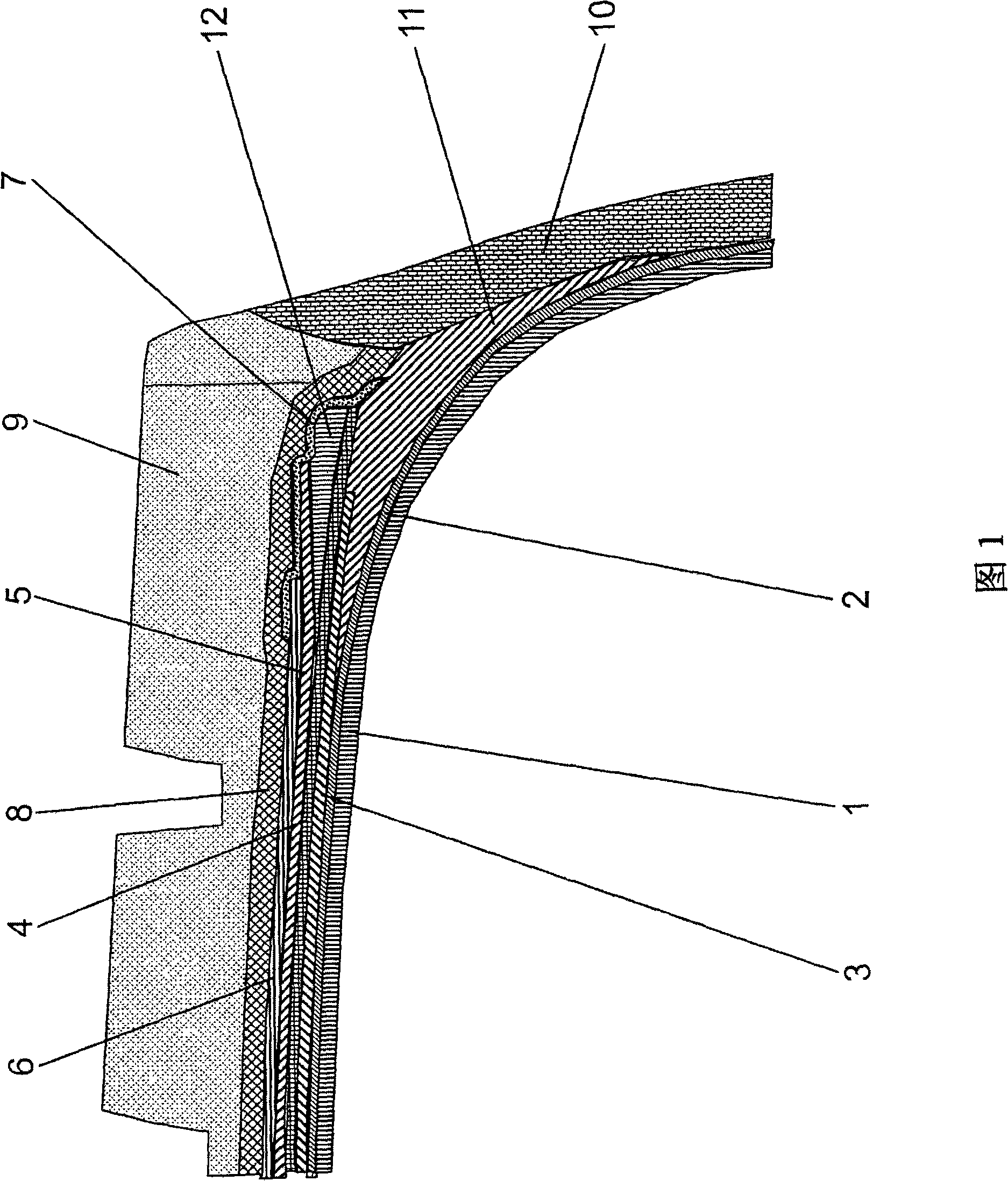

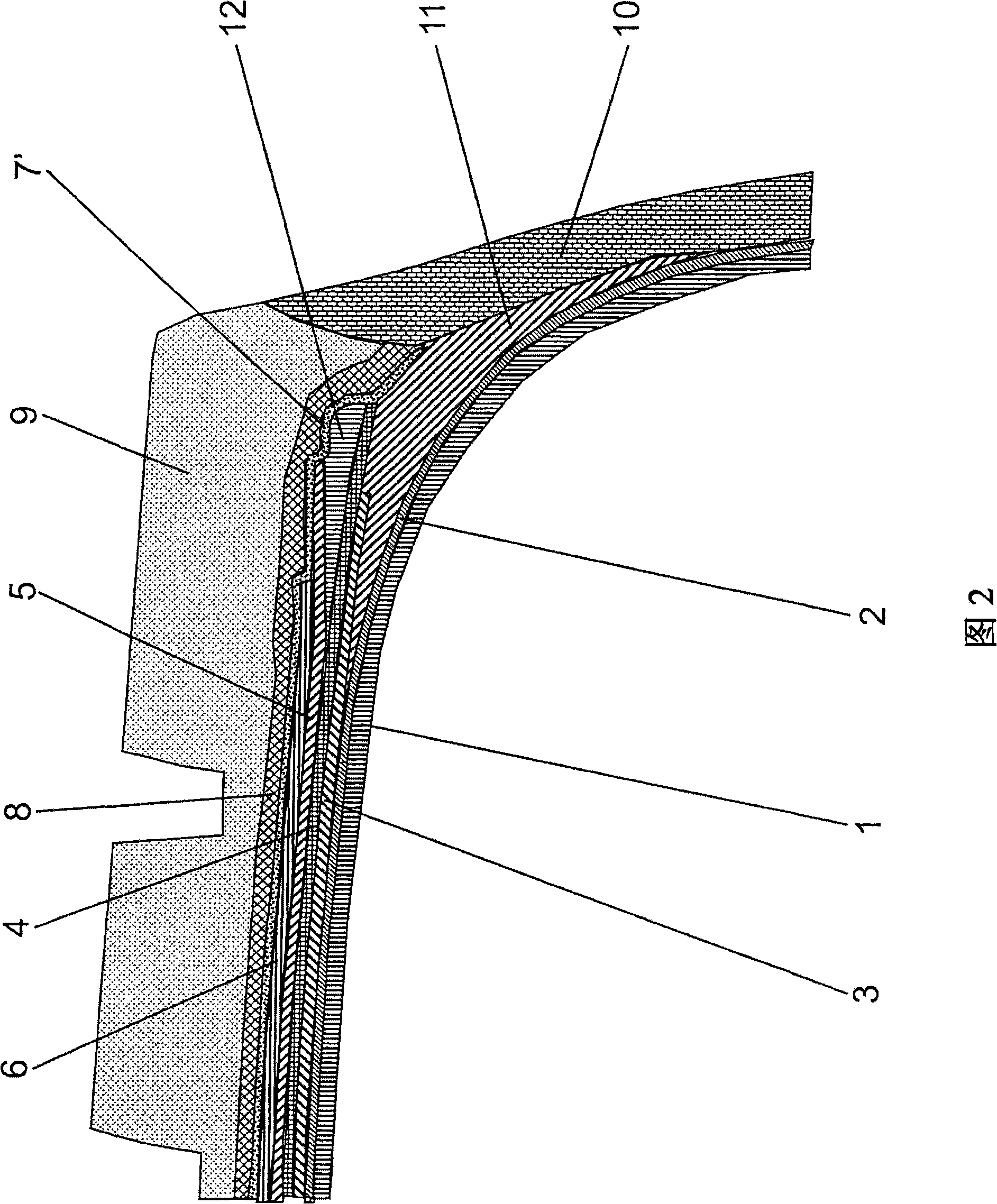

[0018] The figure shows a section through one of the upper sidewall regions of a tire for commercial vehicles and in the region of the tread rubber adjacent thereto. The conventional tire components illustrated have a standard construction, for example, a frame insert 2 specially equipped with steel cords as reinforcing elements, an airtight inner layer 1, a breaker belt assembly comprising four plies 3, 4, 5 and 6, and side wall 10. Shoulder pads 11 are fitted between the cushioning strap assembly, frame insert 2 and side walls 10 . The tread rubber comprises a tread rubber cap 9 and a tread rubber base 8; the edges of the breaker plies 4, 5 and 6 are covered by a layer of undertread rubber 7 (Fig. 1) or 7' (Fig. 2). The tire components not shown, such as the bead regions, can be constructed in known manner.

[0019] In the case of the illustrated embodiment, this fourth, radially outermost breaker ply 6 has the smallest width of all the plies and is the so-called protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com