Novel high viscosity asphalt and preparation method thereof

A technology of high-viscosity asphalt and asphalt, which is applied in the field of petroleum asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

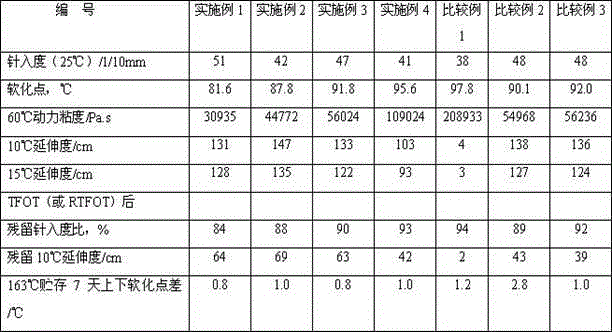

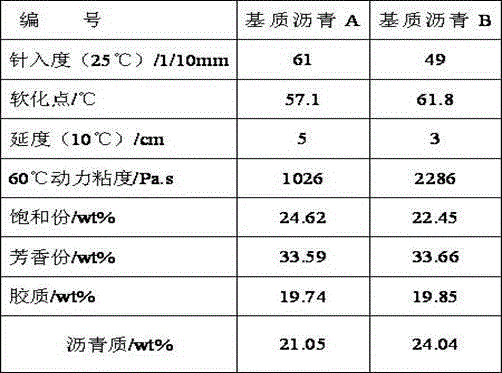

[0030] Heat the base asphalt A to 150°C until it is molten and flowing, take 100 parts of the base asphalt and send it into the reaction tank, start the agitator, keep the temperature of the reaction tank at 160°C, and add 0.3 parts of polyphosphoric acid into the reaction tank , reacted for 70 minutes at a stirring speed of 2000 rpm, then added 3.0 parts of extender mother liquor, continued high-speed stirring for 60 minutes, and finally added 2.0 parts of vinylbisstearamide (EBS) and 0.3 parts of silane coupling Agent KH-560 was stirred and reacted for 30 minutes to obtain the high-viscosity bitumen of the present invention. The basic properties of the product are shown in Table 2.

Embodiment 2

[0032] Heat base asphalt B to 150°C until it is molten and flowing, take 100 parts of base asphalt and send it into the reaction tank, start the agitator, keep the temperature of the reaction tank at 160°C, add 0.6 parts of polyphosphoric acid into the reaction tank , reacted for 100 minutes at a stirring speed of 2000 rpm, then added 6.0 parts of extender mother liquor, continued high-speed stirring for 60 minutes, and finally added 3.0 parts of vinylbisstearamide (EBS) and 0.2 parts of silane coupling Agent KH-560 was stirred and reacted for 30 minutes to obtain the high-viscosity bitumen of the present invention. The basic properties of the product are shown in Table 2.

Embodiment 3

[0034] Heat the base asphalt A to 150°C until it is molten and flowing, take 100 parts of the base asphalt and send it into the reaction tank, start the agitator, keep the temperature of the reaction tank at 160°C, and add 0.8 parts of polyphosphoric acid into the reaction tank , reacted for 120 minutes at a stirring speed of 2000 rpm, then added 8.0 parts of extender mother liquor, continued high-speed stirring for 60 minutes, then added 0.3 parts of cetyl alcohol, stirred and reacted for 15 minutes, and finally, the reaction tank When the temperature was raised to 165°C, 4.0 parts of vinyl bisstearamide (EBS) and 0.3 parts of silane coupling agent KH-560 were added, and the reaction was stirred for 30 minutes to obtain the high-viscosity bitumen of the present invention. The basic properties of the product are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com