High-chromium-steel supporting roller and preparing method thereof

A backup roll, high-chromium steel technology, used in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of non-conforming strip surface quality, large bandwidth pressure, large loss, etc., to avoid fatigue cracks and spalling. Block drop, toughness and thermal fatigue resistance, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

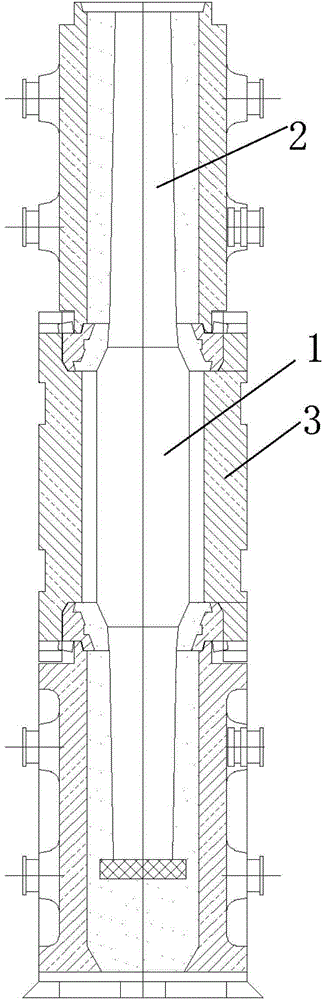

[0025] Figure 1 shows a schematic diagram of casting a high chromium steel backing roll with a centrifugal roll mold. The high chromium steel backing roll includes a roll body 1 at the middle and roll necks 2 at both ends of the roll body 1; the backing roll consists of a core at the center and The outer layer located outside the core; the length of the roll body 1 is 560-1320mm, the outer diameter is 450-750mm; the thickness of the outer layer of the roll body 1 is 20-30mm; the hardness of the roll surface is 50-65HSD; the roll neck 2 is resistant to Tensile strength ≥ 550MPa; roll body 1 matrix structure is a mixture of martensite + granular carbide + a small amount of retained austenite.

[0026] The preparation method of high chromium steel support roll comprises the following steps:

[0027] Step 1: Ingredients: Configure molten steel with high chromium steel on the outer layer of the back-up roll, and its chemical composition weight percentage is: C: 1.20-1.50, Si: 0.30-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com