Prefabricating construction method of steel and superhigh performance concrete combined beam of steel rib plate type bridge floor

A technology with ultra-high performance and construction methods, applied in the field of composite beams, can solve problems such as fatigue and increase the cost of steel bridge projects, and achieve the effects of light weight, improved fatigue performance, and reduced stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

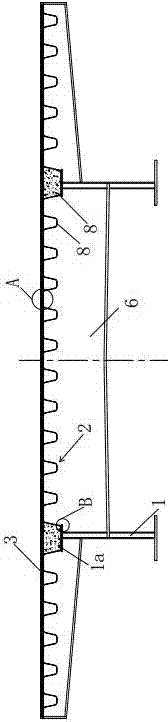

[0034] refer to Figure 1 to Figure 6

[0035] A prefabricated construction method for a steel-ultra high performance concrete composite beam of a steel-ribbed bridge deck, comprising the following steps:

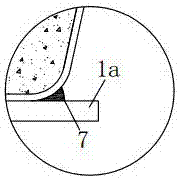

[0036] (1) Processing, manufacturing and installation of the steel main girder: During the construction of the bridge substructure, the processing and manufacturing of the steel main girder 1 is carried out simultaneously. Method for erecting steel girder;

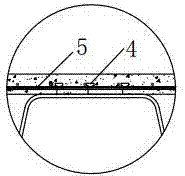

[0037] (2) Folded steel plate processing: process the folded steel plate according to the design size, and weld the shear connector 4 on the upper edge (wave crest) of the folded steel plate 2;

[0038](3) Pouring ultra-high-performance concrete bridge deck: ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com