Internal combustion engine aluminum piston with reinforced pin hole and preparation method of internal combustion engine aluminum piston

A technology for internal combustion engines and pistons, which is applied in the direction of pistons, mechanical equipment, engine components, etc., can solve problems such as the shedding of reinforced bushes, and achieve the effects of improving thermal fatigue strength, light weight, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

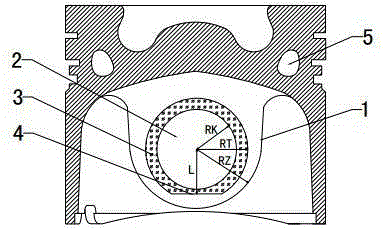

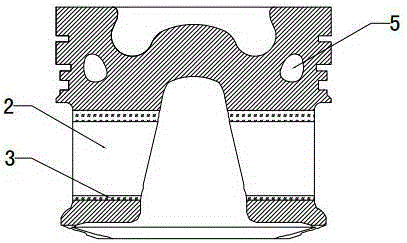

[0029] 1) if figure 1 , 2 According to the shape, size and strength requirements of the piston pin hole 2 and the piston pin seat 1, the ceramic fiber sleeve prefabricated parts are manufactured and processed. Make an installation and positioning plane 4 on the side (piston seam side);

[0030] 2) Process the piston casting mold, process the pins for installing and fixing the prefabricated ceramic fiber sleeve on the mold, and process the positioning platform at the root of the pin corresponding to the positioning plane of the prefabricated ceramic fiber sleeve;

[0031] 3) Install the ceramic fiber sleeve prefabricated part preheated to 880°C on the mold, pour the liquid aluminum alloy at 740°C, after the pouring is completed, add 5bar nitrogen inert gas pressure through the milling riser, so that the liquid aluminum alloy is immersed in the prefabricated The aluminum matrix ceramic fiber reinforced composite material is formed after cooling out of the mold and fully combin...

Embodiment 2

[0035] 1) if figure 1 , 2 According to the shape, size and strength requirements of the piston pin hole 2 and the piston pin seat 1, the ceramic fiber sleeve prefabricated parts are manufactured and processed. Make an installation and positioning plane 4 on the side (piston seam side);

[0036] 2) Process the piston casting mold, process the pins for installing and fixing the prefabricated ceramic fiber sleeve on the mold, and process the positioning platform at the root of the pin corresponding to the positioning plane of the prefabricated ceramic fiber sleeve;

[0037]3) Install the ceramic fiber sleeve prefabricated part preheated to 850°C on the mold, and pour the liquid aluminum alloy at 760°C. After the pouring is completed, add 5bar nitrogen inert gas pressure through the milling riser, so that the liquid aluminum alloy is immersed in the prefabricated The aluminum matrix ceramic fiber reinforced composite material is formed after cooling out of the mold and fully com...

Embodiment 3

[0041] 1) if figure 1 , 2 According to the shape, size and strength requirements of the piston pin hole 2 and the piston pin seat 1, the ceramic fiber sleeve prefabricated part is manufactured and processed. Make an installation and positioning plane 4 on the side (piston seam side);

[0042] 2) Process the piston casting mold, process the pins for installing and fixing the prefabricated ceramic fiber sleeve on the mold, and process the positioning platform at the root of the pin corresponding to the positioning plane of the prefabricated ceramic fiber sleeve;

[0043] 3) Install the ceramic fiber sleeve prefabricated part preheated to 920°C on the mold, and pour the liquid aluminum alloy at 730°C. After the pouring is completed, add 6bar argon inert gas pressure through the milling riser to make the liquid aluminum alloy immerse In the prefabricated part and combined with ceramic fiber material, aluminum matrix ceramic fiber reinforced composite material is formed after coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com