Patents

Literature

397 results about "Area fraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ai-ni-la system ai-based alloy sputtering target and process for producing the same

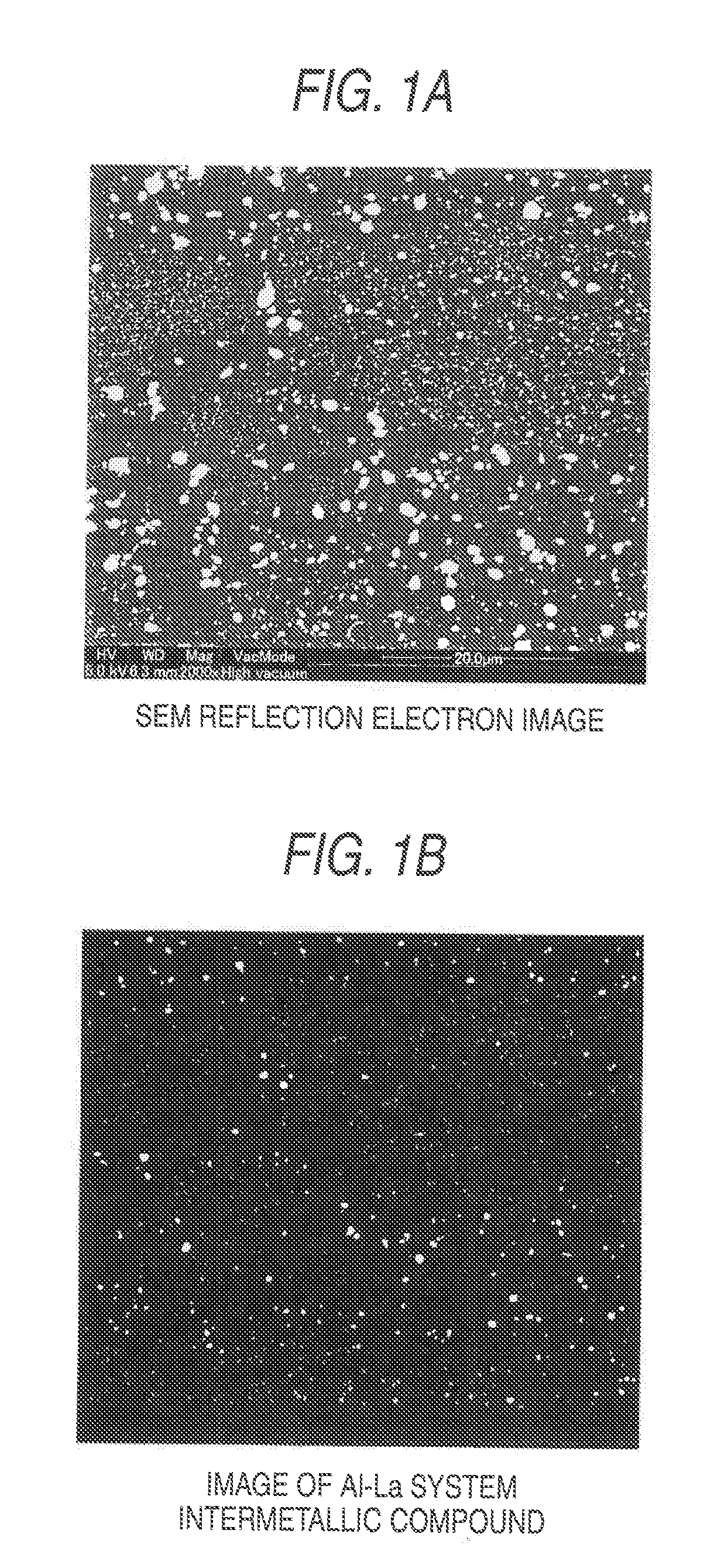

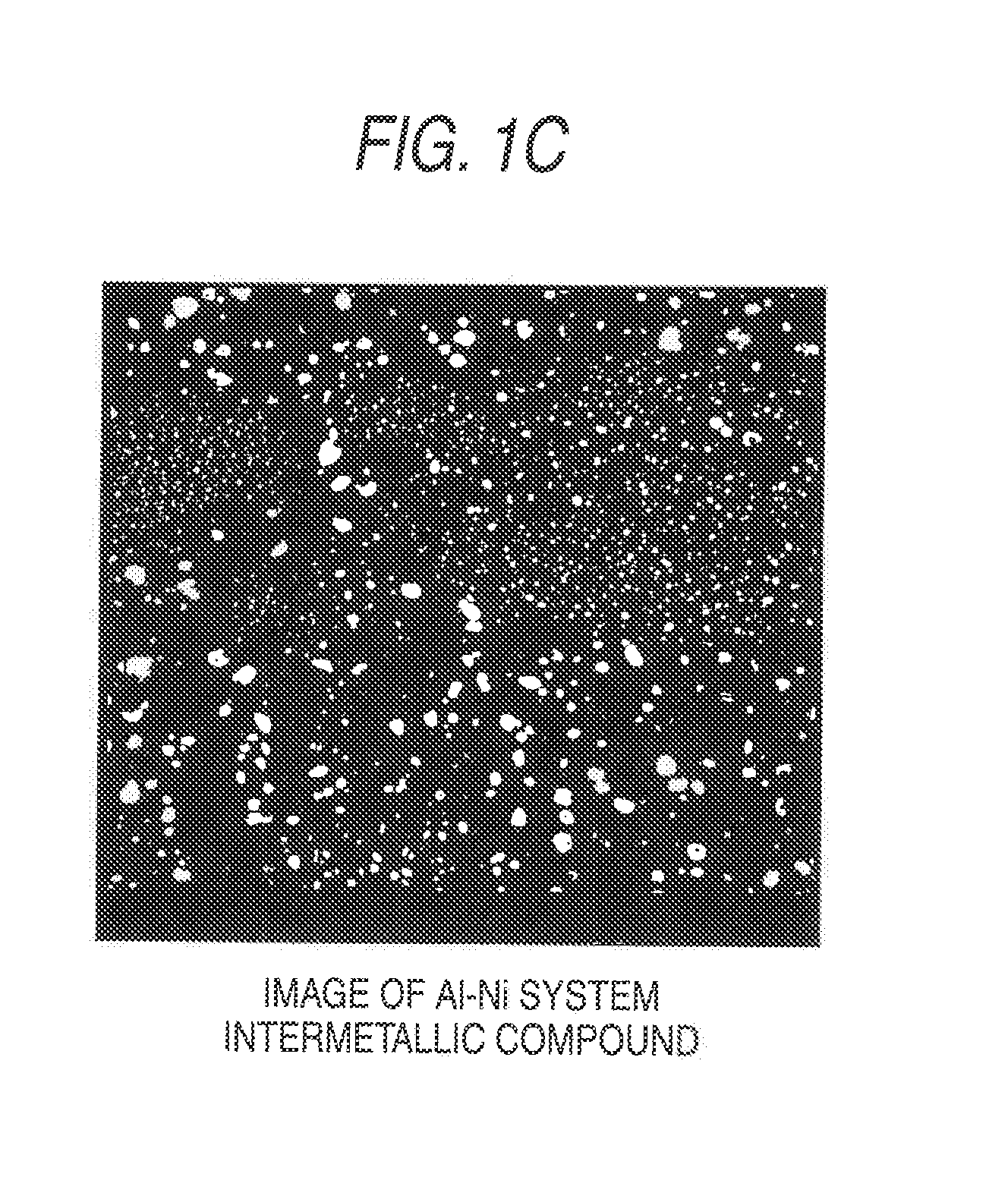

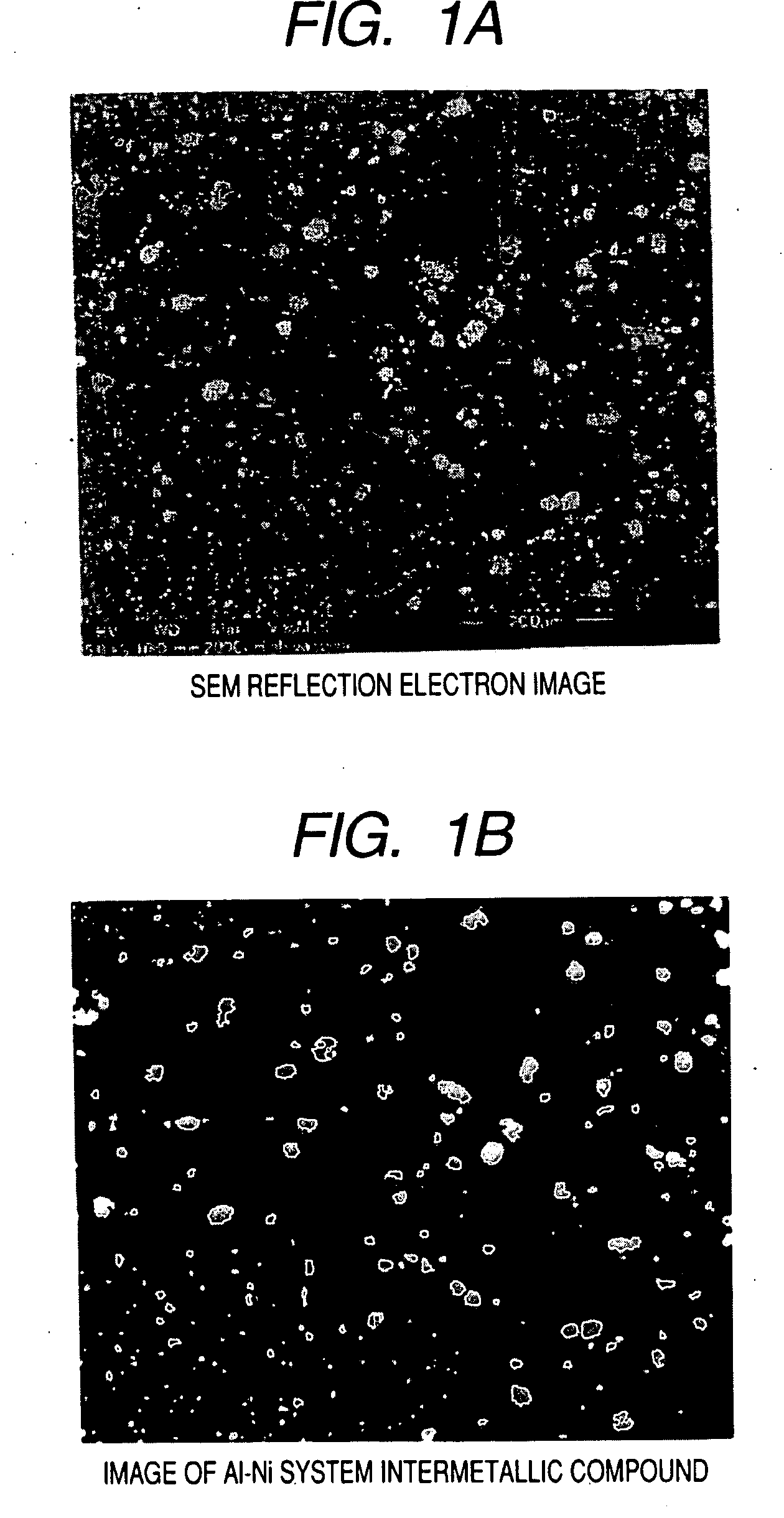

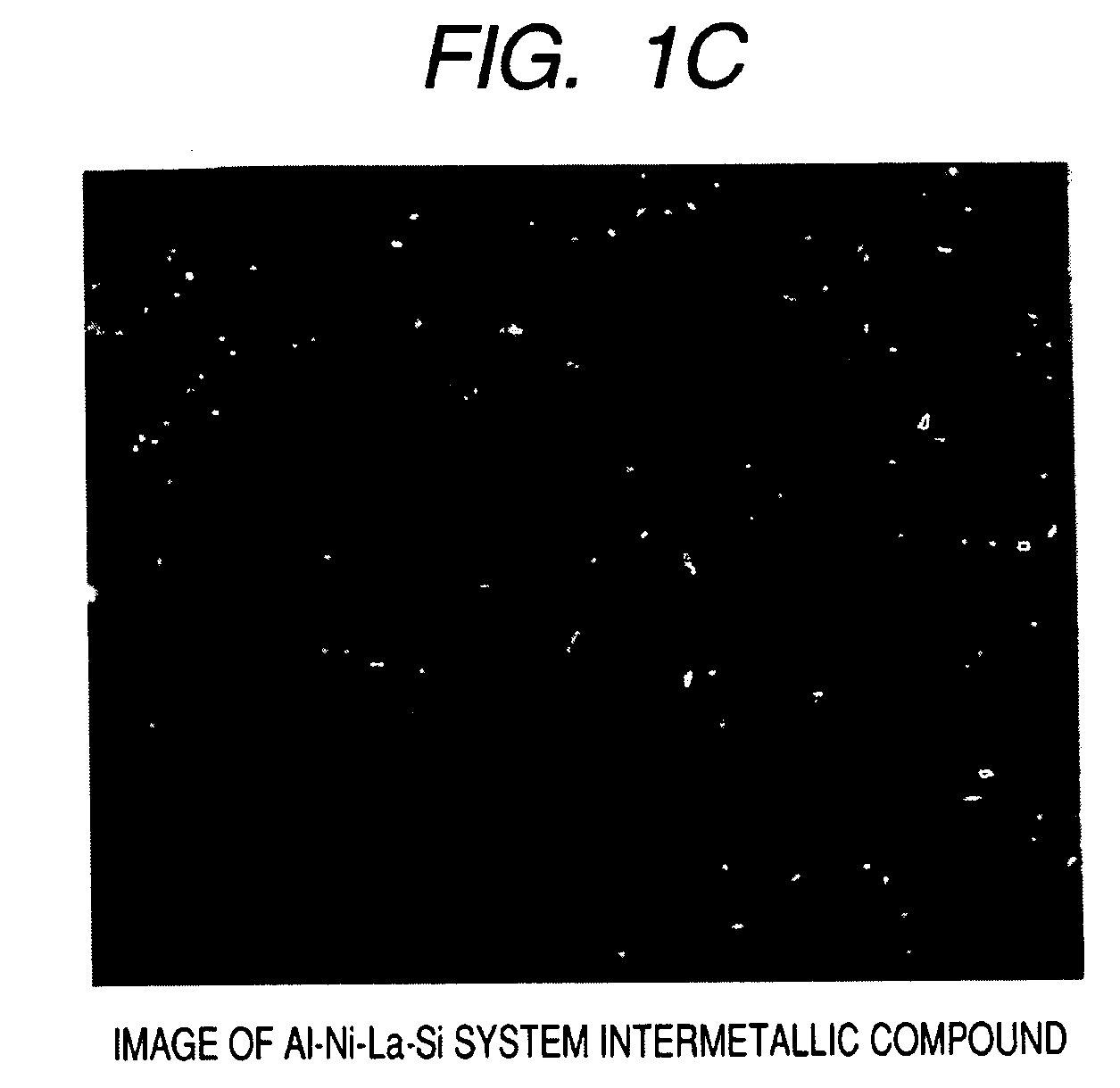

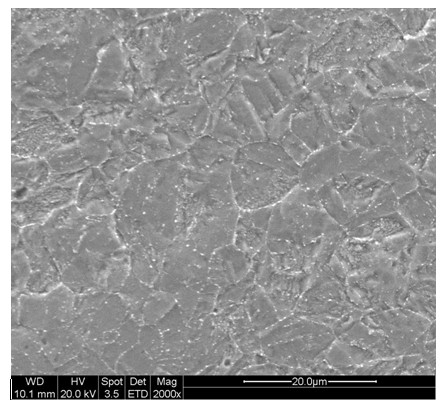

ActiveUS20080121522A1Reduce splashCellsMolten spray coatingScanning electron microscopeMagnification

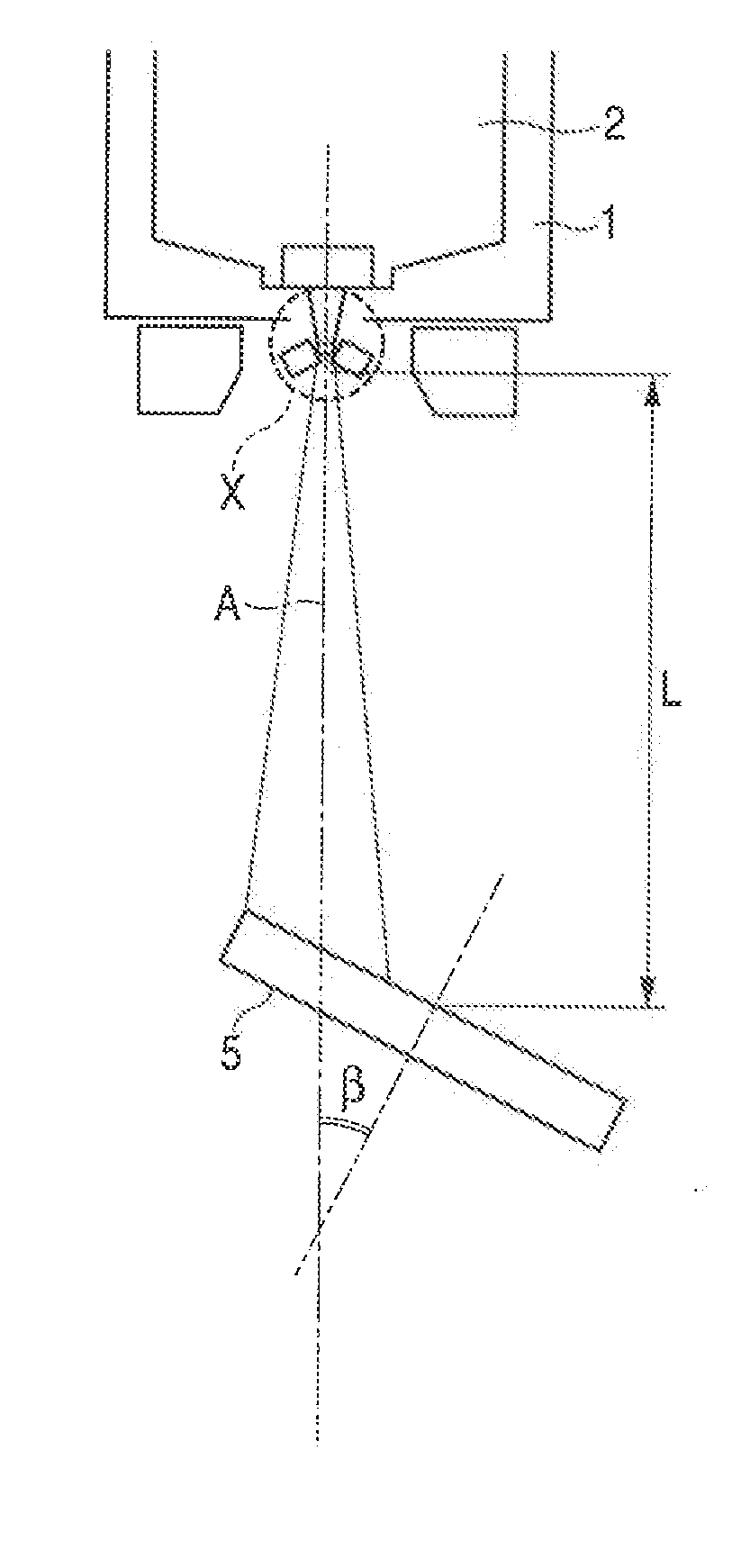

The invention relates to an Al—Ni—La system Al-based alloy sputtering target comprising Ni and La, wherein, when a section from (¼)t to (¾)t (t: thickness) in a cross section vertical to a plane of the sputtering target is observed with a scanning electron microscope at a magnification of 2000 times, (1) a total area of an Al—Ni system intermetallic compound having an average particle diameter of 0.3 μm to 3 μm with respect to a total area of the entire Al—Ni system intermetallic compound is 70% or more in terms of an area fraction, the Al—Ni system intermetallic compound being mainly composed of Al and Ni; and (2) a total area of an Al—La system intermetallic compound having an average particle diameter of 0.2 μm to 2 μm with respect to a total area of the entire Al—La system intermetallic compound is 70% or more in terms of an area fraction, the Al—La system intermetallic compound being mainly composed of Al and La.

Owner:KOBE STEEL LTD +1

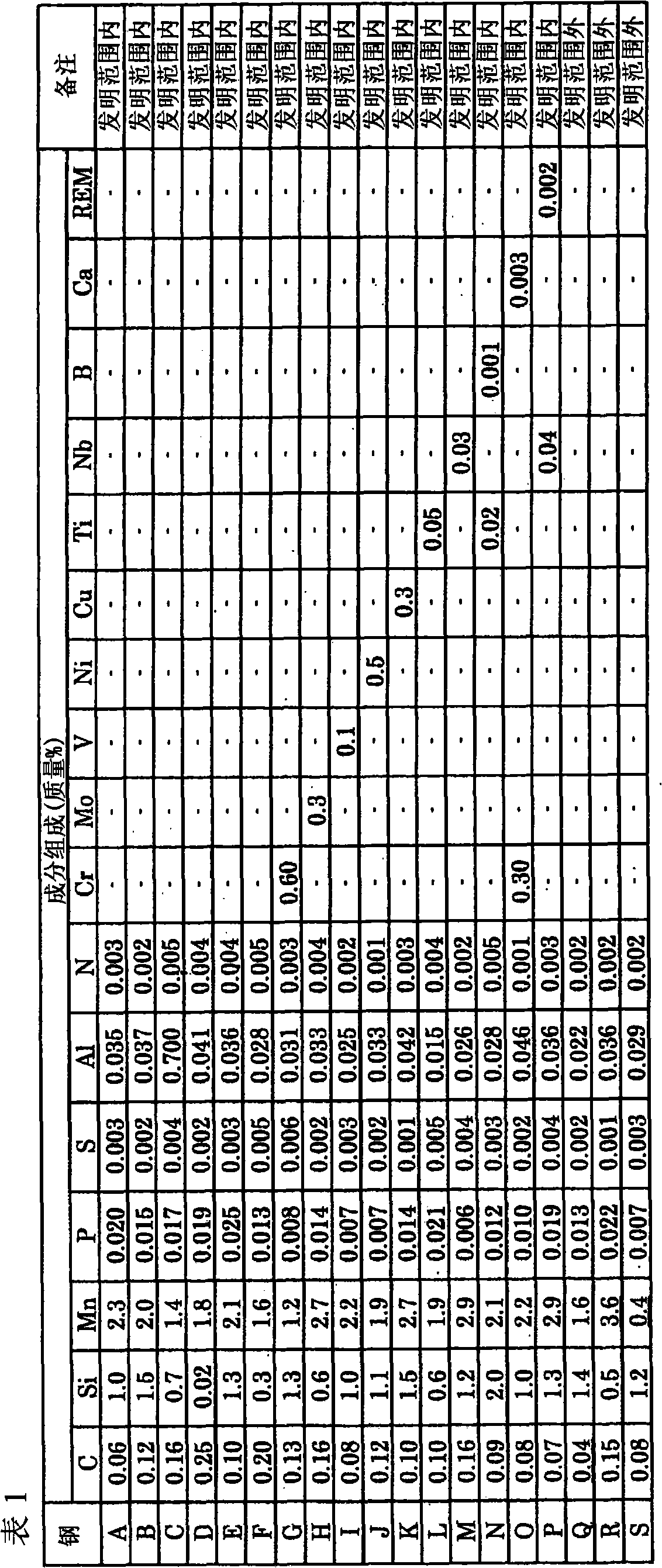

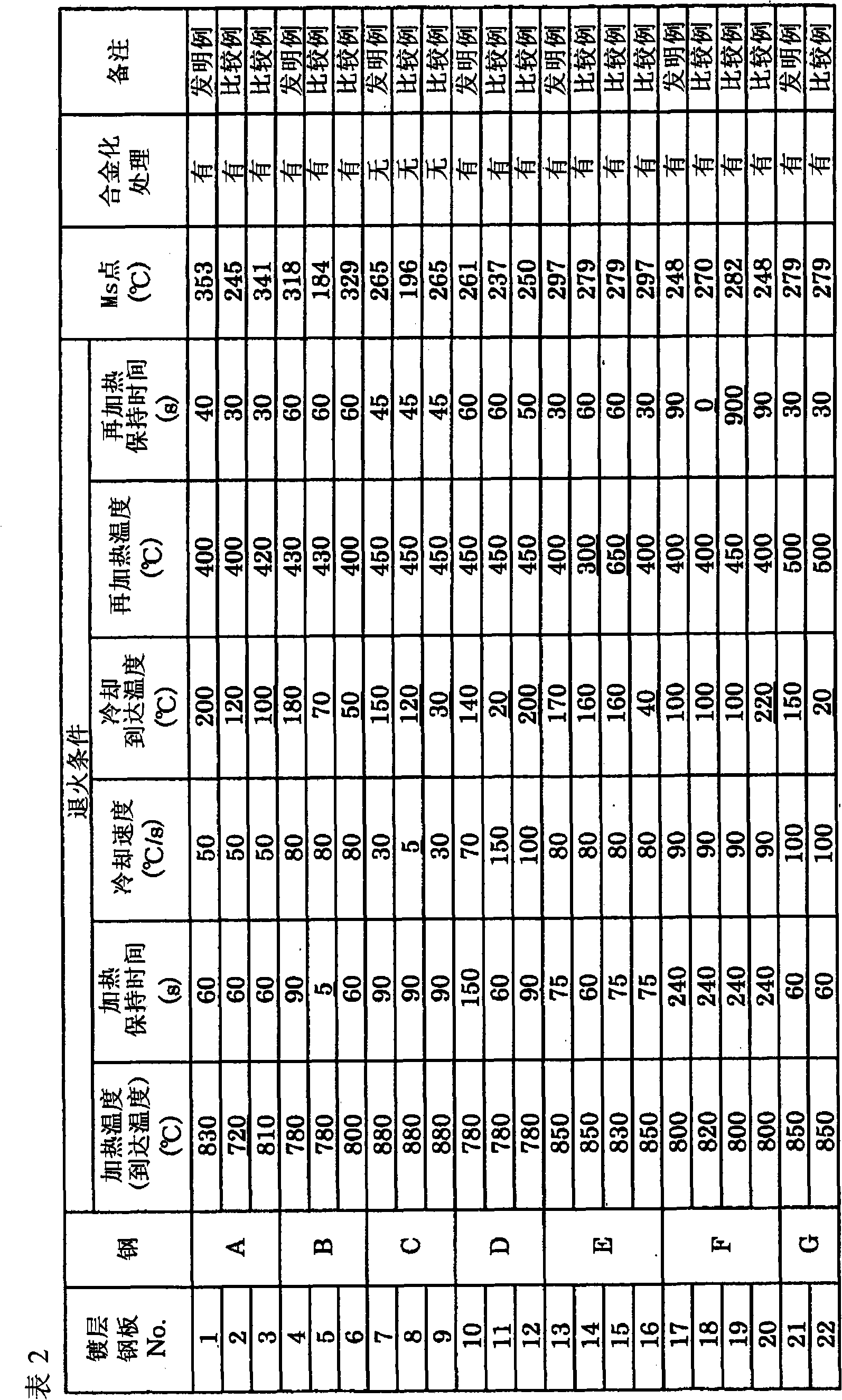

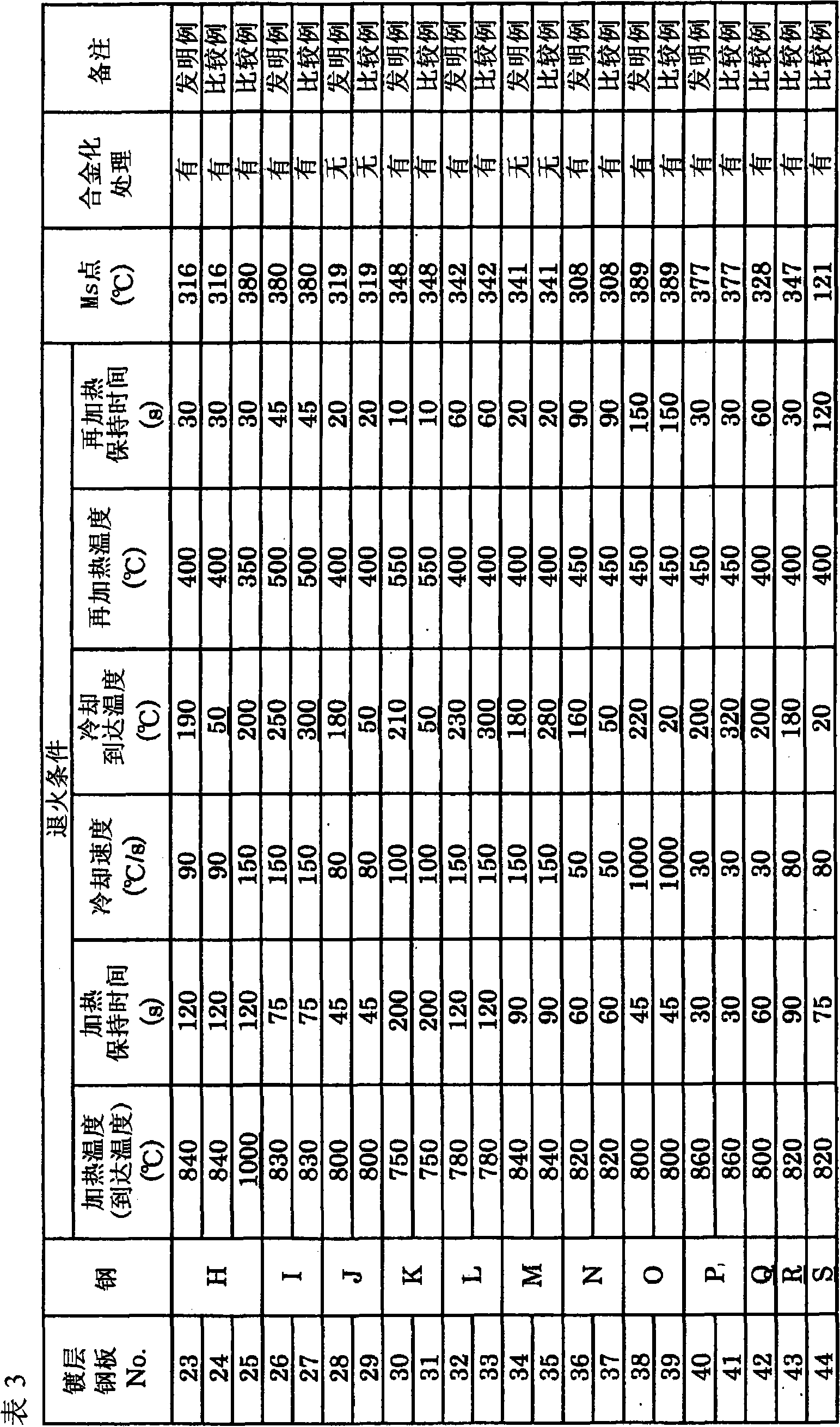

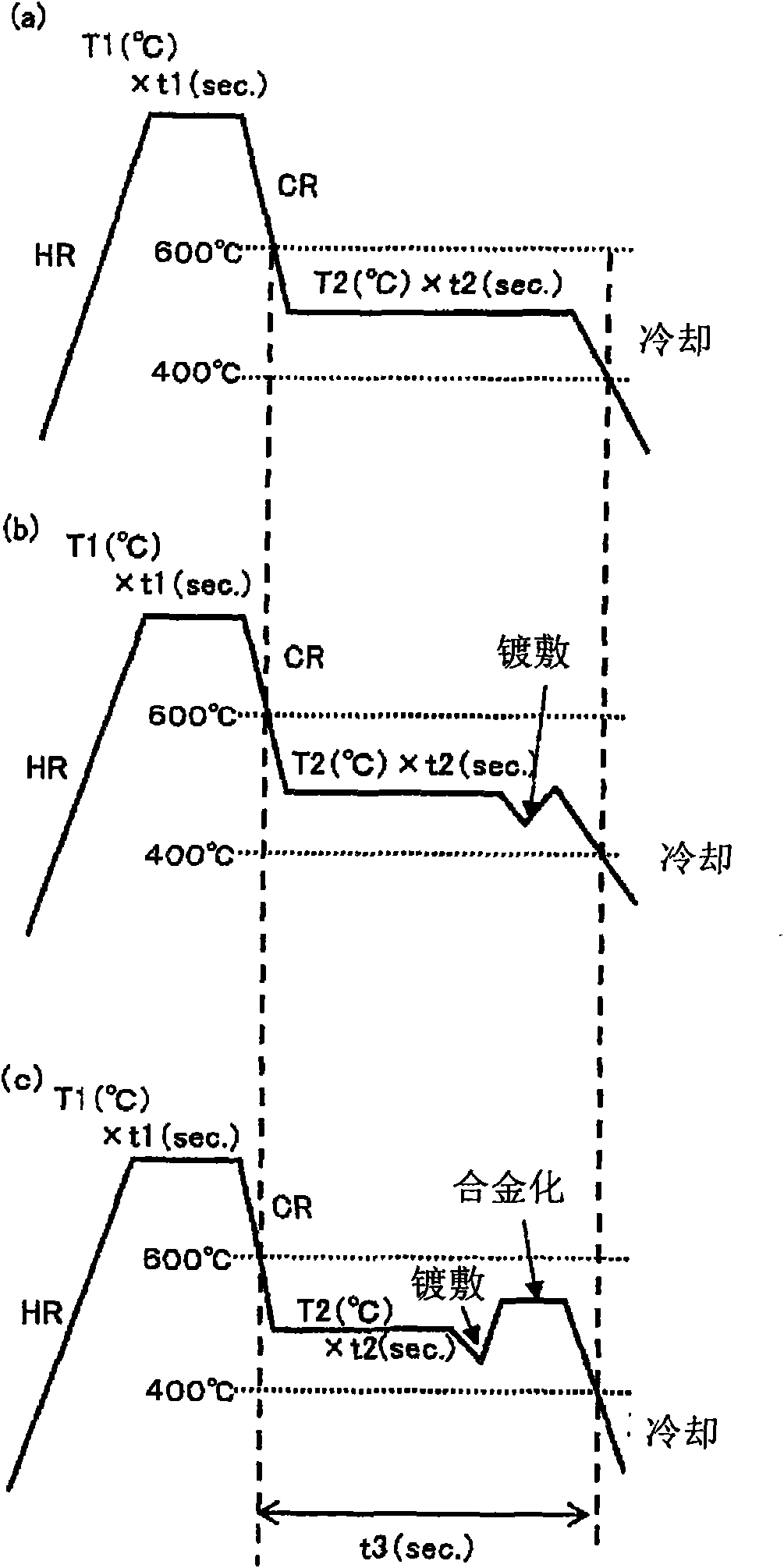

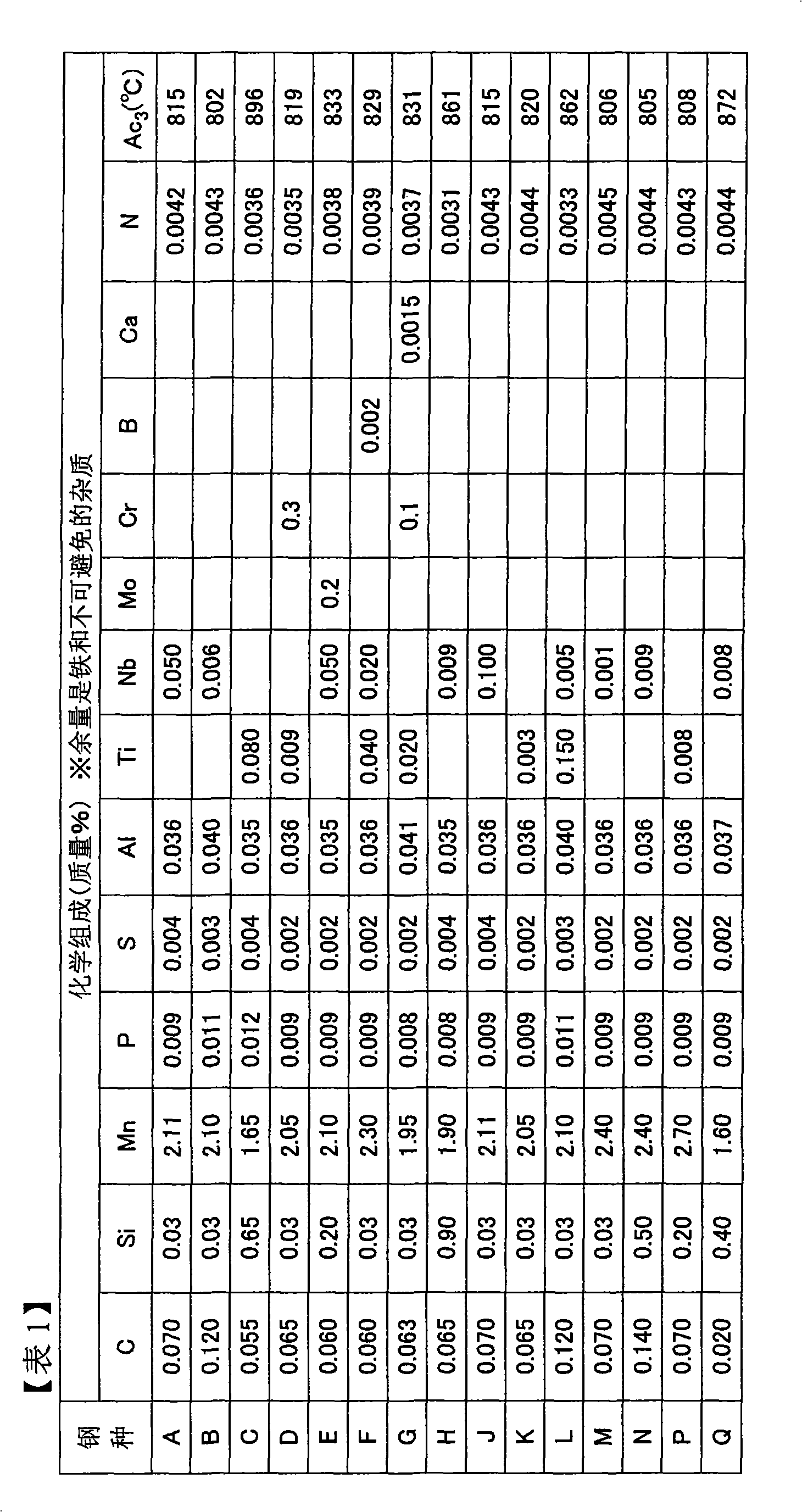

High-strength steel sheet and process for production thereof

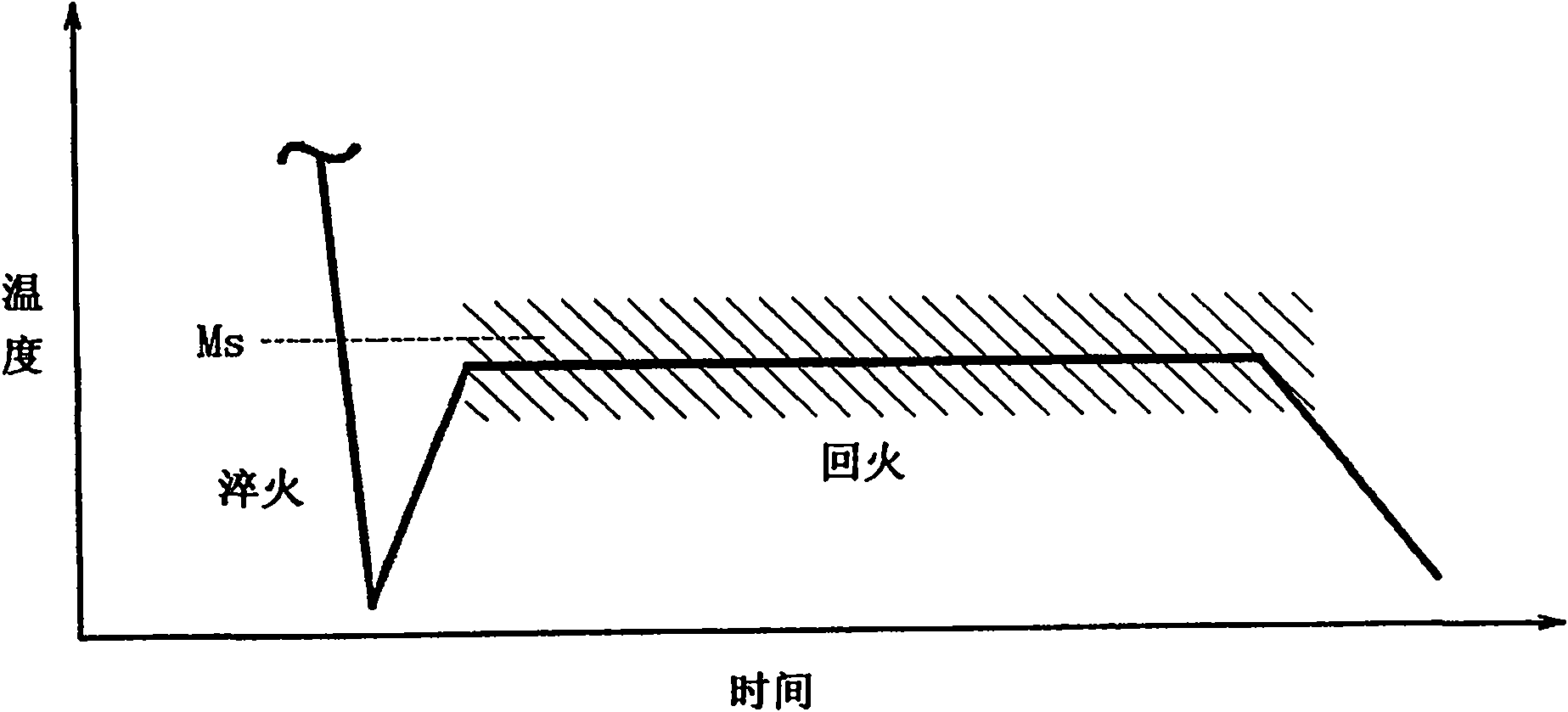

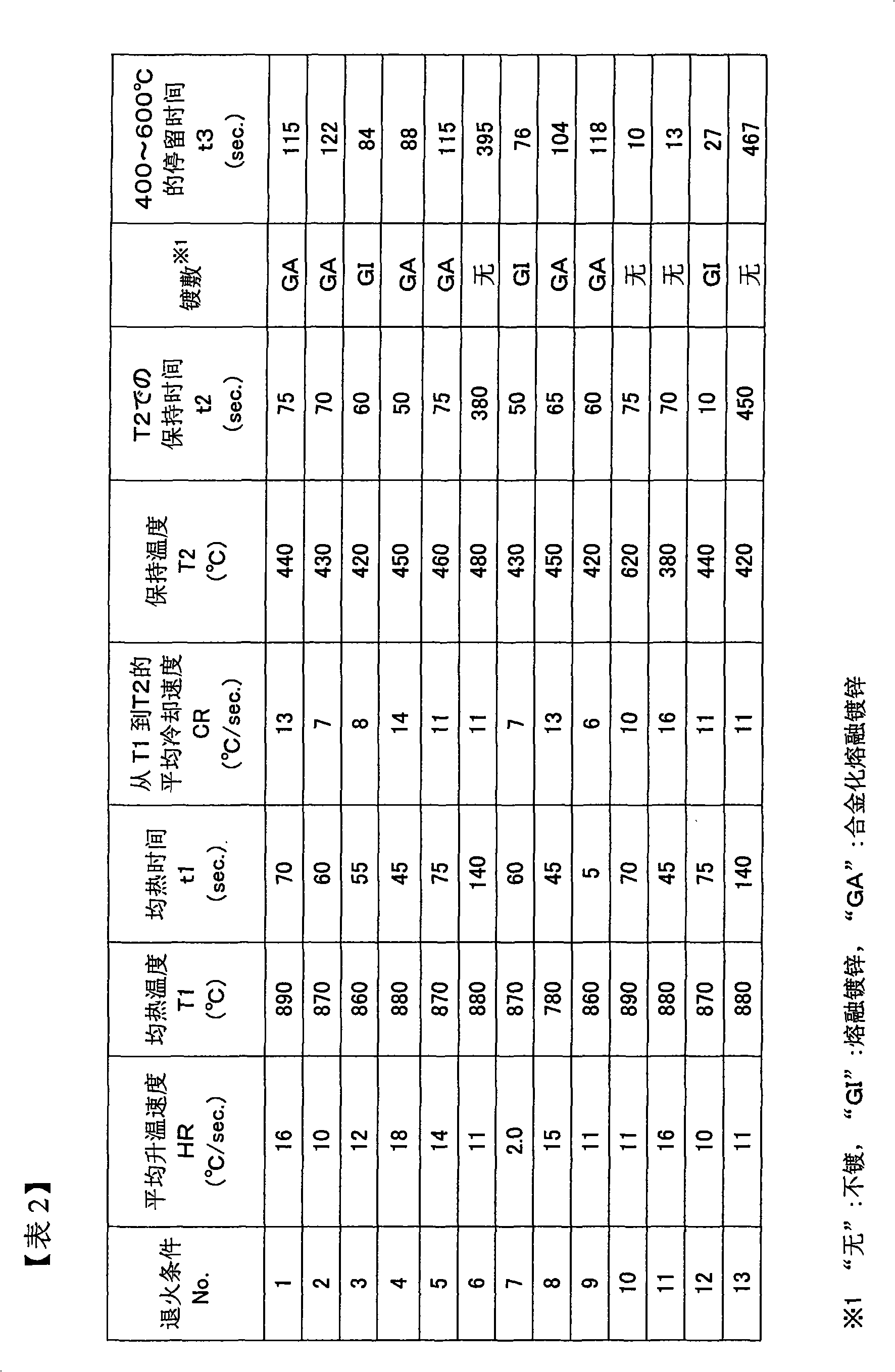

ActiveCN101932745AHigh strengthHelps to reduce weightHot-dipping/immersion processesFurnace typesSheet steelCarbide

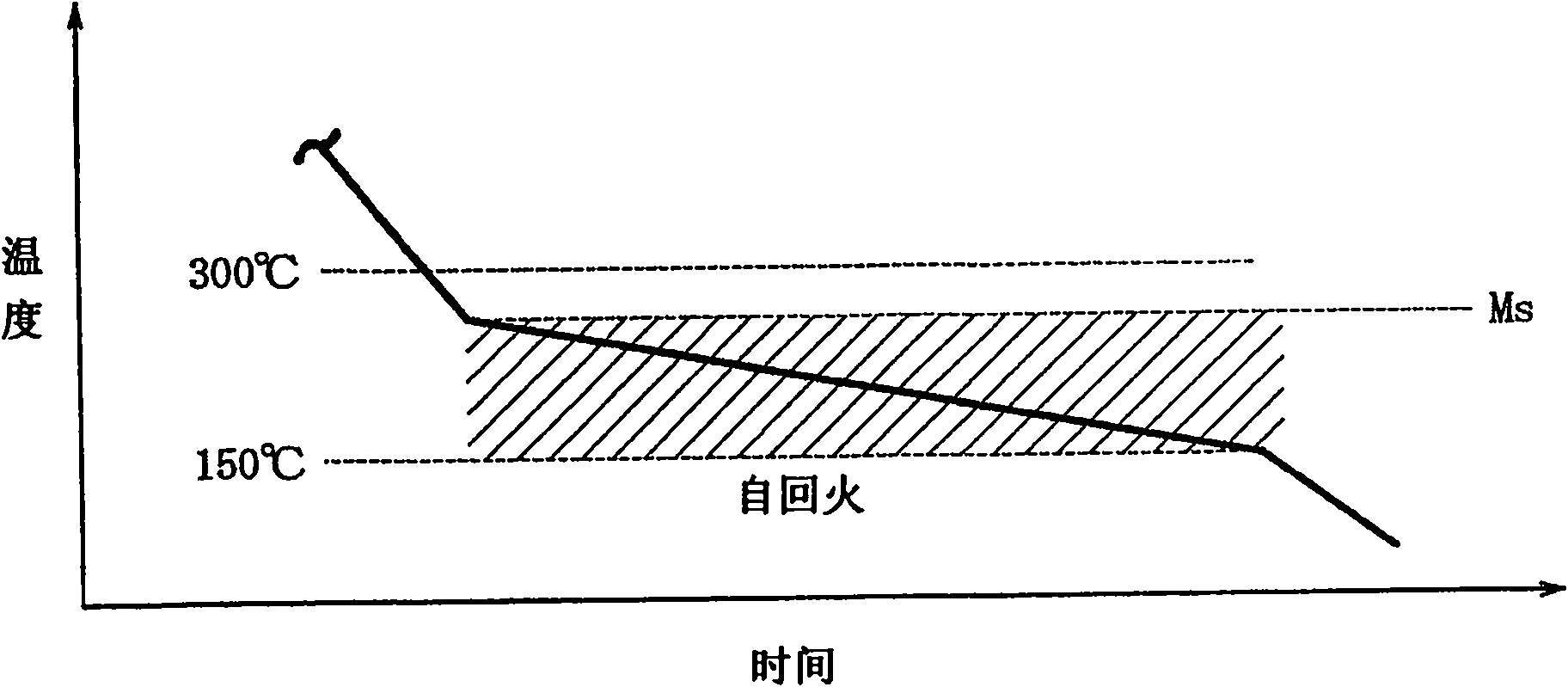

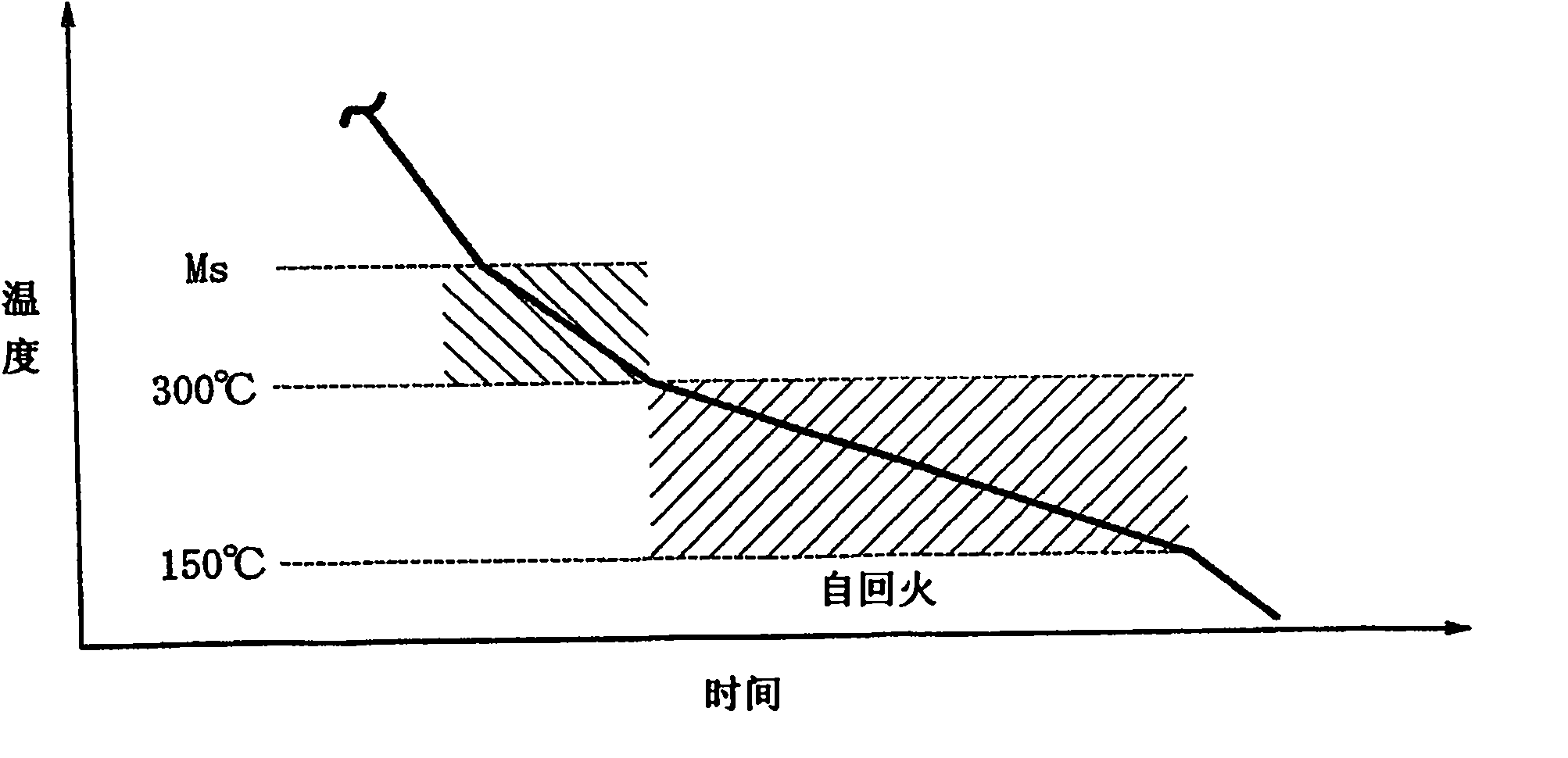

Disclosed are an ultra-high-strength steel sheet having both a tensile strength of as high as 1400MPa or above and excellent formability and an advantageous process for manufacturing the same. A high-strength steel sheet having both a composition which contains by mass C: 0.12 to 0.50%, Si: 2.0% or less, Mn: 1.0 to 5.0%, P: 0.1% or less, S: 0.07% or less, Al: 1.0% or less, and N: 0.008% or less with the balance being Fe and unavoidable impurities, and a structure which comprises, in terms of area fraction, autotempered martensite: 80% or more, ferrite: less than 5%, bainite: 10% or less, and retained austenite: 5% or less and in which the average number of precipitated iron carbide particles of 5nm to 0.5[mu]m in the autotempered martensite is 5OE04 or above per mm2.

Owner:JFE STEEL CORP

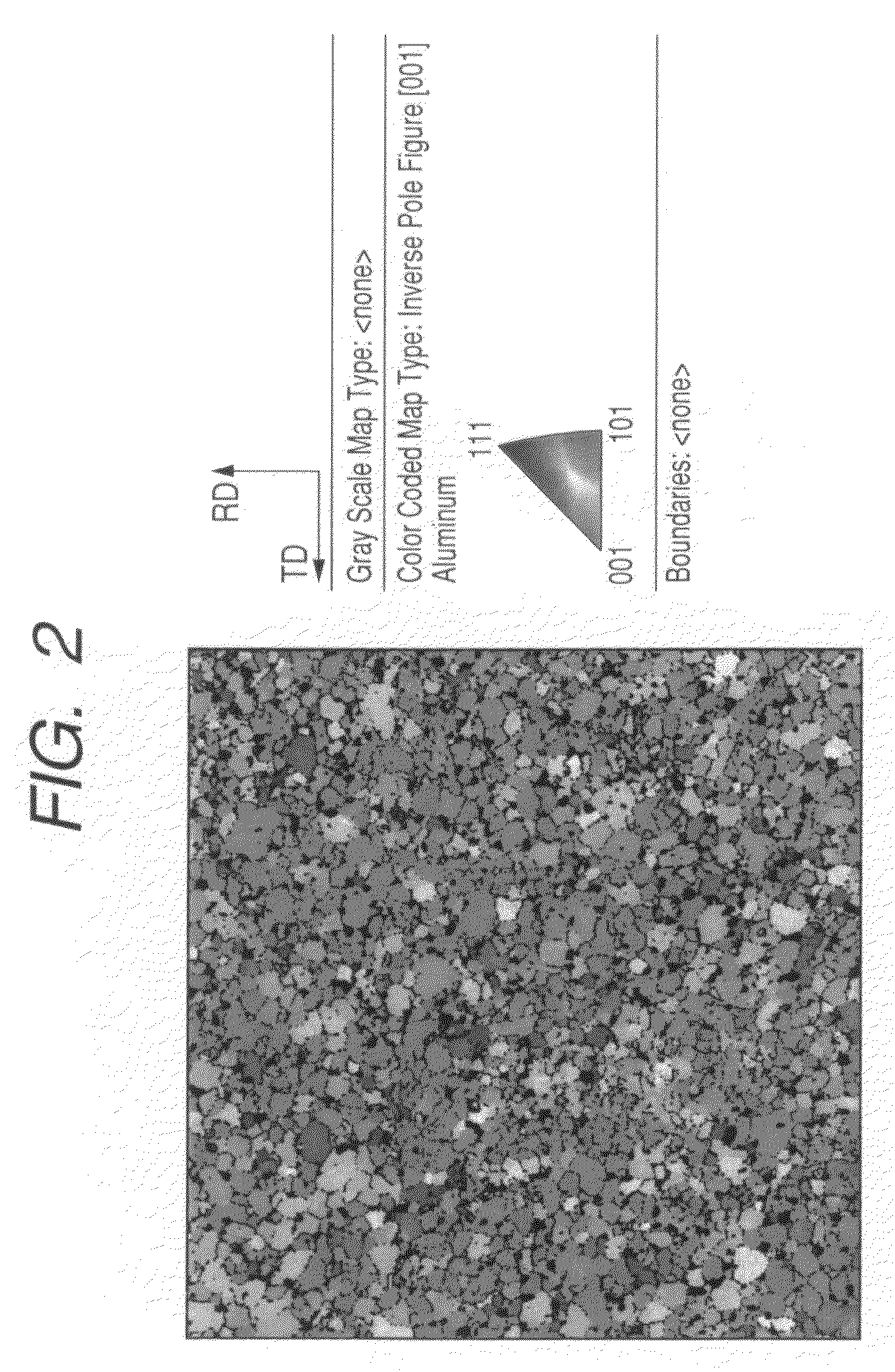

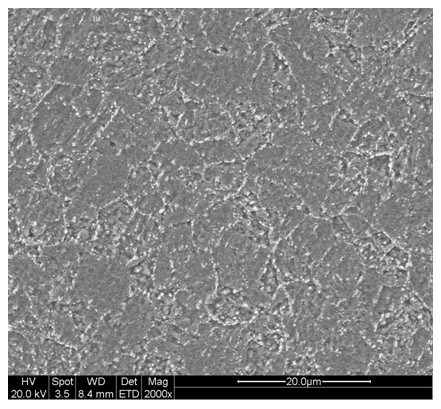

Ai-based alloy sputtering target and process for producing the same

InactiveUS20080223718A1Increase deposition rateSuppress the sputtering defectsCellsSemiconductor/solid-state device detailsSputteringAlloy

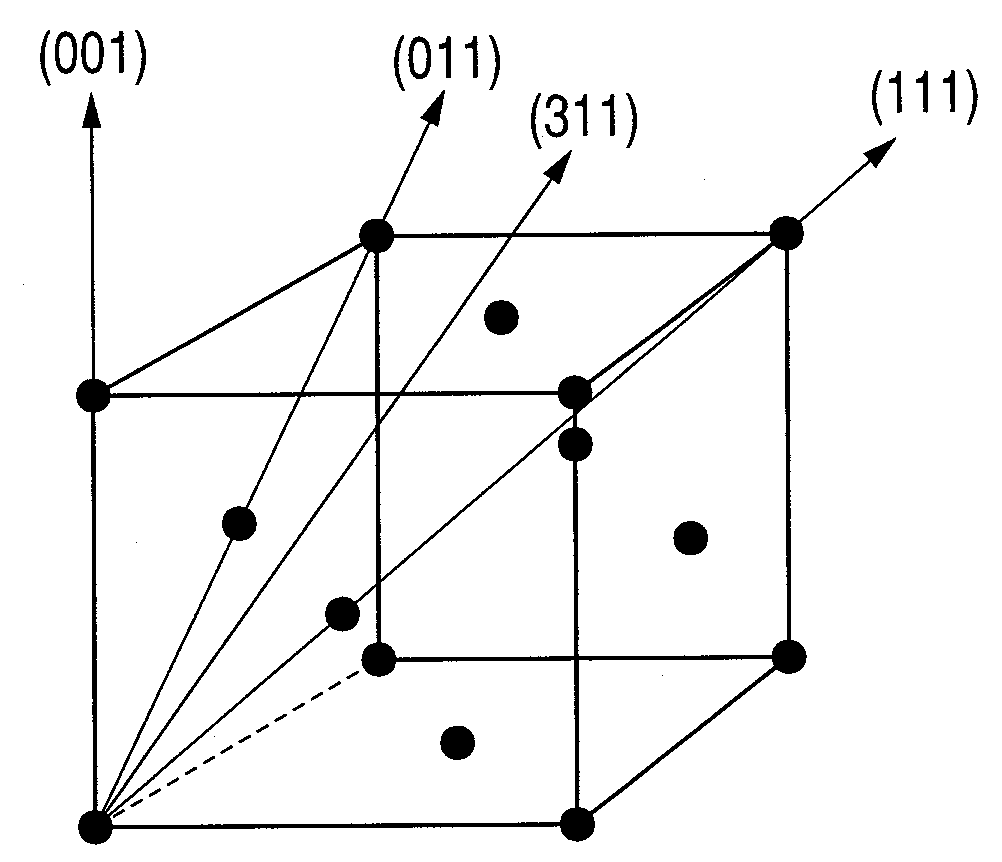

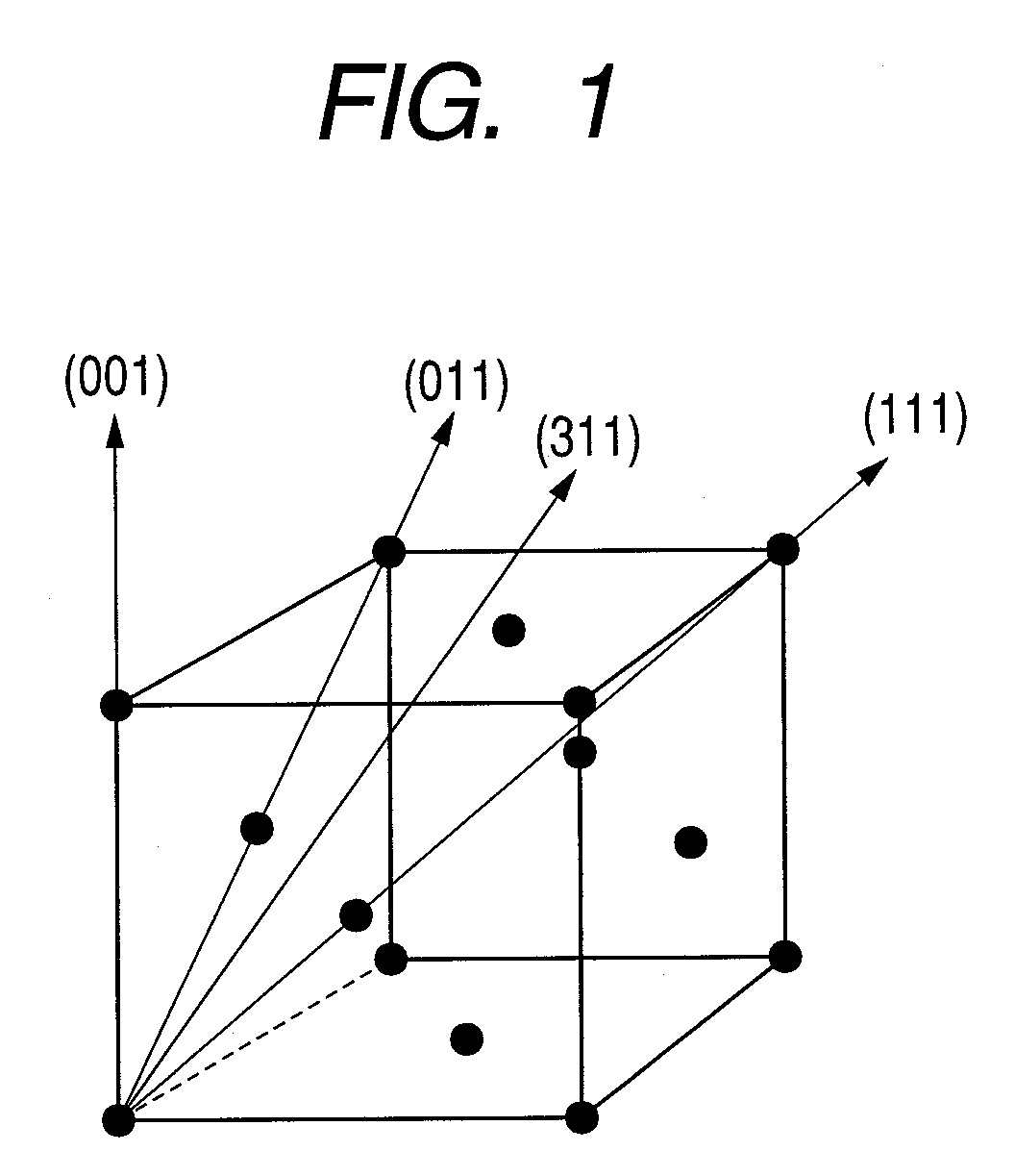

The present invention relates to an Al-based alloy sputtering target, comprising Ni in an amount of 0.05 to 10 atomic percent, wherein the Al-based alloy sputtering target satisfies: (1) that a ratio of a P value to a total area of a sputtering surface is 70% or more, wherein the P value indicates a total of area fractions of <001>±15°, <011>±15°, <111>±15° and <311>±15°; (2) that a ratio of the area fraction of <011>±15° to the P value is 30% or more; and (3) that a ratio of the area fraction of <111>±15° to the P value is 10% or less, when crystallographic orientations <001>, <011>, <111> and <311> in a normal line direction to a sputtering surface of the Al-based alloy sputtering target are observed in accordance with the electron backscatter diffraction pattern method.

Owner:KOBE STEEL LTD +1

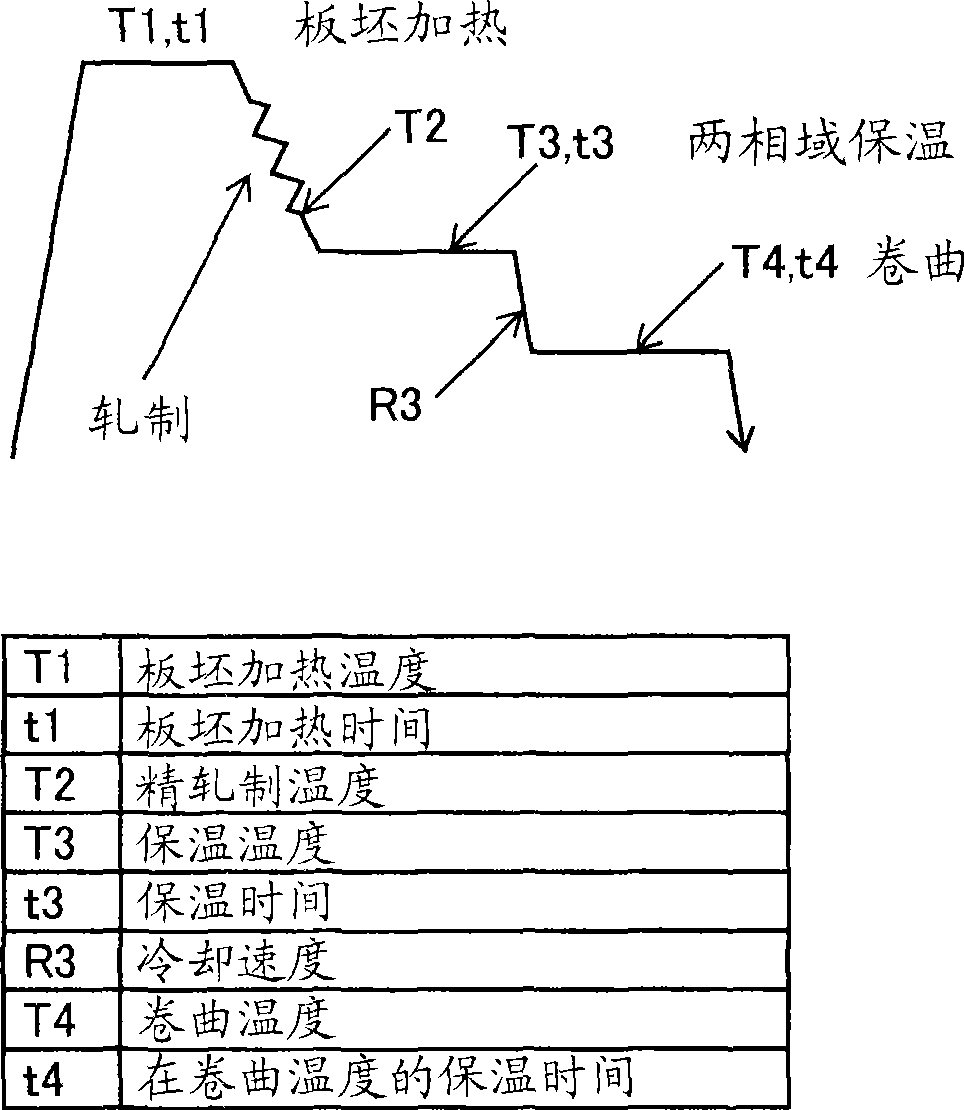

High Strength Thin-Gauge Steel Sheet Excellent in Elongation and Hole Expandability and Method of Production of Same

InactiveUS20080000555A1High strengthHigh elongationFurnace typesMetal rolling arrangementsSectilityHigh intensity

The present invention provides high strength thin-gauge steel sheet with excellent elongation and hole expandability having a tensile strength of 500 MPa or more and a method of production of high strength thin-gauge steel sheet with excellent elongation and hole expandability enabling production of this on an industrial scale, that is, high strength thin-gauge steel sheet comprised of, by mass %, C: 0.03 to 0.25%, Si: 0.4 to 2.0%, Mn: 0.8 to 3.1%, P≦0.02%, S≦0.02%, Al≦2.0%, N≦0.01%, and a balance of Fe and unavoidable impurities and having a microstructure comprised of ferrite with an area fraction of 10 to 85% and residual austenite with a volume fraction of 1 to 10%, an area fraction of 10% to 60% of tempered martensite, and a balance of bainite.

Owner:NIPPON STEEL CORP

High-strength hot-dip zinc plated steel sheet excellent in workability and process for manufacturing the same

ActiveCN101821419AImprove balanceExcellent stretch flangeabilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

The invention provides a high-strength hot-dip zinc plated steel sheet which exhibits high TS-El balance, excellent stretch frangeability, excellent workability due to low YR, and excellent impact characteristics, and a process for manufacturing the same. A high-strength hot-dip zinc plated steel sheet excellent in workability and impact characteristics, having a composition which contains by mass C: 0.05 to 0.3%, Si: 0.01 to 2.5%, Mn: 0.5 to 3.5%, P: 0.003 to 0.100%, S: 0.02% or below, Al: 0.010 to 1.5%, and N: 0.007% or below and further contains at least one element selected from among Ti, Nb and V in a total amount of 0.01 to 0.2% with the balance being Fe and unavoidable impurities and a microstructure which comprises, in terms of area fraction, 20 to 87% of ferrite, 3 to 10% (in total) of martensite and retained austenite, and 10 to 60% of tempered martensite and in which the average grain diameter of the second phase consisting of the martensite, retained austenite, and tempered martensite is 3[mu]m or below.

Owner:JFE STEEL CORP

High-strength steel sheet and process for production thereof

ActiveCN101932746AHigh strengthEasy to processHot-dipping/immersion processesFurnace typesSheet steelCarbide

Provided is a high-strength steel sheet having both high strength and excellent formability which exhibits a tensile strength of 900 MPa or above. The steel sheet has both a composition which contains by mass C: 0.1 to 0.3%, Si: 2.0% or less, Mn: 0.5 to 3.0%, P: 0.1% or less, S: 0.07% or less, Al: 1.0% or less and N: 0.008% or less with the balance being Fe and unavoidable impurities, and a structure which comprises, in terms of area fraction, ferrite: 5 to 80%, autotempered martensite: 15% or more, bainite: 10% or less, retained austenite: 5% or less, and as-quenched martensite: 40% or less and in which the average hardness of the autotempered martensite is 700HV or below and the average number of precipitated iron carbide particles of 5nm to 0.5[mu]m in the autotempered martensite is 5OE04 or above per mm2.

Owner:JFE STEEL CORP

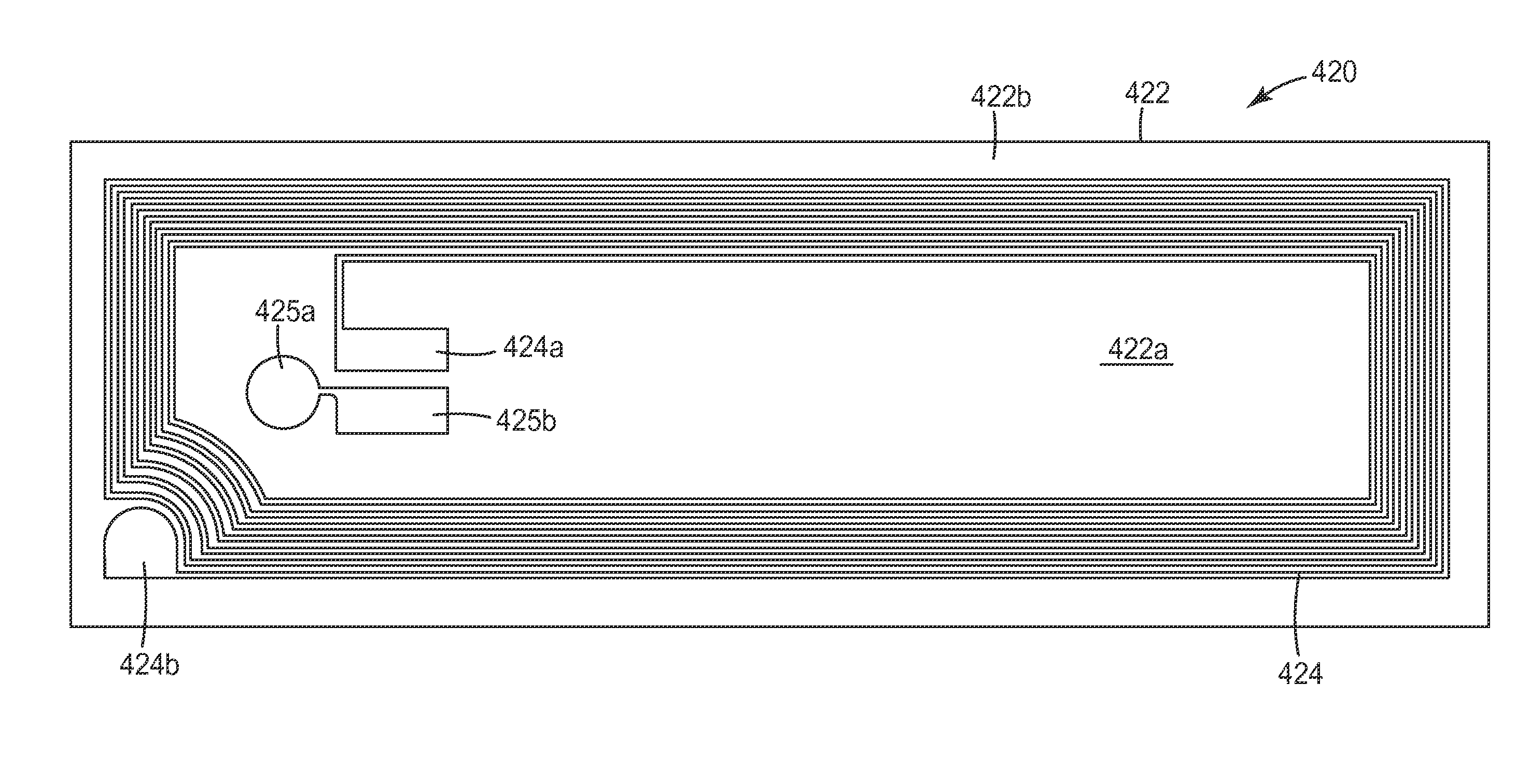

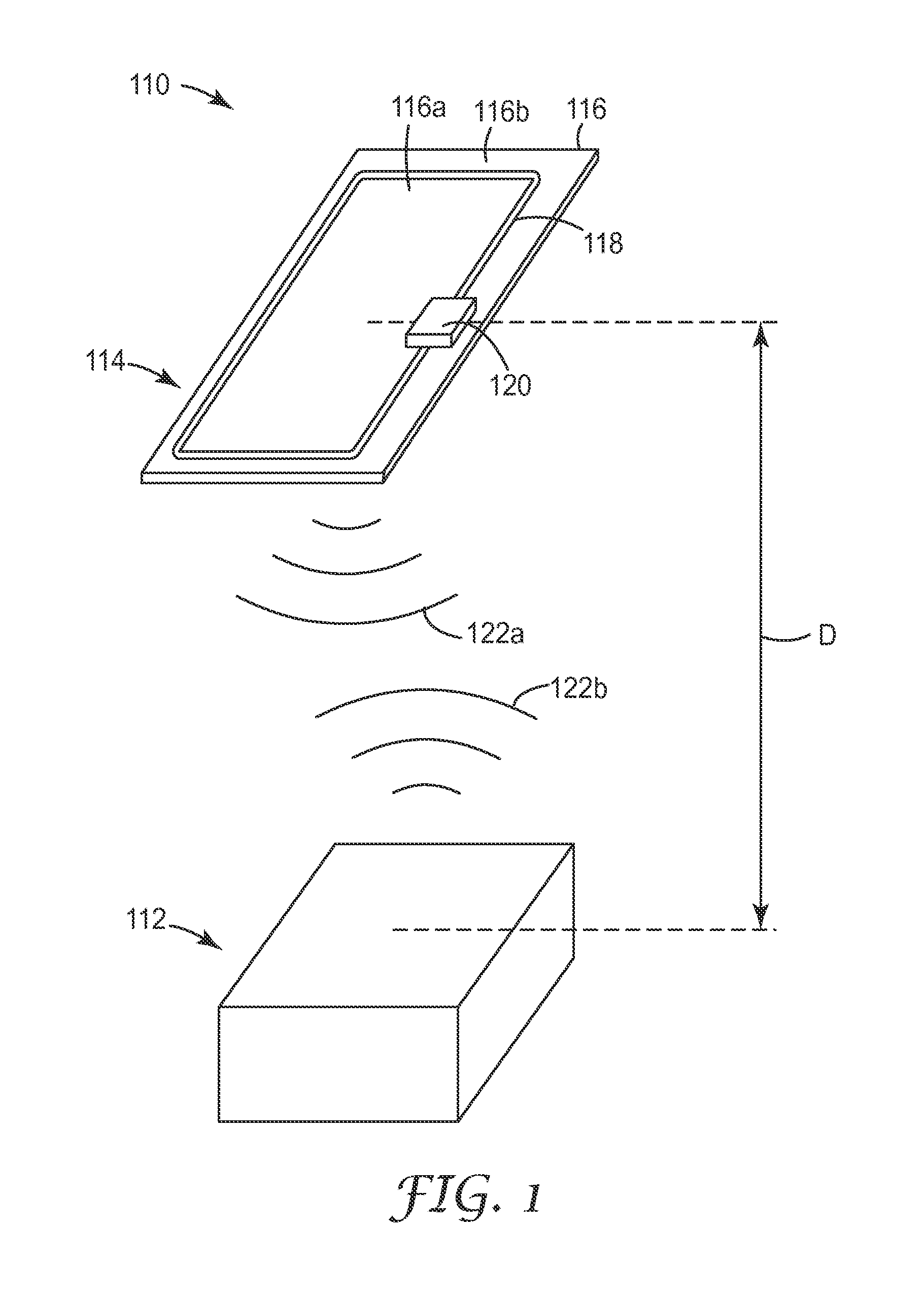

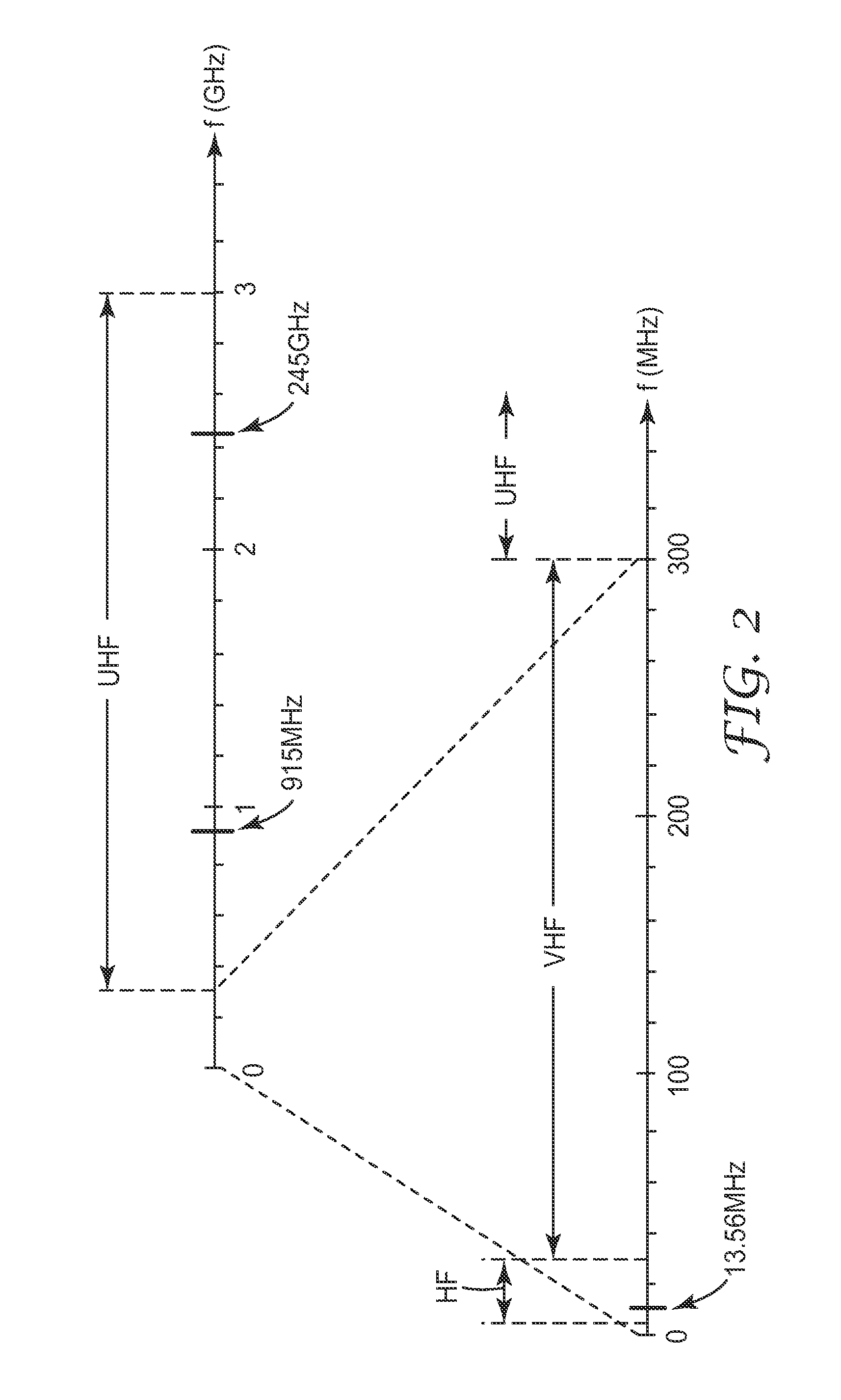

Transparent Micropatterned RFID Antenna and Articles Incorporating Same

InactiveUS20130264390A1Simultaneous aerial operationsRadiating elements structural formsElectrical conductorFinancial transaction

Antennas suitable for use in RFID devices include an insulating substrate and a first conductive micropattern disposed on or in the substrate, the first conductive micropattern defining a contiguous mesh conductor. The first conductive micropattern forms an antenna responsive to at least a frequency of 915 MHz, and includes interconnected traces having a trace width in a range from 0.5 to 20 microns. Furthermore, the first conductive micropattern is characterized by an open area fraction of at least 80% or 90%. RFID devices include such an antenna and an integrated circuit configured to transmit and receive signals using the antenna. Cards, such as financial transaction cards or identification cards, include such an antenna carried by a card layer.

Owner:3M INNOVATIVE PROPERTIES CO

Aluminum alloy brazing sheet

ActiveUS20110287277A1Increase resistanceHigh strengthWelding/cutting media/materialsHeat exchange apparatusNumber densityIntermetallic

An aluminum alloy brazing sheet includes a core material containing Si, Cu and Mn by a predetermined amount, the balance being Al and inevitable impurities, a sacrificial anode material disposed on one face side of the core material and containing Si, Zn and Mg by a predetermined amount, the balance being Al and inevitable impurities, and a brazing filler material disposed on the other face side of the core material and formed of an aluminum alloy, and the area fraction of Zn—Mg-based intermetallic compounds with 2.0 μm or above particle size on the surface of the sacrificial anode material may be 1.0% or below. Or otherwise, in the aluminum alloy brazing sheet, the number density of Al—Cu-based intermetallic compounds with 0.5 μm or above particle size inside the core material may be 1.0 piece / μm2 or below.

Owner:KOBE STEEL LTD

High-strength steel sheet superior in formability

InactiveCN101649415AImprove balanceHot-dipping/immersion processesFurnace typesHardnessHigh intensity

Disclosed is a high-strength steel sheet which has a predetermined component composition, structurally has a ferrite matrix structure and bainitic and martensitic second phase structures, and has a ferrite fraction of from 50 to 86 percent by area, a bainite fraction of from 10 to 30 percent by area, and a martensite fraction of from 4 to 20 percent by area, relative to the entire structure, in which the bainite area fraction is larger than the martensite area fraction, the ferrite has an average grain size of 2.0 to 5.0 [mu]m, and the ratio of the average ferrite hardness (Hv) to the tensilestrength (MPa) of the steel sheet is equal to or more than 0.25. The steel sheet excels both in TS-EL balance and TS-[lambda] balance at high strengths on the order of 590 to 780 MPa.

Owner:KOBE STEEL LTD

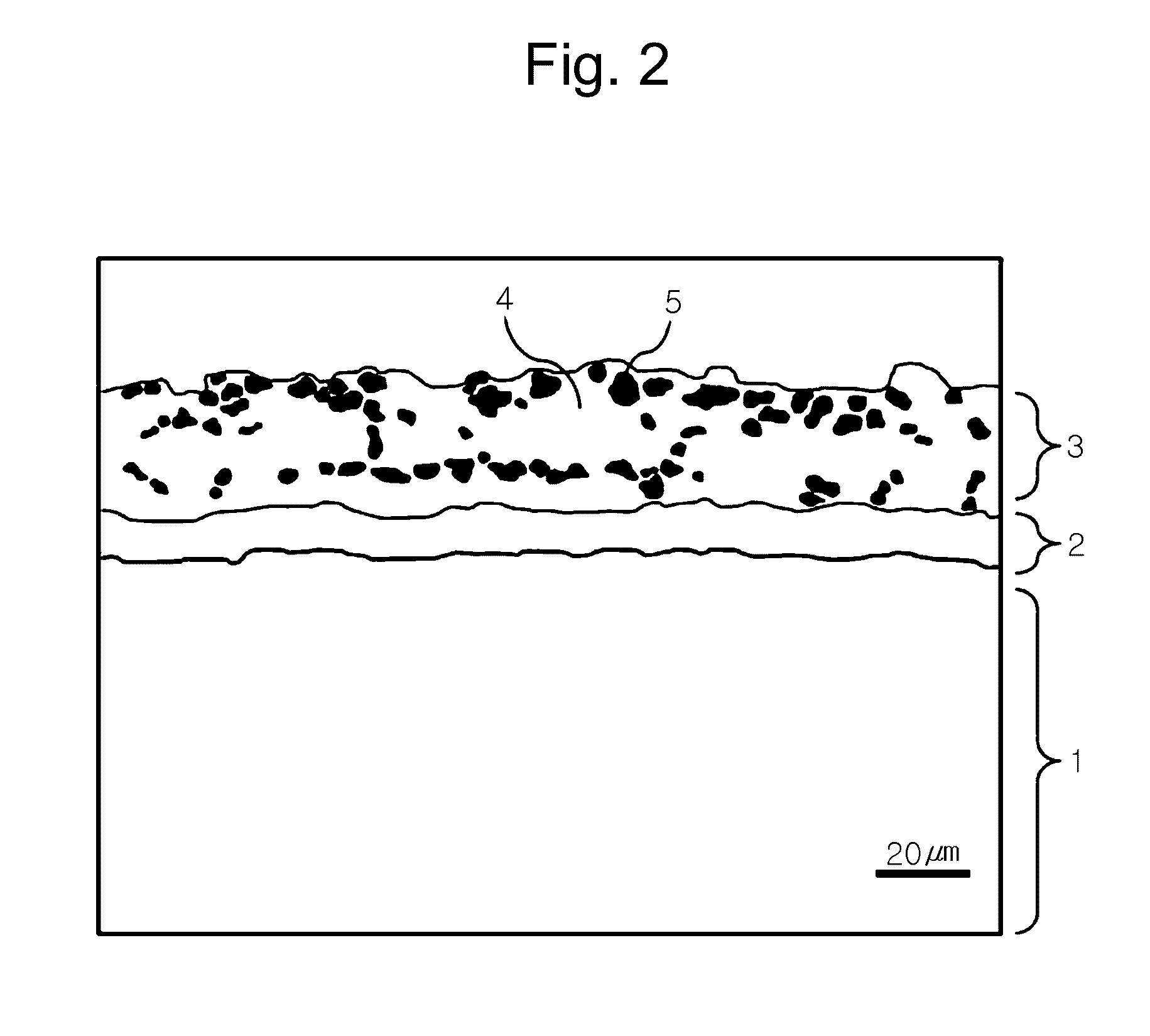

Electroacoustic transduction film

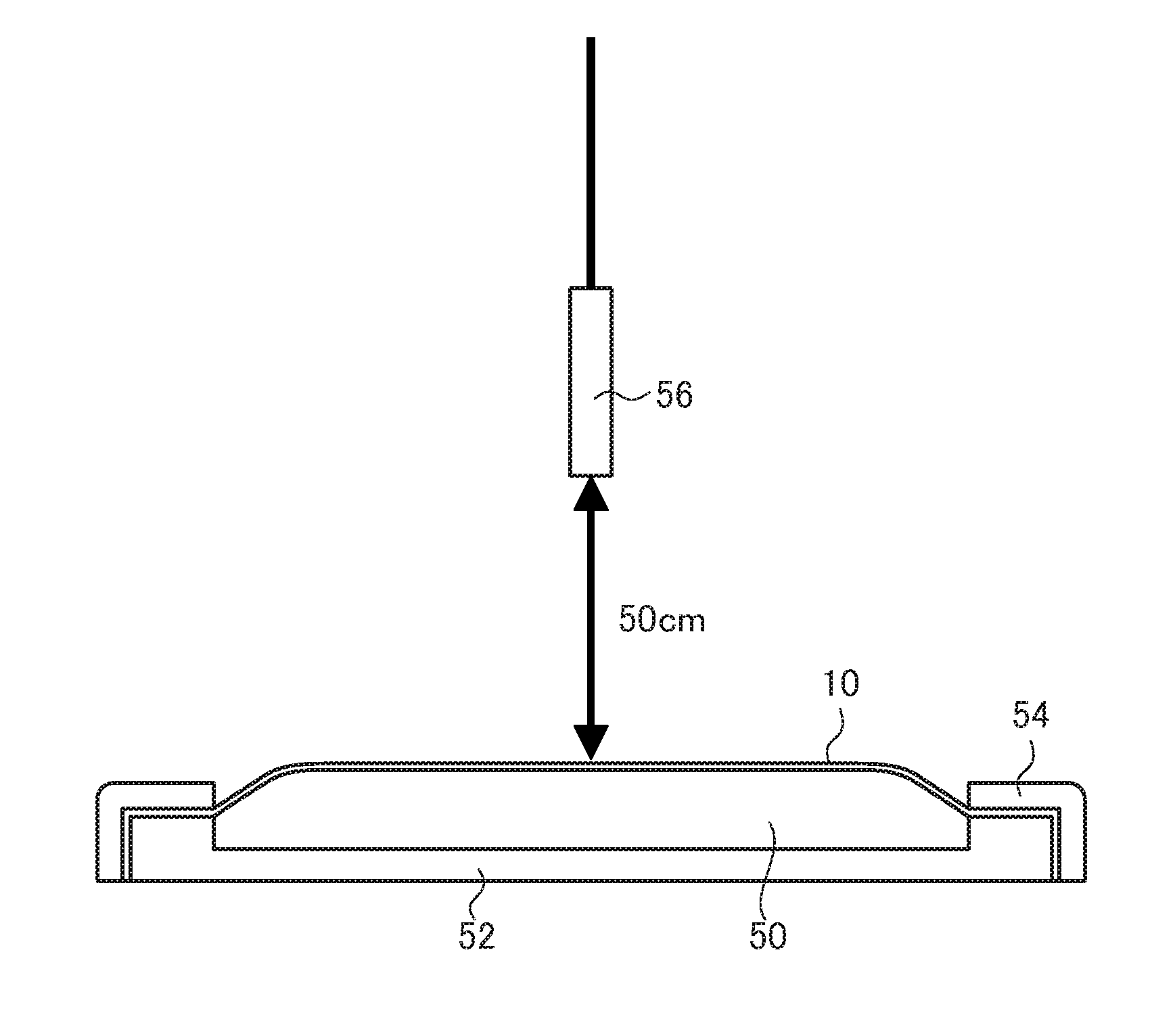

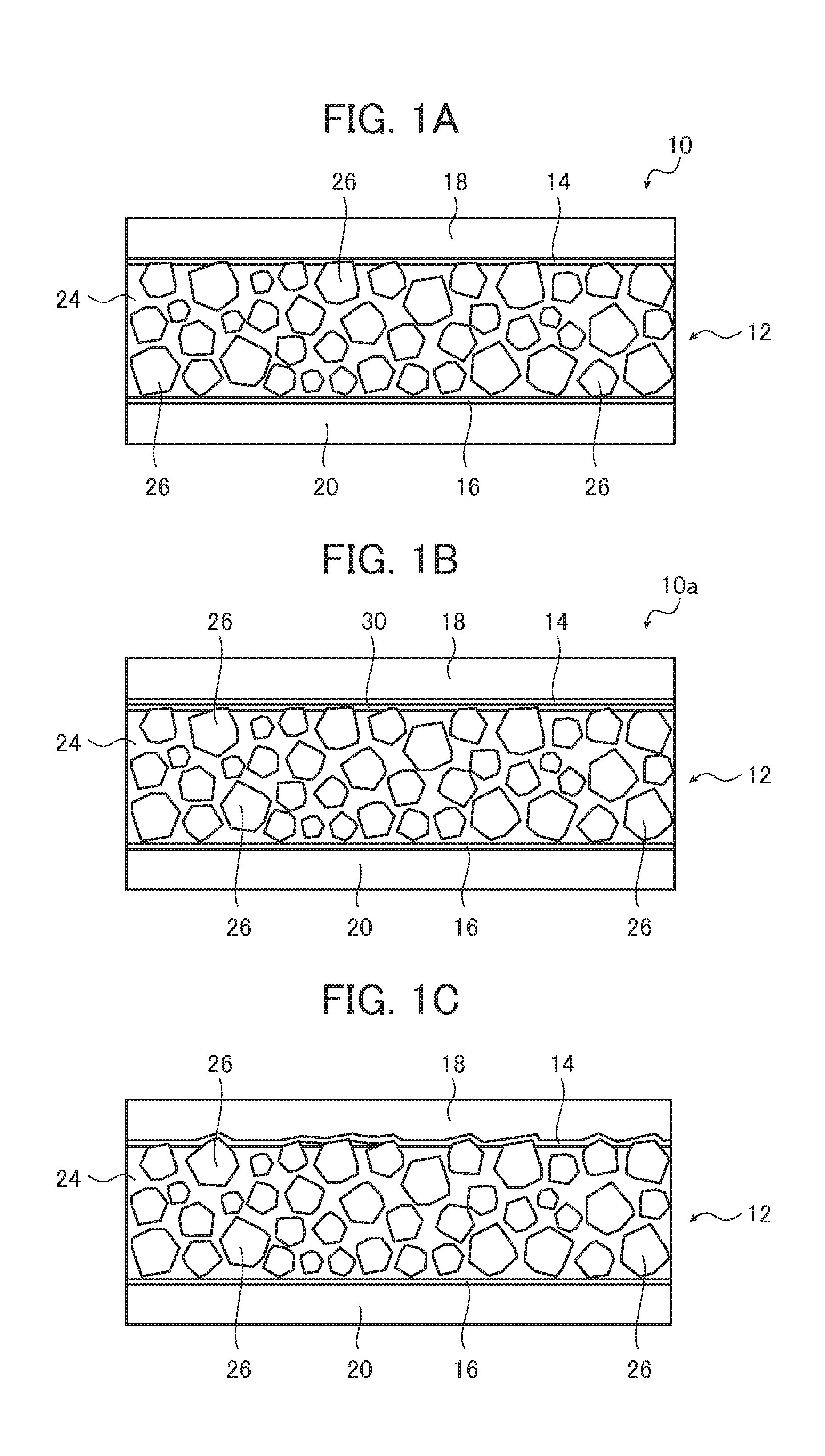

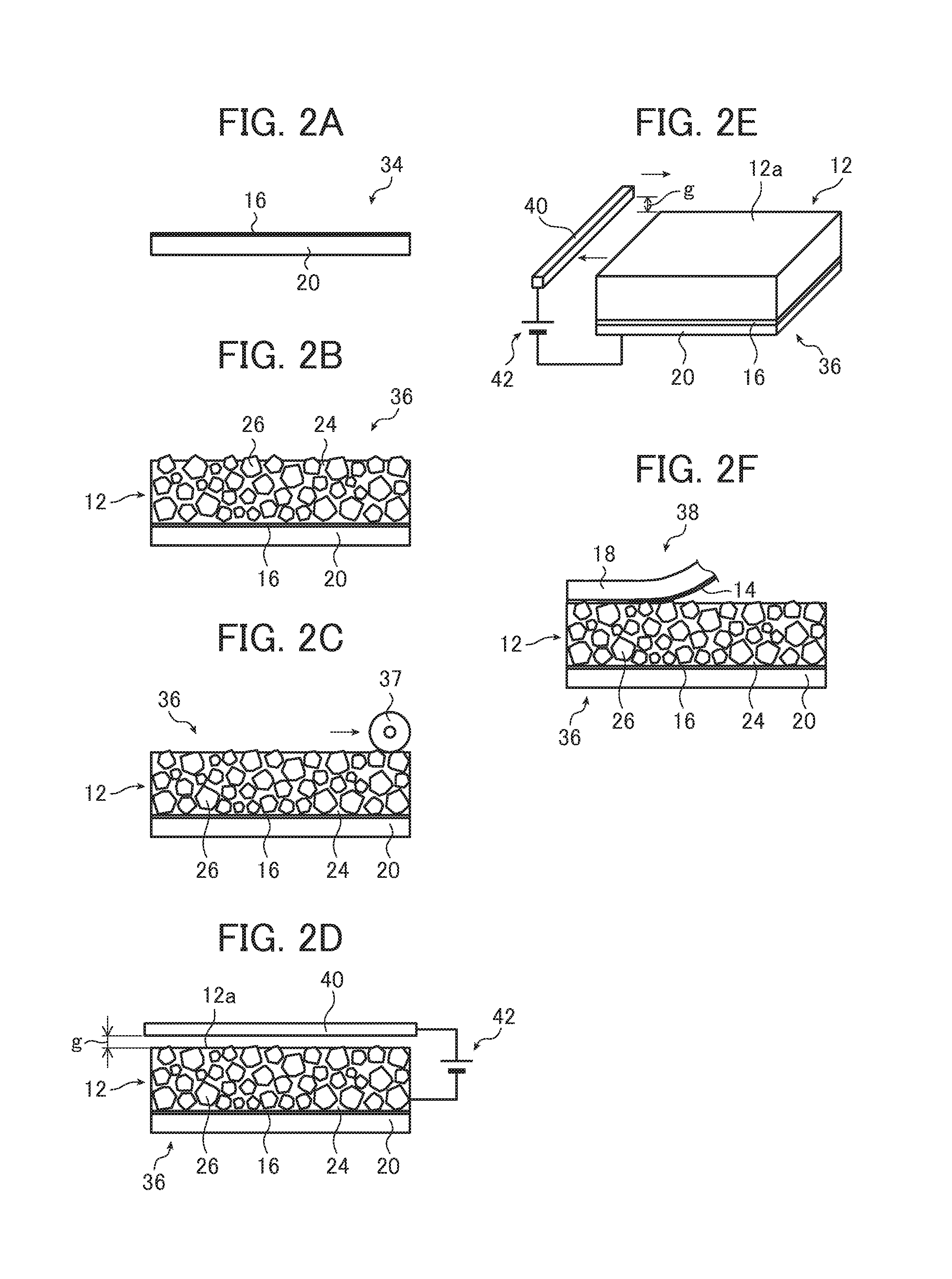

ActiveUS20160014526A1Improve propertiesAvoid separationPlane diaphragmsDeaf-aid setsPolymer compositesLoudspeaker

Disclosed is an electroacoustic transduction film suitable for a flexible speaker or the like, in which predetermined acoustic properties are able to be stably exhibited regardless of a bending state. The electroacoustic transduction film includes a polymer composite piezoelectric body in which piezoelectric body particles are dispersed in a viscoelastic matrix formed of a polymer material having viscoelasticity at a normal temperature, and electrode layers interposing the polymer composite piezoelectric body therebetween, and an area fraction of the piezoelectric body particles in a contact surface with respect to the electrode layer is less than or equal to 50%, and thus the object is attained.

Owner:FUJIFILM CORP

Al-ni-la-si system al-based alloy sputtering target and process for producing the same

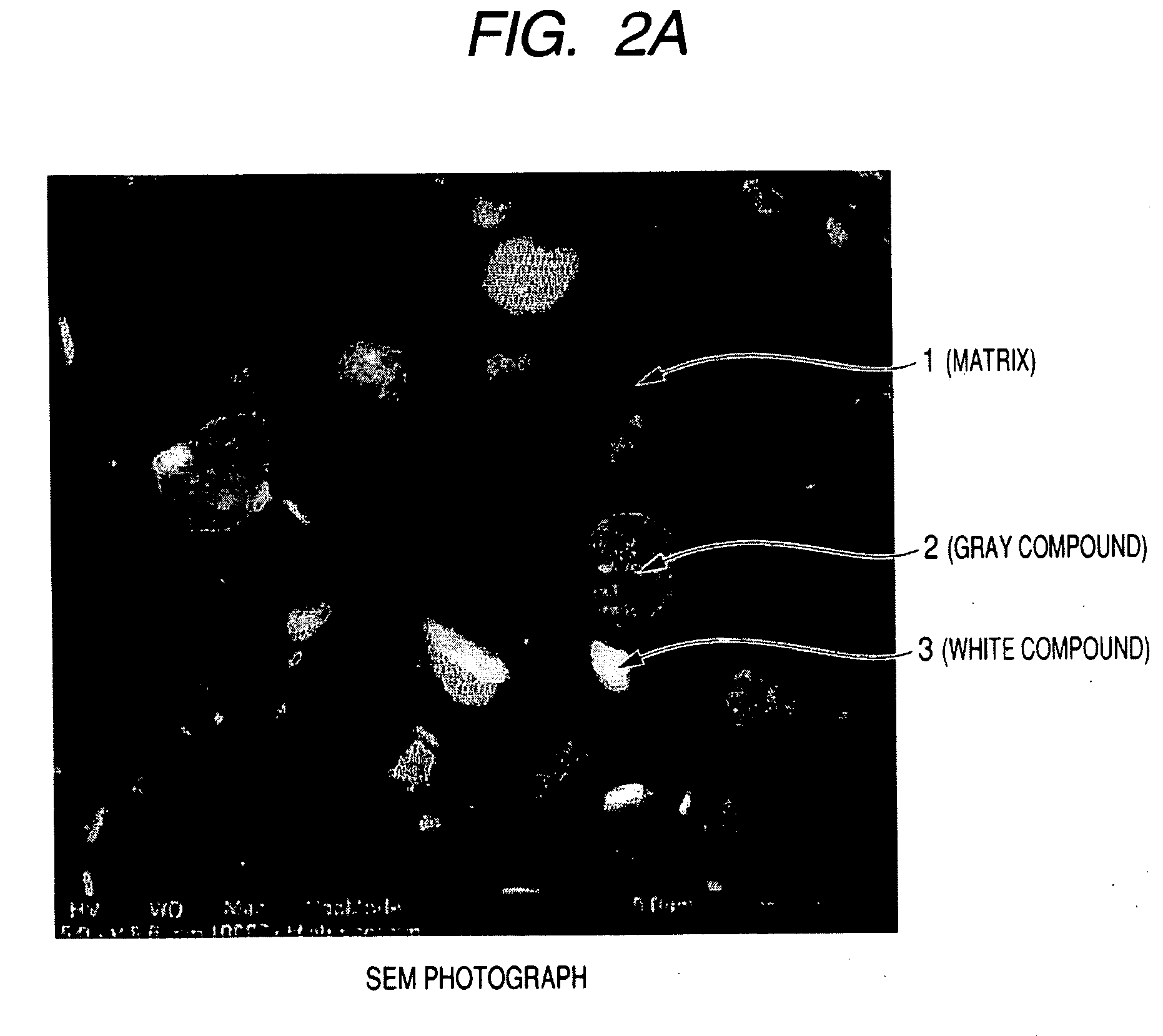

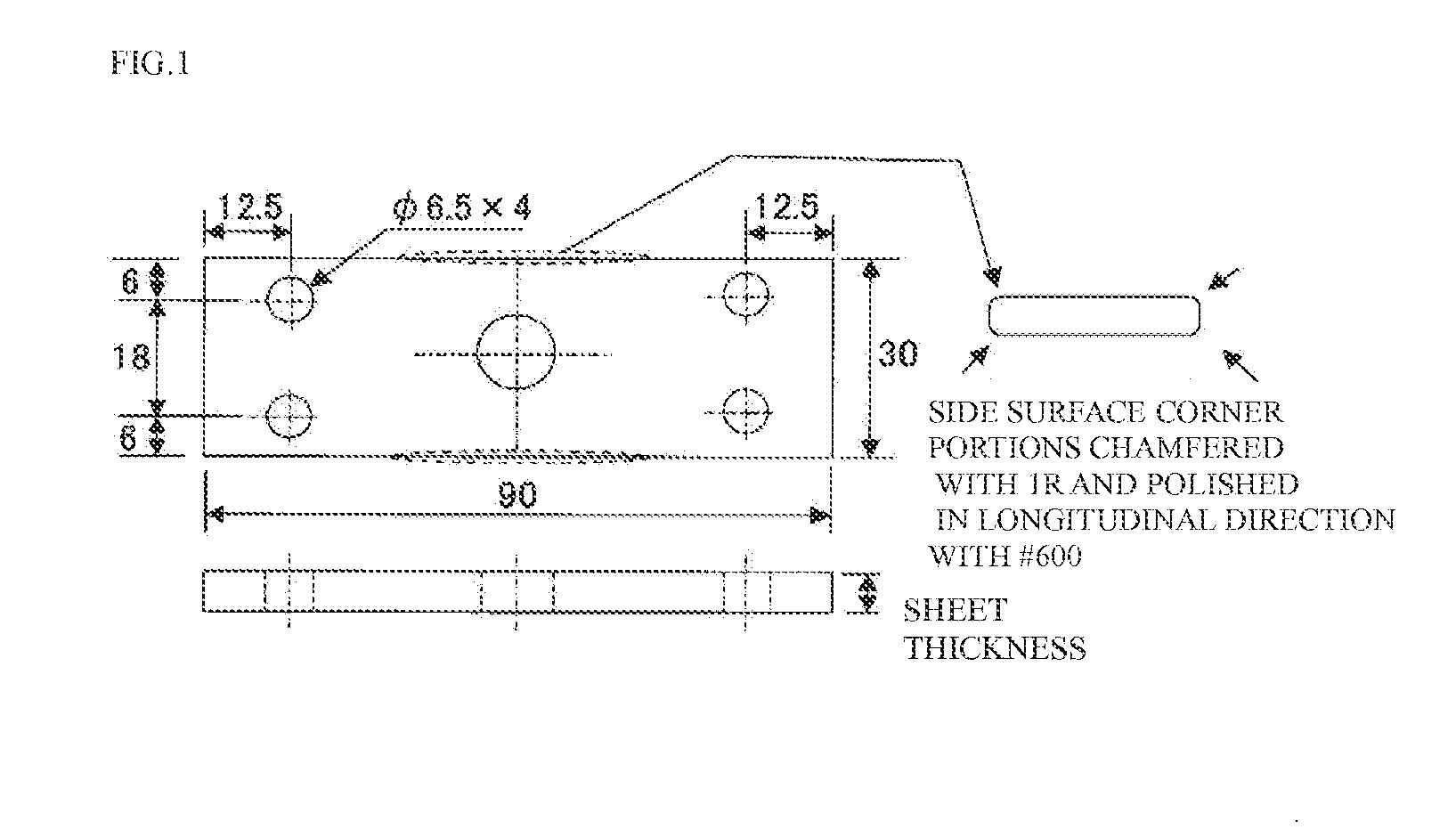

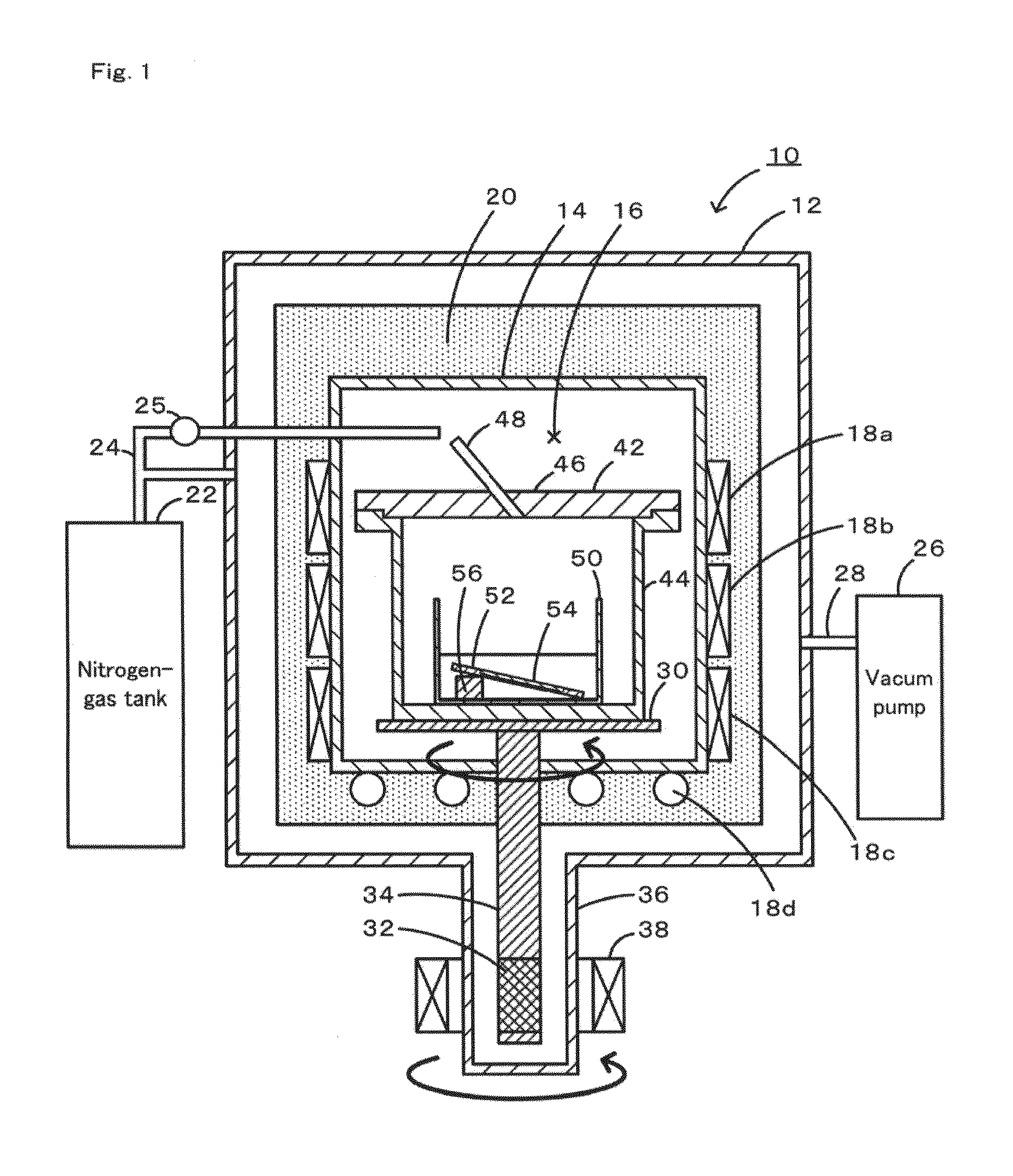

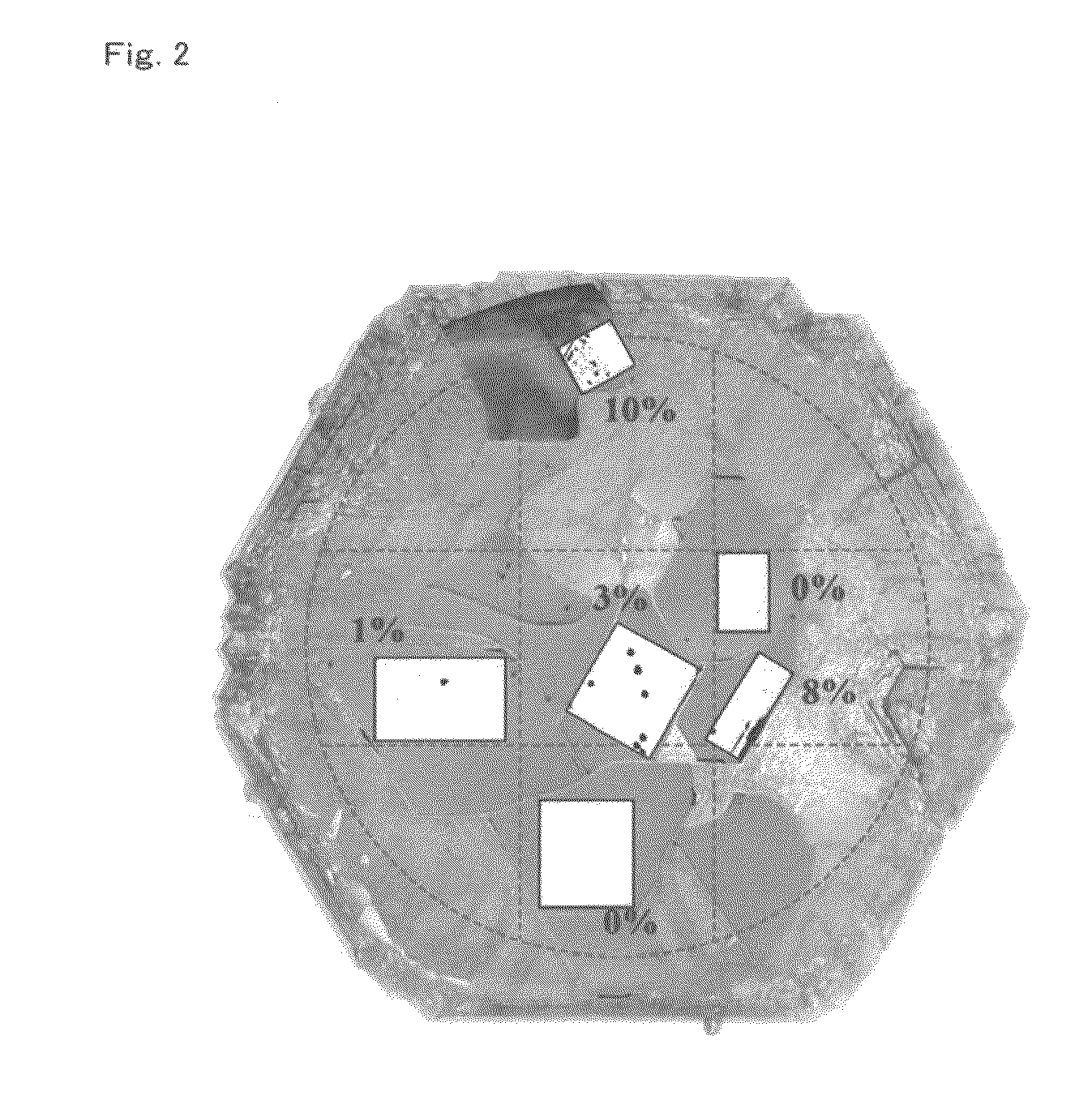

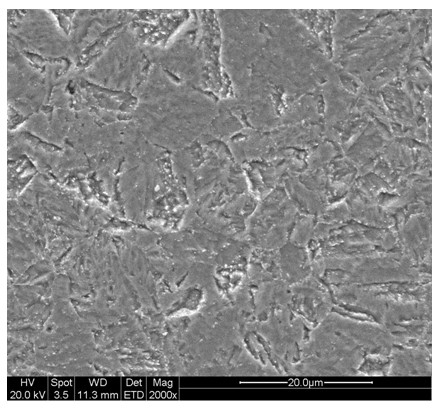

ActiveUS20090026072A1Avoid it happening againSputtering defects can be effectively suppressedCellsVacuum evaporation coatingMetallurgyScanning electron microscope

The present invention relates to an Al—Ni—La—Si system Al-based alloy sputtering target including Ni, La and Si, in which, when a section from (¼)t to (¾)t (t: thickness) in a cross section vertical to a plane of the sputtering target is observed with a scanning electron microscope at a magnification of 2000 times, (1) a total area of an Al—Ni system intermetallic compound having an average particle diameter of 0.3 μm to 3 μm with respect to a total area of the entire Al—Ni system intermetallic compound is 70% or more in terms of an area fraction, the Al—Ni system intermetallic compound being mainly composed of Al and Ni; and (2) a total area of an Al—Ni—La—Si system intermetallic compound having an average particle diameter of 0.2 μm to 2 μm with respect to a total area of the entire Al—Ni—La—Si system intermetallic compound is 70% or more in terms of an area fraction, the Al—Ni—La—Si system intermetallic compound being mainly composed of Al, Ni, La, and Si.

Owner:KOBE STEEL LTD +1

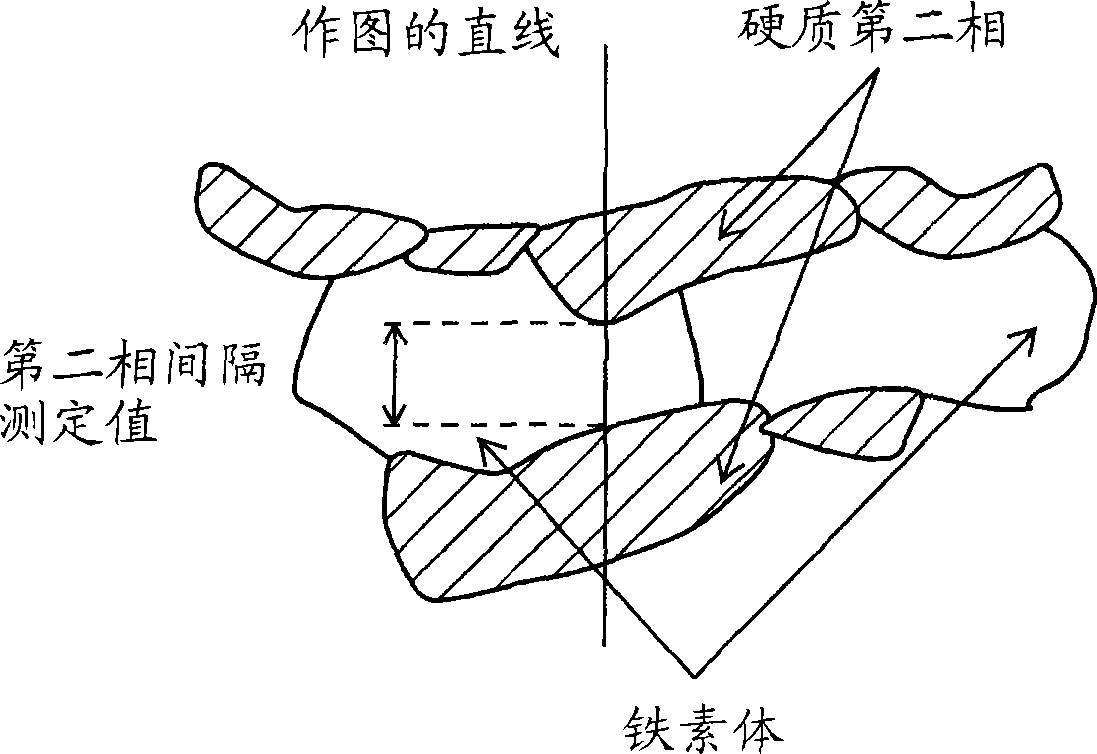

Dual phase steel sheet and manufacturing method thereof

ActiveUS20150203949A1Improve surface propertiesSignificant contributionHot-dipping/immersion processesFurnace typesPhysical chemistryCarbide

A dual phase steel sheet including: in mass %, C: 0.01 to 0.1%; Mn: 0.2 to 3%; Al: 0.04 to 1.5%; Ti: 0.015 to 0.2%; P: 0.01% or less; S: 0.005% or less; N: 0.01% or less, in which [Ti]−48 / 14×[N]−48 / 32×[S]≧0% is satisfied and when Ex.C (%)=[C]−12 / 48×{[Ti]+48 / 93×[Nb]−48 / 14×[N]−48 / 32×[S]} is set, 0.001≦Ex.C (%) / fsd (%)≦0.01 is satisfied, and a balance being composed of Fe and impurities, in which at the position of ¼ thickness of a sheet thickness, a microstructure is a dual phase with its main phase composed of polygonal ferrite precipitation-strengthened by carbide of Ti and its second phase composed of 1 to 10% in area fraction (fsd (%)) of low-temperature transformation products dispersed plurally, and an average crystal diameter of the low-temperature transformation product is 3 to 15 μm and an average value of a distance of closest approach between the low-temperature transformation products is 10 to 20 μm.

Owner:NIPPON STEEL CORP

High strength hot rolled steel sheet having excellent bendability and method for manufacturing the same

ActiveUS20130167985A1High strengthImprove bending performanceFurnace typesHeat treatment furnacesUltimate tensile strengthHot rolled

A steel sheet including C at 0.05 to 0.15%, Si at 0.2 to 1.2%, Mn at 1.0 to 2.0%, P at not more than 0.04%, S at not more than 0.0030%, Al at 0.005 to 0.10%, N at not more than 0.005% and Ti at 0.03 to 0.13%, the balance being Fe and inevitable impurities, includes surface regions having an area fraction of bainite of less than 80% and an area fraction of a ferrite phase with a grain diameter of 2 to 15 μm of not less than 10%, the surface regions extending from both surfaces of the steel sheet each to a depth of 1.5 to 3.0% relative to a total sheet thickness, as well as an inner region other than the surface regions having an area fraction of a bainite phase of more than 95%, and has a tensile strength of not less than 780 MPa.

Owner:JFE STEEL CORP

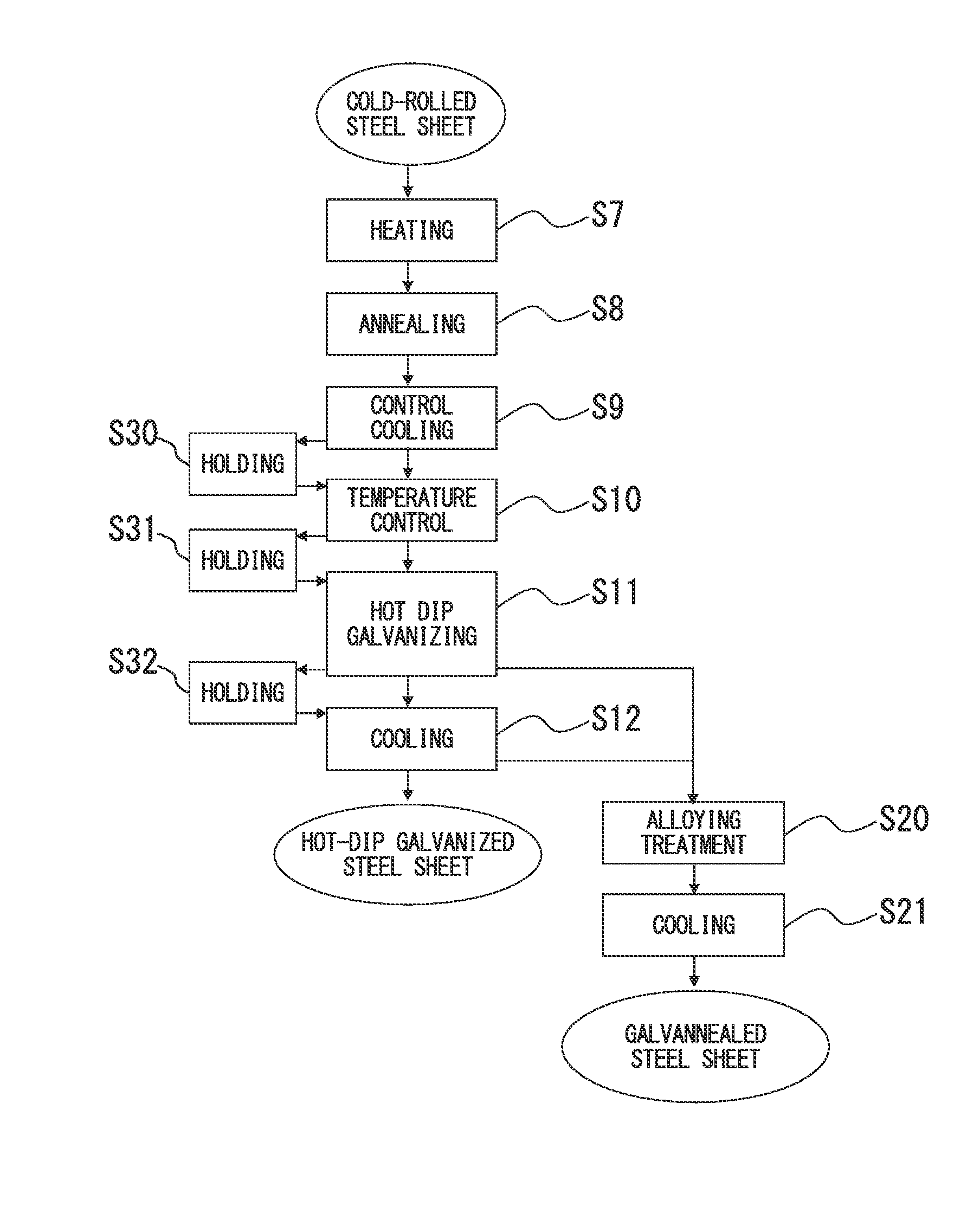

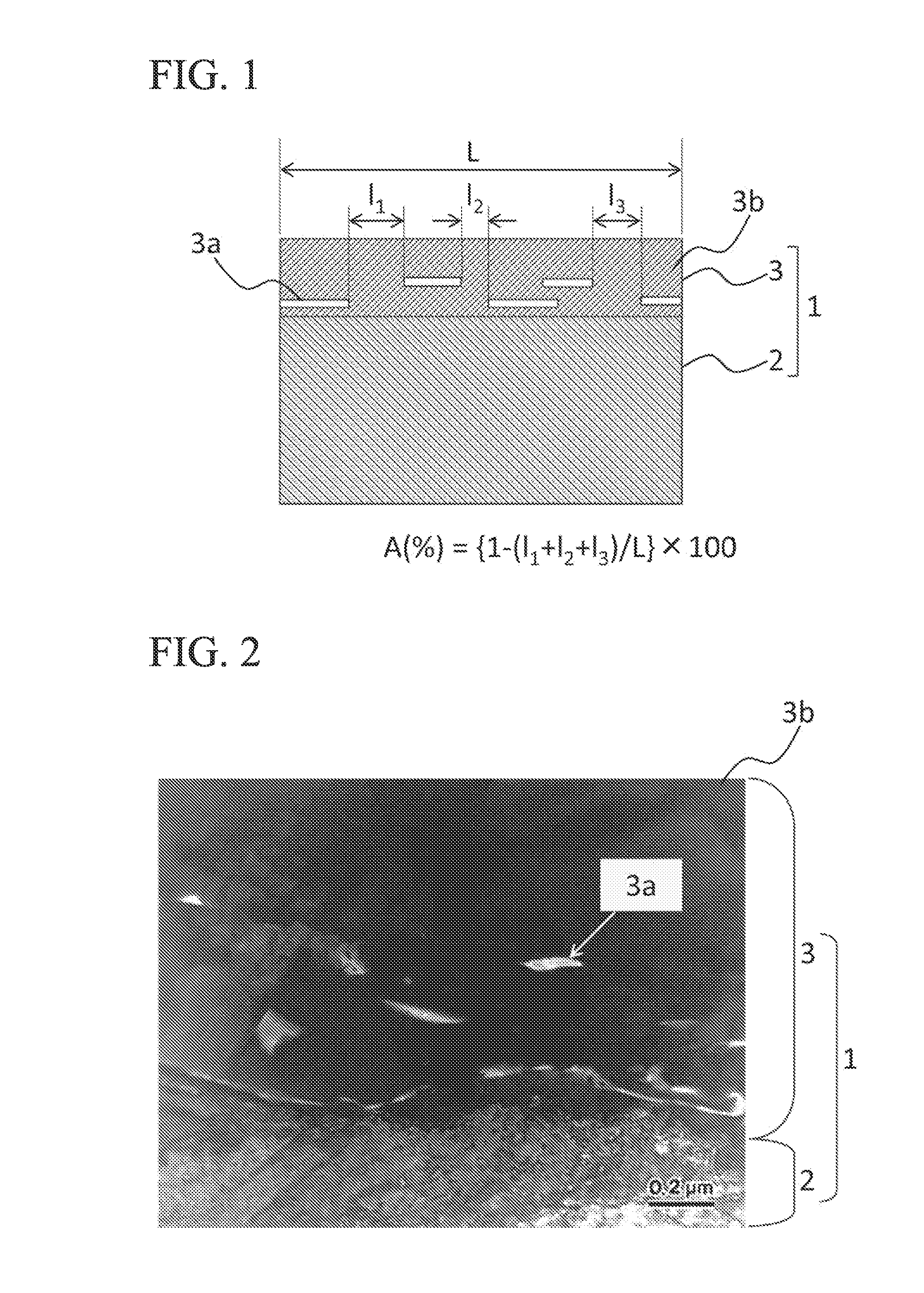

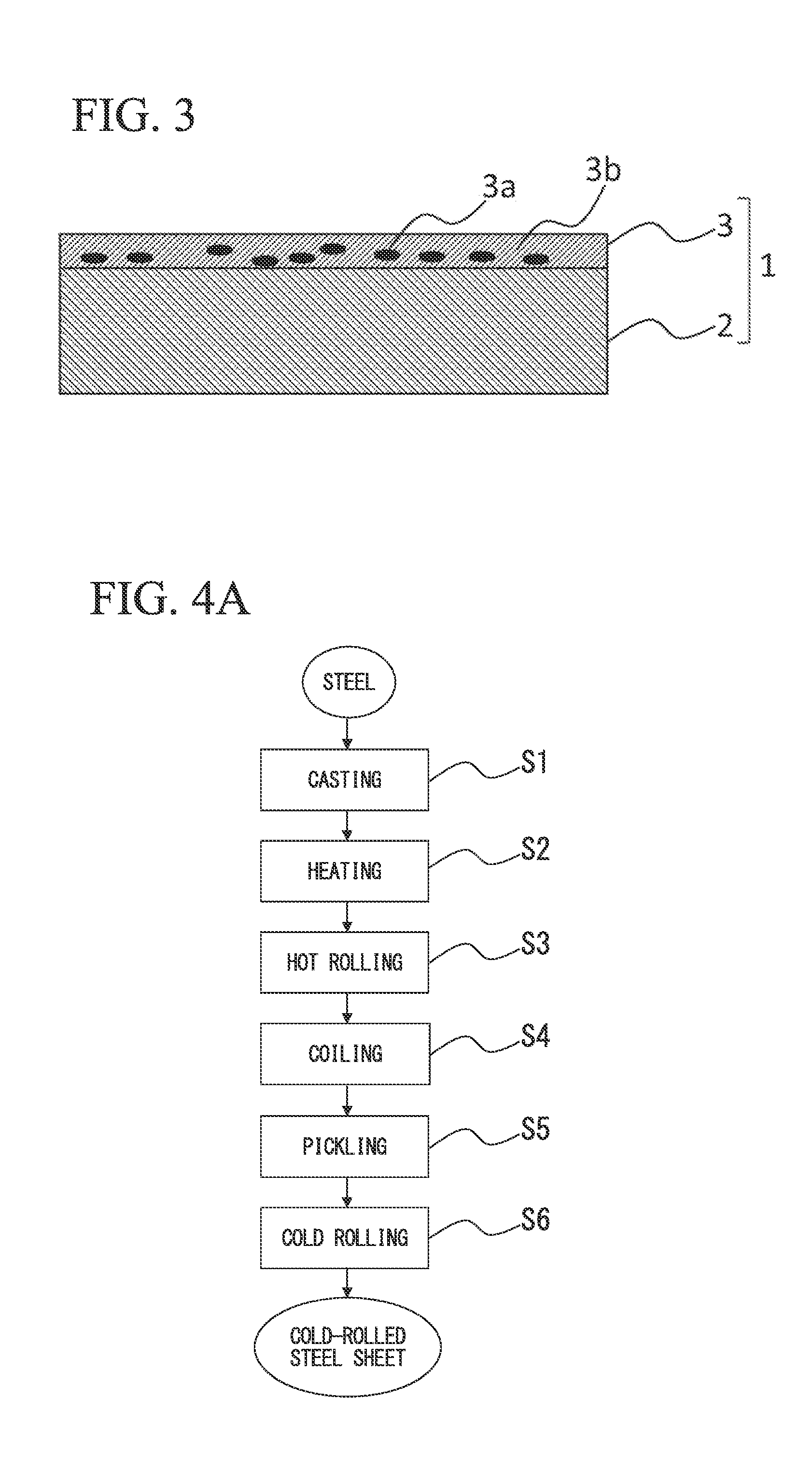

Galvanized steel sheet and method of manufacturing the same

ActiveUS20140234658A1Improve fracture resistanceLow costHot-dipping/immersion processesFurnace typesChemical compositionUltimate tensile strength

A galvanized steel sheet includes a steel sheet and a plating layer on the surface of the steel sheet, in which the steel sheet includes, as a steel chemical composition, by mass %, C: 0.05 to 0.40%, Si: 0.5 to 3.0% and Mn: 1.5 to 3.0%, a microstructure of the steel sheet includes ferrite, bainite, by volume fraction, 30% or more of a tempered martensite, and 8% or more of an austenite, and tensile strength of the steel sheet is 980 MPa or more, and the plating layer includes an oxide including at least one chemical element selected from Si, Mn and Al, and when seen at a cross section including the steel sheet and the plating layer in a plate thickness direction, a projection area fraction of the oxide is 10% or more.

Owner:NIPPON STEEL CORP

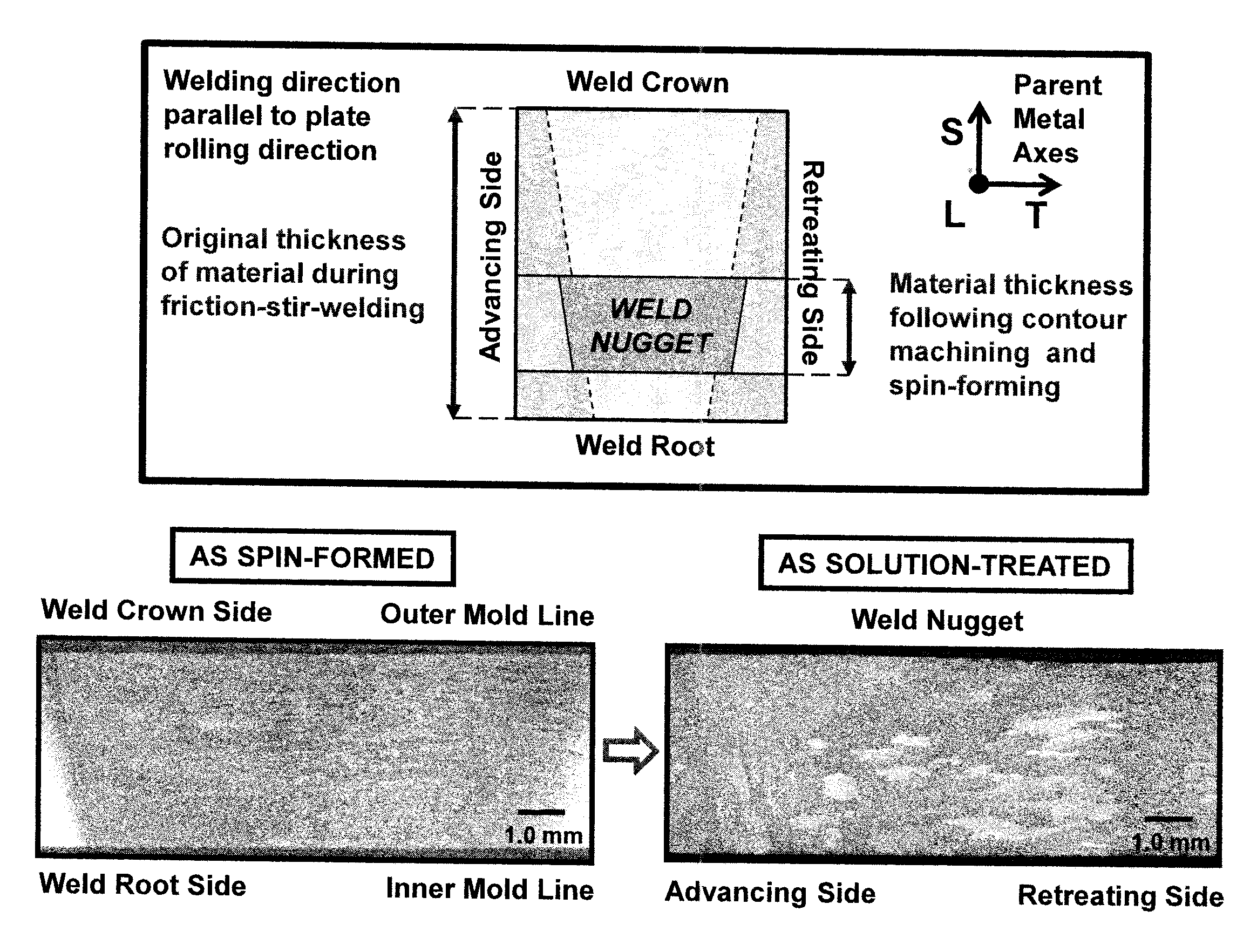

Abnormal Grain Growth Suppression in Aluminum Alloys

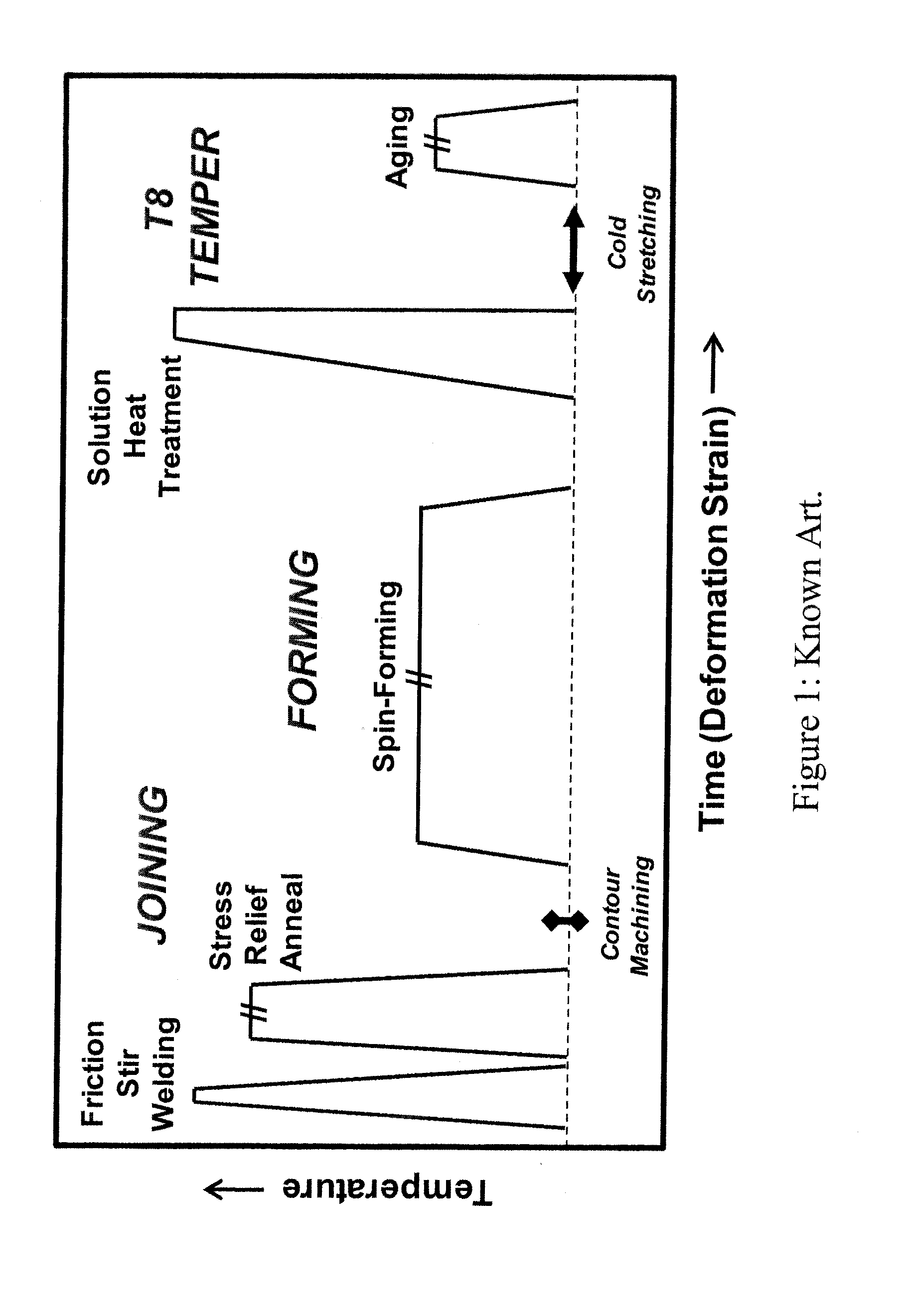

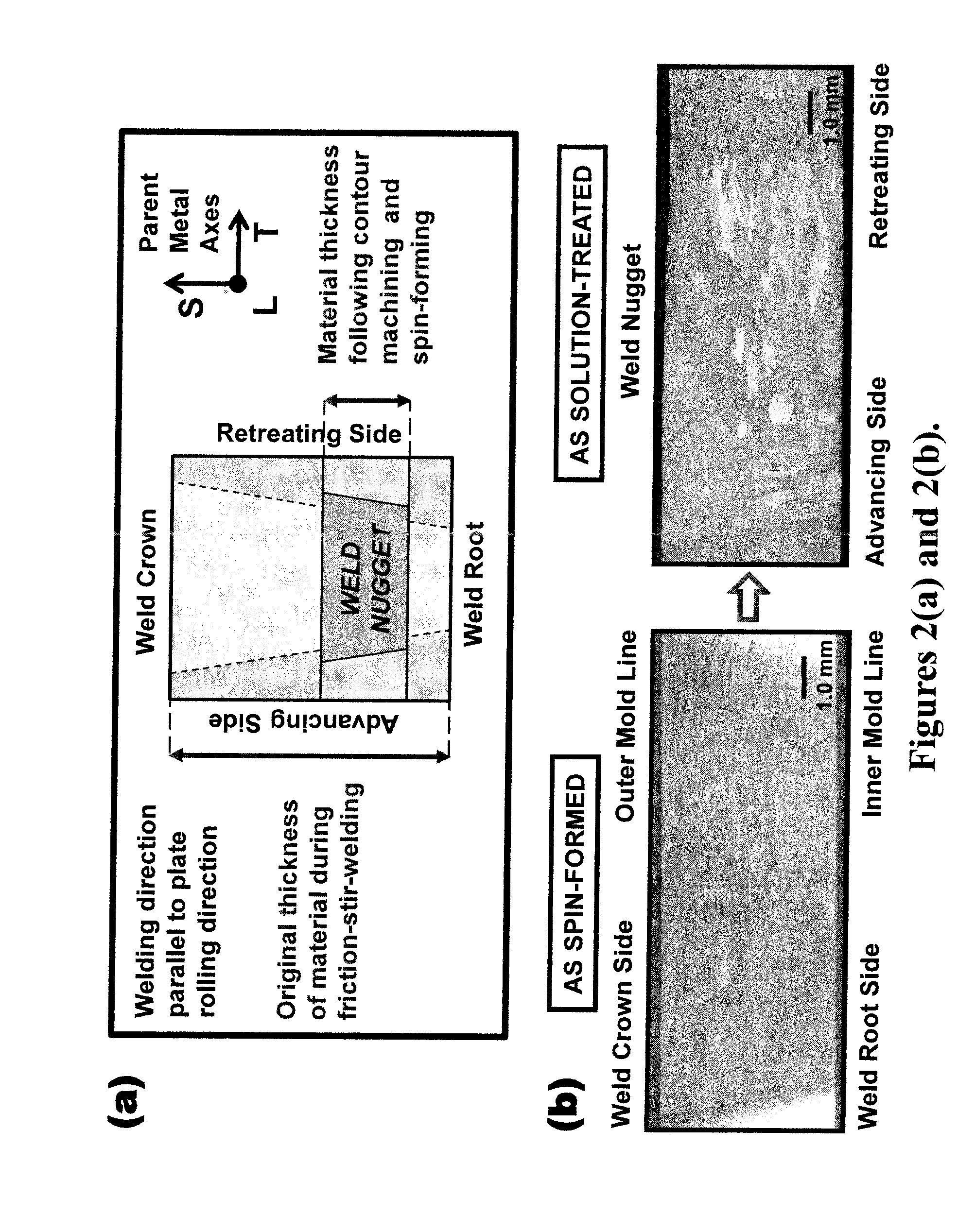

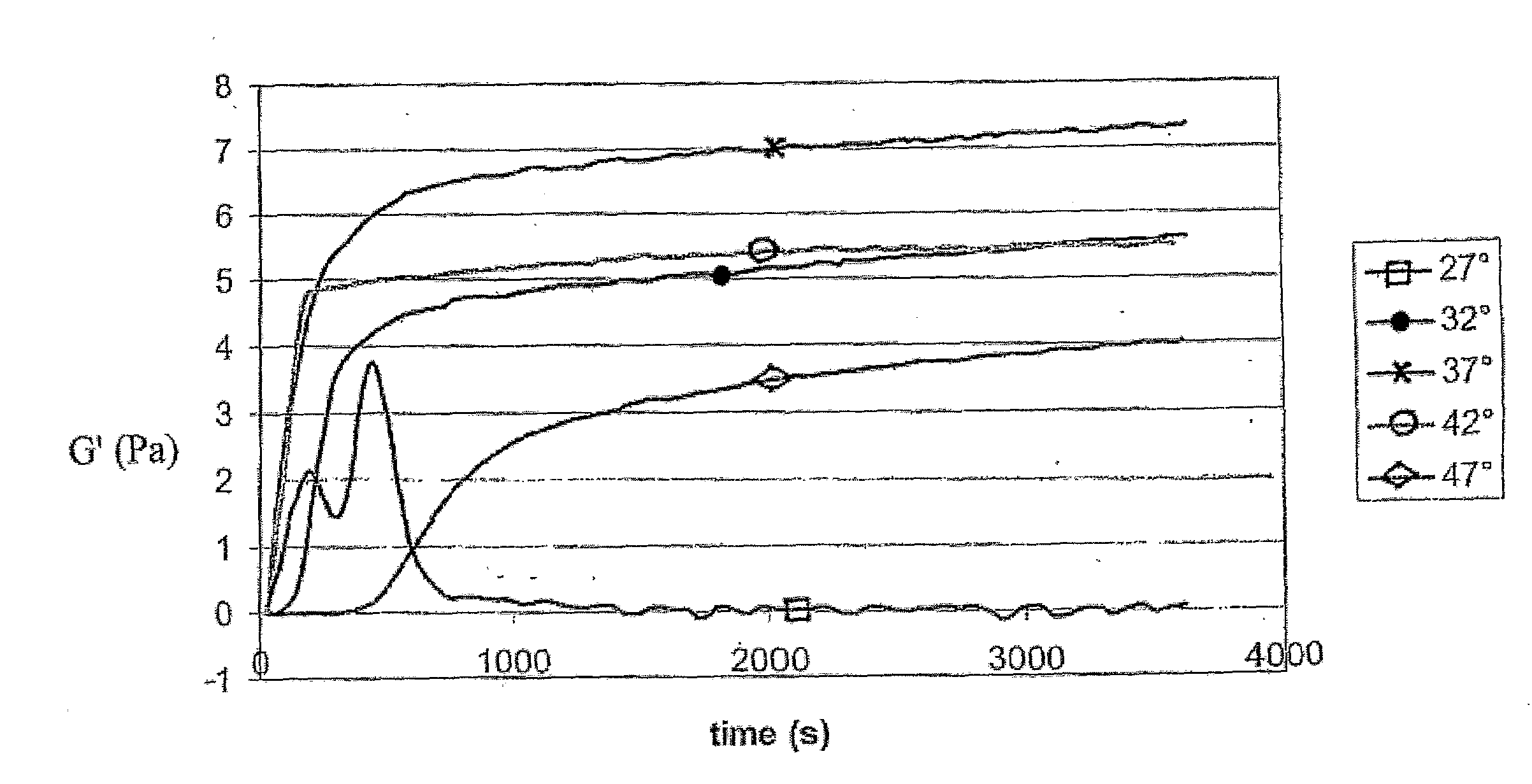

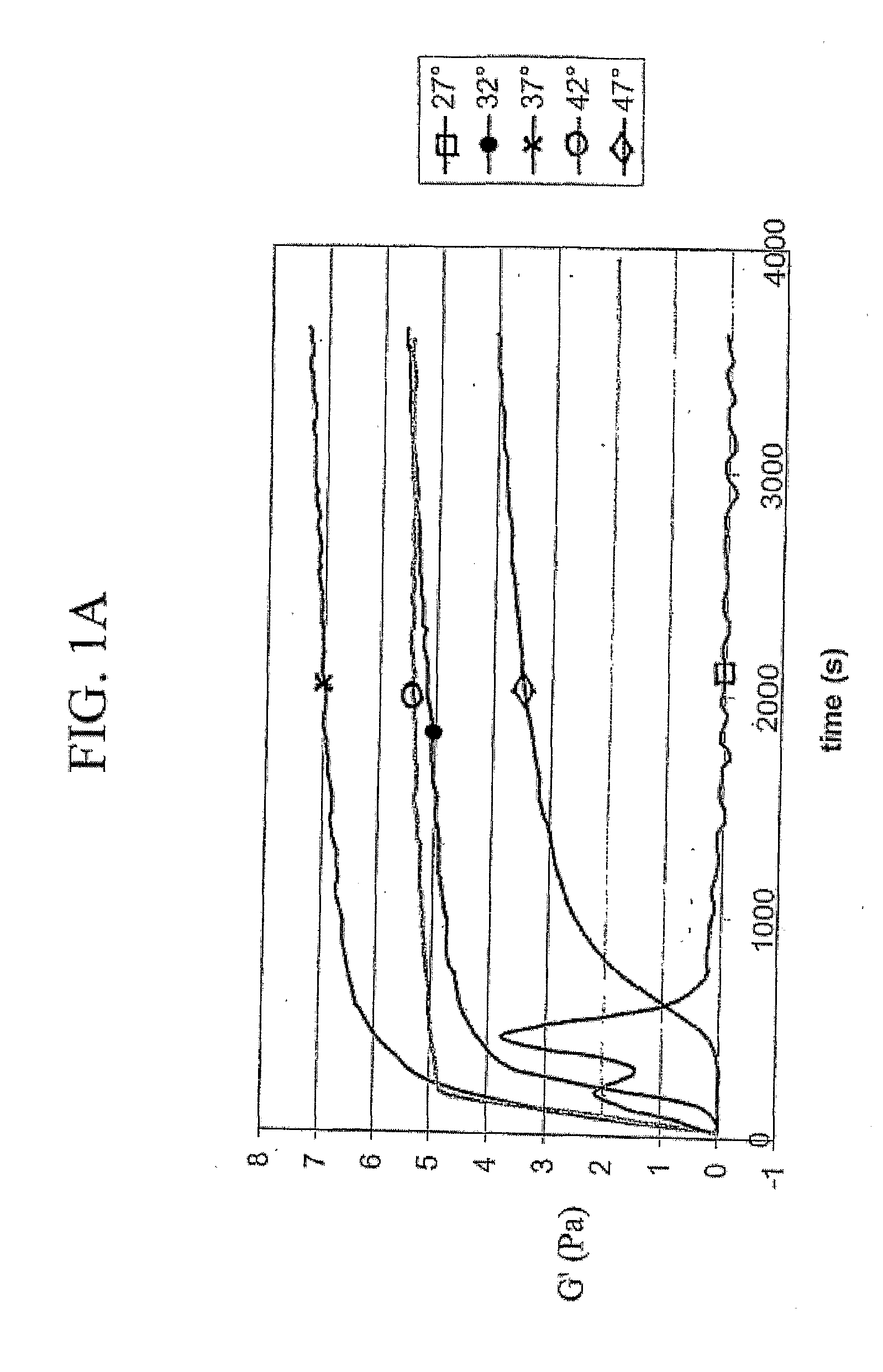

ActiveUS20120090738A1High strengthImprove ductilityFurnace typesHeat treatment furnacesAbnormal grain growthSpins

The present invention provides a process for suppressing abnormal grain growth in friction stir welded aluminum alloys by inserting an intermediate annealing treatment (“IAT”) after the welding step on the article. The IAT may be followed by a solution heat treatment (SHT) on the article under effectively high solution heat treatment conditions. In at least some embodiments, a deformation step is conducted on the article under effective spin-forming deformation conditions or under effective superplastic deformation conditions. The invention further provides a welded article having suppressed abnormal grain growth, prepared by the process above. Preferably the article is characterized with greater than about 90% reduction in area fraction abnormal grain growth in any friction-stir-welded nugget.

Owner:NASA

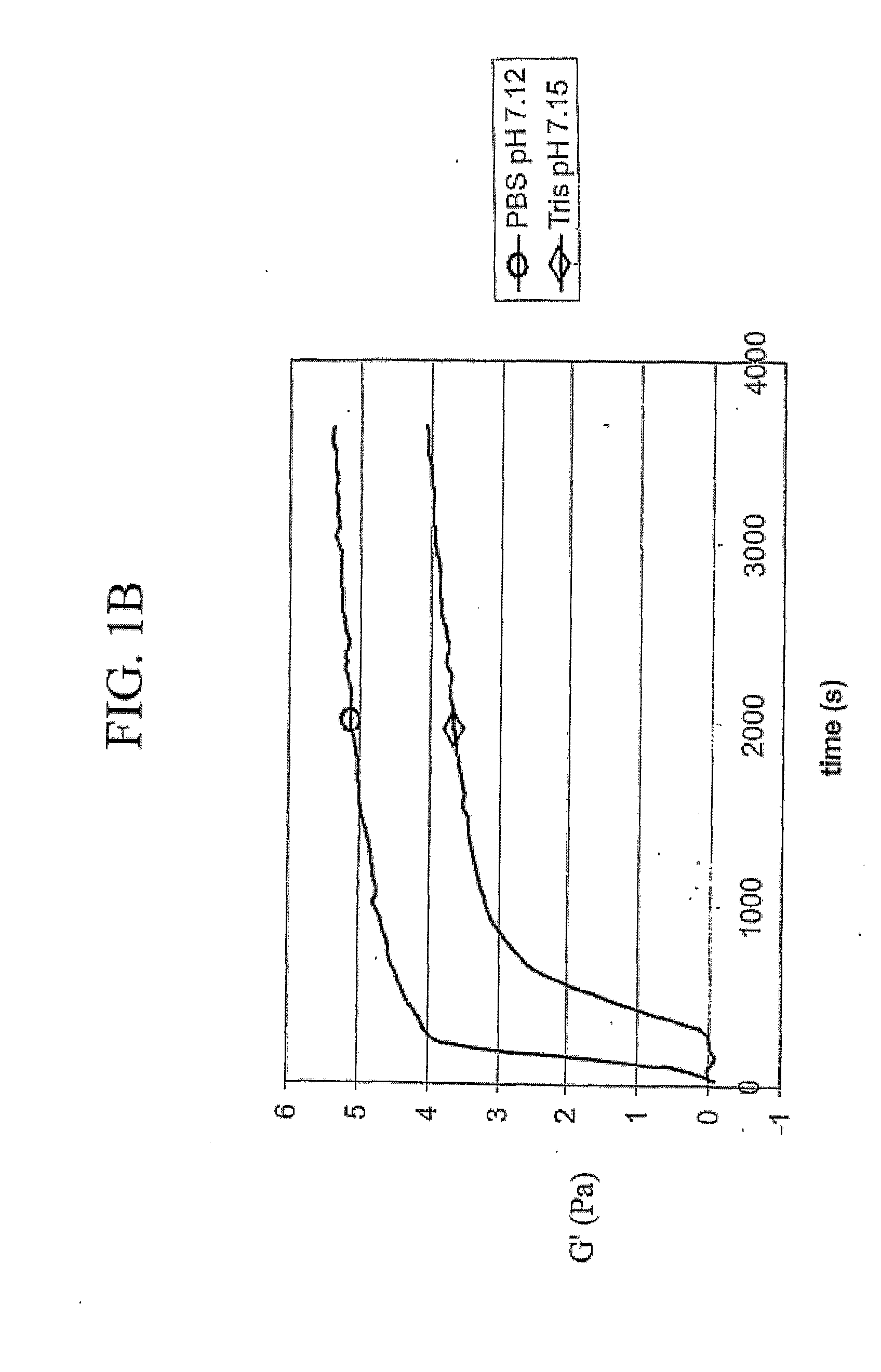

Engineered Extracellular Matrices

ActiveUS20090011021A1Improve mechanical propertiesImprove compliancePowder deliveryPeptide/protein ingredientsFiberCell-Extracellular Matrix

The invention relates to engineered matrices comprising collagen fibrils with specific characteristics, including, but not limited to, a specific fibril area fraction (i.e., density) and / or a specific elastic or linear modulus (i.e., stiffness). The invention also relates to methods of preparation and use of the matrices.

Owner:PURDUE RES FOUND INC

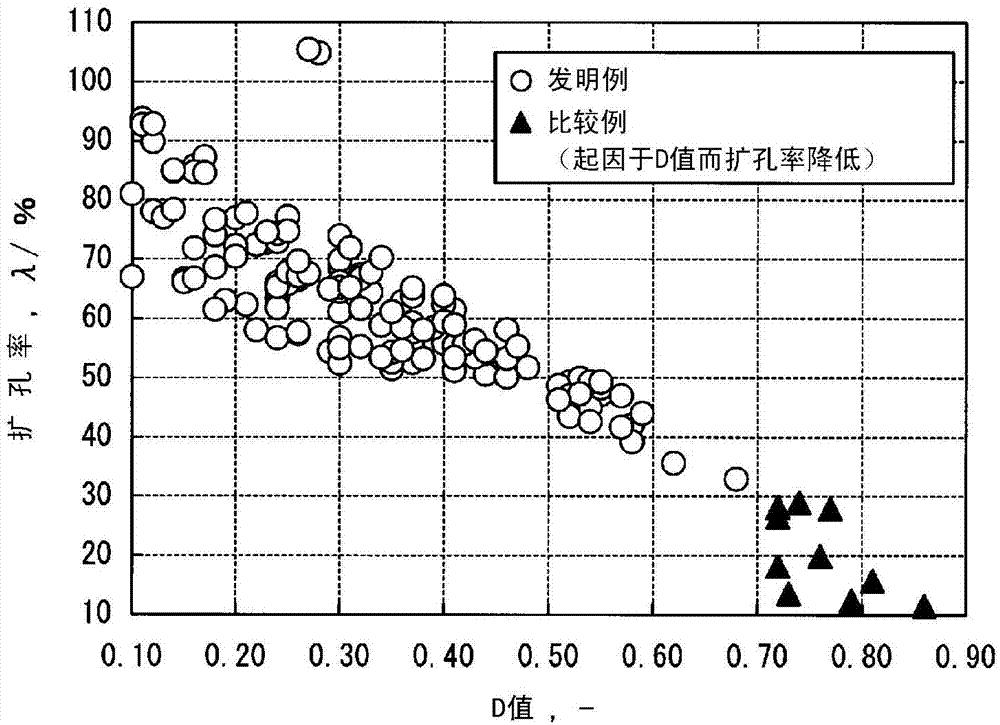

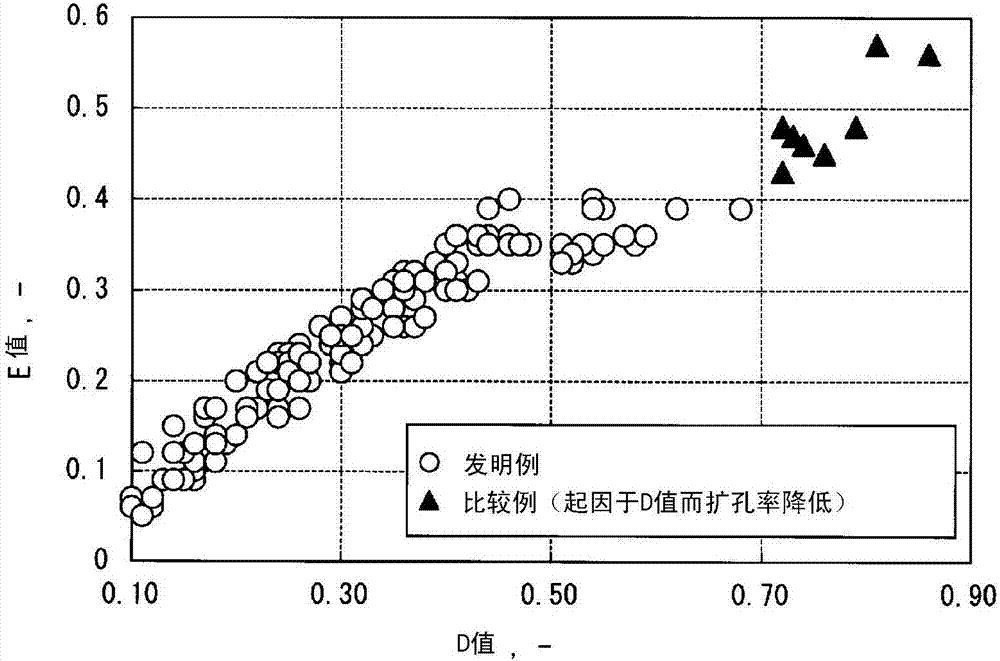

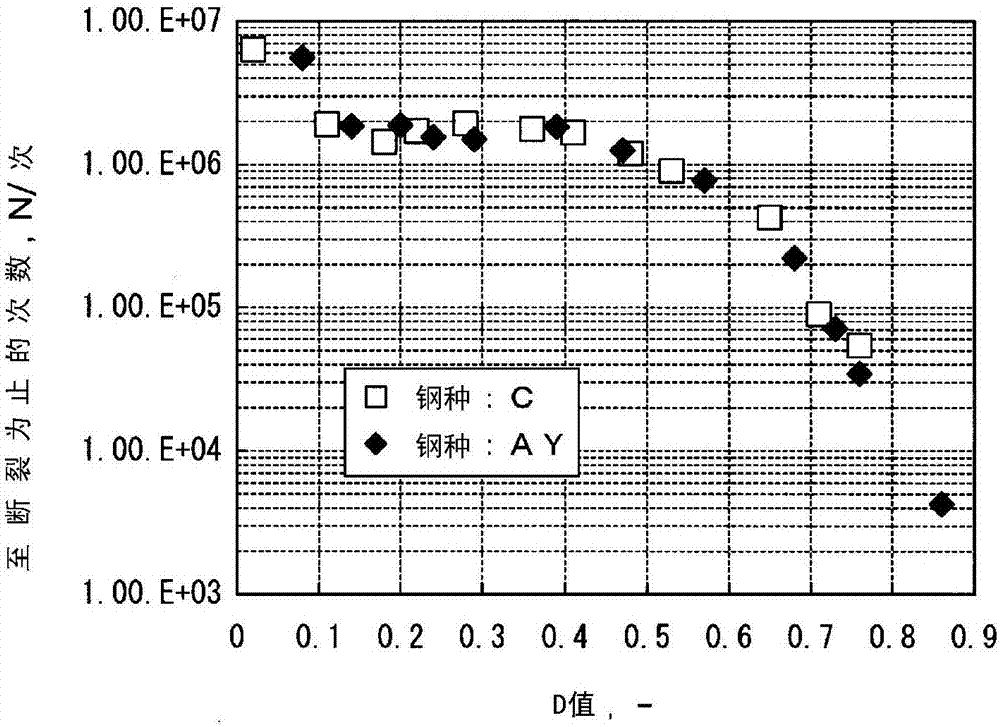

Cold-rolled steel sheet and method for manufacturing same

ActiveCN107429369AExcellent punching fatigue propertiesHigh elongationHot-dipping/immersion processesFurnace typesChemical compositionMartensite

This cold-rolled steel sheet has a predetermined chemical composition, and has a metallographic structure containing, by area fraction, 40.0% to below 60.0% of polygonal ferrite, 30.0% or more of bainitic ferrite, 10.0-25.0% of retained austenite, and 15.0% or less of martensite. In the retained austenite, the proportion of retained austenite having an aspect ratio of 2.0 or less, a major axis length of 1.0 microns or less, and a minor axis length of 1.0 microns or less is 80.0% or more. In the bainitic ferrite, the proportion of bainitic ferrite which has an aspect ratio of 1.7 or less, and in which the average crystallographic misorientation is 0.5 degrees to below 3.0 degrees in a region surrounded by grain boundaries having a crystallographic misorientation of 15 degrees or more, is 80.0% or more. The connectivity D value between the martensite, the bainitic ferrite, and the retained austenite is 0.70 or less.

Owner:NIPPON STEEL CORP

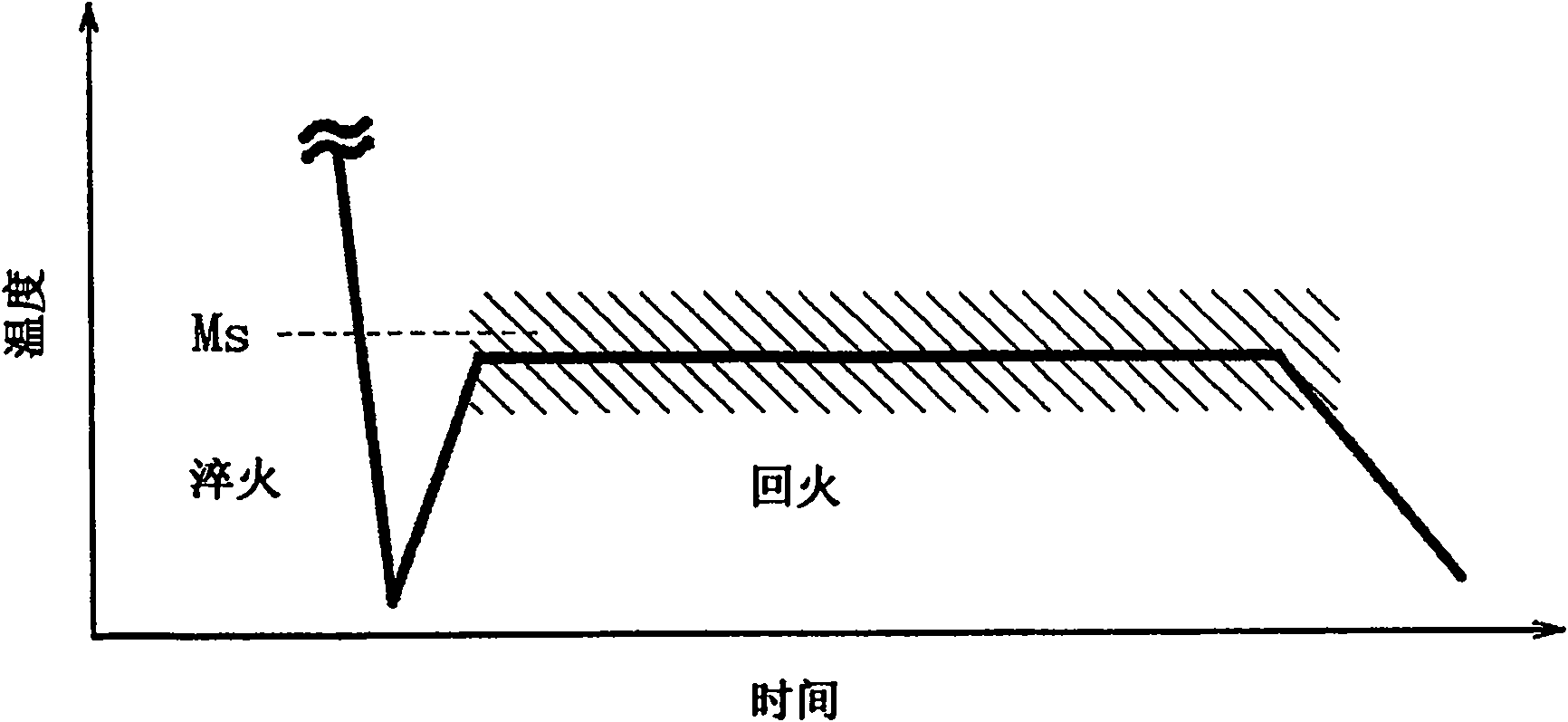

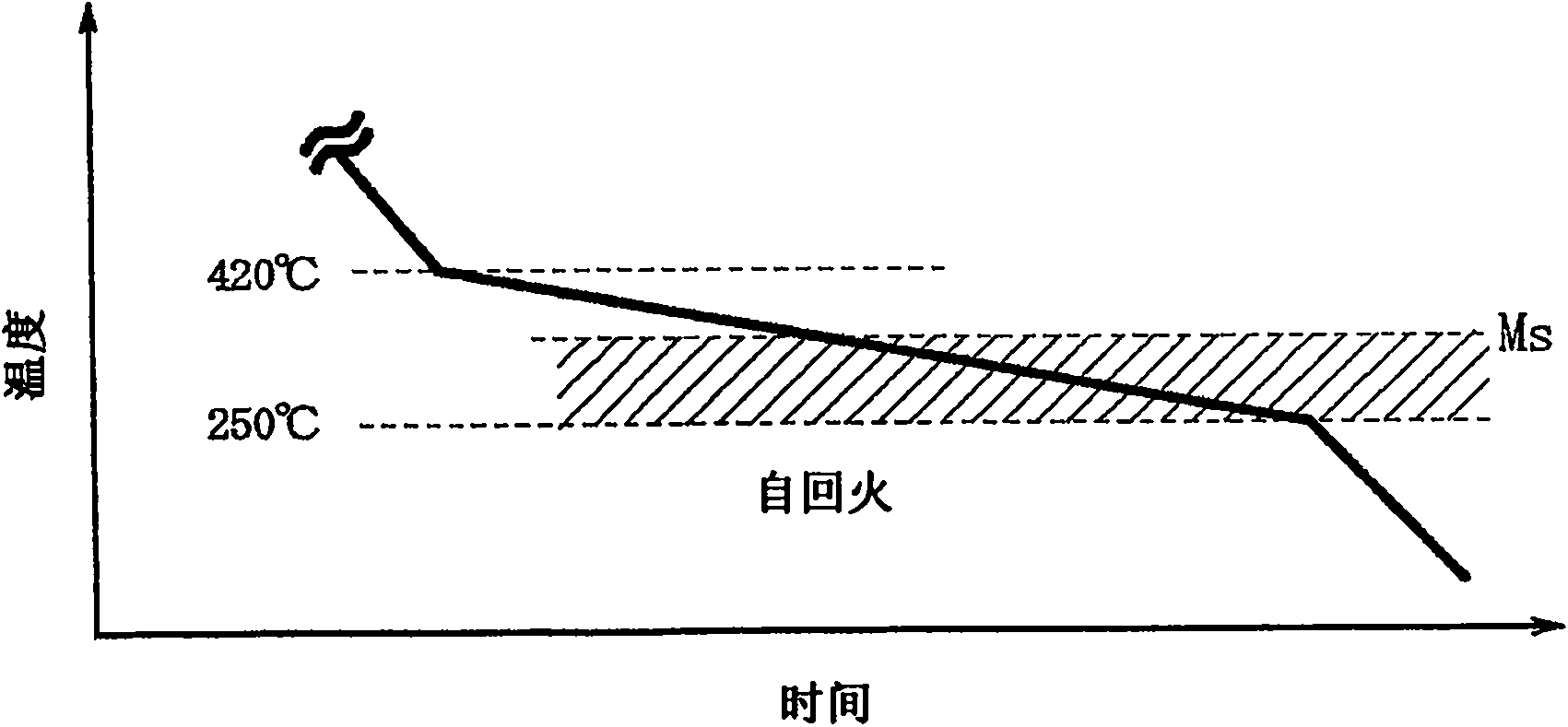

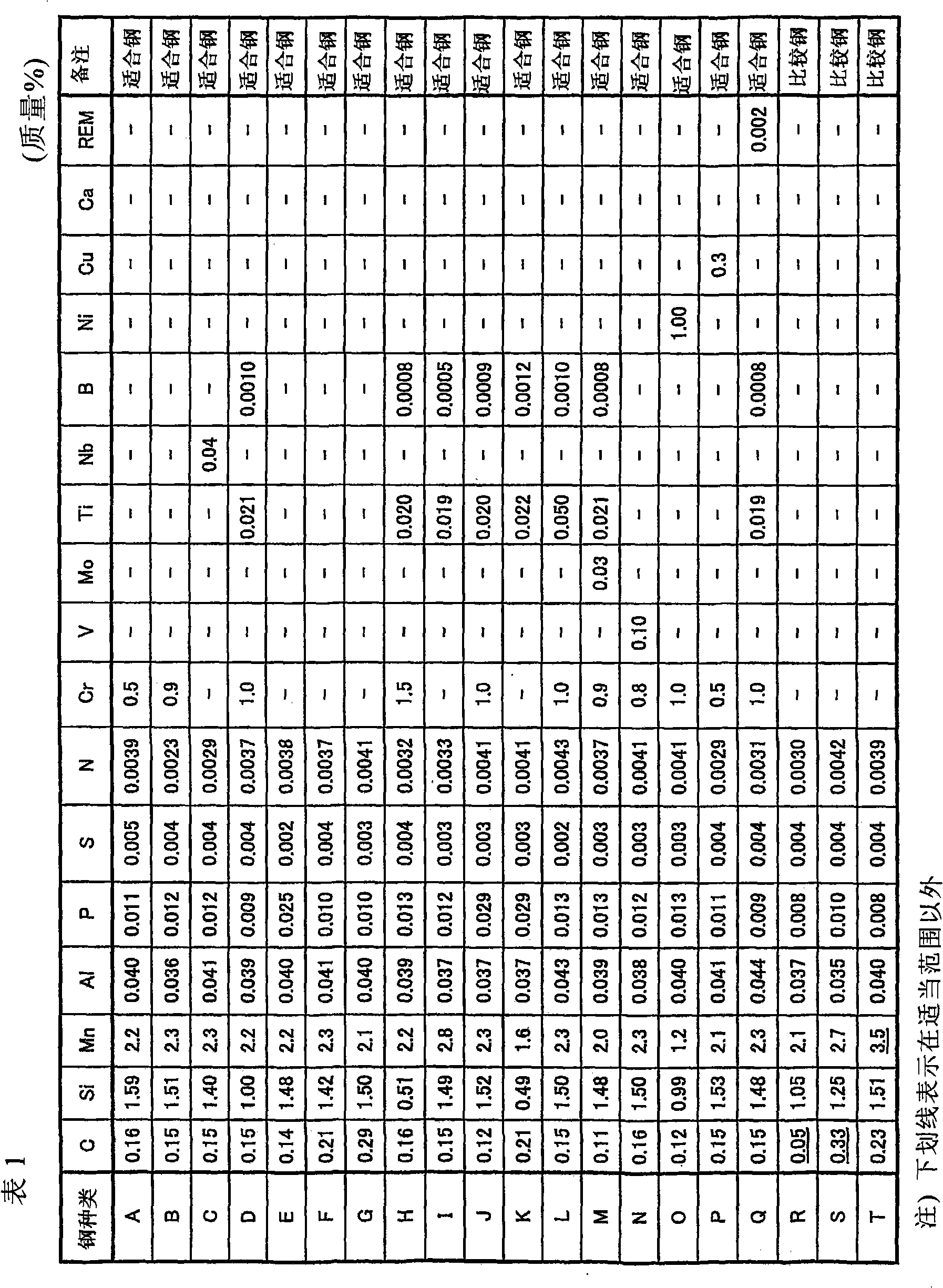

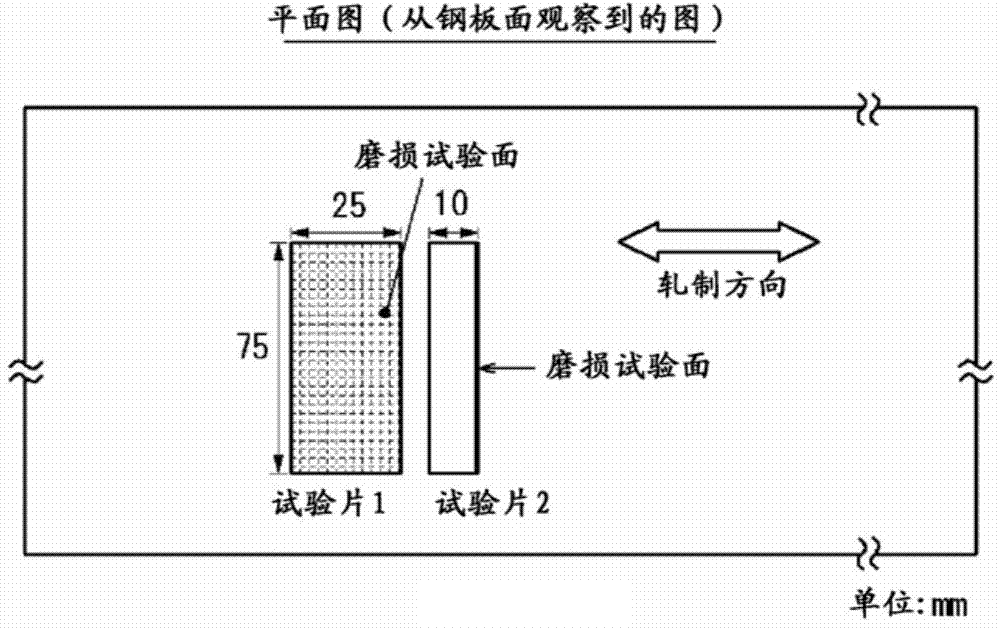

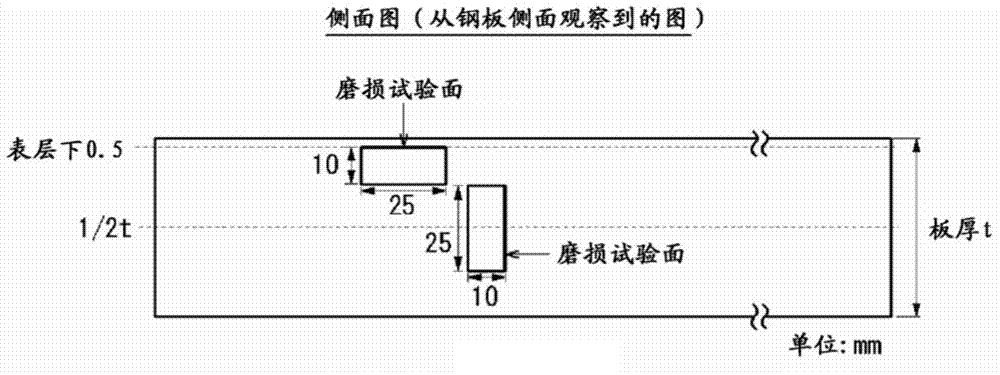

Abrasion-resistant steel plate and manufacturing process therefor

ActiveCN104508166AExcellent impact and wear resistanceImprove production efficiencyFurnace typesHeat treatment furnacesSurface layerHardness

The purpose of the present invention is to provide: an abrasion-resistant steel plate which exhibits excellent impact-abrasion resistance characteristics and which is suitable for use in construction machinery, shipbuilding, steel tubing, civil engineering, architecture and so on; and a manufacturing process therefor. In view of the problem, this abrasion-resistant steel plate is characterized in that: the steel plate has a specific steel composition; the DI* defined by formula (1) is 100 to 250; the surface layers of the plate comprise at least 90% of martensite in area fraction and exhibit a Brinell hardness of 450HBW10 / 3000 or more; and the thicknesswise central zone of the plate comprises at least 70% of lower bainite in area fraction, the thicknesswise central zone being a zone which spreads from the position corresponding to one half of the plate thickness to the positions corresponding to depths of 0.5mm from both surfaces. DI*=33.85 × (0.1×C)0.5 × (0.7×Si+1) × (3.33×Mn+1) × (0.35×Cu+1) × (0.36×Ni+1) × (2.16×Cr+1) × (3×Mo+1) × (1.75×V+1) × (1.5×W+1) ··(1) [wherein the symbols of elements represent the contents (mass%) of the elements respectively]

Owner:JFE STEEL CORP

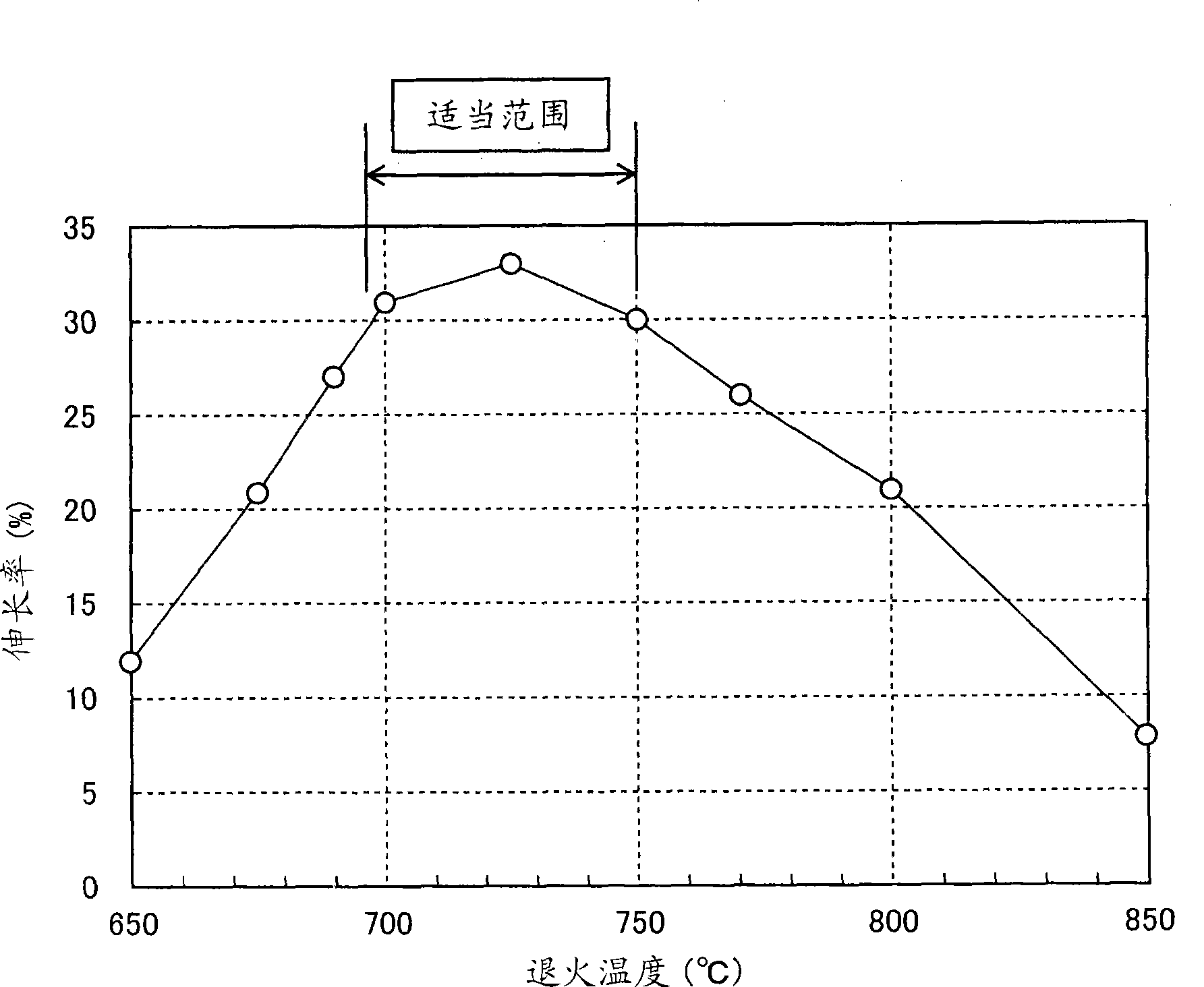

High strength cold rolled steel sheet with excellent deep drawability and material uniformity in coil and method for manufacturing the same

ActiveUS20140290810A1Improve uniformityUniform formatFurnace typesMetal rolling arrangementsChemical compositionMartensite

A high strength cold rolled steel sheet includes a chemical composition containing, by mass %, C: 0.010% or more and 0.060% or less, Si: more than 0.5% and 1.5% or less, Mn: 1.0% or more and 3.0% or less, P: 0.005% or more and 0.100% or less, S: 0.010% or less, sol.Al: 0.005% or more and 0.500% or less, N: 0.0100% or less, Nb: 0.010% or more and 0.100% or less, Ti: 0.015% or more and 0.150% or less and the balance comprising Fe and inevitable impurities. The microstructure includes, in area fraction, 70% or more of a ferrite phase and 3% or more of a martensite phase. The tensile strength is 440 MPa or more and an average r value is 1.20 or more.

Owner:JFE STEEL CORP

Group 3B nitride crystal substrate

ActiveUS20110274609A1Quality improvementGood colorPolycrystalline material growthLiquid-phase epitaxial-layer growthNitrideSeed crystal

A group 13 nitride crystal substrate according to the present invention is produced by growing a group 13 nitride crystal on a seed-crystal substrate by a flux method, wherein a content of inclusions in the group 13 nitride crystal grown in a region of the seed-crystal substrate except for a circumferential portion of the seed-crystal substrate, the region having an area fraction of 70% relative to an entire area of the seed-crystal substrate, is 10% or less, preferably 2% or less.

Owner:NGK INSULATORS LTD

Aluminum-alloy sheet and method for producing the same

An aluminum-alloy sheet includes 0.10 to 0.40 mass % of Si, 0.35 to 0.80 mass % of Fe, 0.10 to 0.35 mass % of Cu, 0.20 to 0.80 mass % of Mn, and 1.5 to 2.5 mass % of Mg, the balance being Al and unavoidable impurities, wherein a content ratio (Si / Fe) of the Si to the Fe is 0.75 or less, the area fraction of Mg2Si intermetallic compound grains having a maximum length of 1 μm or more is 0.10% or more in a region of a section of the aluminum-alloy sheet, the region being a central region in the thickness direction of the aluminum-alloy sheet, and the aluminum-alloy sheet has a proof stress of 225 to 270 N / mm2 after having been baked at 270° C. for 20 seconds.

Owner:KOBE STEEL LTD

Aluminum-base alloy sheet

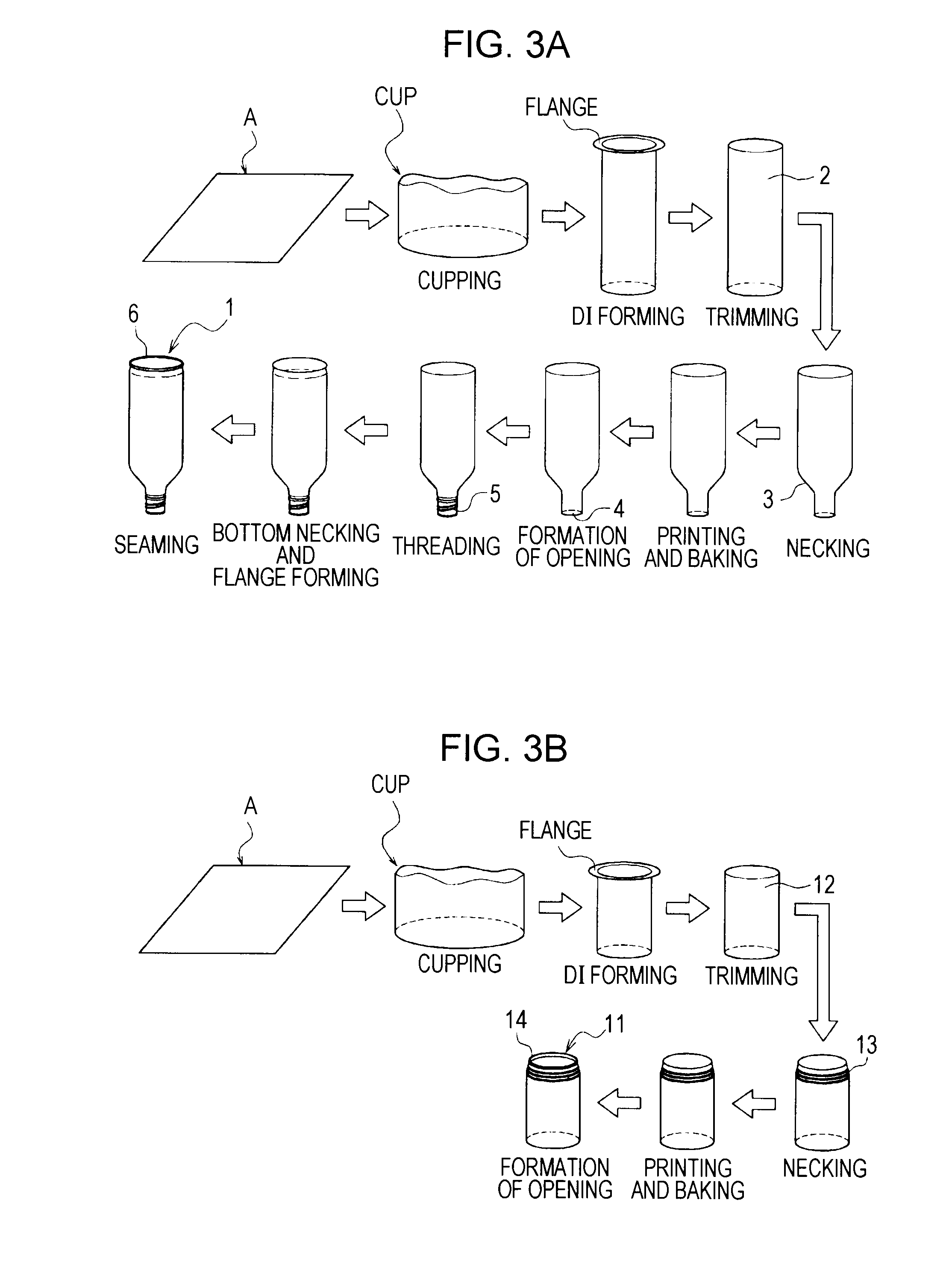

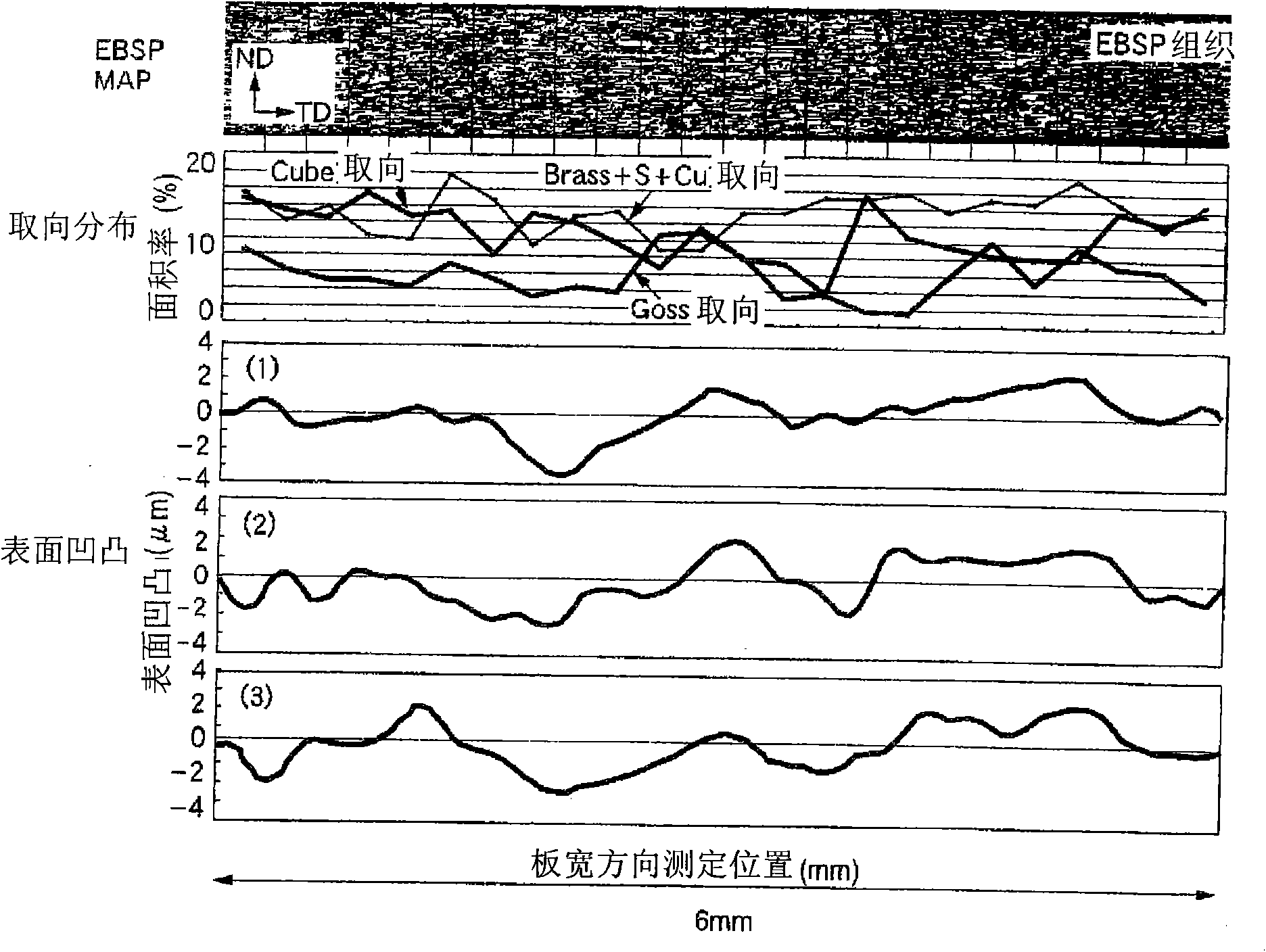

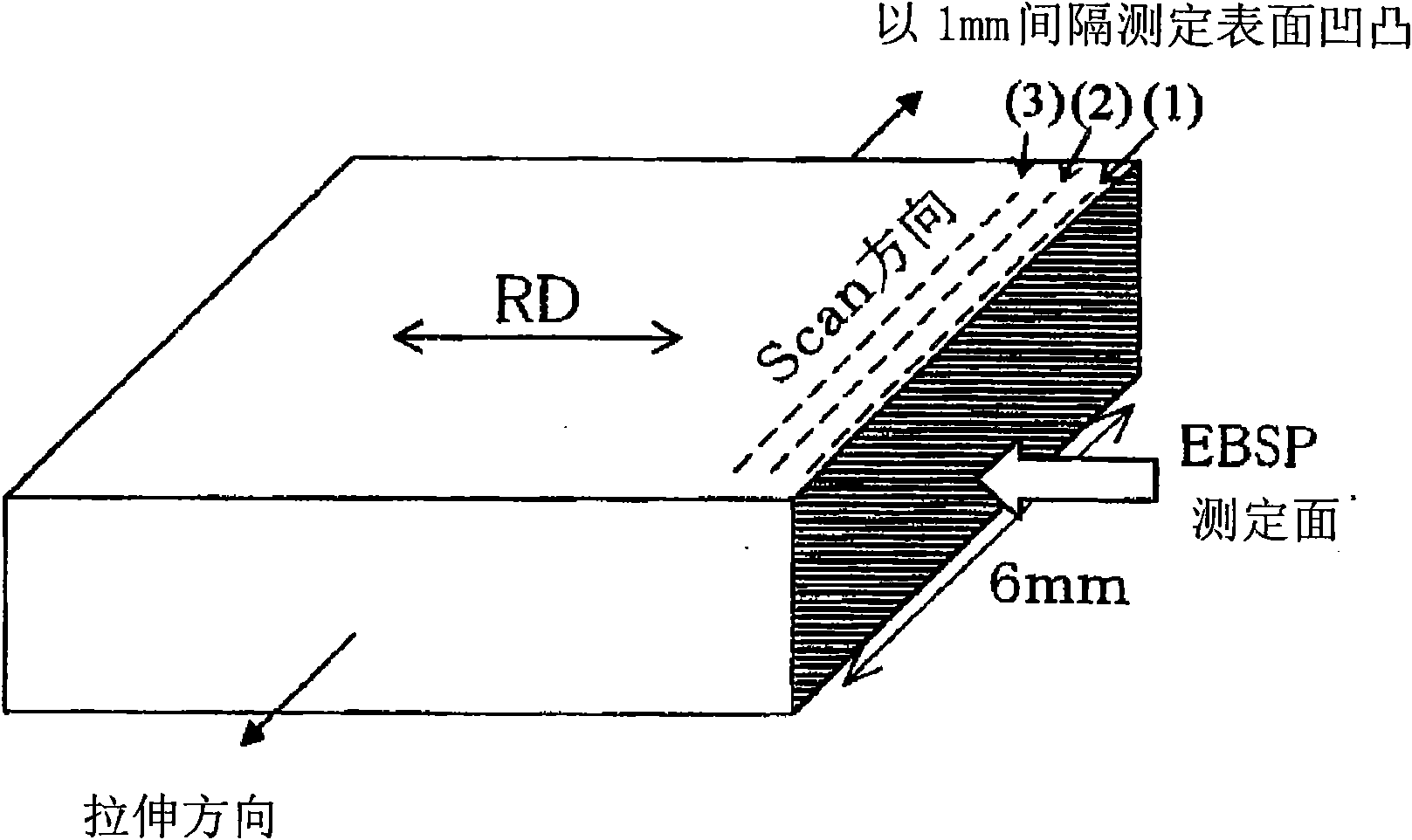

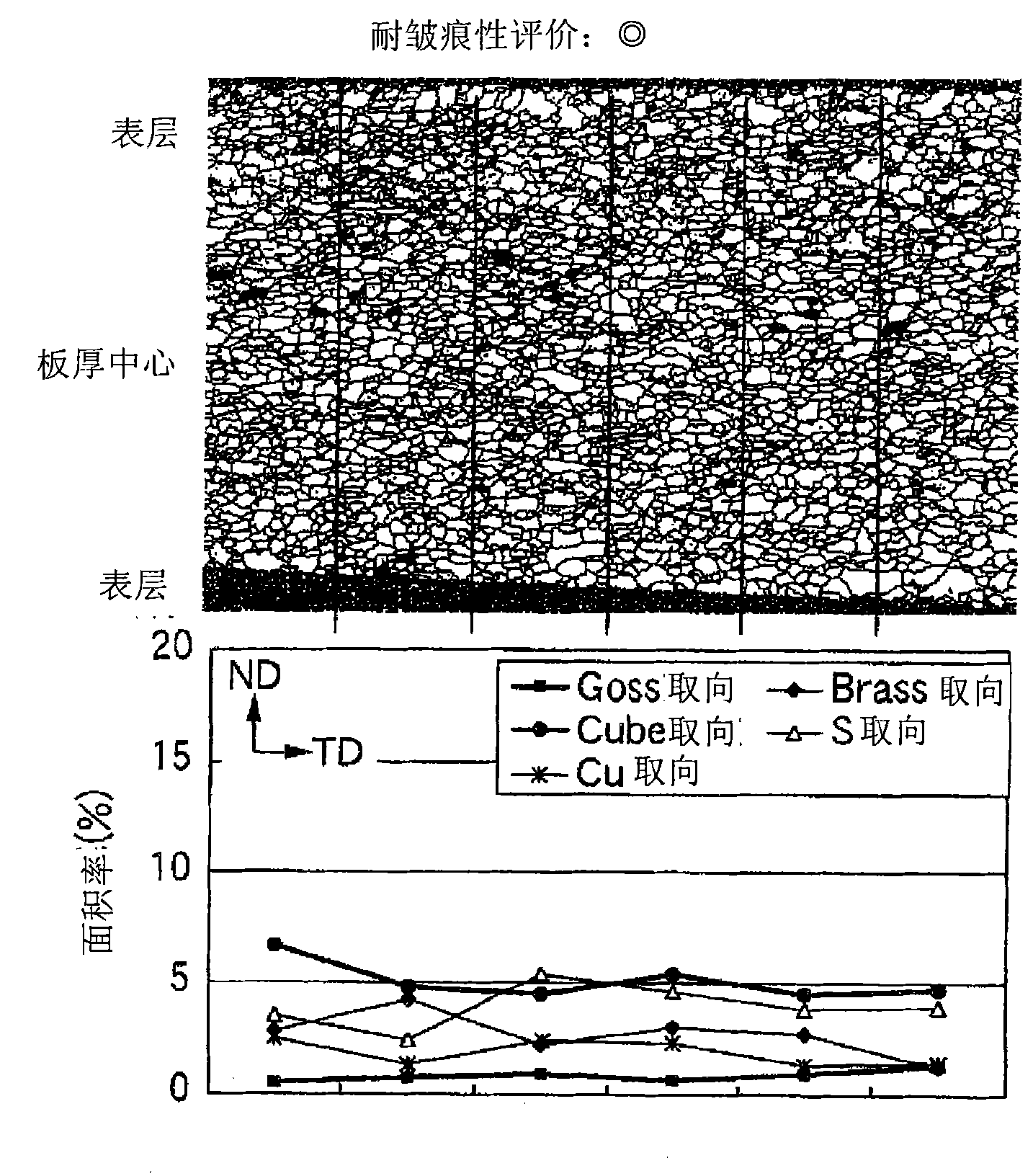

An Al-Mg-Si aluminum-base alloy sheet which is inhibited at high repeatability from forming ridging marks in press forming even when the forming conditions are more severe. The aluminum-base alloy sheet has a specific composition and has, in the sheet widthwise direction in a relatively wide area, a texture wherein the Goss and Cube orientation components are reduced in terms of average area fraction in the sheet widthwise direction and the variations of Goss and Cube orientation components in the texture are reduced in terms of difference between the maximum and minimum area fractions in the sheet widthwise direction. Thus, the aluminum alloy sheet is inhibited from forming uneven ridging marks having a relatively large period in the sheet widthwise direction on the surface of the sheet.

Owner:KOBE STEEL LTD

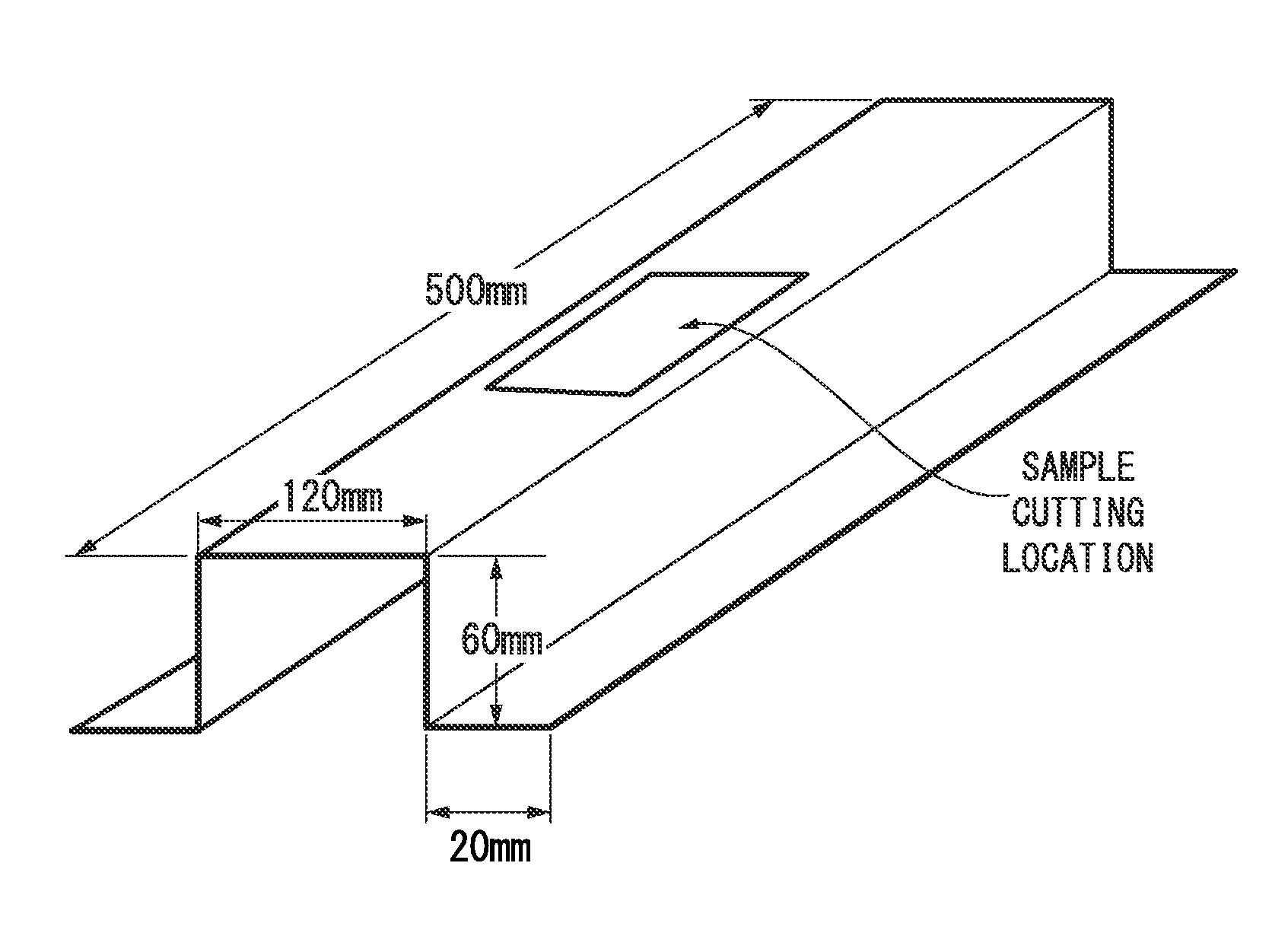

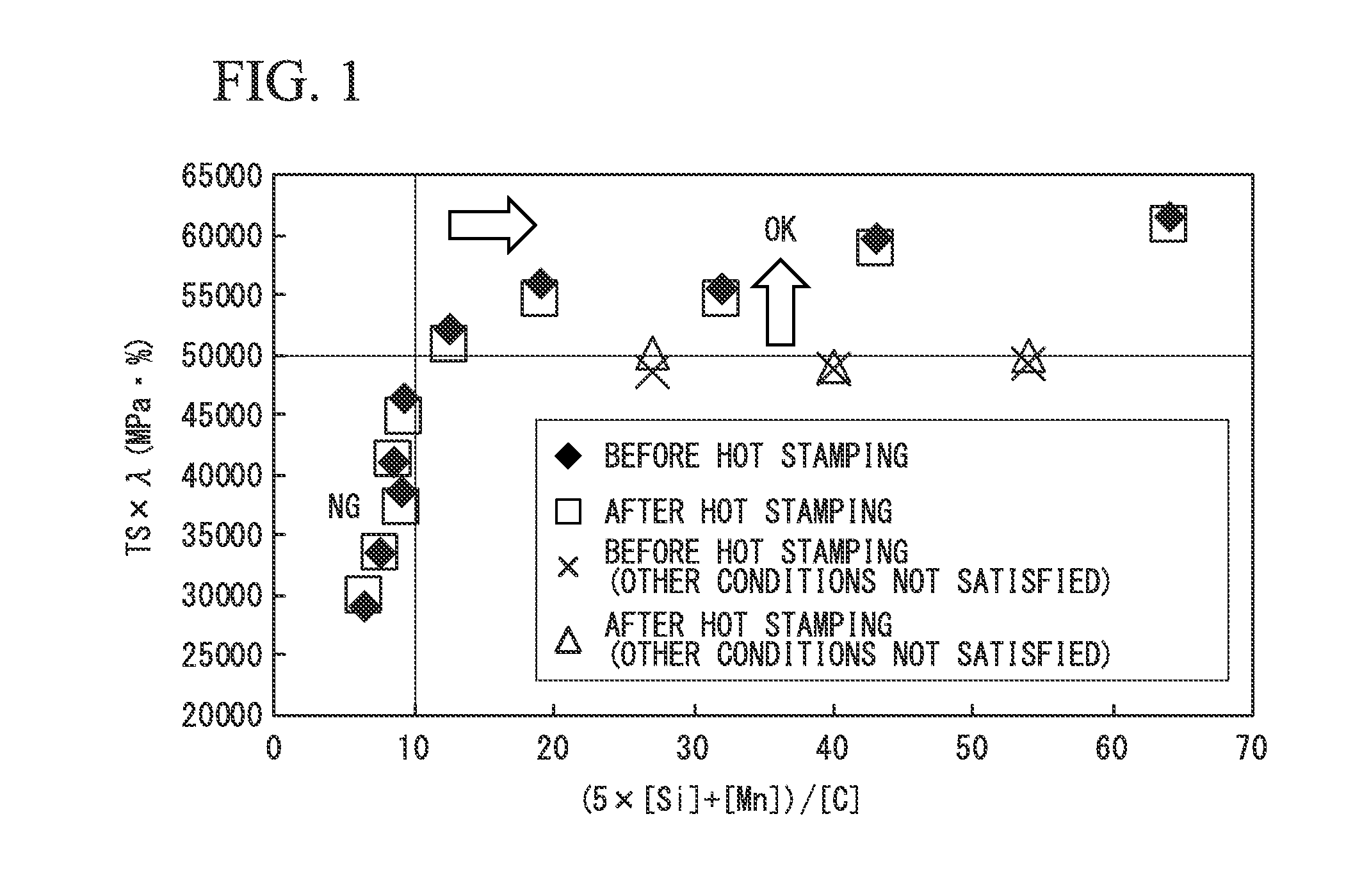

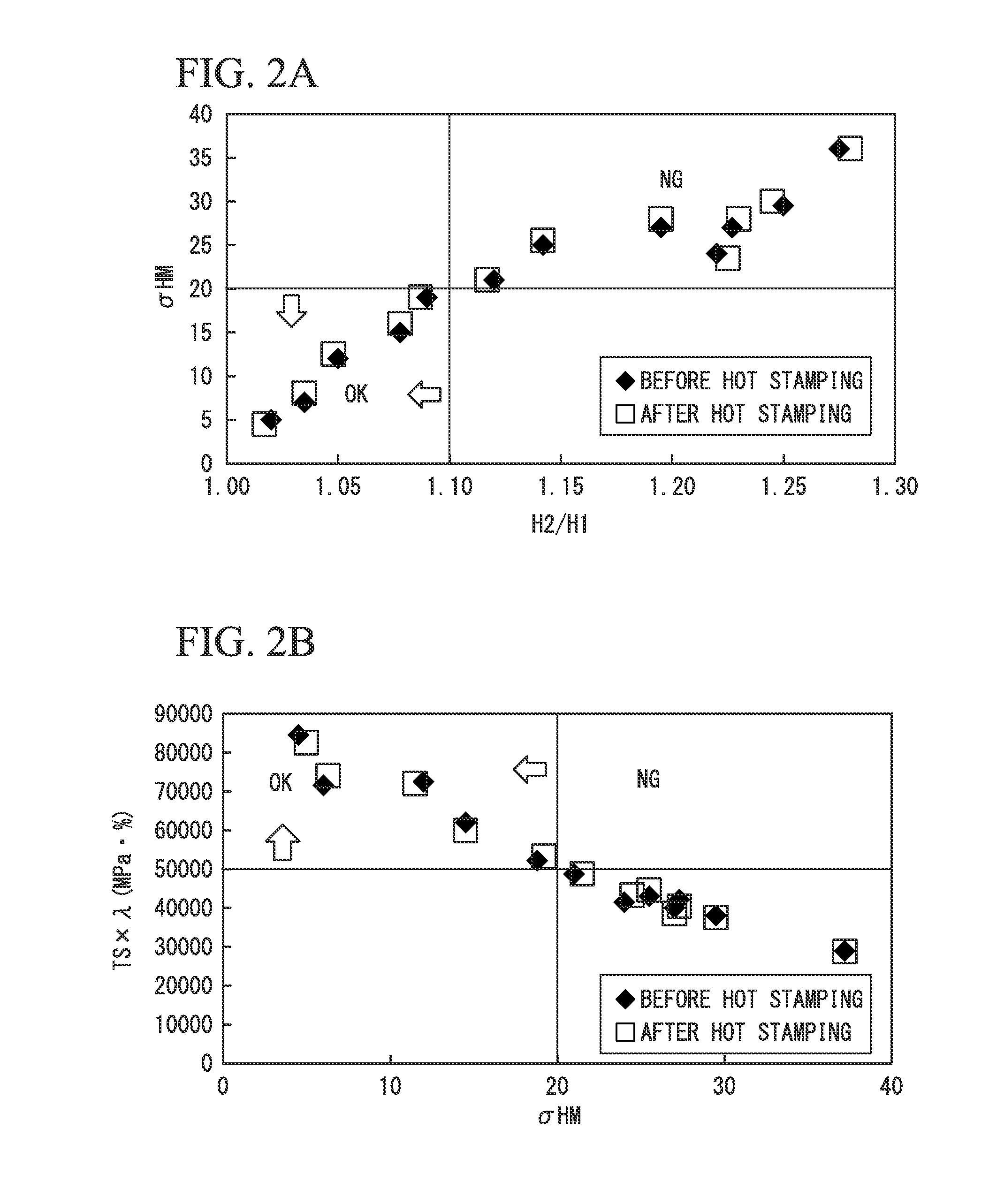

Hot stamped steel and method for producing the same

ActiveUS20150050519A1Excellent hole expandabilityHot-dipping/immersion processesSurface reaction electrolytic coatingCrystallographyHardness

In a hot stamped steel, when [C] represents an amount of C (mass %), [Si] represents an amount of Si (mass %), and [Mn] represents an amount of Mn (mass %), an expression of 5×[Si]+[Mn]) / [C]>10 is satisfied, a metallographic structure includes 80% or more of a martensite in an area fraction, and optionally, further includes one or more of 10% or less of a pearlite in an area fraction, 5% or less of a retained austenite in a volume ratio, 20% or less of a ferrite in an area fraction, and less than 20% of a bainite in an area fraction, TS×λ, which is a product of TS that is a tensile strength and λ that is a hole expansion ratio is 50000 MPa·% or more, and a hardness of the martensite measured with a nanoindenter satisfies H2 / H1<1.10 and σHM<20.

Owner:NIPPON STEEL CORP

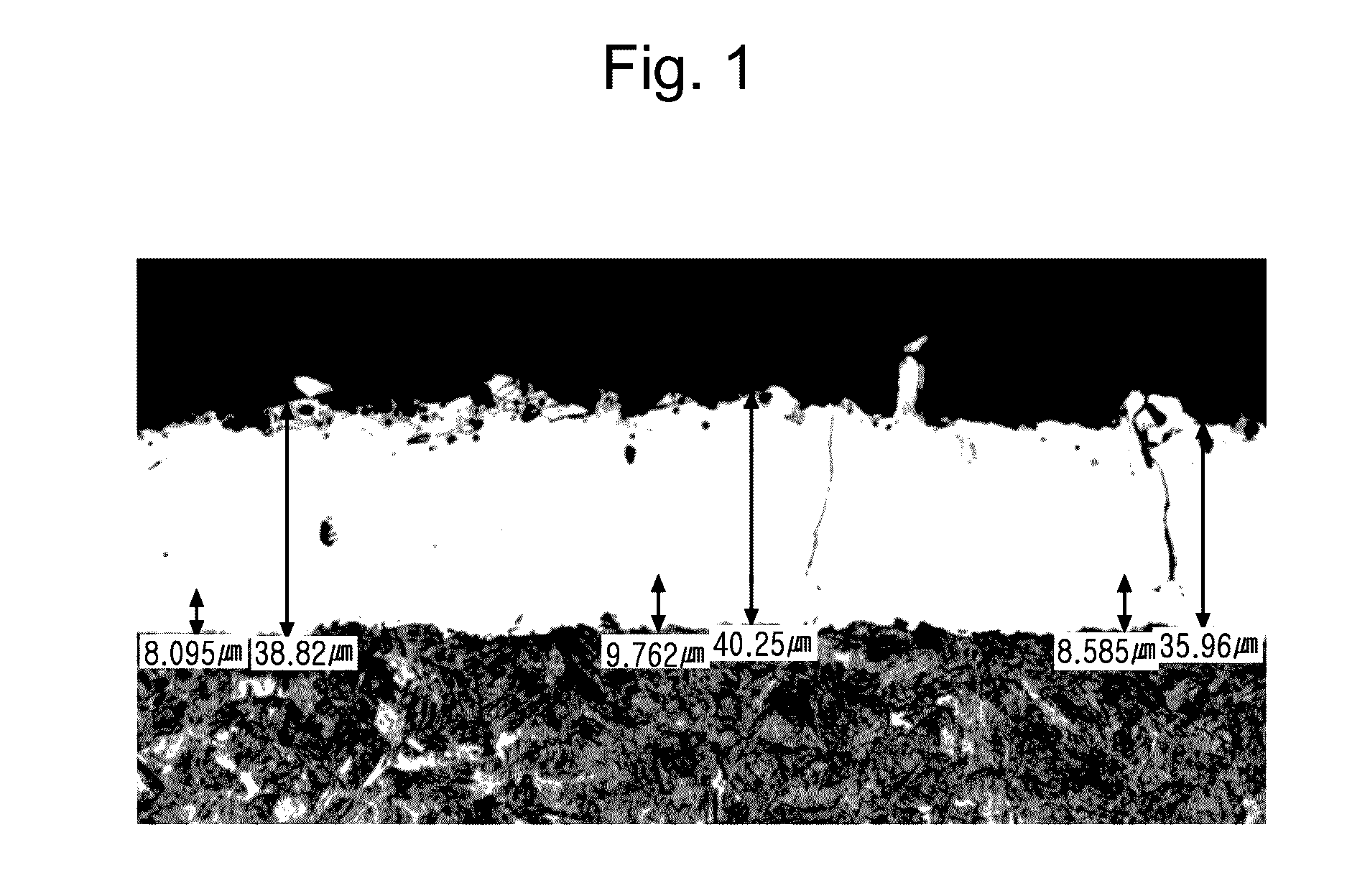

Hot press formed article having excellent delamination resistance and method for manufacturing the same

ActiveUS20160376679A1Excellent delamination resistanceDecreasing difference in hardnessHot-dipping/immersion processesFurnace typesAlloyImpurity

An HPF molding member having a melted aluminum plating layer formed on the surface of a base steel sheet and excellent delamination resistance. The base steel sheet comprises: 0.18-0.25% by weight of C; 0.1-1.0% by weight of Si; 0.9-1.5% by weight of Mn; 0.03% by weight or less of P; 0.01% by weight or less of S; 0.01-0.05% by weight of Al; 0.05-0.5% by weight of Cr; 0.01-0.05% by weight of Ti; 0.001-0.005% by weight of B; 0.009% by weight or less of N; and the balance Fe and other impurities. The plating layer consists of a soft diffusion layer and a hard alloy layer, the hard alloy layer having a tau layer irregularly and non-continuously dispersed and distributed on the inside thereof at 10% or more of the entire area fraction. The difference in hardness between the alloy layer and the diffusion layer is 400 (Hv) or less.

Owner:POHANG IRON & STEEL CO LTD

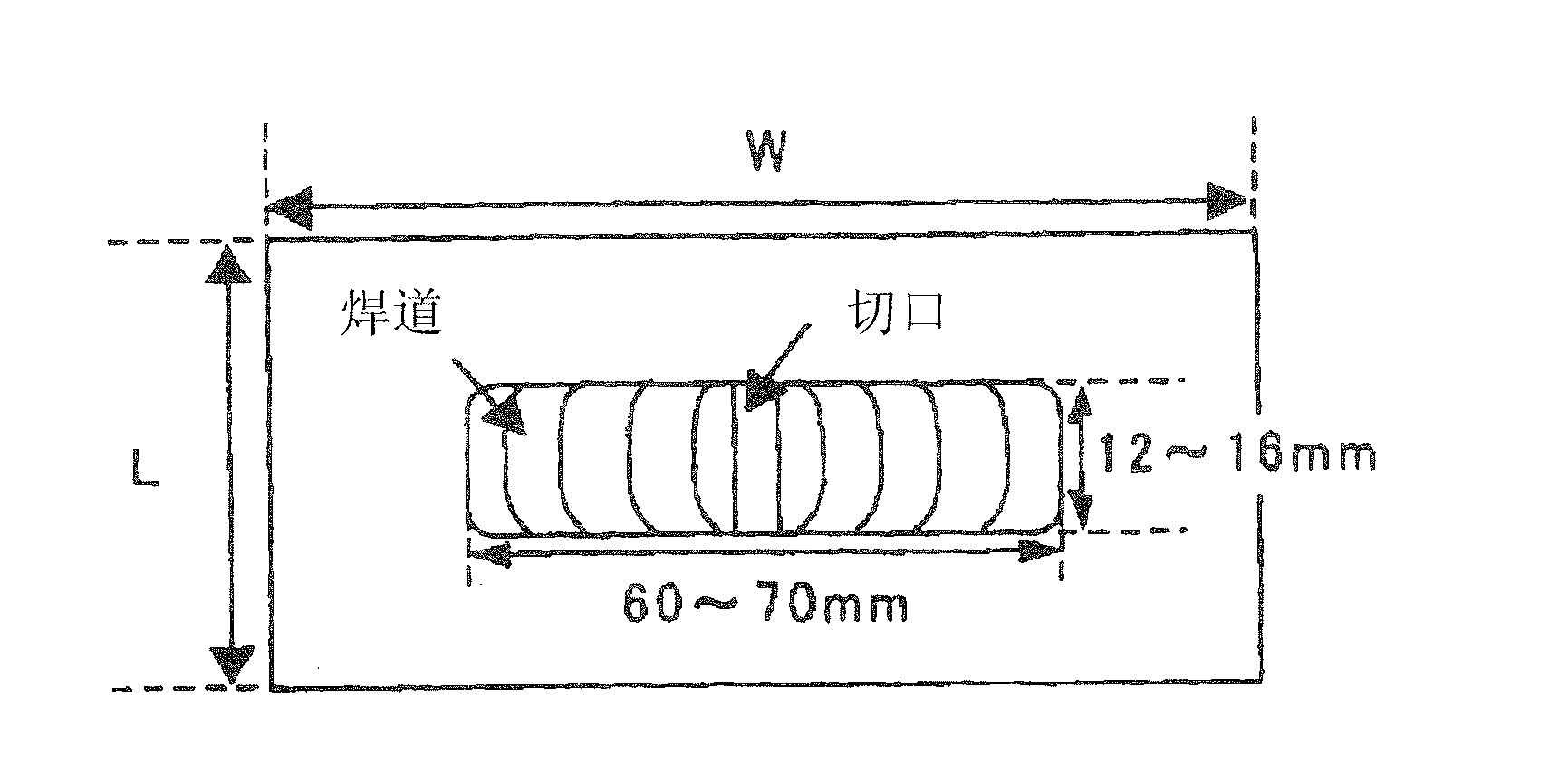

High-strength thick steel plate with excellent drop weight characteristics

The disclosed high-strength thick steel plate satisfies prescribed chemical component composition requirements, and is useful as a structural material in marine structures, ships, bridges, and also as a material in pressure vessels in nuclear power plants. In the microstructure positioned at a depth of t / 4-t / 2 from the surface (t is the plate thickness, same below), the area fraction of bainite is 90% or greater, the average value of the bainite lath width is 3.5 [mu]m or less, and the circle equivalent diameter of island martensite in the bainite has a maximum value of 3.0 [mu]m or less.

Owner:KOBE STEEL LTD

T/P91 steel ageing rating method based on precipitated phase fractional area

InactiveCN102692425AConvenience to workPreparing sample for investigationScanning probe microscopyMetallurgyTest sample

The invention discloses a T / P91 steel ageing rating method based on precipitated phase area fraction. The method comprises the following steps of: 1, intercepting a test sample to be evaluated, and preparing a metallographic phase test sample; 2, acquiring a metallographic phase tissue picture of the metallographic phase test sample; 3, calculating the precipitated phase area fraction according to the pixel difference of the precipitated phase in the metallographic phase tissue picture, wherein the metallographic phase tissue picture is the percentage of the precipitated phase particle area to the field-of-view total area; and 4, performing ageing rating on the test sample to be evaluated according to the precipitated phase area fraction. The invention provides a T / P91 steel ageing rating method with quantitative reaction, so that an intuitive evaluation parameter on ageing of T / P91 steel is provided for scientific research and process study personnel.

Owner:WUHAN UNIV

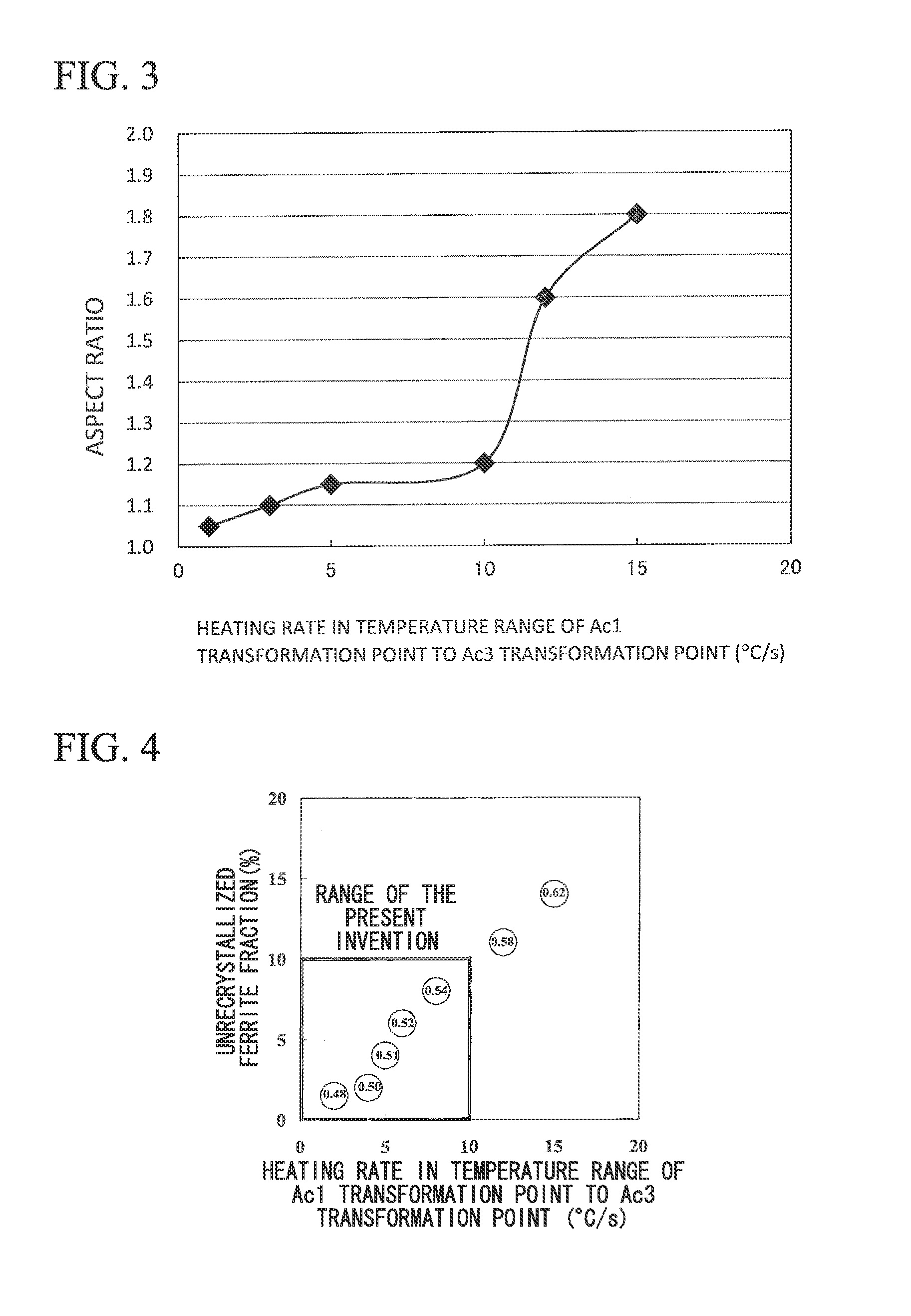

High-strength steel sheet having excellent processability and paint bake hardenability, and method for producing of high-strength steel sheet

InactiveUS20120282487A1Lower ratioLow strengthHot-dipping/immersion processesFurnace typesManganeseMaterials science

The high-strength steel sheet includes, by mass %: C: 0.01% to 0.10%; Si: 0.15% or less; Mn: 0.80% to 1.80%; P: 0.10% or less; S: 0.015% or less; Al: 0.10% to 0.80%; Cr: 0.01% to 1.50%; N: 0.0100% or less; and a balance consisting of iron and inevitable impurities, in which a metallic structure is composed of ferrite and a hard second phase, the area fraction of the ferrite is 80% or more, the area fraction of the hard second phase is 1% to 20%, the fraction of unrecrystallized ferrite in the ferrite is less than 10%, the ferrite grain sizes are 5 μm to 20 μm, and the fraction of the ferrite crystal grains having an aspect ratio of 1.2 or less in the entire ferrite crystal grains is 60% or more.

Owner:NIPPON STEEL CORP

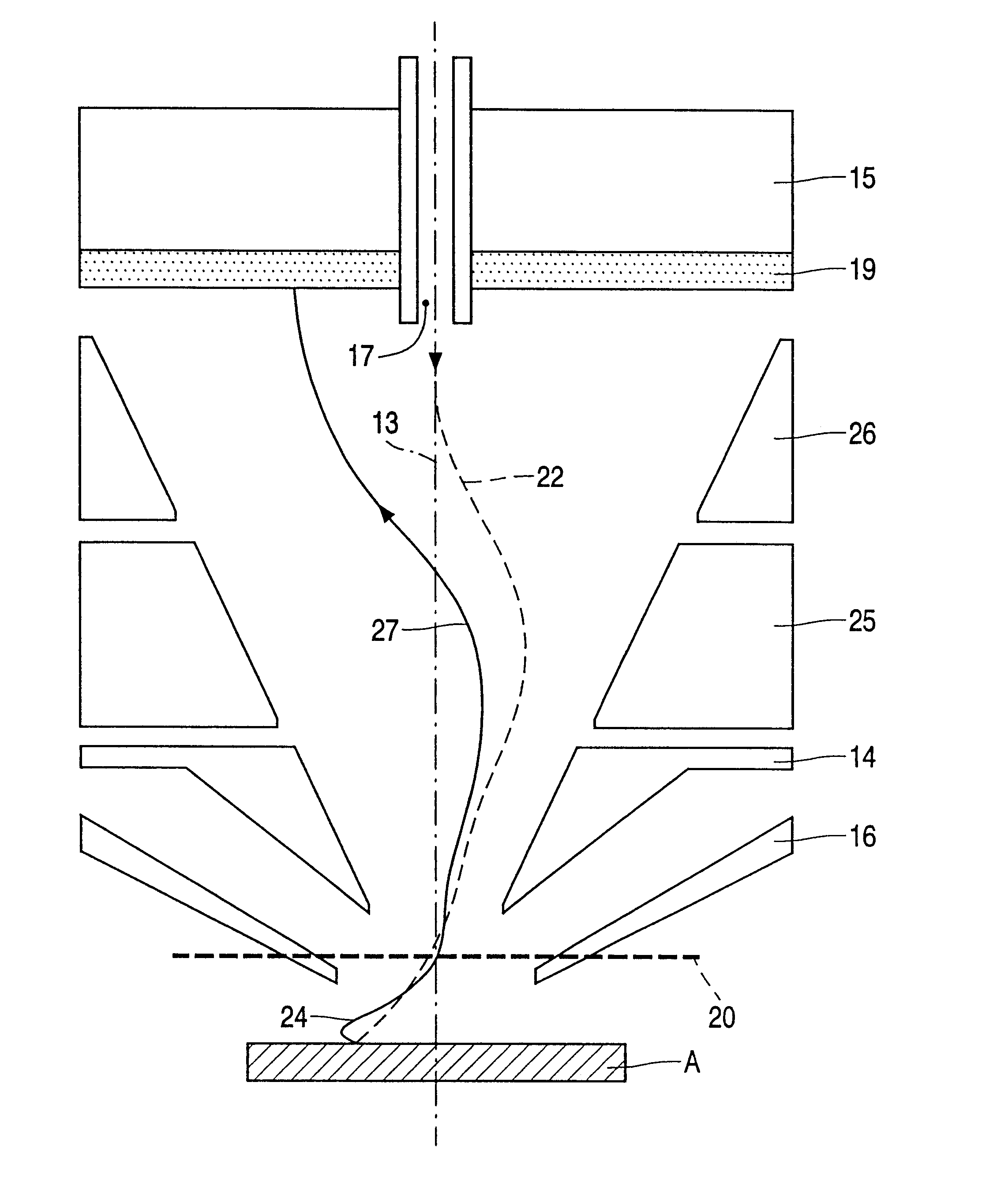

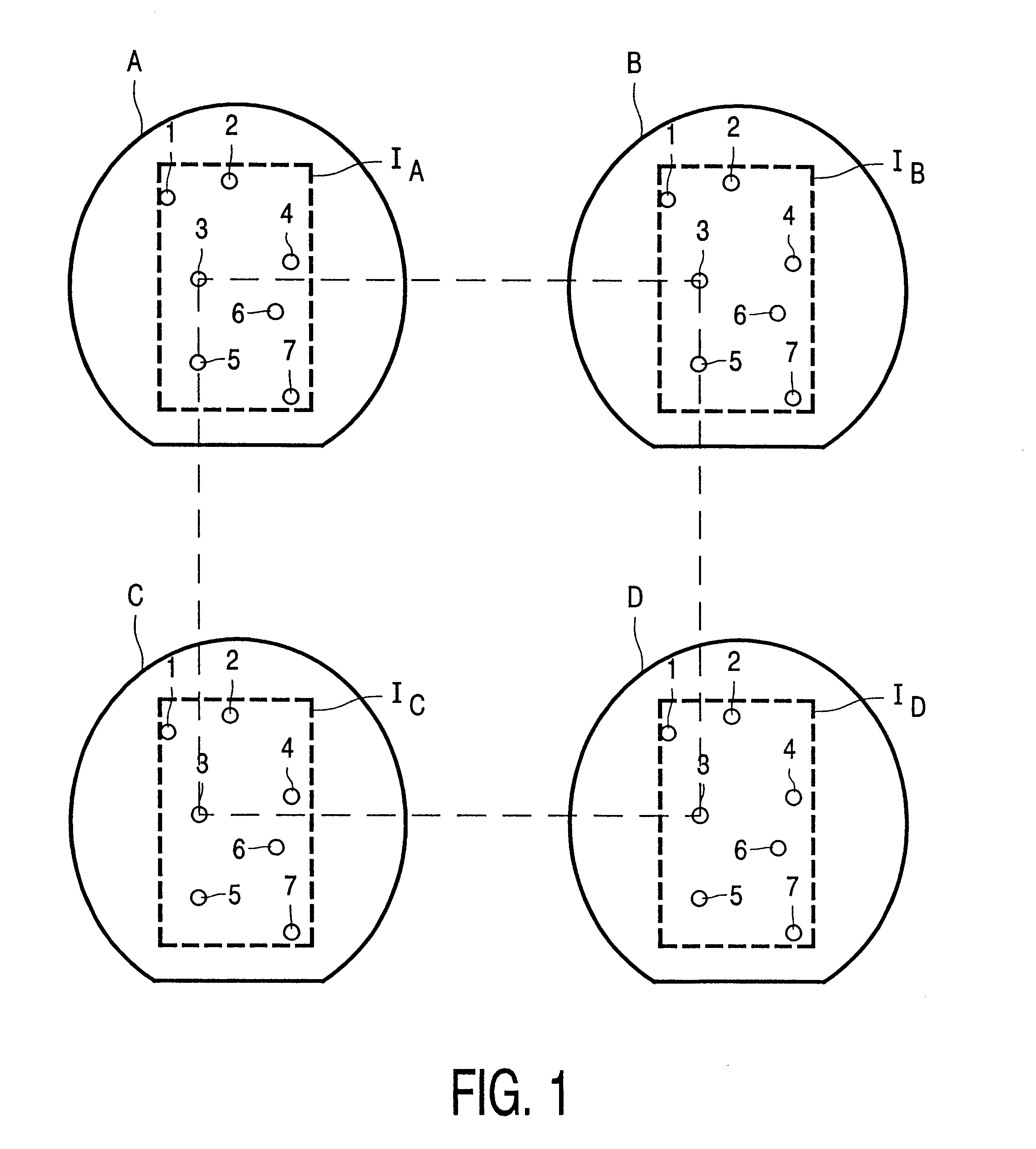

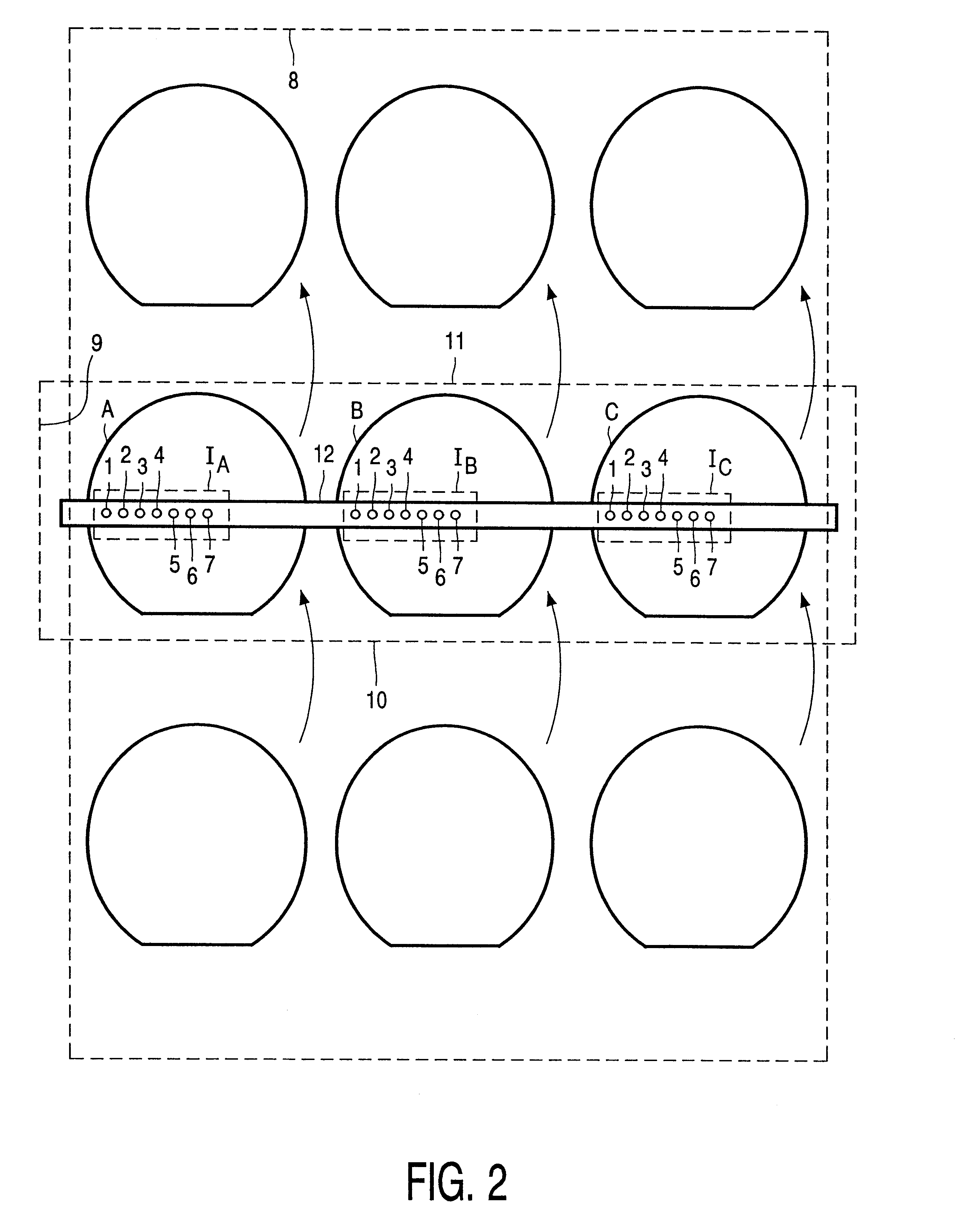

Particle-optical inspection device especially for semiconductor wafers

InactiveUS6693278B2Easy to reachPrevent magnetic saturationSemiconductor/solid-state device testing/measurementElectric discharge tubesLight beamEngineering

In the production of semiconductors it is necessary to inspect circuit patterns on wafers. In circuits having very small details (for example, 40 nm), inspection can be carried out by means of electron beam columns, a plurality of wafers then being inspected at the same time and the signals being compared on-line. In an inspection apparatus in accordance with the invention more beam columns 1 to 7 are provided for every wafer A, B, C in order to obtain a high feed-through rate. The inspection is carried out by way of an x-y scan and the wafers are fed through according to a rectilinear movement, thus providing the possibility of scanning only the Care Area Fraction of the wafers, resulting in a high feed-through rate for the wafers in the inspection apparatus.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

High-strength steel sheet and its production method

InactiveCN101460644AInhibition effectFurnace typesMetal rolling arrangementsSheet steelEnergy absorption

A high-strength steel sheet which has a metallic structure comprising a ferrite phase and a second hard phase dispersed in the steel sheet. In the metallic structure, the areal proportion of the second hard phase is 30-70%. In the ferrite phase, the areal proportion of ferrite having a crystal grain diameter not larger than 1.2 [mu]m is 15-90% and the average grain diameter of ferrite having a crystal grain diameter not larger than 1.2 [mu]m (ds) and the average grain diameter of ferrite having a crystal grain diameter exceeding 1.2 [mu]m (dL) satisfy the relationship dL / ds=3. The size of the ferrite crystal grains has been reduced by reducing the amount of alloying elements to be added. The steel sheet hence has an increased strength. The steel sheet has an excellent balance between strength and ductility, which is important for press molding. It is excellent in energy absorption in high-speed deformation. Also provided is a process for producing the steel sheet.

Owner:HONDA MOTOR CO LTD

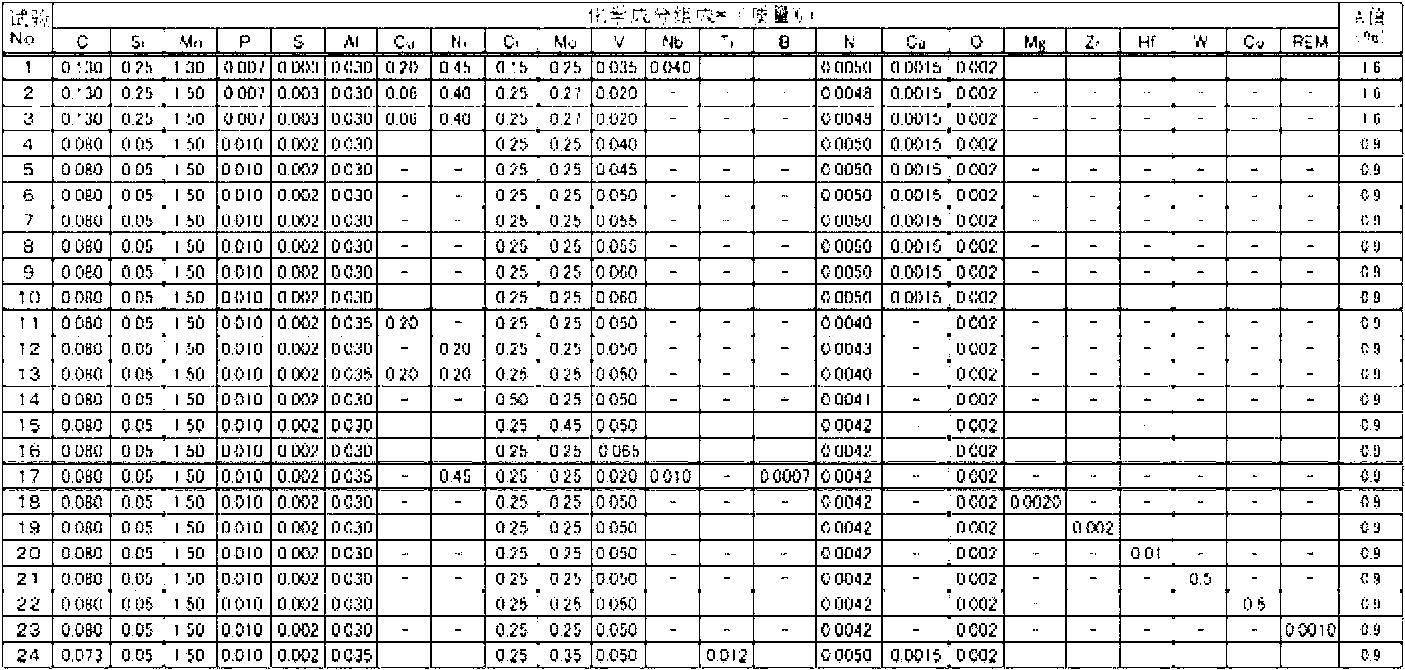

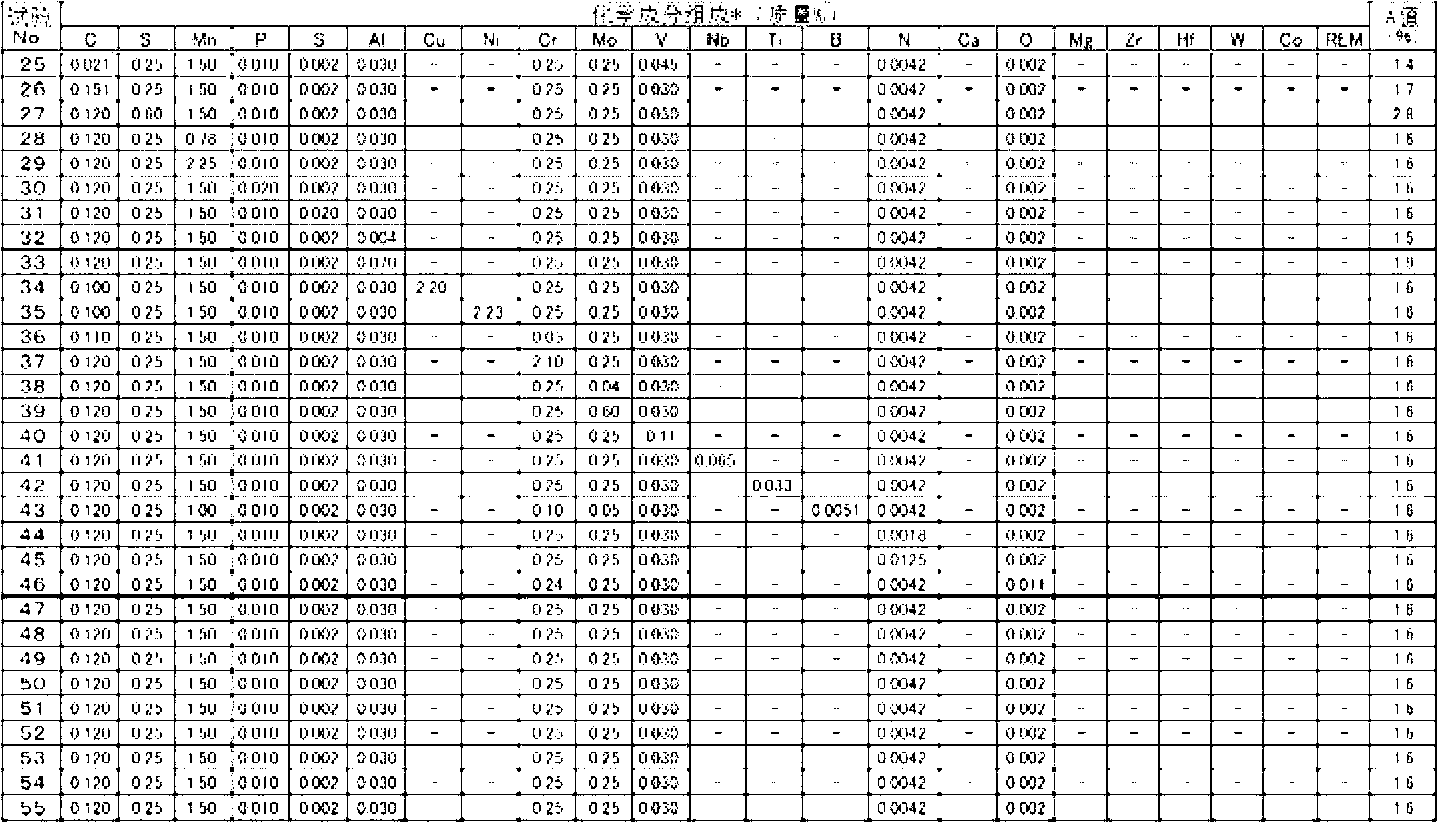

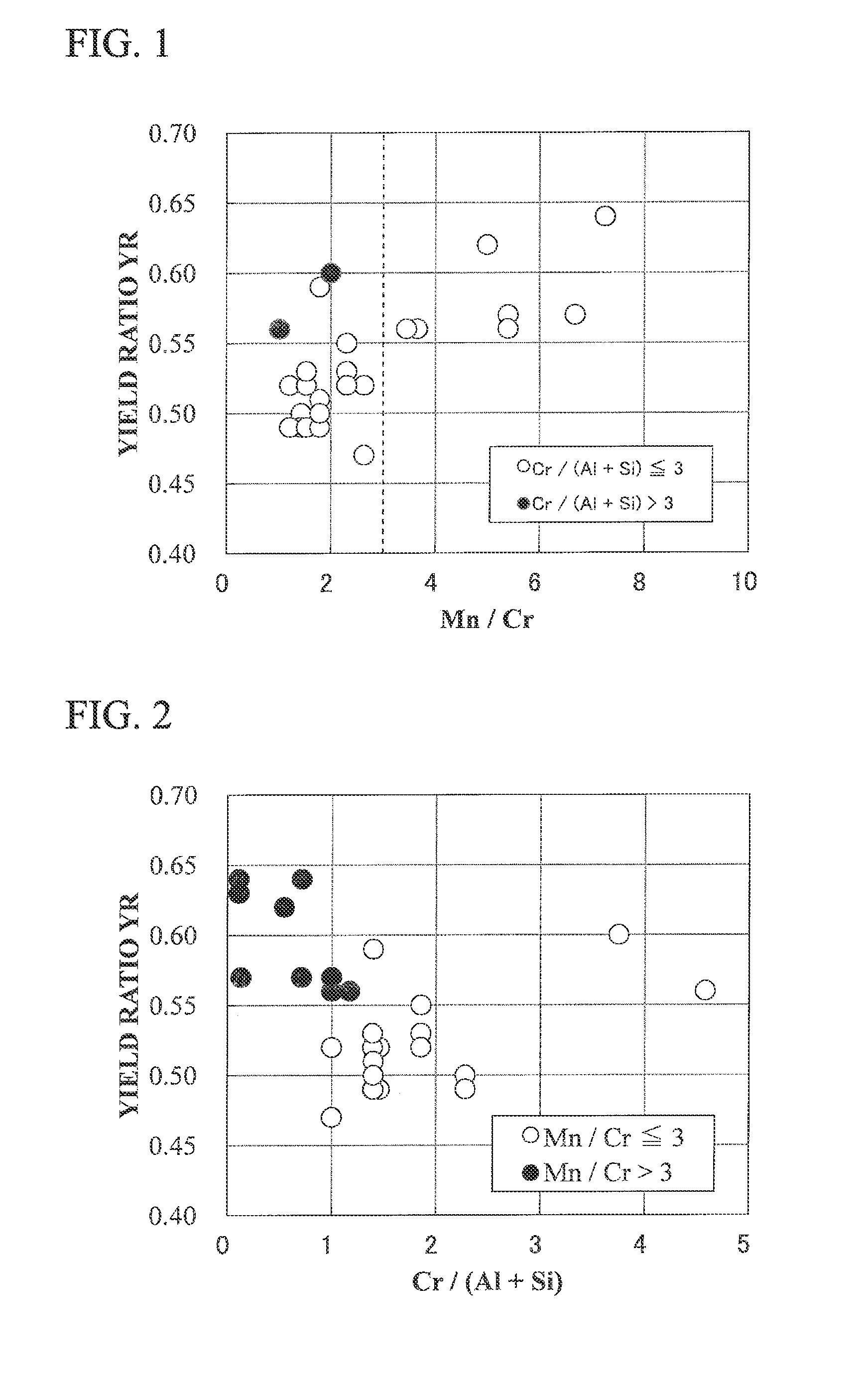

High-strength steel plate and process for production thereof, and high-strength steel pipe

The invention provides a high-strength steel plate which exhibits excellent cutting-crack resistance, Charpy absorption energy and DWTT characteristics, a low yield ratio and a tensile strength of 900 MPa or above; a process for the production thereof; and high-strength steel pipes made by using the same. The high-strength steel plate is one which contains by mass C: 0.03 to 0.12%, Si: 0.01 to 0.5%, Mn: 1.5 to 3%, Al: 0.01 to 0.08%, Nb: 0.01 to 0.08%, Ti: 0.005 to 0.025%, N: 0.001 to 0.01%, and at least one of Cu: 0.01 to 2%, Ni: 0.01 to 3%, Cr: 0.01 to 1%, Mo: 0.01 to 1%, and V: 0.01 to 0.1% and satisfies the following relationship (1) as to the contents of Ca, O and S, whose microstructure is composed of ferrite and a hard second phase at an area fraction of ferrite of 10 to 50% with the cementite contained in the hard second phase having a mean particle diameter of 0.5[mu]m or below, and in which the content of Nb contained as carbide in the steel is at most 10% based on the whole Nb content of the steel. 1 < (1 - 130 [O]) [Ca] / (1.25 [S]) < 3 ... (1).

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com