High-strength steel sheet and its production method

A technology of high-strength steel sheets and manufacturing methods, which can be applied to the manufacture of high-strength steel sheets and high-strength steel sheets for automobiles, and can solve problems such as low ductility, insufficient characteristics, and reduced production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

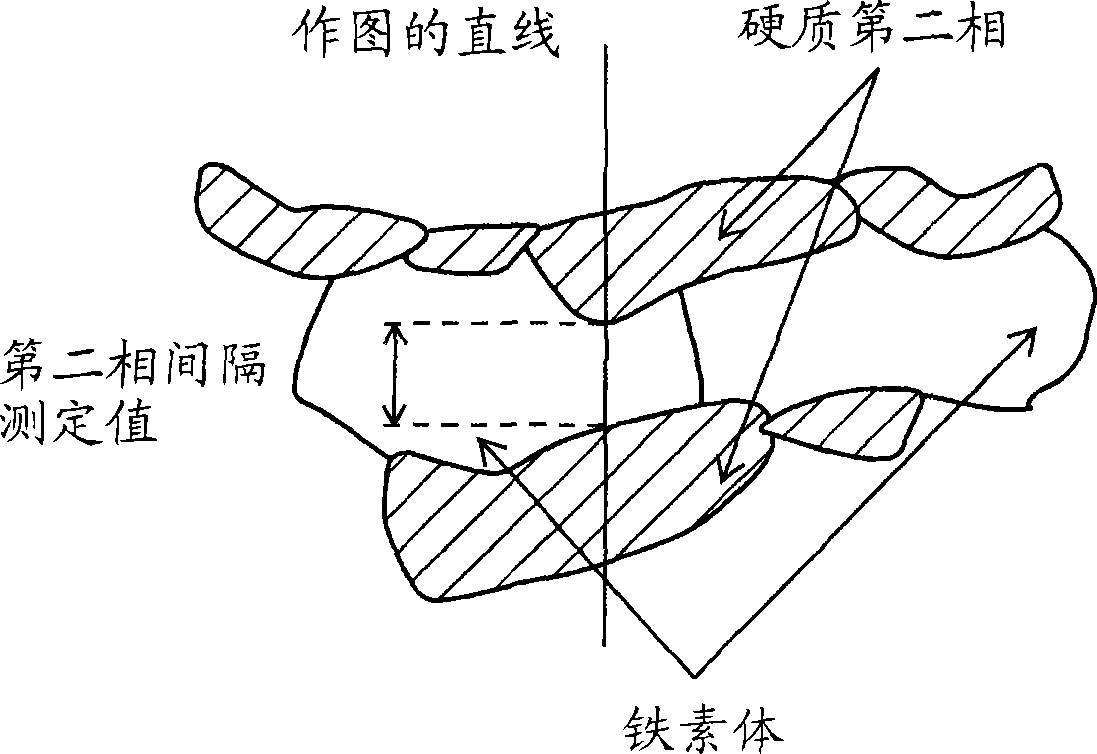

[0246] The high-strength steel plate produced by the present invention presents a metal structure composed of a ferrite phase and a hard second phase dispersed in the above-mentioned ferrite phase, and the area fraction of the hard second phase in the metal structure is 3%. ~30%, the area fraction of nano-grains in the ferrite phase is 15%-90%, in the ferrite phase, the average particle size dS of nano-grains and the average particle size dL of micro-grains satisfy the following (31) formula.

[0247] dL / dS≧3 (31)

[0248] Such a high-strength steel sheet is preferably on a cross section parallel to the rolling direction of the steel sheet. When nine or more square lattices of 3 μm square are randomly selected, the area fraction of the hard second phase in each lattice is set to is Ai (i=1, 2, 3, ...), at this time, the average A(ave) and standard deviation s of said Ai satisfy the following (32) formula, meanwhile, the average particle diameter of the hard second phase dp a...

Embodiment

[0408] 1. First Embodiment

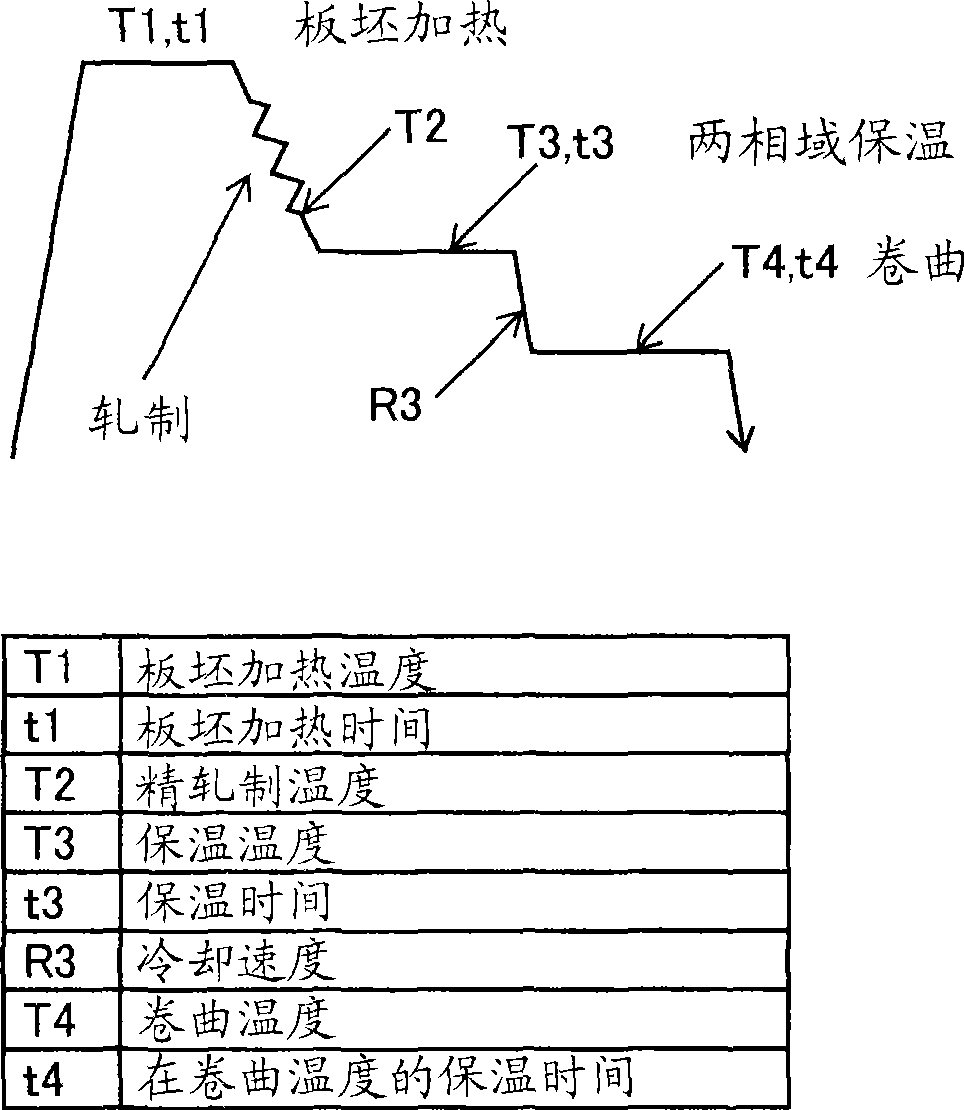

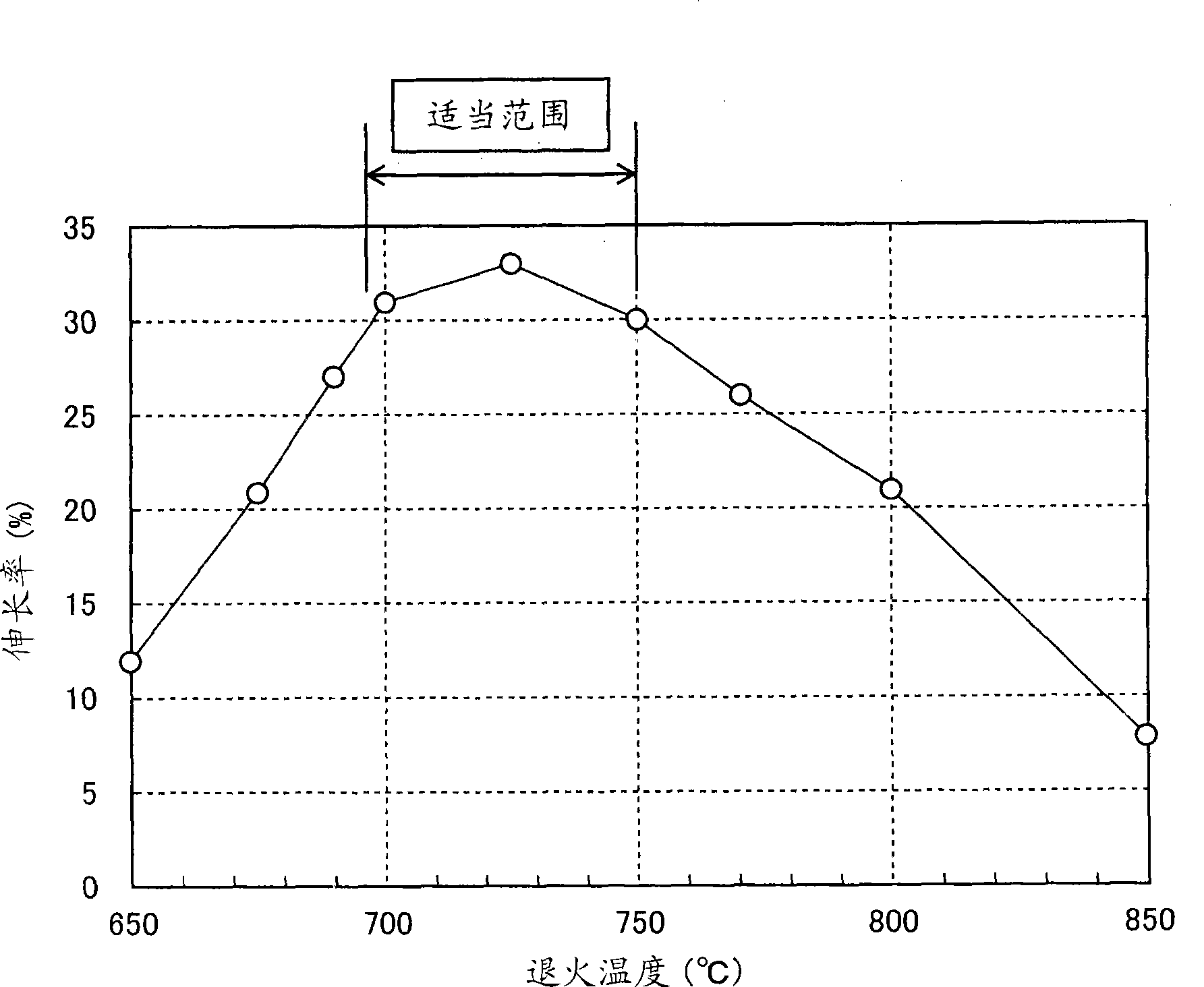

[0409] Slabs having the chemical compositions shown in Table 4 (invention slabs 1 to 8 and comparative slabs 1 to 9) were melted. Next, using these slabs, hot-rolled sheets were produced under the conditions shown in Table 5, and then cold-rolled and annealed under the conditions shown in Table 6 to obtain steel sheets having the annealed structure and the like shown in Table 7. Then, cut out from each steel plate so that the direction parallel to the rolling direction becomes the drawing axis. Figure 14 Pull test pieces of the shape shown for tensile testing. From the obtained nominal stress and nominal strain curves, the yield point, tensile strength, bake hardening amount (BH amount) and total elongation were obtained, and the product of tensile strength × elongation was calculated at the same time. These results are recorded together in Table 5. In Comparative Example 4, as in Comparative Example 3, both sides of the hot-rolled sheet were ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mean interval | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com