High-strength steel sheet superior in formability

A steel plate, temperature zone technology, used in manufacturing tools, hot dipping processes, metal material coating processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

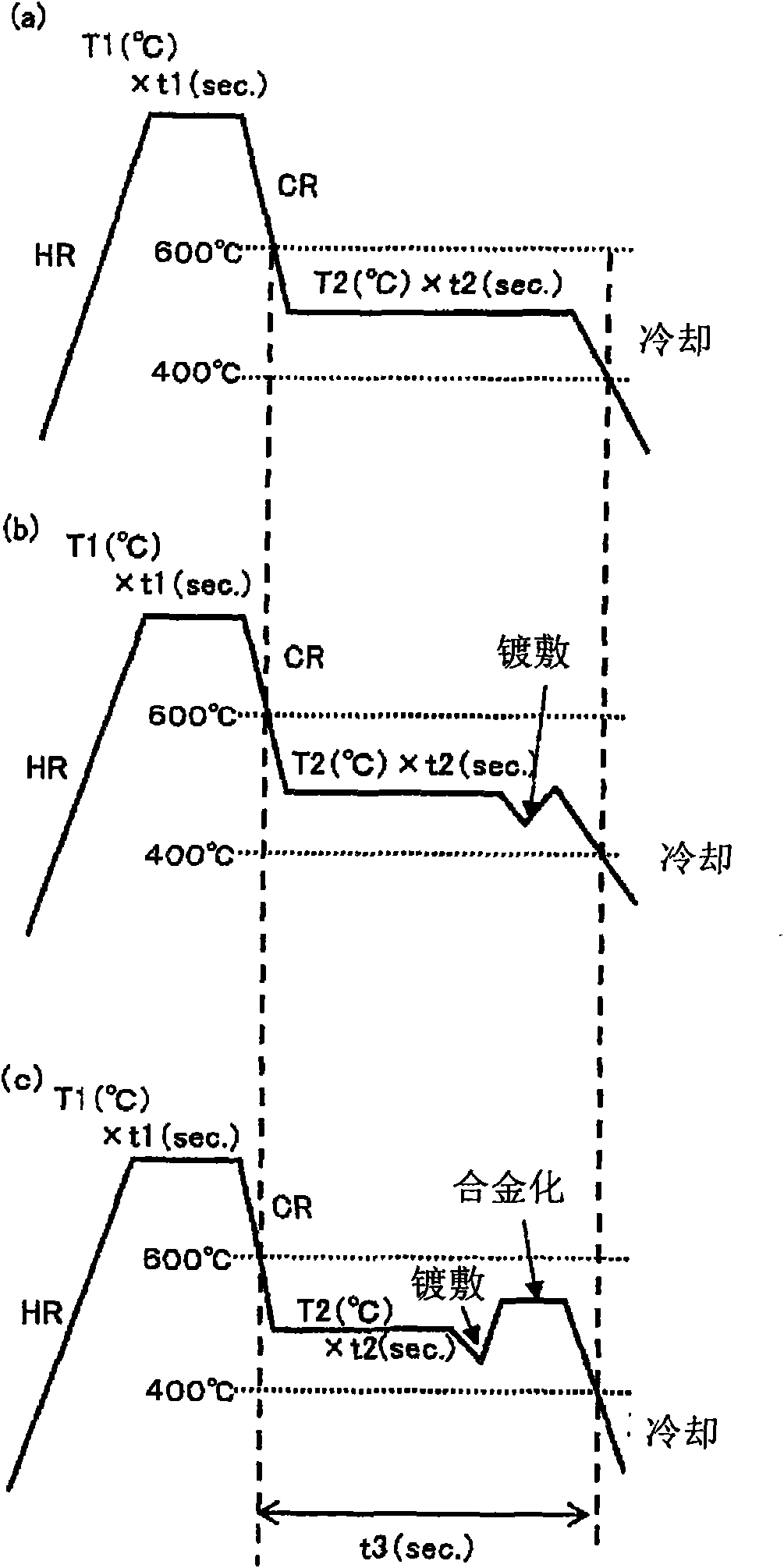

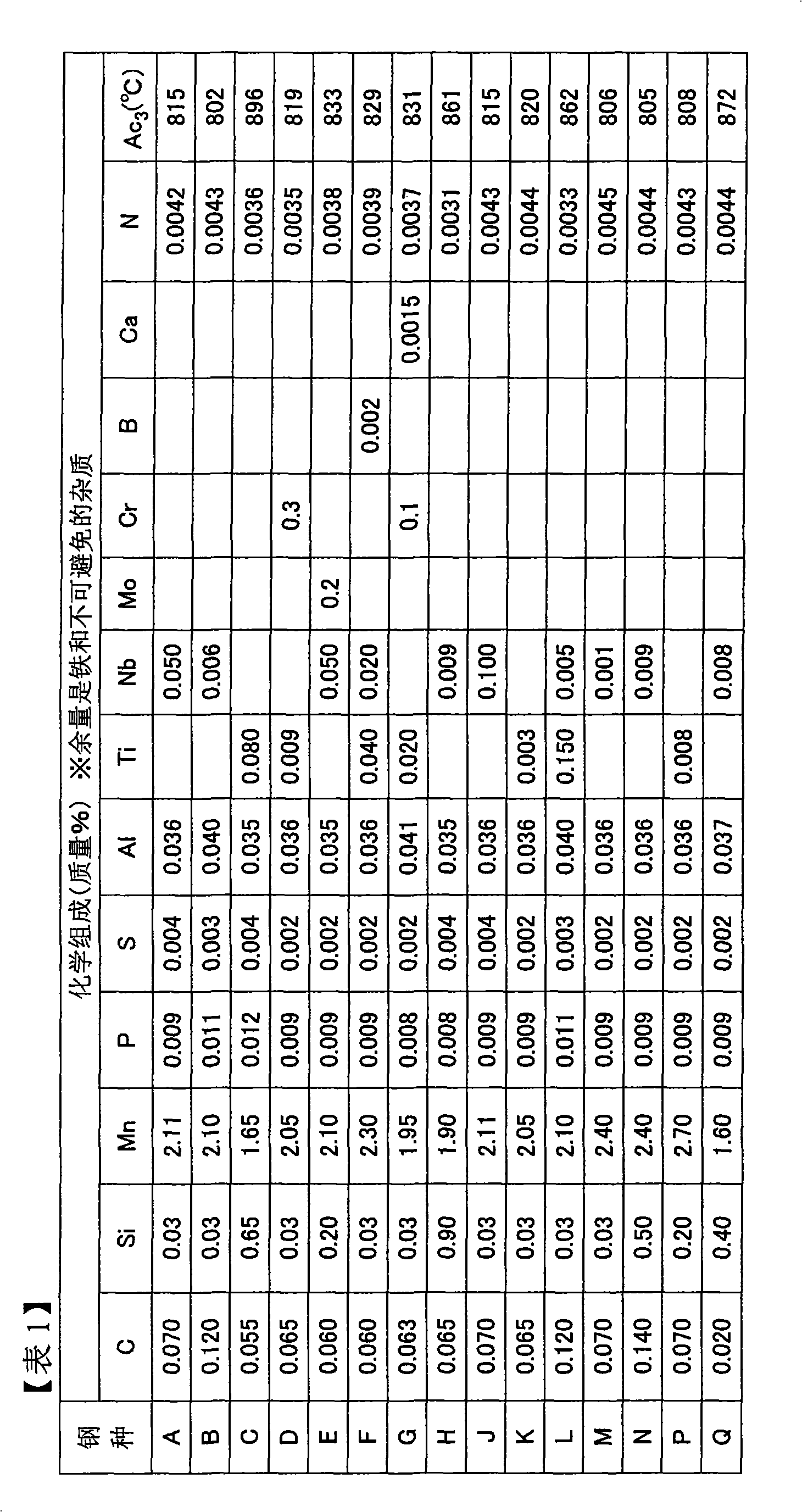

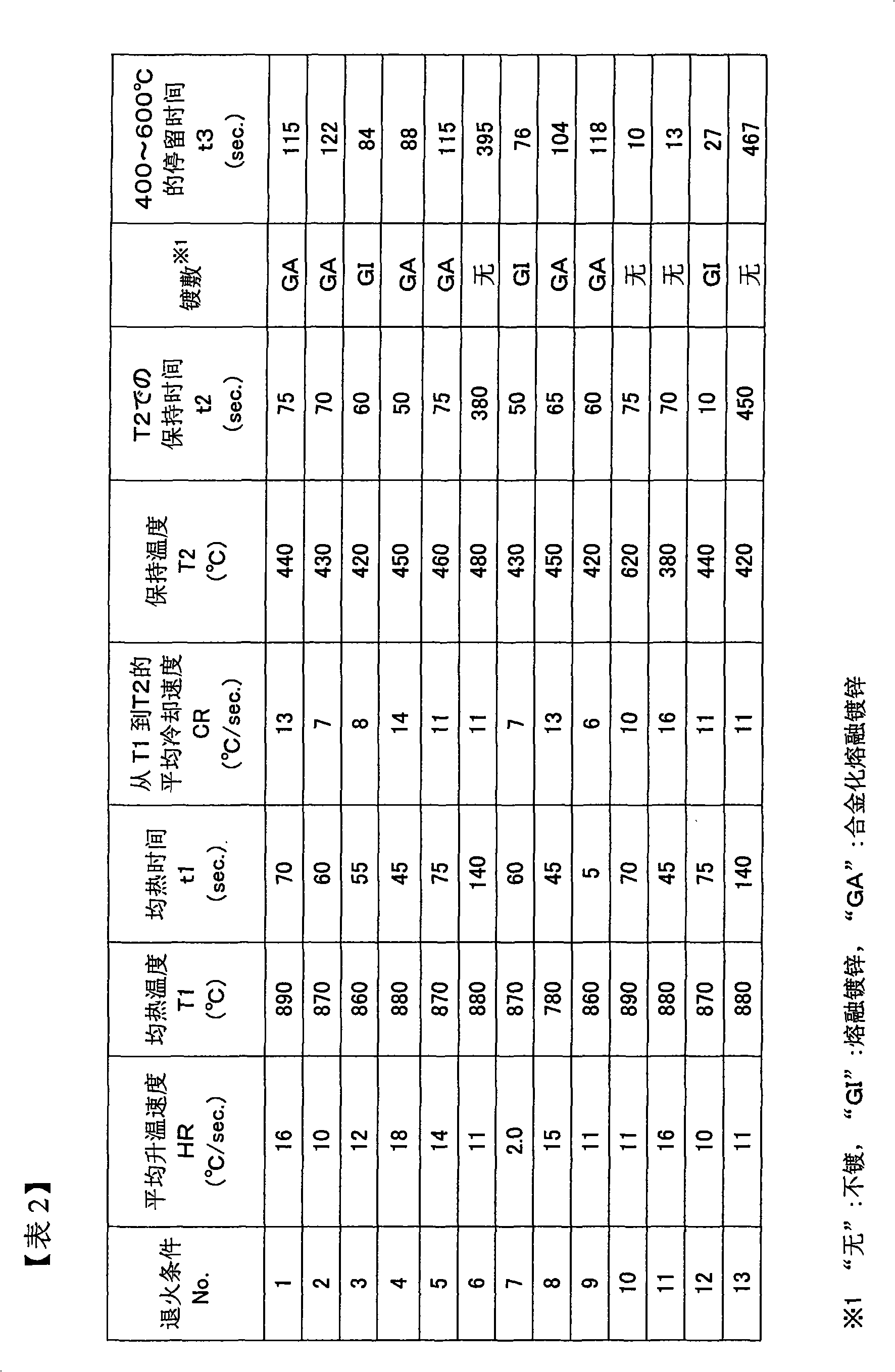

Method used

Image

Examples

Embodiment Construction

[0011] The present invention relates to a technique for improving the workability of a steel plate with a composite structure of 590 to 780 MPa, which contains ferrite as a parent phase and hard phases such as martensite (M) and bainite (B) as a second phase structure ( low temperature phase transition).

[0012] Specifically, it is possible to obtain such a high-strength steel sheet as follows. For the structure, in particular, the following control is appropriately performed: control of the composition and ratio of the second phase structure; control of the hardness of the parent phase structure (specifically, iron The average hardness of the ferrite is controlled to be more than specified relative to the tensile strength of the steel plate, and the ratio of the average hardness of the ferrite as the parent phase to the average hardness of the bainite and martensite as the second phase structure is presented. Some are small); the refinement of the parent phase structure (ave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com