T/P91 steel ageing rating method based on precipitated phase fractional area

A technology of area fraction and precipitated phase, which is applied in the preparation of test samples, material analysis by measuring secondary emissions, instruments, etc., to achieve the effect of convenient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention proposes a T / P91 steel aging rating method based on the area fraction of precipitated phases, and its specific implementation method is as follows:

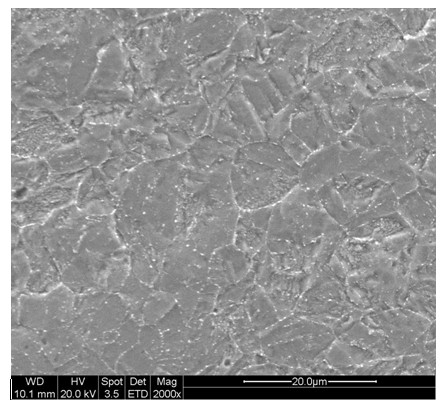

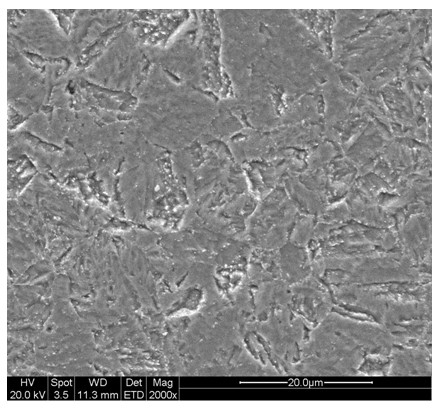

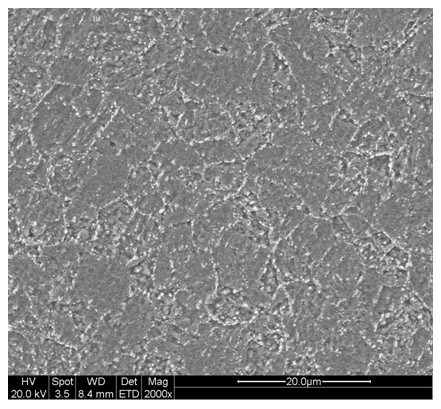

[0030] First, intercept the sample to be evaluated and prepare the metallographic sample, specifically: intercept the sample to be evaluated so that its size meets the metallographic sample, then use metallographic sandpaper to grind sequentially, after polishing, immerse in the metallographic corrosion solution for corrosion , to obtain a metallographic sample.

[0031] Secondly, obtain the metallographic structure picture of the metallographic sample, specifically, a scanning electron microscope (SEM) or an optical microscope can be used to obtain the metallographic structure picture.

[0032] Then, calculate the area fraction of the precipitated phase according to the pixel difference of the precipitated phase in the metallographic structure diagram, and the area fraction of the precipitated phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com