High-strength steel sheet and process for production thereof

A technology of high-strength steel plate and manufacturing method, applied in the direction of manufacturing tools, coatings, furnace types, etc., to achieve the effects of cost reduction, excellent processability, and process saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

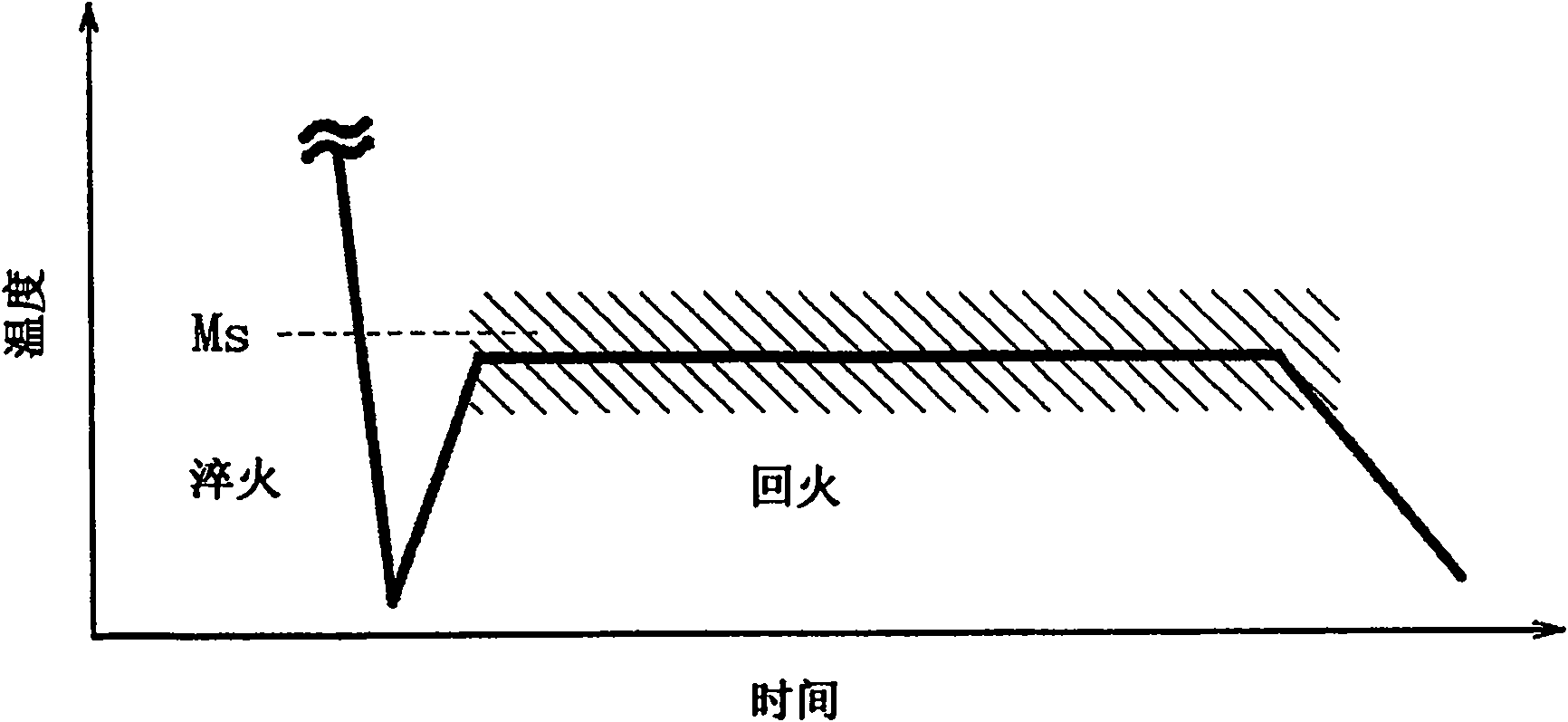

Method used

Image

Examples

Embodiment 1

[0132] Hereinafter, the present invention will be further described through examples, but the following examples do not limit the present invention. Furthermore, structural changes made within the scope of the gist of the present invention are included in the scope of the present invention.

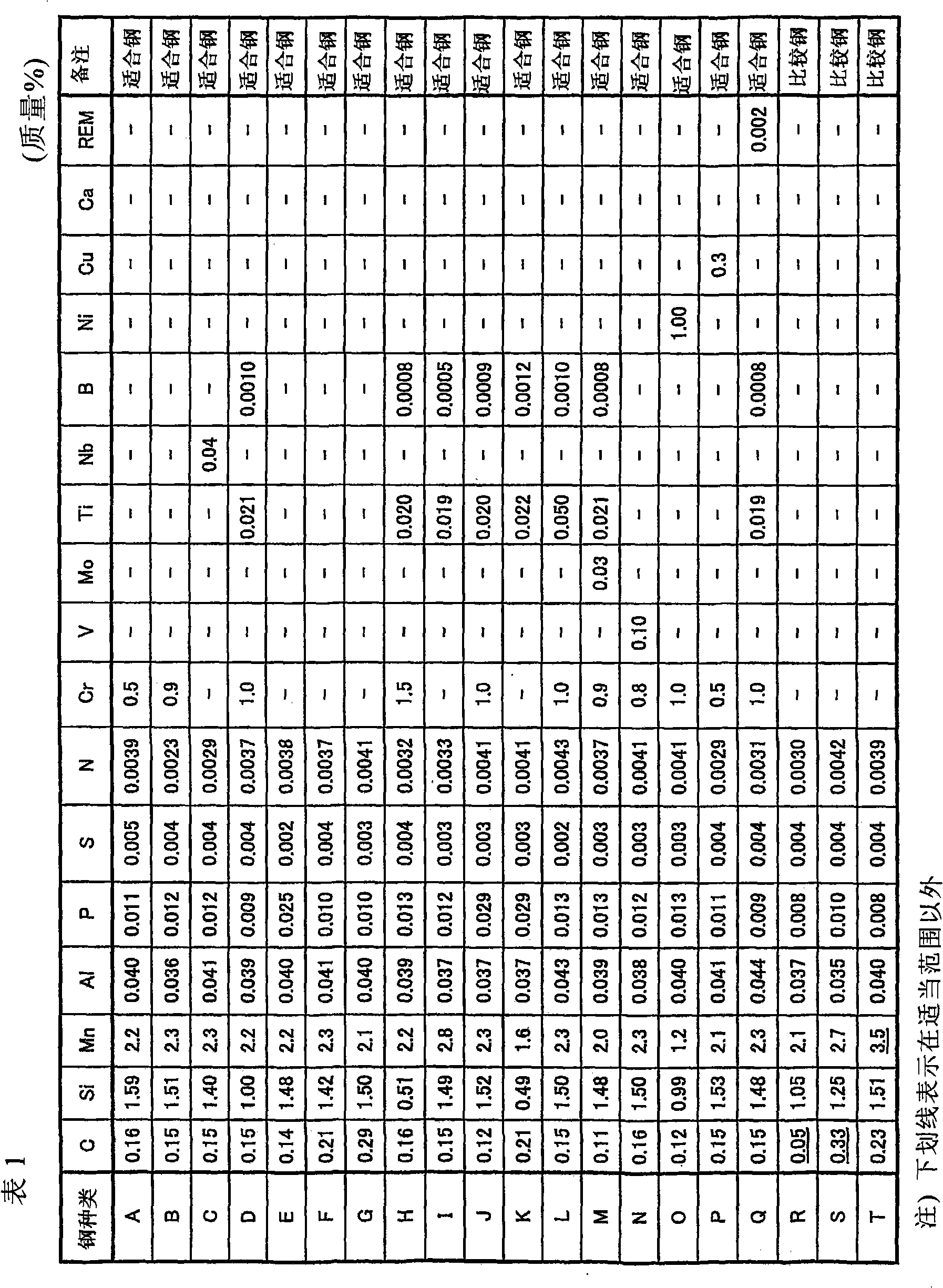

[0133] The steel slab with the composition shown in Table 1 was heated to 1250°C, then hot-rolled at 880°C, and the resulting hot-rolled steel sheet was coiled at 600°C, and then the hot-rolled steel sheet was pickled and then heated at 65% Cold-rolled at a rolling rate of 1.2 mm to make a cold-rolled steel plate with a thickness of 1.2 mm. The obtained cold-rolled steel sheets were heat-treated under the conditions shown in Table 2. None of the samples in the same table were quenched. In addition, the holding time in Table 2 is the holding time at the holding temperature in Table 2, and the annealing time in the first temperature range of 700°C to 950°C under any condition in the table...

Embodiment 2

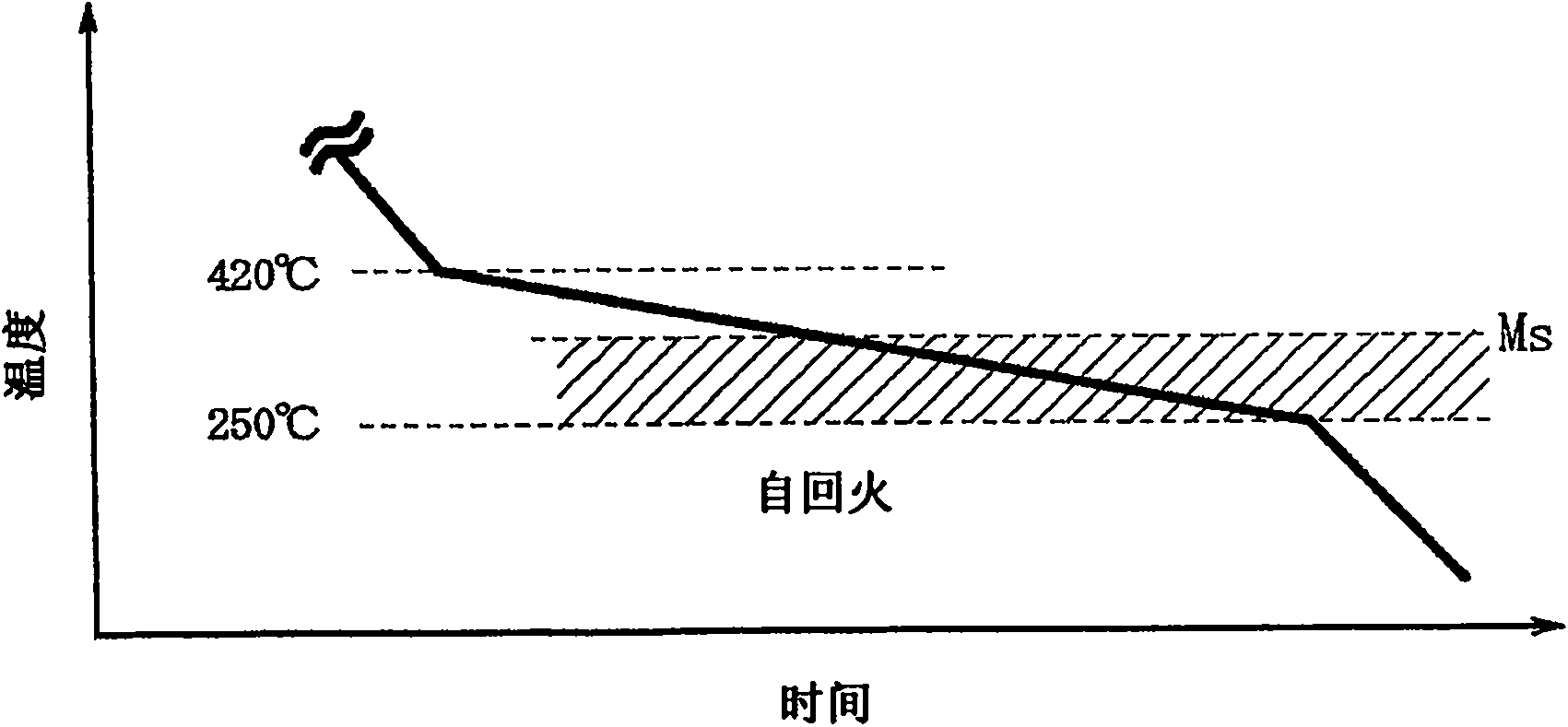

[0154] In order to confirm the effect of further improving ductility by properly controlling the distribution state of iron carbides in self-tempered martensite, in addition to the third temperature range, 250°C or more and (Ms point-50)°C Samples were produced by the same method as the samples shown in Table 2 except that the cooling rate in the following temperature ranges was changed as shown in Table 4. In addition, in Table 4, sample Nos. 9, 11, 13, 14, and 26 are the same as the samples of the same sample No. shown in Table 2, and the temperature range of 250°C or higher and (Ms point-50)°C or lower is clarified. Also, M (° C.) is used as the Ms point.

[0155]

[0156] Various properties of the steel sheets obtained above were evaluated by the same methods as in Example 1. In addition, in the autotempered martensite, the number of precipitated iron carbides of 0.1 μm or more and 0.5 μm or less per 1 mm 2 Medium is 5×10 4 The amount of self-tempered martensite belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com