High-strength steel sheet and process for production thereof

A technology of high-strength steel plate and manufacturing method, which is applied in the direction of manufacturing tools, coatings, furnace types, etc., can solve the problems of reduced formability, etc., and achieve the effects of excellent processability, cost reduction, and process reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] Hereinafter, the present invention will be further described through examples, but the following examples do not limit the present invention. Furthermore, structural changes made within the scope of the gist of the present invention are included in the scope of the present invention.

[0119] Steel slabs with various compositions shown in Table 1 were heated to 1250°C, then hot-finish rolled at 880°C, and the resulting hot-rolled steel sheets were coiled at 600°C, and then the hot-rolled steel sheets were pickled and placed in Cold rolling was performed at a rolling reduction rate of 65% to produce a cold-rolled steel sheet having a thickness of 1.2 mm. The obtained cold-rolled steel sheets were heat-treated under the conditions shown in Table 2. None of the samples in the same table were quenched.

[0120] Hot-dip galvanizing is performed at a plating bath temperature of 463°C and an adhesion weight (per single side) of 50g / m 2 (Double-sided plating) under the condi...

Embodiment 2

[0135] The steel slabs having the compositions shown in steel grades A, C and F in Table 1 are heated to 1250°C, and then the hot-rolled steel sheets after hot finish rolling at 880°C are coiled at 600°C, and then the hot-rolled steel sheets are pickled After that, it was cold-rolled at a rolling reduction rate of 65% to produce a cold-rolled steel sheet with a thickness of 1.2 mm. The obtained cold-rolled steel sheets were heat-treated under the conditions shown in Table 4.

[0136] Regardless of the presence or absence of plating, the obtained steel sheets were subjected to temper rolling at a rolling ratio (elongation) of 0.3%.

[0137] The steel sheets obtained above were evaluated by the same method as in Example 1. The results are shown in Table 5.

[0138] Sample Nos. 24 to 27 all use suitable steel, but the cooling rate of the heat treatment is outside the range specified by the present invention, so the steel structure and the number of iron carbides are not within ...

Embodiment 3

[0142] Heat the steel slabs with the composition shown in the steel types P, C and F in Table 1 to 1250°C, and then coil the hot-rolled steel sheet after hot-rolling at 880°C at 600°C, and then pickle the hot-rolled steel sheet , cold rolled at a rolling rate of 65%, and made into a cold-rolled steel plate with a thickness of 1.2mm. The obtained cold-rolled steel sheets were heat-treated under the conditions shown in Table 6. Regardless of the presence or absence of plating, the obtained steel sheets were subjected to temper rolling at a rolling ratio (elongation) of 0.3%. In addition, in Table 6, Nos. 28, 30, and 32 represent the same samples as Nos. 4, 6, and 11 shown in Table 2, respectively.

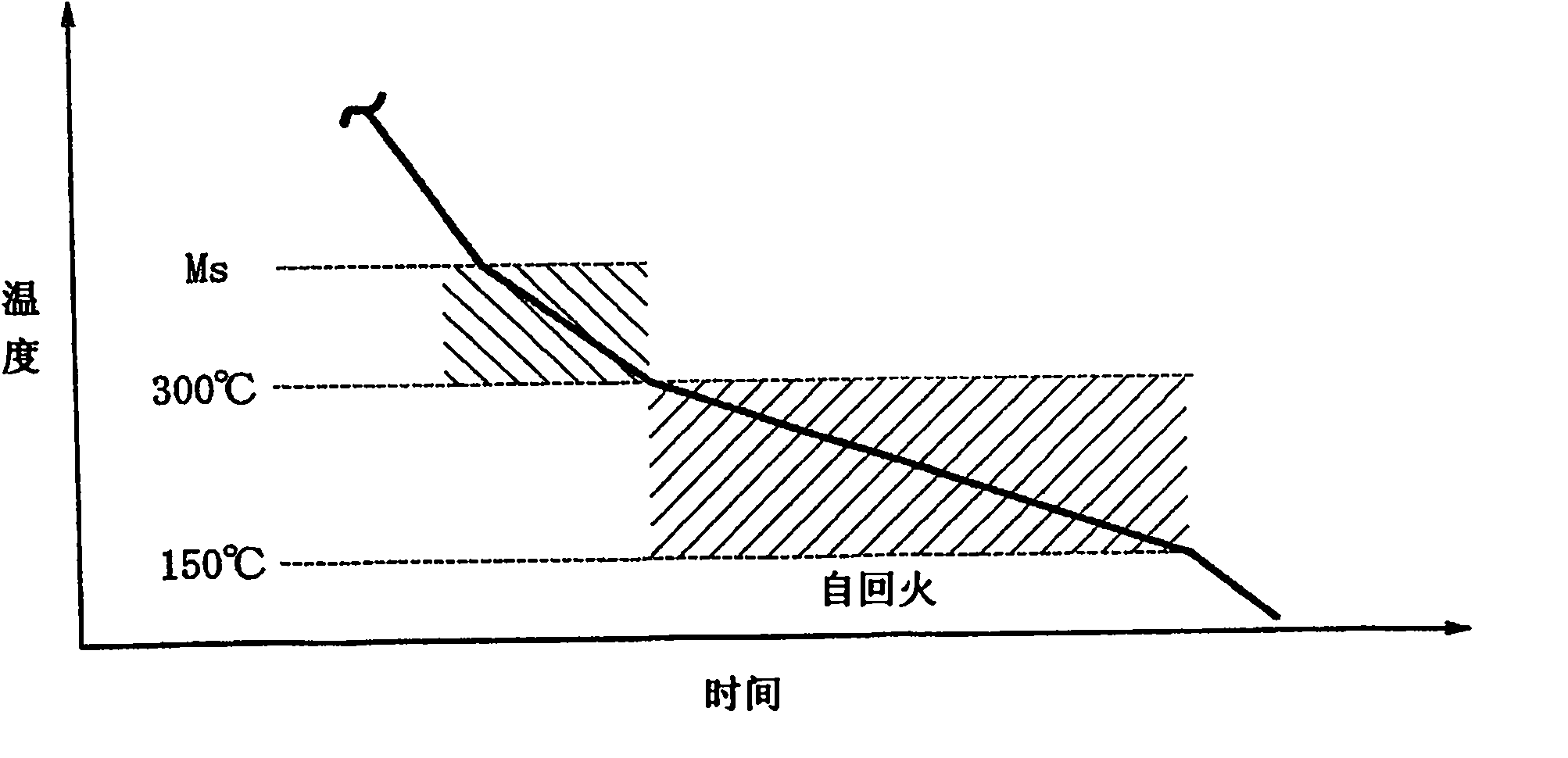

[0143] The steel sheets obtained above were evaluated by the same method as in Example 1. In addition, in the self-tempered martensite, the number of precipitated iron carbides of 0.1 μm or more and 0.5 μm or less per 1 mm 2 Medium is 5×10 2 The amount of self-tempered martensite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com