Abrasion-resistant steel plate and manufacturing process therefor

A technology of wear-resistant steel plate and manufacturing method, applied in the field of wear-resistant steel plate, can solve the problems of cold crack sensitivity and poor toughness, and achieve the effect of improving manufacturing efficiency and excellent impact wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

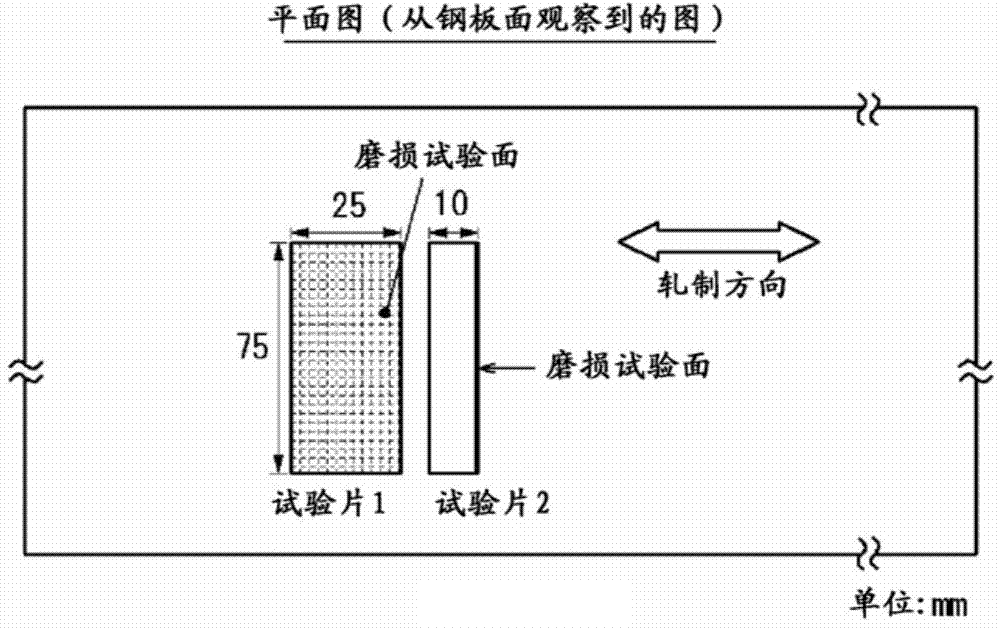

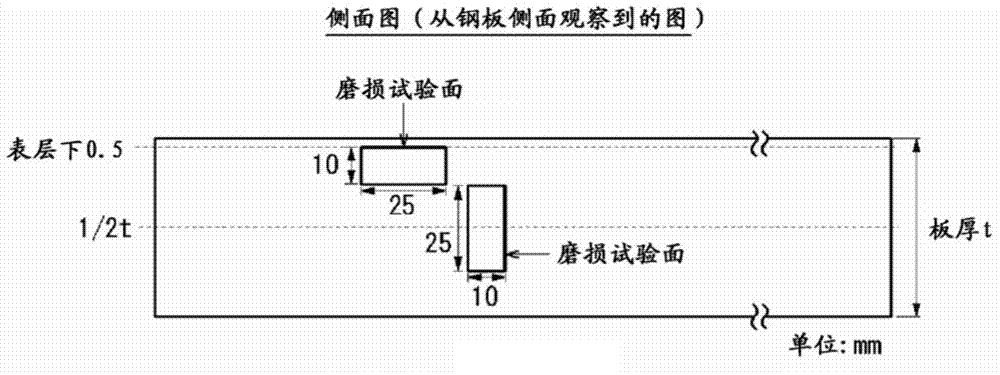

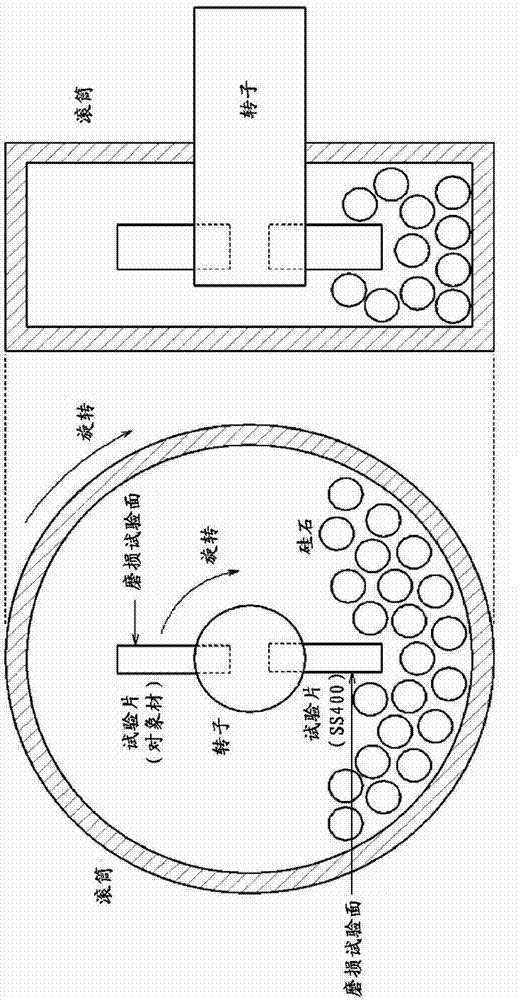

[0099] Examples are described below.

[0100] Through the converter-pot refining-continuous casting method, the steel slabs prepared with various compositions shown in Table 1 are heated to 1000-1200°C under the conditions shown in Table 2, and then hot-rolled. Direct quenching (DQ) is carried out immediately after production. Quenching (RQ) is performed on a part of the steel plate that has undergone direct quenching (DQ) by reheating to 900°C. In addition, quenching (RQ) was performed after reheating to 900 degreeC of some steel plates after hot rolling and cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com