Composite material hammer head of crusher and method for casting same

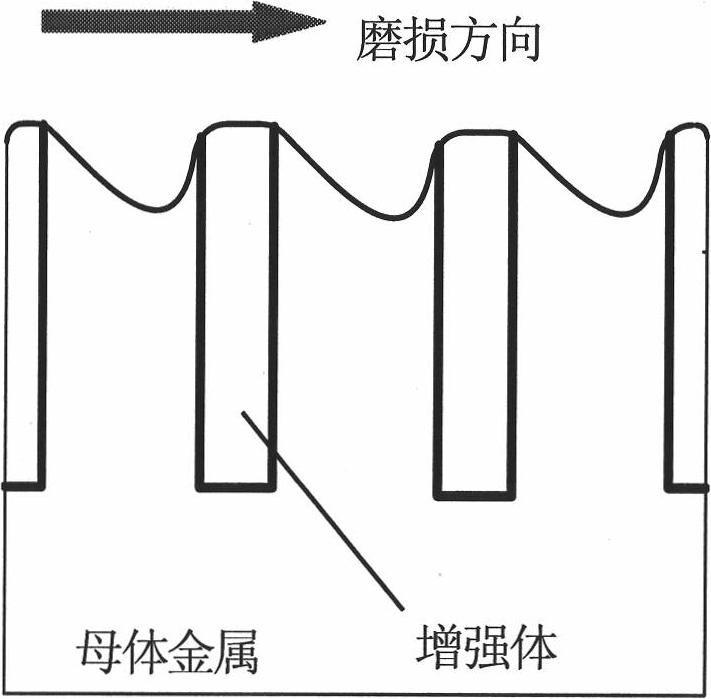

A composite material and crusher technology, applied in grain processing and other directions, can solve the problems of separation of composite material layer and metal matrix, failure of hammer head, and insufficient use of microscopic shadow effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

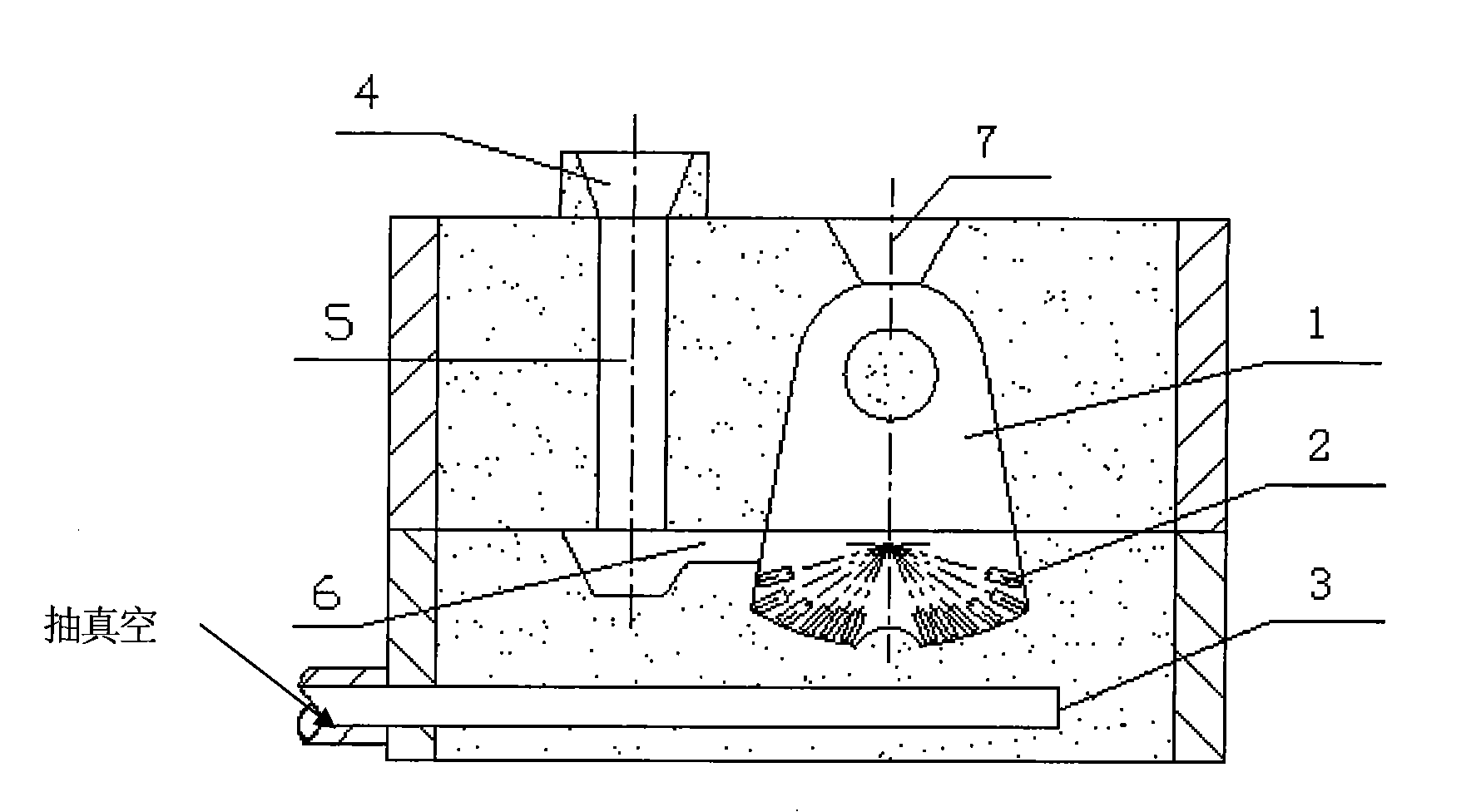

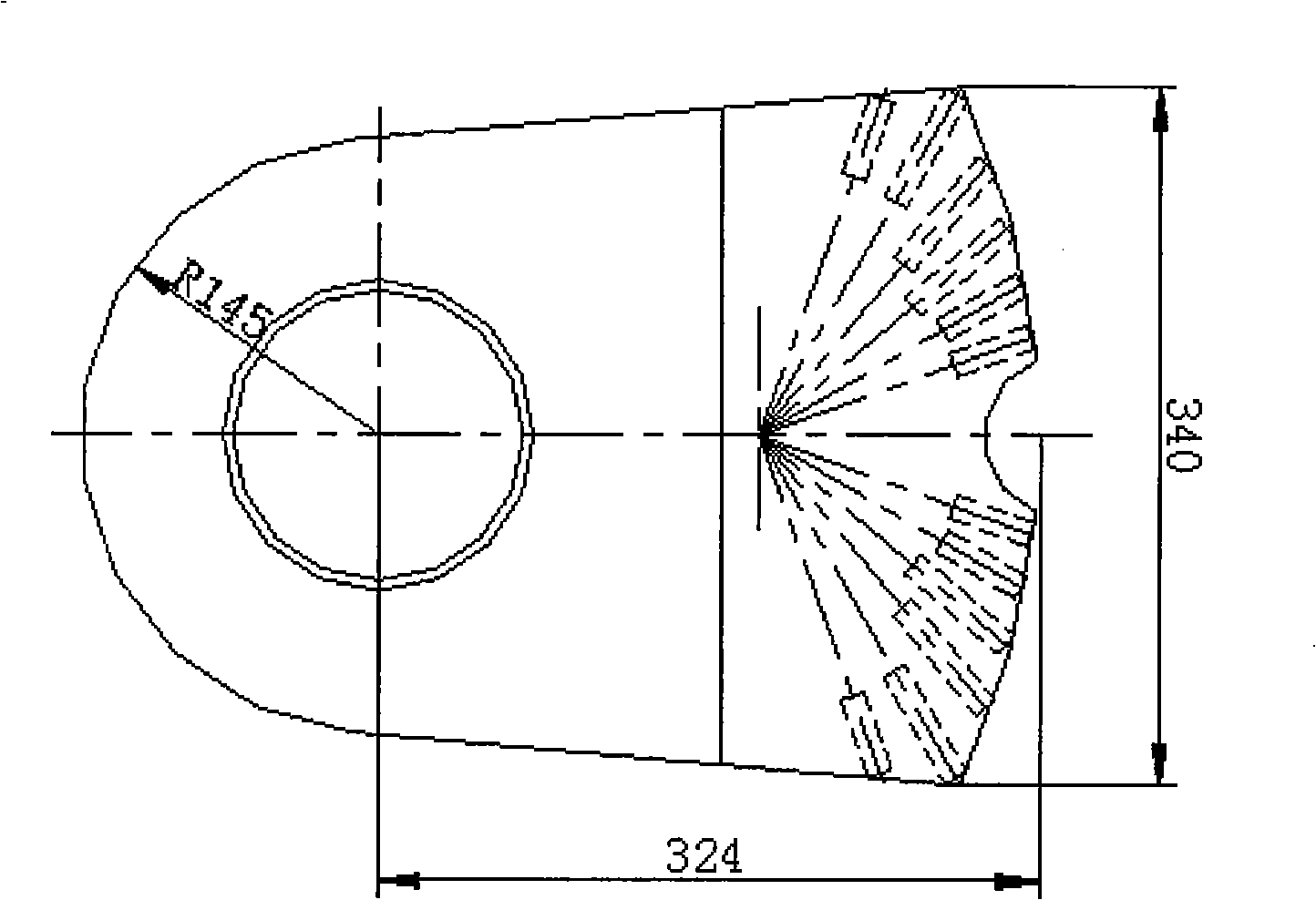

[0028] Embodiment 1: see figure 1 , first use sodium silicate sand to shape the hammer head of the crusher, and then make the hardness 2500-3000Hv, density 15.8-16.5g / mm 3 , WC particles with a particle size of 300 μm to 750 μm are filled in several identical columnar metal meshes made of 1Cr18Ni9Ti, with a bottom diameter of 10 mm, a length of 30 mm, a metal wire diameter of 220 μm, and a mesh size of 280 μm×280 μm. Several prefabricated bodies 2 are placed side by side (working surface or striking surface) of the mold cavity 1 side by side. A 250kg medium-frequency induction furnace is used to melt high manganese steel to form molten metal. The temperature of the molten metal is 1540°C, and the pouring temperature is 1470°C. The vacuum pump is started 5 minutes before the molten metal is released, and the vacuum degree is 0.12MPa. Then the molten metal is poured out of the furnace. When pouring The molten metal enters the mold cavity 1 through the sprue cup 4, the sprue 5 ...

Embodiment 2

[0040] Embodiment 2: see attached figure 1 , first use resin sand to shape the hammer head of the crusher, and then set the hardness to 2500-3000Hv and density to 15.8-16.5g / mm 3 , WC particles with a particle size of 300 μm to 750 μm are filled in several identical columnar metal meshes made of 1Cr18Ni9Ti, with a bottom diameter of 10 mm, a length of 28 mm, a metal wire diameter of 220 μm, and a mesh size of 280 μm×280 μm. Several prefabricated bodies 2 are placed side by side (working surface or striking surface) of the mold cavity 1 side by side. A 250kg intermediate frequency induction furnace is used to smelt alloy steel to form molten metal. The temperature of the molten metal is 1650°C, and the pouring temperature is 1580°C; the vacuum pump is started 5 minutes before the molten metal is released, and the vacuum degree is 0.12MPa, and then the molten metal is poured out of the furnace. The liquid enters the mold cavity 1 through the sprue cup 4, the sprue 5 and the in...

Embodiment 3

[0052] Embodiment 3: see attached figure 1 , first use resin sand to shape the hammer head of the crusher, and then set the hardness to 2500-3000Hv and density to 15.8-16.5g / mm 3 , WC particles with a particle size of 300 μm to 750 μm are filled in several identical columnar metal meshes made of 1Cr18Ni9Ti, with a bottom diameter of 10 mm, a length of 32 mm, a metal wire diameter of 220 μm, and a grid size of 280 μm×280 μm. Several prefabricated bodies 2 are placed side by side (working surface or striking surface) of the mold cavity 1 side by side. A 250kg medium-frequency induction furnace is used to melt carbon steel to form molten metal. The temperature of the molten metal is 1600°C, and the pouring temperature is 1500°C; the vacuum pump is started 5 minutes before the molten metal is released, and the vacuum degree is 0.12MPa. Then the molten metal is poured out of the furnace. The liquid enters the mold cavity 1 through the sprue cup 4, the sprue 5 and the ingate 6, cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com