Composite material tup and its casting method

A technology of composite materials and hammer heads, which is applied in the manufacturing field of hammer heads of crushers, can solve problems such as complex surfacing welding process, poor process stability, and complicated manufacturing process, and achieve high bonding strength, uniform distribution, and excellent impact and wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

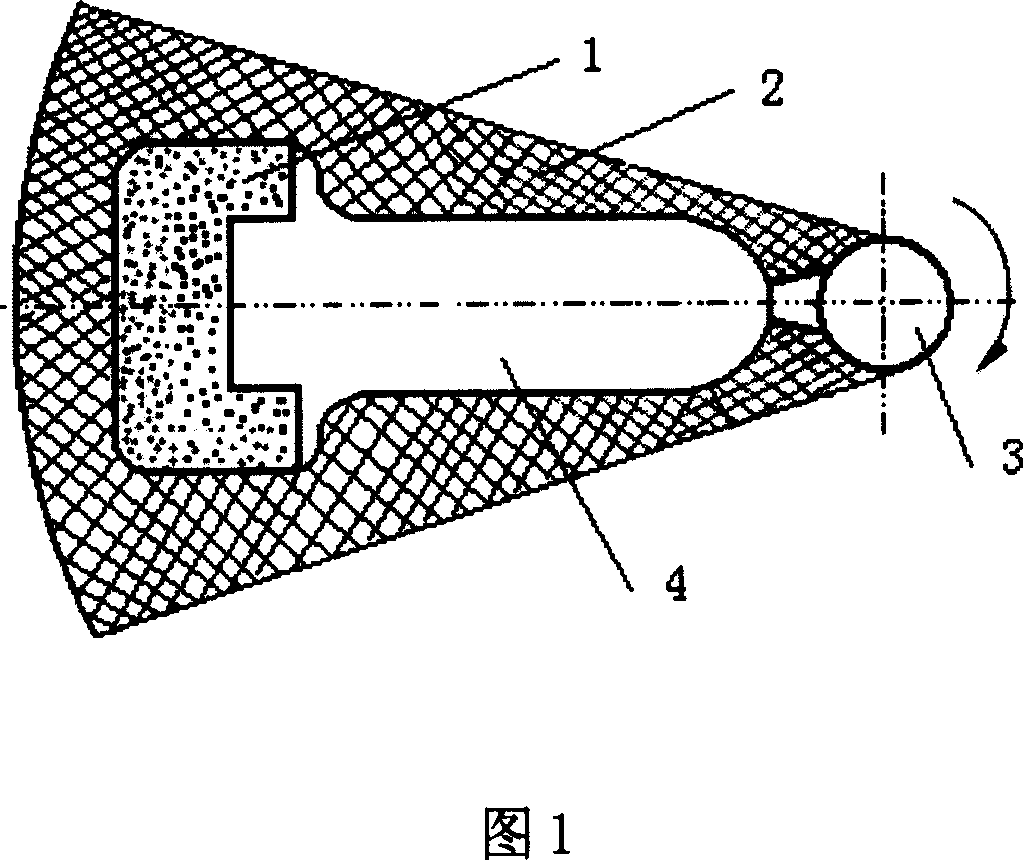

[0020] Embodiment 1: Referring to Fig. 1, firstly, high manganese steel is smelted in a 250kg medium frequency induction furnace to form molten metal, the temperature of the molten metal is 1680°C, and the pouring temperature is 1500°C; the hardness is 2500-3000Hv, and the density is 15.8-16.5g / mm 3 , WC particles with a particle size of 150-600 μm are prefabricated in polystyrene plastic foam 1, and then the polystyrene plastic foam 1 prefabricated with WC particles is put into the end face side of the cavity 4 of the hammer mold 2 made of resin sand , install the hammerhead mold 2 on the turntable of the vertical centrifugal casting machine, start the vertical centrifugal casting machine, control the speed of the vertical centrifugal casting machine at 200 rpm, and pour the molten metal out of the furnace. When pouring, the molten metal is poured directly The gate 3 enters the cavity 4 of the hammer mold 2, the sprue 3 is also the rotating shaft of the turntable of the vert...

Embodiment 2

[0029] Example 2: Firstly, a 250kg intermediate frequency induction furnace is used to melt alloy steel to form molten metal. The temperature of the molten metal is 1650°C, and the pouring temperature is 1480°C; the hardness is 2500-3000Hv, and the density is 15.8-16.5g / mm 3 , WC particles with a particle size of 150-600 μm are prefabricated in polystyrene plastic foam 1, and then the polystyrene plastic foam 1 prefabricated with WC particles is put into the end face of the cavity 4 of the hammer head mold 2 made of water glass sand side, install the hammer mold 2 on the turntable of the vertical centrifugal casting machine, start the vertical centrifugal casting machine, the speed of the vertical centrifugal casting machine is controlled at 50 rpm, and the molten metal is poured out of the furnace. The gate 3 enters the cavity 4 of the hammer mold 2, and the straight gate 3 is also the rotating shaft of the turntable of the vertical centrifugal casting machine, and the pouring...

Embodiment 3

[0038] Example 3: First, ordinary carbon steel is smelted in a 250kg medium-frequency induction furnace to form molten metal. The temperature of the molten metal is 1600°C, and the pouring temperature is 1420°C; the hardness is 2500-3000Hv, and the density is 15.8-16.5g / mm 3 , WC particles with a particle size of 150-600 μm are prefabricated in polystyrene plastic foam 1, and then the polystyrene plastic foam 1 prefabricated with WC particles is put into the end face side of the cavity 4 of the hammer mold 2 made of resin sand , Install the hammer head mold 2 on the turntable of the vertical centrifugal casting machine, start the vertical centrifugal casting machine, control the speed of the vertical centrifugal casting machine at 80 rpm, and pour the molten metal out of the furnace. When pouring, the molten metal is poured directly The gate 3 enters the cavity 4 of the hammer mold 2, and the straight gate 3 is also the rotating shaft of the turntable of the vertical centrifuga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com