Aluminum-base alloy sheet

A technology of aluminum alloy plate and plate width, which is applied in the field of aluminum alloy plate and can solve problems such as insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

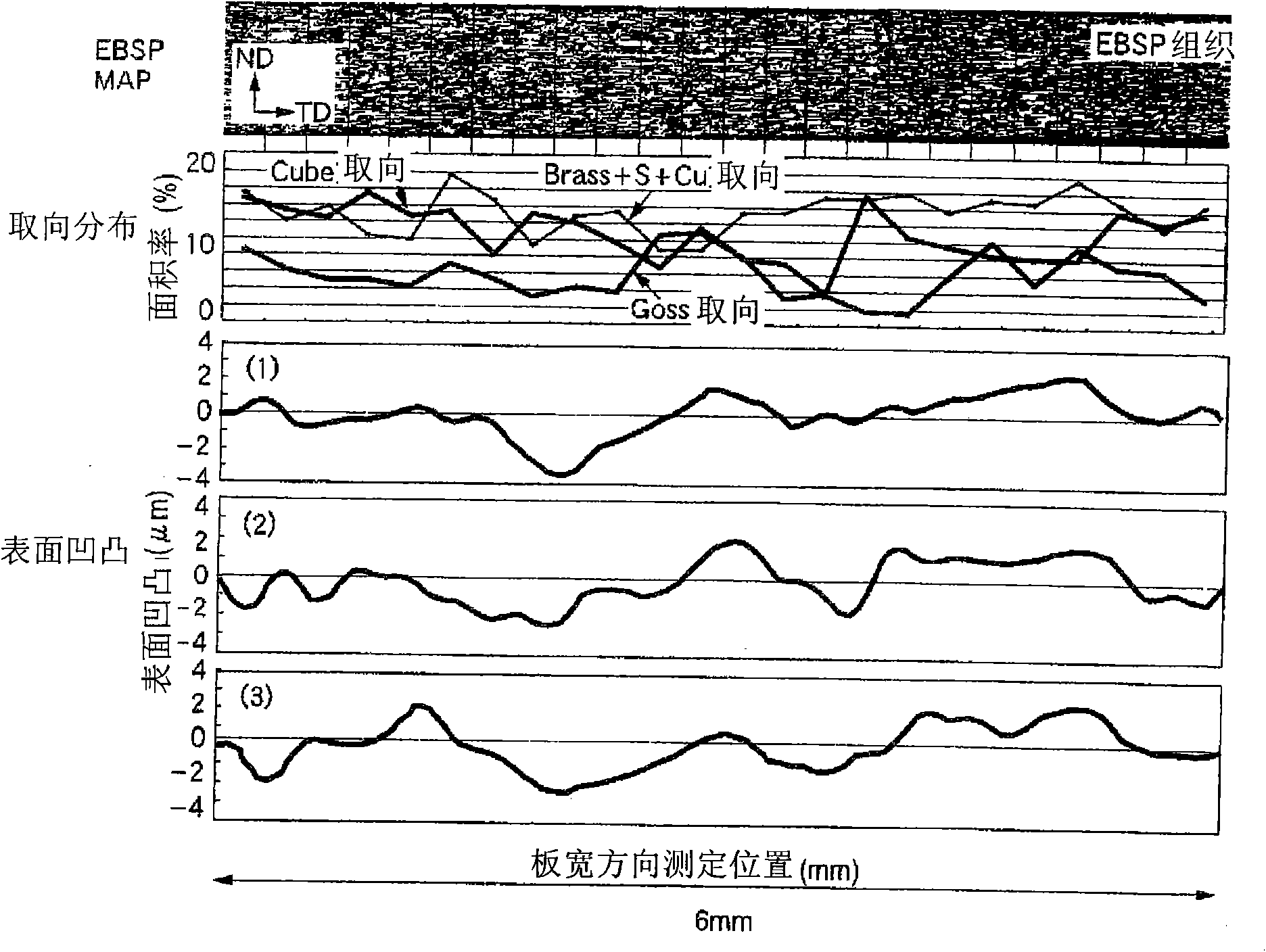

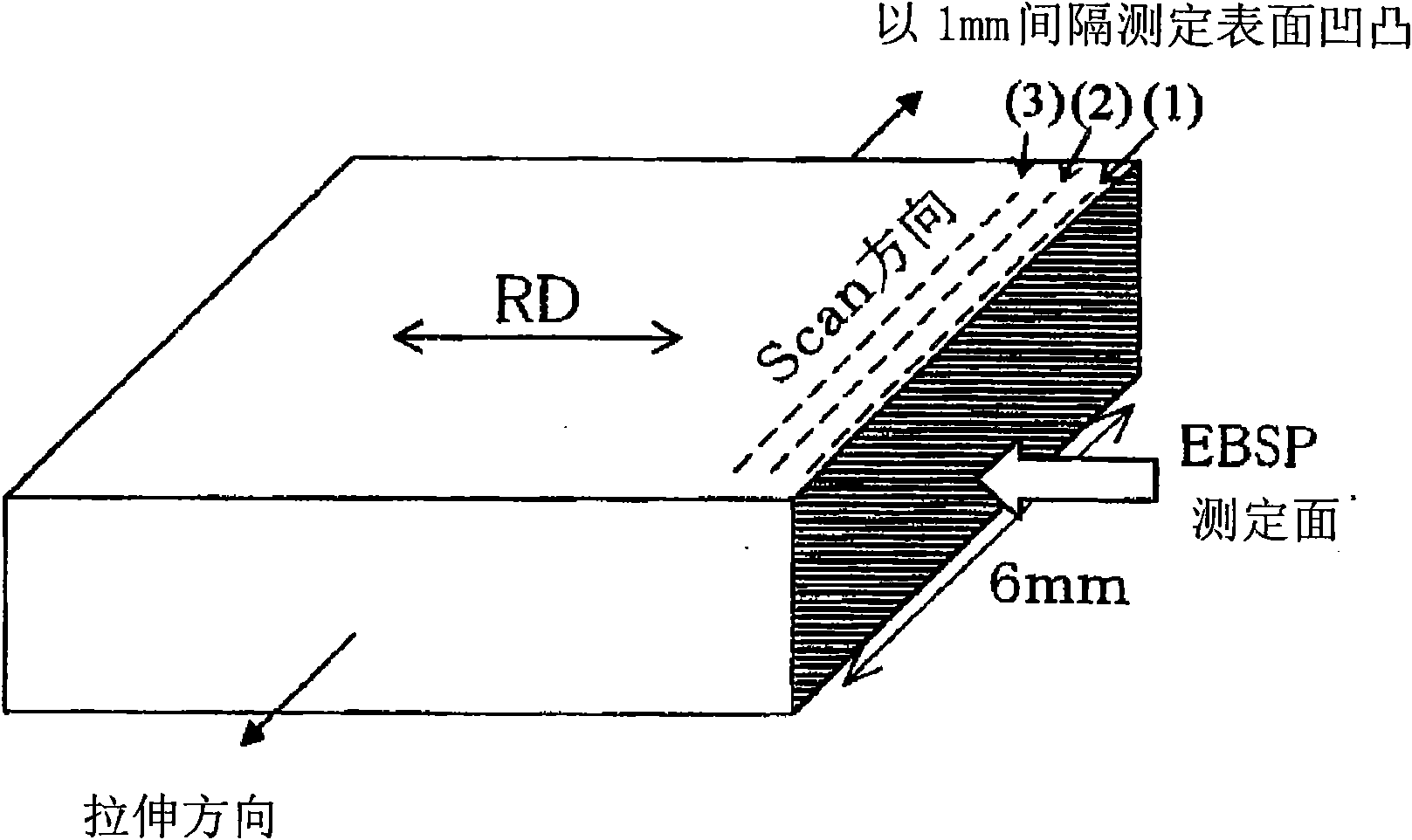

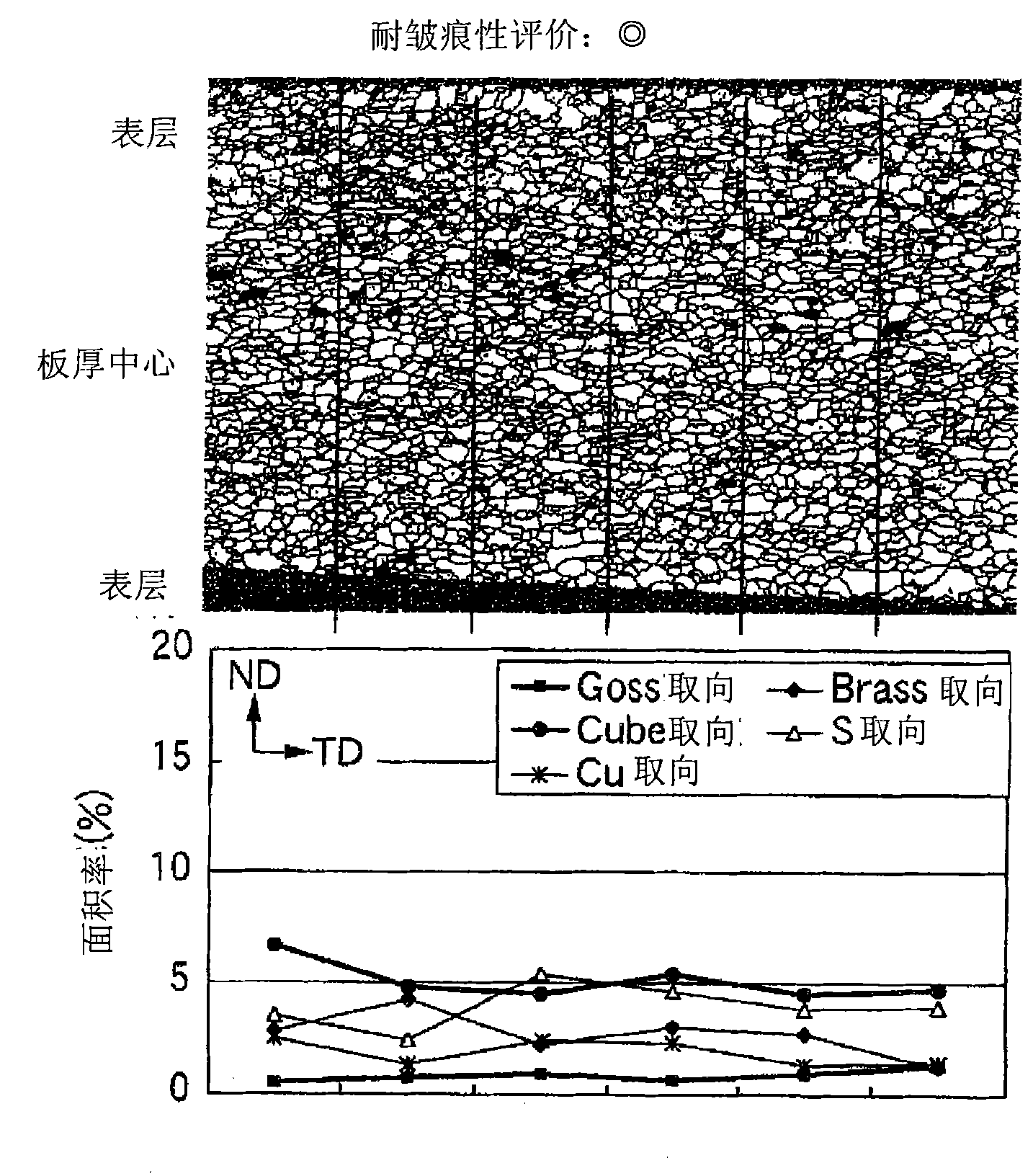

Image

Examples

Embodiment

[0135] Next, examples of the present invention will be described. Under the conditions shown in Table 2, homogenization heat treatment (abbreviated as soaking treatment) and hot rolling (abbreviated as hot rolling) were carried out for the 6000 series aluminum alloy plates with A-K composition shown in Table 1, and then cold rolled. Manufactured by rolling, solution and quenching. In addition, in the expression of the content of each element in Table 1, "-" shows below a detection limit.

[0136] More specific production conditions of the aluminum alloy plate are as follows. Ingots having a thickness of 500 mm, a width of 2000 mm, and a length of 7 m each having the compositions shown in Table 1 were melted by the DC casting method. At this time, as shown in Table 2, the cooling rate (°C / min) during casting was changed in the following two stages: from the usual melting temperature (about 700°C) of each example to the liquidus temperature (approximately The same about 650°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com