High-strength thick steel plate with excellent drop weight characteristics

A drop hammer impact and high-strength technology, applied in the field of thick steel plates, can solve problems such as difficulties in high strength, and achieve good drop hammer impact characteristics and high strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

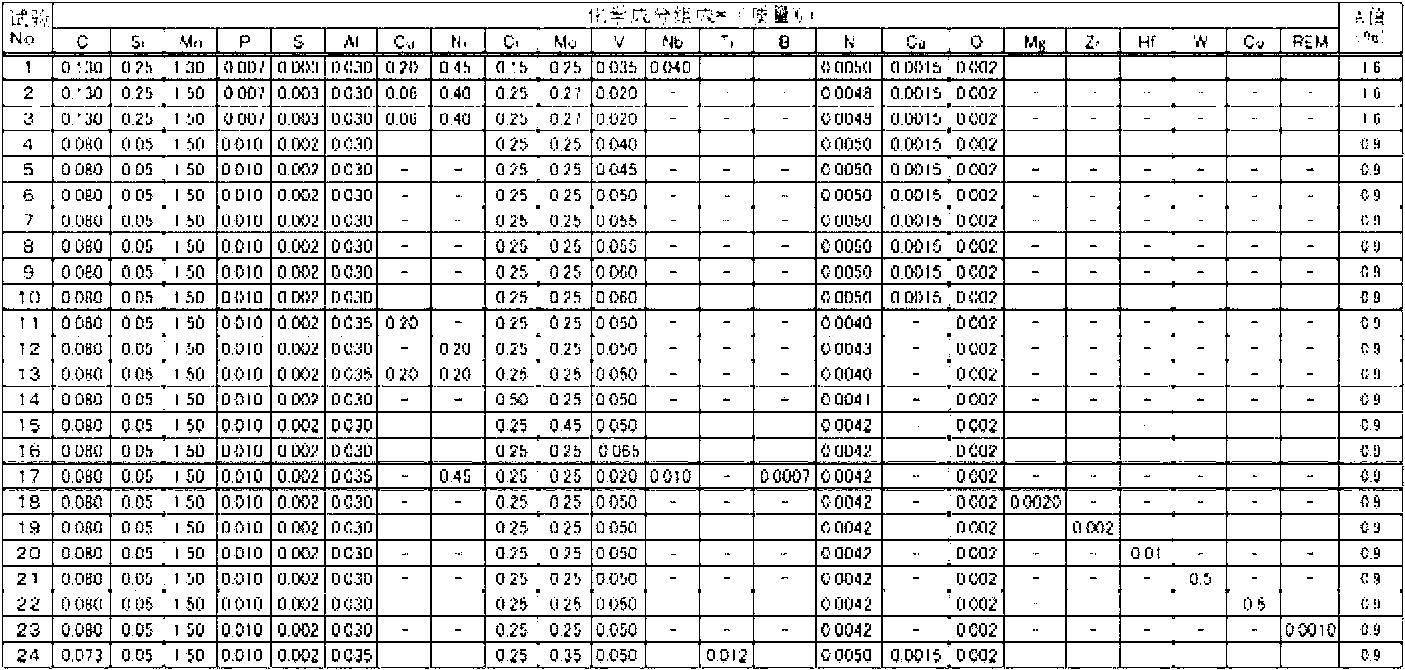

[0090] Various molten steels whose chemical compositions are shown in the following Tables 1 and 2 were smelted by a normal melting method, and the molten steel was cooled to form a slab (thickness: 300mm), and hot-rolled under the conditions shown in the following Tables 3 and 4. , cooled and tempered to obtain various steel plates (thickness: 100mm). In addition, in the following Tables 1 and 2, REM is added in the form of mischmetal containing about 50% of Ce and about 25% of La. In addition, in the following Tables 1 and 2, the column of "-" shows that no element was added.

[0091] 【Table 1】

[0092]

[0093] *: Impurities are unavoidable impurities other than iron, P and S

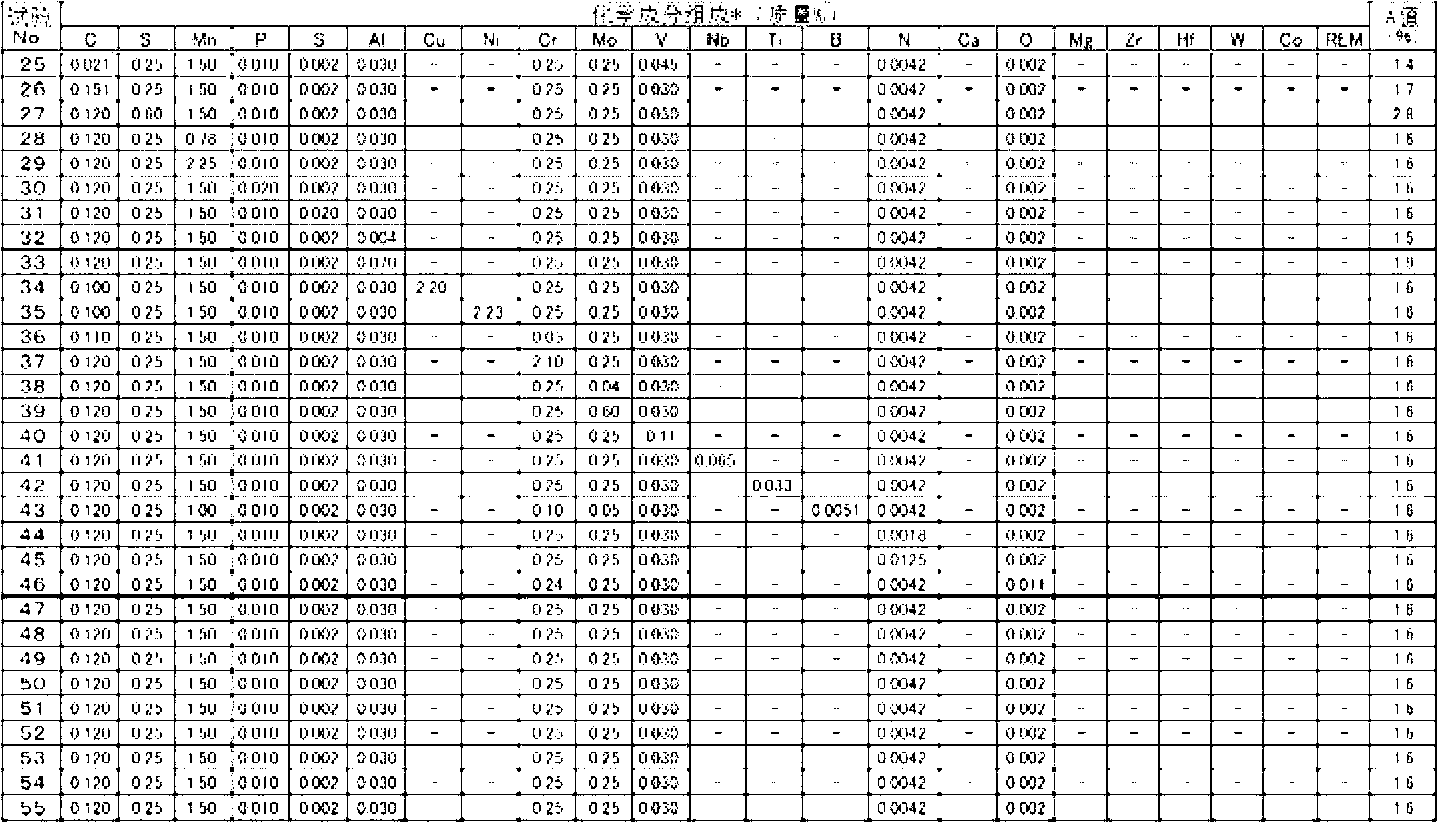

[0094] 【Table 2】

[0095]

[0096] *: The balance is iron and unavoidable impurities other than P and S

[0097] 【table 3】

[0098]

[0099] 【Table 4】

[0100]

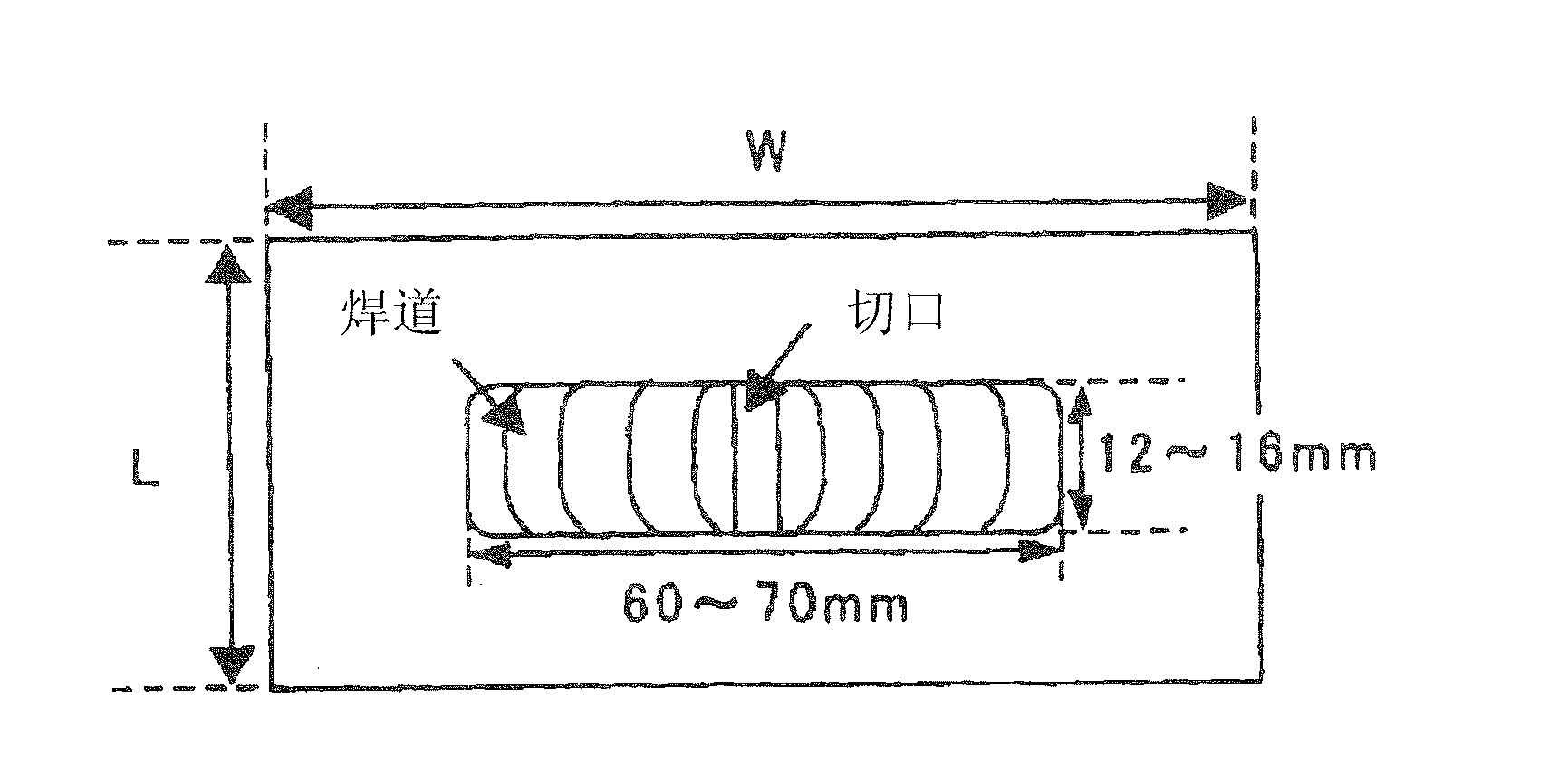

[0101] For each of the obtained thick steel plates, the structure [bainite area fraction, bainite lath width, MA size (av...

Embodiment 2

[0132] Various molten steels having the chemical compositions shown in the following Table 7 were smelted by a common melting method, and the molten steel was cooled to form a slab (thickness: 300mm), and then hot rolled under the conditions shown in the following Table 8, and cooled and Tempering was performed to obtain various steel plates (thickness: 100 mm). In addition, in Tables 7 and 8, for reference, Test No. 24 shown in the aforementioned Tables 1, 3, and 5 is also shown.

[0133] 【Table 7】

[0134]

[0135] *: The balance is iron and unavoidable impurities other than P and S

[0136] 【Table 8】

[0137]

[0138] For each thick steel plate obtained, by the method shown in Example 1, the structure [area fraction of bainite, lath width of bainite, size of MA (average equivalent circle diameter and maximum equivalent circle diameter)], Mechanical properties (yield strength YS of thick steel plate, tensile strength TS, dart impact property NDT), and the size (aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com