Wheel of motor vehicle

A technology for motor vehicles and wheels, applied in the direction of wheels, spoked wheels, vehicle components, etc., can solve the problems of shortening the service life of the wheel, fatigue cracks, and damage to the spokes, and achieve the effect of prolonging the service life, improving the strength and avoiding damage.

Inactive Publication Date: 2014-02-12

ANHUI IND & TRADE VOCATIONAL TECHN COLLEGE

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The fixed part of the web plate needs to bear the fastening force, centering force and working stress at the same time, so it needs to bear a large stress, which is prone to fatigue cracks or fractures, which will cause damage to the web plate and shorten the service life of the wheel

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

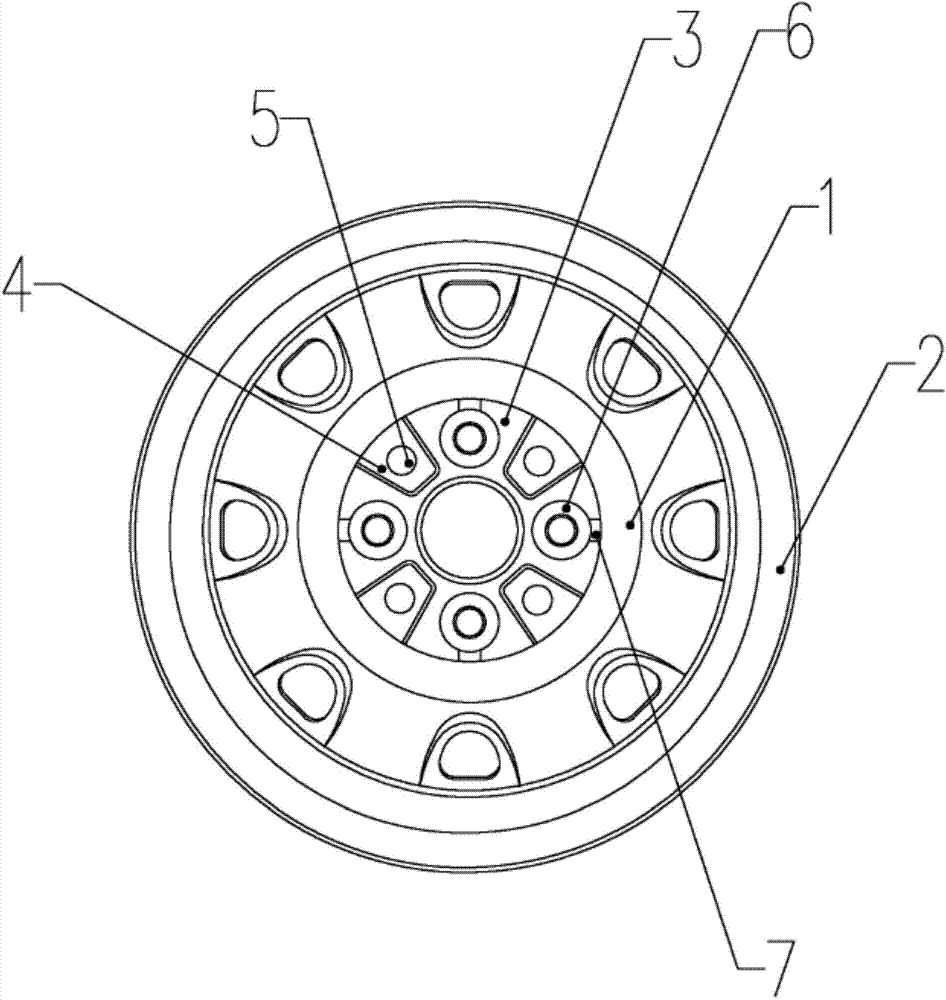

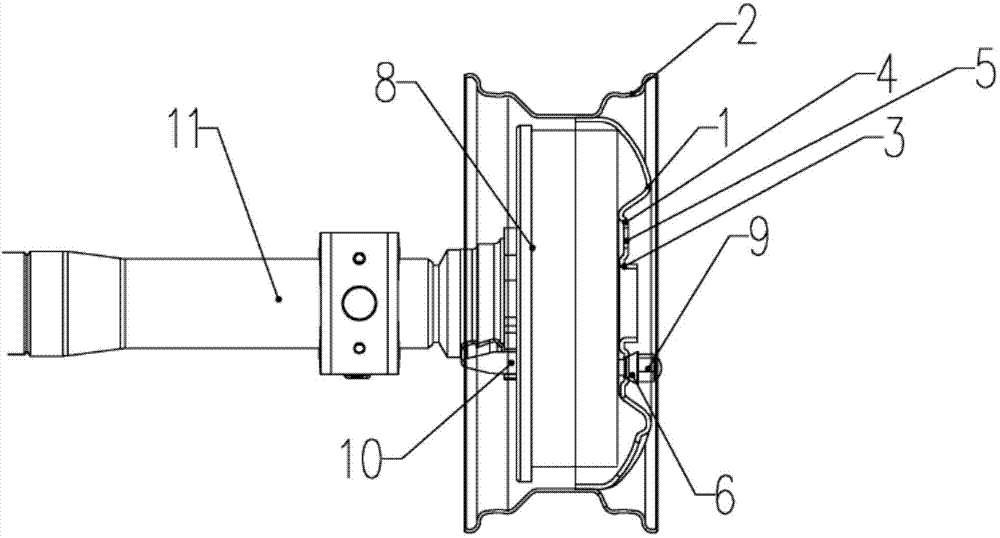

The invention discloses a wheel of a motor vehicle. The wheel comprises a wheel spoke and a wheel rim which is arranged around the wheel spoke and fixedly connected with the wheel spoke, wherein a plurality of first reinforcing bodies are bulged on a fixed part of the wheel spoke and formed by bulging towards the outer side of the wheel spoke; heat dissipation holes are formed in the first reinforcing bodies; screw cap bases are bulged on the fixed part of the wheel spoke; a plurality of second reinforcing bodies are bulged on the fixed part of the wheel spoke and connected with the screw cap bases; the screw cap bases and the second reinforcing bodies are formed by bulging towards the outer side of the wheel spoke; the first reinforcing bodies and the second reinforcing bodies extend in the radial direction of the wheel spoke; and the plurality of the first reinforcing bodies and the plurality of the second reinforcing bodies are distributed at intervals in the circumferential direction of the wheel spoke. The wheel of the motor vehicle is good in work stability and long in service life.

Description

technical field [0001] The invention relates to a component of a motor vehicle, in particular to a wheel of a motor vehicle. Background technique [0002] Automobile wheels include webs and rims. In order to install the wheel on the hub, a central positioning hole and a screw mounting hole are usually provided on the web. When installing, put the hub shaft head in the center positioning hole, and pass the screw through the screw installation hole to connect the spoke plate and the hub. Since the fixed part of the web needs to bear the fastening force, the centering force and the working stress at the same time, it needs to bear a large stress, which is prone to fatigue cracks or fractures, resulting in damage to the web and shortening the service life of the wheel. Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a wheel of a motor vehicle with good working stability and long service life. [0004] In order to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B60B3/04

Inventor 朱家艳

Owner ANHUI IND & TRADE VOCATIONAL TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com