Patents

Literature

48results about How to "Avoid temperature cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

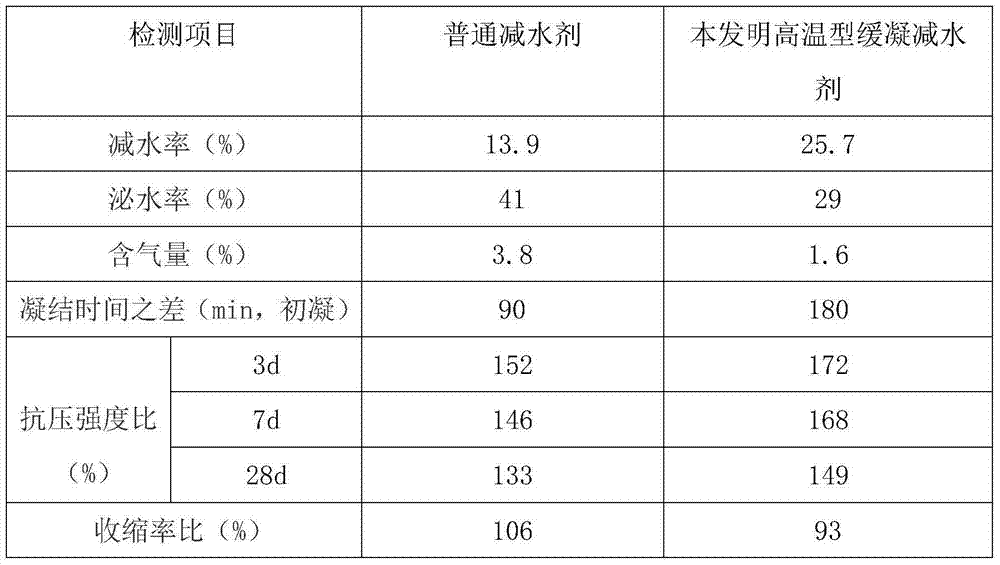

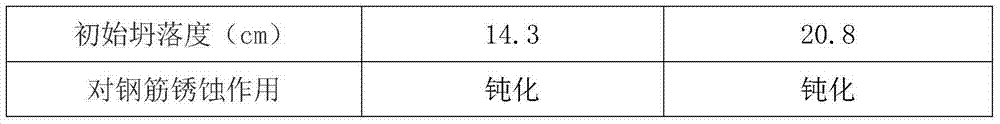

High-temperature retarding and water reducing agent

InactiveCN104119017AImprove high temperature resistanceSuitable for a wide temperature rangeSlagPENTAERYTHRITYL DISTEARATE

The invention discloses a high-temperature retarding and water reducing agent prepared by mixing the following raw materials in parts by weight: 35-45 parts of polycyclic aromatic hydrocarbon sulfonated formaldehyde condensates, 20-30 parts of acyclic hydroxyl sulfonate condensates, 10-15 parts of diethylenetriaminepenta(methylene-phosphonic acid), 8-16 parts of calcium saccharate, 12-18 parts of alunite powder, 5-10 parts of xanthan gum powder, 4-8 parts of barium metaborate, 3-6 parts of sodium lauryl sulfate, 2-4 parts of pentaerythrite di-n-stearate, 6-12 parts of maleic anhydride-styrene sulfoacid copolymers, 10-15 parts of blast furnace slag powder, 5-10 parts of waste saccharide slag powder, 7-13 parts of nekal and 4-7 parts of auxiliary. The water reducing agent disclosed by the invention is excellent in high temperature resistance, relatively wide in applicable temperature range (150-250 DEG C), capable of reducing cement hydration heat release, reducing the temperature stress of the concrete, avoiding generating temperature cracks and completely meeting the construction requirement for high-temperature and high-pressure well cementation, suitable for continuously pouring mass concrete under a high temperature condition, remarkable in water reducing enhancement effect, good in slump loss resistance and wide in market prospect.

Owner:WUHU SANXING CONCRETE ADMIXTURE

High-strength concrete composite material and preparation method thereof

The invention discloses a high-strength concrete composite material which comprises the following components in parts by weight: 100 parts of cement, 1-5 parts of fiber, 2-20 parts of silica fume, 1-20 parts of coal ash, 1-10 parts of composite rare earth, 10-20 parts of magnesium silicate granules, 140-200 parts of sand, 140-200 parts of macadam and 30-50 parts of water. The product is high in anti-cracking ability and small in loaded crack width and has long-term durability. Moreover, the interaction of composite concrete is improved, the material performance is far higher than basic performance of common concrete, main indexes of the concrete are obviously improved, a temperature crack is avoided, and the strength, freezing resistance and anti-permeability of the concrete are guaranteed.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

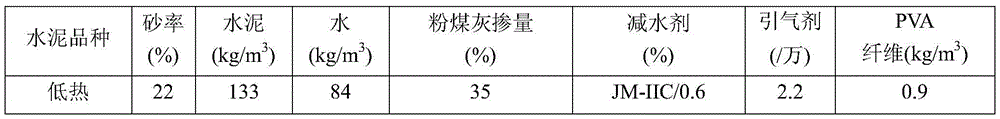

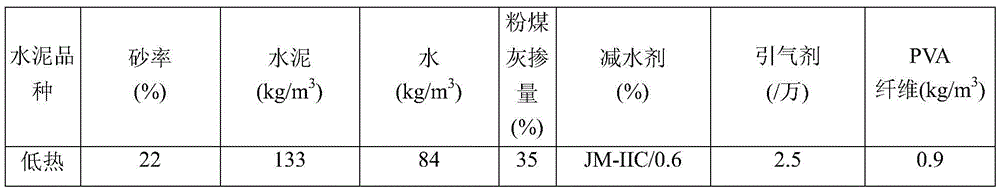

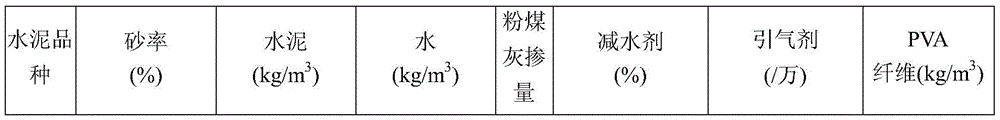

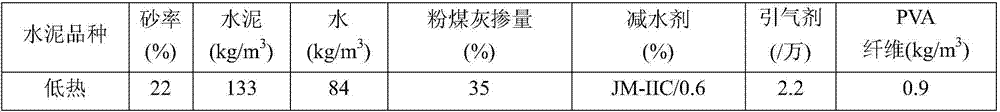

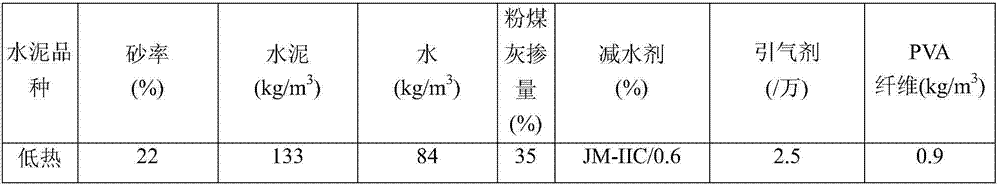

Temperature control anti-cracking method for large-volume hydraulic concrete for super high arch dam

ActiveCN105541234AMeet the requirements of temperature changesSatisfy Restricted Shrinkage RequirementsFoundation engineeringArch damsFiberPre cooling

The invention discloses a temperature control anti-cracking method for a large-volume hydraulic concrete for a super high arch dam. According to the method, the concrete out-of-mixer temperature and the concreting temperature are controlled by pre-cooling aggregate, and adding flake ice and cold water; low-heat cement and highly-doped grade I coal ash are taken as a cementing material; cooling water pipes are buried and water is introduced to reduce the maximum temperature of the hydraulic concrete; grade-4 aggregate and PVA (Polyvinyl Acetate) fibers are adopted to prevent cracks. The purposes of controlling the hydraulic concrete out-of-mixer temperature to be lower than or equal to 7 DEG C in summer and lower than or equal to 9 DEG C in winter, the concreting temperature to be lower than or equal to 12 DEG C, and the maximum temperature to be lower than or equal to 27 DEG C are achieved. By actual application of the temperature control anti-cracking method for the large-volume hydraulic concrete to the super high arch dam, the maximum temperature is remarkably reduced, and cracks are not found on site.

Owner:CHINA THREE GORGES CORPORATION

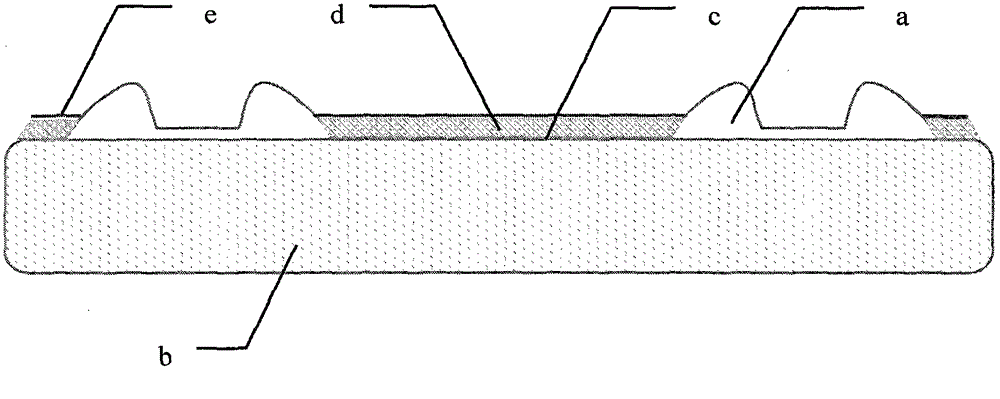

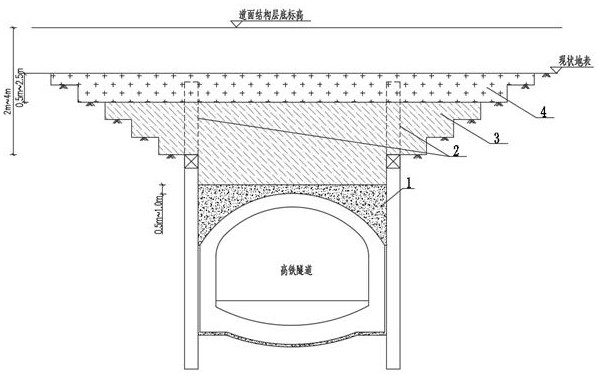

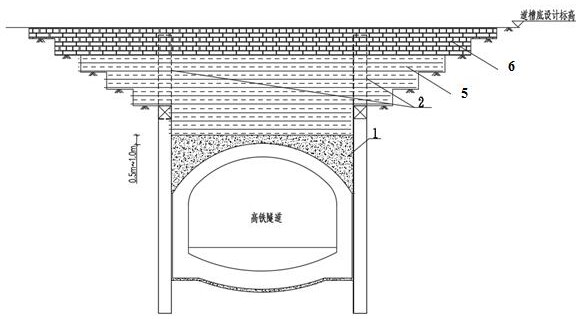

Spray polyurethane foam material for track board and construction method thereof

InactiveCN104558479AAvoid temperature cracksWith thermal insulation effectRailway tracksPolyesterPowder mixture

The invention relates to a spray polyurethane foam material for a track board and a construction method thereof, wherein a spray polyurethane component A consists of polyether polyol, polyester polyol, a foam stabilizer, a foaming agent, a catalyst, a flame retardant, an antioxidant and a modified titanium dioxide-glass fiber powder mixture; and a component B consists of an isocyanate mixture. The construction method comprises the following steps: pre-sealing a rail fastener (a); smearing a primer (c) on the track board (b); then spraying a 5-10mm polyurethane foam material (d); and finally smearing an aliphatic polyurethane coating (e) to accomplish construction. The spray polyurethane foam material provided by the invention is mainly applied to the track board of a high speed railway to fundamentally solve the temperature cracking problem of a concrete member. The material provided by the invention has a thermal insulation effect and excellent mechanical property, and the bonding strength with the track board can reach over 0.3MPa.

Owner:BEIJING ACAD OF BUILDING ENG

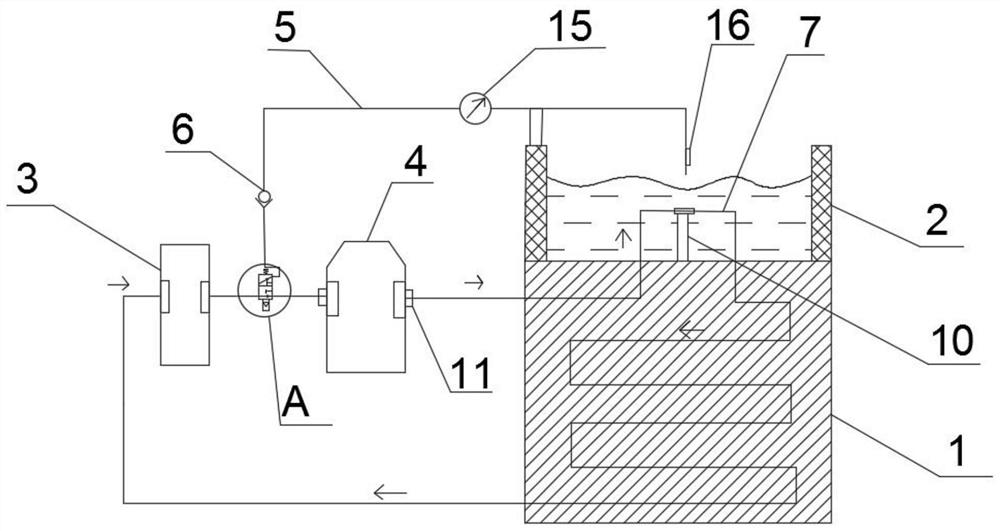

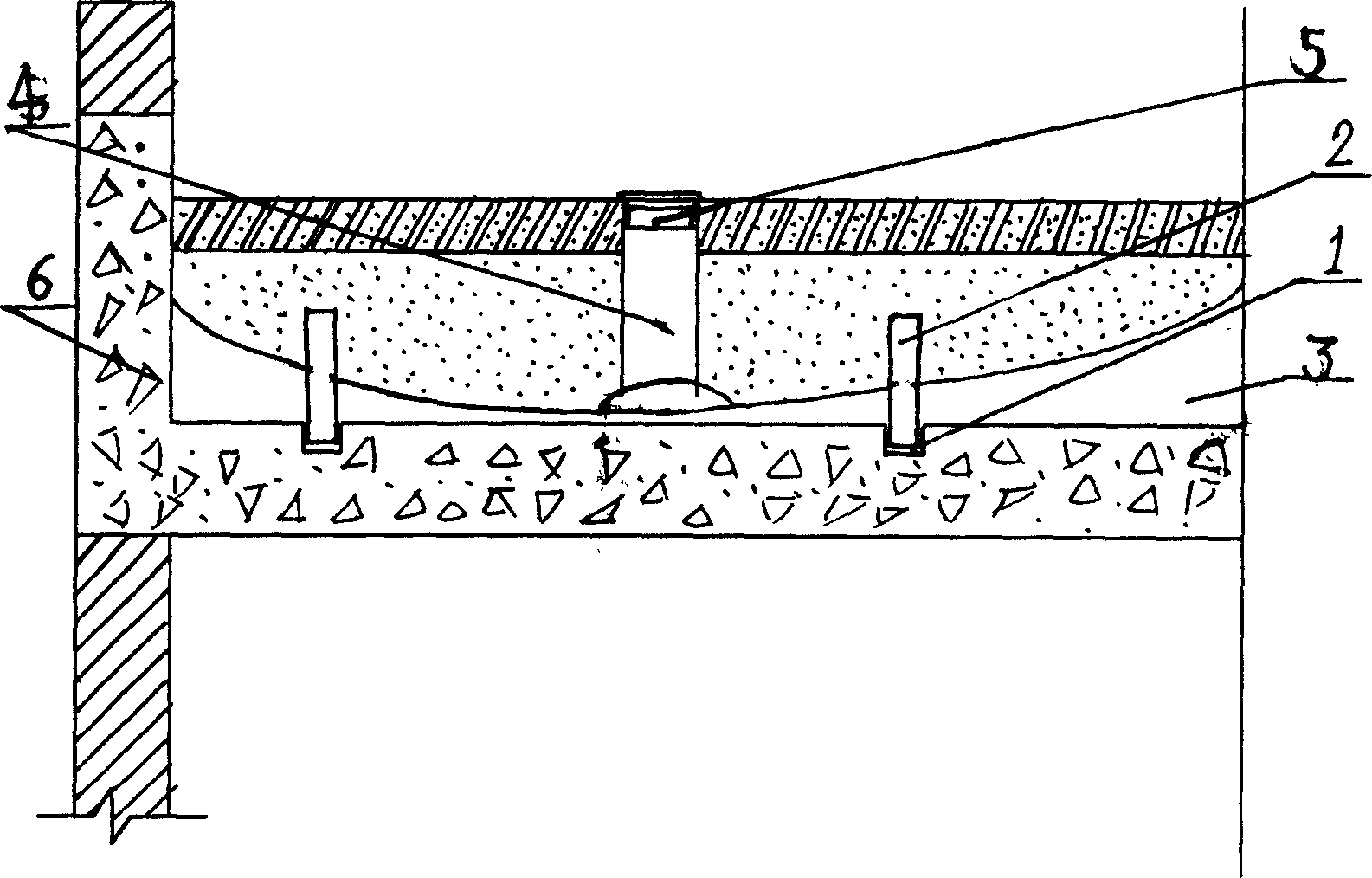

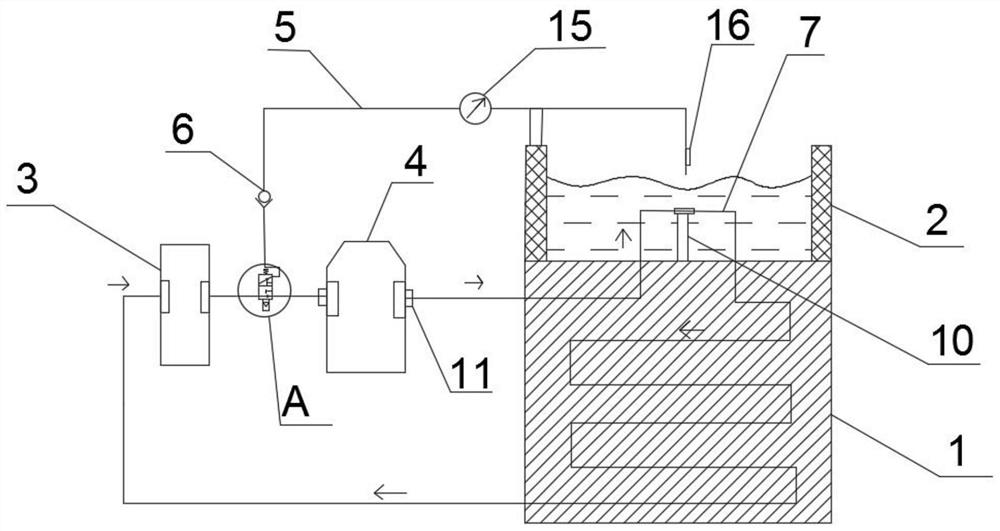

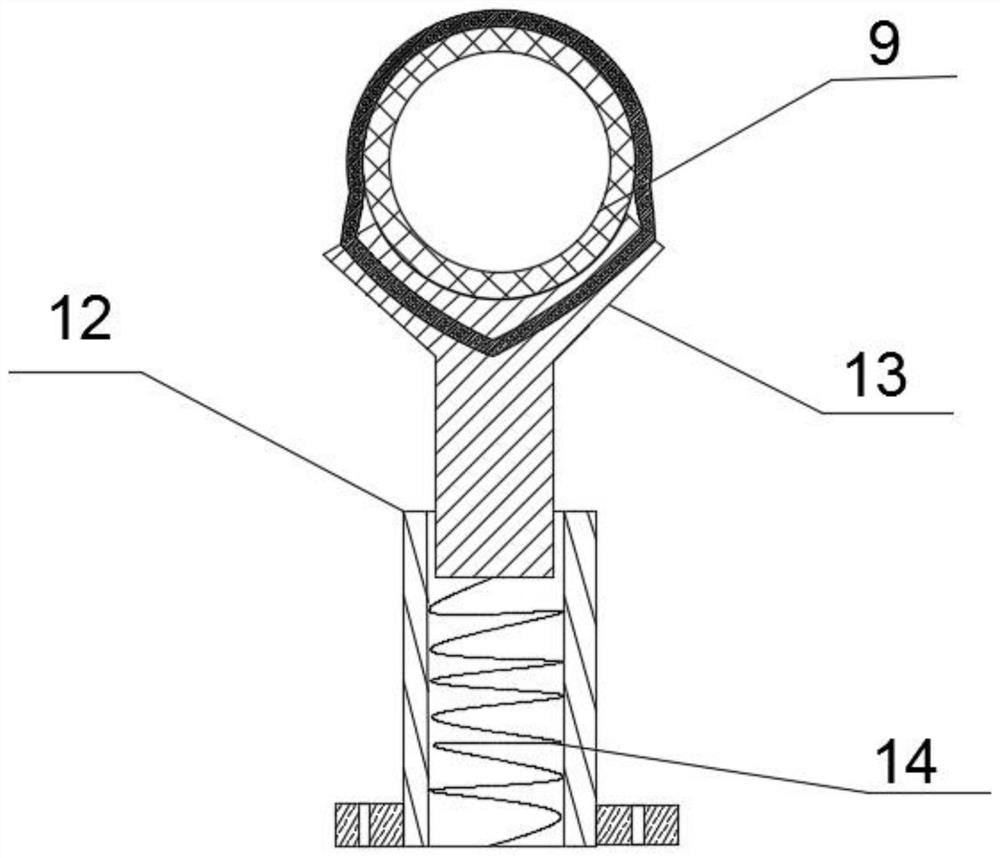

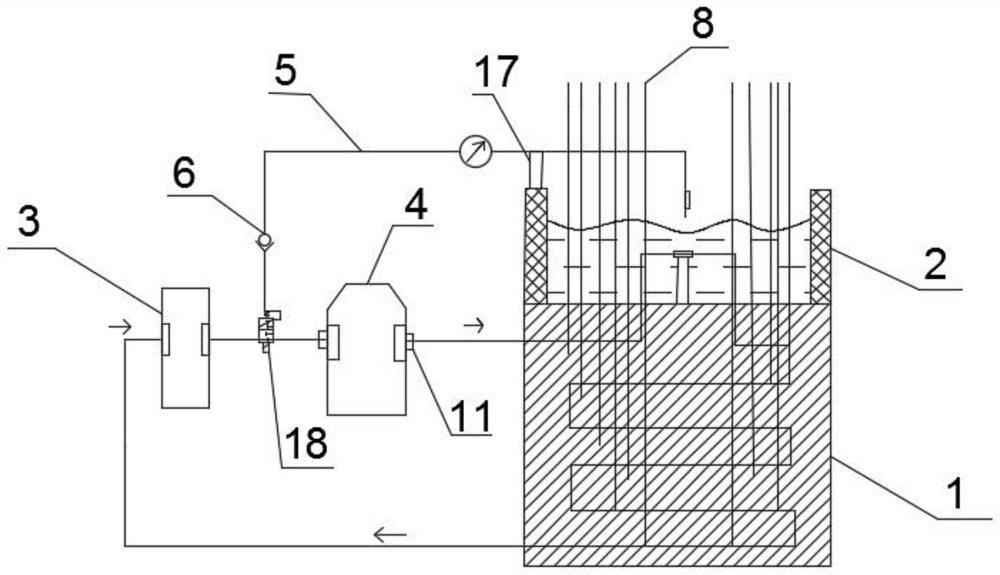

Mass concrete cooling water circulation and construction method

ActiveCN111980408AGuaranteed internal and external temperature differenceAvoid temperature cracksMeasurement devicesFoundation engineeringWater storageCooling tower

The invention discloses a mass concrete cooling water circulation and construction method, and belongs to the field of mass concrete construction in constructional engineering. The mass concrete cooling water circulation comprises a water circulation module and a water storage module, the water circulation module comprises a conveying pipeline, the conveying pipeline is laid in a pouring pit, anda waterproof wall is arranged along the upper surface of the pouring pit. The waterproof wall is suitable for storing water and curing concrete, the water storage module comprises a flow dividing branch pipe and a control part, and an inlet of the flow dividing branch pipe is formed between a water storage tank and a cooling tower. The flow dividing branch pipe is suitable for guiding water into the waterproof wall, and the control part is located at the port, close to one end of the water storage tank, of the flow dividing branch pipe and suitable for controlling the flow direction of water of the flow dividing branch pipe. The surface, located in the pouring pit, of the conveying pipeline is a protruding part, and the protruding part is suitable for conveying water of the waterproof wallinto the conveying pipeline in the concrete in the water flow direction. The problems are solved that large temperature difference is generated and rapidly reduced when an existing drainage pond stores water for curing the surface of the concrete and water circulation is conducted in the concrete, and cracks are generated due to sudden temperature change.

Owner:CHINA MCC17 GRP

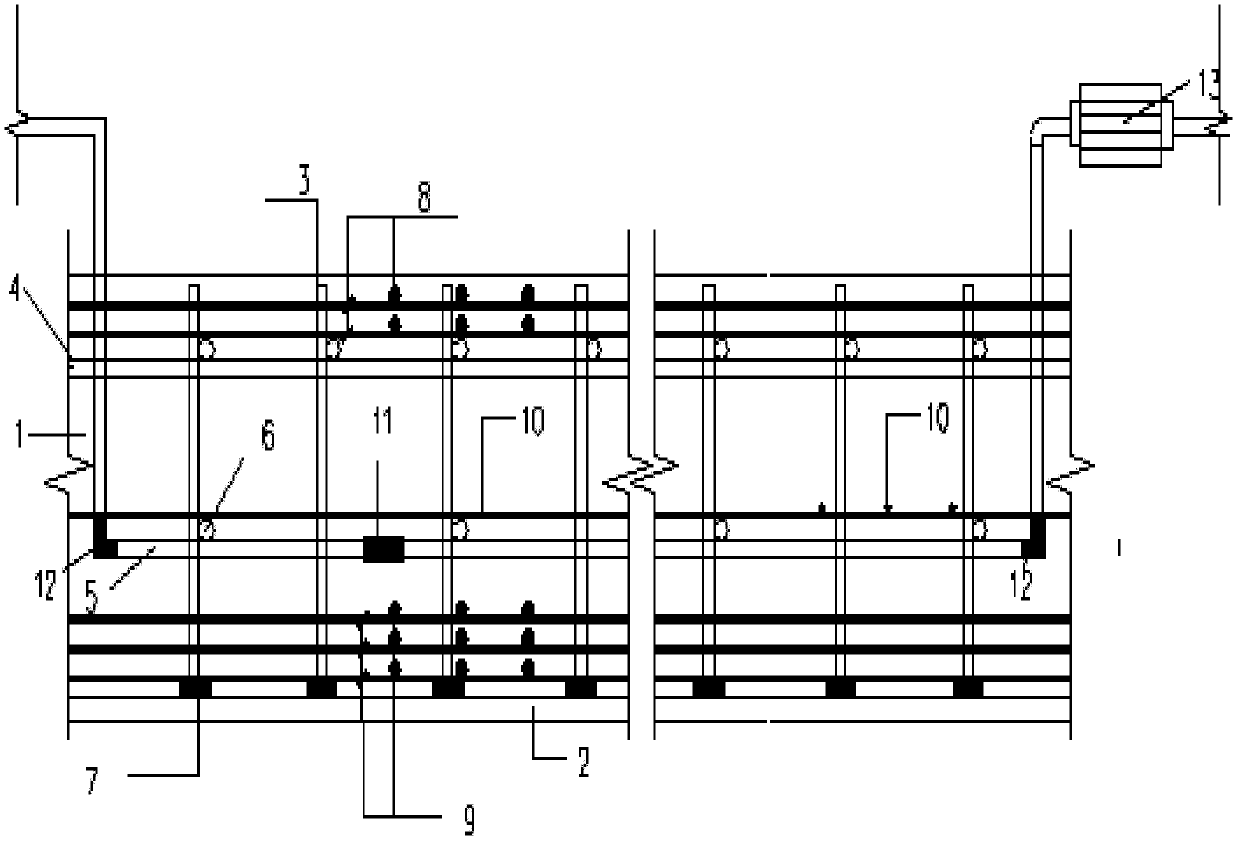

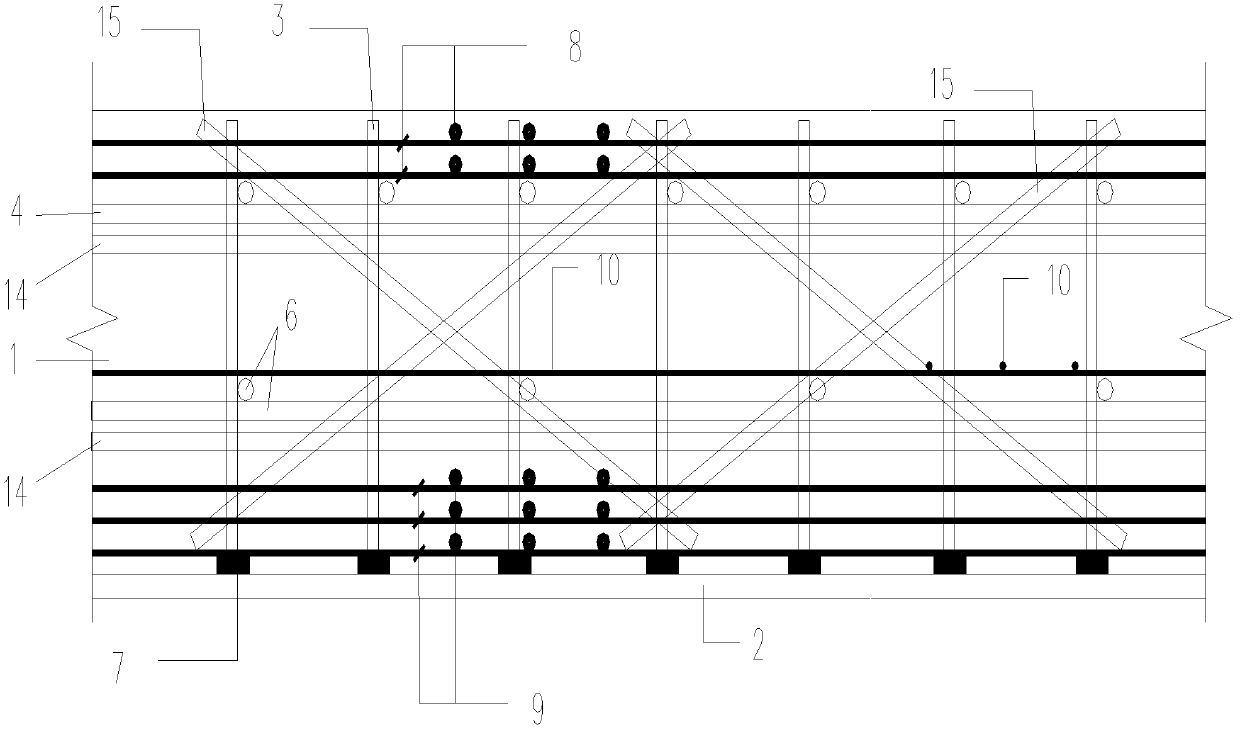

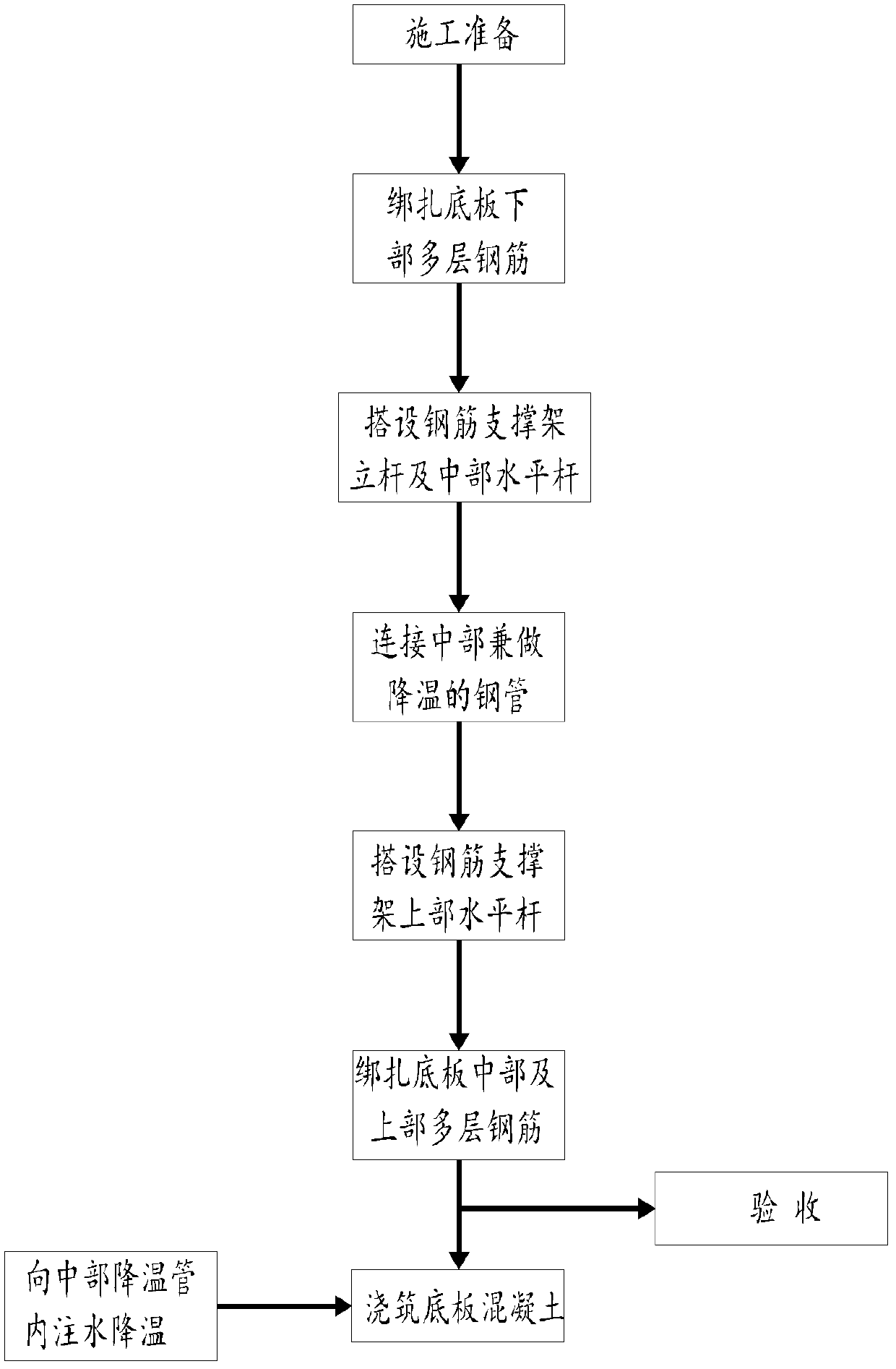

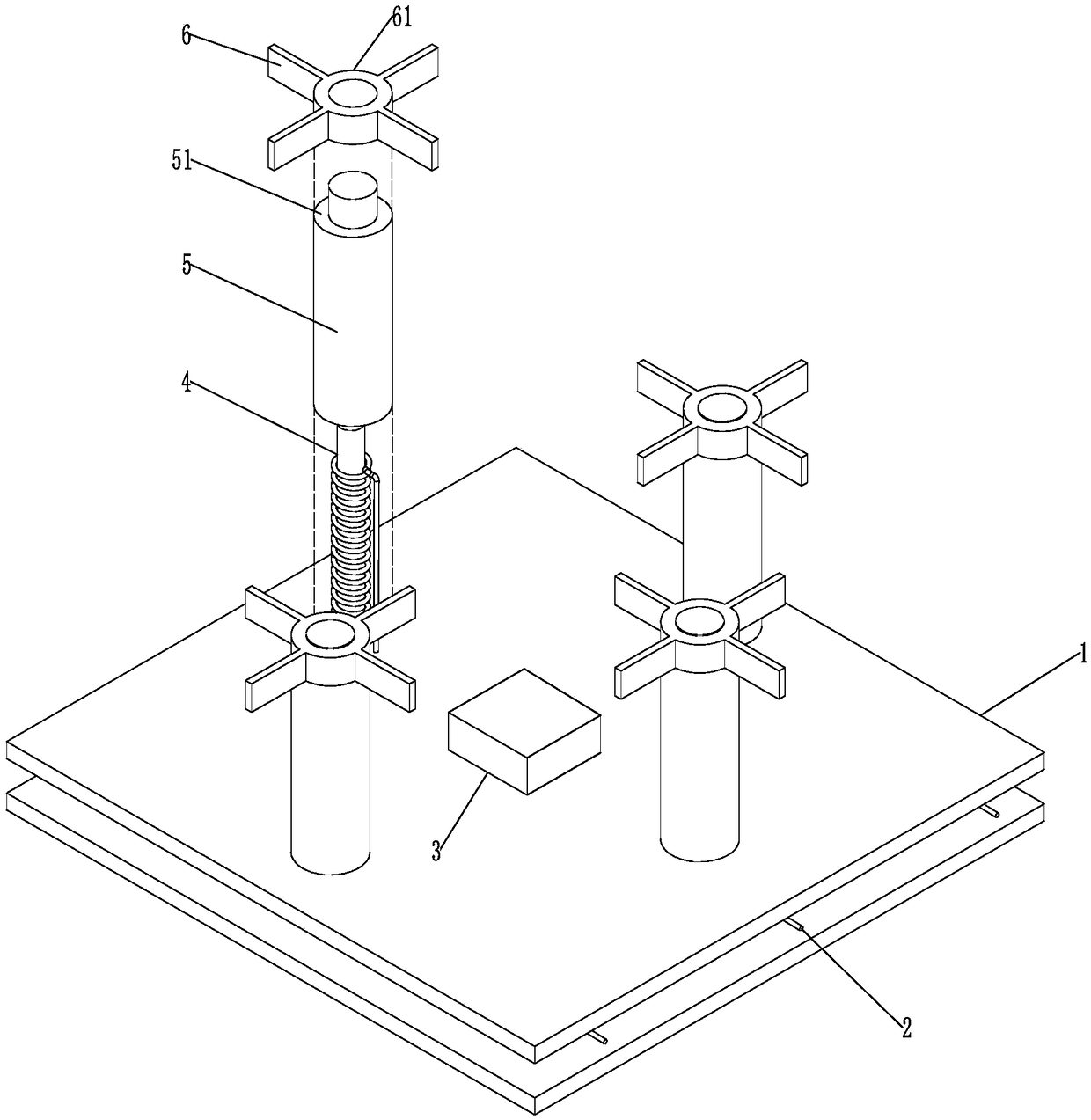

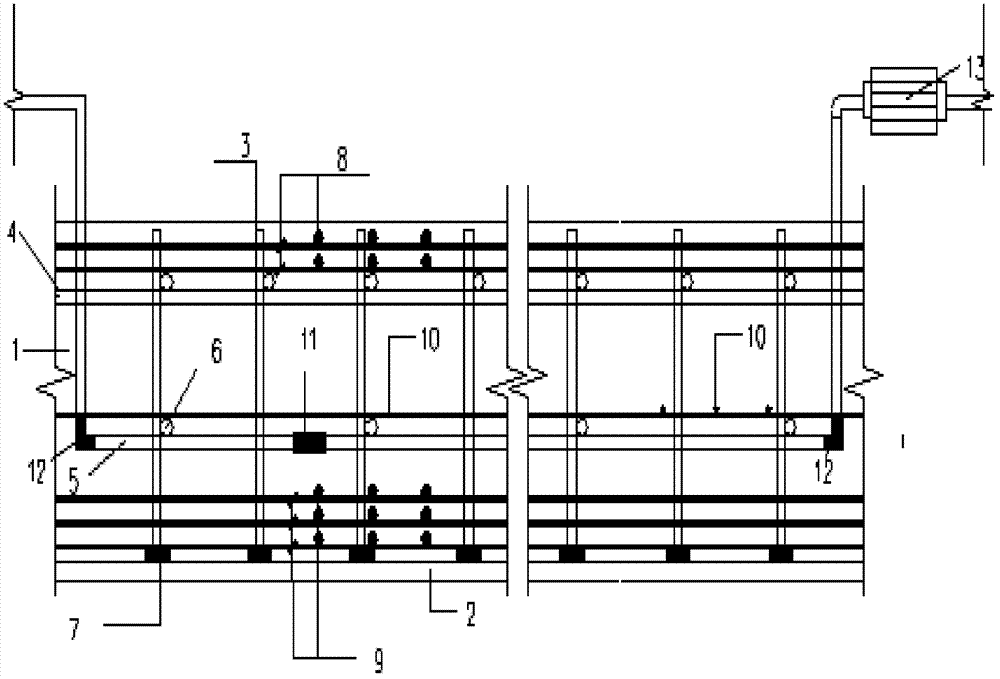

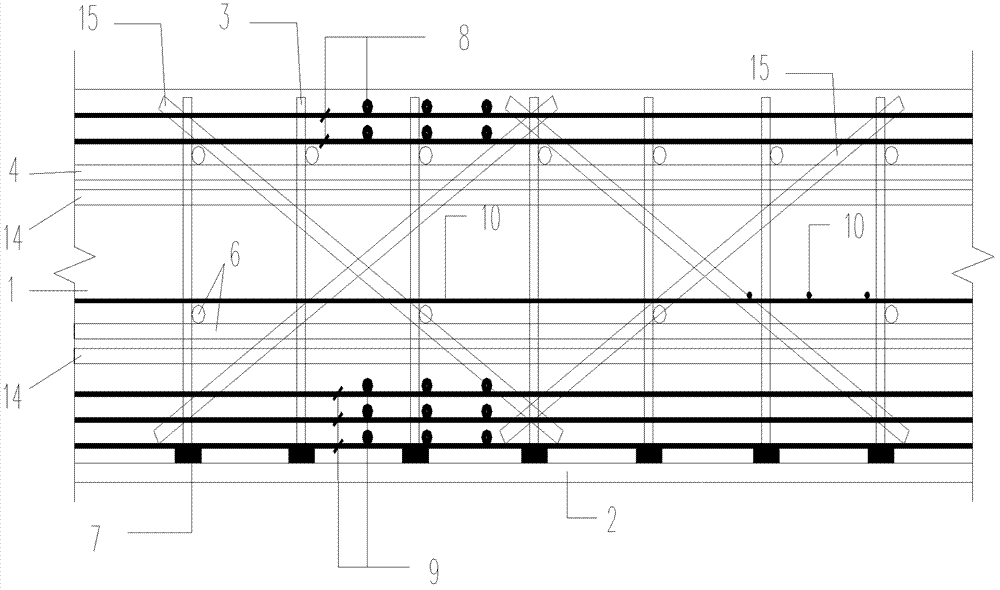

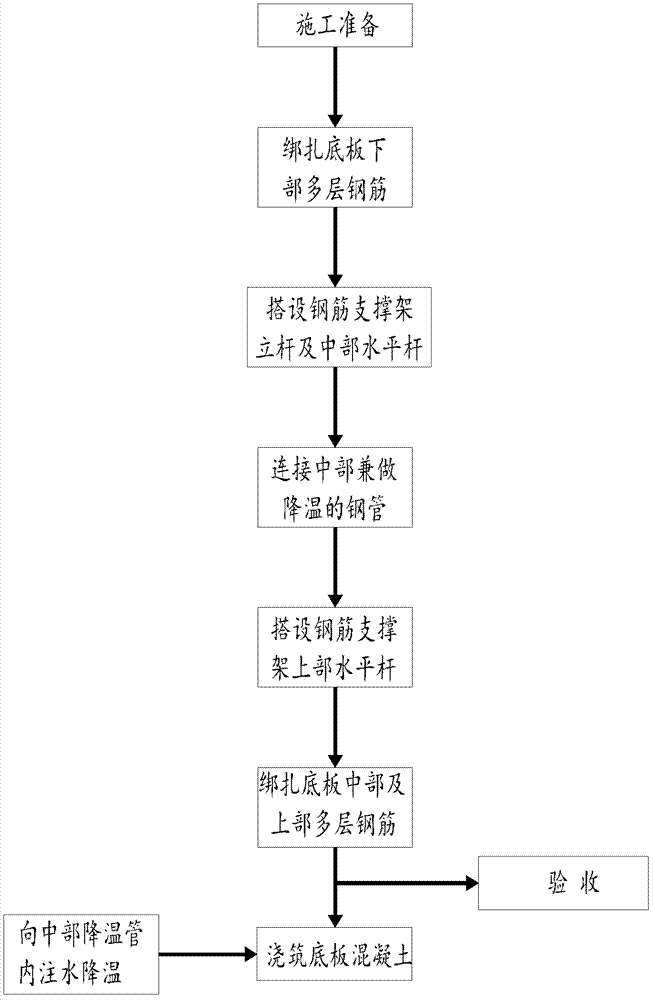

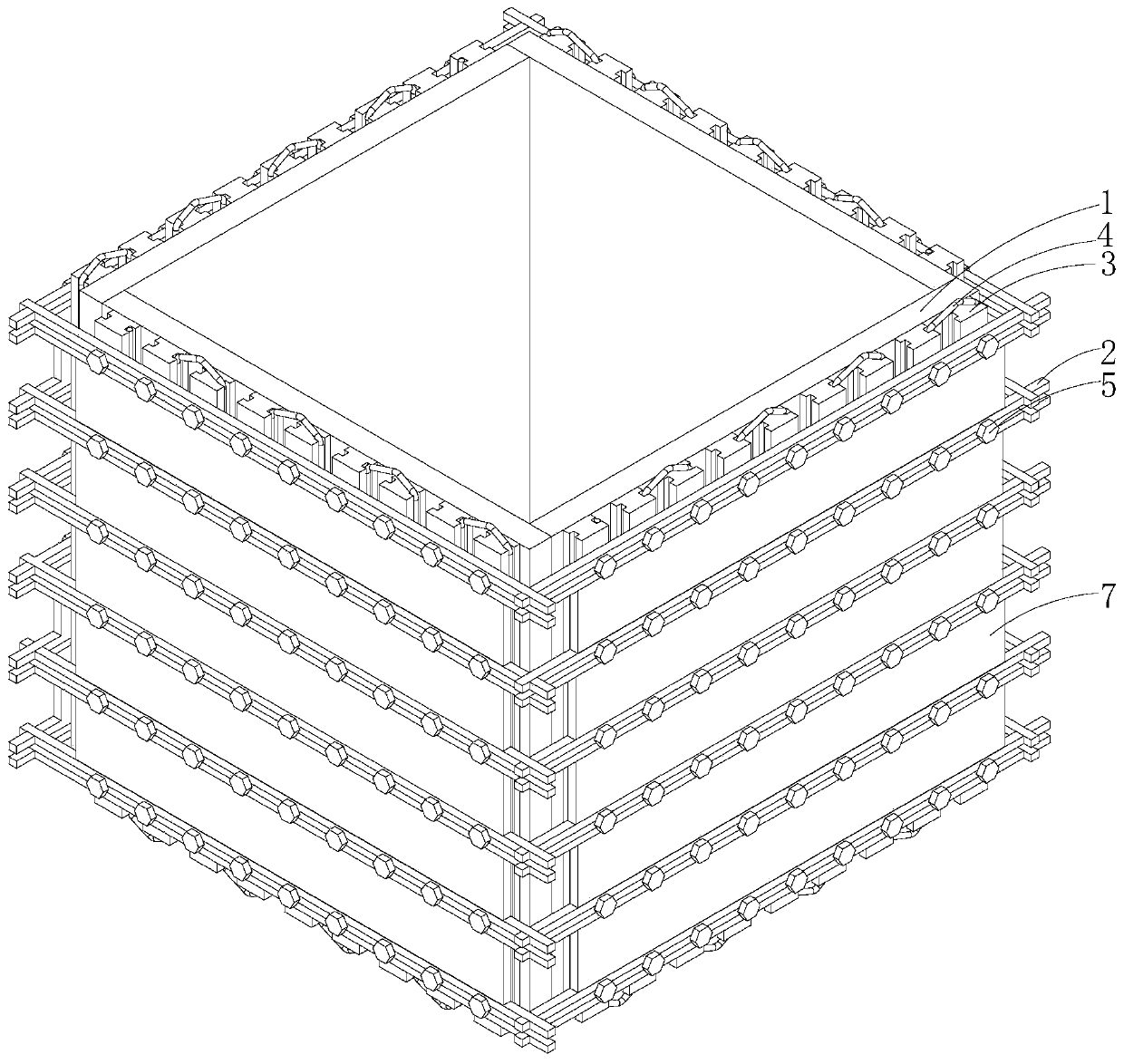

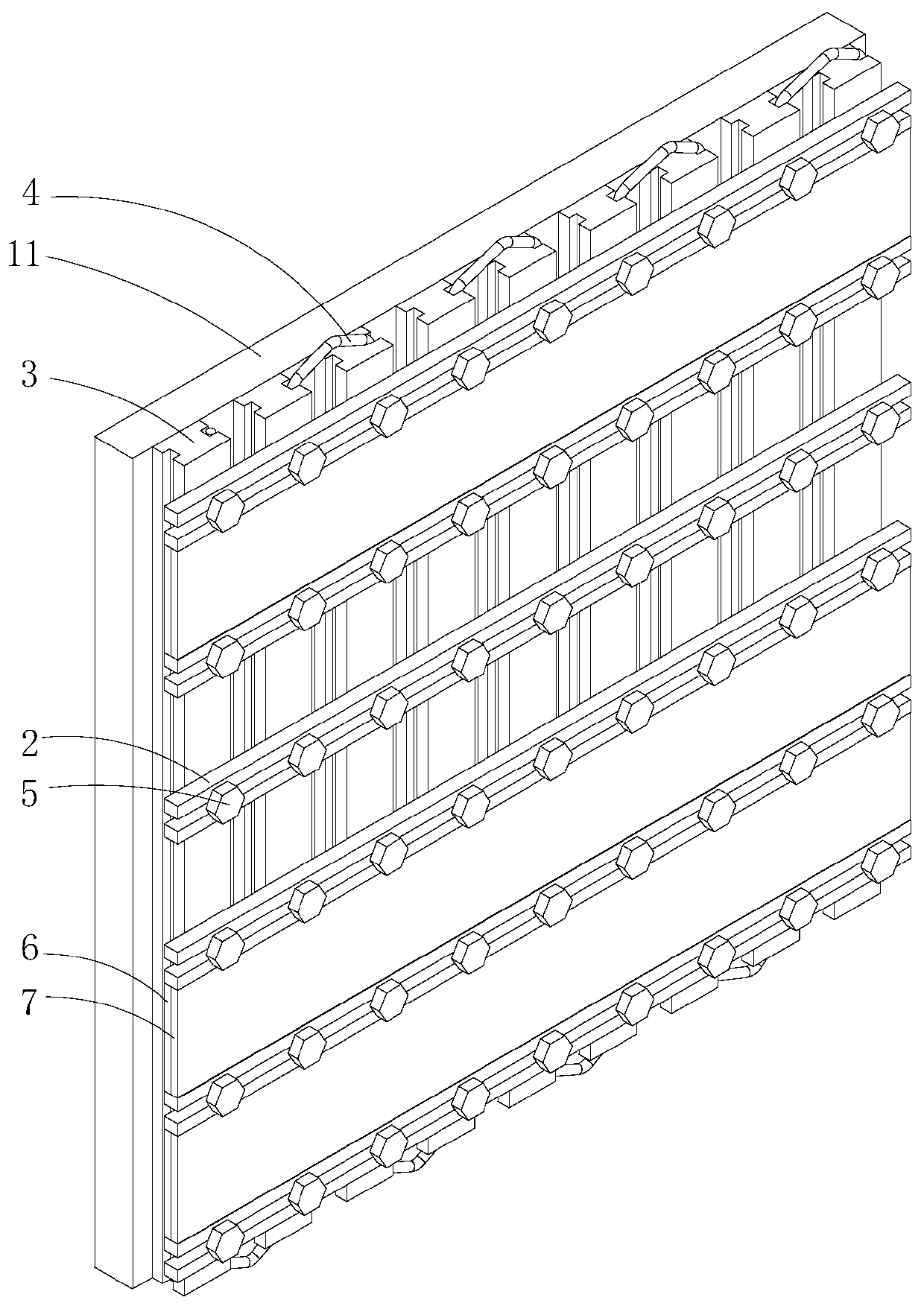

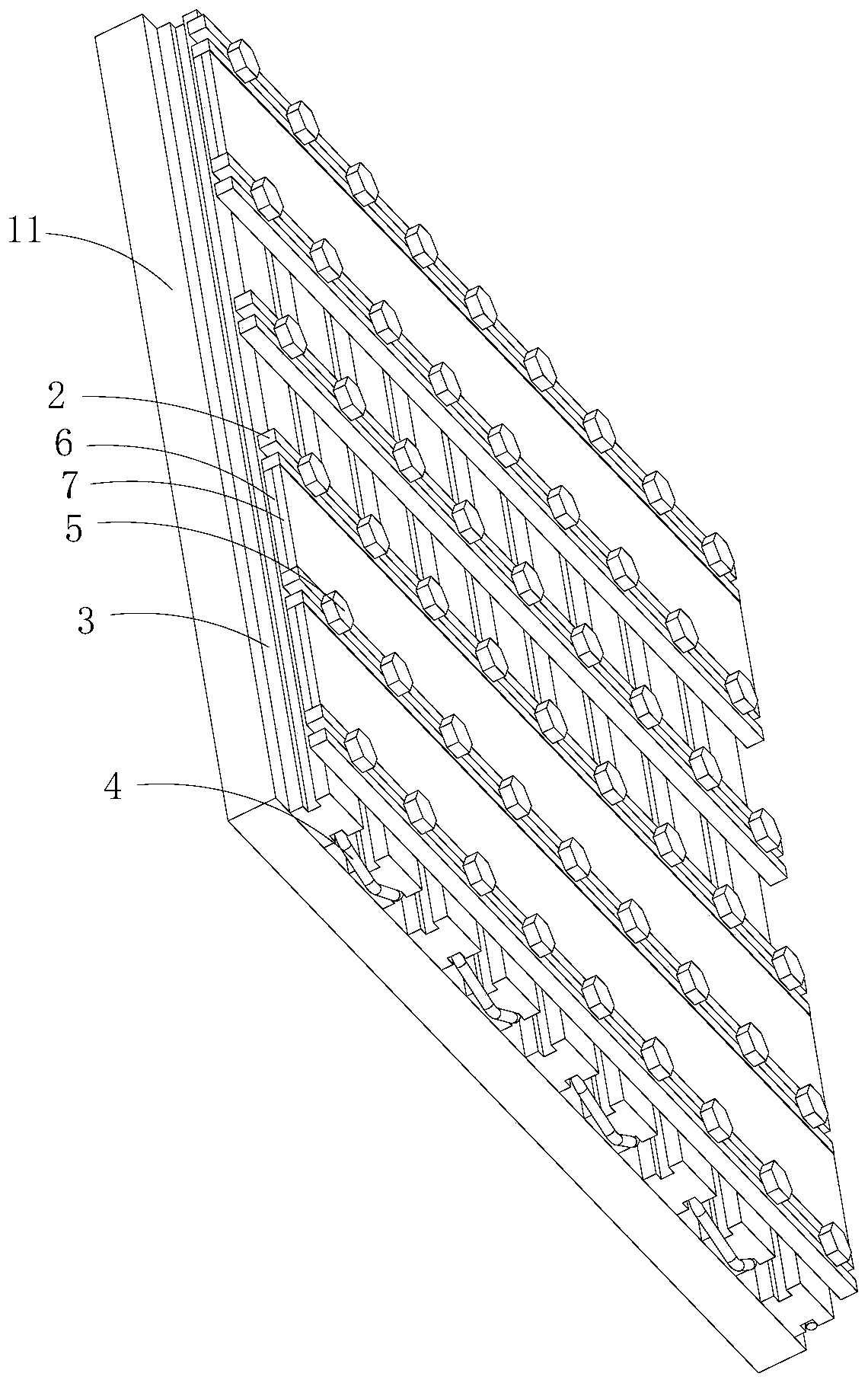

Method for taking cooling pipe network as building bottom plate multi-layer reinforced support frame

ActiveCN102704483AEasy to removeReduce heat of hydrationArtificial islandsUnderwater structuresRebarCooling pipe

The invention provides a method for taking a cooling pipe network as a building bottom plate multi-layer reinforced support frame and aims to provide a method for building bottom plate reinforced support frame, which is fast in construction progress, low in construction cost and high in safety. The method is realized by the following steps of: erecting a fastening steel pipe frame on a concrete bottom plate (1); connecting an upright rod (3) steel pipe and a horizontal rod steel pipe with a fastener, and respectively binding and placing the steel bars (10) in the middle of the bottom plate and the steel bars (8) on the upper part of the bottom on a horizontal rod (6) in the middle of the fastening steel pipe frame and a horizontal rod (4) on the upper part of the fastening steel pipe frame; erecting the steel pipe frame from the edge of a raft board for supporting by employing the fastening steel pipes after the bottom plate steel bars are bound, and continuously arranging vertical diagonal bridging (15) and two pieces of horizontal diagonal bridging (14) which are arranged on the upper and lower parts according to the column space at the periphery of the raft board; and taking the horizontal rod in the middle of the fastening steel pipe frame as a large-volume concrete cooling pipe, mounting a pressure pump at one end of a middle horizontal rod (5) serving as the cooling pipeso as to inject cold water into the pipeline, and taking the other end of the middle horizontal rod as a water outlet.

Owner:CHENGDU SIXTH CONSTR ENG

Water-proof concrete roofing for preventing temperature fracture

InactiveCN1570321AAvoid temperature cracksTo achieve the purpose of self-waterproofBuild-up roofsRubber materialElastomer

This invention publicized one kind of non- temperature crack Tong roofing in roofing board on to reserve certain scoop channels from the waterproofing, in the scoop channel the establishment and the scoop channel close coordination elastomer. This invention states roofing board on covers has looks for the slope level. States the elastomer by the rubber material, the damping part, the polyurethane is made, also may be the PVC tube. This invention Tong roofing board the expansion and contraction distortion which will produce under the open air temperature function, through will reserve the scoop channel to carry on the decomposition, each scoop channel will undertake part of distortions, because the elastomer elasticity far will be bigger than Tong, the roommate kneading board scoop channel distortion passable elastomer reverse distortion has been able freely to realize, has the foreword to release in the roommate kneading board the temperature stress, thus has avoided the roommate kneading board temperature crack production, will achieve roofing counter- from the waterproof goal. This invention structure simple, practical, is easy to construct, compares the cost with the traditional waterproofing form lowly, the durable performance better, turns on the water the effect to be better.

Owner:周新华

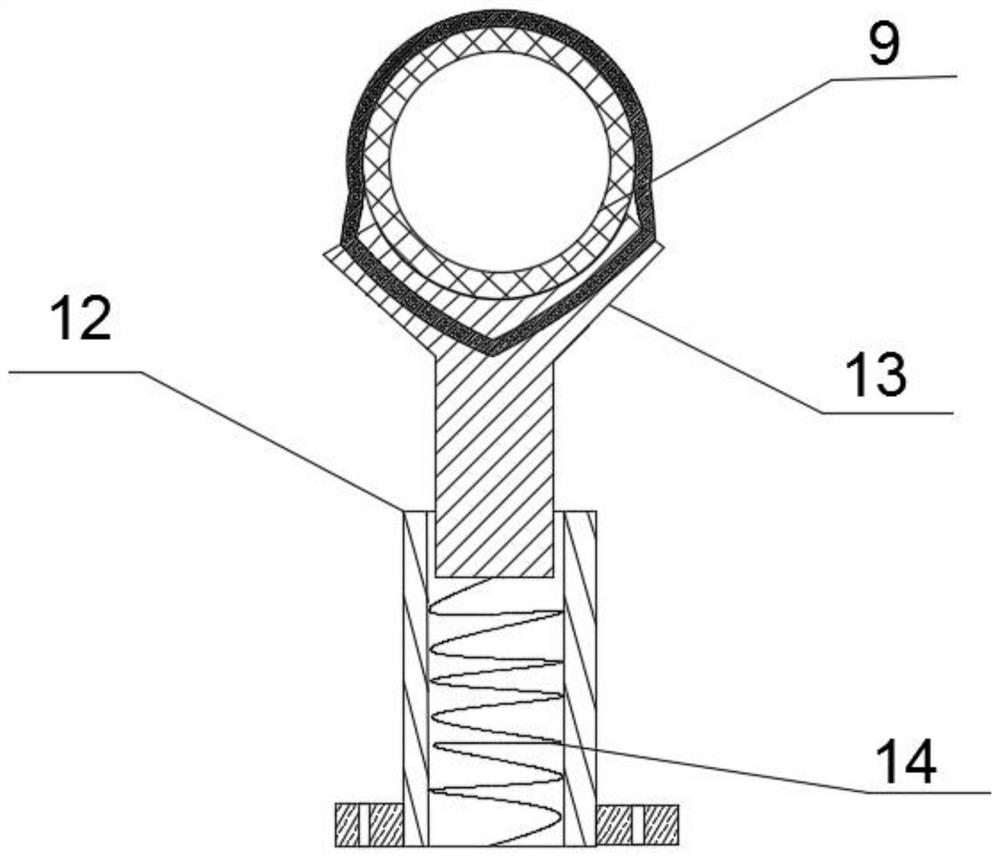

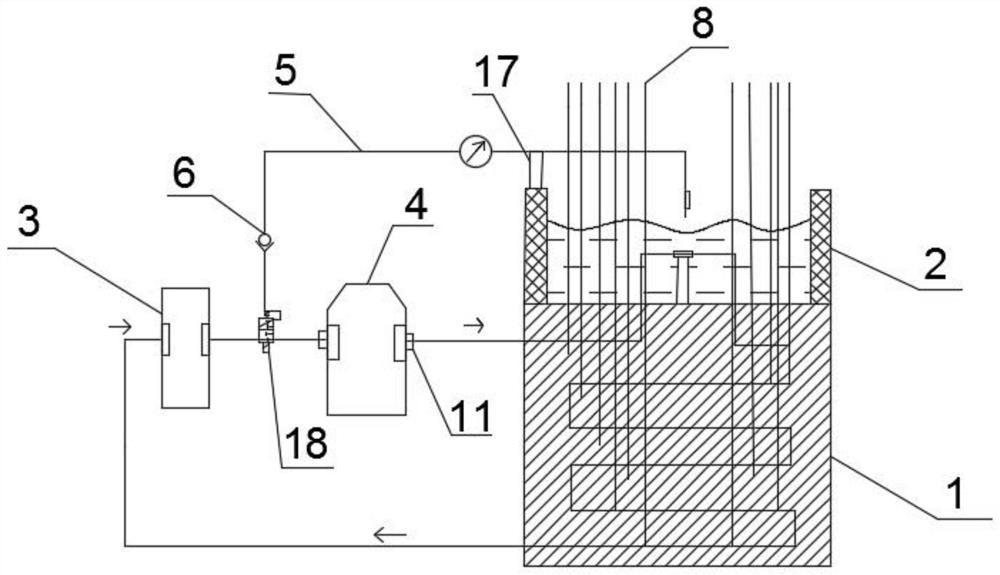

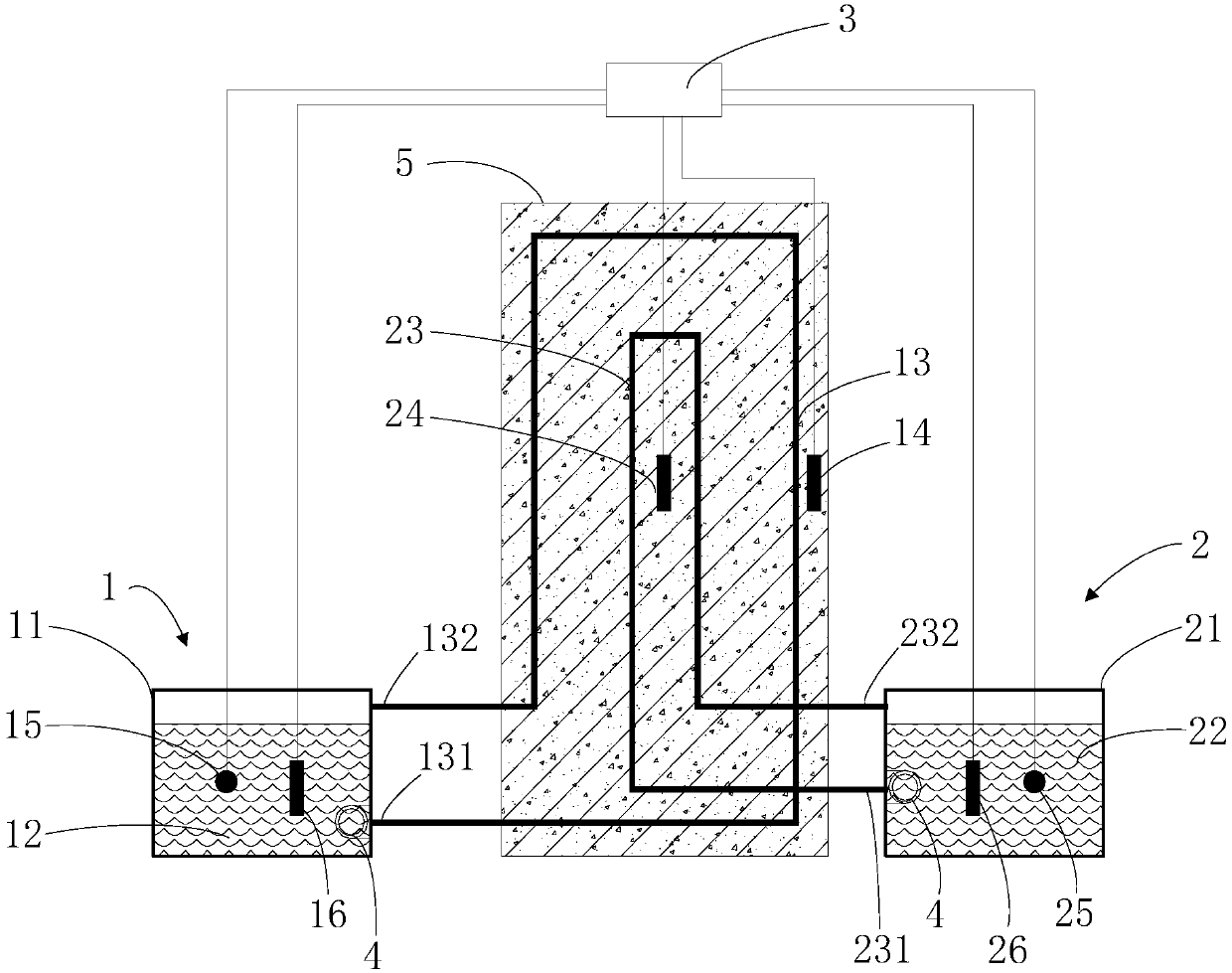

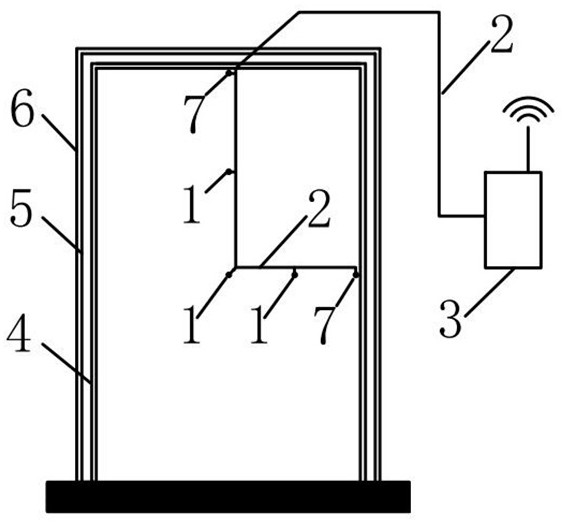

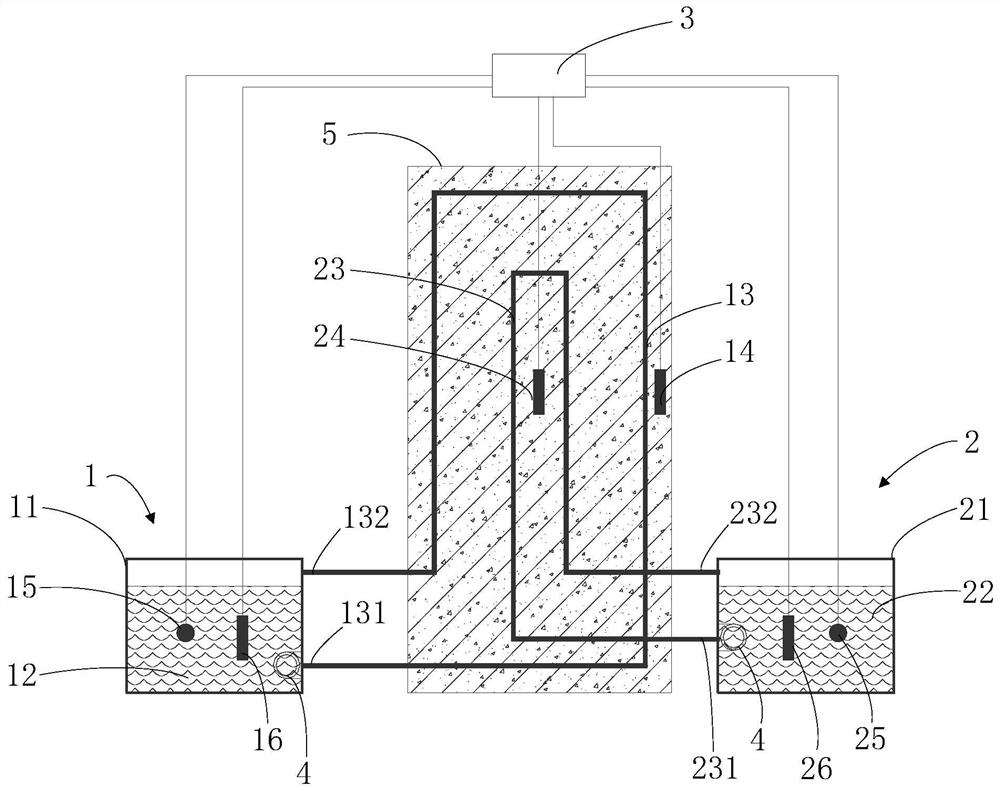

Mass concrete double-condensation-loop temperature control equipment and temperature control method based on mass concrete double-condensation-loop temperature control equipment

ActiveCN108049644AAvoid temperature cracksHeat of hydration controlBuilding material handlingTemperature controlSurface layer

The invention provides mass concrete double-condensation-loop temperature control equipment and a temperature control method based on the mass concrete double-condensation-loop temperature control equipment. The mass concrete double-condensation-loop temperature control equipment comprises a surface layer device, an internal layer device and a controller. The surface layer device comprises a firstliquid storage tank, first condensed fluid, a first condensation pipe buried into the surface layer of concrete and a first temperature sensor, a second temperature sensor and a first heater are arranged in the first condensed fluid, the first condensation pipe communicates with the first liquid storage tank, the first condensed fluid circulates in the first condensation pipe in a circulating mode, the internal layer device comprises a second liquid storage tank, second condensed fluid, a second condensation pipe buried into the internal layer of the concrete and a third temperature sensor, afourth temperature sensor and a second heater are arranged in the second condensed fluid, the second condensation pipe communicates with the second liquid storage tank, and the second condensed fluidcirculates in the second condensation pipe in a circulating mode; and the controller is connected to the first temperature sensor, the second temperature sensor, the third temperature sensor, the fourth temperature sensor, the first heater and the second heater. According to the mass concrete double-condensation-loop temperature control equipment, the problem that a temperature joint is prone tobeing generated by the mass concrete is solved.

Owner:SICHUAN TAILONG CONSTR GRP CO LTD

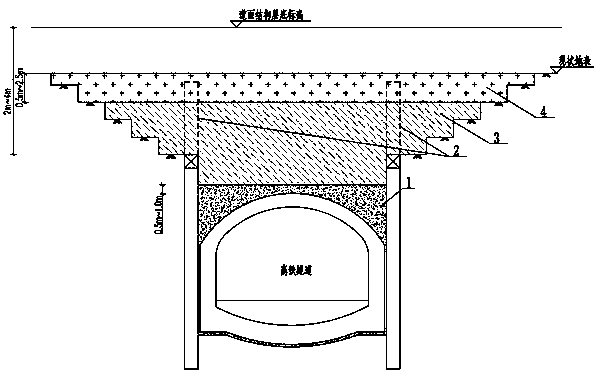

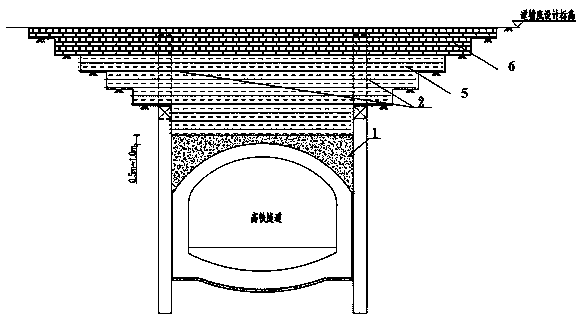

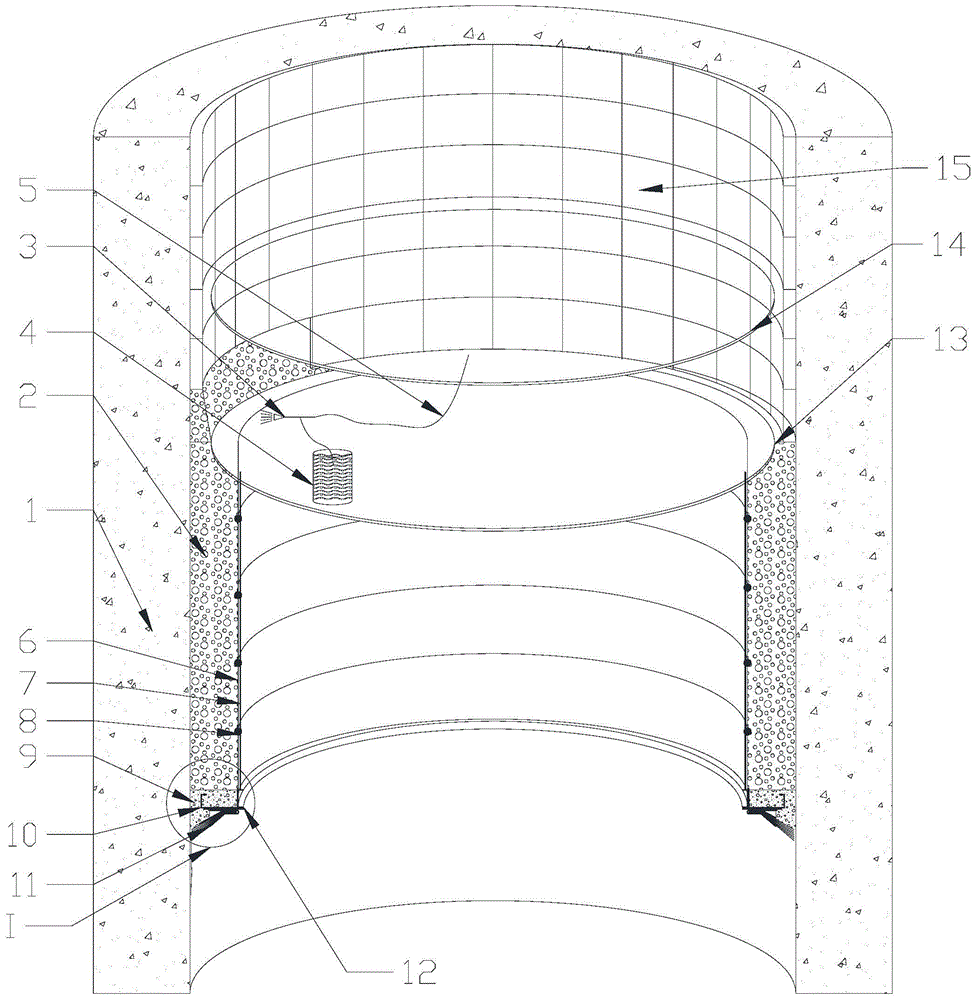

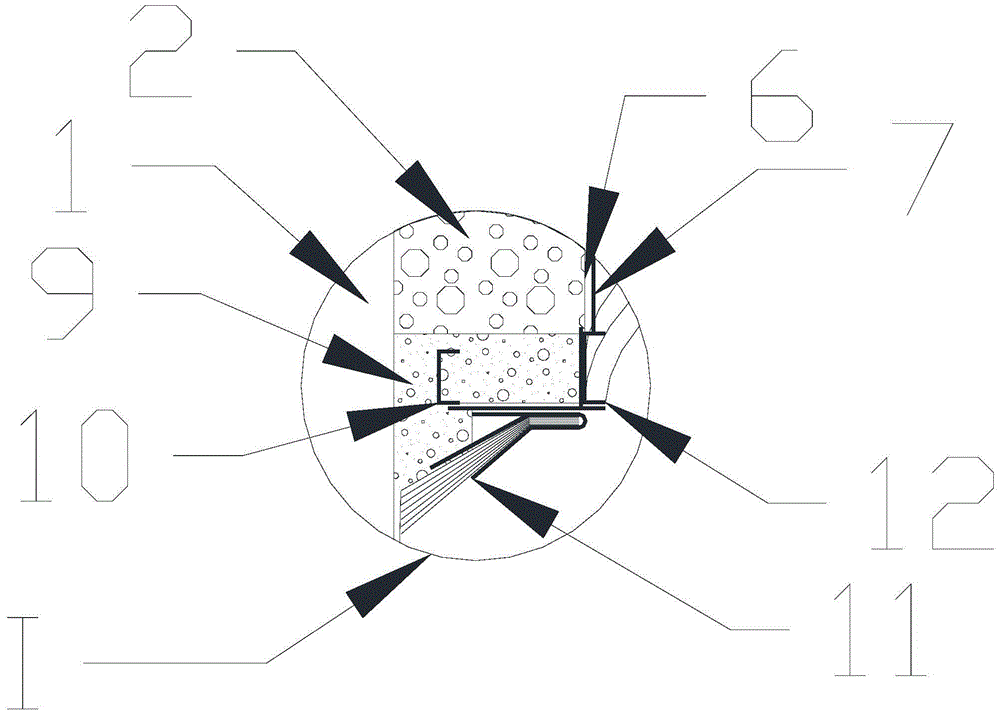

A non-uniform settlement control structure for an airfield pavement roadbed passed by a high-speed rail tunnel and a construction process

The invention discloses a construction process of a non-uniform settlement control structure for an airfield pavement roadbed passed by a high-speed rail tunnel. The construction process comprises thefollowing steps: cleaning and leveling a construction site, and pouring plain concrete; dismantling part of foundation pit maintenance walls; filling a plain soil above the plain concrete in a layered mode, pouring a foam light soil foundation on the plain soil in a segmented, partitioned and layered mode, or laying reinforced soil layers in a layered mode, laying geogrids between the reinforcedsoil layers in a layered mode, laying geocells on the reinforced soil layers in a layered mode, laying broken stones on the geocells, and setting a plurality of deformation joints in the longitudinaldirection; carrying out construction of a pavement structure layer and other ancillary facilities, and forming the roadbed non-uniform settlement control structure after the construction process is finished. The construction process has the advantages that the overall uniformity of the soil foundation is improved, and the non-uniform settlement volume of the soil foundation is adjusted; the construction process is convenient, the construction period is shortened and the problem of uneven settlement of the roadbed when the high-speed rail tunnel passes through the airfield pavement is successfully solved.

Owner:TONGJI UNIV +2

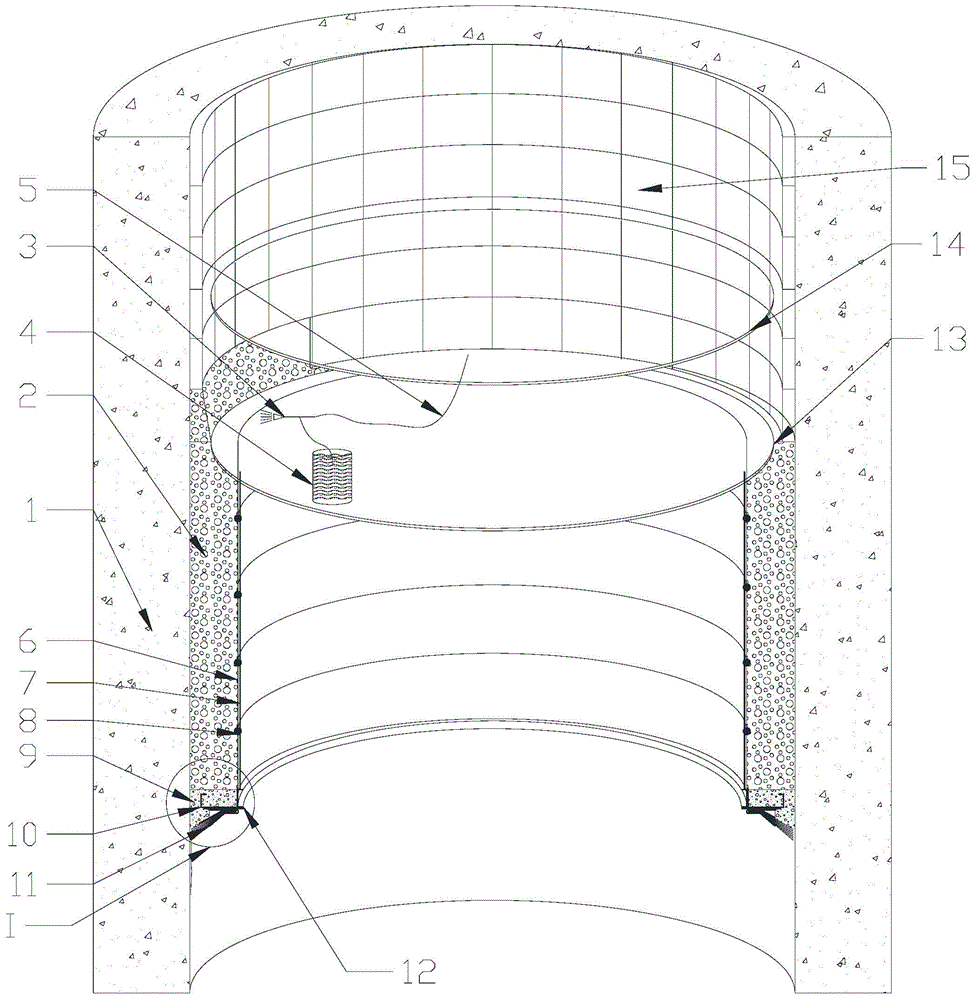

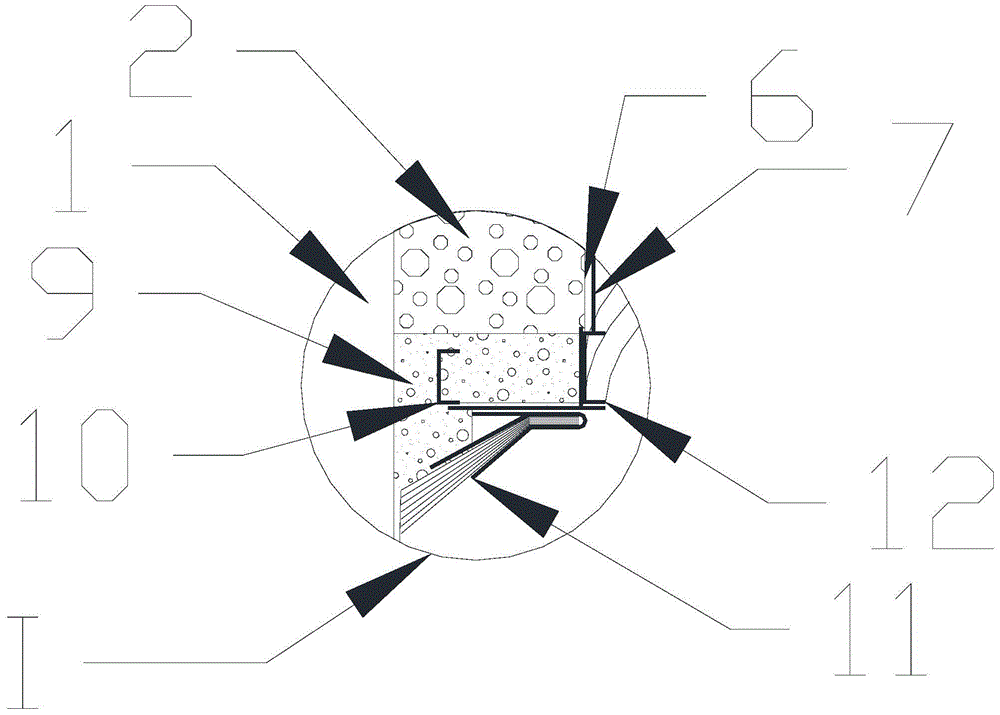

Maintenance for foam in inner-layer well wall concrete of freezing shaft

The invention discloses a maintenance device for foam in inner-layer well wall concrete of a freezing shaft. The maintenance device for the foam in the inner-layer well wall concrete of the freezing shaft comprises a liquid foam layer, a foam maintenance drum, a foam original solution storage vessel, a foam generator and a warm water pipe. The foam maintenance drum comprises a drum wall and a drum bottom. The drum bottom is located at the outer side of the drum wall and is fixedly connected with the drum wall. The liquid foam layer is formed between the concrete inner-layer well wall and the drum wall of the foam maintenance drum. The foam maintenance drum is arranged at the inner side of the concrete inner-layer well wall and is hung at the lower portion of a form stripping disk. A liquid inlet of the foam generator is communicated with a liquid outlet of the foam original solution storage vessel and fluid in a water outlet of the warm water pipe. According to the maintenance device for the foam in the inner-layer well wall concrete of the freezing shaft, a good maintenance condition is provided for the inner-layer well wall concrete of the freezing shaft, a plenty of water can be saved, and at the same time, temperature cracking caused by different temperatures of the inside and the surface of the concrete inner-layer well wall, so that the quality of the shaft is guaranteed.

Owner:内蒙古伊泰广联煤化有限责任公司 +2

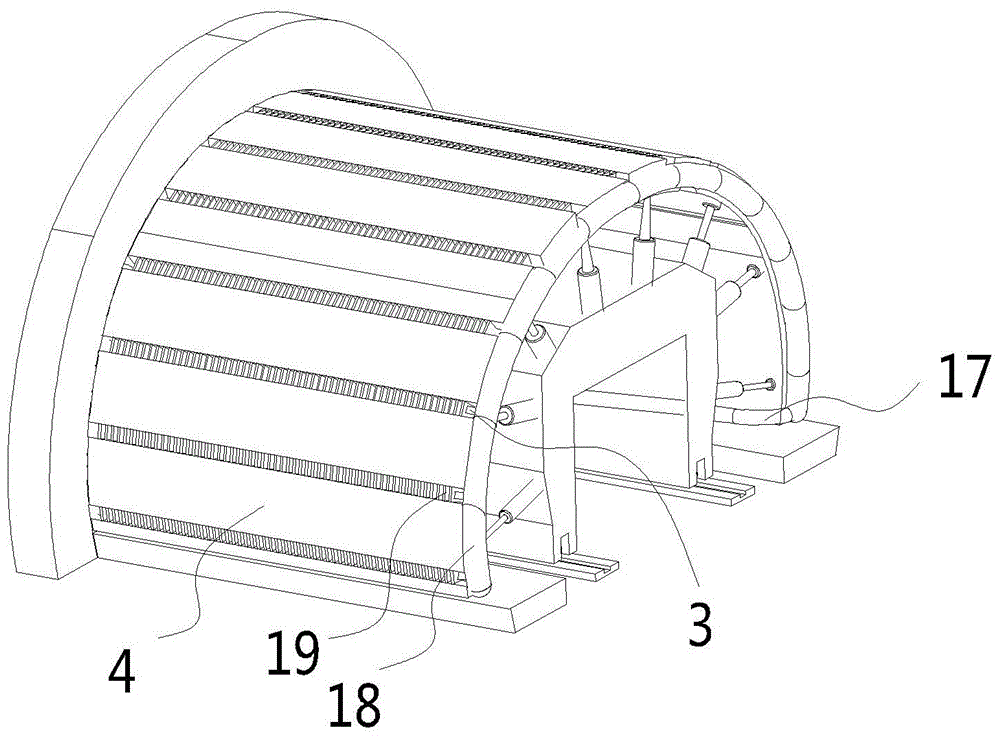

High and cold region low-temperature season concrete construction method

ActiveCN108868143AIncrease temperatureNormal sclerosisBuilding material handlingCopper wireHeat conducting

The invention discloses a high and cold region low-temperature season concrete construction method, and relates to the technical field of concrete construction. By means of a specially-made electrothermal template, heating is conducted when concrete pouring is conducted, heating copper wires are uniformly distributed in the electrothermal template, temperature sensors and heating rods are arrangedon the side face, facing concrete, of the template, the heating copper wires wind around the heating rods, a heat conducting shell is arranged outside each heating rod, the heating rods are vertically inserted into the concrete, and the concrete is heated; the temperature sensors are arranged every 1-2 m<2>, and the heating rods are arranged every 0.04-0.1 m<2>; the inner side of the electrothermal template and the surface of the heat conducting shell are coated with waterproof paint. The high and cold region low-temperature season concrete construction problem can be solved, and the concreteengineering construction efficiency is improved.

Owner:四川锦城智信建设工程有限公司

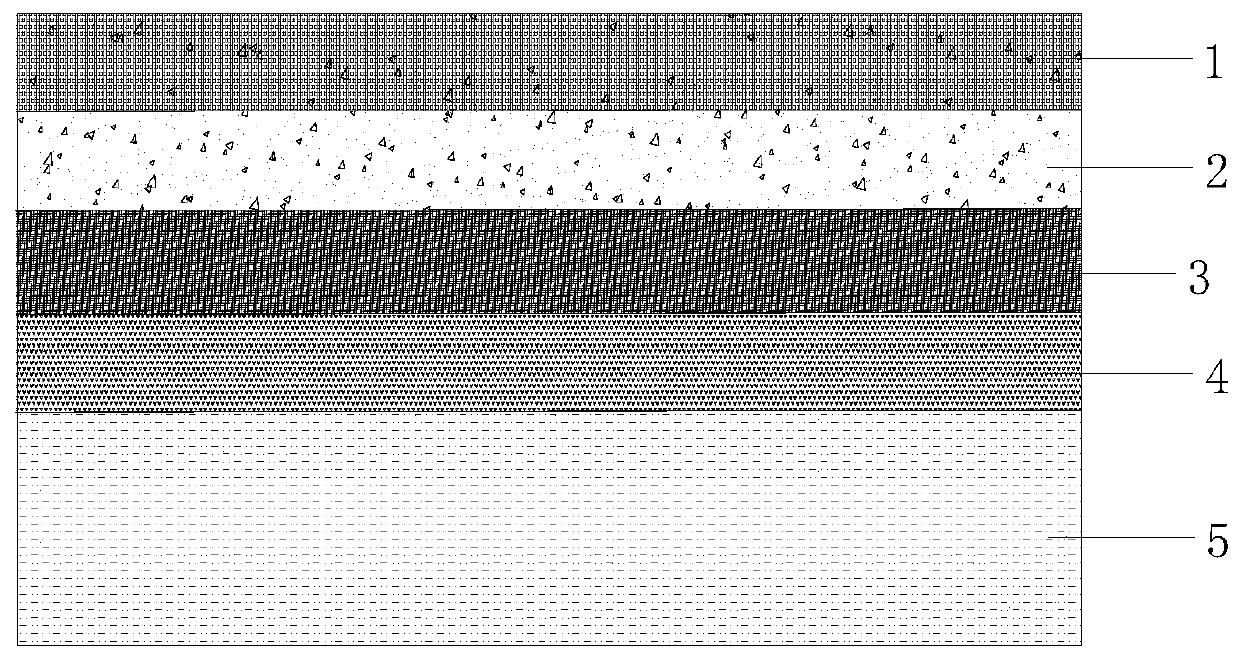

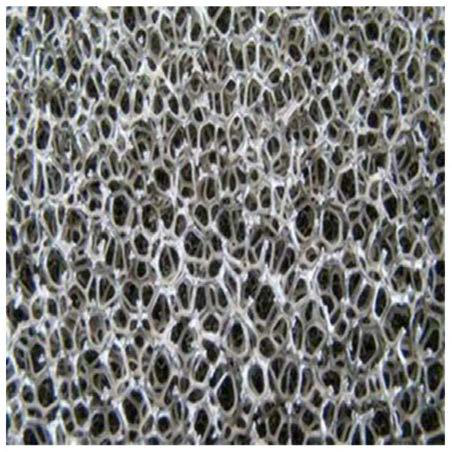

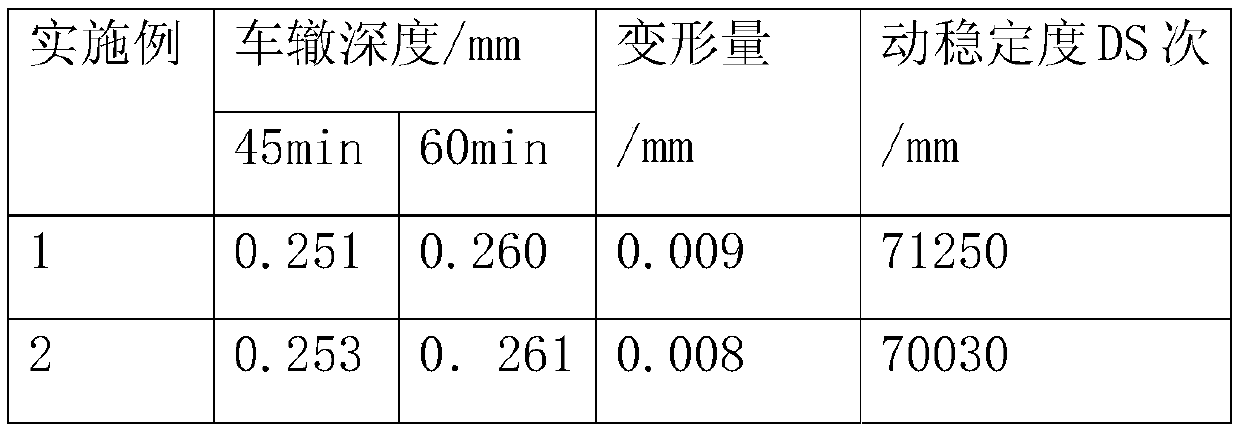

Steel slag semi-flexible composite pavement structure

ActiveCN110230240AReduce temperature stressAvoid temperature cracksIn situ pavingsPaving detailsCement boardTemperature stress

The invention discloses a steel slag semi-flexible composite pavement structure. The pavement structure sequentially comprises an asphalt concrete surface layer, a steel slag semi-flexible layer, a three-dimensional porous material layer, an old cement board layer subjected to fragmentation and a steel slag base layer from top to bottom, wherein the asphalt concrete surface layer is provided witha structure depth; glass beads loaded with nano titanium dioxide are embedded in the structure depth; three-dimensional communication structures are formed among pores of the three-dimensional porousmaterial, wherein the communication porosity is 50-99%, and the pore diameter is 0.1-20 mm; a specific composite structure layer is adopted, therefore, the shrinkage caused by cooling is relatively small, and relatively small temperature stress is generated to avoid temperature cracks; meanwhile, through interaction of different structural layers of all the layers, mutual tensile stress exists among all the layers, and fatigue cracking can be relieved by combining with use of specific functional materials; and the steel slag semi-flexible composite pavement has excellent high-temperature stability, low-temperature crack resistance, fatigue durability and water stability.

Owner:河北迁曹高速公路开发有限公司 +1

Activate micro powder prepared through wind quenching method steel slag and directly-discharged pulverized fuel ash and method

The invention discloses activate micro powder prepared through wind quenching method steel slag and directly-discharged pulverized fuel ash and a method. A raw material comprises 60 to 70% of steel slag, 20 to 30% of pulverized fuel ash, 16 to 20% of lime mixture and 0.1 to 0.3% of polycarboxylate superplasticizer powder by mass percent, the raw material is added into a weightless mixing stirrer,stirring is carried out to enable the material to be sufficiently mixed to be uniform, through a wind quenching method, the amorphous mineral phase on the surface of the steel slag is obviously increased, potential activity is increased, through a grinding aid, reinforced fibers, the polycarboxylate superplasticizer powder and monox, the activity is higher, compatibility with cement is good, the pulverized fuel ash delays the hydration speed, the temperature rise caused by heat transmission by water of the concrete can be reduced, temperature cracks generated by the concrete can be prevented,binding force of the concrete can be obviously improved, durability is improved, and for solving the problem that the grinding effect is affected due to the inconsistent steel slag sizes, and a screening auxiliary device for smashing of the steel slag is specially made

Owner:国宏联绿(北京)科技发展有限公司

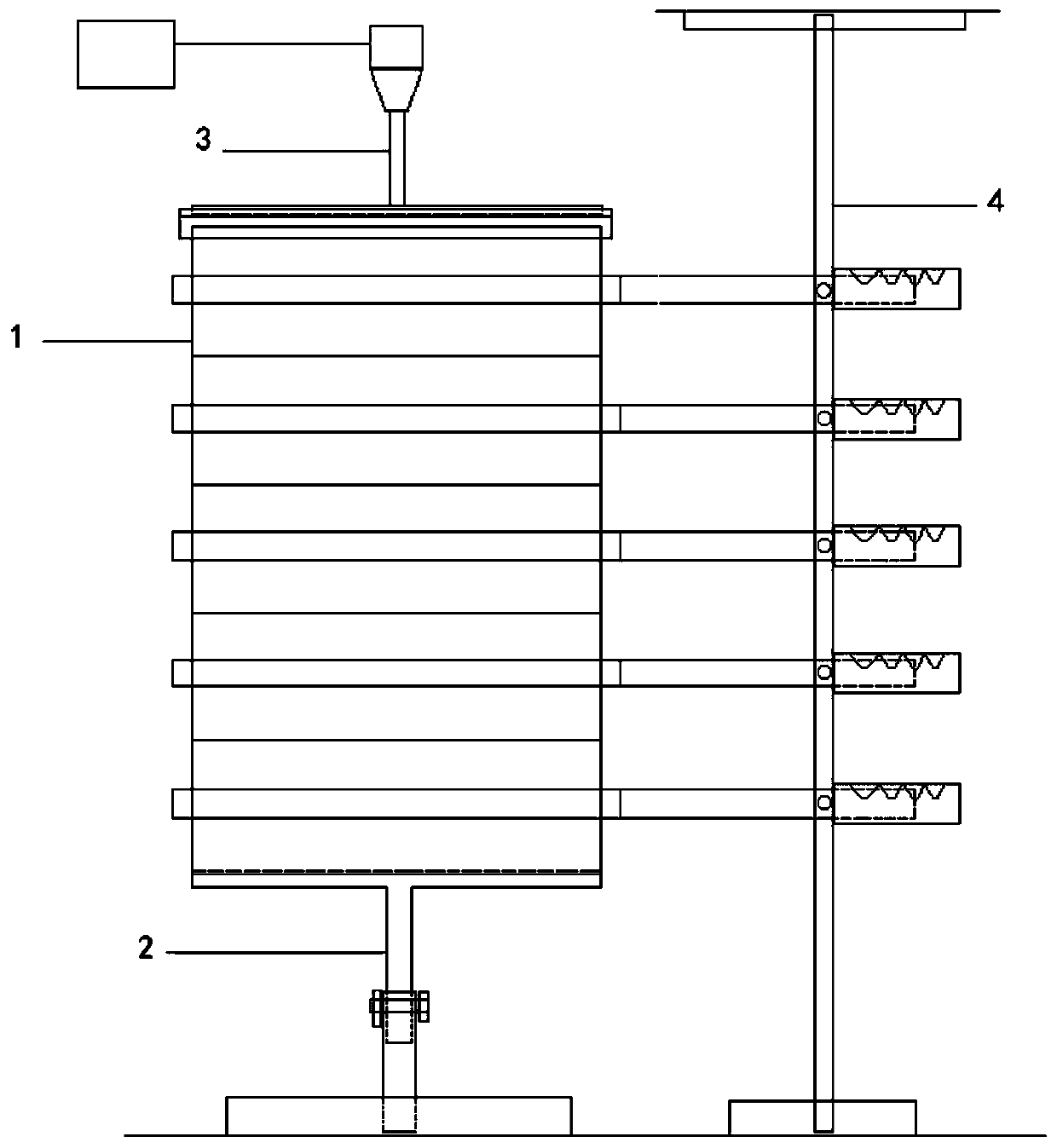

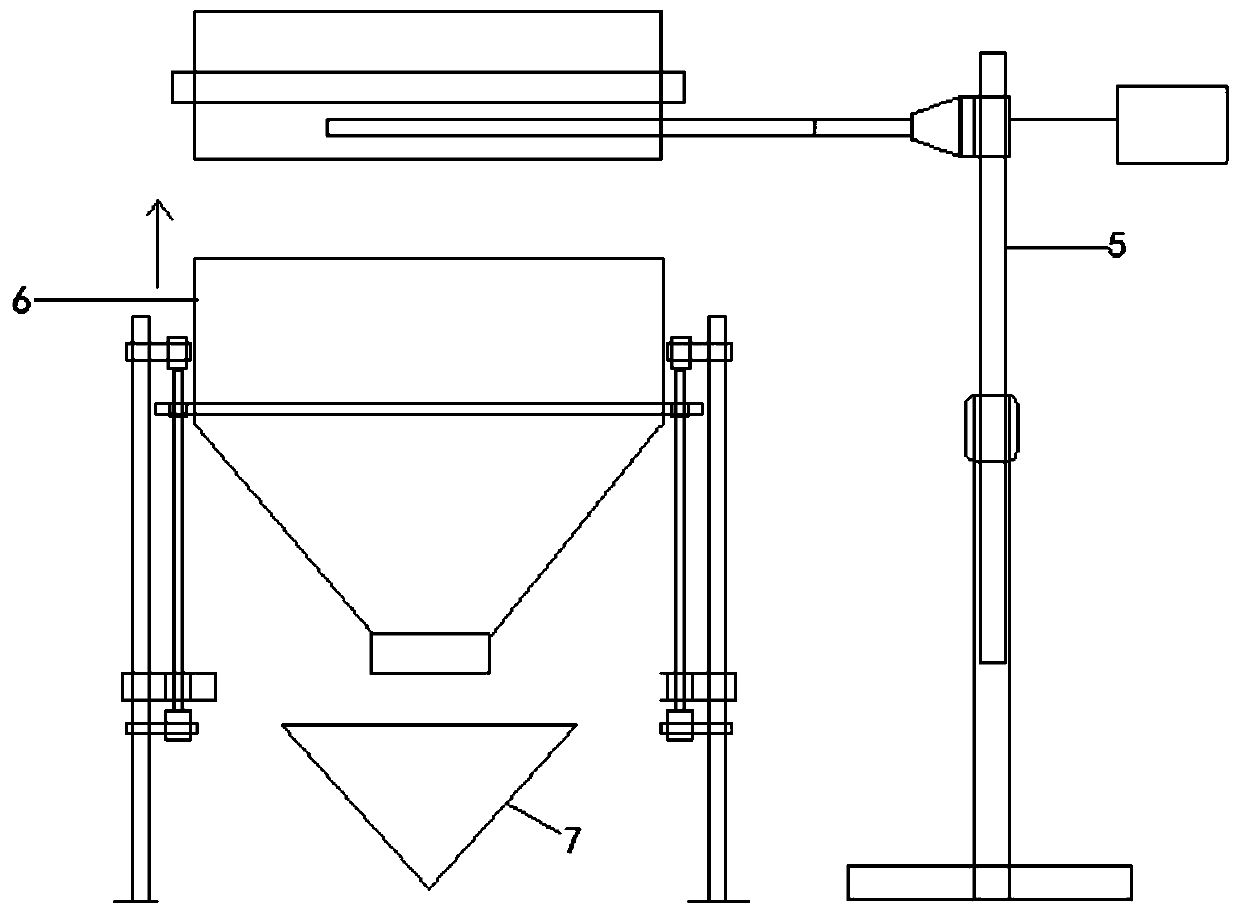

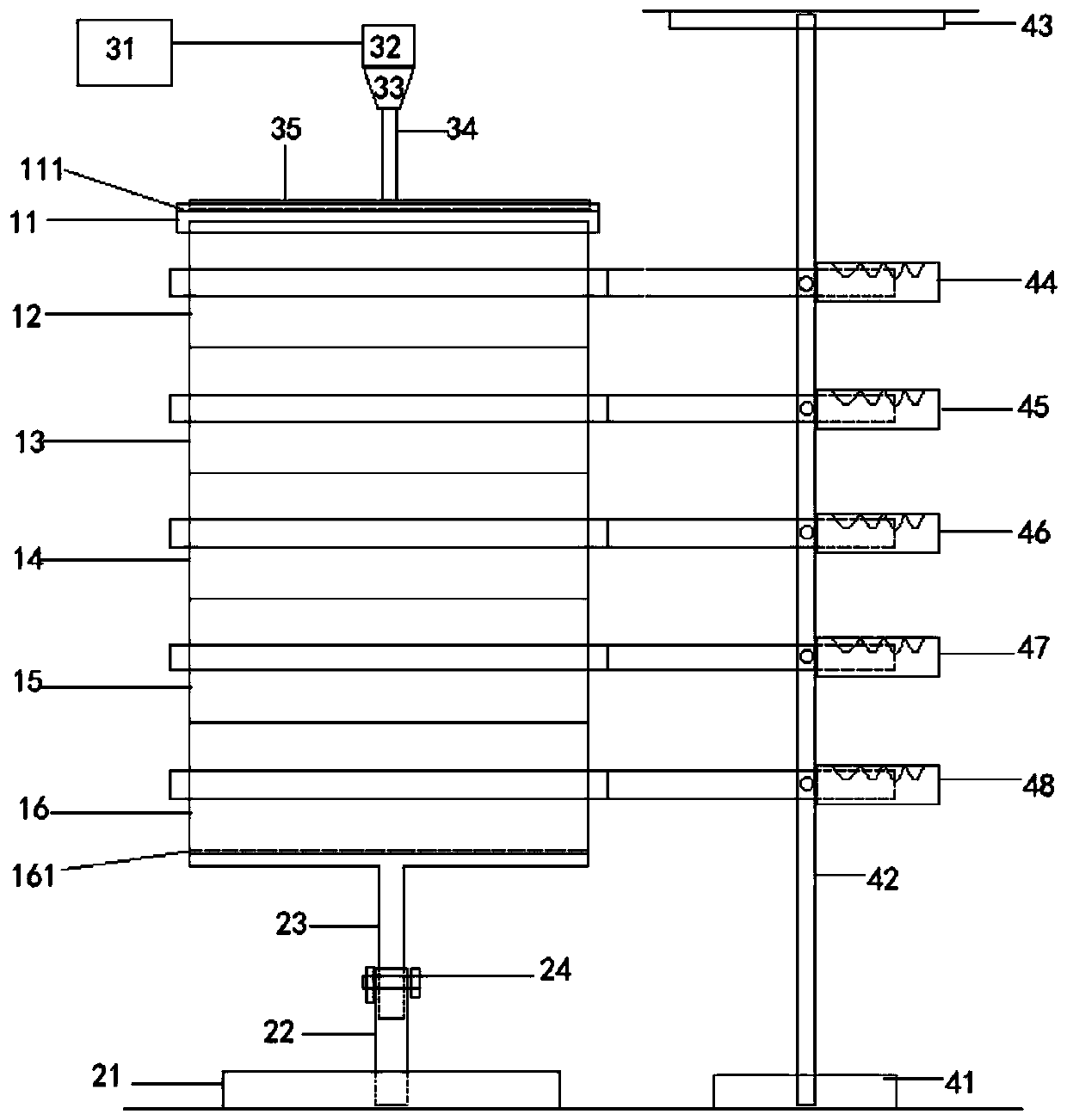

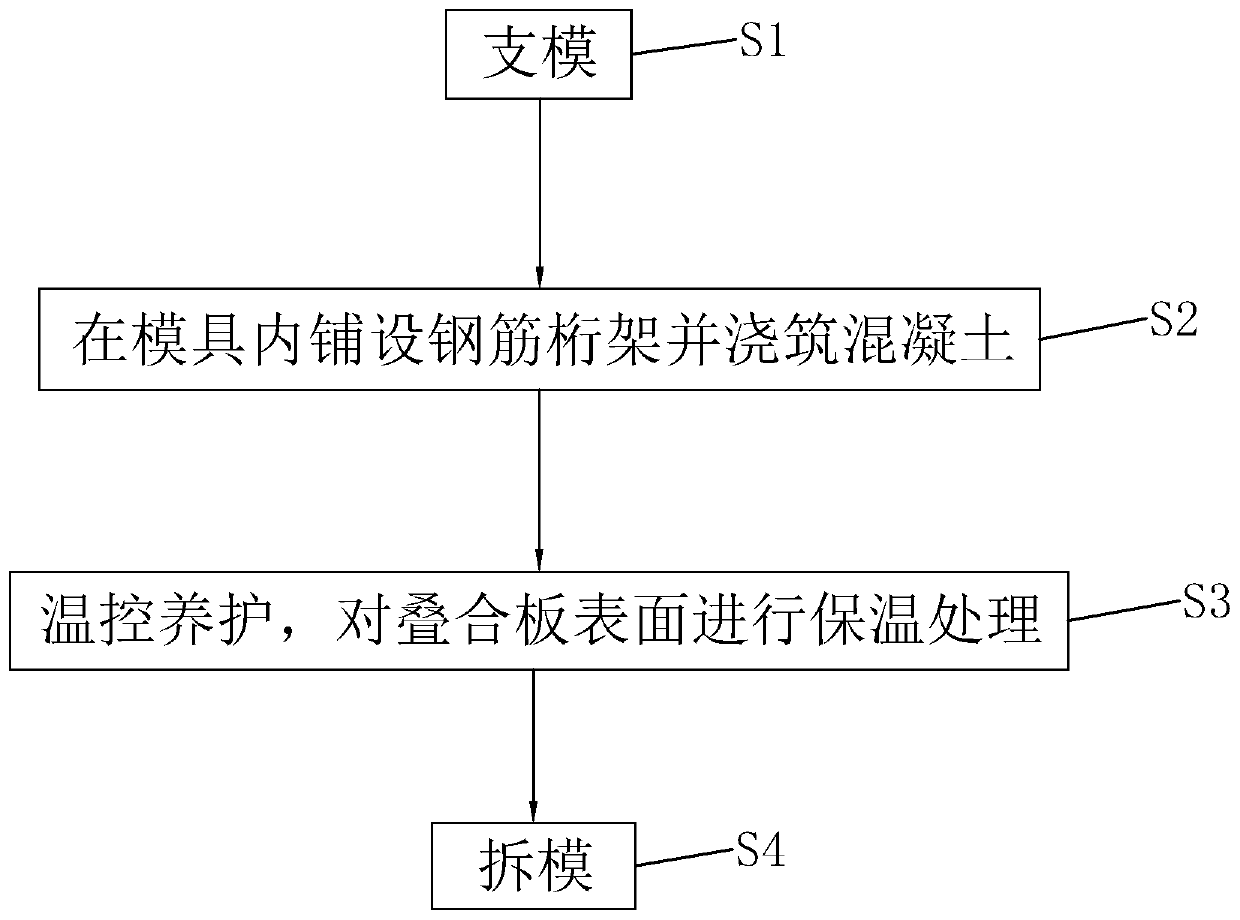

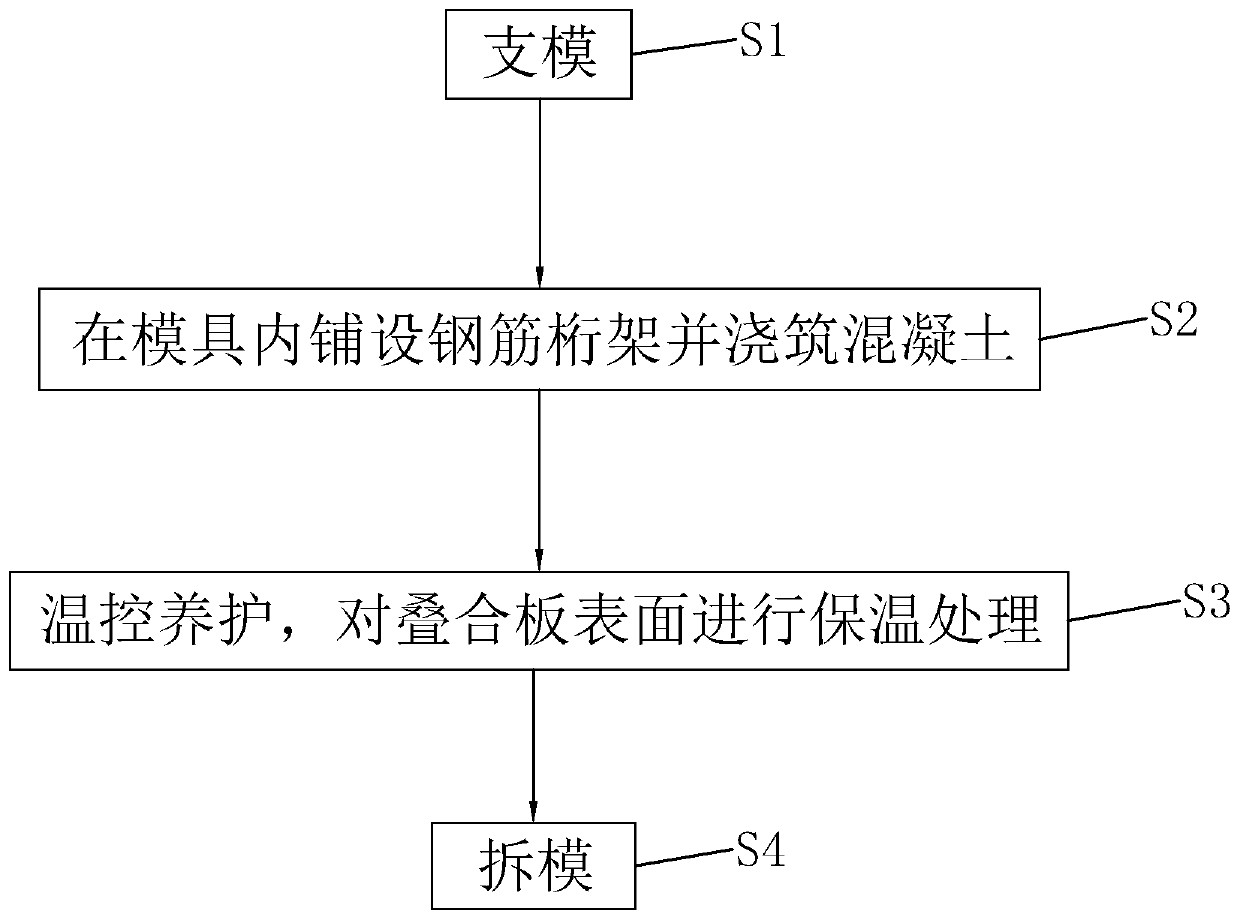

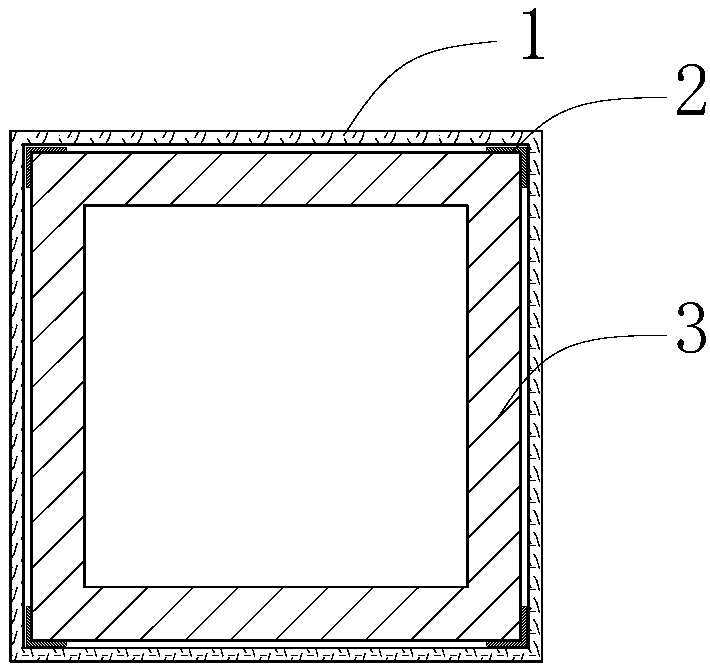

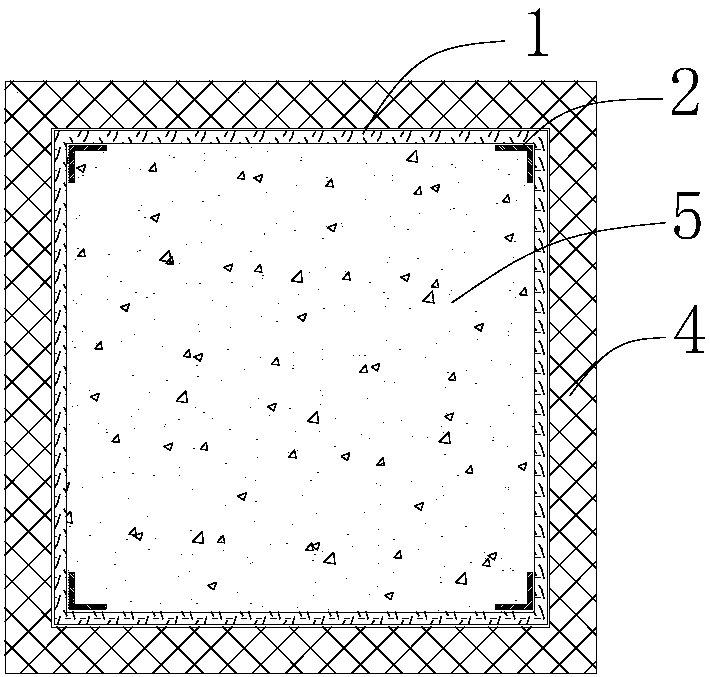

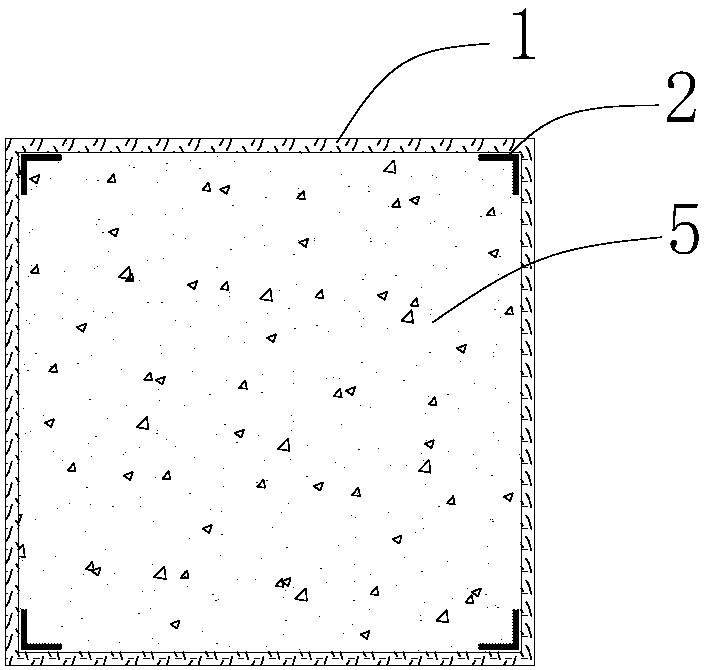

Production process of laminated boards under low-temperature condition

InactiveCN109702888AGuaranteed structural strengthImprove molding qualityCeramic shaping apparatusTemperature controlReinforced concrete

The invention discloses a production process of laminated boards under a low-temperature condition, and relates to the technical field of prefabricated laminated boards. The production process includes the steps of erecting molds, laying reinforced concrete trusses and pouring concrete in the molds, maintaining through temperature control, demoulding and the like. The cementitious materials of theconcrete are slag cement; the concrete is mixed with 15%-20% high-quality fly ash; and layered pouring is carried out in pouring concrete, and the longest interval between layers is less than the initial setting time of the concrete. According to the production process of the laminated boards under the low-temperature condition, the production efficiency of the laminated boards is improved, the structural strength of the laminated boards is ensured, the temperature cracks are effectively avoided, and the production cost is greatly reduced.

Owner:上海住信住宅工业有限公司

Concrete pumping retarder

The invention discloses a concrete pumping retarder, and relates to the technical field of concrete admixtures. The concrete pumping retarder is prepared from, by weight, 40 parts to 50 parts of soybean molasses, 30 parts to 40 parts of isomaltitol, 20 parts to 25 parts of sulfonated melamine, 15 parts to 20 parts of tephra, 15 parts to 20 parts of modified starch, 13 parts to 17 parts of polyacrylamide, 12 parts to 15 parts of fatty alcohol-polyoxyethylene ether, 12 parts to 15 parts of microcrystalline cellulose, 10 parts to 13 parts of fructus gleditsiae powder, 10 parts to 13 parts of tea seed powder, 8 parts to 11 parts of naphthalene water reducers, 6 parts to 10 parts of nanometer rubber powder, 6 parts to 10 parts of polycarbamate, 5 parts to 8 parts of palmitic acid, 15 parts to 20 parts of coconut oil and 300 parts to 400 parts of water. The prepared retarder is free of chloride and alkali, the setting time of concrete can be effectively prolonged, heat of hydration can be reduced, generation and development of temperature cracks of the concrete can be greatly reduced and even avoided, the workability of the concrete can be further obviously improved, the bleeding rate can be greatly reduced, and endurance performance such as freezing resistance and corrosion resistance can be improved.

Owner:滁州京安工贸有限责任公司

Fabric concrete block and preparation method

ActiveCN108590017AReduce water-cement ratioWith thermal insulation functionConstruction materialCeramic shaping apparatusEngineeringCompressive strength

The invention relates to a fabric concrete block and a preparation method. The block has high crush resistance strength, no holes and pitted surfaces, good appearance quality and strong wall adhesionability, and can restrain wall cracks and prolong wall life to enable the block is matched with the service life of a main structure. The block comprises four L-shaped angle shafts arranged to form arectangular barrel corner angle, a fabric shell which is fixed outside the L-shaped angle shafts in tension winding mode and form a rectangular barrel structure and filler, wherein the fabric shell isfilled with the filler.. The preparation method comprises the steps that 1, the preparation of the fabric shell is carried out; 2, the fabric shell is filled with the filler, pressing and concrete vibrating are carried out to enable the filler to be compact, so that the fabric adheres to the inner wall of a steel mould; and 3, maintenance is carried out for molding, maintenance is carried out until the initial solidification of the filler is completed, the steel mould is removed, maintenance is carried out until the filler is fully solidified, and the block production is completed.

Owner:CHANGAN UNIV

Method for taking cooling pipe network as building bottom plate multi-layer reinforced support frame

ActiveCN102704483BEasy to removeReduce heat of hydrationArtificial islandsUnderwater structuresRebarCooling pipe

Owner:CHENGDU SIXTH CONSTR ENG

Temperature-control anti-cracking curing method for mass concrete

PendingCN113463934AReduce the temperature difference between the inner surface and the outer surfaceAvoid temperature cracksThermometer detailsFoundation engineeringWater pipeMechanical engineering

The invention discloses a temperature-control anti-cracking curing method for mass concrete. According to the temperature-control anti-cracking curing method, according to the construction steps and requirements of mixing, temperature measuring and curing of the concrete, by adopting a concrete formula with a small cement dosage and applying a high-tech temperature measuring means, the temperature change which cannot be seen or touched inside the concrete is visualized, and a high-molecular moisturizing material and a heat-preservation rainproof material are combined for use, so that moisturizing and heat-preservation curing is carried out under the guidance of visualized temperature information, and the purposes of not using a cooling water pipe, reducing the temperature difference between the inner surface and the outer surface and avoiding temperature cracks after the concrete is hardened are achieved. According to the temperature-control anti-cracking curing method, the cooling water pipe does not need to be embedded, the technology is simple, the operation is controllable, the cost is saved, the performance is reliable, and no temperature crack occurs in the construction of a plurality of mass concrete.

Owner:江西省交通工程集团建设有限公司

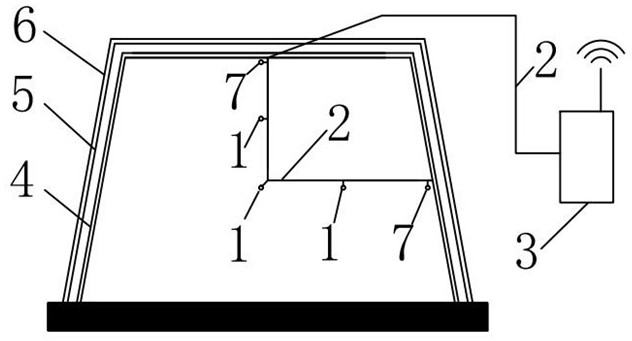

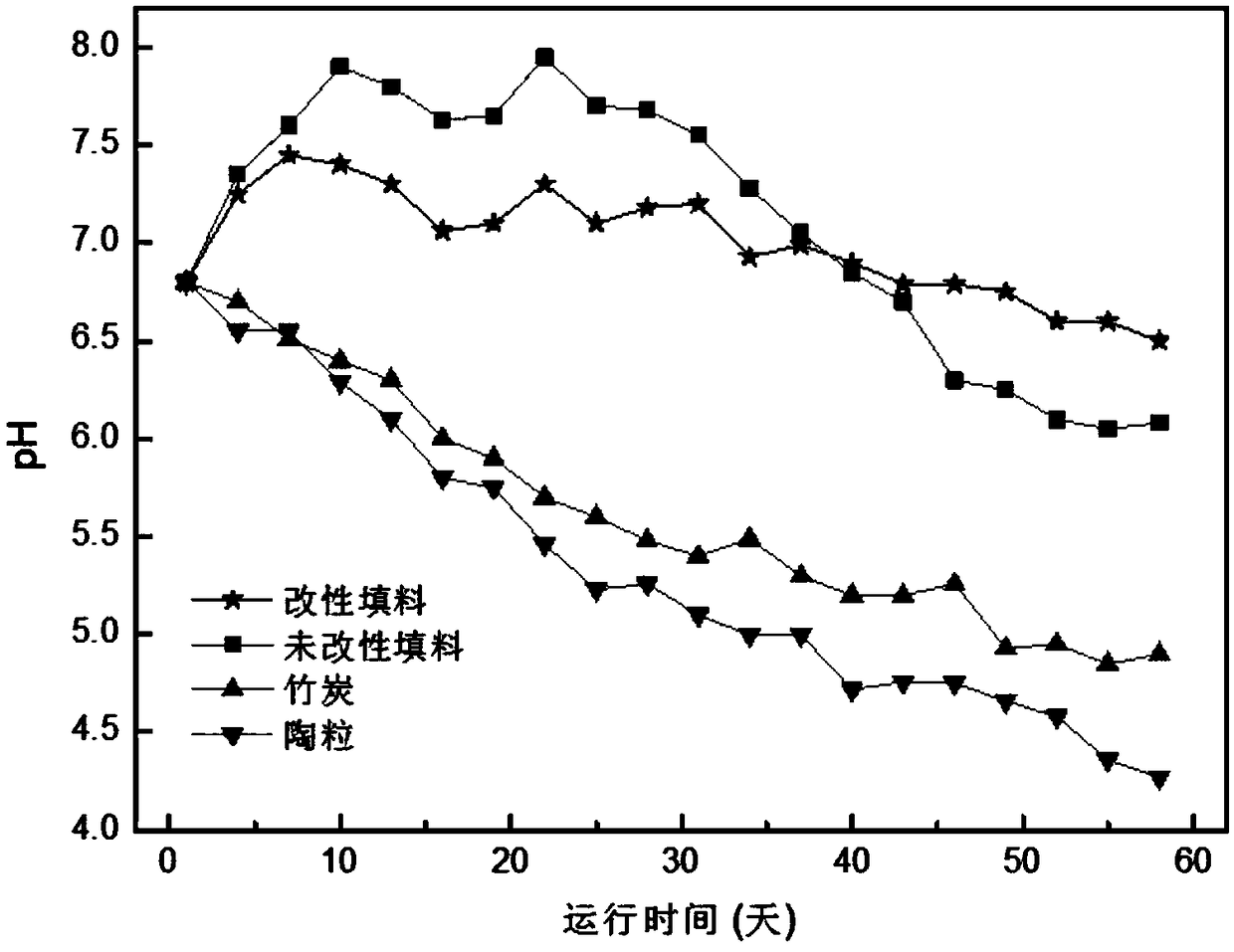

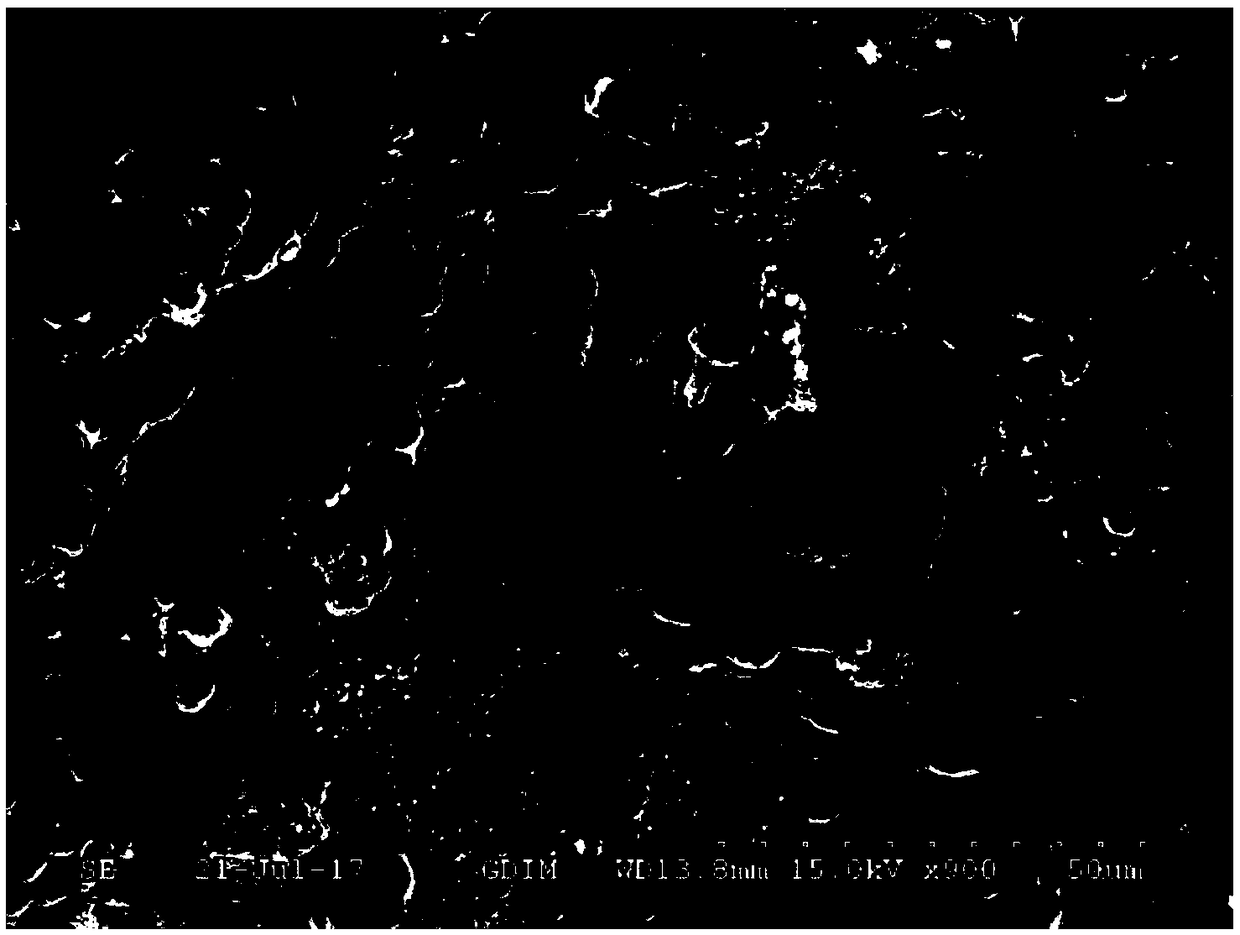

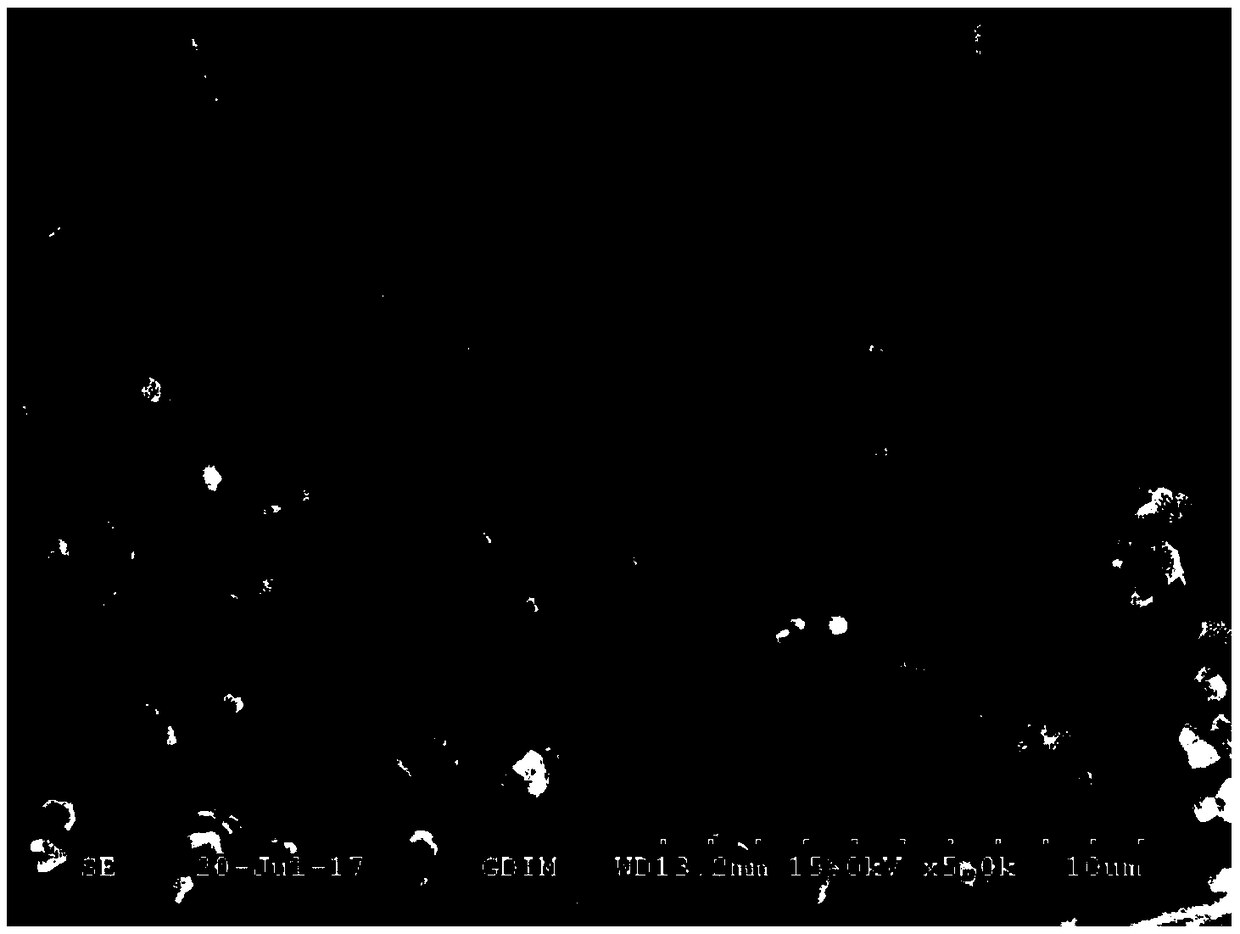

Bio-filler for absorbing and degrading hydrophobic organic waste gases, and preparation method of bio-filler

ActiveCN109046004APromote absorptionImprove adsorption capacityGas treatmentDispersed particle separationExpanded clay aggregateHYDROSOL

The invention discloses bio-filler for absorbing and degrading hydrophobic organic waste gases, and a preparation method of the bio-filler. The bio-filler is prepared from the following raw materials:modified iron-based beta-cyclodextrin, diatomaceous earth, biochar, ceramsite, calcium oxide, silicate inorganic gel and water. The preparation method of the bio-filler comprises the following steps:dissolving the modified iron-based beta-cyclodextrin and the calcium oxide to obtain sol A; evenly mixing the diatomaceous earth, the biochar and the silicate inorganic gel to obtain powder B; dipping the ceramsite into the sol A for 5min, then placing the product in a drum granulator for granulating together with the powder B, spraying the sol A in the granulation process so as to obtain preliminarily-cured gel granules, and curing to obtain the bio-filler for absorbing and degrading the hydrophobic organic waste gases. The bio-filler prepared by the method can be widely applied to various types of organic waste gas biological purification systems, and enables the hydrophobic organic waste gases to more easily penetrate a wet water film on the surface of the filler and be in contact withmicroorganisms so as to enable the hydrophobic organic waste gases to be subjected to efficient catalytic degradation.

Owner:广东省南方环保生物科技有限公司

Heat preservation composite formwork and concrete construction method applied to strong wind forest area

InactiveCN111255227AGuaranteed stabilityIncrease stiffnessForms/shuttering/falseworksBridge erection/assemblyArchitectural engineeringStructural engineering

The invention provides a heat preservation composite formwork and a concrete construction method applied to a strong wind forest area, and belongs to the technical field of civil construction. The heat preservation composite formwork comprises a formwork body, heating units and a plurality of supporting units; concrete is poured into the formwork body, a plurality of supporting units are arrangedon the periphery of the formwork body and used for supporting the formwork body, and a heat preservation layer is arranged between every two adjacent supporting units; a plurality of fixing plates arearranged between the formwork body and the supporting units; the heating units are arranged on the fixing plates and used for heating concrete poured in the formwork body. The invention further provides the concrete construction method applied to the strong wind forest area, and the construction method adopts the heat preservation composite formwork. According to the heat preservation composite formwork and the concrete construction method applied to the strong wind forest area, the formwork body is not prone to deformation in the concrete pouring process, and the internal and external temperature difference of the concrete in the pouring process is reduced.

Owner:中铁十八局集团第二工程有限公司 +1

Large-volume concrete double condensation circuit temperature control equipment and temperature control method

ActiveCN108049644BAvoid temperature cracksHeat of hydration controlBuilding material handlingTemperature controlLiquid storage tank

The invention provides mass concrete double-condensation-loop temperature control equipment and a temperature control method based on the mass concrete double-condensation-loop temperature control equipment. The mass concrete double-condensation-loop temperature control equipment comprises a surface layer device, an internal layer device and a controller. The surface layer device comprises a firstliquid storage tank, first condensed fluid, a first condensation pipe buried into the surface layer of concrete and a first temperature sensor, a second temperature sensor and a first heater are arranged in the first condensed fluid, the first condensation pipe communicates with the first liquid storage tank, the first condensed fluid circulates in the first condensation pipe in a circulating mode, the internal layer device comprises a second liquid storage tank, second condensed fluid, a second condensation pipe buried into the internal layer of the concrete and a third temperature sensor, afourth temperature sensor and a second heater are arranged in the second condensed fluid, the second condensation pipe communicates with the second liquid storage tank, and the second condensed fluidcirculates in the second condensation pipe in a circulating mode; and the controller is connected to the first temperature sensor, the second temperature sensor, the third temperature sensor, the fourth temperature sensor, the first heater and the second heater. According to the mass concrete double-condensation-loop temperature control equipment, the problem that a temperature joint is prone tobeing generated by the mass concrete is solved.

Owner:SICHUAN TAILONG CONSTR GRP CO LTD

Cast-in-place construction method of cast-in-place concrete bridge

PendingCN114457682APrevent buildupAvoid timeBridge erection/assemblyBuilding material handlingArchitectural engineeringRebar

The invention provides a cast-in-place construction method of a cast-in-place concrete bridge, and relates to the technical field of building construction. The cast-in-place construction method of the cast-in-place concrete bridge comprises the following steps that a full framing is erected, bottom formworks are sequentially installed on the full framing according to a bridge design drawing, the full framing is pre-pressed and adjusted, then webs and inner formworks are installed on the bottom formworks, and a steel reinforcement framework is installed; concrete pouring operation is sequentially carried out from low to high, in the pouring process, concrete pouring is carried out for the first time, a layered dislocation method is adopted, after 5-10 m of bottom formworks are poured, pouring of webs is completed in a layered mode, and after pouring of the last section of bottom formworks and webs is completed, circulating construction is carried out till concrete pouring of all structures is completed. According to the construction method, the pouring construction period of the box girder can be obviously shortened while the construction quality of the box girder is guaranteed, and the construction efficiency is improved.

Owner:黑龙江省龙建路桥第五工程有限公司 +1

Mass concrete and preparation method thereof

InactiveCN112062521AReduce temperature and pressureAvoid temperature cracksUltimate tensile strengthMechanical engineering

The invention provides mass concrete and a preparation method thereof, and the mass concrete is characterized by comprising the following components in parts by weight: 170 KG / M < 3 > of water, 308 KG / m < 3 > of cement, 70 KG / M < 3 > of mineral powder, 56 KG / M < 3 > of fly ash, 10.3 KG / M < 3 > of an admixture, 694 KG / M < 3 > of sand and 1076 KG / M < 3 > of stone. The performance of the mass concrete produced according to the invention can meet the requirements of strength grade, impermeability, volume stability and the like, and the hydration temperature rise of a cementing material is also controlled, so that the purposes of reducing temperature and pressure and preventing temperature cracks are achieved.

Owner:天津市堃淏混凝土有限公司

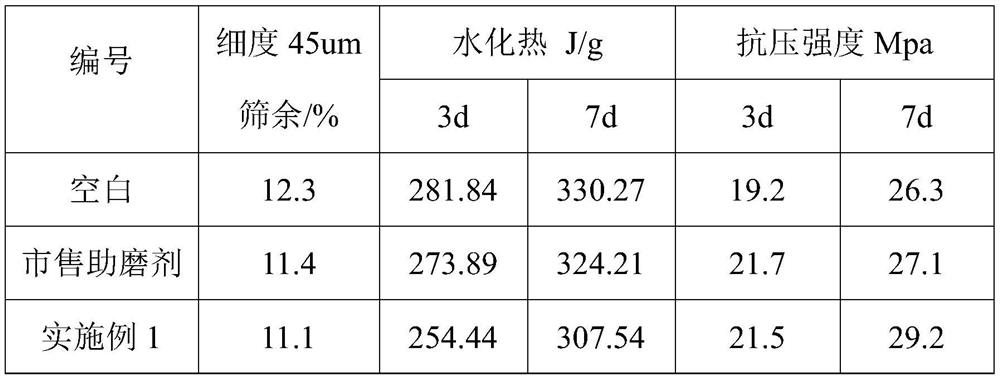

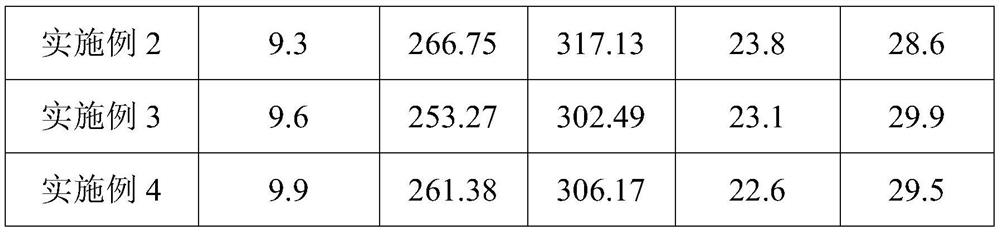

Special grinding aid for maritime work cement and preparation method thereof

The invention discloses a special grinding aid for maritime work cement and a preparation method of the special grinding aid. The special grinding aid for maritime work cement is prepared from the following raw materials: 5-9% of grinding aid mother liquor, 13-18% of an industrial salt, 3-9% of a superplasticizer, 7-15% of slag powder, 3-5% of limestone powder, 3-8% of silica fume and 36-66% of fly ash; specifically, the percentages are mass percentages. By using the superplasticizer with high dispersion performance, cement particles can be highly dispersed, and in addition, through dispersionpermeation, charges carried by the cement particles are neutralized, so that the agglomeration phenomenon is reduced. Slag powder, limestone powder and fly ash are used, so that hydration heat of marine cement can be remarkably reduced, adiabatic temperature rise in concrete is reduced, temperature stress caused by internal and external temperature difference is reduced, generation of concrete temperature cracks is prevented, the overall integrity of a concrete structure is guaranteed, therefore, the corrosion resistance and the durability of the concrete structure are effectively improved.

Owner:NANJING YONGNENG MATERIALS

A mass concrete cooling water circulation and construction method

ActiveCN111980408BGuaranteed internal and external temperature differenceAvoid temperature cracksMeasurement devicesFoundation engineeringWater storageCooling tower

The invention discloses a large-volume concrete cooling water circulation and construction method, which belongs to the field of large-volume concrete construction in construction engineering, and includes a water circulation module and a water storage module. A water partition wall is arranged on the upper surface, and the water partition wall is suitable for water storage and curing of concrete; the water storage module includes a branch pipe and a control piece, and the inlet of the branch pipe is located between the water storage tank and the cooling tower, and the branch pipe is suitable for diverting water into the water partition wall , the control piece is located at the port of the branch pipe close to the water storage tank, and the control piece is suitable for controlling the flow direction of the water in the branch pipe; the conveying pipe is located on the surface of the pouring pit as a raised part, and the raised part is suitable for the water barrier Water is conveyed into the conveying pipe in the concrete along the direction of water flow; the present invention solves the problem of water storage and maintenance of the concrete surface in the existing drainage pond and water circulation in the concrete, resulting in a large temperature difference that rapidly shrinks, resulting in sudden temperature changes and cracks.

Owner:CHINA MCC17 GRP

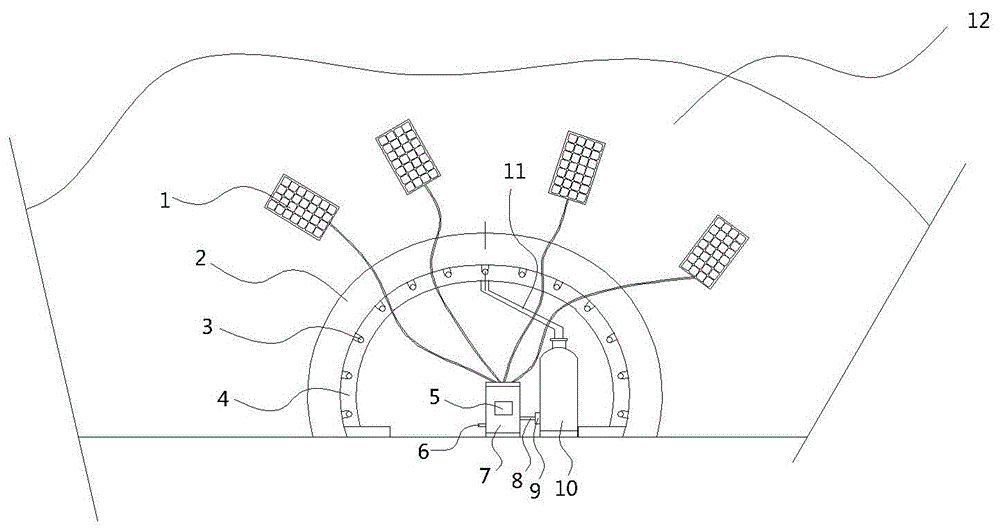

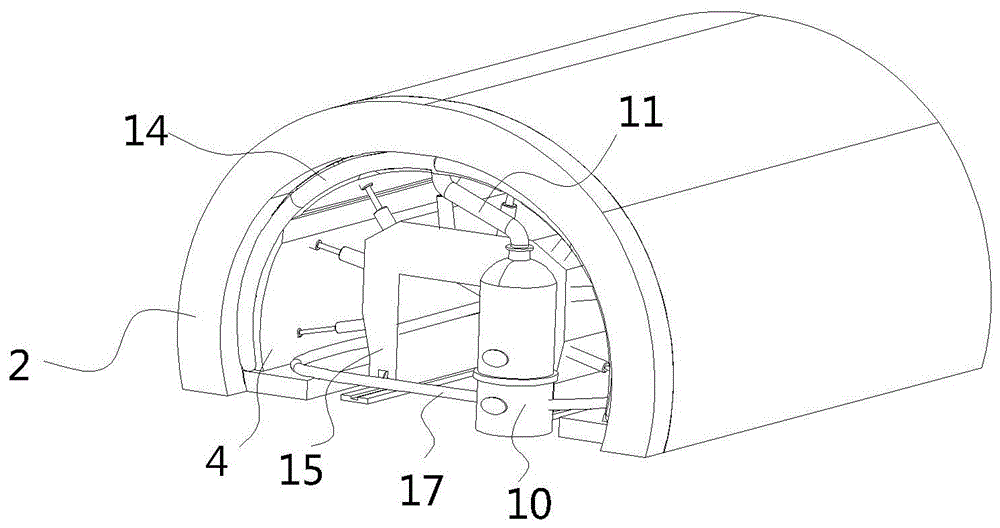

A tunnel lining concrete insulation system and its construction method

InactiveCN104533462BAvoid temperature cracksImprove insulation effectUnderground chambersTunnel liningThermal insulationWater flow

A tunnel lining concrete thermal insulation system comprises a lining trolley and a heating boiler. The tunnel lining concrete thermal insulation system is characterized in that a formwork of the lining trolley is provided with a thermal insulation layer, floor heating pipes are evenly mounted on the thermal insulation layer, cooling fins are mounted on the floor heating pipes, a hot water flow dividing pipe which is communicated with the floor heating pipes is mounted at one end of the lining trolley, and a cold water backflow pipe which is communicated with the floor heating pipes is mounted at the other end of the lining trolley; the hot water flow dividing pipe is communicated with the heating boiler through a water outlet pipe, and the cold water backflow pipe is communicated with the heating boiler through a backflow pipe. The tunnel lining concrete thermal insulation system has the advantages that the cooling fins can be cooled through a heating circulation system, a heat layer is generated around the formwork, hence, the inner and outer temperature difference is reduced in the concrete pouring process, and temperature cracks are avoided. The tunnel lining concrete thermal insulation system has the advantages of being good in thermal insulation effect and capable of controlling construction quality easily, thereby having a wide market prospect.

Owner:广东明隆辉实业有限公司

Frozen Shaft Inner Layer Concrete Foam Curing Device

The invention discloses a maintenance device for foam in inner-layer well wall concrete of a freezing shaft. The maintenance device for the foam in the inner-layer well wall concrete of the freezing shaft comprises a liquid foam layer, a foam maintenance drum, a foam original solution storage vessel, a foam generator and a warm water pipe. The foam maintenance drum comprises a drum wall and a drum bottom. The drum bottom is located at the outer side of the drum wall and is fixedly connected with the drum wall. The liquid foam layer is formed between the concrete inner-layer well wall and the drum wall of the foam maintenance drum. The foam maintenance drum is arranged at the inner side of the concrete inner-layer well wall and is hung at the lower portion of a form stripping disk. A liquid inlet of the foam generator is communicated with a liquid outlet of the foam original solution storage vessel and fluid in a water outlet of the warm water pipe. According to the maintenance device for the foam in the inner-layer well wall concrete of the freezing shaft, a good maintenance condition is provided for the inner-layer well wall concrete of the freezing shaft, a plenty of water can be saved, and at the same time, temperature cracking caused by different temperatures of the inside and the surface of the concrete inner-layer well wall, so that the quality of the shaft is guaranteed.

Owner:内蒙古伊泰广联煤化有限责任公司 +2

Control structure and construction technology of uneven settlement of roadbed subgrade under high-speed railway tunnel passing through airport

The invention discloses a construction process of a non-uniform settlement control structure for a high-speed railway tunnel passing through an airport road surface. To build plain soil, on-site pouring foam lightweight soil foundation in sections, partitions, and layers on the plain soil, or fill reinforced soil layers layer by layer, lay geogrids between the reinforced soil layers, and lay geogrids between the reinforced soil layers. Pave the geocell on the upper layer, pave gravel on the geocell, and set multiple deformation joints along the longitudinal direction; carry out the construction of the pavement structure layer and other auxiliary facilities, and adopt the above-mentioned construction technology to form uneven settlement of the subgrade control structure. The invention has the advantages of improving the overall uniformity of the soil foundation, adjusting the uneven settlement of the soil foundation, convenient construction, saving construction period, and successfully solving the problem of uneven settlement of the roadbed when the high-speed railway tunnel crosses the airport pavement.

Owner:TONGJI UNIV +2

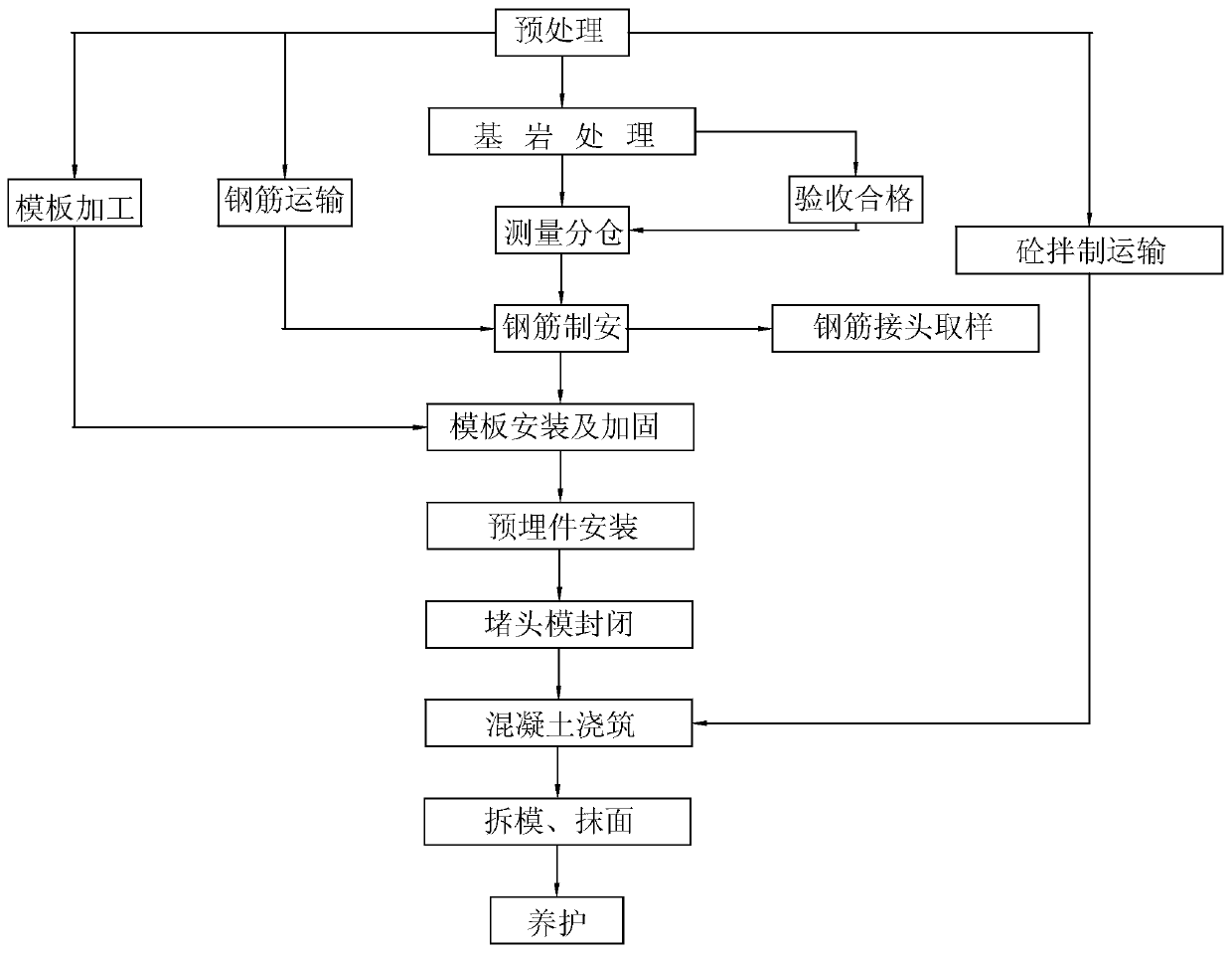

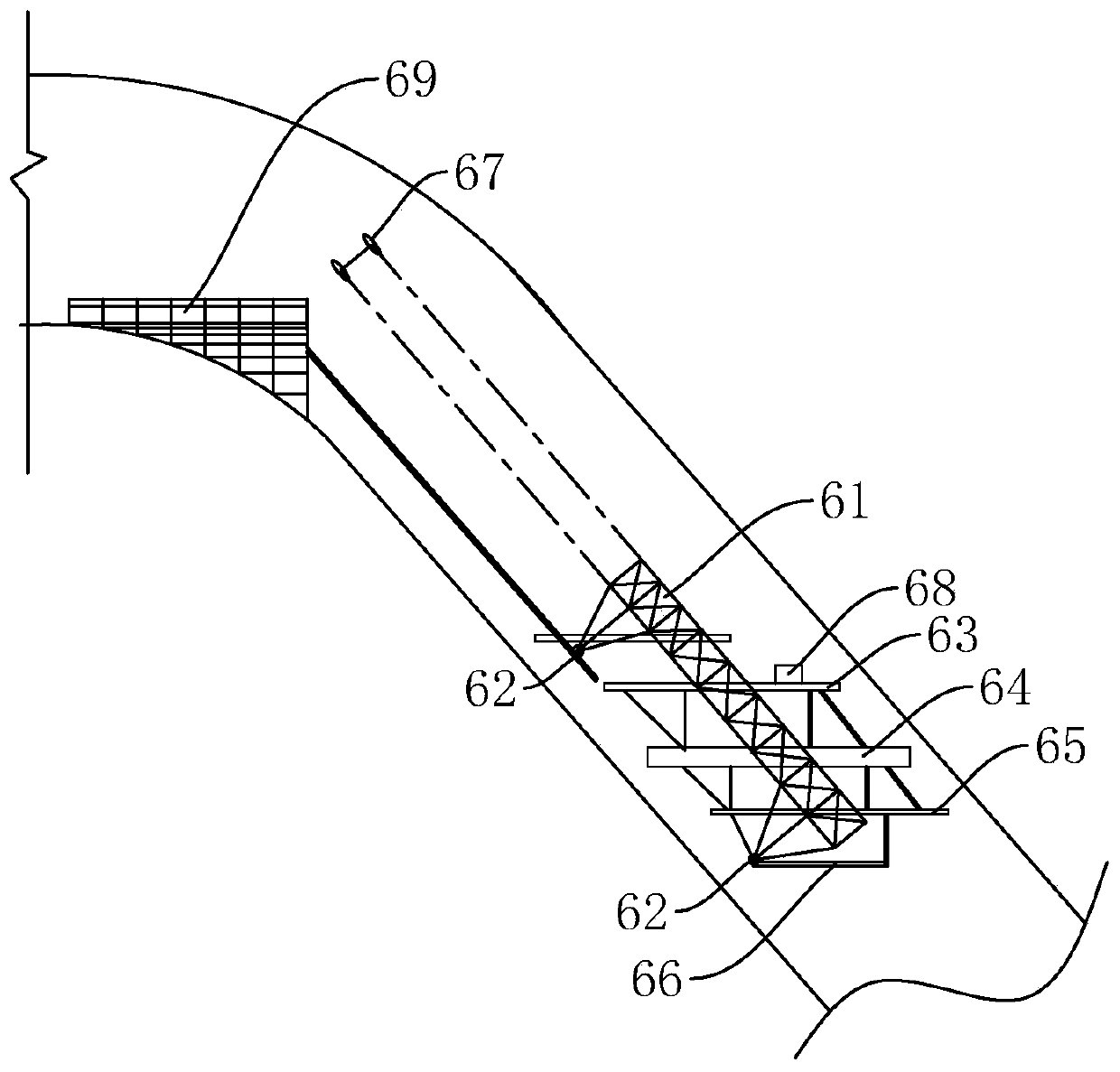

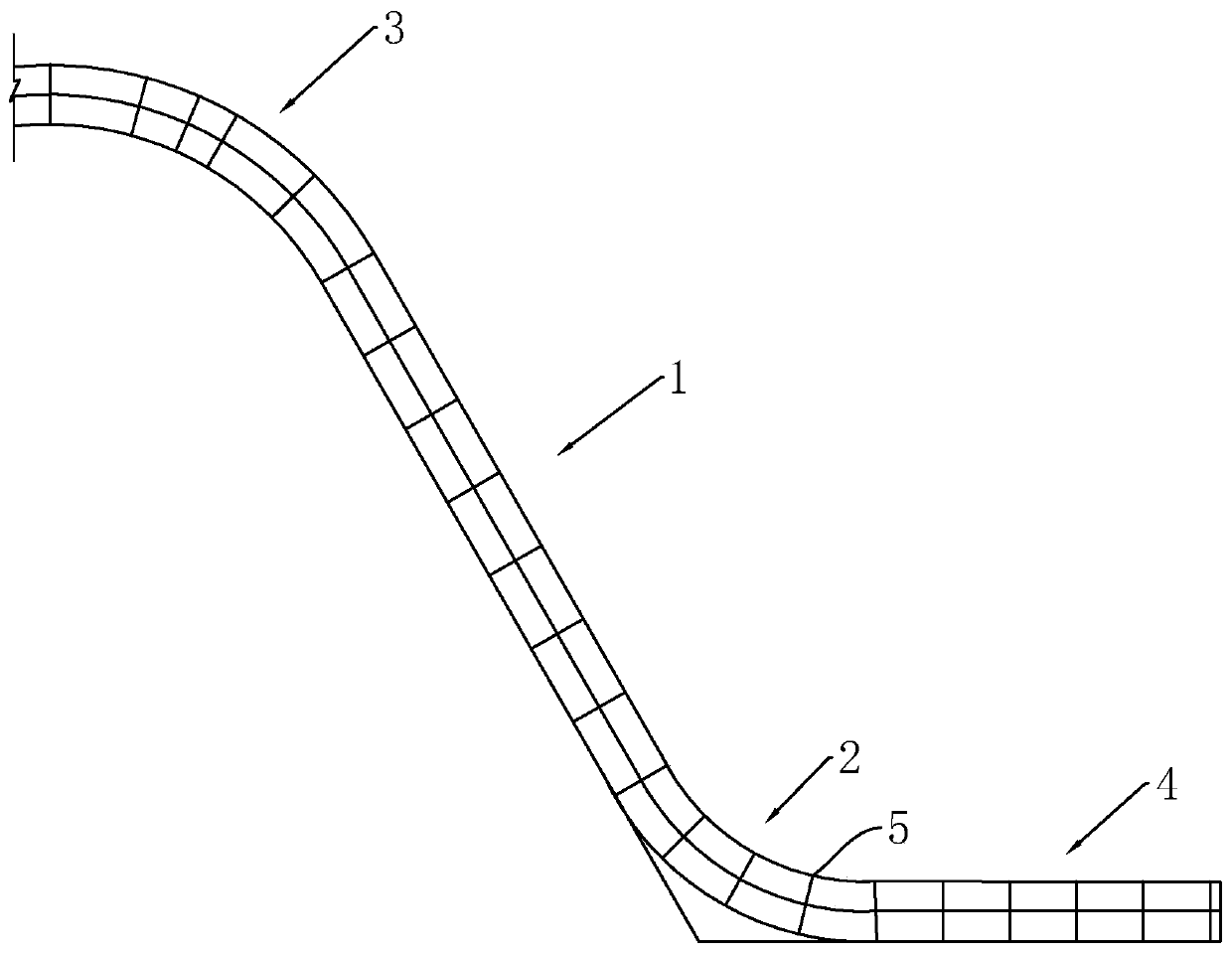

A Construction Technology for Concreting of Inclined Shafts

ActiveCN107100649BReduce constructionAvoid deformationUnderground chambersDrainageSurface cleaningSteel bar

The invention discloses a construction technology for inclined shaft concrete pouring. According to the construction technology for the inclined shaft concrete pouring, the problem that the construction quality is difficult to ensure because the span of an inclined shaft is large, and the soil textures of rock stratums everywhere have differences is solved. According to the technical scheme, the construction technology is characterized in that the range of the inclined shaft concrete pouring comprises an upper bending section, a straight section, a lower bending section and a lower flat section, and the specific construction technology includes the following steps of rock surface cleaning ; paying off and warehouse separating; reinforcing steel bar production and installation; installing of sliding molds on the straight section part of the inclined shaft; examining of the mold surface radian and flatness of a set-shaped steel mold on the upper bending section, the lower bending section and the lower flat section; painting of releasing agents; synchronous conducting of installation and correction; reinforcing by adopting a set-shaped steel arch frame, a steel pipe and a tiepiece; installing of embedded parts; installing of end cap molds; concrete pouring; and demolding and maintenance. The fact that targeted construction is conducted for each section of the inclined shaft is achieved, so that the construction quality is improved.

Owner:浙江华东工程咨询有限公司

Temperature Control and Anti-cracking Method of Massive Hydraulic Concrete for Extra-high Arch Dam

ActiveCN105541234BMeet the requirements of temperature changesSatisfy Restricted Shrinkage RequirementsFoundation engineeringArch damsFiberArch dam

The invention discloses a temperature control anti-cracking method for a large-volume hydraulic concrete for a super high arch dam. According to the method, the concrete out-of-mixer temperature and the concreting temperature are controlled by pre-cooling aggregate, and adding flake ice and cold water; low-heat cement and highly-doped grade I coal ash are taken as a cementing material; cooling water pipes are buried and water is introduced to reduce the maximum temperature of the hydraulic concrete; grade-4 aggregate and PVA (Polyvinyl Acetate) fibers are adopted to prevent cracks. The purposes of controlling the hydraulic concrete out-of-mixer temperature to be lower than or equal to 7 DEG C in summer and lower than or equal to 9 DEG C in winter, the concreting temperature to be lower than or equal to 12 DEG C, and the maximum temperature to be lower than or equal to 27 DEG C are achieved. By actual application of the temperature control anti-cracking method for the large-volume hydraulic concrete to the super high arch dam, the maximum temperature is remarkably reduced, and cracks are not found on site.

Owner:CHINA THREE GORGES CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com