Spray polyurethane foam material for track board and construction method thereof

A technology of spraying polyurethane and foam materials, which is applied to tracks, roads, buildings, etc., to achieve the effect of easy operation, simple construction method and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In conjunction with specific examples, the present invention will be further described.

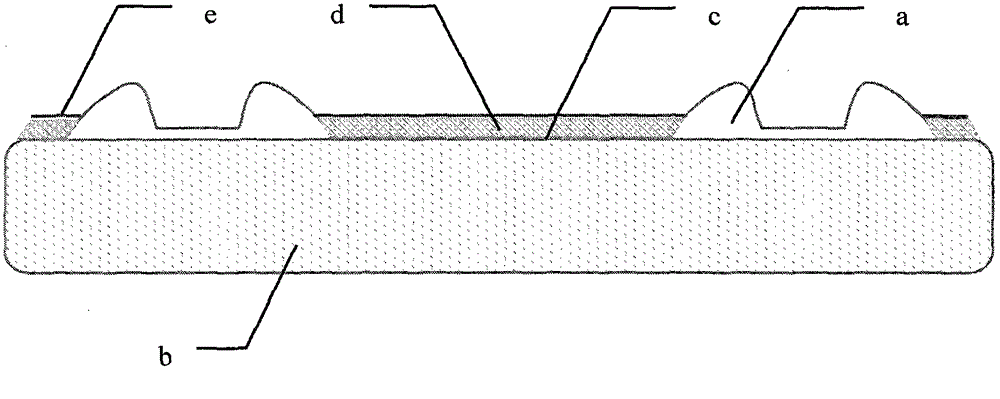

[0027] The invention relates to a sprayed polyurethane foam material, in particular to a sprayed polyurethane foam thermal insulation material for a high-speed railway track plate; the invention also relates to a construction method of the material.

[0028] A spray polyurethane foam material for track board, its A component consists of 20% polyether polyol, 39% polyester polyol, 2% foam stabilizer, 10% blowing agent, 3.8% catalyst, 15% flame retardant , 1.5% antioxidant, 15% modified titanium dioxide - glass fiber powder mixture; B component is composed of isocyanate mixture.

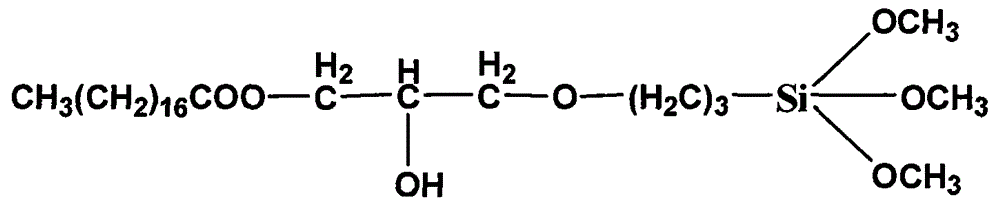

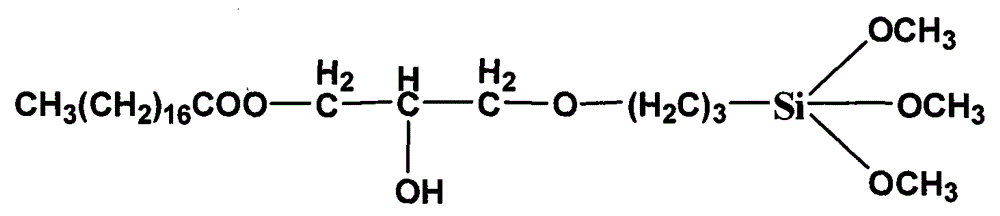

[0029] The modification method of the modified titanium dioxide-glass fiber powder is to mix titanium dioxide: glass fiber powder: modifying agent = 1: 0.3: 0.4, and disperse it in deionized water of equal mass, at a speed of 600r / min, heat up Stir at high speed for 40 minutes at 90°C, take out and filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com