A tunnel lining concrete insulation system and its construction method

An insulation system and concrete technology, applied in tunnel linings, tunnels, shaft linings, etc., can solve problems such as concrete temperature cracks, and achieve the effects of low cost, broad market prospects, and easy control of construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

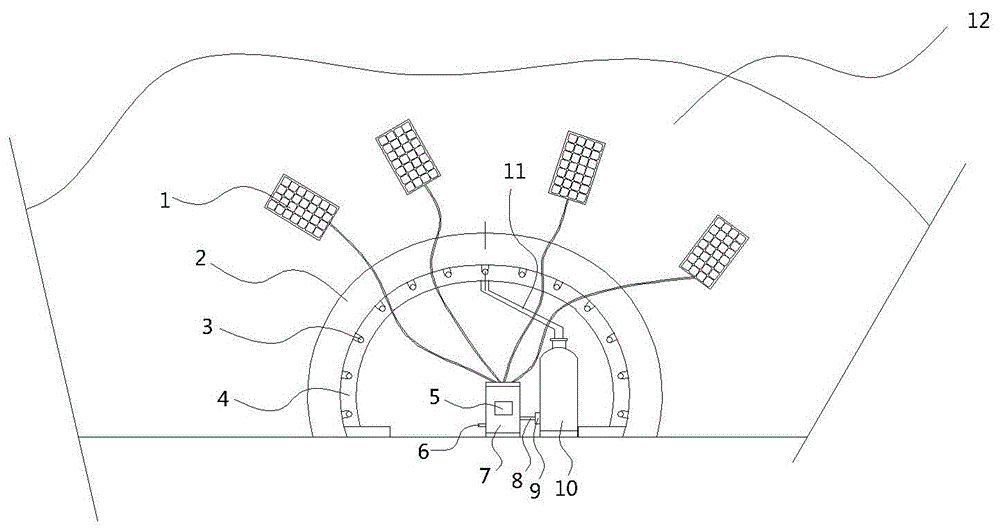

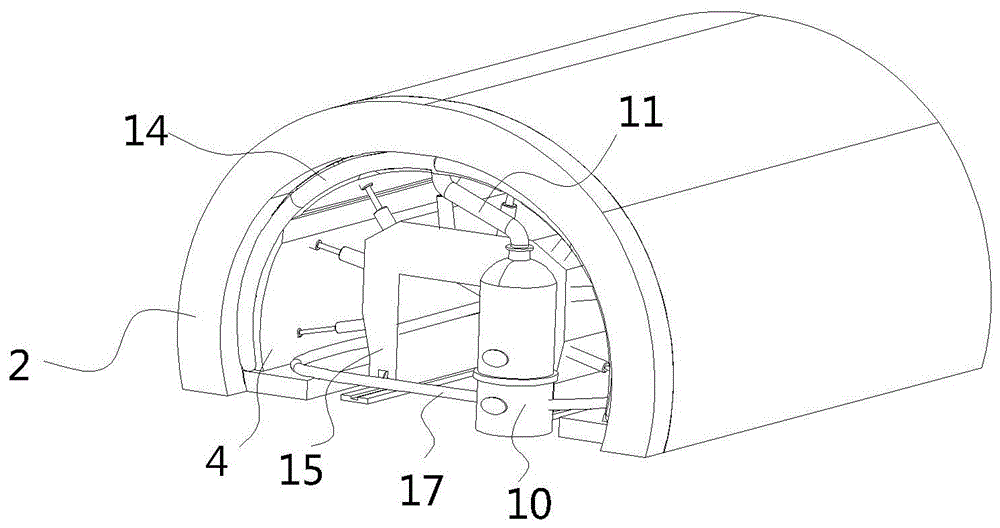

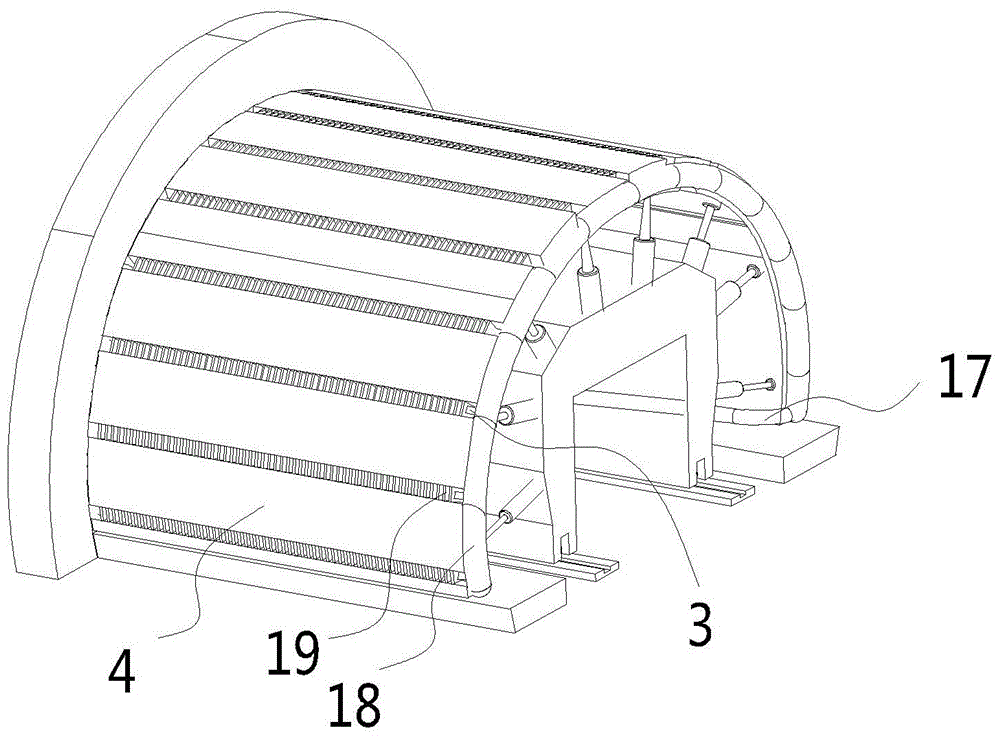

[0021] As shown in the figure, a tunnel lining concrete heat preservation system includes a lining trolley 15 and a heating boiler 10. The formwork of the lining trolley 15 is provided with an insulation layer 4, and floor heating pipes 3 are evenly distributed on the insulation layer 4. Radiating fins 19 are installed on the floor heating pipe 3, and the cooling fins 19 are copper cooling fins, so that the heat dissipation is very fast, ensuring that the thermal insulation layer 4 forms heat conduction quickly. One end of the lining trolley 15 is equipped with a hot water distribution pipe 14 communicating with the floor heating pipe 3, and the other end is equipped with a cold water return pipe 18 communicating with the floor heating pipe 3; the hot water distribution pipe 14 passes through the outlet pipe 11 communicates with the heating boiler 10, and the cold water return pipe 18 communicates with the heating boiler 10 through the return pipe 17.

[0022] During the const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com