Temperature Control and Anti-cracking Method of Massive Hydraulic Concrete for Extra-high Arch Dam

A hydraulic concrete, temperature control and anti-cracking technology, which is applied in the direction of arch dams, dams, and infrastructure engineering, etc., can solve problems such as cracks, large mutual constraints between the upper and lower layers, and excessive tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Firstly, the water-reducing agent will be prepared on-site to make a solution with a mass concentration of 20%, and the air-entraining agent will be prepared on-site to make a solution with a mass concentration of 1% for later use; then, the fourth-grade aggregate is cooled to a temperature of -2~1°C; according to the procedure, weigh the weight of various raw materials, and after weighing the small stones, add PVA fiber into the small stone weighing hopper; finally put in the weighed raw materials according to the set sequence. Mixing, adjust the concrete production speed in real time according to the pouring situation on site, to achieve coordination between pouring and production.

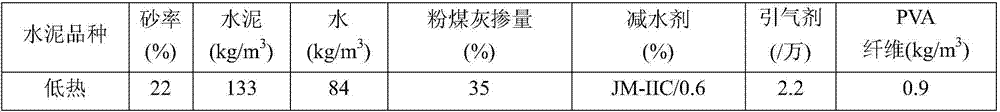

[0037] The formula of the hydraulic concrete of the present embodiment is as shown in table 1:

[0038] Formulation of table 1 hydraulic concrete

[0039]

[0040] In Table 1, said percentage sign all refers to the dosage of this raw material.

Embodiment 2

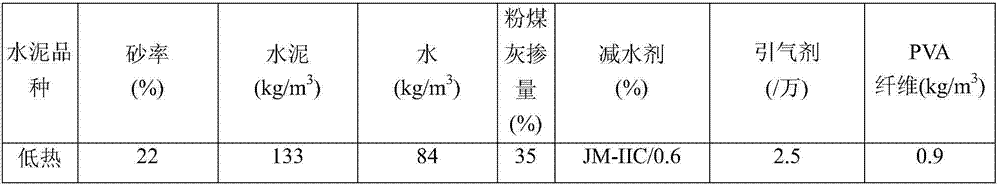

[0042] The preparation process of its hydraulic concrete is the same as embodiment 1, and the formula of its hydraulic concrete is as shown in table 2:

[0043] Formulation of table 2 hydraulic concrete

[0044]

Embodiment 3

[0046] The preparation process of its hydraulic concrete is the same as embodiment 1, and the formula of its hydraulic concrete is as shown in table 3:

[0047] Formulation of table 3 hydraulic concrete

[0048]

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com