A Construction Technology for Concreting of Inclined Shafts

A construction technology and concrete technology, applied in shaft equipment, wellbore lining, earthwork drilling, etc., can solve the problems of difficulty in ensuring construction quality, complex construction conditions, large span of inclined wells, etc., to reduce water loss and save construction time. , the effect of saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

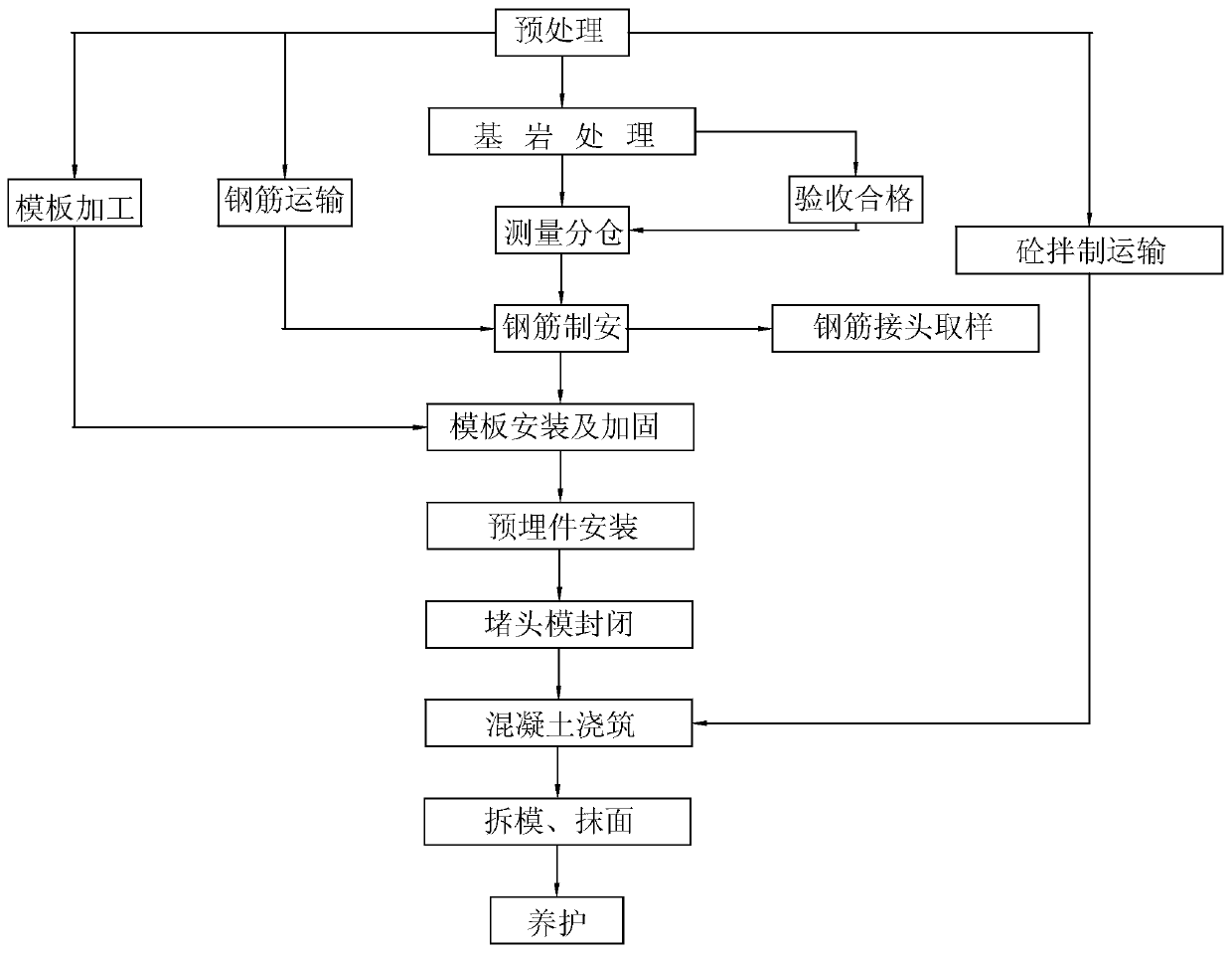

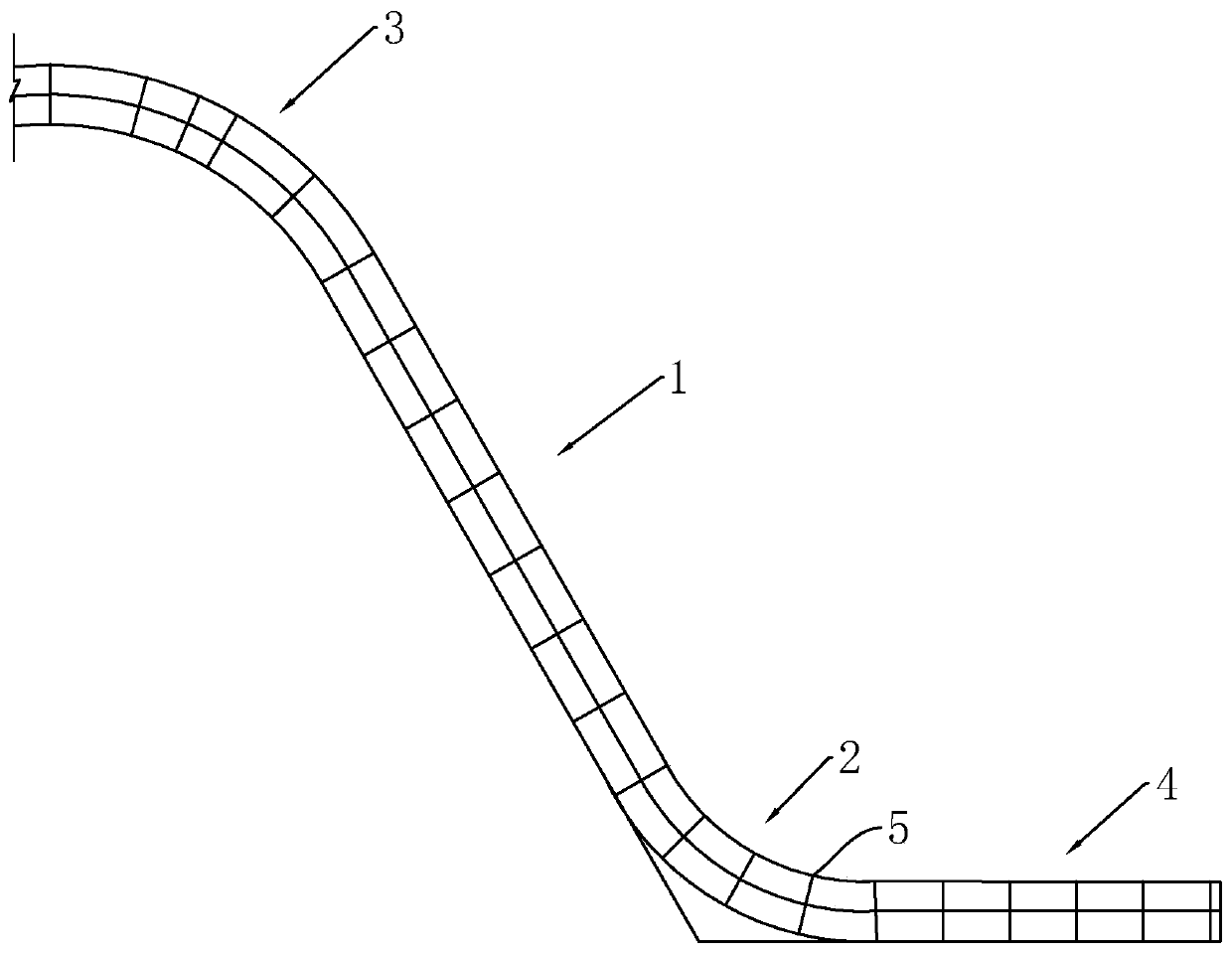

[0045] see figure 1 , a construction technique for concrete pouring of inclined shafts, which is applied to the arrangement of inclined shafts of water diversion tunnels in underground works of hydropower stations. The lining concrete pouring construction is carried out on the upper curved section 3, the straight section 1, the lower curved section 2 and the lower flat section 4 of the inclined shaft whose excavation and support construction has been completed.

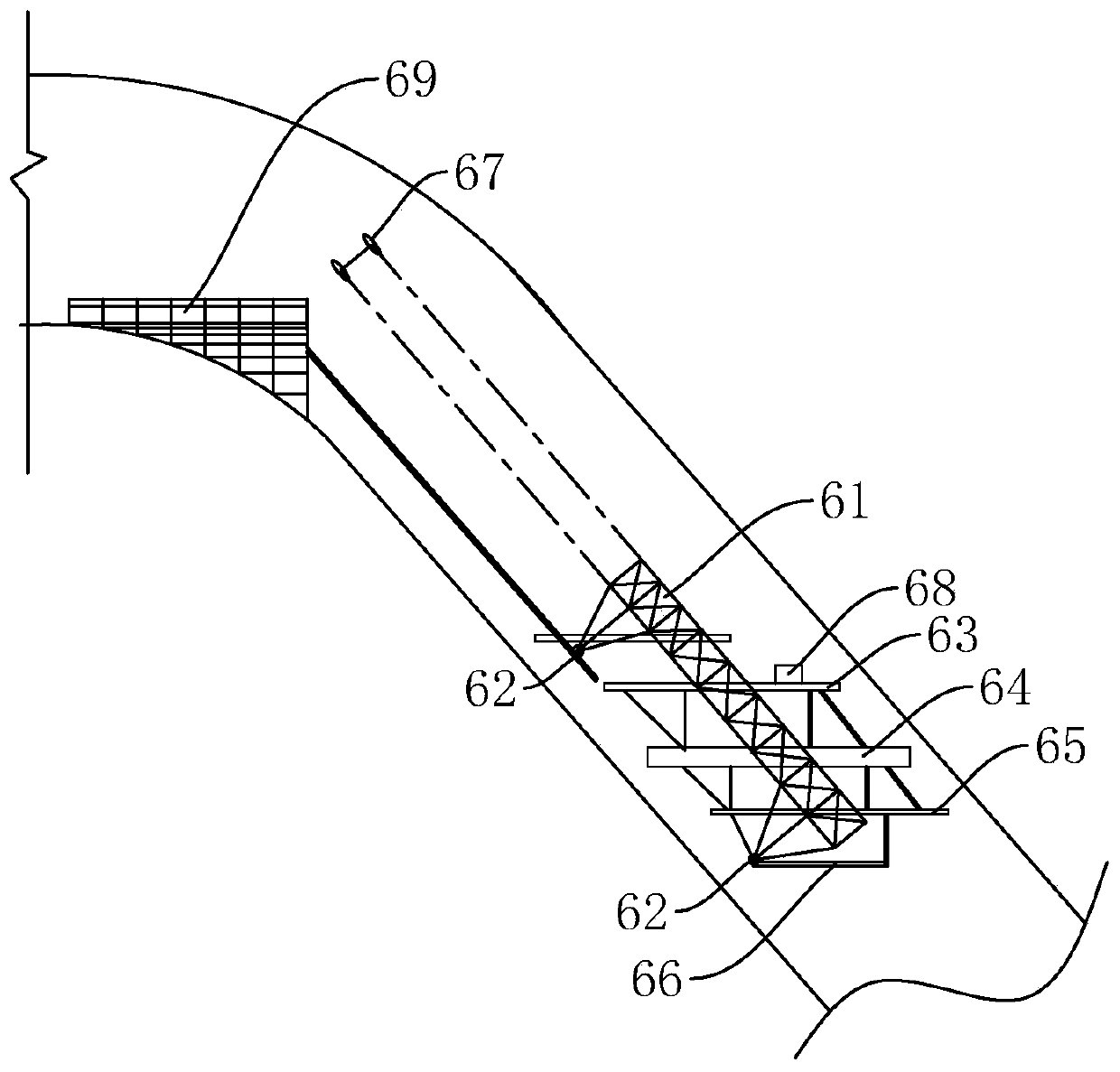

[0046] see figure 2 , in the straight section 1 of the inclined shaft, the concrete is poured through the slip form. The sliding form includes a central beam 61, a sliding form traveling mechanism 62, an operating platform 63, a formwork system 64, a plastering platform 65, a tail platform 66, a wellhead locking beam 67, and a hydraulic climbing system 68. The sliding up of the sliding form utili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com